Abstract

The amount of municipal solid waste (MSW) generated worldwide is constantly growing. In many countries, anaerobic digestion (AD) is the recommended process for converting organic waste, playing a crucial role in the transition to a circular economy. Capturing and using biogas helps to reduce greenhouse gas emissions. This paper summarizes the results of comprehensive studies conducted at three municipal waste biogas plants (MWBPs) located in Poland. These studies include measurements related to concentrations of odor (cod) and odorants (C) as well as microclimate parameters. We statistically analyzed the research obtained. However, the microclimatic parameters were not used in a final PCA model and were only used in exploratory correlation. Principal component analysis (PCA) is one of the methods of statistical factor analysis, which allows for the organization of a large set of data from three objects from the annual study. The use of PCA allowed us to determine which substance at a specific biogas plant is primarily responsible for odor nuisance and to estimate the percentage of variability contained in the first two principal components. The obtained results clearly indicate the influence of the technological regime and the type of fermentation feed on the determining effect of a specific odorant. In connection with the vision of creating new MWBPs that are consistent with circular economy assumptions, it seems advisable to extend the conducted analysis to include an immission study outside the plant boundaries. This study could play a crucial role in public consultations and serve as a tool for minimizing odor nuisance.

1. Introduction

Issues surrounding the management of municipal solid waste (MSW) in European Union countries have become increasingly important in recent years. The amount of waste generated is constantly rising, particularly in developing countries, due to the steady growth of industrialization, urbanization, and population [1,2]. The improper management of MSW has a negative impact on the natural environment and poses a threat to public health. At the same time, waste treatment technologies related to energy production, including pyrolysis, gasification, incineration, and biomethanation, offer a safe and environmentally friendly approach to MSW management [3,4].

In many countries, anaerobic digestion (AD) is the recommended process for converting organic waste into energy and is also an important element in achieving a circular economy, increasing resource efficiency, and bioenergy [3]. The biogas produced during the AD process consists mainly of methane (CH4, 40–75%), carbon dioxide (CO2, 25–60%), nitrogen (N2, 0–2%), oxygen (O2, 0–1%), hydrogen sulphide (H2S, 0.005–2%) and other compounds in trace amounts [5]. The World Bioenergy Association [6] reports that global biogas production in 2014 was estimated at 58.7 billion Nm3, corresponding to an associated energy production potential at 3.5 × 105 GWh. The capture and use of biogas contribute to a reduction in greenhouse gas emissions into the air. The advantages of AD have contributed to the increased use of the organic fraction of MSW AD for energy recovery in the form of biogas in the last few years, and many scientists and government agencies are working on improving this process [7,8].

Both investment costs and biogas production have a significant impact on the profitability of biogas installations [9]. In terms of energy efficiency, environmental impact, and adherence to the principles of a circular economy, biogas cogeneration in MWBP is more beneficial than waste disposal through landfilling. According to Chowdhury [10], MWBP becomes more cost-effective than sanitary landfilling when MSW production exceeds 150,000 to 210,000 Mg per year.

Despite the undeniable benefits of using biogas and its renewable nature as an energy source, biogas technologies often encounter opposition. Public opposition to the construction of biogas plants, among other projects, stems from their potential negative impacts, including odor and noise emissions. The local social behaviors manifested in opposition to industrial plants, which are considered beneficial, have been widely studied and are typically referred to as NIMBY (Not In My Back Yard) [11,12,13].

Odor emissions, which may be caused by various types of plants and installations, such as sewage treatment plants [14], poultry farms [15], agricultural biogas plants [16], landfills [17], or waste treatment plants [18], may contribute to complaints and protests of residents living near these types of facilities. These emissions can also have a psychosomatic effect [19].

Odor perception is the feeling of the olfactory sensation that enables the recognition of an odor type and the assessment of its intensity [20]. It is a natural biological response that occurs when the concentration of a given substance, an odorant (C), is above its olfactory detection threshold (ODT) [21]. The concept of threshold concentration forms the basis of olfactometry, in which quantitative sensory measurements are used to determine the odor concentration [22]. Odor is a negative impression, most often resulting from a mixture of various compounds. Parameters describing odor include mainly odor concentration, cod, expressed in ou/m3, which can be determined by the olfactometry method [23,24,25].

The odor activity value (OAV) is a commonly used parameter for assessing the level of odor stimulation and the individual odor contribution of plants that are sources of odorous compound emissions [26,27,28,29,30]. However, the OAV parameter is valid and reliable only when the antagonistic and synergistic effects of the compounds included in the analyzed gases can be ignored [31]. Information obtained via the OAV can be extremely valuable in developing functional solutions for odor deodorization. Correlating OAV with the chemical composition of ambient air samples (i.e., the types and concentrations of compounds present) enables the identification of the compounds that have a predominant impact on the intensity of the perceived odor. Compared to olfactometric techniques, this approach is characterized by a relatively high repeatability and reproducibility of results [32].

Monitoring volatile compounds, both analytically and sensorially, is crucial when implementing a strategy to minimize the odor impact of objects [33,34,35]. To determine the odor concentration (cod), a gas sample is diluted with clean air to determine the dilution factor at which half of the assessors perceive the odor [23]. When implementing analytical methods, such as gas chromatography (GC), gas chromatography coupled with mass spectrometry (GC/MS), colorimetric gas tubes, and wet methods (scrubbers and traps), it is important to assess the qualitative and quantitative chemical compositions of the substances being tested [36,37,38,39].

This paper summarizes the results of comprehensive studies conducted at three MWBPs located in Poland. The studies were conducted annually to account for seasonality [40]. These studies include measurements related to concentrations of odor (cod) and odorants (concentrations of NH3, H2S, CH3SH, and VOC, as well as parameters related to the microclimate, such as air temperature (T) and relative air humidity (RH). Previous studies [25,41] presented the results of pilot studies conducted at six plants, forming the basis for the development of a more intensive research concept for the three selected plants.

