Printability Metrics and Strain Rate Sensitivity of Multirole PVDF in Extrusion-Based Additive Manufacturing

Abstract

1. Introduction

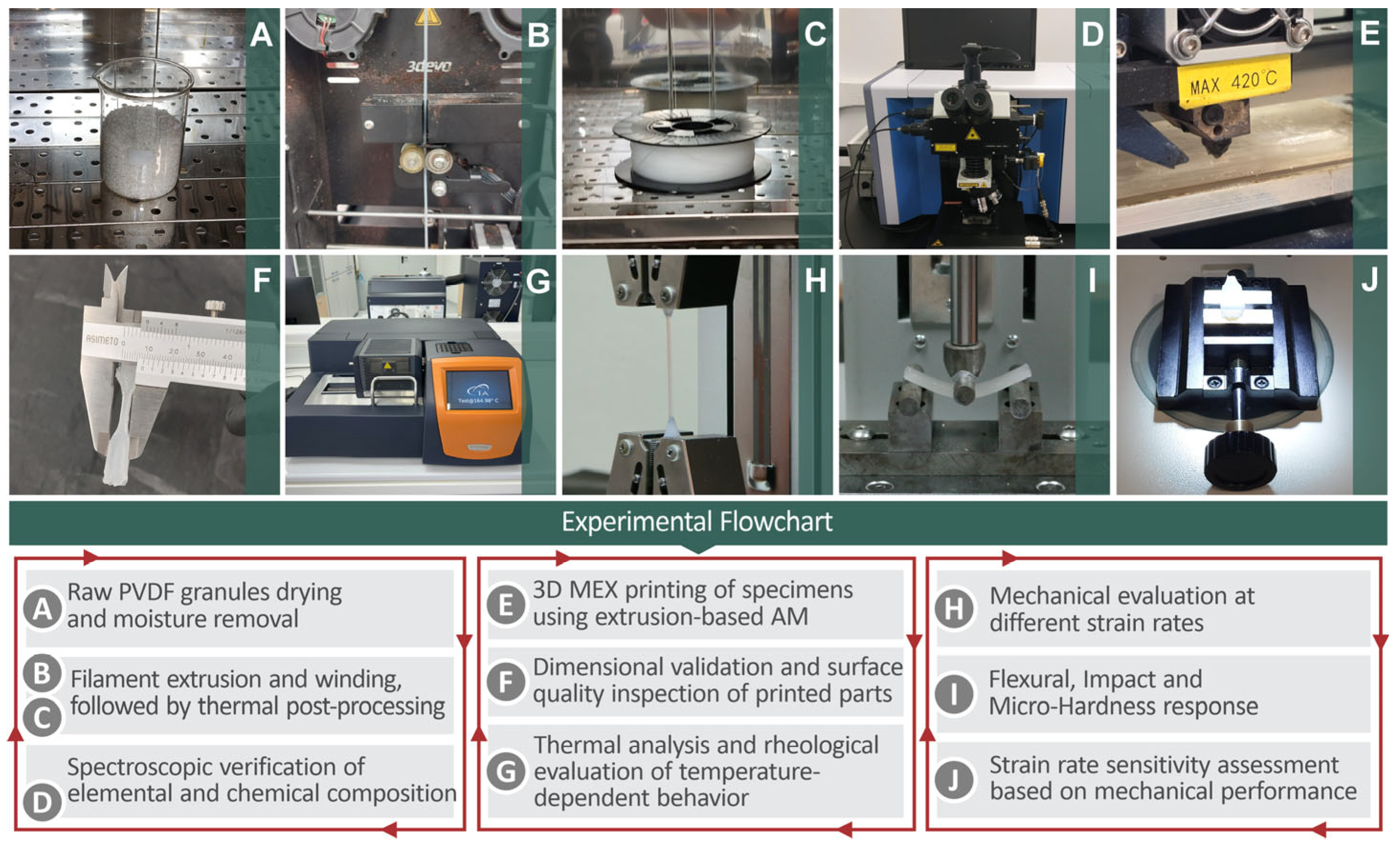

2. Materials and Methods

2.1. PVDF Material Characteristics

2.2. PVDF Filament Extrusion and Pre-Printing Preparation

2.3. PVDF Characterization: Raman, Rheology, Morphological, and Thermal

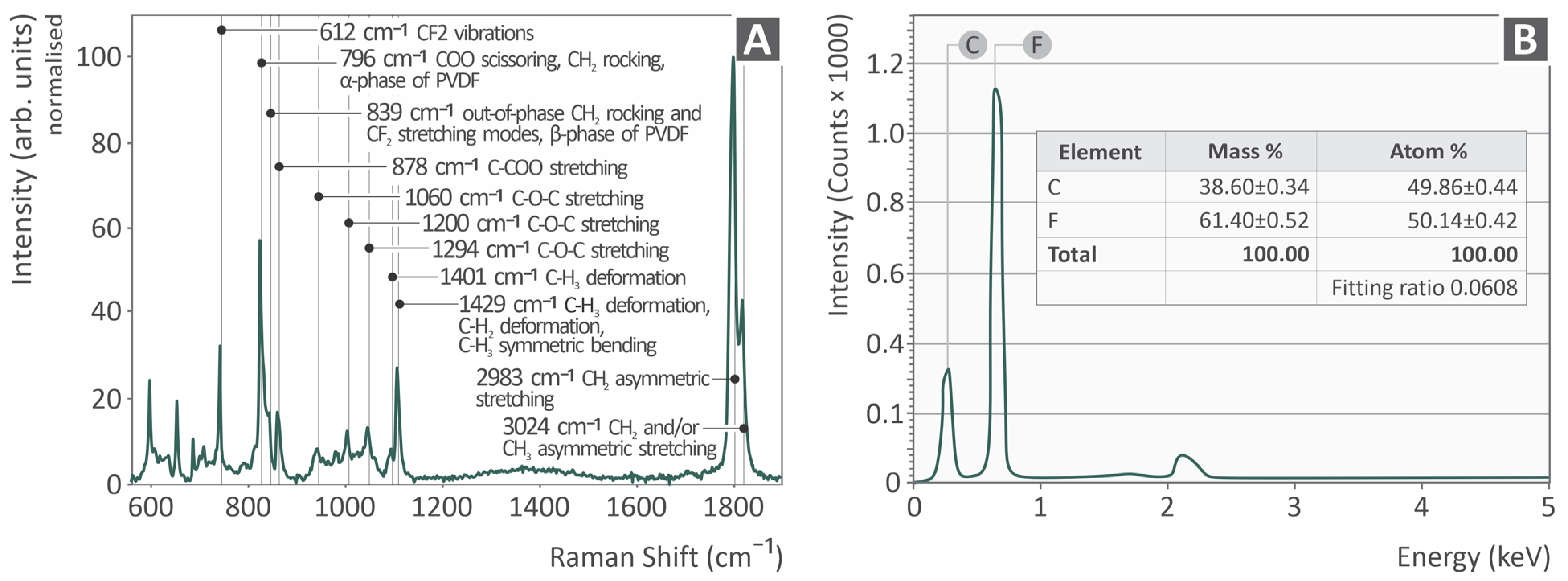

- Raman spectra were obtained using a spectrometer from HORIBA Scientific in Kyoto, Japan (LabRAM HR Raman spectrometer).

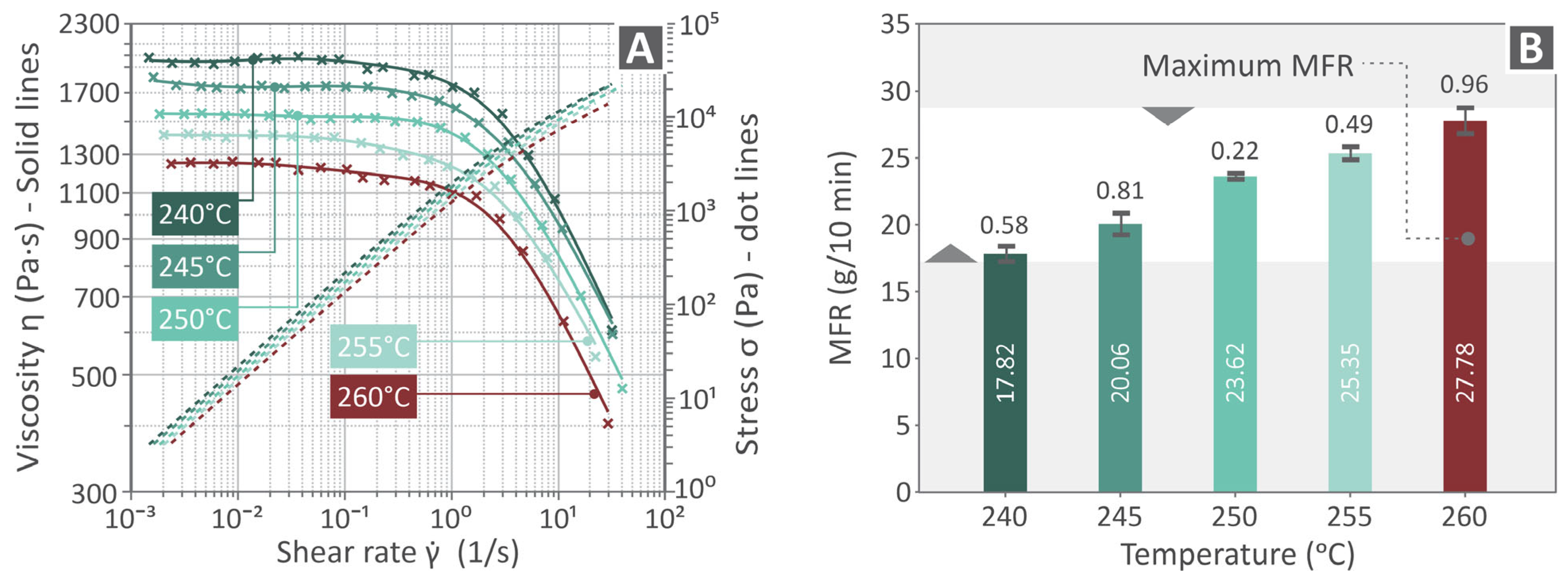

- Rheological characteristics, including viscosity and MFR, were assessed using a DHR-20 rotational rheometer (TA Instruments, New Castle, DE, USA). The MFR experimental procedure was implemented in accordance with the ASTM D1238 standard [138].

- Elemental analysis was performed using EDS (JSM-IT700HR-field-emission, Jeol Ltd., Tokyo, Japan), and SEM images were captured with a JSM 6362LV (Jeol Ltd., Peabody, MA, USA) in high-vacuum mode at 20 kV after Au sputtering of the PVDF 3D printed samples for morphological analysis.

