Abstract

The growing consumer awareness of functional foods has increased interest in fermented plant-based products with enhanced nutritional and health-promoting properties. This comprehensive narrative literature review examines the potential of diverse raw materials for tempeh production beyond traditional soybeans, analysing their nutritional composition, bioactive compounds, and functional properties. A structured literature search was conducted on peer-reviewed publications up to July 2025, focusing on tempeh fermentation technology, chemical composition, and bioactive compounds from various substrates using recognised analytical methods according to Association of Official Analytical Collaboration (AOAC) standards. The analysis of over 25 different substrates revealed significant opportunities for enhancing tempeh’s nutritional profile through alternative raw materials including legumes, cereals, algae, seeds, and agricultural by-products. Several substrates demonstrated superior nutritional characteristics compared with traditional soybean tempeh, notably tarwi (Lupinus mutabilis) with exceptional protein content ((32–53% dry matter (DM)) and mung bean (Vigna radiata) exhibiting remarkably high polyphenol concentrations (137.53 mg gallic acid equivalents (GAE)/g DM). Fermentation with Rhizopus oligosporus consistently achieved substantial reductions in anti-nutritional factors (64–67% decrease in trypsin inhibitors, up to 65% reduction in phytates) while maintaining consistent antioxidant activities (39–70% 2,2-diphenyl-1-picrylhydrazyl (DPPH) inhibition) across most variants. The diversity of bioactive compounds across different substrates demonstrates potential for developing targeted functional foods with specific health-promoting properties, supporting sustainable food system development through protein source diversification.

1. Introduction

Interest in the consumption of functional foods that have a positive impact on health is growing every day due to increased consumer awareness [1]. Fermentation is one of the oldest and most versatile biotechnological processes used in food production. Its importance goes far beyond traditional preservation functions—fermentation influences the nutritional value, microbiological safety, sensory properties, and health-promoting potential of food. Modern research confirms that fermentation, especially the fermentation of legumes (e.g., tempeh), is the basis for the development of modern, functional, and sustainable plant foods [2,3,4].

The fermentation process leads to the breakdown of complex macronutrients into more easily digestible forms, increases protein digestibility, releases essential amino acids, and improves mineral bioavailability by breaking down anti-nutritional compounds [2,3,5]. Fermentation produces bioactive compounds (peptides, isoflavones, polyphenols, B vitamins), and fermented products show higher antioxidant and immunomodulatory activity [4,6,7]. Fermentation reduces the development of pathogens, improves sensory characteristics, and extends food shelf life [8].

Tempeh is a traditional ingredient in Indonesian cuisine made from fermented soybeans (Glycine max) [9]. The importance of fermentation in tempeh production is to improve protein digestibility; reduce anti-nutritional factors; increase the content of peptides, isoflavones, and polyphenols; and shape the unique sensory characteristics of the product. Soya has traditionally been used in the production of tempeh, but other raw materials are now increasingly used. The choice of raw material influences the nutritional value, amino acid profile, presence of bioactive compounds, and sensory attributes of the product.

The aim of this article is to provide a comprehensive literature review on the potential use of various plant raw materials for the production of tempeh (not only soybeans), with particular emphasis on their nutritional composition, bioactive compound content, and functional properties. The authors analyse how fermentation with Rhizopus oligosporus affects the nutritional value, antioxidant activity, and reduction of anti-nutritional compounds in tempeh based on over 25 different substrates (including legumes, cereals, algae, seeds, and agricultural processing by-products). The article also aims to highlight the potential of innovative, functional food products based on tempeh that support sustainable food systems by diversifying plant protein sources.

2. Methods

A structured narrative literature review was conducted without adherence to PRISMA guidelines, as the aim was to provide a comprehensive and integrative synthesis of existing knowledge on tempeh production from diverse raw materials rather than a narrowly focused quantitative analysis. This approach allowed for the inclusion of varied research designs, processing methods, and analytical techniques, which would not have been feasible through a conventional systematic review. The search encompassed peer-reviewed publications up to July 2025, focusing on the fermentation technology, nutritional composition, bioactive compounds, and functional properties of tempeh produced from both traditional and innovative substrates.

Specific keywords included “tempeh”, “Rhizopus oligosporus”, “solid-state fermentation”, “legume fermentation”, “alternative substrates”, “soybean alternatives”, “protein digestibility”, “isoflavones”, “polyphenols”, “antioxidant activity”, “anti-nutritional factors”, “phytates”, “trypsin inhibitors”, “functional foods”, “plant-based protein”, “fermented foods”, “bioactive compounds”, “nutritional composition”, and “processing technology.” The reference lists of all retrieved articles and prior reviews were manually screened to identify additional relevant studies. Only studies published in English were included due to practical limitations related to translation and consistency.

All data on chemical composition presented in this review were obtained from studies using recognised reference analytical methods in accordance with AOAC. This review did not include a formal risk-of-bias assessment or meta-analysis and should be interpreted as a qualitative synthesis of the current literature on tempeh fermentation from diverse raw materials.

3. Characteristics of the Raw Materials Used for Tempeh Fermentation

The classic raw material for making tempeh is soybeans [2,5,7,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28], but tempeh is produced from a wide range of alternative raw materials. Among these are the following:

- Legumes: broad beans (Vicia faba L.) [15,29,30,31,32], chickpeas (Cicer arietinum) [5,15,33,34], Jack bean (Canavalia ensiformis) [6,35,36,37,38,39,40], cowpea bean (Vigna unguiculata), Bambara groundnut (Vigna subterranea) [41], mung bean (Vigna radiata) [26,42], winged bean (Psophocarpus tetragonolobus) [23], common bean (Phaseolus vulgaris) [15,43,44,45,46,47], large pea (Lathyrus sativus) [48,49,50], lentils (Lens culinaris) [15], narrow-leaved lupin (Lupinus angustifolius) [51,52], tarwi (Lupinus mutabilis) [53], white mimosa (Leucaena leucocephala) [54];

- Cereals: oats (Avena sativa) [31,55], pearl barley (Hordeum vulgare) [56], basmati rice (Oryza sativa) [56], rice (Oryza sativa) [42], sorghum [26];

- Seeds and nuts: lotus seeds (Nelumbo nucifera) [57,58,59], Moringa oleifera seeds [60], rubber seeds (Hevea brasiliensis) [61];

- Algae: Porphyra sp. [62,63], Eucheuma spinosum [64];

- Plant additives: butterfly pea (Clitoria ternatea) flower petals [65];

- Other plants: wild turmeric (Curcuma aromatica) [66];

- By-products: brewer’s thresh [67], linseed pomace [50], rapeseed pomace [68].

Based on an analysis of the data in Table 1, the protein content in the tested materials shows a wide range of values, from a minimum of 0.3% in butterfly pea flowers (Clitoria ternatea) to a maximum of 52.0% in narrow-leaved lupin (Lupinus angustifolius). The classification of raw materials according to protein content allows three main categories to be distinguished: High-protein raw materials (≥35% DM), which include six raw materials, with a predominance of legumes. The highest protein concentration is found in lupin (Lupinus mutabilis, 44.7%) and narrow-leaved lupin (31.0–52.0%), confirming their potential as alternative protein sources to conventional raw materials. Soybeans (Glycine max, 39.0–40.0%) and rapeseed meal (38.1%) are excellent sources of plant protein used in both human nutrition and animal feed. Moderate-protein raw materials (20–34% DM) represent the most numerous group (15 materials), dominated by legumes such as field beans (Vicia faba, 26.0–33.0%), chickpeas (Cicer arietinum, 18.7–41.8%), and common beans (Phaseolus vulgaris, 20.0–27.0%). Low-protein raw materials (<20% DM) mainly include cereals and other plant raw materials, with the lowest protein content found in pea flowers (0.3%) and Eucheuma spinosum (6.0–7.3%).

Analysis of the data in Table 1 reveals a remarkable variation in fat content between the raw materials, ranging from trace amounts to values exceeding 50% of dry matter. The raw materials with the highest fat content include Brazilian rubber (Hevea brasiliensis), which by far leads the way in fat content with 42.5–54.2% of dry weight. Rubberwood seed oil is rich in unsaturated fatty acids such as 39.6–40.5% linoleic acid, 17–24.6% oleic acid, and 16.3–26% linolenic acid [69,70]. Moringa oleifera seeds rank second with 43.6% fat content.

Table 1.

Characteristics of raw materials for tempeh production.

Table 1.

Characteristics of raw materials for tempeh production.

| Raw Material | Protein (% DM) | Fat (% DM) | Carbohydrates (% DM) | Fibre (% DM) | Bioactive Compounds | Health-Promoting Properties | Anti-Nutritional Factors |

|---|---|---|---|---|---|---|---|

| Adlay (Coix lacryma-jobi) | 20.0–31.7 [71] | 1.0–8.2 [72] | 56.0–75.0 [71] | 2.5–17.0 [72] | Polyphenols, flavonoids, coixol, phytosterols, saponins [71] | Hypolipidaemic, antidiabetic, antioxidant, prebiotic [71] | Phytic acid, saponins, trypsin inhibitors [73] |

| Broad beans (Vicia faba L.) | 26.0–33.0 [74] | <1.0 [74] | 45.7–70.1 [75] | 11.4–16.6 [74] | Polyphenols, flavonoids, L-DOPA, tannins, lectins [76] | Cholesterol lowering, heart support, antioxidant [77] | Phytic acid, trypsin inhibitors, saponins, vicine, convicine, lectins, tannins [74] |

| Chickpeas (Cicer arietinum) | 18.7–41.8 [78] | 2.7–6.5 cooked [79] | 60.0–65.0 [79] | 18.0–22.0 [80] | Polyphenols, sterols, carotenoids, tannins, isoflavones [80] | Cholesterol lowering, heart support, glycaemic control, antioxidant [81] | Phytates, lecithins, enzyme inhibitors, oligosaccharides [78] |

| Red algae (Porphyra sp.) | 33.7–41.8 [82] | Up to 1.2 [83] | 30.0–40.0 [84] | up to 48.0 [85] | Polysaccharides (porphyran), phycobiliproteins, polyphenols, flavonoids [84,86,87,88]. | Antioxidant [86], immune support [84], cholesterol lowering, heart support [89], antidiabetic and anti-inflammatory [84], improved iron bioavailability [90] | Phytic acid, saponins [91] |

| Eucheuma spinosum | 6.0–7.3 [92] | <0.1 [92] | 69.0–70.0 [92] | 15.0–20.0 [92] | Polyphenols, flavonoids, saponins, tannins, steroids, triterpenoids [93] | Antioxidant, antimicrobial, prebiotic, support for bone mineralisation [93] | Phytic acid, tannins [92] |

| Cowpea bean (Vigna unguiculata) | 17.5–32.5 [94] | 1.5 [95] | 62.1 [95] | 7.0–11.0 [96] | Polyphenols, flavonoids, saponins, tannins, phytosterols, L-DOPA [97] | Cholesterol lowering, glycaemic regulation, microbiome support, antioxidant [97] | Phytic acid, tannins, trypsin inhibitors [97] |

| Jack bean (Canavalia ensiformis) | 25.2 [98] | 5.2 [98] | 58.4 [98] | 7.1 [99] | Polyphenols, flavonoids, kaempferol glycosides, α-glucosidase inhibitors [100] | Antidiabetic [100], immunomodulatory [101] | Canavanine, trypsin inhibitors, lectins, oligosaccharides [99] |

