Effect of Steel Slag and Ground Slag on the Properties of Cement-Based Greener Grouting Material in Sandy Strata

Abstract

1. Introduction

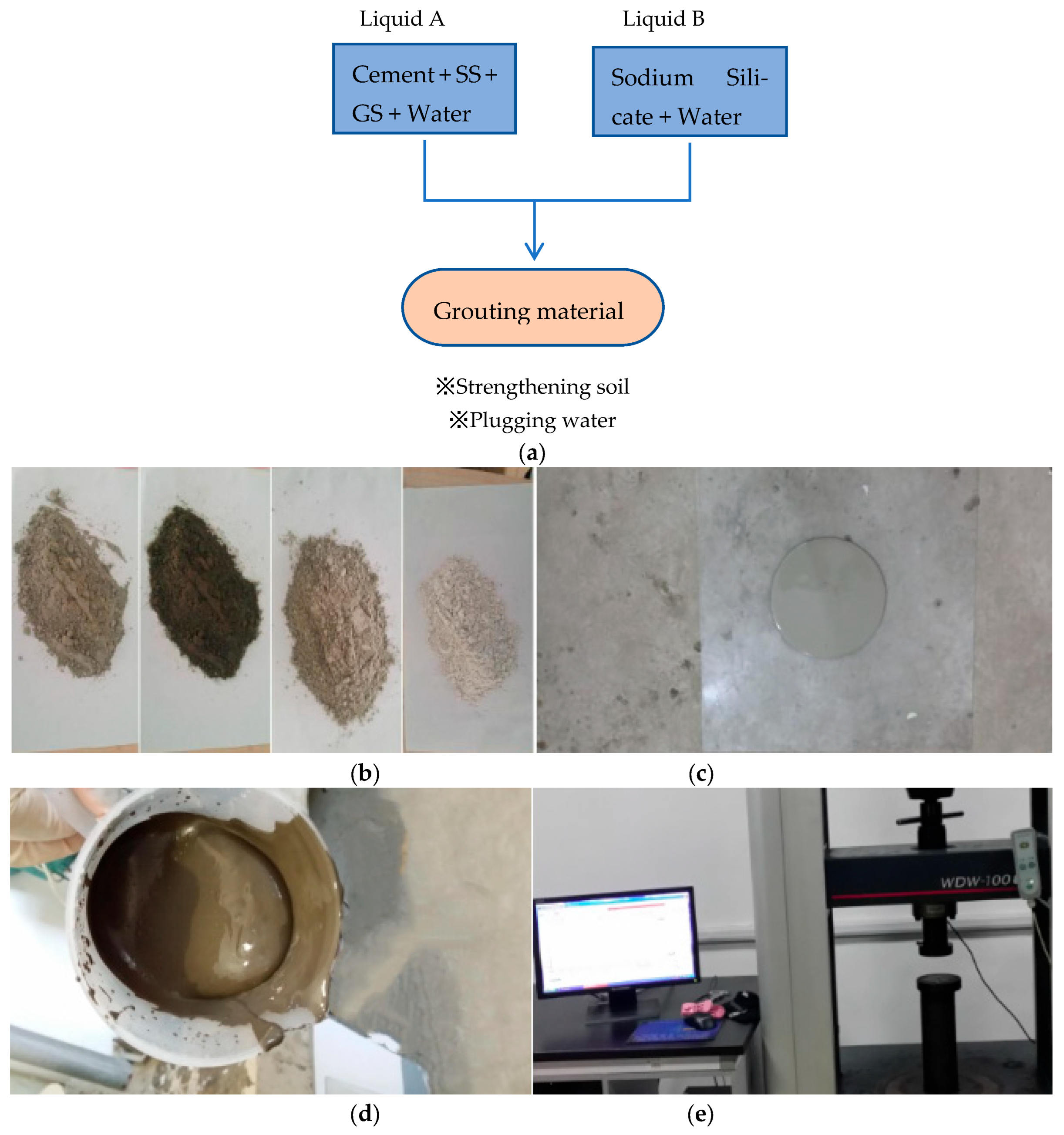

2. Materials and Methods

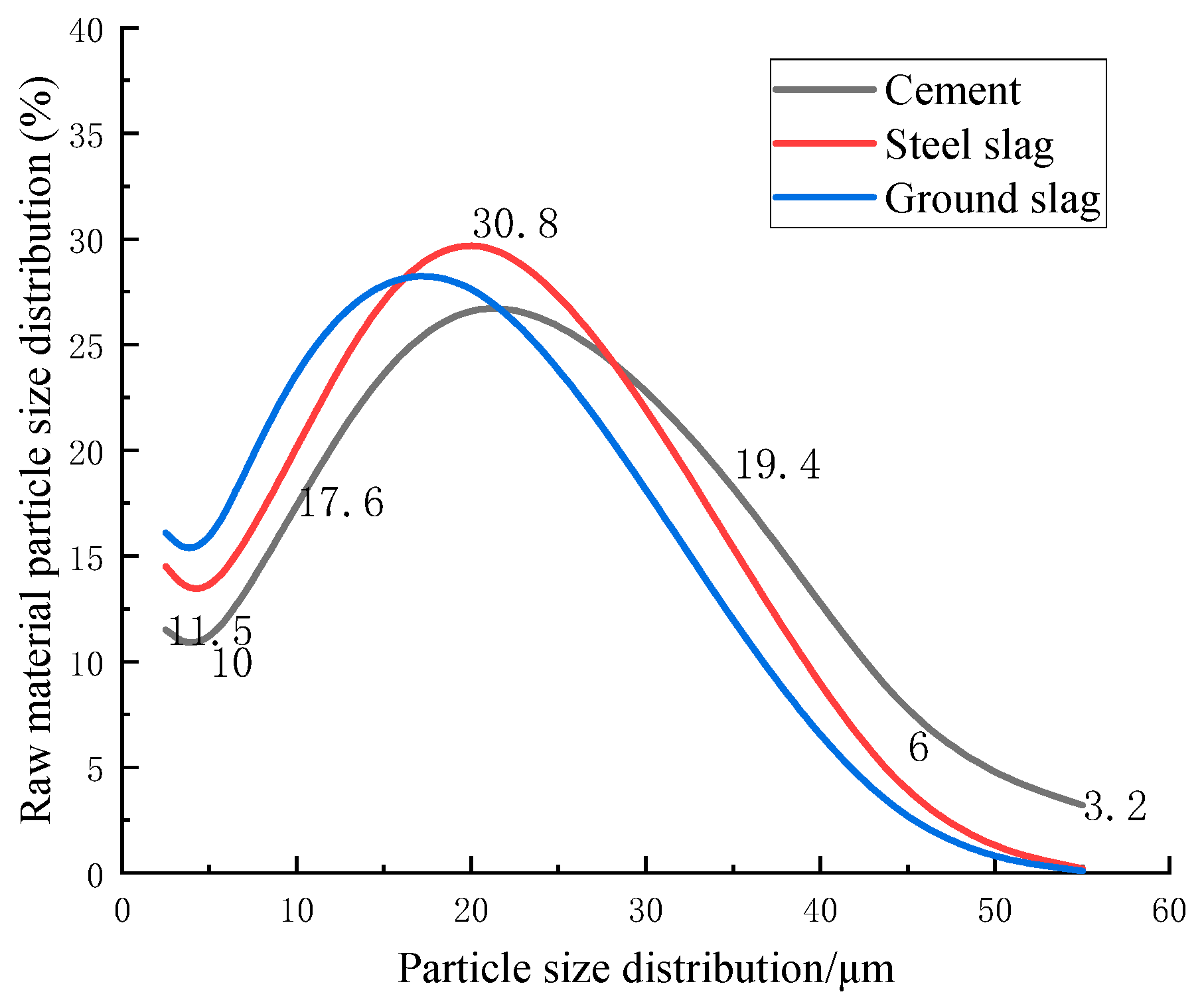

2.1. Materials

2.2. Preparation of Specimens and Testing Procedures

3. Results and Discussion

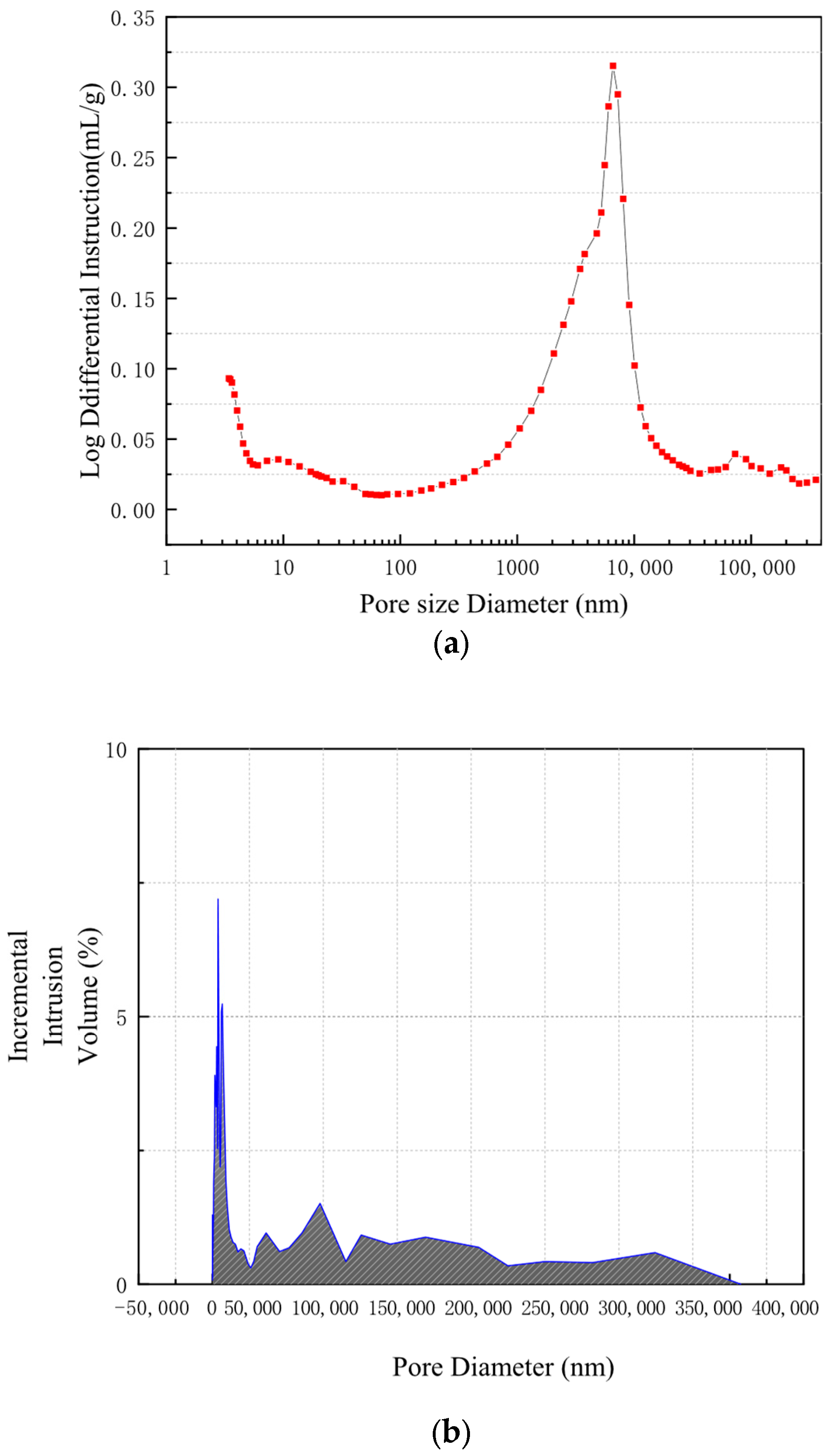

