Requirements and Variability Affecting the Durability of Bonded Joints

Abstract

1. Introduction

1.1. Background and Quasi-Static Design Considerations

- The adhesive in the joint should not yield at 115% DLL;

- The adhesive in the joint should not failure at DUL;

- The joint should have an adequate fatigue life.

1.2. Cyclic-Fatigue Design Considerations

2. Materials and Methods

2.1. Research Methodology

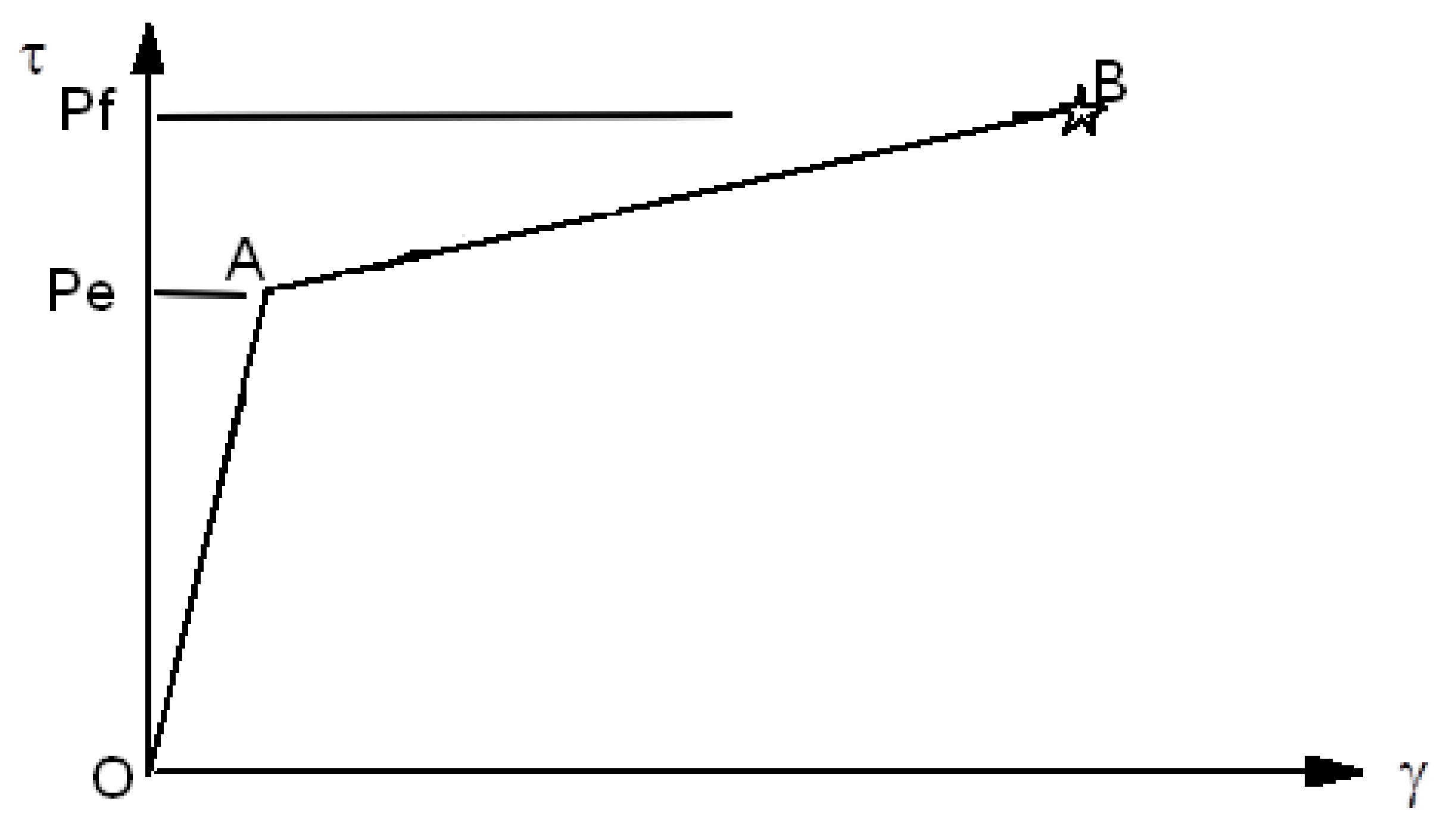

2.2. Theoretical Considerations

3. Characterising Cyclic Fatigue Crack Growth in Two F/A-18 Structural Epoxy Adhesives

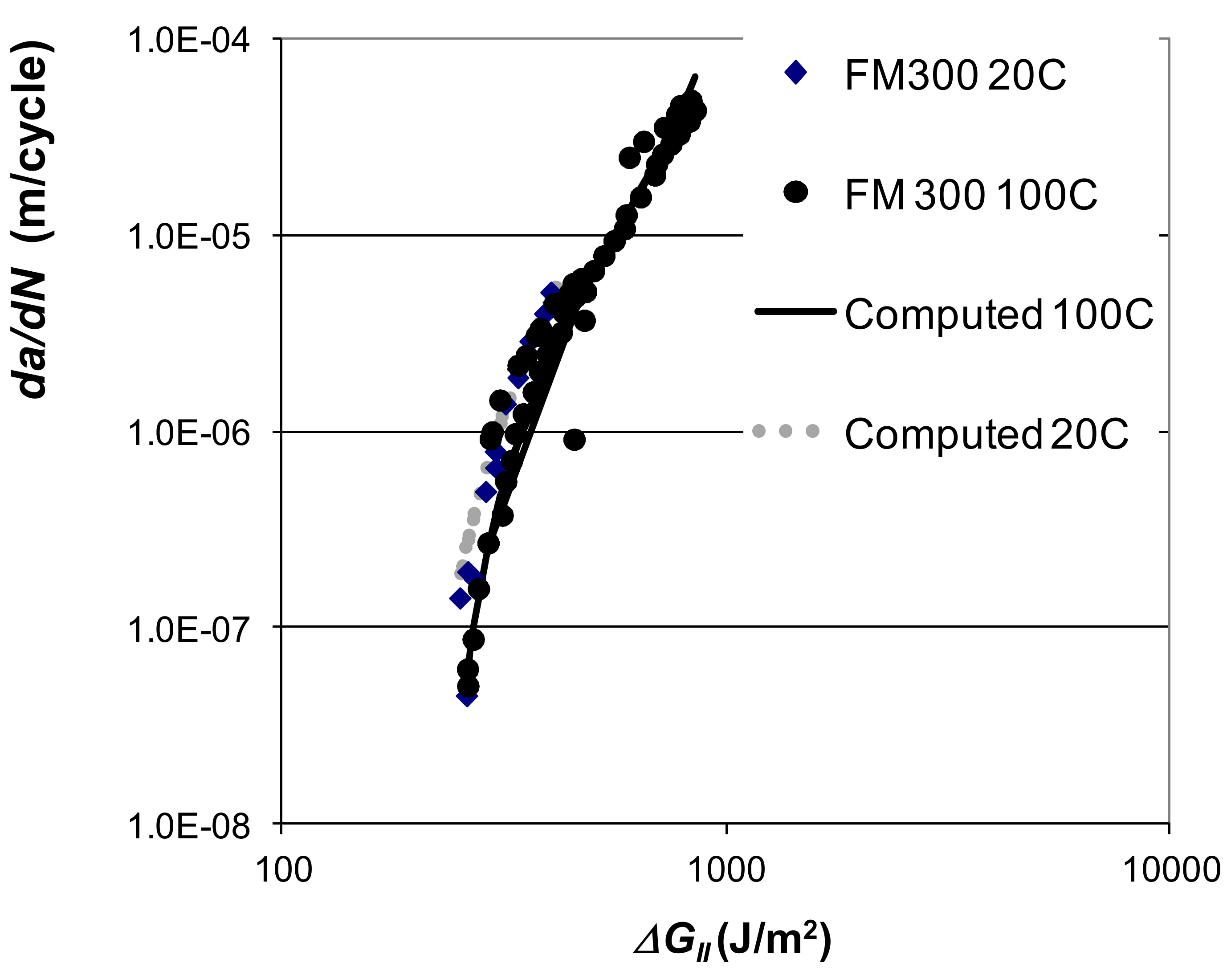

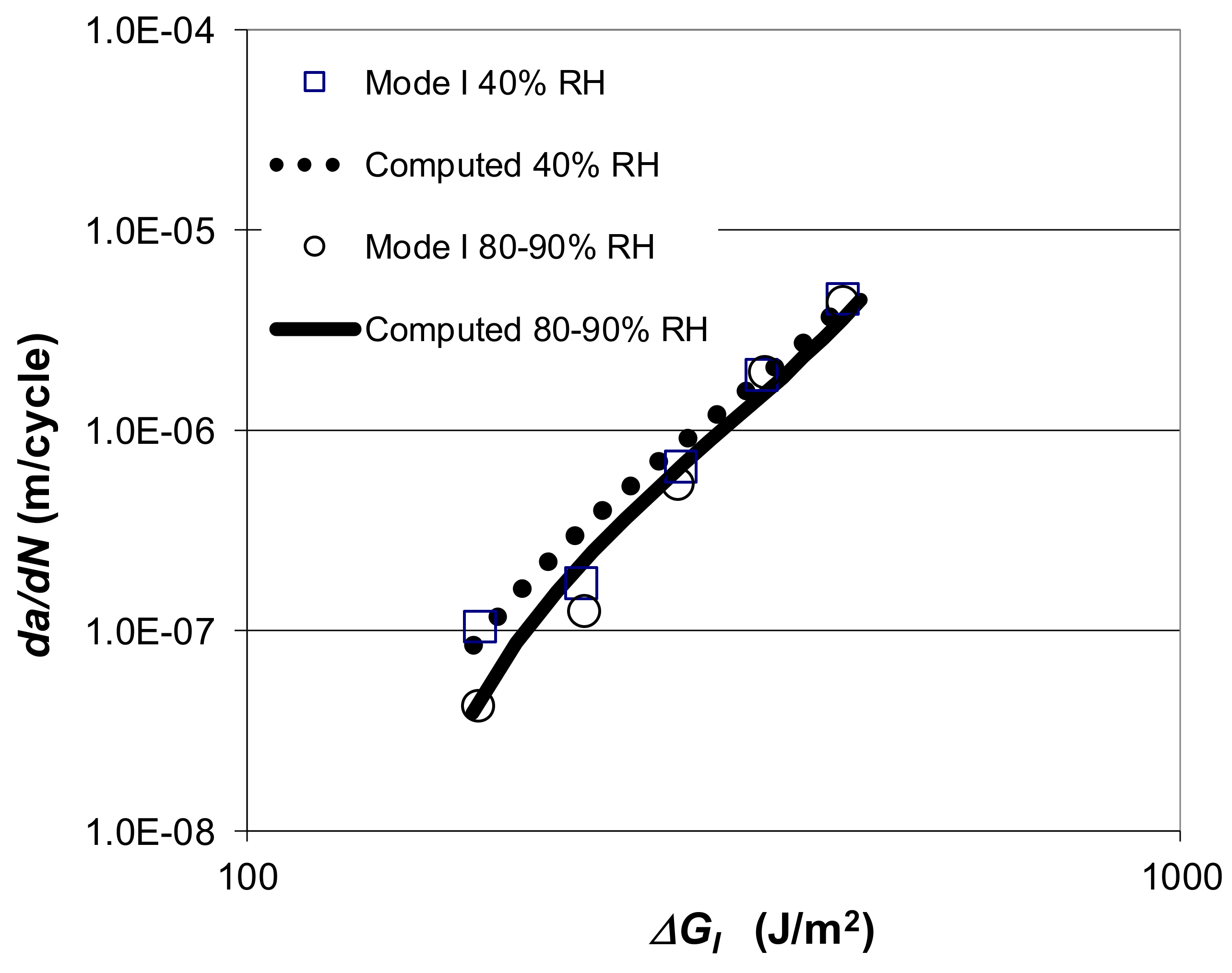

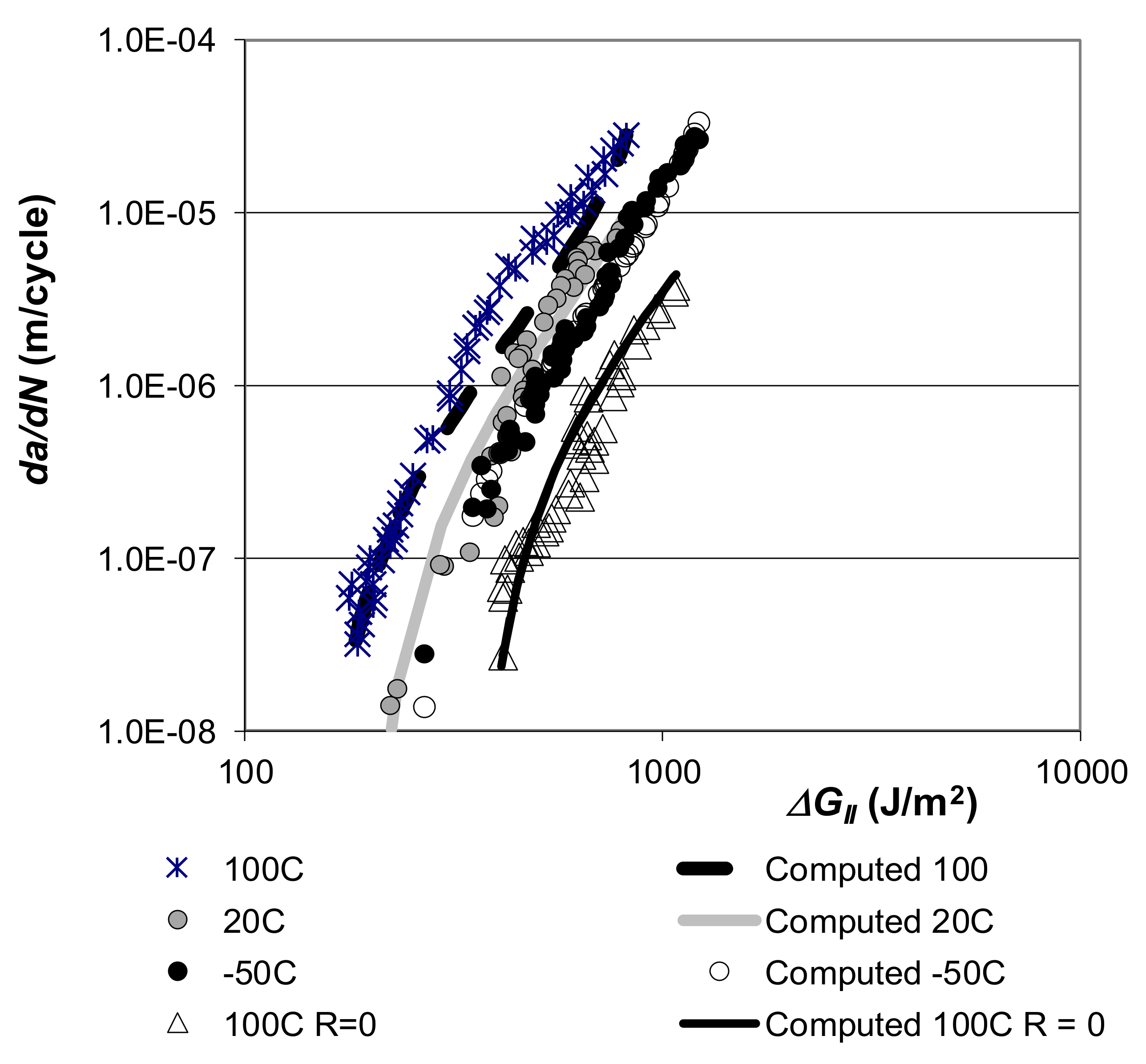

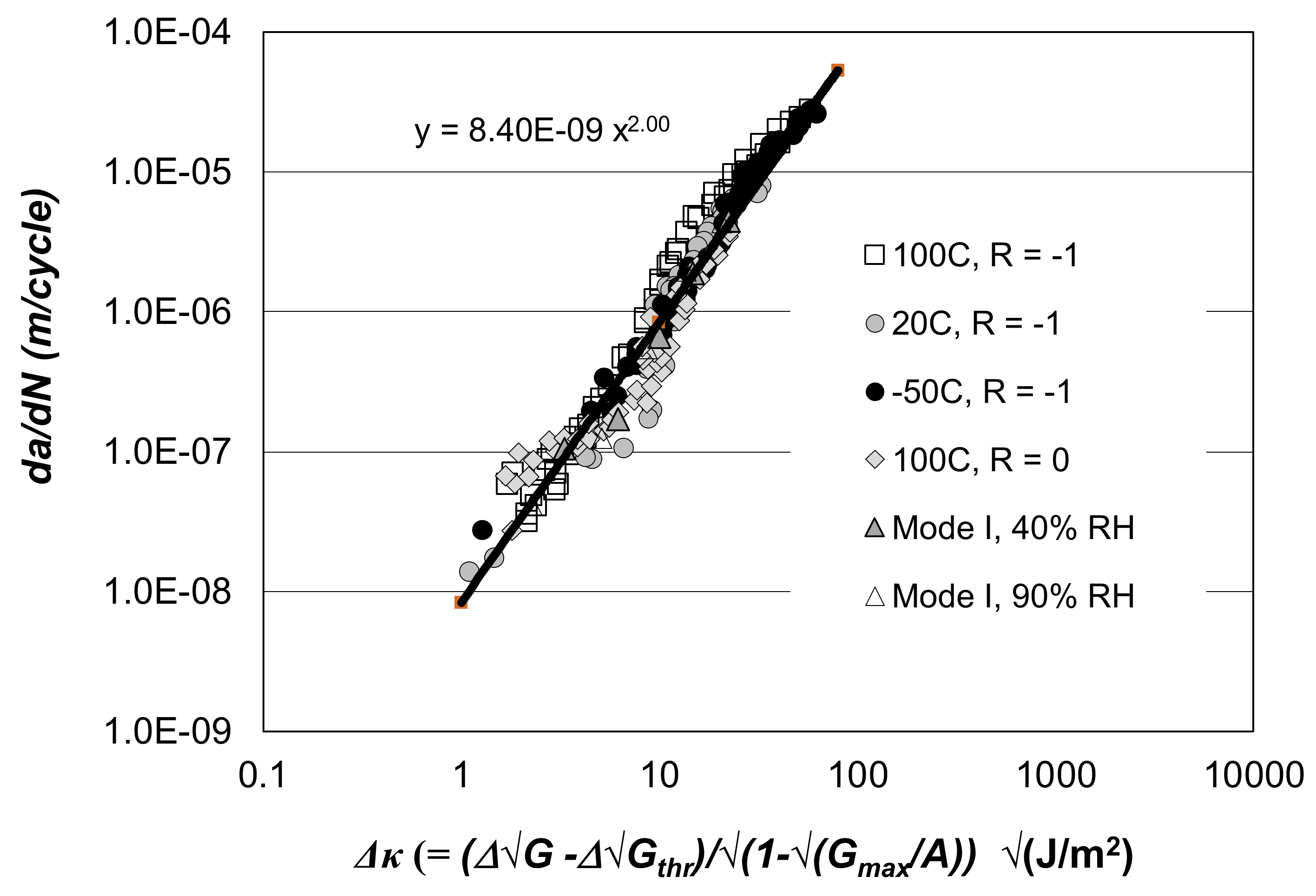

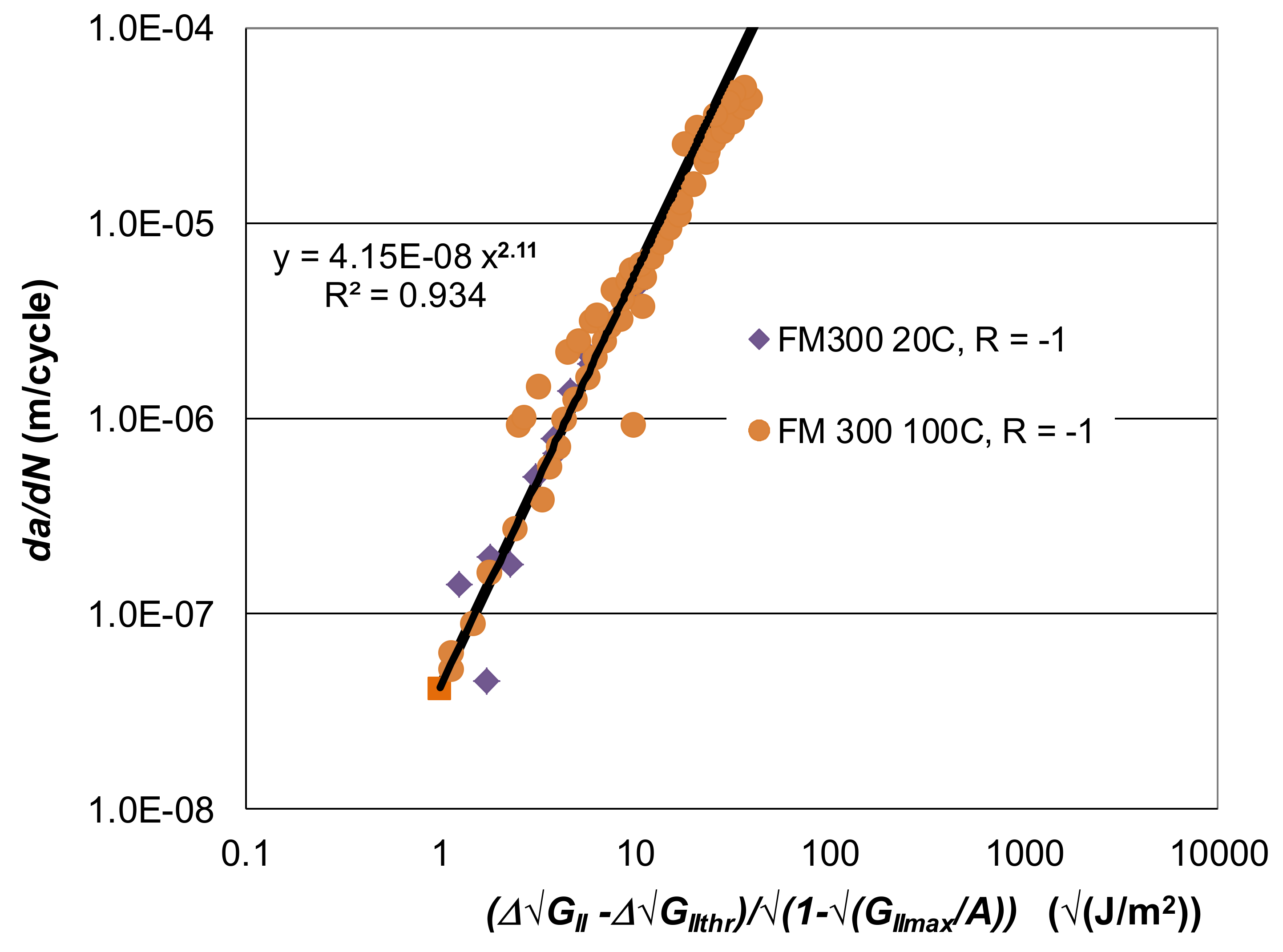

