Sensor-Centric Intelligent Systems for Soybean Harvest Mechanization in Challenging Agro-Environments of China: A Review

Abstract

1. Introduction

2. Materials and Methods

(“soybean harvesting” OR “soybean harvest mechanization”) AND (sensor* OR “intelligent system*” OR “agricultural robot”) AND (“hilly” OR “mountainous” OR “challenging terrain” OR “complex terrain”); (“soybean-corn intercropping” OR “maize-soybean intercropping”) AND (“harvest*” OR “mechanization”) AND (“robot*” OR “sensor fusion” OR “machine vision” OR “LiDAR”); (“precision agriculture” OR “smart farming”) AND “soybean harvest*” AND (“sensor technology” OR “IMU” OR “GPS”); (“agricultural machinery” OR “combine harvester”) AND “terrain sensing” AND “soybean”; Review AND “soybean harvesting” AND “intelligent agriculture”

- (1)

- publication type must be a peer-reviewed journal article, a high-level international conference paper, or a doctoral dissertation; (2) research content must directly focus on sensor technologies, intelligent control systems, robotics, or related mechanized equipment applied to the soybean-harvesting process; (3) the research context must be explicitly set in hilly and mountainous areas, intercropping systems, or other complex agricultural environments with similar challenges; and (4) the language of publication must be English or Chinese.

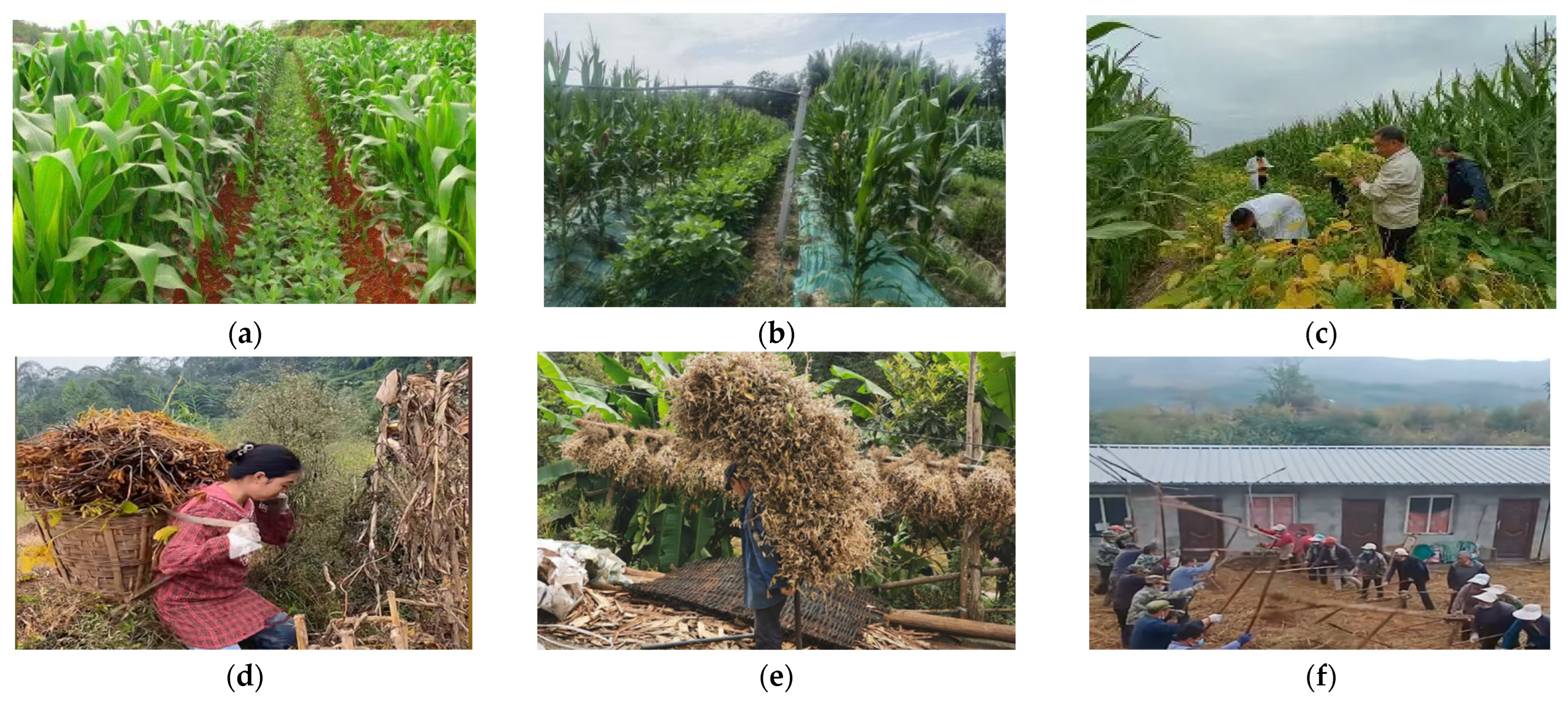

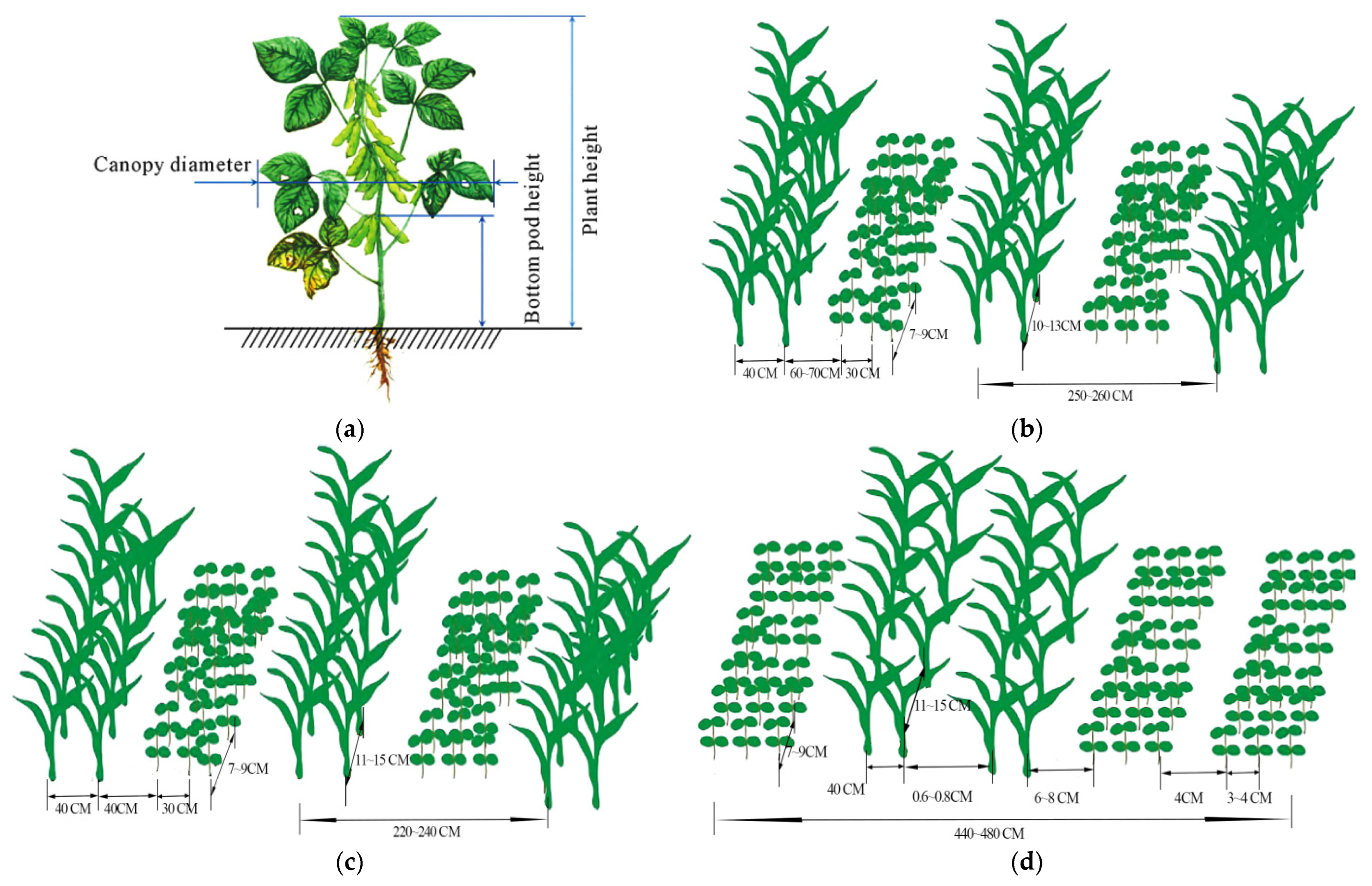

3. Agronomic Characteristics and Severe Terrain Constraints of Soybean–Corn Intercropping Pattern in Southwest Hilly–Mountainous Areas

