Abstract

The circular economy (CE) has become a key sustainability discourse in the last decade. The Netherlands seeks to become fully circular by 2050 and the EU has set ambitious circularity targets in its CE Action Plan of 2015. The plastics sector, in particular, has gained a lot of attention as it is a priority area of both the EU and Dutch CE policies. However, there has been little research on the different and often contested discourses, governance processes and policy mechanisms guiding the transition to a circular economy and society. This paper aims to fill these gaps by asking what circular discourses and policies are being promoted in the Netherlands and what sustainability implications and recommendations can be drawn from it. It does so through a mix of media analysis, policy analysis, semi-structured interviews, and surveys using Q-methodology. Results indicate a dominance of technocentric imaginaries, and a general lack of discussion on holistic, and transformative visions, which integrate the full social, political, and ecological implication of a circular future. To address those challenges, this research brings key policy insights and recommendations which can help both academics and practitioners better understand and implement the transition towards a sustainable circular plastics economy.

1. Introduction

The unsustainable accumulation of plastic waste has often been described as one of the most pressing environmental challenges of our time [1,2]. The global consumption of synthetic polymers (hereafter: plastics) has risen 20-fold since 1960 and is projected to keep rising by 3.8% per year (it will thereby triple from now to 2050) [2,3]. Yet, only about 9% of all plastic waste generated by humanity until 2015 has been recycled, the rest was either incinerated (12%) or ended up in landfills and the environment (79%) [4]. Nevertheless, it is undeniable that plastics provide key benefits to global economies as they are cheap, versatile, multifunctional, and lightweight materials that often substitute the use of scarce resources and materials which often have higher environmental footprints [5]. They also have valuable health and safety applications, such as protection from biohazards, preventing food contamination, ensuring access to clean water and sanitation, and securing the hygiene of medical devises, etc. [6]. However, dealing with plastic waste sustainably and responsibly remains a monumental challenge. Plastic waste presents a significant threat to biodiversity as an incalculable number of animals die due to plastic ingestion or entanglement every year and many more are affected by the toxicity of plastic compounds and additives that leach into the environment [7,8,9,10]. Plastics also present a risk to human health, with micro and nano-plastics now present virtually everywhere, including table salt [11], beer [12], honey and sugar [13], tap water [14] and even the air we breathe [15]. Research has linked plastic production, use and pollution to various serious diseases including cancer [16,17,18], endocrine system disorders [18,19,20], reproductive hazards [17,21,22] and obesity, diabetes, and cardiovascular diseases [21,23,24]. Moreover, producing, transporting, and recycling plastics produces significant amounts of greenhouse gases, thereby exacerbating global warming [25].

The circular economy (CE) is often promoted as a solution to these problems as it could allow for the elimination of plastic waste through innovative recovery processes, bio-based alternatives and reuse and reduce solutions. Various initiatives have thus been created to foster a CE transition for the plastic sector such as the ‘Global Commitment’ lead by the Ellen MacArthur Foundation [26], the ‘European Plastic Pact’ initiated by France, the Netherlands and Denmark [27] and the ‘Circular Plastics Alliance’ established by the European Commission [28].

The Dutch government, in particular, has set the ambitious target to become 100% circular by 2050 and its Circular Economy Action Plan focuses on plastics as a strategic sector to lead the transition [29]. Despite having a strong plastic waste management system with high recovery figures (with a 99% combined recycling and incineration rate for plastic packaging), the Netherlands is still facing key challenges. Indeed, Dutch plastic consumption continues to rise, and a proportion of its plastic waste is leaked to third countries and ends up in the environment [30,31]. Moreover, nearly 50% of end-of-life plastics in the Netherlands are incinerated instead of recycled [32].

The transition to a CE for plastics in the Netherlands, therefore, remains a significant challenge. Yet, there has been very limited research on the topic as there are just over a dozen academic papers on the CE of plastics in the Netherlands (based on a Scopus search for “circular economy” AND Netherlands AND plastic* OR polymer* (Title, Abstract, Keywords) conducted on the 19 July 2021, finding a total of 13 results). Previous research on the topic has focused on analyzing bio-plastic alternatives [33,34,35], consumer habits [36], and polymer recycling practices and innovations [37,38,39,40,41,42]. However, studies have not analyzed the policies and discourses of the CE transition for the plastic sector in the Netherlands. Yet this is a key question as the CE is a contested and diverse concept that can lead the CE transition in many different directions, with different socio-ecological implications, depending on the specific discourse and vision of circularity which is implemented [43,44,45,46]. This paper, therefore, addresses this key research gap by answering the following research question:

What are the main discourses in the transition towards a sustainable circular plastics economy in the Netherlands and what implications and recommendations can be drawn from it?

To answer this question this research conducts a policy, media, and stakeholder analysis as well as 24 semi-structured expert interviews, and a survey and statistical factor analysis with Q-methodology. After presenting the methods and results, this paper discusses the significance of these findings and brings key policy recommendations which can help both academics and practitioners better understand and implement a sustainable circular plastics economy.

2. Methodology

This research uses a single case study approach using Q-methodology to provide an in-depth understanding of the different discourses and policies in the transition towards a sustainable circular plastics economy in the Netherlands.

Q-methodology is an interdisciplinary holistic mixed (quantitative and qualitative) research method, which was first introduced by Stephenson in 1935 [47]. The purpose of a Q study is to identify and represent different perspectives regarding a particular topic [48,49]. It is a commonly used method for discourse analysis as it identifies how different societal groups align with certain viewpoints, ideas, and beliefs [50,51].

Q-methodology can also be applied to elicit alternative policies and solutions to address a particular topic or issue [52]. For instance, Stevenson (2015) used Q-methodology to identify the underpinning green political economy discourses and solutions [50]; Ellis et al. (2007) used it to investigate the acceptability of different wind farm proposals [53]; Gall and Rodwell (2016) used it to evaluate the social acceptability of marine protected areas [54]; and Curry et al., (2013) used it to analyze environmental and resource dimensions of sustainability policies [51]. It is thus particularly well suited to the present research question, as it allows us to clearly and systematically identify different societal discourses in the transition towards a sustainable circular plastics economy in the Netherlands as well as to evaluate different policy options and assess their acceptability amongst different societal groups.

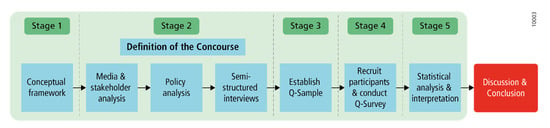

This research followed a 5-stage Q-methodology process adapted from Webler et al. (2009) (see Figure 1) [55]. First, we establish the conceptual framework which provides us with the conceptual lens with which to better understand and analyze the diverse discourses surrounding the transition to a sustainable circular plastics economy in the Netherlands. Second, we define the concourse on the topic, which means mapping the wide variety of stakeholder perspectives and viewpoints on the study object [48]. This is done through a mix of media and stakeholder analysis, policy analysis and semi-structured interviews. A set of representative statements on the topic, called the Q-sample, are then derived from the concourse [52] (stage 3). In a fourth stage, respondents (the Participant set or P-set) are asked to answer a survey where they rank the chosen set of statements (Q-sample) based on individual viewpoint and preference. This process is called ‘Q-sorting’ and it is a key part of the Q-methodology as this is how the participant’s underlying discursive position on the studied topic is revealed [56]. The Q-sorting process is followed by a factor-analysis that evidences groups of respondents which sorted the set of statements (Q-sample) similarly (stage 5). These groups of similar responses are combined into ‘factors’, which reflect a district discourse on the studied topic.

Figure 1.

Research method and process.

2.1. Stage 1: Conceptual Framework

2.1.1. Circularity Discourses

The CE has become a key sustainability discourse in the last 10 years. It is now a major component of many environmental policies in various industries and countries, especially in China where the concept has been part of national policy since 2002 [57] and in the EU, which adopted a comprehensive CE “Action Plan” in 2015 [58].

However the origins of the concept date back much further to ideas such as the Economy of Permanence [59], The Limits to Growth [60], Industrial Ecology [61], Steady-State Economics [62], Ecological Design [63], etc. The CE is thus best understood as an umbrella concept, which encompasses a plurality of different visions and ideas, all of which seek to establish sustainable resource and energy cycles so humanity can live in harmony with the biophysical limits of the Earth [44]. Nevertheless, the CE is still an “essentially contested concept” in the public and academic debate with many actors proposing different CE visions based on their economic and political interests [45].

