In-Situ Calibrated Modeling of Residual Stresses Induced in Machining under Various Cooling and Lubricating Environments

Abstract

1. Introduction

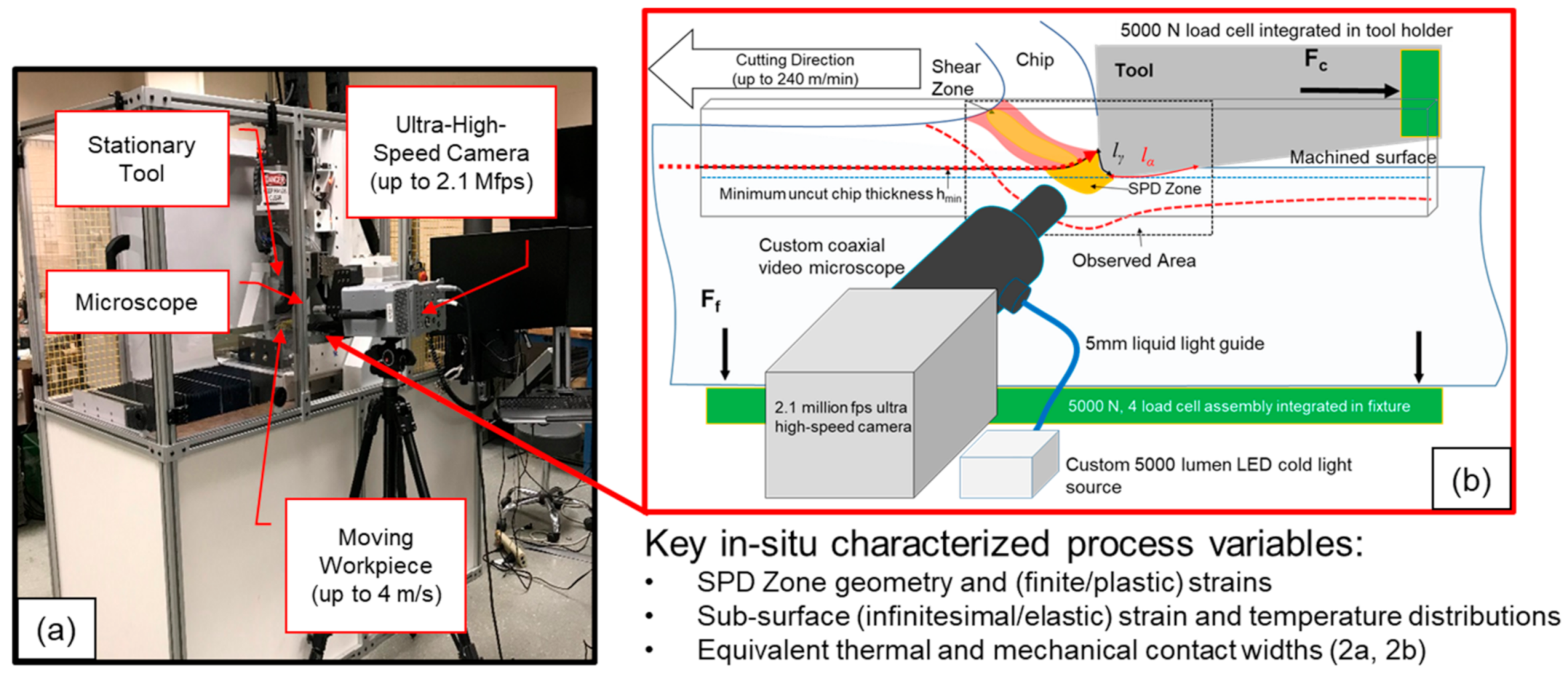

2. Materials and Methods

3. Theory and Results

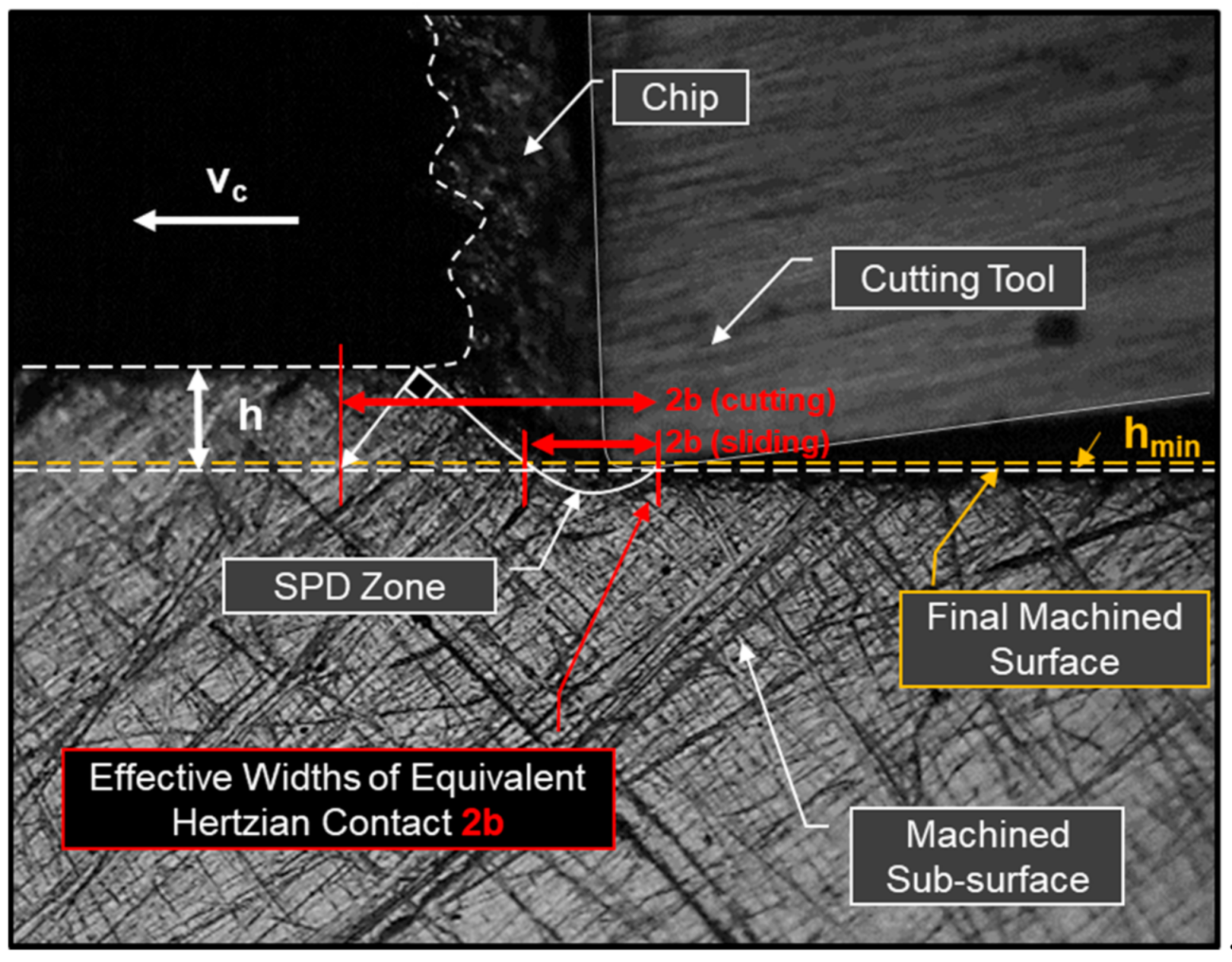

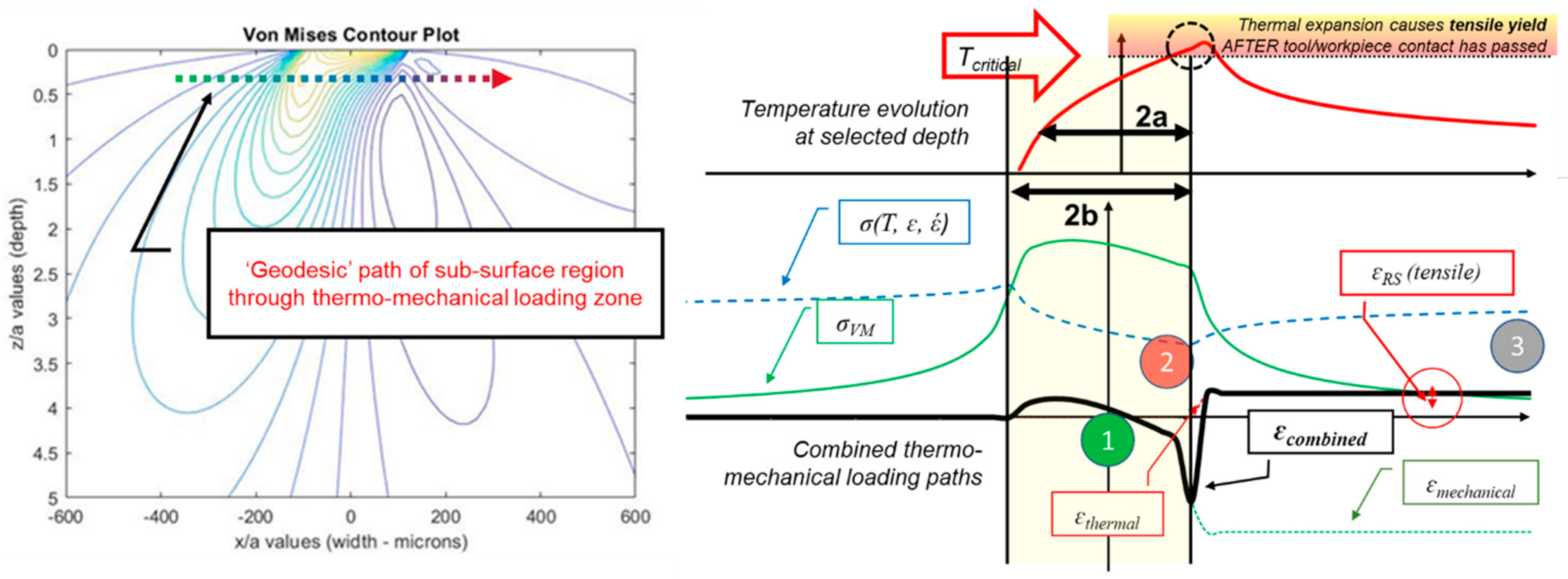

3.1. Thermo-Mechanical Sub-Surface Loading during Machining and Sliding Processes