3.1. Agronomic Characteristics of Soybean–Corn Intercropping Patterns in Southwest China’s Hilly–Mountainous Areas

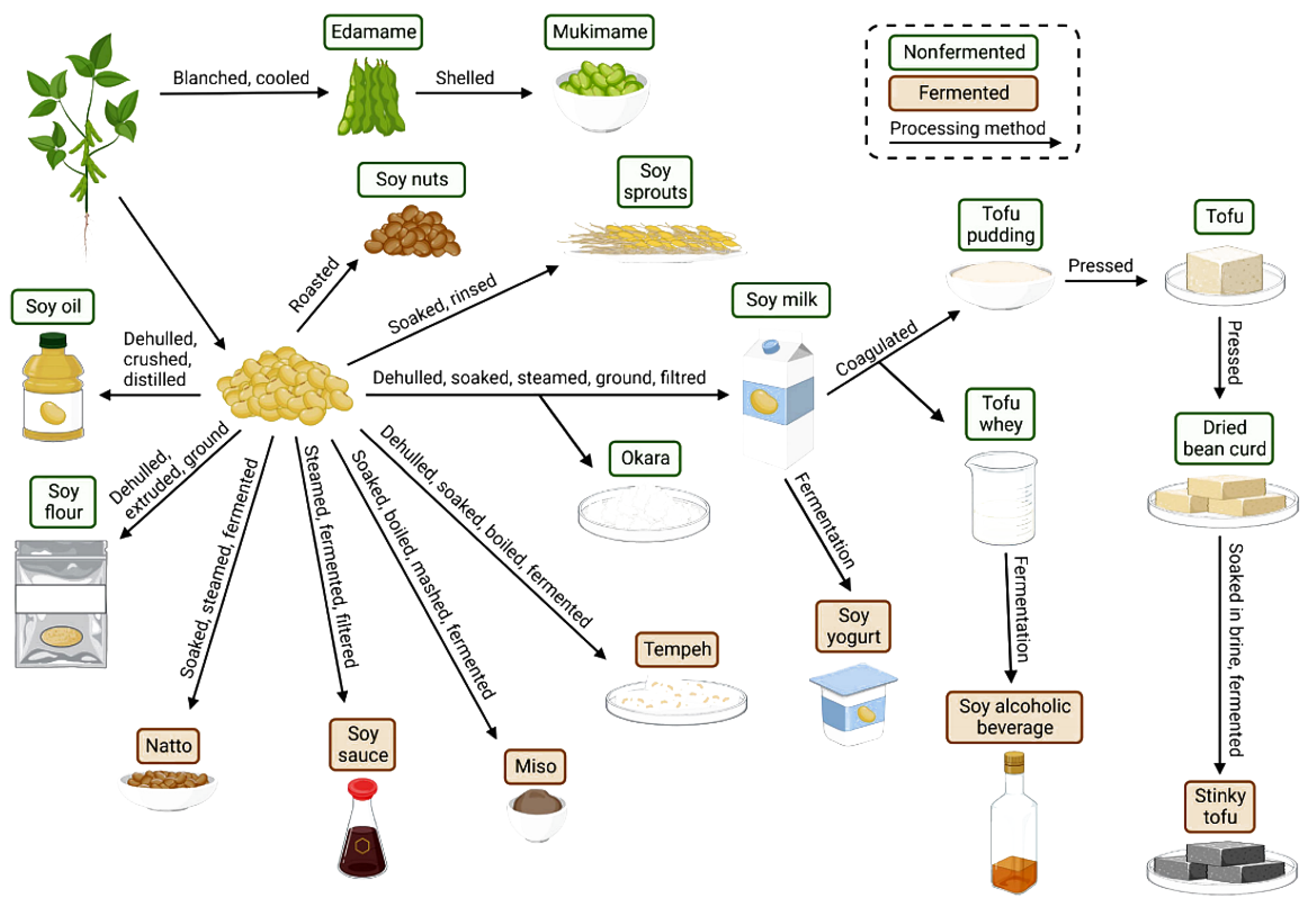

3.2. Significance of Soybean Cultivation in Southwest China for Mechanized Harvesting Development

4. Severe Constraints and Their Impact from Hilly–Mountainous Terrain

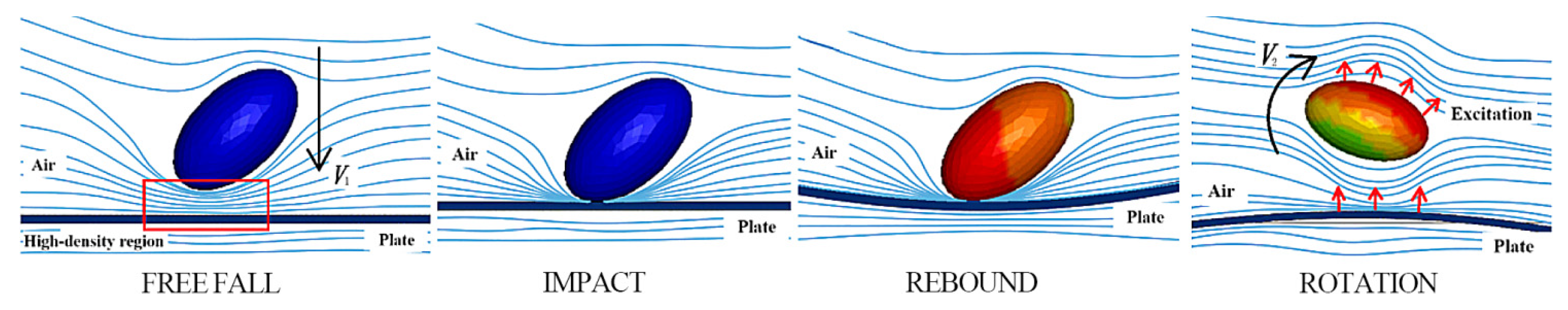

5. Grain Loss and Plant Damage Patterns of Existing Harvesting Machinery Operating in Complex Terrain and Intercropping

5.1. Characterization of Soybean Harvest Losses in Hilly and Mountainous Areas

5.2. Impact of Plant Damage Patterns on Intercropping Crops

6. Key Analysis of Soybean-Harvesting Equipment Technology Research for Complex Agronomy and Rugged Terrain

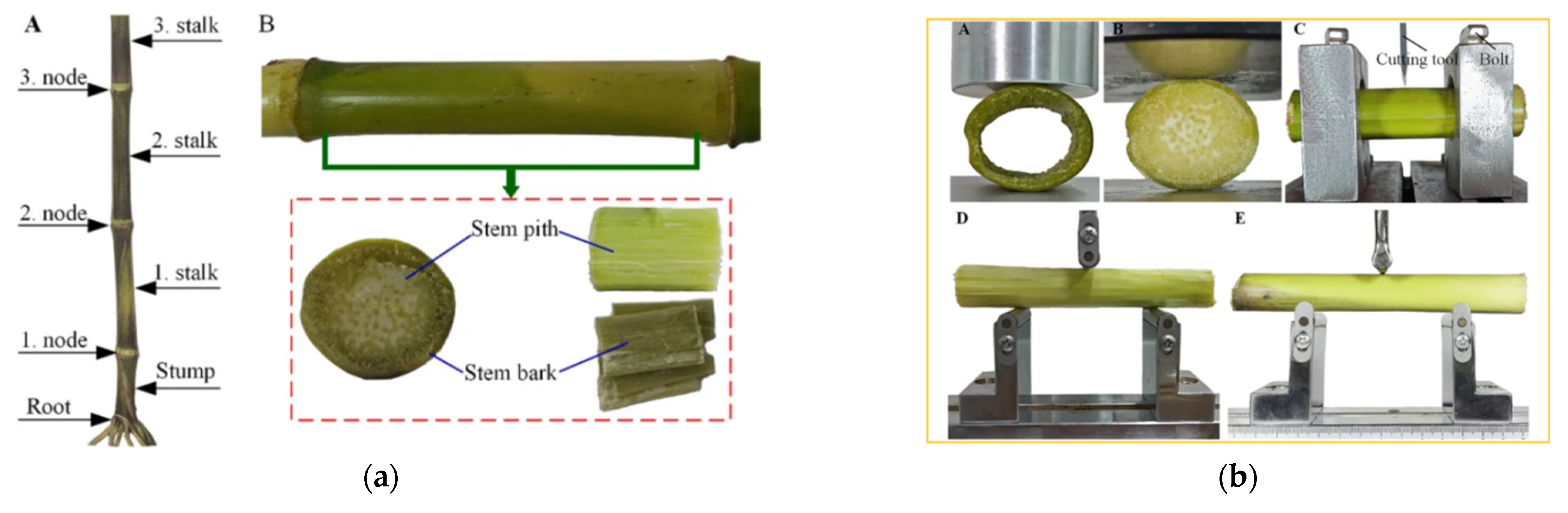

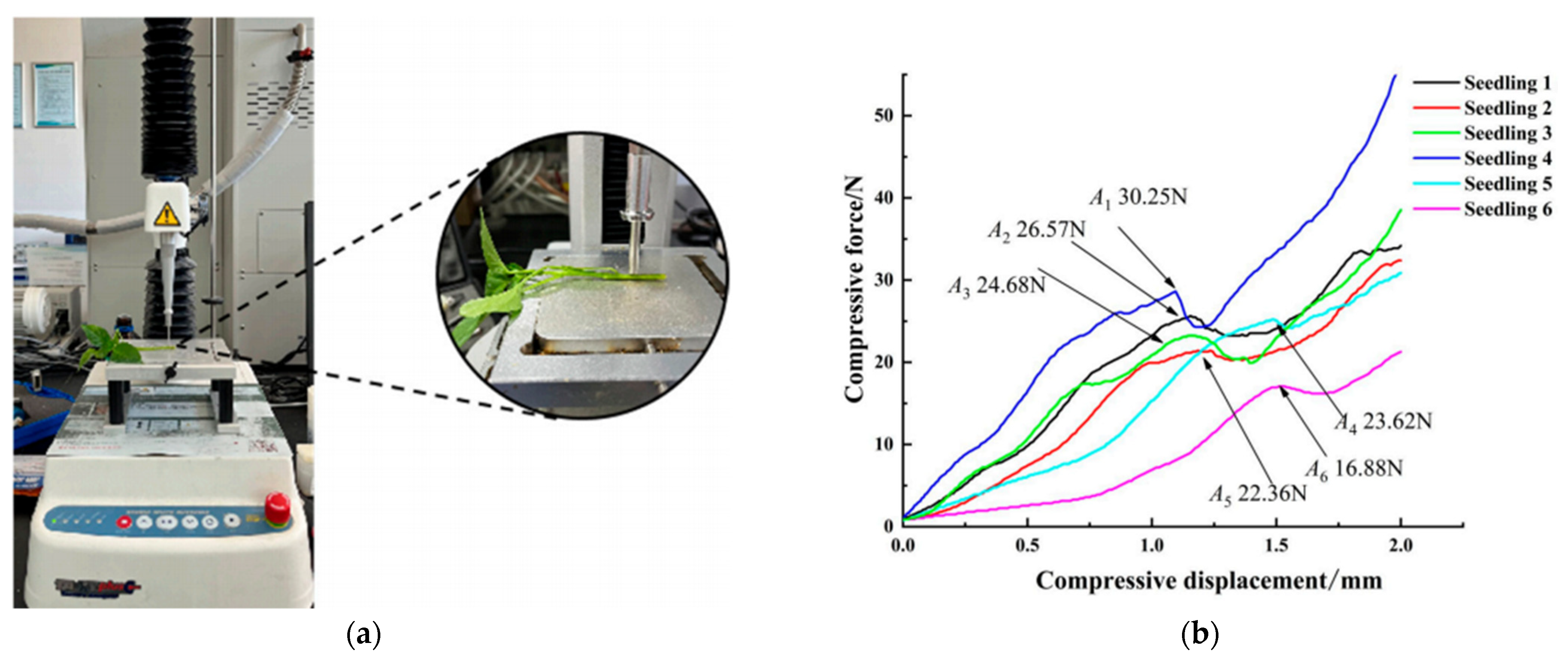

