Lubricants, Volume 9, Issue 3 (March 2021) – 12 articles

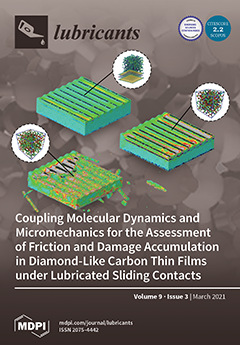

The figures present the principal effects arising from the different lubrication conditions and DLC structure to the resulting coating system damage mechanisms (leading to cumulative wear): (a) graphene-lubricated surface sliding against a flat DLC surface displaying limited damage; (b) a-C:H DLC coating showing initiation of damage with multiple potential failure mechanisms; (c) ta-C DLC coating that has experienced extensive damage and failed. View this paper.

- Issues are regarded as officially published after their release is announced to the table of contents alert mailing list.

- You may sign up for e-mail alerts to receive table of contents of newly released issues.

- PDF is the official format for papers published in both, html and pdf forms. To view the papers in pdf format, click on the "PDF Full-text" link, and use the free Adobe Reader to open them.