Abstract

The growing demand for sustainable materials has driven significant interest in composites reinforced with organic fibers, due to their mechanical performance, availability, and reduced environmental impact. This study investigates the mechanical behavior of two composite configurations: a cross-woven fabric and a sandwich-type panel, both made from totora (Schoenoplectus californicus) and low-density polyethylene–aluminum (LDPE–Al). Our experimental results show that the cross-woven variant achieved higher impact resistance (2.51 J), tensile strength (5.82 MPa), and greater deformation capacity (6.76%), making it more suitable for applications requiring energy absorption and flexibility, such as interior cladding and modular furniture. In contrast, the sandwich configuration exhibited superior stiffness (910 MPa), favoring structural panels and low-load roofing uses. This research distinguishes itself by integrating biodegradable totora fibers with recycled LDPE–Al to fabricate sustainable construction components, advancing circular economy principles while addressing limitations in previous composite formulations through improved mechanical balance and application-specific performance.

Keywords:

mechanical characterization; totora; LDPE–A; composite materials; natural fibers; sustainable materials; LDPE–Al; tensile strength; flexural strength; impact resistance; biodegradable composites; recycled materials; thermocompression; structural panels; circular economy; construction; sustainable architecture 1. Introduction

Composite materials have attracted considerable attention in recent years, due to their wide-ranging applications in the domestic, industrial, and offshore sectors. The composites market’s rapid economic growth reflects this increasing demand [1]. Defined as the macroscopic combination of two or more distinct materials to achieve superior properties compared to their components [2], composites offer significant advantages over traditional materials like wood, concrete, and steel [3,4]. Among the most promising developments are composites reinforced with natural fibers, which are attracting interest for their favorable mechanical performance, low cost, and environmental benefits. These include low density, water and impact resistance, biodegradability, high availability, renewability, and minimal health and ecological risks [5,6,7,8].

Recent reviews have emphasized both the promise and the limitations of hybrid bio-based composites reinforced with recycled matrices. Sriprom et al. [9] demonstrated that alkali-treated natural fibers significantly enhance the tensile and impact strength of recycled polystyrene composites, but they noted weaknesses in flexural performance. Suriani et al. [10] provided a broad overview of hybrid composites, highlighting persistent challenges in fiber–matrix adhesion, cost optimization, and processing methods. Similarly, Elfaleh et al. [11] identified hydrophilicity and moisture sensitivity as major drawbacks in natural fibers, requiring surface modification to improve compatibility with hydrophobic thermoplastics. Das and Chaudhary [12] discussed biofiber–polymer composites as sustainable alternatives to mitigate plastic pollution, while Kuzmanović et al. [13] critically assessed recycled-matrix composites and called for deeper exploration of interfacial behavior, viscosity effects, and structural heterogeneity. These findings collectively expose clear gaps in interfacial optimization, durability, and standardization—gaps this study aims to address through its novel LDPE–Al-and-totora-fiber system.

The transition to sustainable materials is increasingly urgent as the depletion of non-renewable resources and environmental degradation drive the need to replace conventional construction materials [14]. Even though wood is often perceived as eco-friendlier than steel or cement, the growing demand—expected to triple by 2050—has triggered the search for non-timber alternatives like palms, grasses, and aquatic plants [15,16]. In this context, totora (Schoenoplectus californicus), a fast-growing macrophyte traditionally used in Andean communities, emerges as a promising renewable material for structural and architectural applications [17]. Its anatomical and physical properties, combined with environmental advantages, such as reducing pressure on forest plantations, support its valorization as a sustainable construction input [16].

Complementing this is low-density polyethylene–aluminum (LDPE–A), a material derived from the recycling of Tetra Pak waste. This multilayer composite—composed of aluminum, polyethylene, and cardboard—has gained attention for its structural robustness and recyclability [18,19]. In Ecuador alone, over 7800 tons of Tetra Pak waste are generated annually, posing a significant waste-management challenge. However, studies have shown that recycling this material can reduce global warming potential by up to 48% [20], making its re-use a priority for sustainable innovation.

This paper investigates a novel composite material’s mechanical and structural potential by combining cross-woven or sandwiched totora fibers with recycled LDPE–Al through a thermocompression process. While previous studies have evaluated totora in the form of fibers, particles, or stems within polymer matrices [21,22,23,24,25,26,27] and LDPE–A in combination with plant fibers such as fique [28,29], this work proposes an integrated approach that merges traditional artisanal weaving techniques with recycled industrial materials. The result is a composite panel that exhibits mechanical performance, such as tensile strength, flexural resistance, and modulus of elasticity, comparable to other natural fiber-reinforced composites, while enhancing sustainability through biodegradable and recycled inputs.

The significance of this research lies in its contribution to the development of environmentally responsible, socially relevant, and technically viable construction materials. By demonstrating the structural capabilities and potential applications of totora-and-LDPE–Al composites, this study supports broader efforts in material circularity, local resource valorization, and sustainable architecture—positioning these composites as viable alternatives in the transition toward greener building systems.

This paper is organized to provide a structured analysis of the development, testing, and application potential of totora–recycled LDPE–A composites. Section 2 reviews the mechanical performance of totora and LDPE–Al materials from the existing literature, emphasizing their structural behavior and compatibility in composite systems. Section 3 outlines the manufacturing methodology for fabricating the composite panels, including the thermocompression process, specimen preparation, and standard-based mechanical testing. Section 4 presents the results of tensile, flexural, impact, and bulk density tests, analyzing the mechanical response of two composite configurations. Section 5 explores potential applications of the developed materials in sustainable architecture, such as interior panels and corrugated roofing, supported by visual documentation and real-use scenarios. Finally, Section 6 synthesizes the findings and proposes future research directions to optimize environmental performance and industrial scalability.

2. State of the Art

The process and material analysis stage involved extracting detailed information from the selected documents to gain insights into manufacturing methods, materials used, and the performance improvements of fabricated parts. This phase focused on identifying advancements in composite fabrication techniques, emphasizing enhancements over conventional processes. Key data included the efficiency of the materials, durability, and adaptability of natural fibers, like totora and recycled LDPE–Al composites, and comparisons to standard industrial practices. By thoroughly analyzing these aspects, this step established a comprehensive understanding of how these materials and methods contribute to improved performance, providing critical insights for practical applications and further experimentation.

The analysis revealed notable strengths in the characterization of natural fibers, particularly highlighting the exceptional qualities of totora for use in construction. Similar fibers, such as coconut coir, have been extensively investigated and applied in the production of bricks, as mortar and concrete reinforcement [30], and even as acoustic absorbers—applications in which totora has also shown promise [31]. Comparative studies with other Andean fibers used in architectural construction and textiles with thermoacoustic properties emphasize key performance indicators such as density, thickness, absorption coefficients up to 2000 Hz, and noise reduction ratings [32].

Totora, as a species, demonstrates substantial potential as a sustainable construction material. With a maximum plant height of 3.20 m and a stem diameter ranging between 0.5 and 5.0 cm, it presents both scalability and efficiency. Its remarkable density—reaching 280 aerial stems per square meter—reflects a prolific growth cycle, making it an abundant natural resource. The chemical composition of the plant—66.79% alpha-cellulose, 30.71% hemicellulose, and 27.8% lignin—confirms its structural integrity and resistance to environmental stressors. These properties reinforce its viability for construction applications, underscoring the value of continued research and integration of totora into sustainable building practices that respond to the rising demand for locally sourced, eco-friendly materials [33,34].

Totora, a resilient and fast-regenerating aquatic macrophyte, has garnered increasing attention in sustainable construction, due to its mechanical potential and ecological abundance. As evidenced in Table 1, the mechanical behavior of totora varies considerably depending on its processing and structural configuration. Among the tested forms, the woven-beam configuration reported by Mejía-Echeverría et al. (2017) [23] exhibits the highest compressive strength, with values surpassing 250 MPa. This outstanding performance can be attributed to the densification and load-sharing mechanisms introduced by interlaced fibers, which promote a more uniform distribution of applied forces—ideal for applications requiring energy dissipation and material resilience under axial loading.

Table 1.

Mechanical properties of different forms of totora as reported in the literature.