6.1. Research Status of Interacting Mechanical Property Factors During Mechanical Harvesting

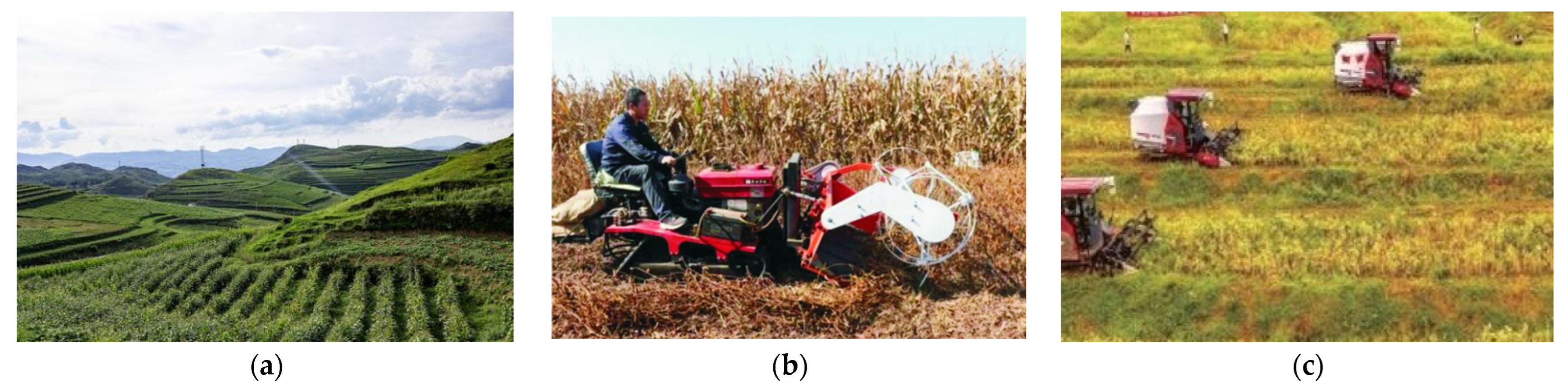

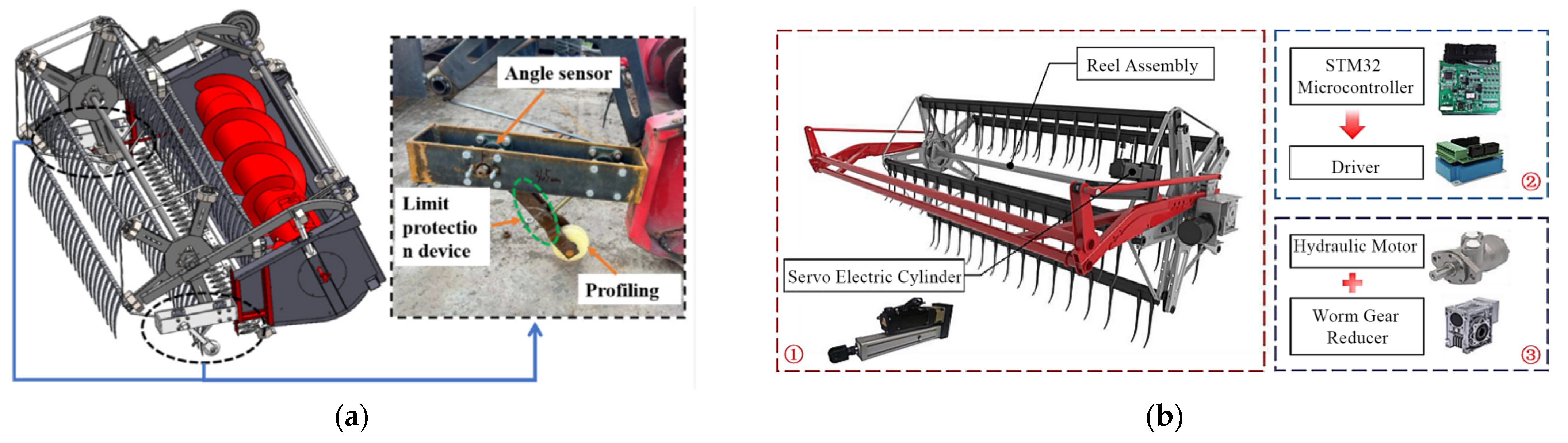

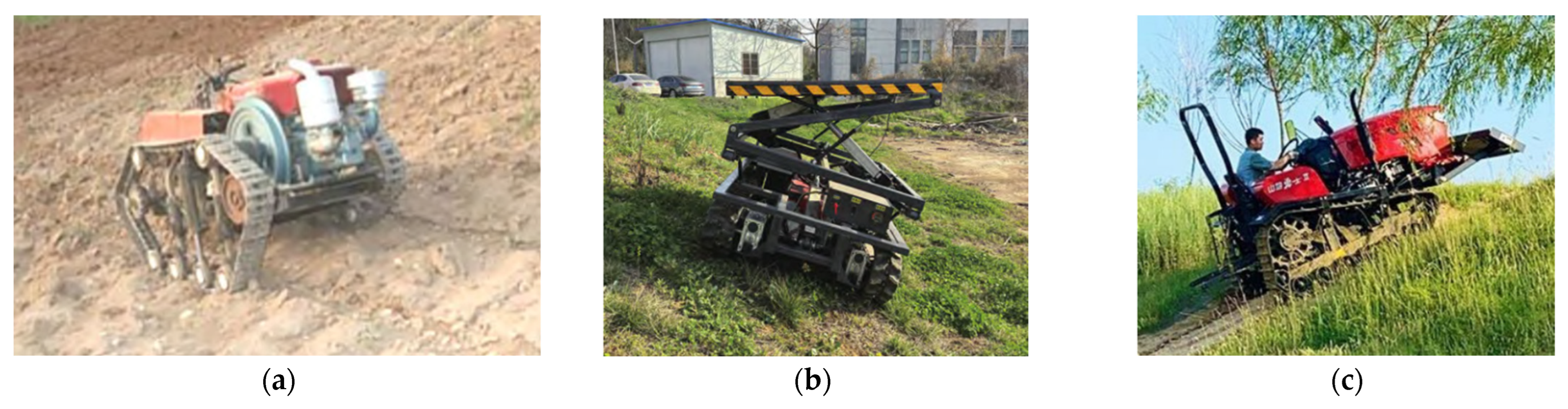

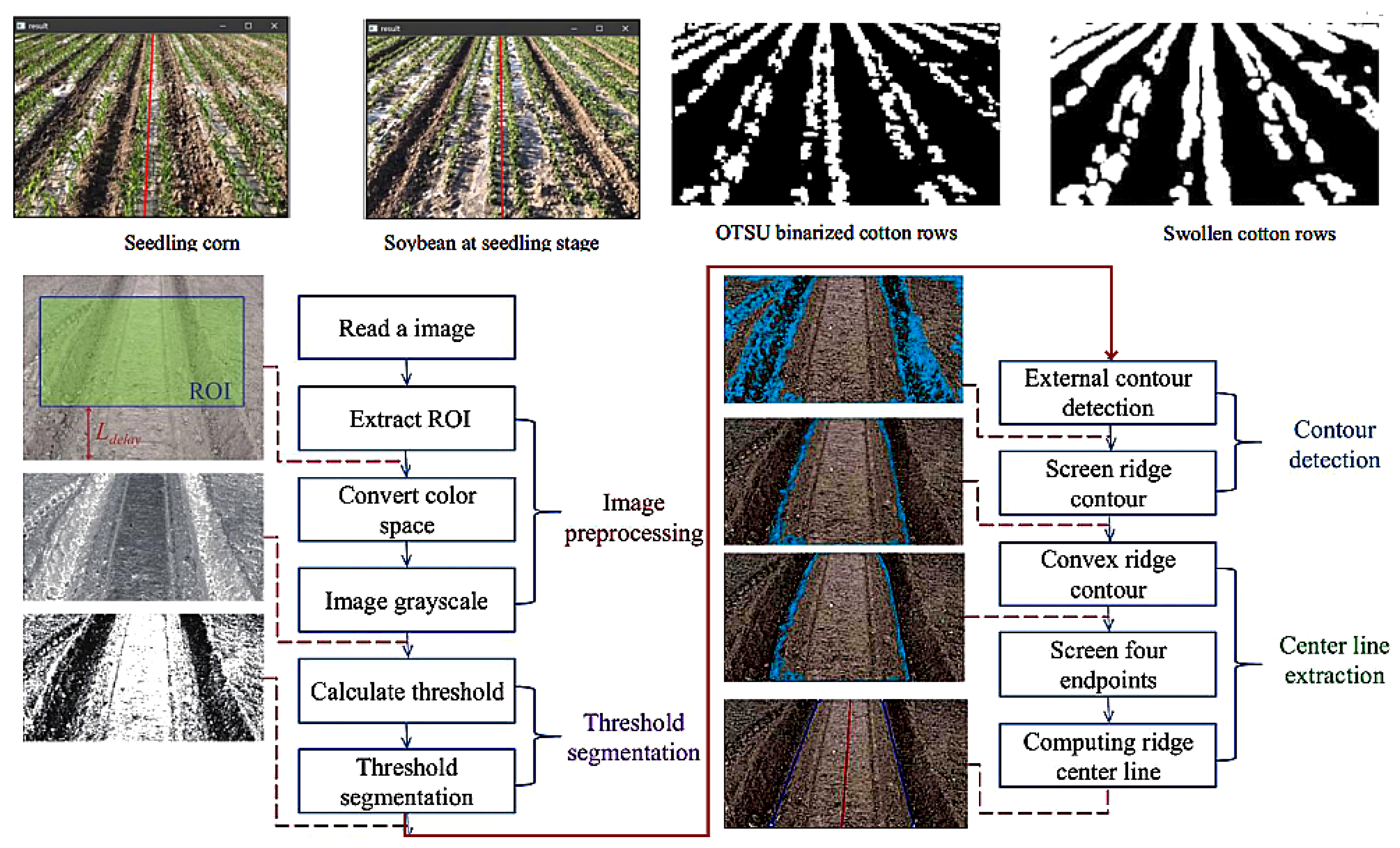

6.2. Existing Harvesting Equipment and Research Methods in Southwest China

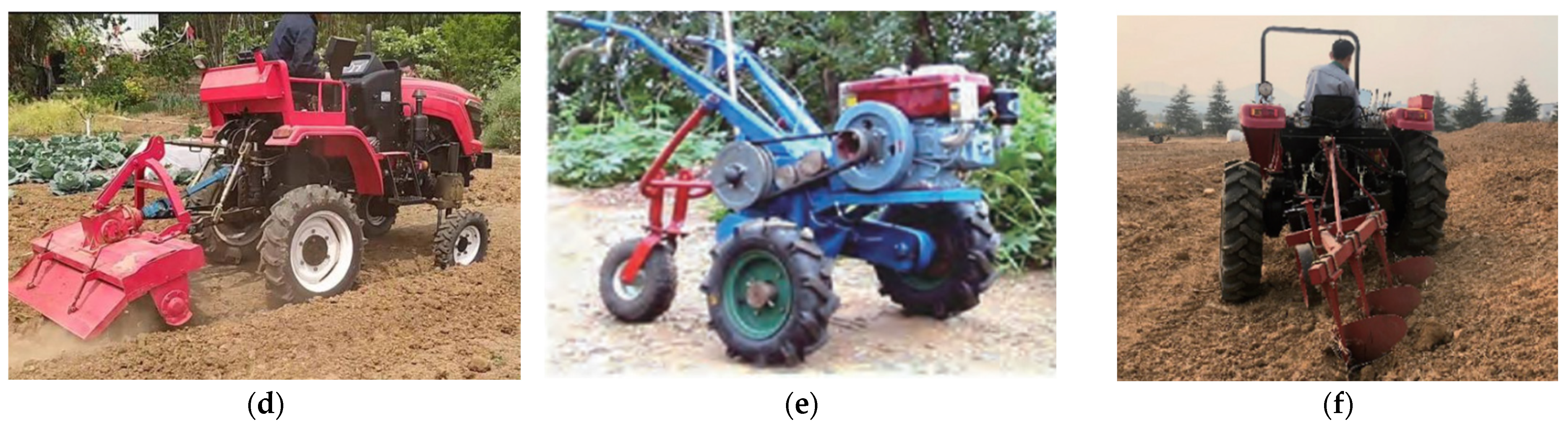

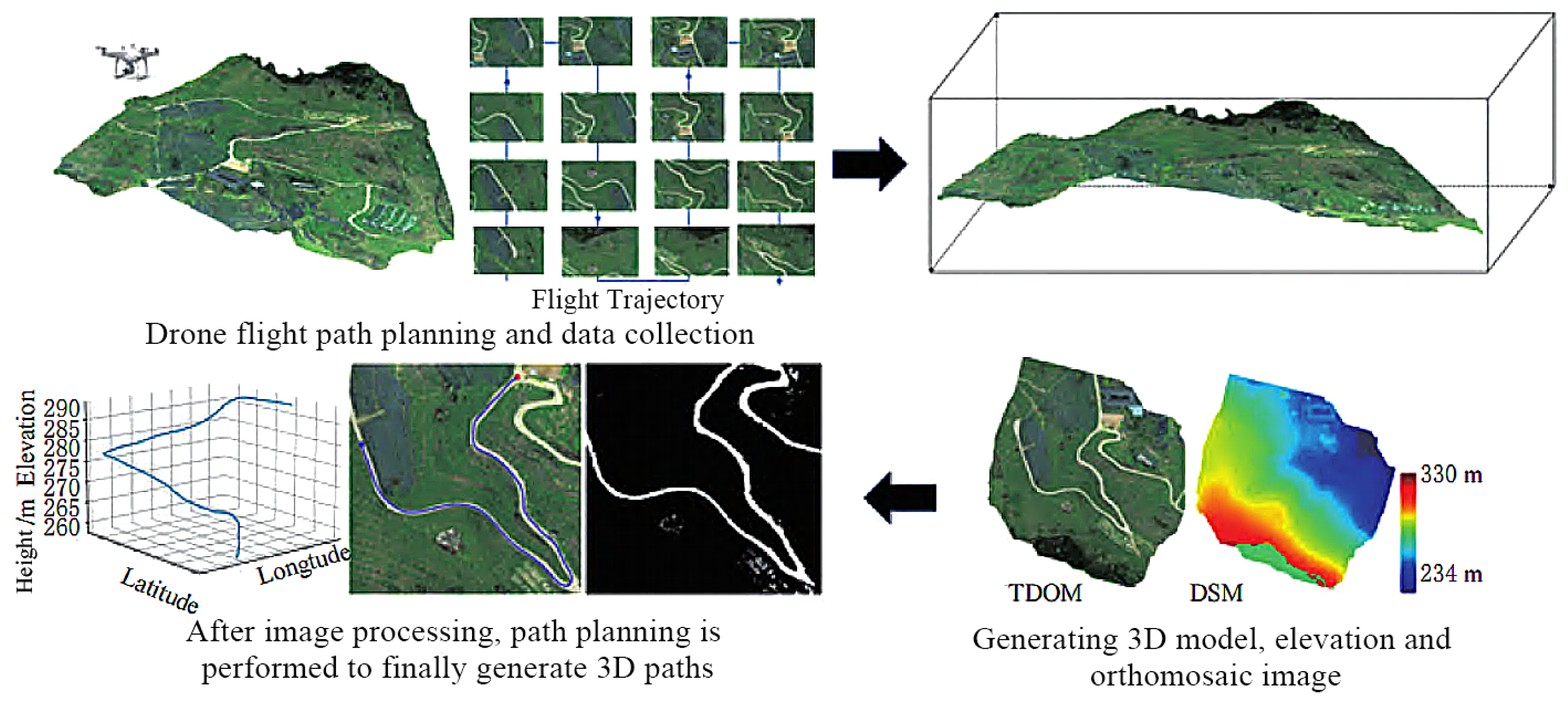

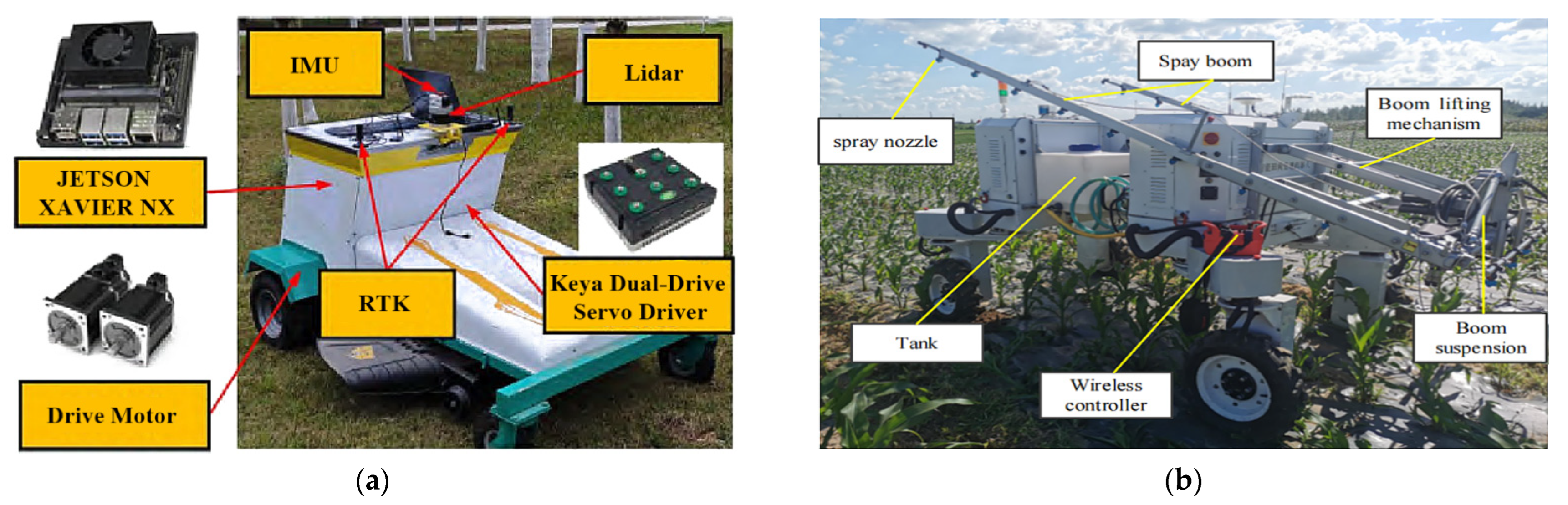

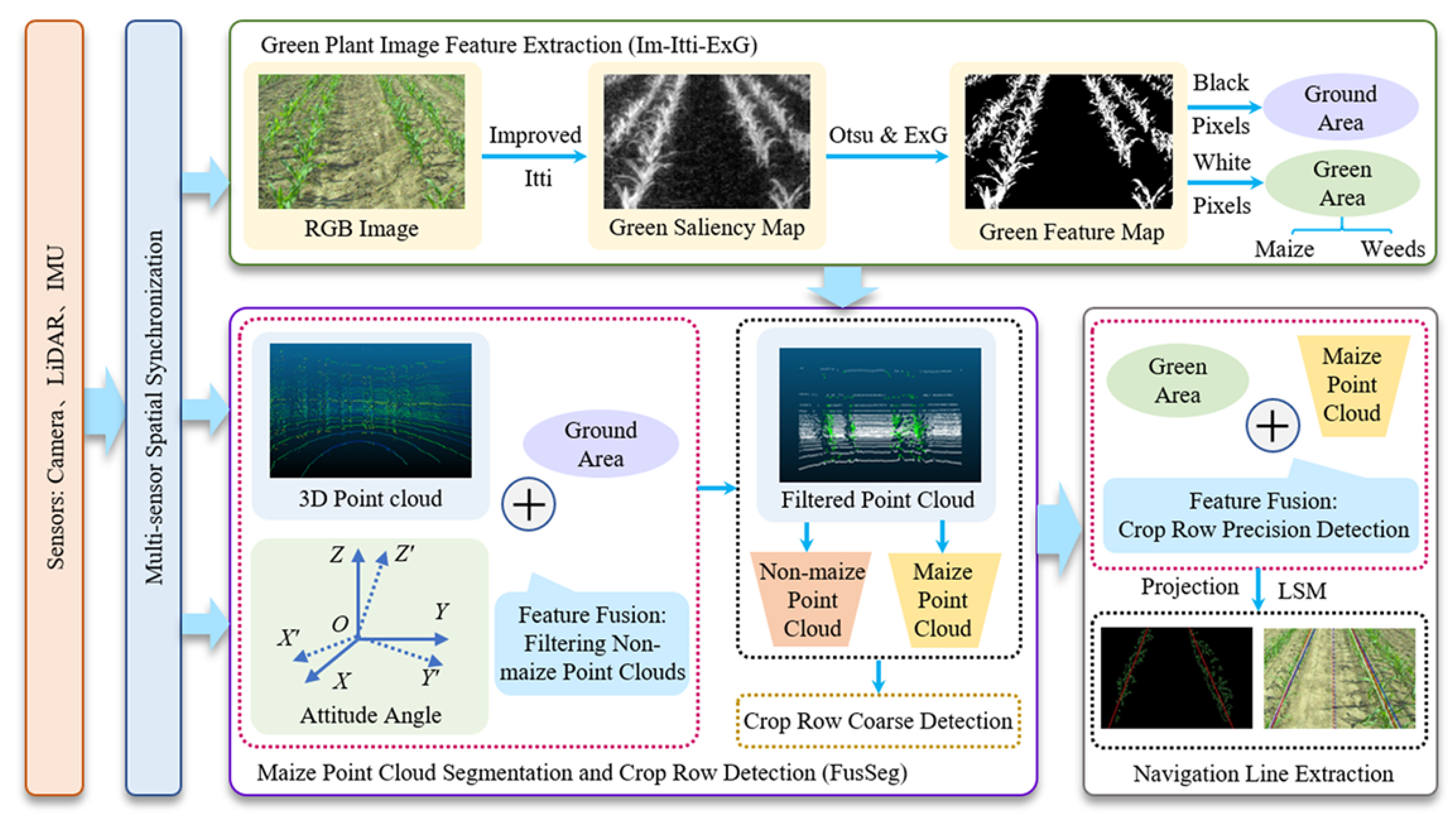

6.3. Intelligent Navigation and Path Planning Technology

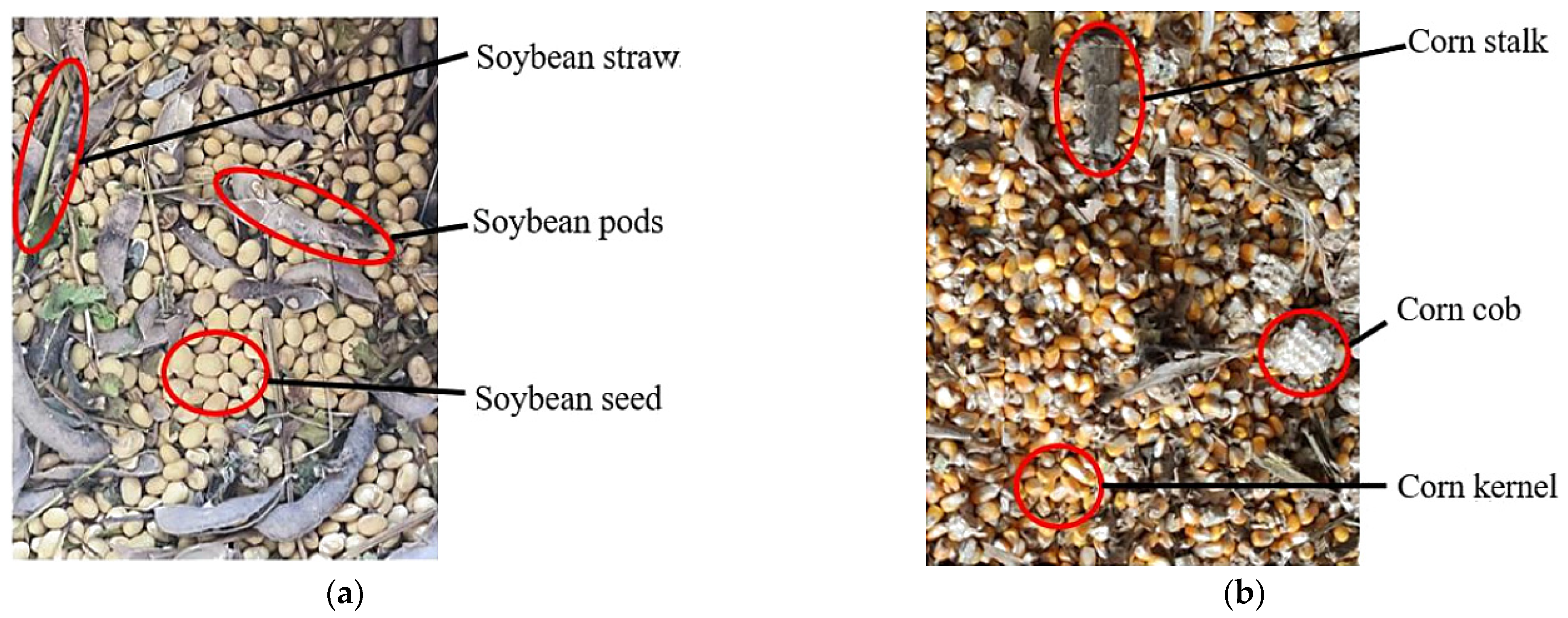

7. Precise Identification, Selective Harvesting, and Impurity Pre-Sorting for Soybeans in Intercropping Pattern

7.1. Precise Soybean Crop Identification and Differentiation

7.2. Multi-Sensor Fusion Applications Based on Deep Learning and Agronomic Perception

