1. Introduction

Urban infrastructure includes transportation, energy, water resources, communication, social services, and disaster prevention systems. These interconnected components play a vital role in maintaining urban functionality and improving the quality of life for citizens [

1,

2,

3].

In recent years, rapid urbanization, climate change, and technological advancement have increased the complexity of infrastructure systems. As a result, efficient and systematic infrastructure management has become essential for achieving sustainable development and social inclusiveness.

The advancement of information and communication technology (ICT) has brought fundamental changes to infrastructure management. The Internet of Things (IoT) enables continuous monitoring of infrastructure conditions through real-time sensor data, while artificial intelligence (AI) provides predictive and optimization models based on accumulated data to enhance operational efficiency.

Digital twin technology also strengthens the resilience of urban infrastructure by allowing predictive maintenance and disaster simulations through virtual modeling [

4]. These technologies together improve both productivity and safety in urban systems and accelerate the transition toward smart infrastructure. However, several challenges remain in achieving efficient infrastructure management.

First, high initial investment costs often delay modernization in small cities and developing countries. Second, ICT-based infrastructure operation requires processing large volumes of data, which raises concerns about data security and privacy. Third, the lack of standardized data structures and interdepartmental collaboration limits integrated management. Finally, insufficient digital literacy among citizens reduces acceptance and utilization of new technologies.

Among various infrastructure sectors, underground utilities have been expanding rapidly due to urbanization, replacement of aging assets, and the adoption of smart technologies.

According to a 2023 report by MarketsandMarkets, the global water and wastewater management market is expected to grow at a compound annual growth rate (CAGR) of 7.3 percent through 2030 [

5]. Similarly, the global utility infrastructure market, including electric and communication conduits, is projected to reach approximately 150 billion USD by 2027 [

6]. Key growth drivers include increasing urban population density [

7], the replacement of infrastructure built in the 1960s and 1970s [

8], and government-led initiatives for integrated safety and management systems [

9].

Underground utilities such as water, sewage, gas, electricity, and communication networks form the backbone of urban functionality. Accurate integration of location, geometry, and attribute data is essential for ensuring safety and sustainability.

To address this need, technologies that integrate Building Information Modeling (BIM) and Geographic Information Systems (GIS) have been actively studied [

10,

11,

12]. Singapore’s Digital Underground project established a three-dimensional geospatial database for underground facilities [

13]. In Europe and North America, the adoption of open formats such as Industry Foundation Classes (IFC) and CityGML has increased [

14]. In Finland, the government introduced the InfraBIM standard and mandated its use in public infrastructure projects, promoting a more integrated management system for underground spaces.

Recent studies have also expanded the application of BIM to infrastructure inspection and maintenance. For example, Xia et al. proposed a complete-coverage path-planning method for surface inspection of cable-stayed bridge towers using climbing robots based on BIM data, demonstrating the potential of BIM for intelligent operation and safety monitoring [

15].

Despite these developments, research on BIM automation based on 2D drawings remains in its early stages. Previous studies have attempted to convert BIM data into GIS formats [

16] or integrate AI technologies to automate workflows [

17].

In parallel, Ning et al. developed a dynamic clustering framework for 3D CAD models using an inertial feature encoder, enabling efficient and automated classification of complex geometric data [

18]. Such approaches highlight the growing role of AI-driven model understanding and data management in the digital construction domain.

However, these approaches still face technical limitations such as the loss of temporal information, reduced geometric accuracy, and inconsistencies in attribute data. On the other hand, BIM supports data integration throughout the entire project lifecycle, improving productivity and safety through clash detection and simulation [

19,

20,

21].

To overcome these limitations, this study proposes an integrated workflow that extracts spatial and attribute information from standardized 2D CAD drawings, converts it into three-dimensional GeoJSON (Geographic JavaScript Object Notation) data [

22], and automatically generates BIM objects in IFC (Industry Foundation Classes) format.

In addition, process (WBS) and cost (CBS) data are defined in JavaScript Object Notation (JSON) format and integrated into the BIM model to achieve automated 5D BIM generation. This workflow allows designers to continue working in the conventional 2D CAD environment without using expensive 3D modeling software, while ensuring seamless integration of geometry, schedule, and cost information without data loss. The accuracy of the GeoJSON conversion process was verified through official software testing conducted by the Korea Testing and Research Institute (KTR) [

23].

The proposed framework enables the digital transformation of underground utility management across the design, construction, and maintenance phases.

It provides a reliable technological foundation for BIM–GIS integrated smart infrastructure management and supports the broader transition toward data-driven construction environments.

2. Materials and Methods

2.1. Integrated Process for Automated BIM Generation Based on Standardized 2D CAD Drawing

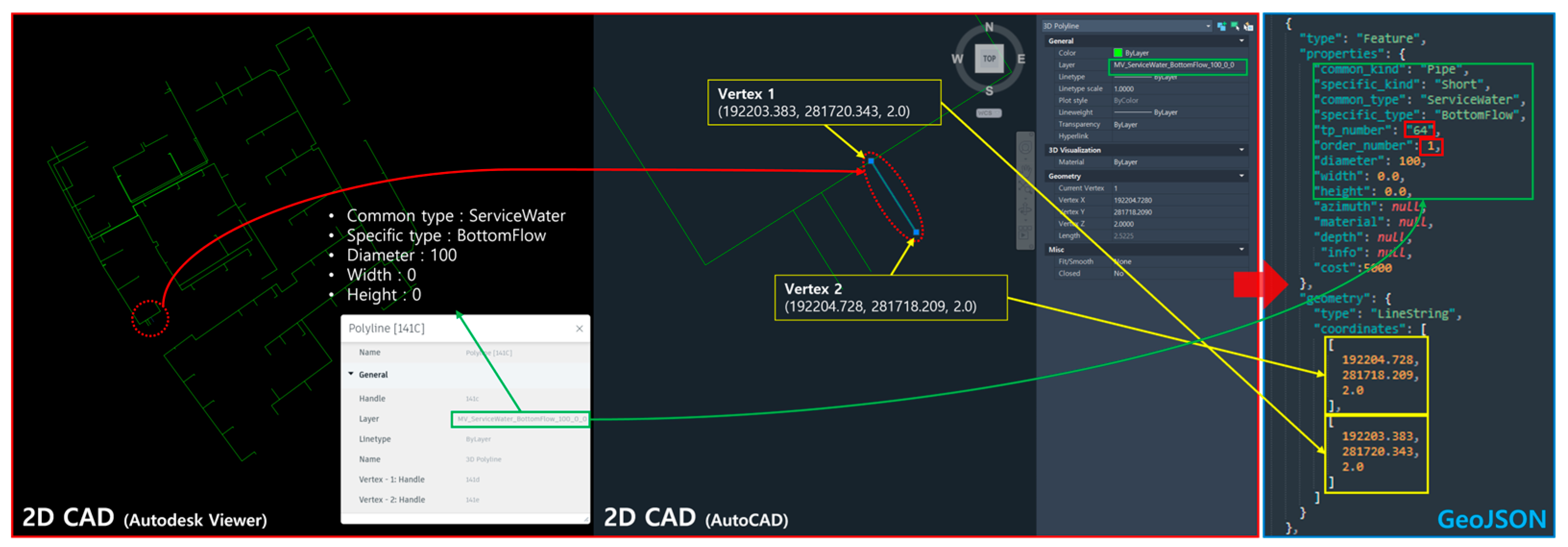

In this study, an integrated process is proposed that extracts location, geometry, and attribute information from standardized underground utility 2D CAD drawings, refines them into three-dimensional spatial data, and subsequently converts them into 3D spatial data in the GeoJSON format. The processed data are then automatically transformed into BIM library data compliant with the IFC format. Furthermore, construction process information of underground utilities is structured in a JSON schema and integrated into the BIM library models, enabling the automatic generation of BIM deliverables according to utility types.

The proposed system allows design engineers to maintain their conventional 2D drawing-based workflows while efficiently generating and utilizing BIM data without the need for dedicated 3D modeling software. This approach facilitates digital transformation and promotes design automation in the field of underground utilities.

2.2. Input Data and Predefined Resource

2.2.1. Standardized 2D CAD Drawings

The CAD drawings used as input data were provided in DXF format, and underground utility information was systematically organized through an attribute-based hierarchical layer structure. Pipelines were represented as 3D Polyline CAD entities, while facilities were represented as Text CAD entities. This standardized input structure enables automated information extraction. By combining the attribute information contained in each layer with the geometric and symbolic information embedded in CAD entities, spatial and functional data of underground utilities can be effectively identified and classified.

2.2.2. GeoJSON Spatial Data Structure

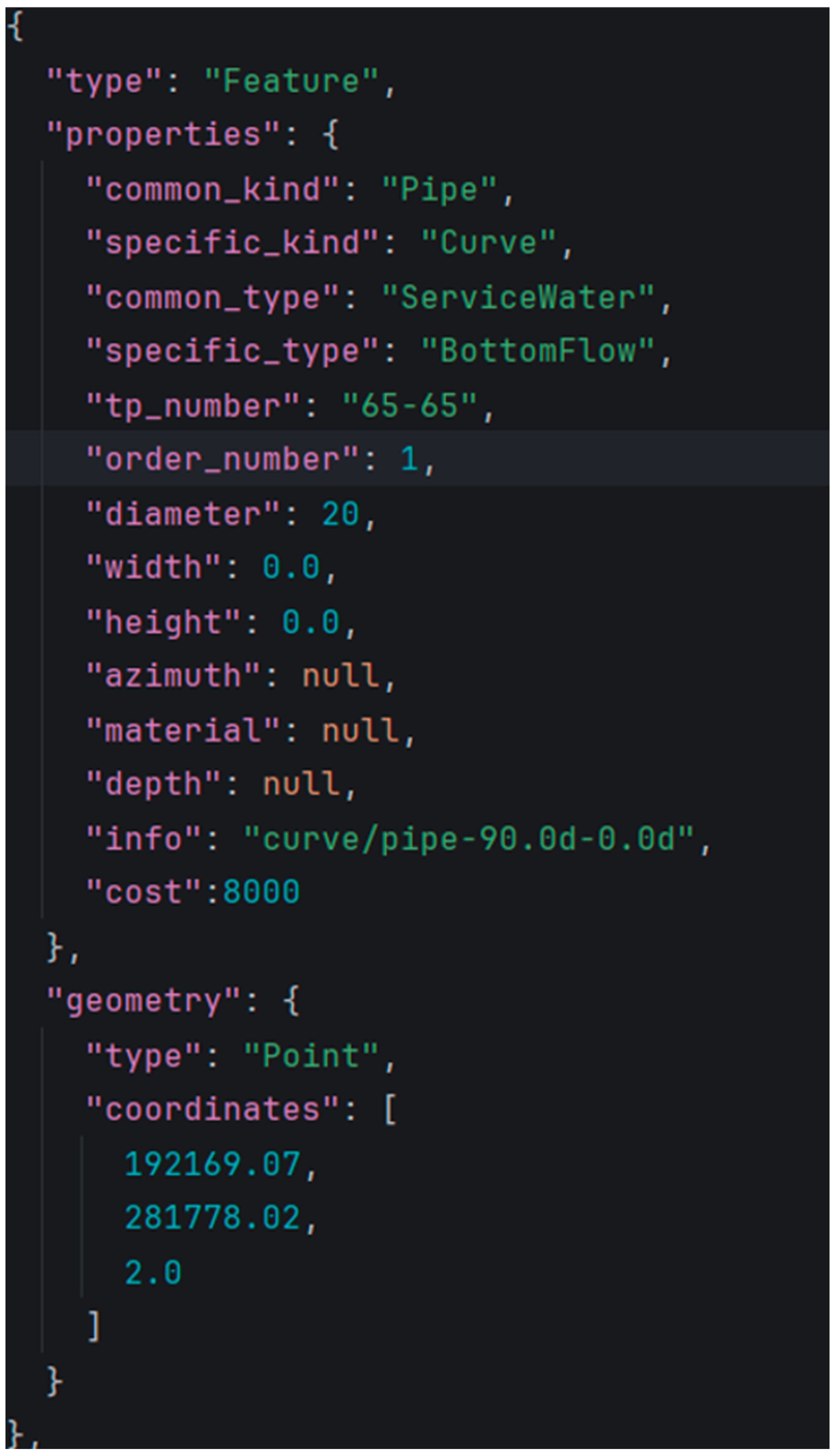

To transform underground utility object information extracted from 2D CAD drawings into structured three-dimensional spatial data, the GeoJSON format was adopted. GeoJSON is a lightweight spatial data format based on JSON, where each dataset is organized as a FeatureCollection. Each Feature consists of a geometry attribute that defines spatial shape and a properties attribute that contains associated attribute information. The geometry element represents spatial forms such as Point and LineString through coordinate arrays, while the properties element stores diverse facility attributes in key-value pairs.