| Bambara groundnut (Vigna subterranea) | 15.0–37.0 [102] | 1.3–7.4 [102] | 45.0–64.0 [102] | 3.7–6.4 [102] | Polyphenols, flavonoids, saponins, tannins, alkaloids, L-DOPA [103] | Cholesterol lowering, glycaemic regulation, satiety, antioxidant, anti-inflammatory [104] | Phytates, tannins, oxalates, trypsin inhibitors, lectins [104] |

| Mung bean (Vigna radiata) | 14.6–32.6 [105] | 1.2–1.9 [105] | 61.0–67.1 [105] | 5.5 [106] | Polyphenols, flavonoids, saponins, phenolic acids, alkaloids, bioactive peptides [107] | Cholesterol lowering, glycaemic regulation, antioxidant, anti-inflammatory, satiety [107] | Phytic acid, tannins, trypsin inhibitors, lectins [105] |

| Winged bean (Psophocarpus tetragonolobus) | 27.2–45.0 [108] | 15.2–23.4 [108] | 14.2–35.7 [108] | 1.6–26.2 [108] | Polyphenols, flavonoids, saponins, phytosterols, bioactive peptides [108] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant, anti-inflammatory [108] | Phytates, tannins, oxalates, trypsin inhibitors, haemagglutinins [109] |

| Common bean (Phaseolus vulgaris) | 20.0–27.0 [110] | 0.6–3.0 [111] | 58.0–70.0 [110] | 30.3–34.2 [112] | Polyphenols, anthocyanins, saponins, tannins, phytosterols [113] | Cholesterol lowering, heart support, glycaemic regulation, antioxidant [110] | Lectins, phytic acid, saponins, trypsin inhibitors, tannins [114] |

| Large peas (Lathyrus sativus) | 17.7–25.6 [115] 20.0–24.9 [116] 18.0–34.0 [117] | 1.7 [118] | 48.0–52.3 [118] | 1.1–1.7 [118] 4.0–7.0 [116] | Polyphenols, flavonoids, saponins, tannins, phytosterols, homoarginine, β-ODAP [118] | Antioxidant, hypolipidaemic, antidiabetic, anti-inflammatory [118] | β-ODAP, phytic acid, saponins, tannins [115,116] |

| Pearl barley (Hordeum vulgare) | 13.6 [119] | 2.8 [119] | 63.9 [119] | 4.7 [119] | β-Glucan, arabinoxylan, polyphenols, flavonoids, phytosterols [119] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant, anti-inflammatory [119]. | Phytic acid, saponins, tannins [119] |

| Rubber (Hevea brasiliensis) | 19.4–30.7 [120] 23.3 [121] 26.1 [122] 31.6 [123] | 42.5–54.2 [120] | 11.6–29.0 [120] | 5.9 [121] 43.0 [122] | Polyphenols, flavonoids [120] | Antioxidant, anti-inflammatory, metabolic, requires detoxification [31,120] | Tannins, saponins [121,123] |

| Wild turmeric (Curcuma aromatica) | 19.4 [124] | 2.5 [124] | 97.5 [124] | n.a. | Polyphenols (curcumin, demethoxycurcumin), flavonoids, terpenoids, essential oils [124,125] | Antioxidant, anti-inflammatory, anticancer, neuroprotective [124,126] | Saponins, tannins, alkaloids [124] |

| Flowers of butterfly pea (Clitoria ternatea) | 0.3 [127] | 2.5 [127] | 2.2 [127] | 2.1 [127] | Anthocyanins (300–500 mg/100 g), flavonoids (100–150 mg/100 g), phenolic acids, saponins, tannins, carotenoids, avenanthramides [127,128,129] | Potent antioxidant, anti-inflammatory, hypoglycaemic, neuroprotective, cardioprotective, anticancer, skin support [127,128] | Tannins, saponins, oxalates [127,128] |

| Lotus (Nelumbo nucifera) | 16.0–21.0 [130] | 2.4–3.0 [130] | 61.0–62.0 [130] | 2.8 [131] | Polysaccharides (porphyran), phycobiliproteins, polyphenols, flavonoids [132] | Antioxidant, immunomodulatory, prebiotic, antidiabetic [133] | Phytic acid, saponins [134,135] |

| Narrow-leaved lupin (Lupinus angustifolius) | 31.6–34.6 [136] 31.0–52.0 [137] | 6.0 [137] | <24.0 [138] | 37.5–40.2 [137] | Polyphenols, flavonoids, bioactive peptides, saponins, phytosterols [137] | Cholesterol lowering, glycaemic improvement, satiety, antioxidant, anti-inflammatory [138] | Alkaloids, phytic acid, trypsin inhibitors [137] |

| White mimosa (Leucaena leucocephala) | 26.6 [139] 31.1 [140] | 5.6 [140] 31.8 [139] | 18.6 [140] 15.3 [139] | 13.2 [140] 15.5 [139] | Polyphenols, flavonoids, saponins, tannins, phytosterols [141] | Antioxidant, hypolipidaemic, immunomodulatory [141,142] | Mimosine, tannins, saponins [141] |

| Brewer’s malt | 15.0–30.0 [143] 20.0 [144] | 3.0–13.9 [144] | n.a. | up to 80.0 [143] 70.0 [144] | Phenolic acids (ferulic, p-coumaric), flavonoids, antioxidant peptides, fibre, melanoidins, healthy fatty acids, and minerals [145,146] | Cholesterol lowering, glycaemic regulation, prebiotic, antioxidant [143] | Phytic acid, tannins, trypsin inhibitors [144] |

| Moringa oleifera (seeds) | 31.4 [147] 35.4 [148] | 36.7 [147] 43.6 [148] | 9.2 [148] 18.4 [147] | 4.7 [148] 7.3 [147] | Polyphenols, flavonoids, saponins, phytosterols, bioactive peptides [149,150] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant [151] | Phytates, glucosinolates, tannins, trypsin inhibitors [150] |

| Oats (Avena sativa) | 10.0–17.2 [151] 13.7 [152] | 2.1–10.3 [151] 7.6 [152] | 47.9–74.3 [151] 62.7 [152] | 2.1–15.4 [151] 10.1 [152] | β-Glucans, avenanthramides, polyphenols, flavonoids [152] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant [152] | Phytic acid, saponins, β-glucan [152] |

| Rice (Oryza sativa) | 16.8–24.1 [153] 6.0–7.8 [154] 5.5 [155] | 1.6–2.8 [154] 0.8 [155] | 82.7–84.5 [154] | 2.1–2.7 [154] | Polyphenols, phytosterols, γ-oryzanol, tocopherols [156] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant [156] | Phytic acid, tannins [156] |

| Basmati rice | 7.6–9.1 [157] | 1.6–2.4 [157] 3.0–3.5 [158] | 77.4–79.4 [157] | 1.0–1.8 [157] | γ-Oryzanol, tocopherols, phytosterols [158] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant [158] | Phytic acid, tannins [157] |

| Lentils (Lens culinaris) | 20.5–26.0 [159] | 0.6–1.0 [159] | 63.7–69.8 [159] | 19.3–26.4 [159] | Polyphenols, flavonoids, saponins, phenolic acids, oligosaccharides [160] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant [160] | Phytic acid, tannins, trypsin inhibitors, lectins [160] |

| Soybean (Glycine max) | 39.0 [14] 40.0 [161] | 17.0–20.0 [14] 20.0 [161] | 18.0 [14] 31.1 [5] | 5.1 [5] | Isoflavones, saponins, phytosterols, lecithins [161] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant [161] | Phytates, trypsin inhibitors, saponins, lectins [161] |

| Sorghum (Sorghum bicolor) | 8.0–12.0 [160] | 1.5–3.5 [160] | 65.0–75.0 [160] | 6.0–10.0 [160] | Polyphenols, tannins, phytosterols, resistant starch [160] | Cholesterol lowering, glycaemic regulation, immune support, antioxidant [160] | Tannins, phytic acid, trypsin inhibitors [160] |

| Tarwi (Lupinus mutabilis) | 44.7 [162] | 15.4 [162] | n.a. | n.a. | Polyphenols, flavonoids, isoflavones, saponins [163] | Cholesterol lowering, glycaemic improvement, satiety, antioxidant, anti-inflammatory [163] | Quinolizidine alkaloids, phytic acid [163] |

| Linseed pomace | 21.3 [164] | 43.9 [164] | n.a. | 6.2 [164] | Lignans, polyphenols, flavonoids, plant mucilages [164] | Cholesterol lowering, glycaemic regulation, prebiotic, antioxidant [50] | Cyanogenic glycosides, phytic acid [50] |

| Rapeseed pomace | 38.1 [165] | 33.5 [165] | n.a. | 15.3 [165] | Polyphenols (mainly ferulic acid, hydroxycinnamic acids), flavonoids, glucosinolates, phytates, isothiocyanates, sinapic acid, tannins, and saponins [68] | Antioxidant and anti-inflammatory, support of lipid and carbohydrate metabolism, promotion of favourable gut microbiota [68] | Glucosinolates, phytates [68] |

DM—dry matter, n.a.—not available.

Moringa seeds are rich in protein, fat, calcium, iron, phosphorus, and vitamin E and can be used to produce a precious oil [166]. Soybean (Glycine max) has a fat content of 17.0–20.0%. Soybean oil has a high content of fatty acids with a predominance of unsaturated acids (oleic, linoleic, linolenic), lecithin, and vitamin E [161]. Four raw materials are characterised by trace amounts of fat: broad beans (Vicia faba L.): <1%, lentils (Lens culinaris): 0.6–1.0, red algae (Porphyra sp.): up to 1.2, and Eucheuma spinosum: <0.1%.

Analysing the data in Table 1, the highest carbohydrate content was found in wild turmeric (Curcuma aromatica), with as much as 97.5% DM, while the lowest content was found in flowers of butterfly pea (Clitoria ternatea), with less than 5% DM.

The analysis of the data in Table 1 shows that brewers’ milling is the richest source of fibre in the raw materials studied (70.0–80.0% DM), while basmati rice contains the least fibre (1.0–1.8% DM). A high fibre content brings numerous health benefits: regulation of intestinal peristalsis, increased feeling of satiety and reduced snacking (body weight control), stabilisation of blood glucose levels (prevention of diabetes), protection of the cardiovascular system by lowering Low-Density Lipoprotein (LDL) levels, reducing the risk of hypertension and heart disease, and a reduction in the risk of colorectal cancer by increasing stool volume and shortening the contact time of carcinogens with the mucosa [167].

