Mechanical Properties, Microstructure, and Chloride Content of Alkali-Activated Fly Ash Paste Made with Sea Water

Abstract

1. Introduction

2. Experiments

2.1. Materials and Sample Preparation

2.2. Testing and Characterization Protocols

3. Results and Discussion

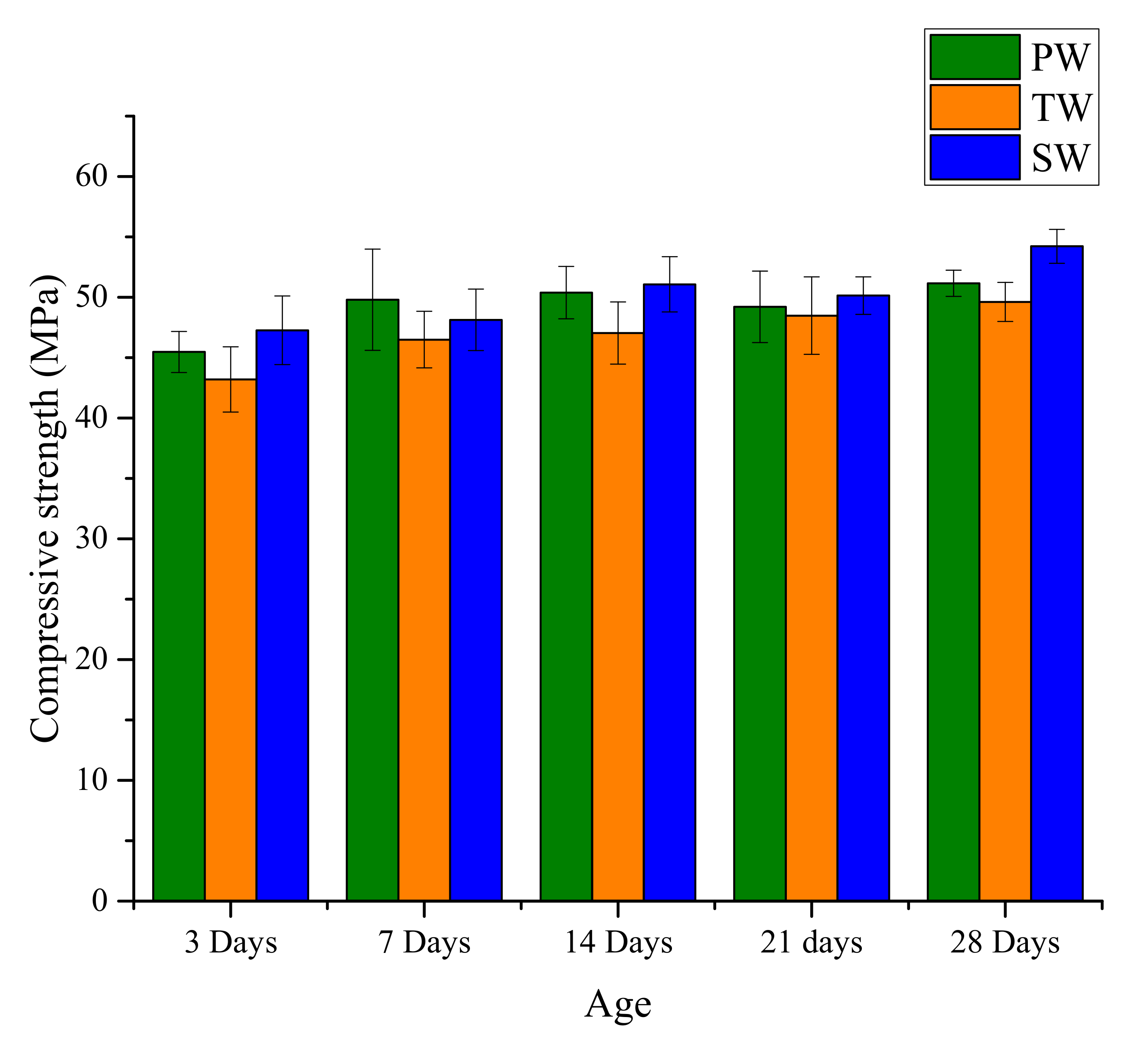

3.1. Compressive Strength

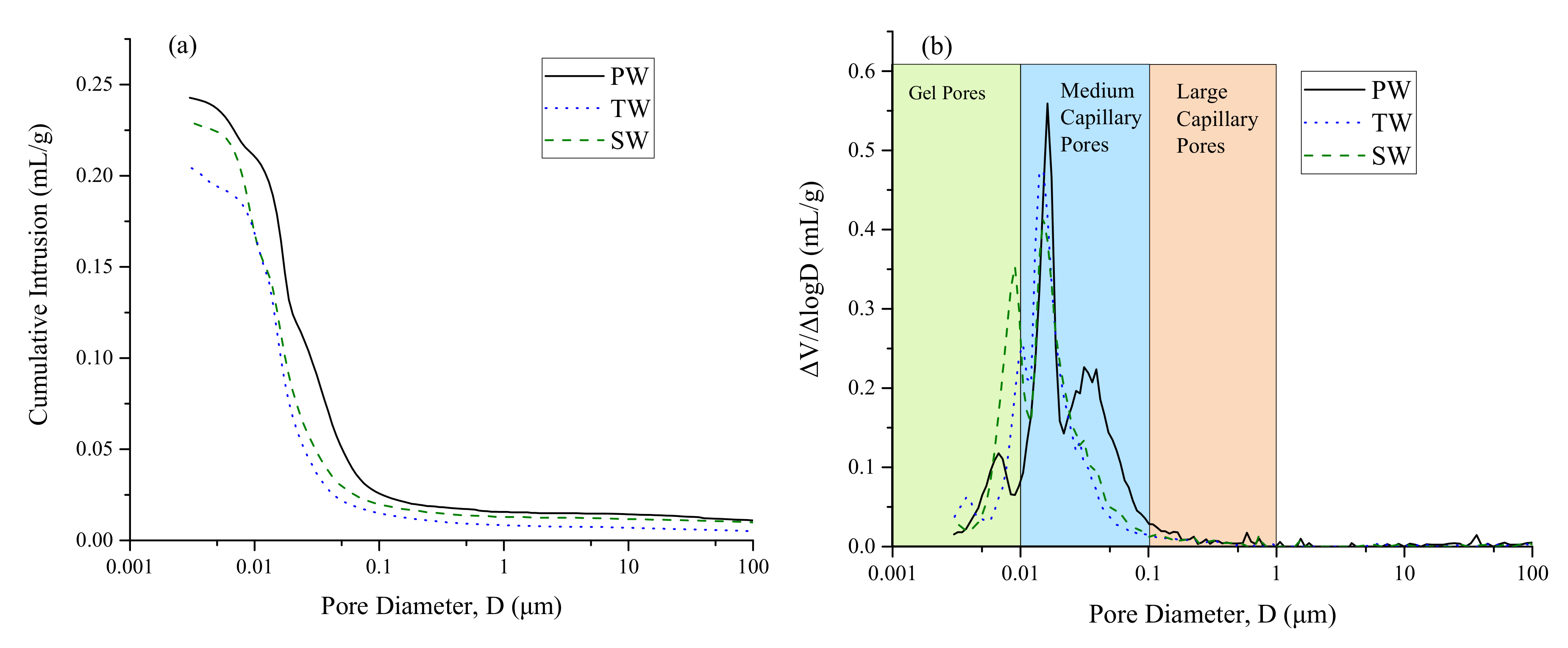

3.2. Porosity

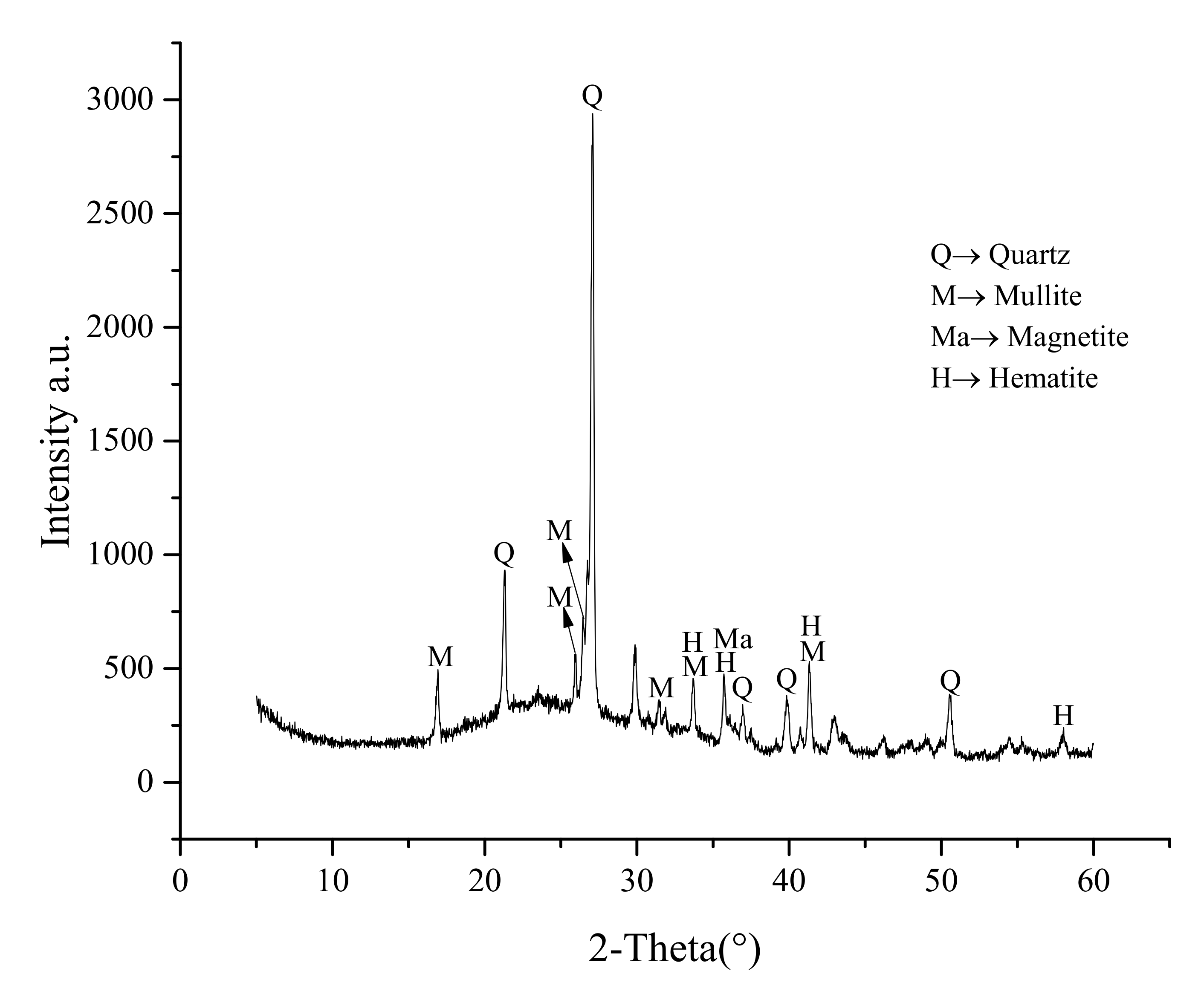

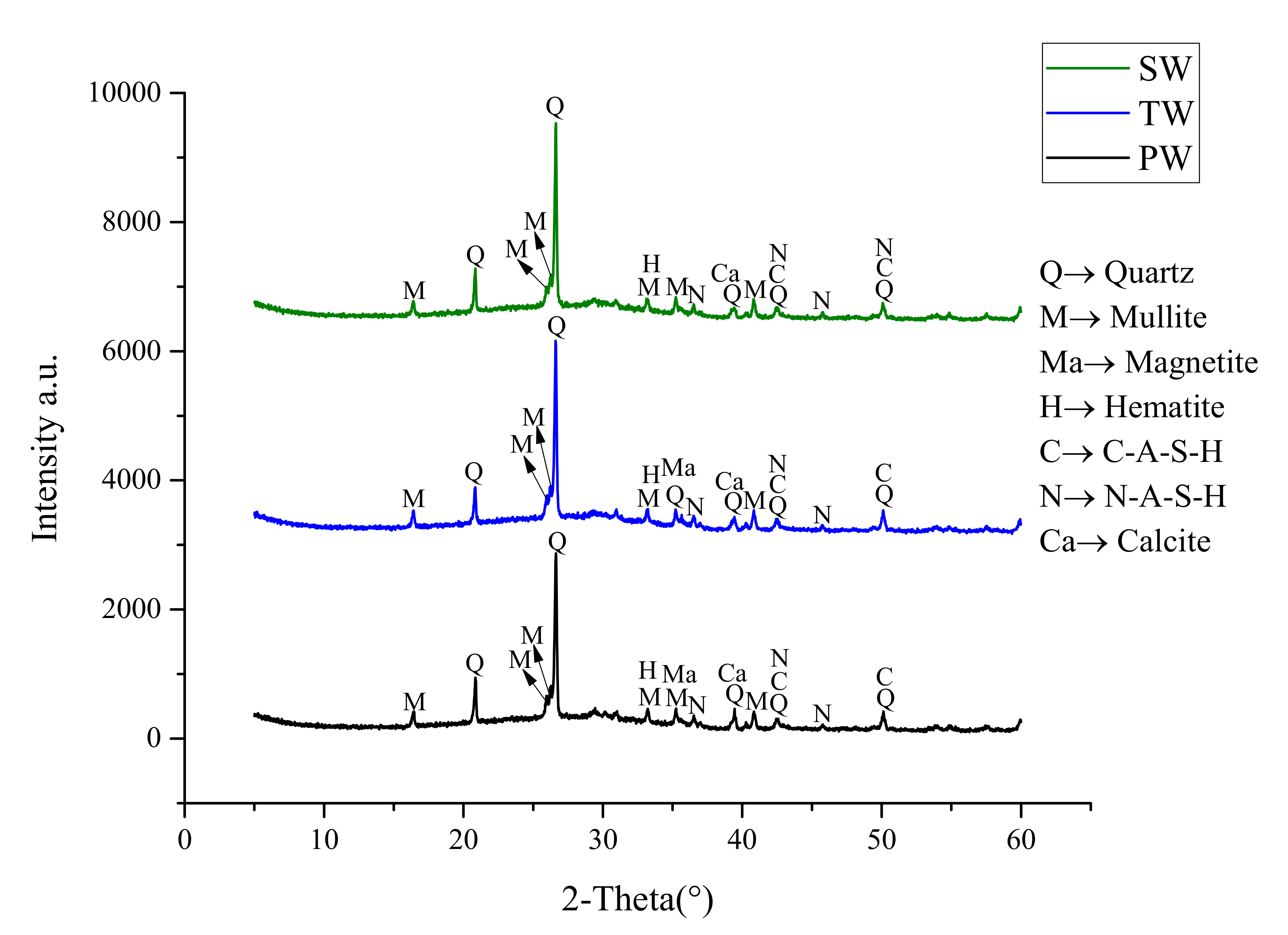