3.2. Thermal Domain Considerations

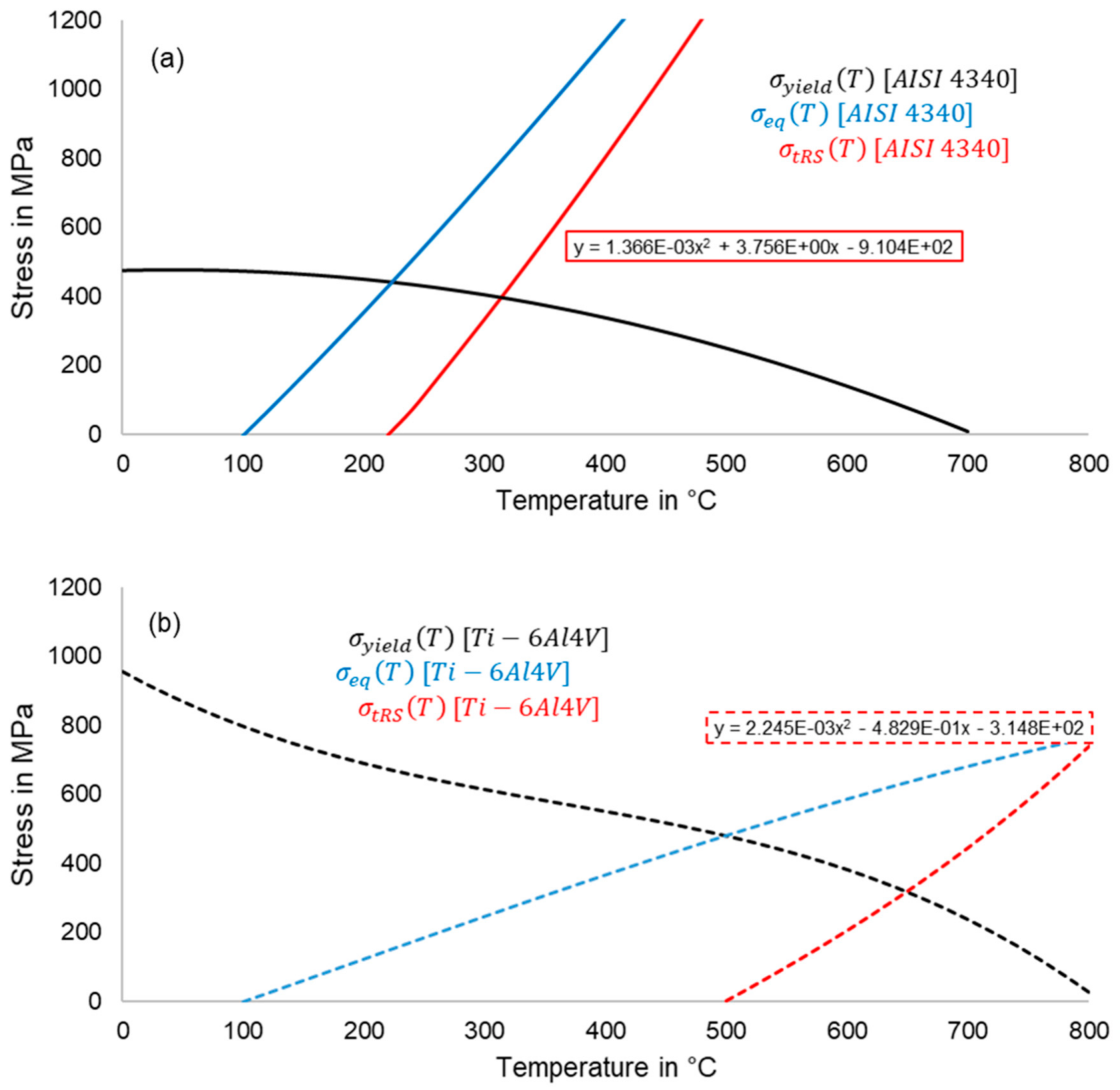

3.3. Residual Stress Calculation via Elastic Sub-domain Model

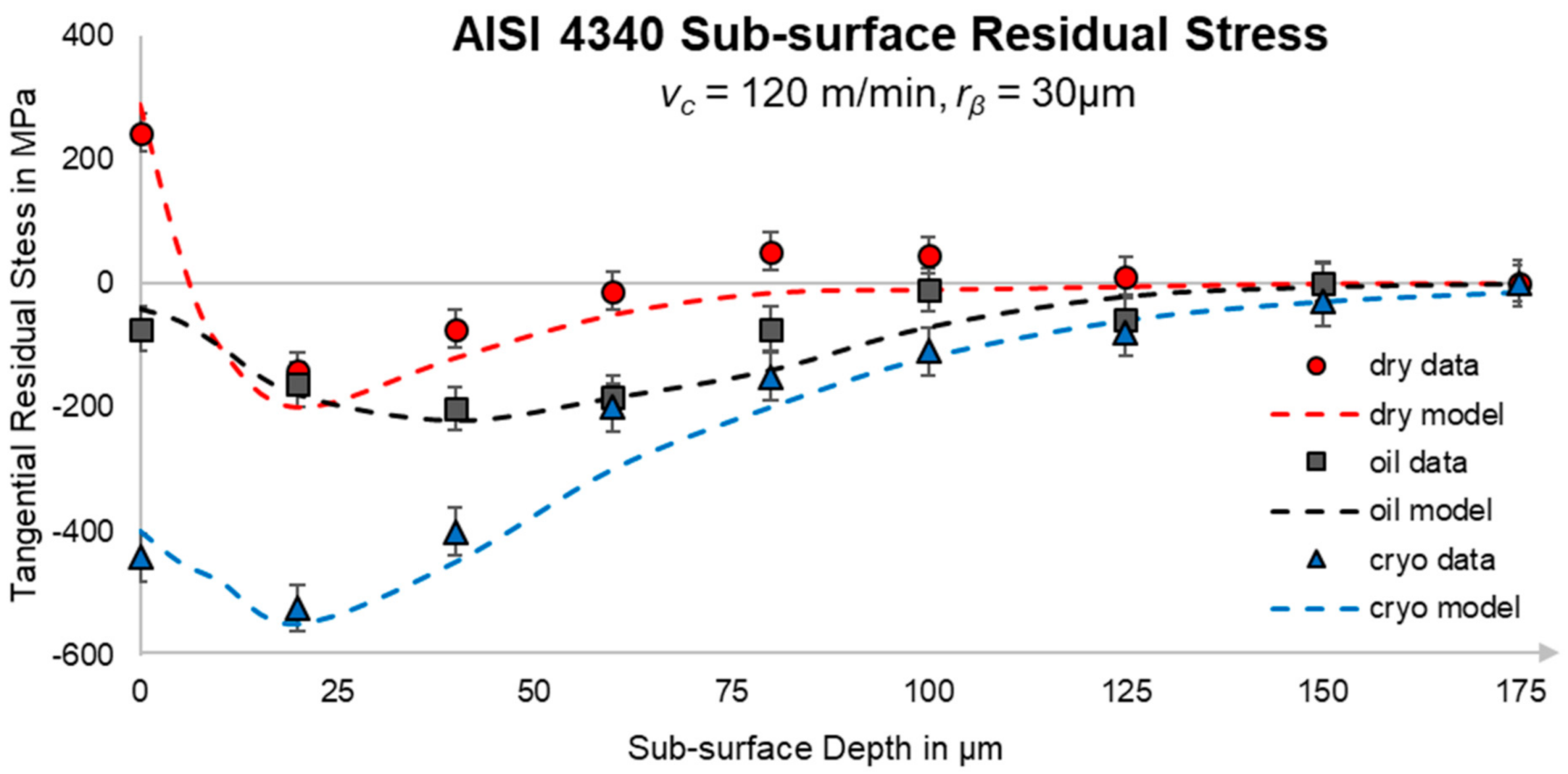

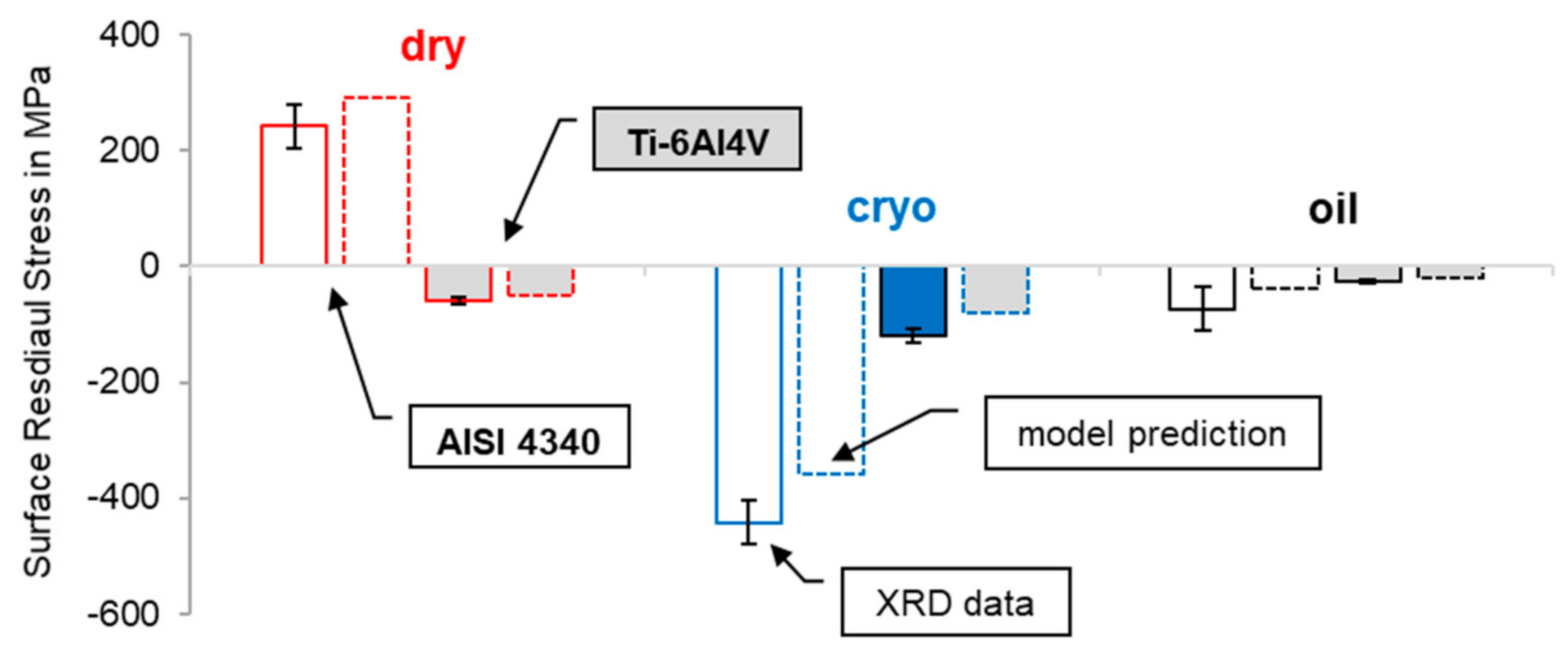

3.4. Preliminary Calibration and Validation of Proposed Model in AISI 4340

4. Discussion

4.1. Limitations and Future Expansion Needs of Proposed Model

