Research on IFC-Based Tunnel Monitoring Information Integration and Visual Warning Scheme

Abstract

1. Introduction

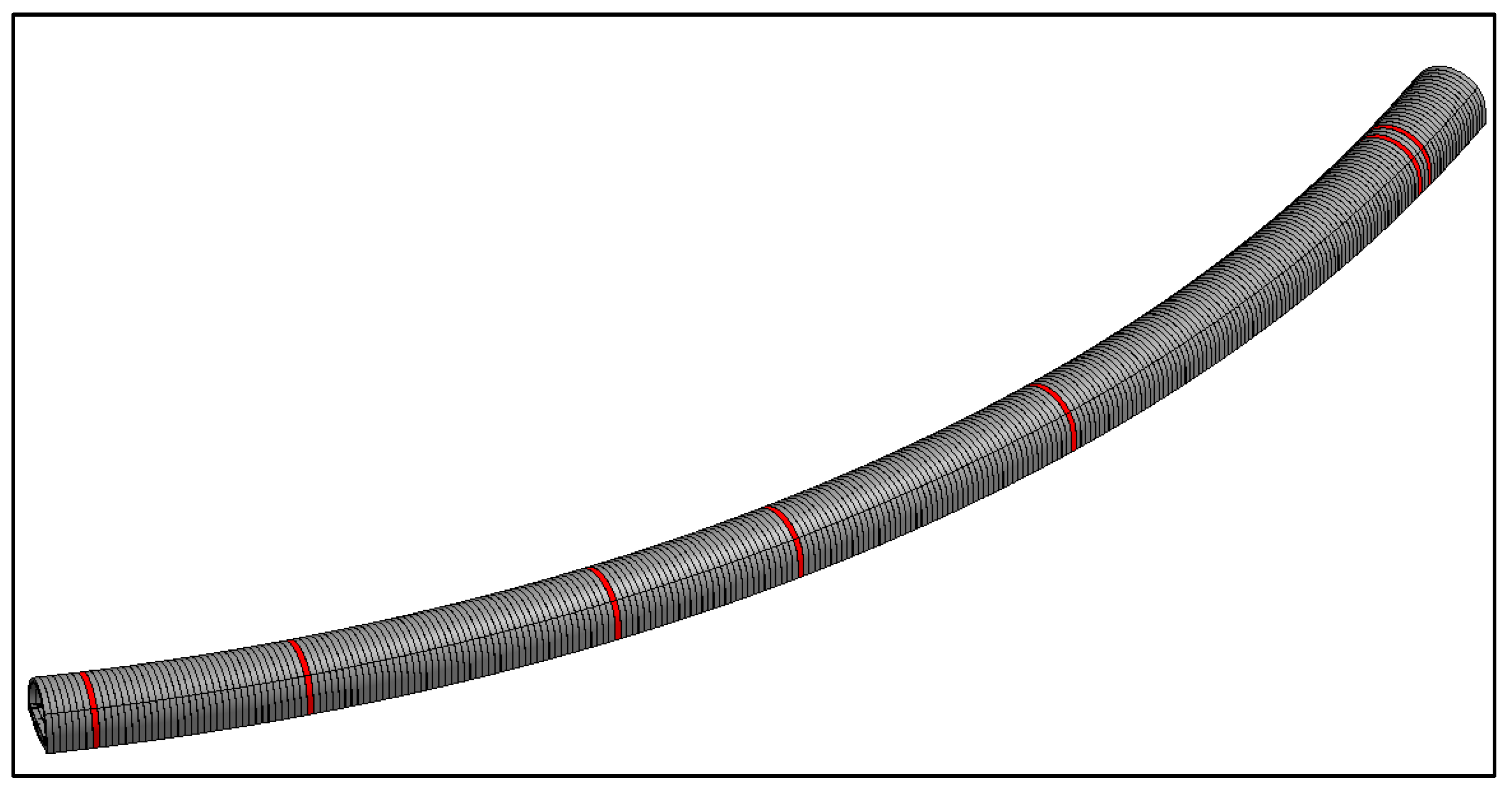

2. Monitoring Data Preprocessing

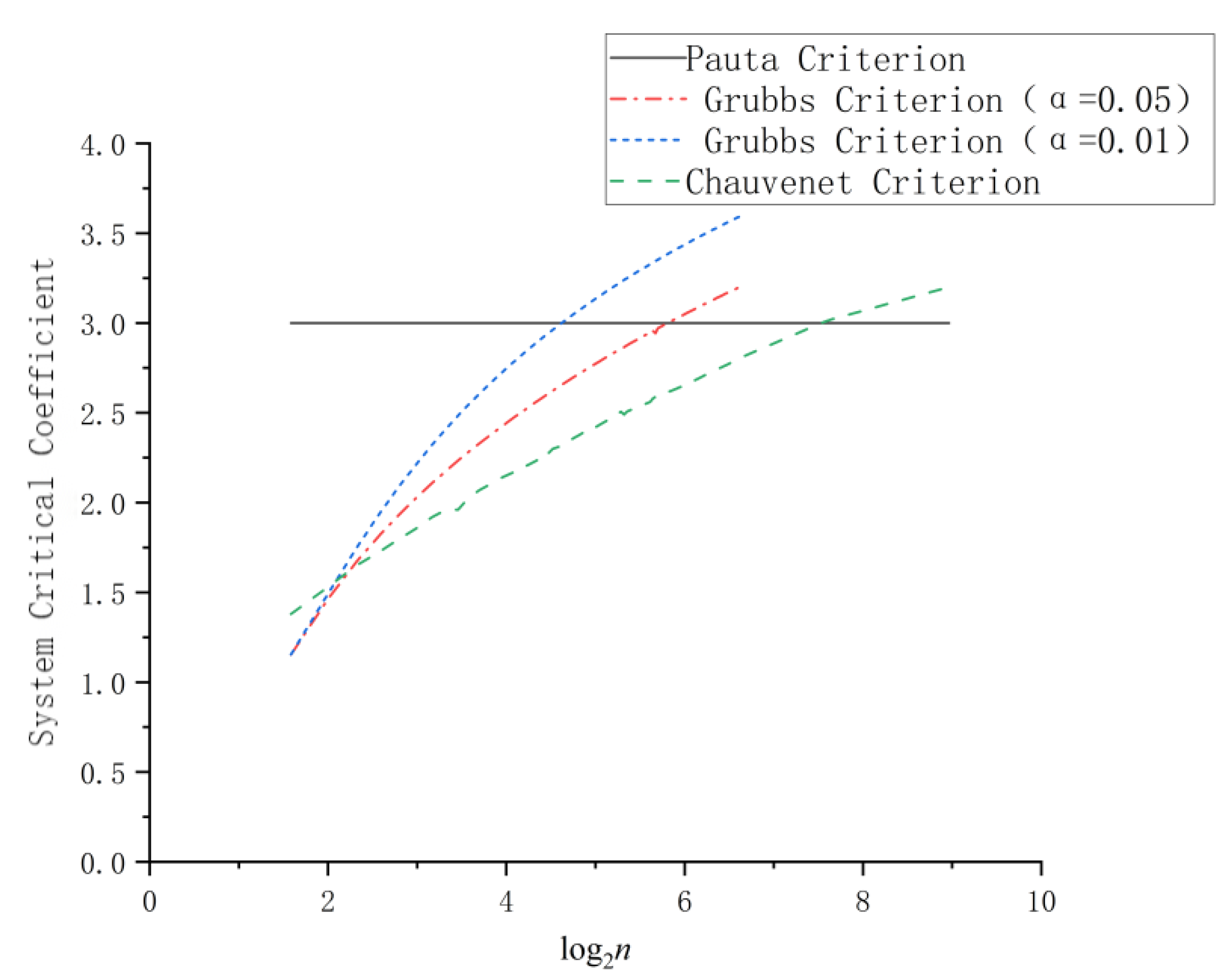

2.1. Gross Error Elimination

2.2. Interpolation Processing

3. IFC-Based Tunnel Monitoring Information Integration Model

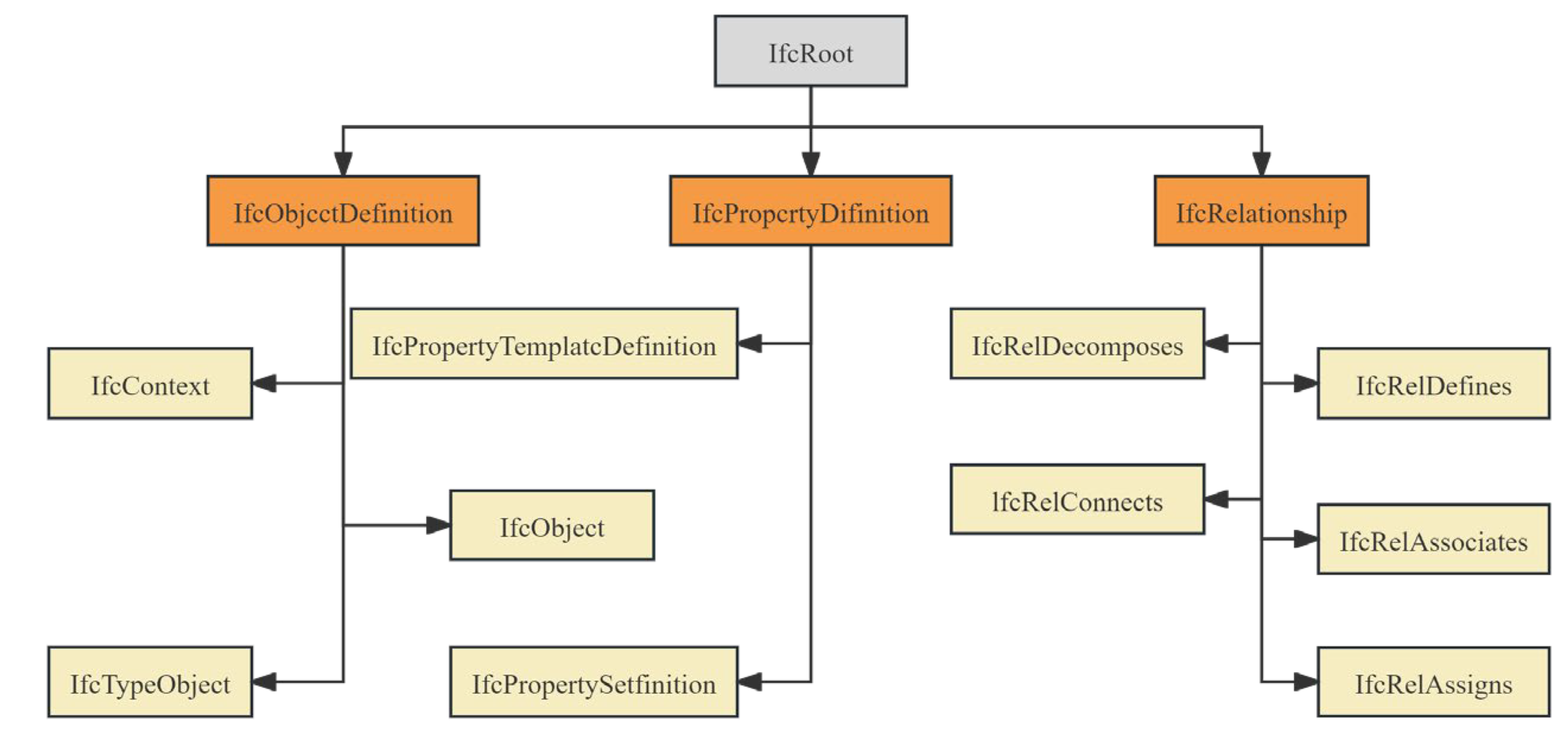

3.1. IFC Infrastructure

3.1.1. IFC Standard Data Framework

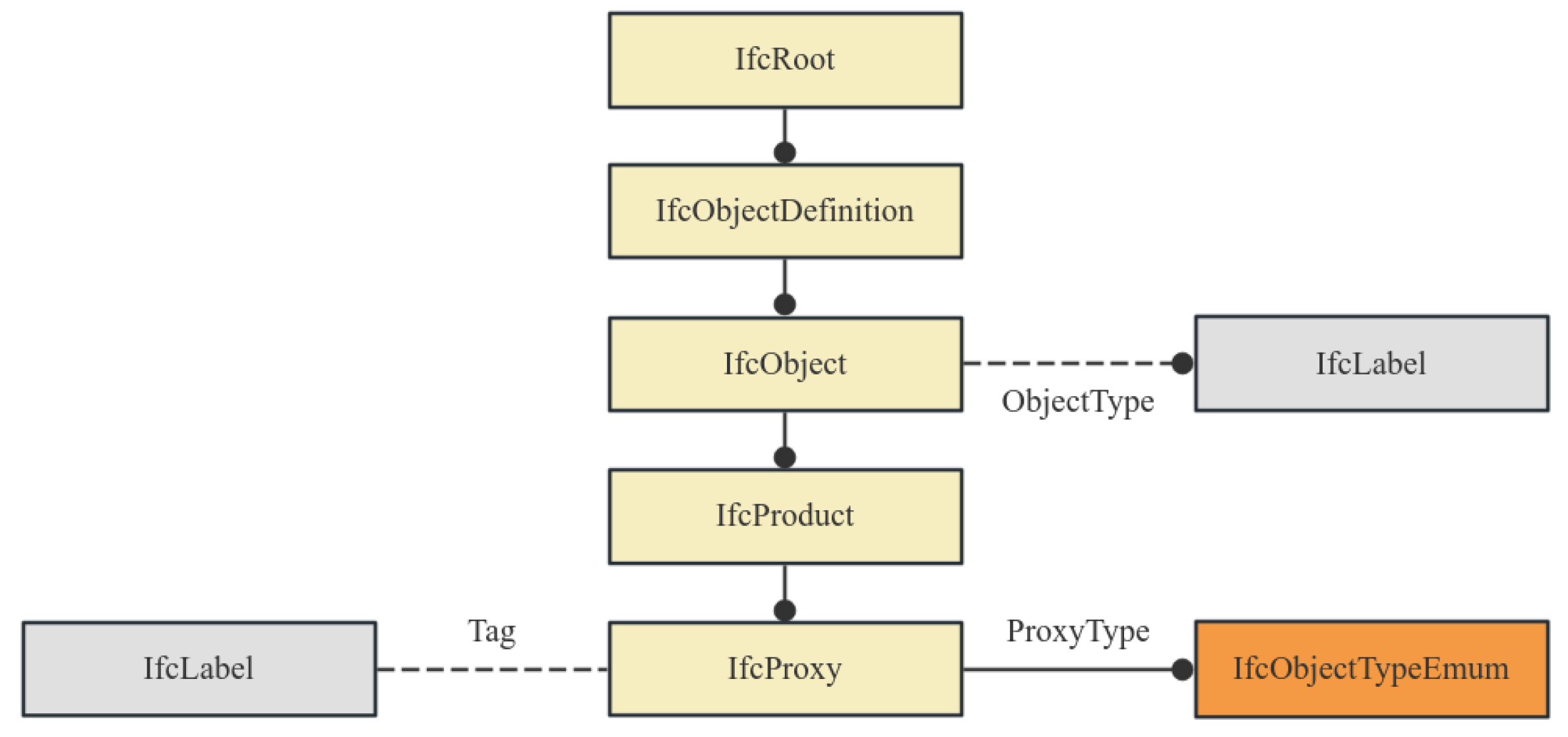

3.1.2. IFC Definition of Entity

3.1.3. IFC Standard Extension Method

3.2. Tunnel Structure Expression Based on IFCs

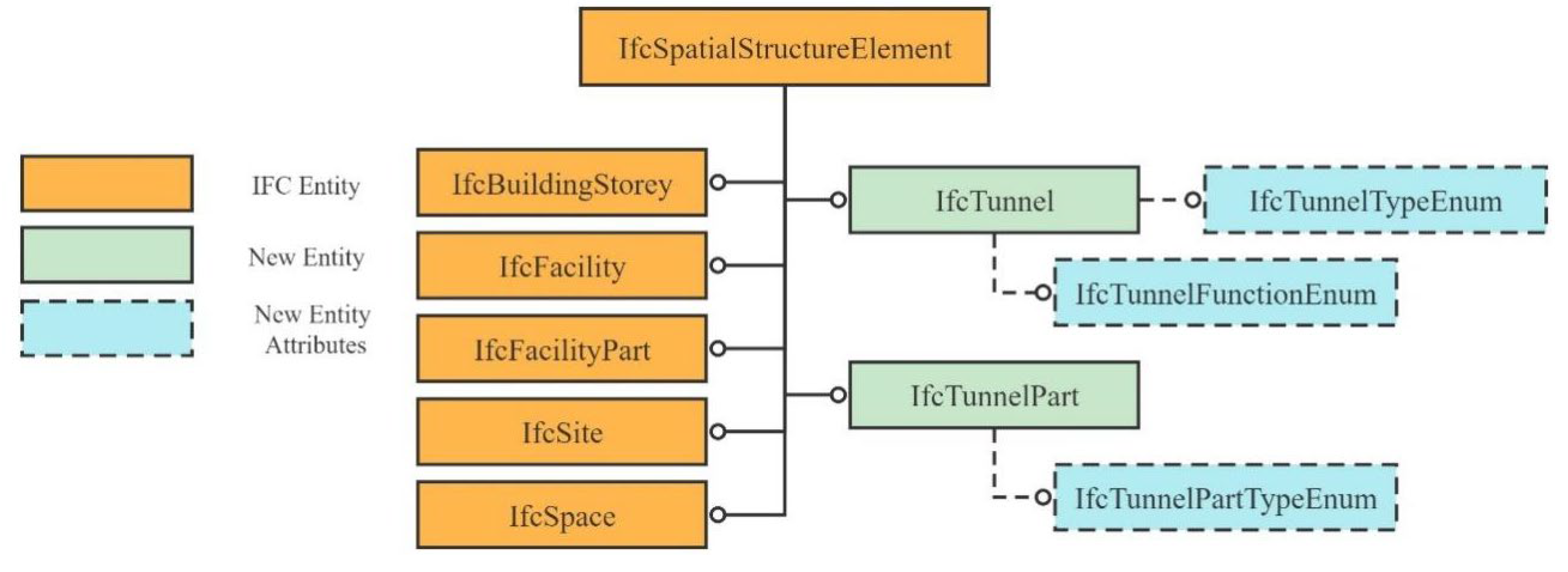