The results of the study address a research gap by providing data from an annual research cycle that accounts for seasonal variation. Additionally, previous studies by other researchers have focused mainly on plant energy efficiency or on different types of biogas plants (agricultural, landfill, or sewage). There is a knowledge gap in the literature regarding both the quantitative and qualitative composition of odorous compounds emitted from biogas plants processing biowaste. Additionally, there is a clear lack of understanding of the physical and chemical factors that determine the magnitude and temporal variability of these emissions. The research results presented here can contribute to the improvement of technologies currently used in municipal waste biogas plants (MWBPs) and can also be helpful when selecting technologies for new plants. Furthermore, they can provide a basis for developing and implementing odor management plans, which is crucial in relation to determining the best available techniques (BAT) [42], as well as forming a basis for predicting the consequences of failing to adhere to technological regimes in waste management plants.

The main aim of this study is to highlight the significance of the influence of the technological regime applied in MWBPs, as well as the type of feedstock used, on the variability and concentration of odorous substances.

Due to the limited number of scientific studies addressing this issue, the results presented in this work—particularly the PCA—represent an innovative approach to assessing the odor impact of MWBPs.

2. Materials and Methods

The presented research results cover three MWBPs (A, B, and C) equipped with biogas installations, each of which carried out fifteen measurement series. Table 1 presents the schedule of the measurement series conducted at the individual plants. In the case of odorants, the number of trials typically comprised 15 series of five repetitions at each of 20 measurement points, whereas for cod, two repetitions were performed. The studies were conducted over the course of the year to observe changes in odor impact under varying conditions. Table 1 summarizes the research schedule for the analyzed biogas plants.

Table 1.

Schedule of research at analyzed biogas plants.

Analyzing the process lines at all three biogas plants, the unit operation related to waste reception and storage was carried out in a closed hall. The same was true for the mechanical treatment. The operation of preparing the feedstock for the fermentation process was carried out in the hall at Biogas Plants A and B, while at Biogas Plant C, it was conducted on the technological field. At Biogas Plants A and B, the feedstock for the fermentation chambers was the biodegradable fraction, mechanically separated from the mixed waste stream. The aerobic stabilization of the digestate at Biogas Plant A took place in the hall, while at Biogas Plant B, it was carried out on the technological field. At Biogas Plant C, the feedstock consisted of selectively collected biowaste, and aerobic stabilization of the digestate was carried out on the technological field. Table 2 presents a comparison of the analyzed plants.

Table 2.

The comparison of the analyzed biogas plants.

During each series, the following were determined:

- Odor concentration

Odor concentration was determined using field olfactometry, specifically the Nasal Ranger® olfactometer (St Croix Sensory Inc., Burlington, ON, Canada) [43]. The olfactometer operates by gradually diluting the contaminated gas inhaled at a rate of 16–20 cm3/s (designated by the green LED on the flow indicator) to the detection threshold. The device is equipped with two measuring orifices. The first allows for dilution of the contaminated gas to a level of Vclean/Vraw = D/T (Dilution-to-Threshold Ratio) = 500–60 (with the accuracy and reproducibility of ±5%). The second allows for dilution to a level of D/T = 60–2 (with an accuracy and reproducibility of ±10%). Before each test, the Sniffin Stix Triangle Test (Burghardt®, Wedel, Germany) was performed according to the ISO 4120:2004 standard [44]. This involves presenting three sticks to the evaluator. The evaluator’s task is to point to the stick impregnated with the fragrance substance n-butanol. This test allows for determining whether the evaluator is fit to participate in olfactometric testing.

Olfactometric determinations were performed twice at each measurement point. The determined D/T values correspond, after conversion, to the ZITE value defined in the PN-EN 13725 standard [22] (individual estimation of the degree of dilution up to the detection threshold):

where

- ZYES means the dilution ratio (–) at which the odor was perceptible;

- ZNO means the dilution ratio (–) at which the odor was imperceptible.

The odor concentration value cod [ou/m3] is the geometric mean of the set of individual estimates (ZITE) collected at a given measurement point.

- Odorant concentrations

Chemical tests, involving the determination of chemical compounds characteristic of and accompanying the decomposition process of organic matter, were performed using a portable MultiRae Pro multi-gas detector. The detector is equipped with three electrochemical sensors: NH3, H2S, and CH3SH, and one photoionization (PID, 10.6 eV): volatile organic compounds (VOCs).

- Microclimate parameters: T and RH of the air

The microclimate parameters were measured at a height of 1.5 m using a Kestrel 4500 NV weather meter. The obtained parameter values are the average result of approximately one-minute observations.

- Measurement point characteristics

Based on the method of gas sampling, measurement points were assigned to three types of places: cubic source (sampling from the hall), surface source (sampling from under a static shield designed to minimize the impact of external factors), and sampling from the organized source with a fixed gas flow. Figure 1, Figure 2 and Figure 3 present the characteristics of the measurement points in individual biogas plants. The measurement points were selected on the basis of previously conducted pilot studies and represent individual components of the MWBP technological line.

