Abstract

The valorization of wood waste in cement-based materials offers a promising path toward reducing the environmental footprint of the construction sector. While short-term properties of wood–cement composites have been studied, their long-term durability remains a critical uncertainty for practical application. This study investigates the long-term mechanical behavior of Portland-cement mortars incorporating 5% by mass of four types of wood waste: spruce, oak, beech, and oriented strand board (OSB). Specimens were subjected to flexural and compressive tests after 28 days and approximately 242 days of curing under natural laboratory conditions to assess the evolution of their properties. The results demonstrate that the long-term performance is highly dependent on the wood type. Composites with spruce sawdust, oak, beech, and OSB exhibited remarkable stability, with strength variations generally within ±8% over the extended period, supporting a scenario of matrix stabilization. In contrast, mortar with spruce shavings suffered a significant strength reduction of approximately 25%, indicating susceptibility to degradation, likely due to its high-water demand and porous resulting matrix. All wood-composite mortars showed a substantial density reduction of 20–36% compared to the reference. The findings confirm that OSB and oak waste provide the best overall performance, combining higher initial strength with excellent long-term stability. This research concludes that carefully selected wood waste can produce durable, lightweight cement composites viable for non-structural applications, thereby supporting the integration of circular economy principles in sustainable construction. Unlike previous studies that primarily assessed short-term strength, this paper provides one of the few comparative long-term assessments under natural curing conditions, highlighting the stabilization–degradation mechanisms across wood types.

1. Introduction

Cement production accounts for roughly 8% of global CO2 emissions [1]. Strategies to mitigate this impact increasingly focus on valorizing waste in cementitious materials. In recent years, increasing attention has been directed toward the development of eco-efficient building materials [2] that incorporate industrial or agricultural waste as secondary raw materials, thus supporting the principles of sustainable development and the circular economy [3].

Wood processing industries generate considerable amounts of residues [4] and by-products such as sawdust, chips, and oriented strand board (OSB) waste, which are often underutilized and disposed of in landfills. The reuse of such lignocellulosic materials in cementitious composites [5] offers an effective route for waste valorization and for reducing the demand for natural aggregates. Previous studies have demonstrated that partial replacement of mineral aggregates with wood waste can decrease the density of mortars and concretes [6], improving their thermal insulation potential [7] and lowering the environmental impact of production [8,9]. However, the incorporation of organic materials also tends to modify the hydration process of cement and to affect the mechanical strength and durability of the resulting composites [10].

Most experimental research on cement–wood composites [11,12,13] has focused on short-term mechanical performance, typically assessed after 7, 14, or 28 days of curing. These periods correspond to the early and standard stages of hydration, during which cementitious materials achieve the majority of their final strength. Little information is available regarding the long-term behavior of mortars containing wood waste, particularly beyond the conventional 28-day testing age. The interaction between the cement matrix and the organic particles can evolve over time through continued hydration, internal drying, or gradual degradation of the wood–cement interface [14]. Understanding these processes is essential for evaluating the suitability of such composites for practical applications, especially in non-structural or low-load-bearing elements.

Previous studies have investigated the short-term mechanical or durability performance of wood–cement composite [15,16], however, few have extended testing beyond 90 days, and even fewer have compared different wood species under the same conditions. Moreover, most prior research was conducted under controlled humidity and temperature, leaving the long-term performance under natural laboratory conditions largely unexplored. This study fills that gap by investigating the long-term mechanical behavior of Portland-cement mortars containing 5% wood waste obtained from four sources: spruce, oak, beech, and oriented strand board (OSB). This long-term, cross-species comparison under realistic curing is scarcely reported in the literature and addresses the current gap regarding whether wood–cement systems tend to stabilize or degrade over prolonged curing.

The experimental program involved testing the specimens at standard curing ages of 7, 14, and 28 days, as well as at an extended period of approximately 242 days, in order to evaluate the evolution and stability of mechanical performance over time. The analysis focuses on changes in density, flexural strength, and compressive strength, aiming to identify whether the mechanical characteristics of wood-modified mortars continue to evolve, stabilize, or degrade during prolonged curing.

The central research question (RQ1) guiding this investigation can be formulated as follows:

RQ1.

How does the presence of wood waste influence the long-term mechanical behavior of cement-based mortars, and does the interaction between the organic inclusions and the mineral matrix lead to degradation or stabilization over time?

