Abstract

Modular construction has the potential to transform the construction industry, as most (80–95%) of the modules, which are considered prefabricated buildings, are manufactured off-site, which is more efficient, safe, cost-effective, sustainable, productive, and faster than traditional construction. It is not without challenges, however, as it requires detailed and comprehensive planning, high initial costs, and navigating transportation and design constraints. The goal of this study was to identify and categorize the benefits and challenges of modular construction and offer strategies for resolving the challenges. This study also provides a comprehensive review of modular construction methods, including permanent modular construction (PMC), movable modular construction (RMC), volumetric modular construction (VMC), and panelized construction, and examines the connectivity of the modules, as well as the integration of advanced technologies like artificial intelligence (AI). The results revealed that the most frequently cited benefits of modular construction were reducing construction time by up to 50%, 20% cost savings, and material waste reduction of up to 83%. The most common challenges included transportation complexity, limited design flexibility, and high initial costs. The results of this study will assist project managers, construction professionals, and company owners in evaluating modular construction by providing quantified benefits and challenges, a comparative analysis of different modular methods, and insights into effective mitigation strategies, allowing them to assess its suitability based on project timelines, budgets, design requirements, and logistical constraints.

1. Introduction

Modular construction is part of a broader movement towards automation and digital integration in the construction industry [1,2]. It is a modernized construction method that has significantly evolved in recent years through the integration of off-site fabrication and digital technologies, and it has the potential to revolutionize the construction industry [3,4]. It involves a high percentage of off-site construction and is lauded for its efficiency in addressing the housing deficit and post-disaster reconstruction [3,4,5]. The prefabricated modules and components are manufactured off-site and transported to a job site for assembly [2,6,7]. Modular construction offers significant benefits to the construction industry, such as the need for fewer laborers [8], enhanced safety [9], optimized cost [10], increased speed of execution [8], increased productivity [9], and environmental sustainability [10].

Prefabricated construction components can be divided into categories such as walls, beams, slabs, and columns that are made of a variety of materials, such as aluminum, which is lightweight and suitable for low-rise construction, timber, which is useful for mid-rise buildings, and concrete and steel elements, which are popular because of their durability and architectural design flexibility [11,12,13]. Modular components can be utilized in a variety of arrangements and patterns, but they lack design flexibility, which makes modifications more challenging, if not impossible [10,14,15].

Modular construction is an important component of disaster relief, as the modules can serve as temporary warehouses for prefabricated building materials such as concrete, steel, timber, and aluminum [16,17] and can even provide temporary shelter for those who find themselves unhoused in disaster-stricken areas. They act as a bridge between post-disaster relief and permanent housing, as they are easy to assemble and environmentally sustainable, can be deployed quickly, and can be easily adapted to whatever is needed [18]. They are an attractive solution for the proposed probabilistic frameworks for post-disaster recovery that emphasize the importance of integrating social, economic, and environmental factors into disaster response strategies [19,20].

The off-site manufacturing and on-site assembly of modular construction significantly reduces the time required for construction, as it is not subject to many of the problems that cause delays in traditional construction, such as inclement weather and material and labor shortages [3,4,21]. It provides long-term cost savings through reducing labor and material waste but requires a substantial initial investment in factory infrastructure, transportation, and workforce training [8,9,21]. Transportation of the modules increases total costs due to the need for special logistics, permits, and heavy equipment [10,22].

Modular construction is more environmentally friendly than traditional construction. It significantly minimizes construction waste, lowers rework rates, and reduces carbon emissions and water usage compared to traditional practices [3,23,24].

Unlike traditional construction, which allows for greater customization and design changes [25,26,27], modular construction design is limited by size constraints, primarily because of the need to transport the modules to the site where they will be assembled. The building safety standards are similar for the two types of construction, but modular structures must be designed with connections and reinforcements that will withstand the moving and lifting that are required for their transportation to the job site [28,29,30].

Recent advances in artificial intelligence (AI), robotics, and automation have improved accuracy, increased efficiency, and minimized material waste in modular construction [22,31]. Robotics equipped with AI have improved the automated assembly of prefabricated components, reduced the dependence on manual labor, and ensured a greater stability of modular structures [32,33]. In Sweden, which is a leader in modular construction, 85% of single-family houses are built with prefabricated timber. The widespread use of modular construction is influenced by the widespread availability of wood and the country’s harsh winter climate, which makes on-site implementation difficult and increases the preference for off-site construction [34,35,36].

Transportation represents a significant part of the total cost of construction. Since modular components are built off-site, large cranes, trucks, and trailers are necessary for transporting them by land or sea to the construction site [28]. Highway transportation is subject to all the normal hazards such as traffic jams and truck breakdowns and is a source of air pollution and greenhouse gas emissions. Water transportation is usually used to import modules from overseas factories, as the cost and environmental impacts are lower over long distances, and customs delays can be avoided [22]. The integration of emerging technologies like AI-based logistics has the potential to optimize the transportation processes of prefabricated components and reduce inefficiencies [37,38].

Numerous papers have been published on modular construction, but few have explored how advanced technologies can support its implementation [28,39]. This study aims to (1) identify modular construction methods, (2) identify and categorize the benefits and challenges of modular construction, (3) calculate the frequency and ranking of the identified benefits and challenges, and (4) identify strategies for mitigating or eliminating each challenge. The findings of this study will help construction decision-makers, project managers, professionals, and company owners better understand the potential of integrating modular construction and technological advancements and will enable them to evaluate and determine the most appropriate modular construction method for their projects.

2. Methodology

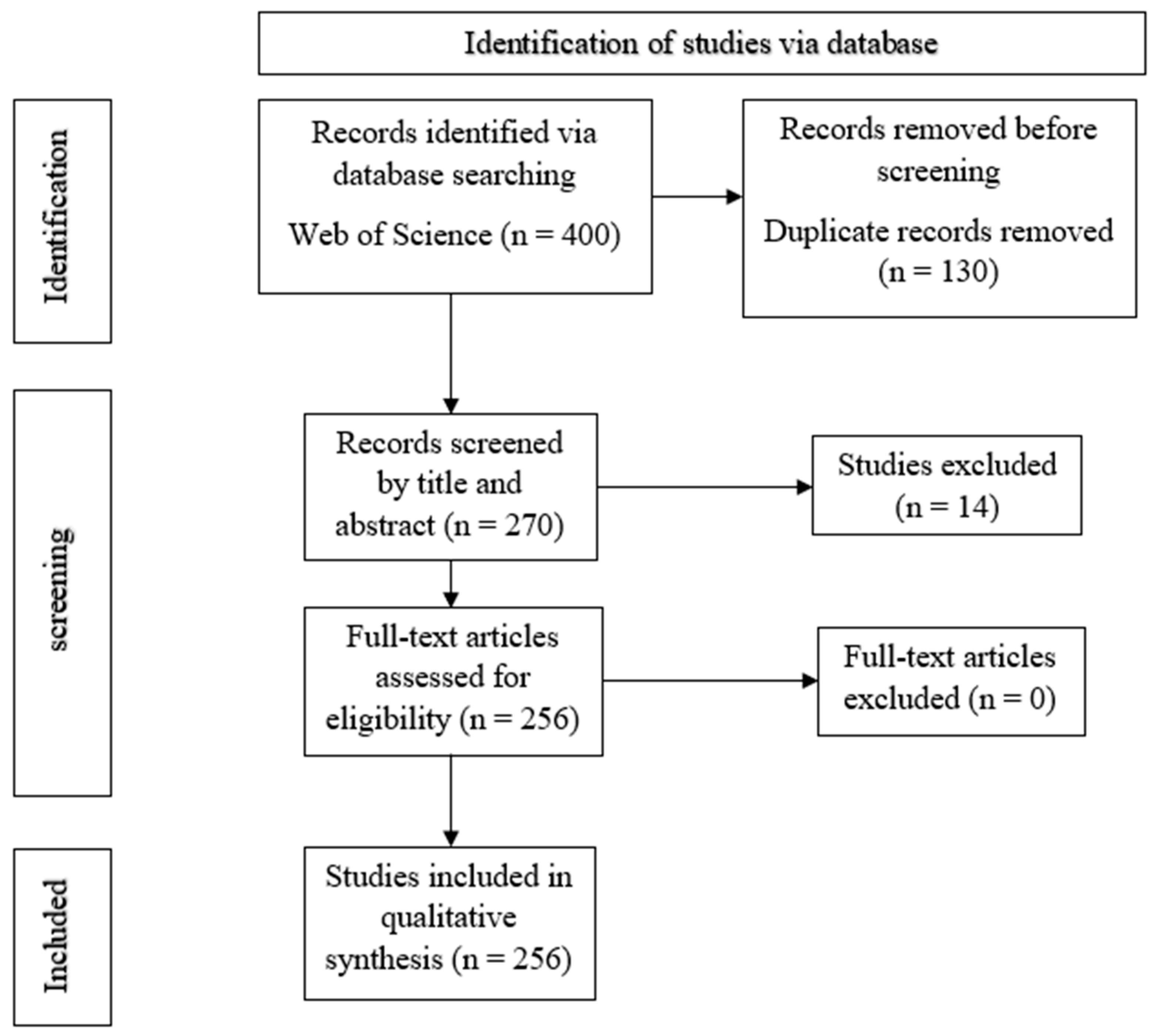

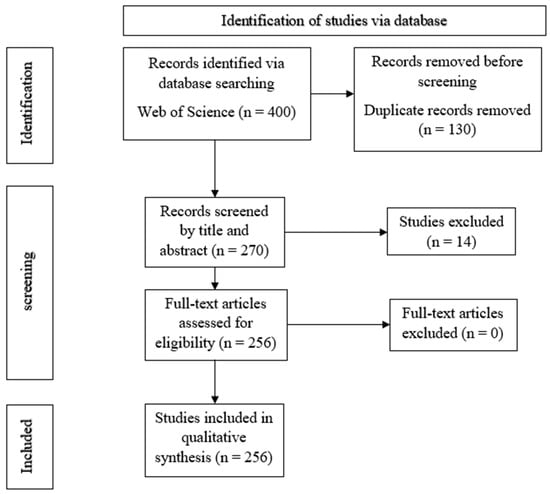

This review was conducted in accordance with the Preferred Reporting Items for Systematic Reviews and Meta-Analyses (PRISMA) guidelines. A systematic literature review was conducted to compile a database of relevant journal articles, technical reports, conference papers, and theses. The search was performed using combinations of keywords including “modular construction”, “prefabricated buildings”, “off-site construction”, “volumetric modular,” “panelized construction”, “modular connection”, and “digital technologies in construction”. Filters were applied to include only English-language publications related to civil engineering and building construction, including journal articles and conference proceedings, published between 2015 and 2024. This search resulted in 400 records, which were screened according to the inclusion and exclusion criteria shown in Figure 1. Duplicate records and irrelevant document types were removed, followed by title and abstract screening to assess relevance. Studies were included if they were published in English and focused on modular construction within civil engineering, architecture, or construction management. Editorials, promotional content, and studies not directly addressing modular construction in the built environment were excluded.