To better navigate and understand these differences, this research uses the discourse typology developed by Calisto-Friant et al. (2020), which has also been used to analyze the EU’s CE policies [64], CE discourses in Norway [65,66], the European plastics strategy [67] and competing discourses on the CE in Australia [68].

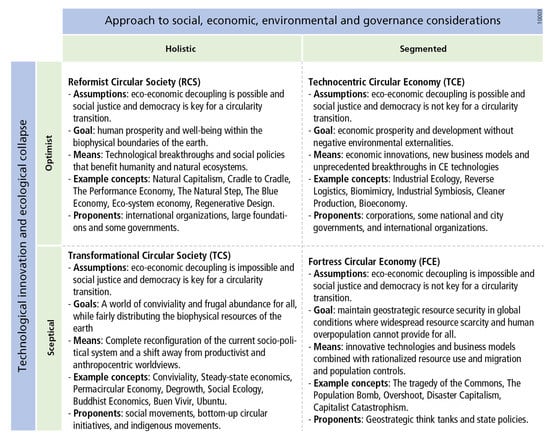

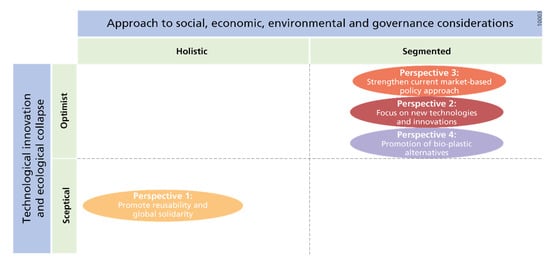

The abovementioned typology divides circularity discourses based on two main criteria (see Figure 2). First, whether discourses have a holistic approach by including the social justice and political empowerment dimensions of circularity or a segmented approach by focusing only on technical and economic means to eco-efficiency. Second, whether discourses are optimist or sceptical regarding the possibility of decoupling environmental degradation from economic growth (eco-economic decoupling). Different combinations of the above criteria lead to 4 main circularity discourse types (More information of each discourse is available in the following article: A Typology of Circular Economy Discourses: Navigating the Diverse Visions of a Contested Paradigm, (2020) Resources Conservation & Recycling, https://doi.org/10.1016/j.resconrec.2020.104917, accessed on 4 November 2021):

Figure 2.

Circularity discourse typology (adapted from Calisto Friant et al. [44]).

Reformist Circular Society (optimist and holistic) discourses seek to create a sustainable circular future through a combination of innovative business models, social policies and technological breakthroughs (such as Cradle to Cradle [69], the Blue Economy [70] and Natural Capitalism [71]).

Technocentric Circular Economy (optimist and segmented) seek to reconcile economic development with ecological sustainability through innovative business models and technological breakthroughs, especially in resource recovery, biotechnology and renewable energy (such as Bioeconomy [72], Reverse Logistics [73], and Industrial Metabolism [74]).

Transformational Circular Society (sceptical and holistic) discourses seek to create a fair, democratic, de-colonial and sustainable post-capitalist future where humanity and nature live in mutual harmony by re-localizing and redistributing power, wealth, and knowledge (such as Degrowth [75], Buen vivir [76], and Steady-state economics [62]).

Fortress Circular Economy (sceptical and segmented) seek to ensure biophysical stability and geostrategic resource security through technological innovations and top-down controls on population and economic shortages (such as the Tragedy of the Commons [77], The Population Bomb [78], and Catton’s Overshoot [79]).

2.1.2. Plastics and Circularity

Future trends show that the production of virgin plastics will increase at a faster pace than the development and deployment of related after-use systems and infrastructure [2,3,80]. Therefore, strong CE actions are required to reverse this trend at both the demand side (through refuse, reduce, reuse, and replace strategies) and the supply side (through better plastic waste collection and recovery systems). Each of these actions have a multitude of social, economic, and environmental implications, which remain poorly researched and understood [81].

Choices between different recovery strategies or plastic alternatives involve complex trade-offs between economic considerations and ecological imperatives. Moreover, social components are essential, as a sustainable circular plastics economy will inevitably necessitate behavioral change (reduced consumption, better sorting, switch to re-usable packaging etc.) and will lead to unavoidable costs and benefits, which must be equitably distributed within society (through progressive taxation and social policies) [81].

Moreover, recovery systems in the Global North are currently dependent on the export of plastic waste to the Global South [30]. However, the impact of indiscriminate export of end-of-life plastics to the Global South poses key social and environmental justice concerns. Indeed, waste is often exported to countries where working conditions and environmental standards are relatively low, and which have limited administrative and technological capacity to control mismanaged waste [31,80]. This not only increases the amount of plastic that ends up polluting natural ecosystems, but also exacerbates human health problems related to unsafe recovery systems. The ban that China placed on the import of most plastic waste in 2018 has brought light to this issue [30]. The above trends have created a renewed momentum for countries in the Global North to transition towards a sustainable circular plastics economy [82].

To operationalize this objective and create a CE for plastics, there are many interrelated actions and strategies that countries may use. These can be categorized through the 10R hierarchy of CE “action imperatives” developed by [83] Reike et al. (2018) (see Table 1 below). This 10R framework not only helps visualize the range of policy options for the transition to a sustainable circular plastics economy, but it also helps reveal stakeholder discourses on CE. Indeed, the research of Calisto Friant et al. shows that different circularity discourses focus on a different set of Rs: Technocentric Circular Economy is associated with R4–R9 as it is mostly concerned with industrial and recycling solutions, a Reformist Circular Economy with R2–R7 as it is highly focused on innovative service-based business models and sharing economies, a Transformational Circular Society with R0–R6 as it seeks to build social and solidarity economies focused on sufficiency and autonomy, and a Fortress Circular Economy with R1–R9 as it pragmatically engages with all value retention options from a top-down perspective [44].

Table 1.

10R framework applied to plastics.

In addition to the above value retention hierarchy, it is important to differentiate bio-based, biodegradable, and fossil-based plastics. Bio-based plastics are polymers made from natural organic matter such as corn, wood, and palm oil [5]. Not all bio-based plastics are biodegradable but many of them are. Those which are biodegradable, however, often only effectively biodegrade in industrial composting facilities [84]. Depending on the type of biomaterial used, the carbon footprint of bio-based plastics can be anywhere from 85% lower to 50% higher than that of fossil-based plastics [85]. However, bio-based plastics compete for limited land resources with biodiversity conservation, food production and renewable energy generation [86]. They can therefore increase food insecurity and intensify the collapse of biodiversity [87]. While only about 1% of plastics in the world are bio-based, they can pose significant problems to recovery systems, which are currently not designed to recycle or compost them [86].

Concerning recycling (R7), it is important to distinguish chemical from mechanical recycling options. In mechanical recycling, plastics are converted into secondary raw material through sorting, washing, grinding, and regranulation processes [88]. Mechanical recycling is not perfectly efficient as a significant portion of plastics are lost in the process (10–30% depending on the technology) [38]. Moreover, the resulting plastics are of lower quality than virgin materials as plastic compounds are degraded and contaminated by the recycling process [25]. Most mechanically recycled plastics are therefore not considered food-grade material and can only be used in lower-value applications such as shampoo bottles, flower pots, and paint buckets [38]. It is nonetheless the most widespread form of recycling as it is economically viable for many different plastic types such as polyethylene terephthalate (PET), polypropylene (PP), and polyethylene (PE) [89].

Chemical recycling processes are relatively recent innovations by which large plastic polymers can be broken down into smaller oligomers and monomers that can be used as building blocks for virgin plastics. This type of recycling is carried out through techniques such as methanolysis, hydrolysis, solvolysis, glycolysis, and pyrolysis [88]. It typically involves heating polymers to high temperatures with different catalysts, such as water or methanol [25]. Chemical recycling can lead to higher-quality and higher-value outputs than mechanical recycling, yet it is more energy-intensive than chemical recycling and has yet to become economically viable on a large scale [5,25,84].

Overall, whether through mechanical or chemical processes, plastic recycling is complex and has many physical limitations. In addition to the abovementioned challenges, the presence of many different types of plastics in the same product (electronics can contain over 14 different polymers) and the widespread use of additives (which are often toxic such as brominated flame retardants) heavily complicates their recovery [41,88,90]. The heavy contamination of waste streams from post-consumer plastic also greatly complicates the recovery process [25,85,89]. Recycling is thus never 100% efficient and higher value retention options are therefore preferred from a sustainability standpoint as they increase the lifespan of plastic products (R2–R6) or reduce the need to produce plastics in the first place (R0–R2). In fact, research has found that re-usable packaging, such as returnable bottles, have significantly lower ecological footprints than single-use plastics [91,92,93].