Conversely, the lowest flexural resistance is seen in the parallel configuration documented by Culcay et al. (2014) [35], with values under 0.2 MPa, emphasizing the directional sensitivity of mechanical behavior when fibers lack bonding or structural integrity. Interestingly, the laminated specimens exhibit intermediate performance, particularly those reported by Aza-Medina (2023) [36], where thinner samples (13 mm) yielded significantly higher flexural strength, almost ninefold compared to the thicker (50 mm) laminates from Culcay’s work. This suggests that thickness influences stiffness and internal stress propagation; thinner sections tend to compact better and allow for more efficient stress transfer across the fiber–matrix interface.

The crushed configuration introduced by Aza-Medina [36] reflects the structural compromise that occurs when the original geometry of the stem is lost, resulting in lower flexural resistance. Although still promising for lightweight filler applications, its performance is notably reduced. These observations underscore the importance of selecting appropriate geometrical and manufacturing parameters to harness totora’s mechanical potential. Thus, whether used in traditional beam construction or innovative bio-composites, optimizing form and dimension is key to engineering sustainable materials that leverage the full strength of this native plant.

Beyond pure totora applications, the integration of recycled LDPE–Al and polymer matrices further diversifies the scope of bio-based composites. Table 2 illustrates the mechanical properties of various hybrid materials incorporating totora and LDPE–Al under flexural and tensile testing. When totora is embedded within a polyester resin or combined with LDPE–A particles, the resulting composites maintain moderate strength. These results validate that totora is an effective reinforcement, even in recycled thermoplastic matrices. Importantly, the test outcomes adhered to ASTM standards, allowing fair comparison with industrial materials. Including natural and recycled inputs aligns these materials with circular economy principles. Moreover, the mechanical results for resin composites, particularly those using orthophthalic polyester, suggest viable applications for architectural panels and modular elements where moderate strength and reduced weight are essential.

Table 2.

Mechanical performance of composites using totora and recycled LDPE–Al.

The influence of fiber content on mechanical behavior is further dissected in Table 3. As totora content increases within polyester matrices, a trend of increasing Flexural strength becomes evident, while flexural strength decreases. This pattern likely results from the increased heterogeneity and porosity introduced by natural fibers at higher loadings. It demonstrates the classic challenge of balancing reinforcement volume with matrix integrity in composite engineering. Optimizing fiber–matrix ratios is critical to achieving tailored mechanical responses. Although the highest percentage of totora reduces tensile capability, the initial increment provides a gain in flexural performance, which may be beneficial in bending-dominated structures like roofing tiles or cladding boards. These insights are particularly useful for future formulations aiming to combine performance with sustainability in building materials.

Table 3.

Effect of totora content on tensile and flexural strength of polyester resin composites.

Expanding the context, Table 4 compiles mechanical responses of construction systems incorporating totora into traditional substrates such as concrete and adobe. The addition of totora into cementitious matrices offers tangible compressive strength improvements at moderate inclusion levels, although excessive fiber content can lead to reductions, due to poor compaction and void formation. In adobe, the trend is more pronounced, with strength decreasing as fiber concentration rises—suggesting that while totora offers bridging potential, its influence must be carefully balanced. Interestingly, a composite with particulate totora at moderate concentrations exhibits favorable tensile and flexural values, indicating a sweet spot where the fiber–matrix interaction enhances energy absorption and cracking resistance. These findings are crucial for low-cost, sustainable housing solutions in rural or semi-urban areas where totora is regionally abundant [34].

Table 4.

Performance of construction materials incorporating totora fibers; source: Aza-Medina (2023) [36].

Finally, Table 5 summarizes the mechanical behavior of LDPE–Al-based panels and sandwich structures. Flexural properties were assessed following ASTM D790-17 [38], which provides a reliable measure of a material’s behavior under three-point bending. Tensile properties is evaluated using specimens prepared by ASTM D3039M-17 [39], a reference method for polymer matrix composites reinforced with continuous fibers. ASTM D143-94 [40], which outlines the procedures for determining the strength and related mechanical properties of wood using small, clear specimens. When reinforced with fique or shredded Tetra Pak, these composites exhibit excellent flexural performance, exceeding the limits typically associated with recycled plastics. The use of sandwich configurations and corrugated geometries contributes to improved stiffness and energy distribution, making them attractive for interior partitions or prefabricated modular components. Their compressive strength, particularly in thick LDPE–Al boards, supports their use in non-load-bearing structural applications where light weight and durability are required. These materials not only close the recycling loop for composite waste but also showcase how simple processing variations can yield significant property enhancements. Taken together, the data in these tables confirm the versatility and potential of totora-and-LDPE–A-based composites in advancing eco-conscious construction materials.

Table 5.

Mechanical properties of LDPE–Al panels and sandwich structures; source: Hidalgo-Cordero (2020) [37].

3. Experimental Results

The experimental development of totora-and-LDPE–Al composite panels involved a controlled thermocompression process, utilizing a methodology inspired by Hidalgo-Cordero (2020) [37]. This approach capitalizes on the re-use of post-consumer Tetra Pak packaging—composed primarily of low-density polyethylene (LDPE) and aluminum—and its integration with natural totora fibers to produce a hybrid material with sustainable and functional properties.

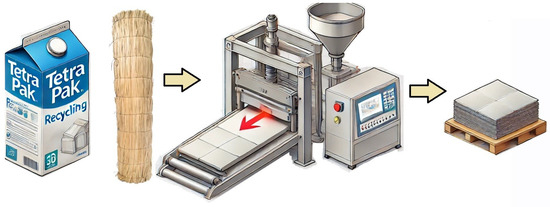

Figure 1 illustrates the manufacturing sequence. The process begins with the collection and mechanical shredding of used Tetra Pak containers. In parallel, bundles of dried totora stems are prepared, often processed into cross-woven mats or fiber-aligned layers depending on the desired reinforcement pattern. Both materials are then arranged in a mold and introduced into a high-temperature compression molding press. This equipment, capable of reaching 300 °C and exerting pressures up to 300 kN, ensures that the LDPE–Al matrix melts sufficiently to encapsulate the totora structure, promoting strong interfacial bonding. The press’s mold opening, extending up to 175 mm, offers flexibility in panel thickness, accommodating diverse construction needs such as tiles, partition panels, or insulating layers [41,42].

Figure 1.

Sequential process for fabricating totora and LDPE–Al composite panels, from raw material recycling to hot-press molding and final stacked products.

The result is a high-strength, lightweight composite panel composed entirely of recycled and natural components. This fusion of traditional botanical material with thermoplastic aluminum waste reduces environmental impact and creates new value chains in green construction. The image in Figure 1 underscores the simplicity and scalability of the process, from raw input to finished modular units. Guided by directional arrows, each stage—material selection, compression, and output—is clearly delineated. By merging artisanal and industrial practices, the process affirms that totora’s historical relevance can evolve into a modern, eco-efficient material platform for sustainable infrastructure.

The development of the totora-and-LDPE–Al composites was executed through a collaborative process rooted in artisanal expertise and supported by structured thermocompression techniques. According to the methodology outlined by Jara (2018) [43], the LDPE–A matrix material—supplied by Ecuaplastic S.C.—was combined with totora harvested from the San José de la Laguna Parish in Otavalo, Ecuador. The fabrication process, led by the artisan group Totorawasi under the direction of Marta Gonza, followed a thermal cycle gradually increasing from (160 °C) to (180 °C), sustained over 35 to 45 min. This temperature range enabled a progressive fusion of the LDPE–Al component without compromising the structural integrity of the totora fibers, thereby facilitating effective interfacial adhesion and minimizing thermal degradation of the plant matrix.

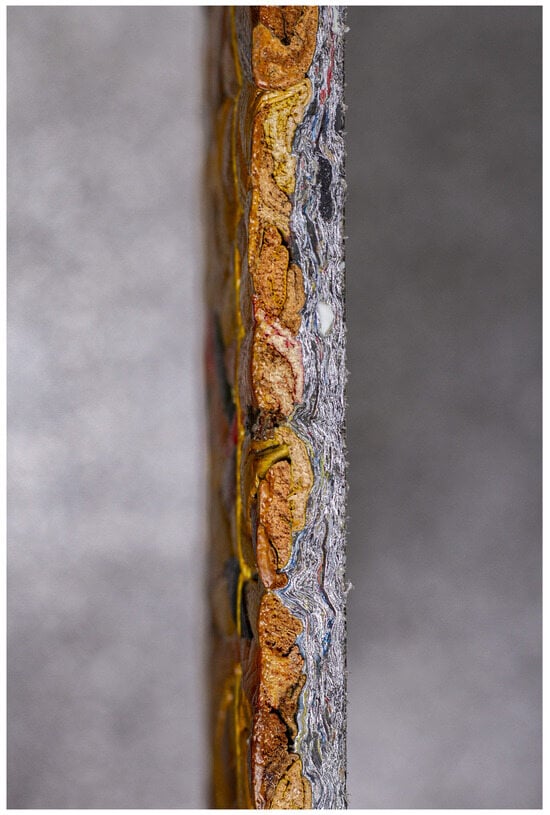

Two distinct composite configurations emerged from this method. The first variant, shown in Figure 2, integrates a cross-woven totora surface directly bonded to an LDPE–A layer. This approach preserves the traditional weaving technique and enhances the material’s anisotropic mechanical behavior by orienting fibers orthogonally. The second configuration, illustrated in Figure 3, adopts a sandwich structure, encapsulating a core of totora between two external LDPE–Al layers. This symmetric laminate mimics the structure of engineered panels, providing improved dimensional stability and environmental resistance.