3.1. Correlation of Mode I and Mode II Fatigue Crack Growth

3.2. Characterising the Variability in Fatigue Crack Growth in Structural Adhesives

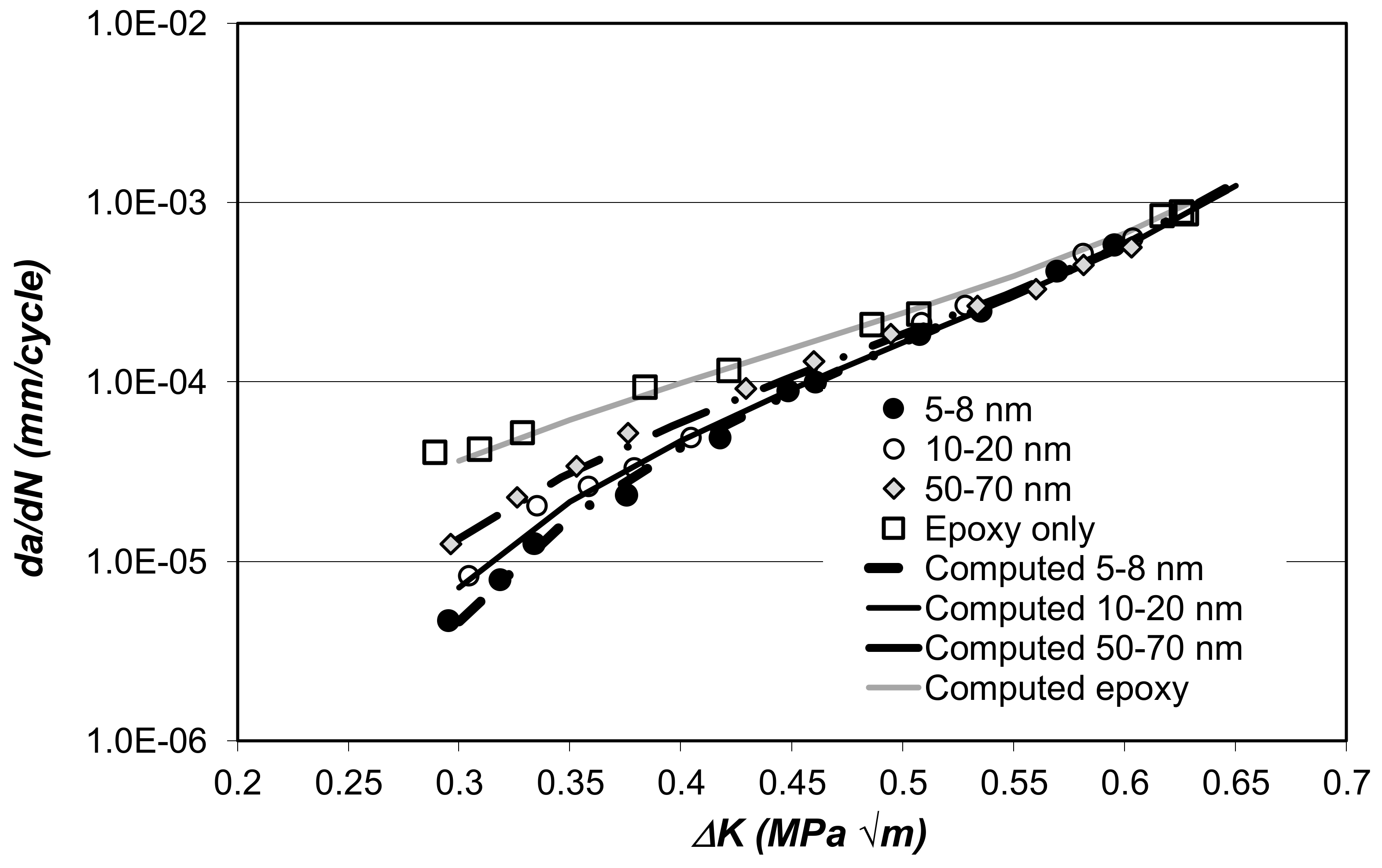

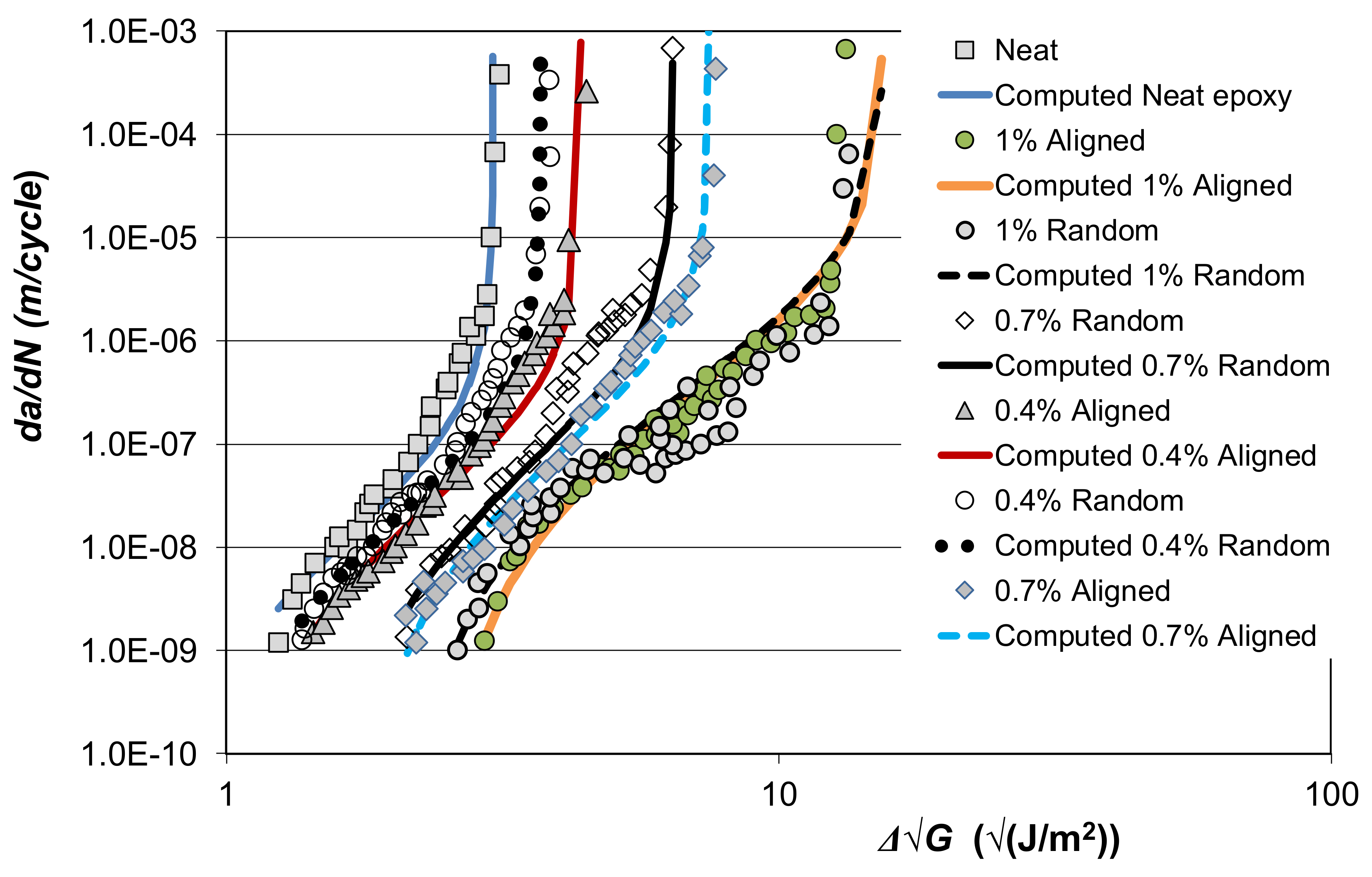

4. Cyclic Fatigue Crack Growth in Nano-Composite Adhesives

- In one case the addition of the nano-constituent only affected the fatigue threshold.