Underground utility objects are mapped to appropriate geometry types according to their characteristics. For instance, pipelines are represented as LineString geometries, whereas point-based facilities such as manholes and valves are represented as Point geometries. Each geometry contains three-dimensional positional data (X, Y, Z coordinates), and properties include attributes such as kind of utility, common_type, specific_type, diameter, material, depth, azimuth, material specifications, and connectivity. These attributes serve as essential data in subsequent BIM conversion and maintenance management processes.

In addition, the GeoJSON structure was extended to express topological and connectivity relationships among objects through the definition of reference values and connection attributes. Each object is identified by unique coordinates and includes attributes such as object_key, start_point_connected_pipe, and end_point_connected_pipe, which represent pipeline connectivity, branch locations, and other relationships that ensure construction relevance and data extensibility.

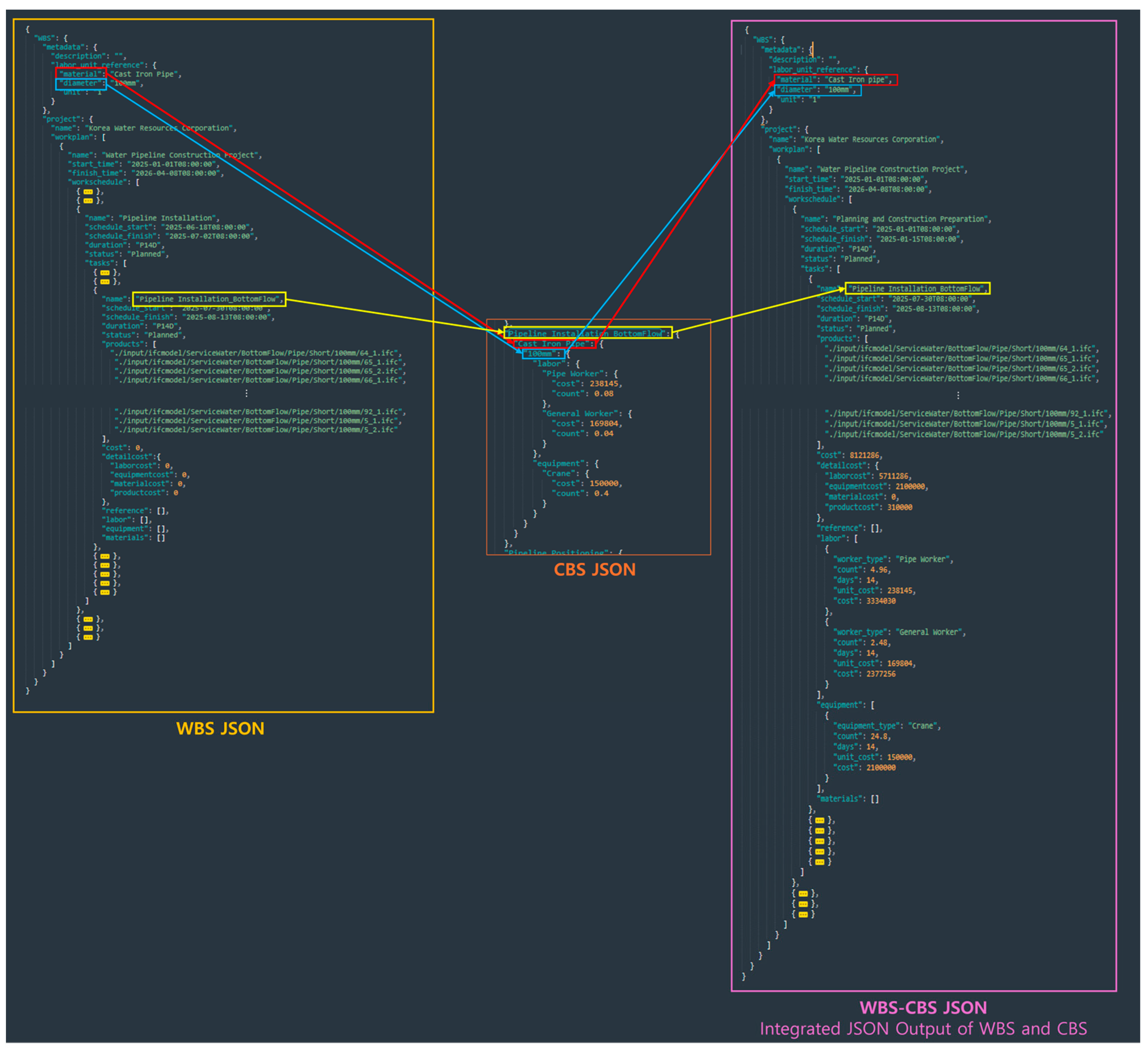

2.2.3. Roles of WBS and CBS in BIM-Based Project Management

In BIM-based project management, the Work Breakdown Structure (WBS) and Cost Breakdown Structure (CBS) are essential tools for systematically managing project scope and cost. WBS is a hierarchical structure that progressively decomposes the entire scope of a project into manageable work packages, focusing on defining “what must be accomplished.” This provides clarity regarding deliverables and activities and allows for systematic scheduling and resource allocation. In contrast, CBS is a hierarchical framework that decomposes project costs into detailed elements, focusing on “how much cost is required.” CBS categorizes cost items such as labor, materials, and equipment, and it is applied to budget estimation and cost control.

WBS and CBS are complementary and interconnected structures. Work packages defined in WBS are linked to CBS, enabling cost estimation and control for each task. Together, they provide an integrated framework for managing both project scope and cost, thereby supporting efficient and transparent project execution.

Table 1 presents a comparative summary of WBS and CBS.

In this study, a JSON-based template was designed to implement the WBS and CBS management framework. The template enables the standardized definition of project work structures and cost structures, allowing WBS and CBS data to be systematically processed and utilized. Furthermore, a process was developed to automatically generate final deliverables from the JSON template files, thereby streamlining repetitive and labor-intensive management tasks through automation. In particular, the JSON data can be modified and applied to each underground utility construction project according to its specific characteristics, providing flexibility to accommodate diverse site conditions and project requirements.