Figure 2.

Cross-section of a composite specimen featuring a cross-woven totora mat fused with LDPE–A, using thermocompression.

Figure 3.

Sandwich-structured composite specimen: totora core encapsulated between two outer layers of thermocompressed LDPE–A.

Both composites exemplify the synergy between biodegradable plant material and recycled thermoplastics, offering an environmentally responsible alternative to conventional rigid panels. Their contrasting architectures allow for tailored performance in construction applications, from interior cladding and partition walls to acoustic panels and lightweight structural elements. These experimental forms were selected based on preliminary fabrication feasibility and structural logic, and they reflect not only the mechanical potential of the hybrid but also the cultural relevance of integrating local materials and knowledge into modern fabrication techniques.

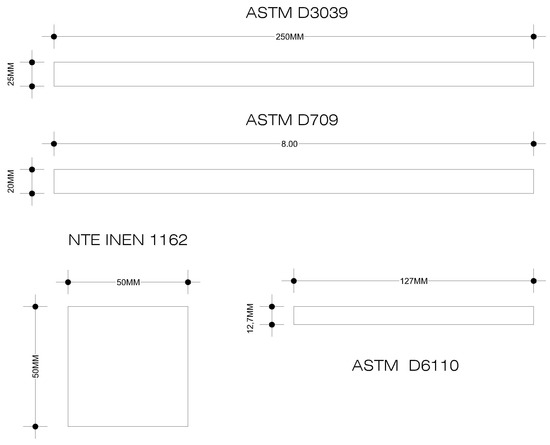

The characterization of the totora-and-LDPE–Al composite required the preparation of test specimens that conformed to established international and national mechanical testing standards. These standards were selected to assess the composite’s performance under various stress conditions commonly encountered in structural applications. Tensile properties were evaluated using specimens prepared in accordance with ASTM D3039M-17 [39], a reference method for polymer matrix composites reinforced with continuous fibers. Flexural properties were assessed following ASTM D790-17 [38], which provides a reliable measure of a material’s behavior under three-point bending, particularly for materials with anisotropic characteristics like fiber-reinforced laminates. Impact resistance was tested using the ASTM D6110-18 standard [44], which employs a Charpy configuration to quantify energy-absorption capacity. Finally, compressive strength was assessed, using specimens prepared as per the Ecuadorian standard NTE INEN 1162 [45], which is specifically oriented toward evaluating bulk materials under compressive loads.

The composite boards composed of cross-woven or sandwiched totora and LDPE–A were first fabricated through the thermocompression process previously described and then precision-cut using a table saw. This ensured consistent geometry and minimal surface defects, maintaining a dimensional tolerance within 2 mm to guarantee testing repeatability. The cut samples were classified and grouped according to the testing protocol they were intended for.

Figure 4 illustrates the exact dimensions of each test specimen format. The tensile specimens for ASTM D3039 were 250 mm long and 25 mm wide, suitable for uniaxial tensile testing. The flexural test specimens, based on ASTM D790, were similarly 250 mm in length but narrower at 20 mm to meet the span-to-depth ratio requirements. The ASTM D6110 specimens for the Charpy impact tests were prepared with dimensions of 127 mm in length and 12.7 mm in thickness, allowing precise measurement of fracture energy. The compression specimens, complying with NTE INEN 1162, were square sections of 50 mm by 50 mm, appropriate for assessing load resistance in planar directions. This dimensional rigor ensured the validity and comparability of the results, establishing a robust foundation for interpreting the mechanical behavior of the innovative composite.

Figure 4.

Standardized specimen dimensions for tensile (ASTM D3039), flexural (ASTM D790), compression (NTE INEN 1162), and impact resistance (ASTM D6110) testing of totora-and-LDPE–Al composites.

The development and evaluation of the totora-and-LDPE–Al composite material followed a structured methodology encompassing raw material selection, fabrication, and mechanical testing. The main stages have been synthesized into a step-by-step algorithm to facilitate reproducibility and offer a clear overview of the entire process, as shown in Algorithm 1. The approach begins with acquiring recycled Tetra Pak packaging and locally sourced totora reeds, followed by specific preparation methods tailored to each material—shredding in the case of LDPE–Al and cutting or weaving for totora. The components are then layered and subjected to thermocompression at controlled temperatures and pressures, producing composite panels with either cross-woven or sandwich structures. After cooling, these panels are cut into standardized specimens, using a precision table saw, ensuring dimensional consistency with a tolerance of ±2 mm. The specimens are tested under widely accepted standards, including ASTM D790-17 [38], ASTM D3039M-17 [39], ASTM D6110-18 [44], and NTE INEN 1162 [45], covering tensile, flexural, impact, and compressive behavior, respectively. This algorithmic representation not only consolidates the methodology but also facilitates its adoption in similar studies involving natural fiber–thermoplastic composites, particularly those leveraging traditional materials like totora in sustainable engineering applications.

| Algorithm 1 Fabrication and testing procedure for totora-and-LDPE–Al composite material |

|

4. Results and Evaluation

The tensile behavior of the developed totora-and-LDPE–Al composites was evaluated using a Shimadzu Autograph AGS X 50 kN testing machine, adhering to the ASTM D3039M-17 standard for polymer matrix composites. A total of seven specimens, drawn from two composite configurations—cross-woven and sandwich—were tested to assess their uniaxial tensile performance. All the tests were conducted under controlled ambient conditions (temperature: 23 ± 2 °C, relative humidity: 50 ± 5%) with a constant crosshead speed of 2 mm/min, as recommended by the standard to ensure reproducibility.

Both composite types exhibited a clearly defined elastic region during initial loading, followed by a gradual progression toward rupture. Notably, the sandwich configuration showed a slightly higher tensile strength, suggesting improved load resistance due to the dual-layer reinforcement of LDPE–A encapsulating the totora core. In contrast, the cross-woven configuration demonstrated enhanced ductility, evidenced by its higher displacement and deformation prior to failure. These distinctions underscore the impact of internal structure on mechanical behavior: while the sandwich type provides superior tensile resistance, the woven configuration may better accommodate flexural or impact-driven applications, due to its greater strain capacity.

These findings confirm the structural viability of both composite designs, highlighting their potential as eco-friendly alternatives in architectural and light structural elements. The quantitative results, detailing maximum stress, displacement, strain, and failure load, are summarized in Table 6, which is expressed as mean values accompanied by standard deviation (mean ± SD). This statistical representation was obtained from repeated tensile tests on multiple specimens (n = 5 per configuration), allowing us to capture the consistency and dispersion of the mechanical performance. Such detail is essential to validate the repeatability of the tests and to reinforce the reliability of the mechanical behavior observed in totora-based materials.

Table 6.

Tensile test results for totora-and-LDPE–Al composite specimens (mean ± SD).

The flexural performance of the totora-and-LDPE–Al composites was evaluated using a Shimadzu Concrete 2000X testing machine (Shimadzu Corporation, Kyoto, Japan). following the ASTM D790-17 standard for determining flexural properties of reinforced plastics. This phase of the study included fourteen cross-woven specimens and seven sandwich-type specimens. In the cross-woven configuration, two test orientations were considered to investigate the influence of fiber positioning: the specimens were loaded with the fiber layer placed either at the bottom (“under fiber”) or at the top (“top fiber”), relative to the direction of bending.

