Abstract

Composite electrolytes for applications in batteries and supercapacitors, i.e., in electrochemical energy technology, are gaining growing attention. In the absence of a commonly accepted definition, binary and ternary combinations of materials, e.g., a polymer with an electrolyte salt or electrolyte salt solution and a third conductivity- and performance-enhancing constituent, are assumed as a definition of a composite electrolyte in the following review. Relevant fundamentals and reported research results, including explanations of the described effects of added ingredients and achieved improvements, are reviewed. Future perspectives and directions of further research are sketched.

1. Introduction

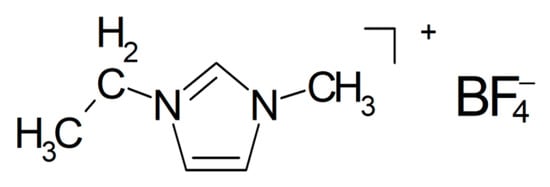

The ionically conducting phase between the two electrodes of a supercapacitor or a battery is frequently and somewhat imprecisely called the electrolyte. According to the commonly accepted definition, an electrolyte is composed of ions (a true electrolyte according to standard textbooks [], e.g., NaCl) or of molecules, which dissociate into ions upon interaction with a suitable solvent (so-called potential electrolytes, e.g., HCl in water), and accordingly, in most cases, electrolyte solutions or molten electrolytes (salts) are employed [,,]. Ionic liquids (ILs; in this report, commonly established acronyms [] are used independently of some authors’ different, but confusing, suggestions) composed of ions only and liquid already at room temperature (room-temperature ionic liquids RTIL) are the rare example in the latter group. In the following text, this distinction between electrolyte and electrolyte solution is ignored for the sake of simplicity and convenience, but mostly because solutions play hardly any role at all, except in the preparation.

Initially, because of safety concerns and risks associated with leakage of devices, the use of liquid electrolytes (solution) was not welcome in most applications []. Consequently, numerous means to replace them with non-liquid, semi-solid, or even solid ion-conducting materials have been proposed and examined; for an overview of recent driving forces, trends, and new opportunities, see []. These attempts started with a general “wish list” for an electrolyte system [,]:

- Wide available electrode potential window or window of electrochemical stability;

- High ionic conductivity at common operating temperatures;

- Sufficient chemical and electrochemical stability;

- Compatibility with electrode and separator materials;

- Thermal stability;

- Environmental compatibility;

- Low price;

- Sustainable resources.

Given the stated flaws, limitations, and challenges of liquid electrolytes, attempts to improve on those via particular solid electrolytes have implicitly or explicitly addressed the following approaches:

- Enhanced ionic conductivity;

- Wider range of operating temperatures;

- Improved mechanical stability;

- Better long-term stability;

- Increased thermal stability.

The crucial and persistent problem of establishing and maintaining electrolyte/electrode interfaces between solid electrodes and solid electrolytes is surprisingly addressed only infrequently; for overviews, see, e.g., [,].

Initially single-constituent solid electrolytes were studied mostly for high-temperature applications in, e.g., sodium/sulfur or sodium/metal chloride batteries. Frequently encountered/employed solid ion conductors for this application and beyond are as follows []:

- Perovskites, e.g., (Li,La)TiO3;

- Garnet-like Li5La3M2O12 (with M = transition metal);

- Mostly amorphous glasses of lithium nitrides, sulfides, borates, or phosphates like lithium phosphoroxydnitride (LiPON);

- “Super ion conductors” of the LISICON or NASICON type: Li(Na)M2(PO4)3 (M = Ti(IV), Zr(IV), Ge(IV));

- Lithium salts like LiI in Li/I2 batteries [].

Unfortunately, these materials frequently show inadequate ionic conductivity; in addition, problems in difficult processing and slow deterioration because of, e.g., phase changes limit their suitability. Combining them with further ingredients into composite materials was identified as a promising option. A very early report by Liang [] from 1973 provided convincing evidence that the addition of around 45 mol% of Al2O3 to LiI resulted in a very significant increase in ionic conduction to around σRT~10−5 S/cm. Solid-state batteries—in particular, high-temperature batteries—of the type Li/LiI(Al2O3)/metal iodide were prepared and tested []. Electronic conductivity of the created composite electrolyte was negligible; the dominant ionic conduction mechanism was proposed to proceed along cation vacancies. Similar observations with other electrolytes, e.g., AgI with Al2O3 [] or LiI with SiO2 [], have been reported later. An understanding of the conductivity enhancement could not be reached. Acceleration of charge carrier movement along the interfaces between electrolyte and filler was suggested []. First hints suggested space-charge-layer formation and a contribution to accelerated ion transport in LiBr hydrate []; surprisingly, earlier, these considerations were elaborated in great detail for the electrolyte CuCl2/Al2O3 []. In later studies, this increase has been attributed to the creation of space charges at the filler/matrix interface, in particular, by surface-active but otherwise inert additives []. Another interpretation and explanation based on lattice considerations and Monte Carlo simulations appears to be less helpful when studying polymer/filler composites []. Effects of Lewis acid/Lewis base interactions at said interfaces and with anions and/or cations of the mobile charge carriers have been considered, and they may be of particular interest in understanding changes in transference numbers caused by, e.g., selective adsorption of only one kind of mobile ion []. Actually, initial observations of enhanced ionic conductivity caused by admixing a second component into an ionic crystal date back to Jander []. Only recently, the special role of filler–bulk interfaces and the conditions influencing ion transport therein has been transformed into the creation of continuous interfaces in the bulk of a solid ion conductor, yielding ion conductors with remarkably high conductivities []. Mechanochemical synthesis methods of solid electrolytes have been reviewed [].

With the discovery of various polymeric materials also suitable as ionic (or ion) conductors, in particular, after the addition of electrolytes, i.e., salts (for the earliest example, see []), the question was asked again about the cause of increased conductivity upon the addition of a filler to a polymer with added salt. Early observations indicated no enhancing effect at, e.g., less than 10 wt.% Al2O3 to poly(ethylene oxide) (PEO; for details, see below) with LiClO4 as the salt []. In any case, crystallinity of the polymer was identified as a major cause of poor conductivity, and lower crystallinity increased conductivity—thus, added materials that decrease crystallinity are welcome fillers. For polymer-based solid electrolytes, for some time, the crystallinity argument pushed the space charge argument promoted for inorganic crystalline conductors completely into the shadows. Only later was this contribution rediscovered for polymeric electrolytes together with further effects related to chemical interactions between the filler surface and the molecular structure of the polymers and the ions of the electrolyte commonly added to the polymers [,,,].

Up to this point, the common definition of a composite as a material wherein two phases can be discerned at least on the microscopic level, not necessarily on the macroscopic one, was tacitly and unreflectedly applied. Solutions of several salts in a solution or addition of one more solute did not and do not make a composite. Depending on the type and extent/intensity of interactions between the constituents, the more general term “composite” may be correctly replaced with the more focused term “hybrid”. Because there is no generally accepted and clear-cut separation between both terms, the usage by the original authors is followed in this contribution without discussing the adequacy of this terminology in every case; an extended review on “hybrid electrolytes” is available []. Actually, the phase boundaries established between the surface of filler nanoparticles and polymeric matrices frequently provide extra fast pathways for ion transport—this may be called a typical case of an interaction calling for the term hybrid, as in [], whereas it remains somewhat confusing to call a mixture of salts and liquids simply a “hybrid electrolyte” [] or to call just everything beyond a solid electrolyte a “hybrid electrolyte”, as in []. Certainly, it is wrong to attribute this—as is the case in []—to the authors of []: the claimed figure is nowhere to be found in the latter report. Clearly, this is a minority opinion anyway; nevertheless, the search string “(“hybrid electrolyte” OR “solid electrolyte”) AND (sodium OR magnesium OR potassium OR zinc OR aluminium OR calcium) AND battery” was tried in our literature searches. These interactions have been reviewed with particular attention to NMR as an experimental tool in a previous study [].

Another option for increased conductivity is the use of additives: If a small amount of another constituent is added, the result may also be called a composite; for examples, see []. Similar imprecision can be found when an electrolyte solution containing several electrolytes is called a composite electrolyte, for examples, see [,,,,,,,,,,,,,], or, with again an additive, a “solvation structure composite electrolyte” in []. “Mixture” is certainly correct and more appropriate, though unfortunately less fashionable.

Essentially, the same arguments prevailed when interest in solid electrolytes as replacements for liquid electrolyte solutions in lithium-ion batteries almost exploded, stimulated at least in part by spectacular battery failures []. But similar limitations were also readily registered []. The same approaches toward improvement were tried: Composite materials are one option.

Finally, the limitations of lithium-ion battery technology and its economy, despite its many impressive advantages, stimulated research into alternatives, so-called post-lithium or non-lithium batteries. Although it appears that both terms are sometimes almost synonyms, they need proper usage: Post-lithium commonly means everything beyond the omnipresent lithium-ion battery based on the rocking-chair principle and thus can include lithium–air and lithium–sulfur [], whereas the term non-lithium is much better defined—and applied here. Composite electrolytes for the former lithium-ion batteries are the subject of a review elsewhere []; materials for the latter, much wider but less densely populated family are the subject of this report. Earlier reviews covering a few details of the present contribution are available [,].

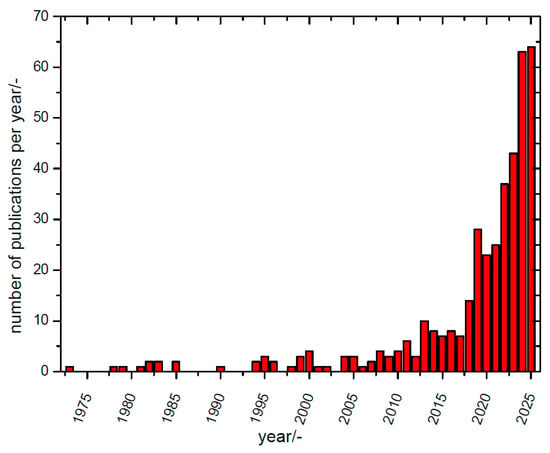

Early reports on composite materials, mostly on solid/solid composites, as solid electrolytes for batteries were already collected in a conference proceedings volume in 1988 [], followed by a conference report on a composite material used as a ceramic solid-state electrolyte for a sodium–sulfur battery (1990) [], and a report in 1995 on solid-state batteries with a negative magnesium electrode and various compounds as the positive electrode, with a solid composite electrolyte as a glue in between []. But only in the 2010 years was there growing general interest in non-lithium battery research, and accordingly, publication activity picked up, as depicted in Figure 1.

Figure 1.

A search with the string ““composite electrolyte” AND (battery OR batteries) NOT lithium” found anywhere in the title, keywords, or abstract (data from Scopus® and Web of Science®) performed on 2 August 2025 initially yielded 304 hits. Reports about, e.g., lithium-ion conductors with the term “lithium” somewhere in the text but not in the title, keywords, or abstract were removed, even those on Li. Reports dealing with electrolytes actually meeting the definition suggested above without mentioning the term “composite electrolyte” were included when detected after extended literature searches. Cases where (composite) “separator” was considered a synonym of (composite) “electrolyte” are also included (for a typical example, see []), and cases where a “composite separator” was actually a modified separator only (for examples, see [,,,,,,,,,,]; for a review, see []) were not included. Modified membranes considered as separators and called composites like [,] are not included; neither are reports dealing with “moderate electrolytes” [] nor electrolyte solutions of salt mixtures [,,,,,,,,,,,,,,], solid electrolyte interphases (SEIs), or similar electrode coatings, as in [,,,,,,,,] or reports wherein “composite electrolyte” is placed only as a teaser in the abstract [,]. This changed the total to 394 reports.