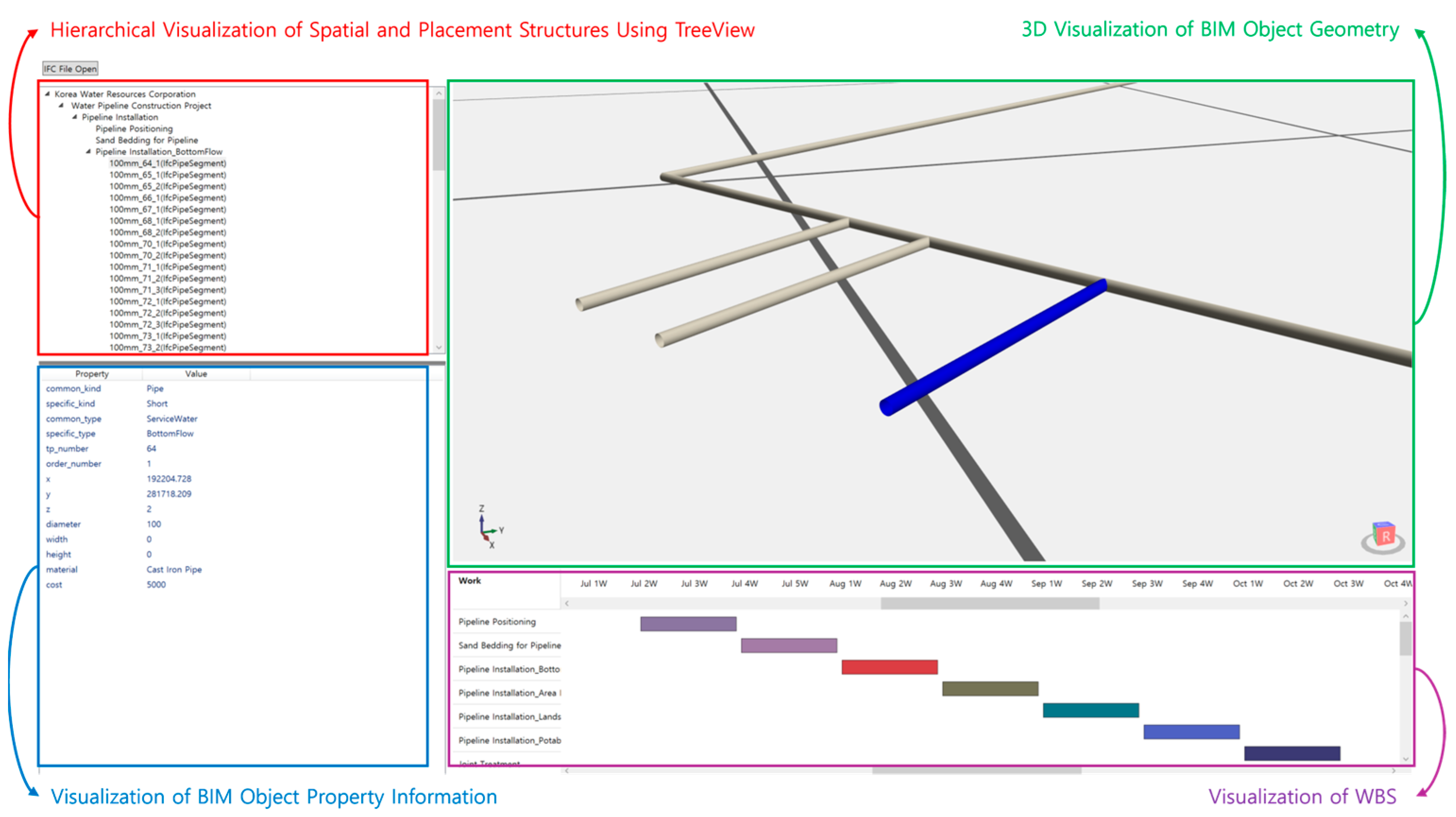

2.3. Steps of Integrated BIM Generation Process

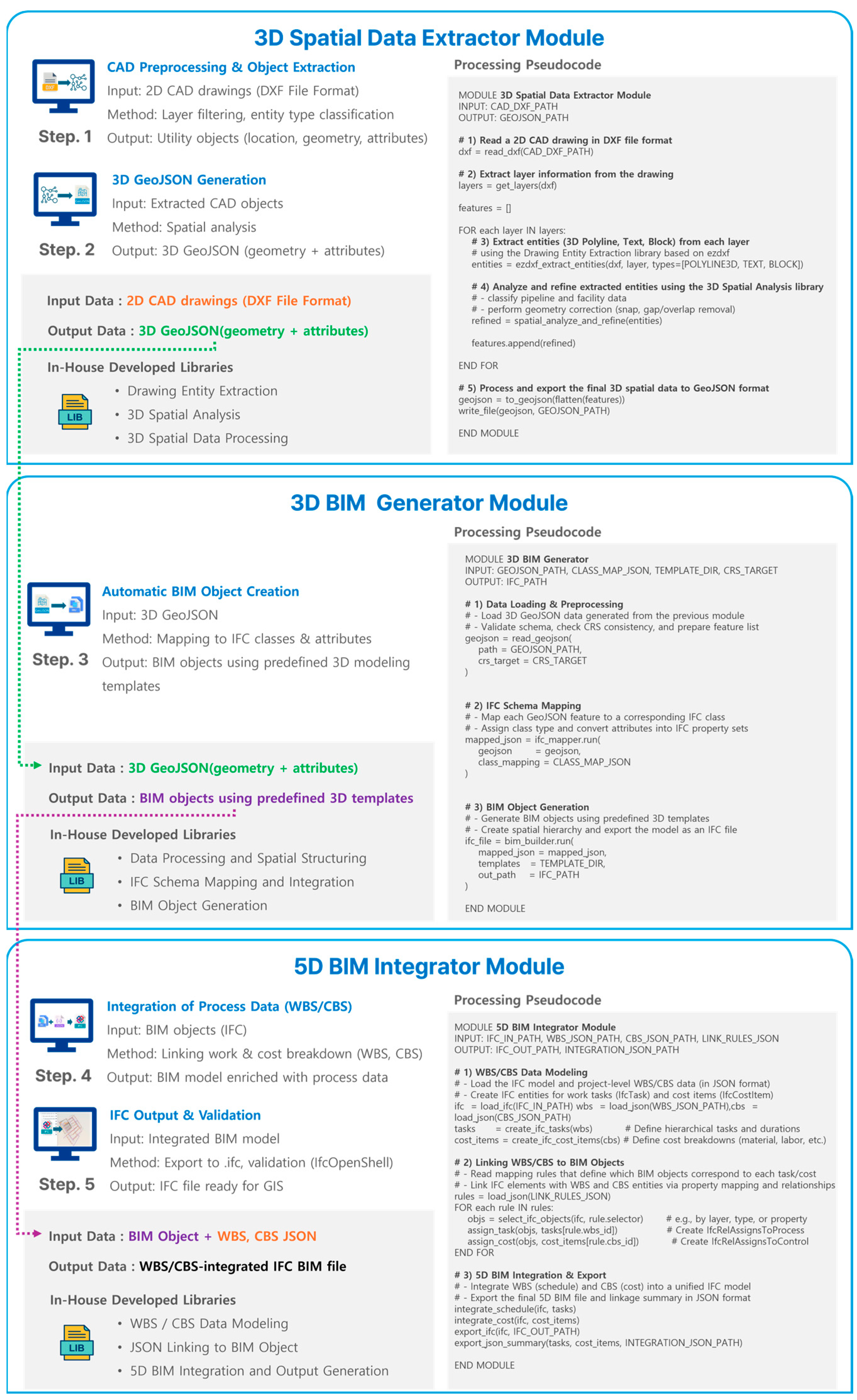

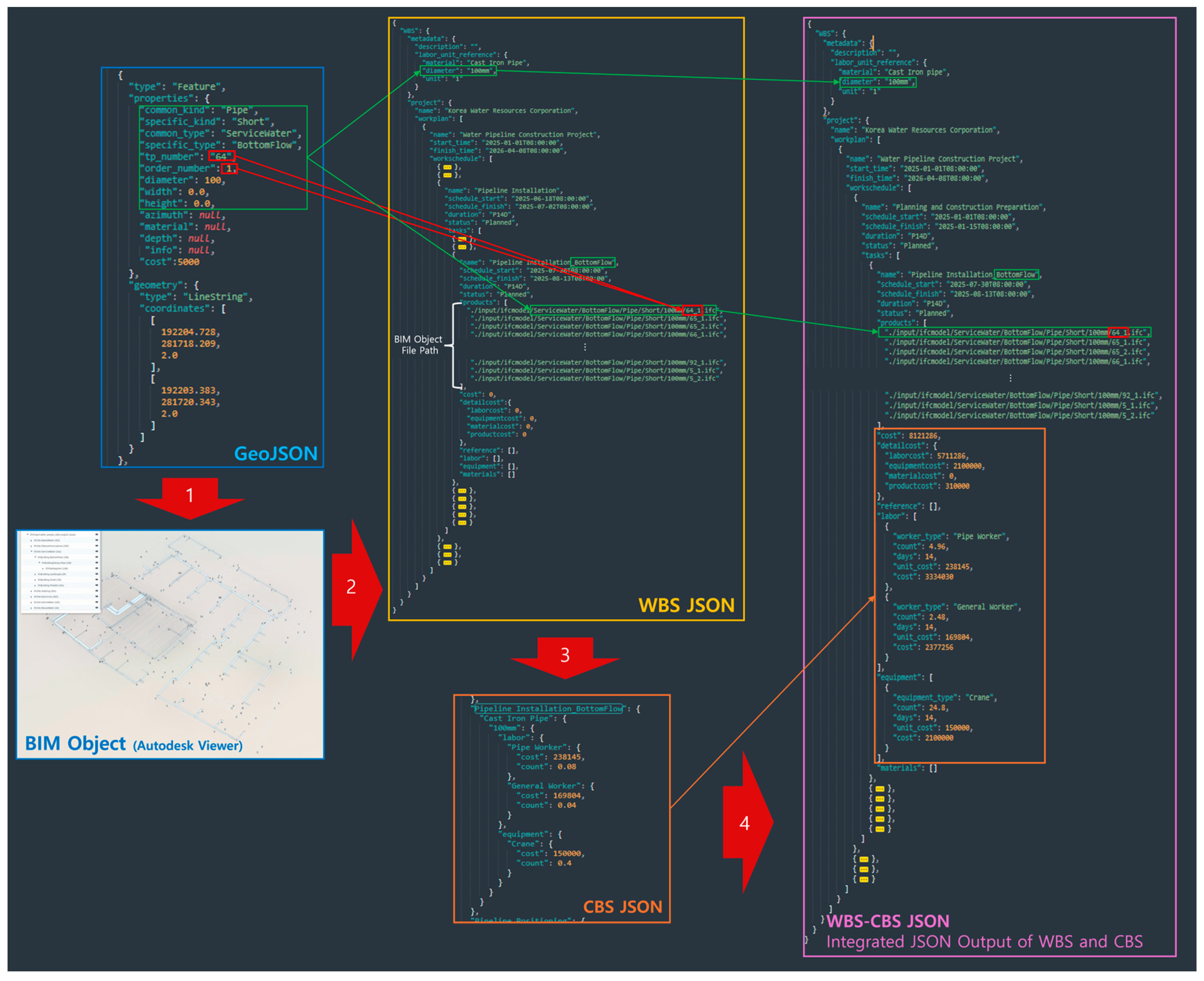

Figure 1 illustrates the overall processing workflow of the proposed system, which consists of five sequential stages.

In the first stage (CAD preprocessing and object extraction), the CAD drawings are analyzed to automatically extract the location, geometry, and attribute information of underground utility objects. This process is performed through layer-based filtering and classification of CAD entity types.

The second stage (3D GeoJSON generation) processes the extracted utility data through spatial analysis to generate 3D spatial data. The resulting GeoJSON file contains both geometric and attribute information and serves as the input for the subsequent BIM mapping stage.

The third stage (automatic BIM object creation) maps the generated GeoJSON data to corresponding IFC classes and attributes to automatically create BIM objects. Each object is generated by applying predefined 3D modeling templates stored in the BIM library and is converted into an IFC-based model.

In the fourth stage (process data integration), the generated IFC objects are linked with work (WBS) and cost (CBS) breakdown data to incorporate construction process information into the BIM model.

Finally, the fifth stage (IFC output and validation) exports the completed BIM model in IFC format and verifies it using open-source viewers such as IfcOpenShell and BIMvision.

The resulting files can be integrated with GIS platforms or digital twin systems, significantly enhancing the interoperability and practical usability of underground utility management. The proposed workflow does not involve coordinate system transformation, and all geometric calculations are performed through spatial analysis within the original CAD coordinate domain.

As a result, no geometric tolerance or distortion occurs, since the process does not generate any new pipeline geometry beyond what exists in the original data. Therefore, the proposed CAD-to-5D BIM conversion process preserves the original geometry and attributes with complete accuracy.

3. Limitations of Underground Utility Management and ICT-Based Countermeasures

3.1. Challenges in Underground Utility Management Systems

Various countries have introduced advanced technologies and systems to ensure the efficient and safe management of underground utility infrastructure. However, several structural, technical, and institutional limitations remain.

First, the accuracy of digital transformation is often reduced due to poor data quality and a lack of standardization. Historical data stored in paper drawings, PDF, or CAD formats are unstructured and incomplete. Furthermore, there is no globally standardized format for underground utilities, which causes low interoperability and data inconsistency among countries and institutions [

11,

24].

Second, information fragmentation between organizations and security constraints restrict data sharing and collaboration. Insufficient legal and institutional frameworks hinder effective inter-agency cooperation, limiting responsiveness in urban planning and disaster management [

24].

Third, the immaturity of 3D model automation and the technical complexity of BIM–GIS integration make it difficult to utilize digital data effectively. In addition, delays in adopting real-time monitoring technologies hinder the transition toward fully smart infrastructure.

Fourth, many current systems suffer from outdated or inconsistent facility information. Newly installed, decommissioned, or maintained assets are often not updated in the system, leading to discrepancies between actual and digital data. Moreover, insufficient maintenance budgets and lack of dedicated personnel reduce the frequency of system updates and verification, further degrading reliability [

11,

24].

Fifth, there is a shortage of professionals capable of integrating BIM, GIS, IoT, and AI technologies. Gaps between field operations and system management lead to delays in feedback and updates, reducing both the accuracy and usability of information [

25].

Sixth, the introduction of smart infrastructure systems faces financial and policy constraints. High implementation costs for 3D scanning, sensing, and data integration make adoption difficult for small cities or organizations. Frequent policy changes and administrative restructuring also disrupt continuity in system development [

11,

25].

3.2. Applications of Smart Technologies for Efficient Underground Utility Management

To overcome these challenges, many countries have been applying ICT-based smart technologies to underground utility management.

First, GNSS (Global Navigation Satellite System) and LiDAR (Light Detection and Ranging) technologies are increasingly used to acquire precise location, geometry, and attribute data, while AI-based recognition algorithms are being developed to extract object information automatically from PDF or CAD drawings [

26,

27]. These technologies significantly improve data quality and reduce manual workload.

Second, efforts are underway to build integrated BIM–GIS platforms that combine the geometric precision of BIM with the spatial analysis capabilities of GIS. Such platforms utilize international open standards such as IFC, CityGML, and LandInfra to enhance data exchange and interoperability. Representative cases include Finland’s InfraBIM initiative and Germany’s IFC-Alignment project [

28]. Similarly, the UNUM (Unification for Underground Resilience Measure) project in New York integrates and publishes underground utility data such as water, power, and communication networks through an API-based cloud platform adopting the OGC MUDDI (Model for Underground Data Definition and Integration) standard, thereby strengthening urban resilience [

29].

