Impact of Orifice-to-Pipe Diameter Ratio on Leakage Flow: An Experimental Study

Abstract

:1. Introduction

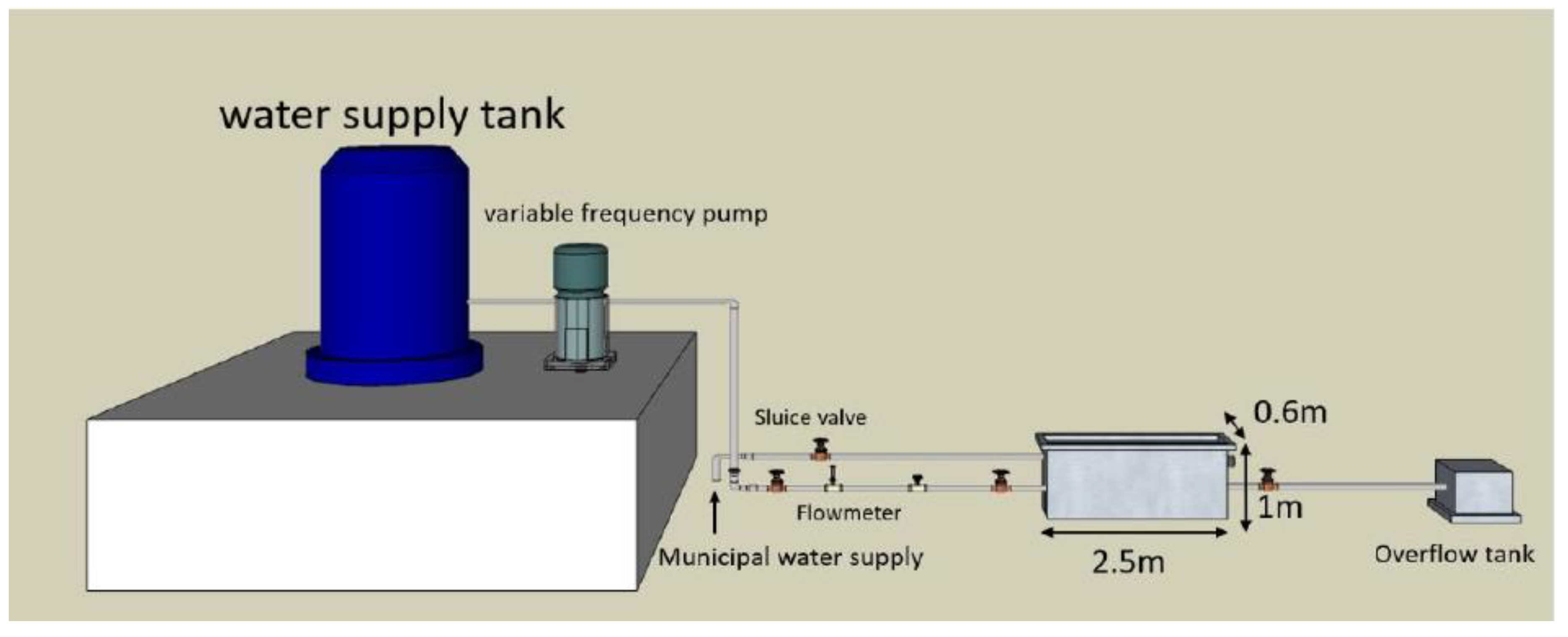

2. Experimental Study

2.1. Experimental Apparatus

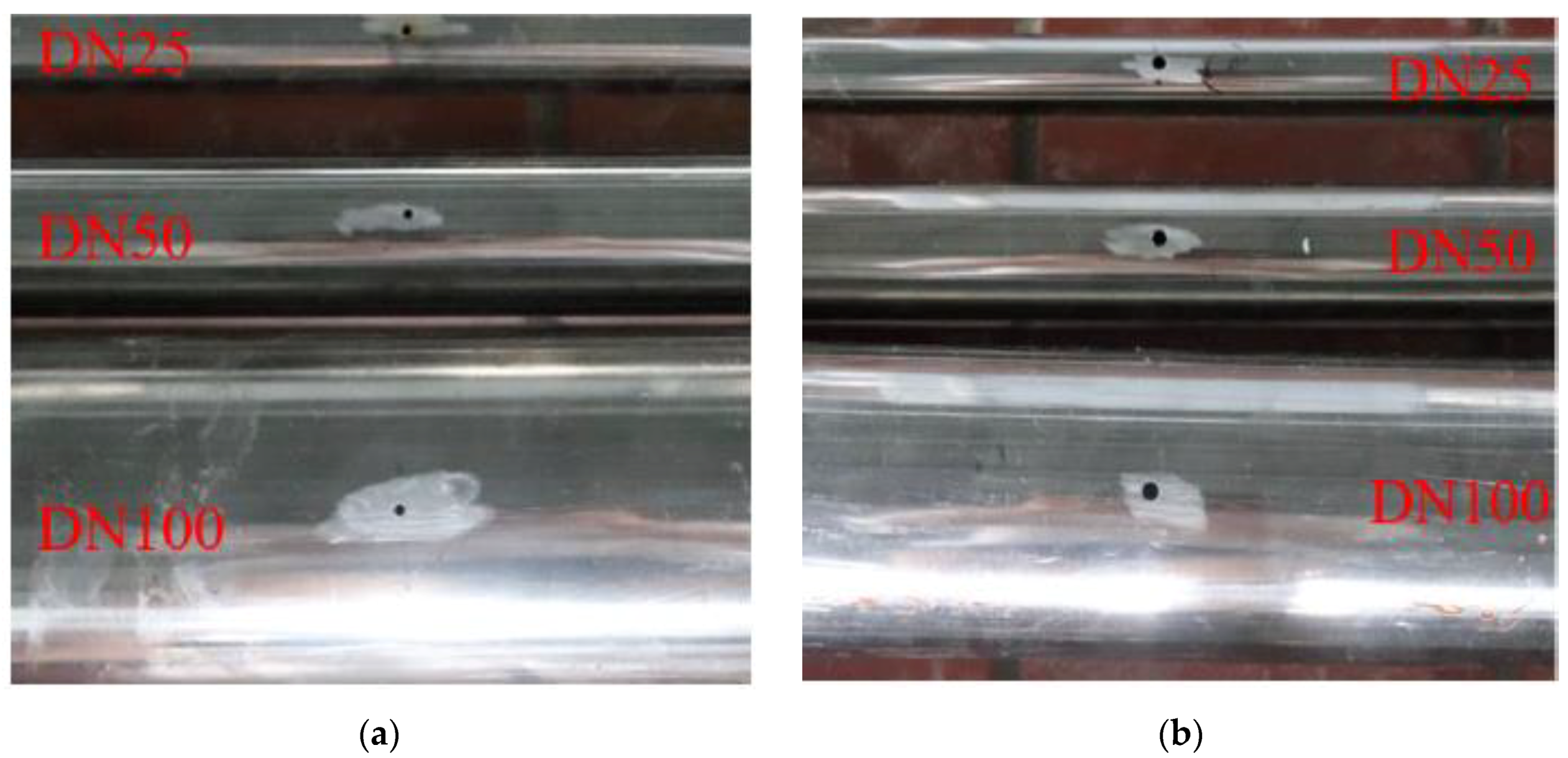

2.2. Experimental Procedures

2.3. Experimental Results

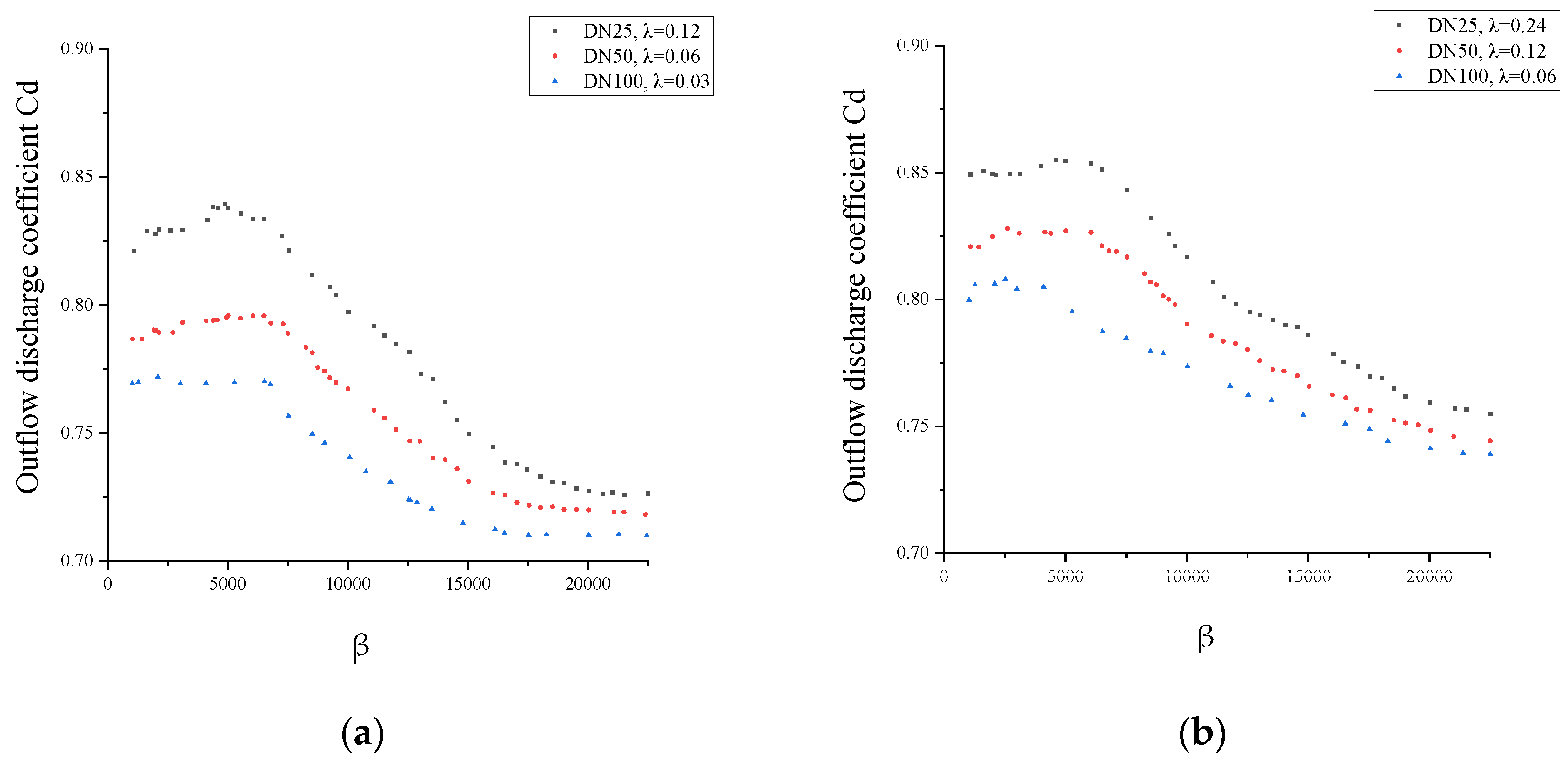

2.3.1. Discharge Coefficient for the Experiments with Water as External Medium

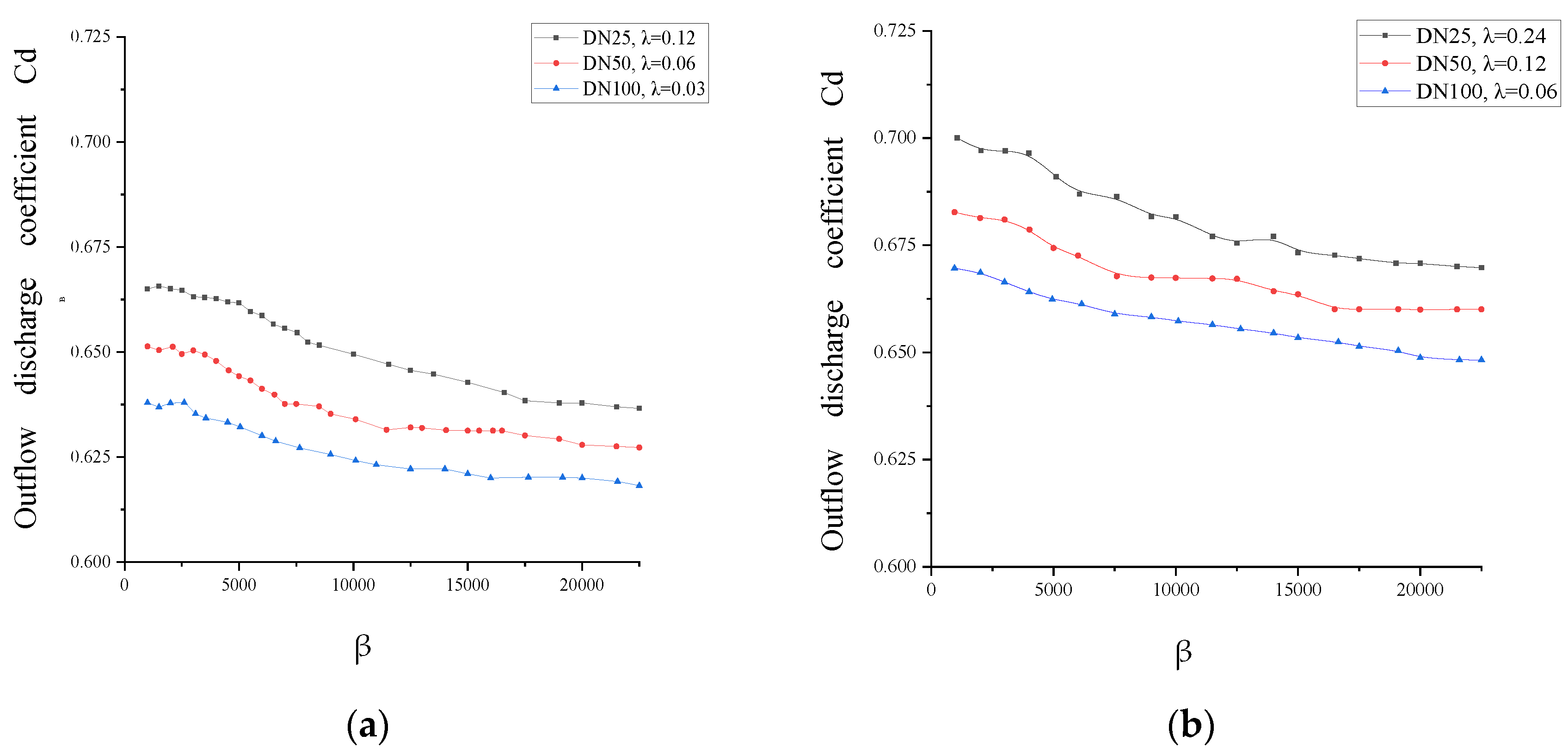

2.3.2. Discharge Coefficient for the Experiments with Air as External Medium

2.3.3. Effect of Reynolds Number

2.3.4. Synthesis of the Experimental Results

3. Conclusions

- The dimensionless parameter λ (the orifice-to-pipe diameter radio) indeed affected the pipe leakage with the same size of orifice. With constant orifice pressure and main pipe flow velocity, λ increased (i.e., with the decrease of the pipe diameter, with the increase of pipe wall curvature), and the outflow discharge coefficient increased. The conclusion in the experimental results was true under three molds of opening leakage, namely, round hole, longitudinal crack, and circumferential crack. was more sensitive to λ when the pipe was around the water under low pressure.

- The discharge coefficient slightly increased with orifice diameter (3 and 6 mm), which also suggests that a general relationship between and the dimensionless parameter λ (the orifice-to-pipe diameter ratio) may exist. Further experimental and numerical studies will be carried out to investigate this potential relationship.

- The water around the orifice favored the outflow. With similar main pipe velocity and constant orifice pressure, the value of in the orifice discharging into water was larger than that outflowing into air. also dropped faster with pressure in the case of air.

- The experiments provided values of ranging from about 0.60 to 0.85, which presented some deviations from the classical range of 0.61–0.67 reported in the literature. This may have a relevant impact on real pipeline systems.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kabir, G.; Tesfamariam, S.; Francisque, A.; Sadiq, R. Evaluating risk of water mains failure using a Bayesian belief network model. Eur. J. Oper. Res. 2015, 240, 220–234. [Google Scholar] [CrossRef]

- Mora-Rodriguez, J.; Delgado-Galvan, X.; Ramos, H.M.; Lopez-Jimenez, P.A. An overview of leaks and intrusion for different pipe materials and failures. Urban Water J. 2014, 11, 1–10. [Google Scholar] [CrossRef]

- Mamlook, R.; Al-Jayyous, O. Fuzzy sets analysis for leak detection in infrastructure systems: A proposed methodology. Clean Technol. Environ. Policy 2003, 6, 26–31. [Google Scholar] [CrossRef]

- Fleming, K.; Dugandzic, J.; Lechevallier, M. Susceptibility of Distribution Systems to Negative Pressure Transients; American Water Works Research Foundation: Denver, CO, USA, 2007. [Google Scholar]

- Besner, M.C.; Ebacher, G.; Lavoie, J. Low and negative pressures in distribution systems: Do they actually result in intrusion? In Proceedings of the World Environmental & Water Resources Congress, Tampa, FL, USA, 15–19 May 2007.

- Beuken, R.H.S.; Lavooij, C.S.W.; Bosch, A.; Schaap, P.G. Low leakage in the Netherlands confirmed. In Proceedings of the 8th Annual Water Distribution Systems Analysis Symposium, Cincinnati, OH, USA, 27–30 August 2006. [Google Scholar]

- Lambert, A.O. Water losses management and techniques. Water Sci. Technol. Water Supply 2002, 2, 1–20. [Google Scholar] [CrossRef]

- Puust, R.; Kapelan, Z.; Savic, D.A.; Koppel, T. A review of methods for leakage management in pipe networks. Urban Water J. 2010, 7, 25–45. [Google Scholar] [CrossRef]

- Van Zyl, J.E.; Lambert, A.O.; Collins, R. Realistic modeling of leakage and intrusion flows through leak openings in pipes. J. Hydraul. Eng. 2017, 143. [Google Scholar] [CrossRef]

- May, J.H. Pressure dependent leakage. World Water Environ. Eng. 1994, 17, 10. [Google Scholar]

- Ferrante, M.; Massari, C.; Brunone, B.; Meniconi, S. Experimental evidence of hysteresis in the head-discharge relationship for a leak in a polyethylene pipe. J. Hydraul. Eng. 2011, 137, 775–780. [Google Scholar] [CrossRef]

- Massari, C.; Ferrante, M.; Brunone, B.; Meniconi, S. Is the leak head-discharge relationship in polyethylene pipes a bijective function? J. Hydraul. Res. 2012, 50, 409–417. [Google Scholar] [CrossRef]

- Greyvenstein, B.; van Zyl, J.E. An experimental investigation into the pressure-leakage relationship of some failed water pipes. J. Water Supply Res. Technol. AQUA 2007, 56, 117–124. [Google Scholar] [CrossRef]

- De Marchis, M.; Fontanazza, C.M.; Freni, G.; Notaro, V.; Puleo, V. Experimental evidence of leaks in elastic pipes. Water Resour. Manag. 2016, 30, 2005–2019. [Google Scholar] [CrossRef]

- Cassa, A.M.; van Zyl, J.E.; Laubscher, R.F. A numerical investigation into the effect of pressure on holes and cracks in water supply pipes. Urban Water J. 2010, 7, 109–120. [Google Scholar] [CrossRef]

- Malde, R. An Analysis of Leakage Parameters of Individual Leaks on a Pressure Pipeline through the Development and Application of a Standard Procedure. Master’s Thesis, University of Cape Town, Cape Town, South Africa, 18 May 2015. [Google Scholar]

- Van Zyl, J.E.; Cassa, A.M. Modeling elastically deforming leaks in water distribution pipes. J. Hydraul. Eng. 2014, 140, 182–189. [Google Scholar] [CrossRef]

- Lambert, A. What do we know about pressure-leakage relationships in distribution systems. In Proceedings of the IWA Conference System Approach to Leakage Control and Water Distribution Systems Management, Brno, Czech Republic, 16–18 May 2000. [Google Scholar]