The above review of the diversity of CE discourses and the key value-retention options for plastics allows us to better understand the complexity of the topic. It thereby provides a solid conceptual basis for the analysis of the discourses and policies regarding the transition to a sustainable circular plastics economy in the Netherlands (Section 3) as well as to develop relevant recommendations based on our findings (Section 4).

2.2. Stage 2: Definition of the Concourse

In this step all different positions and discourses are identified by gathering relevant opinions, ideas, beliefs, and assumptions surrounding the study object. A mixture of media (newspaper) analysis, stakeholder analysis, policy analysis, and semi-structured expert interviews were conducted to define the concourse. While analyzing the concourse, we uncovered that the overweighing majority of plastic waste in the Netherlands and the EU emanates from packaging, this research will thus focus on the abovementioned sector [94].

2.2.1. Media and Stakeholder Analysis

The LexisNexis database was used to gather Dutch newspaper articles on circular economy and plastics. Using “plastic*” OR “kunststof*” AND “circulaire economie” OR “kringloopeconomie” as keywords led to 1212 newspaper articles published between the 1 January 2010 and the 17 December 2019. This sample was reduced to 183 news articles by selecting the 8 national paid newspapers (Trouw, Financieele Dagblad, Nederlands Dagblad, NRC Handelsblad, Volkskrant, Telegraaf, Reformatorisch Dagblad, and Algemeen Dagblad). All articles that did not specifically talk about plastic policies or plastic waste management were excluded, leading to a final selection of 42 articles (see Supplementary Materials A for the full list of newspaper articles).

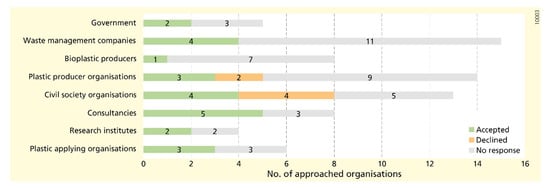

These 42 news articles were carefully reviewed and coded with Discourse Network Analyzer 2.0 to identify and categorize the organizations and actors they mentioned or quoted. This method of stakeholder analysis is similar to the one used by Lazarevic and Valve (2017) who identified actors engaging in the CE debate at the European level by reviewing articles in the EurActiv and ENDS Europe news-services. In addition to this, we identified organizations from the Dutch Plastic Pact [95] and The National Agreement on the CE [96], two government initiatives aimed at promoting the CE through multi-stakeholder agreements. This led to the identification of 211 organizations which were divided into 7 broad actor groups (see Figure 3 and Supplementary Materials B for the full list of identified stakeholders).

Figure 3.

Stakeholder-groups involved in the transition to a circular plastics economy.

2.2.2. Policy Analysis

The authors reviewed 23 policies related to the transition to a sustainable circular plastics economy from the EU, the Dutch government, and the producer responsibility organization (Afvalfonds Verpakkingen) which represents all plastic packaging producers and importers in the Netherlands to comply with the compulsory expended producer responsibility legislation (see Table 2). Policies were analyzed qualitatively to understand the CE legislative framework and transition pathway for plastics in the Netherlands [97].

Table 2.

List of analyzed policy documents.

2.2.3. Semi-Structured Expert Interviews

Semi-structured interviews with professionals in the Dutch plastics sector were held to explore their perspectives on the transition to a sustainable circular plastics economy in the Netherlands. Interviewees were derived from the results of the stakeholder analysis as well as through ‘snowball-sampling’ [55]. The general objectives of the interviews were to identify stakeholder opinions regarding the transition towards a sustainable CE for plastics in the Netherlands, including their perspective on current public policies, business practices, technologies, environmental issues, and social implications (see Supplementary Materials C with full interview questions). Interviews were conducted online between March and April 2020. In total, 74 organizations were approached for an interview of which 24 accepted the interview request (35.4% response-rate). To ensure diversity and plurality of views and perspectives, interviews were sought with actors from all 7 stakeholder groups (see Figure 4 and Supplementary Materials D for further information on each interviewee).

Figure 4.

Overview of interviews in each stakeholder group.

2.3. Stage 3: Establish Q-Sample

The Q-sample is the set of statements used as input for the Q-survey. The Q-sample is obtained from the analysis of the concourse and must reflect the wide variety of opinions and perspectives on the topic. In this research, each statement was formulated directly by the authors following a careful investigation of the concourse and the diversity of different actions and strategies that interviewees, policy documents and newspaper articles advocated on the topic. Diversity was sought by incorporating a wide number of opposing and often conflicting policy alternatives. Consistency was ensured by formulating each statement as a direct policy action to be carried out by one or more clearly identified actor. A first set of 51 statements was established which was then refined by combining and regrouping similar or closely related points. A final set of 42 statements was thereby developed for this research (see Table 3). This number is consistent with Q-method guidelines, which suggest that a Q-sample should have anywhere between 40 and 80 statements [49]. After the final Q-sample was established, the survey was reviewed by 4 researchers from our institution to ensure clarity and refine any ambiguities or potentially confusing statements. Ease of use was also sought by pilot testing the final Q-sample in several online Q-method survey platforms. This led to the choice of “Q-Methods Software” as the most user-friendly platform for this Q-survey.

Table 3.

Q statements for the transition to a sustainable circular plastics economy in the Netherlands (Q-Sample).

2.4. Stage 4: Recruit Participants (P-Set) and Conduct Q-Survey

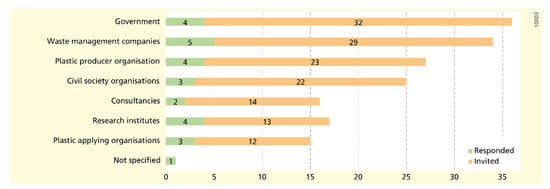

The P-set defines the participants which respond to the Q-survey. The selection of the P-set is not carried out through a random process but is rather a carefully selected sample of participants who are actively involved in the researched topic [48]. A successful Q-study necessitates anywhere from 15 to 60 participants [54]. Moreover, there should always be fewer participants than Q-statements [50]. What matters more than participant numbers is diversity and plurality in participant perspectives [55]. To ensure this diversity 145 participants were invited from all 7 stakeholder groups identified in stage 1. In total, 26 participants answered the Q survey (17.8% response rate), and each stakeholder group had at least 2 respondents, thereby ensuring the plurality and diversity of views needed for a Q-study (see Figure 5).

Figure 5.

Invitations and response to the Q survey per stakeholder group.

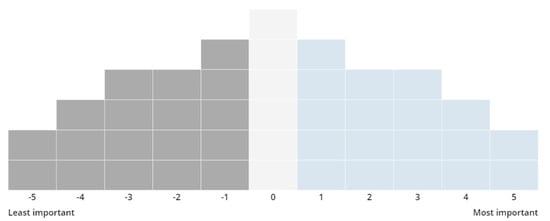

During the Q-survey, participants were asked to rank all the 42 statements (Q-sample) following this leading question: “How important do you consider the following action statements in the transition to a sustainable circular plastics economy in the Netherlands?” To do so, participants had to place the statements on an 11-point quasi-normal distribution ranging from “least important (−5)” to “neutral (0)” to “most important (+5)” (see Figure 6). The nature of the quasi-normal distribution pyramid forced participants to make important trade-offs between statements they considered similarly important or unimportant and, in doing so, participants revealed their underlying opinions and points of view on the topic. Each participant’s final set of submitted ranked statements constitutes his or her “Q-sort” (the full Q-survey process and instructions can be seen in Supplementary Materials E).

Figure 6.

The ranking grid of the Q-sort process.

2.5. Stage 5: Statistical Analysis and Interpretation

The completed Q-sorts from all respondents constitute the main input for the factor analysis. PQMethod software was used to analyze the data. This (free) software is specifically developed for Q factor analysis and is widely used and recognized by researchers in the field [49,51,52,55,98]. The factor analysis groups participants with similar Q-sorts into groups, which reveal their common perspective on the topic [49,55]. Q-survey results were processed using the Centroid method and Varimax rotation, which are widely used statistical tools to systematically uncover different participant discourses through Q-methods [47,49,50,55]

The results of the factor analysis were carefully examined and interpreted by contrasting the perspective of each factor group with the typology of circularity discourses developed by Calisto Friant et al. (2020) [44]. This allowed the mapping of the different factor positions in the wider literature on the transition to a circular economy and society.

