Abstract

To investigate the feasibility of utilizing waste rock wool fiber as an additive in asphalt mixtures for resource recycling, this study evaluates and analyzes the performance of asphalt and asphalt mixtures, as well as their environmental benefits. Initially, the properties and mechanisms of modified asphalt mortar are examined under different shapes (powdery rock wool fiber (RWP) and fibrous rock wool fiber (RWF)) and varying rock wool fiber contents (0%, 1%, 2%, 3%, and 4% of matrix asphalt mass). Subsequently, the pavement performances of asphalt mixtures with different RWF contents (0%, 0.1%, 0.2%, 0.3%, and 0.4% of asphalt mixture mass) are compared. The environmental and economic impacts of RWF-modified asphalt mixtures are assessed using the life cycle assessment (LCA) method and the benefit cost analysis (BCA) method. Finally, the carbon property ratio (CPR), an innovative index, is proposed. It comprehensively evaluates the pavement performances and economic benefits of RWF modified asphalt mixtures in relation to carbon emissions (CEs). The results indicate that compared to RWP, RWF primarily functions as an inert fiber stabilizer. It provides a physical reinforcing effect through its three-dimensional network skeleton structure. Both RWP and RWF-modified asphalts exhibit improved performance compared to matrix asphalt. RWF demonstrates superior temperature susceptibility and high temperature performance. The optimal contents for achieving the best high temperature, water stability, and low-temperature crack resistance performances of RWF-modified asphalt mixtures are 0.3%, 0.2%, and 0.2%, respectively. As the RWF content increases, the energy consumption (EC) and CEs during the pavement construction stage slightly rise within an acceptable range, while positive economic benefits also increase. Additionally, the CPR index can comprehensively assess the favorable effects of pavement performances or economic benefits against the adverse effects of CEs. It offers theoretical guidance for the design of optimal rock wool fiber content.

Keywords:

rock wool; fiber; asphalt; asphalt mixture; pavement performances; recycling; environmental effect 1. Introduction

Asphalt mixtures are among the most widely used materials in highways, urban roads, and parking lots [1,2]. Asphalt pavements offer numerous advantages, including low noise levels, high anti-slip properties, convenient construction, safety, and durability [3]. Moreover, highways are a critical component of transportation infrastructure, with their mileage continuously increasing worldwide. In China alone, over one million kilometers of new highways are added annually, with the majority featuring asphalt pavement [4]. Asphalt mixtures primarily consist of asphalt asphalts, aggregates, and fillers. Aggregates and fillers are non-renewable resources. Therefore, various solid wastes are being recycled to replace these components. Under the backdrop of the dual-carbon goals, this remains a focal point of the current research [5,6,7].

Rock wool is a kind of fine interwoven fiber. It is produced by rotating molten rock at a high speed. There are many advantages, such as good thermal insulation, sound insulation, low density, high tensile strength and low cost. It is widely utilized in building insulation materials, and occupies more than 50% of the world market [8]. Waste rock wool is one of the difficult solid wastes to recycle in the world. The reason is that its own composition characteristics or complex components become contaminated after consumption. For instance, the resin and other adhesives of rock wool will affect the performance of rock wool. In addition, it will be attached to the surface and pores of rock wool by mycological substances, impurity dust, and chemicals after consumption, increasing the difficulty of recycling [9]. The most common solution for waste rock wool is stacking and landfilling. However, the leachate of hydrochloric acid formed by chemical pollution components such as chloride will pollute the environment. It will occupy a lot of land resources, exacerbate the shortage of landfill sites, and increase the cost of waste treatment. Hence, there is research that focuses on the recycling of waste rock wool. It includes the production cycle of rock wool and other materials (composite ceramics, interior decoration ceiling panels, etc.) [10], cement gel materials with filler form [8], soilless cultivation of agricultural crops with artificial substrate [11], and pollutant treatment with modification [12,13]. Nevertheless, there are shortcomings in the above methods such as high processing cost and difficulty to scale application. Thereby, the research and development of recycling technology with low treatment cost and green low-carbon is an urgent problem to be solved [14].

Fibers are among the most commonly used additives in asphalt mixtures [15]. Common fiber types include basalt fiber, glass fiber, carbon fiber, polyester fiber, steel fiber, and lignin fiber, among others [16,17]. Additionally, certain waste materials, such as carpets, cigarette butts, and disposable masks, can also be incorporated into asphalt mixtures. It further promotes the recycling and development of waste fibers [16,18]. Pavement diseases such as rutting, cracking, and sinking significantly affect the service life and driving safety of asphalt pavements. However, fibers with diverse properties and excellent mechanical performance can enhance the performance of asphalt and asphalt mixtures. For example, bagasse fiber and corn stalk fiber exhibit a hollow structure with rougher surface textures compared to bamboo fiber and lignin fiber. This characteristic improves the resistance to permanent deformation in asphalt, while reducing its low-temperature performance [19]. Moreover, fibers can strengthen the elastic component of the viscoelastic behavior of asphalt. The self-healing property of fibers contributes to enhancing the toughness of asphalt [20]. Fibers can absorb more asphalt, preventing asphalt bleeding, and improving the adhesion and high temperature performance of asphalt mixtures [21]. High tensile-strength fibers, such as basalt fiber, can increase the cohesion between asphalt and aggregates. It limits crack formation and propagation through their tensile strength across the crack zone. This enhances the crack resistance and fatigue properties of asphalt mixtures [22]. Glass fiber can improve the elastic modulus and rutting resistance of SMA mixtures, while carbon fiber enhances the Marshall stability of asphalt mixtures [23]. Overall, fibers improve the performance of asphalt and asphalt mixtures, extend their service life, and reduce road maintenance requirements.

Currently, there are still limited studies on the application of waste rock wool fiber in asphalt mixtures. Compared to other fibers such as basalt fiber, incorporating rock wool fiber into hot mix asphalt (HMA) can increase the film thickness. It leads to reduced aging and improved temperature susceptibility of asphalt mixtures. The tensile strength of asphalt with rock wool fiber increases with the rise in rock wool fiber content, enabling it to withstand part of the tensile load. Behbahani et al. [24] found that replacing some aggregates with rock wool fiber can enhance the fatigue life and deformation resistance of asphalt mixtures. The most significant improvement is observed at a rock wool fiber content of 0.8%. Hussein et al. [25] discovered that rock wool fiber can reduce the moisture susceptibility of asphalt mixtures. It achieves the highest tensile strength ratio at a 1.5% rock wool fiber content. Related studies have also indicated that excessive fiber content can limit the performance of asphalt mixtures due to fiber aggregation. In such cases, the fiber surface cannot fully absorb asphalt, reducing the bonding ability between asphalt and aggregates [20]. Moreover, fiber size is a critical factor influencing the performance of asphalt and asphalt mixtures. Guo et al. [26] determined through basket drainage and cone penetration experiments that the optimal length for basalt fibers was 6 mm. Wang et al. [27] investigated the properties of chopped basalt fiber asphalt mixtures with different contents (0.3% and 0.4%) and lengths (3 mm, 6 mm, 9 mm, and 12 mm). It concluded that the optimal combination was 9 mm in length and 0.3% in content. A three-dimensional network structure formed by fibers can significantly enhance the performance of asphalt mixtures. Additionally, low content and long fibers can achieve similar enhancement effects as high content and short fibers in terms of asphalt adhesion [28]. However, excessively long fibers may cause “pilling” issues (fiber mass). It hindered adequate mixing with asphalt and adversely affected stability and reinforcement properties [26]. Relatively short fibers, on the other hand, are not conducive to uniform distribution, resulting in agglomeration [16,26]. In summary, previous studies have primarily focused on the influence of rock wool fiber content and size on the performance of asphalt mixtures, as well as the mechanisms involving other types of fibers and asphalt mixtures. However, there is a lack of research on the impact or mechanisms of different shapes of rock wool fibers on asphalt and its mixtures.

The impact of solid waste fibers on the environment and economy during the construction period of asphalt pavement has garnered increasing attention [29,30]. Martinez-Soto et al. [31] evaluated the environmental impact of HMA and stone mastic asphalt (SMA) mixtures incorporating four different fibers (glass fiber, polyester fiber, aramid fiber, and waste tire fiber). It was found that the CEs of HMA mixtures with waste tire fiber were 3.8 times lower than those of HMA mixtures with aramid fiber, resulting in the smallest environmental load. Daniele et al. [32] discovered that the fatigue resistance of waste tire fiber asphalt mixtures was approximately 70% higher than that of standard asphalt mixtures, with a 25% reduction in environmental indices. Consequently, the application of waste fibers in asphalt mixtures not only enhances pavement performance but also reduces the environmental impact of EC and CEs, promoting sustainable development. Furthermore, while studies on waste rock wool in asphalt mixtures predominantly focus on pavement performance. there is currently no research assessing its environmental and economic benefits during the pavement construction phase. Additionally, the pavement performance trends of asphalt mixtures under varying RWF contents and their corresponding environmental and economic benefit trends are typically evaluated separately. Therefore, this study innovatively introduces the CPR index to comprehensively evaluate the relationship between pavement performance or economic benefits and CEs under different RWF contents. This approach provides theoretical guidance for achieving a reasonable balance between pavement performance, economic benefits, and CEs.

To summarize, in order to promote the application of waste rock wool fiber as an additive in asphalt mixtures, it is essential to conduct a systematic investigation into its related performances and environmental economic effects. Therefore, this study examines the performance and mechanism of modified asphalt mortar under different shapes and contents of rock wool fiber. The pavement performances of varying RWF contents are analyzed. Subsequently, the environmental and economic impacts of different RWF contents are assessed using the LCA and BCA methods. Finally, the CPR index is innovatively introduced to comprehensively evaluate the relative positive environmental benefits, balancing the pavement performances or economic benefits with the CEs of RWF-modified asphalt mixtures. This aims to provide theoretical guidance for the future development and recycling of RWF.