4.2. Comparison and Interpretation of Experimental Data and Model Predictions

5. Conclusions

- The critical temperature of a workpiece material, beyond which localized thermal expansion of the surface results in a thermally-induced tensile residual stress, varies significantly between workpiece materials, and is a key metric in residual stress response to cutting.

- Dry cutting leads to the highest cutting temperatures and most shallow and tensile residual stress profile.

- Oil lubrication reduces near-surface residual stresses, and generally provides and deeper and more compressive residual stress profile than dry cutting.

- Cryogenic cooling significantly increases normal force and contact width, which results in a significantly more compressive and deeper residual stress profile.

- The proposed semi-analytical model was able to capture all of these effects by means of efficient in-situ calibration, and following a qualitatively accurate (physics-based) analytical formulation.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Henriksen, E.K. Residual Stresses in Machined Surfaces; ASME: New York, NY, USA, 1948. [Google Scholar]

- Halverstadt, R. Analysis of residual stress in ground surfaces of high-temperature alloys. Trans. Am. Soc. Mech. Eng. 1958, 80, 80–85. [Google Scholar]

- Kahles, J.; Field, M. Paper 4: Surface Integrity—A New Requirement for Surfaces Generated by Material-Removal Methods. In Proceedings of the Institution of Mechanical Engineers, 1 June 1967; SAGE Publications Sage: London, UK, 1967; Volume 182, pp. 31–45. [Google Scholar]