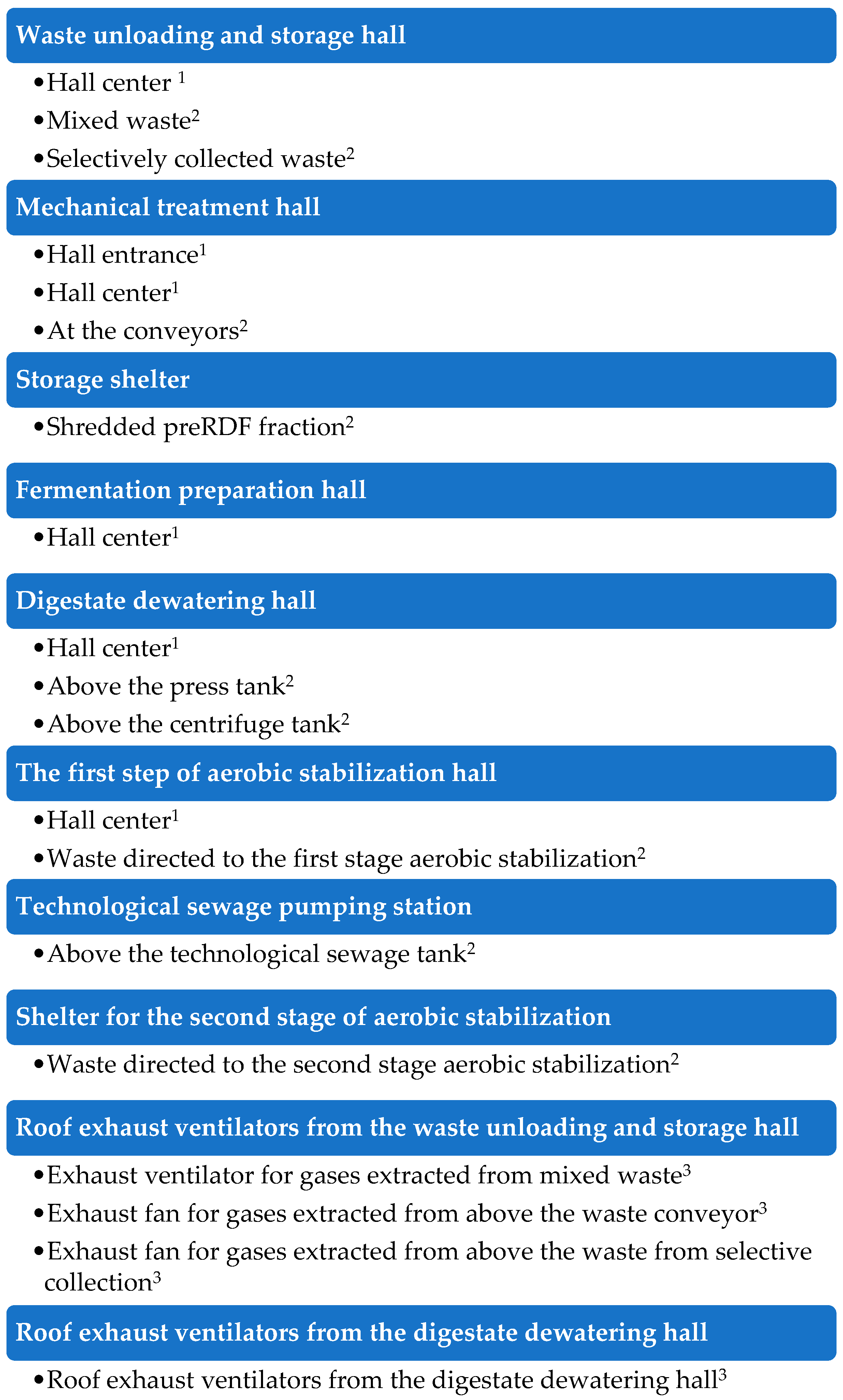

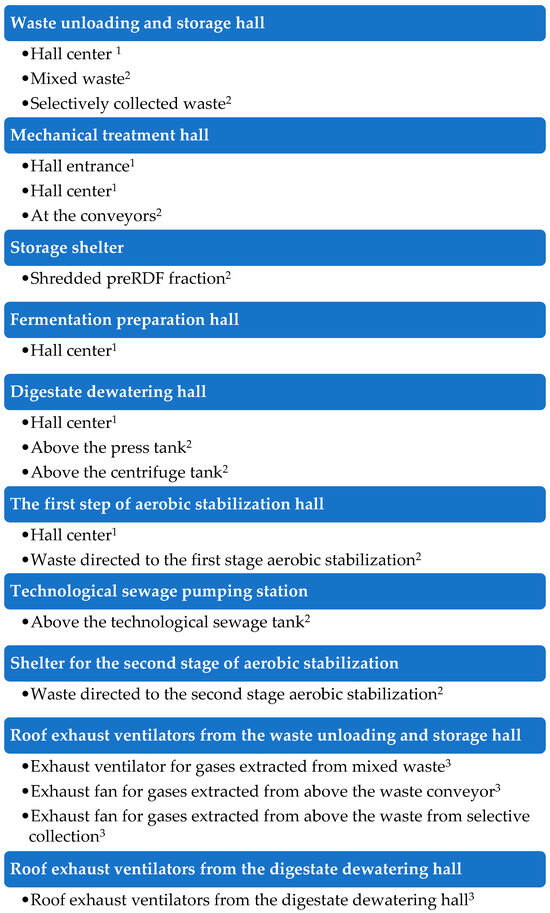

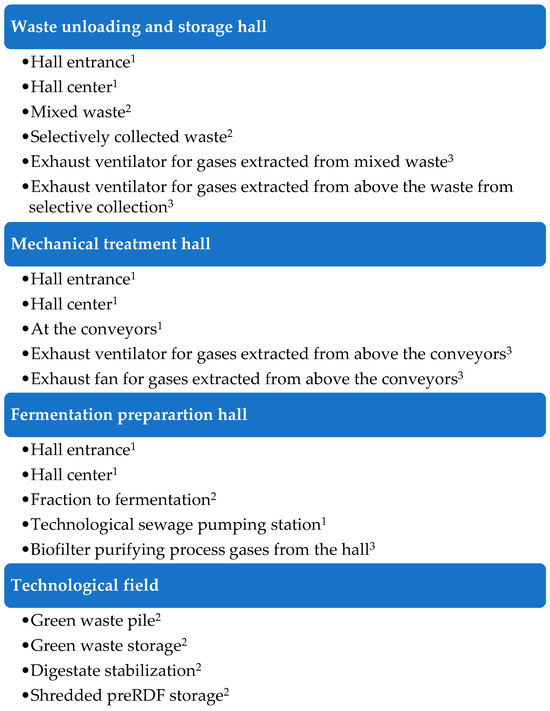

Figure 1.

Measurement points at Biogas Plant A. 1 cubic source—measurement directly from the hall; 2 surface source—measurement made using a static shield; 3 organized source—measurement from a source with a fixed flow rate.