3.3. X-Ray Diffraction

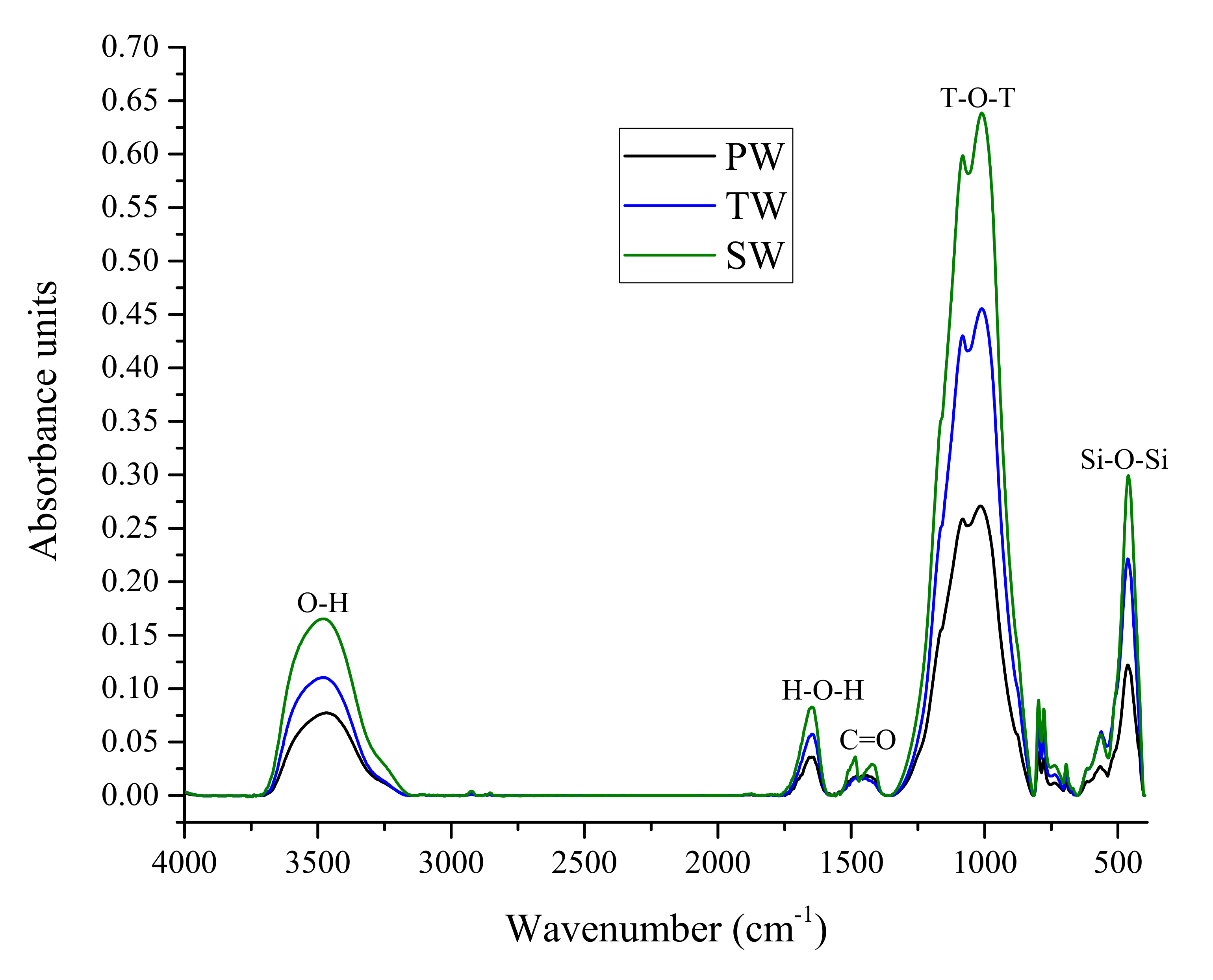

3.4. FT-IR

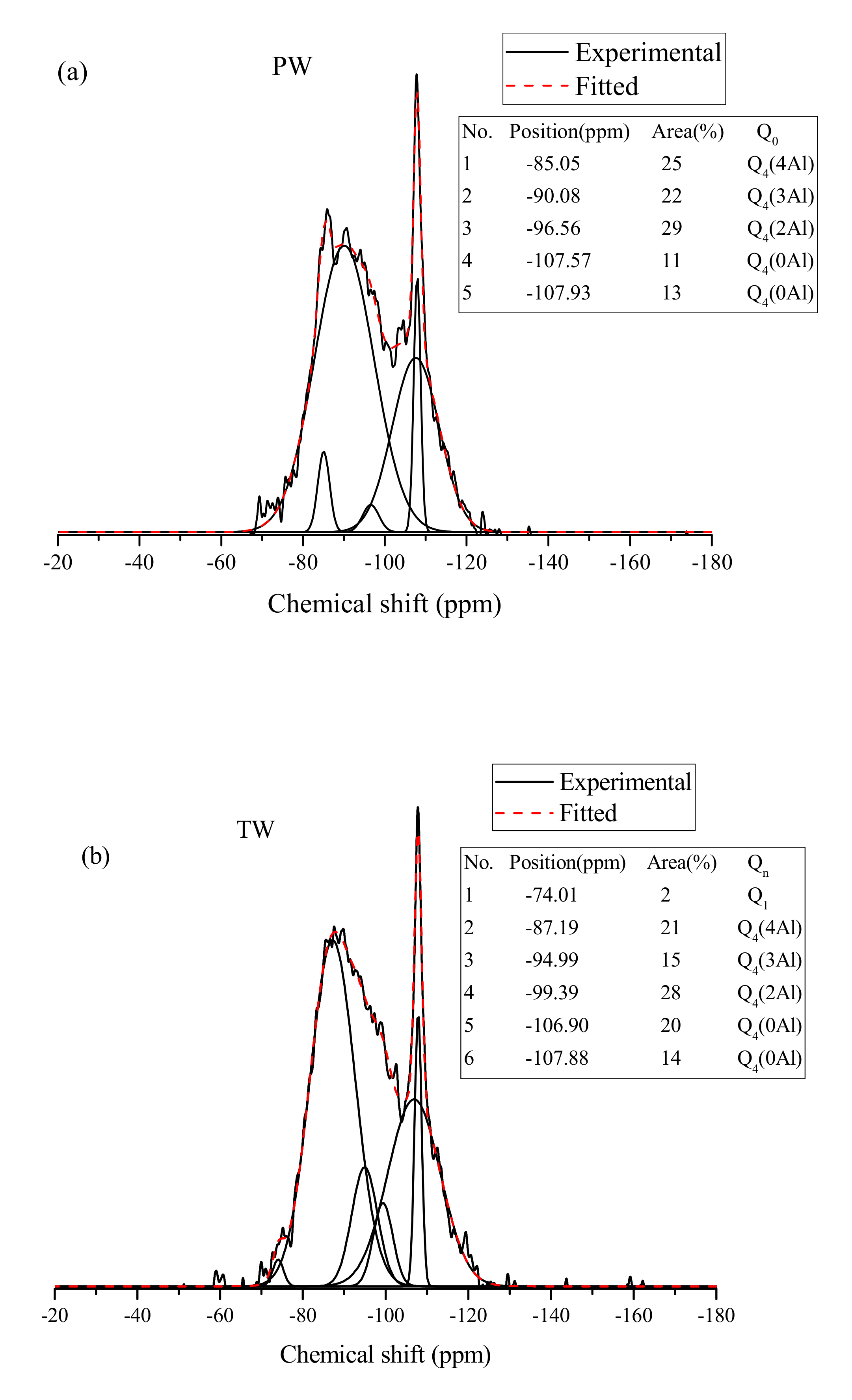

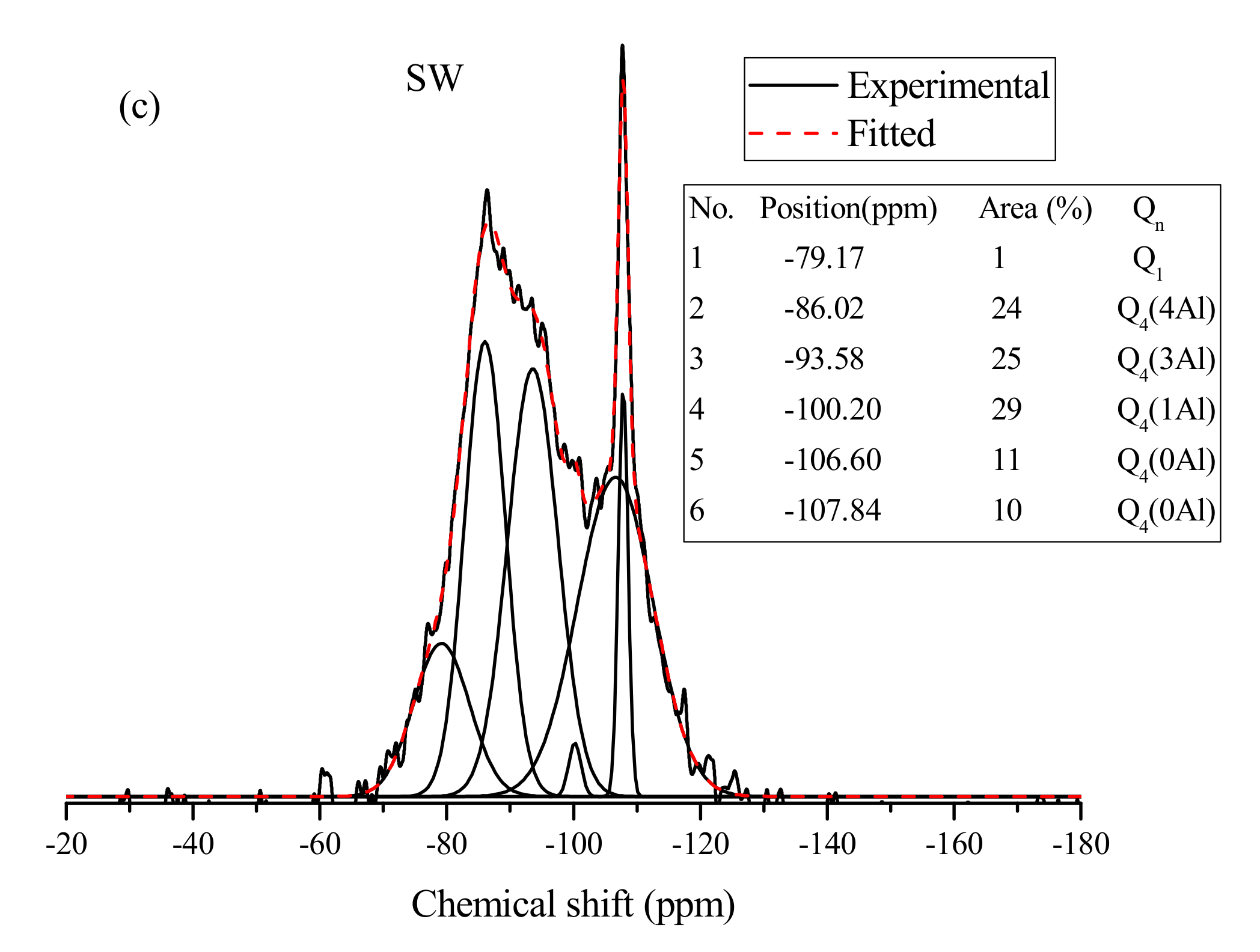

3.5. NMR

3.6. Free Chloride Content

4. Conclusions

- The difference in compressive strength was marginal on utilizing the three different types of water for alkali activating solution. Moreover, the presence of chloride ions and higher pH of sea water were instrumental for slightly greater gain in compressive strength.