- In the other case the addition of the nano-constituent affected both the fatigue threshold and the fracture toughness.

5. Conclusions

- When assessing if a bonded joint meets the certification requirements inherent in MIL-STD-1530D and the US Joint Services Standard JSSG2006, it is necessary to ensure that (a) there is no yielding in the adhesive layer at 115% of design limit load, and (b) that the joint must be able to withstand design ultimate load.

- However, the belief that a bonded joint that meets quasi-static strength requirements will also meet durability requirements, based upon a “no crack growth” criterion from a “knock-down” factor applied to the quasi-static strength analysis, has been shown to be invalid in the applications studied.

- Indeed, considering applications of structural adhesive bonding in aircraft has highlighted the importance of designing bonded joints so as to allow for the fatigue threshold(s), where the rate of fatigue crack growth attains a lower limit, associated with small naturally occurring initial flaws in the adhesive. The requirement to establish the necessary inspection intervals associated with any bonded repairs also highlights the need to be able to predict the slow growth of cracks/disbonds in the adhesive.

- Fatigue crack growth in structural adhesives and in nano-reinforced epoxies under cyclic fatigue loading can be modelled Equations (2) and (3).

- For the structural adhesives FM300 and FM300K the fatigue data from both Mode I and Mode II loading collapse onto essentially the same da/dN versus Δκ master curve, regardless of the R-ratio and test temperatures that ranged from 20 to 100 °C.

- It would appear that the variability in the fatigue crack growth data, that is typically observed in adhesives, can be captured by allowing for the variability in the fatigue threshold term in the crack driving force Δκ is defined as per Schwalbe [32] (i.e., Equation (3)).

- Thus, a methodology has been established for estimating a valid upper-bound curve, for cohesive failure in the adhesive, which encompasses all the experimental data and provides a conservative fatigue crack growth curve which is representative of the structural adhesive. Such a valid, upper-bound curve can then employed for (a) the characterisation and comparison of adhesives, (b) a “no growth” design (if required), (c) for assessing if a disbond, that is found in an in-service aircraft, will grow and (d) the design and lifing of in-service adhesively-bonded aircraft structures, where material allowable properties have to be inputted into a disbond slow growth analysis for cyclic-fatigue loading.

Author Contributions

Funding

Conflicts of Interest

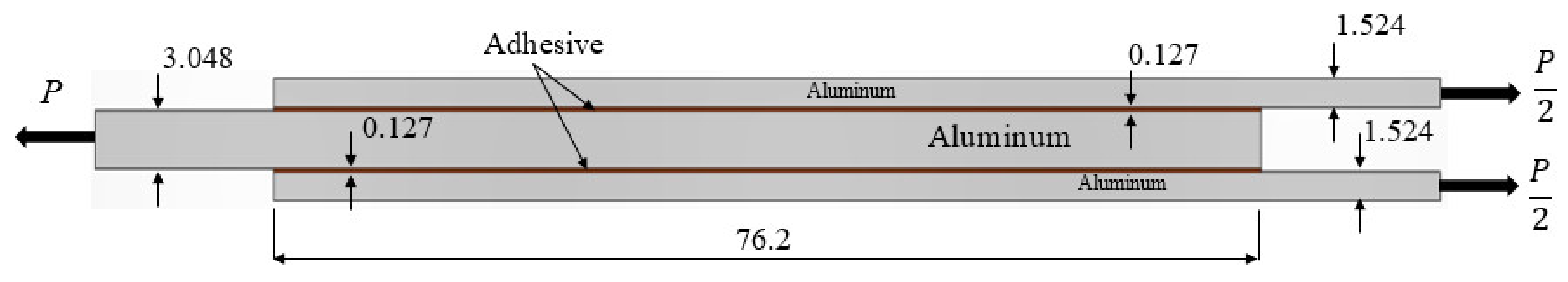

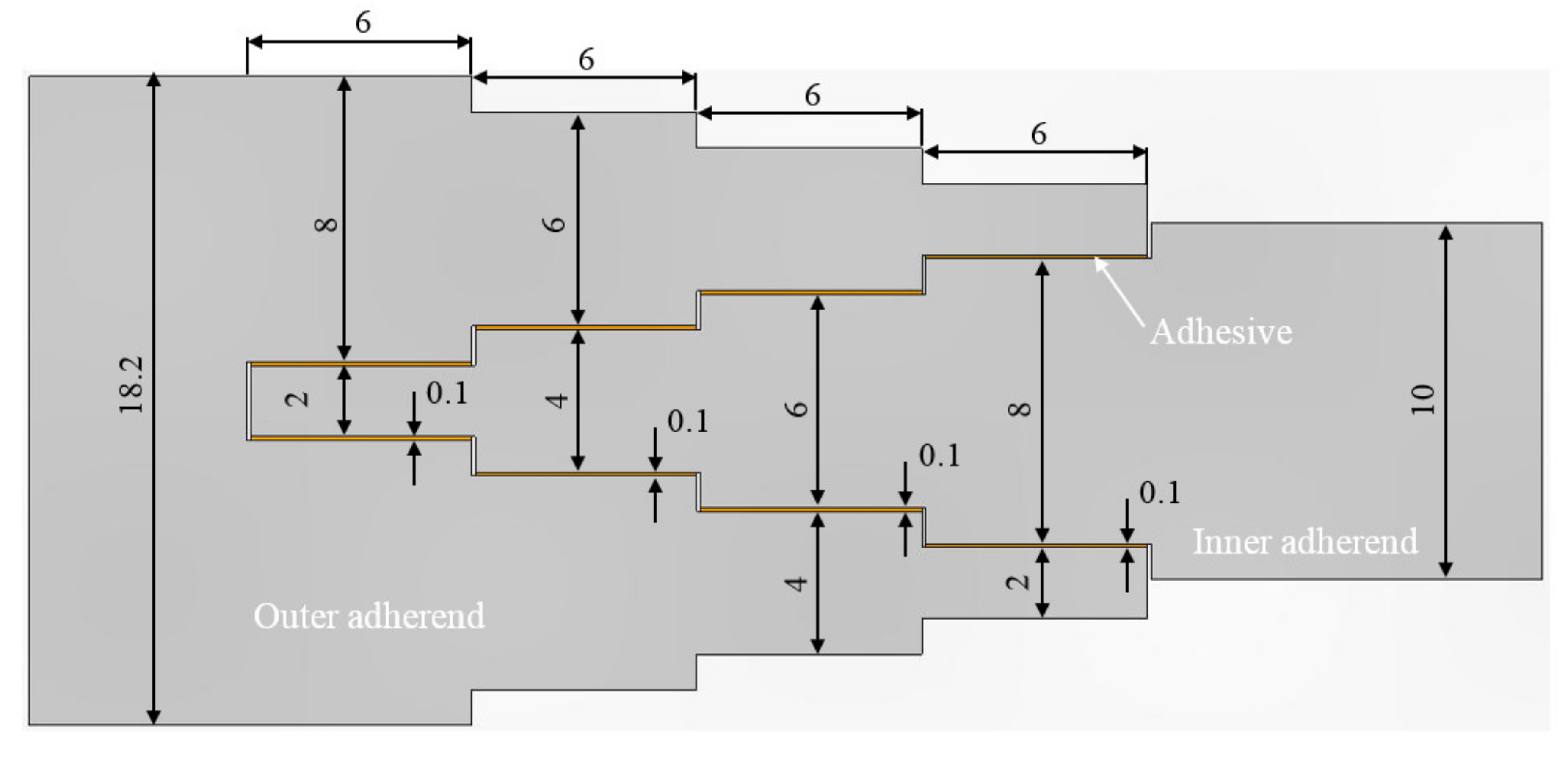

Appendix A. Counter Examples

| Failure load | FE | A4EI | % Difference |

|---|---|---|---|

| Failure load (N/mm) | 1791 | 1821 | 1.7 |

- The adhesive in the joint should not yield at 115% DLL;

- There should be no failure at design ultimate load (DUL);

- The joint should have an adequate fatigue life.