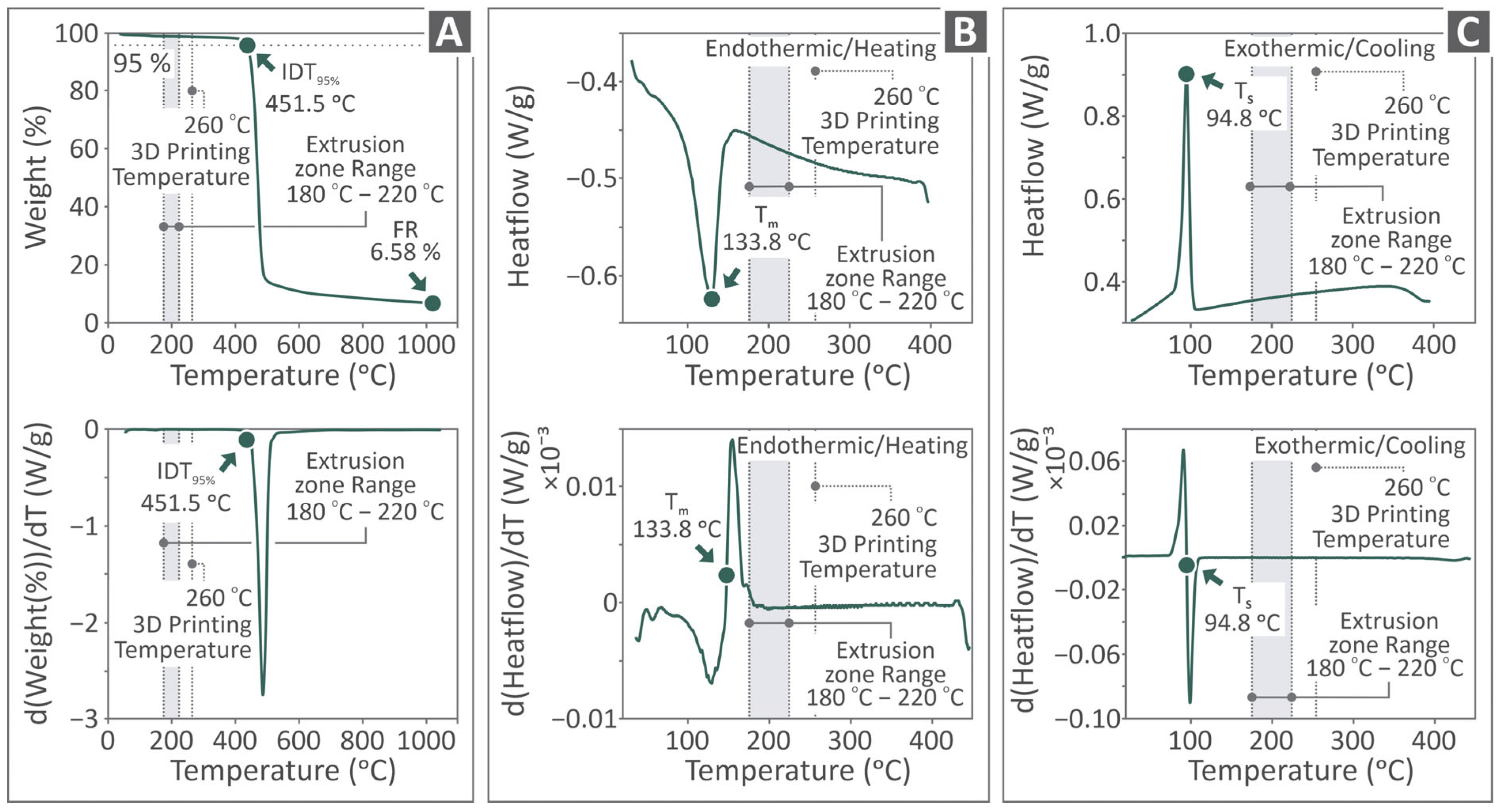

- Thermogravimetric analysis (TGA) was conducted on a thermal analyzer by the company TA Instruments, located in New Castle, DE, USA (model named SDT 650 Discovery Simultaneous Thermal Analyzer).

- DSC was performed using a model named Discovery-Series DSC 25 by the TA Instruments company, established in Delaware, USA.