Figure 1.

PRISMA-based flow diagram illustrating the systematic literature screening and selection process for this study.

After screening, 256 eligible studies remained for detailed review. To identify the most frequently mentioned benefits and challenges of modular construction, the selected 256 peer-reviewed studies were reviewed and coded. Only those benefits or challenges explicitly discussed or supported by evidence were counted. For a mention to be considered explicit, the paper needed to directly address the specific benefit or challenge with a clear statement and often supporting discussion. Passing references or implicit mentions were not included in the count. Each instance was counted once per paper, regardless of how many times it appeared in the text.

The PRISMA-based diagram in Figure 1 illustrates the article selection process. A total of 400 records were identified through database searching. After removing duplicates and screening titles and abstracts, 270 full-text papers were assessed for eligibility, leading to 256 studies included in the final qualitative synthesis.

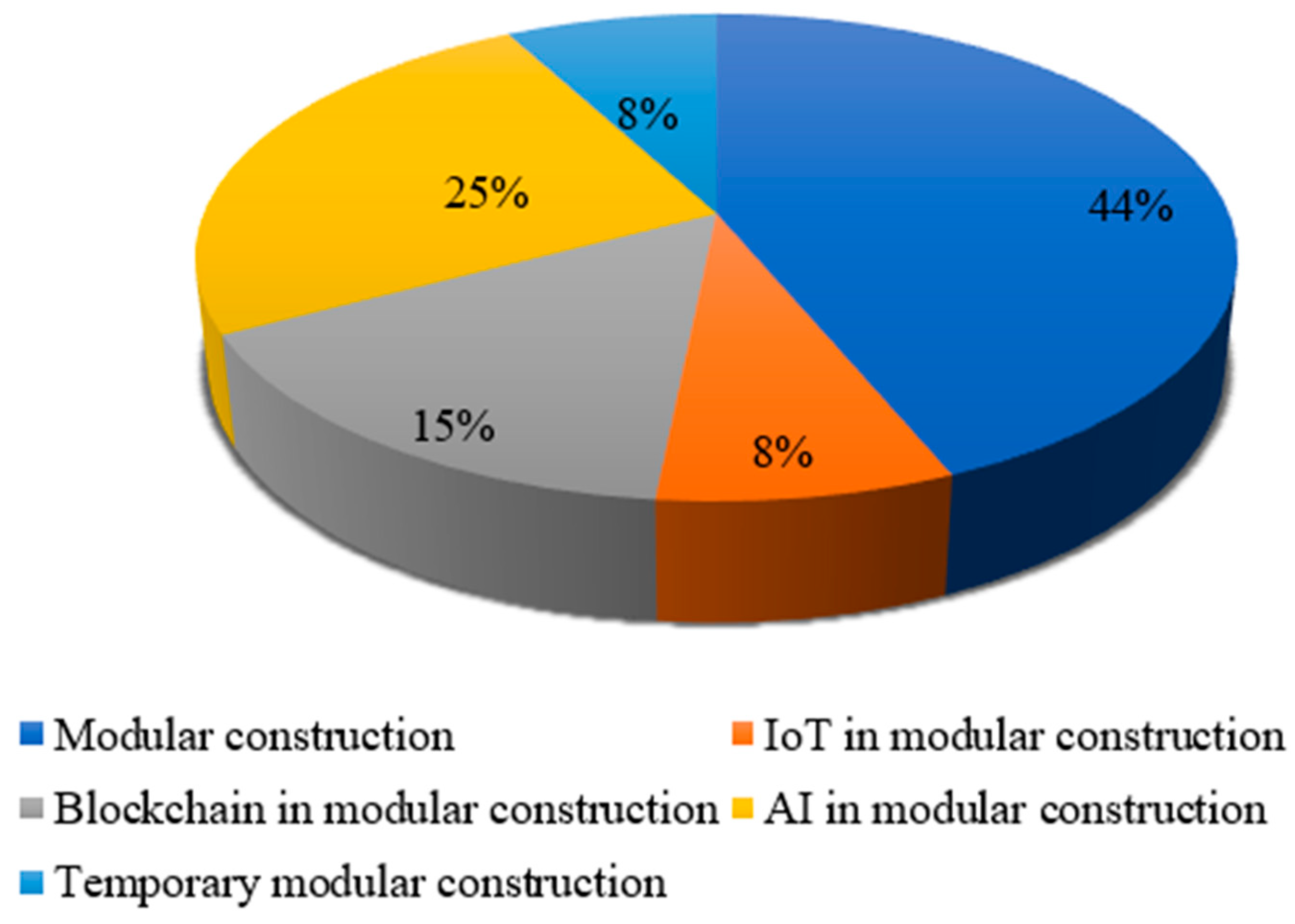

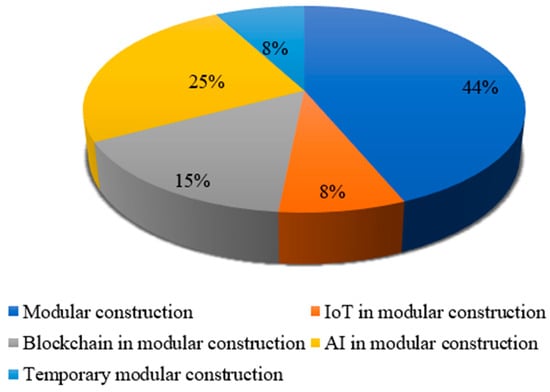

A total of 256 articles were carefully reviewed and categorized into five subjects: modular construction, IoT in modular construction, blockchain applications, AI-driven modular processes, and temporary modular construction. Modular construction in its broadest sense was found to be the focus of 44% of the literature, followed by the role of AI (25%), the integration of blockchain (25%), and temporary modular construction (8%). (See Figure 2).

Figure 2.

Distribution of papers based on research focus areas.