Appendix B. Examples of Disbond Growth under Operational Loads

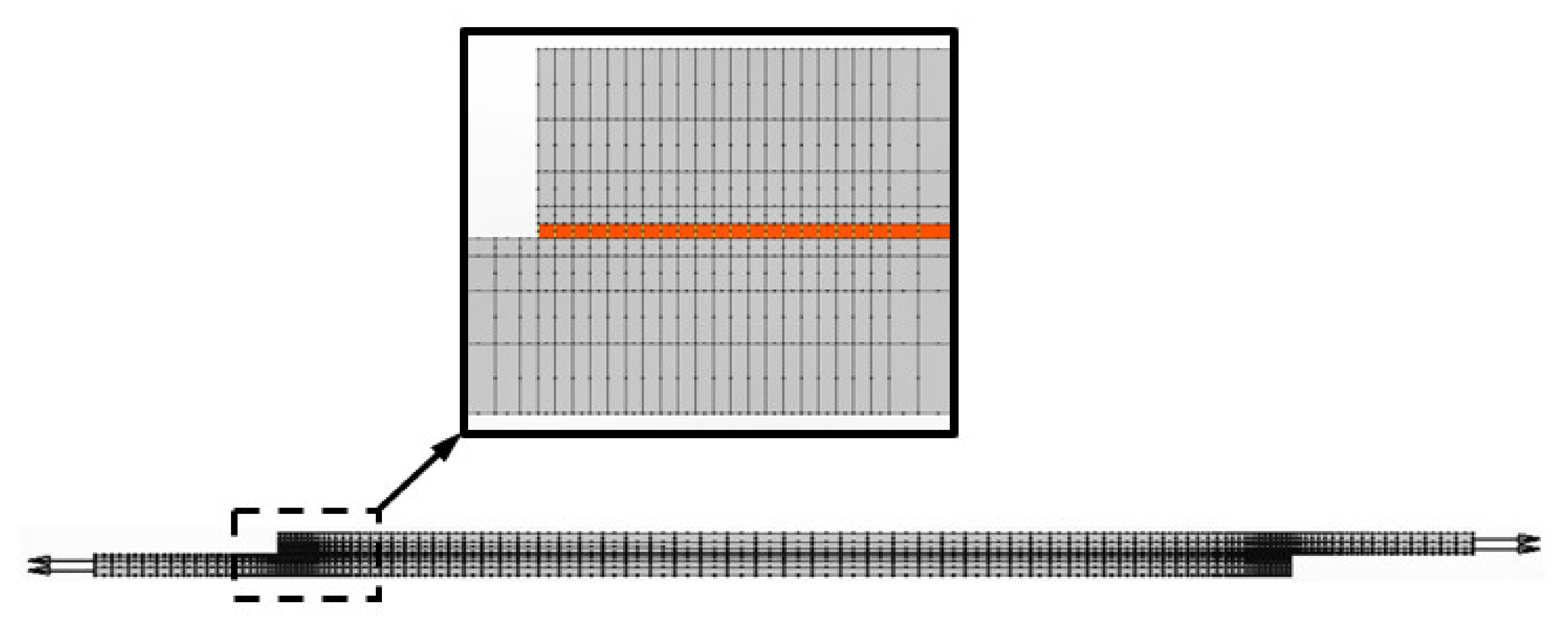

Appendix B.1. Debonding of a Composite Repair to F-111 Lower Wing-Skin

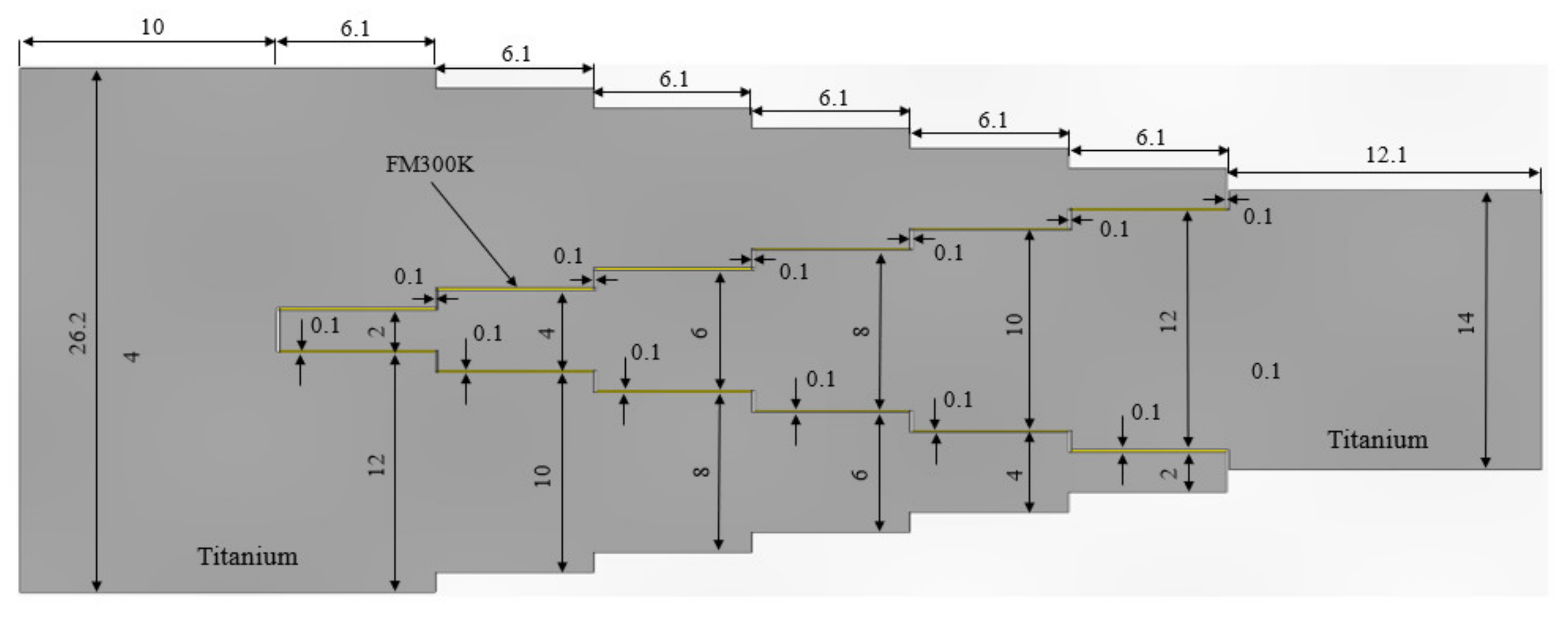

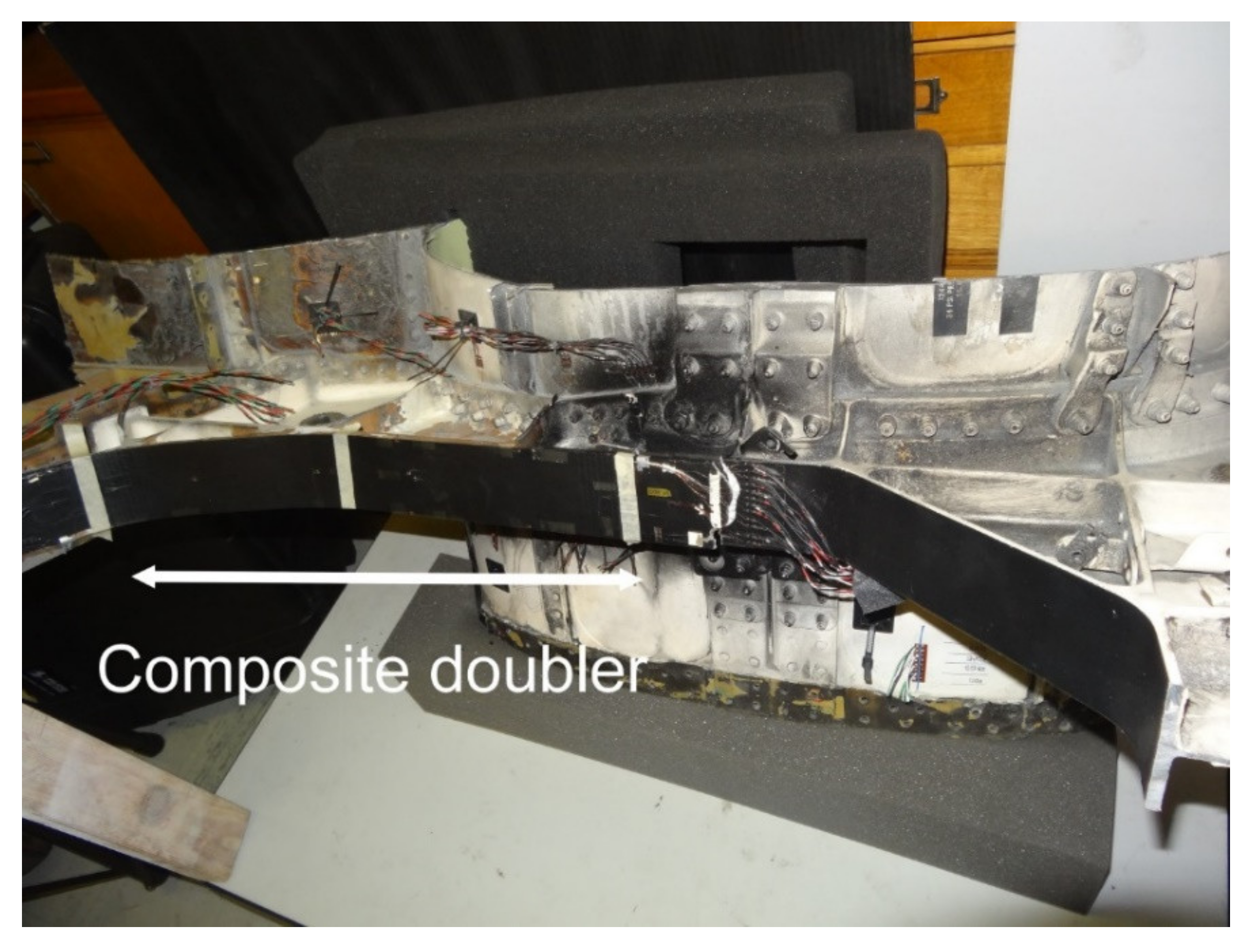

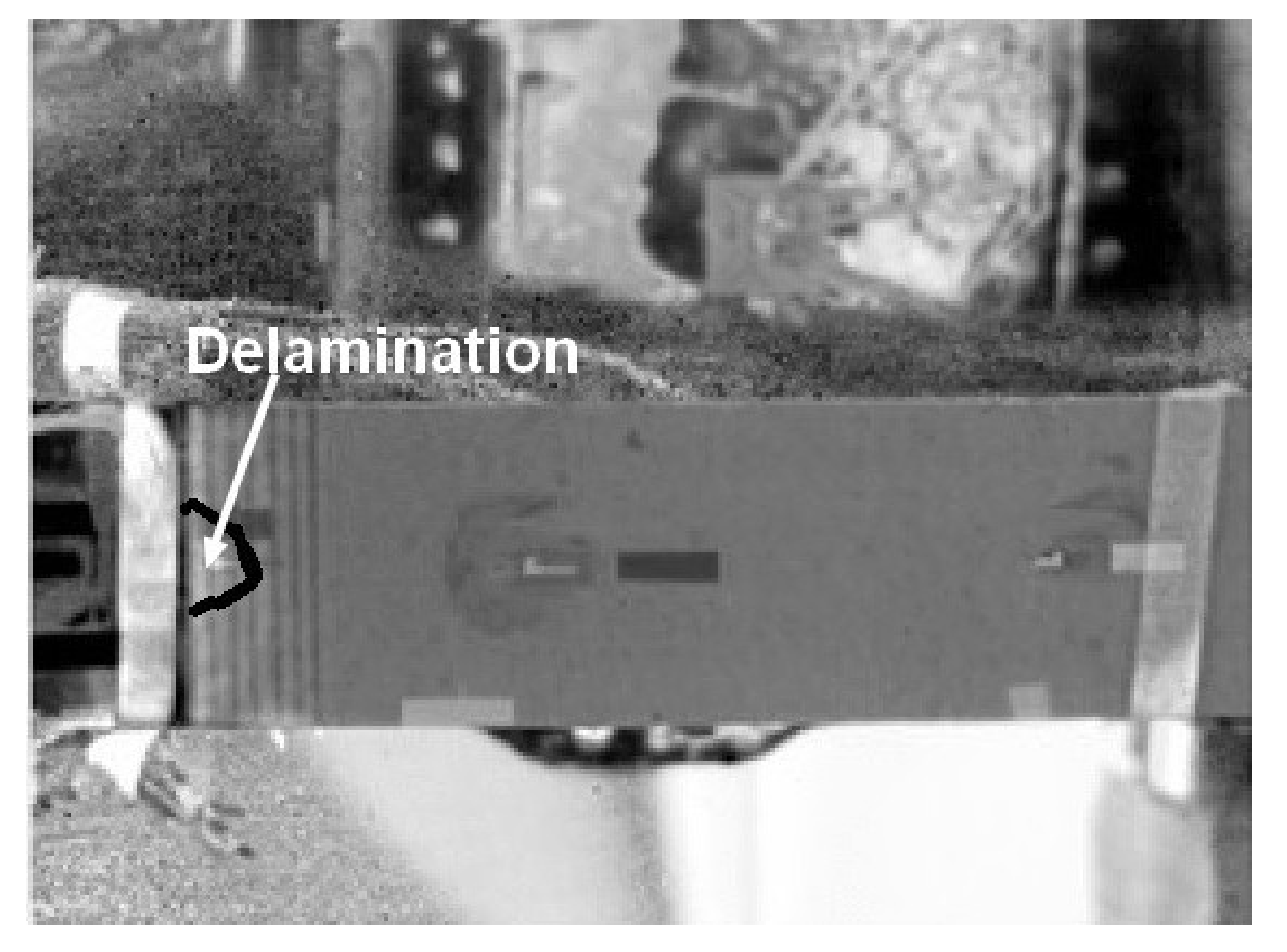

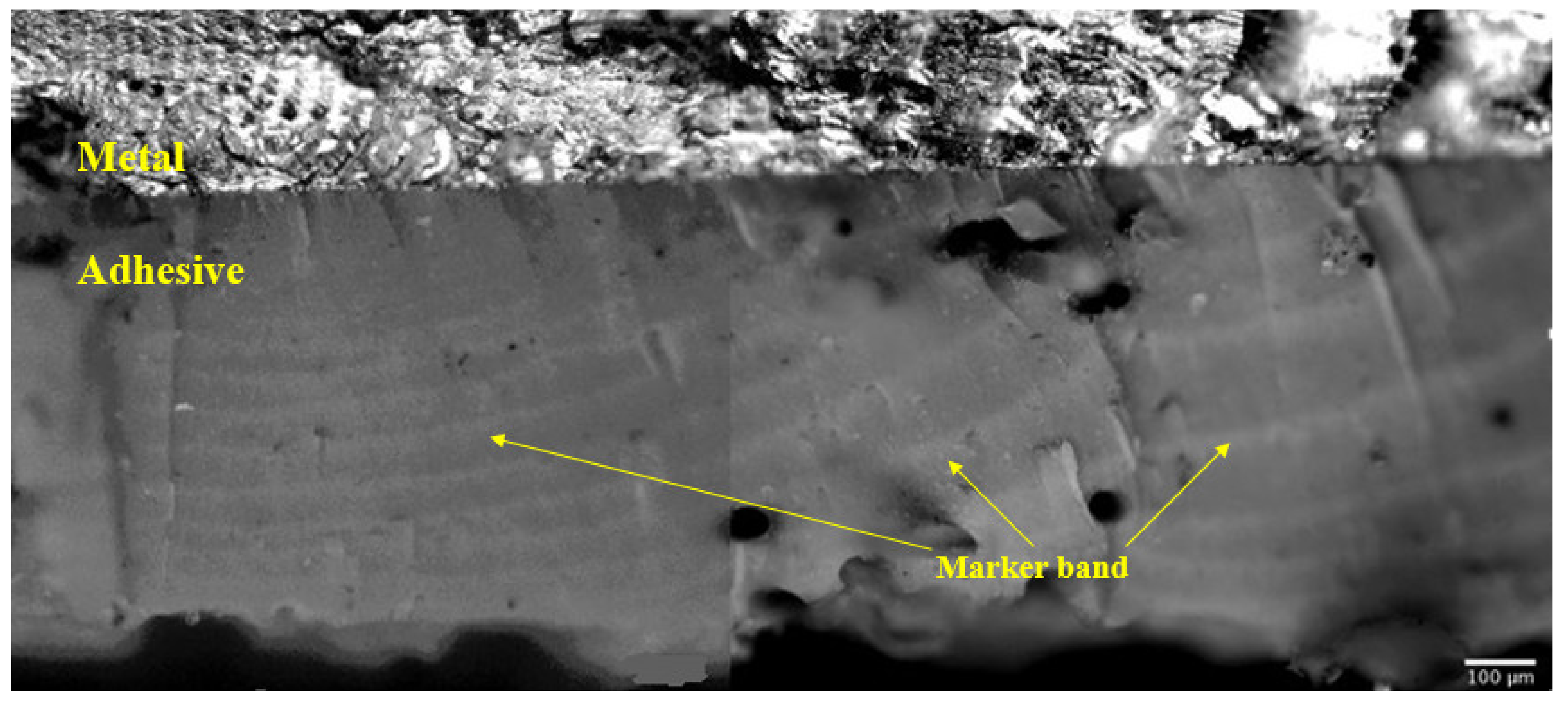

Appendix B.2. Delamination in a Full-Scale Fatigue Tests on a Finnish Aircraft F/A-18 Boron-Fibre/Epoxy-Matrix Doubler Repair

References

- Mueller, E.; Starnes, S.; Strickland, N.; Kenny, P.; Williams, C. The detection, inspection, and failure analysis of a composite wing skin defect on a tactical aircraft. Compos. Struct. 2016, 145, 186–193. [Google Scholar] [CrossRef]

- Jones, R.; Kinloch, A.J.; Michopoulos, J.; Iliopoulos, A.P.; Phan, N.; Goel, K.; Lua, J.; Singh Raman, R.K.; Peng, D. Assessing failure and delamination growth in composites and bonded joints under variable amplitude loads. In Proceedings of the Twenty-Second International Conference on Composite Materials (ICCM22); Melbourne, Australia, 11–16 August 2019. [Google Scholar]

- CMH-17-3G. Polymer Matrix Composites Materials Useage, Design and Analysis. In Composite Materials Handbook Volume 3; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Potter, D.L. Primary Adhesively Bonded Structure Technology (PABST), Design Handbook for Adhesive Bonding; Technical Report AFFDL-79-3129, Final Report; US Airforce: Dayton, OH, USA, 1979.

- Hart-Smith, L.J. User Manual and Computer Codes. In Design Methodology for Bonded-Bolted Composite Joints Volume II; Technical Report AFWAL-TR-81-3154; US Airforce: Dayton, OH, USA, 1982. [Google Scholar]

- Hart-Smith, L.J. Adhesively Bonded Double Lap Joints; NASA Langley Research Center Report NASA CR-112235; NASA: Hampton, VA, USA, 1973.

- Birchfield, E.B.; Cole, R.T.; Impellizzeri, L.F. Reliability of Step-Lap Bonded Joints; Report AFFDL-TR-75-26; US Airforce: Dayton, OH, USA, 1975.