Although the majority of composite electrolytes are solids—in line with the general ambitions of working towards all-solid-state batteries—liquid electrolytes avoiding the problem of flammability are still studied. Eutectic electrolytes based on experiences with deep eutectic solvents [,,,,,,,,] are a prominent example, which have been reviewed []. Fibrous materials as scaffolds for composite electrolytes/membranes/separators have also been surveyed []. Lignocellulose as a typical renewable raw material has been discussed with respect to applications in batteries and composite electrolytes [], and respective overviews on the use of nanocellulose [] and cellulose [] are also available. Composites of metal–organic frameworks as part of solid electrolytes have been reviewed [].

The following report collects the most relevant details of original reports on composite electrolytes studied or at least proposed for the currently researched non-lithium batteries. It is organized along these metals, and in cases of frequently studied metals, there are subsections using the mostly polymeric host material as a criterion. This should provide the reader with a quick overview of previously examined options and materials and serve to identify promising avenues of further studies.

2. Electrolyte Tasks and Challenges

In conventional electrolytes as well as electrolyte solutions, the roles played by the ingredients are perfectly clear in almost every case [,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,,]. Once a further ingredient is added into an electrolyte, e.g., a further ionic or non-ionic compound to a salt, there should be a reason specified together with the suggestion of the addition. Unfortunately, as in many examples presented below, this is not always be the case, and the reader is left wondering about conceivable ideas behind the addition. Depending on the battery chemistry and the operating principle, high general ionic conductivities and, in particular, high conductivities (i.e., high transference number t+ ≈ 1) of the (mostly metal) ion shuttling between the electrodes are highly welcome. This selectivity may also be helpful by suppressing cation concentration gradients and thus suppress dendrite formation when using metal (e.g., lithium, sodium) electrodes. When authors address this detail, it is highlighted below.

2.1. Composite Electrolytes

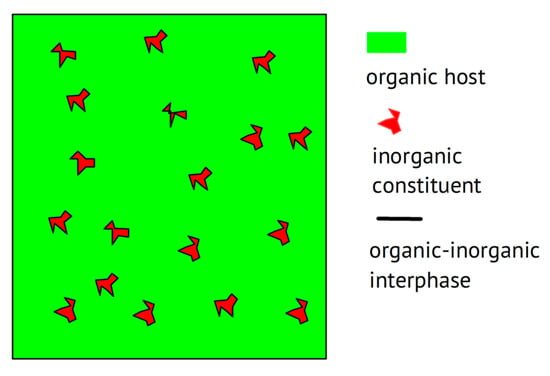

Beyond the trivial statement that any combination of two materials enabling ionic conduction without showing electronic conduction—this may even qualify as the definition of an electrolyte—may be called a composite (wherein these two constituents stay separate in two phases at least on the microscopic level, as illustrated below in Figure 2), the goal of combining materials is commonly pursued with particular improvements in mind. These may range from clear improvements in terms of the electrochemical properties listed above in the wish list to further technical and even economical improvements. When examining composites with a polymer, the mechanical scaffold provided by the macromolecular material—serving as a welcome stiff material rendering a separator possibly superfluous—combined with an improvement of the ionic conductivity of the polymer the focuses of attention. In the case of composites composed of two or more non-polymeric materials, the welcome mechanical contribution of a polymeric scaffold remains absent; another advantage beyond an improved ionic conductance will be the driving force behind mixing. Use of the sometimes-encountered term “filler” for the added ingredient (see above) appears to be a bit unclear, or at least undefined. The distinction between passive (insulating) fillers not providing internal ionic conduction and active (conducting) fillers suggested in [,] has apparently not found widespread use. To call the salt added to a polymer to provide ions a “filler” appears to be positively confusing []; neither makes the term “composite electrolyte” reasonable for a combination of an insulating polymer with a salt, as in [].

Figure 2.

Schematic of a composite with a polymer host.

2.1.1. Composites with Polymer Hosts

Overviews on polymer electrolytes are available [,,,,]. Starting a composite electrolyte with a polymer or a polymer electrolyte is very rational: The polymer will provide the mechanical support (or backbone, but this should not be confused with the chemical structure or molecular backbone) to form a scaffold, desired for an application not needing an extra separator. The added (composite) constituent may, e.g., reduce the crystallinity of a polymer like PEO, thus increasing ionic conductivity [,], or may provide particularly transport-accelerating particle/host interfaces, as demonstrated in [], essentially along the lines already indicated in []. A schematic representation is shown in Figure 2, highlighting these interfacial or interphase regions.

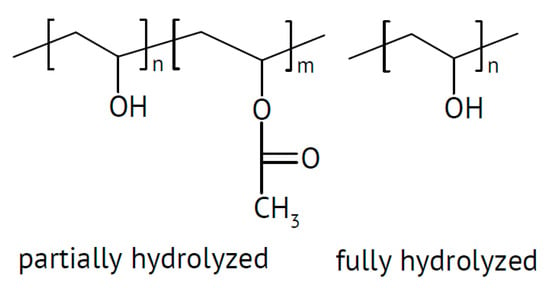

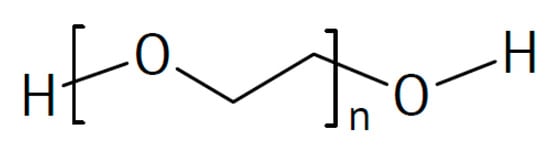

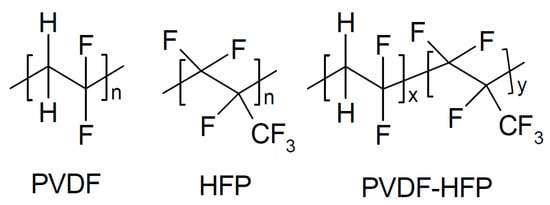

There is also evidence that effects may depend on the particle size, with small particles increasing conductivity only and larger ones increasing the conductivity and transport number []. This applies to all added particular materials. In a further highly unsystematic study of several inorganic components with different particle sizes and dielectric constants, no coherent conclusions were obtained []. Ion-conducting materials may add further ionic conduction pathways inside the particles. Possibilities of enhanced ionic conductivity mechanisms have been reviewed []. Further advantages may be gained by starting from a polymer blend of, e.g., poly(vinylalcohol) PVA (Figure 3) and PEO (Figure 4). Beneficial effects were also observed upon the addition of BaTiO3 as a filler to a polymer blend of PVA and poly(ethylene glycol) PEG (Figure 5), of Li0.5La0.5TiO3 to a blend of PEO and polyvinylidene fluoride (PVDF, see Figure 6), or of ZrO2 to poly(vinylidene fluoride-co-hexafluoropropylene) (PVDF-HFP, see Figure 6). Actual modes of operation of the added ceramic may differ from material to material depending on the exact chemical composition. The case of PEO with inorganic fillers has been reviewed in detail []. In addition, attention has been paid to effects of surface modifications of inorganic fillers added to PEO [].

Figure 3.

Molecular structures of poly(vinyl alcohol).

Figure 4.

PEO and a scheme of interactions ---- between a sodium ion and PEO.

Figure 5.

Molecular structures of poly(ethylene glycol).

Figure 6.

PVDF, HFP, and PVDF-HFP (this acronym is chemically slightly incorrect but is—with very few (see below) misleading exceptions—firmly established and thus used here) [].

Some general procedural aspects of polymer and composite polymer electrolytes (preparation and handling) have been summarized in []. Tuning of the interface between the polymer matrix and embedded mostly inorganic particles (filler) in a solid electrolyte, preferably for photovoltaic devices, has been reviewed []. (Gel) Electrolytes obtained by plastification (gelling) of a polymer with a suitable solvent (this may be a solvent or a solvent mixture but also an electrolyte solution) have been called composite electrolytes infrequently (for an example, see []). Addition of a plasticizer to a polymer appears to be so popular that it is hardly mentioned in the reports, and the same applies to the essential addition of a source of ions, e.g., a sodium salt, either during the preparation of the solid or by soaking the prepared solid in an electrolyte solution—wherein the solvent may also act as a plasticizer. Again, these are details the interested reader should search for in an attempt to avoid experimental failures.

An overview covering PEO-based composite electrolytes with a major focus on batteries is available [], and composites with Li7La3Zr2O12 as an inorganic filler have been discussed in []. Beneficial effects of added small molecules in a polymer–ceramic solid electrolyte are discussed in general terms in []. Segmental motion of the polymer and interfacial polarization are coupled and determine ion transport jointly. A porous inorganic scaffold of freeze-cast Li7La3Zr2O12 for filling with a polymer yielding a composite has been reported []. Further polymer–inorganic filler composites have been reviewed with respect to mass production of solid-state batteries [], and early overviews on polymer–ceramic electrolytes already highlighting the three overarching issues ionic conductivity, transference number, and interfacial aspects are available [,]. Fast and efficient discovery of solid organic–inorganic composite electrolytes supported by unsupervised learning has been discussed in detail []. Approaches to reaching an optimized inorganic filler content enabling better electrolyte–electrode contact supported by machine learning have been discussed []. The beneficial, ion conductivity-increasing effect of nanosized particles of TiO2 added to amorphous polyether with either LiClO4 or LiTFSI as a salt has been studied []. At most studied concentrations, no effect was observed; only at 1.5 m LiClO4 was an increase observed and attributed (somewhat surprisingly) to an effect on crystallinity and disruption of ion aggregation.

Further general aspects of polymer-based composite electrolytes have been discussed [,,].

2.1.2. Binary Composites

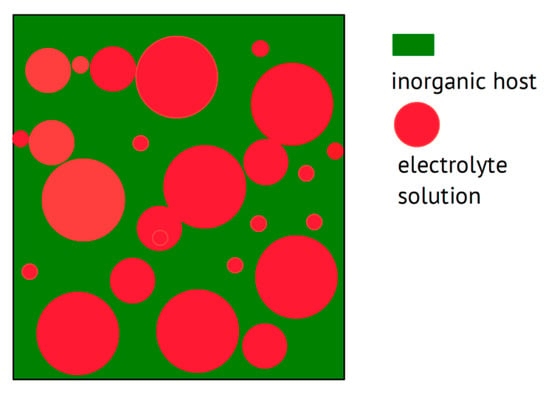

Instead of a polymer acting as a host and providing in most cases the major fraction of a composite electrolyte, an inorganic material like fumed silica may act as a highly porous host material, which is subsequently soaked with an electrolyte solution, yielding a solid material (for the concept of the “soggy sand” electrolyte, see [,]), which may not possess the mechanical properties enabling its use as a separator or similar; for a scheme, see Figure 7.

Figure 7.

Scheme of a porous inorganic host filled with an electrolyte solution.

Ultrafast high-temperature sintering as a method for preparing an inorganic scaffold for a composite electrolyte has been described [].