The results clearly indicate that the cross-woven configuration provides enhanced flexural capacity compared to the sandwich structure. When the totora fiber layer was positioned on the tension side (top fiber) the specimens exhibited the highest flexural strength, supporting a maximum weight of 118.57 N. In contrast, the specimens tested with the fiber positioned on the compression side (under fiber) carried slightly less, with a peak load of 115.71 N. Although the difference is modest, it reveals the effect of fiber placement relative to the neutral axis, confirming that strategic fiber orientation can improve the structural response of the composite under bending loads.

The sandwich-type specimens, which encased the totora layer between two sheets of LDPE–A, recorded the lowest flexural strength, with a maximum load-bearing capacity of 86.14 N. This performance gap underscores the mechanical advantage of continuous fiber distribution and highlights the benefits of interlacing techniques in distributing stresses during flexural loading.

Table 7 summarizes the geometric parameters, mass, and maximum force recorded during testing. These data provide quantitative support for the conclusion that the cross-woven configuration, particularly with optimized fiber orientation, offers superior mechanical performance for applications where bending resistance is critical.

Table 7.

Flexural test results for totora-and-LDPE–Al composite specimens (mean ± SD).

The impact resistance of the totora-and-LDPE–Al composites was assessed using a pendulum-type impact-testing machine (IMPACTEST series, Ibertest brand), following the guidelines established by ASTM D6110-18 for Charpy tests. The objective was to determine the energy-absorption capacity of the materials under sudden loading, simulating the real-world impact conditions that such panels may experience during handling, transportation, or in-service use. Seven specimens of each composite type—cross-woven and sandwich—were evaluated to ensure result consistency.

The results from the tests revealed that the cross-woven configuration exhibited significantly higher impact resistance compared to the sandwich variant. This enhanced performance is attributable to the interlaced structure of the fibers, which promotes a more even distribution of impact forces across the surface and throughout the thickness of the material. The cross-woven samples absorbed more energy upon fracture and exhibited a higher resilience index, underscoring their ability to dissipate dynamic loads without catastrophic failure.

Although the sandwich-type specimens demonstrated lower impact resistance, they still absorbed a moderate amount of energy, indicating their suitability for non-structural applications or environments where mechanical shocks are limited. The comparative results emphasize the critical role of fiber architecture in governing energy dissipation mechanisms, suggesting that the cross-woven configuration is a more appropriate solution for components requiring impact tolerance—such as wall claddings, partition panels, or lightweight enclosures.

A summary of the energy absorption values (KV), resilience (Ur), and cross-sectional area of the specimens is provided in Table 8, offering a concise reference for interpreting the mechanical differences between the two designs.

Table 8.

Charpy impact resistance test results for totora-and-LDPE–Al composites (mean ± SD).

Bulk density was evaluated according to the NTE INEN 1162 standard, using a LEADZM B30002T 3000 g electronic balance and a precision calibrator. This test aimed to determine each composite configuration’s relationship between mass and volume. Five specimens from both the cross-woven and sandwich-type composites were analyzed. Although both configurations presented similar mass values, slight differences in volume resulted in measurable variations in bulk density. These results offer insights into each structure’s internal packing and fiber–matrix interface, which can influence mechanical stiffness and structural performance.

To consolidate the mechanical characterization of the totora-and-LDPE–Al composites, key parameters such as Young’s modulus, Poisson’s coefficient, ultimate tensile strength, elastic (yield) strength, flexural stress, impact resistance, and bulk density were calculated, using standardized procedures. Tensile properties were derived following ASTM D3039M-17, revealing that both materials exhibited comparable ultimate tensile strength, with the sandwich configuration showing slightly higher yield strength. Flexural behavior, measured according to ASTM D790-17, reinforced the previous observation that the sandwich specimens achieved a marginally higher flexural stress. Impact resistance, tested via ASTM D6110-18, confirmed the superior energy absorption of the cross-woven configuration, consistent with its fiber-interlaced architecture.

The mechanical results summarized in Table 9 encapsulate the performance profile of both composite types. Notably, the cross-woven material demonstrated higher impact resistance and lower stiffness (Young’s modulus), favoring applications requiring ductility and shock absorption. In contrast, the sandwich configuration showed greater rigidity and compactness, reflected in its higher modulus and lower density. These complementary behaviors suggest that each design can be strategically deployed according to functional requirements, whether flexibility under load or structural stiffness in compression or bending.

Table 9.

Mechanical properties of the totora-and-LDPE–Al composite materials (mean ± SD).

The statistical significance analysis in Table 10 determined whether the observed differences between the cross-woven and sandwich composites were statistically significant; an independent two-sample t-test was conducted for each mechanical property, using mean, standard deviation, and n = 5 specimens per configuration. The test revealed statistically significant differences (p < 0.01) in impact resistance, strain capacity, and Young’s modulus, confirming that fiber configuration plays a critical role in mechanical performance. The differences in tensile and flexural strength, although measurable, were not statistically significant (p > 0.05). This analysis supports the material selection criteria and validates the experimental results beyond descriptive trends.

Table 10.

Statistical comparison between composite configurations (two-sample t-test results).

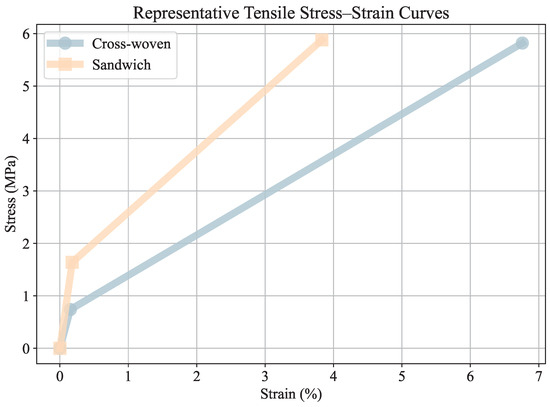

Figure 5 and Figure 6 present representative stress–strain curves for the tensile and flexural behavior of the cross-woven and sandwich composites. The tensile curve (Figure 5) highlights the greater ductility of the cross-woven configuration, which exhibited higher strain before failure, whereas the sandwich structure showed a stiffer yet more brittle response. Similarly, the flexural curve (Figure 6) confirms that the cross-woven composite could endure greater deformation under bending loads, although both configurations reached comparable stress peaks. These differences illustrate how fiber arrangement significantly influences energy dissipation and stiffness, guiding material selection based on performance requirements in structural or architectural applications.

Figure 5.

Representative stress–strain curves for tensile tests of cross-woven and sandwich composites, based on average mechanical parameters.

Figure 6.

Representative flexural stress–strain curves for cross-woven and sandwich composite configurations.

A comparative analysis was conducted to contextualize the mechanical performance of the totora–LDPE–A composite within a broader spectrum of natural fiber-reinforced composites. The results, summarized in Table 11 and Table 12, show that while the totora–LDPE–A material offers moderate strength, it trails behind certain polymer matrix composites reinforced with higher proportions of continuous or aligned natural fibers.

Table 11.

Comparison of mechanical properties: totora-and-LDPE–Al vs. totora–polymer composites.

Table 12.

Comparison of mechanical properties: totora-and-LDPE–Al vs. other natural fiber composites.

Table 11 reveals that the epoxy and polyester matrices reinforced with woven or long totora fibers outperformed the LDPE–A matrix in ultimate tensile strength and flexural strength, with differences as high as 45 MPa and 60 MPa, respectively. Notably, the SINTAPOL (commercial polyester resin) 2074 polyester compound with totora achieved an ultimate tensile strength of 65 MPa and a flexural strength of 78 MPa [23]. However, the totora-and-LDPE–Al composite exhibited a slightly higher modulus of elasticity than some polyester-based alternatives, suggesting that the aluminum matrix imparts a stiffer behavior, despite limited ductility.

When compared to composites reinforced with other natural fibers (Table 12), such as fique or jute, the totora–LDPE–A variant maintained moderate performance. Fique-reinforced LDPE–A achieved tensile strengths up to 63 MPa and modulus values over 6 GPa [28], which significantly exceeded those of the totora-based system. Nonetheless, the PLA-based biocomposites and starch–bamboo blends showed either lower modulus or tensile performance, indicating that the totora-and-LDPE–Al blend holds competitive value among biodegradable alternatives.