7.3. Deep Learning Applications for Advanced Soybean Perception

7.4. Research on Precise Cutting and Selective Harvesting of Soybeans

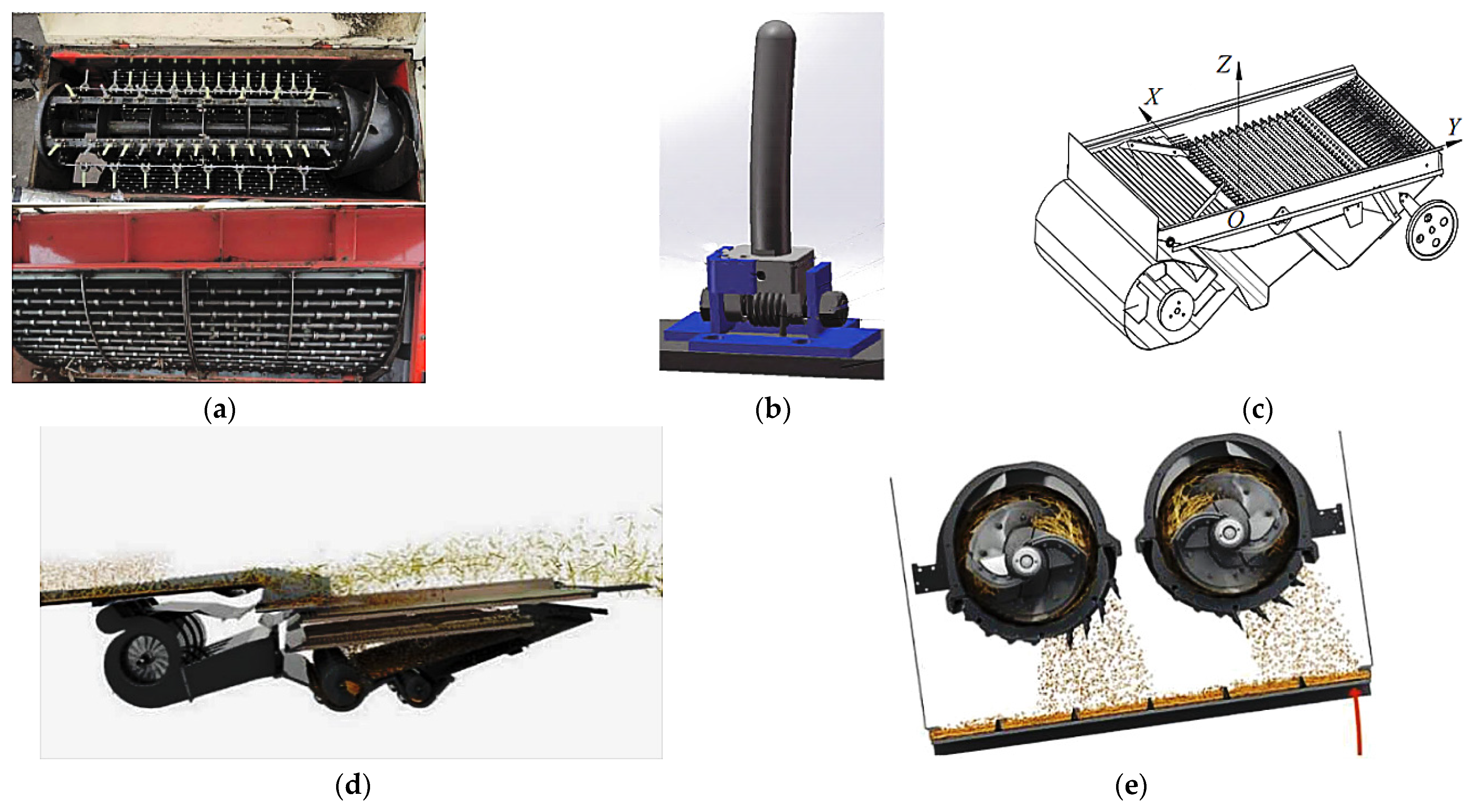

8. Low-Damage, High-Efficiency Soybean Threshing and Optimized Cleaning Performance for Hilly–Mountainous Slopes

9. Conclusions

10. Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, Y.T.; Ma, X.X.; Li, L.; Yang, L.L.; Yu, H.F.; Zhao, Y.; Liu, H.Q. Purine content of different soybean products and dynamic transfer in food processing techniques. Food Chem.-X 2025, 28, 102499. [Google Scholar] [CrossRef]

- Li, J.J.; Li, N.; Hu, X.Y.; Wang, G.J.; Bai, P.Y.; Hu, Y.J.; Yang, Y.; Shao, D.; Gao, H.; Miao, L.; et al. Revealing the distribution pattern of soybean purine content and its influencing factors based on an ultra-micro detection system. LWT-Food Sci. Technol. 2025, 223, 117683. [Google Scholar] [CrossRef]