- The use of sea water resulted in the refined pore structure along with reduced average pore diameter. The primary cause was the higher amount of polymerization products that densified the matrix.

- The XRD results showed that the use of sea water has negligible effects on the mineralogical phases of alkali-activated fly ash material. Moreover, the absence of any chloride and sulphate based crystalline minerals is an evidence of the immobilization potential of the alkali activation process.

- The FT-IR spectra of the alkali-activated samples showed no negative influence of sea water on the bond band of polymerization products. The results suggest that the use of sea water leads to higher crosslinking of sodium aluminosilicates hydrates in alkali-activated fly ash material.

- The ordering structure and higher Si/Al ratio observed from 29Si NMR spectra showed that the sea water-based alkali-activated fly ash material has higher content of Q4 groups. Furthermore, the sea water-based alkali-activated fly ash material has the higher formation of zeolitic Si–O–Al linkages which is indicative of more matured paste matrix.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Miller, S.A.; John, V.M.; Pacca, S.A.; Horvath, A. Carbon dioxide reduction potential in the global cement industry by 2050. Cem. Concr. Res. 2018, 114, 115–124. [Google Scholar] [CrossRef]

- Gerbens-Leenes, P.W.; Hoekstra, A.Y.; Bosman, R. The blue and grey water footprint of construction materials: Steel, cement and glass. Water Resour. Ind. 2018, 19, 1–12. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Shi, Z.; Shui, Z.; Li, Q.; Geng, H. Combined effect of metakaolin and sea water on performance and microstructures of concrete. Constr. Build. Mater. 2015, 74, 57–64. [Google Scholar] [CrossRef]