To address this question, two working hypotheses were established, reflecting the possible mechanisms expected to occur during extended curing:

Hypothesis H1.

Degradation scenario: Over time, wood particles may partially degrade due to moisture fluctuations and chemical incompatibility with the cement matrix. This could lead to microstructural discontinuities, loss of adhesion, and a consequent decrease in flexural and compressive strength after long-term curing.

Hypothesis H2.

Stabilization and hydration scenario: Alternatively, the continued hydration of cement and gradual moisture equilibration within the composite may improve the bond between phases and densify the matrix. Under this mechanism, the wood-modified mortars could exhibit stable or slightly increased strength at 242 days compared with their 28-day performance.

The experimental investigation described in this paper was designed to verify which of these hypotheses more accurately describes the long-term behavior of wood–cement composites. By analyzing the evolution of mechanical properties over a period of approximately eight months, the study provides new insights into the durability and compatibility of wood residues in cementitious materials and supports the broader goal of integrating renewable waste resources into sustainable building materials.

Through this approach, the paper provides new insights into the durability and long-term performance of wood–cement composites. The findings contribute to the optimization of sustainable mortar formulations and to a better understanding of the compatibility between different wood species and cementitious matrices, supporting the broader goal of integrating renewable waste materials into eco-friendly construction products.

2. Experimental Program

2.1. Design of Wood–Cement Composites

The experimental program was based on a Portland-cement mortar formulation designed to evaluate the effect of wood waste incorporation over both short- and long-term curing periods. Portland cement type CEM I 42.5R, commercially available in Romania, was used as the binder. The fine aggregate consisted of natural river sand with a maximum particle size of 2 mm, conforming to the requirements of EN 196-1 [17]. Clean tap water was used for mixing.

Wood waste was collected from four sources, representing both softwood and hardwood species as well as engineered wood products: spruce (Picea abies), oak (Quercus robur), beech (Fagus sylvatica), and oriented strand board (OSB). The residues consisted of dry particles and small fragments produced during sawing or machining operations. Prior to mixing, the wood waste was oven-dried at 105 °C for 24 h to remove moisture and stored in sealed containers at laboratory conditions. Wood waste materials were provided by a local prefabricated wood construction company (WoodStructure SRL, Cluj-Napoca, Romania).

The wood residues were manually sieved to a particle size below 2 mm, consistent with the sand fraction, to ensure homogeneous dispersion. Average particle density and moisture content were measured as 0.42–0.67 g/cm3 and below 1% after drying, respectively. Figure 1 presents representative photos of the wood particles.

Figure 1.

The five types of wood waste used in the experimental program.

The experimental mixtures were prepared with a 5% replacement (by mass of aggregate) of wood waste, maintaining a constant cement-to-sand ratio across all recipes. A reference mix without wood addition was produced for comparison. The water-to-cement ratio varied slightly among mixtures to achieve comparable workability, as summarized in Table 1. Six compositions were therefore analyzed: a control mortar (R1) and five modified mortars containing different types of wood waste. The amount of mixing water was adjusted based on visual workability and consistency during mixing, aiming for comparable flow and compaction among mixtures.

Table 1.

Mix proportions for the experimental phase.

All mixes were prepared using a 5 L laboratory planetary mixer (Cement Mortar Mixer CM-AM5) at 140 rpm for 90 s, followed by a 60 s rest and a second 90 s mixing phase to ensure uniform dispersion of wood particles.

The water–cement ratio varied slightly among mixtures (0.74–1.73) to achieve comparable workability. This adjustment was necessary because wood waste strongly affects water absorption and rheology. Maintaining constant W/C would have produced unworkable mixes and non-comparable compaction levels. Therefore, the variation reflects a practical adjustment rather than an experimental variable. Although wood contains sugars that can influence cement hydration, the low replacement level (5%) and prior oven drying minimized such effects; no retardation was observed during setting.

The influence of natural sugars contained in wood was considered in the design phase. To minimize their potential effect on cement hydration, the wood residues were oven-dried at 105 °C for 24 h prior to mixing, and the substitution rate was limited to 5%. No abnormal setting or hardening delays were observed.

2.2. Specimen Preparation and Curing Conditions

For each mixture, prism specimens measuring 40 × 40 × 160 mm were cast in steel molds in accordance with EN 196-1 [17]. Three prisms (40 × 40 × 160 mm) per mixture were cast and tested at each curing age (7, 14, 28, 242 days), yielding six × 4 × 3 = 72 specimens total. The extended curing period of 242 days (~8 months) was selected to capture the effects of natural seasonal humidity and temperature cycles within a single year, representing realistic service exposure for indoor mortars.