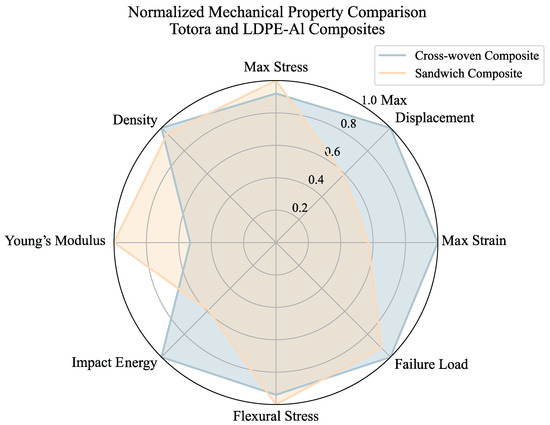

The radar chart presented in Figure 7 offers a comprehensive overview of the normalized mechanical performance of two composite specimens based on totora (Schoenoplectus californicus) fibers reinforced with LDPE–aluminum. This visualization enables a direct comparison between the cross-woven composite and the sandwich composite across eight key mechanical properties, including tensile stress, strain, flexural behavior, impact resistance, and material density. As shown, the cross-woven composite exhibits superior displacement and strain capabilities, indicating greater ductility, while the sandwich composite excels in stiffness, particularly reflected by its higher Young’s modulus. This trade-off highlights the importance of design selection according to the mechanical demands of a specific application. From a materials science perspective, this kind of mapping is essential to optimize the use of native plant fibers like totora in modern composite engineering, ensuring their integration does not compromise structural reliability. The use of normalized values ensures that all parameters contribute equitably to the comparison, regardless of their original scale, thus supporting more informed material selection decisions in eco-conscious architecture and lightweight structural applications [50,51].

Figure 7.

Normalized mechanical property comparison between cross-woven and sandwich totora–LDPE–Al composites across eight performance metrics. The radar chart highlights differences in strain capacity, stiffness, impact resistance, and density.

The bar chart in Figure 8 provides a valuable benchmarking comparison between the totora–LDPE–Al composites developed in this study and other natural fiber-reinforced polymer systems documented in the recent literature. The use of a logarithmic scale enables a wide range of mechanical properties—ultimate tensile strength, modulus of elasticity, and flexural strength—to be visualized clearly, despite their differing orders of magnitude. This chart demonstrates the relatively modest mechanical values of the LDPE–Al–totora composites when compared to high-performance systems like SINTAPOL or epoxy-based reinforcements. However, these results must be contextualized within sustainability, cost, and processing advantages. For instance, while synthetic resins yield higher mechanical outputs, they often entail greater environmental costs. The combination of totora fibers with recycled polyethylene–aluminum not only promotes circular economy principles but also delivers acceptable mechanical performance for medium-load applications. This graphical synthesis underscores that the real contribution of the presented material lies not merely in competing with petrochemical-based composites, but in offering an ecologically responsible alternative that supports local economies and utilizes indigenous plant resources like totora in value-added product development.

Figure 8.

Logarithmic comparison of mechanical properties (ultimate tensile strength, modulus of elasticity, and flexural strength) of the totora–LDPE–Al composite versus other natural fiber-reinforced polymer systems reported in the literature.

The selected thermocompression temperature range of 140–180 °C was determined based on preliminary trials and the literature indicating the softening behavior of recycled LDPE–Al blends. According to Hidalgo-Cordero et al. [16], LDPE–Al begins to exhibit matrix plasticity and adhesion around 160–200 °C, while studies like Collado Cárdenas [19] demonstrate sufficient matrix flow without thermal degradation near 180 °C. Although no differential scanning calorimetry (DSC) analysis or dynamic mechanical analysis (DMA) were performed in this study, these tools would indeed support future optimization by characterizing thermal transitions and improving processing fidelity between the LDPE–Al matrix and totora fibers.

Overall, this analysis confirms that while the current configuration of the totora–LDPE–A composite offers promise, especially in applications requiring rigidity and recyclability, further optimization is needed, particularly in enhancing fiber–matrix adhesion and reducing brittleness, to close the performance gap with established fiber-reinforced composites.

5. Potential Applications in Sustainable Construction and Design

Composite materials formed from recycled LDPE–Al and natural fibers such as totora (Schoenoplectus californicus) are gaining traction in construction and eco-industrial applications, due to their mechanical adaptability and environmental benefits [52]. Prior research by Jara et al. [43] showed that increasing the proportion of fique fibers in LDPE–Al matrices improves tensile strength, stiffness, and flexural performance, with a 50/50 fiber-to-matrix ratio yielding optimal results [43]. This provides a relevant foundation for exploring similar synergies with other plant fibers such as totora.

In the present work, multiple composite prototypes were fabricated using totora in different forms: woven sheets, fiber cords inspired by Kichwa weaving practices, and processed pulp. These natural elements were combined with recycled LDPE–Al and alternative binders, including starch-based adhesives, polyvinyl acetate, and laminated plastic waste. The integration of totora and recycled thermoplastics resulted in material compositions suitable for varying degrees of rigidity and surface finish, depending on the weaving pattern and binder configuration.

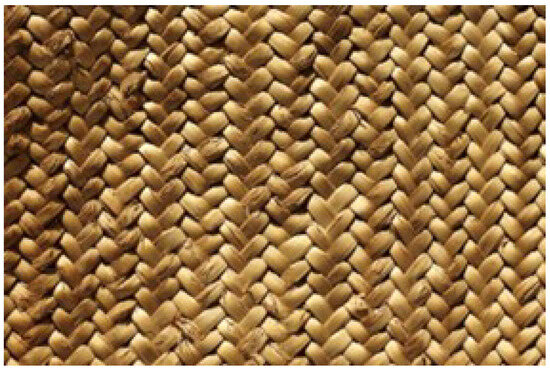

Figure 9 and Figure 10 present two key woven configurations developed during the study. Figure 9 illustrates the cross-weave pattern, characterized by orthogonal strand interlacing that provides dimensional stability and structural integrity. This configuration is well-suited for load-bearing applications such as internal wall panels, ceiling tiles, or modular partitions. In contrast, the design in Figure 10 features a tighter, interlaced weave that enhances pliability while maintaining surface cohesion. This structure is advantageous in applications requiring curved surfaces, decorative coverings, or elements exposed to moderate deformation. Both weave types underscore the aesthetic and mechanical versatility of totora-based composites, highlighting their suitability for sustainable architecture and design innovations grounded in circular economy principles.

Figure 9.

Cross-weave configuration of totora combined with recycled LDPE–Al. The orthogonal pattern promotes mechanical stiffness and is ideal for modular, rigid applications.

Figure 10.

Interlaced weave of totora reinforced with recycled LDPE–Al. The denser pattern improves flexibility and is suited for adaptive and decorative construction elements.

Figure 11 presents a visual narrative of the development process of totora-and-LDPE–Al composite materials, showcasing a sequence that begins with artisanal craftsmanship and concludes in industrial transformation. The upper portion of the image displays a diverse set of weaving styles developed with totora fibers—dyed, structured, and assembled into intricate patterns using traditional techniques. These were prepared in collaboration with Totarawasi and Totorarotot, whose contribution preserved the cultural identity of the materials through their ancestral weaving knowledge. In the lower frames, one can observe the scale-up process carried out at Ecuaplastic S.C., a critical partner in the material’s industrial development. The images depict the manual transport and mechanical cutting of thermoformed panels, emphasizing the ease of handling and dimensional consistency of the final products. Thanks to the infrastructure and technical expertise provided by Ecuaplastic S.C., it was possible to combine natural fiber craftsmanship with recycled LDPE–Al through a precise thermocompression process. The resulting panels, assembled from colorful and textured totora layers bonded with recycled polymer matrix, demonstrate aesthetic richness, structural integrity, and sustainability. This workflow exemplifies the success of a hybrid approach that bridges artisan practice with industrial innovation, enabling environmentally conscious material solutions for construction and design.

Figure 11.

Artisanal preparation and early-stage fabrication of totora-and-LDPE–Al composites. Weaving patterns, cutting, and assembly phases are shown.