Analysing the data in Table 1, it was noted that the raw materials used for tempeh fermentation differ significantly in terms of their bioactive compound profile. Chickpeas (Cicer arietinum), soybeans (Glycine max), and large peas (Lathyrus sativus) are rich sources of isoflavones and tannins; legumes mainly provide polyphenols and flavonoids, while algae (Porphyra sp., Eucheuma spinosum) stand out for their unique polysaccharides (porphyran, phycobiliproteins) with a broad spectrum of immunomodulatory and antioxidant activity [168]. Polyphenols and flavonoids neutralise free radicals, protect cells from oxidative stress, and reduce inflammatory reactions in the body [169]. Curcumin from turmeric (Curcuma aromatica) exhibits potent anti-inflammatory and anticancer properties through modulation of NF-κB and COX-2 pathways [170]. Porphyrans and phycobiliproteins from the red alga Porphyra sp. have prebiotic effects, modulate the composition of the gut microbiota, and stimulate macrophages and lymphocytes [168,171,172]. Saponins from a number of legumes can enhance the immune response and exhibit antiparasitic activity [173]. α-Glucosidase inhibitors (e.g., in Jack beans) slow carbohydrate digestion and lower postprandial glycaemia [100]. Phytosterols from rice (Oryza sativa) and oats (Avena sativa) help lower LDL cholesterol and improve lipid profile [174,175]. Coixol from adlay (Coix lacryma-jobi) inhibits cancer cell proliferation and has hepatoprotective effects [176,177]. Porphyran exhibits anticancer activity by inducing apoptosis and inhibiting the PI3K/Akt pathway [178].

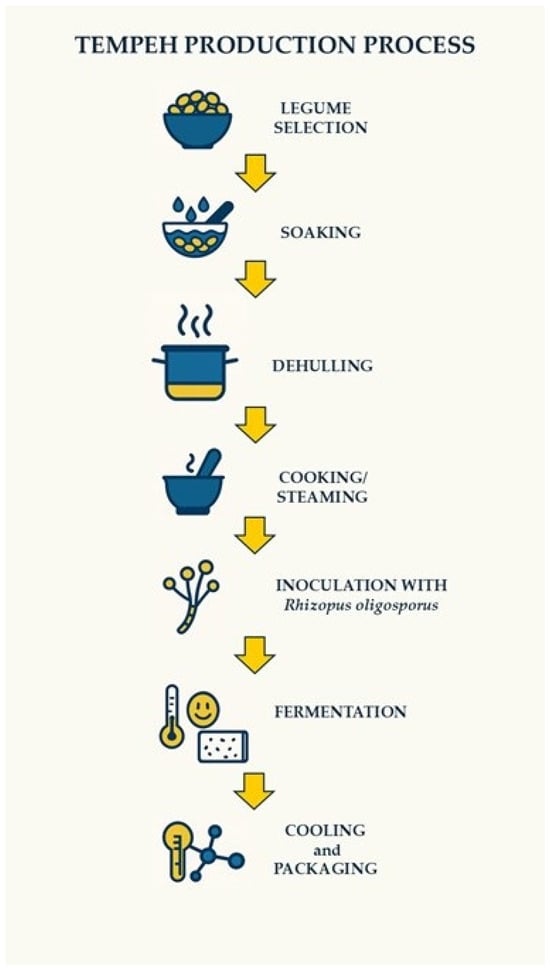

4. Technology for the Production of Tempeh

Tempeh is mainly made with moulds of the genus Rhizopus, especially Rhizopus oligosporus. The production process is based on solid-state fermentation (SSF), carried out under aerobic conditions, which results in the formation of a compact soy “cake”, united by a mould mycelium, with a white colour and a characteristic mushroom and nut smell [179]. The finished tempeh can be consumed after heat treatment (frying, boiling, baking) or stored under refrigeration for up to 10 days, possibly pasteurised or frozen to extend shelf life [4]. Fermentation technology leads to significant biochemical changes in the raw material. Under the influence of mould proteases, soy proteins are broken down into peptides and free amino acids, which increases the digestibility and nutritional value of the product [180]. Phytases produced by Rhizopus degrade phytates (reduction of up to 65%), which improves the bioavailability of iron, zinc, and calcium [179]. β-Glucosidase enzymes convert isoflavones from glycosidic forms to aglycones (genistein, daidzein), which have higher bioavailability and biological activity [4]. Fermentation results in an increase in B vitamins, including vitamin B12 (synthesised by companion bacteria, e.g., Klebsiella pneumoniae, Citrobacter freundii). The reduction of stachyose and raffinose reduces the bloating properties of soya [181]. The basic steps of tempeh production are illustrated in Figure 1, which presents a schematic representation of the typical fermentation process using Rhizopus oligosporus. The tempeh production process begins with the selection of legume seeds. This stage includes seed quality control. Seeds intended for tempeh production must be free from mechanical damage, mould, and other microbiological and physical contaminants. Soaking is a key stage in the preparation of the substrate, during which the seeds are hydrated at a temperature of approximately 25 °C for 6–18 h. This process aims to increase the moisture content of the seeds to a level that allows the subsequent stages of the technological process to be carried out effectively. During soaking, water-soluble components are also partially extracted. In some technologies, acidifying substances such as vinegar or lactic acid are added to lower the pH to around 3.5, which promotes the selective elimination of undesirable bacterial microflora. Dehulling involves the mechanical removal of the seed coat from legumes. Dehulling can be carried out by rubbing the seeds in water while stirring, which causes the husks to be released and float to the surface. The removal of the seed coat is important for the textural properties of the finished product and facilitates the penetration of Rhizopus oligosporus during fermentation. Thermal treatment of seeds involves cooking at 100 °C for 25–30 min or steaming. This process facilitates the availability of nutrients for Rhizopus oligosporus. Thermal treatment also softens the structure of the seeds, which promotes subsequent penetration of the mycelium hyphae. After cooking, the seeds are drained and dried to the appropriate moisture content. Inoculation involves introducing Rhizopus oligosporus spores into the prepared substrate. The spores are evenly distributed throughout the seed mass at a temperature not exceeding 35 °C (maintaining < 35 °C to prevent growth of thermophilic pathogens while supporting desired fungal development). Fermentation is a key stage in the process, during which R. oligosporus mycelium develops, and the substrate is transformed. The process takes place under fermentation conditions in a solid medium for 24–48 h at a temperature of 30–35 °C with a relative air humidity of 85–90%. During fermentation, Rhizopus oligosporus produces a dense network of white hyphae (mycelium), which mechanically bind the seeds into a compact structure resembling dough. At the same time, biochemical processes take place, including partial proteolysis of soy proteins; hydrolysis of oligosaccharides (raffinose and stachyose); and synthesis of enzymes, including phytase, which increases the bioavailability of minerals. After about 12–15 h of fermentation, endogenous heat production begins through the developing mycelium, which requires temperature control of the process. Cooling the product to room temperature completes the fermentation process and stabilises the structure of the tempeh. Rapid cooling stops the further development of Rhizopus oligosporus and extends the shelf life of the product. The finished tempeh is characterised by a compact, plastic structure; a white surface covered with mycelium; and a characteristic aroma with nutty and mushroom notes. Packaging takes place under controlled sanitary conditions, often using vacuum packaging or in a modified atmosphere to extend shelf life. The product can also be pasteurised [9].

Figure 1.

Schematic representation of the tempeh production process.

5. Chemical Composition of Tempeh

All the data on the chemical composition of tempeh collated in this article are from studies using recognised reference analytical methods in accordance with AOAC. For the determination of protein content, the Kjeldahl or Dumas method was used [2,5]. For the determination of fat levels, the Soxhlet extraction or the Bligh and Dyer method was used [2,64]. Differential calculation or the phenol–sulphur method was used to determine carbohydrate concentration [5,62]. Total polyphenol content (TPC) was determined using the Folin–Ciocalteu method [2,6], and antioxidant activity was determined in two ways: as free-radical-neutralisation activity relative to the DPPH radical [2,5,6].

Table 2 shows a comparison of the chemical composition of tempeh obtained from different raw materials. Values in the table in the form of a range indicate differences due to different test methods or raw material varieties.

Table 2.

Chemical composition of tempeh from different raw materials.

Based on the analysis of the data in Table 2, it can be concluded that the average protein content of the tempeh samples tested is about 23.3% DM, with a minimum value of 2.8% for tempeh from tarwi and a maximum value of 47.1% for tempeh from chickpea. The cowpea beans (Vigna unguiculata) and lentils (Lens culinaris) with 46.2% DM are also rich sources of protein in tempeh from innovative substrates. The level of protein in these substrates is comparable to that in tempeh from soya (Glycine max)—44.9% DM. The most protein-poor substrates are brewer’s milling, rice, and barley—less than 10.0% DM is protein.

An analysis of the data in Table 2 found that the average fat content of the tempeh samples tested was about 9.2% DM, with a minimum value of 1.0%—for tempeh from common bean (Phaseolus vulgaris)—and a maximum value of 23.24%—for tempeh from soybean (Glycine max). Tempeh from soybeans (average 15.7%) and tempeh from large peas (Lathyrus sativus) (19.4%) are products with a markedly higher fat content, which may affect the creamier texture and higher calorie content of the finished product. The fat content of legume tempeh varies over a wide range from 1.2% to 19.4%, indicating a strong influence of raw material species and fermentation conditions. The other tempehs show moderate levels of fat (average 8.5%), with rapeseed pomace tempeh as an exception with a fairly high fat content (14.6%). The lack of fat content data for the cereal category makes it difficult to assess the influence of cereals on the fat profile of tempeh.

Tempeh fermentation is a complex biochemical process in which Rhizopus oligosporus produces specific enzymes responsible for the transformation of nutrients. The main mechanisms include protein proteolysis, which increases their bioavailability; the production of phytase, which eliminates phytic acid and increases the absorption of minerals; and the biosynthesis and release of polyphenols with antioxidant properties. These biochemical transformations make tempeh a product with a significantly higher nutritional value compared with the raw material.

Based on the analysis of the data in Table 2, the average carbohydrate content of the analysed tempehs was found to be around 31.2% DM, with a minimum value of 7.3% for tempeh from soybean (Glycine max) and a maximum value of 73.0% for tempeh from lentil (Lens culinaris). The highest concentration of carbohydrates is found in tempeh from lentils (Lens culinaris) (average 44.6%) and large peas (Lathyrus sativus) (66.3%), making them an excellent source of energy. The lowest content is observed in tempeh from soybean (Glycine max) (average 21.4%), which is due to the higher proportion of protein and fat in this raw material. Tempeh from legumes shows a wide range of carbohydrate content (7.3–73.0%), reflecting the diversity of their composition and fermentation methods. Tempeh from algae (Porphyra, Eucheuma) has a relatively low range of carbohydrate content (8.0–12.2%) due to the specific carbohydrate profile of these raw materials. The lack of data for cereals suggests the need to complete studies on tempeh based on barley (Hordeum vulgare), rice (Oryza sativa), and oats (Avena sativa) to assess their impact on the carbohydrate profile of the product.

Analysing the data in Table 2, the highest fibre content was observed in tempeh from Moringa oleifera seeds (average 27.0%). High levels of fibre are shown in tempeh from Jack bean and Eucheuma spinosum—content of approximately 16.0–17.0%. Raw materials with a high fibre content can enrich tempeh to aid peristalsis and increase its health benefits.

6. Content of Polyphenols, Isoflavones, and Antioxidant Activity

Antioxidants are a desirable functional property of food products, known for their beneficial health-promoting properties [26]. Tempeh is a source of valuable polyphenols—mainly isoflavones, flavonoids, and phenolic acids, which are responsible for antioxidant, anti-inflammatory, and anticancer activity and promote hormonal regulation [44,182]. Polyphenol content and antioxidant activity are key indicators of the health-promoting potential of tempeh. Table 3 summarises the polyphenol content and free-radical-neutralising activity against the DPPH radical of different tempeh types.

Table 3.

Summary of polyphenol content and antioxidant activity of tempeh from different raw materials.