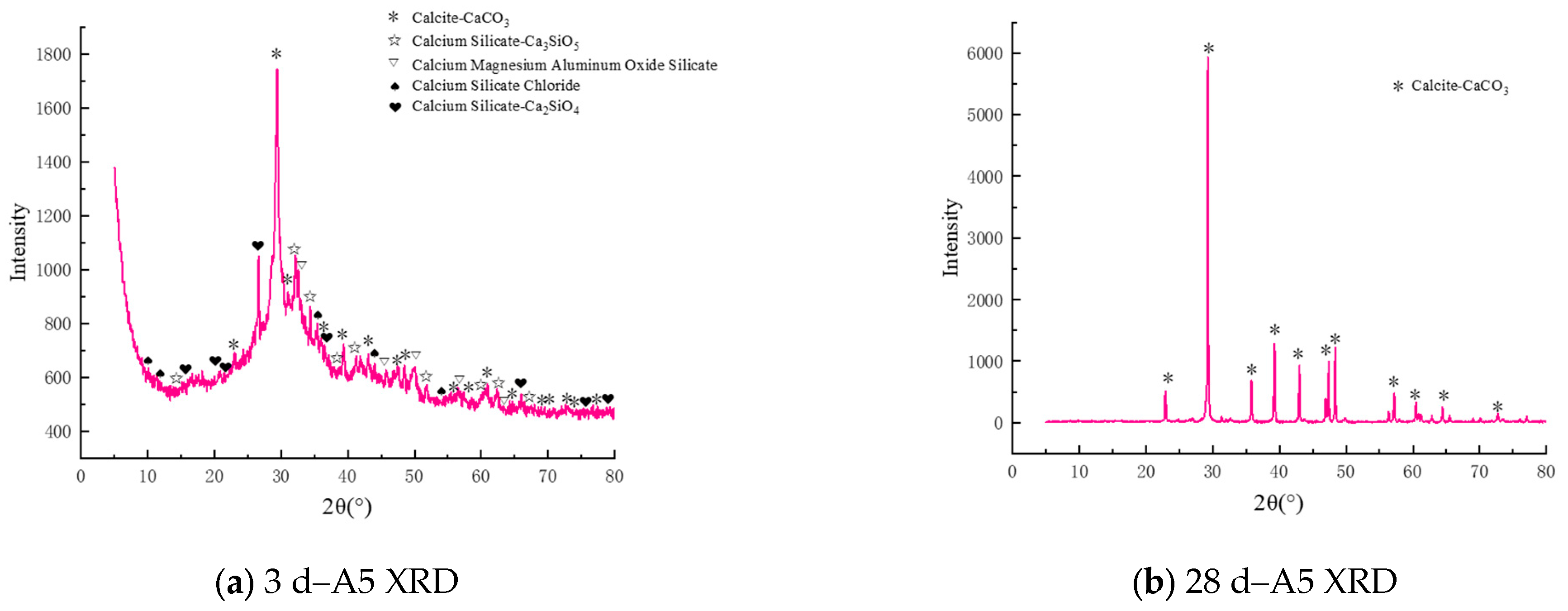

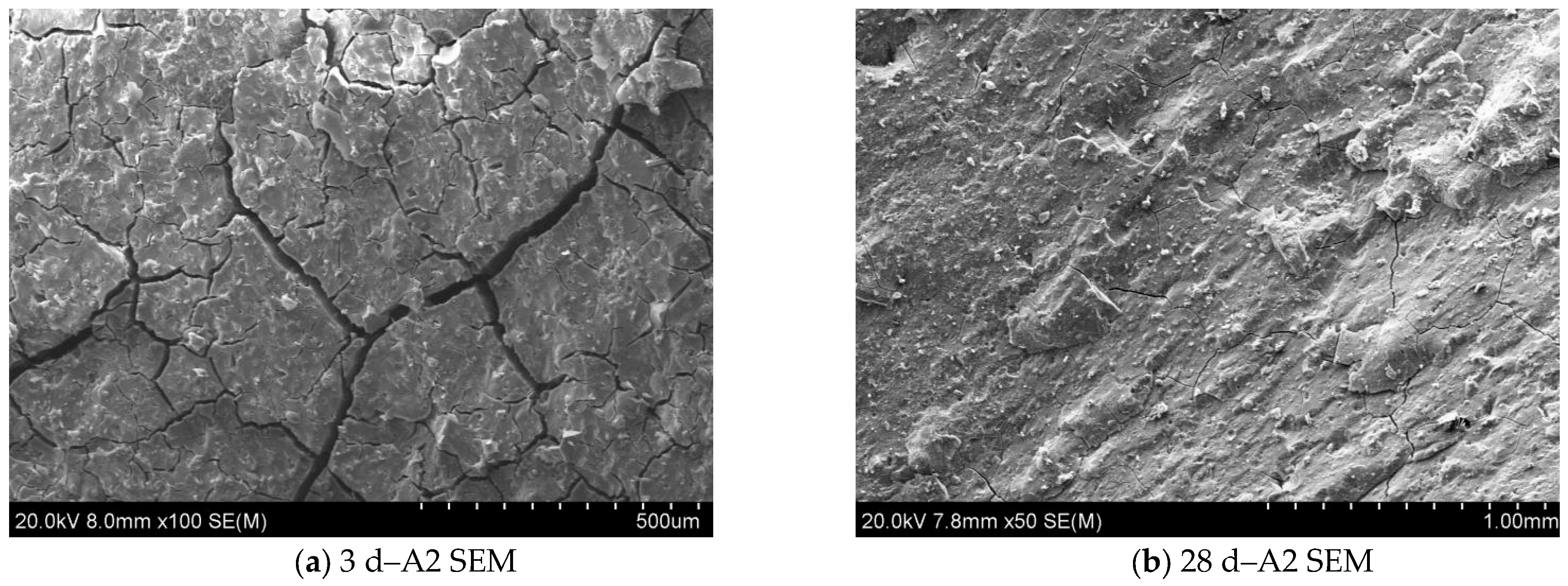

3.1. Selection of the Double-Liquid Grouting Material System

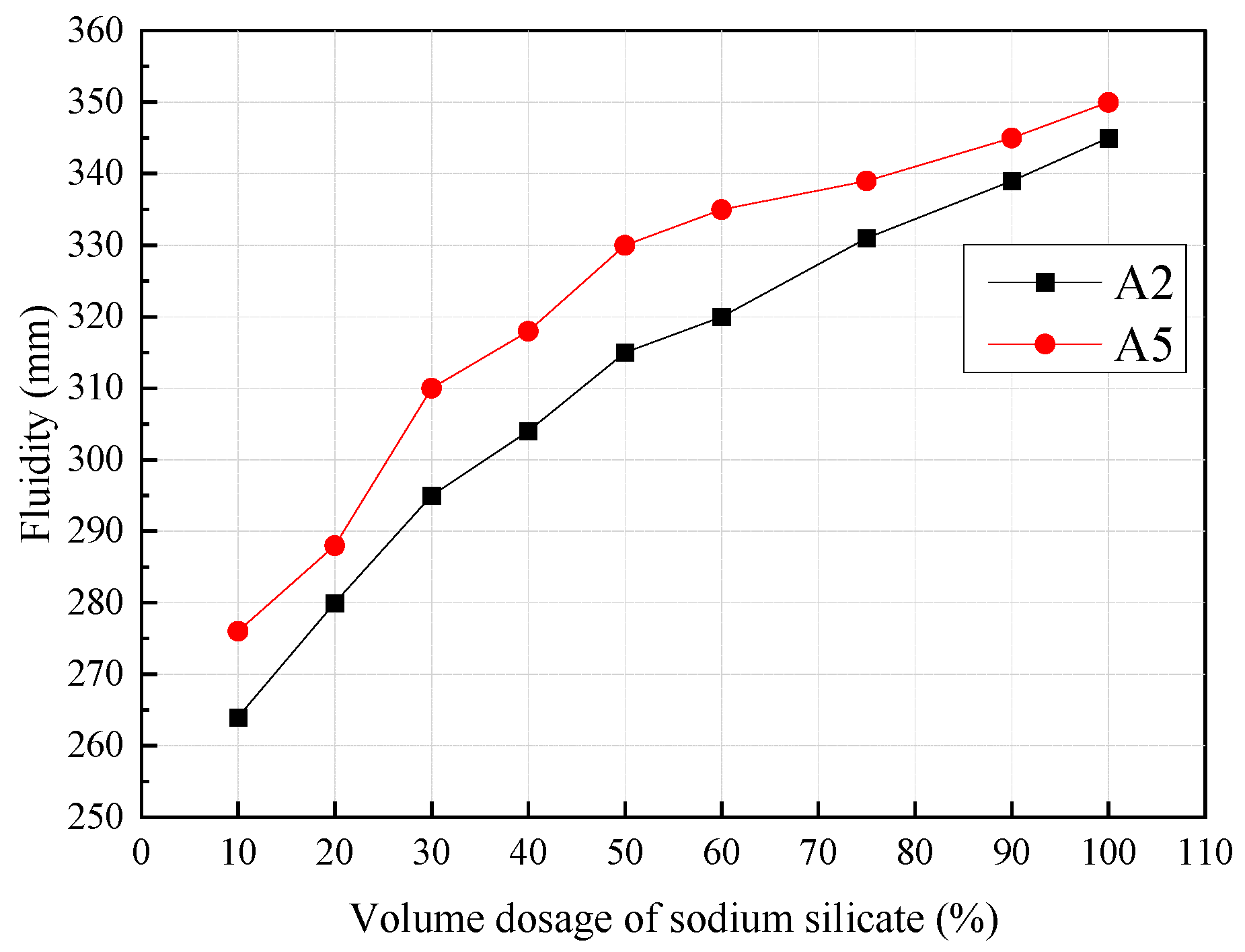

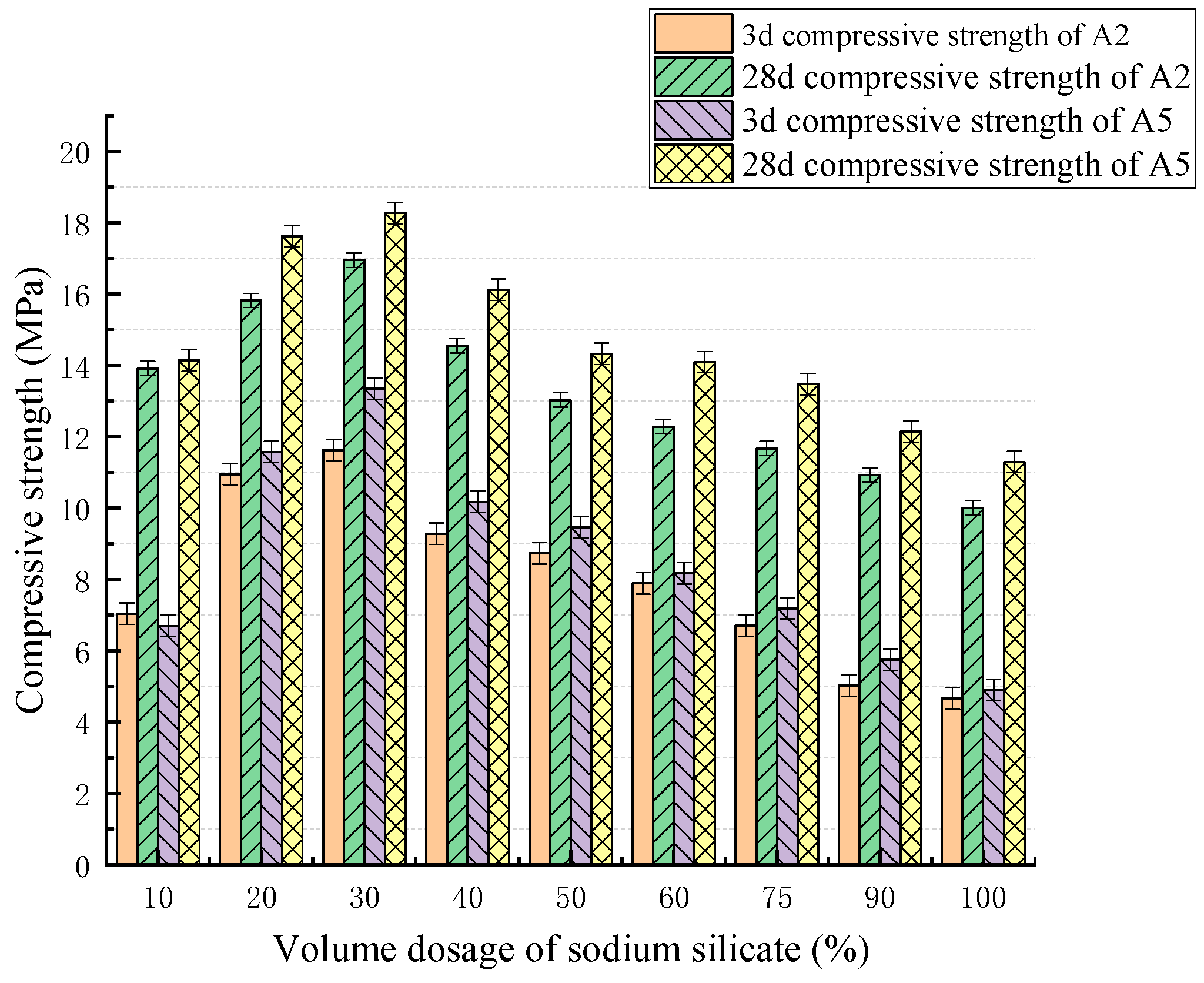

3.2. Effect of the Sodium Silicate Volume on the Performance of Grouting Materials

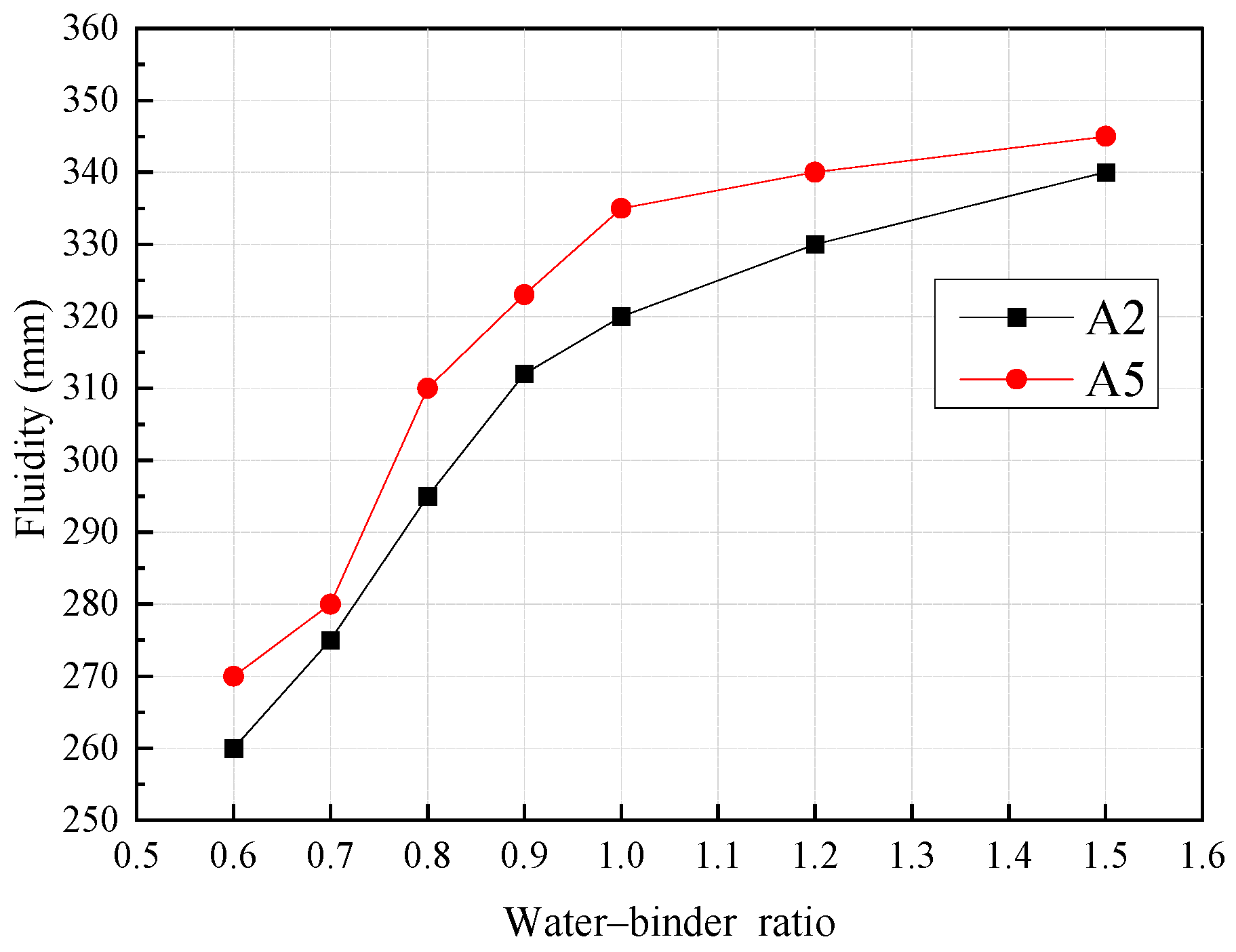

