Abstract

This study develops advanced machine learning (ML) algorithms to predict the tensile strength (Ft) of sustainable recycled aggregate (RA) concrete incorporating supplementary cementitious materials (SCMs—silica fume and fly ash) and polypropylene fibers (PPF). A dataset of 375 Ft results from the literature, characterized by ten input parameters (including cement content, natural and RA contents, SCM dosages, PPF percentage, water–cement ratio, superplasticizer content, and curing period), was used to train and validate two ML algorithms: Random Forest (RF) and Extreme Gradient Boosting (XGBoost). All models demonstrated high predictive accuracy, with results consistently aligning with experimental values, though the XGBoost model outperformed the RF model, achieving superior performance with R2 values of 0.9689 and 0.9632 for the training and testing datasets and lower RMSE and MAE values. To interpret the model decisions and uncover black-box insights. SHapley additive explanations (SHAP) analysis was employed, quantifying the global and local importance of each input variable on tensile strength prediction, revealing complex non-linear relationships and interactions. The findings highlight XGBoost as a robust tool for optimizing the mix design of complex sustainable concrete, while SHAP analysis revealed that curing period has the highest positive impact on predicting Ft, and W/C and RA adversely impact Ft, bridging the gap between data-driven predictions and practical engineering applications. The developed XGBoost model outperformed DNN, OGPR, and GEP in predicting. A graphical user interface (GUI) was developed to be used as a tool for predicting Ft of RA concrete containing SCMs and PPF. This approach facilitates the efficient development of high-performance, eco-friendly concrete with reduced experimental effort.

1. Introduction

The construction industry is a paramount driver of global development but is simultaneously a major consumer of natural resources and a significant generator of waste, which contributes substantially to its environmental footprint. In response to the urgent need for sustainable practices, the concept of “green concrete” has emerged, aiming to reduce the ecological impact of concrete production by incorporating recycled and waste materials. Two of the most prominent strategies in this endeavor are the utilization of recycled aggregate (RA) and the inclusion of SCMs and polypropylene fibers (PPF). The integration of recycled aggregate, sourced from construction and demolition waste, directly addresses the dual challenge of natural resource depletion and landfill overcrowding. By diverting this waste stream back into the production cycle, it fosters a circular economy and can significantly reduce the concrete embodied carbon [1]. However, the inherent weaknesses of recycled concrete aggregate (RCA), including old, adhered mortar, often lead to reduced mechanical properties [2,3] and increased durability concerns in the resulting concrete, limiting its widespread structural application [4].

The surface treatment of RCA is a critical process to enhance its performance by addressing the weak, porous, adhered mortar that typically compromises the strength and durability of resulting concrete. Advanced treatment techniques, such as carbonation curing, pozzolanic slurry coating, and bio-deposition, have gained prominence for effectively densifying the interfacial transition zone (ITZ) and strengthening the aggregate’s surface. Carbonation treatment, for instance, involves exposing RCA to concentrated CO2, which reacts with calcium hydroxide in the old mortar to form stable calcium carbonate, thereby sealing surface cracks and reducing water absorption [5]. Similarly, coating RCA with a pozzolanic slurry composed of materials like nano-silica or fly ash creates a reactive layer that consumes calcium hydroxide and generates additional C-S-H gel during hydration, leading to a stronger bond between the aggregate and the new cement matrix.

To mitigate these drawbacks and improve the performance of RA concrete, the incorporation of polypropylene fibers has been extensively researched. PPF, a synthetic polymer, acts as a micro-reinforcement within the cementitious matrix. Its primary role is to control the propagation of micro-cracks, thereby enhancing the tensile strength, fracture toughness, and impact resistance of the composite material [6]. The integration of polypropylene fiber (PPF) into recycled aggregate (RA) concrete represents a pivotal innovation in the pursuit of sustainable, high-performance construction materials, addressing the inherent weaknesses of RA while amplifying its environmental benefits.

Crucially, for the often more brittle RA concrete, fibers provide crucial ductility and post-cracking integrity. Furthermore, PPF is effective in mitigating plastic shrinkage cracking, a common issue in concrete, and contributes to enhanced durability by creating a more discontinuous pore structure, potentially reducing permeability [7]. The synergy between RCA and PPF is therefore a compelling research focus: while RCA provides the environmental benefit, PPF compensates for its technical deficiencies. This combination represents a significant stride towards high-performance, eco-friendly concrete, aligning with global sustainability goals and circular economy principles without compromising structural integrity.

This synergy is particularly valuable: the fibers compensate for the mechanical drawbacks of RCA, enabling the production of structural-grade concrete without sacrificing sustainability objectives. Recent studies have also highlighted the role of PPF in improving the durability of RA concrete by reducing permeability and mitigating plastic and drying shrinkage cracks [8]. Consequently, the combination of recycled aggregates and polypropylene fibers not only advances the circular economy in construction but also offers a viable pathway to engineering resilient and eco-friendly concrete infrastructures, aligning with global decarbonization goals [9].

The integration of SCMs, such as fly ash and silica fume, into concrete formulations containing RA and PPF represents a transformative strategy for enhancing the sustainability and performance of modern construction materials. While RCA reduces environmental impact by repurposing construction waste, its inherent weaknesses—including high porosity, water absorption, and weakened interfacial transition zones (ITZ)—often compromise mechanical properties and durability. Similarly, PPF improves tensile strength and crack resistance but can disrupt workability and cohesion if not optimized. SCMs address these challenges synergistically: silica fume, with its ultra-fine particles and high pozzolanic reactivity, densifies the matrix and refines the ITZ around RCA, reducing permeability and enhancing bond strength [10]. Fly ash, conversely, improves long-term strength and workability while mitigating shrinkage [11,12] and heat generation, which is critical for fiber-reinforced composites [13]. Together, these materials create a cohesive system where SCMs ameliorate the deficiencies of RCA, enhance the fiber–matrix interface, and contribute to secondary hydration, leading to improved mechanical and durability properties. Recent studies highlight the role of SCMs in facilitating the broader adoption of sustainable concrete by enabling higher RA incorporation rates without sacrificing performance [14]. This approach aligns with global efforts to reduce carbon emissions and promote circular economy principles in the construction sector.

The accurate prediction of concrete’s tensile strength is a critical yet complex challenge in civil engineering, essential for designing durable and safe structural elements that resist cracking and failure. Traditional empirical and analytical models often struggle to capture the intricate, non-linear relationships between mix proportions, material properties, and the resulting mechanical behavior, particularly with the increasing use of innovative materials like recycled aggregates and fibers. In response, machine learning (ML) techniques have emerged as powerful tools for developing high-fidelity predictive models that learn directly from experimental data, offering unprecedented accuracy and efficiency. Techniques such as RF and XGBoost are increasingly employed to model concrete tensile strength [15,16,17], leveraging their ability to handle high-dimensional input parameters—including cement content, water–cement ratio, aggregates content, fiber dosage, superplasticizer content and curing conditions—while accounting for intricate interactions among variables. These data-driven approaches not only achieve superior predictive performance compared to conventional regression methods but also provide insights into parameter importance and behavior through interpretability tools like SHAP analysis and partial dependence plots. The adoption of ML in this domain accelerates optimized mix design, reduces experimental costs, and supports the development of sustainable concrete composites, paving the way for smarter, more resilient infrastructure [18].

The research significance of employing machine learning techniques—such as RF and XGBoost—to predict the tensile strength of RA concrete containing SCMs and PPF lies in their ability to decode the complex, non-linear interactions between these sustainable materials and the resulting mechanical properties. A dataset including 10 input variables and 375 data points was generated from existing literature. K-fold cross-validation and statistical metrics were employed to assess the machine learning model’s performance. SHAP analysis was employed to detect the effect of each feature on the response. A graphical user interface (GUI) was employed to predict the Ft of RA-PPF concrete by allowing users to enter the input values of the variables used in this study.

Traditional models such as linear regression often fail to accurately capture the non-linear interactions in concrete mix formulation [19,20,21] arising from the variability of RA percentage, the types and dosage of SCMs and percentage of PPF, and their combined influence on tensile strength, leading to significant errors in prediction. While ML models have been broadly applied to predict concrete compressive strength, a critical research gap exists in their specialized use for tensile strength prediction [21,22,23] in this specific sustainable composite, where failure mechanisms are distinct and highly sensitive to mix design. By leveraging advanced algorithms such as RF and XGBoost, in addition to developing GUI for predicting Ft of RA concrete containing SCMs and PPF, this research can bridge this gap, providing robust, data-driven tools to optimize eco-friendly mixes, reduce experimental burdens, and facilitate the safe and efficient use of RA-PPF concrete in structural applications.

The objectives of this study are as follows:

- 1.

- To assemble and organize a thorough, high-caliber database from the literature pertaining to RA-SCM-PPF concrete.

- 2.

