Abstract

In situ neutron diffraction of the uniaxial tension test was used to study the effect of the surrounding matrix microstructure on the mechanical stability of retained austenite in high-carbon bearing steels. Comparing the samples with bainitic microstructures to those with martensitic ones, it was found that the retained austenite in a bainitic matrix starts transforming into martensite at a lower strain compared to that within a martensitic matrix. On the other hand, the rate of transformation of the austenite was found to be higher within a martensitic microstructure. Crystal plasticity modeling was used to analyze the transformation phenomenon in these two microstructures and determine the effect of the surrounding microstructure on elastic, plastic, and transformation components of the strain. The results showed that the predominant difference in the deformation accumulated was from the transformation strain and the critical transformation driving force within the two microstructures. The retained austenite was more stable for identical loading conditions in case of martensitic matrix compared to the bainitic one. It was also observed that the initial volume fraction of retained austenite within the bainitic matrix would alter the onset of transformation to martensite, but not the rate of transformation.

1. Introduction

Today’s industrial applications involve bearings and gears that sustain severe static and dynamic loads while serving reliably in extreme environments [1]. High-carbon and chromium-containing steels are widely used in the current bearing industry, where the steel is often heat-treated to obtain either martensitic or bainitic microstructures [2]. High-carbon martensitic steels are very well-known for their high strength and hardness properties, and have been used extensively for bearings over the past century [1,3]. Bainitic or martensitic microstructures are often obtained together with a retained volume fraction of austenite. The volume fraction of the retained austenite (RA) and its morphology are of great interest in the applications of rolling element bearings [4].

The retained austenite in bearing steels is predominantly present in either a film-like form or a block-type form [5,6]. The films of austenite, which are less stable when it comes to decomposition during tempering, are, however, known to be very stable under the application of stress [7]. The film-like austenite has been reported to be very stable due to its carbon enrichment, and such fine microstructures have been known to have an excellent combination of strength and toughness [8]. One of the roles of retained austenite in engineering applications is the enhancement of the ductility of steel, which has been reported by De Cooman [9] and Jacques [10]. The strain-induced transformation of retained austenite increases the work-hardening rate sufficiently to delay plastic instabilities in application loading conditions. Over the years, several studies have found that the presence of retained austenite films around the martensite helps improve the fracture toughness and fatigue of steels in bearings and gears [11,12,13]. The improved fatigue resistance in the presence of RA has been attributed to the enhanced mean compressive stress created by the transformation of the RA into martensite [14]. Voskamp [15] found that the transformation of RA depended on the cumulative effect of cyclic loading, and that the transformation of RA is very sensitive during the entire life cycle of a bearing [16]. It has been well established by now that the kinematic stability of RA is influenced by several factors including size, morphology, and % C in the austenite and surrounding microstructure [17,18,19]. Cui et al. [20,21] have recently studied the stability of retained austenite in martensitic bearing steels, and found that the retained austenite transforms more readily under mechanical loads during the first tens of cycles and at around 1000 cycles, while remaining relatively stable at cycles ranging 100 to 1000. This stability of retained austenite demonstrates the need to further quantify and understand the localized strain magnitudes to trigger the transformation of retained austenite. Recently, Xiong et al. [22] found that low-carbon, film-like austenite is more stable than high-carbon blocky austenite. Ryu et al. [18] found that the stability of retained austenite depends upon the strain partitioning with the surrounding matrix. In their study using steels with different Al content, the authors found that the grain size distribution of the ferritic regions also plays an influential role in the stability of retained austenite. The determination of RA stability actually is extremely challenging, due to many interdependent factors. The majority of the existing research on the stability of austenite and transformation-induced plasticity has been focused on transformation-induced plasticity (TRIP) steels [23,24,25,26]. Jacques et al. [17] studied the mechanical stability of RA in TRIP steels and found that the harder martensite shielded the RA. Hidalgo et al. [27] studied austenite/martensite microstructures by varying the degrees of tempering, and found that the surrounding microstructure influences the stability of RA. However, there has been little progress in the case of martensitic or bainitic (58–60 HRc) bearing steels.

Recent studies on through-hardened bearing steels using X-ray synchrotron [23] and neutron diffraction [25,26,28,29] have shown considerable promise for understanding the behavior of retained austenite in a quantitative and discrete manner. With the advances afforded by the use of neutron diffraction, real-time and continuous studies can be performed in a precise and accurate manner. However, in spite of the significant progress in understanding the deformation mechanisms and stability of austenite in steels, there is very little information regarding the effect of the surrounding microstructure on the onset and rate of austenite transformation in through-hardened bearing steels. The effect of the surrounding microstructure on the mechanical stability of retained austenite has not yet been comprehensively studied. Also, there has been limited research on the comparison between the mechanical stability of austenite within martensitic and within bainitic microstructures. There is also very little information in literature on the actual stress state and evolution of the stress state of the austenite when surrounded by bainite and martensite.

In order to address this gap and further provide a quantitative estimation of the mechanical stability of retained austenite in through-hardened bearing steels, in this work the authors studied the kinematic stability of retained austenite in through-hardened ASTM A485 Grade 1 steel under uniaxial tensile loading. The effects of varying soak times resulting in different amounts of initial RA percentages within the bainitic microstructure was studied using in situ neutron diffraction. The effect of bainite and martensite in the surrounding microstructure was also studied to compare the effect of the surrounding microstructure on the mechanical stability of the retained austenite. The results were then analyzed using a hybrid polycrystal plasticity finite element model to determine the elastic, plastic, and transformation plasticity components of the deformation, so as to understand the predominant portion of the deformation causing the differences in the relative mechanical stability of the retained austenite.