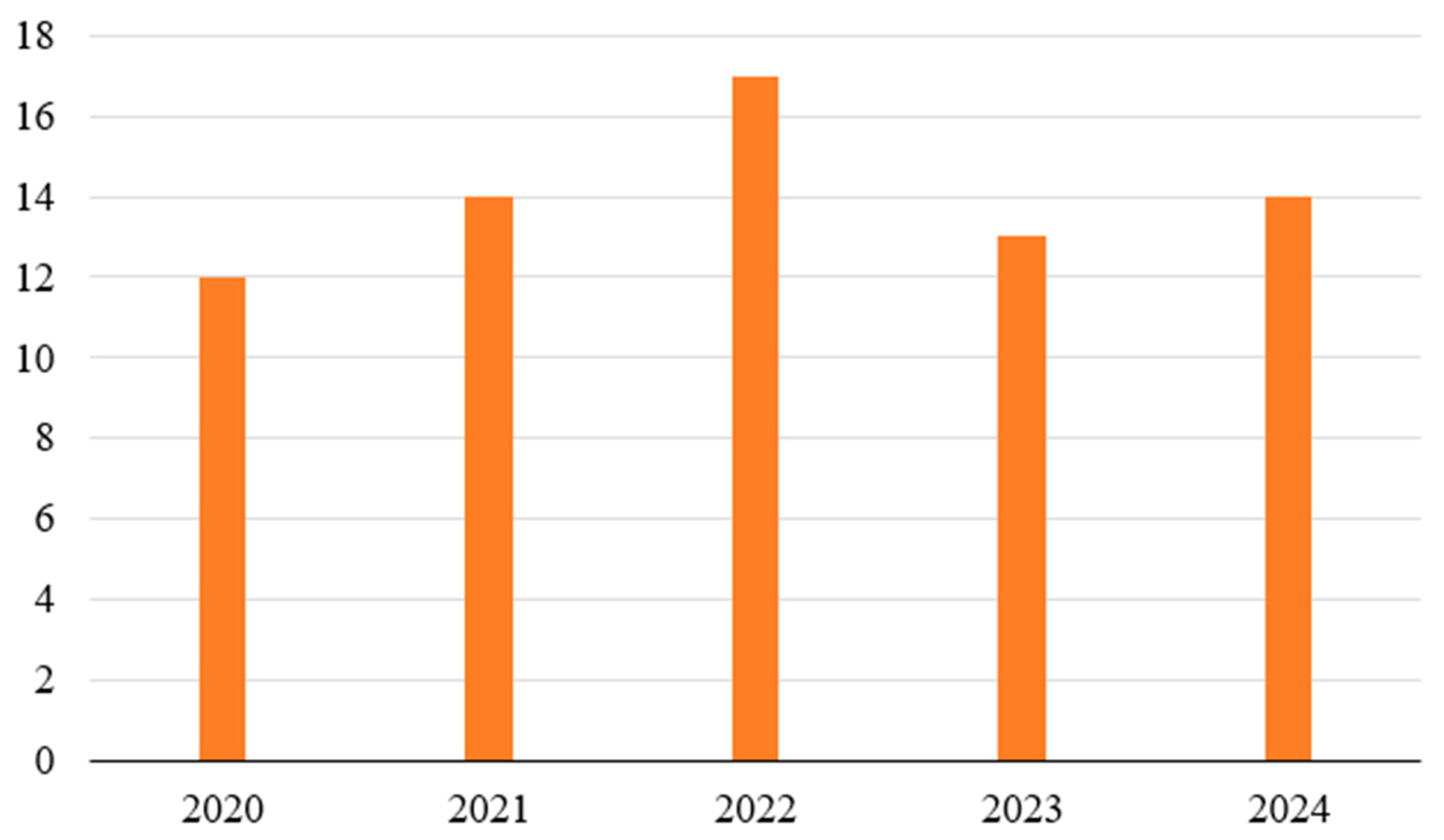

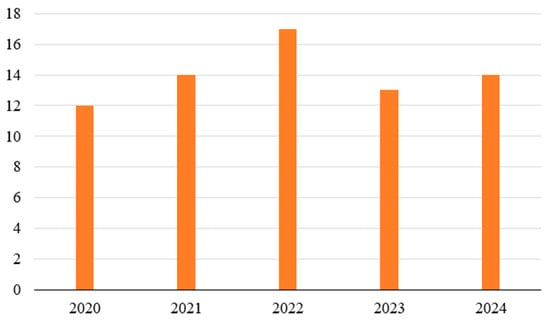

Figure 3 shows the distribution of the literature by year from 2015 to 2024. This provides an overview of how modular construction has evolved over the past two decades and reflects the uptick in research since 2020, corresponding with the increasing adoption of AI. The highest numbers of publications were in 2021 and 2022, representing approximately 18% and 20% of all peer-reviewed articles, respectively.

Figure 3.

Distribution of referenced papers based on publication year.

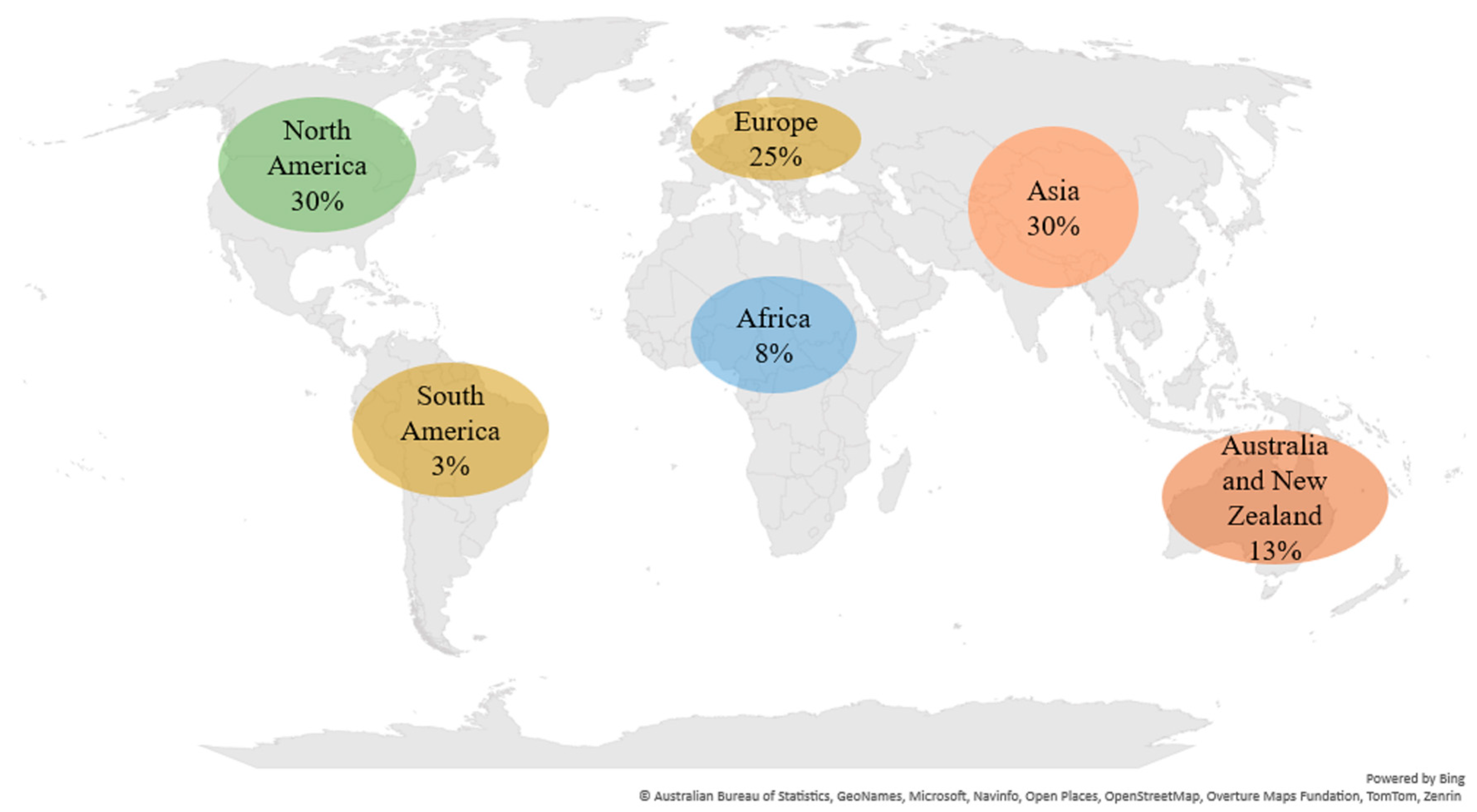

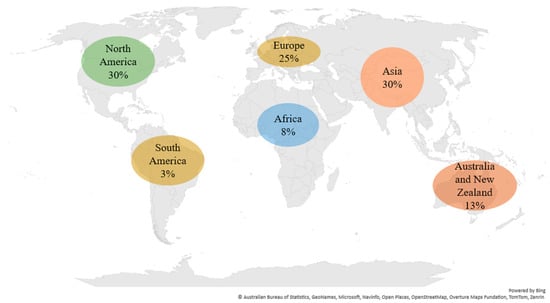

Figure 4 shows the global distribution of research on modular construction. North America and Asia each published 30 percent of the studies reviewed, indicating that these regions are the leaders in modular construction research and technology adoption. Europe followed close behind with 25%, Oceania with 13%, Africa with 8%, and South America with 3%. The distribution of research across these regions indicates that the greatest focus on modular construction was in developed and industrialized countries. The areas with a limited number of studies may be experiencing infrastructure issues and a lower adoption of digital technologies.

Figure 4.

Geographical distribution of research publications over time.

3. Results and Discussion

3.1. Synopsis of Modular Construction

Modular construction is an advanced building process in which the components are prefabricated in an off-site factory then moved to and assembled at a job site. The process enables enhanced quality control, reduced labor dependency, minimal material waste, and fewer environmental impacts [9,40]. Modular construction systems comprise components like structures, joints and connections, enclosures, and interior decorations that are designed to ensure standardization and adaptability to various applications [26].

Modular construction has grown in popularity in sectors with the same design layout, such as hospitals, dormitories, residential buildings, office buildings, retail spaces, and student housing [22,41], because of its greater efficiency, lower labor costs, and heightened environmental sustainability [41,42]. Despite these advantages, however, companies have been slow to adopt modular construction because of the lack of large-scale operational data and advanced management systems [12,28]. The various methods, including permanent modular construction (PMC), relocatable modular construction (RMC), volumetric modular construction (VMC), and panelized systems, are described below [40,43].

The permanent modular construction (PMC) method fabricates volumetric building modules off-site that will be shipped to a construction site where they will be assembled to form structures that are designed and built for long-term use. The process consists of three parts: module fabrication, transportation, and on-site assembly [9,44]. As shown in Table 1, the modules are fabricated using steel, concrete, timber, or aluminum and are equipped with complete mechanical, electrical, and plumbing (MEP) systems. Approximately 70–95% [45,46] of the components are constructed in this manner off-site, significantly reducing construction time, material waste, labor requirements, and delays caused by weather conditions [40,45]. Because of its efficiency, sustainability, and cost effectiveness, this method is widely used for the construction of high-rise residential, commercial, healthcare, educational, and industrial buildings [9,22,45].

The relocatable modular construction (RMC) method is often employed under urgent circumstances to construct temporary facilities for education, disaster relief, healthcare, and construction sites [27,47]. During COVID-19, in China, hospitals with a 10-year projected lifespan were built in just two weeks in Huoshenshan and Leishenshan. In areas with a high student population or where natural disasters have damaged the educational infrastructure, modular classrooms enable students to continue their education without disruption [10,27,47]. This method also plays an important role in the construction industry, especially in providing temporary on-site offices, worker accommodations, and storage facilities. Large-scale infrastructure projects, like road construction, oil and gas extraction, and mining operations, require flexible buildings that can be relocated as project sites change [27,47]. Temporary modular construction also offers a rapid, convenient and cost-effective solution to housing needs, as they use environmentally friendly materials like plywood boards, wheat straw insulation, and clay plaster, which significantly reduce their environmental footprint while meeting high energy efficiency standards [25,26,46], as highlighted in Table 2.