Third, IoT-based real-time monitoring systems are being actively implemented. Sensors installed on underground pipelines collect data on leakage, settlement, vibration, and temperature, which enables AI-based predictive maintenance. Recent studies have demonstrated long-term reliability of battery-free, energy-harvesting IoT sensors for underground applications [

8]. Hybrid models using acoustic emission (AE) signals with CNN–LSTM architectures have also been proposed for leak detection in smart pipeline systems, supporting cost-efficient maintenance scheduling [

30].

Fourth, digital twin technology is being used to create 3D virtual models that replicate real underground utilities for visualization, simulation, risk prediction, and maintenance planning. Web-based 3D viewers and AR (Augmented Reality) collaboration environments allow designers, field engineers, and managers to access and update data in real time. Representative solutions include Trimble SiteVision [

31] and Bentley OpenCities Planner [

32], both of which enhance the precision and safety of underground operations.

3.3. Strategies for Underground Utility Management Using the Proposed Technology

The automated BIM generation technology proposed in this study provides a practical alternative to address the structural and technical limitations identified above. The framework automatically converts 2D CAD drawings into GeoJSON- and IFC-based 3D BIM data through an integrated processing pipeline.

First, it addresses the problem of data quality and standardization. By extracting object information and attributes automatically from standardized CAD templates and converting them into GeoJSON structures, the system ensures data consistency. As both GeoJSON and IFC are open international formats, interoperability among different organizations and countries is greatly improved.

Second, it resolves the issue of fragmented information and inefficient collaboration. The generated BIM data links with WBS and CBS information within the IFC schema, enabling real-time information sharing and collaboration across departments for urban planning, maintenance, and disaster response.

Third, it enhances 3D model automation and BIM–GIS interoperability. The process automatically generates 3D models with Z-values from 2D CAD drawings and converts them into GeoJSON and IFC formats, allowing direct use within GIS platforms. This effectively strengthens interoperability between BIM and GIS environments.

Fourth, it improves data currency and maintenance efficiency.

When updated CAD drawings reflecting new installations, modifications, or repairs are input, the corresponding BIM data are regenerated automatically, maintaining consistency and reliability of facility information.

Fifth, it alleviates the shortage of skilled personnel and the high cost of BIM adoption. By using open-source libraries such as GeoPandas and IfcOpenShell, the system eliminates the need for expensive 3D modeling software. Non-experts can automatically generate BIM files from 2D drawings, making this a viable solution for small cities or organizations with limited budgets.

In summary, the proposed 2D-based automated BIM generation framework offers a realistic and scalable process that directly addresses the existing limitations in underground utility management.

Table 2 summarizes how the proposed technology responds to each of the identified issues and demonstrates its applicability as a key enabling technology for digital transformation and smart infrastructure implementation.

4. Summary of Existing Research and Linkage to the Proposed Method

4.1. Background and Overview of Existing Research

Recent studies have emphasized the importance of constructing high-precision spatial data to support the digital transformation of urban infrastructure. In particular, in the field of underground utilities, accurate three-dimensional (3D) spatial information within design data is essential across all stages of design, construction, and maintenance.

However, most underground utility designs still rely on two-dimensional (2D) CAD drawings, where positional, geometric, and depth information of facilities are often separated or omitted, leading to degradation of data quality. In addition, fragmented data management across different organizations hinders the identification of spatial conflicts during construction and prevents timely updates after field modifications, resulting in inaccurate data for maintenance operations.

To address these limitations, previous research [

23] proposed a standardized 2D CAD-based processing framework that automatically extracts the position (X, Y, Z), geometry, and attribute information of underground utilities and converts them into 3D structured spatial data through spatial analysis.

That study integrated various types of drawings, such as plan views, profile views, and detailed cross-sections, into a single object-based data structure compatible with the GeoJSON format. Specifically, it established drawing rules for CAD entities and layer naming conventions, as well as block- and text-based attribute extraction methods, enabling automated generation of standardized 3D spatial data.

The final outcome of the previous research was a GeoJSON-formatted 3D spatial dataset, which enabled the conversion of conventional 2D CAD drawings into interoperable data structures suitable for integration across different systems. Building upon this technical foundation, the present study extends the approach by developing an automated BIM generation process that converts GeoJSON data into IFC-based BIM objects.

4.2. Structure and Data Composition of Standardized 2D Drawings

Underground utility design drawings generally consist of a plan view, profile view, and detailed section view, each providing complementary spatial information.

The plan view represents the horizontal alignment and connections of pipelines, the profile view illustrates depth (Z-coordinate) and elevation differences, and the detailed section presents specifications such as diameter and material. Because these drawings are managed independently, it is difficult to integrate and interpret the full 3D spatial relationships of underground facilities.

The previous study proposed a standardized drawing structure that embeds Z-values into 3D polylines within the plan view, enabling vertical positioning without requiring a separate profile drawing. In addition, a layer naming convention was defined to include key attribute information such as object type, sub-type, diameter, material, and height.

This information is automatically parsed and converted into structured attributes during data extraction, ensuring consistency regardless of individual drafting practices.

This standardized structure provides a technical foundation for mechanically extracting 3D spatial and attribute data from CAD drawings. It serves as a prerequisite for automated conversion into GeoJSON and BIM formats and plays a crucial role in transforming 2D design drawings into structured digital assets.

4.3. Procedure for Generating 3D Spatial Data Based on the GeoJSON Format

To construct 3D digital models of underground utilities, precise extraction and structuring of positional, geometric, and attribute information from CAD drawings are required.

The previous study adopted GeoJSON, an open format proposed by the IETF, which represents spatial objects through two main components: geometry and properties. The geometry component defines spatial coordinates as points, lines, or polygons, while the properties component stores semantic information in key-value pairs. This lightweight structure is highly compatible with GIS software and web-based visualization tools.

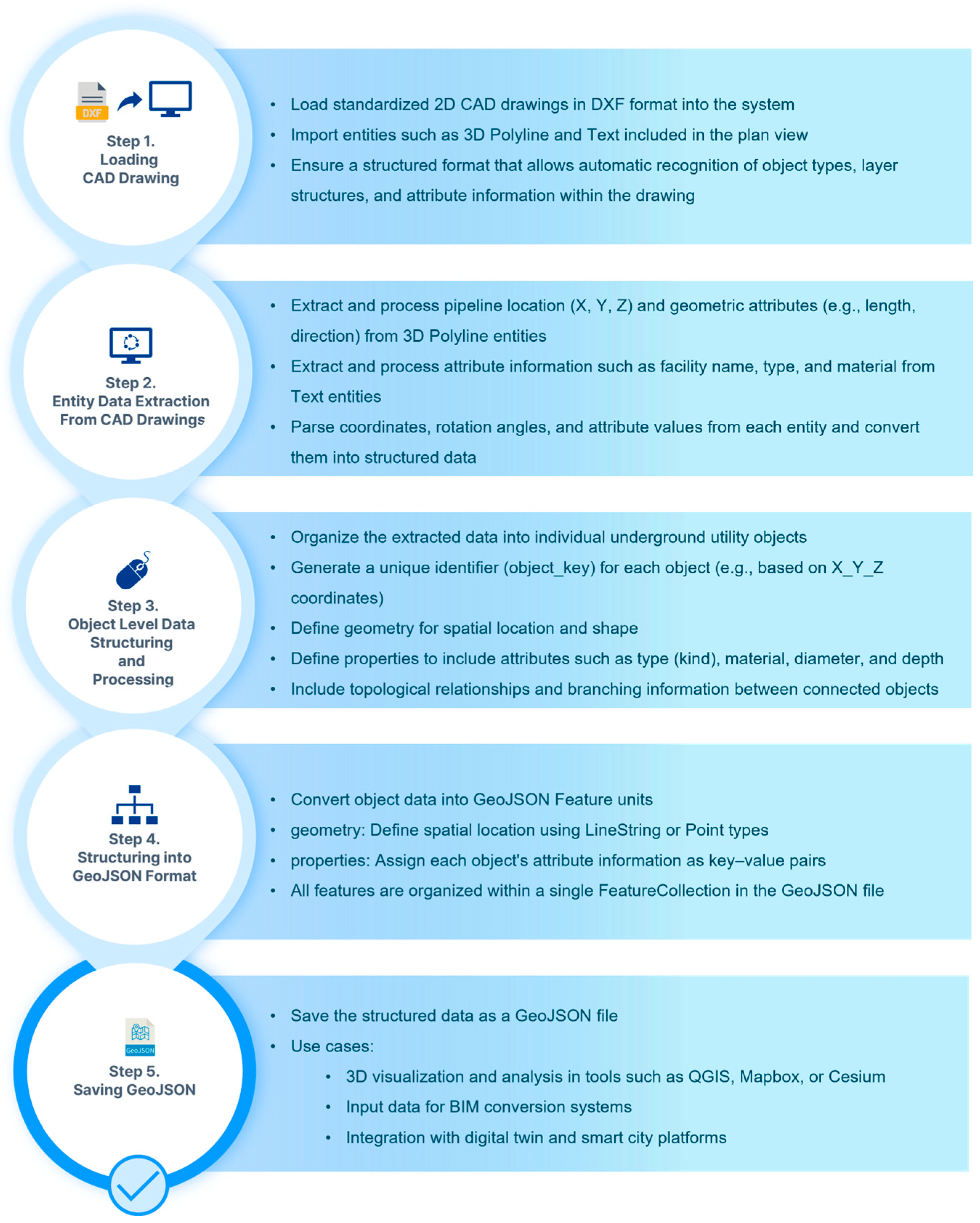

The generation process can be summarized as follows.

First, CAD entities such as 3D polylines and text annotations are analyzed to extract corresponding object information.

Second, linear entities are converted into 3D coordinates with Z-values to represent pipeline routes.

Third, point entities define the positions of facilities, and their attributes are derived from text annotations that describe the type or specification.

Finally, the extracted information is organized as a GeoJSON FeatureCollection, where each feature includes identifiers, geometry, and attributes such as pipe type, material, diameter, installation year, and connection data.