- To systematically train and evaluate the performance of proposed machine learning algorithms: Random Forest and XGBoost.

- 3.

- To utilize SHapley Additive exPlanations (SHAP) for both global and local interpretability, thereby clarifying the non-linear effects and interactions of mix design parameters.

- 4.

- To provide a Graphical User Interface (GUI) tool that incorporates the ideal model for practical application by researchers and engineers.

2. Materials and Methods

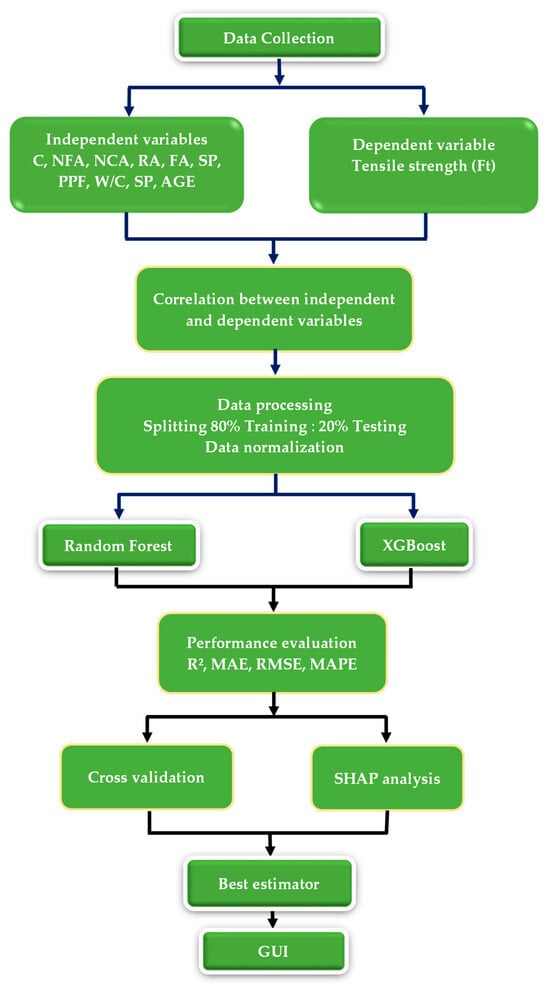

Figure 1 shows the methodology used in this study. This research methodology presents a detailed framework for creating predictive models for the tensile strength of RA concrete that includes extra cementitious materials and polypropylene fibers, utilizing a systematic data-driven approach. The process commences with precise data collection involving critical independent variables such as cement content (C), natural fine and coarse aggregates (NFA, NCA), recycled aggregate (RA), supplementary materials (FA, SF), polypropylene fibers (PPF), water–cement ratio (W/C), superplasticizer (SP), and curing period (AGE), with tensile strength (Ft) serving as the dependent variable. Subsequent to data collecting, the methodology utilizes correlation analysis to discern links between input parameters and the goal output, followed by data processing that entails an 80:20 training–testing split and normalization to guarantee optimal model performance. The primary modeling phase employs two sophisticated ensemble algorithms—Random Forest and XGBoost—accompanied by thorough performance assessment utilizing various statistical metrics (R2, MAE, RMSE, MAPE) to measure predicted accuracy. Random Forest (RF) algorithm was chosen for its resilience to overfitting, intrinsic feature importance metrics, and capacity to describe non-linearities and interactions through an ensemble of decorrelated decision trees. Extreme Gradient Boosting (XGBoost) algorithm was selected for its superior predictive accuracy, efficient management of diverse data formats, and its sequential boosting mechanism that iteratively rectifies faults, rendering it exceptionally effective in capturing complex data patterns. It was anticipated that these ensemble methods would surpass simpler models due to the organized, tabular characteristics of our mixed-design data. Python (version 3.12) [23], which is based on Anaconda, was used for constructing the Ft models. The methodology strengthens robustness using cross-validation techniques and incorporates SHAP analysis for model interpretability and feature relevance assessment to clarify variable impacts. The last stage selects the optimal estimator and results in the creation of a Graphical User Interface (GUI) for practical application, thus converting intricate machine learning models into user-friendly instruments for researchers and practitioners in sustainable concrete design.

Figure 1.

Flowchart of the methodology used.

2.1. Data Collection

The dataset used in this study contained 375 tensile strength data samples collated from an extensive review of peer-reviewed literature [11,12,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39,40,41], focusing on experimental investigations of concrete incorporating sustainable materials. Each data sample represented a unique concrete mixture, characterized by ten input parameters known to significantly influence the tensile properties of concrete. These parameters included: cement (C), natural coarse aggregate (NCA), natural fine aggregate (NFA), percentage of recycled aggregate (%RA, replacing natural coarse aggregate by volume), fly ash (FA), silica fume (SF), polypropylene fiber ratio (PPF, by volume percentage), water–cement ratio (W/C), superplasticizer (SP), and curing period (AGE). The output variable for all models was the tensile strength (Ft) of concrete. To guarantee quality and uniformity, data were extracted according to stringent criteria: only studies utilizing prevalent supplementary cementitious materials such as fly ash or silica fume and macro polypropylene fibers were considered; the target response was confined to splitting tensile strength assessed through standardized methods; and all specimens were mandated to have undergone curing under standard moist conditions and to possess standard geometry. No limitations were imposed on mix proportions within this specified scope, therefore encompassing a wide and realistic range of material variables to enhance the model’s practical applicability and representativeness. This comprehensive feature captures the complex interactions between conventional constituents, sustainable substitutes (RA, SCMs), and fiber reinforcement, providing a robust basis for model training.

2.2. Data Statistics

Table 1 offers a comprehensive statistical description of the input and output parameters for the 375 experimental data samples used in this study, offering critical insights into the distribution, variability, and characteristics of the dataset. The input variables encompass a wide range of concrete mix constituents and conditions, with cement content ranging from 284 to 704 kg/m3 (mean: 440.06 kg/m3, std. deviation: 112.43), reflecting diverse mix design philosophies. The aggregates show substantial variability: natural fine aggregate (NFA) spans from 426 to 962.28 kg/m3 (mean: 654.38 kg/m3), natural coarse aggregate (NCA) spans from 777.1 to 1278 kg/m3 (mean: 1119.7 kg/m3), while recycled aggregate (RA) ranges similarly from 0 to 100% (mean: 45.76%), indicating mixtures with partial to full replacement levels. SCMs like fly ash (FA) and silica fume (SF) exhibit right-skewed distributions (skewness > 1), with means of 19.857 kg/m3 and 17.273 kg/m3, respectively, highlighting their optional but increasingly prevalent use. The PPF content, ranging from 0% to 3% (mean: 0.317%), shows high positive skewness (2.56) and kurtosis (6.122), indicating most studies used low fiber volumes with a few outliers at higher dosages. The water–cement ratio (W/C) varies from 0.26 to 0.66 (mean: 0.4411), capturing both high-performance and conventional mixes, while superplasticizer (SP) usage (0–7.84 kg/m3, mean: 1.7359 kg/m3) demonstrates efforts to maintain workability. The curing period (AGE) data (7–90 days, mean: 27.328 days) is positively skewed (1.76), reflecting a focus on early-age testing. The output variable, tensile strength (Ft), ranges from 1.32 MPa to 7.40 MPa (mean: 3.1190 MPa), with positive skewness (1.14) and kurtosis (2.092), indicating a distribution towards lower strengths with some high-performance outliers. This detailed summary confirms the dataset’s diversity and complexity, ensuring the machine learning models are trained on a representative spectrum of sustainable concrete formulations.

Table 1.

Description of the experimental data.

2.2.1. Correlation Between Independent and Dependent Variables

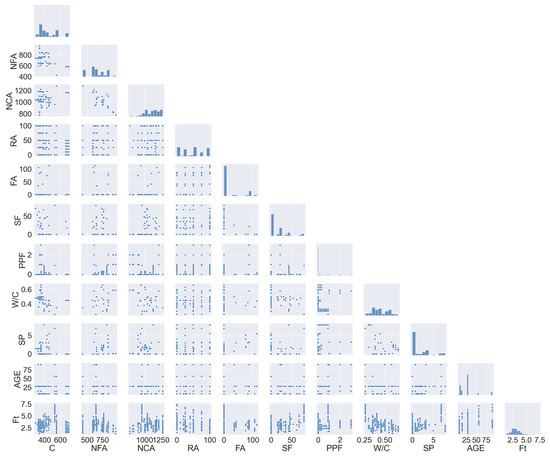

The Pearson correlation heatmap in Figure 2 shows essential insights into the intricate correlations between mixture components and tensile strength (Ft) in recycled aggregate concrete containing extra cementitious ingredients and polypropylene fibers. The analysis indicates that silica fume (SF) demonstrates the most robust positive connection with tensile strength (0.42), highlighting its crucial function as a pozzolanic material that boosts strength via microstructure refinement and better interfacial transition zones. The curing period (AGE) exhibits a significant positive connection (0.37) with Ft, underscoring the essential role of hydration duration in strength enhancement. The water–cement ratio (W/C) has a significant negative association (−0.38) with tensile strength, reinforcing the essential notion that higher water content adversely impacts mechanical properties of concrete. Recycled aggregate (RA) exhibits a moderate negative association with tensile strength (−0.27), indicating a potential loss in strength relative to natural aggregates, likely attributable to increased porosity and diminished interfacial bonding. Polypropylene fibers (PPF) exhibit positive associations with fly ash (0.43) and silica fume (0.23), suggesting potential synergistic effects between fiber reinforcing and supplemental cementitious materials. The robust connection between superplasticizer (SP) and silica fume (0.53) likely indicates mixture design methodologies wherein elevated SP dosages are employed to sustain workability in mixtures with substantial SF concentration. The negative correlation of −0.43 between cement and fly ash exemplifies standard replacement trends in sustainable concrete compositions. The correlation patterns not only affirm recognized concrete technology principles but also offer significant insights into the intricate material interactions that ML models must encompass to effectively forecast tensile strength in these advanced composite materials.