3.3. Effects of the Water–Binder Ratio on the Performance of Grouting Materials

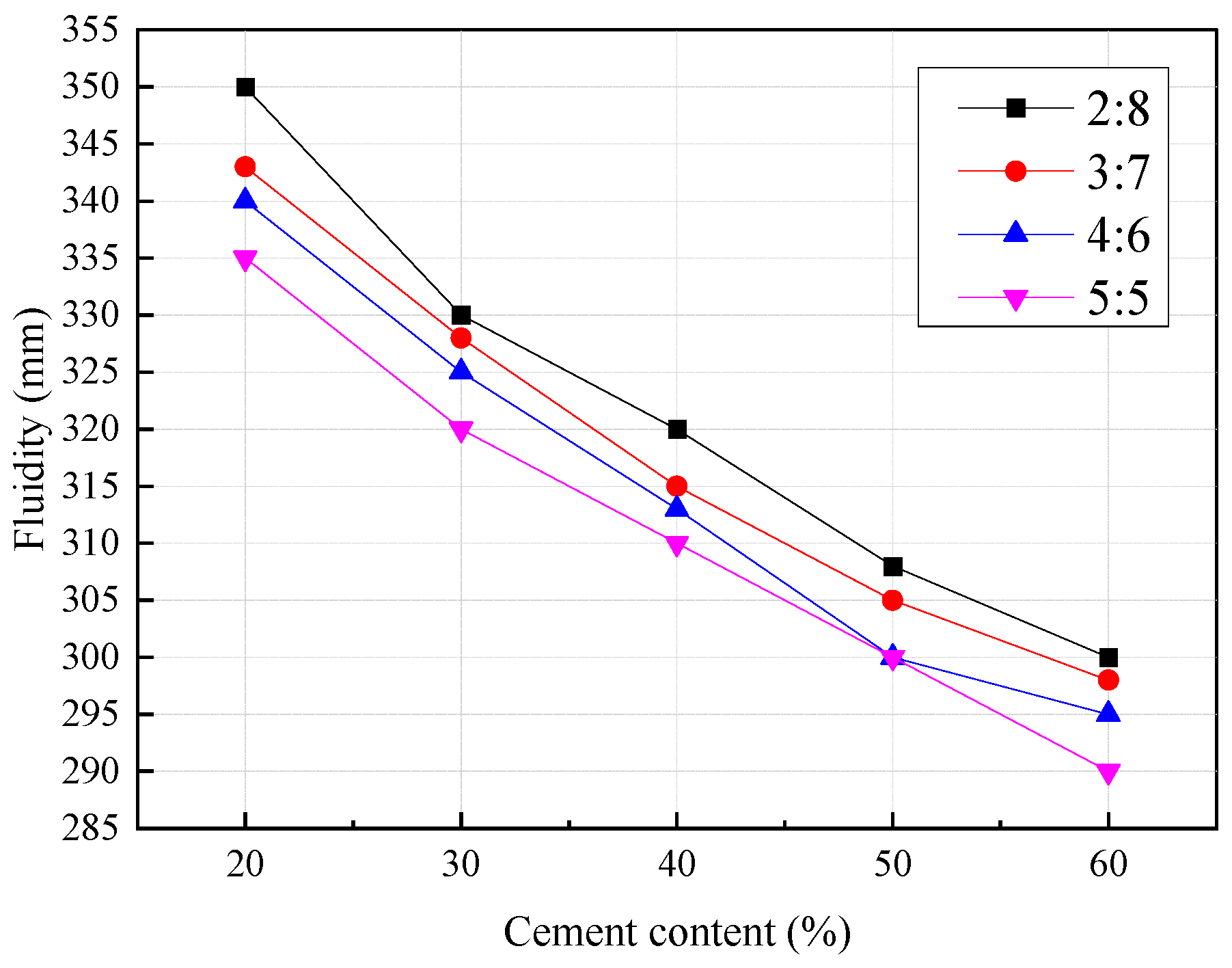

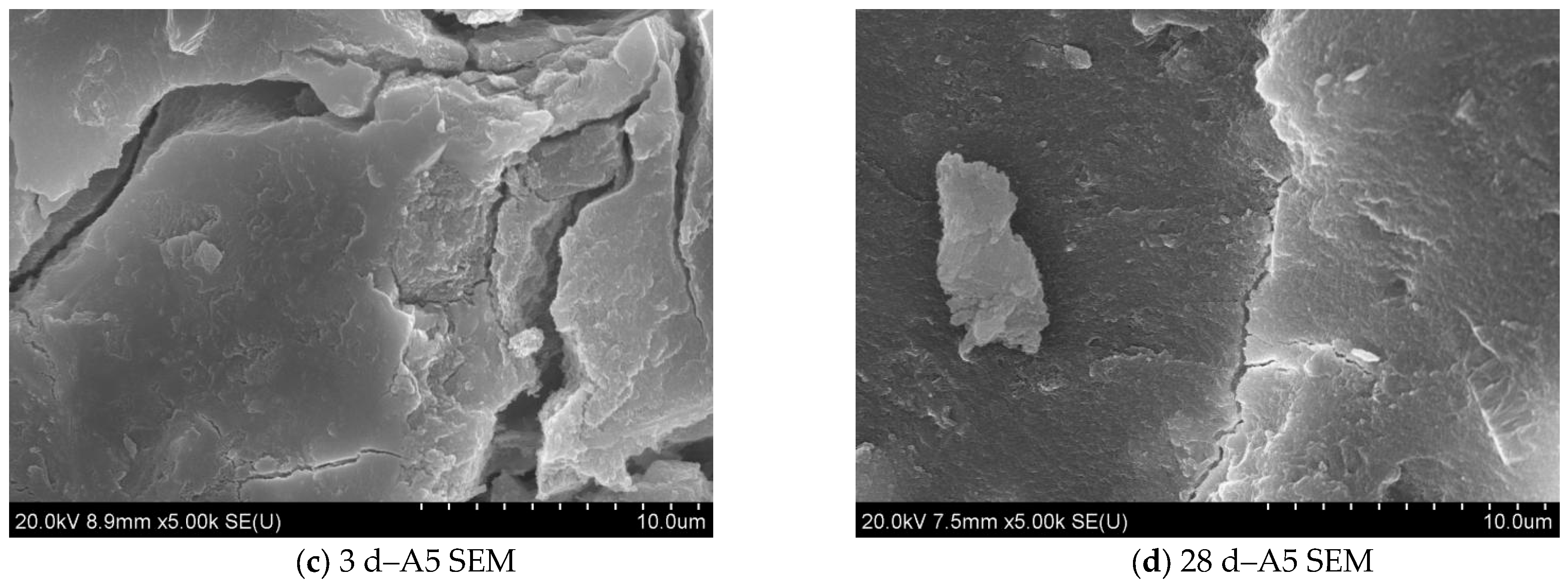

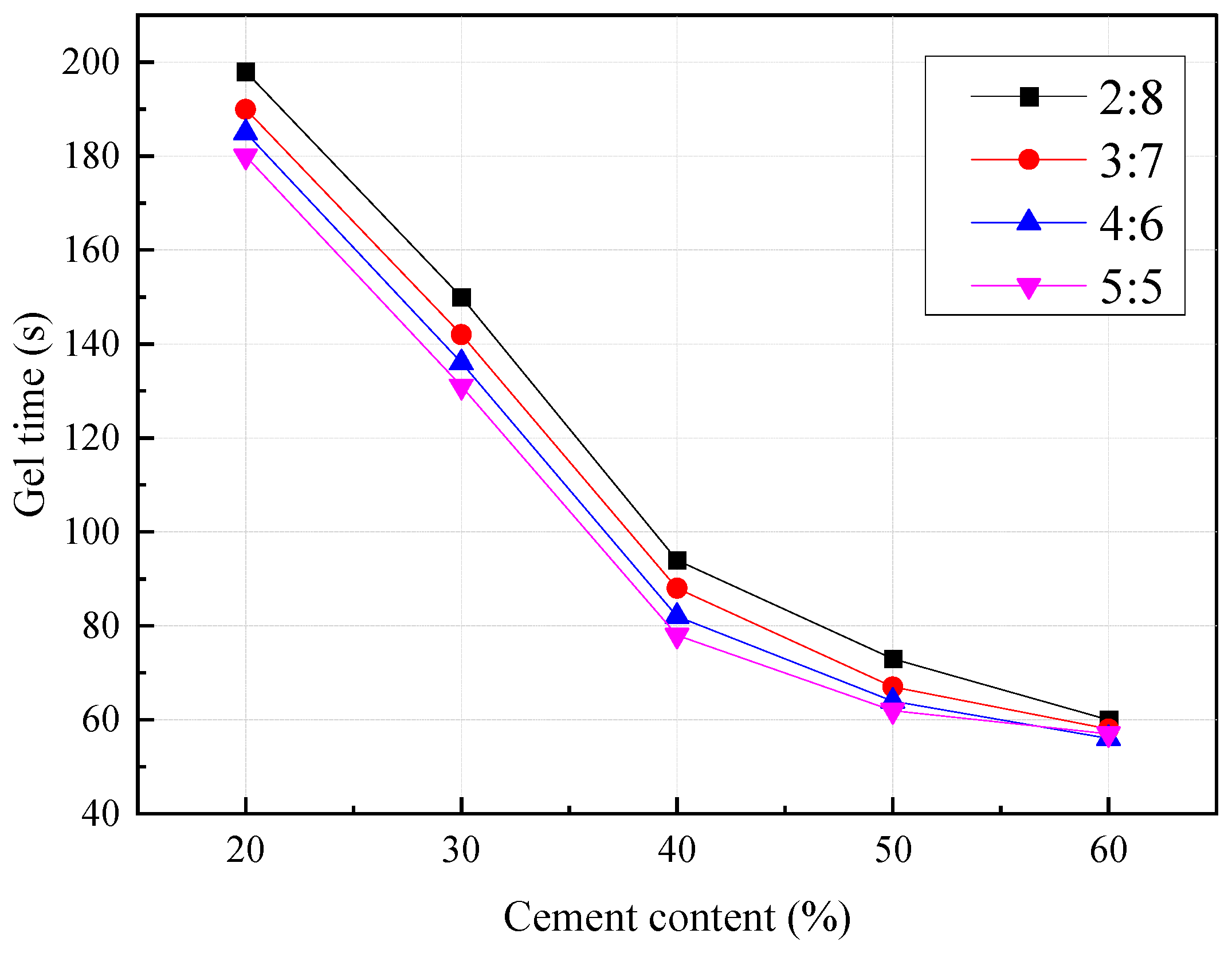

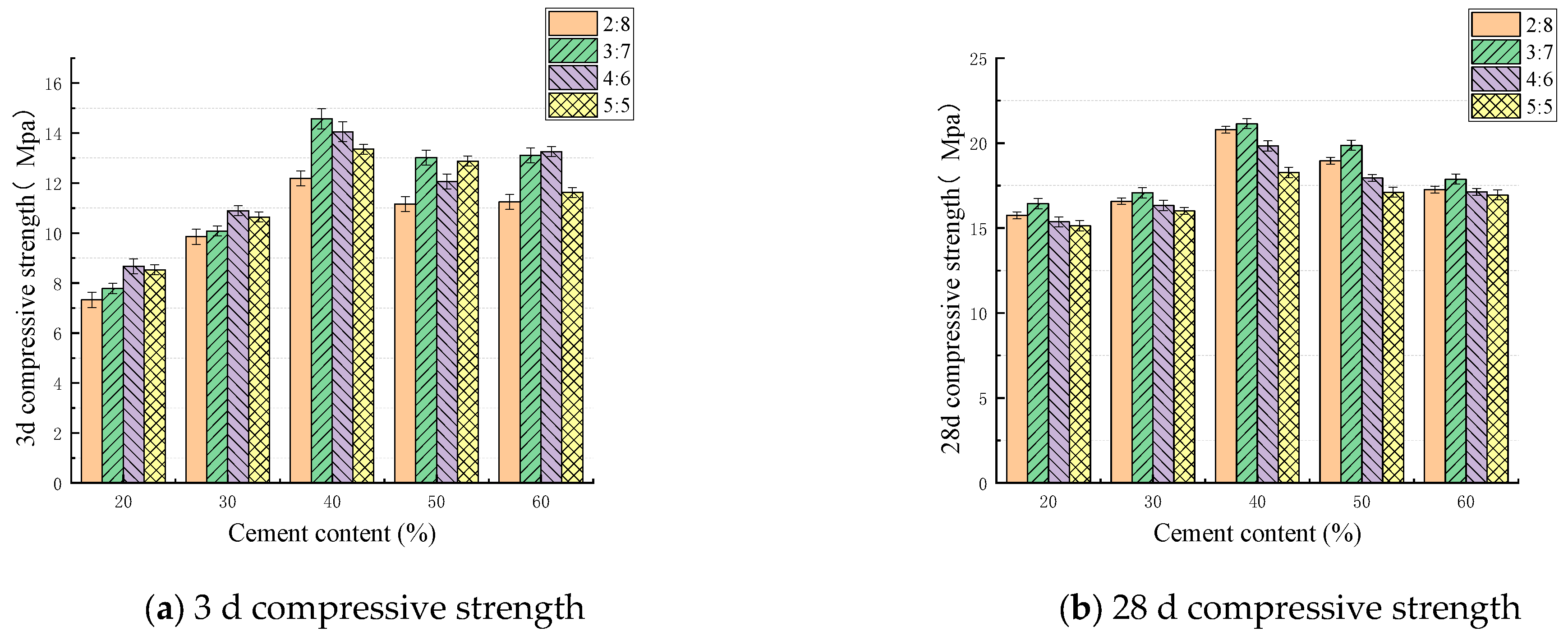

3.4. Effects of the Cement Content and Industrial Waste Ratio on the Performance of Grouting Materials

3.5. Effects of Admixtures on the Performance of Grouting Materials