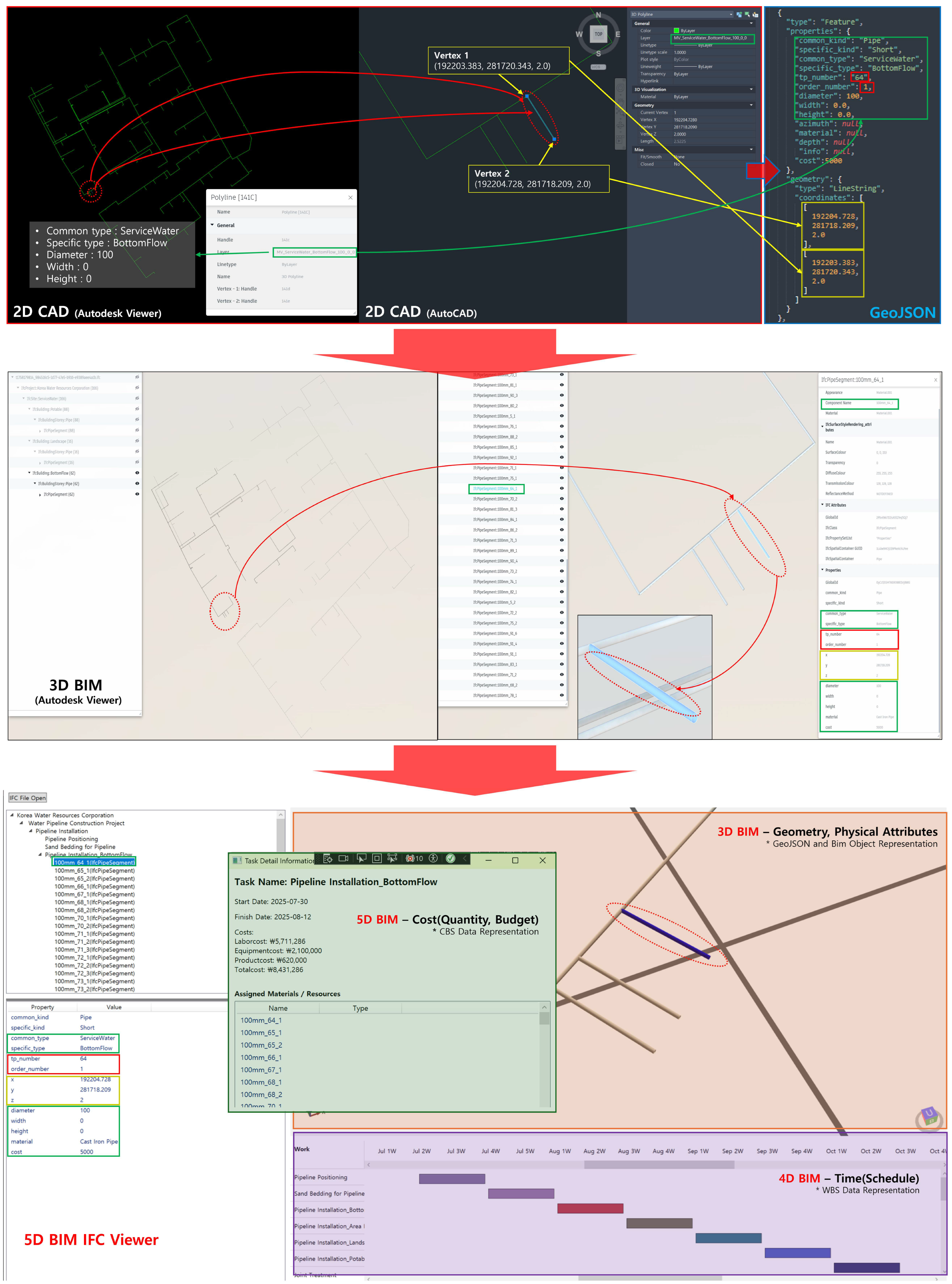

Figure 2 illustrates the complete workflow from CAD drawing input to the generation of the final GeoJSON dataset. Through this automated process, complex CAD data can be systematically transformed into structured and interoperable 3D spatial datasets.

This approach significantly simplifies manual interpretation and provides a solid foundation for subsequent BIM generation and digital twin applications.

4.4. Accuracy Assessment and Technical Significance

For the proposed CAD-based spatial data conversion framework to be reliable in practice, accuracy and consistency must be verified. The previous study conducted quantitative validation using actual underground utility drawings to assess how accurately positional, geometric, and attribute data were reproduced during automatic processing.

The test dataset included real urban utility drawings covering seven facility types (water, sewage, power, communication, etc.), and object information was extracted from DXF drawings and converted into 3D GeoJSON format. The validation showed 100% consistency between the geometric and attribute data of the original CAD drawings and the automatically generated GeoJSON outputs. Spatial overlay analysis using QGIS and Google Maps confirmed perfect alignment without any data loss or distortion.

These results demonstrate that the proposed method can reliably convert 2D CAD drawings into structured 3D spatial datasets in a standardized and repeatable manner. Furthermore, the defined drawing rules and extraction algorithms were proven to work robustly under real-world design conditions, minimizing potential human errors and improving both accuracy and productivity.

This technical foundation was extended in the present study to include GeoJSON-to-IFC conversion and WBS/CBS integration for 5D BIM generation, quantitatively verified through experiments presented in

Section 6.4.3.

The results confirm that the proposed framework advances previous 3D data conversion research into a fully integrated BIM automation process.

5. GeoJSON-Based IFC Conversion Technology for Underground Utilities

5.1. Limitations of the GeoJSON Format and the Need for IFC Conversion

This study proposes a GeoJSON-to-IFC conversion technology that automatically transforms three-dimensional spatial data, extracted from standardized drawings and structured in the GeoJSON format, into IFC files compliant with the open BIM standard.

The GeoJSON format has the advantage of intuitively representing attribute and spatial information and, due to its lightweight structure, provides excellent compatibility with various GIS systems and web-based visualization tools. However, GeoJSON also has inherent limitations. As a coordinate-based format, it lacks visual intuitiveness for three-dimensional shapes and cannot fully represent complex structural details. In particular, real underground utilities are three-dimensional in nature and encompass geometry, attributes, location, and process-related information. Nevertheless, GeoJSON is typically limited to Point and LineString geometries, which makes it difficult to reproduce utility structures in a spatially complete manner.

To overcome these limitations, an automated conversion method was applied to transform GeoJSON-based three-dimensional spatial data into the IFC format. IFC is an open standard capable of representing construction and infrastructure objects as three-dimensional entities. It integrates geometry, attributes, lifecycle data, and process information into a unified structure. In the GeoJSON dataset, pipelines are represented by LineString geometries and facilities by Point geometries, while detailed object attributes are stored in the properties field.

The converted IFC files allow three-dimensional geometry-based visualization, enabling users to intuitively examine objects and query attribute information through IFC viewers in a manner similar to interpreting 2D CAD drawings. This transformation eliminates issues of inconsistency and redundancy that arise in conventional 2D drawings and establishes a unified representation of 3D object-based information. As a result, the proposed approach enhances efficiency and accuracy across the entire project lifecycle, including drawing preparation, design review, construction planning, and maintenance.