After 24 h of initial curing in molds at ambient laboratory conditions, the specimens were demolded and stored for continued curing in the Building Materials Laboratory of the Faculty of Civil Engineering, Technical University of Cluj-Napoca. The specimens were stored in the materials laboratory where temperature varied seasonally between approximately 10 °C (winter) and 28 °C (summer), with corresponding relative humidity fluctuations typical of a non-air-conditioned indoor space. This curing regime was intentionally selected to simulate realistic service conditions for non-structural mortars. Although the environment was not strictly controlled, all specimens from all mixtures were cured in the same location and under identical conditions, ensuring valid cross-comparisons. The absence of mass loss and of visible surface degradation after 242 days indicates that the observed mechanical trends are representative for such indoor exposure.

This mixed curing regime was intentionally maintained to simulate realistic exposure conditions, similar to those experienced by non-structural or interior mortar elements in service. The specimens were stored on open shelves, allowing for gradual moisture exchange with the surrounding air. Such conditions enabled the investigation of the long-term interaction between the cement matrix and the wood particles under variable but realistic environmental influences.

2.3. Testing Procedure

Mechanical tests were carried out after 7, 14, 28, and approximately 242 days of curing to assess both early-age and long-term mechanical performance. At each age, flexural and compressive strength tests were performed according to EN 196-1 [17]. Three prism specimens were tested for each mix and age.

- -

- Flexural strength was determined by three-point bending, applying a monotonic load until failure.

- -

- After flexural testing, the two resulting halves of each prism were used for compressive strength testing, performed on the 40 × 40 mm cross-section faces.

- -

- The maximum load was recorded for each test, and the corresponding stress values were calculated in N/mm2.

In addition, the weight of each specimen was measured before testing to monitor possible changes in density over time. These measurements allowed for the evaluation of potential drying effects or material degradation during the 242-day period.

3. Results and Discussions

3.1. Visual Examination of Specimens

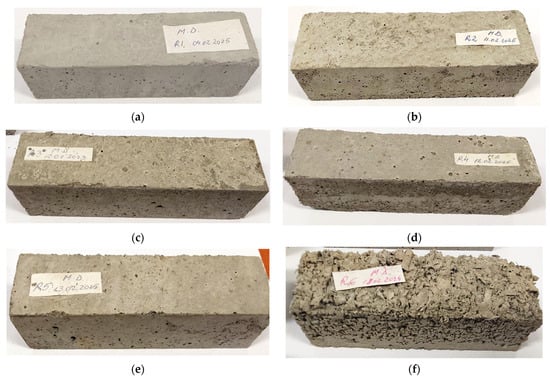

Representative photographs of the mortar prisms corresponding to each mixture, both in their intact state and after mechanical testing, are shown in Figure 2 and Figure 3. The visual evaluation aimed to document the overall appearance, surface condition, and any visible signs of degradation or color alteration that might have occurred during the 242-day curing period.

Figure 2.

Visual appearance of mortar prisms after 242 days of curing (before testing): (a) R1—reference; (b) R2—spruce; (c) R3—oak; (d) R4—beech; (e) R5—OSB; (f) R6—spruce shavings.

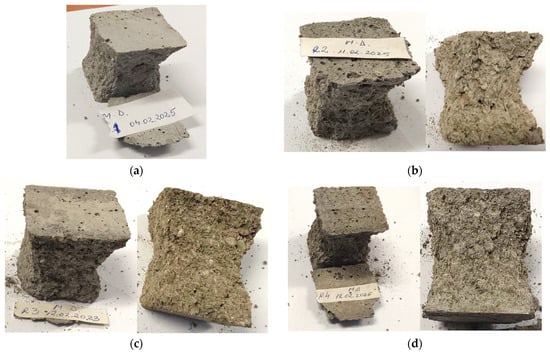

Figure 3.

Fracture surfaces of mortar prisms after flexural and compressive testing (242 days): (a) R1—reference; (b) R2—spruce; (c) R3—oak; (d) R4—beech; (e) R5—OSB; (f) R6—spruce shavings.