RMC offers an array of structural technologies to meet the needs of projects and environmental conditions. One of the most significant and commonly used techniques is light steel frame (LSF) construction, a technique that uses cold-formed steel (CFS) and lightweight galvanized steel as the primary structural components. Metal panels, insulation materials, and other dry building elements make them efficient for permanent and removable modular construction [48,49], and this method is widely used due to its high structural stability, lightweight properties, and flexibility in design.

Table 1.

Comparison of materials used in modular construction.

Table 1.

Comparison of materials used in modular construction.

| Item No | Material | Environmental Impact | Typical Usage | References |

|---|---|---|---|---|

| 1 | Concrete | High CO2 emissions | Structural elements, foundations | [11,22] |

| 2 | Steel | Recyclable, but energy-intensive production | Beams, columns, frames, LSF structures | [26,28] |

| 3 | Timber | Sustainable, lower emissions | Mid-rise buildings, temporary structures, modular homes | [14,15] |

| 4 | Aluminum | Lightweight, highly recyclable | Low-rise, non-structural applications | [10,17] |

Volumetric modular construction (VMC) is the off-site fabrication of fully finished, three-dimensional (3D) modules. These modules range from semi-assembled structures that allow for customization to fully enclosed structures that are ready-to-use units [6,50]. Like the previously described methods, VMC modules are also transported to and assembled on a construction site. A key benefit of VMC is its use of lateral force-resisting systems like steel plates, shear walls, braces, and steel stud walls that effectively manage seismic forces. It also enhances seismic resilience with innovative module-to-module and module-to-foundation connections [51].

The standardization that is inherent in modular construction facilitates the construction of components that are manageable in size and dimensions [51], offers cost-effective customization without sacrificing quality [15,52], and renders the modules adaptable for a variety of applications, such as residential and educational buildings. Conversely, the lack of interoperability between systems and the need to standardize modular components limits the scalability of these technologies [31,51]. Although the application of modular construction in high-rise buildings is limited due to lack of strong structural systems [9,30], VMC has significant potential for application in mid-rise buildings, repetitive plan buildings, and construction in earthquake-prone areas [16,53], as shown in Table 2.

Furthermore, the panelized method is used to construct three categories of prefabricated structures: one-dimensional (1D) single-element systems, two-dimensional (2D) panel systems, and three-dimensional (3D) volumetric and hybrid systems. The 1D single-element approach involves the prefabrication of individual structural components like beams, columns, and slabs, which are then assembled on site [26,54].

The 2D panel system consists of prefabricated wall, floor, and roof cassettes that are transported to the job site for assembly. They can be assembled up to 70% before being transported to the job site, which reduces construction time and results in a cost savings of approximately 17% [52,54].

The 3D volumetric system consists of fully fabricated structural and service modules that are transported as complete units and assembled on site. Using a 3D volumetric system can reduce costs by approximately 24% compared to conventional construction [11,44].

When 2D and 3D construction methods are combined to leverage the advantages of both prefabricated systems [11,54], it is known as a hybrid system. The panelized construction method is efficient, reduces the time required for construction, and increases site safety [28,55], as illustrated in Table 2.

Table 2.

Comparison of modular construction methods.

Table 2.

Comparison of modular construction methods.

| Item No | Method | Features | Applications | Benefits | Limitations | References |

|---|---|---|---|---|---|---|

| 1 | PMC | Completed 70–95% off-site, reduced waste, highly efficient | High-rise buildings, healthcare, education | Reduces construction time, material waste, labor requirements, and delays | High initial cost, limited design flexibility, transportation | [24,52] |

| 2 | RMC | Lightweight, adaptable, quick assembly, reduced waste | Disaster relief, post-disaster construction; temporary offices, schools, warehouses | High production of building components, reduces environmental footprint, high energy efficiency standards | Durability concerns, limited lifespan, short-term usage, transportation | [7,42] |

| 3 | VMC | Up to 70% factory-assembled, flexible transportation, reduced waste | Earthquake-prone areas, mid-rise buildings, repetitive structures | Uses resilient lateral force-resisting systems, cost-effective customization while maintaining quality | High transportation costs, limited scalability | [19,28] |

| 4 | Panelized | Up to 70% factory-assembled, flexible transportation | Residential, commercial, industrial | Cost savings of 17–24%, reduces labors requirements, reduces project delays, and increases site safety | Requires on-site integration and transportation | [2,14] |

3.2. Benefits and Challenges of Modular Construction

Manufacturing modular components off-site offers significant benefits over traditional construction [12,52,56,57]. It is flexible and adaptable, less expensive, produces a high-quality finished product with few defects in less time, makes construction sites safer, lowers the number of reworks to approximately 1% [41,52], reduces the amount of material that is wasted [58], and is energy-efficient and environmentally sustainable [8,9,48], as shown in Table 3.

Table 3.

Benefits of modular construction.

The prefabrication process minimizes material waste [59] and labor costs, reducing overall project costs by 20% [3]. Many of the modular building materials are reusable and recyclable (87.9% and 6.2%, respectively) [58,59], manufacturing the components off-site requires approximately half the time of on-site construction [52], and controlled factory settings help improve the quality and reduce the number of defects in the manufactured components [12,25]. Standard processes ensure consistent output, eliminate common on-site problems, and result in fewer material changes and higher standards of manufacturing [12,25], as outlined in Table 3.

Increased safety and environmental benefits are additional key advantages that modular construction has over traditional construction methods. On-site hazards are reduced by up to 80% [60], as most of the manufacturing is completed in the factory, minimizing exposure to falls, electrical hazards, and heavy machinery accidents. Waste is reduced by up to 83.2%, carbon emissions are reduced by approximately 34% [9], water consumption is reduced by at least 80% [9,48], and the levels of noise and dust are reduced [8,9,48]. By integrating high-performance insulation and photovoltaic panels, modular constructions achieve significant reductions in energy consumption and support long-term sustainability [61], as illustrated in Table 3.

Despite these benefits, modular construction faces challenges that impact its use. Among these are limited on-site storage areas, transport cost, road network capacity, design freeze, site access, and designing modular construction against crucial loads [3,5,51]. The space required to store prefabricated components can be a daunting challenge in urban areas and dense cities [62], and moving the components from the construction site requires accurate planning, selecting the appropriate trailers, trucks, and cranes, and securing permits [28,50,63]. Any delay can affect the project’s timeline and cost [63], so highway limitations like weight restrictions, low bridges, and narrow streets have to be considered when transporting large modules to the site [64]. Automated code compliance is another barrier, as building information modeling (BIM) with regulatory frameworks can incur semantic ambiguities, interoperability issues, and conflicting interpretations of regulations that cause inefficient compliance verification [7,46]. Complexities in the supply chains for off-site construction can be difficult to navigate because of fragmented supplier networks, unpredictable delivery schedules, and inadequate coordination between the manufacturers and jobsite personnel; these can present inefficiencies that result in higher costs and project delays [15,65], as shown in Table 4.

Table 4.

Modular construction challenges.

The designs of modules are generally standard and do not allow a lot of flexibility. Once manufacturing begins, changing the design is costly and may be impossible [66]. This is especially true of small-scale projects without any repetitive parts [48,60], which require high initial costs in factory setup, specialized equipment and skilled labor that may not be justifiable for one-off projects [5,27,42]. In addition, changes to small-scale projects often result in higher per-unit costs because the cost benefits of mass production are not realized. The lack of experienced contractors and designers familiar with modular construction methods is one of the reasons for this, as well as one of the main limitations [49,67]. The unique characteristics of modular construction, like off-site fabrication, transportation methods, and assembly processes, present cost control challenges [42,51,68]; however, one of the biggest and important challenges in designing modular structures is ensuring their structural integrity against critical loading conditions, including seismic loads, wind forces, and stresses caused by transportation [15,68,69], as summarized in Table 4.

The frequency values mentioned are derived from the number of times each benefit or challenge was referenced in the reviewed studies. They emphasize which aspects of modular construction have been more thoroughly examined in the literature, potentially revealing well-studied areas or, conversely, gaps that have been less explored. However, these values do not directly indicate the real-world significance of these aspects, which can vary considerably based on regional and contextual factors.

3.3. Modular Construction Connections

Prefabricated modular construction involves many joints and connections due to the need to assemble the individual structural components into module units or connect multiple modules to expand the entire structure. The connections assist in transferring loads between components and finally to the foundation [50,68]. Modular construction connections can be categorized as inter-modular, intra-modular, and module-to-foundation connections [70].

Inter-modular connections play a key role in resisting both vertical and lateral forces, ensuring load sharing between modules and providing structural integrity throughout the system [69,70]. Common connection types include bolted, welded, or hybrid connections, depending on the structural requirements [68,71]. Bolted connections, which are commonly used due to their easy assembly, are vulnerable to bearing buildup, slippage failures, and challenging alignments [1,66,70]. This vulnerability is particularly pronounced under cyclic loading conditions such as those experienced during seismic events [24,38]. The level of pre-tension in the bolts is a critical factor influencing their resistance to these forces [1,72]. Welded connections offer greater strength but require more time and skilled labor for proper execution [1,70]. However, their rigid nature can limit energy dissipation under dynamic loads like earthquakes [38,66], potentially leading to brittle failure if not properly designed [1]. Post-tensioned connections and plug-in shear key mechanisms have been proposed as an alternative to increase the vertical stability and reduce load redistribution challenges under extreme loading conditions [69,70].