Given the wide variations in terms of employed compounds and constituents as well as battery chemistries, organization of the material making it easily accessible for the reader was based on a rough discrimination between room-temperature (RT) and elevated-temperature applications, with a further classification according to the metal used in a given system for the RT batteries and a further distinction based on the polymer host material.

The presumably central challenge of a sufficiently intimate contact between electrolyte and electrode—in particular, positive ones—is somewhat surprisingly addressed only sometimes, while the traditional sandwiching of electrodes with an electrolyte in between is still popular. Because this interface has been identified as a major problem [,], the following attempts to enhance this interface are highlighted.

The most prominent property of an ionic conductor is its ionic conductivity. Accordingly, measured data attract the most attention. For a given application, the actual Ohmic resistance caused by the ionic phase between the electrodes is much more relevant—but rarely reported, only sometimes included in some cell resistance and cell impedance data. A highly conducting material that can be applied only as a relatively thick layer may thus be less attractive than a relatively poorer conducting material that can be made into a very thin film. Nevertheless, data—when reported—are included below to provide at least a first number. Given the pronounced temperature dependency of ionic conductivity, most authors provide values—if at all—for a specified temperature, like room temperature σRT or σ60°C; when this basic detail is missing, σ? is provided. Temperatures like T = 50 or 60 °C are still found in the part of this report dealing with room-temperature systems because the authors do not explicitly mention the use of the reported materials at elevated or high temperatures. Some general information on experimental testing aspects can be found [], and some early materials not assigned to a particular battery chemistry have been described []. The use of NMR and EPR spectroscopy for in situ studies of rechargeable batteries has been reviewed [].

3. The Materials

3.1. Room-Temperature Systems

The careful distinction between lithium and lithium-ion or more generally metal and metal-ion batteries with the rocking-chair principle operative in the latter ones may be applicable also for post-lithium batteries. Evidence suggests otherwise and confusion reigns, and the following assignments picked by the authors were used when specified at all. These include the explicit use of the term “metal-free” (like sodium-metal-free in []), which so far appears to be reserved for batteries where essentially a negative metal electrode formed only by metal deposition from the electrolyte solution/dissolution without the solid metal being present at the start (enabling simplified manufacturing) is used (see for examples, [,,,,]) and not for a cell with a host electrode. Actually, even these cells are not called metal-free (which appears to be a rather striking characterization anyway) but “zero excess metal”, “reservoir-free”, or “anode-free” (with the precision in describing the facts decreasing in this sequence).

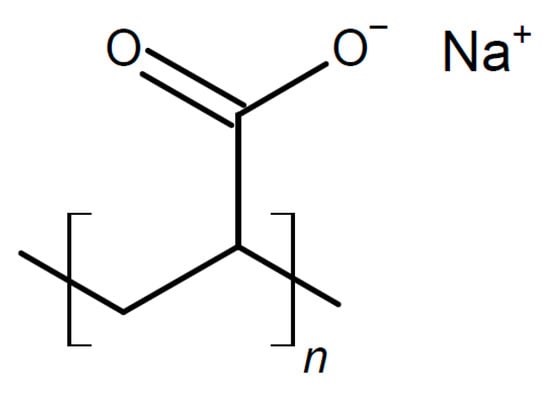

3.1.1. Sodium and Sodium-Ion Batteries

Inorganic Materials

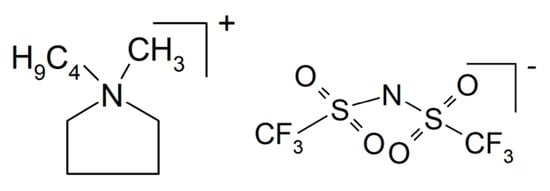

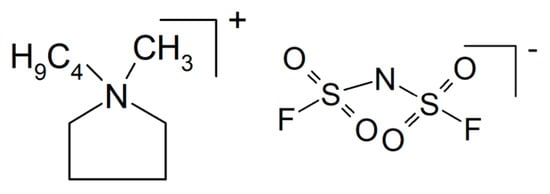

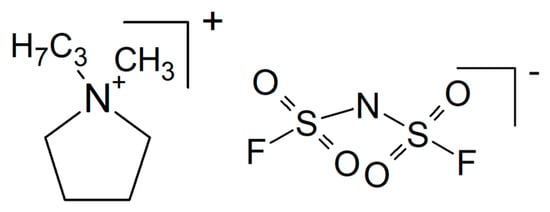

A composite of NaAlCl4 with embedded particles of Al2O3 was prepared by mechanochemical synthesis []. The latter provides additional conduction along an oxychloride interface between the two constituents, yielding σRT > 0.1 × 10−3 S/cm. An all-solid-state battery demonstrated electrolyte suitability. An overview on sodium-conducting halides as potential solid electrolyte materials is available []. Also, by mechanochemical synthesis, a composite of NaI and Na2.88Sb0.88W0.12S4 has been prepared, where the formed solid electrolyte Na2.88Sb0.88W0.12S4·0.5NaI showed σ = 3.6.1 × 10−2 S/cm and was tested in an all-solid-state battery []. For enhanced ion conduction of Na3Zr2Si2PO12 (called NACICON instead of NASICON or NASICON-like for unknown reasons), a glass of 35Na2O-5Cr2O3-30TiO2-30P2O5 was infiltrated into the porous ceramic, and use of the product in sodium-ion batteries was proposed []. Increased ionic conductivity of Na3Zr2Si2PO12 by adding NaF into the precursor mixture during preparation has been reported, where conductivity increased from σRT = 4.5 × 10−4 S/cm to σRT = 1.7 × 10−3 S/cm []. A porous pellet of Na2ZnSiO4 (halloysite) with an ionic liquid N-butyl-N-methylpyrrolidinium bis(trifluoromethyl sulfonyl) imide (PYR14TFSI, see Figure 8) and NaTFSI yielded a solid electrolyte with σ300°C = 1.1 × 10−3 S/cm and t+ = 0.5, suggesting to the authors its use in sodium-ion batteries []. A composite of clay and cellulose nanocrystals has been described as a sodium-ion-conducting electrolyte with conductivities around 10−3 S/cm, without revealing its preparation details []. NaNH2 was reacted with B10H14, yielding solid electrolyte core–shell composites of NaBH4 and Na2B12H12 with σ100°C = 1 × 10−4 S/cm []. A solid-state sodium-ion battery with this composite electrolyte was run for 100 cycles.

Figure 8.

Molecular structures of N-butyl-N-methylpyrrolidinium bis(trifluoromethyl sulfonyl) imide.

PVA-Based Materials

To PVA with NaClO4 as the salt (presumably not the filler as claimed in the text), Y2O3 was added as an inorganic filler, affording a solid composite electrolyte with σRT = 3.25 × 10−4 S/cm and t+ = 0.919 at the optimum composition with 3 wt.% filler (because the total composition of this material was given as 123%, uncertainty remains, and that is also the case regarding other barely comprehensible claims in this report) []. High conduction and t+ were attributed to lower crystallinity caused by the filler and strong interactions between it and the salt anion. For the assembled complete cell, the typical zinc electrode reaction was provided for the negative electrode, and for the positive one, the PbO2 and the V2O5 reactions. The decrease in crystallinity of PVA by adding various amounts of salts like MgSO4 or Li2SO4 has been demonstrated []. The effect was more pronounced with the lithium salt. At concentrations beyond around 20 wt.%, crystallization of the added salt starts, and conductivity decreases again.

Addition of sulfuric acid to a mixture (PVA)0.7(NaI)0.3 yielded a proton-conducting solid electrolyte tested in a sodium/MnO2 battery []. The addition of acid resulted in σRT = 10−3 S/cm attributed to disruption of the semi-crystalline structure of the mixed solid. Electrical properties of a polymer blend of PVA and methylcellulose with NaI as the electrolyte have been studied [].

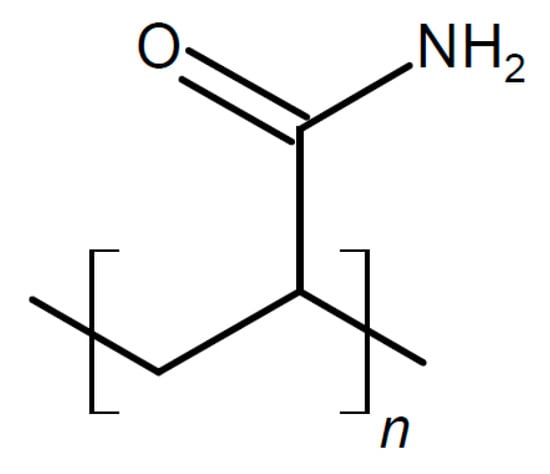

PEO-Based Materials

The notorious tendency of PEO to crystallize (for a study of correlations between crystallinity and ionic conductivity as a function of the fraction of added ceramic filler, see []) has been decreased by grafting yielding a hyperbranched polyether, and with NaTFSI (see Figure 9), it showed an increased conductivity σRT = 5.7 × 10−4 S/cm []. A cell with a sodium-metal electrode (called a sodium-ion battery) nevertheless kept 92% of its initial capacitance after 300 cycles. A solid composite electrolyte of PEO and NaTFSI with added NASICON-type Na3.4Zr1.8Mg0.2Si2PO12 with σ80°C = 2.8 × 10−3 S/cm was used in a sodium/Na3V2(PO4)3 (NVP) battery operated for 80 cycles without significant losses []. To a mixture of PEO and NaFSI (see Figure 9) with the mass ratio 20:1 (this is presumably meant with the rather uncommon designation P(EO)20NaFSI and later EO:Na = 20:1) the researchers dissolved in acetonitrile various amounts of PYR14FSI (see Figure 10), yielding after evaporation of the solvent a solid electrolyte with σRT = 1.15 × 10−4 S/cm (without the ionic liquid σRT = 2.85 × 10−6 S/cm) tested in a sodium-metal/NVP battery at T = 60 °C []. A capacitance retention 85% after 300 cycles was reported. Conductivity improvement by the added ionic liquid was attributed to increased amorphicity and stronger interactions between NaFSI and the PEO oxygen atoms. With respect to desired sodium-ion transport and electrostatics, presumably interactions between said functionalities and the anion FSI− were meant.

Figure 9.

Molecular structures of sodium bis(trifluoromethylsulfonyl) imide NaTFSI and sodium bis(fluorosulfonyl) imide NaFSI.

Figure 10.

Molecular structures of N-butyl-N-methylpyrrolidinium bis(fluorosulfonyl) imide PYR14FSI.

A composite electrolyte was prepared from PEO, NaTFSI, and zeolite A (LTA, presumably its sodium aluminosilicate form) with σ30°C > 1.42 × 10−4 S/cm and t+ = 0.44 and used in a sodium/NVP battery with 88% capacity retention after 100 cycles at T = 60 °C []. A Cu-metal organic framework on PEO combined with PAN yielded a solid electrolyte with σRT = 0.103 × 10−3 S/cm and t+ = 0.58 for sodium batteries []. A full cell showed a stable performance for 2000 cycles. A Zr-metal organic framework material was combined with PEO, yielding a solid electrolyte for a sodium battery with 97% capacitance retention after 1000 cycles []. σ60°C = 6.62 × 10−4 S/cm and t+ = 0.67 were attributed to adsorption of anions on zirconium sites. A composite electrolyte has been prepared from PEO, NaCF3SO3, and as a filler MOF MIL-53(Al) and has been used in a sodium/sulfur battery []. At 3.24 wt.% of the filler, t+ = 0.4 and σ50°C = 1.5 × 10−5 S/cm were recorded, and without filler, the value decreased by almost an order of magnitude. Operated at T = 60 °C, the battery kept 75% of the initial capacitance after 50 cycles. Promising results for lithium/sulfur batteries obtained with a cubic-garnet Li7La3Zr2O12 applied in a bilayer arrangement to ameliorate electrolyte/lithium incompatibilities may indicate a direction of further development [].

