An Investigation into the Influence of Sample Height on the Consolidation Behaviour of Dredged Silt

Abstract

:1. Introduction

2. Test Scheme

2.1. Sampled Location

2.2. Sampling

2.3. Test Instrument

- (1)

- It facilitates real-time data capture, aligning with test parameters set for specific time and load sequences. The device visually projects both the square root of time curve and the logarithmic time curve. Consequently, it offers superior adaptability and accelerates the testing phase when compared to the single lever consolidation device.

- (2)

- The apparatus autonomously collects testing data. Both larger and smaller ring knives can be individually adjusted and loaded, reducing human involvement and enhancing test accuracy.

2.4. Samples Preparing

2.5. Test Method

3. Test Results and Analysis

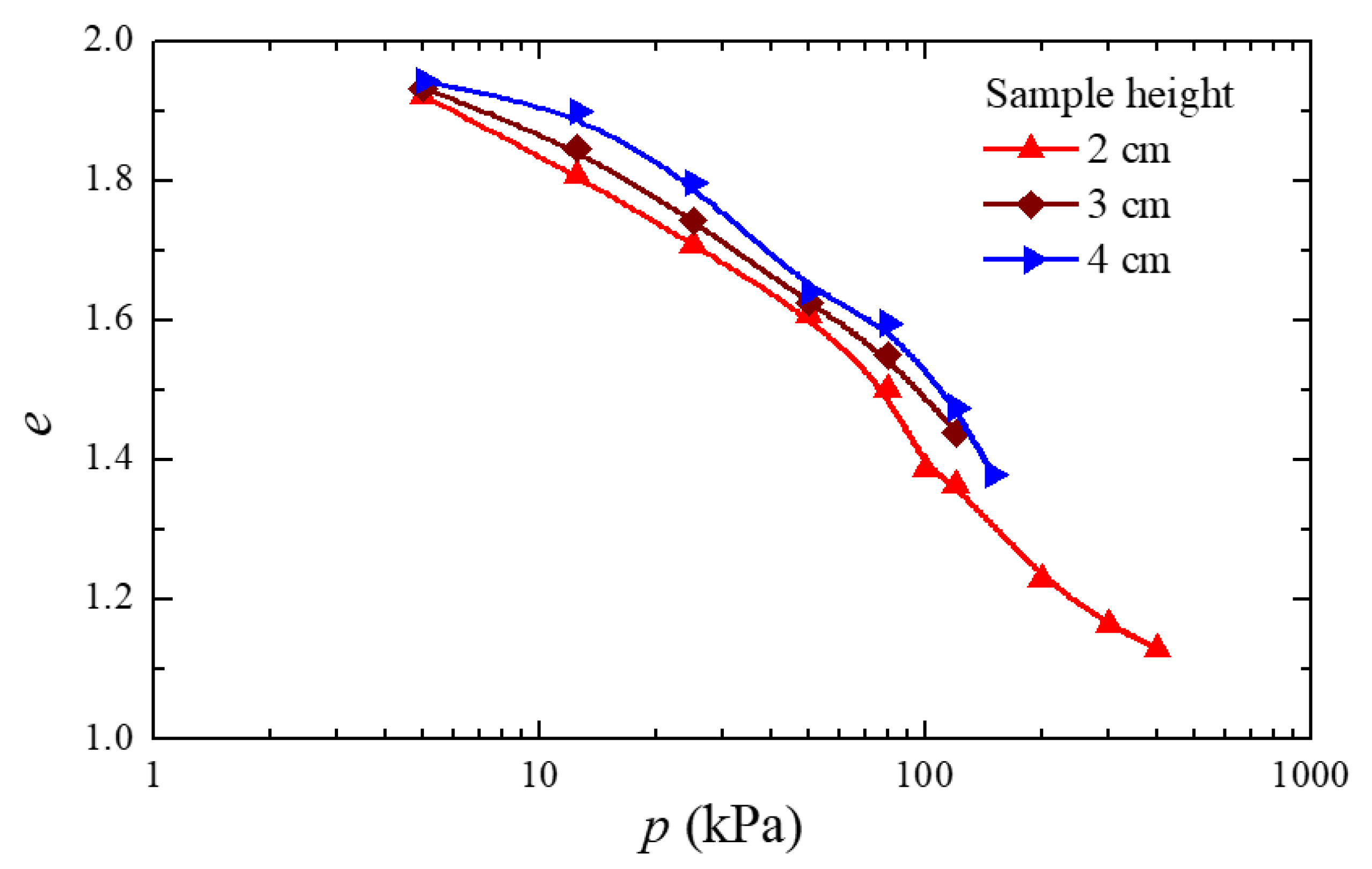

3.1. Compression Curve

- (1)

- Initial Load Disturbance Phase (consolidation pressure p ≤ 12.5 kPa): This phase features a pronounced compression curve with a high compression coefficient. Owing to the initially loose state of the dredged silt, significant deformation arises even under minimal consolidation pressure. Intense extrusion of inter-particle film water leads to a notable reduction in the void ratio. This behaviour distinctly contrasts with the compression characteristics typically observed in natural soft clays.

- (2)

- Elastic Deformation Phase: As the consolidation pressure rises (p = 25~150 kPa), the soil undergoes continuous compaction, establishing a renewed structural strength. This strength partially counters the added pressure, resulting in a gentler curve trajectory which aligns closely with a linear pattern. During this period, the soil’s skeletal structure primarily experiences elastic deformation. With only a minor amount of film water being extruded, the deformation is significantly less pronounced compared to the first phase, and the compression coefficient remains relatively low.

- (3)

- Plastic Deformation Phase: With further escalation in consolidation pressure, the soil structure becomes compromised. Clay particles undergo relative slippage and adopt a tighter arrangement. Predominantly characterized by plastic deformation, the curve in this stage adopts a concave upwards trajectory. This effect becomes increasingly evident with rising consolidation pressures.