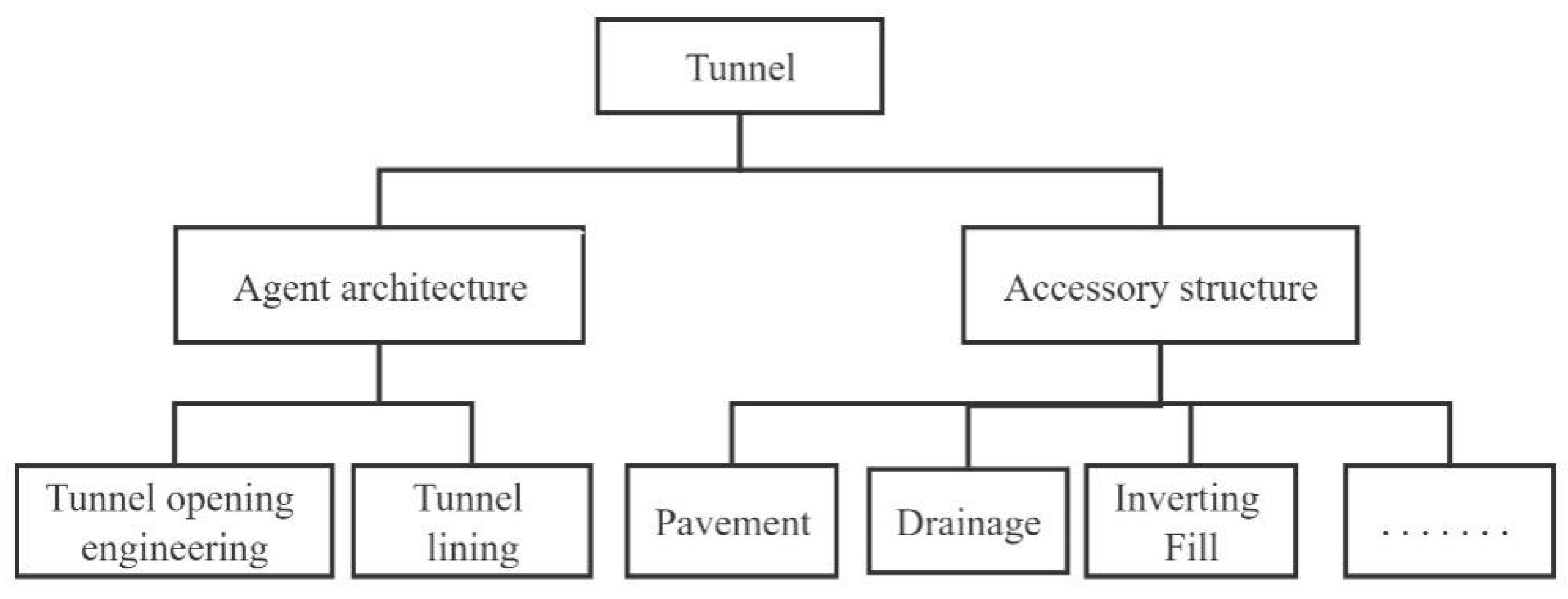

3.2.1. Definition of the Tunnel Spatial Structure

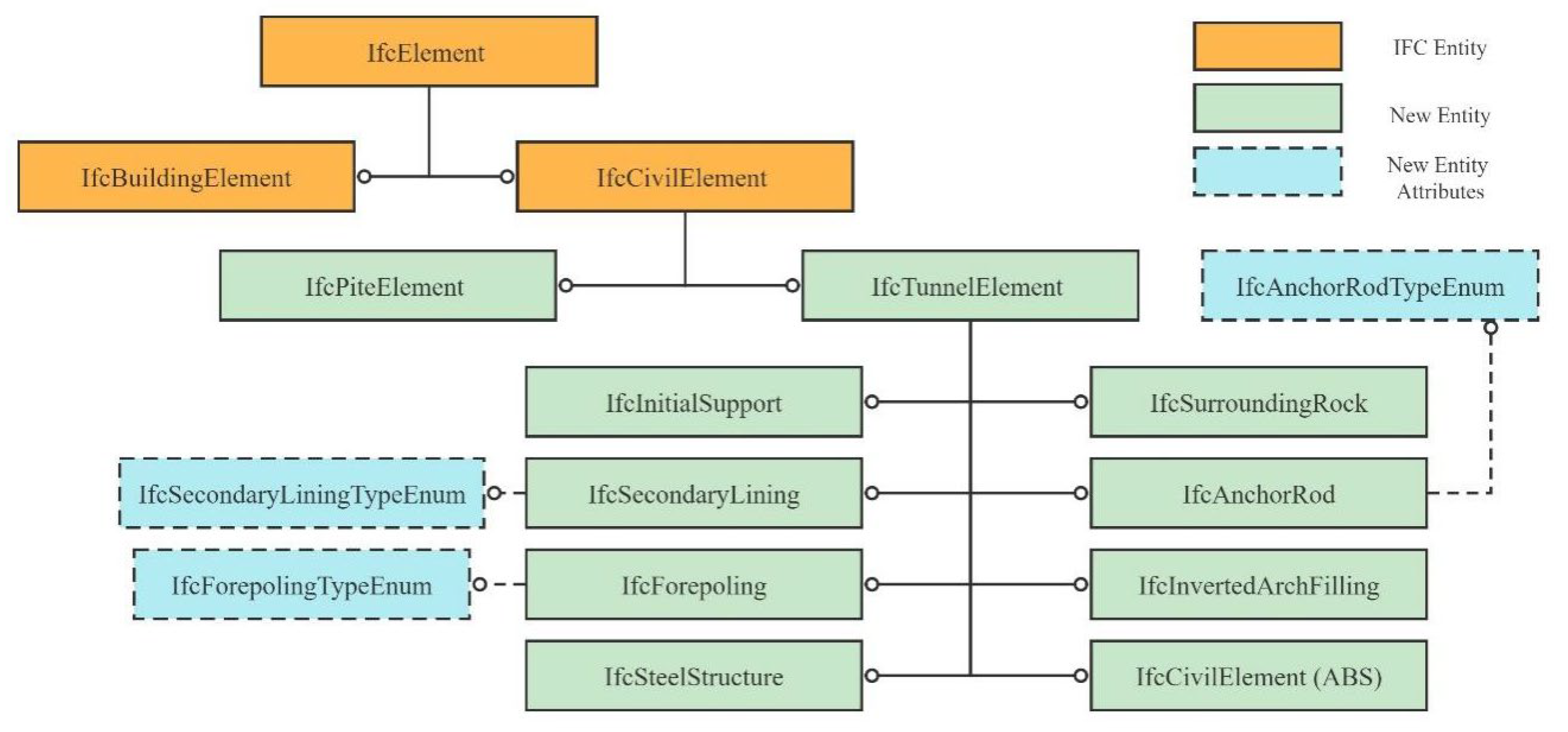

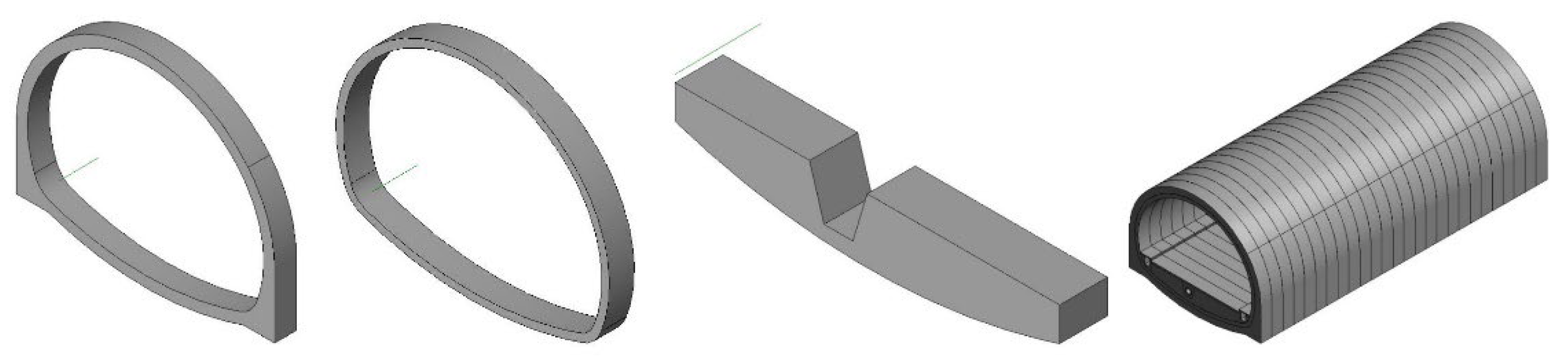

3.2.2. Definition of the Tunnel Geometry

3.3. IFC Extension of the Tunnel Structure

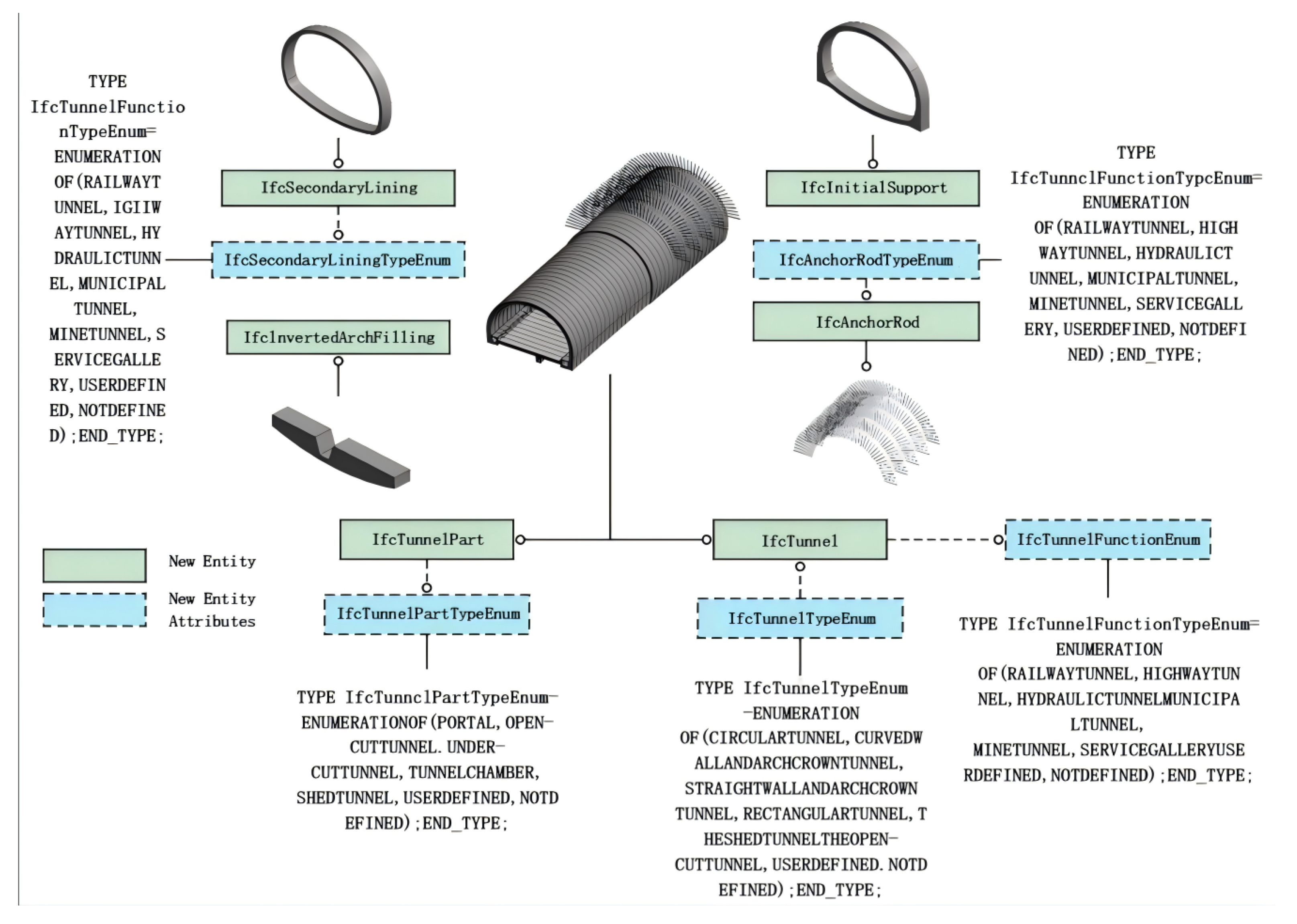

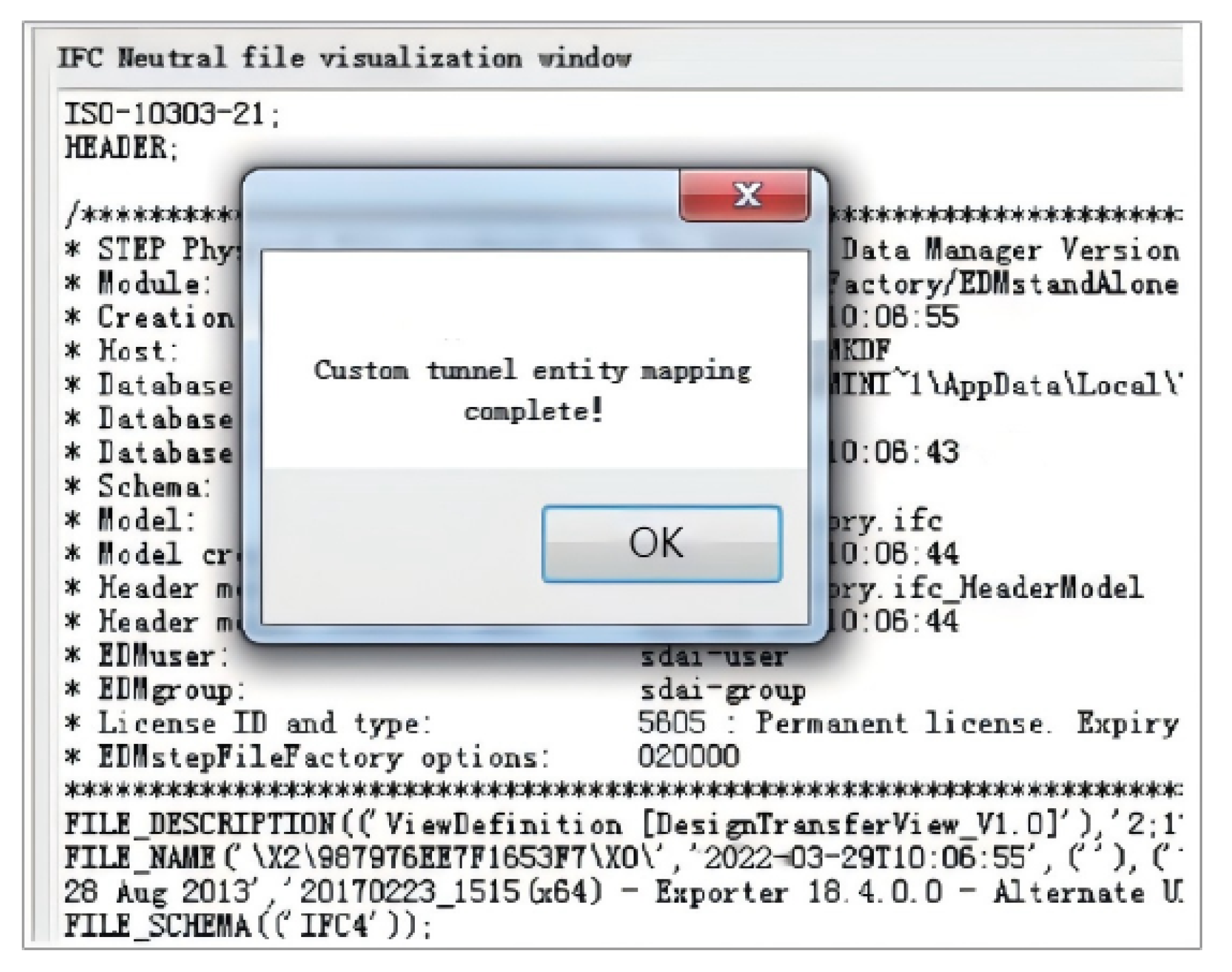

3.3.1. Definition of the Tunnel Entity Based on IFCs

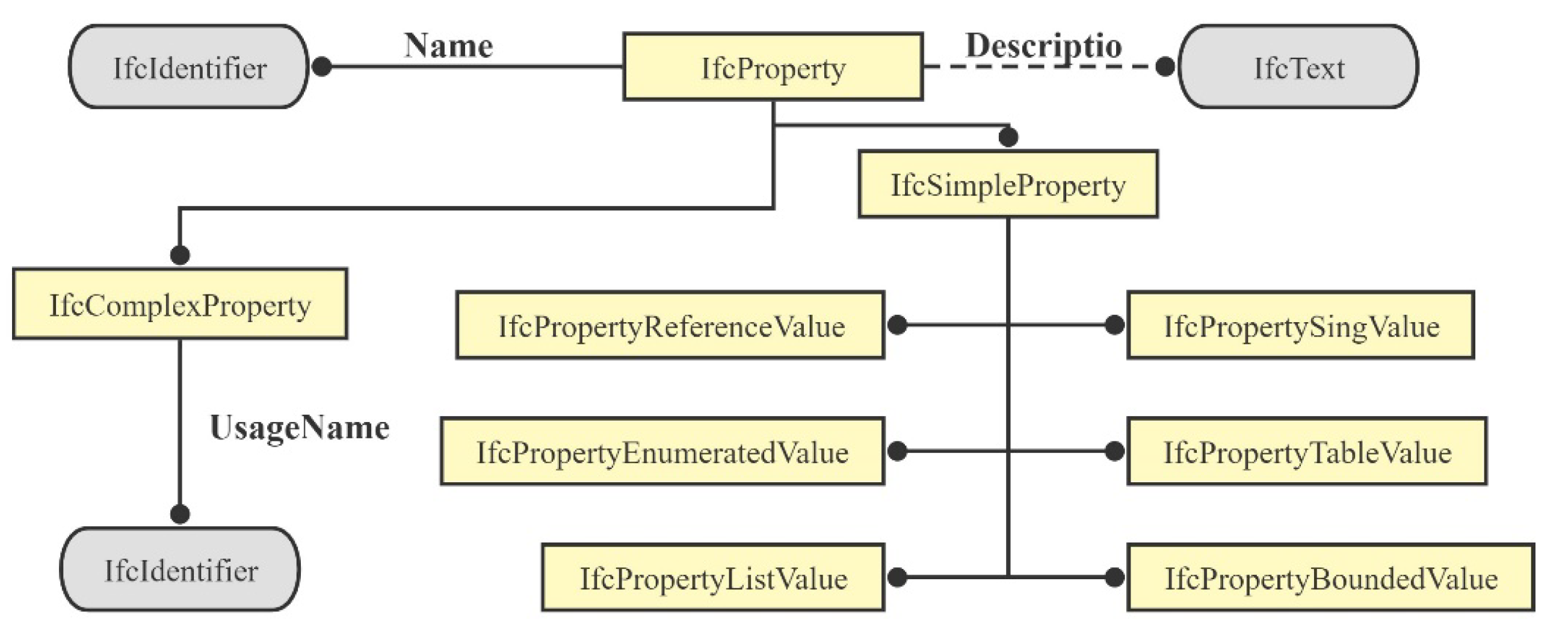

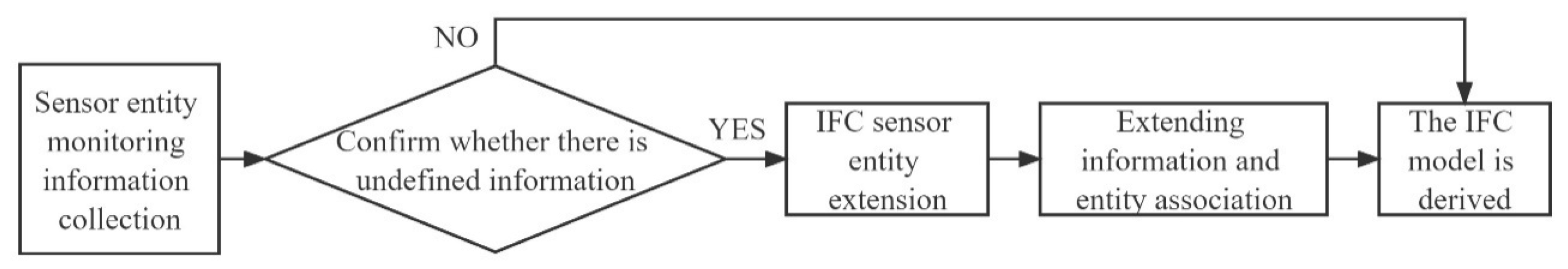

3.3.2. The Definition of Sensor Attributes Based on IFCs

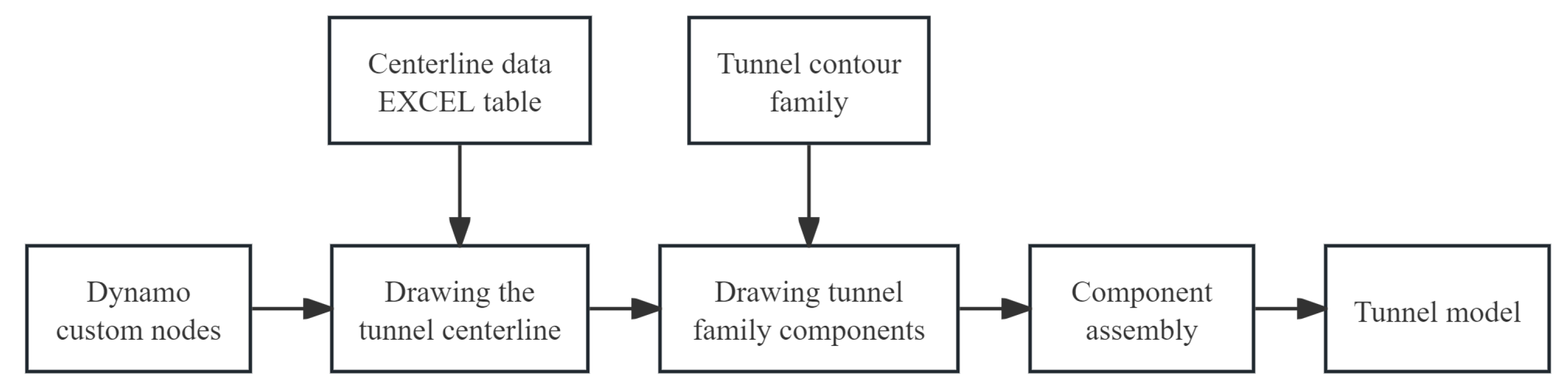

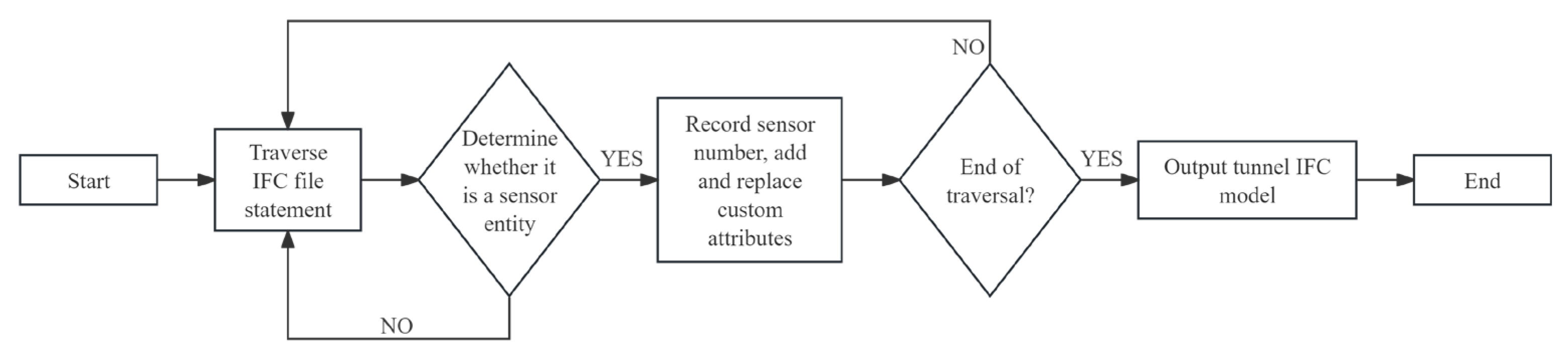

3.4. Tunnel IFC Model Creation