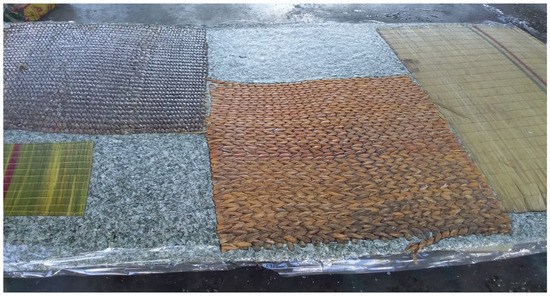

Figure 12 and Figure 13 highlight the refinement and scaling capabilities made possible through the support of Ecuaplastic S.C., whose production facilities enabled the thermocompression of handwoven totora into full-format composite panels. In Figure 12, a close-up captures the vivid surface of a dyed, interlaced weave, laid over a uniformly pressed recycled matrix. The fusion of colors and fiber texture offers not only mechanical reinforcement but also an aesthetic identity well-suited for interior finishes and custom architecture. This panel, prepared through manual layering and machine-pressing, represents a fusion of artisanal quality with industrial-grade durability. Figure 13 shows a multi-section experimental board integrating various weave geometries into a single unit, allowing comparative evaluation of adhesion, rigidity, and visual consistency. These prototypes are essential for iterating technical parameters such as fiber saturation, panel thickness, and surface adhesion. Their production was only possible thanks to the collaborative environment at Ecuaplastic S.C., where academic research, local tradition, and material engineering intersected. Through this partnership, the project succeeded in converting waste materials and renewable biomass into panels that meet structural performance expectations while aligning with circular economy values, offering tangible solutions for sustainable and culturally rooted construction.

Figure 12.

Detail of multi-colored woven totora surface integrated into recycled LDPE–Al matrix during the Ecuaplastic fabrication process.

Figure 13.

Full-format composite prototype incorporating diverse totora weave styles and recycled matrix sections, manufactured at Ecuaplastic S.C.

The composite panels developed in this study exhibit significant versatility, enabling their application in diverse architectural and interior environments. Potential uses include wall claddings, floor coverings, false ceilings, modular furniture, cabinetry, and ventilated facades. Figure 14 displays two manufactured flat panels featuring a richly colored interlaced weave. These panels demonstrate how natural totora fibers, when combined with recycled LDPE–Al, can result in high-performance materials that are both visually distinctive and mechanically robust. The interplay between the natural fiber texture and the laminated thermoplastic matrix not only provides strength and dimensional stability but also adds an artisanal aesthetic, ideal for contemporary and heritage-sensitive design contexts.

Figure 14.

Flat composite panels manufactured with interlaced totora fibers and recycled LDPE–Al. Their uniformity and decorative texture make them suitable for interior architecture applications such as walls, ceilings, or furnishings.

In addition to flat panels, corrugated composite sheets were fabricated to explore structural applications, particularly in roofing. As shown in Figure 15, these sheets incorporate a cross-weave of totora fibers embedded in a recycled LDPE–Al matrix, shaped through thermoforming into a sinusoidal profile. The corrugated geometry significantly enhances mechanical stiffness and improves water runoff management—two critical requirements for roofing systems. These panels achieve a balance between material flexibility and structural durability. Optimization of the fiber–matrix composition was essential in tuning performance characteristics, including impact resistance and load-bearing capacity, which are directly influenced by the density and orientation of the reinforcing fibers. These innovations represent a sustainable, locally sourced alternative to conventional roofing materials, offering an environmentally responsible solution for rural and low-income housing initiatives.

Figure 15.

Corrugated composite panel using cross-woven totora and LDPE–Al matrix. The undulating geometry enhances structural integrity and promotes water drainage for roofing applications.

Despite the promising performance and versatility observed in preliminary testing, the proposed totora-and-LDPE–Al composite materials still require extensive mechanical and physical characterization to fully define their functional limits and long-term behavior. Early results indicate several favorable properties: dimensional stability under thermal cycling, improved mechanical strength over untreated totora, resistance to moisture absorption, thermoformability, and notable acoustic insulation performance. These attributes position the material as a viable solution for roofing applications, particularly in low-cost or sustainable housing initiatives where local resources and biodegradable inputs are prioritized.

As illustrated in Figure 16, the corrugated panels leverage the natural flexibility of totora and the structural reinforcement of LDPE–Al to create an effective roofing element. The undulating form improves both rigidity and hydrodynamic runoff, supporting their implementation in regions prone to heavy rainfall. Furthermore, their lightweight profile and ease of molding make them suitable for prefabricated assembly and modular construction.

Figure 16.

Thermoformed corrugated roofing panel manufactured with totora and recycled LDPE–Al. The structure promotes water drainage and mechanical efficiency for eco-friendly construction.

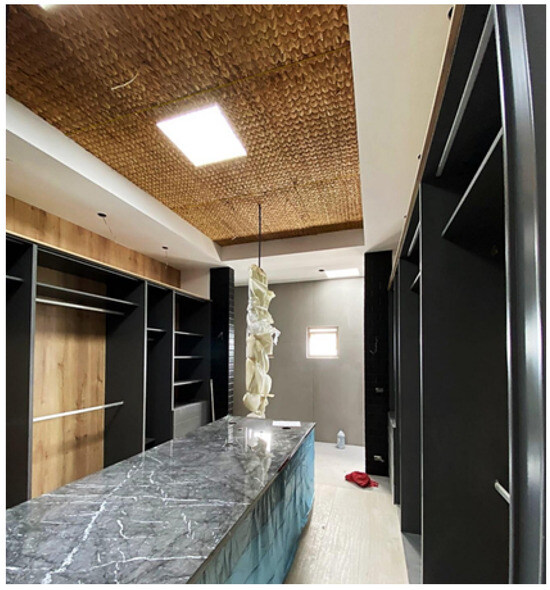

In addition to external structural use, these composites exhibit excellent potential in interior design. Figure 17 presents an application in ceiling architecture, where the material not only contributes structurally but also enhances the visual and textural identity of the space. The natural tone and fiber pattern of totora introduce warmth and organic appeal, while the recycled matrix ensures durability and longevity. Such applications illustrate the hybrid role of this material—as both a load-bearing and aesthetic element—demonstrating its adaptability across architectural scales. Continued exploration is needed to assess fire behavior, UV resistance, and lifecycle performance, which will support broader implementation in both commercial and residential environments.

Figure 17.

Ceiling application of totora-and-LDPE–Al composite panels. Their organic texture and reinforced structure contribute to both aesthetics and architectural functionality.

Totora, as a naturally abundant and biodegradable fiber, plays a central role in enhancing the environmental sustainability of the proposed composite panels. Compared to conventional synthetic composites, the incorporation of totora significantly reduces the environmental footprint of the material system. Among the two configurations studied, the composition with a higher percentage of totora exhibited superior biodegradability, offering promising end-of-life advantages. In contrast, the variant with greater polyethylene–aluminum content compromised biodegradability, due to the thermoplastic barrier, although it enhanced rigidity and durability under mechanical stress.

Despite these benefits, one of the key limitations in the current formulation lies in the recyclability of the composite. The intimate bonding between natural fibers and the LDPE–Al matrix complicates material separation and limits post-consumer re-use. This presents a technical challenge for advancing circular design principles in hybrid composites. Nevertheless, the intentional inclusion of recycled LDPE–Al—sourced from post-consumer Tetra Pak waste—contributes to mitigating the environmental burden of plastic and aluminum residues. This re-use strategy embodies a circular economy mindset by valorizing materials that would otherwise contribute to persistent pollution.

Moving forward, it is critical to advance research efforts in sustainable composite engineering. Future phases of this project will focus on comprehensive environmental and functional assessments. These include life cycle analysis (LCA), carbon footprint evaluation, durability and degradation testing, and the development of feasible strategies for mechanical or chemical separation of composite constituents. By coupling material innovation with rigorous sustainability metrics, we aim to refine the ecological and performance profile of totora-and-LDPE–Al panels. The broader goal is to establish these materials as viable alternatives in green construction—offering a balance between renewable content, recycled inputs, and long-term functional reliability in diverse architectural applications.

6. Conclusions

The literature review confirms that totora (Schoenoplectus californicus) significantly influences the mechanical properties of composite materials, with effects varying by composition. For instance, tensile strength in epoxy composites increases by up to 300% when totora fiber content rises from 5% to 35%, while flexural strength in adobe decreases by approximately 45% beyond 3% fiber addition. These results highlight the importance of fiber percentage and matrix compatibility in tailoring structural performance.

The manufacturing methodology developed in this study effectively integrates cross-woven and sandwich configurations of totora with recycled low-density polyethylene-aluminum (LDPE–Al), using thermo-compression processes that allow for material versatility. Combining biodegradable fibers with post-consumer thermoplastics promotes circular economy principles while enabling scalable production for construction-oriented applications.