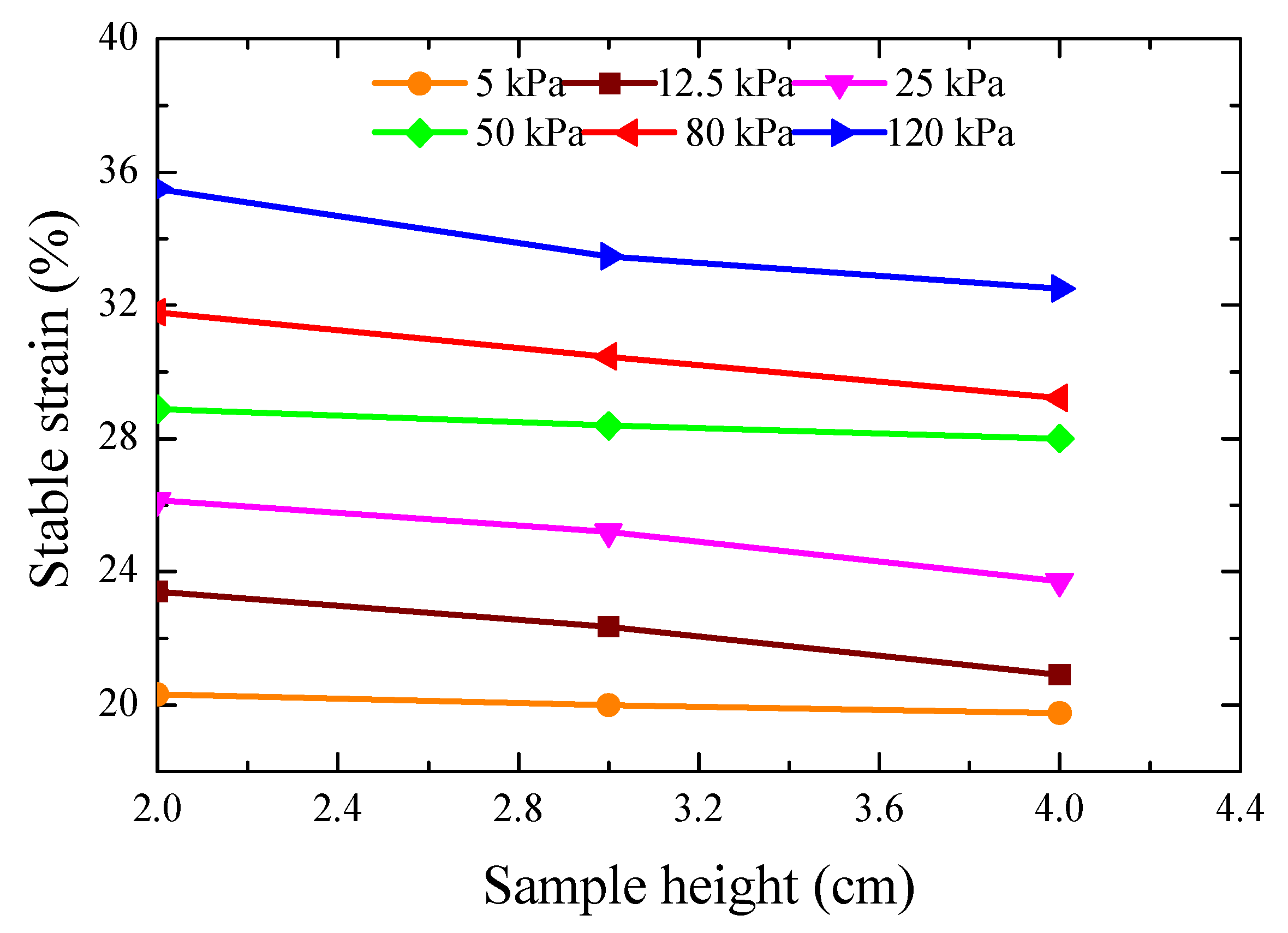

3.2. Compression Strain

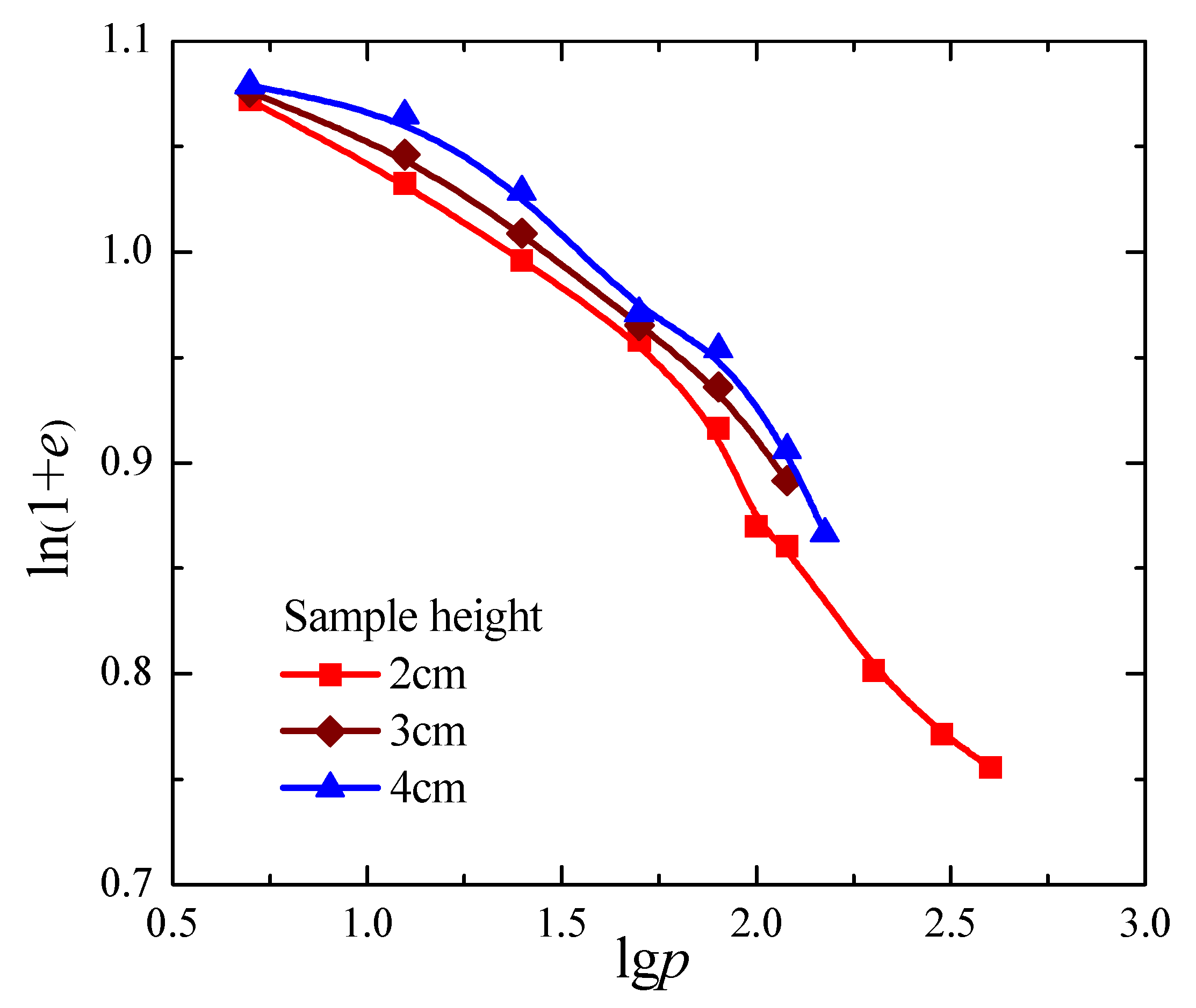

3.3. Yield Stress of Soil Structure and Compression Index

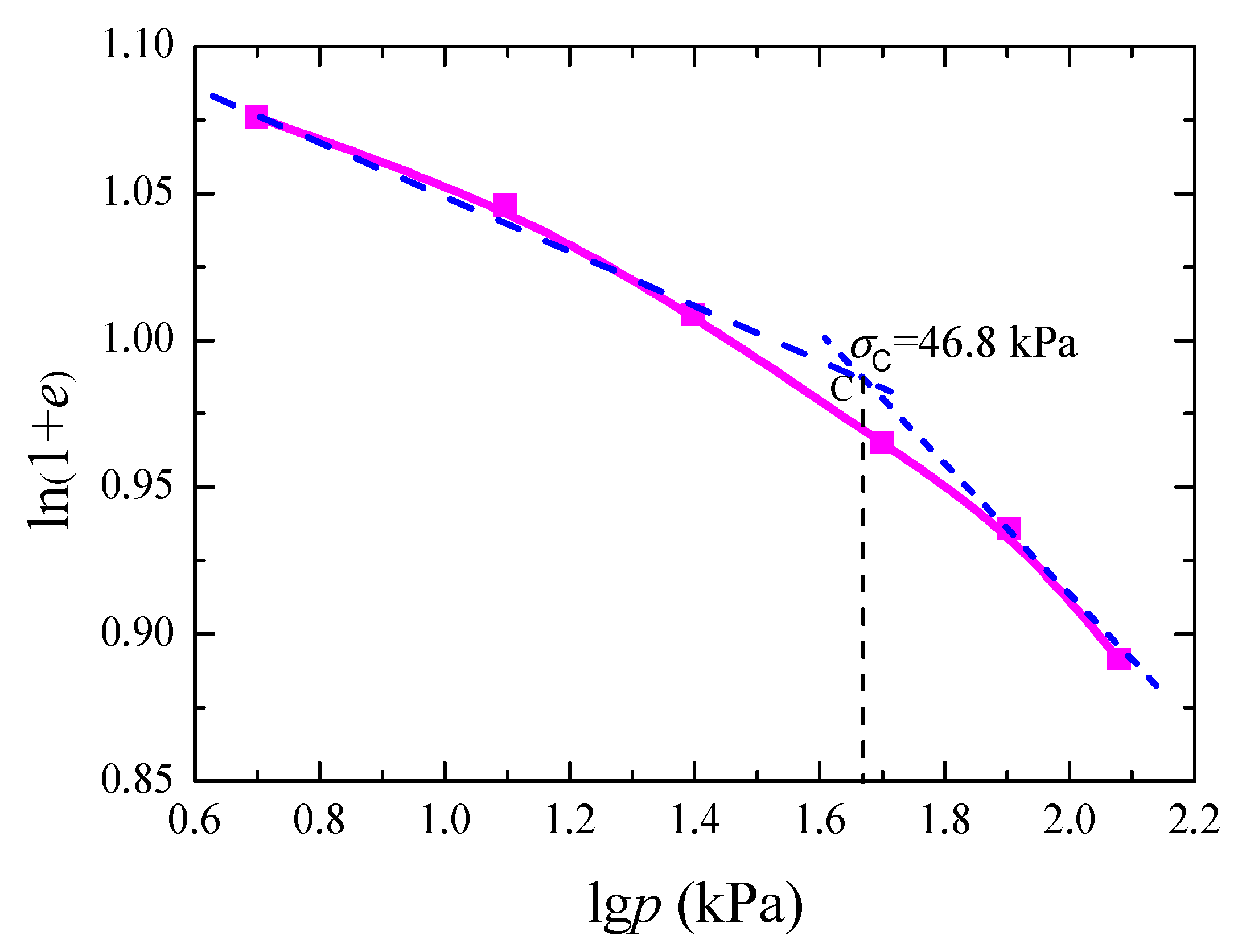

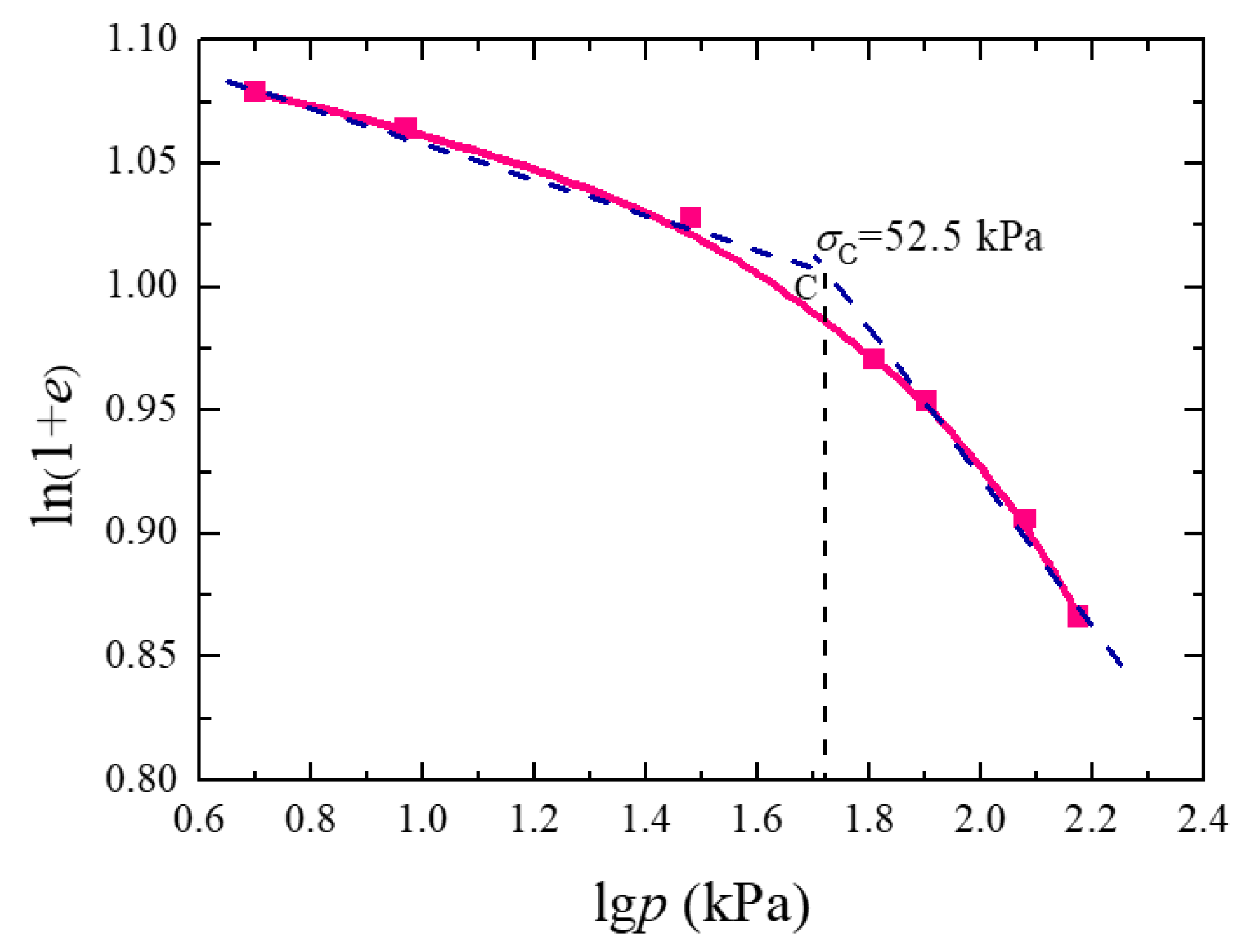

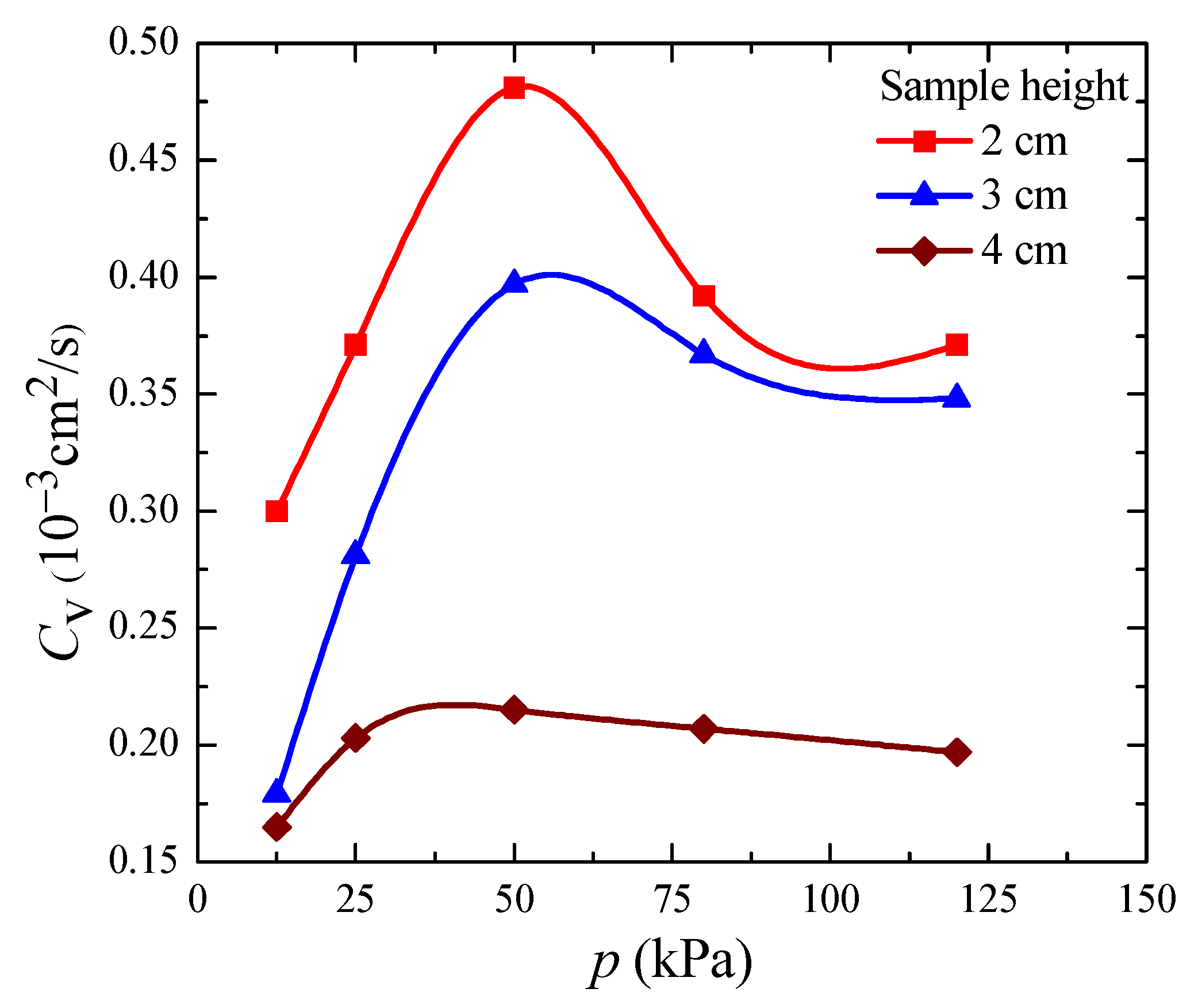

3.4. Coefficient of Consolidation

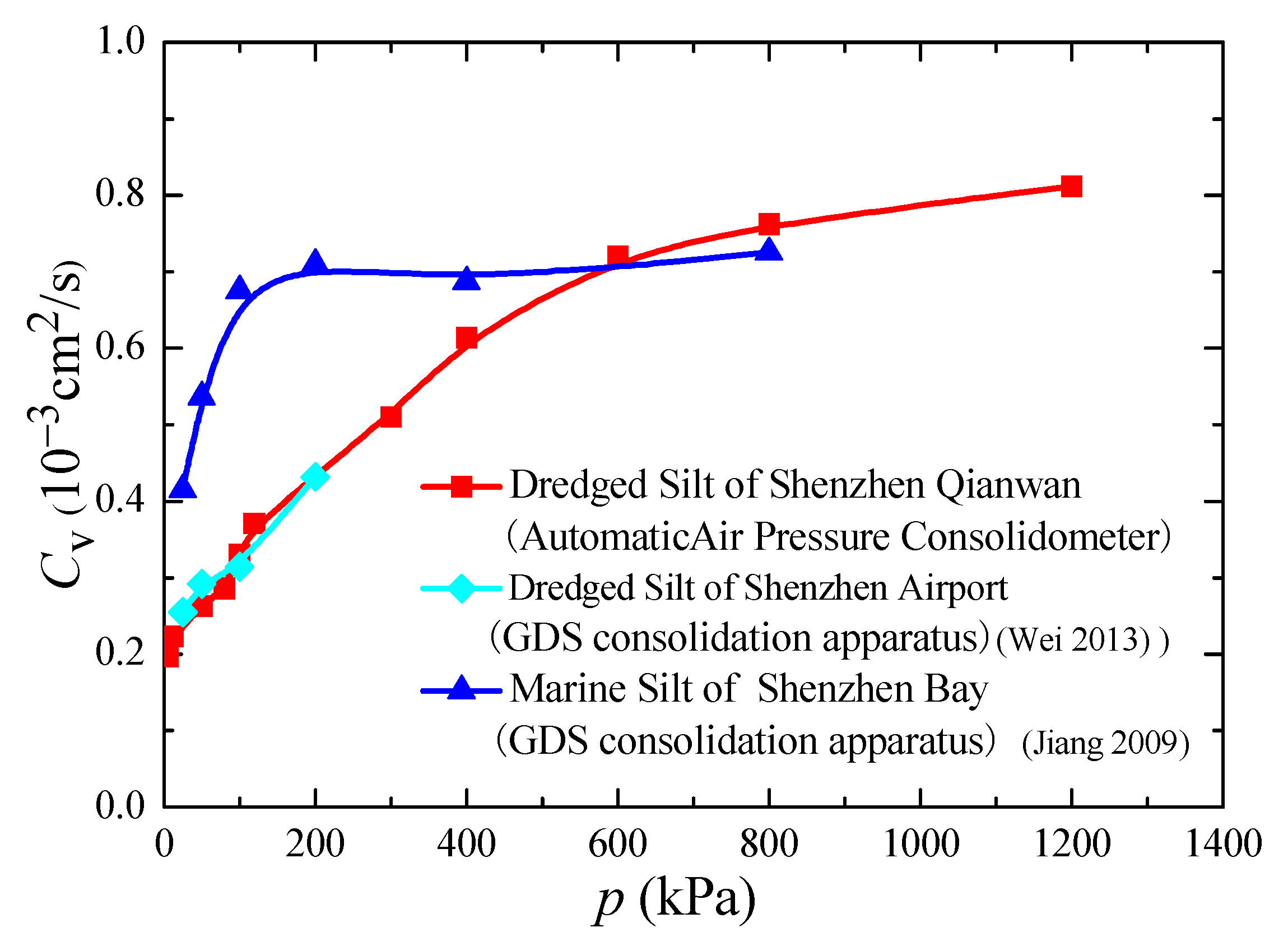

3.5. Comparative Analysis of Consolidation Coefficient between Dredged Silt and Marine Silt

- (1)

- The consistency between the curves representing the consolidation coefficient of dredged silt from Shenzhen Qianwan and Shenzhen Airport suggests the reliability of the different consolidation devices employed. As the consolidation pressure amplified, the consolidation coefficient of dredged silt followed suit. Specifically, below or at 200 kPa, it continually rose in proportion to the intensifying consolidation pressure. For instance, under a preloading load ranging from 50 to 300 kPa, the coefficient surged from 0.263 × 10−3 cm2/s to 0.510 × 10−3 cm2/s. This doubling emphasizes the potential inaccuracies if one were to use a static consolidation coefficient for predicting settlement progression and consolidation intensity.

- (2)

- At pressures less than or equal to 200 kPa, marine silt’s consolidation coefficient significantly surpassed that of the two dredged silt types. As this pressure escalated, the disparity between the silts diminished, eventually converging at a singular point. At a consolidation pressure of 600 kPa, the dredged silt’s coefficient outperformed that of marine silt. These findings highlight the inferior initial consolidation properties of dredged silt. However, post-preloading treatment, it can either match or surpass marine silt’s drainage consolidation rate.