4. System Development and Application

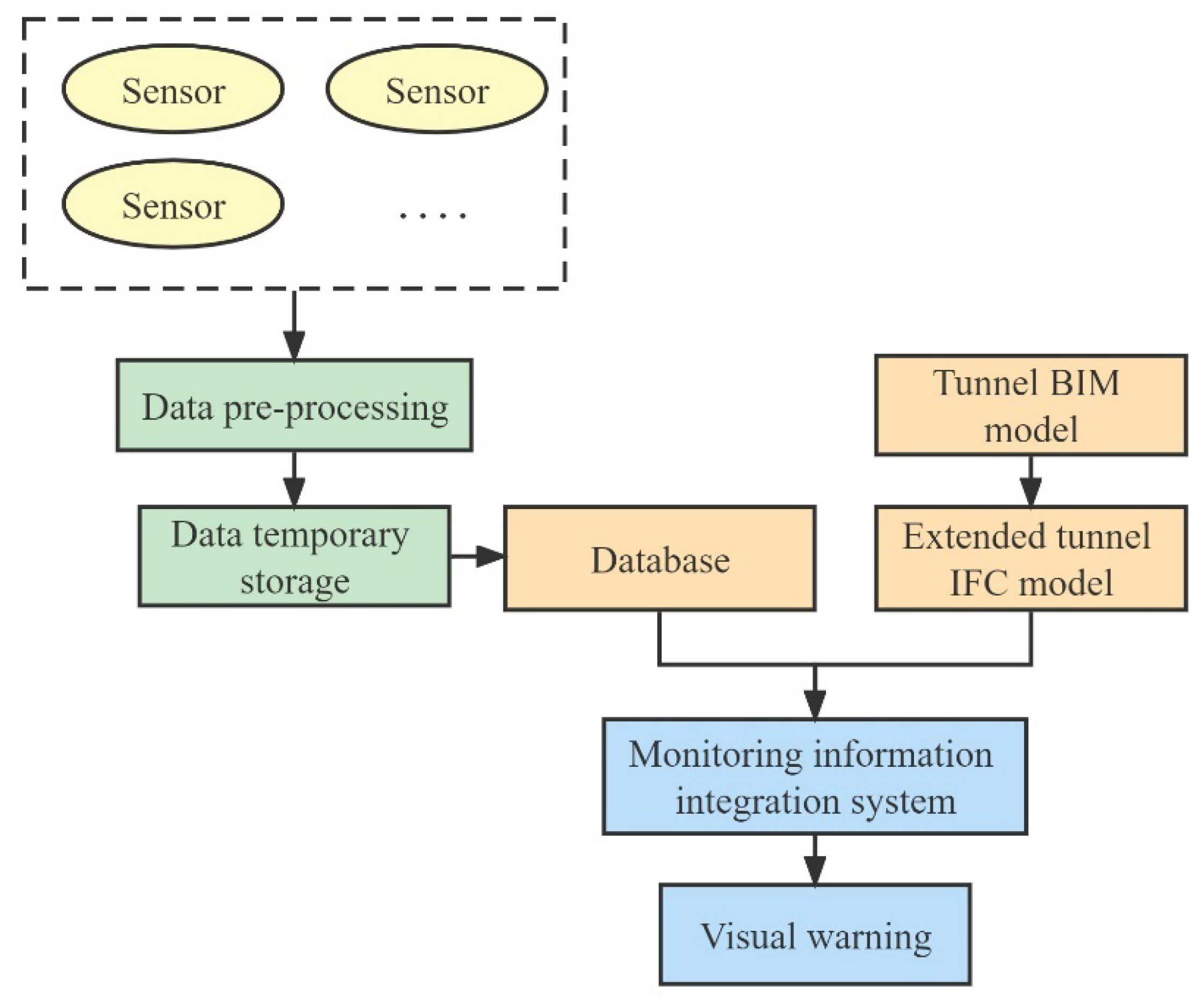

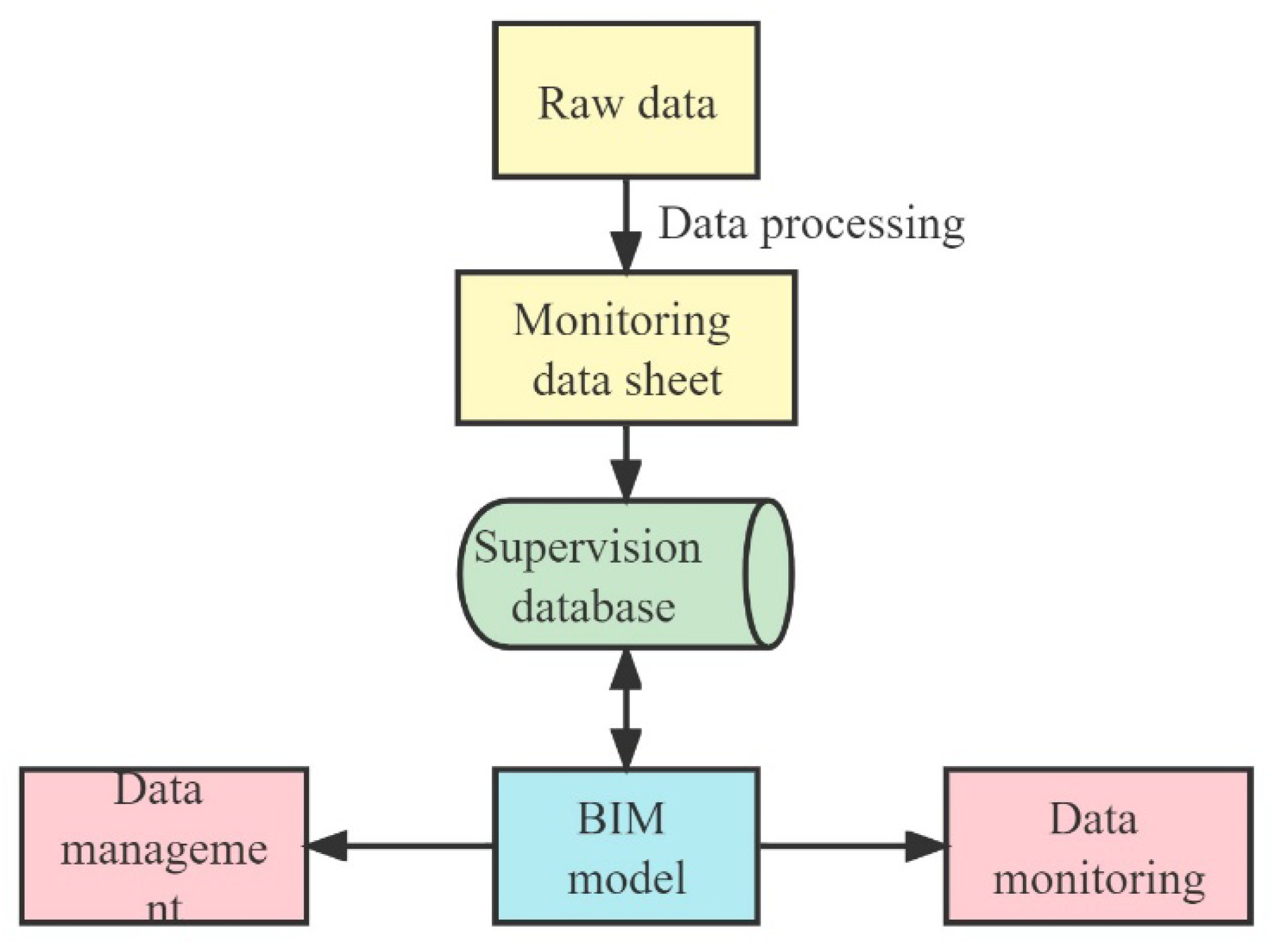

4.1. Monitoring Information Integration System Based on the Database

4.1.1. System Framework

4.1.2. Database Requirement Analysis

4.1.3. Database Structure Design

4.2. Engineering Application

4.2.1. Project Overview

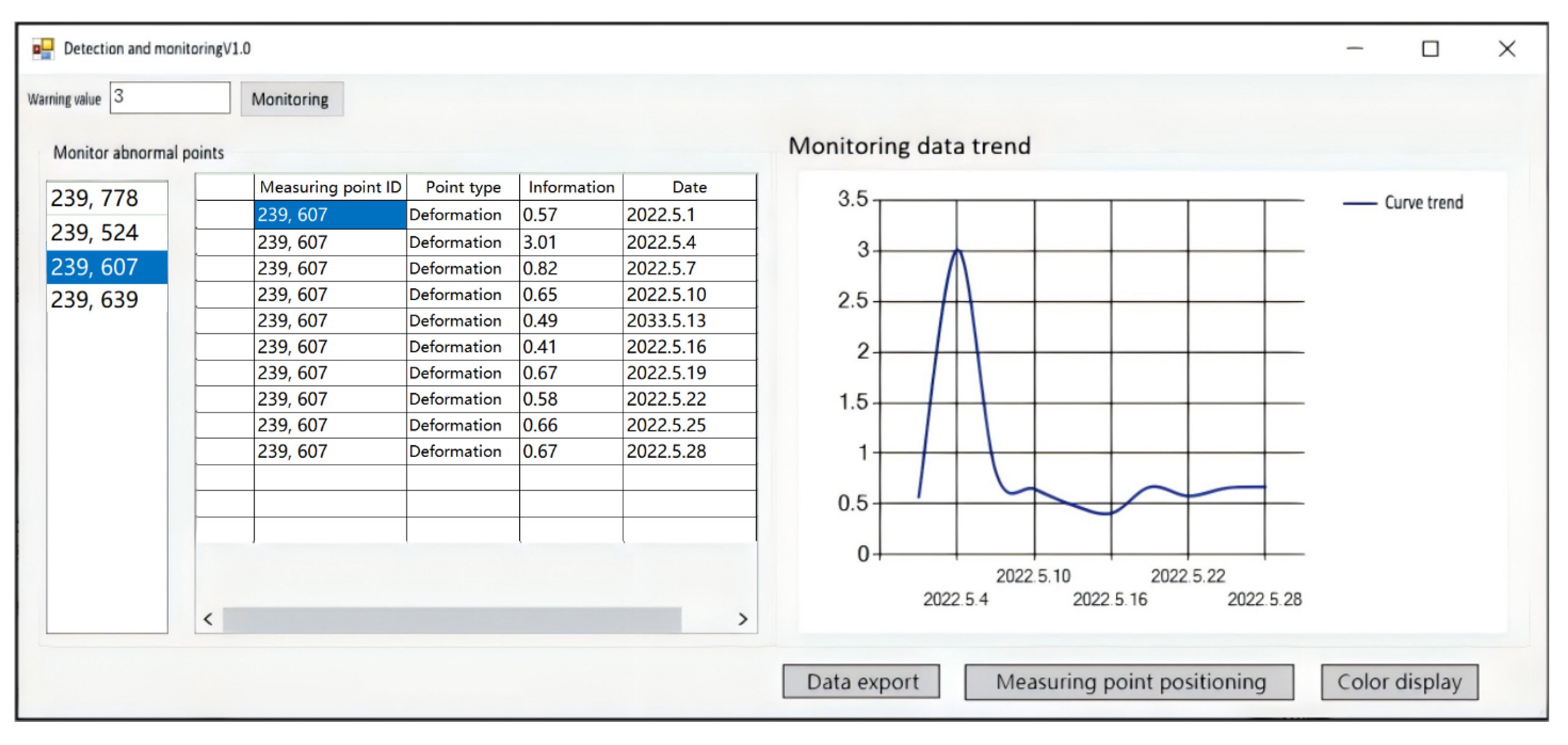

4.2.2. Visual Warning Application

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ismail, A.; Strug, B.; Ślusarczyk, G. Building Knowledge Extraction from BIM/IFC Data for Analysis in Graph Databases. In Artificial Intelligence and Soft Computing; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 652–664. [Google Scholar]