Figure 2.

Pearson’s correlation coefficient heat map.

Pairwise correlation plots (Figure 3) for the dataset of the tensile strength (Ft) of RA concrete incorporating SCMs and PPF reveal numerous significant patterns in material interactions. The cement content (C) exhibits a moderately positive correlation with tensile strength, with data points ranging from approximately 300–700 kg/m3, indicating that increased cement dosages typically enhance tensile performance, albeit with variability suggesting the presence of optimal ranges. NFA and NCA exhibit intricate correlations with tensile strength, with NFA values between 400 and 900 kg/m3 and NCA values between 800 and 1300 kg/m3, demonstrating varied distributions that highlight the complex equilibrium necessary in aggregate proportioning. The content of recycled aggregate (RA), ranging from 0 to 100%, exhibits a primarily negative correlation with tensile strength, as indicated by the declining trend in data points, substantiating the strength reduction commonly linked to increased RA usage due to subpar interfacial properties.

Figure 3.

Pairwise plots.

The supplemental cementitious materials exhibit unique behavioral patterns: fly ash (FA) concentration, varying from 0 to 100 kg/m3, demonstrates a relatively modest association with tensile strength, indicating that its impact may be more contingent upon other combination parameters and curing circumstances. Conversely, the amount of silica fume (SF), reaching around 80 kg/m3, has a distinct positive correlation with tensile strength, underscoring its efficacy as a pozzolanic additive. The amount of PPF, ranging from 0 to 3 kg/m3, exhibits a positive yet saturating correlation with tensile strength, signifying diminishing returns at elevated fiber levels. The water–cement ratio (W/C), varying from 0.25 to 0.65, demonstrates a pronounced negative connection with tensile strength, evidencing a distinct downward trend that substantiates the inherent inverse link between water content and mechanical performance. The dosage of superplasticizer (SP), reaching up to 8 kg/m3, and the curing period (AGE), extending to 80 days, both exhibit positive correlations with tensile strength, albeit with varying gradient patterns that indicate their unique mechanisms of action—SP primarily reduces water-to-cement (W/C) ratios, whereas AGE promotes sustained hydration and strength enhancement over time.

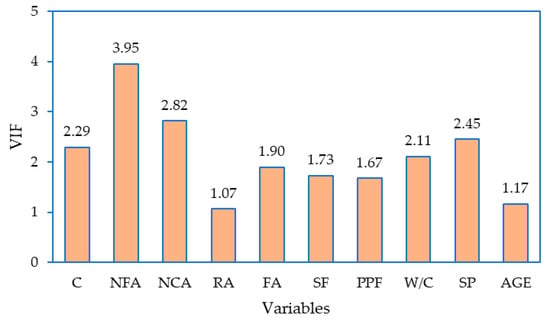

2.2.2. Multicollinearity Check

The Variance Inflation Factor (VIF) analysis shown in Figure 4 for the dataset of tensile strength model of recycled aggregate concrete, which includes supplementary cementitious materials and polypropylene fibers, indicates an acceptable degree of multicollinearity among the input variables, as all VIF values are significantly below the conservative threshold of 5 and considerably lower than the critical value of 10. Natural fine aggregate (NFA) exhibits the highest VIF value of 3.95, signifying a considerable correlation with other mixture components, presumably indicative of its interdependent relationship with other aggregate phases and binder elements within the concrete matrix. Subsequently, natural coarse aggregate (NCA) exhibits a variance inflation factor (VIF) of 2.82, while superplasticizer (SP) registers at 2.45, indicating a potential covariance, perhaps attributable to mixture proportioning limitations or synergistic influences on workability demands. The residual features—cement (2.29), water–cement ratio (2.11), fly ash (1.90), silica fume (1.73), polypropylene fibers (1.67), curing period (1.17), and recycled aggregate (1.07)—demonstrate low VIF values, hence affirming their statistical independence and negligible linear coupling. The notably low VIF for recycled aggregate (1.07) signifies its capacity to function as an independent predictor, despite its intricate interactions with the concrete microstructure. The VIF profile indicates that the dataset exhibits adequate feature independence for dependable machine learning model development, with no significant multicollinearity that would undermine parameter estimates or the interpretability of tensile strength predictions for these sustainable concrete composites.

Figure 4.

Variance inflation factor.

2.3. Data Processing

2.3.1. Data Splitting

To ensure the development of predictive models capable of generalizing effectively to unseen data, a random splitting method was employed to partition the entire dataset into distinct subsets for training and testing. Specifically, 80% of the data (300 samples) was randomly selected to form the training set, used to build and tune the machine learning models. The remaining 20% (75 samples) was allocated to the testing set, reserved exclusively for evaluating the final model’s predictive performance and generalization ability. This 80:20 ratio is widely adopted in ML research to balance the need for sufficient training data with the necessity of validation.

2.3.2. Data Scaling

To mitigate the impact of features operating on vastly different scales and to enhance the convergence and stability of the models, min–max normalization was applied to all input variables. This preprocessing technique scaled each feature to a fixed range between 0 and 1. This step ensured that no single parameter dominated the learning process due to its magnitude, thereby enhancing the reliability and accuracy of the developed models.

2.4. Machine Learning (ML) Approach

This study employs two advanced machine learning algorithms—RF and XGBoost—to develop robust predictive models for the tensile strength of sustainable concrete incorporating recycled aggregate, supplementary cementitious materials, and polypropylene fibers. These techniques were selected for their complementary strengths in handling complex, non-linear relationships and high-dimensional data.

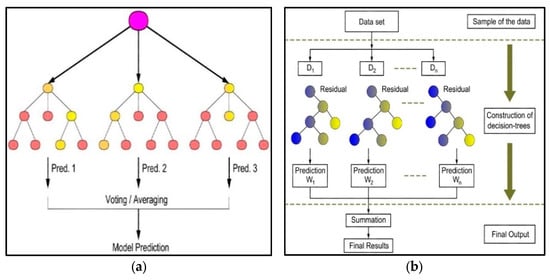

2.4.1. Random Forest (RF)

Random forest (RF) regression is an ensemble machine learning technique that builds numerous decision trees during training and produces the average forecast of these trees to mitigate overfitting and enhance predictive accuracy. Developed by Leo Breiman [42], the algorithm utilizes “bagging” (bootstrap aggregating), wherein each tree is constructed from a random bootstrap sample of the training data, and node splitting is executed using a random subset of features, thus de-correlating the trees and improving model robustness. The core premise is that an extensive aggregation of weakly connected trees, when amalgamated, yields a more precise and consistent forecast than any individual tree. For a specified input vector, each tree in the forest generates a prediction, and the final output is the mean of these individual tree predictions for regression problems. This ensemble method adeptly identifies intricate, non-linear correlations and interactions in the data while demonstrating relative insensitivity to outliers and noise. Critical hyperparameters that dictate the model’s efficacy encompass the number of trees (n_estimators), the maximum depth of the trees (max_depth), and the number of features evaluated for splitting at each node (max_features). The intrinsic feature importance scoring of RF Regression offers critical insights into variable significance by quantifying the mean reduction in impurity across all utilized trees (Figure 5a). Owing to its adaptability, superior performance, and interpretability, RF Regression has emerged as a prevalent tool in computational materials science and engineering informatics, evidenced by its effective utilization in forecasting the properties of intricate composite materials such as concrete.

Figure 5.

ML algorithms: (a) RF and (b) XGB.