3.6. Comparative Analysis of Permeability Coefficient between Dredged Silt and Marine Silt

- (1)

- The permeability coefficient of dredged silt measured by different consolidation apparatuses in Shenzhen Qianwan and Shenzhen Airport had the same variation under the consolidation pressure. When the consolidation pressure p ≤ 50 kPa, that is, the consolidation pressure was less than the structural yield stress, the permeability coefficient of dredged silt decreased significantly with the increase of the consolidation pressure. When the consolidation pressure increased, the permeability coefficient of dredged silt stabilised at a specific value. When the preloading load was 5~400 kPa, the permeability coefficient of dredged silt in Shenzhen Qianwan Bay decreased from 5.39 × 10−7 cm/s to 2.20 × 10−8 cm/s (it went down an order of magnitude). A constant permeability coefficient was used to predict the consolidation settlement process, and a significant error occurred.

- (2)

- Under the same consolidation pressure, the permeability coefficient of two kinds of dredged silt was found to be significantly greater than that of marine silt. The significance was particularly greater when the smaller consolidation pressure p ≤ 50 kPa. When the consolidation pressure p = 25 kPa, the permeability coefficient of dredged silt was three times that of marine silt. When the consolidation pressure increased, the permeability coefficient of marine silt decreased and stabilised at a certain value. When the preloading load was 25–800 kPa, the permeability coefficient of marine silt decreased from 6.77 × 10−8 cm/s to 3.80 × 10−9 cm/s. This value is nearly approximately one order of magnitude smaller than that of the dredged silt.

4. Conclusions

- The compression process of dredged silt samples of varying heights progressed through three distinct stages: small load disturbance, elastic deformation, and plastic deformation. During the small load disturbance stage, there was a minimal difference in the void ratio variations among samples of different heights. However, as one progressed through the elastic and plastic deformation stages, the rate of void ratio variation diminished with an increase in the initial height of the samples.

- As the initial height of the dredged silt samples increased, both the cumulative stable strain and the compression index showed a decline. The structural strength of the soil primarily hinged on the attributes, interconnections, and spatial arrangement of the soil particles. Consequently, the initial height of the sample exerted a minimal influence on the structural yield stress of the dredged silt.

- For dredged silt samples of different heights, the consolidation coefficient escalated with rising consolidation pressure, peaking at the structural yield stress. As the sample height increased, the consolidation coefficient of the dredged silt diminished. Therefore, the potential influence of the size effect on the consolidation coefficient warrants further exploration.

- At lower consolidation pressures (typical preloading ranges), the consolidation coefficient of dredged silt was significantly lower than that of marine silt. However, as the consolidation pressure intensified, the disparity between the two decreased. This observation suggests that, after a high preloading regimen, dredged silt might achieve, or even match, the drainage consolidation rate intrinsic to marine silt.

- The permeability coefficient of dredged silt contracted with increasing consolidation pressure, experiencing a 10-fold reduction within standard preloading loads. Consequently, employing a consistent permeability coefficient for projecting its consolidation settlement process could introduce substantial errors. Given the observable differences in particle composition and pore dynamics between dredged and marine silt, it is evident that under low consolidation pressures, the permeability coefficient of dredged silt exceeded that of marine silt.

Author Contributions

Funding

Conflicts of Interest

References

- Gibson, R.E.; England, G.L.; Hussey, M.J.L. The theory of one-dimensional consolidation of saturated clays: I. Finite non-linear consolidation of thin homogeneous layers. Geotechnique 1967, 17, 261–273. [Google Scholar] [CrossRef]

- Schiffman, R.L. Finite and infinitesimal strain consolidation. J. Geotech. Eng. Div. 1980, 106, 203–207. [Google Scholar] [CrossRef]

- Znidarcic, D.; Schiffman, R.L. Finite strain consolidation: Test conditions. J. Geotech. Eng. Div. 1981, 107, 684–688. [Google Scholar] [CrossRef]

- Xie, X.Y.; Zhu, X.R.; Xie, K.H.; Pan, Q.Y. New developments of one-dimensional large strain consolidation theories. Chin. J. Geotech. Eng. 1997, 19, 30–38. [Google Scholar]

- Xie, K.H.; Zheng, H.; Leo, C.J. Analytical solution for 1-D large strain consolidation of saturated soft clay under time-depending loading. Shuili Xuebao 2003, 10, 6–13. [Google Scholar] [CrossRef]

- Wen, H.J.; Zhang, Y.X.; Liu, Y. FDM for large strain consolidation of multi-layers super soft ground. J. Chongqing Univ. 2003, 26, 101–104. [Google Scholar]

- Chen, J.Y.; Hai, Y. Analytical solutions of Gibson’s finite non-linear consolidation equation of soil. J. Jiaxing Univ. 2011, 23, 41–46. [Google Scholar] [CrossRef]

- Zheng, H.; Xie, K.H.; Yang, X.Q. Study of one-dimensional large strain consolidation of double-layered saturated soft soils. Rock Soil Mech. 2004, 25, 1770–1774. [Google Scholar] [CrossRef]

- Li, C.X.; Dong, X.Q.; Jin, D.D.; Xie, K.H. Nonlinear large-strain consolidation analysis of soft clayconsidering threshold hydraulic gradient. Rock Soil Mech. 2017, 38, 377–384. [Google Scholar] [CrossRef]

- Li, G.; Zhang, J.L.; Yang, Q.; Jiang, M.J. Analysis of large-strain consolidation with non-Darcy flow and variable permeability coefficient. J. Cent. South Univ. Sci. Technol. 2016, 47, 977–983. [Google Scholar] [CrossRef]

- Dong, X.Q.; Li, C.X.; Chen, M.M.; Zhang, J.; Xie, K.H. Analysis of large-strain nonlinear consolidation of double-layer soft clay foundation with considering effect of non-Darcy’s flow. Rock Soil Mech. 2016, 37, 2321–2331. [Google Scholar] [CrossRef]