Inter-modular connections have been examined under various loading conditions, especially in relation to seismic and wind forces. These connections play a crucial role in ensuring the overall stability and safety of modular buildings, both during their normal service life and in temporary situations such as lifting and transport. While bolted inter- modular connections are commonly used, their performance can vary based on several geometric and mechanical parameters, including bolt diameter, plate thickness, and the level of pre-tension applied [70,71]. For instance, smaller bolt diameters or insufficient pre-tension can lead to increased slippage under lateral loads [70,72]. Pre-tensioned bolts greatly improve resistance to axial loads. This is particularly beneficial in resisting uplift forces caused by wind [1,37]. While welded intermodal connections are effective in high-load environments, they have limitations regarding reusability and flexibility. Their stiffness can also lead to stress concentrations under certain loading scenarios [1,38]. Hybrid bolt–weld connections provide a balanced solution by combining structural strength with ease of construction. The design of these connections must carefully consider the load sharing between the bolts and the welds under different types of stress [66,72]. Mechanical connections, such as plug-in shear keys and self-locking systems, show enhanced energy dissipation under cyclic loads and have been found to perform better than conventional welded joints in seismic applications [13,71]. These systems often rely on frictional interfaces or interlocking mechanisms to dissipate energy during seismic shaking [13,71].

Recent experimental studies and finite element modeling [49,73] demonstrated that adding stiffeners or friction plates to inter-modular connections can delay progressive collapse and significantly reduce inter-story drift under cyclic loading. The research also emphasized that anti-uplift features and shear transfer plates help maintain alignment during lifting and after installation, which minimizes misalignment and structural gaps. Additionally, parametric evaluations revealed that factors such as bolt diameter, plate thickness, and pre-tension level play a crucial role in determining the connection’s axial and shear resistance [52,73]. When optimized, hybridized joints not only fulfill structural requirements but also simplify on-site assembly, reduce construction time, and enhance safety margins [30,73]. These optimizations often involve balancing the stiffness and ductility of the connection to suit the anticipated loading conditions [1,72].

Intra-modular connections are similar to the beam–column connections utilized in conventional steel structures. The stiffness and ductility of intra-modular connections affect the overall performance of the modular unit [70] and increase the lateral performance and structural integrity of constructions, allowing them to effectively resist dynamic loads like wind and seismic forces [74]. End plate and fin plate connections are typically used between columns and beams. They are designed to transfer forces between members, consequently, their stiffness and rotational behavior must be carefully considered to prevent progressive collapse [57], as outlined in Table 5. Welded connections have high stiffness but require great precision, which increases the need for on-site work and detailed engineering design [70].

Table 5.

Types of connections in modular construction.

This high stiffness can be advantageous for resisting wind loads [1,37] but might limit energy dissipation under seismic stress [1,38]. Recent experimental studies have shown that bolted semi-rigid intra-module connections significantly affect the lateral stiffness and load-carrying capacity of modular steel joints. Specifically, studies [3,75] revealed that bolted semi-rigid connections, which include corner-fitting reinforcement, demonstrate improved lateral stiffness and ductility during full-scale static tests. These connections exhibited superior performance under various conditions of intra-module connection stiffness. The finite element analyses conducted in this study support the experimental results and provide reliable theoretical models for predicting structural behavior under lateral loads [3,33]. The semi-rigid nature of these connections can offer a balance between stiffness for wind resistance and ductility for seismic performance [3,38].

Another study [76] underscored the effectiveness of reinforcing intra-module connections with vertical stiffeners and cover plates. This reinforcement effectively shifted local buckling away from the beam ends, enhanced force resistance, and significantly increased initial lateral stiffness during seismic cyclic loading conditions [44,76]. Furthermore, the authors of [38] highlighted the crucial role of semi-rigid connections, demonstrating that the stiffness of intra-module connections greatly influences buckling behavior and the overall stability of modular frames. Their work emphasizes the importance of accurately categorizing intra-module connections by their rigidity for proper structural analysis and design [38]. Accurate categorization is essential for predicting the frame’s response to both wind and seismic excitations [29,38].

Plug-in connections, post-tensioning systems, and shear key mechanisms are recent advancements in connection designs. They enhance the efficiency of load transfers, reduce the need for in situ welding, and improve the seismic performance. Unfortunately, they also often increase the geometric complexity and the dimensions of the components, which raises construction costs. Tolerance issues during assembly and load redistribution challenges are also significant obstacles, particularly for high-rise modular buildings [39,77]. Module-to-foundation connections play a critical role in ensuring stability and interaction between modular units and transferring loads to the foundation. Column connections and bolt anchor systems are essential for enhancing seismic resistance and reducing the risks of sliding and overturning failures. To reduce these risks, strong anchor systems and advanced base plate designs are commonly utilized [47,71], as summarized in Table 5.

Ensuring a strong and stable connection between the foundation and modular components is essential to prevent movement, structural damage, or collapse in medium- to high-scale modular structures. Hence, engineers design the connections for vertical and lateral loads (e.g., wind and earthquakes) to ensure the safety and resilience of the structure over the long term [46,52], as shown in Table 5. The design must account for both the magnitude and the cyclic nature of these loads [18,46]. The utilization of self-locking mechanisms and pre-tensioned systems simplifies the assembly and improves structural reliability, thus increasing the flexibility of modular buildings [47,71]. Pre-tensioning in foundation connections can significantly enhance resistance to uplift forces from wind and overturning moments from seismic activity [19,71].

Recent experimental studies have shown that rotary module-to-foundation connections exhibit substantial ductility and resilience under cyclic seismic loading conditions. These connections effectively transfer internal forces without failure, even when minor gaps occur at the interfaces between corner fittings and foundations [43]. Furthermore, the use of composite connection techniques—such as grouted, bolted, and hybrid connections—has significantly enhanced structural integrity, improved load transfer, and boosted seismic performance. For instance, energy dissipation capacities have increased by up to 30% compared to conventional systems [16]. Additionally, advancements in stiffness-coupling spring matrix approaches have provided a more accurate representation of the complex nonlinear behavior of these connections under seismic stress. Numerical analyses indicate that maintaining consistent stiffness in module-to-foundation connections is essential for achieving optimal seismic performance, particularly in systems subjected to severe seismic events [19].

Employing new technologies in connections ensures that module components are aligned accurately, and utilizing IoT enhances the structural performance and simplifies on-site installation [50,62].

Digital twins facilitate the monitoring and adjustment of connections, reducing errors and ensuring high-quality assembly outcomes [46,78], but connection design is in the early stages, and more experimental, numerical, and laboratory studies (e.g., cyclic loading tests, shear tests) are needed to optimize their performance. Future developments in automated and self-locking connection systems have the potential to make modular construction even more efficient and adaptable [69,70]. Challenges such as minimizing lifting time and ensuring collision-free lifting paths require careful planning of crane locations and operations to ensure proper alignment and stability of the inter-modular connections during assembly, as misalignment or error during lifting and positioning can compromise the structural integrity of the assembly [65].

3.4. Digital Technologies in Modular Construction

The integration of AI and robotics in modular construction has significantly improved the automation and accuracy of off-site manufacturing. AI-based machine learning (ML) algorithms can detect defects in prefabricated components and reduce reliance on labor [32]. Robotic systems can perform repetitive tasks more efficiently, rapidly, and with greater accuracy, reducing the amount of wasted materials [79]. AI-based planning optimizes logistics and ensures the timely delivery of prefabricated components to construction sites. The integration of human–robot collaboration (HRC) in modular construction enhances efficiency, reduces safety risks, and enhances the flexibility required for customization. Future advances in AI-based robotics, real-time sensor technologies, and adaptive automation will improve the cooperation between human workers and robotic systems in construction [38,59], as shown in Table 6.

Despite favorable conditions for automation, companies have been slow to adopt the use of robotics in modular construction [38]. This is due in large part to their limited flexibility in adapting to changes in production components, as modular construction must adapt to a variety of needs while responding to economic fluctuations and maintaining flexibility. The parallel production of a number of diverse modular construction projects also makes the process more complex [38]. This plus the economic barriers associated with robotic implementation make full automation challenging [37].

The integration of AI and digital twins has been explored to optimize modular construction processes, but despite advancements in modular construction and the utilization of AI technology and digital tools, transportation and logistics management are still in the early stages [19,77]. Recent studies have demonstrated the practical applications of digital twin technologies in modular construction. For instance, [80] examined a modular construction manufacturer in Hong Kong, highlighting how digital twins enhanced logistics and on-site module installation processes. Similarly [51], developed a digital twin framework integrating BIM and GIS to simulate real-time logistics in a six-story modular apartment project, effectively predicting risks and optimizing delivery routes [48,51].

Table 6.

Benefits of digital technologies in modular construction.

Table 6.

Benefits of digital technologies in modular construction.

| Item No | Benefits | References |

|---|---|---|

| 1 | Robotic automation reduces reliance on labor and enhances precision. | [27,79] |

| 2 | Blockchain improves tracking of prefabricated components and enhances collaboration. | [60] |

| 3 | IoT sensors enable real-time data collection for assembly and monitoring. | [62,81] |

| 4 | Smart contracts automate payments, verify materials, and track logistics. | [27,53] |

| 5 | Blockchain enhances supply chain transparency and reduces the risk of data manipulation. | [21,72] |

| 6 | AI-based ML improves the detections of defects. | [32] |

| 7 | BIM and blockchain integration enhance predictive analytics and project monitoring. | [14,21] |

Blockchain is a decentralized ledger system that provides a secure and transparent system for data sharing and collaboration between stakeholders. It automates parts of modular construction, thereby improving the tracking of prefabricated components from the manufacturing site to the construction site [24,27,60], optimizes logistics, and improves overall efficiency [27,77]. Integrating blockchain with IoT and BIM increases collaboration and reduces errors in modular construction [39], while eliminating data manipulation and creating a transparent environment. Modular components equipped with IoT sensors enhance real-time data collection for construction, assembly, and operational monitoring, enabling informed decision-making throughout the construction lifecycle [62,81]. Key applications like smart contracts, supply chain management, and decentralized data management make blockchain crucial for the future of modular construction [82]. Supply chain management benefits significantly from the integration of blockchain, IoT, and BIM technologies, and IoT sensors increase traceability and visibility by rapidly collecting real-time data and accurately linking physical resources with BIM models [27,71].