2. Materials and Methods

2.1. Material Characterization and Sample Preparation

The samples used in this study were dogbone tensile specimens of A485 Grade 1 (A485-1) steel, the composition of which is shown in Table 1. Three samples with different surrounding microstructures (two bainitic, B1 and B2, and one martensitic, M1) were created by altering the heat treatment. Sample B1, with a bainitic microstructure containing 18% retained austenite, was prepared by austenitizing at 850 °C for 45 min, followed by soaking in a salt bath at 230 °C for 2 h. Sample B2 was austenitized at the same temperature and time, but soaked at 230 °C for 4 hours. The longer hold time allowed continued transformation of the austenite, reducing its volume to 9.1%. It should be noted that the longer soak times transform the less stable austenite into bainite, leaving behind austenite that is stable and enriched with carbon. Sample M1, with a martensitic microstructure and 18% retained austenite, was prepared by hardening at 850 °C followed by tempering at 180 °C for 1.3 h.

Table 1.

Chemical composition of A485-1 steel (wt %) [28].

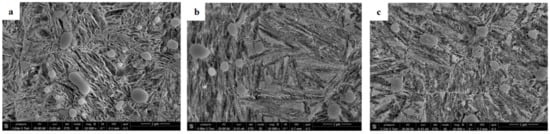

The % C in the austenite was calculated using a technique described by Jatczak et al. [30], and was found to be higher in the bainitic samples B1 (0.98%) and B2 (1.09%) than in the martensitic M1 sample (0.9%). The hardness and microstructural parameters estimated for the three specimens are summarized in Table 2. The specimen dimensions were chosen to allow appropriate testing for neutron diffraction, and the manufacturing process was carefully monitored to ensure that the surrounding martensitic and bainitic microstructures could be compared appropriately. SEM microstructure images showed a mix of film-like and blocky RA structures in the bainitic sample B1, as shown in Figure 1. The retained austenite in sample B2 was less blocky and contained more film-like austenite compared to samples M1 and B1. The martensitic M1 sample has a mix of blocky and fine retained austenite.

Table 2.

Specimen details for martensitic and bainitic samples.

Figure 1.

Scanning Electron Microscopy (SEM) Images of (a) M1 (martensitic), reproduced from [28], with permission of Elsevier 2018, (b) B1 (bainitic with 2 h soak), and (c) B2 (bainitic with 4 h soak) microstructures.

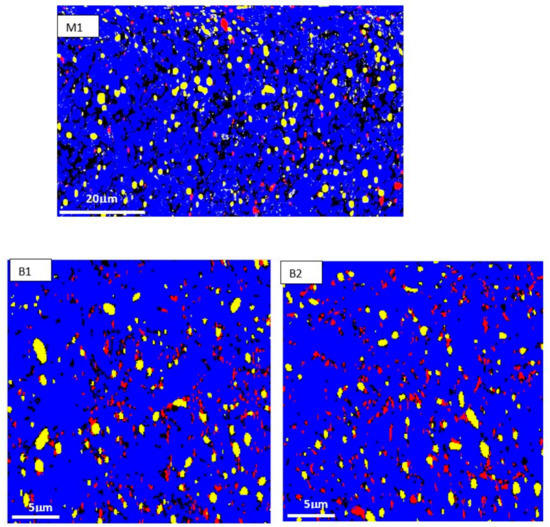

Electron backscatter diffraction (EBSD) samples were finally polished by a colloidal silica VibroMet for 7.5 h. EBSD analysis was conducted using a dual beam high resolution SEM equipped with field emission gun(Thermo Fisher Scientific, Waltham, MA, United States). EBSD analysis was performed using an Oxford Nordlys high resolution detector (Oxford instruments, Abingdon, United Kingdom). Phase maps (Figure 2) were acquired from ~250 µm from the surface. EBSD data was acquired using a 20 kV, 17 nA current with 8 x 8 binning, low gain, and two-frame average. The martensite maps were acquired at a 100 x 100 μm area, while bainite maps were acquired at 25 µm x 25 µm with a step size of 0.1 µm. Wild spike reduction was conducted on all the data. The index rate for bainite was 85%, and the data was filtered by a minimum of 6 neighbors until the final index rate was above 90%. Due to lower hit rate (~50%) on martensite microstructure, the data was extrapolated at 4 neighbors until the final index rate was near 70%. The index rate of martensite was lower due to the transformation of retained austenite during polishing. The EBSD maps indicate finely dispersed carbides, with mix of fine and blocky retained austenite at the grain boundaries. The blocky RA in M1 sample is clearly evident; however, the finely structured RA around the grain boundaries could not be revealed, most likely due to transformation during polishing. For bainitic samples, most of the RA appeared to be around prior austenite grain boundaries. Pole figure analysis indicated that the austenite grains were highly textured. The texture was represented by MUD (mean uniform density). An MUD greater than unity indicates more datapoints in a particular direction. In this case, martensite sample M1 indicated an MUD of 4.3, while austenite in bainitic samples B1 and B2 showed stronger textures, with MUD up to 9 and 13, respectively.

Figure 2.

Electron backscatter diffraction (EBSD) phase fractions of bainitic (B1, B2) and martensitic (M1) samples.