2.4.2. Extreme Gradient Boosting (XGBoost)

XGBoost regression is a sophisticated ensemble learning technique that utilizes a gradient boosting framework to iteratively develop a robust predictive model by integrating several weak learners, usually decision trees. Conceived by Chen and Guestrin [43], the technique functions via an additive training methodology, wherein each subsequent tree is engineered to rectify the residual errors of the cumulative ensemble (Figure 5b), therefore progressively decreasing a specified loss function through gradient descent optimization [44]. XGBoost, in contrast to traditional gradient boosting, integrates several pivotal innovations, such as a second-order Taylor expansion of the loss function for enhanced optimization accuracy, L1 (Lasso) and L2 (Ridge) regularization terms in the objective function to mitigate model complexity and avert overfitting, and sophisticated methods for managing sparse data along with a weighted quantile sketch for approximate tree learning. The methodology utilizes shrinkage via a learning rate parameter to adjust each tree’s contribution, column subsampling to randomize feature selection, and tree pruning techniques that enhance computational efficiency while preserving high prediction accuracy. This advanced amalgamation of approaches enables XGBoost to effectively manage intricate non-linear relationships, interactions, and absent data, while delivering feature importance metrics that improve model interpretability. The algorithm’s computational efficiency, scalability, and cutting-edge performance render it especially valuable in materials informatics applications, where predicting mechanical properties such as tensile strength necessitates the capture of complex relationships between mixture constituents and processing parameters.

2.5. Model Efficiencies

The assessment of machine learning model efficiencies primarily depends on four principal statistical metrics: R-squared (R2), Mean Absolute Error (MAE), Root Mean Squared Error (RMSE), and Mean Absolute Percentage Error (MAPE), each offering unique insights into predicting performance. R2, computed as (1), measures the proportion of variation in the dependent variable elucidated by the model, with values approaching 1 signifying enhanced explanatory efficacy. MAE, as described in (2), provides a clear metric for the average size of prediction error, devoid of directional bias, thereby facilitating a robust interpretation, particularly in the presence of outliers. RMSE, calculated as (3), disproportionately penalizes greater mistakes due to the squaring of residuals, rendering it especially sensitive to forecast outliers and variance. MAPE, as articulated in (4), provides an error interpretation in %, enabling an intuitive comprehension of relative prediction accuracy across varying value scales. Collectively, these metrics establish a thorough assessment framework wherein R2 denotes overall model fit, MAE signifies average error magnitude, RMSE illustrates error variance and the influence of outliers, while MAPE contextualizes performance in comprehensible percentage terms, facilitating a multifaceted evaluation of predictive model efficacy across various applications and datasets.

2.6. PSO Hyperparameter Optimization

The Particle Swarm Optimization (PSO) hyperparameter tuning shown in Table 2 for both Random Forest and XGBoost models demonstrated unique optimization patterns essential for improving the predictive accuracy of tensile strength in RA concrete with SCMs and PPF. The Random Forest-PSO model optimization converged on a configuration that prioritized model complexity with 166 n_estimators, maintained significant depth with a max_depth of 17, and emphasized maximum node purity through minimal min_samples_split and min_samples_leaf values of 2 and 1, respectively, alongside a moderate feature sampling ratio of 0.57. This setup indicates that the RF model advantages from intricate, comprehensive trees that thoroughly utilize the feature space while preserving variation via regulated feature randomization. The XGBoost-PSO produced a distinctly different architecture, featuring an extensive ensemble of 927 estimators, shallow trees (maximum depth of 3), a conservative learning rate of 0.1519, and moderate subsampling parameters for rows (0.5601) and columns (0.5414). The incorporation of modest L1 (0.4076) and L2 (0.3669) regularization enhanced the model’s generalization capacity. This configuration demonstrates that the XGBoost model attains optimal performance via a substantial ensemble of weak, constrained learners with regularization—an architecture particularly adept at capturing the intricate, non-linear relationships among mixture components while effectively mitigating overfitting in the high-dimensional parameter space of concrete formulation.

Table 2.

PSO hyperparameter optimization values.

3. Results and Discussion

3.1. Performance of ML Models

The performance evaluation of the two ML models—RF and XGBoost—reveals critical insights into their predictive accuracy, robustness, and applicability for estimating the tensile strength of sustainable concrete incorporating recycled aggregate, supplementary cementitious materials, and polypropylene fibers. Across key statistical metrics such as R2 (coefficient of determination), RMSE (Root Mean Square Error), and MAE (Mean Absolute Error), all models demonstrated strong alignment with experimental data, underscoring their capability to capture the complex, non-linear relationships inherent in the dataset. Notably, XGBoost consistently outperformed RF, achieving the highest R2 values and the lowest error rates on the testing set, a result attributable to its gradient boosting framework, which iteratively minimizes errors through additive tree building and regularization. Random Forest provided robust and stable predictions, leveraging its bagging approach to reduce variance, though it occasionally struggled with extreme values due to its averaging mechanism. This comparative analysis not only validates the efficacy of ML techniques for tensile strength prediction but also highlights the trade-offs between accuracy and interpretability, guiding practitioners in selecting the most suitable model based on specific project needs, whether for high-stakes precision or actionable engineering insights.

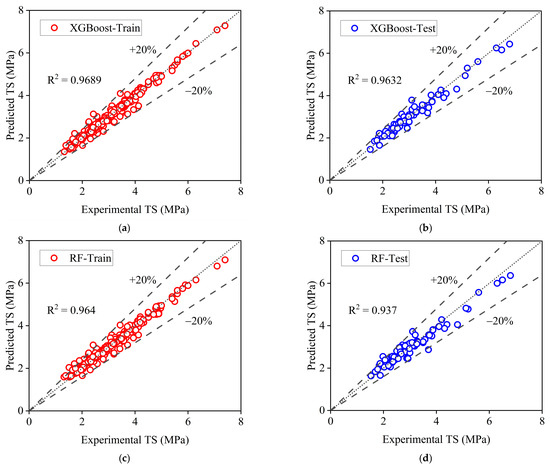

3.1.1. XGBoost Regression

The regression plot analysis to predict the tensile strength of RA concrete with SCMs and PPF indicates that the XGBoost model exhibits strong predictive performance in both training and testing datasets, albeit with noticeable discrepancies in accuracy and precision between the two phases. The XGBoost model attained a notable R2 value of 0.9689 for the training dataset (Figure 6a), signifying that it accounts for nearly 96.89% of the variance in experimental tensile strength values. The data points aggregate closely around the optimal prediction line (y = x), with most residing within the ±20% error margins, illustrating the model’s robust ability to comprehend the intricate correlations between mixture parameters and tensile strength results. The distribution of test data points in Figure 6b exhibits a comparable, well-distributed pattern around the ideal line with R2 value of 0.9632, devoid of significant deviation. The persistence of this pattern, with most predictions staying within the 20% error margin, validates that the model has effectively discerned the fundamental controlling patterns instead of simply memorizing the training data. The minor anticipated increase in dispersion for the test set relative to the training set is standard and does not diminish the model’s practical applicability. The results confirm that the XGBoost algorithm is a dependable and precise tool for predicting the tensile strength of sustainable concrete mixes, serving as a significant resource for mix proportion optimization and preliminary design of concrete containing recycled aggregate, supplementary cementitious materials, and polypropylene fibers within the tested variable ranges.

Figure 6.

Regression plots: (a) XGBoost-training; (b) XGBoost-testing; (c) RF-training; and (d) RF-testing.

3.1.2. Random Forest (RF) Regression

The regression plot analysis of the RF model, which predicts the tensile strength of RA concrete containing SCMs and PPF, indicates robust predictive performance with significant consistency between the training and testing phases. The training dataset findings demonstrate outstanding performance with an R2 value of 0.964, signifying that the model accounts for roughly 96.4% of the variance in experimental tensile strength measurements Figure 6c. The data points exhibit close clustering around the optimal prediction line (y = x), with the bulk of observations being comfortably within the ±20% error margins spanning the complete strength spectrum of around 2 MPa to 8 MPa. This illustrates the model’s proficient understanding of the intricate non-linear correlations between mixture parameters and the evolution of tensile strength. The Random Forest model has remarkable performance on the testing dataset, achieving an R2 value of 0.937, as shown in Figure 6d, indicating just a slight reduction in predicting accuracy for novel data. Despite the testing results indicating a marginal increase in dispersion relative to the training set, especially within the mid-to-high strength range of 4–8 MPa, most predictions fall within the allowed error margin, thus affirming the model’s strong generalization capacity. The sustained clustering pattern along the optimal line across the strength spectrum indicates that Random Forest proficiently encapsulates the essential mechanical behavior of these intricate composite materials, adeptly modeling the complex interactions among recycled aggregate properties, supplementary cementitious material traits, and polypropylene fiber reinforcement that collectively dictate tensile strength performance in sustainable concrete formulations.