Blockchain improves transparency and ensures that stakeholders have access to immutable data by recording and securing transactions made throughout the entire process, from prefabrication and transportation through assembly [50]. Smart contracts improve automation processes such as material verification, tracking logistics, and stakeholder communication, reducing errors and fraud and ensuring efficient project execution. They automate the payment process after specific conditions are met, thereby reducing reliance on intermediaries and minimizing payment disputes [27,53]. In supply management, blockchain enhances logistics tracking by monitoring the progress of modular components from the factory to the construction site in real time, mitigating delays, increasing transparency, and optimizing delivery schedules [21,72], as shown in Table 7. Blockchain can also enhance BIM by facilitating real-time project monitoring and securing data sharing between stakeholders, preventing unapproved changes, and adding to the integrity of construction records [14,21]. The integration of BIM and blockchain in modular construction improves predictive data analytics, optimizing material usage, planning, and the efficiency of on-site installation [5,82].

Table 7.

Digital technologies challenges in modular construction.

While blockchain technology has the potential to revolutionize modular construction by improving its efficiency, security, and automation, the interoperability issues between BIM and management systems, high initial implementation costs, and the lack of regulatory frameworks for smart contracts in the construction sector are barriers to its implementation [72,82], as summarized in Table 7.

3.5. Modular Construction Strategies and Challenges

The authors of this paper analyzed the relationships between eight challenges and fourteen strategies, and the results are shown in Table 8. The most important challenges, such as transportation complexity, high initial costs, and structural stability, require targeted strategies to reduce their impact. Therefore, challenges related to the organizational category are emphasized in the literature.

Table 8 shows that regional modular manufacturing hubs and just-in-time delivery systems can effectively overcome logistical constraints and ensure efficient handling and storage of prefabricated components [4,22]. The integration of AI technologies offers a solution to the challenge of early design freezing, allowing for flexibility and real-time design changes [50,62]. Empirical evidence from recent studies confirms that parametric and generative design tools, such as Grasshopper and Dynamo, facilitate rapid prototyping and optimization based on real-time performance criteria. AI integration with BIM frameworks, like the Generative AIBIM approach, further enables adaptive and efficient exploration of multiple design configurations, supporting dynamic project requirement [83].

The shortage of contractors, designers, and experienced labor remains a significant issue, highlighting the need for workforce development programs and parametric design tools [43,67]. Addressing the higher costs of small-scale projects requires that modular designs and financial incentives be standardized to improve their scalability and cost-effectiveness [3,84]. Strategies like advanced connection techniques and segmented module design can increase the safety, durability, and stability of structures against seismic and wind events [9,68].

The selection of materials is a fundamental factor in structural integrity, as lightweight prefabricated materials and reinforced connections can increase the structures’ integrity and ease the transportation of the modules [14,15]. Advanced materials like high-strength steel and composite panels allow for greater resilience during seismic events while reducing the overall weight of the module, which reduces transportation costs [22]. Integrating AI technologies provides maintenance and real-time monitoring systems, supports the modular components’ lifespan, reduces the number of reworks, and optimizes the use of materials [50]. Recent studies indicate that collaborative human–robot interactions enhance efficiency and accuracy in modular assembly, particularly in off-site factories, significantly mitigating issues related to labor shortages and improving overall production quality [82].

AI-driven design tools, such as generative and parametric systems, allow designers to evaluate multiple configurations in real time based on performance, material usage, or cost criteria. These tools enable rapid iterations and adaptive layouts, allowing for quick adjustments to modular components in response to site conditions or client requirements. For instance, parametric modeling platforms like Grasshopper and Dynamo allow users to modify modular configurations dynamically by altering key parameters [15]. Meanwhile, AI-based layout optimizers enhance spatial efficiency and reduce material waste [32,50]. These technologies promote design flexibility and facilitate critical early-stage decisions in modular workflows [14,84].

AI technologies like blockchain improve the efficiency of modular construction by facilitating real-time tracking of modular components from manufacturing to final assembly, ensuring greater transparency and reducing delays [3,4]. Collaborative human–robot interactions for assembling modular components can significantly increase efficiency and accuracy, especially in off-site prefabricated factories [38]. When blockchain is integrated with smart contracts, it automates the payment process and reduces project costs [56]. Empirical evidence shows that BIM-based mapping significantly improves regulatory compliance by enabling automated code review. This reduces semantic ambiguities and increases interoperability, leading to significant cost and time savings [82].

Challenges related to regulatory compliance and sustainability require innovative approaches. BIM-based ontology mapping enables automated code compliance checks, minimizing semantic ambiguities, and increasing interoperability in modular projects [46]. Complex supply chain issues can be resolved by integrating AI technologies that improve real-time tracking and optimize logistics [65], as highlighted in Table 8. Adopting circular economy principles such as design for separation and traceability with AI-based technologies can improve sustainability by enabling material reuse and life cycle monitoring [51]. Implementing circular economy strategies such as Design for Disassembly (DfD) and Active Disassembly (AD) ensures that modular components are easily reusable, significantly reducing construction and demolition waste. Digital tracking of components through embedded tags or digital twins further enhances traceability and sustainable lifecycle management [3,79].

The findings from examining the challenges and potential strategies of these methods can serve as guidelines for practitioners and decision-makers, enabling them to take appropriate actions and develop effective policies, as summarized in Table 8.

Table 8.

Relationships between modular construction strategies and challenges.

Table 8.

Relationships between modular construction strategies and challenges.

| ID | Strategies | Challenges | References |

|---|---|---|---|

| S1 | Just-in-time delivery system | C3, C4 | [22,63] |

| S2 | Regional modular manufacturing hubs | C1, C3 | [9,22] |

| S3 | Prefabrication of multi-purpose components | C2, C7 | [3,84] |

| S4 | Standardization of modular designs | C10, C8 | [14,15] |

| S5 | Optimal on-site assembly | C1, C3, C7 | [4,62] |

| S6 | BIM Integration and AI-driven adaptability | C2, C6, C1, C7, C5 | [50,62] |

| S7 | Government incentives and financial subsidies | C9, C10 | [3,24] |

| S8 | Segmented module design | C1, C11 | [9,25,40] |

| S9 | Advanced connection techniques | C11 | [9,25,40] |

| S10 | Workforce development and training programs | C5 | [43,67] |

| S11 | Parametric design | C2 | [14,15] |

| S12 | Circular economy strategies (DfD, AD, lifecycle tracking) | C8 | [32,51] |

| S13 | Blockchain integration and smart contracts | C6, C4 | [3,10] |

| S14 | Human–robot collaboration in off-site construction | C5 | [38,82] |

4. Conclusions

Modular construction has the potential to transform, expand, and enhance the construction sector by increasing its efficiency, cost effectiveness, quality control, safety, and sustainability while reducing the time required for construction. This comprehensive review analyzed 256 peer-reviewed studies to evaluate the current state of modular construction, highlighting its key advantages, challenges, and practical strategies for improvement. The analysis revealed that the most significant benefits of modular construction include a reduction in construction time by approximately 50%, cost savings of up to 20%, and a reduction in material waste by more than 80%. Additional benefits identified include improved workplace safety, lower rework rates, enhanced energy efficiency, and decreased carbon and water usage. The study also identified major challenges faced during the implementation of modular construction. These challenges include transportation complexities, limited design flexibility due to an early design freeze, fragmented supply chains, high initial costs, and a shortage of experienced professionals. The study addressed each of these challenges with practical strategies supported by the literature.

A key contribution of this study is the systematic linking of specific challenges with practical mitigation strategies, grounded in recent research. By establishing clear connections between problems and solutions, the study provides construction stakeholders with actionable knowledge to guide their decision-making and implementation processes. Additionally, it emphasizes the role of digital technologies such as AI, BIM, blockchain, and digital twins in optimizing various aspects of modular construction, from logistics and planning to connection design and lifecycle management. This study offers a structured synthesis of the current modular construction literature, laying the groundwork for future empirical investigations into connection design, life cycle cost analysis, and long-term performance assessments.

The findings of this study will benefit project managers, professionals, and company owners by enabling them to first compare modular and traditional construction methods in terms of efficiency, cost, safety, and environmental performance and then select the most suitable method based on the specific requirements, limitations, and priorities of their projects. Additionally, these findings provide a structured overview of how smart technologies combined with modular methods can address significant limitations.

To increase the scalability of modular methods, the authors recommend that future studies should focus on validating the effectiveness of the identified challenge-strategy relationships through real-world case studies and pilot implementations and evaluating the cost-effectiveness and integration of digital tools such as AI, digital twins, and blockchain can inform strategic investment and policy development.

Author Contributions

Conceptualization, M.Z., A.P., S.K. and D.A.; methodology, M.Z. and A.P.; design and development of data analysis, M.Z., S.K. and A.P.; data collection, M.Z.; analysis and interpretation of results, M.Z. and D.A.; writing—original draft preparation, M.Z.; writing—review and editing, M.Z., S.K., A.P. and D.A.; supervision, S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable. No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could influence the work reported in this paper.