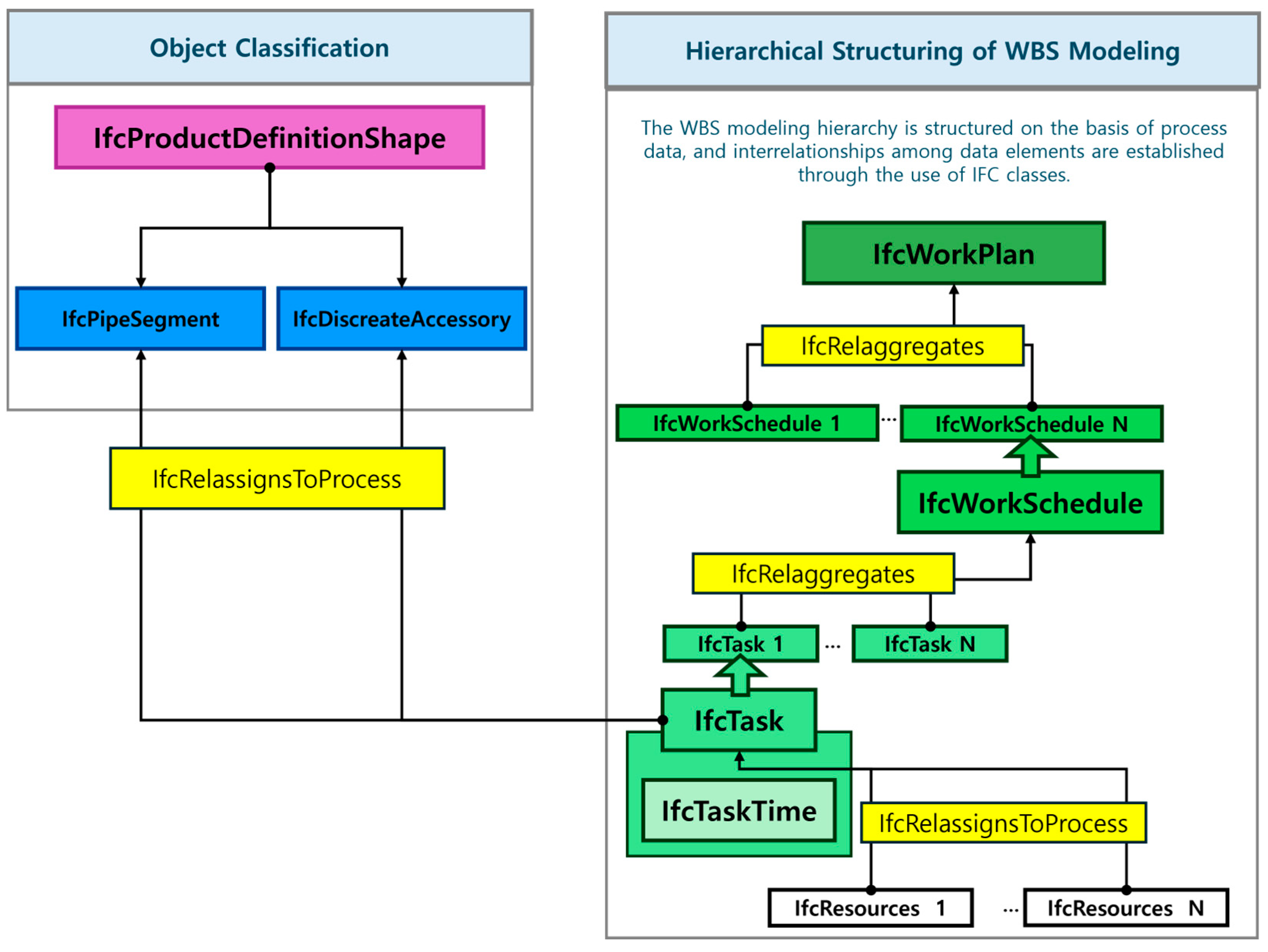

5.2. Mapping of Underground Utilities Structures Based on IFC Spatial and Placement Structure

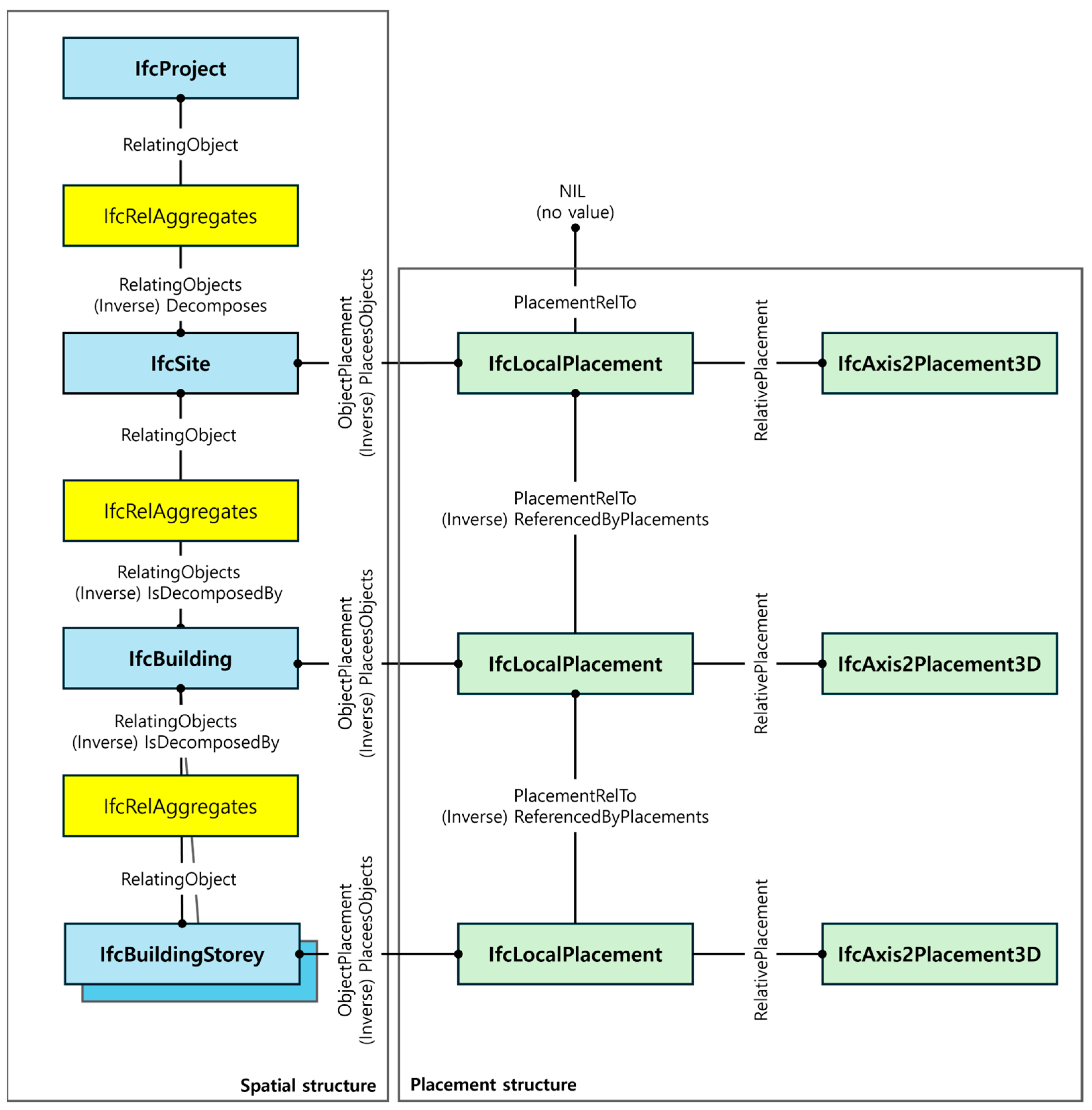

The IFC file format employs two primary hierarchical structures, the spatial structure and the placement structure, to systematically organize information [

33]. The spatial structure is responsible for the logical classification and organization of data, while the placement structure defines the position and orientation of each object within the IFC 3D model. These two structures are independent concepts: the spatial structure describes the logical grouping of objects and the space to which an object belongs, whereas the placement structure specifies how and where the object is located within the three-dimensional coordinate system.

Figure 3 illustrates the relationship between the spatial and placement structures.

The spatial structure in IFC follows a hierarchical order consisting of

IfcProject,

IfcSite,

IfcBuilding, and

IfcBuildingStorey.

IfcProject serves as the top-level container of an IFC file and includes fundamental information such as the project name, measurement units, and ownership details.

IfcSite represents the physical land or site where the project is located, while

IfcBuilding denotes the facility constructed on that site.

IfcBuildingStorey expresses vertical spatial subdivisions such as the floors of a building. These containers can include multiple objects within higher-level structures, thereby forming a hierarchical organization.

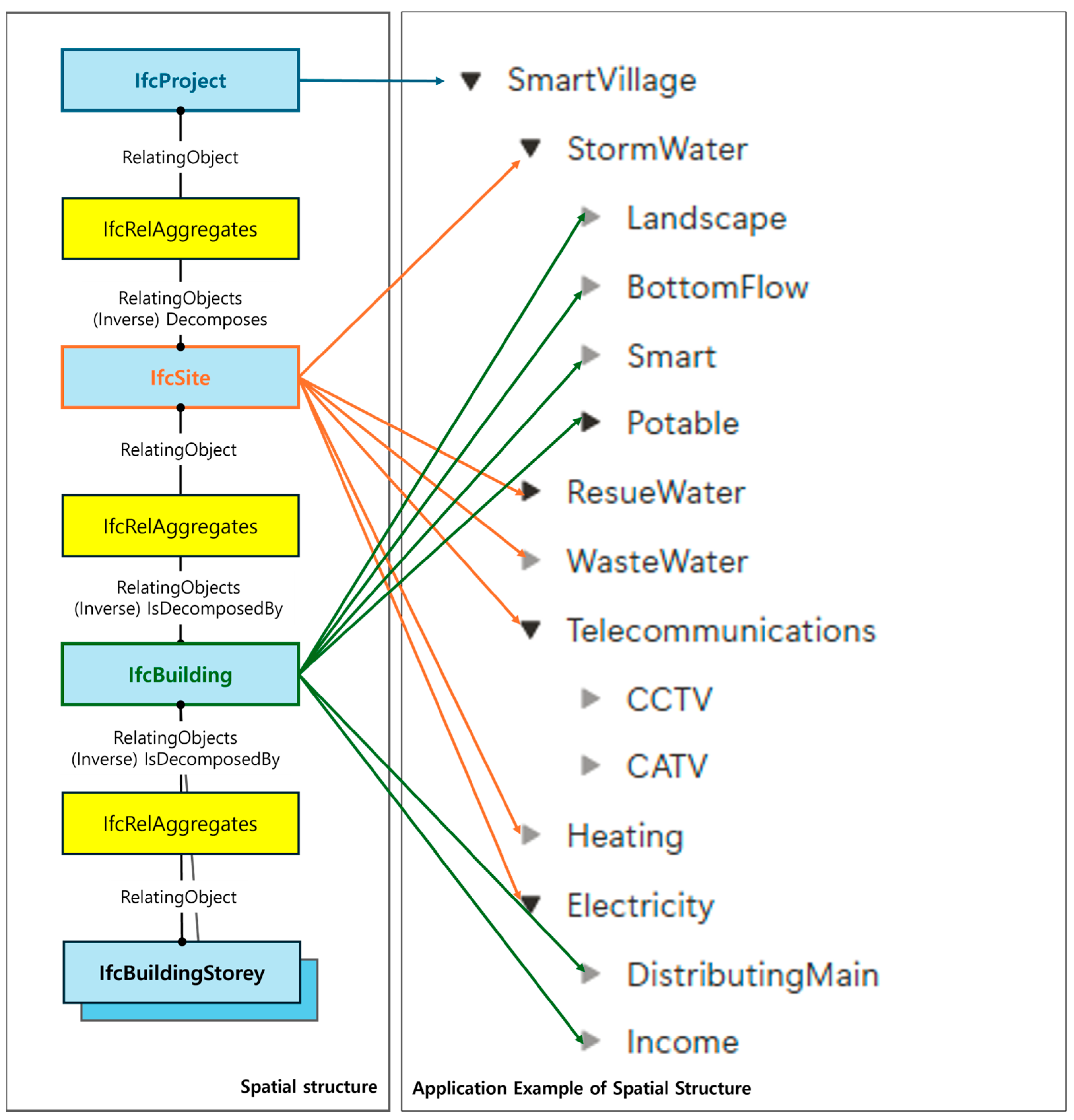

Figure 4 illustrates an example of the spatial hierarchy applied to underground utilities.

In this study, the utilized underground utility drawings were defined as IfcProject, and the types of pipelines included in the drawings were mapped to IfcSite. Furthermore, the detailed categories of each pipeline were connected to IfcBuilding, enabling hierarchical structuring of the data according to the spatial structure.

The placement structure is based on the global coordinate system and local coordinate systems. The global coordinate system provides the absolute reference point for the entire project, while each object is positioned using its own local coordinate system defined by an origin and orientation.

In an IFC 3D model, all objects are derived from the IfcProduct class. IfcProduct is the superclass that encompasses every type of object in a project, including physical elements such as IfcWall, IfcDoor, and IfcWindow, facility components such as IfcPump and IfcPipeSegment, and spatial elements such as IfcSpace, IfcBuildingStorey, and IfcSite. Each IfcProduct object defines its position and orientation through the IfcLocalPlacement attribute, which specifies its placement relative to the parent object.

5.3. Processing of BIM Object Geometry

To generate BIM objects in IFC format, the properties and geometry items of the GeoJSON-structured underground utility data are utilized.

Figure 5 shows the three-dimensional (3D) spatial data in GeoJSON format extracted from standardized 2D CAD drawings, containing the spatial position and attribute information of each object.

The common_type attribute represents the general type of the pipeline (e.g., water supply), while the specific_type attribute provides more detailed classification information.

The common_kind and specific_kind attributes distinguish whether the object is a pipeline or a point-based facility such as a manhole, and the specific_type value specifies the geometric characteristics of the pipeline (e.g., straight pipe, curved pipe).

In addition, the tp_number attribute stores the unique pipeline ID, and order_number records the creation order of underground utilities during CAD drafting. Geometric parameters such as diameter, width, and height define the main dimensions of each object, and additional information, including orientation, material, and burial depth, is also defined in the properties item. If an attribute value is not available, a “null” value is assigned so that the data can later be updated when new information is acquired. This structure provides high flexibility in terms of data scalability and maintenance.

To generate the 3D geometry of pipelines and facilities, the object type is first determined based on the common_kind and specific_kind attributes in the properties item, and then the geometry is constructed using an appropriate method.

For straight pipelines, the geometry coordinates and the diameter, width, and height values are directly used to create the shape.

For more complex geometries, such as curved pipes or manholes, pre-modeled 3D reference objects are loaded through the file path defined in the info attribute.

This approach enables accurate and consistent 3D modeling of various types of underground utilities.

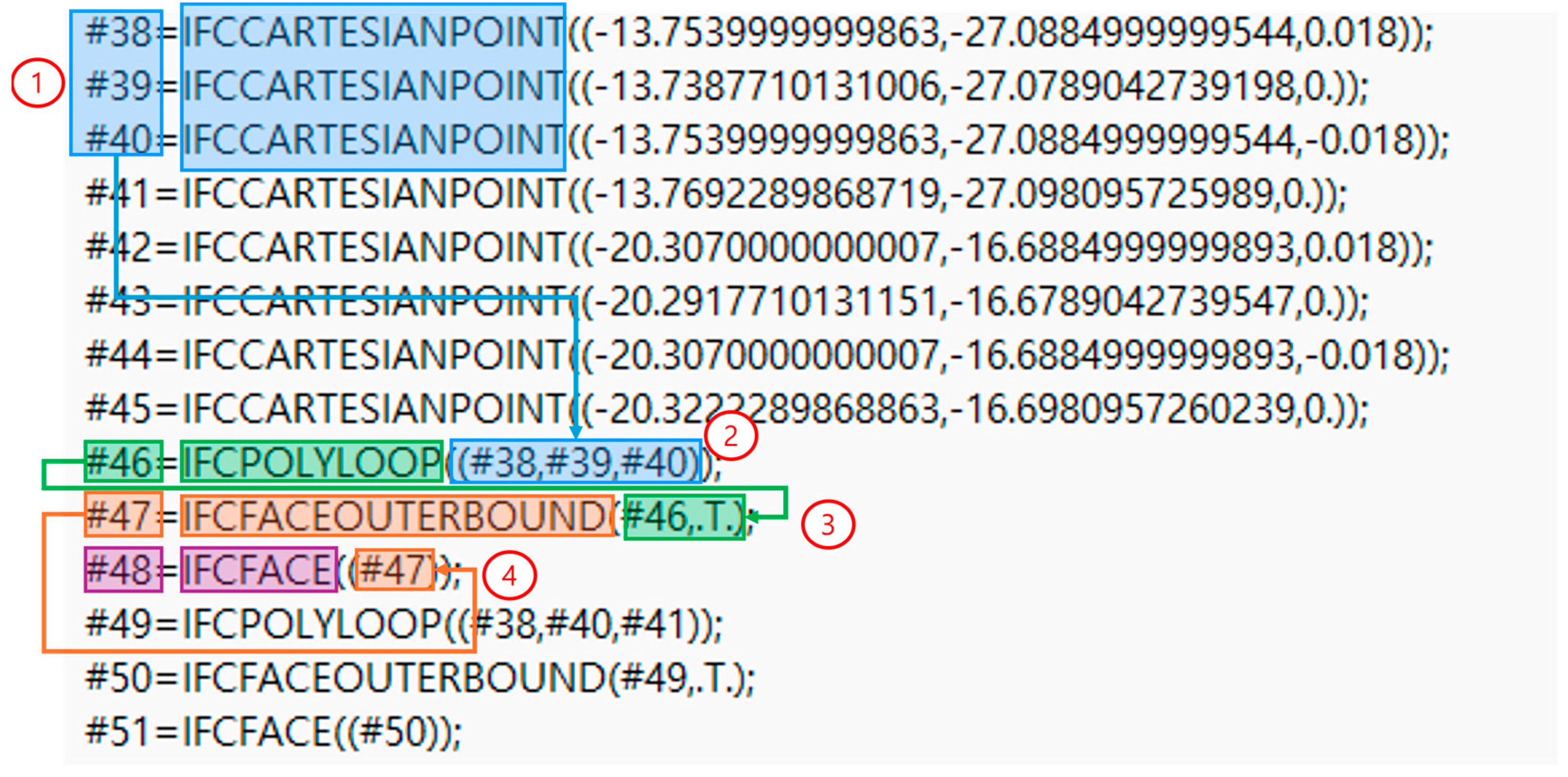

The process of creating the 3D geometry proceeds as follows.