The problem of agglomeration of one (mostly the inorganic) constituent in a polymer/inorganic filler composite electrolyte has been addressed in detail [] and experimentally verified for some composites [], and similar observations with composites of polymers with graphene, graphene oxide, etc., are discussed elsewhere []. Surface modification of the inorganic filler Na3Zr2Si2PO12 with polydopamine improved the wettability, with the polymer component PEO enabling an all-solid-state sodium-metal battery running stably for 1350 cycles at T = 60 °C. According to results of modeling the surface modification of the inorganic filler, this also influenced sodium ion transport, helping to suppress dendrite formation. An optimized Na3.3Zr1.7La0.3Si2PO12 with σRT = 3.4 × 10−3 has been used in a sodium-metal battery []. For improved electrode/electrolyte interaction at the positive electrode, a small amount of organic liquid electrolyte or ionic liquid was soaked into the porous electrode body. Following the initial considerations provided above, no reason to call this a composite electrolyte is evident.

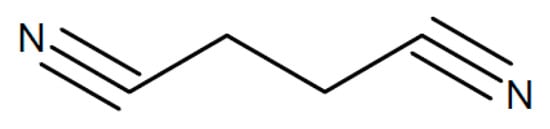

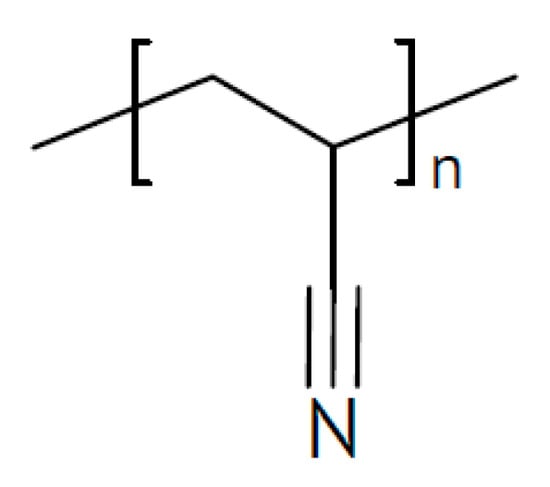

A laminated two-layer electrolyte has been proposed for sodium-ion batteries []. Facing the negative sodium-metal electrode a PEO film with added succinonitrile (see Figure 11) for better sodium-ion conduction is placed, and on the other side, there is a polyacrylonitrile (PAN) film (see Figure 12) with added NASICON-type Na3Zr2Si2PO12 for the same purpose. A value σRT = 1.36 × 10−4 S/cm has been reported.

Figure 11.

Molecular structures of succinonitrile (SN).

Figure 12.

Molecular structures of polyacrylonitrile.

An asymmetric composite electrolyte with a harder (or tougher) side facing the sodium-metal electrode (for better dendrite suppression) and a softer side for the positive electrode, enabling formation of a better interface, has been proposed []. The tougher side was prepared from PEO, NaTFSI, and a metal–organic framework ZIF-67, and upon this, more PEO/NaTFSI was deposited. Overall conductivity was σRT = 5.23 × 10−4 S/cm, and a complete cell showed 0.12% capacitance loss per cycle for 300 cycles. Mixtures of PEO and NaTFSI have been studied, and with growing fraction of the salt, the mix becomes more gum-like, suggesting plasticizer-like properties of the salt []. Somewhat surprisingly—when considering the effects of this filler in other composites—5 wt.% of nanosized SiO2 did not change the ionic conductivity. The interfacial resistance with the sodium electrode slightly increased, where t+ increased from t+ = 0.39 to t+ = 0.51. A membrane made from a mixture of a PEO-like polymer and Al2O3 (2:1 by weight) soaked in a solution of 1 M NaClO4 in a carbonate solvent mixture yielded a composite electrolyte tested in a sodium/Na2MnFe(CN)6 battery []. The filler blocked dendrite formation, and the cell showed no capacitance loss after 400 cycles. Suitability of a composite electrolyte prepared from PEO and NaPF6 with TiO2 (4 wt.%) as a filler for a solid-state sodium battery Na/NaTi2(PO4)3 has been studied []. Without filler, σRT ~ 0.013 × 10−3 S/cm, and at T = 80 °C, 0.2 × 10−3 S/cm was measured (for comparison, see []); upon filler addition, the latter value increased to 0.44 × 10−3 S/cm with t+ = 0.68, and at T = 80 °C, the battery showed a stable capacitance during 110 cycles. A solid composite electrolyte of PEO with NaClO4 as a salt and 5 wt.% TiO2 as a filler showed an increase in the conductivity from σRT = 1.35 × 10−4 S/cm to σRT = 2.62 × 10−4 S/cm and good compatibility with an electrode of Na2/3Co2/3Mn1/3O2 [].

Addition of 50% succinonitrile (SN, Figure 11) to a solid electrolyte of PEO and NaTFSI increased the ionic conductivity to σRT ~ 1.1 × 10−4 S/cm, about 45 times the value without SN []. SN has been called a “non-ionic plastic crystal” apparently because it is an organic crystalline solid at room temperature, with specific properties found in more details elsewhere [,].

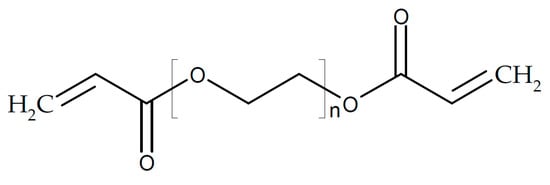

A composite of PEO, NaTFSI, and Na6[Re4As2S2(CN)12] with a cubane-like anion showing σRT = 1.05 × 10−5 S/cm was tested successfully in a sodium/NaVPO4 cell []. A composite of PEO with partially hydrolyzed NaBH4 has been examined as a solid electrolyte for a sodium-ion battery []. σ45°C = 11.6 × 10−3 S/cm and t+ = 0.54 were found. Functionalized carbon carboxylate composited with sodium bis(oxalate)-borate yielding an electrolyte for sodium-ion batteries has been prepared []. A porous disk of alumina was soaked with a slurry of PEO, SiO2, and NaClO4 (for its preparation, see []), yielding a solid composite electrolyte with σRT = 1.6 × 10−4 S/cm for a sodium-metal battery (although according to a displayed figure, the electrolyte is permeable for lithium ions!) []. A ceramic/polymer composite has been proposed for use in a sodium-ion battery at T = 80 °C []. NASICON-type powders of Na3Zr2Si2PO12/Na3.4Zr1.8Mg0.2Si2PO12 as the ceramic constituent were combined with PEO (see Figure 4) and NaTFSI, where the obtained film was sandwiched between the negative sodium ion and the positive Na3V2(PO4)3 electrode. Sodium-ion conductivity of 2.4 mS·cm−1 was reported. PEO with NaTFSI was composited with Na3Zr2Si2PO12, yielding a composite electrolyte with σRT = 1.4 × 10−4 S/cm at the optimum composition []. A solid electrolyte based on Na3Zr2Si2PO12 and PEO with NaClO4 and some PEG “for better film formation” and σ55°C > 10−4 S/cm has been described []. A cell with a sodium-metal electrode kept 98% of the initial capacitance after 100 cycles. The same composite electrolyte was used in a sodium-ion battery of symmetric design with two Na3V2(PO4)3, showing 86.4% of its initial capacitance after 650 cycles []. When using a positive Prussian blue electrode instead, 0.005% capacity loss per cycle during 9000 cycles was observed. To PEO with NaClO4 as a salt, Na3Zr2Si2PO12 has been added, affording a solid composite electrolyte with increased conductivity σ30°C = 2.1 × 10−5 S/cm and enhanced dendrite suppression []. It was used in a sodium-metal-Prussian Blue-type positive electrode battery providing 0.05% capacitance loss per cycle during 300 cycles. To a solid electrolyte of PEO with sodium percarbonate, Na3Zr2Si2PO12 was added, yielding a conductivity σRT = 2.6 × 10−4 S/cm (the unit SCm−1 remains a mystery) []. High conductivity was attributed to lower crystallinity, and sodium dendrite formation was suppressed, yielding 73% capacitance retention after 100 cycles. A polyether-based composite electrolyte with NaTFSA as a salt and Na3Zr2Si2PO12 as an inorganic filler showed increasing conductivity with a decreasing filler content, e.g., σRT = 1.03 × 10−5 S/cm (t+ = 0.04) at 30 wt.% filler []. This behavior was attributed to improved segmental mobility of the polyether at a lower filler content, promoting dissociation of the added salt. A PEO-based solid electrolyte with added NASICON-type Na3Zr2Si2PO12 doped with Sc and Ge and enriched ceramic content near the electrolyte surface has been used in a sodium-ion battery []. Overall conductivity of the electrolyte was σ30°C = 4 × 10−5 S/cm. A complete cell with a negative electrode Sn4P3CNT/C and a NVP positive one provided 100 cycles with 88% capacitance retention. A further increase in sodium-ion conductivity as well as transference number t+ were obtained by doping NASICON-type ceramic Na3Zr2Si2PO12 with Mg2+ and Sc3+; similar to the preceding example, the ceramic was mixed with NaTFSI and PEO, yielding a composite electrolyte with t+ ≈ 0.998 and σRT = 7.96 × 10−5 S/cm were reported with an optimized composition of the ceramic []. A full sodium ion cell was operated at T = 60 °C stably for 80 cycles. Using as a salt NaClO4 instead, a cell with a sodium-metal electrode retaining 97% of its initial capacitance after 100 cycles was reported []. PEO with NaClO4 added as a salt was infiltrated into a skeleton of electro-spun Na3Zr2Si2PO12, yielding σRT = 4.43 × 10−4 S/cm and t+ = 0.61 []. A full cell with a sodium electrode kept 83% of its initial capacitance after 1500 cycles. A composite of this ceramic with polyethylene glycol diacrylate and succinonitrile as a plasticizer has been suggested as an electrolyte for sodium batteries []. The ceramic enhanced ionic conductivity (σRT = 4.5 × 10−4 S/cm) and suppressed dendrite formation, contributing to 87% capacitance retention after 100 cycles.

A glass fiber mat coated with polyethylene glycol diacrylate was soaked with PEG in the presence of NaClO4, yielding a composite electrolyte (σRT = 0.8 × 10−4 S/cm), and tested in a Na/NVP battery, showing 99% capacity retention after 1100 cycles [].