- Li, Q.; Geng, H.; Huang, Y.; Shui, Z. Chloride resistance of concrete with metakaolin addition and seawater mixing: A comparative study. Constr. Build. Mater. 2015, 101, 184–192. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A.; Pardo, P. Influence of seawater and blast furnace cement employment on recycled aggregate concretes’ properties. Constr. Build. Mater. 2016, 115, 496–505. [Google Scholar] [CrossRef]

- Li, H.; Farzadnia, N.; Shi, C. The role of seawater in interaction of slag and silica fume with cement in low water-to-binder ratio pastes at the early age of hydration. Constr. Build. Mater. 2018, 185, 508–518. [Google Scholar] [CrossRef]

- Li, Y.-L.; Zhao, X.-L.; Singh Raman, R.K.; Al-Saadi, S. Thermal and mechanical properties of alkali-activated slag paste, mortar and concrete utilising seawater and sea sand. Constr. Build. Mater. 2018, 159, 704–724. [Google Scholar] [CrossRef]

- Shi, D.; Yao, Y.; Ye, J.; Zhang, W. Effects of seawater on mechanical properties, mineralogy and microstructure of calcium silicate slag-based alkali-activated materials. Constr. Build. Mater. 2019, 212, 569–577. [Google Scholar] [CrossRef]

- Yang, S.; Xu, J.; Zang, C.; Li, R.; Yang, Q.; Sun, S. Mechanical properties of alkali-activated slag concrete mixed by seawater and sea sand. Constr. Build. Mater. 2019, 196, 395–410. [Google Scholar] [CrossRef]

- ASTM International. Standard Practice for the Preparation of Substitute Ocean Water; ASTMD1141; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM International. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTMC618; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); ASTMC109; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Rashad, A.M.; Ezzat, M. A Preliminary study on the use of magnetic, Zamzam, and sea water as mixing water for alkali-activated slag pastes. Constr. Build. Mater. 2019, 207, 672–678. [Google Scholar] [CrossRef]

- Jang, J.G.; Lee, H.K. Effect of fly ash characteristics on delayed high-strength development of geopolymers. Constr. Build. Mater. 2016, 102, 260–269. [Google Scholar] [CrossRef]

- Ma, Y.; Hu, J.; Ye, G. The pore structure and permeability of alkali activated fly ash. Fuel 2013, 104, 771–780. [Google Scholar] [CrossRef]

- Jeon, D.; Jun, Y.; Jeong, Y.; Oh, J.E. Microstructural and strength improvements through the use of Na2CO3 in a cementless Ca(OH)2-activated Class F fly ash system. Cem. Concr. Res. 2015, 67, 215–225. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J. Concrete: Microstructure, Properties, and Materials; Tata Mcgraw Hill Education: New York, NY, USA, 2006. [Google Scholar]

- Kim, T.; Kim, I.-T.; Seo, K.-Y.; Park, H.-J. Strength and pore characteristics of OPC-slag cement paste mixed with polyaluminum chloride. Constr. Build. Mater. 2019, 223, 616–628. [Google Scholar] [CrossRef]

- Mohammed, T.U.; Hamada, H.; Yamaji, T. Performance of seawater-mixed concrete in the tidal environment. Cem. Concr. Res. 2004, 34, 593–601. [Google Scholar] [CrossRef]

- Etxeberria, M.; Gonzalez-Corominas, A. Properties of Plain Concrete Produced Employing Recycled Aggregates and Sea Water. Int. J. Civ. Eng. 2018, 16, 993–1003. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Zhang, Z. Chloride binding of alkali-activated slag/fly ash cements. Constr. Build. Mater. 2019, 226, 21–31. [Google Scholar] [CrossRef]

- He, W.; Liu, C.; Zhang, L. Effects of sodium chloride on the mechanical properties of slag composite matrix geopolymer. Adv. Cem. Res. 2019, 31, 389–398. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Mid-infrared spectroscopic studies of alkali-activated fly ash structure. Microporous Mesoporous Mater. 2005, 86, 207–214. [Google Scholar] [CrossRef]

- Kovalchuk, G.; Fernández-Jiménez, A.; Palomo, A. Alkali-activated fly ash: Effect of thermal curing conditions on mechanical and microstructural development—Part II. Fuel 2007, 86, 315–322. [Google Scholar] [CrossRef]

- Kumar, S.; Mucsi, G.; Kristály, F.; Pekker, P. Mechanical activation of fly ash and its influence on micro and nano-structural behaviour of resulting geopolymers. Adv. Powder Technol. 2017, 28, 805–813. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R. Mechanical activation of fly ash: Effect on reaction, structure and properties of resulting geopolymer. Ceram. Int. 2011, 37, 533–541. [Google Scholar] [CrossRef]

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A. Characterisation of fly ashes. Potential reactivity as alkaline cements. Fuel 2003, 82, 2259–2265. [Google Scholar] [CrossRef]

- Thrush, K.A.; Kuznicki, S.M. Characterization of chabazite and chabazite-like zeolites of unusual composition. J. Chem. Soc. Faraday Trans. 1991, 87, 1031–1035. [Google Scholar] [CrossRef]