- Marmo, R.; Polverino, F.; Nicolella, M.; Tibaut, A. Building performance and maintenance information model based on IFC schema. Autom. Constr. 2020, 118, 103275. [Google Scholar] [CrossRef]

- Lai, H.H.; Deng, X.Y. Interoperability analysis of IFC-based data exchange between heterogeneous BIM software. J. Civ. Eng. Manag. 2018, 24, 537–555. [Google Scholar] [CrossRef]

- Zeng, Q.; Zhang, Q.L.; Zhang, J.H. Research on IFC Data Storage Based on Object-oriented Hierarchical Database. J. Inf. Technol. Civ. Eng. Archit. 2021, 13, 17–23. [Google Scholar]

- Zhang, Z.B.; Meng, X.M. IFC-based Information Exchange Framework Research and Implementation Between Architectural Design and Structural Design. Build. Struct. 2024, 54, 149–154. [Google Scholar]

- Söbke, H.; Peralta, P.; Smarsly, K.; Armbruster, M. An IFC schema extension for BIM-based description of wastewater treatment plants. Autom. Constr. 2021, 129, 103777. [Google Scholar] [CrossRef]

- Guan, L.; Hu, J.H.; Li, J.Q.; Wang, H.; Dong, J.Z.; Zhang, J.M. Research on Substation Gantry Modeling Based on IFC Standard. In Proceedings of the 2019 3rd International Conference on Electronic Information Technology and Computer Engineering (EITCE), Xiamen, China, 18–20 October 2019; pp. 759–762. [Google Scholar]