A solid electrolyte of PEO with NaTFSI as a salt and hydroxyapatite added as a filler, yielding about σ70°C ~ 10−4 S/cm and t+ = 0.38, was tested in a sodium/Na4CrFe(PO4)3 battery []. A composite of PEO with NaClO4 with BaTiO3 filler for a sodium-ion battery has been reported []. At 5 wt.% filler, σRT ~ 1 × 10−5 S/cm was reported, and reduced crystallinity was noted as the cause of increased conductance. Addition of electrospun fibers of MgAl2O4 to PEO with NaClO4 yielded a composite electrolyte with increased ionic conductivity (σ55°C = 1.89 × 10−4 S/cm with t+ = 0.55) and higher mechanical and thermal stability []. The increased conductivity is attributed to lower crystallinity and stronger interaction between the filler and the anions of the salt.

To PEO with NaTFSI as salt, Ga-doped Na2Zn2TeO6 filler at various concentrations was added, yielding a solid composite electrolyte with σ30°C = 4 × 10−5 S/cm at 50 wt.% filler from σ30°C = 1 × 10−6 S/cm without filler, with the increase ascribed to the high ionic conductivity of the filler itself and suppressed crystallization []. A sodium/NVP battery was assembled; at T = 80 °C, cells with both micro- and nanosized NVP lost about 10% of the initial capacity during 100 cycles.

A PEO-based (not cellulose-based as claimed in the title) polymer electrolyte with NaClO4 as a salt blended with sodium carboxymethyl cellulose (CMC) has been prepared, characterized, and tested in Na/TiO2 and Na/NaFePO4 batteries []. The composite showed σRT < 10−6 S/cm and t+,60°C = 0.15, and batteries were run for 12 and 20 cycles, respectively.

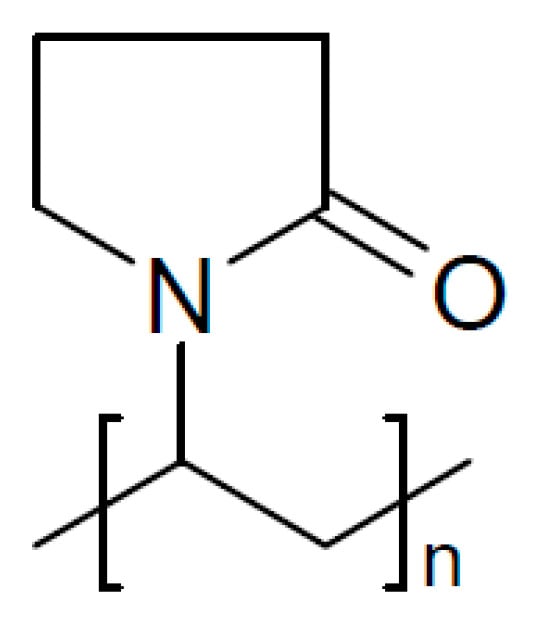

A polymer blend of PEO and polyvinyl pyrrolidone (PVP, Figure 13) with NaIO4 as a salt composited with TiO2 nanoparticles has been prepared for a sodium []. At 10 wt.% salt and 3 wt.% filler, σRT = 9.82 × 10−6 S/cm was found, and as a reason, the increase in the dielectric constant of the material causing an increase in the concentration of mobile ions and their mobility was suggested.

Figure 13.

Molecular structures of polyvinyl pyrrolidone.

Ionic conductivity of a PEO/PVP blend with added NaF has been studied, where a maximum conductivity σ30°C = 1.19 × 10−7 S/cm was reported []. A polymer blend of PEO and PEMA with NaIO4 with ZnO as a filler and PEG as plasticizer has been prepared and studied []. Growing filler content resulted in higher conductivity.

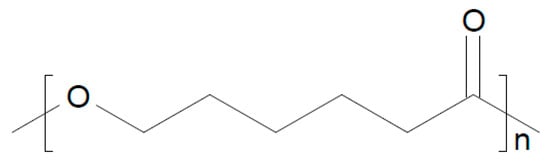

To a blend of PEO/polycaprolactone (see Figure 14), graphitic C3N4 and Na-β-Al2O3 have been added, yielding a composite electrolyte tested at T = 50 °C in a Na/NVP battery, showing a stable capacity for 55 cycles [].

Figure 14.

Molecular structures of polycaprolactone.

Although inhibition of crystallization by adding a plasticizer seems to be a popular and well-established approach to soften hard and/or brittle plastics, the title of a report highlighting plasticizing as something special suggests otherwise []. Adding N-propyl-N-methylpyrrolidinium bis(fluorosulfonyl)imide (PYR13FSI, see Figure 15) as a plasticizer to PEO with NaClO4 as an electrolyte yielded a composite electrolyte (with this term used generously in a somewhat wider sense, see above) with σRT = 6.8 × 10−5 S/cm and t+ = 0.44 at 40 wt.% of the ionic liquid. A Na/NVP battery kept 86% of the initial capacity after 70 cycles.

Figure 15.

Molecular structures of N-propyl-N-methylpyrrolidinium bis(fluorosulfonyl) imide.

PVDF-Based Materials

A PVDF-based composite electrolyte with NaTFSI as a salt and an inorganic filler of β″-Al2O3 has been prepared, characterized, and tested in Na/CFx and Na/NaNi1/3Mn1/3Fe1/3O2 batteries []. σRT = 4.55 × 10−4 S/cm, and the six-fold increase in comparison to the conductivity of the solid electrolyte without filler was attributed to a “destruction of the ordered arrangement of PVDF chains”, i.e., reduced crystallinity. Lower Coulomb efficiency of the solid-state cell in comparison to a conventional cell with liquid electrolyte solution was attributed to a poor electrolyte/electrode interface in the solid-state cell, as already addressed above. Capacity retention was 87% after 50 cycles for the Na/NaNi1/3Mn1/3Fe1/3O2 battery. Na/CFx cells with carbon fluorides of different degrees of fluoridation performed poorly.

To PVDF with succinonitrile as a plasticizer and NaTFSI as a salt, Na3.4Zr1.8Ni0.2Si2PO12 was added for improved sodium-ion conduction (σRT = 1.02 × 10−3 S/cm), yielding a solid electrolyte for a sodium-metal battery with 90% capacitance retention after 700 cycles []. A solid electrolyte of PVDF with Na3Zr2Si2PO12 and NaClO4 as salt (σRT = 1.1×10−4 S/cm, for plain PVDF σRT = 3.1 × 10−5 S/cm) was used as a composite electrolyte in a sodium metal/Na0.67MnO2 battery []. Wetting the porous positive electrode with a very small amount of a liquid organic electrolyte solution helped in establishing a good electrode/electrolyte interface. At an optimized content of liquid a capacitance retention of 100% after 100 cycles was observed. A solid electrolyte of PVDF with NaCF3SO3 as salt and SiO2 as a filler yielded a solid composite electrolyte with σRT = 0.06 × 10−3 S/cm []. The complete Na/NVP battery kept 70% of its initial capacitance after 100 cycles, for better contact between electrolyte and positive electrode some liquid electrolyte solution was added to the latter.

Cyclic stability was attributed to prevented dendrite formation at the sodium electrode and inhibited manganese dissolution at the positive electrode. Electrospun fibers of PVDF/NaFSI with a shell of Na3Zr2Si2PO12 were made into a separator/composite electrolyte with σ60°C = 6.6 × 10−4 S/cm, enabling a sodium-metal battery showing relatively poor specific capacity, attributed to the poor electrode/electrolyte contact []. Into a solid electrolyte of PVDF with NaClO4 as a salt Na3Zr2Si2PO12 was added, yielding a composite electrolyte with σRT = 1.069 × 10−4 S/cm tested in a sodium-ion battery keeping 95% of its initial capacitance after 290 cycles []. Into a solid electrolyte of PVDF with NaPF6 sodium β”, alumina was added []. The modified composite electrolyte had σRT = 0.19 × 10−3 S/cm and t+ = 0.91, and a complete sodium/carbon nanofiber (CNF) cell kept 95% of its initial capacitance after 100 cycles. A composite of this ceramic with PVDF-HFP with “Salt-Ionic liquid” (this apparently means an ionic liquid EMIMTFSI as a plasticizer and NaTFSI as a salt) has been prepared, yielding σRT = 1 × 10−3 S/cm and t+ = 0.57 [].

A composite electrolyte was obtained by coating both sides of a glass fiber mat first with PVDF-HFP and then with polydopamine and by finally soaking the material in a 1 M solution of NaClO4 []. σRT = 4.6 × 10−3 S/cm was reported, and with polydopamine coating, the value increased to σRT = 5.4 × 10−3 S/cm; a sodium/Na2MnFe(CN)6 battery showed 89% capacity retention after 100 cycles.

Into a porous skeleton of PVDF-HFP and Na3Zr2Si2PO12, an interpenetrating network of poly(ether-acrylate), PEO, and NaPF6 was embedded, providing a composite electrolyte with σ60°C = 1.32 × 10−4 S/cm and t+ = 0.63 at T = 60 °C []. Operated at this temperature, sodium-metal cells and various positive electrode materials showed stable capacities over 100 cycles. The multilayer structure of the electrolyte frequently claimed in the report is nowhere evident.

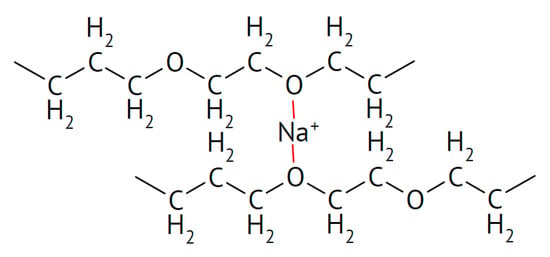

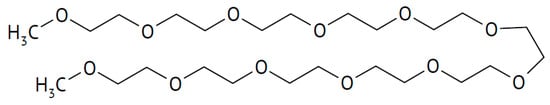

A solid electrolyte Na3Zr2Si2PO12 with added BaTiO3 (in the abstract, it is called reinforcement, but in the report, this claim does not show up again) better prevents dendrite formation, enabling a full cell to keep 84.4% of its initial capacitance after 400 cycles []. A composite sheet of Na3Zr2Si2PO12 and PVDF-HFP soaked in an electrolyte solution of sodium triflate and TEGDME (presumably tetraethylene glycol dimethyl ether, see Figure 16) showed σ0°C = 1.2 × 10−4 S/cm, σRT = 3.6 × 10−4 S/cm, and t+ = 0.92 [].

Figure 16.

Molecular structures of tetraethylene glycol dimethylether (TEGDME).

In a complete battery, only a slight capacitance loss was observed over 200 cycles.

A composite of PVDF-HFP and Na3Zr2Si2PO12 soaked in a solution of 1 M NaPF6 in a mixed carbonate solvent was used as an electrolyte (σRT = 7.94 × 10−4 S/cm) in a Na/Sn-C battery []. The high conductivity was attributed to the liquid electrolyte solution trapped inside the porous composite. After initial major capacity losses (about 50%), the cell capacity stayed constant for the following 80 cycles.