2.4. 3D-Printed Specimens Manufacturing

2.5. Mechanical Properties Testing and Evaluation

3. Results

3.1. Raman and EDS Spectroscopy

3.2. Thermal Properties of the PVDF Sample

3.3. Viscosity and Stress Curves vs. Shear Rate and MFR

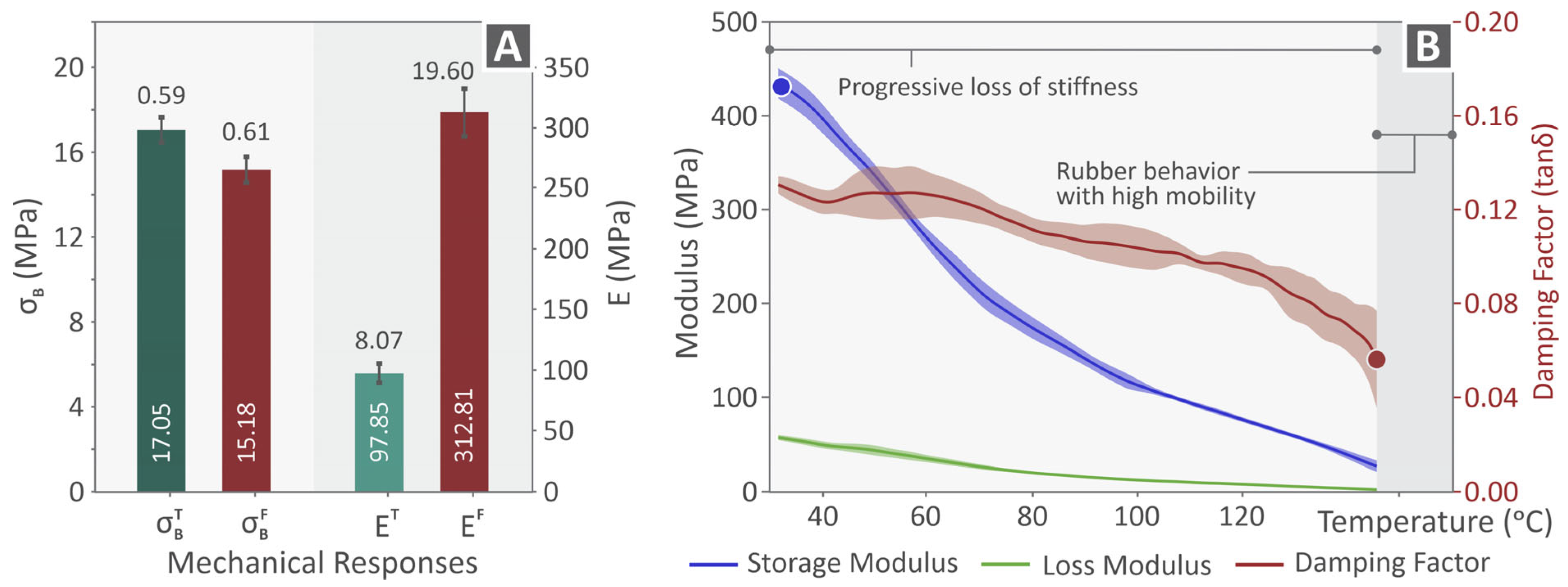

3.4. DMA Results and Mechanical Properties of the PVDF Tested Samples

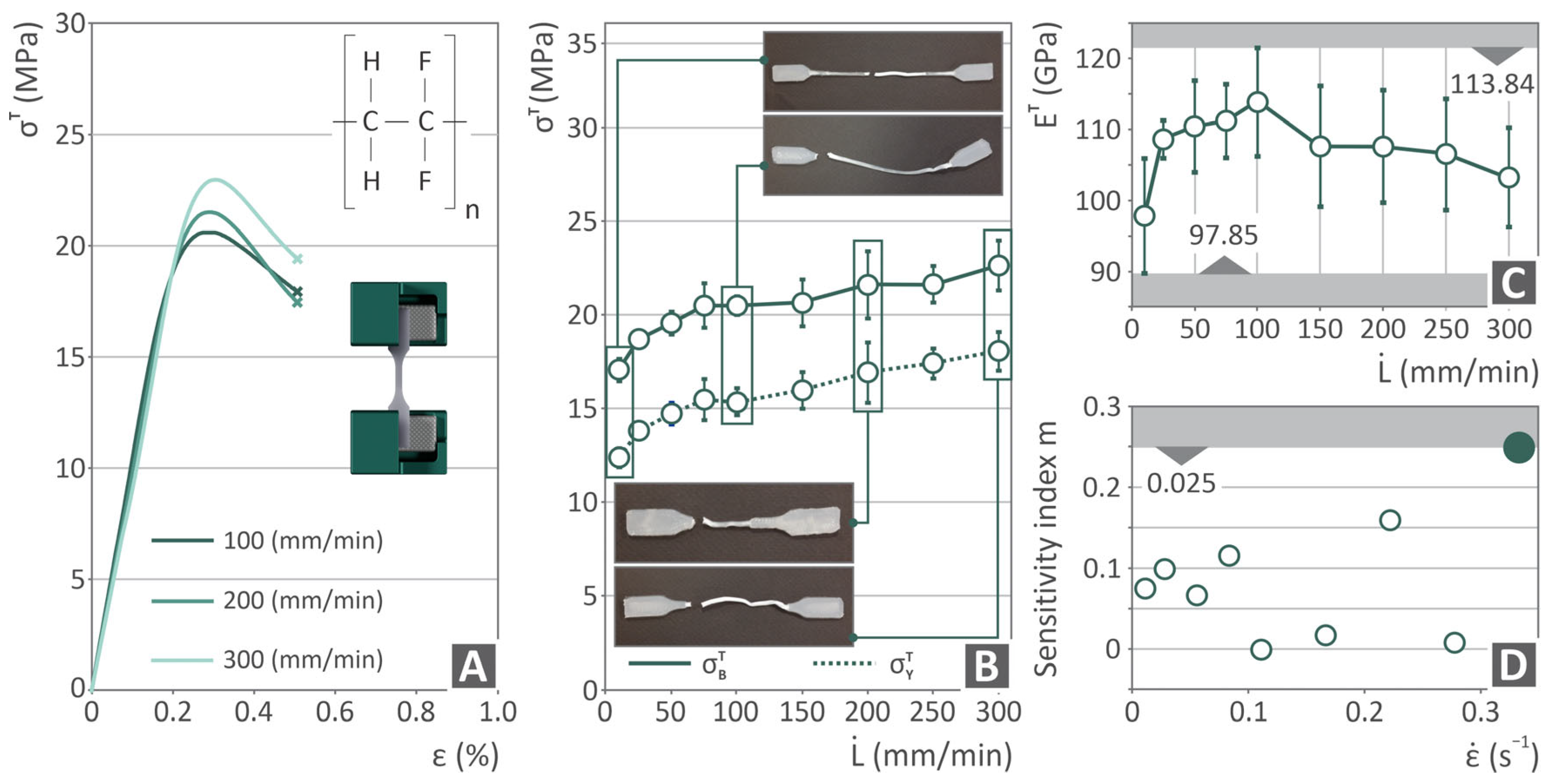

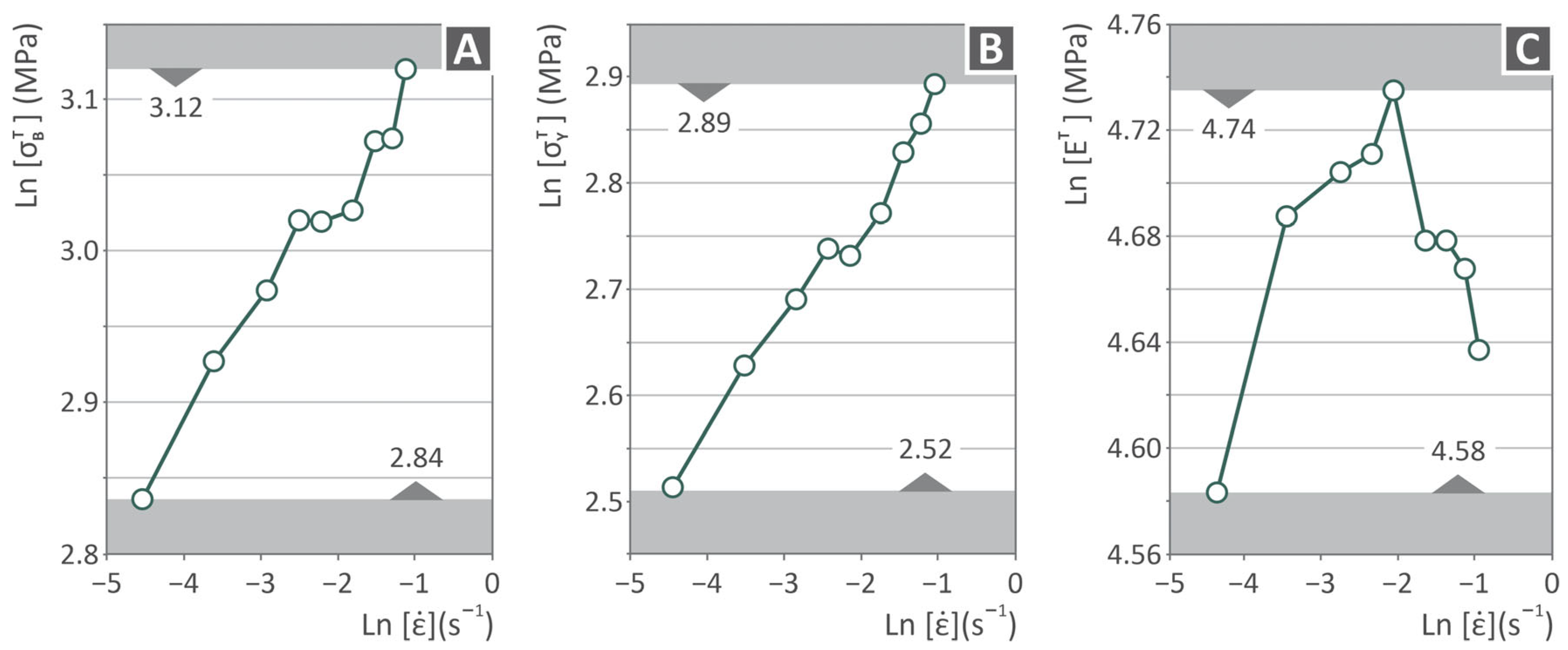

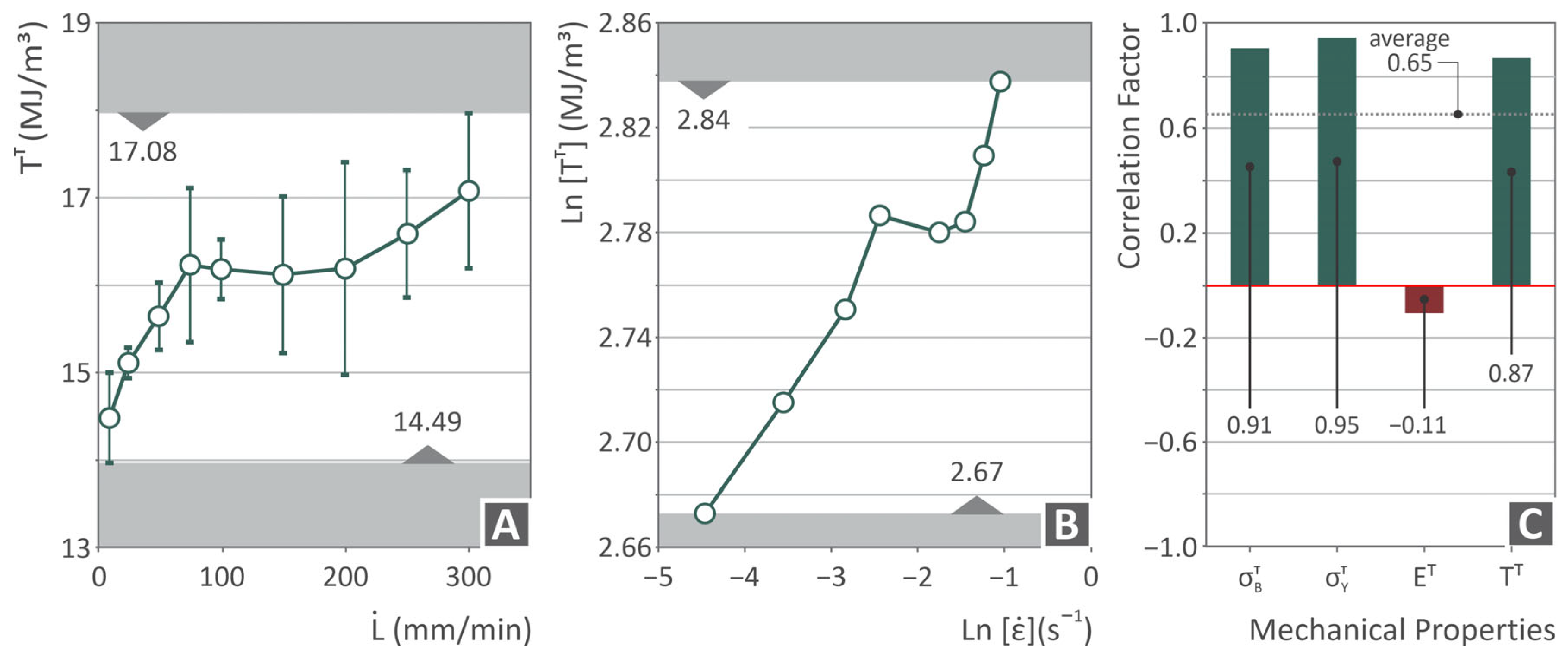

3.5. Tensile Testing Under Different Strain Rates

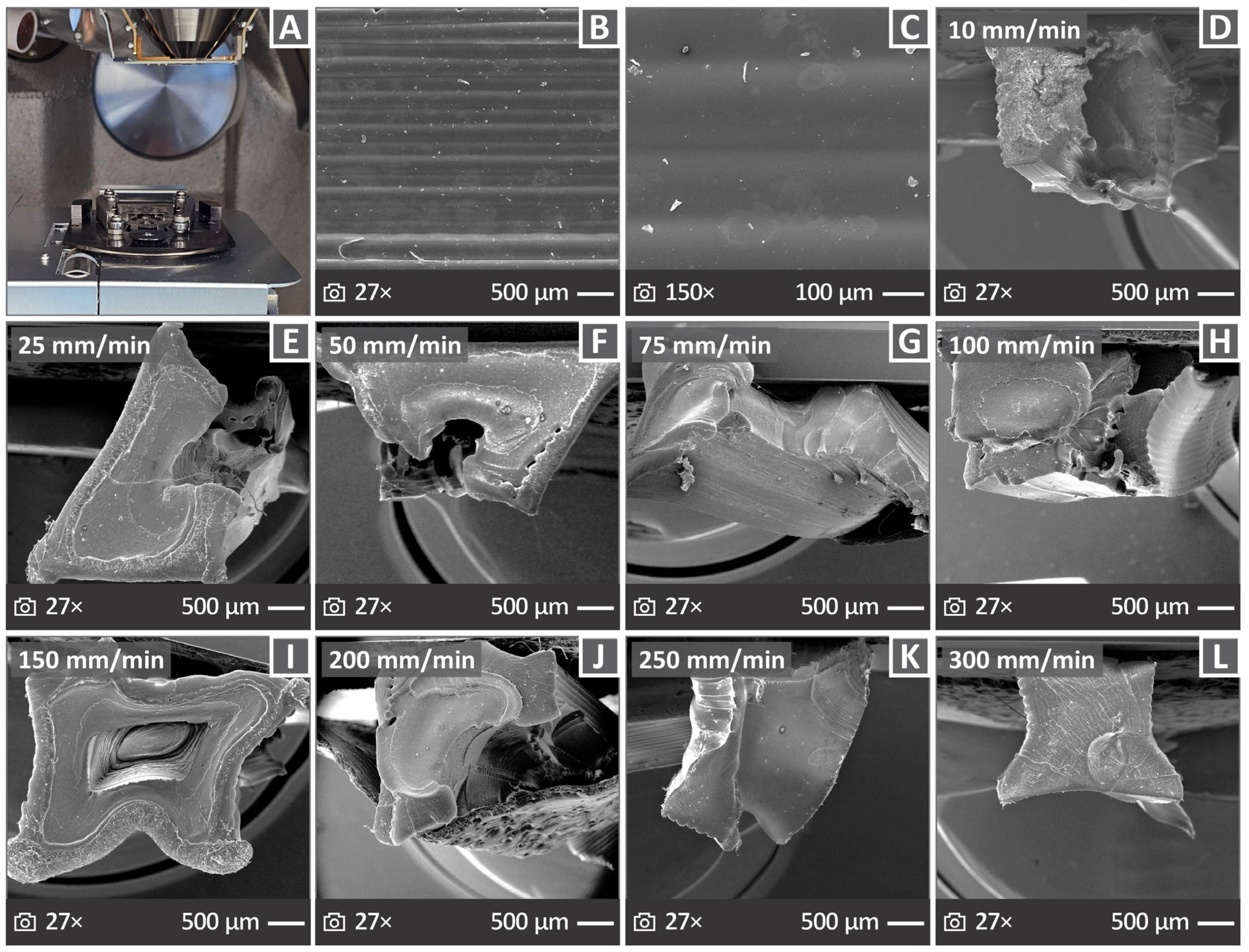

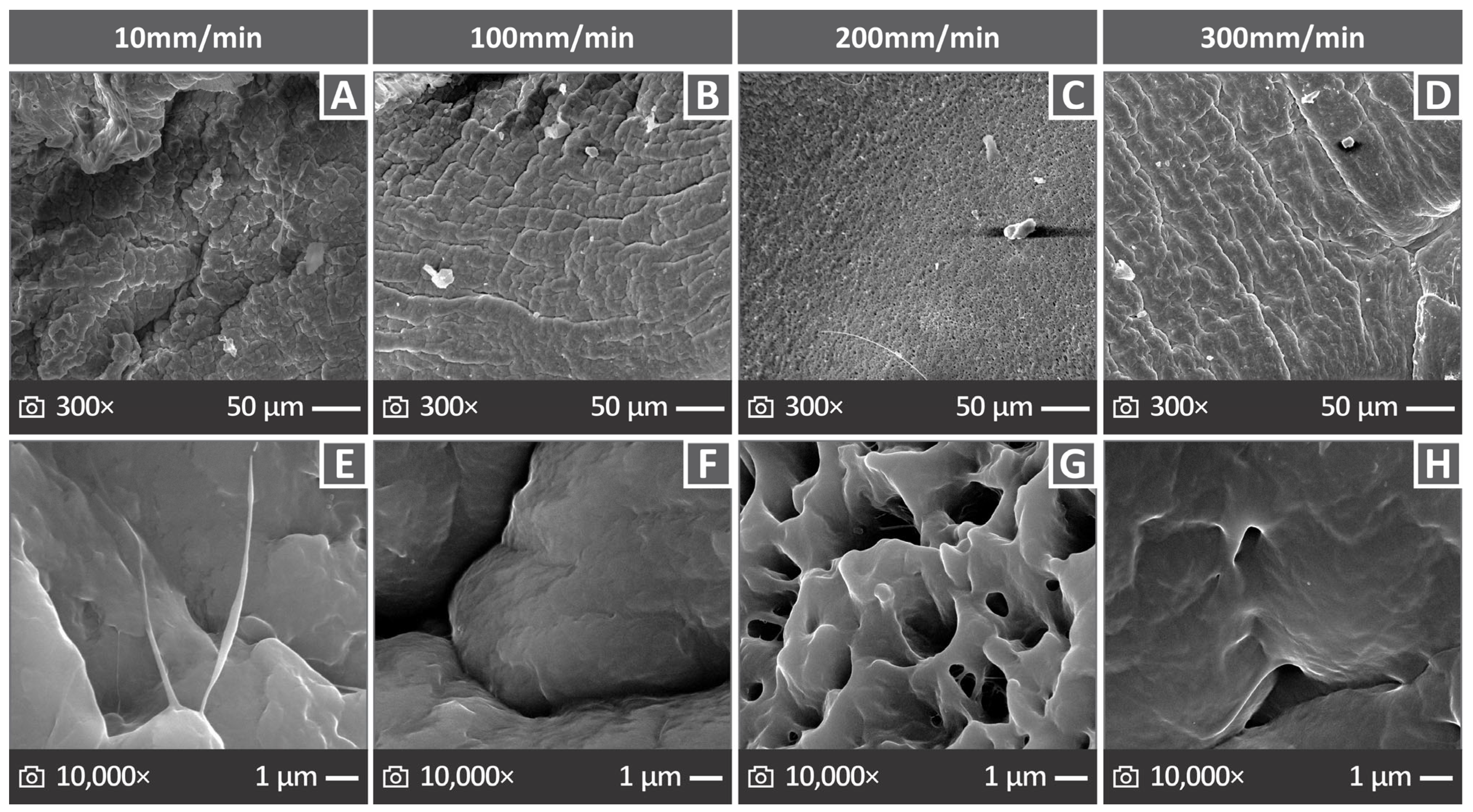

3.6. Morphology of the PVDF 3D Printed Samples Through SEM

4. Discussion

5. Conclusions

- The AM PVDF samples exhibited typical (for polymers) strain-hardening behavior at higher strain rates.

- The tensile strength and Young’s modulus increased by ~25% and 5%, respectively, at the highest elongation speed (300 mm/min).

- The ductility of the samples was not affected by the increase in the testing speed.

- The toughness was also increased with the increase in the testing speed.

- The highest Young’s modulus (stiffness) was found at an elongation speed of 100 mm/min, which was approximately 15% higher than the lowest value found at 10 mm/min.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schuhmann, D.; Rupp, M.; Merkel, M.; Harrison, D.K. Additive vs. Conventional Manufacturing of Metal Components: Selection of the Manufacturing Process Using the AHP Method. Processes 2022, 10, 1617. [Google Scholar] [CrossRef]

- Kaikai, X.; Yadong, G.; Qiang, Z. Comparison of Traditional Processing and Additive Manufacturing Technologies in Various Performance Aspects: A Review. Arch. Civ. Mech. Eng. 2023, 23, 188. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A Comparison of Traditional Manufacturing vs Additive Manufacturing, the Best Method for the Job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Goh, G.D.; Yap, Y.L.; Tan, H.K.J.; Sing, S.L.; Goh, G.L.; Yeong, W.Y. Process–Structure–Properties in Polymer Additive Manufacturing via Material Extrusion: A Review. Crit. Rev. Solid State Mater. Sci. 2020, 45, 113–133. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Material Extrusion. In Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; pp. 171–201. [Google Scholar]

- Pagac, M.; Hajnys, J.; Ma, Q.P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Medellin, A.; Du, W.; Miao, G.; Zou, J.; Pei, Z.; Ma, C. Vat Photopolymerization 3D Printing of Nanocomposites: A Literature Review. J. Micro Nanomanuf. 2019, 7, 031006. [Google Scholar] [CrossRef]

- Ladani, L.; Sadeghilaridjani, M. Review of Powder Bed Fusion Additive Manufacturing for Metals. Metals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Popov, V.V.; Grilli, M.L.; Koptyug, A.; Jaworska, L.; Katz-Demyanetz, A.; Klobčar, D.; Balos, S.; Postolnyi, B.O.; Goel, S. Powder Bed Fusion Additive Manufacturing Using Critical Raw Materials: A Review. Materials 2021, 14, 909. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Tamer, A. The State of the Art of Material Jetting—A Critical Review. Polymers 2021, 13, 2829. [Google Scholar] [CrossRef]

- Piłczyńska, K. Material Jetting. In Polymers for 3D Printing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 91–103. [Google Scholar]

- Li, M.; Du, W.; Elwany, A.; Pei, Z.; Ma, C. Metal Binder Jetting Additive Manufacturing: A Literature Review. J. Manuf. Sci. Eng. 2020, 142, 090801. [Google Scholar] [CrossRef]

- Ziaee, M.; Crane, N.B. Binder Jetting: A Review of Process, Materials, and Methods. Addit. Manuf. 2019, 28, 781–801. [Google Scholar] [CrossRef]

- Pilipović, A. Sheet Lamination. In Polymers for 3D Printing; Elsevier: Amsterdam, The Netherlands, 2022; pp. 127–136. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Sheet Lamination. In Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; pp. 253–283. [Google Scholar]

- Dass, A.; Moridi, A. State of the Art in Directed Energy Deposition: From Additive Manufacturing to Materials Design. Coatings 2019, 9, 418. [Google Scholar] [CrossRef]

- Svetlizky, D.; Das, M.; Zheng, B.; Vyatskikh, A.L.; Bose, S.; Bandyopadhyay, A.; Schoenung, J.M.; Lavernia, E.J.; Eliaz, N. Directed Energy Deposition (DED) Additive Manufacturing: Physical Characteristics, Defects, Challenges and Applications. Mater. Today 2021, 49, 271–295. [Google Scholar] [CrossRef]