- Zhu, H.X.; Xu, Z. Research on information collaboration and model construction for top-down design of prefabricated buildings. J. Graph. 2021, 42, 289–298. [Google Scholar]

- Bao, L.S.; An, P.L.; Wang, P.; Liang, W.; Yu, L. Research on Visualization of Bridge Safety Information Based on IFC. J. Shenyang Archit. Univ. (Nat. Sci.) 2022, 38, 682–689. [Google Scholar]

- Zhao, L.G.; Jiang, A.N.; Wu, H.T.; Duan, L.M.; Zhang, G.T.; Shen, F.Y. Information integration model of tunnel dynamic design based on IFC standard. J. Dalian Marit. Univ. 2019, 45, 66–74. [Google Scholar]

- Mobaraki, B.; Vaghefi, M. The Effect of Protective Barriers on the Dynamic Response of Underground Structures. Buildings 2024, 14, 3764. [Google Scholar] [CrossRef]

- Mobaraki, B.; Ma, H.; Lozano Galant, J.A.; Turmo, J. Structural Health Monitoring of 2D Plane Structures. Appl. Sci. 2021, 11, 2000. [Google Scholar] [CrossRef]

- Xiong, Y.Y.; Wu, X.Q. The Generalizing Application of Four Judging Criterions for Gross Errors. Phys. Exp. Coll. 2010, 23, 66–68. [Google Scholar]

- Li, W.H. Intelligent Information Agent with Ontology on Semantic Web. Comput. Eng. Appl. 2002, 38, 136–138. [Google Scholar]

- Chen, G.L.; Wu, J.M.; Zhong, Y.; Chen, J.; Chen, B.; Wang, Y.D. Research on IFC-based standard extension for 3D geological model. Rock Soil Mech. 2020, 41, 2821–2828. [Google Scholar]