The control mortar (R1) exhibited a uniform light-gray appearance typical of Portland-cement composites, with smooth and compact surfaces and no visible cracks or discoloration. In contrast, the mortars containing wood waste presented slightly rougher textures and minor color variations, depending on the type and density of the incorporated wood particles. The spruce (R2) and OSB (R5) mixtures displayed lighter tones with visible inclusions of wood fibers near the surface, while the oak (R3) and beech (R4) mortars appeared denser and more homogeneous. The spruce shavings mixture (R6) showed a coarser texture due to the irregular geometry and larger particle size of the waste material.

After long-term curing, no biological degradation, mold growth, or efflorescence was observed on any of the samples, despite the natural variations in temperature and humidity in the laboratory during the eight-month storage period. The prisms retained their shape and cohesion, with no evidence of surface scaling or delamination.

No evidence of swelling-induced cracking, delamination, or surface damage was observed on any sample, despite the natural fluctuations in temperature and humidity. This suggests that the limited wood content (5%) and adequate cement encapsulation prevented moisture-induced expansion effects.

Following mechanical testing, the fracture surfaces of the specimens (Figure 3) revealed a relatively uniform dispersion of wood particles within the cement matrix. In most mixtures, the wood fragments appeared well embedded, without noticeable interfacial voids or pull-out regions, indicating satisfactory bonding and adhesion between the phases. The cross-sections of the oak and beech mixtures were particularly compact, while the spruce and spruce-shavings mixtures showed slightly more porous textures.

Overall, the visual assessment confirms that under the natural laboratory conditions used in this study, the inclusion of 5% wood waste did not lead to visible degradation or instability over time. The prisms maintained their physical integrity, supporting the assumption that wood–cement composites can remain visually and structurally stable during prolonged curing, provided that the exposure environment is moderate and the replacement ratio remains limited.

3.2. Weight and Density Evolution

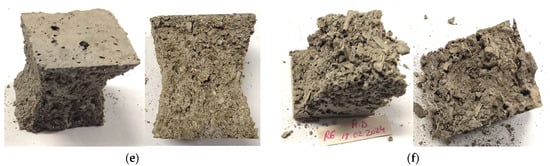

To emphasize the long-term behavior, Figure 4 illustrates the percentage variation in specimen weight between 28 and 242 days. Measuring weights reflect both the intrinsic density of the mixtures and the moisture exchange between the specimens and their environment during curing.

Figure 4.

Evolution of specimen weight over curing time for reference and wood-composite mortars (28 and 242 days).

Average densities at 28 days ranged between 1.50 g/cm3 (OSB) and 1.23 g/cm3 (spruce shavings), representing 20–36% reduction compared to the reference (1.91 g/cm3).

For the reference mortar, the weight remained virtually unchanged (+0.05%), confirming equilibrium with the environment. Among the wood-modified mixtures, changes ranged between −0.3% (spruce) and +4% (oak and beech), values well within the normal moisture-fluctuation range for cementitious materials. This stabilization indicates that the specimens reached equilibrium with the surrounding environment and that no measurable degradation, decomposition, or material loss occurred during the long-term storage period.

The oak and beech mixtures maintained the highest average weights among the modified mortars (approximately 420–437 g), suggesting a denser internal structure and better packing of the particles within the matrix. In contrast, the spruce and spruce-shavings mixtures were the lightest, with average masses of 350–360 g, due to their lower particle density and more irregular geometry. The OSB mixture showed intermediate values (415–420 g) and displayed consistent stability between 28 and 242 days.

These results confirm that the addition of 5% wood waste effectively produces lightweight mortars, with mass reductions ranging between 20% and 35% compared with the reference. More importantly, the absence of significant mass loss after eight months of exposure supports Hypothesis H2—that wood particles remain dimensionally and physically stable in the cementitious environment and do not undergo visible degradation over time.

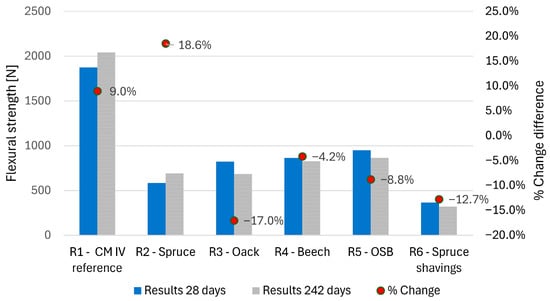

3.3. Flexural Strength Development

The flexural load-bearing capacity of the specimens at 28 days and 242 days is presented in Figure 5. This property, measured as the maximum load at failure, is a direct indicator of the composite’s resistance to bending and the integrity of the wood–cement interface.