- Jiang, W.H.; Zhan, L.T. Large strain consolidation of sand-drained ground considering the well resistance and the variation of radial permeability coefficient. Rock Soil Mech. 2021, 42, 755–766. [Google Scholar] [CrossRef]

- Hu, T. Experimental study on the consolidation characteristics of two dredged ultra-soft soils. Soil Eng. Found. 2020, 34, 247–250. [Google Scholar]

- Lu, J.X. Experimental Study on Nonlinear Characteristics of Permeability and Compressibility of Soft Clay. Master’s Thesis, Tianjin University, Tianjin, China, 2015. [Google Scholar]

- Zhang, M.; Wang, W.; Zhao, Y.M.; Liu, G.N.; Ma, D.H. Study on coefficient of consolidation of dredged fill based on GDS consolidation and permeability test. J. Beijing Univ. Technol. 2012, 38, 1214–1219. [Google Scholar]

- Zhang, M.; Zhao, Y.M.; Gong, L.; Hu, R.H. Test study of coefficient of consolidation of fresh hydraulic fill ultra-soft in Shenzhen Bay. Chin. J. Rock Mech. Eng. 2010, 29, 3157–3161. [Google Scholar]

- Komurlu, E. Loading rate conditions and specimen size effect on strength and deformability of rock materials under uniaxial compression. Int. J. Geo-Eng. 2018, 9, 17. [Google Scholar] [CrossRef]

- Faramarzi, L.; Rezaee, H. Testing the effects of sample and grain sizes on mechanical properties of concrete. J. Mater. Civ. Eng. 2018, 30, 04018065. [Google Scholar] [CrossRef]

- Xu, W.J.; Zhang, H.Y. Research on the effect of rock content and sample size on the strength behavior of soil-rock mixture. Bull. Eng. Geol. Environ. 2021, 80, 2715–2726. [Google Scholar] [CrossRef]

- Celik, S.B. The effect of cubic specimen size on uniaxial compressive strength of carbonate rocks from Western Turkey. Arab. J. Geosci. 2017, 10, 426. [Google Scholar] [CrossRef]

- Yang, E.I.; Choi, J.C.; Yi, S.T. Effect of specimen sizes and shapes on compressive strength of concrete. J. Korea Concr. Inst. 2004, 16, 375–382. [Google Scholar] [CrossRef]

- Zhou, F.P.; Balendran, R.V.; Jeary, A.P. Size effect on flexural, splitting tensile, and torsional strengths of high strength concrete. Cem. Concr. Res. 1998, 28, 1725–1736. [Google Scholar] [CrossRef]

- Zhang, N. Size Effect and Failure Characteristics on Splitting Tensile Strength of Concrete. Master’s Thesis, Da Lian University of Technology, Dalian, China, 2016. [Google Scholar]

- Han, W.W.; Liu, S.H. Size effect on the strength and durability of high strength concrete. Ready-Mix. Concr. 2016, 2, 73–77. [Google Scholar]

- Zheng, A.R. Experimental study on consolidation characteristics of fresh hydraulic fill ultra-soft clay soil samples at different heights. In 25th China National Symposium of Geotechnical Testing; Zhejiang University Press: Hangzhou, China, 2008; pp. 245–248. [Google Scholar]

- Lei, H.Y.; He, C.F.; Qiu, W.W.; Chen, L. Experimental research on size effect upon consolidation property of hydraulic reclamation soft clay. J. Tianjin Univ. Sci. Technol. 2016, 49, 73–79. [Google Scholar] [CrossRef]

- Zhou, C.Y.; Zeng, Q.; Li, Y. Research on consolidation deformation test of large-size soft clay samples. Acta Sci. Nat. Univ. Sunyaseni 2005, 44, 25–29. [Google Scholar] [CrossRef]

- Kongkitkul, W.; Kongwisawamitr, K.; Suwanwattana, V.; Thaweeprasart, V.; Sukkarak, R. Comparisons of one-dimensional consolidation characteristics of clays by using two different specimen Sizes. Soil Behav. Geomech. ASCE 2004, 236, 333–342. [Google Scholar] [CrossRef]

- Chen, K.S.; Lv, M.F. Influences of size effects and constraints on the rebound modulus of subgrade. J. Water Resour. Archit. Eng. 2017, 15, 35–38. [Google Scholar] [CrossRef]

- Zheng, Y.Q.; Chen, S.F.; Pan, S.G.; Yang, H.; Chen, Z.B. Study on specimen size effect of triaxial test of granite residual soil in coastal zone. Fujian Constr. Sci. Technol. 2020, 1, 26–28, 66. [Google Scholar]

- Lin, K.B.; Ke, G.G. Size effect on the shear strength of granitic residual soils. Soil Eng. Found. 2017, 31, 521–525. [Google Scholar]

- Lin, K.B. Study on Size Effect of Granite Residual Soil Triaxial Test and Its Effect on Slope Stability Analysis. Master’s Thesis, Fuzhou University, Fuzhou, China, 2016. [Google Scholar]

- Li, C.Y.; Chen, Z.B. Specimen size effect of strongly weathered granite of seabed in triaxial under K0-consolidation condition. J. Cent. South Univ. Sci. Technol. 2020, 51, 1646–1653. [Google Scholar] [CrossRef]

- Omar, T.; Lakkaraju, S.K.; Osouli, A.; Sadrekarimi, A. Influence of specimen size in engineering practice. Geo-Congr. ASCE 2014, 234, 2960–2969. [Google Scholar] [CrossRef]

- Li, C.; He, C.R.; Wang, C.; Zhao, H.F. Study of scale effect of large-scale triaxial test of coarse-grained materials. Rock Soil Mech. 2008, 29, 563–566. [Google Scholar]

- Mei, Y.J.; Liang, N.X.; Li, Z.Y. Dimension effect to the deformation characteristic of aggregate. J. Chongqing Jiaotong Univ. 2005, 24, 79–82. [Google Scholar] [CrossRef]

- Cerato, A.B.; Lutenegger, A.J. Specimen size and scale effects of direct shear box tests of sands. Geotech. Test J. 2006, 29, 507–516. [Google Scholar]