- Ai, Y.F.; Jane, J.L. Macronutrients in Corn and Human Nutrition. Compr. Rev. Food Sci. Food Saf. 2016, 15, 581–598. [Google Scholar] [CrossRef]

- Li, H.B.; Chen, L.W.; Zhang, Z.Y. A Study on the Utilization Rate and Influencing Factors of Small Agricultural Machinery: Evidence from 10 Hilly and Mountainous Provinces in China. Agriculture 2023, 13, 51. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, T.T.; Wei, W.W.; Li, Z.; Li, G.Y.; Shen, L.; Zhang, W. In arid regions, the different Intercropping Pattern reduce interspecific competition to improve system productivity. Plant Soil 2025, 506, 137–155. [Google Scholar] [CrossRef]

- Chen, X.F.; Sun, N.; Gu, Y.; Zheng, H.Y.; Li, J.F.; Wu, C.S.; Wang, Z.M. Photosynthetic and Chlorophyll Fluorescence Responses in Maize and Soybean Strip Intercropping System. Int. J. Agric. Biol. 2020, 24, 799–811. [Google Scholar]

- Savary, S.; Willocquet, L.; Pethybridge, S.J.; Esker, P.; McRoberts, N.; Nelson, A. The global burden of pathogens and pests on major food crops. Nat. Ecol. Evol. 2019, 3, 430–439. [Google Scholar] [CrossRef] [PubMed]

- Raza, M.A.; Cui, L.; Khan, I.; Din, A.M.U.; Chen, G.P.; Ansar, M.; Yang, W.Y. Compact maize canopy improves radiation use efficiency and grain yield of maize/soybean relay intercropping system. Environ. Sci. Pollut. Res. 2021, 28, 41135–41148. [Google Scholar] [CrossRef]

- Chen, X.F.; Sun, N.; Gu, Y.; Liu, Y.L.; Li, J.F.; Wu, C.S.; Wang, Z.M. Maize-Soybean Strip Intercropping Improved Lodging Resistance and Productivity of Maize. Int. J. Agric. Biol. 2020, 24, 1383–1392. [Google Scholar]