Mechanical testing demonstrated that the cross-woven configuration achieved 41%-higher impact resistance than the sandwich type. In contrast, the sandwich composite exhibited a 47%-higher modulus of elasticity, confirming the importance of fiber orientation. These results validate the potential of this hybrid composite as a lightweight, rigid, and durable alternative for structural use.

Application-wise, the developed materials are suitable for ceilings, cladding, and corrugated roofing. Their thermoformability and acoustic properties, combined with natural fibers, position them as a sustainable substitute for traditional polymer-based panels. With proper waterproofing and material separation innovations, these composites can reduce plastic waste and promote regional biomaterial use in architecture and design.

Future work will focus on assessing the interfacial adhesion quality between LDPE–Al and totora fibers, using microscopic and mechanical techniques. Additional efforts will include long-term durability testing, fiber surface treatments, and matrix modification to improve mechanical bonding and overall performance. Furthermore, thermal analysis methods such as differential scanning calorimetry (DSC) and dynamic mechanical analysis (DMA) will be incorporated to precisely characterize the melting behavior and viscoelastic properties of the recycled LDPE–Al matrix. Future experimentation will also evaluate fire resistance, biodegradability in real environments, and UV or thermal aging, especially for applications like roofing. Additionally, failure mechanisms such as delamination or fiber pull-out will be analyzed, using microscopy to better understand fracture patterns and improve structural reliability.

Author Contributions

Methodology, conceptualization, formal analysis, software, resources, and validation, O.J.-V., W.P., A.R., F.A., M.G. and E.M.F.; investigation, O.J.-V., W.P. and E.M.F.; project administration and funding acquisition, O.J.-V. and E.M.F.; supervision, O.J.-V., W.P., F.A. and M.G.; visualization, W.P. and E.M.F.; writing—original draft preparation, W.P., F.A., M.G. and A.R.; writing—review and editing, O.J.-V., W.P., A.R., F.A. and M.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Universidad de las Américas, Universidad UTE and by Universidad Central del Ecuador.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

Our thanks to Ecuaplastic S.C. Ecuador in 2025.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Amaechi, C.V.; Agbomerie, C.O.; Orok, E.O.; Ye, J. Economic Aspects of Fiber Reinforced Polymer Composite Recycling; Elsevier: Amsterdam, The Netherlands, 2020. [Google Scholar] [CrossRef]

- Gómez-Suarez, S.; Córdoba Tuta, E.; Vega, C.; Gómez, S.A. Manufacture of Student Chair in Composite Material Reinforced with Fique Fiber. Sci. Tech. 2021, 26, 6–13. [Google Scholar] [CrossRef]

- Paredes Salinas, J.G.; Pérez Salinas, C.F.; Castro Miniguano, C.B. Análisis de las Propiedades Mecánicas del Compuesto de Matriz Poliéster Reforzado con Fibra de Vidrio 375 y Cabuya Aplicado a la Industria Automotriz. Enfoque UTE 2017, 8, 1–15. [Google Scholar] [CrossRef]

- Jeremic, N.; Zuccaro Marchi, L. Floating Towards Sustainable Future: Learning from Vernacular Waterborne. In Proceedings of the 2nd International Conference on Trends in Architecture and Construction: ICTAC-2024, Chandigarh, India, 9 April 2025; Lecture Notes in Civil Engineering. Springer Nature: Berlin/Heidelberg, Germany, 2025; Volume 527, p. 323. [Google Scholar] [CrossRef]

- Kerni, L.; Singh, S.; Patnaik, A.; Kumar, N. A Review on Natural Fiber Reinforced Composites. Mater. Today Proc. 2020, 28, 1616–1621. [Google Scholar] [CrossRef]

- Keya, K.N.; Kona, N.A.; Koly, F.A.; Maraz, K.M.; Islam, M.N.; Khan, R.A. Natural Fiber Reinforced Polymer Composites: History, Types, Advantages and Applications. Mater. Eng. Res. 2019, 1, 69–85. [Google Scholar] [CrossRef]

- Marcalla, A.M.; Coyago, A.P.R. Materiales Compuestos de Polímero Reforzado con Fibra de Cabuya y Coco Aplicado al Sector Automotriz. Dominio Las Cienc. 2021, 7, 436–465. [Google Scholar]

- Pabón, G.; Rodés, R.; Pérez, L.; Vásquez, L.; Ortega, E. Relaciones Morfológicas en Schoenoplectus californicus (Cyperaceae) en Lagos Alto-Andinos de Ecuador. Rev. Del Jardín Botánico Nac. 2019, 40, 109–119. [Google Scholar]

- Sriprom, W.; Sirivallop, A.; Choodum, A.; Limsakul, W.; Wongniramaikul, W. Plastic/Natural Fiber Composite Based on Recycled Expanded Polystyrene Foam Waste. Polymers 2022, 14, 2241. [Google Scholar] [CrossRef]

- Suriani, M.J.; Ilyas, R.A.; Zuhri, M.Y.M.; Khalina, A.; Sultan, M.T.H.; Sapuan, S.M.; Ruzaidi, C.M.; Nik Wan, F.; Zulkifli, F.; Harussani, M.M.; et al. Critical Review of Natural Fiber Reinforced Hybrid Composites: Processing, Properties, Applications and Cost. Polymers 2021, 13, 3514. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Das, P.P.; Chaudhary, V. Moving Towards the Era of Bio Fibre Based Polymer Composites. Clean. Eng. Technol. 2021, 4, 100182. [Google Scholar] [CrossRef]

- Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. The Feasibility of Using the MFC Concept to Upcycle Mixed Recycled Plastics. Sustainability 2021, 13, 689. [Google Scholar] [CrossRef]

- Hidalgo-Cordero, J.F.; Aza-Medina, L.C. Analysis of the Thermal Performance of Elements Made with Totora Using Different Production Processes. J. Build. Eng. 2023, 65, 105777. [Google Scholar] [CrossRef]

- Hidalgo-Cordero, J.F. Constructive Applications of Totora (Schoenoplectus californicus) in Binderless Boards. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2019. Available online: https://dialnet.unirioja.es/servlet/tesis?codigo=267531 (accessed on 1 April 2025).

- Hidalgo-Cordero, J.F.; García-Navarro, J. Totora (Schoenoplectus californicus (C.A. Mey.) Soják) and Its Potential as a Construction Material. Ind. Crops Prod. 2018, 112, 467–480. [Google Scholar] [CrossRef]

- González Ramón, E.M. Revalorización de la Totora como Material de Construcción. Master’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2020. Available online: https://upcommons.upc.edu/handle/2117/179406 (accessed on 1 April 2025).

- Hidalgo-Salazar, M.A.; Muñoz, M.F.; Mina, J.H. Influence of Incorporation of Natural Fibers on the Physical, Mechanical, and Thermal Properties of Composites LDPE-Al Reinforced with Fique Fibers. Int. J. Polym. Sci. 2015, 2015, 386325. [Google Scholar] [CrossRef]

- Collado Cárdenas, E.N. Reciclado del Polialuminio de Envases Tetra Pak en la Ciudad de Arequipa y Determinación de Propiedades Fisicomecánicas; Universidad Nacional de San Agustín de Arequipa: Arequipa, Peru, 2021; Available online: https://dialnet.unirioja.es/servlet/tesis?codigo=346475 (accessed on 1 April 2025).

- Chiluiza, J.; García, E. Criterios para la Construcción Sostenible de una Vivienda de Interés Social con Estructura Mixta, a Partir del Uso del Cartón Tetrapack y Estructura Metálica; UCE: Quito, Ecuador, 2017; Available online: https://www.dspace.uce.edu.ec/entities/publication/2c9c1708-848e-4b7a-b9b3-0b9252e32da4 (accessed on 2 April 2025).

- Gaibor Chacha, E.R. Caracterización de un Material Compuesto con Matriz de Resina de Poliéster Reforzado con Partícula de Totora; Universidad Internacional SEK: Quito, Ecuador, 2017; Available online: https://repositorio.uisek.edu.ec/handle/123456789/2540 (accessed on 2 April 2025).

- Merchán, A.P.H. Totora: Paneles Prefabricados para Cubiertas Mediante el Uso de Resina de Poliéster; Universidad Católica de Cuenca, Carrera de Arquitectura: Cuenca, Ecuador, 2018; Available online: https://dspace.ucacue.edu.ec/handle/ucacue/1751 (accessed on 3 April 2025).