References

- Nadeem, G.; Safiee, N.A.; Bakar, N.A.; Abd Karim, I.; Nasir, N.A.M. Connection design in modular steel construction: A review. Structures 2021, 33, 3239–3256. [Google Scholar] [CrossRef]

- Thurairajah, N.; Rathnasinghe, A.; Ali, M.; Shashwat, S. Unexpected Challenges in the Modular Construction Implementation: Are UK Contractors Ready? Sustainability 2023, 15, 8105. [Google Scholar] [CrossRef]

- Rashid, K.M.; Louis, J. Activity identification in modular construction using audio signals and machine learning. Autom. Constr. 2020, 119, 103361. [Google Scholar] [CrossRef]

- Baduge, S.K.; Thilakarathna, S.; Perera, J.S.; Arashpour, M.; Sharafi, P.; Teodosio, B.; Shringi, A.; Mendis, P. Artificial intelligence and smart vision for building and construction 4.0: Machine and deep learning methods and applications. Autom. Constr. 2022, 141, 104440. [Google Scholar] [CrossRef]

- Li, X.; Lu, W.; Xue, F.; Wu, L.; Zhao, R.; Lou, J.; Xu, J. Blockchain-enabled IoT-BIM platform for supply chain management in modular construction. J. Constr. Eng. Manag. 2022, 148, 04021195. [Google Scholar] [CrossRef]

- Elsayed, K.; Mutalib, A.A.; Elsayed, M.; Azmi, M.R. Numerical study of PPVC modular steel constructions (MSCs) with selected connection strategies under varied earthquake scenarios. Results Eng. 2024, 22, 102076. [Google Scholar] [CrossRef]

- Xu, Z.; Zayed, T.; Niu, Y. Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore. J. Clean. Prod. 2020, 245, 118861. [Google Scholar] [CrossRef]

- Pan, M.; Yang, Y.; Zheng, Z.; Pan, W. Artificial intelligence and robotics for prefabricated and modular construction: A systematic literature review. J. Constr. Eng. Manag. 2022, 148, 03122004. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A quantitative assessment of greenhouse gas (GHG) emissions from conventional and modular construction: A case of developing country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Safapour, E.; Kermanshachi, S.; Habibi, M.; Shane, J. Resource-based exploratory analysis of project complexity impact on phase-based cost performance behavior. In Construction Research Congress 2018; Curran Associates, Inc.: Red Hook, NY, USA, 2018; pp. 439–448. [Google Scholar]

- Choi, J.O.; Chen, X.B.; Kim, T.W. Opportunities and challenges of modular methods in dense urban environment. Int. J. Constr. Manag. 2019, 19, 93–105. [Google Scholar] [CrossRef]

- Tsz Wai, C.; Wai Yi, P.; Ibrahim Olanrewaju, O.; Abdelmageed, S.; Hussein, M.; Tariq, S.; Zayed, T. A critical analysis of benefits and challenges of implementing modular integrated construction. Int. J. Constr. Manag. 2023, 23, 656–668. [Google Scholar] [CrossRef]

- Zhou, J.X.; Shen, G.Q.; Yoon, S.H.; Jin, X. Customization of on-site assembly services by integrating the internet of things and BIM technologies in modular integrated construction. Autom. Constr. 2021, 126, 103663. [Google Scholar] [CrossRef]

- Opabola, E.A.; Galasso, C. A probabilistic framework for post-disaster recovery modeling of buildings and electric power networks in developing countries. Reliab. Eng. Syst. Saf. 2024, 242, 109679. [Google Scholar] [CrossRef]

- Kermanshachi, S. Decision Making and Uncertainty Analysis in Success of Construction Projects. Ph.D. Thesis, The Pennsylvania State University, University Park, PA, USA, 2016. [Google Scholar]

- Dash, S.P.; Pati, D.J.; Mohamed, Z.S.; Ramesh, S. To study the material feasibility and propose design prototype for temporary housing structures for emergency relief. Mater. Today Proc. 2022, 60, 123–131. [Google Scholar] [CrossRef]

- Thai, H.T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Chong, O.W.; Zhang, J.; Voyles, R.M.; Min, B.C. BIM-based simulation of construction robotics in the assembly process of wood frames. Autom. Constr. 2022, 137, 104194. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, Z.; Liu, J.; Zhong, X.; Liu, X.; Jiang, J. Effects of various reinforcing intra-module connection details on seismic behavior of corner-supported steel modular buildings. In Structures; Elsevier: Amsterdam, The Netherlands, 2022; Volume 40, pp. 555–570. [Google Scholar]

- Yuan, Y.; Ye, S.; Lin, L. Process Monitoring with Support of IoT in Prefabricated Building Construction. Sens. Mater. 2021, 33, 1167–1185. [Google Scholar] [CrossRef]

- Rouhanizadeh, B.; Kermanshachi, S.; Dhamangaonkar, V.S. Reconstruction of critical and interdependent infrastructure due to catastrophic natural disasters: Lessons learned. In Construction Research Congress; American Society of Civil Engineers: Reston, VA, USA, 2020; pp. 895–904. [Google Scholar]

- Ghaly, M.; Elbeltagi, E.; Elsmadony, A.; Tantawy, M.A. Integration of Blockchain-Enabled Smart Contracts in Construction: SWOT Framework and Social Network Analysis. Civ. Eng. J. 2024, 10, 1662–1697. [Google Scholar] [CrossRef]

- Kifokeris, D.; Tezel, A. Blockchain and lean construction: An exploration of bidirectional synergies and interactions. Archit. Eng. Des. Manag. 2023, 21, 171–189. [Google Scholar] [CrossRef]

- Liu, J.; Chen, Z.; Liu, Y.; Bai, Y.; Zhong, X. Full-scale corner-supported modular steel structures with vertical inter-module connections under cyclic loading. J. Build. Eng. 2021, 44, 103269. [Google Scholar] [CrossRef]

- Ghansah, F.A.; Edwards, D.J. Digital Technologies for Quality Assurance in the Construction Industry: Current Trend and Future Research Directions towards Industry 4.0. Buildings 2024, 14, 844. [Google Scholar] [CrossRef]

- Resta, G.; Gonçalves, S. Design for disassembly and cultural sites. The use of modular architecture and prefabrication in exhibition venues. Vitr. Int. J. Arch. Technol. Sustain. 2024, 9, 78–95. [Google Scholar] [CrossRef]

- Kermanshachi, S.; Rouhanizadeh, B. Feasibility analysis of post disaster reconstruction alternatives using automated BIM-based construction cost estimation tool. In Proceedings of the CSCE 6th International Disaster Mitigation Specialty Conference, Fredericton, NB, Canada, 13–16 June 2018; Canadian Society of Civil Engineering: Montreal, QC, Canada, 2018; pp. 13–16. [Google Scholar]

- Ahn, S.J.; Han, S.; Altaf, M.S.; Al-Hussein, M. Integrating off-site and on-site panelized construction schedules using fleet dispatching. Autom. Constr. 2022, 137, 104201. [Google Scholar] [CrossRef]

- Wu, L.; Lu, W.; Zhao, R.; Xu, J.; Li, X.; Xue, F. Using blockchain to improve information sharing accuracy in the onsite assembly of modular construction. J. Manag. Eng. 2022, 38, 04022014. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Critical success factors for modular integrated construction projects: A review. Build. Res. Inf. 2020, 48, 763–784. [Google Scholar] [CrossRef]

- Ali, A.H.; Elyamany, A.; Ibrahim, A.H.; Kineber, A.F.; Daoud, A.O. Modelling the relationship between modular construction adoption and critical success factors for residential projects in developing countries. Int. J. Constr. Manag. 2024, 24, 1314–1325. [Google Scholar] [CrossRef]

- Liu, H.; Zainul Abidin, N. A Review on Research of Prefabricated Building Costs: Exploring Collaborations, Intellectual Basis, and Research Trends. Sustainability 2024, 16, 9823. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Cai, J.; Du, A.; Liang, X.; Li, S. Prediction-based path planning for safe and efficient human–robot collaboration in construction via deep reinforcement learning. J. Comput. Civ. Eng. 2023, 37, 04022046. [Google Scholar] [CrossRef]

- Turner, C.; Oyekan, J.; Stergioulas, L.K. Distributed manufacturing: A new digital framework for sustainable modular construction. Sustainability 2021, 13, 1515. [Google Scholar] [CrossRef]

- Zokaee, M.; Tavakkoli-Moghaddam, R.; Rahimi, Y. Post-disaster reconstruction supply chain: Empirical optimization study. Autom. Constr. 2021, 129, 103811. [Google Scholar] [CrossRef]

- Sendanayake, S.V.; Thambiratnam, D.P.; Perera, N.J.; Chan, T.H.T.; Aghdamy, S. Enhancing the lateral performance of modular buildings through innovative inter-modular connections. Structures 2021, 29, 167–184. [Google Scholar] [CrossRef]

- Deng, E.F.; Zong, L.; Ding, Y.; Zhang, Z.; Zhang, J.F.; Shi, F.W.; Cai, L.M.; Gao, S.C. Seismic performance of mid-to-high rise modular steel construction—A critical review. Thin-Walled Struct. 2020, 155, 106924. [Google Scholar] [CrossRef]

- Akinradewo, O.; Aigbavboa, C.; Aghimien, D.; Oke, A.; Ogunbayo, B. Modular method of construction in developing countries: The underlying challenges. Int. J. Constr. Manag. 2023, 23, 1344–1354. [Google Scholar] [CrossRef]

- Shahzad, W.M.; Rajakannu, G.; Kordestani Ghalenoei, N. Potential of modular offsite construction for emergency situations: A New Zealand study. Buildings 2022, 12, 1970. [Google Scholar] [CrossRef]

- Chourasia, A.; Singhal, S.; Manivannan. Prefabricated volumetric modular construction: A review on current systems, challenges, and future prospects. Pract. Period. Struct. Des. Constr. 2023, 28, 03122009. [Google Scholar] [CrossRef]

- Bello, A.O.; Khan, A.A.; Idris, A.; Awwal, H.M. Barriers to modular construction systems implementation in developing countries’ architecture, engineering and construction industry. Eng. Constr. Archit. Manag. 2024, 31, 3148–3164. [Google Scholar] [CrossRef]

- Romero Quidel, G.; Soto Acuña, M.J.; Rojas Herrera, C.J.; Rodríguez Neira, K.; Cárdenas-Ramírez, J.P. Assessment of Modular Construction System Made with Low Environmental Impact Construction Materials for Achieving Sustainable Housing Projects. Sustainability 2023, 15, 8386. [Google Scholar] [CrossRef]