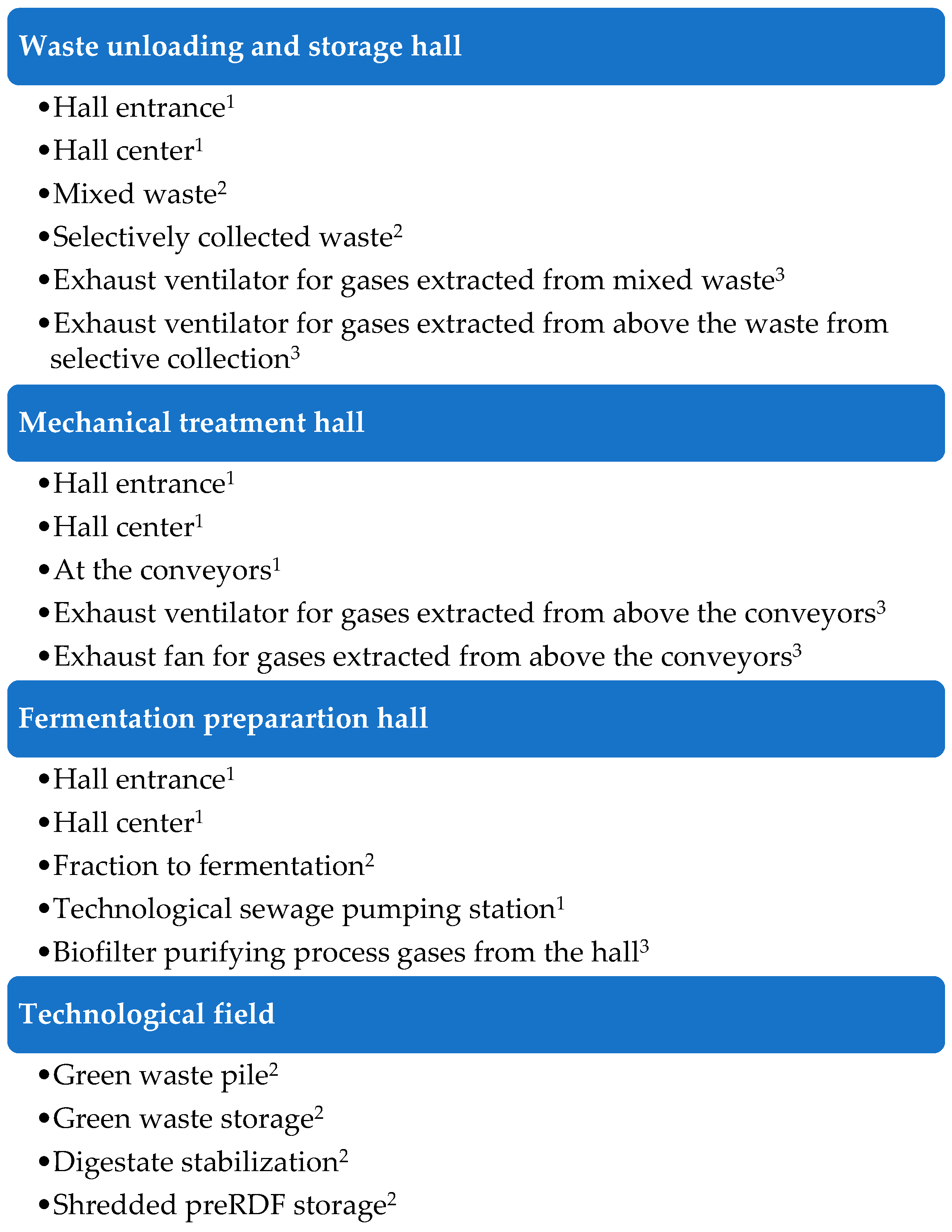

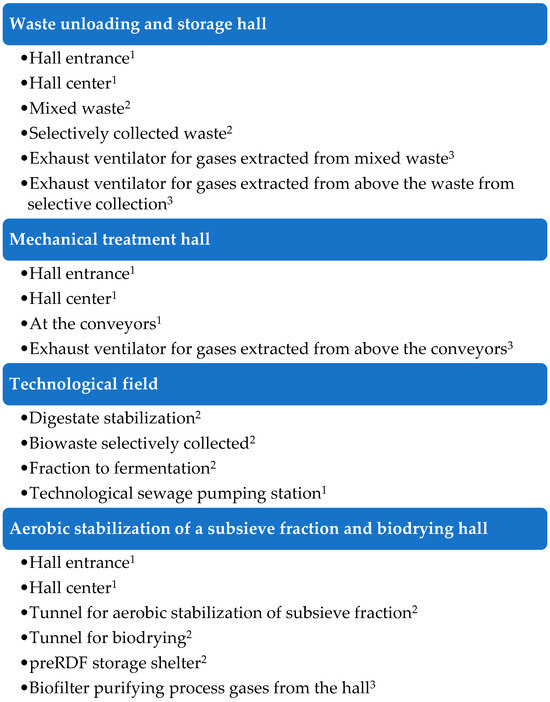

Figure 2.

Measurement points at Biogas Plant B. 1 cubic source—measurement directly from the hall; 2 surface source—measurement made using a static shield; 3 organized source—measurement from a source with a fixed flow rate.