Figure 5.

Evolution of maximum flexural load between 28 and 242 days of curing.

Mass measurements were performed on the same specimens before mechanical testing at both 28 and 242 days. Minor geometric irregularities were accounted for by using the average density values calculated from the triplicate samples. The higher mass loss recorded for R6 (spruce shavings) is attributed to the large, irregular geometry of the shavings and their higher water demand, which produced a more porous matrix susceptible to internal drying

As anticipated, the reference mortar (R1) exhibited a significant increase in flexural load capacity (+9.0%) over the long term, from 1873 N to 2042 N. This is consistent with the ongoing hydration of Portland cement, which continues to densify the matrix and enhance its mechanical properties over time.

The behavior of the wood–cement composites revealed two distinct trends, highlighting the influence of wood species and particle type:

- Stability and Strength Gain: The composites with spruce (R2) and beech (R4) not only maintained their integrity but also showed a noticeable increase in flexural load over time. Spruce (R2) increased by 18.6% (583 N to 692 N), and beech (R4) remained stable with a slight decrease of 4.1% (863 N to 828 N). This indicates a stable or even improving bond between the cement matrix and these wood particles, supporting Hypothesis 2 (Stabilization).

- Strength Reduction: In contrast, the composites with oak (R3), OSB (R5), and spruce shavings (R6) experienced a reduction in their load-bearing capacity. The decreases were 17.0% for oak (823 N to 683 N), 8.8% for OSB (950 N to 867 N), and 12.7% for spruce shavings (367 N to 320 N). For oak and OSB, this reduction is moderate and may be attributed to internal stress development or slight degradation at the interface. However, the consistent underperformance of R6 (Spruce Shavings) across all measured properties aligns with Hypothesis H1 (Degradation), likely due to its high-water demand and the resulting porous, weak matrix.

It is noteworthy that despite these changes, OSB (R5) maintained the highest absolute flexural load among all wood-composite specimens at 242 days, followed by beech (R4). This confirms that engineered wood residues and certain hardwoods can provide superior mechanical performance in the long term.

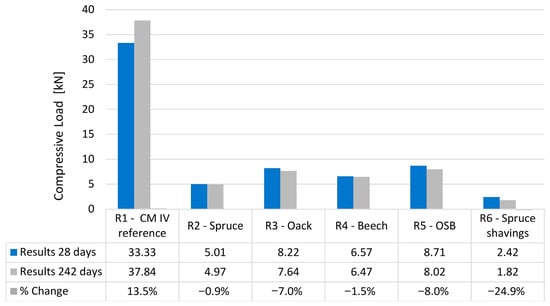

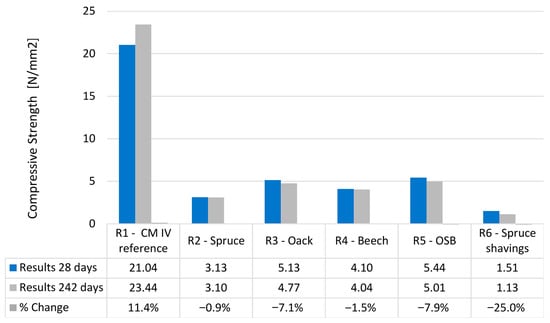

3.4. Long-Term Evolution of Compressive Strength

The long-term mechanical behavior was evaluated by comparing the flexural and compressive strength results at 28 days and 242 days, as shown in Figure 6 and Figure 7. These figures combine the absolute strength values with the relative percentage change, providing a comprehensive view of performance evolution.

Figure 6.

Evolution of maximum compressive load and relative change over 242 days of curing.

Figure 7.

Evolution of compressive strength and relative change over 242 days of curing.

The compressive load-bearing capacity, a fundamental property for classifying construction materials, was monitored over the long term, with results at 28 and 242 days presented in Figure 6. The maximum load at failure provides a direct measure of the composite’s ability to carry structural loads.

The data reveals a clear divergence in long-term behavior between the reference mortar and the wood-composite specimens:

- Reference Mortar (R1): The control mix demonstrated a significant 13.5% increase in compressive load, from 33.33 kN to 37.84 kN. This robust strength gain is characteristic of ongoing cement hydration and microstructural densification in a pure cementitious system.