The positional data in the geometry item are mapped to IfcCartesianPoint objects to generate point data.

The IfcCartesianPoints are connected to form a closed polyloop using IfcPolyLoop.

Before generating a face, the outer boundary and normal direction are aligned and defined as IfcFaceOuterBound.

A surface is then created by incorporating IfcFaceOuterBound to form the geometry of the underground utility.

Figure 6 illustrates the IFC data structure for constructing a single face from point data.

However, the geometry data alone are insufficient to construct a complete pipeline model. Therefore, the radius is calculated based on the diameter value, and rotation transformation is applied. To prevent the gimbal lock problem, a quaternion-based rotation method was adopted [

34].

- 5.

The surfaces generated as IfcFace are combined into a 3D solid object using the IfcClosedShell class, which is represented as IfcFacetedBrep.

- 6.

The generated BRep geometry is mapped through IfcShapeRepresentation to define the representation type.

- 7.

The coordinate system and units are defined by IfcGeometricRepresentationContext.

- 8.

Finally, the geometric information is integrated into IfcProductDefinitionShape, and the resulting objects are classified as IfcPipeSegment for pipelines and IfcDiscreteAccessory for facilities. Through this process, the objects become complete BIM entities with semantic attributes.

Figure 7 presents the step-by-step procedure for processing the BIM object geometry.

Classifying each object according to its type-specific IFC entity ensures correct recognition when importing the IFC file into widely used BIM software such as Autodesk Revit or Civil 3D. This enables users to edit object properties individually through the standard BIM interfaces.

In this study, the schema-level compatibility between the GeoJSON data structure and the IFC schema was examined. The properties structure in GeoJSON is conceptually equivalent to the IfcPropertySet structure in IFC, and each field is designed to be mapped to a corresponding IFC entity and attribute.

For example, the GeoJSON attributes type, diameter, and material correspond to IfcPipeSegmentType, IfcPropertySingleValue, and IfcRelAssociatesMaterial, respectively.

Through this mapping, both geometric and attribute information are represented in the IFC model with structural consistency. Furthermore, the geometry item of GeoJSON corresponds one-to-one with the Spatial Structure Hierarchy of IFC. Each object is converted into an IfcProduct subclass, such as IfcPipeSegment or IfcManhole, while preserving its position, orientation, and property information.

The comparison of data types, property structures, and hierarchical relationships confirmed that all elements were either directly representable in or compatible with the IFC4 schema, and that no data loss or structural inconsistency occurred during the transformation process.

These findings demonstrate that the proposed GeoJSON-to-IFC conversion process is structurally compatible with the IFC standard schema and contributes to achieving standardized data exchange and interoperability in underground utility management.

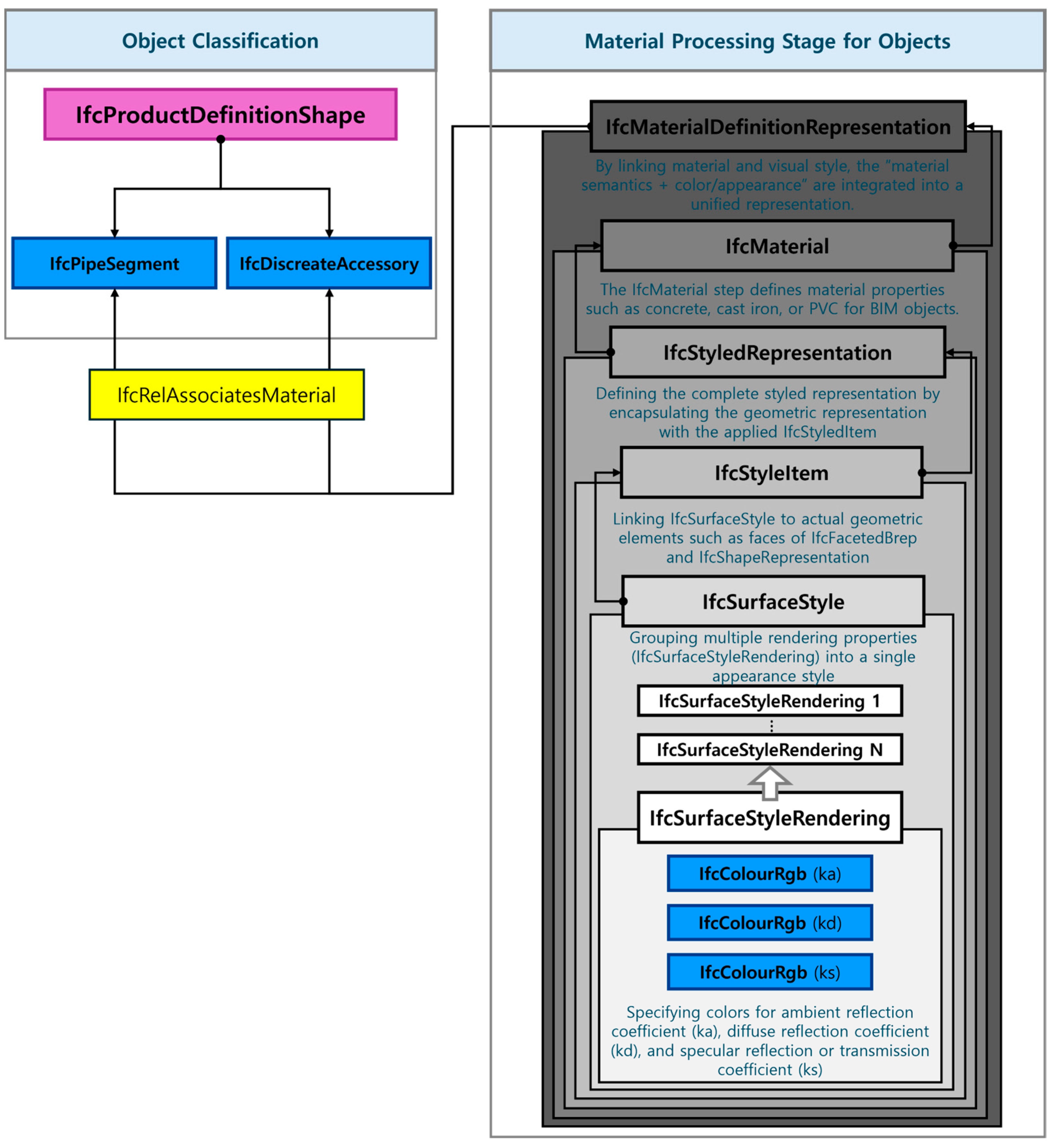

5.4. Processing of Material Information for BIM Objects

The processing and integration of material information in IFC-based BIM objects are carried out in the following steps. First, general material information is defined for each type of underground utility, and detailed material information is subsequently processed for each BIM object based on these definitions. Second, visual attributes are generated for the BIM object geometry, and these visual attributes are linked to the corresponding material information of the BIM objects.

For the visualization of underground utilities, it is common practice to apply color coding systems defined by national standards.

Table 3 presents examples of the designated color schemes adopted in major countries.

In this study, the material information of BIM objects was expressed using colors. For each type of underground utility, designated color information was defined in RGB (Red–Green–Blue) values using the IfcColourRgb class. In the BIM and AEC (Architecture, Engineering, and Construction) domains, it is standard practice to represent color values as floating-point numbers within the range of 0 to 1 rather than the conventional 0 to 255 range, and this convention was also adopted in this study.

The IfcSurfaceStyleRendering class defines rendering attributes and references the previously created IfcColourRgb objects to set color information. In addition to color, this class can specify various optional visual properties such as transparency, reflectance, and glossiness. The generated rendering properties are integrated into a surface style through the IfcSurfaceStyle class. The IfcSurfaceStyle object is linked as an internal element of IfcStyledRepresentation, which assigns surface-level styles during the generation of IfcFacetedBrep geometry.

The IfcStyledRepresentation class constructs style-based shape representations, which are concretely defined by IfcStyledItem objects. These styled representations are visualized by BIM viewers or through Model View Definitions (MVD), enabling both material and geometry to be represented together for users.

To further specify the physical properties of materials, the IfcMaterial class was used to define major underground utility materials such as concrete, PVC, cast iron, and polyethylene (PE). The IfcMaterialDefinitionRepresentation class was then applied to connect IfcMaterial objects with IfcStyledRepresentation objects, thereby integrating visual representation with semantic information.

Finally, the

IfcRelAssociatesMaterial class was employed to link the generated BIM objects (e.g.,

IfcPipeSegment,

IfcDiscreteAccessory) with their material information. This process achieves a complete integration of geometry and material attributes within the BIM objects.

Figure 8 illustrates the step-by-step procedure of processing and integrating material information for BIM objects.