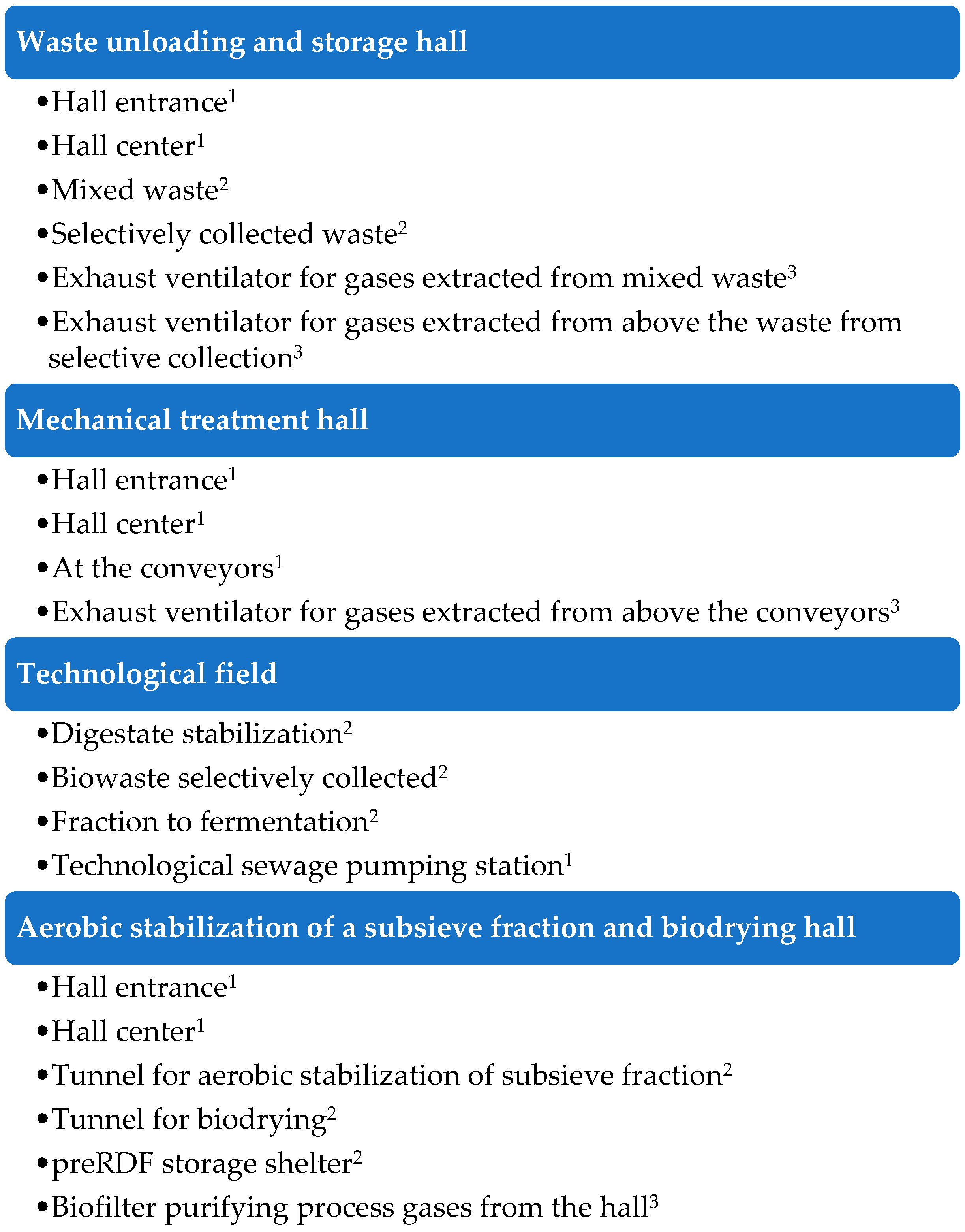

Figure 3.

Measurement points at Biogas Plant C. 1 cubic source—measurement directly from the hall; 2 surface source—measurement made using a static shield; 3 organized source—measurement from a source with a fixed flow rate.

- Statistical analysis of the results obtained

The research results obtained were statistically analyzed using STATISTICA 13 software. All analyses were conducted for biogas plants, categorized by point type. The research results obtained were pre-filtered to remove data below the 2nd and above the 98th percentile as outliers. In analyses by category, the data are filtered only after the split. This prevents situations in which, in the case of a true difference in means for different categories, data from only one or two categories are removed, thus minimizing the statistical difference.

The data filtration does not significantly affect the distribution of values. The data presented in this work do not have a normal distribution, even after logarithmization.

This paper presents a PCA with multivariate regression analysis. Multivariate regression makes possible the examination of relationships between multiple data variables. The objective of multivariate regression is to quantify the relationships between multiple independent variables (also known as explanatory variables, factors) and a dependent variable (criterion variable, explanatory variable, or response variable). The multivariate regression formula used in this research is as follows:

where

- y—the predicted value of the dependent variable,

- β0—the y-intercept (value of y when all other parameters are set to 0),

- β1X1—the regression coefficient (β1) of the first independent variable (X1) (the effect that increasing the value of the independent variable has on the predicted y value),

- βnXn—the regression coefficient of the last independent variable,

- ε—model error (how much variation there is in our estimate of y).

Since significant correlation coefficients between the independent and dependent variables were obtained in most of the analyzed cases (facilities, divisions, and overall), the logical next step was to examine how much of the variability in the dependent variables could be attributed to the independent variables when considered collectively. Multivariate regression was used for this purpose.

The subsequent step involved applying PCA to identify the main axes of variability in the independent variable datasets, given their correlations. This approach allowed us to determine which substances in a specific biogas plant were primarily responsible for odor nuisance. PCA is a statistical method of factor analysis that allows us for the identification of chemical compounds that independently contribute to variability in the dataset. The PCA results also enabled us to estimate the percentage of variability captured by the first two components.

Furthermore, these analyses allowed us to determine the extent to which the variability in the dependent parameter, cod, is explained by the tested odorant concentrations, thereby confirming the usefulness of these measurements.

3. Results and Discussion

3.1. Descriptive Statistics

The results of the descriptive statistics include the mean, standard deviation, minimum, maximum, and median for the three biogas plants together. The results of these descriptive statistics are presented in Table 3.

Table 3.

Descriptive statistics results for all biogas plants together.

Table 3 shows that the lowest average CH3SH concentration is observed at the cubic source (0.01 ppm), while the highest concentrations are observed at the organized source (0.63 ppm) and the surface source (0.65 ppm). The same pattern emerges for H2S (0 ppm, 0.38 ppm, and 0.45 ppm, respectively) and VOCs (1.31 ppm, 2.20 ppm, and 3.60 ppm, respectively). For NH3, the lowest average concentration is also observed at the cubic source (1.77 ppm), whereas the highest one is observed far more at the surface source (15.56 ppm). The same situation is observed in the case of odor concentration (145.78). These dependencies indicate a significant relationship between the average concentrations of the determined parameters and the location of the emission source.

Table 4 shows the biogas plants where the highest and lowest values of the tested parameters were recorded, categorized by type of emission source. The data obtained in the research study do not follow a normal distribution, and taking their logarithm did not change this. Table 4 shows the descriptive statistics results comparing the individual biogas plants, highlighting the highest and the lowest average value.

Table 4.

Descriptive statistics results for individual biogas plants (A, B, and C) with the highest and the lowest average value.

Analyzing Table 4, we observed that Biogas Plant A recorded the highest concentrations. This plant is characterized by the highest concentrations of compounds such as H2S, NH3, and CH3SH in all point categories and cod in the emission point category.

However, the technological regime was maintained to the greatest extent at Biogas Plant A. The lowest values of the tested parameters were recorded at Biogas Plant C, which had a different preparation process and type of input compared to the other plants (feedstock material in the form of selectively collected and prepared biowaste at the technological field).

Biogas Plant B, on the other hand, is characterized by the largest cod in terms of cubic and surface sources. This plant had the smallest hall cubic capacity and, above all, insufficient space for storing incoming waste, resulting in the overloading of the waste storage halls.