2.2. In situ Neutron Diffraction

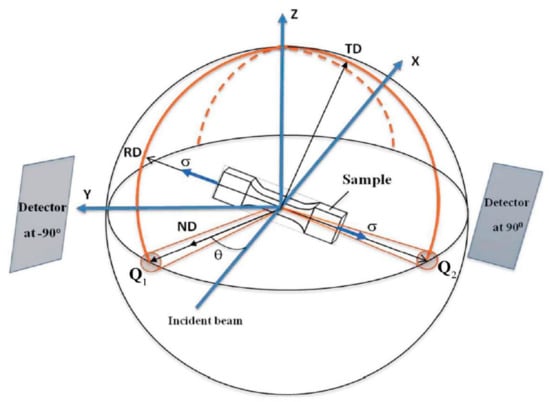

The in situ neutron diffraction experiment was conducted during monotonic tension testing of the three specimens, as depicted by the schematic in Figure 3. Understanding the deformation modes and quantifying the effect of the surrounding microstructure on individual phases and the mode of deformation can be realized using neutrons. The local deformation at the lattice level can be determined due to the large penetration depth of the neutrons and the volume-averaged nature of the bulk measurement, which is characteristic of a scattering beam [30]. The in situ neutron diffraction experiments were conducted on the VULCAN engineering diffractometer (Oak Ridge National Laboratory, Oak Ridge, TN, USA) at the Spallation Neutron Source in the Oak Ridge National Laboratory. The VULCAN time of flight diffractometer enabled rapid collection of structural changes in the sample under dynamic loading conditions. The uniaxial tension test was performed at a strain rate of 5 x 10−6. The tensile specimen was exposed to a 5 mm x 5 mm neutron beam with a 5 mm collimator, allowing data collection over a 125 mm3 gauge volume. The data was collected in situ using two detector banks located in the longitudinal and transverse directions. Data was chopped at 2 min intervals and analyzed using VDRIVE (Vulcan Data Reduction and Interactive Visualization) software [31]. Reference scans were conducted in the unloaded condition over a period of ten minutes to minimize the propagated statistical error [32]. The peak positions were fit using single peak fit.

Figure 3.

Schematic for the in situ measurements (loading) for the VULCAN diffractometer: XYZ is the instrument coordinate system, xyz is the sample coordinate system (identified, respectively, with the main processing directions: rolling (RD), transverse (TD), and normal (ND)), is the mechanical loading along the RD, is the diffraction angle, and Q1 and Q2 are the scattering vectors [32]. Reproduced with permission of the International Union of Crystallography.

3. Constitutive Model

From a purely mechanistic analysis, the rates of transformation and the variations in the quantified deformation during uniaxial tension testing of the test specimens can be attributed to several factors, because the deformation in the microstructure consists of elastic, plastic, and transformation plasticity components. In order to analyze the neutron diffraction data and understand the underlying deformation mechanisms within the two surrounding microstructures studied in this work, the empirical data must be coupled with a suitable computational or analytical technique that will help to determine the major factor contributing to the differences observed in the mechanical characterization. In order to address this, we used a crystal plasticity finite element (CPFE) approach to study the differences between the three specimens.

The use of a crystal plasticity formulation to describe the transformation plasticity and deformation of bearing steels has demonstrated significant success with martensitic through-hardened and case-carburized microstructures. Recent works by Woo et al. [25], Kim et al. [26], and Voothaluru et al. [28] have shown that CPFE modeling can help quantify the micro-mechanical parameters, as it captures the deformation mechanisms that occur during the in situ neutron diffraction of multi-phase steels. For this work, the CPFE model was developed in ABAQUS, based upon the implementation of the constitutive model proposed by Turteltaub and Suiker [33]. The implementation of the constitutive model into a user material subroutine (UMAT) was carried out by following the methods of Voothaluru and his co-authors [34]. The computational model is semi-empirical in nature, and the material parameters are evaluated for elastic, plastic, and transformation plasticity components by determining the best fit of the simulated result with the empirical data. For the CPFE model, the total deformation gradient is given by:

where is the transformation gradient that accounts for the volumetric strain produced by austenite–martensite phase transformation, is the plastic deformation gradient, and is the elastic deformation gradient.

In this work, the model assumes that the 48 body centered cubic (BCC) slip systems within a representative volume element (RVE) will exhibit behavior approximately similar to that of tempered martensite and bainite. Both the bainitic and martensitic microstructures are modeled as BCC for computational purposes, as discussed in prior works [35,36,37,38]. At the end of each time step, the rate of transformation and shear are computed. The shear and transformation rates are computed at the end of each time step. The plastic shearing rate on the slip system is governed by the rate-dependent flow rule:

where m is the strain rate sensitivity exponent, is the shearing rate coefficient, is the drag stress, is the back stress, and is the resolved shear stress on the slip system. The resolved shear stress on each slip system is related to the Cauchy stress tensor , according to:

Here, and are unit vectors defined in the crystal coordinate system representing the slip direction and the normal slip plane, respectively. The drag stress and back stress evolution follow the expressions in Equations (4) and (5), respectively:

where and are the isotropic hardening and dynamic recovery coefficient, and is the dynamic recovery coefficient for back stress. The volume fraction transformation rate on a transformation system is given by Equation (6):

where is the maximum rate of austenite transformation, is the viscosity parameter, is the critical driving stress, and is the driving stress on the transformation system. Equation (7) shows the estimation of the driving stress for transformation on the system, which is related to the transformation and habit vectors and and the Cauchy stress tensor:

where is the shape strain magnitude—a parameter that is uniform for all transformation systems. The rate of change of the volume fraction transformed from austenite to martensite is given by Equation (8), where is the rate of transformation of retained austenite:

The critical driving force is controlled by the transformation rates along transformation plane (), and the increased resistance to transformation is accounted by the transformation hardening coefficient, Q as shown in Equation (9). The increased resistance to transformation in any system is assumed to be the identical in this work, along the line of the observations from Alley and Neu [36].

The transformation gradient in the multiplicative decomposition, as a result of the aforementioned individual relations, accounts for the volumetric transformation from austenite to martensite, following Equation (10):

The model described here was used to study the micro-mechanical response of the RVE in order to determine the single crystal elastic constants, micro-plasticity parameters, and transformation plasticity parameters of the hybrid representation. This determination allows a comparison between the three specimens and provides a means for understanding the influence of the microstructure on the variation in austenite stability.

4. Results

4.1. Experiment Results

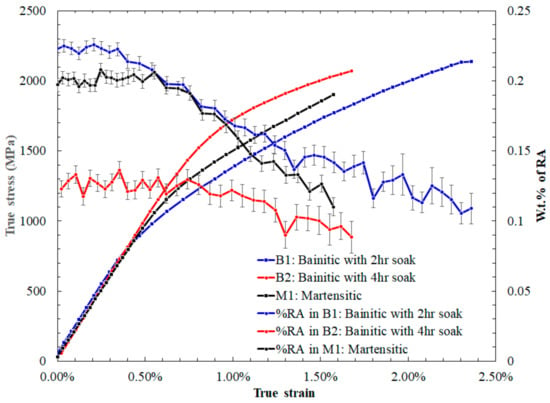

The macroscopic stress–strain response, RA transformation for the bainitic samples B1 and B2, and the results for the martensitic sample M1 from a previous study [28] are shown in Figure 4. In sample B1 (bainitic microstructure), the apparent macroscopic yield point was observed to be at a true stress of 722 MPa (0.344% strain). In sample B2, which had lower retained austenite (9%) in a bainitic microstructure, the deviation from linearity occurred at a true stress of 1340 MPa (0.7% strain). Rietveld analysis and single peak fitting were performed on the diffraction data using the General Structural Analysis System (GSAS) software package, and the volume fraction of RA was estimated for the duration of the uniaxial tension test. From Figure 4, we can see that the onset of RA transformation into product martensite for each specimen (B1, B2, and M1), coincides with its corresponding macroscopic yield point from the true stress and true strain curve. This can be attributed to the fact that under uniaxial tension, the specimens are more susceptible to undergoing an austenite transformation that is strain-induced or strain-assisted, as hypothesized and discussed in prior works in the literature [39].

Figure 4.

Macroscopic stress vs true strain with respect to retained austenite (RA) transformation for B1, B2, and M1 Samples.

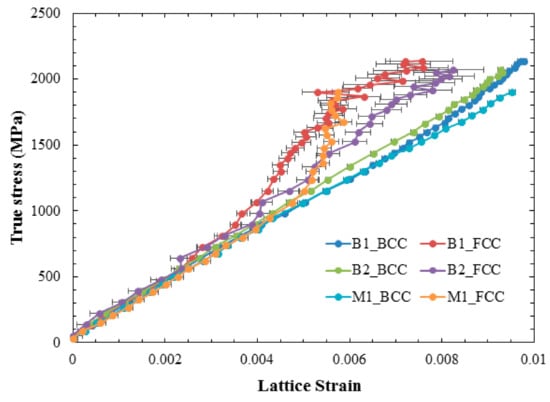

The austenite transformation appears to initiate only after some amount of micro-plasticity is observed within the austenite, which can be tracked from the change in slope of the lattice strain estimated for the specimens using in situ neutron diffraction. Figure 5 shows the lattice strain as a function of true stress, calculated using Equation (11).

Figure 5.

Lattice strain plot for the three specimens evaluated from in situ neutron diffraction.

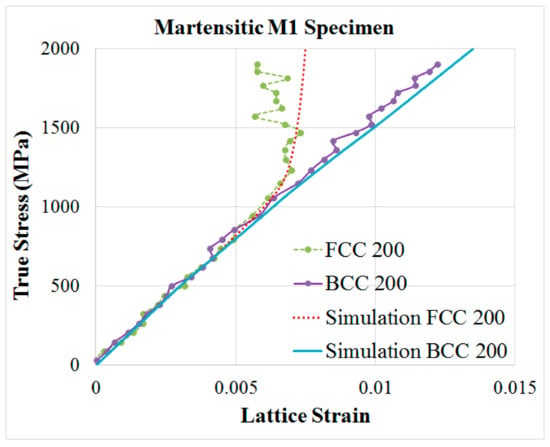

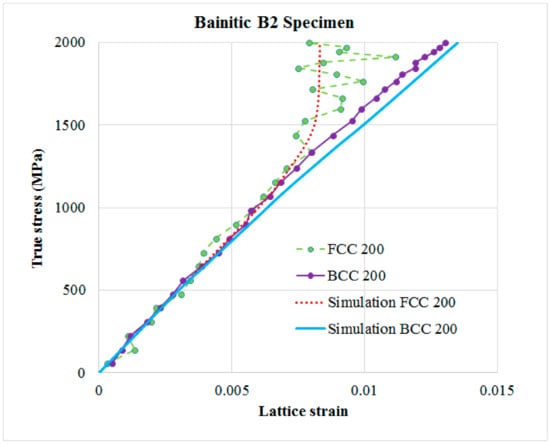

The lattice strain data for the face centered cubic (FCC) austenite in all three specimens shows that the response is elastic until the macroscopic yield point is reached. The onset of RA transformation into martensite matches with the deviation from linearity of the lattice strain for austenite within all three materials. It can be seen that the TRIP transformation was triggered only when the plastic deformation occurred in the FCC austenite. In addition, it can be observed that the entire BCC matrix, which in this case represents both the bainite and martensite (approximated from its body centered tetragonal (BCT) structure), remains perfectly elastic for the full loading period. Thus, it can be concluded that the macroscopic yield point, onset of RA transformation, and deviation of the FCC lattice are all indications that the critical transformation driving force was being met.

From Figure 4 and Figure 5, it can be seen that the RA in B2 is more stable compared to B1. The longer soak time facilitated the continued transformation of RA into bainite. In this process, the more stable austenite with a higher % C would be retained; as a result, the RA in B2 did not transform until a macroscopic stress of 1340 MPa (and a corresponding strain of 0.7%) was reached. The apparently higher mechanical stability of RA in B2 would be due to the lower volume fraction of blocky RA present in the microstructure. As discussed by Olson and Cohen [39], in the case of strain-induced austenite transformation, the presence of a lower volume fraction of RA results in a lower probability of product martensite nuclei being formed under similar loading conditions. It is also important to note that the presence of more film-like austenite in B2 compared to B1 would further cause the RA to be more stable under similar mechanical loading conditions.

In a similar fashion, comparing the results for bainitic and martensitic surrounding microstructures by looking at B1 and M1, we can see from Figure 4 and Figure 5 that the onset of transformation of the retained austenite into martensite occurred earlier in the bainitic microstructure than in the martensitic. Under identical stress states, the austenite was relatively more stable under uniaxial tension loading in the martensitic microstructure, and needed 40% more true strain for RA transformation to initiate. This is intriguing, considering that the martensitic sample did not have film-like RA, and the % C in the austenite was lower than that of both the bainitic samples. The higher relative stability of RA in the martensitic microstructure could, however, be attributed to the fact that the harder martensite appears to shield the austenite by accommodating more strain during loading, as hypothesized and discussed in some earlier works by Jacques et al. [17] and Ryu et al. [18]. This shows that for same amount of initial RA, the martensitic sample would be more stable at comparable strains when compared to the bainitic sample.

On the other hand, from Figure 4, it can also be seen that during the monotonic loading of both the B1 and M1 specimens, the martensitic specimen ended with 8.5% RA at fracture, whereas the bainitic specimen B1 had 11% RA at failure. This shows that while the austenite is more stable in the martensitic microstructure for specific applied loads, the rate of austenite transformation after the transformation has initiated is relatively greater in the martensitic specimen than in the bainitic one. After the onset of the austenite transformation, the blocky austenite in sample M1 transformed at a faster rate compared to the austenite in sample B1. In order to further understand the effect of the surrounding microstructure on the different deformation modes in these samples, the crystal plasticity model was used to determine the material parameters using a purely mechanistic analysis, so as to understand the rate of transformation and the criterion for initial transformation.

4.2. Crystal Plasticity Model Results

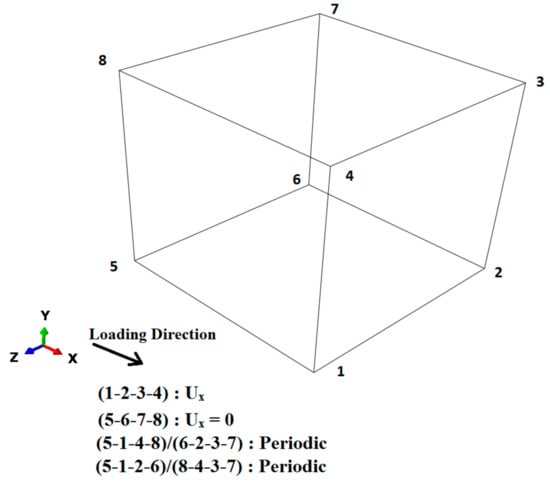

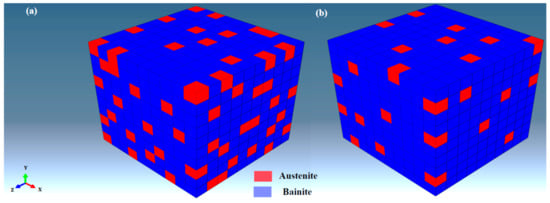

In order to determine and quantify the differences in the transformation of RA, the constitutive model was implemented in ABAQUS using a UMAT, as described earlier. The models for the B1, B2, and M1 specimens were created by generating an RVE with C3D8R elements in ABAQUS. The boundary conditions were chosen to simulate the real deformation as closely as possible. As a result, periodic boundary conditions were implemented in line with existing models [40,41], to accurately depict the real loading conditions on the RVE. A complete description of the boundary conditions, RVE generation [38], and UMAT implementation have been discussed in the prior work. The computational models generated were set up using 1000 elements (10 x 10 x 10), with initial volume fractions of retained austenite that matched the measured values from the microstructural characterization. The hybrid crystal plasticity formulation employed herein allowed us to generate identical RVEs, with the orientation information populated through a Monte Carlo simulation. In addition, the material response from the finite element model was analyzed from 50 such instantiations of the RVE. The values of the shape strain magnitude (), transformation viscosity parameter () and the maximum rate of transformation () in the austenite transformation model were assumed to be constant for this current composition of steel for all three specimens, and were set to 0.1809, 0.17, and 0.003 s−1, respectively [42]. Hdir was set to 6.9 GPa for the BCC phase of all three specimens and 6.4 GPa for the FCC austenite in all three specimens [28]. In case of the FCC austenite, was set to 6.4 GPa, and the initial drag stress fit was set to 560 MPa from Voothaluru et al. [28]. The retained austenite volume fraction in each of the three specimens was estimated using in situ neutron diffraction; the model was updated to reflect this in the input parameters. The material model and the corresponding input parameters were determined by performing a two-step iterative fit following the numerical implementation scheme proposed by Alley and Neu [37]. The single crystal elastic constants for the BCC and FCC phases were chosen to be constant across the three specimens, as the material response under elastic loads was largely the same, as seen in Figure 4 and Figure 5.

The single crystal elastic constants for the BCC and FCC phases are summarized in Table 3. The transformation plasticity parameters and microplasticity parameters were iteratively determined to fit the micromechanical response from the model to the empirical results from neutron diffraction. The material parameters used for the model are summarized in Table 4. The RVE was built in ABAQUS with C3D8R elements, and periodic boundary conditions were applied to the RVE along the loading axis, so as to simulate the representative loads from the uniaxial tension test. Figure 6 illustrates the boundary conditions on the RVE. The individual phases within the microstructure were randomly flagged so as to distribute a volume fraction of austenite that is representative of the sample being modeled. Figure 7 shows an illustration of two such RVEs, representing B1 and B2 samples.

Table 3.

Material model parameters (GPa).

Table 4.

Transformation plasticity and microplasticity parameters.

Figure 6.

Boundary conditions for crystal plasticity finite element (CPFE) modeling.

Figure 7.

(a) Illustration of an RVE instantiation for the B1 sample and (b) illustration of an RVE instantiation for the B2 sample in ABAQUS.

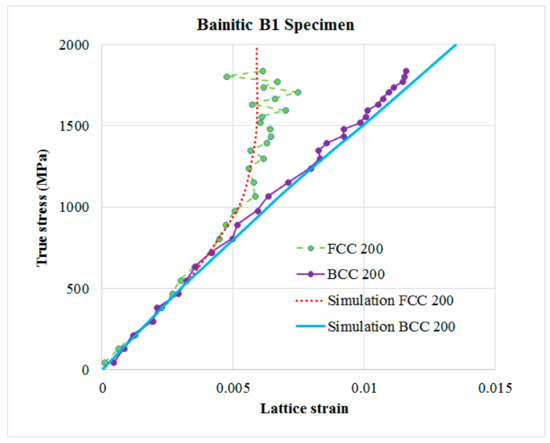

The modeling results using the material constants in Table 3 and Table 4 match well with experimental results collected using in situ neutron diffraction on the specimens, as shown in Figure 8, Figure 9 and Figure 10. The microplasticity and transformation plasticity parameters were primarily estimated so as to capture the transformation initiation in all three specimens, as well as the austenite transformation observed during the overall loading cycle. As a result, the modeling results had some minor deviations at large load levels, which were inherent as the material morphology is not accounted for as an input into the constitutive model or the computational model. The material model and the corresponding parameters have been used to study and analyze the differences in the corresponding material parameters, in order to understand the influence of the elastic, plastic, and transformation plasticity components on the stability of the retained austenite within the martensitic and bainitic matrices. The lattice strain results for grains along the <200> direction was compared in Figure 8, Figure 9 and Figure 10 with the modeling results from the CPFE model. Using the multiplicative decomposition of the deformation gradient, and by determining the appropriate critical transformation driving force and hardening coefficients, it is possible to capture the lattice strain response of the different microstructures. The austenite transformation is observed at true stress that is close to the macroscopic yield stress from Figure 4 in all three samples. Moreover, we can also see that there is little change in the martensitic or bainitic phases for most parts of the loading regime. The model is able to capture this well.

Figure 8.

CPFE estimation and experiment results for lattice strains in the bainitic B1 specimen.

Figure 9.

CPFE estimation and experiment results for lattice strains in the martensitic M1 specimen. Reproduced from [28], with permission of Elsevier 2018.

Figure 10.

CPFE estimation and experiment results for lattice strains in the bainitic B2 specimen.

5. Discussion

Comparing the results from the neutron diffraction experiment and the crystal plasticity model, we can see that while the elastic response is identical and the material constants are relatively same, the plastic deformation and the onset of transformation differ greatly in all three cases. From Table 4, the initial drag stress was slightly lower for the bainitic microstructures, which is expected as the martensite is a harder phase than the bainite. It can also be observed that the critical driving force for the transformation was estimated to be 21% higher for the martensitic microstructure compared to B1, demonstrating that in the bainitic microstructure, the onset of transformation is much earlier, primarily because the threshold limit for the critical transformation driving force is lower. This observation is further validated by the fact that there is little difference in the strain accumulated within the BCC phases of the B1 and M1 samples. On the other hand, the transformation hardening coefficient is 14% higher for B1 than for M1; showing that, in the bainitic microstructure after the onset of RA transformation, the resistance to subsequent transformation increases, thereby causing the austenite to behave as a more stable volume. This can also be attributed to the fact that the retained austenite in the bainitic microstructures (B1 and B2) has a higher amount of carbon than in the martensitic specimen (M1).

From the modeling material parameters in Table 4, we can also see that the major portion of the initial inelastic portion of the deformation is influenced by the transformation of the RA to martensite in both the B1 and M1 specimens, and that the surrounding microstructure directly affects the critical driving force that determines the onset of transformation and the overall evolving stress state in these specimens. As a result, the modeling data and the material parameters estimated using this model confirm our hypothesis that the predominant factor affecting the stability of the RA in these specimens (B1 and M1) is the effect of the surrounding microstructure. The higher-strength martensite directly impacts the critical driving force necessary for the transformation, causing the transformation to occur at a slightly higher strain than in B1. In addition, we can observe from Table 4 that the micro-hardening parameters for M1 and B1 are identical in this case. Therefore, the only parameter affecting the rate of transformation into martensite is the transformation hardening coefficient Q. As a result, we conclude that the difference in the rate of transformation is directly influenced by the microstructure morphology in B1 and M1. It is in line with our initial hypothesis that the primary reasons this transformation is more rapid in M1 is the lack of any film-like austenite and the potential of the blocky austenite in M1 to transform faster. This conclusion can be used to further infer that once the austenite starts to strain plastically, the number of shear bands per unit volume of austenite is higher in the martensitic M1 than in the bainitic B1.

In order to further understand the effect of the bainitic microstructure and its influence on austenite stability, we compared specimens B1 and B2, both of which have a bainitic microstructure but different amounts of initial RA. From Figure 3 and Figure 4, we can clearly see that B2 with 9% initial RA is much more stable RA than B1 with 18% initial RA. This is to be expected, since the lower initial volume fraction of austenite limits the number of available shear bands for martensite nucleation [39]. The quantified micro-mechanical parameters for B1 and B2 directly demonstrates this effect—the critical driving stress for transformation in B2 is significantly higher than that in B1. However, it is interesting to note that the transformation hardening coefficient from Table 4 and the corresponding slope of the RA volume fraction from Figure 3 remain relatively constant. This demonstrates that the majority of the RA transforming to martensite in the bainitic microstructure is the blocky RA. Because the amount of available blocky RA is smaller in B2, the transformation occurs only when the corresponding austenite is plastically strained. However, once plastic strain was induced, the observed transformation rate did not change significantly. Based upon this, we can hypothesize that the number of shear bands available at the austenite lattice level is essentially identical with both B1 and B2 microstructures.

6. Conclusions

This work presents a first-of-its-kind effort to quantify the mechanical stability of retained austenite in martensitic and bainitic bearing steels by conducting in situ neutron diffraction and comparing this to the computational response from crystal plasticity modeling. The results have shown that the retained austenite in a martensitic microstructure has a higher critical driving force compared to that of a bainitic microstructure. This has been explained by the fact that the harder martensitic phase would partially shield the austenite from being plastically deformed under lower macroscopic loads. In addition, we found that once plastically deformed, the probability that a shear band intersection would generate a martensitic nucleation would be higher in the austenite of the martensitic microstructure. To further understand the stability of retained austenite in a bainitic microstructure, the effect of the initial volume fraction of retained austenite was studied. The results show that, as expected, the higher volume fraction of initial RA results in an earlier RA transformation. However, if a large proportion of the RA transforming under plastic strain is blocky RA, then, the probability that a shear band will generate a martensitic nucleation is relatively constant irrespective of the initial volume fraction of RA. This allows the rate of transformation to be constant after the onset of RA transformation in the bainitic microstructures.

Author Contributions

Conceptualization, R.V. and V.B.; methodology, R.V., V.B., and D.Y.; software, R.V., Q.X., and D.Y.; validation, R.V. and V.B.; resources, K.A., R.S.H., and P.P.; data curation, Q.X. and D.Y.; investigation, R.V., V.B., and D.Y., writing—original draft preparation, R.V. and V.B.; writing—review and editing, K.A., R.S.H., and P.P.; visualization, R.V. and V.B.; supervision, K.A.; project administration, R.S.H; funding acquisition, R.V., V.B., and R.S.H.

Funding

A portion (neutron diffraction) of this research used resources at the Spallation Neutron Source, a U.S. Department of Energy Office of Science User Facility operated by the Oak Ridge National Laboratory (ORNL).

Acknowledgments

The authors thank Ryan D. Evans (Director, R&D Bearings, The Timken Company) and Stephen P. Johnson (Director, Business Development, The Timken Company) for permission and support of this work. We would also like to thank Matt Boyle, Chris Akey, Robert Pendergrass, and the associates in the Prototype department for sample preparation.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Luzginova, N.; Zhao, L.; Sietsma, J. Evolution and thermal stability of retained austenite in SAE 52100 bainitic steel. Mater. Sci. Eng. A 2007, 448, 104–110. [Google Scholar] [CrossRef]

- Hossain, R.; Pahlevani, F.; Quadir, M.Z.; Sahajwalla, V. Stability of retained austenite in high carbon steel under compressive stress: an investigation from macro to nano scale. Sci. Rep. 2016, 6. [Google Scholar] [CrossRef]

- Zaretsky, E.V. Rolling bearing steels–a technical and historical perspective. Mater. Sci. Technol. 2012, 28, 58–69. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Edmonds, D.V. The bainite transformation in a silicon steel. Metall. Trans. A 1979, 10, 895–907. [Google Scholar] [CrossRef]

- Bhadeshia, H. Martensite and Bainite in Steels: Transformation Mechanism & Mechanical Properties. J. Phys. IV Colloq. 1997, 07, C5-367–C5-376. [Google Scholar]

- Podder, A.S.; Lonardelli, I.; Molinari, A.; Bhadeshia, H.K.D.H. Thermal stability of retained austenite in bainitic steel: an in situ study. Proc R Soc A 2011, 467, 3141–3156. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. High Performance Bainitic Steels. Mater. Sci. Forum 2005, 500–501, 63–74. [Google Scholar] [CrossRef]

- De Cooman, B.C. Structure–properties relationship in TRIP steels containing carbide-free bainite. Curr. Opin. Solid State Mater. Sci. 2004, 8, 285–303. [Google Scholar] [CrossRef]

- Jacques, P.J. Transformation-induced plasticity for high strength formable steels. Curr. Opin. Solid State Mater. Sci. 2004, 8, 259–265. [Google Scholar] [CrossRef]

- Thomas, G. Retained austenite and tempered martensite embrittlement. Metall. Trans. A 1978, 9, 439–450. [Google Scholar] [CrossRef]

- Abudaia, F.B.; Evans, J.T.; Shaw, B. Characterization of retained austenite in case carburized gears and its influence on fatigue performance. Gear Technol. 2003, 20, 12–16. [Google Scholar]

- Rivero, I.V.; Ruud, C.O. Deviation of residual stress patterns in 52100 bearing steel due to inherent microstructural transformations after rolling contact. Mater. Charact. 2004, 53, 381–393. [Google Scholar] [CrossRef]

- Stickels, C.A. Plastic deformation of quenched and tempered 52100 bearing steel in compression. Metall. Trans. A 1977, 8, 63–70. [Google Scholar] [CrossRef]

- Voskamp, A.P. Material Response to Rolling Contact Loading. J. Tribol. 1985, 107, 359–364. [Google Scholar] [CrossRef]

- Voskamp, A.P.; Österlund, R.; Becker, P.C.; Vingsbo, O. Gradual changes in residual stress and microstructure during contact fatigue in ball bearings. Met. Technol. 1980, 7, 14–21. [Google Scholar] [CrossRef]

- Jacques, P.J.; Delannay, F.; Ladrière, J. On the influence of interactions between phases on the mechanical stability of retained austenite in transformation-induced plasticity multiphase steels. Metall. Mater. Trans. A 2001, 32, 2759–2768. [Google Scholar] [CrossRef]

- Ryu, J.H.; Kim, D.-I.; Kim, H.S.; Bhadeshia, H.K.D.H.; Suh, D.-W. Strain partitioning and mechanical stability of retained austenite. Scr. Mater. 2010, 63, 297–299. [Google Scholar] [CrossRef]

- Xie, Z.J.; Ren, Y.Q.; Zhou, W.H.; Yang, J.R.; Shang, C.J.; Misra, R.D.K. Stability of retained austenite in multi-phase microstructure during austempering and its effect on the ductility of a low carbon steel. Mater. Sci. Eng. A 2014, 603, 69–75. [Google Scholar] [CrossRef]

- Cui, W.; San-Martín, D.; Rivera-Díaz-del-Castillo, P.E.J. Stability of retained austenite in martensitic high carbon steels. Part I: Thermal stability. Mater. Sci. Eng. A 2018, 711, 683–695. [Google Scholar] [CrossRef]