- Bouzaglou, O.; Golan, O.; Lachman, N. Process Design and Parameters Interaction in Material Extrusion 3D Printing: A Review. Polymers 2023, 15, 2280. [Google Scholar] [CrossRef] [PubMed]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Aversa, A.; Marchese, G.; Lombardi, M.; Biamino, S.; Ugues, D.; Manfredi, D. Additive Manufacturing of Titanium Alloys in the Biomedical Field: Processes, Properties and Applications. J. Appl. Biomater. Funct. Mater. 2018, 16, 57–67. [Google Scholar] [CrossRef]

- Comotti, C.; Regazzoni, D.; Rizzi, C.; Vitali, A. Additive Manufacturing to Advance Functional Design: An Application in the Medical Field. J. Comput. Inf. Sci. Eng. 2017, 17, 031006. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A. Additive Manufacturing Applications in Orthopaedics: A Review. J. Clin. Orthop. Trauma 2018, 9, 202–206. [Google Scholar] [CrossRef]

- Galante, R.; Figueiredo-Pina, C.G.; Serro, A.P. Additive Manufacturing of Ceramics for Dental Applications: A Review. Dent. Mater. 2019, 35, 825–846. [Google Scholar] [CrossRef]

- Pant, M.; Pidge, P.; Nagdeve, L.; Kumar, H. A Review of Additive Manufacturing in Aerospace Application. Rev. Des Compos. Matériaux Avancés 2021, 31, 109–115. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ashraff Ali, K.S.; Ranganathan, K.; Allen Jeffrey, J.; Ravikumar, M.M.; Rajkumar, S. The Roles and Applications of Additive Manufacturing in the Aerospace and Automobile Sector. Mater Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- Colorado, H.A.; Cardenas, C.A.; Gutierrez-Velazquez, E.I.; Escobedo, J.P.; Monteiro, S.N. Additive Manufacturing in Armor and Military Applications: Research, Materials, Processing Technologies, Perspectives, and Challenges. J. Mater. Res. Technol. 2023, 27, 3900–3913. [Google Scholar] [CrossRef]

- Bird, D.T.; Ravindra, N.M. Additive Manufacturing of Sensors for Military Monitoring Applications. Polymers 2021, 13, 1455. [Google Scholar] [CrossRef] [PubMed]

- Lipton, J.I.; Cutler, M.; Nigl, F.; Cohen, D.; Lipson, H. Additive Manufacturing for the Food Industry. Trends Food Sci. Technol. 2015, 43, 114–123. [Google Scholar] [CrossRef]

- Divakaran, N.; Das, J.P.; P V, A.K.; Mohanty, S.; Ramadoss, A.; Nayak, S.K. Comprehensive Review on Various Additive Manufacturing Techniques and Its Implementation in Electronic Devices. J. Manuf. Syst. 2022, 62, 477–502. [Google Scholar] [CrossRef]

- Omiyale, B.O.; Kayode Farayibi, P. Additive Manufacturing in the Oil and Gas Industries. Analecta Tech. Szeged. 2020, 14, 9–18. [Google Scholar] [CrossRef]

- Sireesha, M.; Lee, J.; Kranthi Kiran, A.S.; Babu, V.J.; Kee, B.B.T.; Ramakrishna, S. A Review on Additive Manufacturing and Its Way into the Oil and Gas Industry. RSC Adv. 2018, 8, 22460–22468. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Yang, L.; Hsu, K.; Baughman, B.; Godfrey, D.; Medina, F.; Menon, M.; Wiener, S. Additive Manufacturing of Metals: The Technology, Materials, Design and Production; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-55127-2. [Google Scholar]

- Mansfield, B.; Torres, S.; Yu, T.; Wu, D. A Review on Additive Manufacturing of Ceramics. In Additive Manufacturing; Manufacturing Equipment and Systems; Bio and Sustainable Manufacturing, Proceedings of the International Manufacturing Science and Engineering Conference, Erie, PA, USA, 10–14 June 2019; American Society of Mechanical Engineers: New York, NY, USA, 2019; Volume 1. [Google Scholar]

- Lakhdar, Y.; Tuck, C.; Binner, J.; Terry, A.; Goodridge, R. Additive Manufacturing of Advanced Ceramic Materials. Prog. Mater. Sci. 2021, 116, 100736. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Rodríguez Hernandez, J. Antimicrobial Polymers for Additive Manufacturing. Int. J. Mol. Sci. 2019, 20, 1210. [Google Scholar] [CrossRef] [PubMed]

- Devine, D.M. (Ed.) Polymer-Based Additive Manufacturing; Springer International Publishing: Cham, Switzerland, 2019; ISBN 978-3-030-24531-3. [Google Scholar]

- Abderrafai, Y.; Diouf-Lewis, A.; Sosa-Rey, F.; Farahani, R.D.; Piccirelli, N.; Lévesque, M.; Therriault, D. Additive Manufacturing and Characterization of High Temperature Thermoplastic Blends for Potential Aerospace Applications. Compos. Sci. Technol. 2023, 231, 109839. [Google Scholar] [CrossRef]

- Das, A.; Shanmugham, N.; Bortner, M.J. Customized Blends of Polypropylene for Extrusion Based Additive Manufacturing. J. Vinyl Addit. Technol. 2023, 29, 649–661. [Google Scholar] [CrossRef]