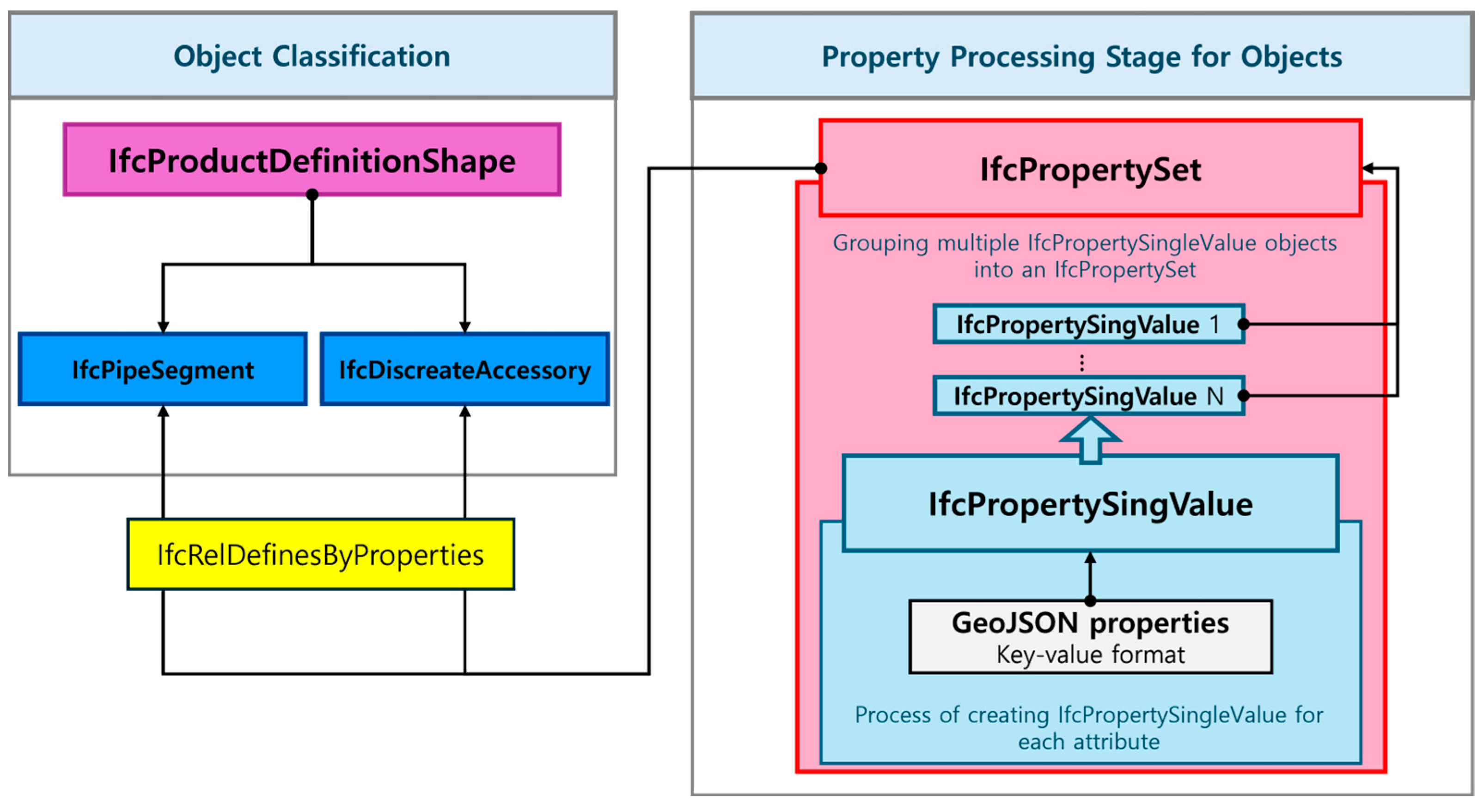

5.5. Processing of Attribute Information for BIM Objects

The attribute data stored in the

properties field of the GeoJSON-based three-dimensional spatial dataset are processed and integrated as attribute information within BIM objects. Through this procedure, the attribute information of underground utilities can be systematically managed as object-level properties within the BIM model.

Figure 9 illustrates the step-by-step process of processing and integrating attribute information into BIM objects.

The attribute information extracted from the properties field of GeoJSON is structured in a key-value format and converted into property data within the IFC schema. Specifically, each attribute is represented as an object using the IfcPropertySingleValue class. The converted attributes are then aggregated and managed as a single property set using the IfcPropertySet class. The resulting IfcPropertySet object is integrated with BIM objects (IfcPipeSegment or IfcDiscreteAccessory) through the pset.add_pset() API provided by IfcOpenShell.

Maintaining attributes at the level of individual IfcPropertySingleValue objects ensures flexibility for adding, modifying, or deleting properties in the future. Since attributes defined at the design stage are continuously updated due to design revisions or construction requirements, managing them as individual elements rather than as a single bundled object guarantees maintainability and extensibility of the attribute data.

The generated IfcPropertySet is linked to the corresponding BIM object (IfcPipeSegment or IfcDiscreteAccessory) through the IfcRelDefinesByProperties relationship class. As a result, all metadata defined in GeoJSON is systematically managed within the IFC structure and transformed into a format that supports editing and querying of properties in BIM software. In addition, material information is associated with objects through IfcRelAssociatesMaterial, resulting in BIM objects where geometry, material, and properties are fully integrated.

Finally, the conversion module merges all generated objects into a single integrated IFC file. In this process, geometric, material, and property information are combined without loss, producing a high-quality 3D IFC model that can be effectively utilized in construction planning and maintenance phases.

7. Conclusions

This study proposed an automated process that extracts location, geometry, and attribute information from standardized 2D CAD drawings, converts them into 3D BIM objects in IFC format through GeoJSON, and integrates WBS (work) and CBS (cost) data to construct a unified 5D BIM.

The proposed framework resolves data fragmentation between the design and construction phases and enables consistent management of the entire process—from drawing-based design to schedule planning and cost estimation—within a single IFC file. In particular, by adopting IfcWorkPlan, IfcTaskTime, IfcCostSchedule, and IfcProduct entities, a practical data management structure was established to integrate geometry, schedule, cost, and time information.

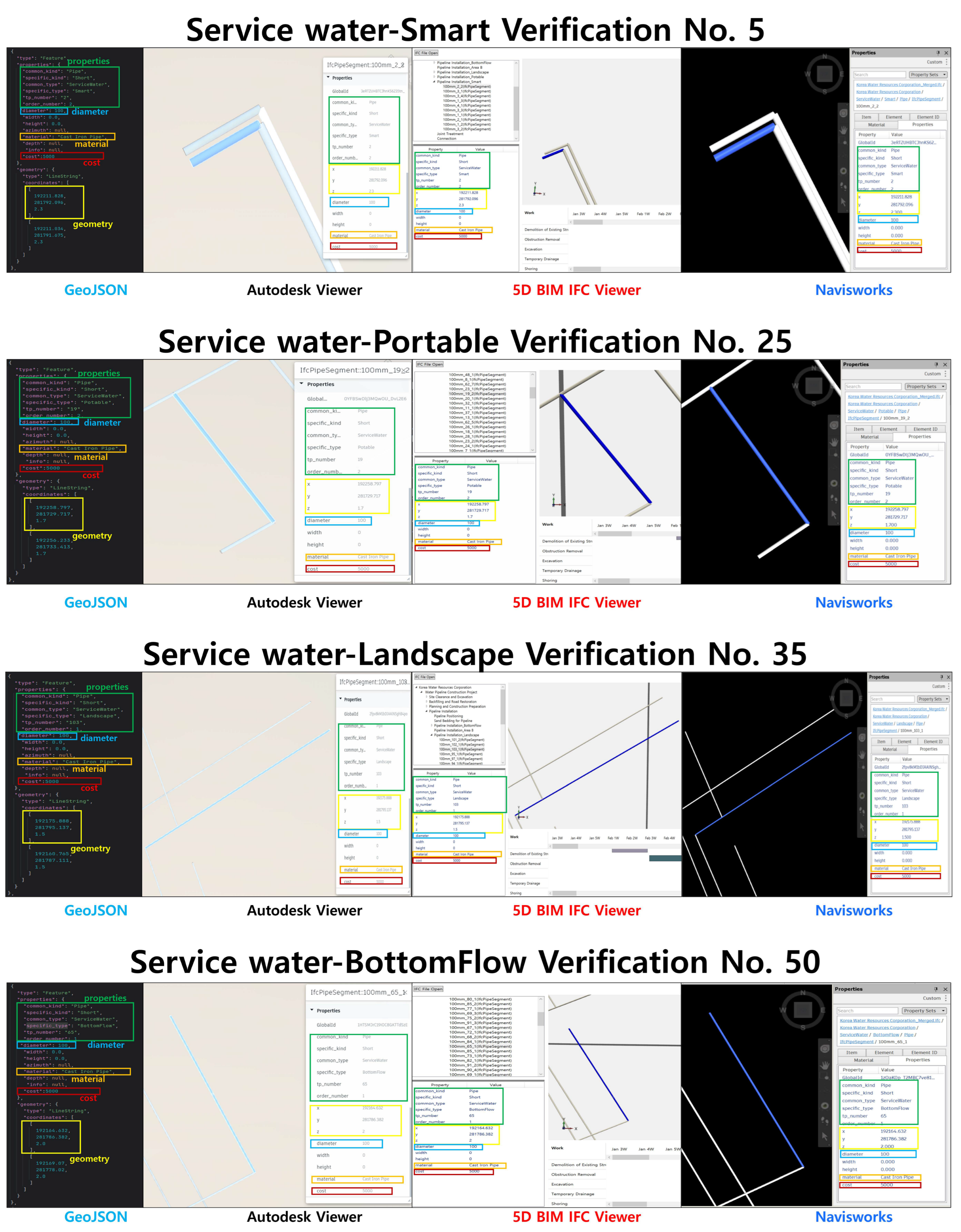

Validation confirmed that GeoJSON data were accurately converted and processed into IFC format without any omission or distortion. For fifty sample objects, positional, geometric, attribute, and cost data were compared, showing a 100% consistency rate. Cross-validation using Autodesk Web Viewer, Navisworks, and a custom IFC viewer also verified that all data precisely matched the original drawings. These results demonstrate that the proposed conversion and integration process ensures complete data integrity.

The engineering contributions of this study are as follows.

First, it provides a practical transition path that allows designers to continue working in a familiar 2D CAD environment while automatically generating 3D, 4D, and 5D deliverables. This reduces dependence on specialized BIM modeling skills and enables designers and field engineers to produce BIM-based outputs without costly software licenses or extensive training.

Second, as BIM technology becomes increasingly widespread across industries, many organizations face high costs for system adoption and retraining. The proposed approach serves as an efficient alternative that minimizes both system implementation and training costs by automatically generating BIM results while maintaining existing 2D design workflows.

Third, by adopting open standard formats such as GeoJSON and IFC, along with open-source tools, the framework reduces implementation costs and allows BIM data to be automatically updated whenever drawings are revised. This approach ensures consistency and currency between drawings and BIM model, while maintaining interoperability between BIM and GIS environments.

Lastly, by integrating geometric, schedule, and cost information within a single IFC model, the framework enhances project transparency and supports efficient data-driven decision-making in practical applications.

The limitations and applicability (Threats to Validity) of this study are as follows. The proposed process assumes standardized 2D CAD drawings; therefore, the accuracy of conversion may be reduced when using irregular or incomplete drawings. In addition, the current GeoJSON schema has limited capability to fully represent complex fittings or multi-geometry objects, and the WBS–CBS integration model operates on a static calendar basis. These limitations will be addressed in future studies through automated data preprocessing, enhanced object representation, and dynamic schedule–cost modeling extensions.

Future research will extend the proposed 5D BIM framework toward 6D (performance) and 7D (operation and maintenance) dimensions, incorporating lifecycle management capabilities that integrate long-term deformation monitoring, maintenance records, and sensor data. In addition, interoperability validation will be expanded through multi-project and multi-asset performance testing.

To advance the framework, additional functions will be implemented. The IFC4.3 Alignment and LinearPlacement entities will be applied to extend the approach to linear infrastructures such as roads and tunnels. A rule-based topological quality assurance (QA) layer will be introduced to detect spatial inconsistencies such as gaps, overlaps, and disconnections in advance. Furthermore, BCF (BIM Collaboration Format)–based issue management functions will be added to support collaborative design review and transparent version tracking.

These advancements will serve as a technical foundation for evolving the proposed CAD-to-IFC approach into a comprehensive and highly interoperable smart infrastructure management framework.

In conclusion, this study demonstrated a practical transition from 2D design to automated 3D, 4D, and 5D generation, presenting a quantitatively validated CAD-to-5D BIM pipeline that integrates geometry, schedule, and cost data without loss. The proposed approach accelerates the digital transformation of underground utilities and proves its practical applicability as a data-centric management framework characterized by low cost, high accuracy, and strong interoperability.