- Fan, Z.; Liu, P.Z.; Lin, Y.R.; Qiang, B.B.; Li, Z.P.; Cheng, M.W.; Chen, X.L. Root plasticity improves the potential of maize/soybean intercropping to stabilize the yield. Soil Tillage Res. 2025, 251, 106553. [Google Scholar] [CrossRef]

- Cao, M.; Wang, J.; Cui, Y.; Deborah Joy, B.; Li, S.; Chen, X.; Gu, Y. Effects of Different Maize and Soybean Intercropping Ratios on Photosynthetic Characteristics and Yield of Soybean. Soybean Sci. 2023, 42, 48–54. [Google Scholar]

- Zheng, Y.; Jiang, S.; Chen, B.; Lu, H.; Wan, C.; Kang, F. Review on Technology and Equipment of Mechanization in Hilly Orchard. Trans. Chin. Soc. Agric. Mach. 2020, 51, 1–20. [Google Scholar]

- Yao, C.; He, Y.; Cao, Z. Spatial-temporal evolution and driving mechanism of mechanization level of staple food grain production in China. J. China Agric. Univ. 2021, 26, 208–220. [Google Scholar]

- Jiang, L.; Zhang, Z.; Zhong, Y.; Xu, W. The effect of farmland suitability for agricultural machinery operation on non-grain conversion in hilly and mountain areas of China. Resour. Sci. 2024, 46, 1394–1405. [Google Scholar]

- Tarolli, P.; Straffelini, E. Agriculture in Hilly and Mountainous Landscapes: Threats, Monitoring and Sustainable Management. Geogr. Sustain. 2020, 1, 70–76. [Google Scholar] [CrossRef]

- Dixit, J.; Khan, J.N.; Shukla, R.M. Mechanization Possibilities of Maize Cultivation in Hilly Regions of Jammu and Kashmir State of India. Ama-Agric. Mech. Asia Afr. Lat. Am. 2010, 41, 59–63. [Google Scholar]

- Wang, J.; Cao, R.; Jiang, Y.Z.; Yang, M.; Liu, W.C.; Wang, X.G.; Zhao, Q.T.; Yang, J.T. Problems and solutions for soybean-maize intercropping in Hunan Province. Agric. Dev. Equip. 2023, 11, 199–201. [Google Scholar]

- Luo, H.; Wang, J.; Lian, X.; Geng, B.; Li, F. Design and experiment of small narrow range segmented soybean harvester in hilly area. Agric. Res. Arid Areas 2024, 42, 283–293. [Google Scholar]

- Hwang, S.; Lee, T.G. Integration of lodging resistance QTL in soybean. Sci. Rep. 2019, 9, 6540. [Google Scholar] [CrossRef]

- Shi, R.J.; Chang, L.L.; Zhao, W.Y.; Dai, F.; Liang, Z.W. Simulation of Flax Threshing Process by Different Forms of Threshing Drums in Combined Harvesting. Agronomy 2025, 15, 36. [Google Scholar] [CrossRef]

- Li, X.; Zhang, X.; Chen, G.; Wang, X.; Yang, W. Cost and comprehensive benefit analysis of maize-soybean relay strip intercropping system in Southwest China. Chin. J. Oil Crop Sci. 2023, 45, 427–436. [Google Scholar]

- Yao, M.J.; Yang, Y.; Fan, J.; Ma, C.M.; Liu, X.F.; Wang, Y.; Sun, Q.C. Production, purification, and functional properties of microbial fibrinolytic enzymes produced by microorganism obtained from soy-based fermented foods: Developments and challenges. Crit. Rev. Food Sci. Nutr. 2024, 64, 3725–3750. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Hubbard, K.G.; Wilhite, D.A. An agricultural drought risk-assessment model for corn and soybeans. Int. J. Climatol. 2004, 24, 723–741. [Google Scholar] [CrossRef]

- Sun, W.X.; Zhang, R.J.; Fan, J.; He, Y.; Mao, X.H. Comprehensive transformative profiling of nutritional and functional constituents during germination of soybean sprouts. J. Food Meas. Charact. 2018, 12, 1295–1302. [Google Scholar] [CrossRef]

- Lin, F.; Huang, Y.; Chu, H.; Wang, W.; Song, Y.; Xue, Y.; Li, G. Current situation and development trend of Chinese soybean protein processing industry. China Oils Fats 2023, 48, 33. [Google Scholar]

- Lesa, K.N.; Ahmad, N.; Mayangsari, Y.; Khandaker, M.U.; Iqbal, F.M.R.; Fibri, D.L.N.; Omara, T. Health Benefits of Okara for the Management of Diabetes Mellitus. J. Food Qual. 2023, 2023, 5540118. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Wu, G.F.; Wu, Y.H.; Tang, N.; Huang, L.; Dai, D.Q.; Chen, X. Diversity Analysis and Comprehensive Evaluation of 101 Soybean (Glycine max L.) Germplasms Based on Sprout Quality Characteristics. Foods 2024, 13, 3524. [Google Scholar] [CrossRef]

- Gao, X.L.; Zhao, X.; Hu, F.; Fu, J.Y.; Zhang, Z.K.; Liu, Z.; Ho, C.T. The latest advances on soy sauce research in the past decade: Emphasis on the advances in China. Food Res. Int. 2023, 173, 113407. [Google Scholar] [CrossRef]

- Padalkar, G.; Mandlik, R.; Sudhakaran, S.; Vats, S.; Kumawat, S.; Kumar, V.; Sonah, H. Necessity and challenges for exploration of nutritional potential of staple-food grade soybean. J. Food Compos. Anal. 2023, 117, 105093. [Google Scholar] [CrossRef]

- Zhang, H.; Zeng, F.P.; Zou, Z.G.; Zhang, Z.Q.; Li, Y.Z. Nitrogen uptake and transfer in a soybean/maize intercropping system in the karst region of southwest China. Ecol. Evol. 2017, 7, 8419–8426. [Google Scholar] [CrossRef]

- Xiang, D.B.; Yong, T.-W.; Yang, W.-Y.; Yu, X.-B.; Guo, K. Effects of planting system on soil and water conservation and crop output value in a sloping land of Southwest China. Ying Yong Sheng Tai Xue Bao J. Appl. Ecol. 2010, 21, 1461–1467. [Google Scholar]

- Zhang, S.; Cai, R. Marked—Oriented reform of soybean purchase and storage system and its production pattern in China. J. Arid Land Resour. Environ. 2024, 38, 31–41. [Google Scholar]

- Fu, J.T.; Lyu, D.; Sun, J. China’s Grain Trade Research Based on DEA model of National Food Security Perspective: Soybean as an Example. Teh. Vjesn. -Tech. Gaz. 2021, 28, 609–615. [Google Scholar] [CrossRef]

- Han, L.H.; Liu, Y.; Mo, M.H.; Ma, H.R.; Kumi, F.; Mao, H.P. Development and Evaluation of a Walking Type Two-row Semi-automatic Transplanter for Vegetable Plug Seedlings. Ama-Agric. Mech. Asia Afr. Lat. Am. 2023, 54, 57–67. [Google Scholar]

- Zhu, X.F.; Xu, Y.; Han, C.J.; You, J.; Zhang, X.J.; Mao, H.P.; Ma, X. Design and Experiment of In-Situ Bionic Harvesting Device for Edible Sunflower. Agriculture 2024, 14, 1169. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, Z.N.; Li, S.P.; Su, Z.H.; Xin, M.J. Design of 4YZ-4 type hilly and mountainous corn combine harvester based on TRIZ theory. J. Chin. Agric. Mech. 2025, 46, 27–32. [Google Scholar] [CrossRef]

- Geng, D.; Sun, Y.; Li, H.; Mou, X.; Zhang, G.; Wang, Z.; Lu, X. Design and experiment of crawler corn harvester for sloping fields. Trans. Chin. Soc. Agric. Eng. 2021, 37, 11–19. [Google Scholar]

- Wang, S.G.; Liu, Z.; Zhao, H.W. Design of a snapping device for small corn headers in hilly areas. J. Guilin Univ. Aerosp. Technol. 2024, 29, 678–684. [Google Scholar]

- Li, P.; Gu, Y.C.; Feng, W.; Zhang, X.F.; Zhou, X.H.; Ding, X.B.; He, Y.C.; Ren, G.Y. Optimization of the threshing device for a lightweight and simple combine harvester for mountain soybean. J. Agric. Mech. Res. 2025, 47, 99–106. [Google Scholar] [CrossRef]

- Kong, C.Y.; Wang, Q.X.; Liao, Y.; Xia, J.; Jin, Y.Y. Research and Optimization of the Inclination Angle Difference of the Digging Shovel Surface of Potato Harvester in Hilly Areas. Eng. Agric. 2025, 45, e20240140. [Google Scholar] [CrossRef]

- Sun, X.X.; Zong, W.Y.; Ma, L.N.; Wan, X.Y. Design and experiment of a dual-air-duct cleaning device for a rape pickup harvester in hilly and mountainous areas. Trans. Chin. Soc. Agric. Eng. 2025, 41, 72–82. [Google Scholar] [CrossRef]