- Mejía, E.C.; Ojeda, D.; Goyos, L. Mechanical Behavior Under Tension of Schoenoplectus californicus Fiber. J. Nat. Fibers 2019, 16, 68–76. [Google Scholar] [CrossRef]

- Eduardo Palomino, C.L.; Zegarra Lazo, L.E. Tabiqueía Ecológica, Empleando Totora con Revestimiento de Yeso o Mortero, Como Técnica de Bioconstrucción en la Ciudad de Puno. 2015. Available online: https://repositorio.unap.edu.pe/handle/20.500.14082/2055 (accessed on 4 April 2025).

- Moyano Arévalo, J.R. Caracterización y Aplicación de Material Compuesto de Resina de Poliéster y Refuerzo de Totora para la Fabricación de Parachoques Delantero de Autobús Urbano. 2017. Available online: https://repositorio.uisek.edu.ec/handle/123456789/2656 (accessed on 5 April 2025).

- Pico Vaca, J.L. Caracterización Mecánica del Material Compuesto de Matriz Poliéster Reforzada con Fibra Natural de Totora (Schoenoplectus californicus) y su Posible Aplicación en la Industria. 2022. Available online: https://repositorio.uta.edu.ec/items/80c0ad10-8baf-4794-9b40-ae1aaaf250de (accessed on 5 April 2025).

- Vilañez Espinoza, P.H. Caracterización de las Propiedades Mecánicas de un Material Compuesto Fabricado con Matriz de Resina Epóxica y Refuerzo de Fibra Natural de Totora. 2020. Available online: https://repositorio.espe.edu.ec/items/52f43fcc-1762-4dd1-a508-91c3204fedb2 (accessed on 5 April 2025).

- Hidalgo, M.A.; Muñoz, M.F.; Quintana, K.J. Desempeño Mecánico del Compuesto Polietileno Aluminio Reforzado con Agrofibras Continuas de Fique. Rev. Latinoam. Metal. Mater. 2011, 31, 187–194. [Google Scholar]

- Hidalgo, M.; Muñoz, M.; Quintana, K. Análisis Mecánico del Compuesto Polietileno Aluminio Reforzado con Fibras Cortas de Fique en Disposición Bidimensional. Rev. Latinoam. Metal. Mater. 2012, 32, 89–95. [Google Scholar]

- Vera, A.P.A.; Lastra, O.A.A.; García, J.N.A. Mortero con Incorporación de Fibra de Coco y Cerámica para Acabados Interiores de Edificaciones. Polo Del Conoc. Rev. CientíFico-Prof. 2021, 6, 315–336. [Google Scholar]

- Fouladi, M.H.; Ghassem, M.; Ayub, M.; Jailani, M.; Nor, M. Implementation of Coir Fiber as Acoustic Absorber Material. Noise Vib. Worldw. 2011, 42, 11–16. [Google Scholar] [CrossRef]

- Bravo-Moncayo, L.; Argotti-Gómez, M.; Jara, O.; Puyana-Romero, V.; Ciaburro, G.; Guerrero, V.H. Thermo-Acoustic Properties of Four Natural Fibers, Musa textilis, Furcraea andina, Cocos nucifera, and Schoenoplectus californicus, for Building Applications. Buildings 2024, 14, 2265. [Google Scholar] [CrossRef]

- Jara-Vinueza, O.; Pavon, W.; Remache, A. Sustainable Construction with Cattail Fibers in Imbabura, Ecuador: Physical and Mechanical Properties, Research, and Applications. Buildings 2024, 14, 1703. [Google Scholar] [CrossRef]

- Wille, V.K.D.; Gentil, M.; Nunes, G.R.S.; da Rosa, R.C.; Jardim, J.M.; Berger, C.; Costa, H.W.D.; Gatto, D.A.; Pedrazzi, C. Totora Fibers as a New Source for Papermaking. Biomass Convers. Biorefinery 2023, 13, 5235–5241. [Google Scholar] [CrossRef]

- Culcay Chérrez, A. Experimentación con la Fibra Totora. Bachelor’s Thesis, Universidad del Azuay, Cuenca, Ecuador, 2014. Available online: http://dspace.uazuay.edu.ec/handle/datos/3903 (accessed on 5 April 2025).

- Aza-Medina, L.C.; Palumbo, M.; Lacasta, A.M.; González-Lezcano, R.A. Characterization of the Thermal Behavior, Mechanical Resistance, and Reaction to Fire of Totora (Schoenoplectus californicus (C.A. Mey.) Sojak) Panels and Their Potential Use as a Sustainable Construction Material. J. Build. Eng. 2023, 69, 105984. [Google Scholar] [CrossRef]

- Hidalgo-Cordero, J.F.; Revilla, E.; García-Navarro, J. Comparative Chemical Analysis of the Rind and Pith of Totora (Schoenoplectus californicus) Stems. J. Nat. Fibers 2020, 17, 954–965. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D143-94; Standard Test Methods for Small Clear Specimens of Timber. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- González, T.; Puigagut, J.; Vidal, G. Organic Matter Removal and Nitrogen Transformation by a Constructed Wetland-Microbial Fuel Cell System with Simultaneous Bioelectricity Generation. Sci. Total Environ. 2021, 753, 142075. [Google Scholar] [CrossRef] [PubMed]

- Romero, M.; Flores, M.; Bravo-Thais, S.; Guzman, M. Schoenoplectus californicus as Potential Remover of Metal Elements from Mine Effluents: A Laboratory Assessment. CLEAN—Soil Air Water 2023, 51, 2200029. [Google Scholar] [CrossRef]

- Jara Vinueza, O.D. Artes y Oficios (Constructivos en Totora) como Vinculación Material al Diseño y Detalle Arquitectónico. 2018. Available online: https://repositorio.uta.edu.ec/items/70a44ca1-3bab-4a04-8173-a2275d6d5f42 (accessed on 5 April 2025).

- ASTM D6110-18; Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. ASTM International: West Conshohocken, PA, USA, 2018. [CrossRef]

- Restrepo, J.; Morales, A. Uso de la Norma Técnica Ecuatoriana NTE INEN 1162 para la Determinación de la Resistencia a la Compresión de Materiales Compuestos. In Revista Técnica INEN; Instituto Ecuatoriano de Normalización: Quito, Ecuador, 2016; Volume 34, pp. 45–52. [Google Scholar]

- George, J.; Bhagawan, S.S.; Prabhakaran, N.; Thomas, S. Short Pineapple-Leaf-Fiber-Reinforced Low-Density Polyethylene Composites. J. Appl. Polym. Sci. 1995, 57, 843–854. [Google Scholar] [CrossRef]

- Gómez-Suarez, S.A.; Córdoba-Tuta, E. Materiales Compuestos Reforzados con Fibras de Fique—Revisión. Rev. UIS Ing. 2022, 21, 163–178. [Google Scholar] [CrossRef]

- Yusof, F.M.; Wahab, N.; Rahman, N.L.A.; Kalam, A.; Jumahat, A.; Taib, C.F.M. Properties of Treated Bamboo Fiber Reinforced Tapioca Starch Biodegradable Composite. Mater. Today Proc. 2019, 16, 2367–2373. [Google Scholar] [CrossRef]

- Fang, C.-c.; Zhang, Y.; Qi, S.-y.; Liao, Y.-c.; Li, Y.-y.; Wang, P. Influence of Structural Design on Mechanical and Thermal Properties of Jute Reinforced Polylactic Acid (PLA) Laminated Composites. Cellulose 2020, 27, 9397–9407. [Google Scholar] [CrossRef]

- Colorado, H.A.; Henkin, J.M. Fire-Resistant Plants: A Review of Plant Morphology, Tissues, Habits, Ecological Adaptations, and Other Factors Contributing to Bioderived Environmental Solutions and Technologies. Eng. Sci. 2023, 27, 1024. [Google Scholar] [CrossRef]

- de la Cruz-Velasco, L.; Chamorro-Mejía, J.; Córdoba-Cely, C. Characterization Physico-Chemical and Mechanical of 4 Vegetable Fibers Used as Artisanal Raw Materials in the Department of Nariño. Dyna 2021, 88, 96–102. [Google Scholar] [CrossRef]

- Núñez-Torres, S.; Fuentes-Pérez, E.; Freire-Valdiviezo, P.; Balseca-Clavijo, C. Methodological Guide for the Design of Structures for Tourist and Community Interaction in the Laguna de Colta. CienciAmérica 2022, 11, 54–70. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).