3. Results

Results are divided into 3 sub-sections. Section 3.1 summarizes the relevant policies and practices surrounding the transition towards a sustainable circular plastics economy in the Netherlands as evidenced by the policy analysis, media analysis, and expert interviews (stage 2 of the methods). Section 3.2 analyzes these findings in light of the conceptual framework and its circularity discourse typology. Section 3.3 presents the statistical analysis and interpretation of the Q-survey results and describes the different resulting perspectives regarding the transition to a sustainable circular plastics economy (stage 5 of the methods).

3.1. Results from the Analysis of the Concourse

As part of its CE Action Plan, the European Commission adopted the “European Union Strategy for plastics in a Circular Economy” which addresses issues such as recyclability, biodegradability, the presence of hazardous substances in certain plastics, and marine litter (European Commission, 2018). Several plastic specific directives were implemented to address these issues, such as Directive 2019/904 on the reduction of the impact of certain plastic products on the environment, which banned several single-use plastic products such as cotton buds, cutlery, stirrers, plates and straws and established eco-design and separate collection requirements for single-use plastic bottles. Moreover, the EU set new recycling targets for plastics packaging (50% by 2025 and 55% by 2030) (Directive 2018/852) and established the obligation for the separate collection of municipal plastic waste (Directive 2018/851).

In addition to this, the EU has mandated the establishment of extended producer responsibility (EPR) systems to manage plastic packaging waste (Directive 2018/852). An EPR system is a policy mechanism by which the administrative, financial, and physical responsibility to manage the entire life cycle of a product, and especially, the take-back, recycling and final disposal, is given to the producers or importers of a product rather than to the government [99].

Three key policies regulate plastic waste within the Netherlands, the “National Waste Plan” established in 2003, as well as the “Packaging and Paper and Cardboard Management Decree” and the “Framework Agreement on Packaging and Litter”, which were both established in 2007. These policies set minimum plastic packaging recycling targets which rose from 32% in 2009 to 38% in 2010, and further to 42% in 2012. They also created a deposit system for large PET bottles and established the Dutch EPR system for packaging waste. These policies were updated in 2014 to increase the minimum recycling targets from 43% in 2013 to 52% in 2022 (with an increase of 1% per year).

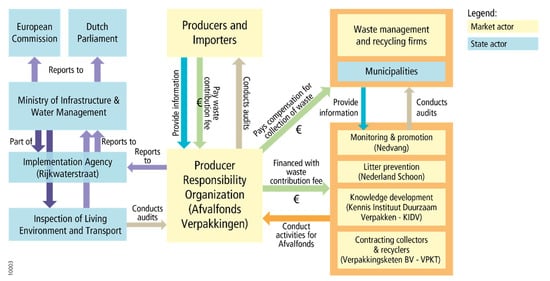

The producers and importers of plastic packaging founded Afvalfonds Verpakkingen to collectively implement their obligations under the abovementioned policies (it is the so-called producer responsibility organization or PRO [100], which is responsible for the implementation of the packaging EPR system in the Netherlands). Afvalfonds Verpakkingen is financed by the packaging industry via a ‘waste management contribution fee’. This fee must be paid by producing and importing organizations when they bring and/or discard 50,000 (or more) kilos of packaging on the Dutch market, even if an organization is located outside the Netherlands.

The organizational and financing structure of Afvalfonds Verpakkingen and its recovery activities are presented in Figure 7.

Figure 7.

EPR-system of packaging in the Netherlands (source: developed by authors based on Afvalfonds Verpakkingen, 2018).

Each Dutch municipality organizes their waste collection system independently, thereby resulting in a multiplicity of different collection systems. Afvalfonds Verpakkingen compensates municipalities for their collection by paying a specific fee based on the volume and quality of waste they collect. While this incentivizes an efficient collection, it also means that some municipalities which have poorly separated waste, do not receive enough compensation to cover their costs. In those cases, the costs for collection are not fully covered by Afvalfonds Verpakkingen, but rather by local taxpayers [89].

In 2016, the Dutch government established its national CE strategy “A circular economy in the Netherlands by 2050”, where it set the ambition to reduce raw material consumption by 50% in 2030 and to become 100% circular by 2050 [29]. This policy established plastics as one of the central components of the transition and seeks that “in 2050, 100% renewable (recycled and biobased) plastics will be used without any harmful impact on the environment, wherever such is technically feasible” (p. 51).

In the following years, the “National agreement on the circular economy (2017)”, the “Transition agenda of plastics (2018)”, and the “Plastic Pact NL (2019)” were enacted as part of this commitment. The above policies represent various multi-stakeholder agreements, containing voluntary commitments from a wide variety of market, state, and civil society actors (see Supplementary Materials B with a list of pact members). They notably set several voluntary targets for 2025, such as ensuring that all single-use plastic packaging is 100% recyclable; reducing plastic usage by 20% (in kg) compared to 2017; reaching a 70% rate of plastic packaging recycling; ensuring that new plastic packaging contains at least 35% recycled content and increasing the use of sustainably produced biobased plastics [95].

In July 2019, a third “National Waste Management Plan” was implemented. It prohibited landfilling and incineration without energy recovery for all sorts of plastic waste.

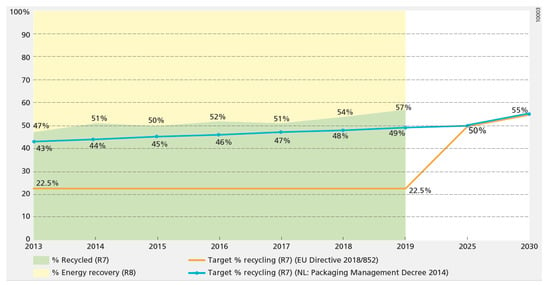

The performance of the plastic recovery operations of Afvalfonds Verpakkingen can be seen in Figure 8 (numbers in green represent recycling figures). It shows that the Dutch and European recycling targets were largely achieved, and that recycling rates improved almost every year except for 2017. According to Afvalfonds Verpakkingen, China’s ban on the import of post-consumer plastic waste was a key factor explaining this setback (Annual monitoring report of 2017, p. 5). In fact there is insufficient recycling capacity in the country and Europe as a whole (Interview with Director of a consultancy firm on CE) [89]. Therefore, Afvalfonds Verpakkingen is highly dependent on the export of its waste to third countries to fulfil its recycling targets and the Netherlands is thus one of the leading exporters of plastic waste in the world [30,101]. While data on the exact amount of Dutch plastics which are exported for recycling are unavailable, studies have found that, in the EU, as much as 46% of plastics that are destined for recycling are exported [31].

Figure 8.

Results of recycling (R7) targets and energy recovery (R8) rates for plastic packaging of between 2013–2019 (author’s work based on Afvalfonds Verpakkingen annual monitoring reports 2013–2019, see Supplementary Materials F for full data).

The problem with this is that it is very hard to control what happens to plastic waste once it is exported. Although exports of plastics are highly regulated under international law, actual controls are rather weak, so it is virtually impossible to guarantee how plastic waste will actually be processed and where it will end up (interview with Associate Director of a consultancy firm on CE and interview with Director of consultancy firm in biotechnology). In practice, plastic waste changes hands multiple times along complex international trading routes, causing many leakages to the environment along the way and often ending up in countries in the Global South will little capacity to recycle it sustainably [80]. A large proportion of European plastic waste which is reported as recycled thus ends up in landfills or rivers and oceans across the globe [31]. Even Afvalfonds Verpakkingen recognised, in their 2017 monitoring report, that “there is uncertainty about the quantities and actual recycling of plastic packaging waste that has been exported to customers outside the EU” (p. 44). Moreover, recent research has found that actual Dutch recycling figures for 2017 were closer to 23% than to the reported 51% [32,38]. According to Bishop et al. the Netherlands is, in fact, the 5th largest European contributor to ocean plastic debris (in yearly kg of plastic debris per capita) [31]. Moreover, research suggests that China’s ban will likely further increase the rate of mismanaged plastic as plastic waste exports are now being channeled to other countries with lower capacities to process and recycle plastic waste in a sustainable manner [31].

It is also worth noting that there is little demand for recycled plastic in the Netherlands, Europe, and the world as a whole because of its higher price and lower quality compared to virgin plastic (Interview with Professor in plastic packaging of Dutch University). This means that most recycled plastic is not re-used in high-quality products and applications, and much of it ends up stockpiled until it finds a buyer (interview with Business Development Manager of large recycling firm). In fact, the actual use of recycled plastic in new plastic products is only around 10% in the Netherlands [86].