4. Engineering Applications

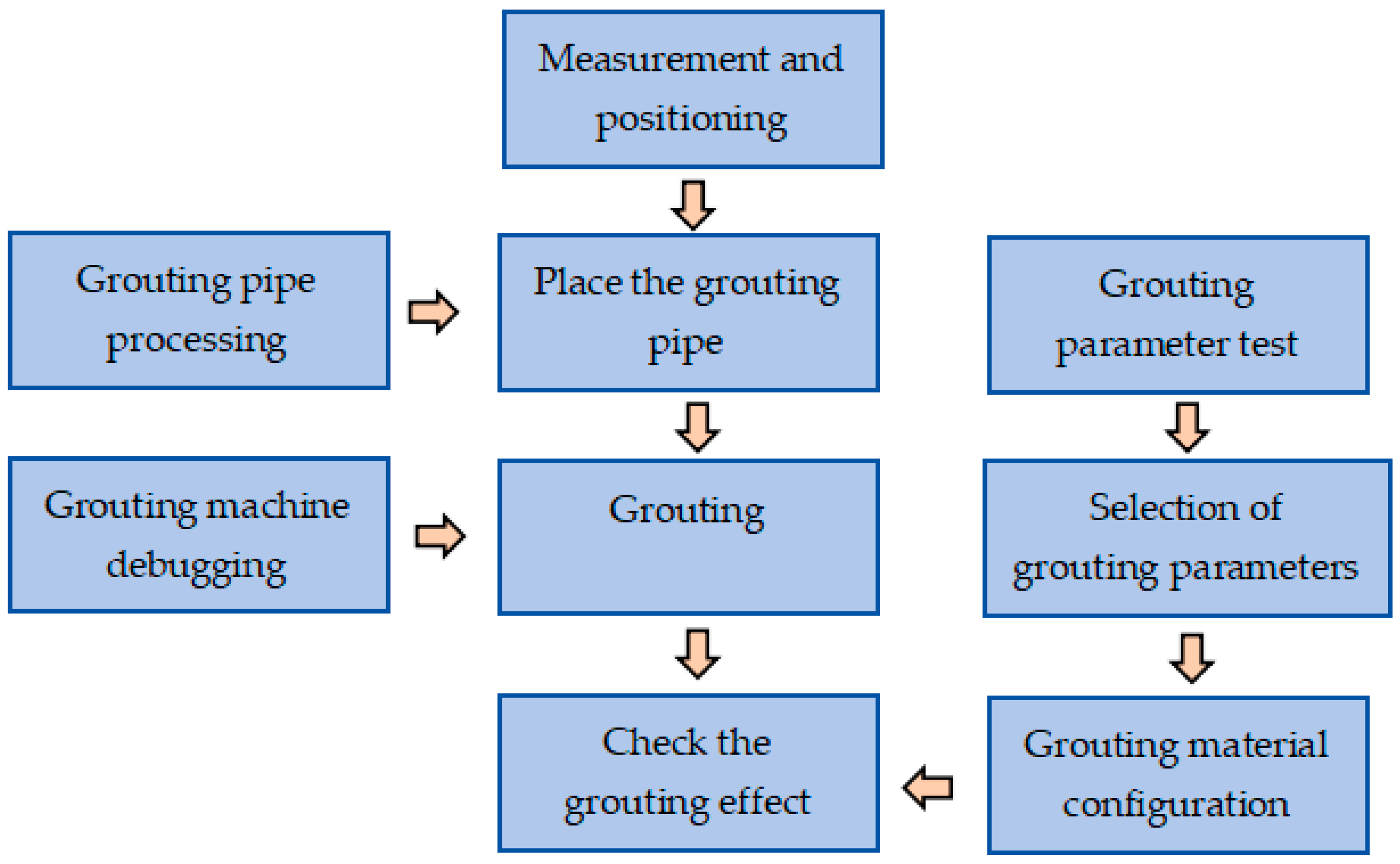

4.1. Grouting Scheme Design

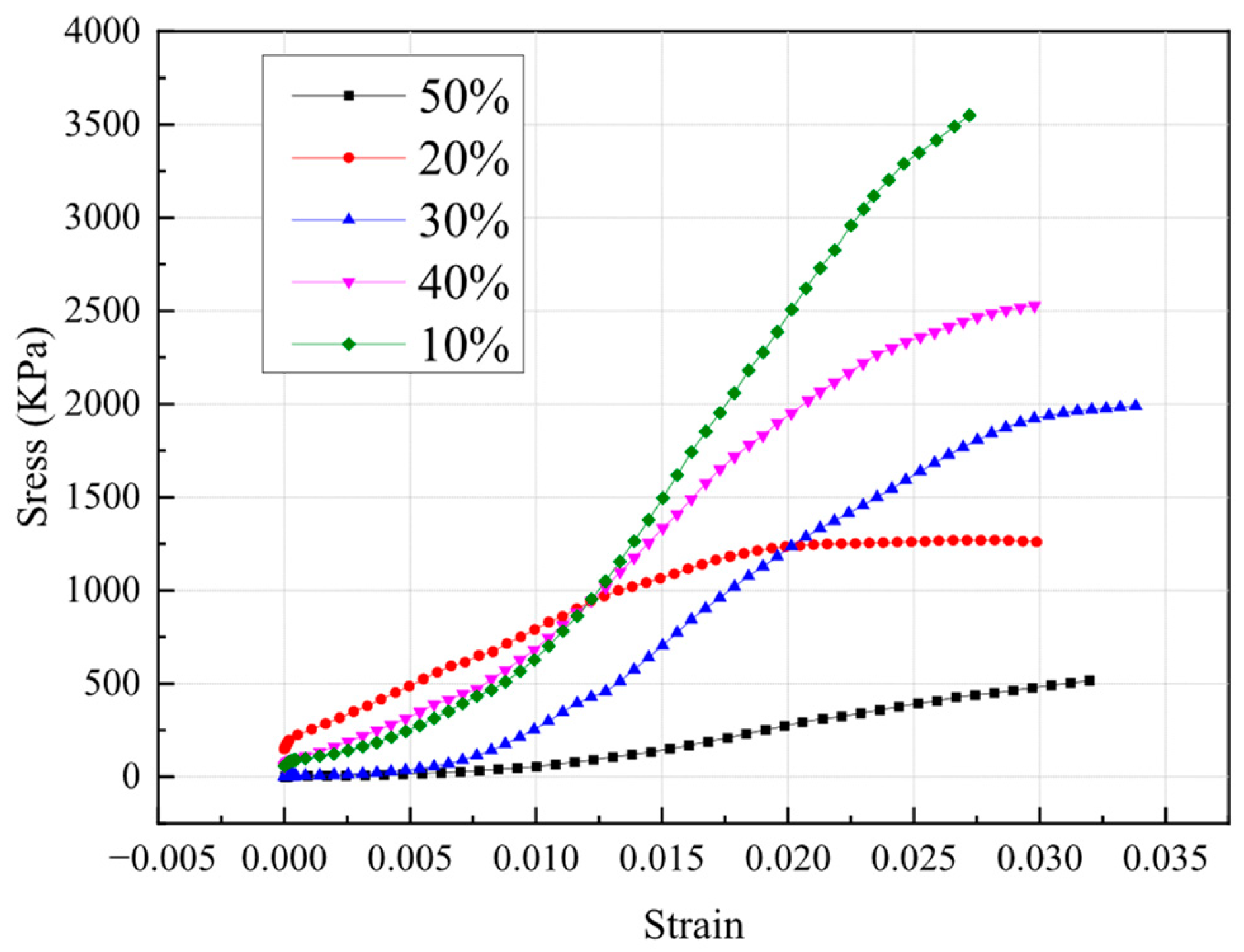

4.2. Effect of the Water Content of Sandy Soil on the Strength of Sandy Soil Consolidation

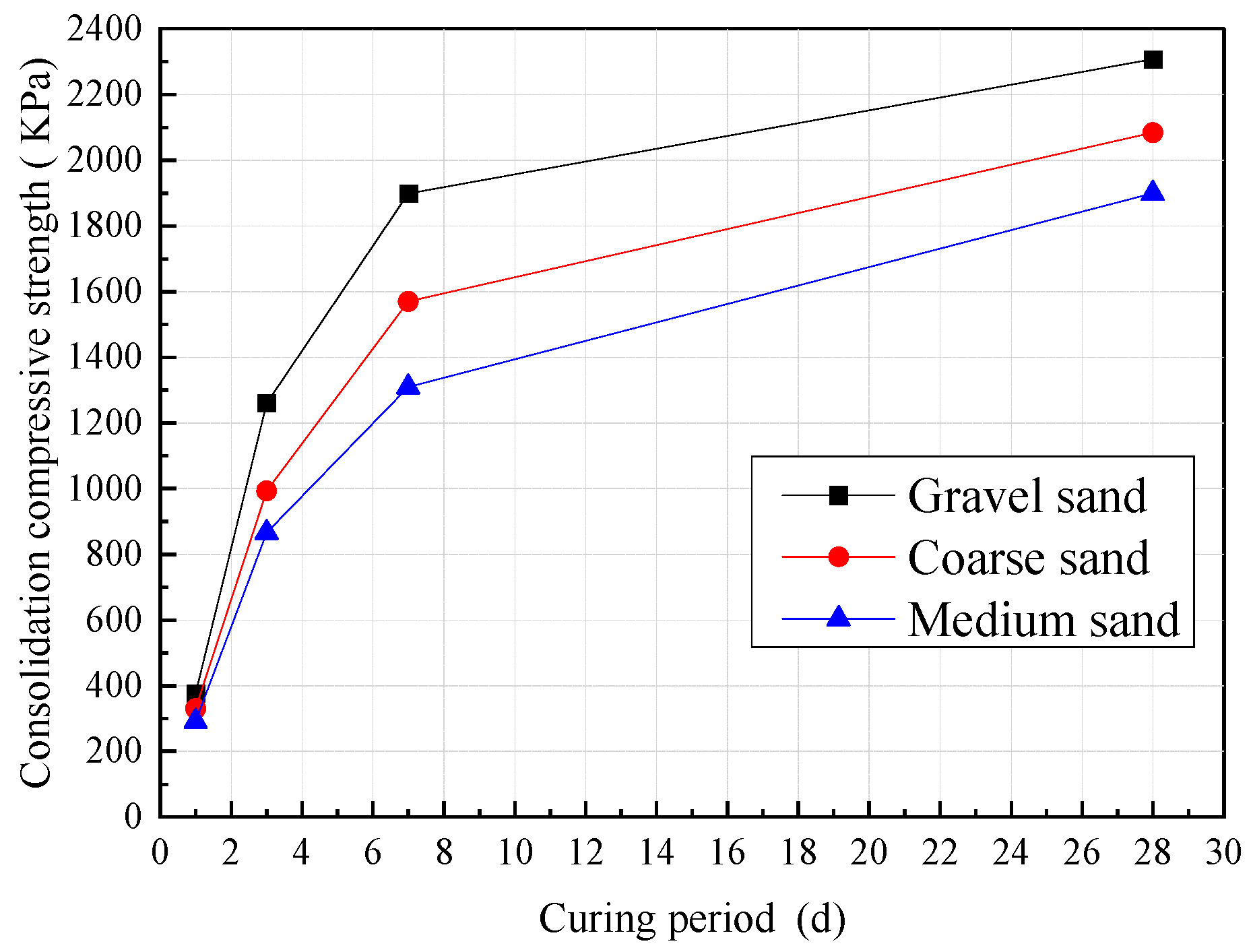

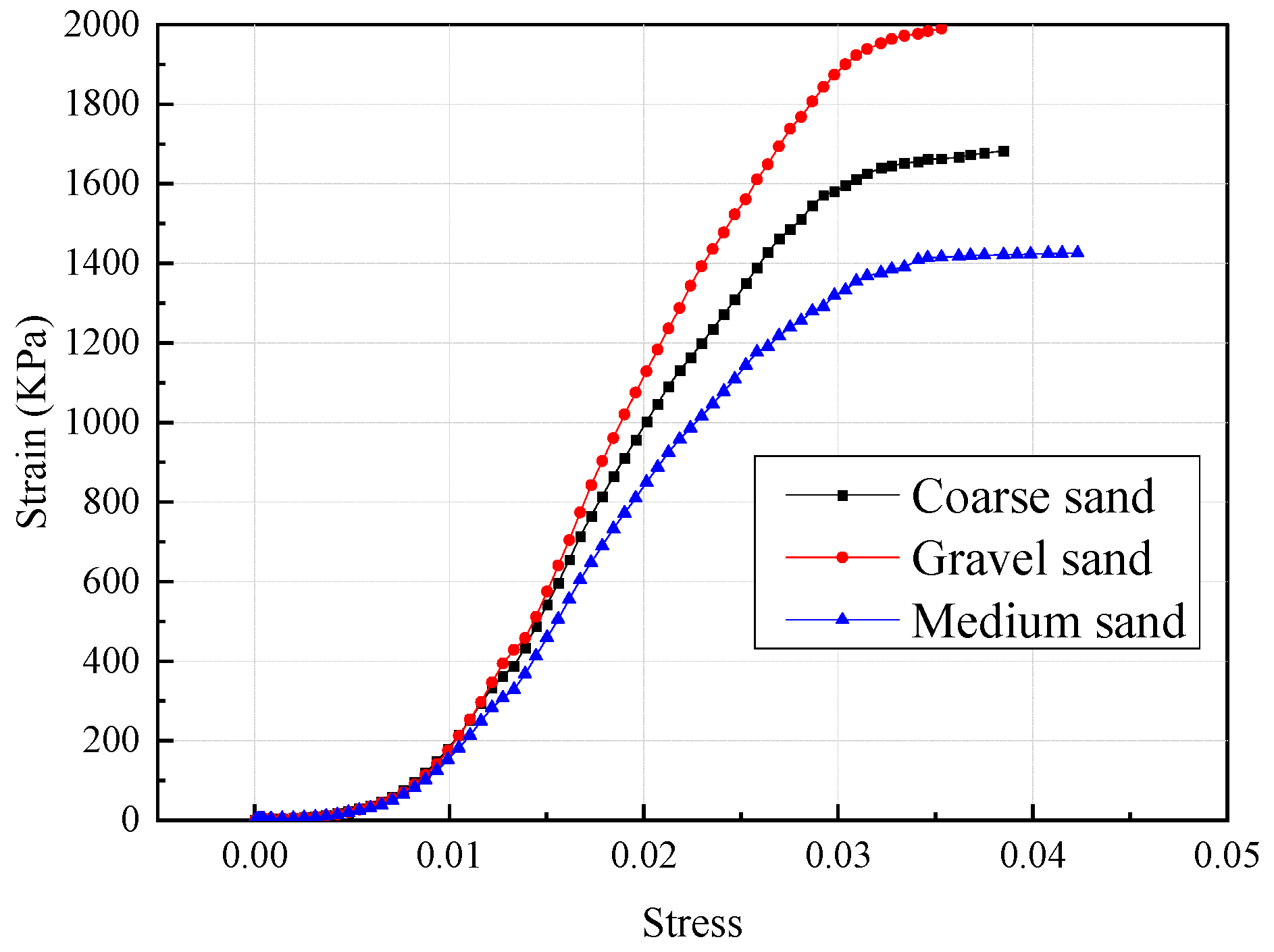