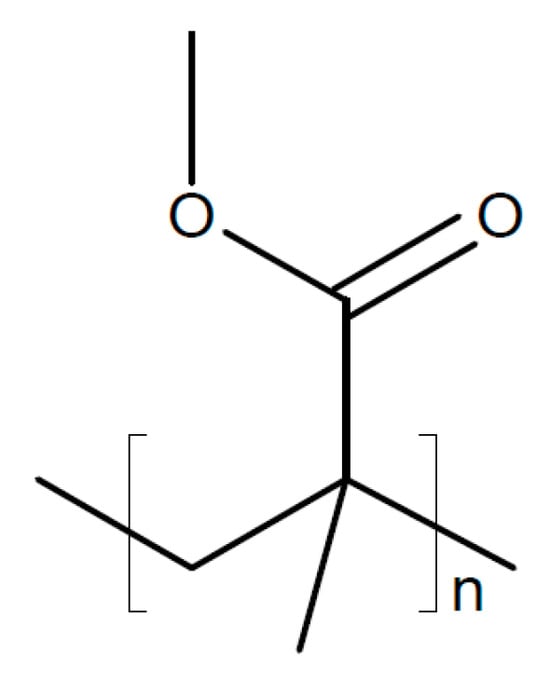

PVDF-HFP coated on both sides of a disk of Na2.5Zr1.95Ce0.05Si2.2P0.8O11.3F0.7 (σRT = 1.7 × 10−3 S/cm) was used as a solid electrolyte in a sodium-metal/Na0.67Mn0.47Ni0.33Ti0.2O2 battery, showing a stable performance over 300 cycles []. A similar ceramic Na3.2Zr1.9Ca0.1Si2PO12 combined with PVDF-HFP showing σRT = 1.32 × 10−4 S/cm has been suggested as solid electrolyte for a sodium/CO2 battery []. A solid composite electrolyte was prepared from PVDF-HFP with NaClO4 and Na3.2Zr1.9Mg0.1Si2PO12 added as a filler for use in a sodium/CO2 battery []. Partial substitution of Zr by Mg resulted in σRT = 1.16 × 10−3 S/cm. A polymer composite membrane of PVDF-HFP and Na3Zr2Si2PO12 filled with poly(methyl methacrylate) (PMMA, see Figure 17) was used as a solid electrolyte with σRT = 2.78 × 10−3 S/cm and t+ ~ 0.63, which enabled a stable cycling performance of a sodium-ion battery for 600 cycles [].

Figure 17.

Molecular structures of poly(methyl methacrylate) (PMMA).

A composite of PVDF-HFP as the matrix and a sodium-rich anti-perovskite/perovskite material has been suggested as electrolyte for sodium batteries []. σRT = 1.11 × 10−4 S/cm and stability over 500 cycles were reported. To improve the low-temperature ionic conductivity of PVDF-HFP (not PVDF as suggested in the title of the report) with NaClO4 as the salt, graphitic C3N4 has been added []. This addition increased conductivity by enhancing salt dissociation and reducing crystallinity of the copolymer. σRT = 5.171 × 10−5 S/cm without g-C3N4 increased to σRT = 1.67 × 10−4 S/cm, and t+ improved from 0.61 to 0.78. In a sodium-metal battery, 98% of the initial capacitance was retained after 200 cycles; with the addition, this decreased to 69%. A polymer blend of PVDF-HFP and PMMA was dissolved and β-alumina nanopowder was added, possibly (the report leaves this detail open) the blend was soaked in a 1 M NaClO4 in a blend of carbonate solvents []. Solution uptake was highest at 4 wt.% filler content, conductivity was highest at this composition with σRT = 3.39 × 10−3 S/cm attributed to lower crystallinity, t+ = 0.58 was attributed to a weaker interaction between fluoride atoms in the polymer and sodium ions caused by the added filler. In a test with this composite electrolyte a sodium/Na3V2(PO4)3 battery kept 85% of its initial capacitance after 300 cycles.

To a polymer blend of PVDF-HFP and PMMA with NaCF3SO3 dissolved in a carbonate solvent mixture presumably also acting as a plasticizer and as a salt, Al2O3 was added as a filler, providing a gel electrolyte with σRT ~ 1.5 × 10−3 S/cm and t+ ~ 0.29. 0.33 (not T as reported) at a 6 wt.% optimum filler content []. Enhanced conductivity caused by addition of PMMA was attributed to the amorphous nature of this polymer, whereas the added filler increased salt dissociation. PVDF-HFP combined with β-Al2O3 powder surface modified with silane for better compatibility with the polymer matrix yielded a solid electrolyte after soaking with an electrolyte solution of NaPF6 in a mixed carbonate solvent for a sodium-metal battery with σ20°C = 1.37 × 10−3 S/cm and t+ = 0.424, enabling 92% capacitance retention after 1000 cycles []. A copper-based MOF HKUST-1 [] was used as inorganic filler for PVDF-HFP (confusingly named PH), and the obtained membrane soaked in a 1 M NaClO4 solution in ethylene carbonate with 5% fluoroethylene carbonate yielded a composite electrolyte with σ30°C = 3.2 × 10−4 S/cm and t+ = 0.64 []. When tested in a sodium/Na3V2O2(PO4)2 battery, 75% of the initial capacitance was kept after 400 cycles. Inhibition of dendrite formation was attributed to the inorganic filler; in addition, the filler enhanced liquid electrolyte solution absorption and amorphicity.

A ternary polymer blend of PVDF-HFP, PEO, and PMMA has been combined with 10 wt.% silica fillers and soaked in an electrolyte solution of NaPF6 in propylene carbonate, yielding a composite electrolyte subsequently tested in a sodium/Na3V2(PO4)2F3 []. σRT = 0.88 × 10−3 S/cm and t+ = 0.86 were found, or without filler, only σRT = 0.63 × 10−3 S/cm and t+ = 0.74. The cell kept 93% of its initial capacitance after 100 cycles.

Using Sb2O3 instead of Al2O3 as a filler for a polymer mixture of PVDF-HFP and PVP yielded a highly flexible composite membrane, which was soaked with an electrolyte solution of 1 M NaClO4 in a carbonate solvent mixture []. The result, called a separator, had a “large electrolyte window”—whatever that means, it blocked dendrite formation. The same approach has been reported with SiO2 as a filler material []. Here, 6 wt.% filler was found as the optimum fraction, yielding an electrolyte with σRT = 0.71 × 10−3 S/cm and stable performance in a symmetric Na//Na cell for 200 cycles. Into a polymer blend PVDF-HFP and PEO with NaClO4 as salt and EMIMFSI as plasticizer, microtubular Na3Zr2Si2PO12 was added, yielding a solid electrolyte with σRT = 6.93 × 10−4 S/cm and t+ = 0.882 for a sodium-metal battery [].

Nanoparticles of a zeolitic imidazolate framework ZIF-67 impregnated into a fibrous membrane of PVDF-HFP and PAN yielded a sodium-ion-conducting membrane with σRT = 1.42 × 10−3 S/cm and t+ = 0.58 []. The interface established between this membrane and the sodium-metal electrode prevented sodium dendrite formation during cycling. A complete cell showed 0.052% capacitance decline per cycle during 100 cycles.

Other Polymer-Based Materials

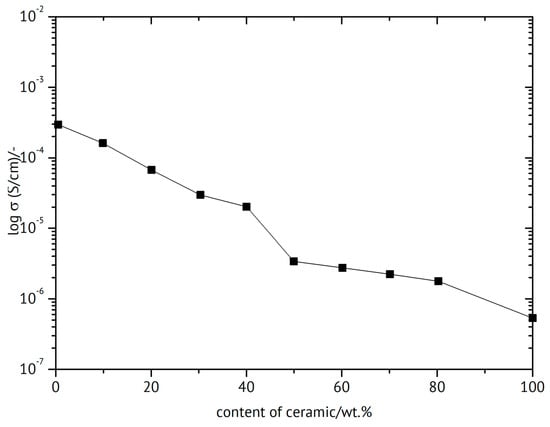

An overview of polymer electrolytes focused on sodium batteries is available []. An epoxy-reinforced ceramic sheet of NASICON type of Na3Zr2Si2PO12 has been suggested for a solid-state sodium-ion battery []. The beneficial effect of the added polymer beyond improving mechanical strength is illustrated in Figure 18, showing the ionic conductivity as a function of the polymer/ceramic composition. The porous sintered ceramic pellet was filled with the polymer. Sintering of the inorganic components before combining the constituents was found to be highly advantageous in terms of conductivity of the product.

Figure 18.

Ionic conductivity of a ceramic/polymer composite as a function of composition at room temperature, based on data in [].

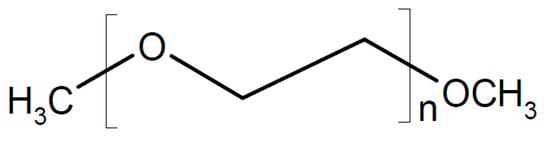

A highly sodium-ion-conducting SiO2/polymer hybrid has been reported []. For an increased value of t+, anions were immobilized by grafting anions of 2-[(trifluoromethane-sulfonylimido)-N-4-sulfonylphenyl]ethyl onto SiO2 particles, and this hybrid material was dispersed in a polymer matrix of polyethylene oxide (PEO, see Figure 4) or polyethylene glycol dimethylether (PEGDME, see Figure 19), yielding a composite electrolyte.

Figure 19.

Molecular structures of polyethylene glycol dimethylether.

Conductivities σRT > 10−5 S/cm were found. A matrix of electrospun SiO2 fibers was filled with a copolymer of 2-(methacryloyloxy) ethyl acetoacetate and N,N′-methylenebisacrylamide, yielding a composite electrolyte with σ−30°C = 0.153 × 10−3 S/cm []. A final coating with AlF3 suppressed sodium dendrite formation. Capabilities of this electrolyte were demonstrated by 5500 h steady sodium plating/stripping. How a pouch half-cell (elsewhere in the text, full cell) was powered by several LEDs was not explained; a cell kept 94% of its initial capacitance after 475 cycles. With Al2O3 as a filler, an acrylate-based polyester polymer yielded an electrolyte for a sodium-metal battery with σRT = 5.59 × 10−3 S/cm []. A composite of polysulfone-sodium sulfonate and poly(polyethylene glycol methacrylate) with nanosized hexagonal boron nitride for sodium-ion batteries has been reported []. σ100°C = 5.5 × 10−5 S/cm was noted.

A copolymer of acrylonitrile and polyethylene glycol methacrylate with NaClO4 as the salt and hexagonal boron nitride as the filler has been developed []. An optimum composition of σ? = 3.6 × 10−4 S/cm at an unknown temperature (possibly, according to a displayed figure, T = 100 °C) was reported, and the proposed use in a sodium-ion battery was not described. A composite electrolyte of poly(ethylene glycol) diacrylate (see below) reinforced with glass fibers and σ? = 1.38 × 10−3 S/cm/t+ = 0.79 has been tested in a sodium-metal battery, yielding 91% capacitance retention after 1000 cycles []. Felts of electrospun ceramic fibers surface-modified with acyl amino groups for enhanced interfacial sodium ion transport were filled with a deep eutectic electrolyte for long-range ion transport []. A value of σ26°C = 3.29 × 10−4 S/cm and 98% capacity retention after 1000 cycles were reported. Cross-linked β-alumina nanowires provided the scaffold for a PVDF-HFP-based gel polymer electrolyte in a sodium-metal battery []. The mechanical rigidity of the electrolyte supported smooth sodium deposition, resulting in 95% capacitance retention after 1000 cycles.