- Hofstätter, T.; Pedersen, D.B.; Tosello, G.; Hansen, H.N. Applications of Fiber-Reinforced Polymers in Additive Manufacturing. Procedia CIRP 2017, 66, 312–316. [Google Scholar] [CrossRef]

- Michailidis, N.; Petousis, M.; Maniadi, A.; Papadakis, V.; Mountakis, N.; Argyros, A.; Nasikas, N.K.; Stratakis, E.; Vidakis, N. Printability and Thermomechanical Metrics of High-Density Polyethylene Doped with Nano Antimony TiN Oxide. Eur. J. Mater. 2025, 5, 2463330. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef]

- Chacón, J.M.; Caminero, M.A.; García-Plaza, E.; Núñez, P.J. Additive Manufacturing of PLA Structures Using Fused Deposition Modelling: Effect of Process Parameters on Mechanical Properties and Their Optimal Selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Petousis, M.; Michailidis, N.; Kulas, V.; Papadakis, V.; Spiridaki, M.; Mountakis, N.; Argyros, A.; Valsamos, J.; Nasikas, N.K.; Vidakis, N. Sustainability-Driven Additive Manufacturing: Implementation and Content Optimization of Fine Powder Recycled Glass in Polylactic Acid for Material Extrusion 3D Printing. Int. J. Lightweight Mater. Manuf. 2025, 8, 595–610. [Google Scholar] [CrossRef]

- Jin, M.; Neuber, C.; Schmidt, H.W. Tailoring Polypropylene for Extrusion-Based Additive Manufacturing. Addit. Manuf. 2020, 33, 101101. [Google Scholar] [CrossRef]

- Spoerk, M.; Holzer, C.; Gonzalez-Gutierrez, J. Material Extrusion-based Additive Manufacturing of Polypropylene: A Review on How to Improve Dimensional Inaccuracy and Warpage. J. Appl. Polym. Sci. 2020, 137, 48545. [Google Scholar] [CrossRef]

- Petousis, M.; Michailidis, N.; Papadakis, V.; Argyros, A.; Spiridaki, M.; Mountakis, N.; Valsamos, J.; Nasikas, N.K.; Moutsopoulou, A.; Vidakis, N. Enhanced Engineering and Biocidal Polypropylene Filaments Enabling Melt Reduction of AgNO3 through PVP Agent: A Scalable Process for the Defense Industry with MEX Additive Manufacturing. Def. Technol. 2024, 44, 52–66. [Google Scholar] [CrossRef]

- Dana, H.R.; Barbe, F.; Delbreilh, L.; Ben Azzouna, M.; Guillet, A.; Breteau, T. Polymer Additive Manufacturing of ABS Structure: Influence of Printing Direction on Mechanical Properties. J. Manuf. Process 2019, 44, 288–298. [Google Scholar] [CrossRef]

- Petruse, R.E.; Puşcaşu, S.; Pascu, A.; Bondrea, I. Key Factors towards a High-Quality Additive Manufacturing Process with ABS Material. Mater. Today Proc. 2019, 12, 358–366. [Google Scholar] [CrossRef]

- Vidakis, N.; Saltas, V.; David, C.; Sagris, D.; Nasikas, N.K.; Mountakis, N.; Spiridaki, M.; Petousis, M. Interpretation of MEX Additive Manufacturing Generic Control Settings Impact on the Spatial Dielectric Response of ABS: Challenges and Opportunities for the Defense Industry. Int. J. Interact. Des. Manuf. (IJIDeM) 2024, 19, 5491–5523. [Google Scholar] [CrossRef]

- Vidakis, N.; Michailidis, N.; Nasikas, N.K.; David, C.; Sagris, D.; Argyros, A.; Valsamos, I.; Gkagkanatsiou, K.; Papadakis, V.; Petousis, M. Biocidal and Reinforced PETG/Antibacterial Blend Nanocomposite for Extrusion-Based Additive Manufacturing: Optimization Course and Printability Scores. Int. J. Lightweight Mater. Manuf. 2025, 8, 726–746. [Google Scholar] [CrossRef]

- Vidakis, N.; Michailidis, N.; Kalderis, D.; Maravelakis, E.; Papadakis, V.; Argyros, A.; Mountakis, N.; Spyridaki, M.; Nasikas, N.; Petousis, M. Cyclic Economy-Driven Composites for Material Extrusion Three-Dimensional Printing: Poly(Methyl Methacrylate) from Recycled Scrap with Optimized Biomass-Derived Biochar Filler Content. ACS Omega 2025, 10, 24980–24995. [Google Scholar] [CrossRef]

- Wencke, Y.L.; Kutlu, Y.; Seefeldt, M.; Esen, C.; Ostendorf, A.; Luinstra, G.A. Additive Manufacturing of PA12 Carbon Nanotube Composites with a Novel Laser Polymer Deposition Process. J. Appl. Polym. Sci. 2021, 138, 50395. [Google Scholar] [CrossRef]

- Ferreira, I.; Madureira, R.; Villa, S.; de Jesus, A.; Machado, M.; Alves, J.L. Machinability of PA12 and Short Fibre–Reinforced PA12 Materials Produced by Fused Filament Fabrication. Int. J. Adv. Manuf. Technol. 2020, 107, 885–903. [Google Scholar] [CrossRef]

- Nasikas, N.K.; Petousis, M.; Papadakis, V.; Argyros, A.; Valsamos, J.; Gkagkanatsiou, K.; Sagris, D.; David, C.; Michailidis, N.; Maravelakis, E.; et al. A Comprehensive Optimization Course of Antimony Tin Oxide Nanofiller Loading in Polyamide 12: Printability, Quality Assessment, and Engineering Response in Additive Manufacturing. Nanomaterials 2024, 14, 1285. [Google Scholar] [CrossRef]

- Bulanda, K.; Oleksy, M.; Oliwa, R.; Budzik, G.; Przeszłowski, Ł.; Fal, J.; Jesionowski, T. Polymer Composites Based on Polycarbonate (PC) Applied to Additive Manufacturing Using Melted and Extruded Manufacturing (MEM) Technology. Polymers 2021, 13, 2455. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Michailidis, N.; David, C.; Mountakis, N.; Papadakis, V.; Sfakiotakis, E.; Sagris, D.; Argyros, A. Optimization of Cellulose Nanocrystal (CNC) Concentration in Polycaprolactone Bio-Composites for Bio-Plotting: A Robust Interpretation of the Reinforcement Mechanisms. Cellulose 2024, 31, 3657–3680. [Google Scholar] [CrossRef]

- Strong, A.B. Plastics: Materials and Processing; Prentice Hall: Englewood Cliffs, NJ, USA, 2006. [Google Scholar]

- Almonti, D.; Aversa, C.; Piselli, A. Mechanical Properties and Dynamic Response of 3D Printed Parts in PLA/P (3HB)(4HB) Blends. In Proceedings of the Italian Manufacturing Association Conference: XVI AITeM, Naples, Italy, 13–15 September 2023; Volume 35, p. 206. [Google Scholar]

- Vidakis, N.; Petousis, M.; Spyridaki, M.; Mountakis, N.; Dimitriou, E.; Michailidis, N. Ultra- and High-Performance Polymers for Material Extrusion Additive Manufacturing: Recent Advancements, Challenges, and Optimization Perspectives. Mater. Sci. Eng. R Rep. 2025, 167, 101086. [Google Scholar] [CrossRef]

- Mbogori, M.; Vaish, A.; Vaishya, R.; Haleem, A.; Javaid, M. Poly-Ether-Ether-Ketone (PEEK) in Orthopaedic Practice- A Current Concept Review. J. Orthop. Rep. 2022, 1, 3–7. [Google Scholar] [CrossRef]

- Ma, H.; Suonan, A.; Zhou, J.; Yuan, Q.; Liu, L.; Zhao, X.; Lou, X.; Yang, C.; Li, D.; Zhang, Y. PEEK (Polyether-Ether-Ketone) and Its Composite Materials in Orthopedic Implantation. Arab. J. Chem. 2021, 14, 102977. [Google Scholar] [CrossRef]

- Bathala, L.; Majeti, V.; Rachuri, N.; Singh, N.; Gedela, S. The Role of Polyether Ether Ketone (Peek) in Dentistry—A Review. J. Med. Life 2019, 12, 5–9. [Google Scholar] [CrossRef]

- El Magri, A.; Vaudreuil, S. Effects of Physical and Chemical Ageing on 3D Printed Poly (Ether Ether Ketone)/Poly (Ether Imide) [PEEK/PEI] Blend for Aerospace Applications. J. Mater. Sci. 2023, 58, 1465–1479. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Spyridaki, M.; Valsamos, I.; Kymakis, E. Strain Rate Sensitivity Metrics of PSU and PPSU High-Performance Polymers in Extrusion-Based Additive Manufacturing. Results Eng. 2025, 27, 105889. [Google Scholar] [CrossRef]

- Polyakov, I.V.; Vaganov, G.V.; Yudin, V.E.; Smirnova, N.V.; Ivan’kova, E.M.; Popova, E.N. Study of Polyetherimide and Its Nanocomposite 3D Printed Samples for Biomedical Application. Polym. Sci. Ser. A 2020, 62, 337–342. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; David, C.; Nasikas, N.K.; Sagris, D.; Mountakis, N.; Spiridaki, M.; Moutsopoulou, A.; Stratakis, E. Critical Quality Indicators of High-Performance Polyetherimide (ULTEM) over the MEX 3D Printing Key Generic Control Parameters: Prospects for Personalized Equipment in the Defense Industry. Def. Technol. 2024, 43, 150–167. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. Polyether Ether Ketone (PEEK) and Its Manufacturing of Customised 3D Printed Dentistry Parts Using Additive Manufacturing. Clin. Epidemiol. Glob. Health 2019, 7, 654–660. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Karapidakis, E. Box-Behnken Modeling to Quantify the Impact of Control Parameters on the Energy and Tensile Efficiency of PEEK in MEX 3D-Printing. Heliyon 2023, 9, e18363. [Google Scholar] [CrossRef]

- Garmabi, M.M.; Shahi, P.; Tjong, J.; Sain, M. 3D Printing of Polyphenylene Sulfide for Functional Lightweight Automotive Component Manufacturing through Enhancing Interlayer Bonding. Addit. Manuf. 2022, 56, 102780. [Google Scholar] [CrossRef]

- Yang, C.; Jiang, P.; Qin, H.; Wang, X.; Wang, Q. 3D Printing of Porous Polyimide for High-Performance Oil Impregnated Self-Lubricating. Tribol. Int. 2021, 160, 107009. [Google Scholar] [CrossRef]

- Husain, M.; Singh, R.; Pabla, B.S. On 3D Printing of PVDF Composite- Based Sensors for Biomedical Applications. Natl. Acad. Sci. Lett. 2024, 47, 147–152. [Google Scholar] [CrossRef]

- Precision Buisiness Insights. Polyvinylidene Fluoride (PVDF) Market Size, Share, Growth, Trends, and Global Industry Analysis: By Resin Type (Alpha, Beta, Delta and Gamma), By Application (Wires and Semicon Processing, Pipes and Fittings, Membranes, Li-Ion Batteries, Films and Sheets and Coatings), By End User (Aerospace and Defence, Automotive and Transportation, Building and Construction, Chemical Processing, Electrical and Electronics and Oil and Gas), and Region Forecast 2020–2031; Precision Buisiness Insights: London, UK, 2023. [Google Scholar]

- IndustryARC. Polyvinylidene Fluoride Market—Forecast (2025–2031); IndustryARC: Hyderabad, India, 2025. [Google Scholar]

- Mordor Intelligence. Polyvinylidene Fluoride (PVDF) Market Size—Industry Report on Share, Growth Trends & Forecasts Analysis Up to 2029 Source; Mordor Intelligence: Telangana, India, 2025; Available online: https://www.mordorintelligence.com/industry-reports/polyvinylidene-fluoride-pvdf-market (accessed on 10 October 2025).