- Zhu, J.G.; Liu, Z.; Weng, H.Y.; Wu, Z.F.; Fu, H.Y. Study on effect of specimen size upon strength and deformation behavior of coarse-grained soil in triaxial test. J. Sichuan Univ. Eng. Sci. Ed. 2012, 44, 92–96. [Google Scholar]

- Yang, Y.H.; Zhao, Y.; Guang, P.Q.; Li, F. Study on size effect of shear strength of expansive soil. Yangtze River 2007, 38, 18–19, 22. [Google Scholar] [CrossRef]

- Huang, Y.J. Size effect of sample of testing shearing strength for swelling soil. Technol. Dev. Enterp. 2013, 32, 56–57. [Google Scholar]

- Butterfield, R. A natural compression law for soils. Geotechnique 1979, 29, 469–480. [Google Scholar] [CrossRef]

- Sridharan, A.; Abraham, B.M.; Jose, B.T. Improved technique for estimation of preconsolidation pressure. Geotechnique 1991, 41, 263–268. [Google Scholar] [CrossRef]

- Hong, Z.; Onitsuka, K. A method of correcting yield stress and compression index of Ariake clays for sample disturbance. Soils Found. 1998, 38, 211–222. [Google Scholar] [CrossRef]

- Jiang, H.H. Consolidation Calculation of Super-Soft Ground with Vertical Drains. Ph.D. Thesis, China Academy of Railway Sciences, Beijing, China, 2009. [Google Scholar]

- Wei, G.F. Study on compression characteristics of marine silt in Shenzhen bay. Sci. Technol. Eng. 2013, 13, 795–798. [Google Scholar]

| W (%) | ρ (g/cm3) | Gs | e0 | wL (%) | wP (%) | IP |

|---|---|---|---|---|---|---|

| 95.7 | 1.480 | 2.759 | 2.666 | 51.2 | 22.5 | 23.6 |

| Sample Number | Sample Height (cm) | Consolidation Pressure (kPa) | Group Number | Remark |

|---|---|---|---|---|

| S-1 | 2 | 5, 12.5, 25, 50, 80, 100, 200, 300, 400, 600, 800, 1200, 1600 | 64 | High-pressure Consolidation Test |

| S-2 | 2 | 5, 12.5, 25, 50, 80, 100, 120, 200, 300, 400 | 64 | Standard Consolidation Test |

| M | 3 | 5, 12.5, 25, 50, 80, 120 | 64 | Standard Consolidation Test |

| L | 4 | 5, 12.5, 25, 50, 80, 120 | 64 | Standard Consolidation Test |

| Consolidation Pressure p (kPa) | Accumulative Strain A (2 cm) (%) | Accumulative Strain B (3 cm) (%) | Accumulative Strain C (4 cm) (%) | A-B (%) | B-C (%) | A-C (%) |

|---|---|---|---|---|---|---|

| 5 | 20.315 | 19.997 | 19.755 | 0.318 | 0.242 | 0.560 |

| 12.5 | 23.400 | 22.350 | 20.910 | 1.050 | 1.440 | 2.490 |

| 25 | 26.140 | 25.197 | 23.715 | 0.943 | 1.482 | 2.425 |

| 50 | 28.880 | 28.383 | 27.990 | 0.497 | 0.393 | 0.890 |

| 80 | 31.795 | 30.450 | 29.208 | 1.345 | 1.242 | 2.587 |

| 120 | 35.495 | 33.473 | 32.498 | 2.022 | 0.975 | 2.997 |

| Sample Height (cm) | Structural Yield Stress σc (kPa) | Compression Index Cc |

|---|---|---|

| 2 | 50.1 | 0.5335 |

| 3 | 46.8 | 0.5276 |

| 4 | 52.5 | 0.5206 |

| Silt Sample | w (%) | ρ (g/cm3) | Gs | e0 | p (kPa) | Sample Size (cm) |

|---|---|---|---|---|---|---|

| Marine Silt in the West Channel Port of Shenzhen Bay [44] | 99.2 | 1.420 | 2.67 | 2.703 | 25, 50, 100, 200, 400, 800 | 2 |

| Dredged Silt in Shenzhen Airport [45] | 100.63 | 1.448 | 2.681 | 2.712 | 6, 12.5, 25, 50, 100, 200 | 2 |

| Silt Sample | Composition Content of Soil Particles (%) | Absolute Content of Clay Minerals (%) | ||||

|---|---|---|---|---|---|---|

| Powder Particle (0.005–0.075 mm) | Clay Particle (0.002–0.005 mm) | Colloidal Particle (<0.002 mm) | Kaolinite | Illite/Montmori-Llonite | Chlorite | |

| Dredged silt in Qianwan Bay, Shenzhen | 53.0 | 20.7 | 26.3 | 14.2 | 18.4 | 2.8 |

| Dredged silt in Shenzhen airport | 51.8 | 21.5 | 26.7 | 13.8 | 17.9 | 3.0 |

| Marine silt in the west channel port of Shenzhen Bay | 43.2 | 16.8 | 38.0 | 28.6 | 4.7 | 5.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, R.; Zhang, M.; Wang, J. An Investigation into the Influence of Sample Height on the Consolidation Behaviour of Dredged Silt. Appl. Sci. 2023, 13, 10419. https://doi.org/10.3390/app131810419

Hu R, Zhang M, Wang J. An Investigation into the Influence of Sample Height on the Consolidation Behaviour of Dredged Silt. Applied Sciences. 2023; 13(18):10419. https://doi.org/10.3390/app131810419

Chicago/Turabian StyleHu, Ronghua, Ming Zhang, and Jiaqi Wang. 2023. "An Investigation into the Influence of Sample Height on the Consolidation Behaviour of Dredged Silt" Applied Sciences 13, no. 18: 10419. https://doi.org/10.3390/app131810419

APA StyleHu, R., Zhang, M., & Wang, J. (2023). An Investigation into the Influence of Sample Height on the Consolidation Behaviour of Dredged Silt. Applied Sciences, 13(18), 10419. https://doi.org/10.3390/app131810419