Based on the analysis of the data in Table 3, it was found that the average polyphenol content among the tempeh samples tested was typically in the range of 2.0 to 137.5 mg GAE/g DM.

The highest polyphenol levels (>50.0 mg GAE/g DM) were recorded in mung bean (Vigna radiata) tempeh—as high as 137.5 mg GAE/g DM; sorghum (Sorghum bicolor) tempeh—64.2 mg GAE/g DM; and adlay (Coix lacryma-jobi) tempeh—58.2 mg GAE/g DM. The lowest values (<5 mg GAE/g DM) are shown by tempeh from lentils (Lens culinaris), large peas (Lathyrus sativus), oats (Avena sativa), broad beans (Vicia faba L.), common beans (Phaseolus vulgaris), and chickpeas (Cicer arietinum).

Analysing the data in Table 3, it was noted that the vast majority of tempeh showed moderate-to-high DPPH-radical-neutralising activity: 39.0–70.0% inhibition. The highest antioxidant activities were recorded for soybean (Glycine max) tempeh—50.0–84.0% and Jack bean (Canavalia ensiformis) tempeh—up to 69.7%.

Fermentation of tempeh almost always increases polyphenol levels and DPPH radical scavenging efficiency relative to unfermented seeds. The differences between the tempeh samples analysed are mainly due to type and variety of raw material, duration and course of fermentation, and possible functional additives (e.g., spices [182], tea extracts [183]).

Reduction of Anti-Nutritional Factors Through Fermentation

Fermentation of tempeh results in a significant reduction in the anti-nutritional factors present in the raw legumes. The content of trypsin inhibitors decreases by 64–67% after fermentation, and additional frying of the product further reduces their levels [184,185,186,187]. In each of the variants analysed, there is also a marked decrease in the concentration of phytates and tannins, which are responsible for limiting the bioavailability of minerals [53]. The process of protein hydrolysis, which occurs during fermentation, leads to an increase in free amino acids and peptides, which directly translates into an improvement in the digestibility and bioavailability of the protein in the finished product [8,184,186,187].

7. Conclusions

This comprehensive review demonstrates that tempeh fermentation with Rhizopus oligosporus represents a versatile and sustainable approach for developing innovative plant-based protein foods from diverse raw materials [2,3,5,6]. The analysis of over 25 different substrates reveals significant opportunities for enhancing nutritional and functional properties beyond traditional soybean-based formulations. The fermentation process consistently achieves substantial reductions in anti-nutritional factors, with a 64.0–67.0% decrease in trypsin inhibitors and up to 65.0% reduction in phytates, while simultaneously enhancing protein digestibility and bioactive compound availability across all substrate categories.

Several alternative substrates demonstrate superior nutritional profiles compared with traditional soybean tempeh, notably tarwi (Lupinus mutabilis) with exceptional protein content (32.0–53.0% DM) and mung bean (Vigna radiata) exhibiting remarkably high polyphenol concentrations (137.5 mg GAE/g DM). The diversity of bioactive compounds identified across different substrates, from curcumin in wild turmeric tempeh to phycobiliproteins in algae-based variants, demonstrates potential for developing targeted functional foods with specific health-promoting properties. Consistent antioxidant activities (39.0–70.0% DPPH inhibition) across most tempeh variants further support their potential as functional food ingredients.

Tempeh technology enables the effective utilisation of underutilised raw materials including legumes, cereals, algae, seeds, and agricultural by-products, contributing to sustainable food system development through protein source diversification. The results indicate substantial potential for developing functional plant foods with enhanced nutritional profiles and diverse bioactive ingredient compositions, supporting both human nutrition and environmental sustainability objectives.

8. Remarks on Future Directions

Systematic studies are needed to optimise the fermentation parameters (temperature, humidity, duration, inoculum concentration) for each substrate category. The current literature reveals significant gaps in standardised processing protocols, particularly for cereal and algae-based substrates. Future research should prioritise the complete nutritional profiling of promising substrates, as numerous gaps exist in the current data (particularly with reference to fibre content, amino acid profiles, and mineral bioavailability). Advanced analytical techniques should be employed to characterise the bioactive peptides formed during fermentation.

Limited sensory evaluation data represents a critical research gap. Comprehensive consumer acceptance studies, texture analysis, and flavour profiling are essential for commercial viability, particularly for substrates with distinct organoleptic properties.

Life cycle analyses comparing the environmental impacts of different substrates should be conducted to support sustainable food system development. This includes evaluation of water usage, carbon footprint, and land use efficiency.

Research on large-scale production challenges, including substrate preparation, fermentation control, and quality standardisation, is crucial for commercial implementation. Development of standardised quality parameters and shelf-life studies for innovative tempeh variants are particularly needed.

Establishment of regulatory guidelines for novel tempeh substrates, particularly those containing algae or unconventional plant materials, will be essential for market acceptance and food safety assurance.

Human clinical trials investigating the health effects of specific tempeh variants, particularly those with enhanced bioactive compound profiles, should be prioritised to substantiate functional food claims.

Future research should explore synergistic combinations of different substrates to optimise nutritional profiles, potentially creating tempeh products with enhanced protein quality, improved amino acid balance, and complementary bioactive compound portfolios.

The evidence presented in this review strongly supports the potential for tempeh technology to contribute significantly to global food security and sustainable nutrition through the diversification of protein sources and the enhancement of plant food functionality. However, realising this potential requires coordinated research efforts addressing the identified knowledge gaps and technological challenges.

Author Contributions

Conceptualisation, K.G. and J.H.; methodology, K.G.; investigation, K.G.; data curation, K.G.; writing—original draft preparation, K.G. and J.H.; writing—review and editing, K.G., E.P., and J.H.; funding—E.P.; visualisation, K.G. and J.H.; supervision, J.H.; project administration, J.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kaur, S.; Das, M. Functional Foods: An Overview. Food Sci. Biotechnol. 2011, 20, 861–875. [Google Scholar] [CrossRef]

- Kuligowski, M.; Pawłowska, K.; Jasińska-Kuligowska, I.; Nowak, J. Isoflavone composition, polyphenols content and antioxidative activity of soybean seeds during tempeh fermentation. CyTA J. Food 2017, 15, 27–33. [Google Scholar] [CrossRef]

- Martineau-Côté, D.; Achouri, A.; Karboune, S.; L’Hocine, L. Faba Bean: An Untapped Source of Quality Plant Proteins and Bioactives. Nutrients 2022, 14, 1541. [Google Scholar] [CrossRef] [PubMed]

- Rizzo, G. Soy-Based Tempeh as a Functional Food: Evidence for Human Health and Future Perspective. Front. Biosci. 2024, 16, 3. [Google Scholar] [CrossRef]

- Toor, B.S.; Kaur, A.; Kaur, J. Fermentation of legumes with Rhizopus oligosporus: Effect on physicochemical, functional and microstructural properties. Int. J. Food Sci. Technol. 2022, 57, 1763–1772. [Google Scholar] [CrossRef]

- Tsalissavrina, I.; Murdiati, A.; Raharjo, S.; Lestari, L.A. The Effects of Duration of Fermentation on Total Phenolic Content, Antioxidant Activity, and Isoflavones of The Germinated Jack Bean Tempeh (Canavalia ensiformis). Indones. J. Pharm. 2023, 34, 460–470. [Google Scholar] [CrossRef]

- Barus, T.; Titarsole, N.N.; Mulyono, N.; Prasasty, V.D. Tempeh Antioxidant Activity Using DPPH Method: Effects of Fermentation, Processing, and Microorganisms. J. Food Eng. Technol. 2019, 8, 75–80. [Google Scholar] [CrossRef]

- Sharma, R.; Garg, P.; Kumar, P.; Bhatia, S.K.; Kulshrestha, S. Microbial Fermentation and Its Role in Quality Improvement of Fermented Foods. Fermentation 2020, 6, 106. [Google Scholar] [CrossRef]

- Shurtleff, W.; Aoyagi, A. A Super Soyfood from Indonesia. In The Book of Tempeh; Soyinfo Center: Lafayette, CA, USA, 2001. [Google Scholar]

- Chang, C.-T.; Hsu, C.-K.; Chou, S.-T.; Chen, Y.-C.; Huang, F.-S.; Chung, Y.-C. Effect of fermentation time on the antioxidant activities of tempeh prepared from fermented soybean using Rhizopus oligosporus. Int. J. Food Sci. Technol. 2009, 44, 799–806. [Google Scholar] [CrossRef]

- Omosebi, M.O.; Otunola, E.T. Preliminary studies on tempeh flour produced from three different Rhizopus species. Int. J. Biotechnol. Food Sci. 2013, 1, 90–96. [Google Scholar]

- Chong, B.C.W.; Panizzi, M.C.C.; Mandarino, J.M.G.; Silva, J.B.D.; Benedetti, S.; Ida, E.I. Contents and bioconversion of β glycoside isoflavones to aglycones in the processing conditions of soybean tempeh. Pesqui. Agropecu. Bras. 2016, 51, 271–279. [Google Scholar] [CrossRef]

- Hidayat, S.N.; Nuringtyas, T.R.; Triyana, K. Electronic Nose Coupled with Chemometrics for Monitoring of Tempeh Fermentation Process. In Proceedings of the 2018 4th International Conference on Science and Technology, ICST 2018, Yogyakarta, Indonesia, 7–8 August 2018; Institute of Electrical and Electronics Engineers: New York, NY, USA, 2018. [Google Scholar] [CrossRef]

- Tahir, A.; Anwar, M.; Mubeen, H.; Raza, S. Evaluation of Physicochemical and Nutritional Contents in Soybean Fermented Food Tempeh by Rhizopus oligosporus. J. Adv. Biol. Biotechnol. 2018, 17, 1–9. [Google Scholar] [CrossRef]

- Erkan, S.B.; Gürler, H.N.; Bilgin, D.G.; Germec, M.; Turhan, I. Production and characterization of tempehs from different sources of legume by Rhizopus oligosporus. LWT 2020, 119, 108880. [Google Scholar] [CrossRef]

- Pramudito, T.E.; Putri, E.G.A.; Paluphi, E.; Yogiara, Y. The effect of starter culture on bacterial profile in soybean tempeh. Food Res. 2021, 5, 380–389. [Google Scholar] [CrossRef]

- Rizal, S.; Kustyawati, M.E.; Murhadi; Hasanudin, U. The growth of yeast and fungi, the formation of β-glucan, and the antibacterial activities during soybean fermentation in producing tempeh. Int. J. Food Sci. 2021, 2021, 6676042. [Google Scholar] [CrossRef] [PubMed]

- Yudiono, K.; Ayu, W.C.; Susilowati, S. Antioxidant activity, total phenolic, and aflatoxin contamination in tempeh made from assorted soybeans (Glycine max L. Merrill). Food Res. 2021, 5, 393–398. [Google Scholar] [CrossRef] [PubMed]

- Bintari, S.H.; Purnama, D.F.E.; Saputro, D.D.; Sunyoto, S.; Dewi, P.; Mubarok, I. Microbiological and Biochemical Tests on Tempe Production Using Tempe Mold Innovation. Biosaintifika 2022, 14, 245–253. [Google Scholar] [CrossRef]

- Chitisankul, W.T.; Shimada, K.; Tsukamoto, C. Antioxidative Capacity of Soyfoods and Soy Active Compounds. Pol. J. Food Nutr. Sci. 2022, 72, 101–108. [Google Scholar] [CrossRef]