3.2. Analysis of Dutch Policies

From the above results, it is evident that current CE practices in the Netherlands are primarily focused on eliminating landfilling and incineration and replacing it with energy recovery (R8) and recycling (R7). While recovery figures are quite high compared to other countries (the average rate of plastic packaging recycling in the EU was 41.4% in 2018), the Netherlands is highly dependent on the export of plastic waste to obtain these results. The Dutch plastic recovery system might thus lead to significant unintended socio-environmental impacts throughout the world.

In addition to this, the Netherlands is still highly dependent on energy recovery (R8, see Figure 8). While energy recovery can reduce CO2 emissions by 30 to 45% compared to traditional electricity generation with fossil fuels, it is not a clean process as it produces significantly more greenhouse gases than recycling or re-using packaging [25]. Energy recovery also creates toxic residues that must ultimately be landfilled (about 1.5 to 2% of the net incinerated weight) [38]. Moreover, it fuels the need to continuously produce more virgin plastic, thereby reproducing a linear system.

The Plastic Pact NL has set targets that go beyond recycling and incineration, such as consumption reduction (R0 refuse) and recycled content (R1 reduce) objectives. However, those goals are purely voluntary; companies can therefore agree to those strong commitments to be perceived as greener and more sustainable, without facing much repercussion if they do not reach them [84,86,87]. In fact, research shows that voluntary agreements and partnerships are often used as key greenwashing strategies for corporations in the plastic sector to improve brand reputation and reduce regulatory pressure [84].

The Dutch Government’s target to become 100% circular by 2050 is quite ambitious, yet it is unclear how this will be measured and implemented. It could mean that all manufacturing and recovery operations are delocalized to other countries, thereby exporting environmental impacts from industrial activities, while still allowing for an increase in the consumption of manufactured goods. This goal might therefore not guarantee that overall environmental impacts will be reduced on a global scale. Furthermore, it is, in reality, impossible to create a perfectly circular economy due to the second law of thermodynamics, which demonstrates the inevitability of entropy as materials and energy are irreversibly dissipated in any physical process [102,103,104,105]. This means that it is technically impossible to recycle plastics over and over again as material quality degrades over time and a significant portion is lost in each recovery cycle [46,106,107,108]. The Dutch Government’s goal to achieve full circularity is thus more of a symbolic objective than a realistic aim.

Moreover, the Dutch Government placed economic growth as a cornerstone of its CE strategy, which is seen as bringing plenty of “opportunities for sustainable economic growth” (p. 42) and which relies heavily on an “absolute decoupling of economic growth from environmental impact” (p. 10) [29]. This commitment to green growth is clearly within the Technocentric Circular Economy perspective (see Figure 2), and was chosen despite the fact that academic research has clearly evidenced that absolute decoupling is not happening and will most likely never happen on a scale relevant to significantly reduce current unsustainable patterns of resource use, greenhouse gas emissions, and overall environmental degradation [109,110,111,112].

All in all, the voluntary targets of the Plastic Pact and the 100% circularity objective of the Dutch CE strategy seem to be less science-based goals than marketing stances which allow these actors to be perceived as global leaders and front-runners in the CE transition. In fact, these strong commitments appear rather ambitious and progressive, yet they are not binding. Meanwhile, the policies which are actually compulsory in the Netherlands are doing little to fundamentally transform the linear plastic production and consumption systems. Indeed, recycling (R7) remains the core CE value retention strategy in Dutch policies and the only one with mandatory targets. Yet, recycling has clear limitations and cannot by itself lead to a sustainable circular plastic economy without strong policy measures and targets on higher value retention options such as reducing virgin plastic consumption (R0 refuse), eco-design requirements to reduce the environmental impact of plastics (R1 reduce), and the promotion of re-usable packaging (R2 reuse) [25,86,92].

It is also important to note that Dutch policies do not include specific social justice components. They thus do not address key issues regarding who pays for the transition, who controls CE technologies and how to support countries in the Global South, where a substantial share of Dutch plastic waste currently ends up [31]. All in all, it is clear from the above analysis that the Dutch government’s approach to a CE transition for plastics follows a Technocentric Circular Economy perspective (see Figure 2).

3.3. Analysis of Dutch Societal Discourse on the Transition to a Sustainable Circular Plastics Economy

This section represents stage 5 of the methodology, whereby participant Q-sorts were analyzed with the PQmethod software. This factor analysis led to the description of 4 different perspectives, which reflects 4 statistically significant discourses on the transition to a CE for plastics in the Netherlands (see Figure 9). These 4 perspectives were analyzed and interpreted based on the Z-scores of their ranked statements (see Supplementary Materials G with the full statistical output of the PQmethod software). A Z-score is a standardized score on the statistical importance of each statement for each perspective. Statements with a Z-score of more than 1 demonstrate relative agreement and smaller than −1 demonstrate relative disagreement. The analysis also looks at statistically significant distinguishing statements for each perspective. These distinguishing statements have z-scores which are significantly different between perspectives and therefore denote key points of disagreement between the 4 discourses (distinguishing statements are statistically significant at p < 0.05, and values indicated by an asterisk (*) have a statistical significance at p < 0.01.).

Figure 9.

Four perspectives resulting from factor analysis and the circularity discourse type.

3.3.1. Perspective 1: Promote Reusability and Global Solidarity

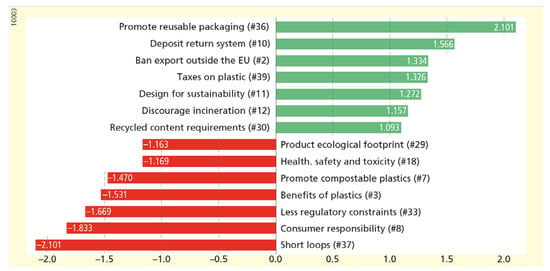

This perspective was represented by people from civil society organizations, government agencies, and research institutes. Figure 10 shows the Z-scores of this perspective and Table 4 shows the statistically significant distinguishing statements between perspective 1 and all other perspectives. The data demonstrate that this perspective seeks strong policy actions to reduce plastic consumption with high support for statements such as promoting reusable packaging, banning non-recyclable plastics (#36), reducing the overall use of plastics per capita (#42), and expanding deposit return systems (#10).

Figure 10.

Perspective 1: most (green) and least (red) important Q statements with Z-score < −1 and > 1.

Table 4.

Significant distinguishing statements of perspective 1 at p < 0.05 and marked with ‘*’ at p < 0.01.

Moreover, this perspective seeks to increase the use of recycled plastic in new products by taxing virgin fossil-based plastics and non-recyclable plastics (#39), designing for sustainability and recyclability (#11), discouraging incineration (#12), and setting high minimum requirements for recycled plastic content in new plastic products (#30).

This perspective also has a rather strong commitment to global solidarity as it is in favor of banning of export of plastic waste outside the EU (#2) and providing financial assistance and technology transfers to countries in the Global South so they can better manage plastic waste (#17).

Moreover, this perspective is strongly opposed to reducing state control as it is strongly opposed to statements favoring fewer regulatory constraints for bio-based, biodegradable, recycled plastics (#33), and increasing consumer responsibility (#8).

Overall considering the emphasis of this perspective on social change towards reusable packaging and reduced plastic consumption and its support towards global solidarity, this perspective is most aligned with the Transformational Circular Society discourse type [44].

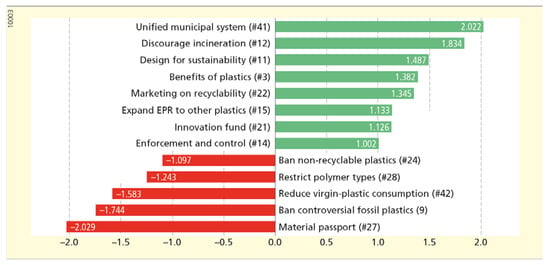

3.3.2. Perspective 2: Focus on New Technologies and Innovations

This perspective was represented by people from the business sector such as plastic applying organizations, plastic producing organizations, and waste management companies. From Figure 11 and Table 5, it is clear that this perspective is highly focused on improving recycling rates with policies such as creating a single system for waste management in all municipalities to generate efficient economies of scale for plastic recovery operations (#41), discouraging incineration (#12), design for sustainability and recyclability (#11), marketing on recyclability (#22), expanding EPR to other plastics (#15), and improving enforcement and control (#14).

Figure 11.

Perspective 2: most (green) and least (red) important Q-statements with Z-score < −1 and > 1.