- Cui, W.; Gintalas, M.; Rivera-Diaz-del-Castillo, P.E.J. Stability of retained austenite in martensitic high carbon steels. Part II: Mechanical stability. Mater. Sci. Eng. A 2018, 711, 696–703. [Google Scholar] [CrossRef]

- Xiong, X.C.; Chen, B.; Huang, M.X.; Wang, J.F.; Wang, L. The effect of morphology on the stability of retained austenite in a quenched and partitioned steel. Scr. Mater. 2013, 68, 321–324. [Google Scholar] [CrossRef]

- Cakmak, E.; Choo, H.; An, K.; Ren, Y. A synchrotron X-ray diffraction study on the phase transformation kinetics and texture evolution of a TRIP steel subjected to torsional loading. Acta Mater. 2012, 60, 6703–6713. [Google Scholar] [CrossRef]

- Lani, F.; Furnémont, Q.; Van Rompaey, T.; Delannay, F.; Jacques, P.J.; Pardoen, T. Multiscale mechanics of TRIP-assisted multiphase steels: II. Micromechanical modelling. Acta Mater. 2007, 55, 3695–3705. [Google Scholar] [CrossRef]

- Kim, E.-Y.; Woo, W.; Heo, Y.-U.; Seong, B.; Choi, J.; Choi, S.-H. Effect of kinematic stability of the austenite phase on phase transformation behavior and deformation heterogeneity in duplex stainless steel using the crystal plasticity finite element method. Int. J. Plast. 2016, 79, 48–67. [Google Scholar] [CrossRef]

- Woo, W.; Em, V.T.; Kim, E.-Y.; Han, S.H.; Han, Y.S.; Choi, S.-H. Stress–strain relationship between ferrite and martensite in a dual-phase steel studied by in situ neutron diffraction and crystal plasticity theories. Acta Mater. 2012, 60, 6972–6981. [Google Scholar] [CrossRef]

- Hidalgo, J.; Findley, K.O.; Santofimia, M.J. Thermal and mechanical stability of retained austenite surrounded by martensite with different degrees of tempering. Mater. Sci. Eng. A 2017, 690, 337–347. [Google Scholar] [CrossRef]

- Voothaluru, R.; Bedekar, V.; Xie, Q.; Stoica, A.D.; Hyde, R.S.; An, K. In-situ neutron diffraction and crystal plasticity finite element modeling to study the kinematic stability of retained austenite in bearing steels. Mater. Sci. Eng. A 2018, 711, 579–587. [Google Scholar] [CrossRef]

- Bedekar, V.; Voothaluru, R.; Xie, Q.; Stoica, A.; Hyde, R.S.; An, K. In-situ neutron diffraction analysis of crystal plasticity of retained austenite in bearing steel. Procedia Eng. 2017, 207, 1958–1963. [Google Scholar] [CrossRef]

- Jatczak, C.F.; Larson, J.A.; Shin, S.W. Retained Austenite and Its Measurements by X-ray Diffraction: An Information Manual; Society of Automotive Engineers: Warrendale, PA, USA, 1980; ISBN 0-89883-224-1. [Google Scholar]

- An, K. VDRIVE-Data reduction and interactive visualization software for event mode neutron diffraction. ORNL Rep. Oak Ridge Natl. Lab. Oak Ridge TN 2012. No ORNL-TM-2012-621. [Google Scholar]

- Stoica, G.M.; Stoica, A.D.; An, K.; Ma, D.; Vogel, S.C.; Carpenter, J.S.; Wang, X.-L. Extracting grain-orientation-dependent data from in situ time-of-flight neutron diffraction. I. Inverse pole figures. J. Appl. Crystallogr. 2014, 47, 2019–2029. [Google Scholar] [CrossRef]

- Turteltaub, S.; Suiker, A.S.J. A multiscale thermomechanical model for cubic to tetragonal martensitic phase transformations. Int. J. Solids Struct. 2006, 43, 4509–4545. [Google Scholar] [CrossRef]

- Voothaluru, R.; Liu, C.R. A crystal plasticity based methodology for fatigue crack initiation life prediction in polycrystalline copper. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 671–681. [Google Scholar] [CrossRef]

- Tjahjanto, D.D.; Turteltaub, S.; Suiker, A.S.J. Crystallographically based model for transformation-induced plasticity in multiphase carbon steels. Contin. Mech. Thermodyn. 2008, 19, 399–422. [Google Scholar] [CrossRef]

- Alley, E.S.; Neu, R.W. Microstructure-sensitive modeling of rolling contact fatigue. Int. J. Fatigue 2010, 32, 841–850. [Google Scholar] [CrossRef]

- Alley, E.S.; Neu, R.W. A hybrid crystal plasticity and phase transformation model for high carbon steel. Comput. Mech. 2013, 52, 237–255. [Google Scholar] [CrossRef]

- Voothaluru, R. A crystal plasticity based methodology for modeling fatigue crack initiation and estimating material coefficients to predict fatigue crack initiation life at micro, nano and macro scales. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2014. [Google Scholar]

- Olson, G.; Cohen, M. Kinetics of strain-induced martensitic nucleation. Metall. Mater. Trans. A 1975, 6, 791–795. [Google Scholar] [CrossRef]

- Smit, R.J.M.; Brekelmans, W.A.M.; Meijer, H.E.H. Prediction of the mechanical behavior of nonlinear heterogeneous systems by multi-level finite element modeling. Comput. Methods Appl. Mech. Eng. 1998, 155, 181–192. [Google Scholar] [CrossRef]

- Voothaluru, R.; Richard Liu, C. Determination of lattice level energy efficiency for fatigue crack initiation. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 670–678. [Google Scholar] [CrossRef]

- Turteltaub, S.; Suiker, A.S.J. Transformation-induced plasticity in ferrous alloys. J. Mech. Phys. Solids 2005, 53, 1747–1788. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).