- Zheng, Z.F.; Li, H.Y. Improved design of a hilly sweet potato vine-removing and digging all-in-one machine based on AHP/AD/TRIZ. Design 2025, 38, 127–131. [Google Scholar] [CrossRef]

- Wang, L.; Sun, W.; Zhang, L.H.; Zhao, M.; Simionescu, P.A. Design and Testing of a Self-Propelled Fork-Tooth Harvester for Medicinal Plant Rhizomes. Agriculture 2025, 15, 694. [Google Scholar] [CrossRef]

- Peng, Y.; Liao, K.; Xu, S.; Chen, F.; Li, L.; Tang, G.; Luo, H. Development of a wheeled integrated machine for Camellia oleifera fruit harvesting in hilly and mountainous areas. Trans. Chin. Soc. Agric. Eng. 2024, 40, 31–38. [Google Scholar]

- Pan, L.; Yang, H.G.; Yu, Z.Y.; Shen, H.Y.; Gu, M.; Luo, W.W.; Hu, Z.C. Development and Test of a Self-Propelled Peanut Combine Harvester for Hilly and Mountainous Regions. Agriculture 2025, 15, 457. [Google Scholar] [CrossRef]

- Yi, F.Y.; Liu, J.; Jiao, Z.P.; Zhou, J.M. Study on height Control of Corn harvester in Hilly and mountainous area. In Proceedings of the Chinese Automation Congress (CAC), Shanghai, China, 6–8 November 2020. [Google Scholar]

- Zhang, D.Z.; Zhang, R.R.; Chen, L.P.; Zhang, L.H.; Yi, T.C.; Feng, Q. Adaptive Tracking and Cutting Control System for Tea Canopy: Design and Experimental Evaluation. Agriculture 2025, 15, 557. [Google Scholar] [CrossRef]

- Shi, M.Q.; Li, Y.Z.; Pan, Y.C.; Lu, L.F.; Wei, J. Design of an Adaptive Height Control System for Sugarcane Harvester Header. Agronomy 2024, 14, 1644. [Google Scholar] [CrossRef]

- Yu, Y.; Kang, F.; Zheng, Y.; Lu, H.; Wang, Y. Design and simulation of the automatic-leveling high-position platform in orchards. J. Beijing For. Univ. 2021, 43, 150–159. [Google Scholar]

- Zhu, X.; Zhao, Y.; Yuan, S.; Liu, J.; Tang, L. Current situation and development considerations of mechanized irrigation in hilly and mountainous areas. J. Drain. Irrig. Mach. Eng. 2024, 42, 294–303. [Google Scholar]

- Zhao, C.; Ma, C.; Li, J.; Wang, X. Research status and prospects of mechanization technology for rice in hilly and mountainous areas. Trans. Chin. Soc. Agric. Eng. 2025, 41, 1–11. [Google Scholar]

- Xing, S.F.; Yu, Y.; Cao, G.Q.; Hu, J.P.; Zhu, L.J.; Liu, J.Y.; Xu, L.Z. Design and Parametric Optimization Study of an Eccentric Parallelogram-Type Uprighting Device for Ratoon Rice Stubbles. Agriculture 2024, 14, 534. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, S.; Jia, W. Current situation and development of agricultural mechanization in hilly and mountainous areas. J. Drain. Irrig. Mach. Eng. 2022, 40, 535–540. [Google Scholar]

- Li, Y.; Xu, L.Z.; Gao, Z.P.; Lu, E.; Li, Y.M. EFFECT OF VIBRATION ON RAPESEED HEADER LOSS AND OPTIMIZATION OF HEADER FRAME. Trans. Asabe 2021, 64, 1247–1258. [Google Scholar] [CrossRef]

- Jin, M.Z.; Zhao, Z.; Chen, S.R.; Chen, J.Y. Improved piezoelectric grain cleaning loss sensor based on adaptive neuro-fuzzy inference system. Precis. Agric. 2022, 23, 1174–1188. [Google Scholar] [CrossRef]

- Liang, Z.W.; Li, Y.M.; Xu, L.Z.; Zhao, Z.; Tang, Z. Optimum design of an array structure for the grain loss sensor to upgrade its resolution for harvesting rice in a combine harvester. Biosyst. Eng. 2017, 157, 24–34. [Google Scholar] [CrossRef]

- Xu, L.Z.; Wei, C.C.; Liang, Z.W.; Chai, X.Y.; Li, Y.M.; Liu, Q. Development of rapeseed cleaning loss monitoring system and experiments in a combine harvester. Biosyst. Eng. 2019, 178, 118–130. [Google Scholar] [CrossRef]

- Shen, Y.H.; Gao, J.M.; Jin, Z.P. Research on Acoustic Signal Identification Mechanism and Denoising Methods of Combine Harvesting Loss. Agronomy 2024, 14, 1816. [Google Scholar] [CrossRef]

- Chen, J.; Ning, X.; Li, Y.; Yang, G.; Wu, P.; Chen, S. A Fuzzy Control Strategy for the Forward Speed of a Combine Harvester Based on Kdd. Appl. Eng. Agric. 2017, 33, 15–22. [Google Scholar] [CrossRef]

- Li, Y.M.; Chandio, F.A.; Ma, Z.; Lakhiar, I.A.; Sahito, A.R.; Ahmad, F.; Suleman, M. Mechanical strength of wheat grain varieties influenced by moisture content and loading rate. Int. J. Agric. Biol. Eng. 2018, 11, 52–57. [Google Scholar] [CrossRef]

- Chen, J.; Lian, Y.; Zou, R.; Zhang, S.; Ning, X.B.; Han, M.N. Real-time grain breakage sensing for rice combine harvesters using machine vision technology. Int. J. Agric. Biol. Eng. 2020, 13, 194–199. [Google Scholar] [CrossRef]

- Chandio, F.A.; Li, Y.M.; Ma, Z.; Ahmad, F.; Syed, T.N.; Shaikh, S.A.; Tunio, M.H. Influences of moisture content and compressive loading speed on the mechanical properties of maize grain orientations. Int. J. Agric. Biol. Eng. 2021, 14, 41–49. [Google Scholar] [CrossRef]

- Qing, Y.R.; Li, Y.M.; Xu, L.Z.; Ma, Z. Screen Oilseed Rape (Brassica napus) Suitable for Low-Loss Mechanized Harvesting. Agriculture 2021, 11, 504. [Google Scholar] [CrossRef]

- Qing, Y.R.; Li, Y.M.; Xu, L.Z.; Ma, Z.; Tan, X.L.; Wang, Z. Oilseed rape (Brassica napus L.) pod shatter resistance and its relationship with whole plant and pod characteristics. Ind. Crops Prod. 2021, 166, 113459. [Google Scholar] [CrossRef]

- Han, D.L.; Zhang, H.; Li, G.Y.; Wang, G.L.; Wang, X.Z.; Chen, Y.C.; Zhao, R.Q. Development of a Bionic Picking Device for High Harvest and Low Loss Rate Pod Pepper Harvesting and Related Working Parameter Optimization Details. Agriculture 2024, 14, 859. [Google Scholar] [CrossRef]

- Li, D.P.; Wang, Z.M.; Liang, Z.W.; Zhu, F.Y.; Xu, T.B.; Cui, X.Y.; Zhao, P.G. Analyzing Rice Grain Collision Behavior and Monitoring Mathematical Model Development for Grain Loss Sensors. Agriculture 2022, 12, 839. [Google Scholar] [CrossRef]

- Liang, Z.W.; Li, Y.M.; Xu, L.Z.; Zhao, Z. Sensor for monitoring rice grain sieve losses in combine harvesters. Biosyst. Eng. 2016, 147, 51–66. [Google Scholar] [CrossRef]

- Jin, C.Q.; Qi, Y.D.; Liu, G.W.; Yang, T.X.; Ni, Y.L. Mechanism analysis and parameter optimization of the reel of a soybean combine harvester. Trans. Chin. Soc. Agric. Mach. 2023, 54, 104–113. [Google Scholar] [CrossRef]

- Gao, Y.Y.; Yang, Y.F.; Hu, Y.Y.; Han, X.; Feng, K.Y.; Li, P.Y.; Zhai, C.Y. Study on Operating Vibration Characteristics of Different No-Tillage Planter Row Units in Wheat Stubble Fields. Agriculture 2024, 14, 1878. [Google Scholar] [CrossRef]

- Qian, J.; Ma, S.C.; Xu, Y.; Li, W.Y.; Wang, C.Y.; Yang, S.; Wang, F.L. Experimental study on the sugarcane stubble base-cutting mechanism. Biosyst. Eng. 2024, 245, 122–134. [Google Scholar] [CrossRef]

- Liu, Y.B.; Li, Y.M.; Zhang, T.; Huang, M.S. Effect of concentric and non-concentric threshing gaps on damage of rice straw during threshing for combine harvester. Biosyst. Eng. 2022, 219, 1–10. [Google Scholar] [CrossRef]

- Zhang, L.; Qiu, Q.; Qin, D.; Luo, H.; Yuan, S.; Nie, J. Design and test of the dual-purpose cleaning device for soybean and corn. Trans. