- Article

RUL Prediction Method for Tools Based on Multi-Channel CNN and Cross-Modal Transformer

- Changfu Liu,

- Yubai Liu and

- Jingjing Gao

- + 4 authors

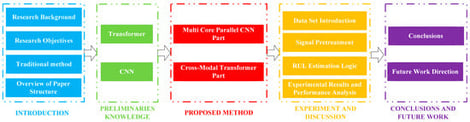

Excessive tool wear can compromise machining precision and increase costs, rendering accurate tool remaining useful life (RUL) prediction imperative in intelligent manufacturing. Traditional methods exhibit intrinsic limitations in cross-modal modeling accuracy and capturing temporal dependencies, failing to meet practical requirements. To transcend these bottlenecks, this study proposes a robust tool RUL prediction framework that combines a multi-channel CNN and a Cross-Modal Transformer. The CNN performs convolution operations to extract local features from wear signals, while the Transformer adaptively synchronizes heterogeneous features (cutting force, vibration, and acoustic emission) to capture long-term degradation trends. Empirical evaluations conducted on the PHM2010 dataset demonstrate the model’s robustness and generalization capability: under the random shuffle–split protocol, the proposed method achieves an R2 of up to 0.99, with the RMSE and MAE reaching 2.51 and 1.98, respectively. To further evaluate the framework’s extrapolation ability under domain shifts, a cross-cutter validation protocol was implemented. Under this condition, the experimental results yield an R2 of 0.961, an RMSE of 6.92, and an MAE of 6.09. Additionally, the correlation between modality-specific attention weights and their corresponding physical interpretations is systematically investigated. These results confirm the model’s potential for cross-cutter life cycle management in smart manufacturing, providing stable and physically consistent wear estimation and remaining useful life prediction in noise-intensive environments.

1 March 2026

![Structures of choline hydroxide [ChOH] and glycerol [G].](https://mdpi-res.com/cdn-cgi/image/w=281,h=192/https://mdpi-res.com/lubricants/lubricants-14-00106/article_deploy/html/images/lubricants-14-00106-ag-550.jpg)