- Dwiatmaka, Y.; Yuniarti, N.; Lukitaningsih, E.; Wahyuono, S. Fermentation of Soybean Seeds Using Rhizopus oligosporus for Tempeh Production and Standardization Based on Isoflavones Content. Int. J. Appl. Pharm. 2022, 14, 131–136. [Google Scholar] [CrossRef]

- Lo, D.; Romulo, A.; Lin, J.Y.; Wang, Y.T.; Wijaya, C.H.; Wu, M.C. Effect of Different Fermentation Conditions on Antioxidant Capacity and Isoflavones Content of Soy Tempeh. AIMS Agric. Food 2022, 7, 567–579. [Google Scholar] [CrossRef]

- Maitresya, L.B.; Surya, R. Development of Tempeh Made from Soybeans, Black-Eyed Beans, and Winged Beans. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: Bristol, UK, 2023; Volume 1200. [Google Scholar] [CrossRef]

- Rizal, S.; Kustyawati, M.E.; Suharyono, A.S.; Suyarto, V.A. Changes of Nutritional Composition of Tempeh during Fermentation with the Addition of Saccharomyces Cerevisiae. Biodiversitas 2022, 23, 1553–1559. [Google Scholar] [CrossRef]

- Yodsenee, K.; Suthirawut, S.; Pilasombut, K.; Urairong, H.; Rumjuankiat, K. In Vitro Study of Antioxidant and Antimicrobial Activities of Soybean Tempeh and Split Gill Fungus (Schizophyllum Commune) as Plant-Based Diets. Int. J. Agric. Technol. 2022, 18, 1339–1354. [Google Scholar]

- Herawati, H.; Kamsiati, E.; Afifah, D.N.; Kusumaningtyas, E.; Bachtiar, M.; Sunarmani; Agustinisari, I. Characteristics of GABA (Gamma Amino Butyric Acid), Antioxidant and Sensory Quality of Modified Tempeh. Int. J. Food Prop. 2023, 26, 3532–3543. [Google Scholar] [CrossRef]

- Liu, W.T.; Huang, C.L.; Liu, R.; Yang, T.C.; Lee, C.L.; Tsao, R.; Yang, W.J. Changes in Isoflavone Profile, Antioxidant Activity, and Phenolic Contents in Taiwanese and Canadian Soybeans during Tempeh Processing. LWT 2023, 186, 115207. [Google Scholar] [CrossRef]

- Syahputra, T.S.; Ihsan, N.; Kombo, K.O.; Faizah, K.; Wahyono; Widada, J.; Triyana, K. Integration of Low-Cost Multispectral Sensors and Electronic Nose for Enhanced Fermentation Monitoring in Tempeh Production. J. Food Meas. Charact. 2025, 19, 3687–3701. [Google Scholar] [CrossRef]

- Polanowska, K.; Szwengiel, A.; Kuligowski, M.; Nowak, J. Degradation of Pyrimidine Glycosides and L-DOPA in the Faba Bean by Rhizopus oligosporus. LWT 2020, 127, 109353. [Google Scholar] [CrossRef]

- Fernandez Castaneda, L.A.; Auer, J.; Leong, S.L.L.; Newson, W.R.; Passoth, V.; Langton, M.; Zamaratskaia, G. Optimizing Soaking and Boiling Time in the Development of Tempeh-Like Products from Faba Bean (Vicia faba L.). Fermentation 2024, 10, 807. [Google Scholar] [CrossRef]

- Fernandez Castaneda, L.A.; Saini, S.; Laaksonen, O.; Kårlund, A.; Leong, S.L.L.; Newson, W.R.; Zamaratskaia, G. Sensory and volatile compound profiles in tempeh-like products from faba bean and oats. Curr. Res. Food Sci. 2025, 10, 101029. [Google Scholar] [CrossRef]

- Thulesen, L.; Duque-Estrada, P.; Zhang, L.; Martin, M.S.; Aaslyng, M.D.; Petersen, I.L. Faba bean tempeh: The effects of fermentation and cooking on protein nutritional quality and sensory quality. Food Chem. Adv. 2025, 6, 100894. [Google Scholar] [CrossRef]

- Tan, Z.J.; Abu Bakar, M.F.; Lim, S.Y.; Sutimin, H. Nutritional composition and sensory evaluation of tempeh from different combinations of beans. Food Res. 2024, 8, 138–146. [Google Scholar] [CrossRef]

- Kim, J.S.; Kim, J.; Kim, S.H.; Moon, K.D. Development of chickpea tempeh using Rhizopus oryzae for dysphagia diet: Effect of fermentation time and heat treatment. Innov. Food Sci. Emerg. Technol. 2025, 100, 103940. [Google Scholar] [CrossRef]

- Andriati, N.; Anggrahini, S.; Setyaningsih, W.; Sofiana, I.; Pusparasi, D.A.; Mossberg, F. Physicochemical characterization of jack bean (Canavalia ensiformis) tempeh. Food Res. 2018, 2, 481–485. [Google Scholar] [CrossRef]

- Purwandari, F.A.; Fogliano, V.; Capuano, E. Tempeh fermentation improves the nutritional and functional characteristics of Jack beans (Canavalia ensiformis (L.) DC). Food Funct. 2024, 15, 3680–3691. [Google Scholar] [CrossRef]

- Rizal, S.; Kustyawati, M.E.; Sartika, D.; Sasriany, R.; Hidayat, R.; Suyantohadi, A. Innovation of tempeh from jack bean (Canavalia ensiformis) fermented with Mosaccha inoculum. Food Biosci. 2024, 62, 105564. [Google Scholar] [CrossRef]

- Yarlina, V.P.; Djali, M.; Andoyo, R.; Lani, M.N.; Rifqi, M. Effect of Soaking and Proteolytic Microorganisms Growth on the Protein and Amino Acid Content of Jack Bean Tempeh (Canavalia ensiformis). Processes 2023, 11, 1161. [Google Scholar] [CrossRef]

- Yarlina, V.P.; Nabilah, F.; Zaida; Nurhasanah, S.; Lani, M.N. Optimal Fermentation Time for Jack Bean (Canavalia ensiformis) Tempeh: A Comprehensive Pattern Analysis of Chemical and Enzyme Changes. Curr. Res. Nutr. Food Sci. 2024, 12, 1143–1153. [Google Scholar] [CrossRef]

- Agustia, F.C.; Winarsi, H.; Fitriani, A.; Latifasari, N. Impact of Packaging Variations on the Amino Acid Profile, Proximate Content, and Antinutritional Components of Tempeh from Jack Bean Sprouts. Prev. Nutr. Food Sci. 2025, 30, 56–67. [Google Scholar] [CrossRef]

- Amadi, E.N.; Uneze, R.; Barimalaa, I.S.; Achinewhu, S.C. Studies on the production of bambara groundnut (Vigna subterranea) tempe. Plant Foods Hum. Nutr. 1999, 53, 199–208. [Google Scholar] [CrossRef]

- Lakshmy, P.S.; Usha, V.; Sharon, C.L.; Aneena, E.R. Rice and Green Gram Based ‘Tempeh’—Development and In Vitro Mineral Bioavailability. J. Trop. Agric. 2015, 53, 166–172. [Google Scholar]

- Reyes-Bastidas, M.; Reyes-Fernández, E.Z.; López-Cervantes, J.; Milán-Carrillo, J.; Loarca-Piña, G.F.; Reyes-Moreno, C. Physicochemical, Nutritional and Antioxidant Properties of Tempeh Flour from Common Bean (Phaseolus vulgaris L.). Food Sci. Technol. Int. 2010, 16, 427–434. [Google Scholar] [CrossRef] [PubMed]

- Kuligowski, M.; Gorzan, A.; Jasińska-Kuligowska, I.; Nowak, J. Ocena Wpływu Obróbki Hydrotermicznej i Czasu Fermentacji na Zawartość Polifenoli i Właściwości Antyoksydacyjne Produktów Tempeh. Zesz. Probl. Post. Nauk. Roln. 2014, 577, 73–82. [Google Scholar]

- Starzyńska-Janiszewska, A.; Stodolak, B.; Mickowska, B. Effect of Controlled Lactic Acid Fermentation on Selected Bioactive and Nutritional Parameters of Tempeh Obtained from Unhulled Common Bean (Phaseolus vulgaris) Seeds. J. Sci. Food Agric. 2014, 94, 359–366. [Google Scholar] [CrossRef]

- Vital, R.J.; Bassinello, P.Z.; Cruz, Q.A.; Carvalho, R.N.; De Paiva, J.C.M.; Colombo, A.O. Production, Quality, and Acceptance of Tempeh and White Bean Tempeh Burgers. Foods 2018, 7, 136. [Google Scholar] [CrossRef]

- Jaijaroensakundee, C.; Shen, J.; Zhou, Z.; Xiao, H. Exploring Black Bean Tempeh: A Novel Addition to Plant-Based Nutrition. Curr. Dev. Nutr. 2025, 9, 106688. [Google Scholar] [CrossRef]

- Stodolak, B.; Starzyńska-Janiszewska, A.; Mickowska, B. Effect of Flaxseed Oil-Cake Addition on the Nutritional Value of Grass Pea Tempeh. Food Sci. Technol. Res. 2013, 19, 1107–1114. [Google Scholar] [CrossRef][Green Version]

- Starzyńska-Janiszewska, A.; Stodolak, B.; Wikiera, A. Proteolysis in Tempeh-Type Products Obtained with Rhizopus and Aspergillus Strains from Grass Pea (Lathyrus sativus) Seeds. Acta Sci. Pol. Technol. Aliment. 2015, 14, 125–132. [Google Scholar] [CrossRef]

- Stodolak, B.; Starzyńska-Janiszewska, A.; Wikiera, A. Wpływ Dodatku Wytłoków Lnianych na Potencjał Antyoksydacyjny Tempe z Nasion Lędźwianu. Żywność Nauka Technol. Jakość/Food Sci. Technol. Qual. 2015, 22, 96–105. [Google Scholar] [CrossRef]

- Signorini, C.; Carpen, A.; Coletto, L.; Borgonovo, G.; Galanti, E.; Capraro, J.; Scarafoni, A. Enhanced vitamin B12 production in an innovative lupin tempeh is due to synergic effects of Rhizopus and Propionibacterium in cofermentation. Int. J. Food Sci. Nutr. 2018, 69, 451–457. [Google Scholar] [CrossRef]

- Wolkers-Rooijackers, J.C.M.; Endika, M.F.; Smid, E.J. Enhancing vitamin B12 in lupin tempeh by in situ fortification. LWT 2018, 96, 513–518. [Google Scholar] [CrossRef]

- Parra-Gallardo, G.; Quimbiulco-Sánchez, K.; Salas-Sanjuán, M.d.C.; del Moral, F.; Valenzuela, J.L. Alternative Development and Processing of Fermented Beverage and Tempeh Using Green Beans from Four Genotypes of Lupinus mutabilis. Fermentation 2023, 9, 590. [Google Scholar] [CrossRef]

- Suryanti, V.; Marliyana, S.D.; Rohana, G.L.; Trisnawati, E.W.; Widiyanti, W. Bioactive compound contents and antioxidant activity of fermented lead tree (Leucaena leucocephala (Lmk.) de Wit) seeds. Molekul 2021, 16, 192–199. [Google Scholar] [CrossRef]