- US Department of Defense. Department of Defense Standard Practice; MIL-STD-1530D; US Department of Defense: Washington, DC, USA, 2016.

- US Airforce. Department of Defense Joint Service Specification Guide; Aircraft Structures, JSSG-2006; US Airforce: Dayton, OH, USA, 2006.

- Jones, R.; Callinan, R.J. Structural Design of BFRP Patches for Mirage Wing Repair; ARL Structures Note 461; Aeronautical Research Laboratories, Department of Defence: Melbourne, Australia, 1980. Available online: https://apps.dtic.mil/dtic/tr/fulltext/u2/a097195.pdf (accessed on 7 October 2019).

- Jones, R.; Baker, A.A.; Matthews, N.; Champagne, V., Jr. Aircraft Sustainment and Repair; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Jones, R.; Hui, D. Analysis, design and assessment of composite repairs to operational aircraft. In Aircraft Sustainment and Repair; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Molent, L.; Jones, R. The F111C wing pivot fitting repair and implications for the design/assessment of bonded joints and composite repairs. In Aircraft Sustainment and Repair; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Molent, L.; Callinan, R.; Jones, R. Design of an all boron/epoxy doubler reinforcement for the F-111C wing pivot fitting: Structural aspects. Compos. Struct. 1989, 11, 57–83. [Google Scholar] [CrossRef]

- Chalkley, P.; Geddes, R. Service History of the F-111 Wing Pivot Fitting Upper Surface Boron/Epoxy Doublers; DSTO-TN-0168; Aeronautical Research Laboratories, Department of Defence: Melbourne, Australia, 1998.

- Raizenne, D. Case History: CF116 Upper Wing Skin Fatigue Enhancement Boron Doubler. In Advances in the Bonded Composite Repair of Metallic Aircraft Structure; Baker, A., Rose, L.R.F., Jones, R., Eds.; Elsevier Applied Science Publishers: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Loss of Rudder in Flight Air Transat Airbus A310-308 C-GPAT, Miami, Florida, 90 nm S, 6 March 2005; Report Number A05F0047; Transportation Safety Board of Canada: Gatineau, QC, Canada, 2007.