2. Experimental Scheme and Research Method

2.1. Materials Preparation

2.1.1. Raw Materials

Rock wool fibers are sourced from fire and sound insulation basalt wool boards of Class A, Xingyiyuan brand, manufactured in China. RWP is obtained by crushing the rock wool board and filtering it through a 0.075 mm sieve. RWF is produced by crushing for 5–7 s and filtering through an 8-mesh sieve. The basic performance indices and morphology of the rock wool fibers are presented in Table 1 and Table 2 and Figure 1. Overall, under the same mass, the volume and void ratio of RWF are larger than those of RWP. Additionally, the matrix asphalt (MA) used is AH-70# paving asphalt from the Maoming Petrochemical Donghai brand in Guangdong, China. Its basic properties are listed in Table 3 and comply with JTG E20-2011 standards [33]. The aggregates and mineral powders are limestone, and all mechanical properties meet current standards.

Table 1.

The basic performance indexes of RWP.

Table 2.

The basic performance indexes of RWF.

Figure 1.

Rock wool fiber of different shapes: (a) rock wool board; (b) RWP; (c) RWF.

Table 3.

The basic performance indexes of matrix asphalt.

2.1.2. Preparation of Asphalt Mortar

Two different shapes (RWP and RWF) and five different contents of rock wool fiber (0%, 1%, 2%, 3%, and 4% of matrix asphalt (MA) mass) are used to prepare RWP and RWF-modified asphalt mortars. The preparation process is as follows: first, the required quantities of RWP, RWF, and asphalt are determined. These materials are dried in an oven at 140 ± 5 °C until they reach constant weight and a flowing state. Additionally, due to its fluffy characteristics, the volume and void ratio of RWF are larger than those of RWP under the same mass. During testing, adding RWF all at once results in significant agglomeration. Therefore, RWF is added in multiple steps to avoid this issue. Subsequently, the mixture is stirred at 1000 r/min for 20 min at 140 °C using a mixer. Bubbles are then eliminated by stirring at a low speed of 300 r/min for 10 min. This produces the RWP and RWF-modified asphalt mortars. As the fiber content increases, RWF-modified asphalt mortar becomes increasingly viscous. Consequently, the mixing temperature is adjusted to approximately 160 °C, while subsequent operations remain unchanged. Furthermore, the asphalt mortar ratios are presented in Table 4, where AM-RWP-1 and AM-RWF-1 denote asphalt mortars containing 1% RWP and RWF, respectively.

Table 4.

The asphalt mortar ratios under different shapes and contents of rock fiber.

2.1.3. Preparation of Asphalt Mixtures

The AC-13 asphalt mixtures with different RWF contents (0%, 0.1%, 0.2%, 0.3%, and 0.4% of the asphalt mixture mass) are prepared [35]. The target mineral gradation of the AC-13 asphalt mixture is calculated using the Marshall design test. It is presented in Table 5. The optimal asphalt aggregate ratio, defined as the ratio of asphalt mass to mineral aggregate mass, is determined. Additionally, the methods for incorporating fibers into asphalt mixtures primarily include the wet method and the dry method [16]. The dry method minimizes fiber clumping or pilling within the mixture and ensures a more uniform distribution of fibers [15,36].

Table 5.

Mineral gradation of AC-13 RWF-modified asphalt mixture.

The dry method is adopted in this study, and the preparation process is as follows: (1) first, the asphalt mixture mixer is heated to approximately 180 °C, and the dried aggregates are poured into the mixer and stirred for 60 s; (2) then, RWF is added to the mixer in two separate batches, and the aggregates are dry-mixed at approximately 180 °C for 60 s; (3) after thorough mixing, mineral powder is added and stirred for an additional 60 s; (4) finally, MA is added and mixed for 90 s.

2.2. Test Methods

2.2.1. Aging Test of Rock Wool

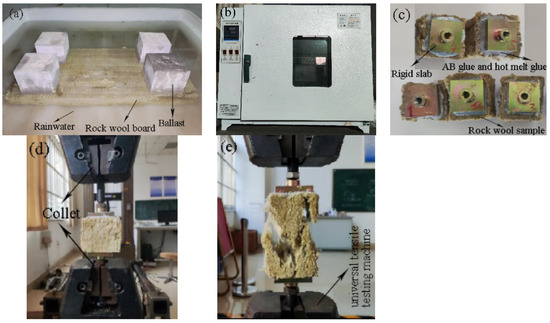

The aging performance test and Environmental Scanning Electron Microscope (ESEM) test are employed to investigate the influence of rock wool fiber on its own properties after aging [37]. The process is as follows (Figure 2): first, the rock wool board is placed in a container with rainwater covering the board. It is pressed with ballast and left for 28 days. Then, the soaked rock wool board is cut into rock wool samples measuring 50 mm × 50 mm × 50 mm and aged in an oven until constant weight is achieved. Subsequently, the aged rock wool samples are bonded to a rigid slab using AB glue and hot melt glue and fixed on the collet of a universal tensile testing machine for loading. Finally, a tensile load is applied at a constant rate of (10 ± 1) mm/min until the samples are damaged. The tensile strength retention rate of the rock wool board surface in the vertical direction and the micromorphology of the rock wool fiber after aging are used to evaluate the aging degree of the rock wool fiber. Repetition tests are conducted five times for each group. Samples are discarded if the test fails at the binder. The corresponding calculation formulae are as follows:

where Fm refers to the maximum tensile load (kN); A refers to the sectional area of the sample (m2); refers to tensile strength perpendicular to the rock wool sample surface (MPa); P refers to unaged tensile strength (MPa); and P1 refers to the tensile strength after aging (MPa).

Figure 2.

Rock wool aging test: (a) rock wool board soaking; (b) oven; (c) rock wool sample after aging; (d) fixed on the collet; (e) failure pattern of the sample.

2.2.2. Characteristic Test of Rock Wool Fiber

The micromorphology of rock wool fiber is characterized using ESEM. The chemical composition and proportion of rock wool fiber are analyzed via X-ray fluorescence spectrometer (XRF). Additionally, the mineral composition of rock wool fiber is investigated using X-ray diffraction (XRD) with a German-made X-ray diffractometer.

2.2.3. Performances Test of Modified Asphalt Mortar with RWP and RWF

The penetration index (PI) at different temperatures of 15 °C, 25 °C, and 30 °C is obtained through the penetration test. It characterizes the temperature susceptibility of asphalt mortar [38,39]. The softening point and rutting resistance factor (G*/sinδ) are obtained via dynamic shear rheological testing [40]. It is used to evaluate the high temperature deformation and rutting resistance of asphalt mortar [41]. Ductility is adopted to assess the low-temperature crack resistance of asphalt mortar. Meanwhile, microscopic tests such as ESEM and Fourier Transform Infrared Spectroscopy (FTIR) are employed to investigate the interaction between asphalt and rock wool fiber.

2.2.4. Performance Tests of RWF-Modified Asphalt Mixture

The dynamic stability and relative deformation rate are used to evaluate the high temperature stability of asphalt mixtures [38]. The residual stability is employed to assess the water stability of asphalt mixtures [42]. The maximum flexural strain in the Beam Bending Test and the fracture energy in the splitting test are utilized to evaluate the low-temperature crack resistance.

2.3. Evaluation Methods of Environmental Benefits

2.3.1. Life Cycle Assessment (LCA) Method

The LCA method is widely used to evaluate the environmental impact and resource utilization across the entire life cycle. The EC and the environmental impact of greenhouse gas emissions during the entire life cycle of asphalt pavement are primarily assessed [43,44]. The LCA method mainly consists of four key steps: system boundary definition, inventory analysis, impact assessment, and interpretation analysis [45].

The primary objective of the LCA method is to evaluate the environmental impact of EC and CEs during the construction phase of the pavement. This method is applied under different RWF contents for the recovery or direct landfill treatment of rock wool. Additionally, the process is defined by the system boundary, which is primarily divided into three stages: raw material production and rock wool recovery, asphalt mixture mixing and transportation, and spreading and rolling [46]. Inventory analysis focuses on quantifying the input and output processes during the construction phase of the pavement. Specifically, it involves calculating the unit EC and CEs of each material at each stage and obtaining the sum of the products of the corresponding quantities [45]. Impact assessment and interpretation analysis are conducted based on evaluation indicators such as EC and greenhouse gas emissions to assess their environmental impacts.

The lists of common unit EC and CEs of energy and raw material production are mainly referred to in the China Life Cycle Database (CLCD) [46]. The data list is shown in Table 6. Asphalt mixture mixing mainly includes aggregates and rock wool fiber heating, asphalt heating, and mixing. Moreover, the transportation stage of rock wool recycling and utilization mainly includes rock wool waste point-recovery stations/quarry and oil plant–asphalt mixture mixing station–construction sites. The fuel consumption data of transport vehicles is from the Chinese specification (JT/T 719-2016) [47]. The typical truck load is 15 t. The fuel consumption of 100 km under full load and unloaded is 31.5 and 23.63 L, respectively, during transportation. It is assumed that the distance from the rock wool waste point to the landfill is 40 km. The distance from the rock wool waste point to the recycling station is 20 km. The average distance from the rock wool recycling station or quarry and oil plant to the asphalt mixture mixing station is 45 km. The distance from the asphalt mixture mixing station to the construction site is 5 km. Hence, direct landfilling waste rock wool including transportation and landfilling processes with EC and CEs are 112.58 MJ/t and 8.73 kg CO2e/t, respectively. The recycling waste rock wool including transportation and treatment processes with EC and CEs are 47.25 MJ/t and 5.62 kg CO2e/t, respectively. Furthermore, 1 km of two-lane highway with asphalt mixture is adopted for LCA. It is with a single lane width of 3.5 m and a thickness of 8 cm [4].

Table 6.

Unit EC and CE of energy and raw material production.

2.3.2. Economic Analysis

The BCA is employed to evaluate the economic benefits of rock wool recovery and its application in asphalt pavement. The same 1-km two-lane highway used in the above LCA serves as the evaluation unit. The quantity of the 1-km two-lane asphalt mixture and its components can be determined based on the optimal asphalt aggregate ratio and density of the asphalt mixtures under different RWF contents, as described in Section 3.3.1. The unit prices of each raw material are primarily determined according to the actual market prices in Jiangxi Province, as shown in Table 7. Here, the RWF landfill cost only considers the transportation fee and land occupation cost, amounting to approximately USD 536/t. Additionally, the net present value (NPV) and benefit–cost ratio (BCR) are commonly adopted to assess the total economic profit over the period T in BCA. The annual income (Bi) and cost (Ci) for year i are converted into the NPV over the period T. It takes into account the future investment value with the discount rate r,

where, respects , is net profit for year i; respects , and is cost for year i; r is the discount rate with 10% [4]. is the time period with the highway maintenance period of 15 years. and are total benefits and total costs during 15 years, respectively.

Table 7.

Unit cost of raw materials.

2.3.3. Carbon Performance Ratio (CPR)

A more accurate assessment of CEs is conducted by considering the pavement performance or economic benefits of asphalt mixtures under different RWF contents. The concept of “carbon performance ratio (CPR)” is introduced, defined as the Ces per unit of pavement performance or economic benefit. Although the best pavement performance or economic benefits under different RWF contents may correspond to higher Ces, resulting in adverse environmental impacts, ideally, the CPR obtained from the minimum Ces under the highest pavement performance or economic benefits would be the smallest, leading to better environmental benefits. Consequently, the optimal RWF content can be determined. CPR serves as a quantitative index for comprehensively evaluating the relatively positive environmental benefits of asphalt mixtures by balancing pavement/economic performance with Ces. The calculation formula is shown in Equation (5), where CEi represents the Ces under different RWF contents. PEi represents the pavement performance or economic benefit values under different RWF contents. In order to more intuitively show the distribution law of CPR under different contents, the units of CPR under dynamic stability, residual stability, maximum flexural strain, fracture work, and NPV are kg-CO2eq/100 times/mm, kg-CO2eq/20%, kg-CO2eq/100 με, kg-CO2eq/J, and kg-CO2eq/USD 100, respectively.

3. Results and Discussion

3.1. The Characteristic of Rock Wool Fiber

3.1.1. Micromorphology of Rock Wool Fiber

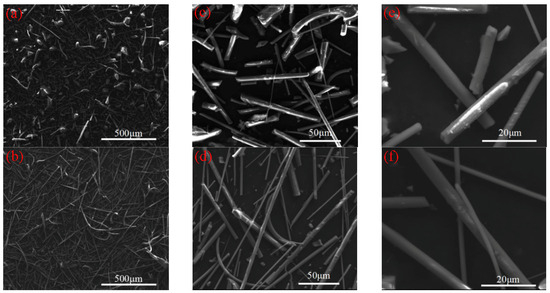

The micromorphologies of RWP and RWF observed via ESEM are presented in Figure 3. Overall, the morphologies of RWP and RWF exhibit similar characteristics. They consist of a mixture of needle-like rods and fine particles, with a relatively loose and disordered distribution, and no significant agglomeration. The smooth surfaces of RWP and RWF suggest weak asphalt adsorption. Since the surface area of RWP is larger than that of RWF at the same mass, its oil absorption capacity is superior. The length of RWP ranges from approximately 0.02 to 0.075 mm. It is more inclined toward the characteristics of mineral powder, and it is difficult to form a stable network structure. In contrast, RWF is significantly longer than RWP, with lengths ranging from about 1.5 to 5.0 mm. Additionally, the contact surface between fibers is larger, enabling the formation of a dense, staggered, and stable three-dimensional spatial network structure. Moreover, the cohesion between fibers and asphalt is stronger. The fibers themselves bear part of the tensile stress, thereby limiting the displacement, deformation, and cracking of the asphalt. This plays a critical role in bridging and toughening [43].

Figure 3.

Microtopographies of RWP and RWF: (a) RWP magnification 200 times; (b) RWF magnification 200 times; (c) RWP magnification 1500 times; (d) RWF magnification 1500 times; (e) RWP magnification 5000 times; (f) RWF magnification 5000 times.

3.1.2. Chemical Compositions and Mineral Compositions of Rock Wool Fiber

The chemical compositions of rock wool fiber are shown in Table 8. The main chemical components are SiO2, CaO, Al2O3, and MgO, etc. Their contents are 43.1%, 20.0%, 12.9%, and 9.9% respectively. In addition, the total content of SiO2 and Al2O3 is 56%. The total content of CaO and MgO is 29.9%. The acidity coefficient MK is the ratio of the total content of SiO2 and Al2O3 to the total content of CaO and MgO. It can be seen that the greater the proportion of SiO2 and Al2O3, the better the water resistance, chemical stability and tensile strength of the rock wool fiber [48].

Table 8.

Chemical compositions of rock wool fiber.

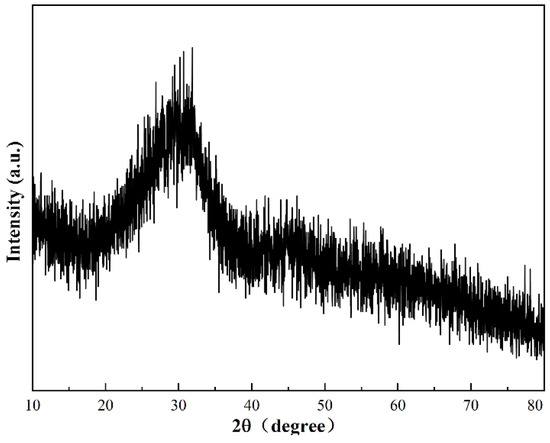

The X-ray diffraction pattern of rock wool fiber is presented in Figure 4. A more prominent diffraction peak is observed near 20° to 35°. The characteristic diffraction peak of SiO2 falls within the range of 23° to 24°. It aligns with the XRF analysis indicating that rock wool fiber contains a significant amount of SiO2 [8]. Moreover, no obvious diffraction peaks are observed in other regions, and the spectrum exhibits significant fluctuations. This may be attributed to the fact that the rock wool board cannot form a crystalline structure after high-speed spinning and high temperature as well as extremely cold treatment. It results in a higher content of vitreous body and potential chemical activity.

Figure 4.

The X-ray diffraction pattern of rock wool fiber.

3.1.3. Aging Properties of Rock Wool Fiber

The tensile strength retention rates of rock wool samples are presented in Table 9. The initial tensile strength of the rock wool samples, divided into five groups, ranges from 38.91 to 42.92 kPa, with a mean value of 41.03 kPa. After aging for 28 days, the tensile strength ranges from 32.78 to 34.79 kPa, with an average value of 33.66 kPa. Although the tensile strength retention rate has decreased, it remains significantly higher than 50%. Thus, it meets the specification requirements set by the European Committee for Standardization.

Table 9.

The tensile strength retention rate of rock wool samples.

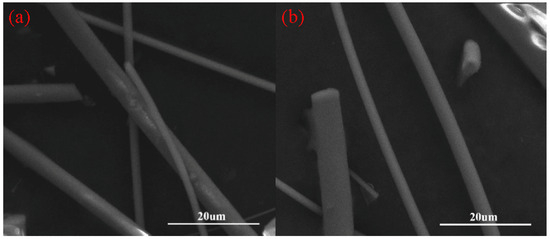

Moreover, the microtopographies of rock wool samples after aging under 5000 magnification are presented in Figure 5. After soaking and aging, the rock wool samples exhibit no obvious powder fracture phenomenon. It indicates that rock wool fibers remain stable under natural rain conditions and possess strong stability. However, the observation is inconsistent with the fact that the decreased tensile strength of rock wool samples is attributed to aging. The possible reason is that the binder between rock wool interlayers is partially destroyed during the soaking and drying process. As a result, some rock wool fibers in the samples become fluffy and cannot effectively participate in force transmission. It leads to a reduction in tensile strength after aging. Nevertheless, the rock wool fibers themselves do not undergo aging. Therefore, the influence of rock wool fiber aging on the performance of asphalt mortar and asphalt mixtures is not considered in subsequent tests.

Figure 5.

Micromorphologies of rock wool fiber: (a) unaged rock wool fiber magnification 5000 times; (b) aged rock wool fiber magnification 5000 times.

3.2. Performances and Mechanism of Modified Asphalt Mortar with RWP and RWF

3.2.1. Temperature Susceptibility

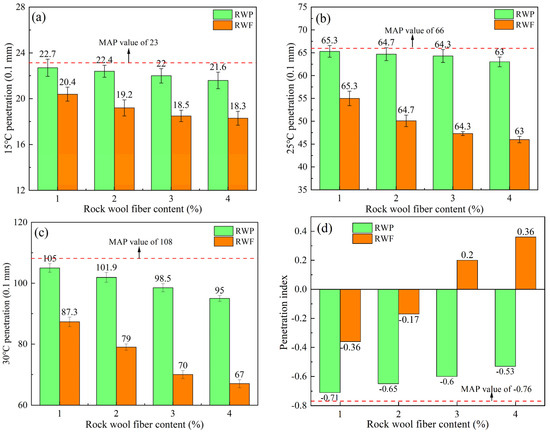

It can be observed from Figure 6a–c that the penetration of RWP and RWF-modified asphalt mortars at different contents is lower than that of matrix asphalt penetration (MAP). It indicates that there is improved relative viscosity and consistency performance. With increasing RWP and RWF content at the same temperature, the penetration of asphalt mortar exhibits a decreasing trend. Additionally, the optimal penetration for both RWP and RWF occurs at a content of 4%. Compared with MAP at 15 °C, 25 °C, and 30 °C, the penetration decrease rates of RWP and RWF at 4% content are 6.1% and 20.4%, 4.5% and 30.3%, and 12.0% and 37.9%, respectively. Furthermore, the penetration of RWF-modified asphalt mortar is 15.3%, 27.0%, and 29.5% lower than that of RWP-modified asphalt mortar at 15 °C, 25 °C, and 30 °C, respectively. Overall, the decreasing trend in the penetration of RWP-modified asphalt mortar is not significant. The influence of temperature changes on the penetration of asphalt mortar is greater than that of content changes [16]. The decreasing trend in the penetration of RWF-modified asphalt mortar is more pronounced compared to RWP-modified asphalt mortar and MAP. A larger decrease rate is observed within the content range of 1–3%, while a smaller decrease rate is observed within the content range of 3–4%.

Figure 6.

The penetration and penetration index of asphalt mortar: (a) 15 °C penetration; (b) 25 °C penetration; (c) 30 °C penetration; (d) Penetration index.

As shown in Figure 6d, the PI of RWP and RWF-modified asphalt mortar is higher than that of MA with a value of −0.76. It indicates an improvement in high temperature performance. Compared to MA, the PI of RWP and RWF-modified asphalt mortars at contents of 1%, 2%, 3%, and 4% increases by 6.6% and 52.6%, 14.5% and 77.6%, 21.1% and 126.3%, and 30.3% and 147.4%, respectively. Additionally, the PI of RWF-modified asphalt mortar is 49.3%, 73.8%, 133.3%, and 167.9% higher than that of RWP-modified asphalt mortar at the same contents of 1%, 2%, 3%, and 4%, respectively. With the increase in RWP and RWF content, the PI of both RWP and RWF-modified asphalt mortars exhibits an increasing trend.

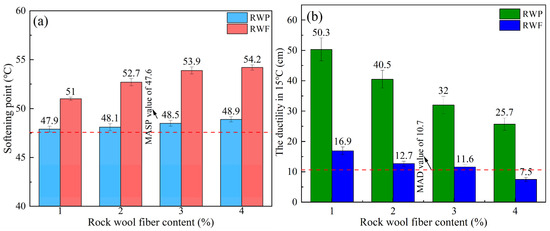

3.2.2. High Temperature Performance

According to Figure 7a, the softening points of RWP and RWF-modified asphalt mortars increase to varying degrees with increasing content. The softening points of asphalt mortars containing RWP and RWF are higher than that of MA at 47.6 °C. Moreover, compared to MA, the softening points of RWP and RWF-modified asphalt mortars increase by 0.6% and 7.1% at 1% content, 1.1% and 10.7% at 2% content, 1.9% and 13.2% at 3% content, and 2.73% and 13.86% at 4% content, respectively. Additionally, under the same content levels of 1%, 2%, 3%, and 4%, the softening points of RWF-modified asphalt mortars are 6.5%, 9.6%, 11.1%, and 10.8% higher than those of RWP-modified asphalt mortars, respectively. Consequently, the softening point of RWF-modified asphalt mortar is superior to that of RWP-modified asphalt mortar.

Figure 7.

Softening point and ductility with different rock wool fiber contents: (a) softening point; (b) the ductility in 15 °C.

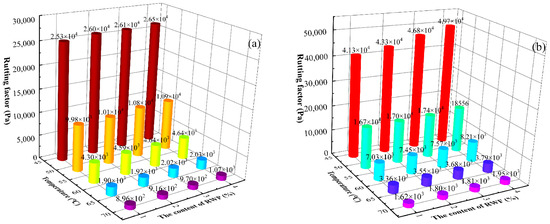

Furthermore, as shown in Figure 8, the G*/sinδ of RWP and RWF-modified asphalt mortars exhibit the same trend with changes in temperature and fiber content. It decreases with increasing temperature and increases with increasing fiber content. The impact of temperature changes is greater than that of fiber content changes, which is consistent with the findings of Xing et al. [49]. Compared to RWP-modified asphalt mortar, there is a more significant improvement in rutting resistance for RWF-modified asphalt mortar. Specifically, at a fiber content of 4%, the G*/sinδ of RWF-modified asphalt mortars at 46 °C, 52 °C, 58 °C, 64 °C, and 70 °C increases by 81.9%, 86.9%, 76.9%, 70.1%, and 87.3%, respectively, compared to RWP-modified asphalt mortar. This indicates that RWF can enhance the high temperature performance of asphalt mortar more effectively. The primary reason is that the bond strength within the three-dimensional network structure formed by RWF includes both the bond strength between asphalt and fibers and between fibers themselves. In contrast, the bond strength between smaller RWP particles and asphalt is weaker, leading to greater rheological behavior. Therefore, RWF can limit the displacement and deformation of asphalt mortar to a greater extent.

Figure 8.

Rutting factors of different asphalt mortars: (a) RWP-modified asphalt mortar; (b) RWF-modified asphalt mortar.

3.2.3. Low-Temperature Performance

The plastic deformation ability of asphalt mortar is primarily reflected in its ductility, where a larger ductility indicates better low-temperature plasticity. As shown in Figure 7b, the ductility of RWP and RWF-modified asphalt mortars at low content levels is higher than that of MA. Meanwhile, as the content increases, the ductility of both RWP and RWF-modified asphalt mortars decreases. Specifically, at the same content levels of 1%, 2%, 3%, and 4%, the ductility of RWF-modified asphalt mortars is 66.4%, 68.6%, 63.8%, and 70.8% lower than that of RWP-modified asphalt mortars, respectively. Additionally, compared to mortars with 1% content, the ductility of RWP and RWF-modified asphalt mortars with 4% content decreases by 48.9% and 55.6%, respectively.

The probable reason lies in the different structures and damage patterns. It results from the distinct shapes of rock wool fibers when combined with asphalt. The appropriate contents of RWP and RWF are evenly distributed within the asphalt. It forms good adhesion with the asphalt and thereby enhances its ductility. Moreover, the three-dimensional network structure formed by RWF creates a thicker asphalt film. It increases the hard component of the asphalt mortar. Additionally, RWP, with its smaller length and uniform distribution, exhibits higher flexibility and plasticity. Consequently, the ductility of RWF-modified asphalt mortar is relatively lower [49]. With increasing content, the ductility of RWP gradually decreases as it absorbs more asphalt, leading to an uneven colloidal structure.

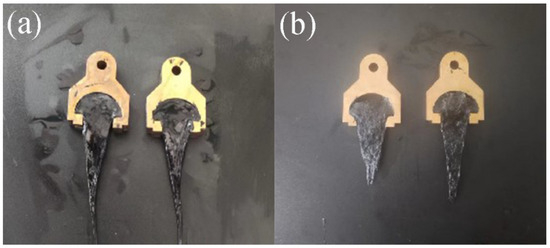

According to the failure pattern of the ductility test of RWP-modified asphalt mortar (Figure 9a), there is a filamentary shape in the fracture of RWP-modified asphalt mortar, and it is an adhesive failure. It is the case that when there is external force, adhesive failure occurs at the interface between the asphalt and the aggregates, with the cohesive force between the asphalts being greater than the adhesive force between the asphalt and the aggregates. In addition, with the increase of the longer RWF content, a more stable three-dimensional spatial network structure can be formed. It limits its deformation ability and slows down the ductility decline rate. Nevertheless, since the RWF content exceeds 3%, there is an obvious fracture surface at the asphalt mortar fracture. It belongs to brittle failure (Figure 9b). The reason is that there is fiber aggregation and agglomeration with excessive fibers. It cannot fully absorb asphalt, resulting in weakened adhesion. Aside from this, the increase of pores also weakens its stress dispersion ability, resulting in a rapid decline in ductility [50,51].

Figure 9.

Failure patterns of RWP and RWF-modified asphalt mortar in ductility test: (a) adhesive failure of RWP-modified asphalt mortar; (b) brittle failure with 3% RWF content.

3.2.4. Mechanism of RWF-Modified Asphalt Mortar

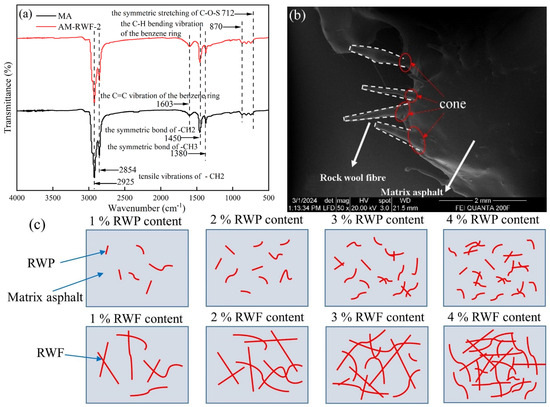

The FTIR results of MA and AM-RWF-2 are presented in Figure 10a. The characteristic absorption peaks of the two samples are almost identical. Two strong absorption peaks at 2925 cm−1 and 2854 cm−1 correspond to the tensile vibrations of –CH2. The absorption peaks at 1603 cm−1, 1450 cm−1, 1380 cm−1, 870 cm−1, and 712 cm−1 represent the C=C vibration of the benzene ring, the symmetric deformation of –CH2-, the symmetric deformation of -CH33-, the C-H bending vibration of the benzene ring, and the symmetric stretching of C-O-S, respectively. These results indicate that rock wool fiber acts as a physically inert stabilizer, without new functional groups or chemical interactions introduced.

Figure 10.

Mechanism of RWF-modified asphalt mortar: (a) the FTIR of MA and AM-RWF-2; (b) the fracture surface scan of RWF-modified asphalt mortar; (c) the schematic diagram of asphalt–fiber interaction.

As shown in Figure 10b, the rock wool fibers are well integrated with the asphalt infiltration, exhibiting no obvious agglomeration. Moreover, RWF significantly protrudes beyond the fracture surface of the asphalt mortar. Its root junction with asphalt forms a conical shape, indicating good adhesion. As illustrated in Figure 10c, with increasing RWP content, RWP transitions from an initial state of random dispersion within the asphalt to localized short connections. Due to size limitations, it is unable to form a network structure. Additionally, characteristics such as length, orientation, and random distribution have limited effects on enhancing asphalt adhesion. RWP primarily functions as a filler to enhance plastic deformation capacity [52]. Its resistance to external forces mainly relies on the cohesion of the asphalt itself, resulting predominantly in adhesive failure.

With the increase in RWF content, it is observed that initially a longer RWF forms a local network rudimentary structure. Subsequently, RWF gradually overlaps and evolves to form a stable three-dimensional spatial network structure. At this stage, the characteristics such as length, orientation, and distribution of RWF become more critical. Longer RWF with its network distribution is more likely to form a stable three-dimensional spatial network structure [20]. Conversely, parallel-interacting RWF is more prone to agglomeration. Additionally, the cohesion and adhesion within the interfacial transition zone of fiber–asphalt–fiber in the network structure formed by RWF are enhanced, which can effectively limit the movement of free asphalt. Under the network structure, rock wool fibers inherently possess a certain tensile strength and resilience modulus. It enables them to restrict crack formation and development to some extent, thereby serving as reinforcement, toughening, and stress dispersion agents [16,53]. Moreover, when larger amounts of longer or variably sized RWF are added, there is increased stress redistribution and stress concentration. It potentially leads to a shift from adhesive failure to brittle failure.

3.3. RWF-Modified Asphalt Mixture Performances

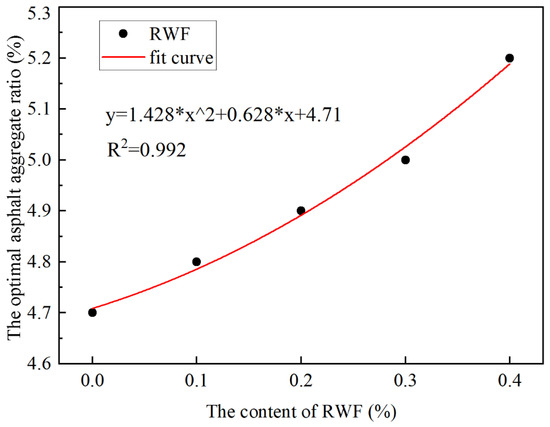

3.3.1. Marshall Test Results

The optimal asphalt aggregate ratio and Marshall indices for different RWF contents are presented in Table 10. Due to the oil absorption capacity of RWF, as its content increases, the optimal asphalt aggregate ratio also gradually rises [9]. Since the density of RWF is lower than that of the asphalt and the aggregates, the density of the asphalt mixtures decreases with increasing RWF content. On the other hand, stability and flow value initially increase and then decrease as RWF content rises. The primary reason is that when the RWF content gradually increases to an appropriate level, its dispersion within the asphalt mixture becomes more uniform. It reduces agglomeration and increases structural asphalt. Consequently, stability and asphalt saturation gradually improve, while the flow value gradually decreases. However, when the RWF content exceeds 0.2%, local uneven distribution and higher porosity occur. It leads to a decline in stability and asphalt saturation. The three-dimensional network structure formed by RWF exhibits better cohesiveness, resulting in a lower flow value. Additionally, the relationship between RWF content and the optimal asphalt aggregate ratio is illustrated in Figure 11. The fitting equation is . The R2 is 0.992, and the mean square error is 5.71 × 10−4. It indicates that there is a good fitting effect.

Table 10.

Marshall indexes of different RWF contents.

Figure 11.

The relationship between the RWF content and the optimal asphalt aggregate ratio.

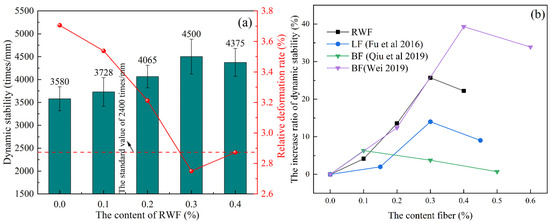

3.3.2. High Temperature Stability

The rutting test results of asphalt mixtures with different RWF contents are presented in Table 11 and Figure 12a. The highest dynamic stability and the lowest relative deformation rate are achieved at a 0.3% RWF content, with values of 4500 times/mm and 2.7%, respectively. Additionally, the dynamic stability under all tested RWF contents exceeds the specification requirement of 2400 times/mm. Compared to mixtures without RWF, the dynamic stability of asphalt mixtures at 0.1%, 0.2%, 0.3%, and 0.4% RWF content increases by 4.1%, 13.5%, 25.7%, and 22.2%, respectively. Dynamic stability gradually increases as the RWF content rises from 0.1% to 0.3%. This is because RWF is a mineral fiber with high modulus and elasticity, capable of absorbing light components in asphalt. Furthermore, the bridging effect enhances the bond strength between aggregates, fibers, and asphalt. It improves the stiffness and deformation resistance of the asphalt mixtures [42]. However, at a 0.4% RWF content, the dynamic stability decreases. This is due to the tendency of excessive RWF content to cause agglomeration and increase porosity. Additionally, the “pilling” problem (fiber block) is caused by some longer fibers with incomplete machine dispersion [16,50]. It reduces the bonding and stability of the asphalt mixtures.

Table 11.

Rutting test of asphalt mixtures with different RWF contents.

Figure 12.

High temperature performance of RWF asphalt mixtures with different contents: (a) dynamic stability of asphalt mixtures; (b) the increase ratio of dynamic stability with different fiber types and contents [54,55,56].

The increase ratio of dynamic stability of asphalt mixtures with lignin fiber (LF) and basalt fiber (BF) under different contents are also compared in the literatures (Fu et al. [54], Guo-Zhou et al. [55], and Wei [56]), as shown in Figure 12b. The three kinds of fibers show a law of first increasing and then decreasing with the increase of the fiber contents. The biggest increase ratio of dynamic stability of asphalt mixtures with 0.3% LF content in Fu et al. [54], 0.1% BF content in Guo-Zhou et al. [55], and 0.4% BF content in Wei [56] are 14%, 6.3%, and 39.3%, respectively. As a result, the effect of RWF on improving the high temperature performance of asphalt mixtures is between that of BF and LF.

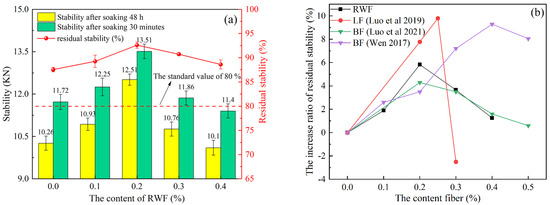

3.3.3. Water Stability

As can be seen from Table 12 and Figure 13a, there is the maximum residual stability with the RWF content of 0.2%. The residual stabilities with RWF are larger than the standard value of 80%. Aside from this, the residual stability of asphalt mixtures with 0.1%, 0.2%, 0.3%, and 0.4% RWF content increase by 1.9%, 5.8%, 3.7%, and 1.3%, respectively, compared with that without RWF.

Table 12.

Immersion Marshall test results of asphalt mixture with different RWF contents.

Figure 13.

Water stability of RWF-modified asphalt mixtures with different contents: (a) the residual stability under different RWF contents; (b) the increase ratio of residual stability with different fibers and contents [22,57,58].

The residual stability increases when the RWF content is less than 0.2%. The primary reason is that the effective structural asphalt film thickens as the asphalt–aggregate ratio increases. Moreover, its distribution becomes more uniform, reducing porosity and enhancing saturation. Consequently, water stability improves through increased density of the asphalt mixtures and stronger adhesion between the asphalt binder, fibers, and aggregates. This reduces the number of defects in the interfacial transition zone [50]. However, when the RWF content exceeds 0.2%, uneven dispersion occurs, leading to local agglomeration. It increases porosity and water absorption. Then, brittle failure is more likely to occur at the interface defects between the asphalt binder, fibers, and aggregates under water erosion [17].

The increase ratio of residual stability of asphalt mixtures with LF and BF under different contents are also compared in the literatures (Luo et al. [57], Lou et al. [22], and Wen [58]), as shown in Figure 13b. The three kinds of fibers show a law of first increasing and then decreasing with the increase of the fiber contents. The biggest increase ratio of residual stability of asphalt mixtures with 0.25% LF content in Luo et al. [57], 0.2% BF content in Lou et al. [22], and 0.4% BF content in Wen [58] are 9.8%, 4.3%, and 9.3%, respectively. Overall, the effect of RWF on the water stability of asphalt mixtures is similar to BF in Lou et al. [22].

3.3.4. Low-Temperature Crack Resistance Performance

- (1)

- Analysis of low-temperature trabecular bending test

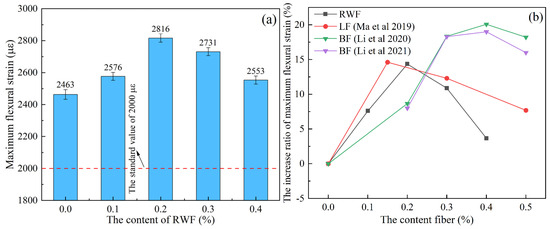

As shown in Figure 14a, the maximum flexural strain initially increases and then decreases with the increase in RWF content. All values remain above the standard threshold of 2000 με. Specifically, the maximum flexural strain reaches 2816 με at a 0.2% RWF content. Compared to mixtures without RWF, the maximum flexural strain increases by 4.6%, 14.3%, 10.9%, and 3.7% for RWF contents of 0.1%, 0.2%, 0.3%, and 0.4%, respectively.

Figure 14.

Low-temperature trabecular bending test of RWF-modified asphalt mixture with different contents: (a) maximum flexural strain of asphalt mixtures; (b) the increase ratio of maximum flexural strain with different fibers and contents [53,59,60].

The increase rate of the maximum flexural strain gradually rises with the increase in RWF content below 0.2%. Conversely, the decrease rate gradually increases as the RWF content exceeds 0.2%. The primary reason is that at a low RWF content (e.g., 0.1%), there is an insufficient overlapping network structure to produce an obvious enhancement effect. Additionally, when the RWF content reaches 0.2%, a more uniform three-dimensional network structure forms due to better dispersion of RWF, which serves as reinforcement and bridging. This provides enhanced tensile force during cracking and improves crack resistance. However, when the RWF content exceeds 0.2%, the structural asphalt film formed by RWF becomes thicker. While the amount of free asphalt decreases, it leads to increased porosity. Furthermore, stress concentration tends to occur at uneven interfaces, resulting in reduced low-temperature crack performance [17].

The increase ratio of maximum flexural strain of asphalt mixtures with LF and BF under different RWF contents are also compared in the literatures (Ma et al. [59], Li et al. [53], and Li et al. [60]), as shown in Figure 14b. The three kinds of fibers show a law of first increasing and then decreasing, with the increase of the fiber contents. The biggest increase ratio of maximum flexural strain of asphalt mixtures with 0.15% LF content in Ma et al. [59] and 0.4% BF content in Li et al. [53] and Li et al. [60] are 14.6%, 20.1%, and 19.0%, respectively. In conclusion, the effect of RWF on the maximum flexural strain of asphalt mixtures is similar to that of LF.

- (2)

- Analysis of low-temperature splitting test

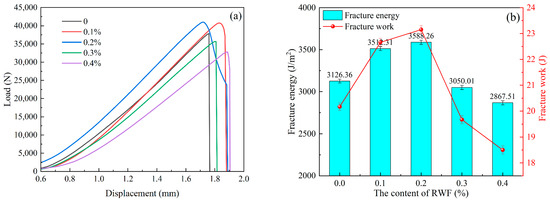

As shown in Figure 15a, the load and displacement curves exhibit the characteristic of first increasing to the peak value with an approximately linear slope and then abruptly decreasing to zero. The trend indicates a tendency toward brittle failure, which aligns with the failure properties of RWF-modified asphalt mortar. From the perspective of horizontal displacement, the displacement and deformation of asphalt mixtures containing RWF are greater than those without RWF. It suggests that RWF enhances the low-temperature deformation resistance of asphalt mixtures. From the vertical load perspective, the peak load is higher for mixtures with 0.1% and 0.2% RWF content. It indicates that an appropriate RWF content improves crack resistance and maximum load capacity. Additionally, from the perspective of the failure curve after reaching the peak value, only the 0.2% RWF content sample exhibits a buffer stage during failure after reaching the peak. In contrast, samples with other RWF contents burst immediately upon reaching the peak load. It suggests that asphalt mixtures with 0.2% RWF content possess certain toughness and elastoplasticity.

Figure 15.

Low-temperature splitting test of RWF-modified asphalt mixtures with different contents: (a) load and displacement curves; (b) fracture work and fracture energy.

As shown in Figure 15b, the fracture energy initially increases and then decreases with the increase in RWF content. The maximum fracture energy is achieved at a 0.2% RWF content, reaching 23.15 J/m2. It indicates the best low-temperature crack resistance. Compared to mixtures without RWF, the fracture energy increases by 12.35% and 14.77% for RWF contents of 0.1% and 0.2%, respectively. An appropriate amount of RWF can enhance toughness and dissipate stress concentration [61]. Conversely, the fracture energy decreases by 2.47% and 8.28% for RWF contents of 0.3% and 0.4%, respectively, compared to mixtures without RWF. The reason for the decrease is that excessive fibers lead to increased stress concentration in some interfacial weak areas.

3.4. Environmental Benefit Analysis

3.4.1. Analysis of EC and CEs During Construction Period

The EC and CEs at each stage during the construction period of pavement asphalt mixtures with different RWF contents are presented in Table 13 and Table 14. These are primarily concentrated in the raw material production, rock wool recovery, and asphalt mixture mixing processes. Among these stages, the asphalt mixture mixing process exhibits the highest EC and CEs, accounting for an average of 42.6% and 39.8%, respectively. The combined EC and CEs of raw material production, rock wool recovery, and asphalt mixture mixing account for 75.1% and 76.7%, respectively. In contrast, transportation, spreading and rolling contribute relatively smaller proportions, with EC and CEs values of 23.1% and 1.8%, and 21.6%, and 1.7%, respectively. The main reason is that the transport distance is relatively short. Additionally, the EC and CEs associated with rolling are also minimal. Most studies indicate that EC and CEs are predominantly concentrated in the production and mixing stages of raw materials [62].

Table 13.

EC and proportion of each stage in the construction period of asphalt pavement under different RWF contents (unit: 103 MJ and %).

Table 14.

CEs and proportion of each stage in the construction period under different RWF contents (unit: 103 kg and %).

Additionally, the total EC and CEs first decrease and then increase with the increase in RWF content. At a 0.4% RWF content, the total EC and CEs are 1.5% and 1.3% higher, respectively, compared to mixtures without RWF. While the increase is relatively small, the reason for the trend is that RWF has a lower density compared to the asphalt and the aggregates. On the other hand, as the RWF content increases, the total mass of asphalt mixture per unit volume (e.g., 1 km of two-lane pavement) decreases. It leads to an increase in the asphalt aggregate ratio, resulting in a higher asphalt content. Although the increased asphalt content reduces the mass of aggregates and mineral powders, the EC and CEs of asphalt are approximately two orders of magnitude higher than those of aggregates and mineral powders [46]. Consequently, the total EC and CEs still increase slightly. Moreover, at a 0.1% RWF content, the total EC and CEs decrease. It is because the slight increase in asphalt content offsets the reduction in aggregate quality during the mixing process. It then leads to a more significant reduction in EC and CEs. Additionally, the EC and CEs during transportation, spreading, and rolling also decrease slightly due to the reduced total mass of asphalt mixtures. With low RWF content, the impact of the asphalt base factor (unit EC and CEs) is minimal. However, as the RWF content increases, the total EC and CEs are predominantly influenced by the asphalt base factor.

Furthermore, the aforementioned environmental impact assessment only considers the EC and CEs during the construction phase of pavement. It does not account for maintenance activities or vehicle traffic during the subsequent operational service period. Compared to asphalt mixtures without RWF, those with RWF exhibit improved high temperature performance, water stability, and low-temperature crack resistance. Consequently, maintenance frequency and exhaust emissions can be reduced, while vehicle driving comfort can be enhanced during the operational phase of the asphalt pavement [63]. Although the EC and CEs increase during the construction phase due to the incorporation of RWF, they may potentially decrease during the subsequent operation and service stage.

3.4.2. Economic Benefit Analysis

The quality of asphalt mixtures and its compositions under different RWF contents are presented in Table 15. The mass of asphalt mixtures, aggregates and mineral powders per kilometer of a two-lane highway shows a decreasing trend as the RWF content increases, while the mass of asphalt increases. When the RWF content reaches 0.4%, each kilometer of a two-lane highway consumes approximately 5.48 tons of RWF. Meanwhile, it saves about twenty-six tons of aggregates and seven tons of mineral powders. While it increases the asphalt content by approximately five tons. There is more than 1 million kilometers of highway construction each year in China, where is 60% asphalt highway [4]. Thereby, the large-scale application of rock wool in asphalt mixtures can consume about 3 million tons of waste rock wool. It avoids environmental pollution caused by landfill disposal of waste rock wool. Additionally, it could save at least 15.6 million tons of natural aggregates and 4 million tons of mineral powders. Meanwhile, it increases the demand for asphalt by approximately 3 million tons.

Table 15.

The quality of asphalt mixtures and its compositions with different contents (unit: t/km).

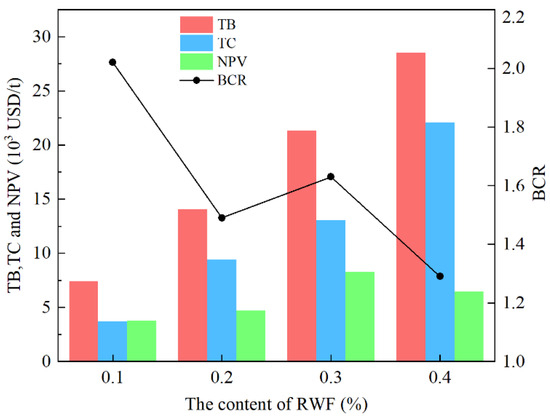

As shown in Figure 16, both TB and TC increase with the increase in RWF content, while NPV initially increases and then decreases. Additionally, the maximum NPV is achieved at an RWF content of 0.3%, reaching USD 8277.51. The BCR exhibits a trend of first decreasing, then increasing, and finally decreasing again. Its range is from 2.02 to 1.29, which is still greater than 1. It indicates that the cost requirement increases with higher RWF content, primarily due to the future price of asphalt. On the whole, there is still a positive economic effect overall when adding RWF.

Figure 16.

The parameters of BCA method under different RWF contents.

3.4.3. CPR Assessment

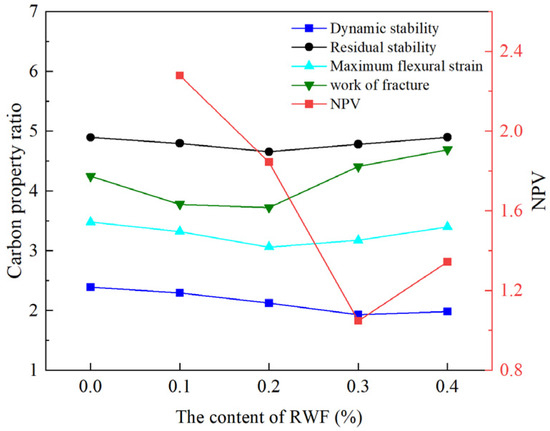

As shown in Figure 17, the CPR under pavement performance or economic benefit exhibits a trend of first decreasing and then increasing, with the increase in RWF content. The CPR values for residual stability, maximum flexural strain, and fracture work are lowest at an RWF content of 0.2%. They are 4.65, 3.06, and 3.72, respectively. Compared to asphalt mixtures without RWF, these values decrease by 4.9%, 12.0%, and 12.3%, respectively. Additionally, water stability and low-temperature crack resistance are optimal at an RWF content of 0.2%. It indicates that the beneficial effects of RWF on pavement performance outweigh its adverse effects on CEs at the content. It also achieves the optimal balance point between pavement performance and CEs. Conversely, when the RWF content exceeds 0.2%, the adverse effects on CEs become more significant. Furthermore, the CPR values for dynamic stability and NPV are lowest at an RWF content of 0.3%, with respective values of 1.92 and 1.04. Compared to RWF content of 0.1%, these values decrease by 19.47% and 54.0%, respectively. The optimal balance point between dynamic stability or NPV and CEs is achieved at an RWF content of 0.3%. It is consistent with the RWF content of best pavement performances or economic benefit, rather than that of best CEs.

Figure 17.

The carbon property ratio of pavement or economic performances of asphalt mixtures under different RWF contents.

In conclusion, the law of CPR indexes under different RWF contents is consistent with the law of pavement and economic performances of different RWF contents. It does not increase with the increase of CEs. This reflects that the adverse effects of CEs under each optimal content are smaller than the beneficial effects of pavement and economic performances. Additionally, there is the application of different RWF contents in asphalt pavement. An amount of 0.3% RWF content can be selected to pay attention to high temperature performances and economic performances. An amount of 0.2% RWF content can be selected to pay attention to water stability and low-temperature crack resistance.

4. Conclusions

The corresponding conclusions are as follows:

- (1)

- Rock wool fiber functions as an inert fiber stabilizer to physically reinforce asphalt. RWP primarily serves as a filler to enhance the strength of asphalt mortar. RWF forms a three-dimensional network structure that plays a stiffening and bridging role, thereby improving the adhesion and toughness of the mixture. Additionally, adhesive failure occurs in RWP-modified asphalt mortar. In contrast, when the RWF content exceeds 3%, the failure mode shifts to brittle failure in RWF-modified asphalt mortar.

- (2)

- The performances of RWP and RWF-modified asphalt is superior to that of matrix asphalt. RWF demonstrates greater superiority in terms of temperature susceptibility and high temperature performance. Among these, RWF-modified asphalt with a 4% content exhibits the best performance. The optimal penetration values at 15 °C, 25 °C, and 30 °C are 18.3 0.1 mm, 46 0.1 mm, and 67 0.1 mm, respectively. The corresponding optimal PI and softening point are 0.36 and 54.2 °C, respectively. The optimal G*/sinδ value at 46 °C is 49,669 Pa. In comparison, RWP exhibits more excellent low-temperature performance. The optimal ductility for RWP-modified asphalt with a 1% RWP content is 50.3 cm.

- (3)

- RWF can improve the high temperature performance, water stability and low-temperature crack resistance of asphalt mixtures. It has the best high temperature performance at 0.3% RWF, and its dynamic stability is 4500 times/mm. The best water stability and low-temperature crack resistance is at 0.2% RWF. The residual stability, maximum flexural strain, and fracture energy are 92.6%, 2816 με, and 3588.26 J/m2, respectively.

- (4)

- The EC and CEs during the construction period of pavement asphalt mixtures are primarily attributed to raw material production, rock wool recovery, and asphalt mixture mixing, accounting for an average of 75.1% and 76.7%, respectively. Moreover, the total EC and CEs first decrease and then increase with the increase in RWF content. The increase range is not exceeding 1.5% and 1.3%, respectively. The trend is consistent with the contribution from the increased asphalt content. The NPV reaches its maximum at an RWF content of 0.3%, with a value of USD 8277.51. Meanwhile, the BCR exhibits a decreasing trend but remains greater than one, with the highest value of 2.02 observed at an RWF content of 0.1%. Overall, the application of RWF demonstrates a positive economic effect.

- (5)

- The CPR of pavement performance and economic benefit for asphalt mixtures first decreases and then increases with the increasing RWF content. The CPR values for residual stability, maximum flexural strain, and fracture work are lowest at an RWF content of 0.2%, with respective values of 4.65, 3.06, and 3.72. Additionally, the CPR values for dynamic stability and NPV are smallest at an RWF content of 0.3%, with respective values of 1.92 and 1.04. The comprehensive environmental benefits between pavement performance or economic benefit and CEs can be quantified using the CPR index.

- (6)

- The feasibility of RWF as an asphalt mixture additive has been preliminarily verified. However, further research is required on fiber mixing methods, multi-size effects, and complex interfacial adhesion between aggregates, fibers, and asphalts, as well as the long-term performance of asphalt mixtures. Additionally, in future studies, long-term data such as EC for maintenance frequency and CEs during traffic operations in the operation and maintenance phases should be collected to assess the environmental impact during these phases. Moreover, the environmental impact over the full life cycle could be evaluated by integrating the EC and CEs during the construction phase.

Author Contributions

Conceptualization, J.C.; methodology, B.Z.; software, Z.Z.; validation, N.W.; formal analysis, B.Z.; investigation, S.Z.; resources, X.Y.; data curation, N.W.; writing—original draft preparation, B.Z.; writing—review and editing, J.C.; visualization, Z.Z.; supervision, B.L.; project administration, S.Z.; funding acquisition, B.L. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 52268043), the Training Plan for Academic and Technical Leaders of Major Disciplines in Jiangxi Province—the Leading Talent Project (Grant No. 20204BCJ22003).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Bingjian Zeng, Ni Wan, Sipeng Zhang and Xiaohua Yu were employed by the company PowerChina Jiangxi Hydropower Engineering Bureau Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Oluwasola, E.A.; Hainin, M.R.; Aziz, M.M.A. Evaluation of asphalt mixtures incorporating electric arc furnace steel slag and copper mine tailings for road construction. Transp. Geotech. 2015, 2, 47–55. [Google Scholar] [CrossRef]

- Zhang, H.; Gong, M.; Gao, D.; Yang, T.; Huang, Y. Comparative analysis of mechanical behavior of composite modified asphalt mixture based on PG technology. Constr. Build. Mater. 2020, 259, 119771. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Jiao, Y.; Zhao, W.; Duan, Y.; Liu, H. A review of phase change materials in asphalt binder and asphalt mixture. Constr. Build. Mater. 2020, 258, 119565. [Google Scholar] [CrossRef]

- Wei, Z.; Jia, Y.; Wang, S.; Li, Z.; Li, Y.; Wang, X.; Gao, Y. Utilization of iron ore tailing as an alternative mineral filler in asphalt mastic: High-temperature performance and environmental aspects. J. Clean. Prod. 2022, 335, 130318. [Google Scholar] [CrossRef]

- Niu, D.; Xie, X.; Zhang, Z.; Niu, Y.; Yang, Z. Influence of binary waste mixtures on road performance of asphalt and asphalt mixture. J. Clean. Prod. 2021, 298, 126842. [Google Scholar] [CrossRef]

- Abreu, L.P.F.; Oliveira, J.R.M.; Silva, H.M.R.D.; Fonseca, P.V. Recycled asphalt mixtures produced with high percentage of different waste materials. Constr. Build. Mater. 2015, 84, 230–238. [Google Scholar] [CrossRef]

- Li, H.; Zhang, F.; Feng, Z.; Li, W.; Zou, X. Study on waste engine oil and waste cooking oil on performance improvement of aged asphalt and application in reclaimed asphalt mixture. Constr. Build. Mater. 2021, 276, 122138. [Google Scholar] [CrossRef]

- Cheng, A.; Lin, W.-T.; Huang, R. Application of rock wool waste in cement-based composites. Mater. Des. 2011, 32, 636–642. [Google Scholar] [CrossRef]

- Yap, Z.S.; Khalid, N.H.A.; Haron, Z.; Mohamed, A.; Tahir, M.M.; Hasyim, S.; Saggaff, A. Waste Mineral Wool and Its Opportunities-A Review. Mater. 2021, 14, 5777. [Google Scholar] [CrossRef]

- Väntsi, O.; Kärki, T. Mineral wool waste in Europe: A review of mineral wool waste quantity, quality, and current recycling methods. J. Mater. Cycles Waste Manag. 2014, 16, 62–72. [Google Scholar] [CrossRef]

- Qaryouti, M.; Osman, M.; Alharbi, A.; Voogt, W.; Abdelaziz, M.E. Using Date Palm Waste as an Alternative for Rockwool: Sweet Pepper Performance under Both Soilless Culture Substrates. Plants 2024, 13, 44. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Li, R.; Zhang, G.; Wang, D.; Cai, D.; Wu, Z. Zero-valent iron nanoparticles supported by functionalized waste rock wool for efficient removal of hexavalent chromium. Chem. Eng. J. 2018, 339, 85–96. [Google Scholar] [CrossRef]

- Hao, W.; Xu, J.; Li, R.; Zhao, X.; Qiu, L.; Yang, W. Developing superhydrophobic rock wool for high-viscosity oil/water separation. Chem. Eng. J. 2019, 368, 837–846. [Google Scholar] [CrossRef]

- Özel, G.; Açıkkalp, E.; Görgün, B.; Yamık, H.; Caner, N. Optimum insulation thickness determination using the environmental and life cycle cost analyses based entransy approach. Sustain. Energy Technol. Assess. 2015, 11, 87–91. [Google Scholar] [CrossRef]

- Klinsky, L.M.G.; Kaloush, K.E.; Faria, V.C.; Bardini, V.S.S. Performance characteristics of fiber modified hot mix asphalt. Constr. Build. Mater. 2018, 176, 747–752. [Google Scholar] [CrossRef]

- Guo, Y.; Tataranni, P.; Sangiorgi, C. The use of fibres in asphalt mixtures: A state of the art review. Constr. Build. Mater. 2023, 390, 131754. [Google Scholar] [CrossRef]

- Wu, B.; Pei, Z.; Xiao, P.; Lou, K.; Wu, X. Influence of fiber-asphalt interface property on crack resistance of asphalt mixture. Case Stud. Constr. Mater. 2022, 17, e01703. [Google Scholar] [CrossRef]

- Wang, G.; Li, J.; Massarra, C.; Buckhalter, C.; Rahat, H.H.; Farrington, J.; Collins, T.; Johnson, J. Use of COVID-19 single-use face masks to improve the rutting resistance of asphalt pavement. Sci. Total Environ. 2022, 826, 154118. [Google Scholar] [CrossRef]

- Li, Z.; Li, K.; Chen, W.; Liu, W.; Yin, Y.; Cong, P. Investigation on the characteristics and effect of plant fibers on the properties of asphalt binders. Constr. Build. Mater. 2022, 338, 127652. [Google Scholar] [CrossRef]

- Phan, T.M.; Nguyen, S.N.; Seo, C.-B.; Park, D.-W. Effect of treated fibers on performance of asphalt mixture. Constr. Build. Mater. 2021, 274, 122051. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, S.; Liu, Q.; Zeng, W.; Chen, Z.; Ye, Q.; Pan, P. Self-healing performance of asphalt mixtures through heating fibers or aggregate. Constr. Build. Mater. 2017, 150, 673–680. [Google Scholar] [CrossRef]

- Lou, K.; Xiao, P.; Wu, B.; Kang, A.; Wu, X.; Shen, Q. Effects of fiber length and content on the performance of ultra-thin wearing course modified by basalt fibers. Constr. Build. Mater. 2021, 313, 125439. [Google Scholar] [CrossRef]

- Slebi-Acevedo, C.J.; Lastra-Gonzalez, P.; Pascual-Munoz, P.; Castro-Fresno, D. Mechanical performance of fibers in hot mix asphalt: A review. Constr. Build. Mater. 2019, 200, 756–769. [Google Scholar] [CrossRef]

- Behbahani, H.; Gilani, V.N.M.; Salehfard, R.; Safari, D. Evaluation of Fatigue and Rutting Behaviour of Hot Mix Asphalt Containing Rock Wool. Int. J. Civ. Eng. 2020, 18, 1293–1300. [Google Scholar] [CrossRef]

- Hussein, F.K.; Ismael, M.Q.; Huseien, G.F. Rock Wool Fiber-Reinforced and Recycled Concrete Aggregate-Imbued Hot Asphalt Mixtures: Design and Moisture Susceptibility Evaluation. J. Compos. Sci. 2023, 7, 428. [Google Scholar] [CrossRef]

- Guo, F.; Li, R.; Lu, S.; Bi, Y.; He, H. Evaluation of the Effect of Fiber Type, Length, and Content on Asphalt Properties and Asphalt Mixture Performance. Mater. 2020, 13, 1556. [Google Scholar] [CrossRef]

- Wang, S.; Kang, A.; Xiao, P.; Li, B.; Fu, W. Investigating the Effects of Chopped Basalt Fiber on the Performance of Porous Asphalt Mixture. Adv. Mater. Sci. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef]

- Xing, X.; Liu, T.; Pei, J.; Huang, J.; Li, R.; Zhang, J.; Tian, Y. Effect of fiber length and surface treatment on the performance of fiber-modified binder. Constr. Build. Mater. 2020, 248, 118702. [Google Scholar] [CrossRef]

- Yue, Y.; Abdelsalam, M.; Khater, A.; Ghazy, M. A comparative life cycle assessment of asphalt mixtures modified with a novel composite of diatomite powder and lignin fiber. Constr. Build. Mater. 2022, 323, 126608. [Google Scholar] [CrossRef]

- Khater, A.; Luo, D.; Abdelsalam, M.; Ma, J.; Ghazy, M. Comparative Life Cycle Assessment of Asphalt Mixtures Using Composite Admixtures of Lignin and Glass Fibers. Mater. 2021, 14, 6589. [Google Scholar] [CrossRef]

- Martinez-Soto, A.; Valdes-Vidal, G.; Calabi-Floody, A.; Avendaño-Vera, C.; Martínez-Toledo, C. Comparison of Environmental Loads of Fibers Used in the Manufacture of Hot Mix Asphalt (HMA) and Stone Mastic Asphalt (SMA) Mixes Using a Life Cycle Assessment (LCA). Sustainability 2022, 14, 14246. [Google Scholar] [CrossRef]

- Daniele, L.; Marco, M.; Edoardo, B.; Michele, G. Comparative life cycle assessment of standard, cellulose-reinforced and end of life tires fiber-reinforced hot mix asphalt mixtures. J. Clean. Prod. 2020, 248, 119295. [Google Scholar]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- JTG E40-2004; Technical Specification for Construction of Highway Asphalt Pavements. Ministry of Transport of the People’s Republic of China: Beijing, China, 2004.

- Guo, R.; Zhou, F.; Nian, T. Analysis of primary influencing factors and indices distribution law of rutting performance of asphalt mixtures. Case Stud. Constr. Mater. 2022, 16, e01053. [Google Scholar] [CrossRef]

- Taher, M.N.M.; Aman, M.Y.; Abdullah, N.F.A.; Noranai, Z. Utilization of Synthetic Reinforced Fiber in Asphalt Concrete—A Review. J. Civ. Eng. Technol. 2019, 10, 678–694. [Google Scholar]

- Chen, L.; Yang, C.; Zhang, J.; Cui, J. Studying on the water resistance and durability of rock wool products for exterior insulation. New Build. Mater. 2015, 42, 78–80. [Google Scholar]

- Cheng, Y.; Tao, J.; Jiao, Y.; Tan, G.; Guo, Q.; Wang, S.; Ni, P. Influence of the properties of filler on high and medium temperature performances of asphalt mastic. Constr. Build. Mater. 2016, 118, 268–275. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, X.; Fa, C.; Zhang, Y.; Xiong, J.; Chen, H. Investigation on characteristics and properties of bagasse fibers: Performances of asphalt mixtures with bagasse fibers. Constr. Build. Mater. 2020, 248, 118648. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Lei, B.; Li, X.; Guo, Y.; Qu, F.; Zhao, C.; Tam, V.W.; Wu, V.; Li, W. Recycling of copper tailing as filler material in asphalt paving mastic: A sustainable solution for mining waste recovery. Case Stud. Constr. Mater. 2024, 20, e03237. [Google Scholar] [CrossRef]

- Liu, F.; Pan, B.; Bian, J.; Zhou, C. Experimental investigation on the performance of the asphalt mixture with ceramic fiber. J. Clean. Prod. 2023, 384, 135585. [Google Scholar] [CrossRef]

- Miliutenko, S.; Björklund, A.; Carlsson, A. Opportunities for environmentally improved asphalt recycling: The example of Sweden. J. Clean. Prod. 2013, 43, 156–165. [Google Scholar] [CrossRef]

- Huang, Y.; Qiao, Z.; Zhang, H. Evaluation of an economy-technology-green development system for asphalt pavement construction in China based on synergetics. J. Clean. Prod. 2021, 289, 125132. [Google Scholar] [CrossRef]

- Li, J.; Xiao, F.; Zhang, L.; Amirkhanian, S.N. Life cycle assessment and life cycle cost analysis of recycled solid waste materials in highway pavement: A review. J. Clean. Prod. 2019, 233, 1182–1206. [Google Scholar] [CrossRef]

- Ma, F.; Dong, W.; Fu, Z.; Wang, R.; Huang, Y.; Liu, J. Life cycle assessment of greenhouse gas emissions from asphalt pavement maintenance: A case study in China. J. Clean. Prod. 2021, 288, 125595. [Google Scholar] [CrossRef]

- JT/T 719-2016; Limits and Measurement Methods of Fuel Consumption for Commercial Vehicle for Cargos Transportation. Ministry of Transport of the People’s Republic of China: Beijing, China, 2016.

- Chen, C. Study on Character of Rock Wool Waste Cement-based Cementious Materials. Master’s Thesis, Chang’an University, Xi’an, China, 2016. [Google Scholar]

- Xing, X.; Chen, S.; Li, Y.; Pei, J.; Zhang, J.; Wen, Y.; Li, R.; Cui, S. Effect of different fibers on the properties of asphalt mastics. Constr. Build. Mater. 2020, 262, 120005. [Google Scholar] [CrossRef]

- Zhang, X.; Zhao, H.; Li, C.; Wang, T.; Peng, L.; Li, Y.; Xiao, Y. In-situ micro-characteristics of fiber at the mortar transition zone in asphalt mixtures. Constr. Build. Mater. 2023, 398, 132529. [Google Scholar] [CrossRef]

- Liu, X.; Wu, S. Study on the graphite and carbon fiber modified asphalt concrete. Constr. Build. Mater. 2011, 25, 1807–1811. [Google Scholar] [CrossRef]

- Choudhary, J.; Kumar, B.; Gupta, A. Utilization of solid waste materials as alternative fillers in asphalt mixes: A review. Constr. Build. Mater. 2020, 234, 117271. [Google Scholar] [CrossRef]

- Li, Z.; Shen, A.; Wang, H.; Guo, Y.; Wu, H. Effect of basalt fiber on the low-temperature performance of an asphalt mixture in a heavily frozen area. Constr. Build. Mater. 2020, 253, 119080. [Google Scholar] [CrossRef]

- Fu, Z.; Dang, Y.; Guo, B.; Huang, Y. Laboratory investigation on the properties of asphalt mixtures modified with double-adding admixtures and sensitivity analysis. J. Traffic Transp. Eng. (Engl. Ed.) 2016, 3, 412–426. [Google Scholar] [CrossRef]

- Qiu, G.; Fang, J.; Xu, A.; Wang, Q.; Jiang, S.; Li, H. Research on High-Temperature Performance of Basalt Fiber Asphalt Concrete. Bull. Chin. Ceram. Soc. 2019, 38, 3890–3896. [Google Scholar]

- Wei, Z. Study on road performance of basalt fiber reinforced asphalt mixture. J. Wuhan Univ. Technol. 2019, 43, 1074–1078. [Google Scholar]

- Luo, D.; Khater, A.; Yue, Y.; Abdelsalam, M.; Zhang, Z.; Li, Y.; Li, J.; Iseley, D.T. The performance of asphalt mixtures modified with lignin fiber and glass fiber: A review. Constr. Build. Mater. 2019, 209, 377–387. [Google Scholar] [CrossRef]

- Wen, Y. Research on the Mechanicm and Performance of Basalt Fiber Reiforced Asphalt Mixture. Master’s Thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

- Ma, F.; Pan, J.; Fu, Z.; Han, W.; Zhang, C. Determination of optimum fiber content in fiber asphalt mixture. J. HenNan Polytechinic Univ. 2019, 38, 138–145. [Google Scholar]

- Li, Z.; Shen, A.; Guo, Y.; Wu, H. Low temperature performance correlation of basalt fiber asphalt mortar and mixture. J. Build. Mater. 2021, 24, 124–128+152. [Google Scholar]

- Wang, D.; Wang, L.; Gu, X.; Zhou, G. Effect of Basalt Fiber on the Asphalt Binder and Mastic at Low Temperature. J. Mater. Civ. Eng. 2013, 25, 355–364. [Google Scholar] [CrossRef]

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Praticò, F.G.; Giunta, M.; Mistretta, M.; Gulotta, T.M. Energy and Environmental Life Cycle Assessment of Sustainable Pavement Materials and Technologies for Urban Roads. Sustainability 2020, 12, 704. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).