4.3. Effect of the Grain Gradation of Sand in Sandy Soil on the Strength of Sandy Soil Consolidation

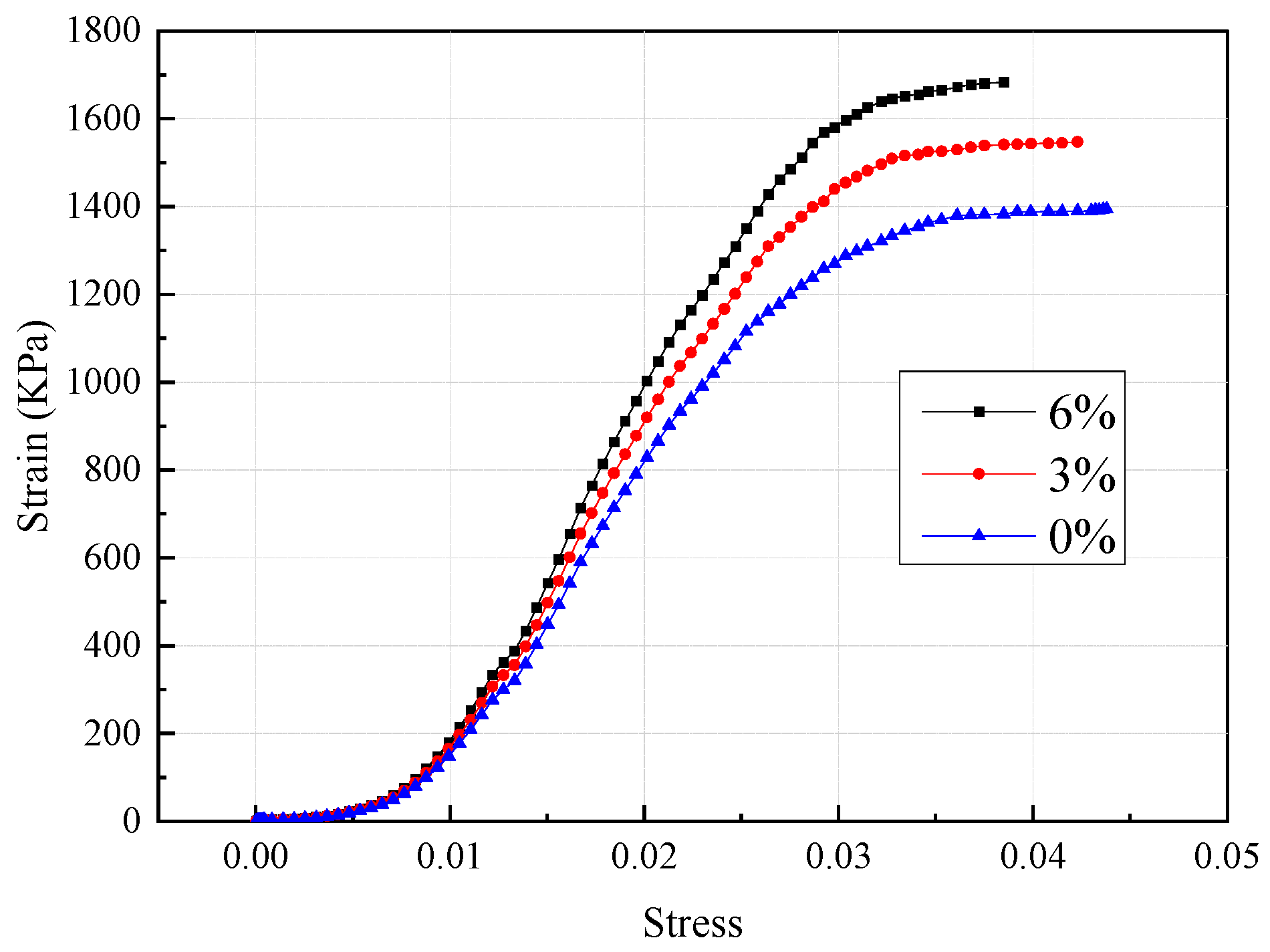

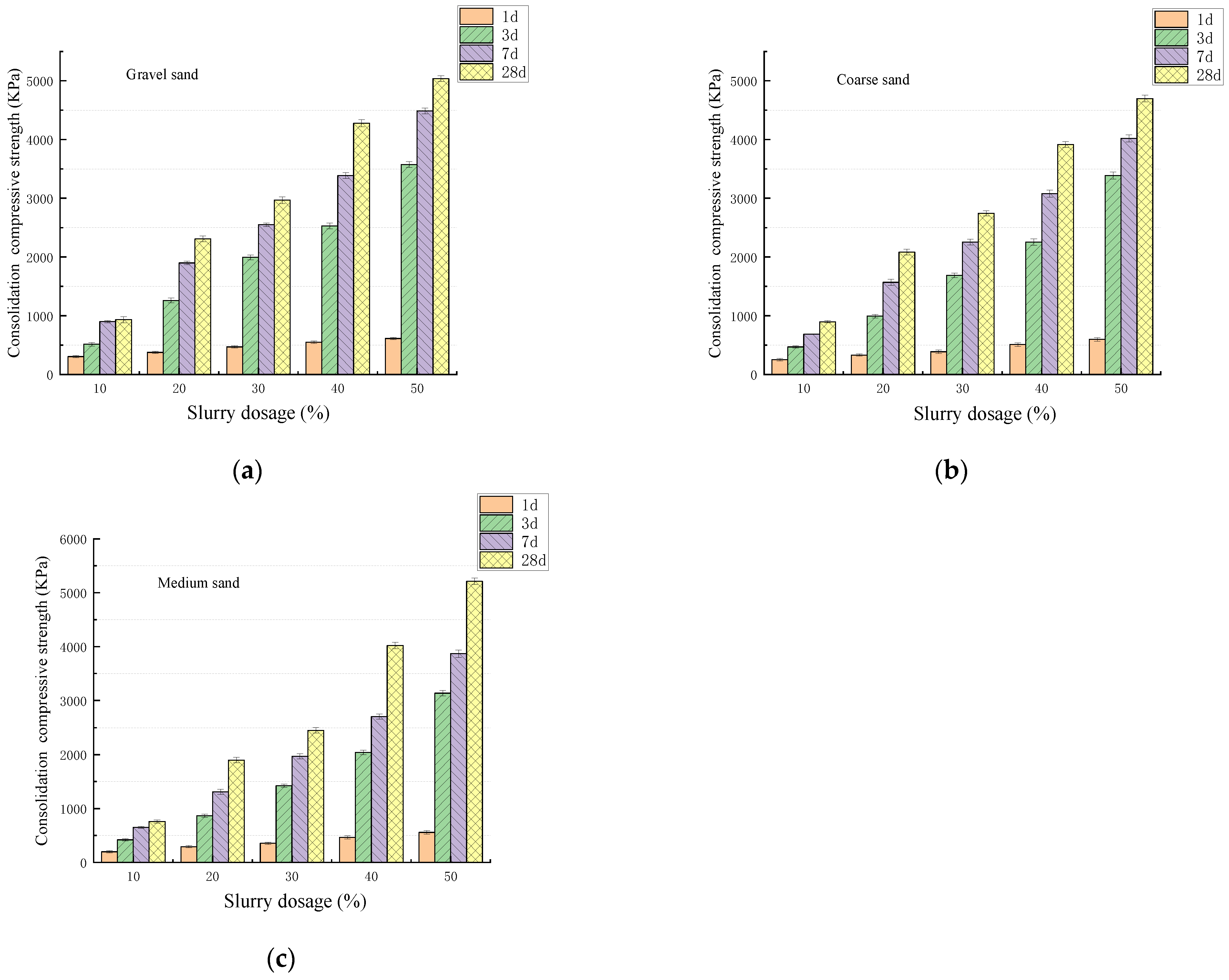

4.4. Effect of Slurry Dosage on the Strength of Sandy Soil Consolidation

5. Conclusions

- (1)

- When the volume of sodium silicate is in the range of 20–40%, the internal structure of the slurry is compact, and the strength of the slurry is high and relatively stable. When the W/B is in the range of 0.7–1.0, the compressive strength and flow performance are better. When the cement content is 40%, the W/B is 0.8, the sodium silicate volume dosage is 30%, and the SS:SL ratio is 3:7, the 3 d compressive strength of the slurry reaches 14.57 MPa and the 28 d compressive strength reaches 21.14 MPa.

- (2)