- Tsavdaridis, K.D.; Corfar, D.A. Modular Building Connections: A review. In Proceedings of the Conference on Coordinating Engineering for Sustainability and Resilience, Irbid, Jordan, 6–9 May 2022. [Google Scholar]

- Kermanshachi, S.; Anderson, S.D.; Goodrum, P.; Taylor, T.R. Project scoping process model development to achieve on-time and on-budget delivery of highway projects. Transp. Res. Rec. 2017, 2630, 147–155. [Google Scholar] [CrossRef]

- Hussein, M.; Zayed, T. Crane operations and planning in modular integrated construction: Mixed review of literature. Autom. Constr. 2021, 122, 103466. [Google Scholar] [CrossRef]

- Lim, Y.W.; Ling, P.C.; Tan, C.S.; Chong, H.Y.; Thurairajah, A. Planning and coordination of modular construction. Autom. Constr. 2022, 141, 104455. [Google Scholar] [CrossRef]

- Hořínková, D. Advantages and disadvantages of modular construction, including environmental impacts. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1203, p. 032002. [Google Scholar]

- Wang, Y.; Bian, S.; Dong, L.; Li, H. Multiresolution modeling of a modular building design process based on design structure matrix. Buildings 2023, 13, 2330. [Google Scholar] [CrossRef]

- Hussein, M.; Karam, A.; Eltoukhy, A.E.; Darko, A.; Zayed, T. Optimized multimodal logistics planning of modular integrated construction using hybrid multi-agent and metamodeling. Autom. Constr. 2023, 145, 104637. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S. Digital twin for supply chain coordination in modular construction. Appl. Sci. 2021, 11, 5909. [Google Scholar] [CrossRef]

- Subramanya, K.; Kermanshachi, S.; Rouhanizadeh, B. Modular construction vs. traditional construction: Advantages and limitations: A comparative study. In Proceedings of the Creative Construction Conference 2020, Online, 28 June–1 July 2020; pp. 11–19. [Google Scholar]

- Eid, M.S.; El-Adaway, I.H. Discussion of “Multiobjective Optimization of Postdisaster Reconstruction Processes for Ensuring Long-Term Socioeconomic Benefits”. J. Manag. Eng. 2021, 37, 07021001. [Google Scholar] [CrossRef]

- Xiao, B.; Chen, C.; Yin, X. Recent advancements of robotics in construction. Autom. Constr. 2022, 144, 104591. [Google Scholar] [CrossRef]

- Zheng, Z.; Zhang, Z.; Pan, W. Virtual prototyping-and transfer learning-enabled module detection for modular integrated construction. Autom. Constr. 2020, 120, 103387. [Google Scholar] [CrossRef]

- Abdul Nabi, M.; El-Adaway, I.H. Modular construction: Determining decision-making factors and future research needs. J. Manag. Eng. 2020, 36, 04020085. [Google Scholar] [CrossRef]

- Chen, C. Advantages and barriers of modular construction method in constructing buildings. Proc. Inst. Civ. Eng. Smart Infrastruct. Constr. 2023, 176, 75–84. [Google Scholar] [CrossRef]

- Loizou, L.; Barati, K.; Shen, X.; Li, B. Quantifying advantages of modular construction: Waste generation. Buildings 2021, 11, 622. [Google Scholar] [CrossRef]

- Mignacca, B.; Locatelli, G.; Velenturf, A. Modularisation as enabler of circular economy in energy infrastructure. Energy Policy 2020, 139, 111371. [Google Scholar] [CrossRef]

- Jeong, G.; Kim, H.; Lee, H.S.; Park, M.; Hyun, H. Analysis of safety risk factors of modular construction to identify accident trends. J. Asian Archit. Build. Eng. 2022, 21, 1040–1052. [Google Scholar] [CrossRef]

- Nazir, F.; Edwards, D.J.; Shelbourn, M.; Martek, I.; Thwala, W.D.D.; El-Gohary, H. Comparison of modular and traditional UK housing construction: A bibliometric analysis. J. Eng. Des. Technol. 2021, 19, 164–186. [Google Scholar] [CrossRef]

- Song, S.H.; Choi, J.O.; Cho, H. Transportation-Induced Impact on a Prefinished Volumetric Modular House Using Trailer Bogie: Case Study. J. Constr. Eng. Manag. 2024, 150, 05024007. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.; Ojo, S.; Yam, M.C. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2022, 46, 103720. [Google Scholar] [CrossRef]

- Chen, C.; Dong, C.; Ng, C.T.; Shi, X. Operations strategy for a construction supply chain: Modular integrated construction and blockchain adoption. Int. Trans. Oper. Res. 2024, 31, 3999–4024. [Google Scholar] [CrossRef]

- Gatheeshgar, P.; Poologanathan, K.; Gunalan, S.; Tsavdaridis, K.D.; Nagaratnam, B.; Iacovidou, E. Optimised cold-formed steel beams in modular building applications. J. Build. Eng. 2020, 32, 101607. [Google Scholar] [CrossRef]

- Rajanayagam, H.; Poologanathan, K.; Gatheeshgar, P.; Varelis, G.E.; Sherlock, P.; Nagaratnam, B.; Hackney, P. A-State-Of-The-Art review on modular building connections. Structures 2021, 34, 1903–1922. [Google Scholar] [CrossRef]

- Srivastava, A.; Jawaid, S.; Singh, R.; Gehlot, A.; Akram, S.V.; Priyadarshi, N.; Khan, B. Imperative role of technology intervention and implementation for automation in the construction industry. Adv. Civ. Eng. 2022, 2022, 6716987. [Google Scholar] [CrossRef]

- Nipa, T.J.; Kermanshachi, S.; Ramaji, I. Comparative analysis of strengths and limitations of infrastructure resilience measurement methods. In Proceedings of the 7th CSCE International Construction Specialty Conference (ICSC), Laval, QC, Canada, 12–15 June 2019; pp. 12–15. [Google Scholar]

- Loo, B.P.; Wong, R.W. Towards a conceptual framework of using technology to support smart construction: The case of modular integrated construction (MiC). Buildings 2023, 13, 372. [Google Scholar] [CrossRef]

- Li, N.; Feng, Y.; Liu, J.; Ye, X.; Xie, X. Research on the Modular Design and Application of Prefabricated Components Based on KBE. Buildings 2023, 13, 2980. [Google Scholar] [CrossRef]

- Rangasamy, V.; Yang, J.B. The convergence of BIM, AI and IoT: Reshaping the future of prefabricated construction. J. Build. Eng. 2024, 84, 108606. [Google Scholar] [CrossRef]

- Farajian, M.; Sharafi, P.; Eslamnia, H.; Kildashti, K.; Bai, Y. Classification of inter-modular connections for stiffness and strength in sway corner-supported steel modular frames. J. Constr. Steel Res. 2022, 197, 107458. [Google Scholar] [CrossRef]

- Nguyen, T.D.H.N.; Park, S.; Jeong, J.; Ahn, Y. Post occupancy evaluation of the relocatable modular construction method for temporary educational facilities. Eng. Constr. Archit. Manag. 2024. ahead of print. [Google Scholar] [CrossRef]

- Jerónimo, R.; Gonçalves, M.; Furtado, C.; Rodrigues, K.; Ferreira, C.; Simões, N. Experimental Assessment and Validation of the Hygrothermal Behaviour of an Innovative Light Steel Frame (LSF) Wall Incorporating a Monitoring System. Buildings 2023, 13, 2509. [Google Scholar] [CrossRef]

- Zhang, Z.; Zou, Y.; Guo, B.H.; Dimyadi, J.; Davies, R.; Jiang, L. Knowledge management for off-site construction. Autom. Constr. 2024, 166, 105632. [Google Scholar] [CrossRef]

- Khan, A.A.; Yu, R.; Liu, T.; Gu, N.; Walsh, J. Volumetric modular construction risks: A comprehensive review and digital-technology-coupled circular mitigation strategies. Sustainability 2023, 15, 7019. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural response of modular buildings–an overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, M.; Guo, D.; Wu, W.; Zhong, R.Y.; Huang, G.Q. Digital twin-enabled smart modular integrated construction system for on-site assembly. Comput. Ind. 2022, 136, 103594. [Google Scholar] [CrossRef]

- Chen, K.; Yang, B.; Tan, K.H. Behaviour of composite beam-column joint with fin plate connection subjected to impact loads. Eng. Struct. 2022, 273, 115143. [Google Scholar] [CrossRef]

- Aldabbas, L.J. Challenges of Digital Twin Technologies Integration in Modular Construction: A Case from a Manufacturer’s Perspective. Int. J. Adv. Comput. Sci. Appl. 2023, 14, 163–169. [Google Scholar] [CrossRef]

- Regona, M.; Yigitcanlar, T.; Xia, B.; Li, R.Y.M. Opportunities and adoption challenges of AI in the construction industry: A PRISMA review. J. Open Innov. Technol. Mark. Complex. 2022, 8, 45. [Google Scholar] [CrossRef]

- Bello, A.O.; Eje, D.O.; Idris, A.; Semiu, M.A.; Khan, A.A. Drivers for the implementation of modular construction systems in the AEC industry of developing countries. J. Eng. Des. Technol. 2024, 22, 2043–2062. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, J.; Lu, W. Human-robot collaboration for modular construction manufacturing: Review of academic research. Autom. Constr. 2024, 158, 105196. [Google Scholar] [CrossRef]

- Keorapetse, M.P.; Utzig, H.; Formoso, C.T. Cost Control in Modular Construction: A Taxonomy for Effective Cost Management. In Proceedings of the 32nd Annual Conference of the International Group for Lean Construction (IGLC32), Auckland, New Zealand, 1–7 July 2024; pp. 167–178. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).