Based on the comparative regression plot analysis shown in Figure 7 for predicting the tensile strength of recycled aggregate concrete containing SCMs and PPF, both RF and XGBoost models demonstrate strong predictive capabilities, though with distinct performance characteristics between training and testing phases. In the training phase, both models exhibit excellent fit with data points tightly clustered along the ideal prediction line, with XGBoost achieving a marginally higher R2 value (0.9689) compared to RF (0.964), indicating its superior ability to capture complex patterns within the training dataset. However, the more significant distinction emerges in the testing phase, where XGBoost demonstrates remarkable generalization capability, maintaining an R2 of 0.9632 with only minimal dispersion beyond the ±20% error bounds. In contrast, the RF model shows more pronounced performance degradation on testing data, with its R2 decreasing to 0.937 and greater scatter observed, particularly in the mid-to-high strength range. The testing plots reveal that XGBoost maintains tighter clustering around the ideal line with fewer outliers approaching the error margins, while RF exhibits wider dispersion, especially for experimental values above 6 MPa. This consistent performance preservation from training to testing underscores XGBoost’s enhanced robustness in handling the complex, non-linear interactions between recycled aggregates, supplementary cementitious materials, and polypropylene fibers, making it more reliable for predicting tensile strength across diverse mixture formulations in sustainable concrete applications.

Figure 7.

Regression plots of RF and XGBoost models: (a) training; (b) testing.

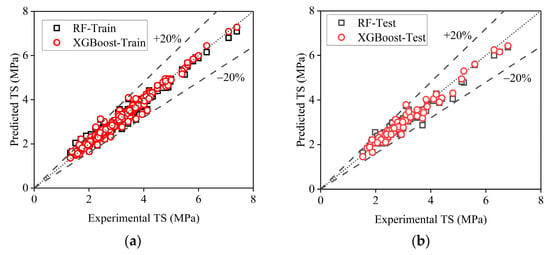

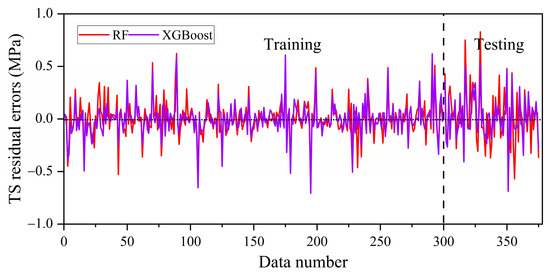

3.1.3. Residual Errors

The residual error analysis shown in Figure 8 for prediction model of the tensile strength of RA concrete with SCMs and PPF indicates that XGBoost exhibits significantly better performance than Random Forest, evidenced by considerably narrower error distributions in both training and testing phases. The XGBoost model demonstrates residual errors closely grouped around zero, primarily limited to the ±0.25 MPa range for training data, with slight dispersion up to approximately ±0.5 MPa for testing data, signifying outstanding predictive accuracy and strong generalization ability. The persistent error pattern near zero in both datasets demonstrates XGBoost’s proficiency in capturing the intricate non-linear interactions that dictate tensile strength behavior without substantial overfitting. Conversely, Random Forest exhibits far broader residual distributions, with training errors often above ±0.5 MPa and testing residuals demonstrating even higher deterioration, frequently exceeding ±0.75 MPa with increased variability across the prediction spectrum. The significant increase in residual spread from training to testing in Random Forest indicates overfitting, as the model does not generalize well to new data. In contrast, XGBoost’s consistent error rates highlight its architectural superiority in managing the complex interactions among recycled aggregates, supplementary cementitious materials, and polypropylene fibers that affect tensile strength development in sustainable concrete composites.

Figure 8.

Residual errors plot of the developed models.

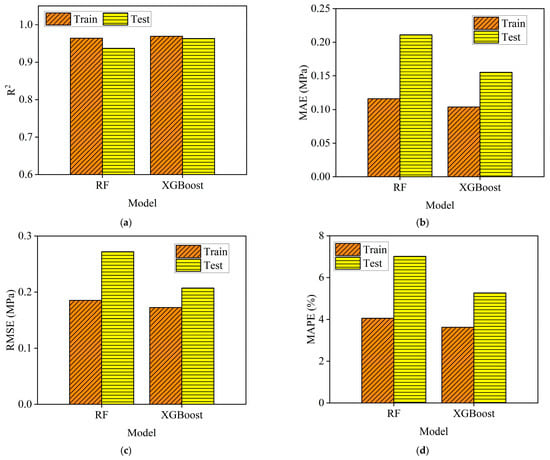

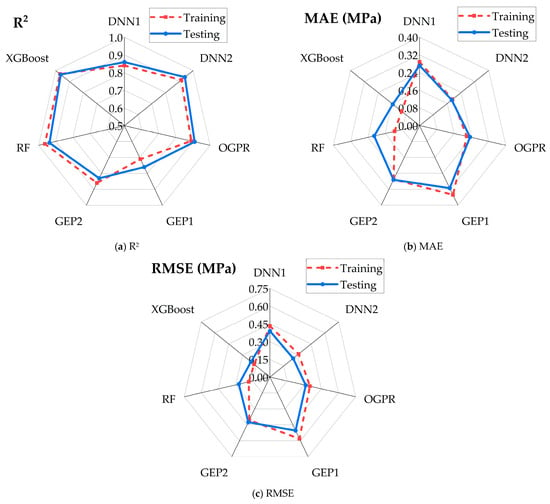

3.1.4. Comparison Between the Developed Models

A thorough analysis of performance metrics for predicting the tensile strength of RA concrete with SCMs and PPF indicates that a detailed comparison between Random Forest and XGBoost models provides substantial insights into their predictive abilities and generalization performance across training and testing datasets. The RF model indicates robust overall performance, with a training R2 of 0.964 and a testing R2 of 0.937 (Figure 9a), signifying substantial explanatory power for the variance in tensile strength; nevertheless, it reveals a significant performance disparity between the training and testing phases. The significant rise in error metrics from training to testing is further substantiated, with MAE escalating from 0.116 MPa to 0.211 MPa (Figure 9b), RMSE climbing from 0.185 MPa to 0.272 MPa (Figure 9c), and MAPE surging from 4.052% to 7.017% (Figure 9d). These measurements indicate that although Random Forest adeptly identifies the inherent patterns in the training data, it suffers from mild overfitting and demonstrates diminished generalization ability when evaluated on unseen testing data.

Figure 9.

Statistical metrics of all the developed models: (a) R2; (b) MAE; (c) RMSE; and (d) MAPE.

Conversely, the XGBoost model demonstrates enhanced performance and notable consistency between the training and testing phases. XGBoost has a training R2 of 0.9689 and a testing R2 of 0.9632 (Figure 9a), surpassing Random Forest in explanatory power and showcasing remarkable generalization capability, with performance essentially consistent across both datasets. The model’s error measures exhibit a markedly reduced decline from training to testing, with MAE escalating from 0.103888 MPa to 0.155171 MPa (Figure 9b), RMSE advancing from 0.172423 MPa to 0.207198 MPa (Figure 9c), and MAPE transitioning from 3.627135% to 5.263579% (Figure 9d). XGBoost’s testing performance significantly exceeds that of Random Forest across all measures, demonstrating a 26.5% reduction in MAE, a 23.8% reduction in RMSE, and a 25.0% reduction in MAPE during the testing phase. The significantly reduced performance disparity between training and testing for XGBoost, along with its enhanced absolute performance on novel data, suggests that its gradient boosting framework with integrated regularization more adeptly captures the intricate, non-linear correlations between mixture parameters and tensile strength while mitigating overfitting. XGBoost is the more dependable and resilient option for practical applications in forecasting the mechanical properties of sustainable concrete composites, especially considering the intricate interactions among RA, SCMs, and PPF that affect tensile strength behavior.

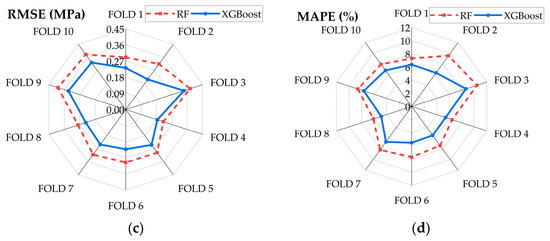

3.2. Cross-Validation

The extensive 10-fold cross-validation results for RF and XGBoost models exhibited strong predictive abilities, albeit with differing performance traits. The RF model demonstrated robust performance, with an average R2 of 0.884 ± 0.051 across all folds (Figure 10a), signifying substantial explanatory power for tensile strength variance, albeit with significant heterogeneity between folds, ranging from 0.775 in Fold 3 to 0.938 in Fold 2. The model attained an MAE of 0.229 ± 0.036 MPa (Figure 10b) and an RMSE of 0.316 ± 0.054 MPa (Figure 10c), indicating satisfactory predictive accuracy, while the MAPE averaged 7.960 ± 1.328% (Figure 10d), demonstrating commendable relative predictive precision. The performance inconsistency across folds, especially the comparatively lower results in Folds 3 and 9 (R2 of 0.775 and 0.811, respectively), suggests sensitivity to specific data partitions and potential limitations in managing certain feature combinations or data distributions within the dataset.