3.2. Correlation Analysis and PCA with Multivariate Regression

Using Biogas Plant C as an example, we observed that NH3 is the main contributor in PC1, with an eigenvalue exceeding 0.99, while the explained variance analysis indicated that PC1 accounts for over 0.78 of the total variance in the dataset. In the second component, the main compound, VOC, also has an eigenvalue above 0.99; however, the second principal component explains less than 22% of the variance. Comparison of this information with the coefficient of determination from the regression model confirms that NH3 and VOC are indeed the main parameters influencing cod.

Extending the analysis by applying multivariate regression to the two principal components, we found that using only the first two principal components for Biogas Plant C yields an R2 of 0.543 for cod, whereas regression using all data results in a slightly higher R2 of 0.544. Table 5 presents the tested odorants (independent variables) and their contribution to the PC1 (the first principal component) and PC2 (the second principal component) components in individual biogas plants. The table shows that, at Biogas Plant A, NH3 is the dominant factor in the first band (0.994), while H2S is the dominant factor in the second band (0.746). PC1 explains 98% of the variability in the entire dataset, while PC2 explains 2%. Applying multivariate regression to the two principal components yielded a coefficient of determination (R2) for cod of 0.98. This coefficient indicates the level to which the independent variables (odorants) can explain the dependent variable (cod). As for Biogas Plant A, the main factor in PC1 at Biogas Plant B is NH3 (0.995), while in PC2 it is VOC (0.995). The explained variance for PC1 at this Biogas Plant is 0.96, and for PC2, 0.04. Biogas Plant C has the same PC1 and PC2 determinants as Biogas Plant B, which in this case are 0.999, respectively. The explained variance for PC1 is 0.78, and for PC2 is 0.22.

Table 5.

The odorant dependencies for PC1 and PC2 values at particular biogas plants determining cod. Types of odorants (for PC1 and PC2) determining cod at particular Biogas Plants A, B, and C. The highest values are marked in Bold.

In the final model of PCA, microclimatic parameters were not used. They were used only in exploratory correlations.

Comparing the explained variance parameters, PC1 dominates at all biogas plants. The highest variance value was recorded at Biogas Plant A (98%), while the lowest was at Biogas Plant C (78%). The results obtained confirm that the technological regime is consistently maintained at Biogas Plant A. The plant employs airtight containment for individual processes and unit operations, particularly in the most odor-intensive biological section, including digestate dewatering and aerobic stabilization. In the case of Biogas Plant C, both the feedstock preparation and the transport and stabilization of the digestate at the processing site are conducted outdoors, without any hermetic containment.

Considering the results of the sample determinations from emitters, the appropriate action appears to be capturing the process gases emanating from them and then deodorizing them.

The literature on this subject provides limited coverage of the odor impacts of biogas plants, particularly regarding odorant emissions. This makes the present study both scientifically interesting and challenging, as it complicates cross-referencing and comparing results.

In their study, Sadegh et al. [45] demonstrated that H2S and methanethiol were the dominant odorants at the two biogas plants they investigated. The researchers suggested that further studies are needed to confirm the observed relationships and the dynamics of odorant variability in other facilities. This is partially consistent with the results of the present study; however, Sadegh et al. did not examine NH3, which was found to be the dominant odorant at all three biogas plants analyzed in this study. Moreover, the methodology used in their study differed: they employed mass spectrometry performed under laboratory conditions (ex situ method). While this method is more accurate, it is also more expensive and time-consuming than the method applied in the present study. Additionally, the ex situ approach requires collecting gas samples in specialized containers and transporting them to the laboratory, during which the gas composition may change [25].

At the European level, emission levels for waste treatment processes are defined in the BAT Conclusions [42]. This document specifies emission levels for substances such as NH3, H2S, and cod, first by mechanical and biological components, and second by emission type. The values reported represent averages over the sampling period. In the case of the biogas plants tested during operation, no emission levels were exceeded.

4. Conclusions

The statistical analysis of the results obtained from intensive field studies conducted at three MWBP allowed for the subsequent formulation of the statement that in two of the three biogas plants (B and C), the main factors influencing odor concentration were odorants such as NH3 and VOC. At Biogas Plant A, the odorants determining the cod to the greatest extent were NH3 and H2S compounds.

Biogas Plant A, which had the highest odorant concentrations, adhered best to the technological regime. By sealing the plant as much as possible, the risk of odor nuisance to nearby residents was minimized. The remaining two biogas plants reported lower odor and odorant concentrations. However, they experienced poor sealing, insufficient processing capacity resulting in the storage of incoming waste on the process site, and problems with regular maintenance of the process wastewater collection system.

Our analysis of the research findings allows us to conclude that the type of input, processing technology, and the ventilation and deodorization used, as well as compliance with the technological regime, significantly influence the odor impact of MWBP.

In both new and existing MWBPs, a crucial element in minimizing odor emissions is the consistent maintenance of the technological regime. Additionally, for new MWBPs, in the analyzed plants, deodorization was applied only to the biological section (aerobic stabilization of the digestate). However, the results of the present study clearly indicate a significant odor impact originating from roof fan exhaust vents in the mechanical section, which includes the waste storage hall, mechanical processing, preparation of feedstock for the fermentation process (at Biogas Plants A and B), and digestate dewatering (Biogas Plant A). Extending deodorization to these parts of the process line could substantially reduce the odor impact of MWBPs.

Future work should include an immission study outside plant boundaries. Such a study could play an important role in public consultations and serve as a tool for minimizing odor nuisance. Considerations on this topic were previously presented in [18]. Immission results, combined with emission data, could also support the design of new MWBPs that align with the principles of a circular economy.

Author Contributions

Conceptualization, M.W., A.K. and K.L.-S.; methodology, M.W., A.K. and K.L.-S.; software, M.W.; validation, M.W., A.K. and K.L.-S.; formal analysis, M.W.; investigation, M.W.; data curation, M.W.; writing—original draft preparation, M.W.; writing—review and editing, P.M. and K.L.-S.; visualization, M.W.; supervision, K.L.-S. and A.K.; project administration, M.W.; funding acquisition, P.M. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by Warsaw University of Technology.