- Giustolisi, O.; Savic, D.A.; Kapelan, Z. Pressure-driven demand and leakage simulation for water distribution networks. J. Hydraul. Eng. 2008, 134, 626–635. [Google Scholar] [CrossRef]

- Salinas-Vázquez, M.; Vicente, W.; Carrizosa, E.; Osnaya, J.; Ballesteros, O. Estudio numérico y experimental de fugas en tubos elásticos. In Proceedings of the XXII Congreso Latinoamericano de Hidráulica, Guayana, Venezuela, 9 October 2006. [Google Scholar]

- Farley, M.; Trow, S. Losses in Water Distribution Networks; IWA Publishing: London, UK, 2003. [Google Scholar]

- López, P.A.; Fuertes, V.; Iglesias, P.; Martínez, J. Modelación mediante cfd de fugas en tuberías de redes de abastecimiento. In Proceedings of the V Seminario Iberoamericano de Planificación, Proyecto y Operación de Sistemas de Abastecimiento de Agua, Valencia, Spain, 29 November–2 December 2005. [Google Scholar]

- Ashton, C.H.; Hope, V.S. Environmental valuation and the economic level of leakage. Urban Water J. 2001, 3, 261–270. [Google Scholar] [CrossRef]

- Walski, T.; Bezts, W.; Posluszny, E.T.; Weir, M.; Whitman, B.E. Modeling leakage reduction through pressure control. J. Am. Water Work. Assoc. 2006, 98, 147–155. [Google Scholar] [CrossRef]

- Mansour-Rezaei, S.; Naser, G. Contaminant intrusion in water distribution system: An ingress model. J. Am. Water Works Assoc. 2013, 105, E29–E39. [Google Scholar] [CrossRef]

- Shao, Y.; Yao, T.; Gong, J.Z.; Liu, J.J.; Zhang, T.Q.; Yu, T.C. Impact of main pipe flow velocity on leakage and intrusion flow: An experimental study. Water 2019, 11, 118. [Google Scholar] [CrossRef]

- Coetzer, A.; van Zyl, J.; Clayton, C. An experimental investigation into the turbulent-flow hydraulics of small circular holes in plastic pipes. In Proceedings of the 8th Annual Water Distribution Systems Analysis Symposium (WDSA), Cincinnati, OH, USA, 27–30 August 2006. [Google Scholar]

- Collins, R.; Boxall, J. Influence of ground conditions on intrusion flows through apertures in distribution pipes. J. Hydraul. Eng. 2013, 139, 1052–1061. [Google Scholar] [CrossRef]

- Mora-Rodríguez, J.; Delgado-Galván, X.; Ortiz-Medel, J. Pathogen intrusion flows in water distribution systems: According to orifice equations. J. Water Supply: Res. Technol. AQUA 2015, 64, 857–869. [Google Scholar] [CrossRef]

- King, H.W.; Barter, E.F. Handbook of Hydraulics; McGraw-Hill: New York, NY, USA, 1976. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, T.; Zhang, X.; E. Lima Neto, I.; Zhang, T.; Shao, Y.; Ye, M. Impact of Orifice-to-Pipe Diameter Ratio on Leakage Flow: An Experimental Study. Water 2019, 11, 2189. https://doi.org/10.3390/w11102189

Yu T, Zhang X, E. Lima Neto I, Zhang T, Shao Y, Ye M. Impact of Orifice-to-Pipe Diameter Ratio on Leakage Flow: An Experimental Study. Water. 2019; 11(10):2189. https://doi.org/10.3390/w11102189

Chicago/Turabian StyleYu, Tingchao, Xiangqiu Zhang, Iran E. Lima Neto, Tuqiao Zhang, Yu Shao, and Miaomiao Ye. 2019. "Impact of Orifice-to-Pipe Diameter Ratio on Leakage Flow: An Experimental Study" Water 11, no. 10: 2189. https://doi.org/10.3390/w11102189

APA StyleYu, T., Zhang, X., E. Lima Neto, I., Zhang, T., Shao, Y., & Ye, M. (2019). Impact of Orifice-to-Pipe Diameter Ratio on Leakage Flow: An Experimental Study. Water, 11(10), 2189. https://doi.org/10.3390/w11102189