Table 5.

Significant distinguishing statements of perspective 2 at p < 0.05 and marked with ‘*’ at p < 0.01.

This perspective is also focused on developing new technologies and innovations with policy actions such as promoting open-source technologies (#25) and establishing a fund focused on innovation and R&D of circular solutions (#21).

Moreover, this perspective is highly opposed to strong government actions such as bans on non-recyclable plastics (#24), bans on plastics made from controversial sources such as tar sands and shale gas (#9), and restrictions on polymer types allowed in the market (#28).

In addition to this, this perspective finds it is highly important for the media to better communicate the health and environmental benefits of plastics (#3).

Overall, the above statements demonstrate a high level of optimism regarding technological change and recycling innovations. It also shows a larger focus on market-based solutions such as EPR schemes, eco-design, and product marketing rather than strong government actions such as bans and restrictions. Moreover, this perspective did not place great importance to any social policies, thereby demonstrating a segmented view on the topic. This perspective thus clearly falls within the Technocentric Circular Economy discourse type [44].

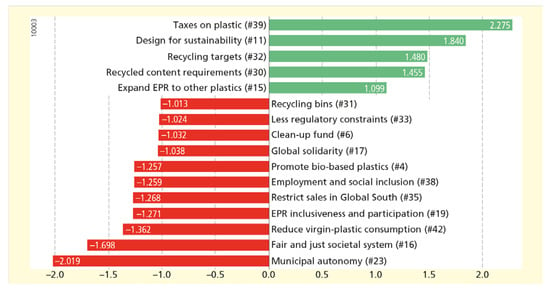

3.3.3. Perspective 3: Strengthen Current Market-Based Policy Approach

This perspective is represented by a wide range of people from government institutions, plastic applying organizations, consultancies, civil society organizations, and waste management companies.

By analyzing results in Figure 12 and Table 6, it is clear that this perspective is mostly characterized by the statements it is opposed to rather than those it found important. It is thus opposed to transformational social justice policies such as creating a fair system where the costs of a circular economy transition for plastics do not fall on the poorest and most vulnerable people (#16), improving the participation of civil society organizations in the EPR system (#19), restricting the sale of non-compostable plastics in the Global South (#35), helping the employment and inclusion of workers from the linear plastic and fossil-fuel industry towards a circular plastic economy (#38), and establishing a fund to clean plastics in the oceans and other natural ecosystems (#6).

Figure 12.

Perspective 3: most (green) and least (red) important Q statements with Z-score < −1 and > 1.

Table 6.

Significant distinguishing statements of perspective 3 at p < 0.05 and marked with ‘*’ at p < 0.01.

This perspective is also clearly against transformational policies such as reducing virgin plastic consumption (#42), and municipal autonomy to develop small-scale disruptive innovations (#23). Instead, it focuses on reinforcing current policies such as improving recycling targets (#32), enhancing recycled content requirements (#30), expanding the EPR system to other plastics (#15), and increasing EPR fees (#20). It is also in favor of market-based solutions such as taxing virgin fossil-based plastics and non-recyclable plastics (#39), and companies designing for sustainability (#11).

Overall, considering its strong opposition to transformational social justice policies and its focus on improving current market and recycling focused policies, this perspective is clearly within the Technocentric Circular Economy discourse type [44].

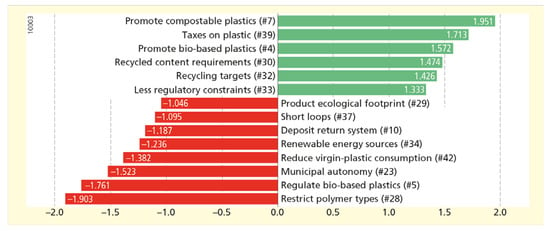

3.3.4. Perspective 4: Promotion of Bio-Plastic Alternatives

This perspective was represented by people: from waste management companies, research institutes, and plastic-producing organizations. Looking at results from Figure 13 and Table 7 demonstrates that this perspective is heavily focused on policies supporting bio-plastics with statements such as promoting the use of compostable plastics (#7), increasing taxes on virgin fossil-based plastics and non-recyclable plastics (#39), encouraging and increasing the use of bio-based plastics (#4), reducing regulatory constraints for bio-based, biodegradable, and recycled plastics, especially for food-uses (#33), and promoting sustainable alternative materials to plastics (#1). Moreover, this perspective is opposed to regulating bio-based plastics so they do not compete with food production and biodiversity conservation (#5).

Figure 13.

Perspective 4: most (green) and least (red) important Q statements with Z-score < −1 and > 1.

Table 7.

Significant distinguishing statements of perspective 4 at p < 0.05 and marked with ‘*’ at p < 0.01.

This perspective also finds the improvement of the current recycling systems rather important with policies such as increasing recycled content requirements (#30), and rising recycling targets (#32). Yet this perspective is opposed to more transformational policy actions such as restricting polymer types in the market (#28), reducing virgin plastic consumption (#42) and greater municipal autonomy to develop small-scale disruptive innovations (#23).

All in all, considering the abovementioned results, which do not place any social justice policies as important, and heavily focus on bioplastics as a technologically innovative alternative to fossil plastics, it is clear that perspective 4 falls within the Technocentric Circular Economy discourse type [44].

4. Discussion

This section discusses the implications of the results and proposes recommendations for the transition to a sustainable circular plastics economy. It also discusses the limitations of this research.

4.1. The Plastic Discourse in The Netherlands

Results from the policy analysis found that the Dutch government followed a Technocentric Circular Economy approach to a CE transition in the plastics sector. Results from the factor analysis found that perspectives two, three, and four also follow a Technocentric Circular Economy discourse, while only one perspective followed a Transformational Circular Society discourse. These results indicate that both Dutch societal perspectives and public policies are dominated by Technocentric Circular Economy discourses. This is in line with results from Palm et al. (2021) which found that the most dominant plastic narratives in government and industry sectors in Europe also fall within the Technocentric Circular Economy discourse type [67].

Plastic governance in the Netherlands is thus not geared towards social justice or reduced plastic consumption and ecological footprints. Instead, it focuses on recycling solutions, whereby people are brought to believe that they can continue consuming more plastic as long as they throw it in the right bin. It thereby obscures the complex technological and logistical challenges of recycling and its impacts on people and ecosystems throughout the world by creating an illusion of perfect circularity, which incentivizes further plastic consumption [80,106,113].

To understand why this is the dominant framing of the plastic problem, it is important to acknowledge that the Netherlands is a key player in the global plastic industry with hundreds of producing firms in the sector generating a turnover of 17.5 billion euros (2% of Dutch GDP) in 2014 and exporting 83% of their production [114]. The powerful oil sector has also strongly pushed for an increased production of plastics as the biggest future use of fossil fuels, now that their use as energy sources must be reduced to comply with climate change commitments [84,115]. There are thus strong lock-ins that tie the economic and geopolitical interests of the Netherlands with the plastic industry and thereby incentivize discourses and policies that do not threaten its position as one of the top plastic producers and exporters in the world [115].

Another way to explain the dominance of Technocentric Circular Economy perspectives in the Netherlands is by acknowledging the role of highly processed foods, and the delivery industry in fostering the dependency on plastic packaging. E-commerce has greatly increased the demand for plastic packaging from the delivery industry, in particular for online food delivery services [116,117]. The rising consumption of ultra-processed foods also contributes to an increased dependence on plastic packaging [118]. Plastic packaging consumption in the Netherlands has thus risen by 11.75% from 2013 to 2019 (see Supplementary Materials F for full data). The continuous growth and convenience of plastic packaging thereby limits the possibility of imagining a reduction in its consumption, through refuse (R-0), reduce (R0), and reuse (R2) alternatives; instead, it biases current discourses and policies towards improved collection, recycling (R7), and recovery (R8) strategies.

4.2. Policy Recommendations

The results from the factor analysis also allow us to see which statements are considered most important by all four perspectives (see Table 8). This can evidence points of consensus for certain policies, which might be quickly implemented as low-hanging fruits for the transition to a sustainable circular plastics economy in the Netherlands.

Table 8.

Q-statements with the highest Z-Scores across all four perspectives.

Short-term policy recommendations, with strong support across societal stakeholders:

- Tax virgin fossil-based plastics and non-recyclable plastics and reduce the taxes on recycled plastics (statement #39). The price of virgin plastics remains too low for recycling to be an economically competitive alternative [37,119]. Taxes can thus make virgin fossil-based plastics and non-recyclable plastics more expensive and thereby stimulate the production and uptake of recycled plastics [81,86].