- Xu, K.; Huo, L.; Shen, T.; Fu, J.Y. Research on Construction Method of Special Knowledge Model of Water Conservancy Safety Monitoring Based on Semantic Web and BIM. Geomat. Spat. Inf. Technol. 2022, 45, 25–28. [Google Scholar]

- Zhou, H.B.; Shi, W.P.; Deng, X.Y. Research on BIM Component Library Based on IFC Standard. J. Graph. 2017, 38, 589–595. [Google Scholar]

- Dai, S.H. Research on BIM Model Extension Technology of Bridge Structure Based on Semantic Ontology. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2019. [Google Scholar]

- Cao, G.; Gao, G.L.; Qiu, Y.H.; Cao, J. Extended Application of Reinforcement Properties Based on IFC Standard. J. Inf. Technol. Civ. Eng. Archit. 2013, 5, 24–28. [Google Scholar]

- Lai, H.H.; Hou, T.; Zhong, Z.L.; Zhao, Y.F. Analysis on Development of BIM Data Standard IFC. J. Civ. Eng. Manag. 2020, 37, 126–133. [Google Scholar]

- Gao, J.X.; Jiang, A.N.; Zhang, Y.; Shen, F.Y.; Wu, H.T.; Duan, L.M. Research on Tunnel Monitoring Information Model Based on IFC Standard and Parameterization. J. Inf. Technol. Civ. Eng. Archit. 2019, 11, 1–6. [Google Scholar]

- Zhang, N.; Bi, Y.Q.; Li, W. Research and Design of City Subway Construction Monitoring Information Management System. Geomat. Spat. Inf. Technol. 2019, 42, 119–120. [Google Scholar]

| Number of Periods/d | Variable Quantity (mm/d) | Cumulant /mm | Number of Periods/d | Variable Quantity (mm/d) | Cumulant /mm |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 13 | 0.42 | 5.33 |

| 2 | 0.18 | 0.18 | 14 | 0.41 | 5.74 |

| 3 | 0.24 | 0.42 | 15 | 0.33 | 6.07 |

| 4 | 0.28 | 0.70 | 16 | 0.37 | 6.44 |

| 5 | 0.46 | 1.16 | 17 | 0.24 | 6.68 |

| 6 | 0.51 | 1.67 | 18 | 0.19 | 6.87 |

| 7 | 0.44 | 2.11 | 19 | 0.12 | 6.99 |

| 8 | 0.67 | 2.78 | 20 | 0.23 | 7.22 |

| 9 | 0.48 | 3.26 | 21 | 0.17 | 7.39 |

| 10 | 0.57 | 3.83 | 22 | 0.15 | 7.54 |

| 11 | 0.66 | 4.49 | 23 | 0.11 | 7.65 |

| 12 | 0.42 | 4.91 | 24 | 0.08 | 7.73 |

| Criterion | 1 Outlier (1.8 mm) | 2 Outliers (1.8 mm, 1.8 mm) | 2 Outliers (1.8 mm, 2.0 mm) |

|---|---|---|---|

| Grubbs criterion (α = 0.01) | 1 | 0 | 0 |

| Grubbs criterion (α = 0.05) | 1 | 0 | 1 |

| Dixon criteria (α = 0.01) | 1 | 2 | 1 |

| Dixon criteria (α = 0.05) | 1 | 2 | 1 |

| Criterion | 1.08 mm | 1.24 mm | 1.44 mm | 1.56 mm |

|---|---|---|---|---|

| Grubbs criterion (α = 0.01) | 0 | 0 | 1 | 1 |

| Grubbs criterion (α = 0.05) | 1 | 1 | 1 | 1 |

| Dixon criteria (α = 0.01) | 0 | 0 | 0 | 1 |

| Dixon criteria (α = 0.05) | 0 | 1 | 1 | 1 |

| Interval | Monitoring Data /mm | Linear Interpolation /mm | Nearest Neighbor Interpolation /mm | Lagrange’s Interpolation /mm | Newton Interpolation /mm |

|---|---|---|---|---|---|

| Stage 1–8 | 2.11 | 2.225 | 2.78 | 2.17245 | 2.18541 |

| Stage 9–16 | 5.74 | 5.7 | 6.07 | 5.71251 | 5.72214 |

| Stage 17–24 | 7.39 | 7.38 | 7.54 | 7.35675 | 7.37441 |

| Interval | Monitoring Data /mm | Linear Interpolation /mm | Nearest Neighbor Interpolation /mm | Lagrange’s Interpolation /mm | Newton Interpolation /mm |

|---|---|---|---|---|---|

| Stage 1–8 | 1.16 | 1.185 | 1.67 | 1.18964 | 1.17992 |

| Stage 9–16 | 4.49 | 4.37 | 4.91 | 4.41457 | 4.43214 |

| Stage 17–24 | 6.68 | 6.655 | 6.87 | 6.64514 | 6.63992 |

| Interval | Monitoring Data /mm | Linear Interpolation /mm | Nearest Neighbor Interpolation /mm | Lagrange’s Interpolation /mm | Newton Interpolation /mm |

|---|---|---|---|---|---|

| Stage 1–8 | 0.42 | 0.44 | 0.70 | 0.43364 | 0.42192 |

| Stage 9–16 | 5.74 | 5.70 | 6.07 | 5.72446 | 5.73578 |

| Stage 17–24 | 7.22 | 7.19 | 7.39 | 7.18692 | 7.19247 |

| Name of the Attribute Set | Entity | Type Value |

| Displacement sensor | IfcSensor | DisplacementSensor |

| Strain sensor | IfcSensor | StrainSensor |

| Acceleration sensor | IfcSensor | AccelerationSensor |

| Name of the Attribute Set | Attribute Type | Type Value |

|---|---|---|

| Sensor category | IfcPropertySingleValue | IfcLabel |

| Sensor range | IfcPropertySingleValue | IfcLabel |

| Measurement accuracy | IfcPropertySingleValue | IfcLabel |

| Measuring point | IfcPropertySingleValue | IfcText |

| Measuring point mileage | IfcPropertySingleValue | IfcText |

| Service life | IfcPropertySingleValue | IfcTimeMeasure |

| Monitoring time | IfcPropertySingleValue | IfcDatetime |

| Attribute Name | Character Name | Data Type |

|---|---|---|

| Measuring point number | MonitoringPointID | varchar (30) |

| Sensor number | SensorNumber | varchar (30) |

| Type of measuring point | PointType | nchar (10) |

| Monitoring value | Value | varchar (30) |

| Attribute Name | Character Name | Data Type |

|---|---|---|

| Sensor number | SensorNumber | varchar (30) |

| Type of measuring point | PointType | nchar (10) |

| Monitoring value | Value | varchar (30) |

| Sensor Model Identifier | ElementGUID | varchar (50) |

| Attribute Name | Character Name | Data Type |

|---|---|---|

| Monitoring time | Time | datetime |

| Measuring point number | MonitoringPointID | varchar (30) |

| Monitoring value | Value | varchar (30) |

| Sensor number | SensorNumber | varchar (30) |

| Attribute Name | Character Name | Data Type |

|---|---|---|

| File name | Name | nvarchar (50) |

| Type | Type | nchar (10) |

| Creation time | Time | datetime |

| File path | Path | char (100) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Li, J.; Yao, H.; Li, Z.; Jia, X. Research on IFC-Based Tunnel Monitoring Information Integration and Visual Warning Scheme. Buildings 2025, 15, 2221. https://doi.org/10.3390/buildings15132221

Wang Q, Li J, Yao H, Li Z, Jia X. Research on IFC-Based Tunnel Monitoring Information Integration and Visual Warning Scheme. Buildings. 2025; 15(13):2221. https://doi.org/10.3390/buildings15132221

Chicago/Turabian StyleWang, Qianqian, Jinjing Li, Hui Yao, Zhihao Li, and Xingli Jia. 2025. "Research on IFC-Based Tunnel Monitoring Information Integration and Visual Warning Scheme" Buildings 15, no. 13: 2221. https://doi.org/10.3390/buildings15132221

APA StyleWang, Q., Li, J., Yao, H., Li, Z., & Jia, X. (2025). Research on IFC-Based Tunnel Monitoring Information Integration and Visual Warning Scheme. Buildings, 15(13), 2221. https://doi.org/10.3390/buildings15132221