- Straits Research. Available online: https://www.technavio.com/report/polyvinylidene-fluoride-pvdf-market-industry-analysis (accessed on 10 October 2025).

- Market Research Future. Global Polyvinylidene Fluoride Market Overview Source; Market Research Future: Pune, India, 2023; Available online: https://www.marketresearchfuture.com/reports/polyvinylidene-fluoride-market-4472 (accessed on 10 October 2025).

- Technavio. Polyvinylidene Fluoride (PVDF) Market Analysis APAC, North America, Europe, Middle East and Africa, South America—China, US, Germany, India, Japan—Size and Forecast 2024–2028; Technavio: Elmhurst, IL, USA, 2025. [Google Scholar]

- Zapsas, G.; Patil, Y.; Gnanou, Y.; Ameduri, B.; Hadjichristidis, N. Poly(Vinylidene Fluoride)-Based Complex Macromolecular Architectures: From Synthesis to Properties and Applications. Prog. Polym. Sci. 2020, 104, 101231. [Google Scholar] [CrossRef]

- Bicy, K.; Gueye, A.B.; Rouxel, D.; Kalarikkal, N.; Thomas, S. Lithium-Ion Battery Separators Based on Electrospun PVDF: A Review. Surf. Interfaces 2022, 31, 101977. [Google Scholar] [CrossRef]

- Pu, W.; He, X.; Wang, L.; Jiang, C.; Wan, C. Preparation of PVDF-HFP Microporous Membrane for Li-Ion Batteries by Phase Inversion. J. Memb. Sci. 2006, 272, 11–14. [Google Scholar] [CrossRef]

- Janakiraman, S.; Agrawal, A.; Biswal, R.; Venimadhav, A. An Amorphous Polyvinylidene Fluoride-Co-Hexafluoropropylene Based Gel Polymer Electrolyte for Sodium-Ion Cells. Appl. Surf. Sci. Adv. 2021, 6, 100139. [Google Scholar] [CrossRef]

- Traidia, A.; Craster, B.; Rondin, J.; Al Tamimi, A. Reduction in the Transport of Sour Gases and Hydrocarbons to Underlying PE-RT through Thin Films of PVDF. J. Memb. Sci. 2024, 694, 122416. [Google Scholar] [CrossRef]

- Yang, Y.; Shi, Z.; Holdcroft, S. Synthesis of Sulfonated Polysulfone-Block-PVDF Copolymers: Enhancement of Proton Conductivity in Low Ion Exchange Capacity Membranes. Macromolecules 2004, 37, 1678–1681. [Google Scholar] [CrossRef]

- Dallaev, R.; Pisarenko, T.; Sobola, D.; Orudzhev, F.; Ramazanov, S.; Trčka, T. Brief Review of PVDF Properties and Applications Potential. Polymers 2022, 14, 4793. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Zhang, C.; Zhang, X.; Wang, C.; Liu, F.; Yuan, R.; Wang, H. Durable Superhydrophobic PVDF/FEVE/GO@TiO2 Composite Coating with Excellent Anti-Scaling and UV Resistance Properties. Chem. Eng. J. 2021, 411, 128632. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Z.; Mai, W.; Min, C.; Zhou, B.; Shan, M.; Li, Y.; Yang, C.; Wang, Z.; Qian, X. Improved Hydrophilicity, Permeability, Antifouling and Mechanical Performance of PVDF Composite Ultrafiltration Membranes Tailored by Oxidized Low-Dimensional Carbon Nanomaterials. J. Mater. Chem. A 2013, 1, 3101–3111. [Google Scholar] [CrossRef]

- Saxena, P.; Shukla, P. A Comprehensive Review on Fundamental Properties and Applications of Poly(Vinylidene Fluoride) (PVDF). Adv. Compos. Hybrid Mater 2021, 4, 8–26. [Google Scholar] [CrossRef]

- Mokhtari, F.; Azimi, B.; Salehi, M.; Hashemikia, S.; Danti, S. Recent Advances of Polymer-Based Piezoelectric Composites for Biomedical Applications. J. Mech. Behav. Biomed. Mater. 2021, 122, 104669. [Google Scholar] [CrossRef]

- Marshall, J.E.; Zhenova, A.; Roberts, S.; Petchey, T.; Zhu, P.; Dancer, C.E.J.; McElroy, C.R.; Kendrick, E.; Goodship, V. On the Solubility and Stability of Polyvinylidene Fluoride. Polymers 2021, 13, 1354. [Google Scholar] [CrossRef]

- Zhong, X.; Han, J.; Chen, L.; Liu, W.; Jiao, F.; Zhu, H.; Qin, W. Binding Mechanisms of PVDF in Lithium Ion Batteries. Appl. Surf. Sci. 2021, 553, 149564. [Google Scholar] [CrossRef]

- Bae, J.H.; Chang, S.H. PVDF-Based Ferroelectric Polymers and Dielectric Elastomers for Sensor and Actuator Applications: A Review. Funct. Compos. Struct. 2019, 1, 012003. [Google Scholar] [CrossRef]

- Andrey, V.; Koshevaya, E.; Mstislav, M.; Parfait, K. Piezoelectric PVDF and Its Copolymers in Biomedicine: Innovations and Applications. Biomater. Sci. 2024, 12, 5164–5185. [Google Scholar] [CrossRef]

- Pullano, S.A.; Critello, C.D.; Bianco, M.G.; Menniti, M.; Fiorillo, A.S. PVDF Ultrasonic Sensors for In-Air Applications: A Review. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2021, 68, 2324–2335. [Google Scholar] [CrossRef] [PubMed]

- Hoe, Z.Y.; Chang, C.C.; Chen, J.J.J.; Yen, C.K.; Wang, S.Y.; Kao, Y.H.; Li, W.M.; Chen, W.F.; Pan, C.T. Enhancement of PVDF Sensing Characteristics by Retooling the Near-Field Direct-Write Electrospinning System. Sensors 2020, 20, 4873. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Tarbutton, J.A. Polyvinylidene Fluoride (PVDF) Direct Printing for Sensors and Actuators. Int. J. Adv. Manuf. Technol. 2019, 104, 3155–3162. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Nadeem, G.; Rafin, T.; Kirubaanand, W. Recent Applications of Carbon-Based Composites in Defence Industry: A Review. Def. Technol. 2022, 18, 1281–1300. [Google Scholar] [CrossRef]

- Nivedhitha, D.M.; Jeyanthi, S.; Venkatraman, P.; Viswapriyan, A.S.; Guru Nishaanth, S.; Manoranjith, S. Polyvinylidene Fluoride as an Advanced Polymer for Multifunctional Applications—A Review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Bhadrapriya, B.C.; Basith, S.A.; Rahul, M.T.; Chandrasekhar, A.; Rouxel, D.; Kalarikkal, N. Unleashing the Potential: Multifunctionality of PVDF-HFP Based Ternary Nanocomposite Films—Magnetoelectric, Energy Harvesting and Impact Sensing Performance. Mater. Chem. Phys. 2024, 315, 129057. [Google Scholar] [CrossRef]

- Alzahrani, M.M.; Alamry, K.A.; Hussein, M.A. Recent Advances of Fiber-Reinforced Polymer Composites for Defense Innovations. Results Chem. 2025, 15, 102199. [Google Scholar] [CrossRef]

- Nasikas, K.N.; Mouzakis, E.D. Advanced Polymers for Defence Applications. In Specialty Polymers; Gupta, R., Ed.; CRC Press: Boca Raton, FL, USA, 2023; pp. 129–141. [Google Scholar]

- Chen, Q.; Fu, X.; Yang, W.; Chen, S.; Guo, Z.; Hu, R.; Zhang, H.; Cui, L.; Xia, X. 3D Printed Hybrid Rocket Fuels with ΜAl Core-Shell Particles Coated with Polyvinylidene Fluoride and Polydopamine: Enhanced Combustion Characteristics. Def. Technol. 2025, 46, 59–70. [Google Scholar] [CrossRef]

- Wen, Y.K.; Xu, L.; Chen, A.J.; Dong, F.D.; Qin, B. Dynamic Compressive Response of Porcine Muscle Measured Using a Split Hopkinson Bar System with a Pair of PVDF Force Transducers. Def. Technol. 2023, 28, 298–305. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, H.; Li, M.; Wang, X.; Das, O.; Han, Z.X.; Jiang, L. Al-Mg@PVDF and Al-Si@PVDF Composites with Enhanced Combustion and Energy Release Characteristics. Def. Technol. 2025, 48, 1–25. [Google Scholar] [CrossRef]

- Liu, R.; Yang, D.; Xiong, K.; Wang, Y.L.; Yan, Q.L. Fabrication and Characterization of Multi-Scale Coated Boron Powders with Improved Combustion Performance: A Brief Review. Def. Technol. 2024, 31, 27–40. [Google Scholar] [CrossRef]

- Liu, T.; Wang, J.; Chen, J.; Nie, C.; Mao, Y.; Nie, F.; Zhong, R.; Cao, W.; Wang, J. The Combustion Reactivity of Core-Shell Al/Fluoropolymers and Application in RDX-Based Explosives. Def. Technol. 2025, 51, 30–39. [Google Scholar] [CrossRef]

- Yang, S.L.; Meng, K.J.; Xie, W.X.; Nie, H.Q.; Yan, Q.L. Tuning the Reactivity of Al–Ni by Fine Coating of Halogen-Containing Energetic Composites. Def. Technol. 2022, 18, 1810–1821. [Google Scholar] [CrossRef]

- Du, G.; Li, Z.; Song, G. A PVDF-Based Sensor for Internal Stress Monitoring of a Concrete-Filled Steel Tubular (CFST) Column Subject to Impact Loads. Sensors 2018, 18, 1682. [Google Scholar] [CrossRef] [PubMed]

- Kawai, H. The Piezoelectricity of Poly (Vinylidene Fluoride). Jpn. J. Appl. Phys. 1969, 8, 975. [Google Scholar] [CrossRef]

- Harris, G.R.; Preston, R.C.; DeReggi, A.S. The Impact of Piezoelectric PVDF on Medical Ultrasound Exposure Measurements, Standards, and Regulations. IEEE Trans Ultrason. Ferroelectr. Freq. Control 2000, 47, 1321–1335. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, H.; Song, X.; Hou, T.; Lin, T. Design and Analysis of a PVDF-TrFE/TiO2 Based Sensor for Monitoring Respiratory, Heart Rate, and Snoring Signals during Sleep. Sens. Actuators A Phys. 2025, 393, 116735. [Google Scholar] [CrossRef]