- Barash, M.; Schoech, W. Semi-Analytical Model of the Residual Stress Zone in Orthogonal Machining. In Advances in Machine Tool Design and Research, Proceedings of the Internat. M. T. D. R. Conference, Manchester, UK, 15-17 September 1971; Pergamon Press: Oxford, UK, 1971; pp. 603–613. [Google Scholar]

- Pomeroy, R.J.; Johnson, K.L. Residual stresses in rolling contact. J. Strain Anal. 1969, 4, 208–218. [Google Scholar] [CrossRef]

- Liu, C.R.; Barash, M.M. The Mechanical State of the Sublayer of a Surface Generated by Chip-Removal Process—Part 1: Cutting With a Sharp Tool. J. Eng. Ind. 1976, 98, 1192–1199. [Google Scholar] [CrossRef]

- Liu, C.R.; Barash, M.M. The Mechanical State of the Sublayer of a Surface Generated by Chip-Removal Process—Part 2: Cutting With a Tool With Flank Wear. J. Eng. Ind. 1976, 98, 1202–1208. [Google Scholar] [CrossRef]

- Jacobus, K.; Devor, R.E.; Kapoor, S.G. Machining-Induced Residual Stress: Experimentation and Modeling. J. Manuf. Sci. Eng. 1999, 122, 20–31. [Google Scholar] [CrossRef]

- Fergani, O.; Lazoglu, I.; Mkaddem, A.; El Mansori, M.; Liang, S.Y. Analytical modeling of residual stress and the induced deflection of a milled thin plate. Int. J. Adv. Manuf. Technol. 2014, 75, 455–463. [Google Scholar] [CrossRef]

- Pan, Z.; Feng, Y.; Ji, X.; Liang, S.Y. Turning induced residual stress prediction of AISI 4130 considering dynamic recrystallization. Mach. Sci. Technol. 2017, 22, 507–521. [Google Scholar] [CrossRef]

- Shan, C.; Zhang, M.; Zhang, S.; Dang, J. Prediction of machining-induced residual stress in orthogonal cutting of Ti6Al4V. Int. J. Adv. Manuf. Technol. 2020, 107, 2375–2385. [Google Scholar] [CrossRef]

- Wang, S.; Li, J.; He, C.; Xie, Z. A 3D analytical model for residual stress in flank milling process. Int. J. Adv. Manuf. Technol. 2019, 104, 3545–3565. [Google Scholar] [CrossRef]

- Zhou, R.; Yang, W. Analytical modeling of machining-induced residual stresses in milling of complex surface. Int. J. Adv. Manuf. Technol. 2019, 105, 565–577. [Google Scholar] [CrossRef]

- Li, B.; Deng, H.; Hui, D.; Hu, Z.; Zhang, W. A semi-analytical model for predicting the machining deformation of thin-walled parts considering machining-induced and blank initial residual stress. Int. J. Adv. Manuf. Technol. 2020, 110, 139–161. [Google Scholar] [CrossRef]

- Jawahir, I.; Brinksmeier, E.; M’Saoubi, R.; Aspinwall, D.; Outeiro, J.; Meyer, D.; Umbrello, D.; Jayal, A. Surface integrity in material removal processes: Recent advances. CIRP Ann. 2011, 60, 603–626. [Google Scholar] [CrossRef]

- Arrazola, P.; Özel, T.; Umbrello, D.; Davies, M.; Jawahir, I. Recent advances in modelling of metal machining processes. CIRP Ann. 2013, 62, 695–718. [Google Scholar] [CrossRef]

- Umbrello, D.; M’Saoubi, R.; Outeiro, J. The influence of Johnson–Cook material constants on finite element simulation of machining of AISI 316L steel. Int. J. Mach. Tools Manuf. 2007, 47, 462–470. [Google Scholar] [CrossRef]

- Kaynak, Y.; Manchiraju, S.; Jawahir, I.S. Modeling and Simulation of Machining-Induced Surface Integrity Characteristics of NiTi Alloy. Procedia CIRP 2015, 31, 557–562. [Google Scholar] [CrossRef]