- Schön, J.; Nyman, T.; Blom, A.; Ansell, H. A numerical and experimental investigation of delamination behaviour in the DCB specimen. Compos. Sci. Technol. 2000, 60, 173–184. [Google Scholar] [CrossRef]

- Mueller, E.M.; Strickland, N.; Kenny, P.; Starnes, S. Analysis of composite wing skin defects on tactical aircraft. In Proceedings of the 24th Advanced Aerospace Materials and Processes (AeroMat) Conference and Exposition, Bellevue, WA, USA, 2–5 April 2013. [Google Scholar]

- Baker, A.A. Structural Health Monitoring of a Bonded Composite Patch Repair on a Fatigue-Cracked F-111C Wing; Report DSTO-RR-0335; Aeronautical Research Laboratories, Department of Defence: Melbourne, Australia, 2008.

- Hu, W.; Barter, S.; Wang, J.; Jones, R.; Kinloch, A. On the USAF ‘risk of failure’ approach and its applicability to composite repairs to metal airframes. Compos. Struct. 2017, 167, 103–111. [Google Scholar] [CrossRef]

- Jones, R. Fatigue crack growth and damage tolerance. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 463–483. [Google Scholar] [CrossRef]

- Federal Aviation Authority. Airworthiness Advisory Circular No: 20-107B. Composite Aircraft Structure; FAA: Washington DC, USA, 2009.

- Jones, R.; Chiu, W.; Paul, J. Designing for damage tolerant bonded joints. Compos. Struct. 1993, 25, 201–207. [Google Scholar] [CrossRef]

- Molent, L.; Bridgford, N.; Rees, D.; Jones, R. Environmental evaluation of repairs to fuselage lap joints. Compos. Struct. 1992, 21, 121–130. [Google Scholar] [CrossRef]

- Chiu, W.K.; Rees, D.; Chalkley, P.; Jones, R. Designing for damage tolerant repairs. Compos. Struct. 1994, 28, 19–38. [Google Scholar] [CrossRef]

- Roach, D. Damage Tolerance Assessment of Bonded Composite Doublers for Commercial Aircraft Applications; Sandia Report, SAND98–1016; Sandia National Laboratories/Department of Energy: Albuquerque, NM, USA, 1998.

- Jones, R.; Bartholomeusz, R.; Kaye, R.; Roberts, J. Bonded-composite repair of representative multi-site damage in a full-scale fatigue-test article. Theor. Appl. Fract. Mech. 1994, 21, 41–49. [Google Scholar] [CrossRef]

- Molent, L.; Jones, R. Repair of multi-site damage in civil transport aircraft—An example of the damage tolerant design of composite repairs. In Aircraft Sustainment and Repair; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Roach, D.; Rackow, K. Development and Validation of Bonded Composite Doubler Repairs for Commercial Aircraft, Sandia Report SAND2007. In Aircraft Sustainment and Repair; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Lincoln, J.W.; Melliere, R.A. Economic Life Determination for a Military Aircraft. J. Aircr. 1999, 36, 737–742. [Google Scholar] [CrossRef]

- Schwalbe, K.-H.; Kalluri, S.; McGaw, R.M.; Neimitz, A.; Dean, S.W. On the Beauty of Analytical Models for Fatigue Crack Propagation and Fracture—A Personal Historical Review. J. ASTM Int. 2010, 7, 3–73. [Google Scholar] [CrossRef]

- Hartman, A.; Schijve, J. The effects of environment and load frequency on the crack propagation law for macro fatigue crack growth in aluminium alloys. Eng. Fract. Mech. 1970, 1, 615–631. [Google Scholar] [CrossRef]

- Liu, H.; Liu, D. A quantitative analysis of structure sensitive fatigue crack growth in steels. Scr. Met. 1984, 18, 7–12. [Google Scholar] [CrossRef]

- Ramsamooj, D. Analytical prediction of short to long fatigue crack growth rate using small- and large-scale yielding fracture mechanics. Int. J. Fatigue 2003, 25, 923–933. [Google Scholar] [CrossRef]

- McEvily, A.; Eifler, D.; Macherauch, E. An analysis of the growth of short fatigue cracks. Eng. Fract. Mech. 1991, 40, 571–584. [Google Scholar] [CrossRef]

- Endo, M.; McEvily, A.J. Prediction of the behaviour of small fatigue cracks. Mater. Sci. Eng. A 2007, 468–470, 51–58. [Google Scholar] [CrossRef]

- Ishihara, S.; Yoshifuji, S.; McEvily, A.J.; Kawamoto, M.; Sawai, M.; Takata, M. Study of the fatigue lifetimes and crack propagation behaviour of a high speed steel as a function of the R value. Fatigue Fract. Eng. Mater. Struct. 2010, 33, 294–302. [Google Scholar] [CrossRef]

- Wang, K.; Wang, F.; Cui, W.; Hayat, T.; Ahmad, B. Prediction of short fatigue crack growth of Ti-6Al-4V. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 1075–1086. [Google Scholar] [CrossRef]

- Jones, R.; Chen, F.; Pitt, S.; Paggi, M.; Carpinteri, A. From NASGRO to fractals: Representing crack growth in metals. Int. J. Fatigue 2016, 82, 540–549. [Google Scholar] [CrossRef]

- Molent, L.; Spagnoli, A.; Carpinteri, A.; Jones, R. Using the lead crack concept and fractal geometry for fatigue lifing of metallic structural components. Int. J. Fatigue 2017, 102, 214–220. [Google Scholar] [CrossRef]

- Jones, R.; Peng, D.; McMillan, A.J. Crack growth from naturally occurring material discontinuities. In Aircraft Sustainment and Repair; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Jones, R.; Molent, L.; Barter, S. Calculating crack growth from small discontinuities in 7050-T7451 under combat aircraft spectra. Int. J. Fatigue 2013, 55, 178–182. [Google Scholar] [CrossRef]

- Tamboli, D.; Barter, S.; Jones, R. On the growth of cracks from etch pits and the scatter associated with them under a miniTWIST spectrum. Int. J. Fatigue 2018, 109, 10–16. [Google Scholar] [CrossRef]

- Main, B.; Evans, R.; Walker, K.; Yu, X.; Molent, L. Lessons from a fatigue prediction challenge for an aircraft wing shear tie post. Int. J. Fatigue 2019, 123, 53–65. [Google Scholar] [CrossRef]

- Tan, J.; Chen, B. Prediction of fatigue life in aluminium alloy (AA7050-T7451) structures in the presence of multiple artificial short cracks. Theor. Appl. Fract. Mech. 2015, 78, 1–7. [Google Scholar] [CrossRef]

- Jones, R.; Raman, R.S.; McMillan, A. Crack growth: Does microstructure play a role? Eng. Fract. Mech. 2018, 187, 190–210. [Google Scholar] [CrossRef]

- Lo, M.; Jones, R.; Bowler, A.; Dorman, M.; Edwards, D. Crack growth at fastener holes containing intergranular cracking. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1664–1675. [Google Scholar] [CrossRef]

- Jones, R.; Peng, D.; Singh Raman, R.K.; Huang, P.; Tamboli, D.; Matthews, N. On the growth of fatigue cracks from corrosion pits and manufacturing defects under variable amplitude loading. JOM 2015, 67, 1385–1391. [Google Scholar] [CrossRef]

- Zhang, Y.; Zheng, K.; Heng, J.; Zhu, J. Corrosion-Fatigue Evaluation of Uncoated Weathering Steel Bridges. Appl. Sci. 2019, 9, 3461. [Google Scholar] [CrossRef]

- Ali, K.; Peng, D.; Jones, R.; Singh, R.R.K.; Zhao, X.L.; McMillan, A.; Berto, F. Crack growth in a naturally corroded bridge steel. Fatigue Fract. Eng. Mater. Struct. 2016, 40, 1117–1127. [Google Scholar] [CrossRef]

- Godefroid, L.B.; Moreira, L.; Vilela, T.; Faria, G.; Candido, L.; Pinto, E. Effect of chemical composition and microstructure on the fatigue crack growth resistance of pearlitic steels for railroad application. Int. J. Fatigue 2019, 120, 241–253. [Google Scholar] [CrossRef]

- Cano, A.; Salazar, A.; Rodríguez, J. Evaluation of different crack driving forces for describing the fatigue crack growth behaviour of PET-G. Int. J. Fatigue 2018, 107, 27–32. [Google Scholar] [CrossRef]

- Clerc, G.; Brunner, A.J.; Niemz, P.; Van De Kuilen, J.W.G. Feasibility study on Hartman–Schijve data analysis for mode II fatigue fracture of adhesively bonded wood joints. Int. J. Fract. 2019, 221, 123–140. [Google Scholar] [CrossRef]

- Jones, R.; Raman, R.S.; Iliopoulos, A.; Michopoulos, J.; Phan, N.; Peng, D. Additively manufactured Ti-6Al-4V replacement parts for military aircraft. Int. J. Fatigue 2019, 124, 227–235. [Google Scholar] [CrossRef]

- Jones, R.; Michopoulos, J.; Iliopoulos, A.; Raman, R.S.; Phan, N.; Nguyen, T. Representing crack growth in additively manufactured Ti-6Al-4V. Int. J. Fatigue 2018, 116, 610–622. [Google Scholar] [CrossRef]

- Iliopoulos, A.; Jones, R.; Michopoulos, J.; Phan, N.; Raman, R.S. Crack Growth in a Range of Additively Manufactured Aerospace Structural Materials. Aerospace 2018, 5, 118. [Google Scholar] [CrossRef]

- Jones, R.; Matthews, N.; Peng, D.; Phan, N.; Nguyen, T. Damage Tolerant Assessment of Additively Manufactured Replacement Parts. In Proceedings of the13th International Conference on the Mechanical Behaviour of Materials (ICM13), Melbourne, Australia, 11–14 June 2019. [Google Scholar]

- Jones, R.; Matthews, N.; Peng, D.; Phan, N.; Nguyen, T. Applications of SPD to enhance the structural integrity of corroded airframes. In Aircraft Sustainment and Repair; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Jones, R.; Hu, W.; Kinloch, A.J. A convenient way to represent fatigue crack growth in structural adhesives. Fatigue Fract. Eng. Mater. Struct. 2014, 38, 379–391. [Google Scholar] [CrossRef]