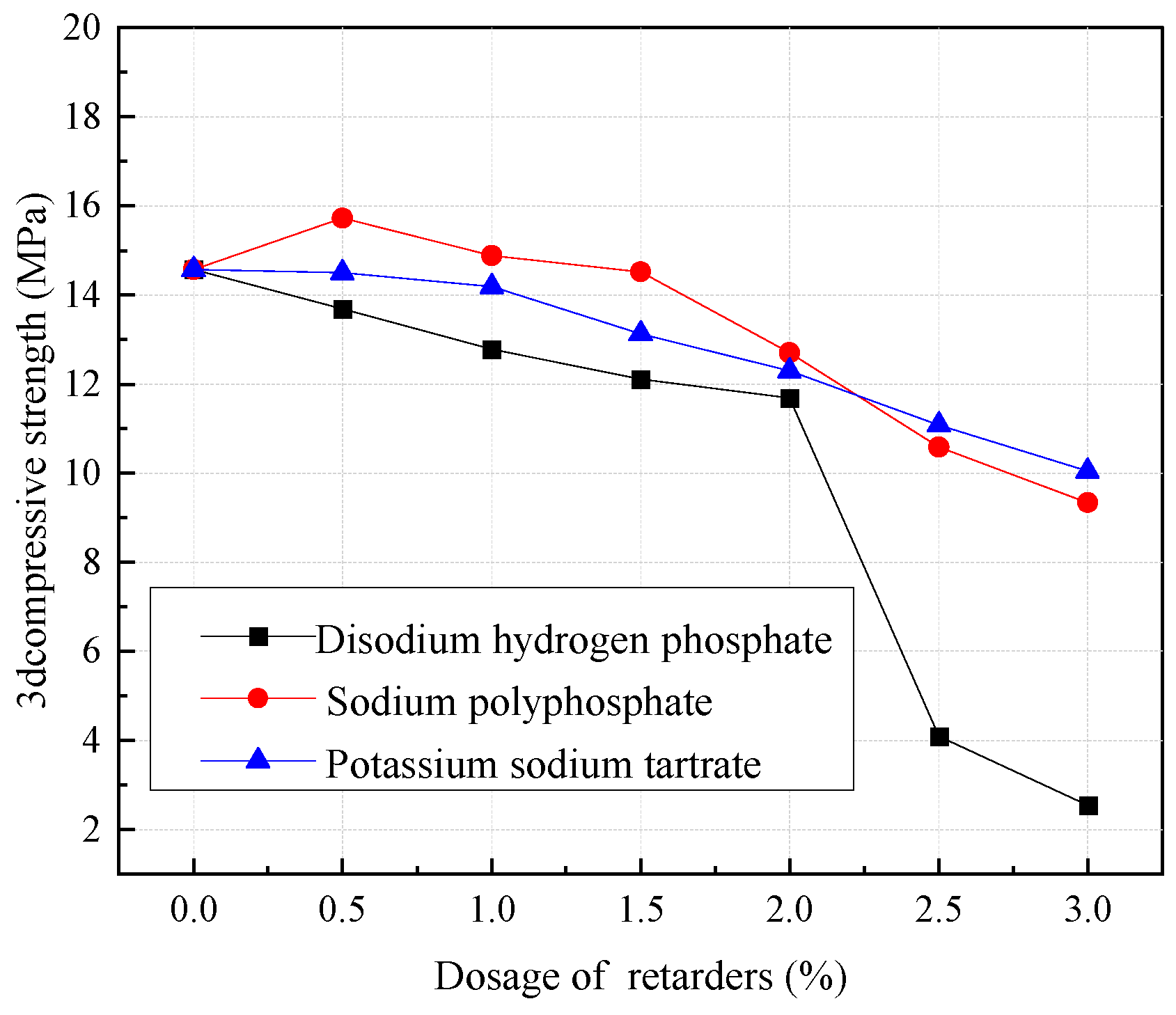

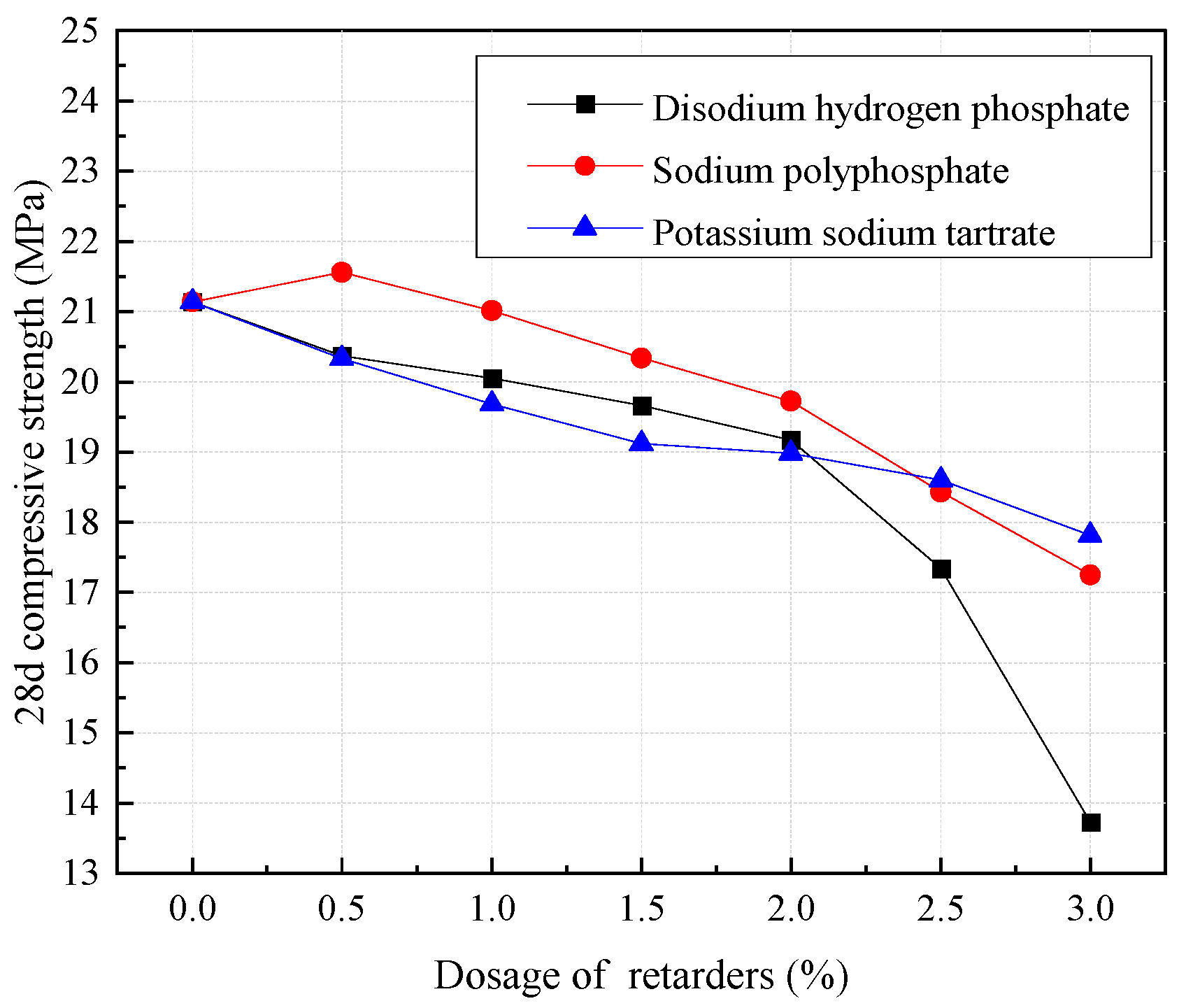

- Compared with NaO18P6 and C4H4KNaO6, Na2HPO4 has the best retarding effect. When the dosage of disodium phosphate is less than 2%, the gel time is prolonged with increasing disodium phosphate dosage, and the rate of decrease in the compressive strength is only slightly affected.

- (3)

- Cement sodium silicate double-liquid grouting material mixed with SS and SL has the best reinforcing effect on gravelly sand, and this system is more suitable for strata above medium sand.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jeng, F.S.; Weng, M.C.; Huang, T.H.; Lin, M.L. Deformational characteristics of weak sandstone and impact to tunnel deformation. Tunn. Undergr. Space Technol. 2002, 17, 263–274. [Google Scholar] [CrossRef]

- Shahrour, I.; Khoshnoudian, F.; Sadek, M.; Mroueh, H. Elastoplastic analysis of the seismic response of tunnels in soft soils. Tunn. Undergr. Space Technol. 2010, 25, 478–482. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.; Yang, J.; Ou, X.; Ye, X.; Zhang, Y. Formulation and performance of grouting materials for underwater shield tunnel construction in karst ground. Constr. Build. Mater. 2018, 187, 327–338. [Google Scholar] [CrossRef]

- Sha, F.; Lin, C.; Li, Z.; Liu, R. Reinforcement simulation of water-rich and broken rock with Portland cement-based grout. Constr. Build. Mater. 2019, 221, 292–300. [Google Scholar] [CrossRef]

- Mollamahmutoğlu, M.; Yılmaz, Y.; Kutlu, I. Grouting performance of microfine cement and silica fume mix into sands. J. ASTM Int. 2007, 4, JAI100462. [Google Scholar] [CrossRef]

- Li, S.; Sha, F.; Liu, R.; Li, W.; Li, Z.; Wang, G. Properties of cement-based grouts with high amounts of ground granulated blast-furnace slag and fly ash. J. Mater. Civ. Eng. 2017, 29, 04017219. [Google Scholar] [CrossRef]

- Saridemir, M. Effect of silica fume and ground pumice on compressive strength and modulus of elasticity of high strength concrete. Constr. Build. Mater. 2013, 49, 484–489. [Google Scholar] [CrossRef]

- Zeng, Q.; Li, K.; Fen, T.; Dangla, P. Determination of cement hydration and pozzolanic reaction extents for fly-ash cement pastes. Constr. Build. Mater. 2012, 27, 560–569. [Google Scholar] [CrossRef]

- Alnahhal, A.M.; Alengaram, U.J.; Yusoff, S.; Singh, R.; Radwan, M.K.; Deboucha, W. Synthesis of sustainable lightweight foamed concrete using palm oil fuel ash as a cement replacement material. J. Build. Eng. 2021, 35, 102047. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Raut, A.N.; Gomez, C.P. Utilization of glass powder and oil palm fibers to develop thermally efficient blocks. Arab. J. Sci. Eng. 2020, 45, 3959–3972. [Google Scholar] [CrossRef]

- Puertas, F.; Santos, H.; Palacios, M.; Martínez-Ramírez, S. Polycarboxylate superplasticizer admixtures: Effect on hydration, microstructure and rheological behaviour in cement pastes. Adv. Cem. Res. 2005, 17, 77–89. [Google Scholar] [CrossRef]

- Messaoud, M.; Glaoui, B.; Abdelkhalek, O. The effect of adding steel fibers and graphite on mechanical and electrical behaviors of asphalt concrete. Civ. Eng. J. 2022, 8, 348–361. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, Q.; Xu, L. Experimental study of cement alkali-resistant glass fiber (C-ARGF) grouting material. Materials 2020, 13, 605. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Yang, J.-S.; Fu, J.-Y.; Ou, X.-F.; Xie, Y.-P.; Dai, Y.; Lei, J.-S. A new clay-cement composite grouting material for tunnelling in underwater karst area. J. Cent. South Univ. 2019, 26, 1863–1873. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Z.; Zhang, J.; Zhang, Q.; Wang, Y. Synergistic use of industrial solid wastes to prepare belite-rich sulphoaluminate cement and its feasibility use in repairing materials. Constr. Build. Mater. 2020, 264, 120201. [Google Scholar] [CrossRef]

- Ghalehnovi, M.; Roshan, N.; Hakak, E.; Shamsabadi, E.A.; de Brito, J. Effect of red mud (bauxite residue) as cement replacement on the properties of self-compacting concrete incorporating various fillers. J. Clean. Prod. 2019, 240, 118213. [Google Scholar] [CrossRef]

- Mashifana, T.; Sithole, T. Clean production of sustainable backfill material from waste gold tailings and slag. J. Clean. Prod. 2021, 308, 127357. [Google Scholar] [CrossRef]

- Mollamahmutoğlu, M.; Avci, E. Ultrafine Portland cement grouting performance with or without additives. KSCE J. Civ. Eng. 2015, 19, 2041–2050. [Google Scholar] [CrossRef]

- Lin, C.; Dai, W.; Li, Z.; Wang, Y. Study on the inorganic synthesis from recycled cement and solid waste gypsum system: Application in grouting materials. Constr. Build. Mater. 2020, 251, 118930. [Google Scholar] [CrossRef]

- Guo, S.; Zhang, J.; Li, M.; Zhou, N.; Song, W.; Wang, Z.; Qi, S. A preliminary study of solid-waste coal gangue based biomineralization as eco-friendly underground backfill material: Material preparation and macro-micro analyses. Sci. Total Environ. 2021, 770, 145241. [Google Scholar] [CrossRef] [PubMed]

- Fang, F.; Wang, Z.; Zhang, F.; Li, D.; Jia, Z.; Wang, Z.; Jiang, T.; Lan, W. Experimental study of alkali-excited steel slag–granulated blast-furnace slag–cement-based grouting material based on response surface methodology. Buildings 2024, 14, 3841. [Google Scholar] [CrossRef]