- Fernández-Jimenez, A.; de la Torre, A.G.; Palomo, A.; López-Olmo, G.; Alonso, M.M.; Aranda, M.A.G. Quantitative determination of phases in the alkali activation of fly ash. Part I. Potential ash reactivity. Fuel 2006, 85, 625–634. [Google Scholar] [CrossRef]

- Engelhardt, G. Multinuclear solid-state NMR in silicate and zeolite chemistry. Trac Trends Anal. Chem. 1989, 8, 343–347. [Google Scholar] [CrossRef]

- Klinowski, J. Solid-state NMR studies of molecular sieve catalysts. Chem. Rev. 1991, 91, 1459–1479. [Google Scholar] [CrossRef]

- Oh, J.E.; Jun, Y.; Jeong, Y. Characterization of geopolymers from compositionally and physically different Class F fly ashes. Cem. Concr. Compos. 2014, 50, 16–26. [Google Scholar] [CrossRef]

- Hunger, M. Solid-State NMR Spectroscopy. In Zeolite Characterization and Catalysis: A Tutorial; Chester, A.W., Derouane, E.G., Eds.; Springer Netherlands: Dordrecht, The Netherlands, 2009; pp. 65–105. [Google Scholar] [CrossRef]

- Peng, Z.; Vance, K.; Dakhane, A.; Marzke, R.; Neithalath, N. Microstructural and 29Si MAS NMR spectroscopic evaluations of alkali cationic effects on fly ash activation. Cem. Concr. Compos. 2015, 57, 34–43. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A.; Aldred, J.; Rawal, A. Chloride diffusion resistance and chloride binding capacity of fly ash-based geopolymer concrete. Cem. Concr. Compos. 2019. [Google Scholar] [CrossRef]

| Oxide Composition | Fly Ash (wt.%) |

|---|---|

| SiO2 | 52.50 |

| CaO | 5.04 |

| Al2O3 | 24.80 |

| Fe2O3 | 6.00 |

| SO3 | 1.00 |

| MgO | 1.56 |

| P2O5 | 0.70 |

| K2O | 1.50 |

| Na2O | 0.90 |

| TiO2 | 1.40 |

| SrO | 0.20 |

| BaO | 0.20 |

| Loss of ignition | 4.20 |

| Compound | Pure Water | Tap Water | Sea Water |

|---|---|---|---|

| F | 0.05 | 0.18 | 4.03 |

| Cl | 0.18 | 52.28 | 41,942.03 |

| NO2 | - | - | - |

| Br | - | 0.15 | 110.86 |

| NO3 | 0.29 | 12.66 | 158.46 |

| PO4 | - | - | - |

| SO4 | 0.75 | 39.35 | 6802.00 |

| pH | 7.00 | 7.71 | 8.38 |

| Element | Pure Water | Tap Water | Sea Water |

|---|---|---|---|

| Al | <0.010 | <0.010 | 0.106 |

| Ba | <0.005 | <0.005 | <0.005 |

| Ca | 1.238 | 23.07 | 381.4 |

| K | <0.010 | 1.981 | 316.2 |

| Mg | <0.005 | 4.516 | 1129 |

| Na | 0.407 | 8.419 | 7359 |

| Sample | Total Pore Area (m2/g) | Average Pore Diameter (nm) | Porosity (%) |

|---|---|---|---|

| PW | 54.80 | 17.70 | 35.84 |

| TW | 59.25 | 13.80 | 32.53 |

| SW | 66.57 | 13.80 | 34.95 |

| Sample | Si/Al Ratio |

|---|---|

| PW | 1.96 |

| TW | 1.91 |

| SW | 2.08 |

| Sample | PW | TW | SW |

|---|---|---|---|

| Free chloride content (ppm) | 407.22 | 528.64 | 5535.00 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siddique, S.; Jang, J.G. Mechanical Properties, Microstructure, and Chloride Content of Alkali-Activated Fly Ash Paste Made with Sea Water. Materials 2020, 13, 1467. https://doi.org/10.3390/ma13061467

Siddique S, Jang JG. Mechanical Properties, Microstructure, and Chloride Content of Alkali-Activated Fly Ash Paste Made with Sea Water. Materials. 2020; 13(6):1467. https://doi.org/10.3390/ma13061467

Chicago/Turabian StyleSiddique, Salman, and Jeong Gook Jang. 2020. "Mechanical Properties, Microstructure, and Chloride Content of Alkali-Activated Fly Ash Paste Made with Sea Water" Materials 13, no. 6: 1467. https://doi.org/10.3390/ma13061467

APA StyleSiddique, S., & Jang, J. G. (2020). Mechanical Properties, Microstructure, and Chloride Content of Alkali-Activated Fly Ash Paste Made with Sea Water. Materials, 13(6), 1467. https://doi.org/10.3390/ma13061467