- Cai, S.; Gao, F.; Zhang, X.; Wang, O.; Wu, W.; Zhu, S.; Ji, B. Evaluation of γ-aminobutyric acid, phytate and antioxidant activity of tempeh-like fermented oats (Avena sativa L.) prepared with different filamentous fungi. J. Food Sci. Technol. 2014, 51, 2544–2551. [Google Scholar] [CrossRef]

- Zwinkels, J.; Wolkers-Rooijackers, J.; Smid, E.J. Solid-state fungal fermentation transforms low-quality plant-based foods into products with improved protein quality. LWT 2023, 184, 114979. [Google Scholar] [CrossRef]

- Ridhowati, S.; Lestari, S.D.; Wulandari, W.; Rinto, R. Lotus (Nelumbo nucifera) tempeh Indonesia as antioxidant and breast anticancer food-a preliminary study. Asian J. Plant Sci. 2020, 19, 406–411. [Google Scholar] [CrossRef]

- Ridhowati, S.; Nainggolan, K.; Sudirman, S. Optimalisasi Respons Surface Terhadap Profil Asam Tempe Lotus (Nelumbo nucifera) Rawa Perikanan. J. FishtecH 2023, 11, 107–115. [Google Scholar] [CrossRef]

- Ridhowati, S.; Herpandi, H.; Widiastuti, I. Profiles of volatile metabolite compounds of lotus tempeh: In-RSM-Boxbehken approach. Int. J. Second. Metab. 2025, 12, 355–367. [Google Scholar] [CrossRef]

- Nurhaeni; Darwis, D.; Satrimafitrah, P. Fermented Moringa oleifera seeds enhanced with Euchema cottonii as an alternative tempeh: Organoleptic analysis, protein, and fiber content. Rasayan J. Chem. 2021, 14, 155–160. [Google Scholar] [CrossRef]

- Pantaya, D.; Wulandari, S.; Yulinarsari, A.P.; Poernomo, H. Evaluation of Rubber Seed Meal (Hevea brasiliensis) by Fermentation Method Using Rhizopus oligosporus and Neurospora sitophila Fungi. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: Bristol, UK, 2023; Volume 1168. [Google Scholar] [CrossRef]

- Surya, R.; Megumi, E.H.; Rombot, O.; Nugroho, D.; Tedjakusuma, F. Supplementation of Red Alga (Porphyra) Improves Nutritional Profile, Protein Digestibility and Sensory Acceptance of Tempeh. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: Bristol, UK, 2024; Volume 1413. [Google Scholar] [CrossRef]

- Surya, R.; Tedjakusuma, F.; Rombot, O.; Nugroho, D. Supplementation of Dried Porphyra Alga (Nori) Improves Antioxidant Activity and Isoflavone Bioavailability of Tempeh. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: Bristol, UK, 2025; Volume 1445. [Google Scholar] [CrossRef]

- Dewi, E.N.; Susanto, E.; Purnamayati, L. Application of Eucheuma spinosum for Enhancing the Nutritional Value of Tempeh. Pertanika J. Trop. Agric. Sci. 2025, 48, 543–560. [Google Scholar] [CrossRef]

- Evangelista, P.; Surya, R. Nutritional Profile, Antioxidant Activities and Organoleptic Properties of Tempeh Fermented with Additional Butterfly Pea Flower Petals. In IOP Conference Series: Earth and Environmental Science; Institute of Physics: Bristol, UK, 2024; Volume 1324. [Google Scholar] [CrossRef]

- Lim, J.; Nguyen, T.T.H.; Pal, K.; Gil Kang, C.; Park, C.; Kim, S.W.; Kim, D. Phytochemical Properties and Functional Characteristics of Wild Turmeric (Curcuma aromatica) Fermented with Rhizopus oligosporus. Food Chem. X 2022, 13, 100198. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Camacho, C.E.; Mollea, C.; Mazzarino, I.; Ruggeri, B.; Bosco, F. Repurposing Tempeh Fermentation: A Promising Protein Source Using Food Residues and Edible Filamentous Fungi. Chem. Eng. Trans. 2022, 93, 37–42. [Google Scholar] [CrossRef]

- Lücke, F.K.; Fritz, V.; Tannhäuser, K.; Arya, A. Controlled Fermentation of Rapeseed Presscake by Rhizopus, and Its Effect on Some Components with Relevance to Human Nutrition. Food Res. Int. 2019, 120, 726–732. [Google Scholar] [CrossRef] [PubMed]

- Gimbun, J.; Ali, S.; Kanwal, C.C.S.C.; Shah, L.A.; Hidayah, N.; Cheng, C.K.; Nurdin, S. Biodiesel production from rubber seed oil using activated cement clinker as catalyst. Procedia Eng. 2013, 53, 13–19. [Google Scholar] [CrossRef]

- Ahmad, J.; Yusup, S.; Bokhari, A.; Kamil, R.N.M. Study of fuel properties of rubber seed oil based biodiesel. Energy Convers. Manag. 2014, 78, 266–275. [Google Scholar] [CrossRef]

- Weng, W.F.; Peng, Y.; Pan, X.; Yan, J.; Li, X.D.; Liao, Z.Y.; Cheng, J.P.; Gao, A.J.; Yao, X.; Ruan, J.J.; et al. Adlay, an ancient functional plant with nutritional quality, improves human health. Front. Nutr. 2022, 9, 1019375. [Google Scholar] [CrossRef]

- Ahmad, R.; Liaquat, M.; Sammi, S.; Al-Hawadi, J.S.; Jahangir, M.; Mumtaz, A.; Khan, I.; Okla, M.K.; Alaraidh, I.A.; AbdElgawad, H.; et al. Physicochemical and nutritional profiles of wild adlay (Coix lacryma-jobi Linn) accessions by GC, FTIR, and spectrophotometer. Food Chem. X 2024, 22, 101418. [Google Scholar] [CrossRef]

- Seyie, Z.; Saikia, K.; Saikia, C.K.; Handique, G.K.; Handique, A.K. Evaluation of Underutilized Cereal Crop Coix lacryma jobi (Job’s Tear) for Nutritive and Nutraceutical Values. Int. J. Agric. Environ. Sci. 2018, 5, 17–24. [Google Scholar]

- Labba, I.-C.M.; Frøkiær, H.; Sandberg, A.-S. Nutritional and antinutritional composition of fava bean (Vicia faba L., var. minor) cultivars. Food Res. Int. 2021, 140, 110038. [Google Scholar] [CrossRef]

- Zhu, M.; Liu, Q.; Zhang, Y.; Chen, J.; Sun, Z.; Ren, C.; Zhang, Z.; Cheng, X.; Huang, Y. Nutritive value of faba bean (Vicia faba L.) as a feedstuff resource in livestock nutrition: A review. Food Sci. Nutr. 2021, 9, 5244–5262. [Google Scholar] [CrossRef]

- Yehmed, J.; Tlahig, S.; Mohamed, A.; Yahia, H.; Lachiheb, B.; Ben Yahia, L.; Loumerem, M. Nutritional and Phytochemical Profiling of Vicia faba L. var. Minor Seeds: A Multifaceted Exploration of Natural Antioxidants and Functional Food Potential. Appl. Biochem. Biotechnol. 2024, 196, 8471–8492. [Google Scholar] [CrossRef]

- Baranowska, A. Health-promoting properties of broad beans (Vicia faba L.) Właściwości Prozdrowotne Bobu (Vicia faba L.). Health Prob. Civ. 2024, 18, 481–490. [Google Scholar]

- Kumar, N.; Hong, S.; Zhu, Y.; Garay, A.; Yang, J.; Henderson, D.; Zhang, X.; Xu, Y.; Li, Y. Comprehensive review of chickpea (Cicer arietinum): Nutritional significance, health benefits, techno-functionalities, and food applications. Compr. Rev. Food Sci. Food Saf. 2025, 24, e70152. [Google Scholar] [CrossRef]

- Kaur, R.; Prasad, K. Technological, Processing and Nutritional Aspects of Chickpea (Cicer arietinum)—A Review. Trends Food Sci. Technol. 2021, 109, 448–463. [Google Scholar] [CrossRef]

- Budryn, G.; Grzelczyk, J. Assessment of the Nutritional Value and Antioxidant Properties of Plant-Based Yogurt from Chickpeas. Appl. Sci. 2024, 14, 9228. [Google Scholar] [CrossRef]

- Akram, S.; Afzal, M.F.; Anwer, K.; Farman, L.; Zubair, M.; Kousar, S.; Iqbal, T.; Khalid, W.; Elawad, M.A.; Ahmed, A.; et al. Nutraceutical Properties, Biological Activities, and Industrial Applications of Chickpea Protein. Cogent Food Agric. 2024, 10, 2338653. [Google Scholar] [CrossRef]

- Guan, B.; Sun, Y.; Liu, X.; Zhong, C.; Li, D.; Shan, X.; Hui, X.; Lu, C.; Huo, Y.; Sun, R.; et al. Comparative Evaluation of Amino Acid Profiles, Fatty Acid Compositions, and Nutritional Value of Two Varieties of Head Water Porphyra yezoensis: “Jianghaida No. 1” and “Sutong No.1”. Food Chem. X 2024, 22, 100825. [Google Scholar] [CrossRef] [PubMed]

- Arakaki, N.; Flores Ramos, L.; Oscanoa Huaynate, A.I.; Ruíz Soto, A.; Ramírez, M.E. Biochemical and Nutritional Characterization of Edible Seaweeds from the Peruvian Coast. Plants 2023, 12, 1795. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Jiang, H.; Fu, L.; Ci, F.; Mao, X. Porphyran and Oligo-Porphyran Originating from Red Algae Porphyra: Preparation, Biological Activities, and Potential Applications. Food Chem. 2021, 349, 129188. [Google Scholar] [CrossRef]

- Cian, R.E.; Fajardo, M.A.; Alaiz, M.; Vioque, J.; González, R.J.; Drago, S.R. Chemical Composition, Nutritional and Antioxidant Properties of the Red Edible Seaweed Porphyra columbina. Int. J. Food Sci. Nutr. 2014, 65, 299–305. [Google Scholar] [CrossRef]

- Venkatraman, K.L.; Mehta, A. Health Benefits and Pharmacological Effects of Porphyra Species. Plant Foods Hum. Nutr. 2019, 74, 10–17. [Google Scholar] [CrossRef]

- Park, S.K.; Kang, J.Y.; Kim, J.M.; Kim, M.J.; Lee, H.L.; Moon, J.H.; Jeong, H.R.; Kim, H.-J.; Chung, M.-Y.; Heo, H.J. Porphyra tenera Protects against PM2.5-Induced Cognitive Dysfunction with the Regulation of Gut Function. Mar. Drugs 2022, 20, 439. [Google Scholar] [CrossRef]

- Peñalver, R.; Lorenzo, J.M.; Nieto, G. Bioaccessibility, Digestibility and Nutritional Properties of Algae and Cyanophyceae as Basis of Their Potential as Functional Food Ingredients. Appl. Food Res. 2024, 4, 100247. [Google Scholar] [CrossRef]