Data Availability Statement

The original contributions presented in the study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AD | Anaerobic Digestion |

| BAT | Best Available Techniques |

| cod | Odor Concentration |

| C | Odorant Concentration |

| MSW | Municipal Solid Waste |

| MWBP | Municipal Waste Biogas Plant |

| OAV | Odor Activity Value |

| ODT | Odor Detection Threshold |

| PCA | Principal Component Analysis |

| PID | Photoionization Detector |

References

- Kanani, M.J.B. Step toward sustainable development through the integration of renewable energy systems with, fuel cells: A review. Sustain. Energy Technol. Assess. 2024, 70, 103935. [Google Scholar] [CrossRef]

- Pinheiro, J.P.; Camiloti, P.R.; Sauer, I.L.; Mady, C.E.K. Exergy Analysis of a Biogas Plant for Municipal Solid Waste Treatment and Energy Cogeneration. Energies 2025, 18, 2804. [Google Scholar] [CrossRef]

- Foster, J.; Montgomery, P. A Study of Environmentally Friendly Menstrual Absorbents in the Context of Social Changes for Adolescent Girls in Low- and Middle-Income Countries. Int. J. Environ. Res. Public Health 2021, 18, 9766. [Google Scholar] [CrossRef]

- Malav, L.C.; Yadav, K.K.; Gupta, N.; Kumar, S.; Sharma, G.K.; Krishnan, S.; Rezania, S.; Kamyab, H.; Pham, Q.B.; Yadav, S.; et al. A review on municipal solid waste as a renewable source for waste-to-energy project in India: Current practices, challenges, and future opportunities. J. Clean. Prod. 2020, 277, 123227. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Drouillon, M.; Vervaeren, H. Techniques for transformation of biogas to biomethane. Biomass Bioenergy 2011, 35, 1633–1645. [Google Scholar] [CrossRef]

- World Bioenergy Association. Global Bioenergy Statisticks; WBA: Stockholms, Sweden, 2017. [Google Scholar]

- Grando, R.L.; de Souza Antune, M.A.; da Fonseca, F.V.; Sánchez, A.; Barrena, R.; Font, X. Technology overview of biogas production in anaerobic digestion plants: A European evaluation of research and development. Renew. Sustain. Energy Rev. 2017, 80, 44–53. [Google Scholar] [CrossRef]

- Seruga, P.; Krzywonos, M.; Wilk, M. Treatment of By-Products Generated from Anaerobic Digestion of Municipal Solid Waste. Waste Biomass Valorization 2020, 11, 4933–4940. [Google Scholar] [CrossRef]

- El Ibrahimi, M.; Khay, I.; El Maakoul, A.; Bakhouya, M. Techno-economic and environmental assessment of anaerobic co-digestion plants under different energy scenarios: A case study in Morocco. Energy Convers. Manag. 2021, 245, 114553. [Google Scholar] [CrossRef]

- Chowdhury, T.H. Technical-economical analysis of anaerobic digestion process to produce clean energy. Energy Rep. 2021, 7, 247–253. [Google Scholar] [CrossRef]

- Lee, G.-E.; Loveridge, S.; Joshi, S. Local acceptance and heterogeneous externalities of biorefineries. Energy Econ. 2017, 67, 328–336. [Google Scholar] [CrossRef]

- Litvin, S.W.; Smith, W.W.; McEwen, W.R. Not in My Backyard: Personal Politics and Resident Attitudes toward Tourism. J. Travel Res. 2020, 59, 674–685. [Google Scholar] [CrossRef]

- Soland, M.; Steimer, N.; Walter, G. Local acceptance of existing biogas plants in Switzerland. Energy Pol. 2013, 61, 802–810. [Google Scholar] [CrossRef]

- Fisher, R.M.; Le-Minh, N.; Alvarez-Gaitan, J.P.; Moore, S.J.; Stuetz, R.M. Emissions of volatile sulfur compounds (VSCs) throughout wastewater biosolids processing. Sci. Total Environ. 2018, 616–617, 622–623. [Google Scholar] [CrossRef]

- Sówka, I.; Pawnuk, M.; Grzelka, A.; Pielichowska, A. The use of ordinary kriging and inverse distance weighted interpolation to assess the odour impact of a poultry farming plant. Sci. Rev. Eng. Environ. Sci. 2020, 29, 17–26. [Google Scholar] [CrossRef]

- Orzi, V.; Riva, C.; Scaglia, B.; D’Imporzano, G.; Tambone, F.; Adani, F. Anaerobic digestion coupled with digestate injection reduced odour emissions from soil during manure distribution. Sci. Total Environ. 2018, 621, 168–176. [Google Scholar] [CrossRef]

- Ighravwe, D.E.; Babatunde, D.E. Evaluation of landfill gas plant siting problem: A multi-criteria approach. Environ. Health Eng. Manag. J. 2019, 6, 1–10. [Google Scholar] [CrossRef]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour Nuisance at Municipal Waste Biogas Plants and the Effect of Feedstock Modification on the Circular Economy—A Review. Energies 2021, 14, 6470. [Google Scholar] [CrossRef]

- Hayes, J.; Stevenson, R.; Stuetz, R. The impact of malodour on communities: A review of assessment techniques. Sci. Total Environ. 2014, 500, 395–407. [Google Scholar] [CrossRef]

- Kośmider, J.; Mazur-Chrzanowska, B.; Wyszyński, B. Odours [Odory]; Wydawnictwo Naukowe PWN: Warsaw, Poland, 2012. (In Polish) [Google Scholar]

- Piringer, M.; Schauberger, G. Dispersion Modelling for Odour Exposure Assessment. In Odour Impact Assessment Handbook; Belgiorno, V., Naddeo, V., Zarra, T., Eds.; John Wiley & Sons Ltd.: Bognor Regis, UK, 2013; pp. 125–174. [Google Scholar]

- Naddeo, V.; Belgiorno, V.; Zarra, T. Odour Characterization and Exposure Effects. In Odour Impact Assessment Handbook; Belgiorno, V., Naddeo, V., Zarra, T., Eds.; John Wiley & Sons Ltd.: Bognor Regis, UK, 2013; pp. 1–5. [Google Scholar]

- EN 13725: 2003; Air Quality-Determination of Odour Concentration by Dynamic Olfactometry. European Committee for Standardization, CEN: Brussels, Belgium, 2003.