Figure 10.

Spider plots for K-fold statistics: (a) R2; (b) MAE; (c) RMSE; and (d) MAPE.

Conversely, the XGBoost model exhibited enhanced and more reliable predictive performance across all assessment metrics. XGBoost demonstrated an average R2 of 0.920 ± 0.047, indicating superior explanatory power and consistent performance across folds, with R2 values exceeding 0.816 in all instances and surpassing 0.947 in five of the ten folds (Figure 10a). The model’s error measures showed significant enhancement, with MAE decreasing to 0.185 ± 0.032 MPa (Figure 10b), RMSE to 0.257 ± 0.058 MPa (Figure 10c), and MAPE to 6.371 ± 1.073% on average (Figure 10d). The model demonstrated remarkable performance in Folds 2, 4, 5, 6, 7, and 8, achieving R2 values above 0.936 and MAPE values below 6.7%, signifying very precise predictions with negligible relative error. The reduced standard deviations across all measures relative to Random Forest further underscore XGBoost’s enhanced generalization ability and resilience to various data partitioning. The consistent superiority of XGBoost across all folds indicates that its gradient boosting framework and regularization features are exceptionally adept at modeling the intricate, non-linear correlations among mixture proportions, material characteristics, and the tensile strength of fiber-reinforced RA concrete with SCMs, rendering it the more dependable option for practical concrete strength prediction applications.

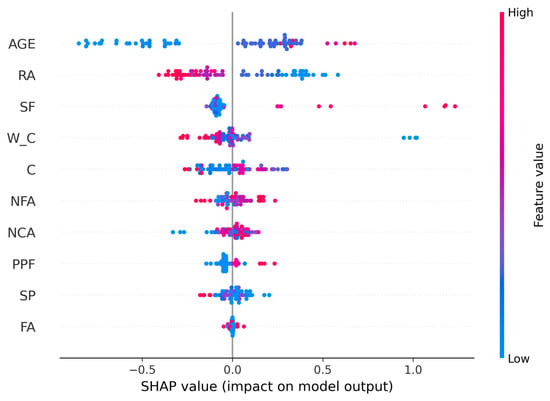

3.3. SHAP Analysis for the Developed Models

The SHAP summary plot analysis for the tensile strength model of RA concrete containing SCMs and PPF, shown in Figure 11, elucidates the relative significance and directional influence of each input variable on the predicted tensile strength (Ft). The plot illustrates that curing time (AGE) is the most significant factor, displaying the greatest variability in SHAP values and consistently imposing a substantial positive effect on tensile strength, where long curing time (represented by red points) aligns with positive SHAP values, corroborating the essential principle that increased curing time positively impacts concrete strength. The recycled aggregate (RA) demonstrates the second significant factor, imposing a substantial negative effect on tensile strength, where higher RA percentages (represented by red points) align with negative SHAP values. Silica fume (SF) consistently contributes positively, keeping with its established function as a pozzolanic material that improves microstructure and interfacial transition zones. W/C imposes a substantial negative effect on tensile strength—where high W/C ratios (represented by red points) align with negative SHAP values, corroborating the essential principle that increased water content adversely impacts concrete strength. The cement content (C) is of significant importance, exhibiting a strong positive correlation with tensile strength, as indicated by high cement concentrations (red points) producing positive SHAP values that enhance model predictions. The content of polypropylene fiber (PPF) demonstrates a moderate, favorable effect, albeit with variability in its efficacy, indicating the presence of ideal dosage ranges for maximum strength improvement. Natural coarse aggregate (NCA) and natural fine aggregate (NFA) exhibit distinctly positive influences on tensile strength, suggesting that their effects are contingent upon particular mixture proportions and interactions with other components. The content of superplasticizer (SP) exhibits a modest favorable influence, chiefly via facilitating reduced water–cement ratios. Fly ash (FA) demonstrates lowest importance feature, evidenced by low SHAP values. Extensive SHAP analysis offers critical insights into the intricate interactions among mixture components, emphasizing how material proportions and their interrelations collectively influence the tensile strength performance of these sustainable concrete composites.

Figure 11.

SHAP plots for XGB model.

The SHAP plots in Figure 12 reveal critical insights into the non-linear and interdependent characteristics of mix design for enhancing the tensile strength of RA concrete. The primary adverse impact of RA is not a constant effect but is dynamically influenced by synergistic interactions among materials. The considerable vertical dispersion of points at RA values (Figure 12a–i) indicates that the influence of RA is not independent; it significantly interacts with other variables in the composition. The adverse effects of RA are most effectively alleviated by increased proportions of silica fume (Figure 12a) and fly ash (Figure 12b), which improve the interfacial transition zone, and by the incorporation of PPF (Figure 12e), which facilitates bridging and crack control. The plots indicate that sustaining a low W/C ratio (Figure 12d) is essential for strength growth in RA concrete, while superplasticizers (Figure 12f) enhance workability without elevating water consumption. Finally, the beneficial interaction with the curing period emphasizes that prolonged hydration is crucial to achieve the full compensating capacity of SCMs in these composite systems. This investigation confirms that the performance disparity caused by RA may be mitigated with a comprehensive, performance-oriented mix design strategy.

Figure 12.

SHAP plots for interaction between RA and other features. (a) SF; (b) FA; (c) C; (d) W/C; (e) PPF; (f) SP; (g) AGE; (h) NCA; (i) NFA.

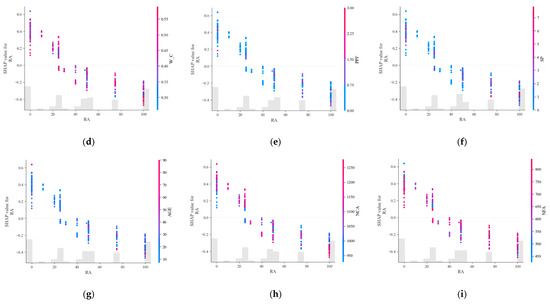

3.4. Comparison of Proposed TS Models with Previous Models

Through a thorough assessment of R2, MAE, and RMSE during both training and testing phases, the newly developed RF and XGBoost models exhibit enhanced predictive accuracy for the tensile strength of RA concrete incorporating SCMs and PPF, surpassing models established in prior literature [18]. DNN2 and OGPR demonstrated superior performance among the models, achieving testing R2 values of 0.94 and 0.91, respectively (Figure 13a), and greatly surpassing the genetic programming methods (GEP1 and GEP2), which recorded testing R2 values of 0.76 and 0.83. Both newly created ensemble approaches surpassed all benchmarks, with XGBoost attaining the greatest testing R2 (0.9632) and the lowest errors (MAE: 0.155, RMSE: 0.207) (Figure 13b,c), closely succeeded by RF (testing R2: 0.937, MAE: 0.211, RMSE: 0.272). The performance advantage persisted throughout training, with XGBoost and RF attaining impressive R2 values of 0.9689 and 0.964, respectively, alongside significantly lower MAE and RMSE values compared to all other models. This demonstrates not only exceptional accuracy but also enhanced generalization and robustness in predicting the intricate mechanical behavior of sustainable concrete composites.

Figure 13.

Comparison of proposed TS models with literature: (a) R2; (b) MAE; (c) RMSE.

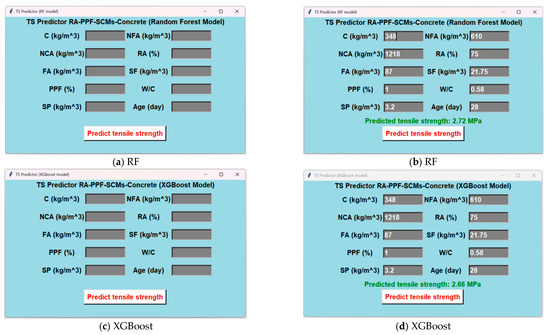

3.5. Graphical User Interface (GUI)

A user-friendly GUI shown in Figure 14 has been created to enable the practical implementation of the extremely precise RF and XGBoost models for forecasting the tensile strength of sustainable concrete. The GUI was developed in Python (version 3.12) [23] utilizing libraries such as Tkinter, scikit-learn (v1.0+), NumPy and Pandas. The interface features intuitive input fields, enabling users to effortlessly input essential mix design parameters, such as cement content (C), natural fine aggregate content (NFA), natural coarse aggregate content (NCA), recycled aggregate percentage (RA), fly ash content (FA), silica fume content (SF), polypropylene fiber percentage (PPF), water/cement ratio (W/C), superplasticizer dose (SP), and the curation period (AGE). Upon submission of these inputs, the GUI efficiently processes the data via the pre-trained models. The output is clearly presented, showcasing the predicted tensile strength values from both the RF and XGBoost algorithms, allowing engineers and researchers to swiftly acquire dependable strength estimates and effectively optimize their concrete mixtures with recycled aggregates and supplementary cementitious materials.

Figure 14.

Graphical User Interface (GUI) for TS.

Verification of the Prediction GUI

The validation of the graphical user interface (GUI) for predicting the tensile strength of recycled aggregate concrete with supplementary cementitious materials (SCM) and polypropylene fiber (PPF) is thoroughly evidenced by the systematic assessment of eight different concrete mix scenarios, as outlined in Table 3. The predictive efficacy of the integrated Random Forest (RF) and XGBoost models, which constitute the primary analytical framework of the GUI, was evaluated by comparing their predictions with real experimental tensile strength measurements across diverse compositions and curing durations. Both models demonstrate remarkable accuracy, with all relative errors (RE) restricted to a small range of ±3.7%, with most remaining below ±2%. The consistently minimal margin of error across several input parameters—such as differing replacement levels of recycled aggregate (RA), supplementary cementitious material (SCM) contents, polypropylene fiber (PPF) doses, water–cement ratios, and curing durations—affirms the reliability and generalizability of the GUI. The strong correlation between predicted and actual results validates that the interface effectively implements the underlying machine learning models, offering researchers and engineers a reliable tool for tensile strength assessment in sustainable concrete design.

Table 3.

Details of eight scenarios for tensile strength.

4. Conclusions

This work employed the XGB and RF algorithms with PSO to simulate the Ft of concrete, incorporating ten input variables, with the output being the tensile strength of concrete. SHAP analysis was used to evaluate the influence of each input variable on Ft prediction. The following conclusions were drawn up:

- The tensile strength (Ft) has a robust positive relationship with SF, followed by AGE and SP, while displaying a significant negative correlation with the W/C and RA.

- The XGBoost model utilizing the PSO optimizer surpassed the RF model with the PSO optimizer in terms of resilience and accuracy during 10-fold cross-validation, having R2 values of 0.9689 and 0.9632 for the training and testing datasets, respectively.

- The XGBoost model findings indicated that the RMSE, MAE, and MAPE values for Ft were 0.207 MPa, 0.155 MPa, and 5.26%, respectively, illustrating that the XGB prediction model displayed enhanced overall performance characterized by a higher R2 and reduced error values.

- The SHAP analysis indicated that the curing period, SP, C, NFA, NCA, PPF, SF, and FA exert a favorable influence on tensile strength. Conversely, W/C and RA adversely impact Ft. The effects of aging and RA are the most pronounced compared to other factors.

- SHAP-based interpretability identifies the fundamental shortcomings of RA-based mixtures and recommends a definitive material synergy—integrating SCMs, fibers, and a low water–cement ratio with proper curing—to develop RAC with consistently improved tensile strength.

- XGBoost outperformed previously established prediction models for Ft, including DNN, OGPR, and GEP.

- An intuitive GUI has been created to efficiently predict the Ft of RA concrete incorporating SCMs and PPF, utilizing essential input parameters, hence reducing the necessity for resource-demanding practical trials.

5. Limitations and Future Work

The predictive model developed in this study demonstrates strong performance, although it is constrained by applications and intrinsic data-driven limits. The scope is explicitly delineated by the curated dataset, which includes concretes containing coarse recycled concrete aggregate, supplementary cementitious materials (SCMs) such as fly ash and silica fume, macro polypropylene fibers, and standard-cured splitting tensile strength results up to 90 days; extrapolation beyond the trained parameters (RA 0–100%, fiber volume ≤3%) is deemed unreliable. Furthermore, the model’s granularity is limited, as it depends exclusively on mix proportions, neglecting factors that account for intrinsic material variability—such as RA morphology and impurities or PPF geometry and surface attributes—which considerably influence interfacial bonding and strength. The current framework is a predictive tool, but it does not directly deal with the inverse engineering problem of changing the mix proportions to obtain the desired strength while staying within budget or material limits. Future research should emphasize (1) augmenting the dataset to encompass a wider range of SCMs, hybrid fibers, and long-term durability characteristics; (2) incorporating fundamental material descriptors (e.g., aggregate absorption, fiber aspect ratio, chemical composition) to enhance physicochemical interpretability; and (3) progressing towards a multi-output, inverse-design framework that can concurrently optimize fresh, mechanical, and durability properties for customized, sustainable concrete.

Author Contributions

Conceptualization, H.A.D.; methodology, M.K.A. and H.A.D.; software, H.A.D.; validation, M.K.A.; formal analysis, H.A.D.; investigation, M.K.A. and H.A.D.; resources, M.K.A.; data curation, H.A.D.; writing—original draft preparation, H.A.D.; writing—review and editing, M.K.A.; visualization, H.A.D.; supervision, H.A.D.; project administration, M.K.A.; funding acquisition, M.K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

All the raw data supporting the conclusion of this paper were provided by the authors.

Acknowledgments

The researchers would like to thank the Deanship of Graduate Studies and Scientific Research at Qassim University for financial support (QU-APC-2025).

Conflicts of Interest

The authors declare there are no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| RA | Recycled aggregate |

| RCA | Recycled concrete aggregate |

| PPF | Polypropylene fiber |

| FA | Fly ash |

| SF | Silica fume |

| Ft | Tensile strength |

| ML | Machine learning |

| RF | Random forest |

| XGBoost | Extreme gradient boosting |

| SHAP | SHapley additive explanations |

| GUI | Graphical user interface |

| SCMs | Supplementary cementitious materials |

| CV | Cross-validation |

| C | Cement |

| NFA | Natural fine aggregate |

| NCA | Natural coarse aggregate |

| W/C | Water/binder ratio |

| SP | Superplasticizer |

| AGE | Curing period |

| R | Correlation coefficient |

| R2 | Coefficient of determination |

| MAE | Mean absolute error |

| RMSE | Root mean squared error |

| MAPE | Mean absolute percentage error |

References

- Fanijo, E.O.; Kolawole, J.T.; Babafemi, A.J.; Liu, J. A Comprehensive Review on the Use of Recycled Concrete Aggregate for Pavement Construction: Properties, Performance, and Sustainability. Clean. Mater. 2023, 9, 100199. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Water Absorption and Electrical Resistivity of Concrete with Recycled Concrete Aggregates and Fly Ash. Cem. Concr. Compos. 2019, 95, 169–182. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of Incorporation of High Volume of Recycled Concrete Aggregates and Fly Ash on the Strength and Global Warming Potential of Concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Junior, G.A.F.; Leite, J.C.T.; Mendez, G.d.P.; Haddad, A.N.; Silva, J.A.F.; da Costa, B.B.F. A Review of the Characteristics of Recycled Aggregates and the Mechanical Properties of Concrete Produced by Replacing Natural Coarse Aggregates with Recycled Ones—Fostering Resilient and Sustainable Infrastructures. Infrastructures 2025, 10, 213. [Google Scholar] [CrossRef]

- Cantero, B.; Seara-Paz, S.; Cuenca, E.; Ferrara, L.; González-Fonteboa, B. Self-Healing Mechanisms in Concrete Cured in CO2-Saturated Environments: Synergistic Effects of Biomass Forest Ash and Metakaolin. Cem. Concr. Compos. 2025, 163, 106160. [Google Scholar] [CrossRef]

- Matar, P.; Assaad, J.J. Concurrent Effects of Recycled Aggregates and Polypropylene Fibers on Workability and Key Strength Properties of Self-Consolidating Concrete. Constr. Build. Mater. 2019, 199, 492–500. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Cao, K.; Sun, L. Review on the Durability of Polypropylene Fibre-Reinforced Concrete. Adv. Civ. Eng. 2021, 2021, 1–13. [Google Scholar] [CrossRef]

- Dahish, H.A.; Alkharisi, M.K. Predicting the Properties of Polypropylene Fiber Recycled Aggregate Concrete Using Response Surface Methodology and Machine Learning. Buildings 2025, 15, 3709. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising Cement and Concrete Production: Strategies, Challenges and Pathways for Sustainable Development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Akbar, D.; Shabbir, F.; Raza, A.; Kahla, N. Ben Synergistic Enhancement of Recycled Aggregate Concrete Using Hybrid Natural-Synthetic Fiber Reinforcement and Silica Fume. Results Eng. 2025, 27, 106291. [Google Scholar] [CrossRef]

- Katar, I.; Ibrahim, Y.; Abdul Malik, M.; Khahro, S.H. Mechanical Properties of Concrete with Recycled Concrete Aggregate and Fly Ash. Recycling 2021, 6, 23. [Google Scholar] [CrossRef]

- Karthik, C.H.; Nagaraju, A. An Experimental Study on Recycled Aggregate Concrete With Partial Replacement of Cement With Flyash and Alccofine. IOP Conf. Ser. Earth Environ. Sci. 2023, 1130, 012012. [Google Scholar] [CrossRef]