- Establish a fund focused on innovation and R&D of circular solutions (such as new sorting and recycling technologies) financed by fees on virgin materials (statement #21). Resources are still needed to improve the cost-effectiveness, eco-efficiency, and commercial readiness of new technologies [37,88]. A fund could thus provide much-needed financial resources while also reducing the competitiveness of unsustainable virgin materials [81,86].

- Establish financial and legal incentives to discourage the incineration of lower-grade plastics (with or without energy recovery) and promote their recycling (statement #12). In the Netherlands, the costs of recycling outweigh those of energy recovery by as much as 36.7% [90]. Financial and legal incentives with key targets to reduce energy recovery could thus help make recycling a more cost-effective solution.

- Design for recyclability and lower overall environmental impacts throughout a product’s lifecycle (including resource use and hazardous substances) (statement #11). Plastic products currently contain a large number of different polymer types and additives, which provide specific textures, colors, and properties, but that heavily reduce recyclability [85]. Moreover, there is no evidence showing that EPR systems lead to changes in the eco-design of products to make them more easily recyclable or longer-lasting [120,121,122,123,124]. To improve recycling potential and reduce the overall environmental impact of plastic packaging, it is thus key to establish direct eco-design regulations that limit the number of additives, multilayer and composite plastic materials and support the use of sustainable alternatives [84,89]. The eco-modulation of EPR fees is a key manner to achieve this objective, whereby producers pay EPR fees based on the environmental impact and recyclability of their product, thereby directly incentivizing eco-design innovations [38,122,125,126,127].

- Increasing plastic recycling targets (statement #32). The Plastic Pact NL voluntary commitment to reach 70% recycling rate by 2025 could become a mandatory target to stimulate the industry and reduce the risks of free riders.

- Set minimum requirements for recycled plastic content in new plastic products (statement #30). The current use of recycled plastic in new products is only about 10% in the Netherlands [86] it is thus key to set new mandatory targets which help create new market avenues for recycled plastics.

- Ban the export of plastic waste outside Europe so plastic waste is recycled and processed within European borders (statement #2). This policy is key to ensure that plastics are properly recycled and do not end up causing more harm to human health and ecosystems [31,80]. Not only will this stimulate the recycling industry in the EU, but it will also allow countries in the Global South to focus the little recycling capacity they have on their own plastic waste.

While they are important, the above policies alone are not enough to create a fair and inclusive transition towards a sustainable circular plastics economy. Other key policies, which might not have the strongest support, are thus necessary, especially considering the recommendations of previous research in the area.

Policy recommendations, which are important from a sustainability and circularity perspective:

- Afvalfonds Verpakkingen should include civil society organizations and local and national government representatives in a participatory and inclusive manner so that its decisions regarding plastics are more democratic, transparent, and inclusive (statement #26). Evidence from this and other research shows that EPR systems tend to choose the cheapest and most profitable recovery option rather than the most social and environmentally sustainable options [100,120,128]. This is why most of the waste in the Netherlands is currently incinerated or exported to the Global South. While EPR costs are borne by society, which pays the EPR fee and suffers the consequences of plastic pollution and incineration, people currently have no say on how EPRs are managed. It is, therefore, key to increase the democratic inclusiveness of the system by placing civil society organizations and local government representatives in the board of Afvalfonds Verpakkingen, with an equal say in decisions compared to private actors. The EPR system would thus not only become more inclusive, but it will also create full transparency and accountability regarding what happens to collected plastics. This can thus lead to key improvements in the social and environmental performance of the EPR system [100,120,123,125].

- Establish targets to reduce overall plastic consumption per capita (statement #42). Reducing overall plastic consumption is the ultimate aim of any CE policy for plastics according to academics and practitioners alike [3,67,80,129]. It is thus key to focus on this goal as a binding policy target.

- The government and companies should highly increase the use of reusable packaging (statement #36). Reusable packaging has been in steady decline in the last decades [91]. Yet, it has a unique potential as it can lead to both economic savings and environmental impact reductions compared to single-use options. Studies have found that reusable packaging outperforms single-use packaging for both business-to-business and business-to-consumer applications [91,92,93]. Moreover, reusable packaging enjoys a renewed customer acceptance [92]. To facilitate the deployment of reusable packaging options, the state should establish deposit-refund systems and reduce taxes for reusable packaging [86]. In addition to this, an eco-efficient and customer-friendly design of standardized reusable packaging containers, bottles, crates, and logistical systems should be established to improve the economic and environmental efficiency of return systems.

- The government should establish a fair and just societal system to make sure that all the fees and costs of a circular economy transition for plastics do not fall on the poorest and most vulnerable people (statement #16). The EPR fees and the additional taxes which are suggested as policy options above will increase the overall price of products for consumers in a regressive manner (those that have the least will pay the most as a percentage of their income) [86,124]. To compensate for this, it is key to redistribute some of these resources to low-income communities through projects and initiatives that employ vulnerable and disenfranchised groups and support local livelihoods [81]. Pay-as-you-throw systems, which reward people for recycling, could also be established to redistribute part of the collected taxes and fees [122].

- Government and companies from the Global North should provide financial assistance and technology transfers to countries in the Global South so they can better manage plastic waste (statement #17). Waste management infrastructure and technology is very expensive, in low-income countries it can be the single highest budget item for municipal governments [31]. Yet these countries must deal with many other key sustainability issues from poverty to climate change and lack of housing [130]. Therefore, they require significant amounts of financial and technical assistance to help them develop their waste management infrastructure [80,81]. Fostering open-source technologies can also help in this regard as they can spread circular innovations and solutions throughout the world and democratize the transition to a circular economy and society [46].

- The government and companies from the Global North should establish a fund to finance clean-up activities of plastics in the oceans and other natural ecosystems (statement #6). Plastic pollution is ultimately a “collective action problem”, which requires global action to succeed [131]. Those that produce and consume the most plastics and have the greatest financial capacity should thus take the lead in solving this problem by funding clean-up activities throughout the world [80,86,132,133].

- Educate citizens and create more public awareness and change the culture of mass consumption to reduce overall plastic use (statement #13). In many ways, plastics themselves are not the problem, they are durable, efficient, and infinitely adaptable materials [5]. Rather, the problem resides in the high-paced capitalist system of mass consumption and production that depends on cheap throwaway plastics. The question is thus not only how to better recover and reuse plastics but rather how to use less of everything [134]. Sustainability education and awareness raising should not focus on individual consumer choices and behaviors, which have very limited environmental impacts [135]. Instead, it should focus on “questioning our over-consumptive consumerist lifestyles” [87] and “challenging entrenched corporate and societal views about growth” [84]. It is indeed key to promote post-materialist worldviews, which not only reduce the demand for unnecessary consumption but also open the door to slower, healthier, and more convivial ways of life [75,136,137].

The above policy recommendations should be understood as a set of integrated policies which complement each other. Plastic poses complex problems, which cannot be addressed through siloed actions or single strategies. A combination of value retention options from refuse (R0) to remine (R9) are thus needed, along with strong social justice and global solidarity policies. While these recommendations are specifically formulated for the Dutch policy context, they might also bring insights and ideas for the transition to a circular economy in other countries and contexts.

4.3. Limitations and Future Research

The first limitation of this research is the long and complex Q-survey process, which participants sometimes find difficult and overwhelming, thereby explaining the low participation rate (17.8%). This is a known implication of using Q-methods, and it is an integral part of this methodology, as the long and complex ranking of statements forces each participant to make key choices that reveal their underlying discourse on the topic [55]. The various pilot tests of our questionnaire in several online Q-method survey platforms helped us choose the most user-friendly option and limit this barrier to participation. However, future research should look at ways to further reduce the complexity of the Q-sorting process, both online and in-person.

Another key limitation of the methods is that the statements of the Q-survey were created from the results of the interviews and the policy and media analysis. They, therefore, replicate hegemonic visions on the CE transition for plastics, meaning that more alternative and radical propositions might not be adequately addressed and represented in the Q-survey. The following policies were therefore missing from the analysis as they were not present in the analyzed concourse, yet they might be important elements of the transition:

- Banning unnecessary plastic uses such as potable water bottles and additives in cosmetics and personal health products [86,132];

- Supporting local farmer markets and shops rather than supermarkets and online stores, which stock more processed and/or packaged goods [118];

- Establishing marine protected areas and banning bottom trawling and other harmful industrial fishing activities which devastate ocean biodiversity and are a key source of plastic pollution [87,133,134].