- Upadhye, P.A.; Chowdhury, S.R.; Kumar, V.; Ranjan, R.; Kumar, S.; Mondal, S.; Oh, J.; Misra, M. Hollow ZnO Nanorod in PVDF Matrix for High-Performance Sensing, Vibration Energy Harvesting and Wearable Application. Sci. Rep. 2025, 15, 19885. [Google Scholar] [CrossRef]

- Hou, D.; Kong, X.; Feng, K.; Zhou, K.; Pei, Y.; Shentu, Y.; Xiang, F. Preparation and Properties of Metal-Core Piezoelectric Fibers for Dynamic Sensing Using the Double Heat-Shrinkage Method. Sci. Rep. 2025, 15, 20481. [Google Scholar] [CrossRef]

- Lin, X.W.; Gajula, P.; Luo, X.S.; Zhao, M.; Zhao, X.B.; Fan, Y. Piezoelectric Properties Improvement in Soft Membrane with Wet-Spinning Prepared Barium Titanate/Polyvinylidenefluoride Composites Fiber. Sci. Rep. 2025, 15, 12887. [Google Scholar] [CrossRef]

- Aliyev, A.R.; Hasanova, U.A.; Israyilova, A.A.; Gakhramanova, Z.O.; Ahmadova, A.B. Nanostructured Bentonite-Based Coatings for PVDF Meshes: Antimicrobial Properties and Controlled Drug Release. Bionanoscience 2025, 15, 426. [Google Scholar] [CrossRef]

- Pourmadadi, M.; Ahmari, A.; Mirshafiei, M.; Omrani, Z.; Yazdian, F.; Rahdar, A.; Fathi-karkan, S.; Aboudzadeh, M.A. Polyvinylidene Fluoride in Biomedical Applications: Properties, Challenges, and Future Prospects. Eur. Polym. J. 2025, 231, 113889. [Google Scholar] [CrossRef]

- Farouk, A. Towards Sustainable Food Packaging Films Using Cellulose Acetate and Polyvinylidene Fluoride Matrix Enriched with Mango Peel Extract. Biomass Convers. Biorefin. 2024, 14, 8957–8978. [Google Scholar] [CrossRef]

- Hazarika, D.; Lu, J.; Wu, J.; Shah, M.N.; Li, J.; Zhang, K.; Xu, L.; Chen, C.; Cao, Z.; Jin, H.; et al. Ion Dipole Interaction and Directional Alignment Enabled High Piezoelectric Property Polyvinylidene Fluoride for Flexible Electronics. npj Flex. Electron. 2025, 9, 20. [Google Scholar] [CrossRef]

- Dong, W.; Li, M.; Chen, C.; Xie, K.; Hong, J.; Yang, L. Flexible Hybrid Self-Powered Piezo-Triboelectric Nanogenerator Based on BTO-PVDF/PDMS Nanocomposites for Human Machine Interaction. Sci. Rep. 2025, 15, 15991. [Google Scholar] [CrossRef] [PubMed]

- Lim, W.; Joshi, B.; Samuel, E.; Huh, J.; Aldalbahi, A.; Periyasami, G.; Lee, H.S.; Ding, B.; Yoon, S.S. Shear Stress-Induced Augmentation of Electroactive Phases of PVDF for High-Power Nanogenerator Using Supersonically Sprayed Sr2SnO4 Nanorods. J. Mater. Sci. Technol. 2025, 240, 299–312. [Google Scholar] [CrossRef]

- Der Kiureghian, A. Reliability Analysis under Stochastic Loads. J. Struct. Div. 1980, 106, 411–429. [Google Scholar] [CrossRef]

- Arslan Bin Riaz, M.; Güden, M. A Review of the Experimental and Numerical Studies on the Compression Behavior of the Additively Produced Metallic Lattice Structures at High and Low Strain Rates. Def. Technol. 2025, 49, 1–49. [Google Scholar] [CrossRef]

- Wei, Y.; Tian, M.; Huang, C.; Wang, S.; Li, X.; Hu, Q.; Yuan, M. Topological Study about Failure Behavior and Energy Absorption of Honeycomb Structures under Various Strain Rates. Def. Technol. 2023, 24, 214–227. [Google Scholar] [CrossRef]

- Ryan, S.; Berk, J.; Rana, S.; McDonald, B.; Venkatesh, S. A Bayesian Optimisation Methodology for the Inverse Derivation of Viscoplasticity Model Constants in High Strain-Rate Simulations. Def. Technol. 2022, 18, 1563–1577. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, R.; Liu, S.; Peng, J.; Liu, Y.; Chen, H.; Zhang, J.; Luo, G.; Shen, Q. Graded Density Impactor Design via Machine Learning and Numerical Simulation: Achieve Controllable Stress and Strain Rate. Def. Technol. 2025, 51, 262–273. [Google Scholar] [CrossRef]

- Zhang, H.; Chang, H.; Li, X.; Wu, X.; He, Q. The Effect of Strain Rate on Compressive Behavior and Failure Mechanism of CMDB Propellant. Def. Technol. 2022, 18, 467–475. [Google Scholar] [CrossRef]

- Shen, L.; Su, S.; Zhang, W.; Shi, S.; Jian, X.; Zhu, T.; Xu, J. Dynamic Hysteresis Brittle Behavior and Temperature–Strain Rate-Coupled Damage Modeling: A Multiscale Study of Poly(Phthalazinone Ether Sulfone Ketone) under Extreme Service Conditions. Def. Technol. 2025, 52, 259–273. [Google Scholar] [CrossRef]

- Lenders, T.; Remmers, J.J.C.; Pini, T.; Veenstra, P.; Govaert, L.E.; Geers, M.G.D. An Elasto-Viscoplastic Constitutive Model for the Rate-Dependent Behavior of Polyvinylidene Fluoride. J. Polym. Sci. 2023, 61, 1439–1456. [Google Scholar] [CrossRef]

- Han, P.; Tofangchi, A.; Carr, D.; Zhang, S.; Hsu, K. Enhancing the Piezoelectric Properties of 3D Printed PVDF Using Concurrent Torsional Shear Strain. Polymers 2023, 15, 4204. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Ntintakis, I.; David, C.; Sagris, D.; Mountakis, N.; Moutsopoulou, A. Quantitative Insight into the Compressive Strain Rate Sensitivity of Polylactic Acid, Acrylonitrile Butadiene Styrene, Polyamide 12, and Polypropylene in Material Extrusion Additive Manufacturing. J. Dyn. Behav. Mater. 2024, 10, 251–269. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Liebscher, M.; Mechtcherine, V.; Tzounis, L. On the Strain Rate Sensitivity of Fused Filament Fabrication (Fff) Processed Pla, Abs, Petg, Pa6, and Pp Thermoplastic Polymers. Polymers 2020, 12, 2924. [Google Scholar] [CrossRef]

- Vairis, A.; Petousis, M.; Vidakis, N.; Savvakis, K. On the Strain Rate Sensitivity of Abs and Abs Plus Fused Deposition Modeling Parts. J. Mater. Eng. Perform. 2016, 25, 3558–3565. [Google Scholar] [CrossRef]

- Petousis, M.; Ntintakis, I.; David, C.; Sagris, D.; Nasikas, N.K.; Korlos, A.; Moutsopoulou, A.; Vidakis, N. A Coherent Assessment of the Compressive Strain Rate Response of PC, PETG, PMMA, and TPU Thermoplastics in MEX Additive Manufacturing. Polymers 2023, 15, 3926. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Velidakis, E.; Mountakis, N.; Charou, C.; Myftari, A. Strain Rate Sensitivity of Polycarbonate and Thermoplastic Polyurethane for Various 3D Printing Temperatures and Layer Heights. Polymers 2021, 13, 2752. [Google Scholar] [CrossRef]

- ASTM D638-02a; Standard Test Method for Tensile Properties of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- ASTM D1238-13; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Gao, G.; Xu, F.; Xu, J.; Tang, G.; Liu, Z. A Survey of the Influence of Process Parameters on Mechanical Properties of Fused Deposition Modeling Parts. Micromachines 2022, 13, 553. [Google Scholar] [CrossRef]

- Li, H.; Wang, T.; Sun, J.; Yu, Z. The Effect of Process Parameters in Fused Deposition Modelling on Bonding Degree and Mechanical Properties. Rapid Prototyp. J. 2018, 24, 80–92. [Google Scholar] [CrossRef]

- Ahn, S.; Montero, M.; Odell, D.; Roundy, S.; Wright, P.K. Anisotropic Material Properties of Fused Deposition Modeling ABS. Rapid Prototyp. J. 2002, 8, 248–257. [Google Scholar] [CrossRef]

- Sol, J.A.H.P.; Sentjens, H.; Yang, L.; Grossiord, N.; Schenning, A.P.H.J.; Debije, M.G. Anisotropic Iridescence and Polarization Patterns in a Direct Ink Written Chiral Photonic Polymer. Adv. Mater. 2021, 33, 2103309. [Google Scholar] [CrossRef]

- Mirsayar, M.; Ghorbani, M.; Jha, R. Experimental and Theoretical Fracture Analysis of Anisotropic Elastomers via Direct Ink Writing. Fatigue Fract. Eng. Mater. Struct. 2025, 48, 3678–3688. [Google Scholar] [CrossRef]

- Friedrich, L.; Begley, M. Printing Direction Dependent Microstructures in Direct Ink Writing. Addit. Manuf. 2020, 34, 101192. [Google Scholar] [CrossRef]

- Zhang, Y.; Huang, Z.; Wang, H.; Li, J. Regulation of the Interface Compatibility of the 3D-Printing Interpenetration Networks Toward Reduced Structure Anisotropy and Enhanced Performances. ACS Appl. Mater. Interfaces 2023, 15, 32984–32992. [Google Scholar] [CrossRef]

- Zohdi, N.; Yang, R. (Chunhui) Material Anisotropy in Additively Manufactured Polymers and Polymer Composites: A Review. Polymers 2021, 13, 3368. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Liu, X.; Tian, Y.; Zhu, W.; Yan, C.; Shi, Y.; Kong, L.B.; Qi, H.J.; Zhou, K. 3D-Printed Anisotropic Polymer Materials for Functional Applications. Adv. Mater. 2022, 34, 2102877. [Google Scholar] [CrossRef] [PubMed]

- Grant, A.; Regez, B.; Kocak, S.; Huber, J.D.; Mooers, A. Anisotropic Properties of 3-D Printed Poly Lactic Acid (PLA) and Acrylonitrile Butadiene Styrene (ABS) Plastics. Results Mater. 2021, 12, 100227. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical Properties of Components Fabricated with Open-Source 3-D Printers under Realistic Environmental Conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- ASTM D6110-04; Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. American Society for Testing and Materials: West Conshohocken, PA, USA, 2004.