- Jones, R.; Kinloch, A.; Michopoulos, J.; Brunner, A.; Phan, N. Delamination growth in polymer-matrix fibre composites and the use of fracture mechanics data for material characterisation and life prediction. Compos. Struct. 2017, 180, 316–333. [Google Scholar] [CrossRef]

- Yao, L.; Alderliesten, R.; Jones, R.; Kinloch, A. Delamination fatigue growth in polymer-matrix fibre composites: A methodology for determining the design and lifing allowables. Compos. Struct. 2018, 196, 8–20. [Google Scholar] [CrossRef]

- Jones, R.; Stelzer, S.; Brunner, A. Mode I, II and Mixed Mode I/II delamination growth in composites. Compos. Struct. 2014, 110, 317–324. [Google Scholar] [CrossRef]

- Brunner, A.; Stelzer, S.; Pinter, G.; Terrasi, G. Cyclic fatigue delamination of carbon fiber-reinforced polymer-matrix composites: Data analysis and design considerations. Int. J. Fatigue 2016, 83, 293–299. [Google Scholar] [CrossRef]

- Chocron, T.; Banks-Sills, L. Nearly Mode I Fracture Toughness and Fatigue Delamination Propagation in a Multidirectional Laminate Fabricated by a Wet-Layup. Phys. Mesomech. 2019, 22, 107–140. [Google Scholar] [CrossRef]

- Simon, I.; Banks-Sills, L.; Fourman, V. Mode I delamination propagation and R-ratio effects in woven composite DCB specimens for a multi-directional layup. Int. J. Fatigue 2017, 96, 237–251. [Google Scholar] [CrossRef]

- Jones, R.; Kinloch, A.J.; Hu, W. Cyclic-fatigue crack growth in composite and adhesively-bonded structures: The FAA slow crack growth approach to certification and the problem of similitude. Int. J. Fatigue 2016, 88, 10–18. [Google Scholar] [CrossRef]

- Rans, C.; Alderliesten, R.; Benedictus, R. Misinterpreting the results: How similitude can improve our understanding of fatigue delamination growth. Compos. Sci. Technol. 2011, 71, 230–238. [Google Scholar] [CrossRef]

- Jones, R.; Pitt, S.; Hui, D.; Brunner, A. Fatigue crack growth in nano-composites. Compos. Struct. 2013, 99, 375–379. [Google Scholar] [CrossRef]

- Jones, R.; Pitt, S.; Bunner, A.; Hui, D. Application of the Hartman–Schijve equation to represent Mode I and Mode II fatigue delamination growth in composites. Compos. Struct. 2012, 94, 1343–1351. [Google Scholar] [CrossRef]

- Hu, W.; Jones, R.; Kinloch, A.J. Computing the growth of naturally-occurring disbonds in adhesively-bonded joints. In Aircraft Sustainment and Repair; Jones, R., Baker, A.A., Matthews, N., Champagne, V., Jr., Eds.; Butterworth-Heinemann Press: Oxford, UK, 2018; ISBN 9780081005408. [Google Scholar]

- Russell, A.J. A Damage Tolerance Assessment of Bonded Repairs to CF-18 Composite Components. Part I: Adhesive Properties; DREP Technical Memorandum-88-25; Canadian Department of National Defence, Defence Research Centre Establishment Pacific, Research and Development Branch: Ottawa, ON, Canada, 1988. [Google Scholar]

- Ripling, J.; Crosley, P.B.; Johnson, W.S. A Comparison of Pure Mode I and Mixed-Mode I-III Cracking of an Adhesive Containing an Open Knit Cloth Carrier; ASTM STP 981; ASTM International: West Conshohocken, PA, USA; pp. 163–182.

- Kinloch, A.J.; Little, M.; Watts, J. The role of the interphase in the environmental failure of adhesive joints. Acta Mater. 2000, 48, 4543–4553. [Google Scholar] [CrossRef]

- Azari, S.; Papini, M.; Schroeder, J.; Spelt, J.K. Fatigue threshold behaviour of adhesive joints. Int. J. Adhes. Adhes. 2010, 30, 145–159. [Google Scholar] [CrossRef]

- Njuguna, J.; Pielichowski, K. Polymer Nanocomposites for Aerospace Applications: Characterization. Adv. Eng. Mater. 2004, 6, 204–210. [Google Scholar] [CrossRef]

- Meyyappan, M. Nanotechnology in Aerospace Applications. In Nanotechnology Aerospace Applications—2006 (7-1–7-2); Educational Notes RTO-EN-AVT-129bis, Paper 7; NATO: Neuilly-sur-Seine, France, 2007; Available online: http://www.rto.nato.int/abstracts.asp (accessed on 7 October 2019).

- Srivastava, I.; Koratkar, N. Fatigue and fracture toughness of epoxy nanocomposites. JOM 2010, 62, 50–57. [Google Scholar] [CrossRef]

- Ladani, R.B.; Wu, S.; Kinloch, A.J.; Ghorbani, K.; Mouritz, A.P.; Wang, C.H. Enhancing fatigue resistance and damage characterisation in adhesively-bonded composite joints by carbon nanofibers. Compos. Sci. Technol. 2017, 149, 116–125. [Google Scholar] [CrossRef]

- Zhang, W.; Picu, R.C.; Koratkar, N.A. The effect of carbon nanotube dimensions and dispersion on the fatigue behavior of epoxy nano-composites. Nanotechnology 2008, 19, 1–5. [Google Scholar] [CrossRef] [PubMed]

- Hart-Smith, L.J. There is no such thing as a composite material—Only composites of materials. In Proceedings of the Twenty-Second International Conference on Composite Materials (ICCM22), Melbourne, Australia, 11–16 August 2019. [Google Scholar]

- Hein, V.; Erdogan, F. Stress singularities in a two-material wedge. Int. J. Fract. 1971, 7, 317–330. [Google Scholar] [CrossRef]

- Swanton, G.; Keinonen, M.; Linna, J. Full-Scale Fatigue Testing of a Boron-Epoxy Bonded Doubler for the Finnish Air Force F/A-18 Hornet Centre Fuselage. In Proceedings of the 28th ICAF Symposium, Helsinki, Finland, 3–5 June 2015. [Google Scholar]

| Test | D | p | A (J/m2) | |

|---|---|---|---|---|

| 100 °C and R = −1 | 8.40 × 10−9 | 2.00 | 975 | 12.5 |

| 20 °C and R = −1 | 8.40 × 10−9 | 2.00 | 1200 | 14.1 |

| −50 °C and R = −1 | 8.40 × 10−9 | 2.00 | 1500 | 15.5 |

| 100 °C and R = 0 | 8.40 × 10−9 | 2.00 | 2700 | 10.0 |

| Test | D | p | A (J/m2) | |

|---|---|---|---|---|

| 100 °C and R = −1 | 4.15 × 10−8 | 2.11 | 1100 | 15.3 |

| 20 °C and R = −1 | 4.15 × 10−8 | 2.11 | 755 | 15.0 |

| Test Relative Humidity (RH) | D | p | A (J/m2) | |

|---|---|---|---|---|

| 40% RH | 8.40 × 10−9 | 2.00 | 630 | 9.8 |

| 80%–90% RH | 8.40 × 10−9 | 2.00 | 630 | 10.5 |

| Test | D | p | A (J/m2) | |

|---|---|---|---|---|

| 1 | 2.07 × 10−9 | 2.87 | 900 | 7.42 |

| 2 | 2.07 × 10−9 | 2.87 | 900 | 7.14 |

| 3 | 2.07 × 10−9 | 2.87 | 900 | 6.80 |

| 4 | 2.07 × 10−9 | 2.87 | 900 | 6.50 |

| 5 | 2.07 × 10−9 | 2.87 | 900 | 7.65 |

| Mean-3σ | 2.07 × 10−9 | 2.87 | 900 | 5.72 |

| Type of Nano-Composite | D | p | ||

|---|---|---|---|---|

| 5–8 nm diameter MWCNT | 8.0 × 10−7 | 2.0 | 0.8 | 0.24 |

| 10–20 nm diameter MWCNT | 6.5 × 10−7 | 2.0 | 0.8 | 0.22 |

| 50–70 nm diameter MWCNT | 5.5 × 10−7 | 2.0 | 0.8 | 0.18 |

| Neat epoxy, no MWNT | 4.0 × 10−7 | 2.0 | 0.8 | 0.07 |

| Type of Nano-Composite | D | p | A (J/m2) | |

|---|---|---|---|---|

| Neat epoxy | 6.0 × 10−9 | 2.2 | 37 | 0.72 |

| 0.4% Random | 6.0 × 10−9 | 2.2 | 55 | 0.89 |

| 0.4% Aligned | 6.0 × 10−9 | 2.2 | 77 | 1.0 |

| 0.7% Random | 6.0 × 10−9 | 2.2 | 160 | 1.58 |

| 0.7% Aligned | 6.0 × 10−9 | 2.2 | 225 | 1.76 |

| 1% Random | 6.0 × 10−9 | 2.2 | 960 | 2.19 |

| 1% Aligned | 6.0 × 10−9 | 2.2 | 950 | 2.49 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jones, R.; Peng, D.; Michopoulos, J.G.; Kinloch, A.J. Requirements and Variability Affecting the Durability of Bonded Joints. Materials 2020, 13, 1468. https://doi.org/10.3390/ma13061468

Jones R, Peng D, Michopoulos JG, Kinloch AJ. Requirements and Variability Affecting the Durability of Bonded Joints. Materials. 2020; 13(6):1468. https://doi.org/10.3390/ma13061468

Chicago/Turabian StyleJones, Rhys, Daren Peng, John G. Michopoulos, and Anthony J. Kinloch. 2020. "Requirements and Variability Affecting the Durability of Bonded Joints" Materials 13, no. 6: 1468. https://doi.org/10.3390/ma13061468

APA StyleJones, R., Peng, D., Michopoulos, J. G., & Kinloch, A. J. (2020). Requirements and Variability Affecting the Durability of Bonded Joints. Materials, 13(6), 1468. https://doi.org/10.3390/ma13061468