- Velumani, S.K.; Venkatraman, S. Assessing the Impact of Fly Ash and Recycled Concrete Aggregates on Fibre-Reinforced Self-Compacting Concrete Strength and Durability. Processes 2024, 12, 1602. [Google Scholar] [CrossRef]

- Fan, M.; Li, Y.; Shen, J.; Jin, K.; Shi, J. Multi-Objective Optimization Design of Recycled Aggregate Concrete Mixture Proportions Based on Machine Learning and NSGA-II Algorithm. Adv. Eng. Softw. 2024, 192, 103631. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, R.; Lu, Y.; Huang, J. Prediction of Compressive Strength of Geopolymer Concrete Landscape Design: Application of the Novel Hybrid RF–GWO–XGBoost Algorithm. Buildings 2024, 14, 591. [Google Scholar] [CrossRef]

- Al Adnan, M.; Babur, M.; Farooq, F.; Shahid, M.; Ahmed, Z.; Das, P. Prediction of Splitting Tensile Strength of Fiber-Reinforced Recycled Aggregate Concrete Utilizing Machine Learning Models with SHAP Analysis. Hybrid Adv. 2025, 11, 100507. [Google Scholar] [CrossRef]

- Guo, L.; Li, Z.; Tian, Q.; Guo, L.; Wang, Q. Prediction of CSG Splitting Tensile Strength Based on XGBoost-RF Model. Mater. Today Commun. 2023, 34, 105350. [Google Scholar] [CrossRef]

- Alarfaj, M.; Qureshi, H.J.; Shahab, M.Z.; Javed, M.F.; Arifuzzaman, M.; Gamil, Y. Machine Learning Based Prediction Models for Spilt Tensile Strength of Fiber Reinforced Recycled Aggregate Concrete. Case Stud. Constr. Mater. 2024, 20, e02836. [Google Scholar] [CrossRef]

- Paruthi, S.; Verma, R.; Sharma, N.; Khan, A.H.; Hasan, M.A. Ensemble Machine Learning Models for Predicting Strength of Concrete with Foundry Sand and Coal Bottom Ash as Fine Aggregate Replacements. Sci. Rep. 2025, 15, 38331. [Google Scholar] [CrossRef]

- Liu, J.; Guan, D.; Liu, X. Comparative Performance Analysis of Machine Learning Models for Compressive Strength Prediction in Concrete Mix Design. Math. Comput. Appl. 2025, 30, 128. [Google Scholar] [CrossRef]

- Alkharisi, M.K.; Dahish, H.A. The Application of Response Surface Methodology and Machine Learning for Predicting the Compressive Strength of Recycled Aggregate Concrete Containing Polypropylene Fibers and Supplementary Cementitious Materials. Sustainability 2025, 17, 2913. [Google Scholar] [CrossRef]

- Li, D.; Tang, Z.; Kang, Q.; Zhang, X.; Li, Y. Machine Learning-Based Method for Predicting Compressive Strength of Concrete. Processes 2023, 11, 390. [Google Scholar] [CrossRef]

- Hasan, M.R.; Shuvo, A.K.; Pranto, E.B.; Hasan, M.; Miah, M.M. Data-Driven Prediction of Concrete Strength by Machine Learning: Hybrid-Fiber-Reinforced Recycled Aggregate Concrete. World J. Eng. 2025. [Google Scholar] [CrossRef]

- Alharthai, M.; Ali, T.; Qureshi, M.Z.; Ahmed, H. The Enhancement of Engineering Characteristics in Recycled Aggregates Concrete Combined Effect of Fly Ash, Silica Fume and PP Fiber. Alex. Eng. J. 2024, 95, 363–375. [Google Scholar] [CrossRef]

- Ali, B.; Ahmed, H.; Ali Qureshi, L.; Kurda, R.; Hafez, H.; Mohammed, H.; Raza, A. Enhancing the Hardened Properties of Recycled Concrete (RC) through Synergistic Incorporation of Fiber Reinforcement and Silica Fume. Materials 2020, 13, 4112. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, T.W.; Ali, A.A.M.; Zidan, R.S. Properties of High Strength Polypropylene Fiber Concrete Containing Recycled Aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Hanumesh, B.; Harish, B.; Venkata Ramana, N. Influence of Polypropylene Fibres on Recycled Aggregate Concrete. Mater. Today Proc. 2018, 5, 1147–1155. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Li, C.; Zhao, J.; Cheng, S. Mechanical Properties of Fully Recycled Aggregate Concrete Reinforced with Steel Fiber and Polypropylene Fiber. Materials 2024, 17, 1156. [Google Scholar] [CrossRef]

- Ali, B.; Fahad, M.; Mohammed, A.S.; Ahmed, H.; Elhag, A.B.; Azab, M. Improving the Performance of Recycled Aggregate Concrete Using Nylon Waste Fibers. Case Stud. Constr. Mater. 2022, 17, e01468. [Google Scholar] [CrossRef]

- Matar, P.; Zéhil, G.-P. Effects of Polypropylene Fibers on the Physical and Mechanical Properties of Recycled Aggregate Concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2019, 34, 1327–1344. [Google Scholar] [CrossRef]

- Khoshroo, M.; Javid, A.A.S.; Bakhshandeh, N.R.; Shalchiyan, M. Investigation of the Mechanical Properties of Concrete Containing Recycled Aggregate and Scrap Crumb Rubber and Polypropylene Fibers. Prog. Rubber Plast. Recycl. Technol. 2021, 37, 167–189. [Google Scholar] [CrossRef]

- Ahmed, L.A.; Hassan, S.S.; Al-Ameer, O.A. Ultra-High Performance Reinforced by Polypropylene Fiber Concrete Made with Recycled Coarse Aggregat. Kufa J. Eng. 2017, 8, 128–141. [Google Scholar] [CrossRef]

- Nazir, S.; Mahajan, A.; Jaggi, S. An Experimental Study on Enhancing Recycled Aggregate Concrete Properties Through Silica Fume Incorporation. 2023. Available online: https://assets-eu.researchsquare.com/files/rs-2830337/v1/7fdd74a7-8649-44ab-89bc-5fd77e098ba2.pdf?c=1684510162 (accessed on 1 May 2025).

- Shahab, M.; Bashar, N. Effect of Silica Fume on Strength of Recycled Aggregate Concrete. Int. J. Res. Eng. Innov. 2024, 8, 101–107. [Google Scholar] [CrossRef]

- Ismail, A.J.; Younis, K.H.; Maruf, S.M. Recycled Aggregate Concrete Made with Silica Fume: Experimental Investigation. Civ. Eng. Archit. 2020, 8, 1136–1143. [Google Scholar] [CrossRef]

- Alamri, M.; Ali, T.; Ahmed, H.; Qureshi, M.Z.; Elmagarhe, A.; Adil Khan, M.; Ajwad, A.; Sarmad Mahmood, M. Enhancing the Engineering Characteristics of Sustainable Recycled Aggregate Concrete Using Fly Ash, Metakaolin and Silica Fume. Heliyon 2024, 10, e29014. [Google Scholar] [CrossRef]

- Nadim, F.; Hasan, R.; Rahman Sobuz, M.H.; Ashraf, J.; Sadiqul Hasan, N.M.; Dip Datta, S.; Islam, M.H.; Islam, M.A.; Awall, M.R.; Rahman, S.A.; et al. Effect of Silica Fume on the Microstructural and Mechanical Properties of Concrete Made with 100% Recycled Aggregates. Revista de la Construcción 2024, 23, 413–435. [Google Scholar] [CrossRef]

- Sun, S.; Du, Y.; Sun, S.; Yu, Q.; Li, Y. Mechanical Properties of Recycled Concrete with Polypropylene Fiber and Its Bonding Performance with Rebars. Mater. Sci. 2024, 30, 396–403. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Dhinakaran, G. Strength Characteristics of High-Volume Fly Ash–Based Recycled Aggregate Concrete. J. Mater. Civ. Eng. 2013, 25, 1127–1133. [Google Scholar] [CrossRef]

- Sowmith, N.; Anjaneya Babu, P.S.S. Influence of Fly Ash on the Performance of Recycled Aggregate Concrete. Int. J. Sci. Res. (IJSR) 2016, 5, 1740–1744. [Google Scholar] [CrossRef]

- Sonkhla, P. Effect of Silica Fume and Recycled Coarse Aggregate in Concrete. Master’s Thesis, Jaypee University of Information Technology, Waknaghat, India, 2016. [Google Scholar]

- Breiman, L. Random Forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Chen, T.; Guestrin, C. XGBoost: A Scalable Tree Boosting System. In Proceedings of the 22nd ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, San Francisco, CA, USA, 13–17 August 2016; ACM: New York, NY, USA, 2016; pp. 785–794. [Google Scholar]

- Wu, J.; Ma, D.; Wang, W. Leakage Identification in Water Distribution Networks Based on XGBoost Algorithm. J. Water Resour. Plan Manag. 2022, 148, 04021107. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).