- Liu, X.; Devor, R.E.; Kapoor, S.G. An Analytical Model for the Prediction of Minimum Chip Thickness in Micromachining. J. Manuf. Sci. Eng. 2006, 128, 474–481. [Google Scholar] [CrossRef]

- Schoop, J.; Adeniji, D.; Brown, I. Computationally efficient, multi-domain hybrid modeling of surface integrity in machining and related thermomechanical finishing processes. Procedia CIRP 2019, 82, 356–361. [Google Scholar] [CrossRef]

- Lescalloy® 4340 VAC-ARC® Data Sheet; Latroboe Speciality Steel Company: Latrobe, PA, USA, 2007.

- Ti-6Al-4V Data Sheet; Report TMC-0150; TIMETAL; Titanium Metals Corporation: Henderson, NV, USA, 2000.

- McEwen, E. Stresses in Elastic Cylinders in Contact Along a Generatix. Philos. Mag. 1949, 40, 454–460. [Google Scholar]

- Applied Mechanics Group; Merwin, J.E.; Johnson, K.L. An Analysis of Plastic Deformation in Rolling Contact. Proc. Inst. Mech. Eng. 1963, 177, 676–690. [Google Scholar] [CrossRef]

- Melkote, S.N.; Grzesik, W.; Outeiro, J.; Rech, J.; Schulze, V.; Attia, H.; Arrazola, P.-J.; M’Saoubi, R.; Saldana, C. Advances in material and friction data for modelling of metal machining. CIRP Ann. 2017, 66, 731–754. [Google Scholar] [CrossRef]

- Schoop, J.; Sales, W.F.; Jawahir, I.S. High Speed Cryogenic Finish Machining of Ti-6Al4V with polycrystalline diamond tools. J. Mater. Process. Technol. 2017, 250, 1–8. [Google Scholar] [CrossRef]

| Workpiece Material | E (20°C) [GPa] | G (20°C) [GPa] | ν | σyield (20 °C) [MPa] |

|---|---|---|---|---|

| AISI 4340 | 206 | 80 | 0.28 | 475 |

| Ti-6Al4V | 113 | 43 | 0.33 | 1015 |

| Workpiece Material | Cooling/Lubricating Condition | 2b [μm] (h = 30 μm) | 2b [μm] (h = hmin) | Fc [N] (h = hmin) | Ff [N] (h = hmin) | μapparent (h = hmin) |

|---|---|---|---|---|---|---|

| AISI 4340 | Dry | 45 | 26 | 36 | 69 | 0.52 |

| AISI 4340 | Cryogenic Cooling (LN2) | 58 | 35 | 38 | 101 | 0.38 |

| AISI 4340 | Lubrication | 48 | 29 | 8 | 61 | 0.13 |

| Ti-6Al4V | Dry | 36 | 21 | 28 | 52 | 0.40 |

| Ti-6Al4V | Cryogenic Cooling (LN2) | 46 | 27 | 20 | 62 | 0.32 |

| Ti-6Al4V | Lubrication | 39 | 23 | 16 | 51 | 0.31 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schoop, J. In-Situ Calibrated Modeling of Residual Stresses Induced in Machining under Various Cooling and Lubricating Environments. Lubricants 2021, 9, 28. https://doi.org/10.3390/lubricants9030028

Schoop J. In-Situ Calibrated Modeling of Residual Stresses Induced in Machining under Various Cooling and Lubricating Environments. Lubricants. 2021; 9(3):28. https://doi.org/10.3390/lubricants9030028

Chicago/Turabian StyleSchoop, Julius. 2021. "In-Situ Calibrated Modeling of Residual Stresses Induced in Machining under Various Cooling and Lubricating Environments" Lubricants 9, no. 3: 28. https://doi.org/10.3390/lubricants9030028

APA StyleSchoop, J. (2021). In-Situ Calibrated Modeling of Residual Stresses Induced in Machining under Various Cooling and Lubricating Environments. Lubricants, 9(3), 28. https://doi.org/10.3390/lubricants9030028