- Wood-Composite Mortars (R2–R6): In contrast, all composites containing wood waste exhibited a stabilization or reduction in their compressive load capacity. The results can be categorized as follows:

- High Stability: The Spruce (R2) composite showed exceptional stability, with a negligible decrease of only 0.8% (5.01 kN to 4.97 kN). This indicates that the cement matrix with spruce particles reached a very stable state, with no significant detrimental interactions over time.

- Moderate Reduction: The composites with Oak (R3), Beech (R4), and OSB (R5) experienced moderate reductions in compressive load, ranging from −1.5% to −7.9%. Specifically, OSB (R5) decreased from 8.71 kN to 8.02 kN (−7.9%), Oak (R3) from 8.22 kN to 7.64 kN (−7.1%), and Beech (R4) from 6.57 kN to 6.47 kN (−1.5%). These relatively small changes suggest that while some minor degradation or internal stress relaxation may have occurred, the overall structural integrity of these composites was largely maintained, lending partial support to Hypothesis H2 (Stabilization).

- Significant Degradation: Once again, the R6 mixture (Spruce Shavings) displayed the most pronounced negative trend, suffering a 24.8% loss in compressive load (2.42 kN to 1.82 kN). This consistent and severe degradation across both flexural and compressive properties strongly supports Hypothesis H1 (Degradation) for this specific mixture. The high water-cement ratio (1.73) required for workability likely resulted in a highly porous matrix, and the specific surface area and chemical composition of the shavings may have further inhibited a strong, durable bond with the cement paste.

Despite the observed reductions, it is important to note the performance hierarchy. On 242 days, OSB (R5) and Oak (R3) still provided the highest compressive load-bearing capacity among the wood-composites, underscoring their relative suitability for applications requiring higher compressive resistance.

The flexural strength (R) results, calculated from the maximum load at failure, are presented in Figure 7. As anticipated, the reference mortar (R1) exhibited a significant increase in flexural strength (+11.4%) over the long term, from 21.04 N/mm2 to 23.44 N/mm2. This is consistent with the ongoing hydration of Portland cement, which continues to densify the matrix and enhance its mechanical properties.

The behavior of the wood–cement composites revealed distinct trends:

- High Stability: The composites with Spruce (R2) and Beech (R4) demonstrated excellent stability, with minimal changes of −0.9% and −1.5%, respectively. This indicates a robust and durable bond between the cement matrix and these wood particles.

- Moderate Reduction: The composites with Oak (R3) and OSB (R5) experienced moderate reductions in flexural strength of −7.1% and −7.9%, respectively. This suggests potential minor degradation at the wood–cement interface or internal stress development, yet the overall integrity was largely maintained.

- Significant Degradation: The R6 mixture (Spruce Shavings) showed a pronounced decrease of 25.0%, underscoring a clear compatibility issue likely driven by its high water-cement ratio and particle morphology. Despite these changes, OSB (R5) maintained the highest flexural strength among all wood composites at 242 days, confirming its superior performance.

4. Synthesis of Mechanical Behavior

The long-term data provides a clear answer to the central research question. For most wood species—Spruce, Oak, Beech, and OSB—the incorporation of 5% waste did not lead to progressive degradation over 242 days. The mechanical properties remained stable or experienced only minor reductions, which strongly supports “Hypothesis H2 (Stabilization scenario)” for these mixtures.

The consistent and severe underperformance of the “R6 (Spruce Shavings)” mixture across both properties aligns with “Hypothesis H1 (Degradation scenario)”. This highlights that the form and size of wood waste are critical factors, with the shavings’ characteristics leading to long-term weakening.

Therefore, the central research question is answered as follows: the interaction leads to stabilization for most wood types, but degradation is a critical risk for wastes with high water absorption and unfavorable particle morphology. From an application perspective, the stability of mixtures R2–R5 is highly promising for non-structural applications. The superior performance of OSB (R5) and oak (R3) makes them the most recommended waste types for producing durable, lightweight cement composites.

Temperature and humidity variations may slow down or accelerate late hydration, but because all mixes were exposed simultaneously, the relative differences observed among wood types can be attributed to the material itself rather than to the environment.