A gel polymer composite electrolyte prepared from cellulose triacetate and a polyionic liquid has enabled a sodium-metal cell to run for more than 800 cycles []. How the electrolyte powered the cell was not explained. A PEO-based gel polymer electrolyte with 1-butyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl) imide as the gelling agent and NaTFSI as the salt was modified with surface-modified sepiolite []. Conductivities’ depended on ionic liquid content, with large fractions of the liquid σRT = 0.95 × 10−3 S/cm found, which, with lower fractions this value, decreased to 0.39 × 10−3 S/cm. The influence of sepiolite on ionic conductivity was rather moderate.

A NASICON-type sodium-ion conductor of unspecified composition with a dense core and porous outer layers has been prepared []. The porous layer facing the sodium electrode was filled with PEO, and the one facing the positive Na3V2(PO4)2F3 with PAN for better compatibility with the respective electrodes. σ30°C = 4.3 × 10−4 S/cm was attributed to long-range ionic pathways, and lower interfacial resistance to the better compatibility between electrodes and the modified inorganic solid. A full cell provided 81% capacity retention after 460 cycles.

A sodium ion-conducting solid electrolyte based on PEG and NaBr with 5 nm silica nanoparticles has been developed []. At 5 wt.%, added silica conductivity enhancement was largest at σRT = 8 × 10−5 S/cm. Adsorption of anions (i.e., Br−) on the silica was upheld as the main reason of conductivity increase.

A solid electrolyte of a copolymer poly(ethylene glycol)-co-ureidopyrimidinone with NaTFSI as the salt was modified by adding hollow mesoporous SiO2, yielding a solid composite electrolyte with σRT = 2.37 × 10−5 S/cm and t+ = 0.17 []. A sodium/NVP battery assembled with this electrolyte kept 77% of its initial capacity after 200 cycles at T = 60 °C, and increased conductivity was ascribed to fast ion pathways along the surfaces of the silica spheres.

Poly(diallyldimethylammonium) bis(fluorosulfonyl)imide with NaFSI (see Figure 9) as the salt dissolved in PYR14TFSI (see Figure 8) soaked into a glass fiber mat yielded a composite electrolyte with σ70°C = 2.1 × 10−3 S/cm, and when tested in a Na/NVP battery, 75% of its initial capacity was retained after 2000 cycles [].

Addition of an antioxidant 4-trifluoromethylphenylboronic acid to a cross-linked gel polymer electrolyte helped to avoid electrolyte decomposition at the positive electrode of a high-voltage sodium-ion battery [].

A composite of Na3Zr2Si2PO12 with cellulose acetate obtained by a simple solution-casting method with σRT = 1.73 × 10−3 S/cm was tested in a solid-state sodium battery, enabling 80% capacity retention after 800 cycles [].

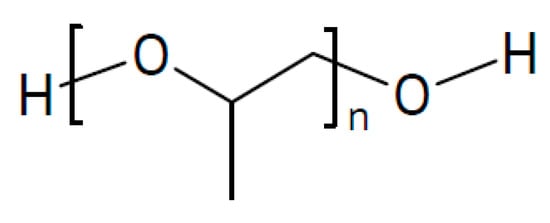

For a sodium-metal battery, a solid electrolyte of porous Na3SbS4 filled with a polymer PPP of PEG and PPG (the meaning of the acronyms is nowhere revealed; evidence suggests that PPP may be a mixture of poly(ethylene glycol) (Figure 5) and poly(propylene glycol) (Figure 20) with NaTFSI as salt has been proposed []. The performance of the sodium-metal electrode was significantly improved, enabling operation for 550 cycles.

Figure 20.

Molecular structures of poly(propylene glycol).

Na3SbS4 is a good sodium-ion conductor but unfortunately chemically incompatible with sodium metal []. Nanoparticles of this material coated with an ionic liquid BMPTFSI (1-butyl-1-methylpyrrolidinium bis(trifluoromethylsulfonyl) imide, see the common acronym PYR14TFSI Figure 8) were soaked into a porous PVDF membrane, subsequently serving as separator and solid electrolyte, yielding a conductivity σRT = 3.18 × 10−3 S/cm and enabling a good cell performance over 400 cycles. In another attempt to utilize this sodium-ion conductor, the sulfide is deposited onto a glass fiber network, and the product is soaked with an ionic liquid []. Good cycling behavior both of the sodium-metal electrode and the positive FeS2 electrode in contact with this electrolyte were reported. Another approach to utilize the attractive conductivity of this sulfide by combining it with sodium carboxymethyl cellulose (7.5 wt.% and 92.5 wt.% sulfide) has been reported []. Because the thickness of the electrolyte could by decreased to 1/5 in comparison to the sulfide alone, effective sodium-ion conduction grew roughly 5-fold. A sodium/Te-C cell showed about 40% capacitance loss after 100 cycles. A hybrid composite electrolyte prepared from Na3SbS4 and cross-linked pentaerythritol tetra acrylate with σRT = 0.047 × 10−3 S/cm has been tested in a Na3SbS4/S cell running for 90 cycles [].

Air stability of ion-conducting sulfides has been reviewed []. In a further attempt, Na3SbS3Se nanoparticles were embedded in a PVDF-HFP polymer matrix with NaPF6 as a salt, yielding a composite electrolyte with σRT = 1.31 × 10−4 S/cm at an optimum sulfide content 10 wt.% []. A Na/TiS2 battery kept 56% of its initial capacitance after 300 cycles. A core/shell composite has been proposed for use in solid-state sodium batteries []. A core of Na3PS4 is coated with a shell of Na2.25Y0.25Zr0.75Cl6, yielding σ? = 0.44 × 10−3 S/cm at an unspecified temperature. Particles of Na3Zr2Si2PO12 were embedded in Na3PS4, yielding at 70% of the ceramic, a solid electrolyte with σ100°C = 1.1 × 10−3 S/cm []. A composite electrolyte was prepared from PEO, NaClO4, Na2S, and P2S5 dissolved in acetonitrile, yielding Na3PS4/PEO/NaClO4 with σRT = 9.4 × 10−5 S/cm (only Na3PS4 σRT = 6.4 × 10−5 S/cm) at 4 wt.% of PEO and NaClO4, and tested in a Na/SnS2 battery []. A thin layer of PEO on Na3PS4 inhibited the detrimental chemical reaction of Na3PS4 with sodium and enabled more reversible sodium cycling, and greater fractions of PEO and NaClO4 resulted in a growing cell impedance because of a larger resistance of said coating.

A structural sodium-ion battery with a PEO-based composite electrolyte with NaClO4 as the salt and added Na3Zr2Si2PO12 showing σ60°C = 1.02 × 10−4 S/cm and t+ = 0.44 kept 80% of its initial capacitance after 225 cycles [].

The transition from liquid to solid electrolytes including hybrid systems for sodium-ion batteries has been surveyed; the acronym NIB (instead of the commonly accepted and used SIB) is certainly a highlight in this contribution in addition to many other inaccuracies [], further aspects of this development are discussed in [,,]. The knowledge of gel electrolytes for sodium-ion batteries has been surveyed in []. Electrolytes including composite ones based on NaCl for fuel cells and electrolyzers have been reviewed [,].

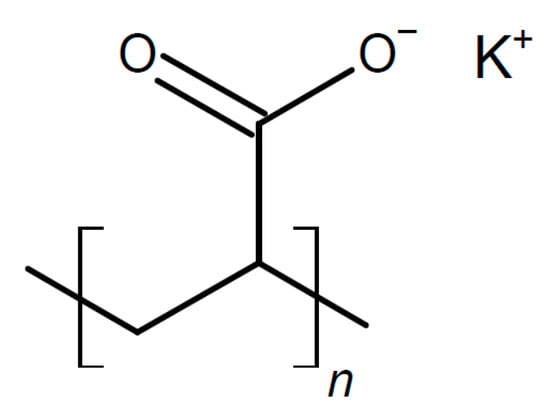

3.1.2. Potassium and Potassium-Ion Batteries

As reported, KTFSI (actually this is potassium bis(trifluoromethanesulfonyl)imide) is not suitable for potassium-ion batteries because of its low melting point, making it mechanically unstable and thus not useful as a “separator” in addition to being the electrolyte []. Inorganic fillers Al2O3 and SiO2 were tried, and they increase the mechanical stability without negatively affecting ionic conductivity. Actually, mixtures or composites of KTFSI and PEO with added fillers were studied. Conductivities above the melting point of the composite (presumably not very helpful for practical application) were not affected by the mechanical filler; at actual operating temperatures, no numbers were provided. A full cell kept 93% of its initial capacitance after 100 cycles. A powder mixture of PEO, potassium β-alumina, and potassium trifluoromethanesulfonimide was pressed into a pellet and heated; in a separate procedure, these compounds were dissolved/suspended in DMF, yielding a membrane after solvent evaporation []. For a trilayer solid electrolyte, the latter liquid was poured on both sides of the pellet and dried. An interfacial resistance but no conductivity or performance in an actual cell were reported.

A composite of potassium polystyrenesulfonate and a polyoxovanadate (HK5[V10O28]·10H2O) was used as an electrolyte in a potassium/Prussian Blue battery [].

A composite electrolyte of polypropylene carbonate with KFSI dissolved in ethylene carbonate/diethyl carbonate as the electrolyte and a nonwoven cellulose membrane as the filler and reinforcement has been prepared (σ20°C = 1.36 × 10−5 S/cm) and tested in a potassium/3,4,9,10-perylene-tetracarboxylicacid-dianhydride battery []. The rapid capacity fading was attributed to the solubility of the active material in the positive electrode, but how the conclusion of a stable cycling performance could be reached remains mysterious.

A solid electrolyte for a potassium-ion battery was obtained by dissolving a powder of perfluorinated resin in DMF and adding some KPF6-containing electrolyte solution in ethylene carbonate and diethyl carbonate []. Using it in a complete cell yielded a sodium-ion battery with a capacitance decay of 0.26% per cycle during 200 cycles.

A solid electrolyte based on polyvinyl butyral with KCl and σ30°C = 1.87 × 10−5 S/cm has been prepared and tested in a potassium-metal/iodine battery [].

3.1.3. Magnesium and Magnesium-Ion Batteries

Inorganic Electrolytes

Along the line reported by Liang [], composites of Mg(NO3)2 and Al2O3 were prepared and their ionic conductivity examined []. With the composition 0.9Mg(NO3)2/0.1Al2O3, σRT~10−4 S/cm was observed and attributed to the presence of MgO. A composite of Mg(BH4)2 with THF and MgO added for stabilization of the composition Mg(BH4)2·1.5THF-MgO(75 wt.%) yielded σ70°C~10−4 S/cm with t+ = 0.99 and was tested in a Mg/TiS2 battery []. A composite of Mg(BH4)2·CH3NH2BH3 with 75 wt.% MgO added for solidification of the initially viscous liquid showed σRT~10−5 S/cm []. Borohydride−amide composites have been prepared by mechanochemical (ball milling) and thermal procedures (annealing with various protective gas atmospheres) and characterized in view of possible applications in magnesium batteries []. Prepared samples always contained Mg(BH4)2·(NH2) and some other phase, and conductivity reached σ100°C = 3 × 10−6 S/cm, higher than earlier reported values of σ150°C = 10−6 S/cm and σ100°C = 10−8 S/cm []. The difference in reported conductivities—certainly less than the three orders of magnitude claimed in []—was attributed to some additional ionic phase.