- Sarkar, U.; Hobbs, S.E. Odour from municipal solid waste (MSW) landfills: A study on the analysis of perception. Environ. Int. 2002, 27, 655–662. [Google Scholar] [CrossRef] [PubMed]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Olfactometric testing as a method for assessing odour nuisance of biogas plants processing municipal waste. Arch. Environ. Prot. 2020, 46, 60–68. [Google Scholar] [CrossRef]

- Agus, E.; Lim, M.H.; Zhang, L.; Sedlak, D.L. Odorous compounds in municipal wastewater effluent and potable water reuse systems. Environ. Sci. Technol. 2011, 45, 9347–9355. [Google Scholar] [CrossRef]

- Lee, H.D.; Jeon, S.B.; Choi, W.J.; Lee, S.S.; Lee, M.H.; Oh, K.J. A novel assessment of odor sources using instrumental analysis combined with resident monitoring records for an industrial area in Korea. Atmos. Environ. 2013, 74, 277–290. [Google Scholar] [CrossRef]

- Parker, D.B.; Gilley, J.; Woodbury, B.; Kim, K.H.; Galvin, G.; Bartelt-Hunt, S.L.; Li, X.; Snow, D.D. Odorous VOC emission following land application of swine manure slurry. Atmos. Environ. 2013, 66, 91–100. [Google Scholar] [CrossRef]

- Trabue, S.; Scoggin, K.; McConnell, L.; Maghirang, R.; Razote, E.; Hatfield, J. Identifying and tracking key odorants from cattle feedlots. Atmos. Environ. 2011, 45, 4243–4251. [Google Scholar] [CrossRef]

- Wu, C.; Liu, J.; Yan, L.; Chen, H.; Shao, H.; Meng, T. Assessment of odor activity value coefficient and odor contribution based on binary interaction effects in waste disposal plant. Atmos. Environ. 2015, 103, 231–237. [Google Scholar] [CrossRef]

- Fielberg, A.; Liu, D.; Adamsen, A.P.S.; Hansen, M.J.; Jonassen, K.E.N. Odorant Emissions from Intensive Pig Production Measured by Online Proton-Transfer-Reaction Mass Spectrometry. Environ. Sci. Technol. 2010, 44, 5894–5900. [Google Scholar] [CrossRef] [PubMed]

- Gębicki, J.; Szulczyński, B.; Byliński, H.; Kolasińska, P.; Dymerski, T.; Namieśnik, J. Application of Electronic Nose to Ambient Air Quality Evaluation With Respect to Odour Nuisance in Vicinity of Municipal Landfills and Sewage Treatment. In Electronic Nose Technologies and Advances in Machine Olfaction; Albastaki, Y., Albalooshi Bahrajn, F., Eds.; IGI Global: Hershey, PA, USA, 2018; pp. 175–201. [Google Scholar] [CrossRef]

- Capelli, L.; Sironi, S.; Del Rosso, R.; Céntola, P.; Il Grande, M. A comparative and critical evaluation of odour assessment methods on a landfill site. Atmos. Environ. 2008, 42, 7050–7058. [Google Scholar] [CrossRef]

- Ueno, H.; Amano, S.; Merecka, B.; Kośmider, J. Difference in the odor concentrations measured by the triangle odor bag method and dynamic olfactometry. Water Sci. Technol. 2009, 59, 1339–1342. [Google Scholar] [CrossRef]

- Wiśniewska, M. Methods of Assessing Odour Emissions from Biogas Plants Processing Municipal Waste. J. Ecol. Eng. 2020, 21, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Blanes-Vidal, V.; Hansen, M.N.; Adamsen, A.P.S.; Feilberg, A.; Petersen, S.O.; Jensen, B.B. Characterization of odor released during handling of swine slurry: Part I. Relationship between odorants and perceived odor concentrations. Atmos. Environ. 2009, 43, 2997–3005. [Google Scholar] [CrossRef]

- Blazy, V.; de Guardia, A.; Benoist, J.C.; Daumoin, M.; Lemasle, M.; Wolbert, D.; Barrington, S. Odorous gaseous emissions as influence by process condition for the forced aeration composting of pig slaughterhouse sludge. Waste Manag. 2014, 34, 1125–1138. [Google Scholar] [CrossRef]

- Rincón, C.A.; De Guardia, A.; Couvert, A.; Le Roux, S.; Soutrel, I.; Daumoin, M.; Benoist, J.C. Chemical and odor characterization of gas emissions released during composting of solid wastes and digestates. J. Environ. Manag. 2019, 233, 39–53. [Google Scholar] [CrossRef]

- Tsai, C.J.; Chen, M.L.; Ye, A.D.; Chou, M.S.; Shen, S.H.; Mao, I.F. The relationship of odor concentration and the critical components emitted from food waste composting plants. Atmos. Environ. 2008, 42, 8246–8251. [Google Scholar] [CrossRef]

- Conti, C.; Guariano, M.; Bacenetti, J. Measurements techniques and models to assess odor annoyance: A review. Environ. Int. 2020, 134, 105261. [Google Scholar] [CrossRef] [PubMed]

- Wiśniewska, M.; Kulig, A.; Lelicińska-Serafin, K. Odour Emissions of Municipal Waste Biogas Plants—Impact of Technological Factors, Air Temperature and Humidity. Appl. Sci. 2020, 10, 1093. [Google Scholar] [CrossRef]

- European Union (EU). Commission Implementing Decision (EU) 2018/1147 of 10 August 2018 establishing Best Available Techniques (BAT) Conclusions for Waste Treatment, Under Directive 2010/75/EU of the European Parliament and of the Council; Publications Office of the European Union (OP): Brussels, Belgium, 2018. [Google Scholar]

- Nasal Ranger—Field Olfactometer. Available online: https://www.fivesenses.com/equipment/nasalranger/nasalranger/ (accessed on 5 November 2025).

- ISO 4120:2004; Sensory Analysis—Methodology—Triangle Test. International Organization for Standardization: Geneva, Switzerland, 2004.

- Sadegh, N.; Uniacke, J.; Feilberg, A.; Kofoed, M.V.W. Assessment of transient hydrogen sulfide peak emissions caused by biogas plant operation. J. Clean. Prod. 2024, 468, 142920. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.