The long-term stabilization observed for spruce, oak, beech, and OSB mixtures is consistent with previously reported interactions in which the cement matrix progressively encapsulates lignocellulosic inclusions and continues to hydrate in partially closed pores. However, the pronounced degradation of the spruce-shavings mixture suggests that particle morphology and water demand can locally increase porosity and weaken the interface. Future work will integrate SEM, XRD or FTIR analyses to confirm these interface-related mechanisms and to differentiate between matrix densification and particle-induced degradation.

Although no microstructural analyses (e.g., SEM or FTIR) were performed, previous studies suggest that the stabilization observed here is linked to secondary C–S–H formation around partially lignified particles and limited ion diffusion at the wood–cement interface. Future work will integrate such techniques to elucidate the stabilization–degradation mechanisms identified.

The fracture morphology revealed brittle failure for the reference mortar and more ductile, fibrous fracture behavior for wood–cement composites. These patterns are typical of materials with higher porosity and energy absorption, consistent with the mechanical results obtained. Although porosity or X-ray analyses were beyond this study’s scope, future work will integrate such techniques to confirm the mechanisms of stabilization and degradation observed

5. Conclusions

This study was guided by a central research question (RQ1): “How does the presence of wood waste influence the long-term mechanical behavior of cement-based mortars, and does the interaction lead to degradation or stabilization?”. After 242 days of monitoring, the experimental data provides a clear and nuanced answer.

The long-term behavior is not universal but is fundamentally dictated by the type of wood waste used. For the majority of the tested materials, spruce (as sawdust), oak, beech, and OSB, the evidence strongly confirms that the wood–cement interaction leads to stabilization, not degradation. These composites exhibited remarkable stability, with mechanical properties remaining largely unchanged or showing only minor reductions (typically within ±8%). This outcome provides robust support for our “Stabilization Hypothesis (Hypothesis H2)”, indicating that the cement matrix can effectively encapsulate these wood particles to form a durable composite under realistic indoor conditions.

However, the study also identified a critical exception that validates the concerns behind the “Degradation Hypothesis (Hypothesis H1)”. The composite with spruce shavings (R6) suffered a severe strength loss of approximately 25%, demonstrating that certain wood forms are susceptible to significant long-term degradation. This was likely due to the shavings’ high-water demand, which resulted in a porous matrix, and potentially their greater chemical interference or susceptibility to moisture fluctuations.

Beyond resolving these hypotheses, the results establish a clear performance ranking: OSB and oak emerged as the most effective waste types, delivering the best combination of initial strength and long-term stability. The successful incorporation of these materials led to a 20–36% reduction in density, creating viable lightweight composites.

In practical terms, this means that the path forward for wood–cement composites is one of selective optimization. Our findings provide a clear guideline: wood waste like OSB and oak are excellent candidates for producing stable, lightweight building materials for non-structural applications, such as insulating panels and acoustic tiles. The case of spruce shavings, meanwhile, serves as a crucial caution, highlighting that particle size and absorption capacity are as important as the wood species itself. By making informed choices, we can confidently transform wood waste from an environmental burden into a valuable resource for a more sustainable construction industry.

While the findings demonstrate clear trends of stabilization versus degradation, the study is limited to a single wood content (5%) and lacks microstructural confirmation. Future investigations will explore multiple replacement ratios, detailed chemical analyses, and exposure to controlled environmental cycles to establish predictive models for long-term durability.

Author Contributions

Conceptualization, D.M. and D.L.M.; methodology, D.M.; software, D.M.; validation, D.M. and D.-R.T.-G.; formal analysis, D.M. and A.Ț.; investigation, D.M. and D.-R.T.-G.; resources, A.Ț.; data curation, P.C.; writing—original draft preparation, D.M., A.Ț. and P.C.; writing—review and editing, D.M., A.Ț. and P.C.; visualization, D.M. and D.-R.T.-G.; supervision, D.L.M.; project administration, D.M.; funding acquisition, D.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the APC was funded from the research grant, number 7164 from GNaC ARUT 2023 competition, with the financial support of Technical University of Cluj-Napoca, Romania, Europe.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Caldas, L.R.; Saraiva, A.B.; Lucena, A.F.P.; Da Gloria, M.Y.; Santos, A.S.; Filho, R.D.T. Building materials in a circular economy: The case of wood waste as CO2-sink in bio concrete. Resour. Conserv. Recycl. 2021, 166, 105346. [Google Scholar] [CrossRef]

- Berger, F.; Gauvin, F.; Brouwers, H.J.H. The recycling potential of wood waste into wood-wool/cement composite. Constr. Build. Mater. 2020, 260, 119786. [Google Scholar] [CrossRef]

- Leone, R.; Campisi, T.; Saeli, M. Wood Industry Wastes Valorisation and Reuse for a Greener Architecture. In Lecture Notes in Civil Engineering (LCNE), Proceedings of the 11th International Conference of Ar.Tec. Scientific (Society of Architectural Engineering), Palermo, Italy, 12–15 June 2024; Springer: Cham, Switzerland, 2025; Volume 611, pp. 439–455. [Google Scholar] [CrossRef]

- Liu, Z.; Han, C.; Li, Q.; Li, X.; Zhou, H.; Song, X.; Zu, F. Study on wood chips modification and its application in wood-cement composites. Case Stud. Constr. Mater. 2022, 17, e01350. [Google Scholar] [CrossRef]

- Do, T.T.H.; Ly, T.B.T.; Hoang, N.T.; Tran, V.T. A new integrated circular economy index and a combined method for optimization of wood production chain considering carbon neutrality. Chemosphere 2023, 311, 137029. [Google Scholar] [CrossRef] [PubMed]

- Farjana, S.H.; Tokede, O.; Ashraf, M. Environmental Impact Assessment of Waste Wood-to-Energy Recovery in Australia. Energies 2023, 16, 4182. [Google Scholar] [CrossRef]

- Yan, S.; Shi, F.; Zheng, C.; Ma, Y.; Huang, J. Whole biomass material envelope system for nearly-zero energy houses: Carbon footprint and construction cost assessment. J. Build. Eng. 2024, 86, 108757. [Google Scholar] [CrossRef]

- Ouellet-Plamondon, C.M.; Ramseier, L.; Balouktsi, M.; Delem, L.; Foliente, G.; Francart, N.; Garcia-Martinez, A.; Hoxha, E.; Lützkendorf, T.; Rasmussen, F.N.; et al. Carbon footprint assessment of a wood multi-residential building considering biogenic carbon. J. Clean. Prod. 2023, 404, 136834. [Google Scholar] [CrossRef]

- Maier, D. A Review of the Environmental Benefits of Using Wood Waste and Magnesium Oxychloride Cement as a Composite Building Material. Materials 2023, 16, 1944. [Google Scholar] [CrossRef] [PubMed]

- Leone, R.; La Scalia, G.; Saeli, M. A critical review on reuse potentials of wood waste for innovative products and applications: Trends and future challenges. Sustain. Futures 2025, 10, 100869. [Google Scholar] [CrossRef]

- Hirschmuller, S.; Unterberger, S.H.; Marte, R.; van de Kuilen, J.-W. Wood-cement-composite behaviour of beech circular hollow sections. Eur. J. Wood Wood Prod. 2021, 79, 301–315. [Google Scholar] [CrossRef]

- Dias, S.; Almeida, J.; Santos, B.; Humbert, P.; Tadeu, A.; António, J.; de Brito, J.; Pinhão, P. Lightweight cement composites containing end-of-life treated wood-Leaching, hydration and mechanical tests. Constr. Build. Mater. 2022, 317, 125931. [Google Scholar] [CrossRef]

- Keskisaari, A.; Butylina, S.; Karki, T. Use of construction and demolition wastes as mineral fillers in hybrid wood-polymer composites. J. Appl. Polym. Sci. 2016, 133, 43412. [Google Scholar] [CrossRef]

- Maier, D. Building Materials Made of Wood Waste a Solution to Achieve the Sustainable Development Goals. Materials 2021, 14, 7638. [Google Scholar] [CrossRef] [PubMed]

- Maier, D.; Manea, D.L.; Gavrea, D.-R.T.; Tiriac, A.; Costin, P. Wood–Cement Composites: A Sustainable Approach for Mitigating Environmental Impact in Construction. J. Compos. Sci. 2024, 8, 474. [Google Scholar] [CrossRef]

- Melichar, T.; Dufka, A.; Dvořák, K.; Bayer, P.; Vasas, S.; Novakova, I.; Schwarzova, I.; Bydžovský, J. Durability of Wood–Cement Composites with Modified Composition by Limestone and Stabilised Spruce Chips. Materials 2024, 17, 6300. [Google Scholar] [CrossRef] [PubMed]

- EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. CEN-CENELEC Management Centre: Brussels, Belgium, 2016.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).