- Aziz, E.; Batool, R.; Khan, M.U.; Rauf, A.; Akhtar, W.; Heydari, M.; Rehman, S.; Shahzad, T.; Malik, A.; Mosavat, S.H.; et al. An Overview on Red Algae Bioactive Compounds and Their Pharmaceutical Applications. J. Complement. Integr. Med. 2020, 17, 1–21. [Google Scholar] [CrossRef]

- García-Casal, M.N.; Ramírez, J.; Leets, I.; Pereira, A.C.; Quiroga, M.F. Antioxidant Capacity, Polyphenol Content and Iron Bioavailability from Algae (Ulva sp., Sargassum sp. and Porphyra sp.) in Human Subjects. Br. J. Nutr. 2009, 101, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Pise, N.M.; Sabale, A.B. Biochemical Composition of Seaweeds along Central West Coast of India. Pharmacogn. J. 2010, 2, 148–150. [Google Scholar] [CrossRef]

- Diharmi, A.; Fardiaz, D.; Andarwulan, N. Chemical and Minerals Composition of Dried Seaweed Eucheuma spinosum Collected from Indonesia Coastal Sea Regions. Int. J. Oceans Oceanogr. 2019, 13, 65–71. [Google Scholar]

- Damongilala, L.J.; Wewengkang, D.S.; Losung, F.; Tallei, T.E. Phytochemical and Antioxidant Activities of Eucheuma spinosum as Natural Functional Food from North Sulawesi Waters, Indonesia. Pak. J. Biol. Sci. 2021, 24, 132–138. [Google Scholar] [CrossRef]

- Boukar, O.; Massawe, F.; Muranaka, S.; Franco, J.; Maziya-Dixon, B.; Singh, B.; Fatokun, C. Evaluation of Cowpea Germplasm Lines for Protein and Mineral Concentrations in Grains. Plant Genet. Resour. 2011, 9, 515–522. [Google Scholar] [CrossRef]

- Amadou, I.; Sankhon, A.; Souley, R.A.; Harou, L.I. Nutritional Physical and Functional Properties of Wild Cowpea (Vigna vexillata (L.)) Grown in the Sahel Region. Am. J. Food Nutr. 2024, 12, 107–113. [Google Scholar] [CrossRef]

- Bai, Z.; Huang, X.; Meng, J.; Kan, L.; Nie, S. A Comparative Study on Nutritive Peculiarities of 24 Chinese Cowpea Cultivars. Food Chem. Toxicol. 2020, 146, 111841. [Google Scholar] [CrossRef]

- Sardar, H.; Hadi, F.; Alam, W.; Halawani, I.F.; Alzahrani, F.M.; Saleem, R.A.; Cerqua, I.; Khan, H.; Capasso, R. Unveiling the Therapeutic and Nutritious Potential of Vigna unguiculata in Line with Its Phytochemistry. Heliyon 2024, 10, e37911. [Google Scholar] [CrossRef]

- Okomoda, V.T.; Tiamiyu, L.O.; Uma, S.G. Effects of Hydrothermal Processing on Nutritional Value of Canavalia ensiformis and Its Utilization by Clarias gariepinus (Burchell, 1822) Fingerlings. Aquac. Rep. 2016, 3, 214–219. [Google Scholar] [CrossRef]

- Solomon, S.G.; Okomoda, V.T.; Oguche, O. Nutritional Value of Raw Canavalia ensiformis and Its Utilization as Partial Replacement for Soybean Meal in the Diet of Clarias gariepinus (Burchell, 1822) Fingerlings. Food Sci. Nutr. 2017, 6, 207–213. [Google Scholar] [CrossRef]

- Sutedja, A.M.; Yanase, E.; Batubara, I.; Fardiaz, D.; Lioe, H.N. Identification and Characterization of α-Glucosidase Inhibition Flavonol Glycosides from Jack Bean (Canavalia ensiformis (L.) DC). Molecules 2020, 25, 2481. [Google Scholar] [CrossRef]

- Madani, A.M.A.; Muhlisin, M.; Kurniawati, A.; Baskara, A.P.; Al Anas, M. Dietary jack bean (Canavalia ensiformis L.) supplementation enhanced intestinal health by modulating intestinal integrity and immune responses of broiler chickens. Heliyon 2024, 10, e034389. [Google Scholar] [CrossRef] [PubMed]

- Musah, M.; Azeh, Y.; Mathew, J.T.; Nwakife, C.N.; Mohammed, A.I.; Saidu, F. Nutritional Evaluation of Bambara Groundnut (Vigna subterranea (L.) Verdc) From Lapai, Nigeria. Afr. J. Agric. Food Sci. 2021, 4, 32–39. [Google Scholar] [CrossRef]

- Sarki, A.A.; Shoge, M.O.; Tamasi, A.A.; Ozioko, E.N.; Aliyu, M.O.; Adegboyega, T.T. Antimicrobial and Phytochemical Evaluation of Vigna subterranean (L.) Verdc. (Bambara groundnut). J. Underutil. Legum. 2021, 7, 22–28. [Google Scholar]

- Okafor, J.N.C.; Jideani, V.A.; Meyer, M.; Le Roes-Hill, M. Bioactive Components in Bambara Groundnut (Vigna subterranea (L.) Verdc) A Potential. Source Nutraceutical Ingredients. Heliyon 2022, 8, e09024. [Google Scholar] [CrossRef] [PubMed]

- Shahrajabian, M.H.; Sun, W.; Cheng, Q. A Short Review of Health Benefits and Nutritional Values of Mung Bean in Sustainable Agriculture. Pol. J. Agron. 2019, 37, 31–36. [Google Scholar]

- Anyiam, P.N.; Phongthai, S.; Sai-Ut, S.; Kingwascharapong, P.; Jung, Y.H.; Zhang, W.; Rawdkuen, S. Nutritional Components and Digestibility Profiles of Some Potential Plant-Based Protein Sources. Foods 2025, 14, 1769. [Google Scholar] [CrossRef]

- Karami, Z.; Changsiripun, C.; Duangmal, K.; Chotechuang, N. Health Benefits and Challenges of Mung Bean Bioactive Compounds: A Systematic Review of In Vivo Evidence for Functional Food Applications. Food Rev. Int. 2025, 41, 1681–1708. [Google Scholar] [CrossRef]

- Bepary, R.H.; Roy, A.; Pathak, K.; Deka, S.C. Biochemical Composition, Bioactivity, Processing, and Food Applications of Winged Bean (Psophocarpus tetragonolobus): A Review. Legum. Sci. 2023, 5, e187. [Google Scholar] [CrossRef]

- Alalade, J.A.; Akinlade, J.A.; Aderinola, O.A.; Fajemisin, A.N.; Muraina, T.O.; Amoo, T.A. Proximate, Mineral and Anti-Nutrient Contents in Psophocarpus tetragonolobus (L) DC. (Winged Bean) Leaves. Br. J. Pharm. Res. 2016, 10, 1–7. [Google Scholar] [CrossRef]

- Singh, A.; Gupta, A.; Sharma, S. Handbook of Cereals, Pulses, Roots, and Tubers; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

- Shimelis, E.A.; Rakshit, S.K. Proximate composition and physico-chemical properties of improved dry bean (Phaseolus vulgaris L.) varieties grown in Ethiopia. LWT 2005, 38, 331–338. [Google Scholar] [CrossRef]

- Brigide, P.; Canniatti-Brazaca, S.G.; Silva, M.O. Nutritional Characteristics of Biofortified Common Beans. Food Sci. Technol. Camp. 2014, 34, 493–500. [Google Scholar] [CrossRef]

- Mani, N.; Beatrice, A.D.; Priyadarshini, D.R. Phytochemical Analysis, In vitro Anti-oxidant, Anti-diabetic and Anti-inflammatory Activity of Red Kidney Bean (Phaseolus vulgaris L.). Int. J. Health Allied Sci. 2024, 13, 76–90. [Google Scholar] [CrossRef]

- Alvarado-Ramos, K.; Bravo-Nunez, Á.; Halimi, C.; Maillot, M.; Icard-Vernière, C.; Forti, C.; Preite, C.; Ferrari, L.; Sala, T.; Losa, A.; et al. Improving the Antinutritional Profiles of Common Beans (Phaseolus vulgaris L.) Moderately Impacts Carotenoid Bioaccessibility But Not Mineral Solubility. Sci. Rep. 2024, 14, 11908. [Google Scholar] [CrossRef]

- Pastor-Cavada, E.; Juan, R.; Pastor, J.E.; Alaiz, M.; Vioque, J. Nutritional characteristics of seed proteins in 15 Lathyrus species (Fabaceae) from Southern Spain. LWT Food Sci. Technol. 2011, 44, 1059–1064. [Google Scholar] [CrossRef]

- Aletor, O.; Onyemem, C.E.; Aletor, V.A. Nutrient Constituents, Functional Attributes and In Vitro Protein Digestibility of the Seeds of the Lathyrus Plant. Trans. Ecol. Environ. 2011, 152, 145–155. [Google Scholar]

- Gonçalves, L.; Rubiales, D.; Bronze, M.R.; Vaz Patto, M.C. Grass Pea (Lathyrus sativus L.)—A Sustainable and Resilient Answer to Climate Challenges. Agronomy 2022, 12, 1324. [Google Scholar] [CrossRef]

- Ramya, K.R.; Tripathi, K.; Pandey, A.; Barpete, S.; Gore, P.G.; Raina, A.P.; Khawar, K.M.; Swain, N.; Sarker, A. Rediscovering the Potential of Multifaceted Orphan Legume Grasspea—A Sustainable Resource with High Nutritional Values. Front. Nutr. 2022, 8, 826208. [Google Scholar] [CrossRef] [PubMed]

- Khalil, I.; Bashir, S.; Saeed, K.; Alsulami, T.; Rafique, H.; Mukonzo, E.K.L. Phytochemical and Structural Portrayal of Barley and Pearl Millet Through FTIR and SEM. Food Sci. Nutr. 2025, 13, e70120. [Google Scholar] [CrossRef]

- Agbai, C.M.; Olawuni, I.A.; Ofoedu, C.E.; Ibeabuchi, C.J.; Okpala, C.O.R.; Shorstkii, I.; Korzeniowska, M. Changes in Anti-Nutrient, Phytochemical, and Micronutrient Contents of Different Processed Rubber (Hevea brasiliensis) Seed Meals. PeerJ 2021, 9, e11327. [Google Scholar] [CrossRef]

- Udo, M.D.; Ekpo, U.; Ahamefule, F.O. Effects of Processing on the Nutrient Composition of Rubber Seed Meal. J. Saudi Soc. Agric. Sci. 2018, 17, 297–301. [Google Scholar] [CrossRef]

- Hossain, M.E.; Karim, M.H.; Alam, S.; Nath, S.K. Nutritive Value of Rubber Seed (Hevea brasiliensis). Online J. Anim. Feed Res. 2015, 5, 18–21. [Google Scholar]

- Soualiho, B.; Yao, J.-C.N.; John, K.K.; Losseyni, K.; Augustin, A.A. Evaluation of the Chemical and Biological Properties of Oil Extracted from Detoxified Rubber Tree (Hevea brasiliensis) Kernels. Am. J. BioSci. 2022, 10, 220–229. [Google Scholar] [CrossRef]

- Umar, N.M.; Parumasivam, T.; Aminu, N.; Toh, S.-M. Phytochemical and Pharmacological Properties of Curcuma aromatica Salisb (Wild Turmeric). J. Appl. Pharm. Sci. 2020, 10, 180–194. [Google Scholar] [CrossRef]