- Li, M.; Huang, G.; Cui, Y.; Wang, B.; Chang, B.; Yin, Q.; Zhang, S.; Wang, Q.; Feng, J.; Ge, M. Coagulation mechanism and compressive strength characteristics analysis of high-strength alkali-activated slag grouting material. Polymers 2022, 14, 3980. [Google Scholar] [CrossRef] [PubMed]

- Cai, X.; Cao, Z.; Sun, J.; Wang, H.; Wu, S. Influence of steel slag on properties of cement-based materials. Buildings 2024, 14, 2985. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Wang, Q.; Zhang, Z.; Ou, Z. Composition design and performance of alkali-activated cements. Mater. Struct. 2017, 50, 178. [Google Scholar] [CrossRef]

- Xu, R.; Kong, F.; Yang, R.; Wang, H.; Hong, T. Influences of silicate modulus and alkali content on macroscopic properties and microstructure of alkali-activated blast furnace slag-copper slag. Constr. Build. Mater. 2024, 442, 137622. [Google Scholar] [CrossRef]

- Yao, G.; Liu, Q.; Wang, J.; Wu, P.; Lyu, X. Effect of mechanical grinding on pozzolanic activity and hydration properties of siliceous gold ore tailings. J. Clean. Prod. 2019, 217, 12–21. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting. 2014. workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Yao, G.; Wang, Q.; Su, Y.; Wang, J.; Qiu, J.; Lyu, X. Mechanical activation as an innovative approach for the preparation of pozzolan from iron ore tailings. Miner. Eng. 2020, 145, 106068. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, D.; Zhuang, S. The soundness of steel slag with different free CaO and MgO contents. Constr. Build. Mater. 2017, 151, 138–146. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers. J. Therm. Anal. Calorim. 1991, 37, 1633–1656. [Google Scholar] [CrossRef]

- Niklioć, I.; Marković, S.; Janković–Častvan, I.; Radmilović, V.V.; Karanović, L.; Babić, B.; Radmilović, V.R. Modification of mechanical and thermal properties of fly ash-based geopolymer by the incorporation of steel slag. Mater. Lett. 2016, 176, 301–305. [Google Scholar] [CrossRef]

- Huang, X.; Huang, T.; Li, S.; Muhammad, F.; Xu, G.; Zhao, Z.; Yu, L.; Yan, Y.; Li, D.; Jiao, B. Immobilization of chromite ore processing residue with alkali-activated blast furnace slag-based geopolymer. Ceram. Int. 2016, 42, 9538–9549. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, D.; Wang, Q. Performance study of alkali-activated phosphate slag-granulated blast furnace slag composites: Effect of the granulated blast furnace slag content. Arch. Civ. Mech. Eng. 2023, 23, 181. [Google Scholar] [CrossRef]

- Singh, S.; Jyoti; Vashistha, P. Development of newer composite cement through mechano-chemical activation of steel slag. Constr. Build. Mater. 2021, 268, 121147. [Google Scholar] [CrossRef]

- Zheng, L.; Wang, W.; Shi, Y. The effects of alkaline dosage and Si/Al ratio on the immobilization of heavy metals in municipal solid waste incineration fly ash-based geopolymer. Chemosphere 2010, 79, 665–671. [Google Scholar] [CrossRef]

- GB 175-2023; Common Portland Cement. Standardization Administration of the People’s Republic of China: Beijing, China, 2023.

- GB/T 1596-2017; Fly Ash Used for Cement and Concrete. Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- Detwiler, R.; Bhatty, J.; Bhattacharja, S. Supplementary cementing materials for use in blended cements. In Research and Development Bulletin RD112; Portland Cement Association: Skokie, IL, USA, 1996. [Google Scholar]

- Liu, C.; Shui, Z.; Gao, X.; Ma, S. Performance Evaluation of Alkali-Activated Coal Gangue-Blast Furnace Slag Composite. Bull. Chin. Ceram. Soc. 2020, 39, 2877–2884. [Google Scholar] [CrossRef]

- Song, S.; Sohn, D.; Jennings, H.M.; Mason, T.O. Hydration of alkali-activated ground granulated blast furnace slag. J. Mater. Sci. 2000, 35, 249–257. [Google Scholar] [CrossRef]

- Hossain, M.M.; Karim, M.R.; Elahi, M.M.A.; Islam, M.N.; Zain, M.F.M. Long-term durability properties of alkali-activated binders containing slag, fly ash, palm oil fuel ash and rice husk ash. Constr. Build. Mater. 2020, 251, 119094. [Google Scholar] [CrossRef]

- Santamaría, A.; Orbe, A.; José, J.S.; González, J. A study on the durability of structural concrete incorporating electric steelmaking slags. Constr. Build. Mater. 2018, 161, 94–111. [Google Scholar] [CrossRef]

- Jiang, L.; Dong, C.-L.; Wang, S.-Y. Reducing volume expansion of steel slag by using a surface hydrophobic waterproof structure. J. Mater. Civ. Eng. 2020, 32, 04020303. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.; Liu, R.; Li, Z.; Zhang, Q. Effects of fineness on viscoelasticity of microfine cement-based grouts with fly ash, silica fume and superplasticizer. Adv. Cem. Res. 2018, 30, 469–481. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.; Liu, R.; Li, Z.; Zhang, Q. Experimental study on performance of cement-based grouts admixed with fly ash, bentonite, superplasticizer and sodium silicate. Constr. Build. Mater. 2018, 161, 282–291. [Google Scholar] [CrossRef]

- Zhang, T.-S.; Liu, F.-T.; Liu, S.-Q.; Zhou, Z.-H.; Cheng, X. Factors influencing the properties of a steel slag composite cement. Adv. Cem. Res. 2008, 20, 145–150. [Google Scholar] [CrossRef]

- Barišić, I.; Dimter, S.; Rukavina, T. Strength properties of steel slag stabilized mixes. Compos. Part B Eng. 2014, 58, 386–391. [Google Scholar] [CrossRef]

- Guo, J.; Bao, Y.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Q.; Liu, J.; Wu, Q. Material properties of steel slag-cement binding materials prepared by precarbonated steel slag. J. Mater. Civ. Eng. 2018, 30, 04018208. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H. Modification of steel slag powder by mineral admixture and chemical activators to utilize in cement-based materials. Mater. Struct. 2013, 46, 1265–1273. [Google Scholar] [CrossRef]

- Li, J.; Yu, Q.; Wei, J.; Zhang, T. Structural characteristics and hydration kinetics of modified steel slag. Cem. Concr. Res. 2011, 41, 324–329. [Google Scholar] [CrossRef]

- Poh, H.Y.; Ghataora, G.S.; Ghazireh, N. Soil stabilization using basic oxygen steel slag fines. J. Mater. Civ. Eng. 2006, 18, 229–240. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, Z. Theoretical and practical discussion of measurement aphysisorption with micro- and mesoporous materials. Chin. J. Catal. 2013, 34, 1797–1810. [Google Scholar] [CrossRef]

- Sabir, B.B.; Wild, S.; O’FArrell, M. A water sorptivity test for martar and concrete. Mater. Struct. 1998, 31, 568–574. [Google Scholar] [CrossRef]

- Kabir, H.; Wu, J.; Dahal, S.; Joo, T.; Garg, N. Automated estimation of cementitious sorptivity via computer vision. Nat. Commun. 2024, 15, 9935. [Google Scholar] [CrossRef]

| Raw Material | SiO2 | CaO | MgO | Al2O3 | Fe2O3 | MnO | TiO2 | f-CaO | Loss |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 22.65 | 62.60 | 2.91 | 4.65 | 3.10 | - | - | 0.81 | 1.75 |

| Steel slag | 14 | 42 | 9.9 | 4 | 20 | - | - | - | 5 |

| Fly ash | 59.29 | 4.24 | 1.18 | 26.64 | 2.57 | - | - | 0.35 | 5.60 |

| Ground Slag | 38 | 43 | 8 | 9 | 0.38 | 0.2 | 0.4 | - | 2.56 |

| Composition | Gravel Grain | Gritty | Silty | Clay Particle | ||

|---|---|---|---|---|---|---|

| Particle Gradation/mm | >2.0 | 2.0–0.5 | 0.5–0.25 | 0.25–0.075 | 0.075–0.005 | 0.005–0 |

| Gravel sand | 35.0 | 22.8 | 20.4 | 12.6 | 9.2 | 0 |

| Coarse sand | 16.1 | 40.8 | 18.2 | 13.4 | 11.3 | 0.2 |

| Medium sand | 11.2 | 24.9 | 38.1 | 14.3 | 11.2 | 0.3 |

| Sample | C % | SS % | FA % | SL % | Fluidity mm | Gel Time s | Concretion Rate % | 3 d Compressive Strength MPa | 28 d Compressive Strength MPa |

|---|---|---|---|---|---|---|---|---|---|

| A0 | 100 | 0 | 0 | 0 | 270 | 25 | 99 | 11.95 | 16.43 |

| A1 | 60 | 40 | 0 | 0 | 278 | 40 | 98 | 9.62 | 14.27 |

| A2 | 60 | 20 | 0 | 20 | 280 | 43 | 98 | 10.95 | 15.82 |

| A3 | 40 | 60 | 0 | 0 | 283 | 47 | 97 | 8.87 | 16.34 |

| A4 | 40 | 0 | 60 | 0 | 285 | 49 | 97 | 7.94 | 16.03 |

| A5 | 40 | 30 | 0 | 30 | 288 | 51 | 96 | 11.07 | 17.58 |

| A6 | 40 | 0 | 30 | 30 | 291 | 54 | 97 | 10.78 | 16.67 |

| Parameter | Description |

|---|---|

| Grouting pressure | Initial grouting pressure: 0.1–0.4 MPa; final grouting pressure: 0.5 MPa. |

| Grouting completion criterion | When the designed final pressure is reached and grouting continues for more than 10 min or when the grout leaks out, the grouting is considered complete. |

| Grouting pipe design | The external pipes are steel pipes with a diameter of Ф40 mm, a wall thickness of 3.5 mm, and a length of 6 m. The upper part is exposed by 15–20 cm. |

| Grouting quantity | The grouting volume per section was 95 L, and the grouting volume per hole was 750 L/hole. |

| Gel time testing | On-site slurry preparation was performed, with the gel time controlled between 1 and 8 min. |

| Grouting effect inspection | After industrial waste residue double-liquid grouting was completed, core sampling and observations during construction indicated that the compressive strength of the consolidation reached 0.5–3 MPa after 3 days. The entire loose soil mass was consolidated, and surface deformation was controlled within 30 mm. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, H.; Bai, Q.; Xie, G. Effect of Steel Slag and Ground Slag on the Properties of Cement-Based Greener Grouting Material in Sandy Strata. Buildings 2025, 15, 4138. https://doi.org/10.3390/buildings15224138

Xu H, Bai Q, Xie G. Effect of Steel Slag and Ground Slag on the Properties of Cement-Based Greener Grouting Material in Sandy Strata. Buildings. 2025; 15(22):4138. https://doi.org/10.3390/buildings15224138

Chicago/Turabian StyleXu, Hang, Qian Bai, and Guoliang Xie. 2025. "Effect of Steel Slag and Ground Slag on the Properties of Cement-Based Greener Grouting Material in Sandy Strata" Buildings 15, no. 22: 4138. https://doi.org/10.3390/buildings15224138

APA StyleXu, H., Bai, Q., & Xie, G. (2025). Effect of Steel Slag and Ground Slag on the Properties of Cement-Based Greener Grouting Material in Sandy Strata. Buildings, 15(22), 4138. https://doi.org/10.3390/buildings15224138