Various cyclopropylamine borohydrides and some of their composites with Al2O3 have been prepared, characterized, and examined as solid electrolytes []. The composite electrolyte Mg(BH4)2·(CH2)2CHNH2·Al2O3 (50:50 by weight) had the highest conductivity σRT = 1.8 × 10−5 S/cm and t+ = 0.99999. A gel composite electrolyte composed of magnesium borohydride Mg(BH4)2, MgCl2, and polyethylene glycol (Figure 6) has demonstrated high thermal stability and ionic conductivity (σRT = 1.01 × 10−4 S/cm, t+ = 0.74) and good compatibility with a magnesium electrode []. Over 1000 cycles, 92.6% of the initial capacitance was retained.

Composite electrolytes based on silicate tetraethylene glycol hybrids with various magnesium salts have been prepared and characterized []. Conductivities around 10−4 to 10−3 S/cm were observed.

Composites of Mg(BH4)2 and various amounts of isopropylamine have been tested as magnesium-ion conductors [,]. The highest ionic conductivity of σ45°C = 2.7 × 10−4 S/cm was found for the composition Mg(BH4)2·1.5(CH3)2CHNH2. Materials start to soften around 50 °C, and addition of 75 wt.% of MgO increased ionic conductivity as well as thermal stability, suggesting a contribution of hydrophobic interactions to increased conductivity. Mg(BH4)2·1.47CH3)2CHNH2 confined in mesoporous silica SBA-15 yielded σ32°C = 9.1 × 10−6 S/cm [].

PEO-Based Electrolytes

In a mechanochemical procedure, a mixture of PEO, Mg(ClO4)2, and EMIMFSI in acetone was ball-milled, which yielded a composite electrolyte after solvent evaporation with σRT = 0.5 × 10−5 S/cm [].

To PEO with magnesium triflate as the salt, urea has been added, yielding a solid electrolyte with σ? = 6.3 × 10−5 S/cm, with possible use in magnesium batteries suggested []. The increase in conductivity caused by added urea was attributed to faster segmental motion in PEO and lower viscosity of the medium. A composite electrolyte of PEO with MgBr2 as the salt and added starch nanocrystals was prepared with σRT = 7.8 × 10−8 S/cm []. Increased conductivity was attributed to additional ion transport channels formed by the starch nanocrystals. To a PEO-Mg(ClO4)2 solid electrolyte, nanochitosan was added as a filler, increasing the ionic conductivity by about two orders of magnitude around σ60°C ≈ 10−3 S/cm with 10 wt.% salt and 10 wt.% filler []. A PEO-based composite electrolyte with Mg(OH)2 as a plasticizer also containing LiTFSI with σRT ≈ 1.6−5 S/cm has been reported []. A liquid (!) composite electrolyte of PEO with magnesium acetate and added nanoparticles of MgO showed σRT = 3.63 × 10−3 S/cm after γ-irradiation [].

PVA-Based Electrolytes

A solid electrolyte of PVA with various amounts of Mg(ClO4)2 has been prepared and characterized, and an optimum conductivity σ30°C ≈ 10−4 S/cm was recorded with PVA/salt composition 0.6/0.4 []. A PVA-based solid electrolyte with MgBr2 as a salt and phosphomolybdic acid (this is presumably the compound called phosphomolbidic acid throughout the report) and TEGDME has been prepared and tested in a Mg/TiO2 battery []. The highest observed ionic conductivity was σ303 K~10−6 S/cm, t+ = 0.4. A polymer electrolyte of PVA with MgBr2 and tetraethylene glycol dimethyl ether as a plasticizer was combined with Li2O, yielding a composite electrolyte with σRT ≈ 10−5 S/cm and t+ = 0.7 at 0.04 wt.% optimum filler content []. It was tested in a Mg/V2O5 battery.

A composite electrolyte of a blend of PVA and SN with a magnesium electrolyte has been characterized and tested in a Mg/TiO2 battery [].

Structural and ion transport properties of a polymer blend of PVA and hydroxypropyl methylcellulose with Mg(NO3)2 as a salt (hardly as dopant as suggested in the report) have been studied []. At the optimum composition (PVA:HPMC = 0.4:0.6, 40 wt.% salt), σRT = 2.48 × 10−4 S/cm was measured, and said mixture had the lowest crystallinity based on XRD data, certainly supporting high ionic conductivity. Unfortunately, the mentioned conductivity value does not match tabulated data; this may be due to the use of NaNO3 for measurement of the tabulated data. A most uncommon use of transference number tion = 0.995 has been reported, and for the electrons, te = 0.005 has been listed. The clearly large value of tion is highlighted, but the cause of electronic conduction is not even mentioned. Presumably, parasitic currents are a cause. Back to standard practice, t+ = 0.247 was finally obtained. A primary Mg/MnO2 battery with this optimized composite electrolyte was assembled and discharged once.

PVDF-Based Electrolytes

To dissolved PVDF, MgBr2 was added as an electrolyte and some TEGDME as a plasticizer, yielding a composite electrolyte with σRT = 1.2 × 10−6 S/cm and t+ = 0.55, showing initially reversible magnesium plating both in a symmetric Mg/Mg and a battery-type Mg/graphene nanoplatelet cell []. XRD data show an almost complete loss of crystallinity of the polymer, and decreasing reversibility of magnesium plating was attributed to a growing “interfacial resistance”.

A membrane of a polymer blend of PVDF and polyurethane with MgO as a filler was soaked in a carbonate solvent-based electrolyte solution with Mg(ClO4) σ60°C = 3.4 × 10−6 S/cm, yielding a gel composite electrolyte with σRT = 4.6 × 10−3 S/cm at the optimum filler content of 7 wt.% []. A mixture of PVDF-HFP, Mg(ClO4)2, and PYR14TFSI with 10 wt.% TiO2 as a filler has been made into a composite electrolyte with σRT = 0.16 × 10−3 S/cm []. In a symmetric Mg/Mg cell, highly reversible magnesium plating was observed.

A composite electrolyte from PVDF-HFP with Mg(ClO4)2 dissolved in a carbonate solvent mix with various amounts of fumed silica as a filler with σRT~1.1 × 10−2 S/cm at optimum filler content 7 wt.% has been prepared and tested in a Mg/MoO3 battery []. Space-charge layers formed at the filler/polymer interfaces were suggested as the cause of the enhanced conductivity. The cell ran for more than 10 (!) cycles.

Into a blend of PVDF-HFP/polyvinyl acetate with Mg(ClO4)2 as the salt, geikeilite (MgTiO3) was added as an inorganic filler at various percentages []. The highest observed ionic conductivity σ30°C ~ 5.80 × 10−3 S/cm and t+ = 0.34 were found at the optimum composition (6 wt.% of MgTiO3), and a complete cell retained 86% of its initial capacitance after 30 cycles.

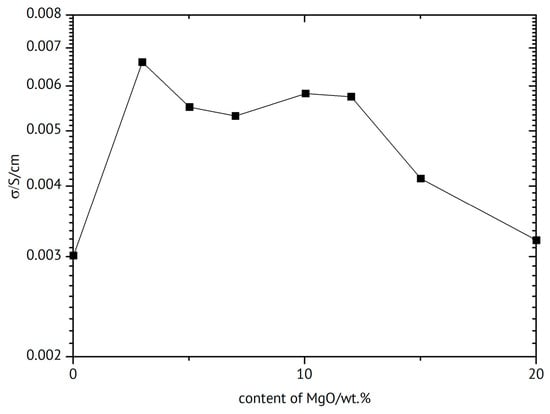

With PVDF-HFP with magnesium triflate as a salt, and SN and some 1-ethyl-3-methylimidazolium trifluoromethanesulfonate for stabilization, a composite electrolyte with σ26°C = 4 × 10−3 S/cm was obtained and tested in a Mg-C/MnO2 battery, showing substantial capacity fading within eight cycles (!) []. The different effects of active and passive fillers (see also []) on magnesium-ion conductivity of PVDF-HFP with Mg(Tf)2 in a mixture of ethylene and propylene carbonate with magnesium-containing and thus possibly actively participating compounds like MgO or MgAl2O4 and passive fillers like TiO2, Al2O3, or SiO2 have been studied []. Whether the absence of peaks in diffractograms clearly attributable to MgAl2O4 or Al2O3 proves complete dissolution appears to be questionable (see also []); more likely is a very fine distribution of the nanoparticles of the filler. With an optimum content of 30 wt.% Al2O3, σRT = 3.3 × 10−4 S/cm was found, and with 30 wt.% MgAl2O4, σRT = 4 × 10−4 S/cm. Addition of fillers resulted in significant increases in transference numbers to t+ = 0.52 in the former and t+ = 0.66 in the latter case. The remarkable difference between changes afforded by active vs. passive fillers was not resolved.

A PVDF-HFP-based composite electrolyte with Mg(ClO4)2 dissolved in a mixture of ethylene carbonate and propylene carbonate (which stayed in the gel) and MgO as inorganic filler yielded σRT~6 × 10−3 S/cm and t+ = 0.39 at optimum composition 10 wt.% filler and was tested in a Mg/V2O5 battery for ten (!) cycles []. Why the even higher conductivity at 3 wt.% filler was not considered the optimum (see Figure 21) was not addressed. Such observation of two maxima has been reported elsewhere [,,,]. The first maximum has been attributed to enhanced dissociation of ion aggregates and/or undissociated salt whereas the second one has been attributed to space charge effects discussed above [,,,]. At higher filler concentrations, the particles hinder ion movement and thus decrease conductivity [].

Figure 21.

Ionic conductivity vs. MgO content (based on data in []).

Other Polymer-Based Electrolytes

Into a PEG-based electrolyte with magnesium acetate as salt various amounts of TiO2 have been added []. At optimum filler content 10 wt.% σRT = 5.01 × 10−5 S/cm was found, without filler it was σRT = 1.07 × 10−6 S/cm.

To a solid electrolyte of methyl cellulose and magnesium acetate, Co3O4 was added yielding a composite electrolyte with σRT = 5.93 × 10−4 S/cm at the optimum composition tested in a Mg/MnO2 battery []. For a magnesium/iodine battery, a PEG-based electrolyte with magnesium acetate as the salt and CeO2 as the inorganic filler has been prepared and tested []. Up to 15 wt.% of added filler, an increase in conductance to σ60°C = 3.4 × 10−6 S/cm with t+ ≈ 0.97 was observed. Into a PEG-based electrolyte with Mg(NO3)2, TiO2 was added as an inorganic filler, providing a composite electrolyte with σRT = 1.06 × 10−4 S/cm and t+ = 0.98 at an optimum filler content of 10 wt.% tested in a Mg/I2 battery []. To a PEG-based polymer electrolyte with magnesium acetate, TiO2 was added as a ceramic filler, yielding a composite electrolyte with σRT = 5 × 10−5 S/cm []. To a chitosan-based polymer electrolyte with MgCl2, various amounts of V2O5 were added as inorganic filler, yielding a composite electrolyte tested in a Mg/MnO2 battery []. Added filler decreased the crystallinity of the composite, with 1 wt.% showing the most pronounced effect, which in turn increases ion mobility, i.e., conductivity. Indeed, conductivity (σRT = 1.4 × 10−3 S/cm and t+ = 0.96) was highest with this composition.