- Albaqami, J.J.; Hamdi, H.; Narayanankutty, A.; Visakh, N.U.; Sasidharan, A.; Kuttithodi, A.M.; Famurewa, A.C.; Pathrose, B. Chemical Composition and Biological Activities of the Leaf Essential Oils of Curcuma longa, Curcuma aromatica and Curcuma angustifolia. Antibiotics 2022, 11, 1547. [Google Scholar] [CrossRef]

- Pintatum, A.; Maneerat, W.; Logie, E.; Tuenter, E.; Sakavitsi, M.E.; Pieters, L.; Vanden Bergh, W.; Sripisut, T.; Deachathai, S.; Laphookhieo, S. In Vitro Anti-Inflammatory, Anti-Oxidant, and Cytotoxic Activities of Four Curcuma Species and the Isolation of Compounds from Curcuma aromatica Rhizome. Biomolecules 2020, 10, 799. [Google Scholar] [CrossRef]

- Hasanah, N.N.; Mohamad Azman, E.; Rozzamri, A.; Zainal Abedin, N.H.; Ismail-Fitry, M.R. A Systematic Review of Butterfly Pea Flower (Clitoria ternatea L.): Extraction and Application as a Food Freshness pH-Indicator for Polymer-Based Intelligent Packaging. Polymers 2023, 15, 2541. [Google Scholar] [CrossRef] [PubMed]

- Mukherjee, P.K.; Kumar, V.; Kumar, N.S.; Heinrich, M. The Ayurvedic Medicine Clitoria ternatea—From Traditional Use to Scientific Assessment. J. Ethnopharmacol. 2008, 120, 291–301. [Google Scholar] [CrossRef] [PubMed]

- Kazuma, K.; Noda, N.; Suzuki, M. Malonylated Flavonol Glycosides from the Petals of Clitoria ternatea. Phytochemistry 2003, 62, 229–237. [Google Scholar] [CrossRef]

- Bangar, S.P.; Dunno, K.; Kumar, M.; Mostafa, H.; Maqsood, S. A Comprehensive Review on Lotus Seeds (Nelumbo nucifera Gaertn.): Nutritional Composition, Health-Related Bioactive Properties, and Industrial Applications. J. Funct. Foods 2022, 89, 104973. [Google Scholar] [CrossRef]

- Purintraphiban, S.; Xia, Y. Effects of Germination on Chemical and Functional Properties of Lotus Seeds. Food Sci. 2012, 33, 91–98. [Google Scholar]

- Awal, M.R.; Rahmatullah, S.M.; Nasrin, S. Nutrient Composition of Lotus (Nelumbo nucifera) Fruits. Asian Australas. J. Biosci. Biotechnol. 2020, 5, 115–120. [Google Scholar] [CrossRef]

- Dai, G.; Wang, J.; Zheng, J.; Xia, C.; Wang, Y.; Duan, B. Bioactive Polysaccharides from Lotus as Potent Food Supplements: A Review of Their Preparation, Structures, Biological Features and Application Prospects. Front. Nutr. 2023, 10, 1171004. [Google Scholar] [CrossRef]

- Lim, S.-H.; Kim, S.-H.; Park, J.-J.; Park, Y.-S.; Dhungana, S.K.; Kim, I.-D.; Shin, D.-H. Quality Characteristics and Antioxidant Activities of Lotus (Nelumbo nucifera Gaertn.) Sprouts Grown Under Different Conditions. Korean J. Plant Res. 2020, 33, 666–674. [Google Scholar]

- Liu, X.; Dong, W.; Yi, Y.; Wang, L.; Hou, W.; Ai, Y.; Wang, H.; Min, T. Comparison of Nutritional Quality and Functional Active Substances in Different Parts of Eight Lotus Seed Cultivars. Foods 2024, 13, 2335. [Google Scholar] [CrossRef] [PubMed]

- Adomas, B.; Piotrowicz-Cieślak, A.; Kowalik, K. Wartość biologiczna białka nasion łubinu. Post. Nauk Rol. 2005, 52, 55–63. [Google Scholar]

- Lemus-Conejo, A.; Rivero-Pino, F.; Montserrat-de la Paz, S.; Millan-Linares, M.C. Nutritional Composition and Biological Activity of Narrow-Leafed Lupins (Lupinus angustifolius L.) Hydrolysates and Seeds. Food Chem. 2023, 420, 136104. [Google Scholar] [CrossRef]

- Castillo, R.F.; García Pérez, R.; González Díaz, A.; Liñán González, A. Therapeutic Applications and Effects of Lupinus angustifolius (Blue Lupin) and Its Components: A Systematic Review and Meta-Analysis. Foods 2023, 12, 2749. [Google Scholar] [CrossRef]

- Hernández-Santos, B.; Quijano-Jerónimo, O.; Rodríguez-Miranda, J. Physical, Chemical, Tecno-Functional, and Thermal Properties of Leucaena leucocephala Seed. Food Sci. Technol. 2022, 42, e74921. [Google Scholar] [CrossRef]

- De Angelis, A.; Gasco, L.; Parisi, G.; Danieli, P.P. A Multipurpose Leguminous Plant for the Mediterranean Countries: Leucaena leucocephala as an Alternative Protein Source: A Review. Animals 2021, 11, 2230. [Google Scholar] [CrossRef]

- Aquino-González, L.V.; Noyola-Altamirano, B.; Méndez-Lagunas, L.L.; Rodríguez-Ramírez, J.; Sandoval-Torres, S.; Bernal, L.G.B. Potential of Leucaena leucocephala and Leucaena esculenta Seeds in Human Nutrition: Composition, Techno-Functional Properties, Toxicology and Pretreatment Technologies. Legum. Res. 2023, 46, 1261–1270. [Google Scholar] [CrossRef]

- Balderas-León, I.; Baigts-Allende, D.; Cardador-Martínez, A. Antioxidant, Angiotensin-Converting Enzyme, and α-Amylase Inhibitory Activities of Protein Hydrolysates of Leucaena leucocephala Seeds. CyTA J. Food 2021, 19, 349–359. [Google Scholar] [CrossRef]

- Shi, P. Unlocking the Potential of Brewer’s Spent Grains: A Mini Review on Health and Nutritional Benefits. Nov. Tech. Nutr. Food Sci. 2024, 7, 766–768. [Google Scholar] [CrossRef]

- Merten, D.; Erman, L.; Marabelli, G.P.; Leners, B.; Ney, Y.; Nasim, M.J.; Jacob, C.; Tchoumtchoua, J.; Cajot, S.; Bohn, T. Potential Health Effects of Brewers’ Spent Grain as a Functional Food Ingredient Assessed by Markers of Oxidative Stress and Inflammation Following Gastro-Intestinal Digestion and in a Cell Model of the Small Intestine. Food Funct. 2022, 13, 5327–5342. [Google Scholar] [CrossRef]

- McCarthy, A.L.; O’Callaghan, Y.C.; Piggott, C.O.; FitzGerald, R.J.; O’Brien, N.M. Brewers’ Spent Grain; Bioactivity of Phenolic Component, Its Role in Animal Nutrition and Potential for Incorporation in Functional Foods: A Review. Proc. Nutr. Soc. 2013, 72, 117–125. [Google Scholar] [CrossRef] [PubMed]

- Ikram, S.; Huang, L.; Zhang, H.; Wang, J.; Yin, M. Composition and Nutrient Value Proposition of Brewers Spent Grain. J. Food Sci. 2017, 82, 2232–2242. [Google Scholar] [CrossRef]

- Leone, A.; Spada, A.; Battezzati, A.; Schiraldi, A.; Aristil, J.; Bertoli, S. Moringa oleifera Seeds and Oil: Characteristics and Uses for Human Health. Int. J. Mol. Sci. 2016, 17, 2141. [Google Scholar] [CrossRef]

- Compaore, W.R.; Nikiema, P.A.; Bassole, H.I.N.; Savadogo, A.; Mouecoucou, J.; Hounhouigan, D.J.; Traore, S.A. Chemical Composition and Antioxidative Properties of Seeds of Moringa oleifera and Pulps of Parkia biglobosa and Adansonia digitata Commonly Used in Food Fortification in Burkina Faso. Curr. Res. J. Biol. Sci. 2011, 3, 64–72. [Google Scholar]

- Divya, S.; Pandey, V.K.; Dixit, R.; Rustagi, S.; Suthar, T.; Atuahene, D.; Nagy, V.; Ungai, D.; Ahmed, A.E.M.; Kovács, B.; et al. Exploring the Phytochemical, Pharmacological and Nutritional Properties of Moringa oleifera: A Comprehensive Review. Nutrients 2024, 16, 3423. [Google Scholar] [CrossRef]

- Jegede, E.R.; Ayeni, G.; Abaniwo, M.R.; Olutoye, A.F.; Audu, A.G.; Haruna, A.; Oluwole, S.O. Evaluation of Nutritional and Therapeutic Effects of Defatted Moringa oleifera Seeds in Protein Energy Malnourished Rats. Direct Res. J. Agric. Food Sci. 2025, 13, 79–89. [Google Scholar] [CrossRef]

- Alemayehu, G.F.; Forsido, S.F.; Tola, Y.B.; Amare, E. Nutritional and Phytochemical Composition and Associated Health Benefits of Oat (Avena sativa) Grains and Oat-Based Fermented Food Products. Sci. World J. 2023, 2023, 2730175. [Google Scholar] [CrossRef]

- Singh, S.; Bisla, G. Nutritional and Lipid Composition of Avena sativa, Hordeum vulgare and Echinochloa frumentacea. World J. Adv. Res. Rev. 2021, 11, 23–27. [Google Scholar] [CrossRef]

- Peng, B.; Jin, K.-X.; Luo, D.-Y.; Tian, X.-Y.; Sun, Y.-F.; Huang, X.-H.; Pang, R.-H.; Wang, Q.-X.; Zhou, W.; Yuan, H.-Y. The Nutritional Components of Rice Are Closely Related to Grain Quality Traits in Rice. J. Biol. Life Sci. 2020, 11, 239–262. [Google Scholar] [CrossRef]

- Alege, G.O.; Animasaun, D.A.; Emmanuel, V.A. Evaluation of Proximate, Mineral and Protein Profile of Five Accessions of Oryza sativa (L.) (Rice). FUW Trends Sci. Technol. J. 2016, 1, 522–526. [Google Scholar]

- Dias, L.G.; Hacke, A.; Souza, E.d.S.; Nath, S.; Canesin, M.R.; Vilella, O.V.; Geloneze, B.; Pallone, J.A.L.; Cazarin, C.B.B.; Blakeslee, J.J.; et al. Comparison of Chemical and Nutritional Compositions between Aromatic and Non-Aromatic Rice from Brazil and Effect of Planting Time on Bioactive Compounds. J. Food Compos. Anal. 2022, 111, 104608. [Google Scholar] [CrossRef]

- Ajmera, I. Is Basmati Rice Healthy? Nutrients and More. 2020. Available online: https://www.healthline.com/nutrition/is-basmati-rice-healthy (accessed on 21 March 2025).

- Bhattacharjee, P.; Singhal, R.S.; Kulkarni, P.R. Basmati Rice: A Review. Int. J. Food Sci. Technol. 2002, 37, 1–12. [Google Scholar] [CrossRef]