Future research should further analyze these and other policy options and approaches to addressing the CE transition for plastics.

Another key limitation lies in the very object of the study. Some authors have argued that the recent focus on the plastic pollution problem is a distraction from more urgent and important challenges of climate change and biodiversity conservation [87,134]. The art of policymaking can be understood as “creating problems that institutions can handle” [67], and, in that regard, the plastic pollution problem can be seen as a perfect opportunity to employ a neoliberal discourse of technocentric, market-based solutions, whereby corporations can resolve the problem with their recycling innovations [84]. Results from this research suggest that this technocentric discourse represents a dominant framing of the problem in the Netherlands. Future research in this regard is necessary, especially research that goes beyond a purely technical approach to plastics and looks at the manyfold social and ecological implications of cheap throwaway plastics within a global system of mass consumption and production. Indeed, plastics themselves are hardly the problem; it is rather how they are used by the current socio-technical system that is the problem [84]. Plastics are merely a cheap, lightweight, and flexible material, yet this system has used them as a throwaway vehicle that replicates a high-speed cycle of endless mass consumption. This systemic perspective on the topic must be further researched and understood, not only because we cannot grow forever on a finite planet, but also because research has shown that human beings aspire for infinitely more meaningful and convivial lives than the productivist materialism on which capitalism depends [75,137,138].

5. Conclusions

This study has found that Dutch policies and discourses on plastics mainly follow a Technocentric Circular Economy perspective, which places high hopes on technological innovations such as chemical and mechanical recycling technologies and pays little attention to reducing global socio-ecological impacts. In the short term, this strategy might make the Netherlands appear as a frontrunner in the transition to a CE and thereby bring unprecedented growth for its plastic recovery industry. Yet, considering the many limitations of recycling technologies, it is highly unlikely that such a strategy will effectively reduce the human and environmental health impact of plastics. Instead, higher value retention options, such as refuse (R0), reduce (R1), and reuse (R2), should be prioritized, along with strong social justice policies. Our research proposes key policy recommendations in this regard (Section 4.2), which are based on a detailed analysis of the current plastic management system in the Netherlands. While these recommendations are specifically formulated for the Dutch policy context, they might also bring valuable insights that can help both practitioners and academics better understand and implement the transition towards a sustainable circular plastics economy in other countries and regions.

All in all, our research has found that the dominant discourse on the CE transition for plastics in the Netherlands assumes that the current system of mass-production and consumption can remain unchanged. Next-day deliveries and highly processed foods and products made with components and ingredients from all over the world are thereby set as unchangeable variables. Our research shows that the dominant imaginaries in the Netherlands are not considering alternatives, such as neighborhood stores and restaurants, repair cooperatives, and community-based markets of local, fresh, healthy, and seasonal goods that require little or no packaging in the first place. We observe that the economic interests of plastic industries, online retailers, and ultraprocessed foods dominate the material and discursive landscape upon which CE policies are formulated. Therefore, the current plastic discourse in the Netherlands does not challenge the capitalist system of fast-paced mass consumption, which fuels the need for so much plastic in the first place. Moreover, it replicates recycling fairy tales and neoliberal imaginaries of continuous economic growth, which disregard the biophysical limits of earth and the laws of thermodynamics. Under this discourse, our findings suggest that plastic production and consumption will likely increase, leading to significant adverse environmental and human health implications.

Further critical research on plastic and CE discourses and policies is needed, especially regarding the construction of discursive path dependencies and institutional lock-ins that reinforce a growth-dependent system. Alternative approaches to the plastic problem are needed from a systemic, plural, and transdisciplinary perspective. We hope the insights and recommendations brought by our research help bring light to this important academic and societal debate, and that future research will further explore the manyfold social, environmental, and political implications that the transition to a sustainable circular plastic economy entails.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/su14010190/s1, A: Newspaper Articles, B: Identified Stakeholders in the Dutch Plastic Sector, C: Interview questions, D: Overview of Interviewees, E: Q-survey process, F: Full data recycling percentages Afvalfonds Verpakkingen 2014–2019, G: Output from PQ Method Software.

Author Contributions

Conceptualization, M.C.F., W.J.V.V. and R.S.; methodology, M.C.F., W.J.V.V. and R.S.; software, D.L. and M.C.F.; validation, M.C.F., W.J.V.V. and R.S.; formal analysis, M.C.F. and D.L.; investigation, M.C.F. and D.L.; resources, W.J.V.V. and R.S.; data curation, D.L., M.C.F. and W.J.V.V.; writing—original draft preparation, M.C.F. and D.L.; writing—review and editing, M.C.F., W.J.V.V. and R.S.; visualization, M.C.F. and D.L.; supervision, W.J.V.V. and R.S.; project administration, W.J.V.V. and R.S.; funding acquisition, W.J.V.V. and R.S. All authors have read and agreed to the published version of the manuscript.

Funding

This article constitutes part of the outcomes of the CRESTING (Circular Economy: Sustainability implications and guiding progress) project, funded by the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No. 765198.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

A previous version of this research was presented at the 26th International Sustainable Development Research Society (ISDRS) Conference in July 2020. We would like to thank the anonymous reviewers for their helpful comments and suggestions, as well as Ton Markus for the design of the figures. We would also like to thank Anna Walker, Kieran Campbell-Johnston, Kaustubh Thapa, and Frank Van Laerhoven for their constructive comments on this research. Finally, we would like to thank all people that took part in this research by volunteering their time for a personal interview and to fill in the Q-survey. This research would not have been possible without them.

Conflicts of Interest

The authors declare no conflict of interest.

References

- European Commission. A European Strategy for Plastics in a Circular Economy; SWD (2018); European Commission: Brussels, Belgium, 2018. [Google Scholar]

- UNEP. Single-Use Plastics: A Roadmap for Sustainability. 2018. Available online: https://www.unep.org/resources/report/single-use-plastics-roadmap-sustainability (accessed on 4 November 2021).

- WEF; EMF; McKinsey. The New Plastics Economy—Rethinking the Future of Plastics. 2016. Available online: https://ellenmacarthurfoundation.org/the-new-plastics-economy-rethinking-the-future-of-plastics (accessed on 4 November 2021).

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Bucknall, D.G. Plastics as a materials system in a circular economy. Philos. Trans. R. Soc. A 2020, 378, 20190268. [Google Scholar] [CrossRef] [PubMed]

- Klemeš, J.J.; Van Fan, Y.; Jiang, P. Plastics: Friends or foes? The circularity and plastic waste footprint. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 43, 1549–1565. [Google Scholar] [CrossRef]

- Azevedo-Santos, V.M.; Brito, M.F.G.; Manoel, P.S.; Perroca, J.F.; Rodrigues-Filho, J.L.; Paschoal, L.R.P.; Gonçalves, G.R.L.; Wolf, M.R.; Blettler, M.C.M.; Andrade, M.C.; et al. Plastic pollution: A focus on freshwater biodiversity. Ambio 2021, 50, 1313–1324. [Google Scholar] [CrossRef]

- Li, P.; Wang, X.; Su, M.; Zou, X.; Duan, L.; Zhang, H. Characteristics of Plastic Pollution in the Environment: A Review. Bull. Environ. Contam. Toxicol. 2020, 107, 577–584. [Google Scholar] [CrossRef] [PubMed]

- Xu, B.; Liu, F.; Cryder, Z.; Huang, D.; Lu, Z.; He, Y.; Wang, H.; Lu, Z.; Brookes, P.C.; Tang, C.; et al. Microplastics in the soil environment: Occurrence, risks, interactions and fate—A review. Crit. Rev. Environ. Sci. Technol. 2019, 50, 2175–2222. [Google Scholar] [CrossRef]

- Law, K.L. Plastics in the Marine Environment. Ann. Rev. Mar. Sci. 2017, 9, 205–229. [Google Scholar] [CrossRef]

- Karami, A.; Golieskardi, A.; Choo, C.K.; Larat, V.; Galloway, T.S.; Salamatinia, B. The presence of microplastics in commercial salts from different countries. Sci. Rep. 2017, 7, 46173. [Google Scholar] [CrossRef]

- Liebezeit, G.; Liebezeit, E. Synthetic particles as contaminants in German beers. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2014, 31, 1574–1578. [Google Scholar] [CrossRef]

- Liebezeit, G.; Liebezeit, E. Non-pollen particulates in honey and sugar. Food Addit. Contam. Part A Chem. Anal. Control Expo. Risk Assess. 2013, 30, 2136–2140. [Google Scholar] [CrossRef]