- ASTM D790-14; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- ASTM E384-11; Standard Test Method for Knoop and Vickers Hardness of Materials1. American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- Elashmawi, I.; Gaabour, L.H. Raman, Morphology and Electrical Behavior of Nanocomposites Based on PEO/PVDF with Multi-Walled Carbon Nanotubes. Results Phys. 2015, 5, 105–110. [Google Scholar] [CrossRef]

- Bichara, L.C.; Alvarez, P.E.; Fiori Bimbi, M.V.; Vaca, H.; Gervasi, C.; Brandán, S.A. Structural and Spectroscopic Study of a Pectin Isolated from Citrus Peel by Using FTIR and FT-Raman Spectra and DFT Calculations. Infrared Phys. Technol. 2016, 76, 315–327. [Google Scholar] [CrossRef]

- Lin, Z.; Guo, X.; He, Z.; Liang, X.; Wang, M.; Jin, G. Thermal Degradation Kinetics Study of Molten Polylactide Based on Raman Spectroscopy. Polym. Eng. Sci. 2021, 61, 201–210. [Google Scholar] [CrossRef]

- Resta, V.; Quarta, G.; Lomascolo, M.; Maruccio, L.; Calcagnile, L. Raman and Photoluminescence Spectroscopy of Polycarbonate Matrices Irradiated with Different Energy 28Si+ Ions. Vacuum 2015, 116, 82–89. [Google Scholar] [CrossRef]

- Stuart, B.H. Temperature Studies of Polycarbonate Using Fourier Transform Raman Spectroscopy. Polym. Bull. 1996, 36, 341–346. [Google Scholar] [CrossRef]

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive Characterization of the Polycarbonate—Octadecylamine Interface by Surface Enhanced Raman Spectroscopy. Polym. Test 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing Cellulose Structures with Vibrational Spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Haponska, M.; Trojanowska, A.; Nogalska, A.; Jastrzab, R.; Gumi, T.; Tylkowski, B. PVDF Membrane Morphology—Influence of Polymer Molecular Weight and Preparation Temperature. Polymers 2017, 9, 718. [Google Scholar] [CrossRef]

- Liu, F.; Hashim, N.A.; Liu, Y.; Abed, M.R.M.; Li, K. Progress in the Production and Modification of PVDF Membranes. J. Memb. Sci. 2011, 375, 1–27. [Google Scholar] [CrossRef]

- Tang, Z.; Fujimoto, K.; Okazaki, S. A Comparison of the Brittle PMMA with the Ductile PC on the Elasticity and Yielding from a Molecular Dynamics Perspective. Polymer 2021, 226, 123809. [Google Scholar] [CrossRef]

- Elkomy, G.M.; Abd-El Salam, M.H.; Osmanc, H.; Nagyb, M.R.; El-Sayedb, F. Temperature-Dependent Mechanical Properties of PVDF/Graphite Composites. Egypt J. Solids 2011, 34, 109. [Google Scholar]

- Uličná, S.; Owen-Bellini, M.; Moffitt, S.L.; Sinha, A.; Tracy, J.; Roy-Choudhury, K.; Miller, D.C.; Hacke, P.; Schelhas, L.T. A Study of Degradation Mechanisms in PVDF-Based Photovoltaic Backsheets. Sci. Rep. 2022, 12, 14399. [Google Scholar] [CrossRef] [PubMed]

- Arruda, E.M.; Boyce, M.C. A Three-Dimensional Constitutive Model for the Large Stretch Behavior of Rubber Elastic Materials. J. Mech. Phys. Solids 1993, 41, 389–412. [Google Scholar] [CrossRef]

- Becker, C.; Oberlercher, H.; Heim, R.B.; Wuzella, G.; Faller, L.M.; Riemelmoser, F.O.; Nicolay, P.; Druesne, F. Experimental Quantification of the Variability of Mechanical Properties in 3D Printed Continuous Fiber Composites. Appl. Sci. 2021, 11, 11315. [Google Scholar] [CrossRef]

- Espino, M.T.; Tuazon, B.J.; Espera, A.H.; Nocheseda, C.J.C.; Manalang, R.S.; Dizon, J.R.C.; Advincula, R.C. Statistical Methods for Design and Testing of 3D-Printed Polymers. MRS Commun. 2023, 13, 193–211. [Google Scholar] [CrossRef]

- Liu, E.; Wu, J.; Li, H.; Liu, H.; Zhao, G.; Kong, L.; Lin, J.; Xiao, G.; Jia, Y. Rate Sensitivity and Deformation Mechanism of Semi-Crystalline Polymers during Instrumented Indentation. J. Polym. Sci. 2021, 59, 451–461. [Google Scholar] [CrossRef]

- Chu, Z.; Liu, L.; Lou, Y.; Zhao, R.; Ma, Z.; Li, Y. Flow-Induced Crystallization of Crosslinked Poly(Vinylidene Fluoride) at Elevated Temperatures: Formation and Evolution of the Electroactive β-Phase. Ind. Eng. Chem. Res. 2020, 59, 4459–4471. [Google Scholar] [CrossRef]

- Chu, Z.; Liu, L.; Liao, Y.; Li, W.; Zhao, R.; Ma, Z.; Li, Y. Effects of Strain Rate and Temperature on Polymorphism in Flow-Induced Crystallization of Poly(Vinylidene Fluoride). Polymer 2020, 203, 122773. [Google Scholar] [CrossRef]

- Wan, C.; Heeley, E.L.; Zhou, Y.; Wang, S.; Cafolla, C.T.; Crabb, E.M.; Hughes, D.J. Stress-Oscillation Behaviour of Semi-Crystalline Polymers: The Case of Poly(Butylene Succinate). Soft Matter. 2018, 14, 9175–9184. [Google Scholar] [CrossRef]

- Ward, I.M.; Sweeney, J. Mechanical Properties of Solid Polymers; Wiley Online Library: Hoboken, NJ, USA, 1971; Volume 313. [Google Scholar]

- Vidakis, N.; Michailidis, N.; Papadakis, V.; Argyros, A.; Spiridaki, M.; Mountakis, N.; Nasikas, N.K.; Petousis, M.; Kymakis, E. Industrially Scalable Reactive Melt Mixing of Polypropylene/Silver Nitrate/Polyethylene Glycol Nanocomposite Filaments: Antibacterial, Thermal, Rheological, and Engineering Response in MEX 3D-Printing. Mater. Des. 2024, 242, 113032. [Google Scholar] [CrossRef]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Papadakis, V.; Kanellopoulou, S.; Gaganatsiou, A.; Stefanoudakis, N.; Kechagias, J. Multifunctional Material Extrusion 3D-Printed Antibacterial Polylactic Acid (PLA) with Binary Inclusions: The Effect of Cuprous Oxide and Cellulose Nanofibers. Fibers 2022, 10, 52. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Papadakis, V.M.; Mountakis, N. Multifunctional Medical Grade Resin with Enhanced Mechanical and Antibacterial Properties: The Effect of Copper Nano-Inclusions in Vat Polymerization (VPP) Additive Manufacturing. J. Funct. Biomater. 2022, 13, 258. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Grammatikos, S.; David, C.N.; Mountakis, N.; Argyros, A.; Boura, O. Development and Optimization of Medical-Grade Multi-Functional Polyamide 12-Cuprous Oxide Nanocomposites with Superior Mechanical and Antibacterial Properties for Cost-Effective 3D Printing. Nanomaterials 2022, 12, 534. [Google Scholar] [CrossRef]

- Vidakis, N.; Michailidis, N.; Petousis, M.; Nasikas, N.K.; Saltas, V.; Papadakis, V.; Mountakis, N.; Argyros, A.; Spiridaki, M.; Valsamos, I. Multifunctional HDPE/Cu Biocidal Nanocomposites for MEX Additive Manufactured Parts: Perspectives for the Defense Industry. Def. Technol. 2024, 38, 16–32. [Google Scholar] [CrossRef]

- Santos, J.D.; Guerrero, J.M.; Blanco, N.; Fajardo, J.I.; Paltán, C.A. Numerical and Experimental Analysis of the Mode I Interlaminar Fracture Toughness in Multidirectional 3D-Printed Thermoplastic Composites Reinforced with Continuous Carbon Fiber. Polymers 2023, 15, 2403. [Google Scholar] [CrossRef]

- Kuncius, T.; Rimašauskas, M.; Rimašauskienė, R. Interlayer Adhesion Analysis of 3D-Printed Continuous Carbon Fibre-Reinforced Composites. Polymers 2021, 13, 1653. [Google Scholar] [CrossRef]

- Samanta, S.; Chatterjee, D.P.; Manna, S.; Mandal, A.; Garai, A.; Nandi, A.K. Multifunctional Hydrophilic Poly(Vinylidene Fluoride) Graft Copolymer with Supertoughness and Supergluing Properties. Macromolecules 2009, 42, 3112–3120. [Google Scholar] [CrossRef]

| Speed of Elongation (mm/min) | Strain Rate (s−1) | Speed of Elongation (mm/min) | Strain Rate (s−1) | Speed of Elongation (mm/min) | Strain Rate (s−1) |

|---|---|---|---|---|---|

| 10 | 0.011 | 75 | 0.083 | 200 | 0.222 |

| 25 | 0.028 | 100 | 0.111 | 250 | 0.278 |

| 50 | 0.056 | 150 | 0.167 | 300 | 0.333 |

| Wavenumber (cm−1) | Intensity | Raman Peak Assignment |

|---|---|---|

| 612 | Strong | CF2 vibrations [153] |

| 796 | Strong | COO scissoring [154]; CH2 rocking, α-phase of PVDF [153] |

| 839 | Medium | out-of-phase CH2 rocking and CF2 stretching modes, β-phase of PVDF [153] |

| 878 | Medium | C-COO stretching [155] |

| 1060 | Weak | C-O-C stretching [153] |

| 1200 | Medium | C-O-C stretching [156] |

| 1294 | Medium | C-O-C stretching [153] |

| 1401 | Weak | C-H3 deformation [157] |

| 1429 | Strong | C-H3 deformation [157,158]; C-H2 deformation [157,158]; C-H3 symmetric bending [155,156,157]; |

| 2983 | Very Strong | CH2 asymmetric stretching [159] |

| 3024 | Strong | CH2 and/or CH3 asymmetric stretching [154] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vidakis, N.; Nasikas, N.K.; Michailidis, N.; Spyridaki, M.; Mountakis, N.; Argyros, A.; Papadakis, V.M.; Moutsopoulou, A.; Petousis, M. Printability Metrics and Strain Rate Sensitivity of Multirole PVDF in Extrusion-Based Additive Manufacturing. Polymers 2025, 17, 3085. https://doi.org/10.3390/polym17223085

Vidakis N, Nasikas NK, Michailidis N, Spyridaki M, Mountakis N, Argyros A, Papadakis VM, Moutsopoulou A, Petousis M. Printability Metrics and Strain Rate Sensitivity of Multirole PVDF in Extrusion-Based Additive Manufacturing. Polymers. 2025; 17(22):3085. https://doi.org/10.3390/polym17223085

Chicago/Turabian StyleVidakis, Nectarios, Nektarios K. Nasikas, Nikolaos Michailidis, Maria Spyridaki, Nikolaos Mountakis, Apostolos Argyros, Vassilis M. Papadakis, Amalia Moutsopoulou, and Markos Petousis. 2025. "Printability Metrics and Strain Rate Sensitivity of Multirole PVDF in Extrusion-Based Additive Manufacturing" Polymers 17, no. 22: 3085. https://doi.org/10.3390/polym17223085

APA StyleVidakis, N., Nasikas, N. K., Michailidis, N., Spyridaki, M., Mountakis, N., Argyros, A., Papadakis, V. M., Moutsopoulou, A., & Petousis, M. (2025). Printability Metrics and Strain Rate Sensitivity of Multirole PVDF in Extrusion-Based Additive Manufacturing. Polymers, 17(22), 3085. https://doi.org/10.3390/polym17223085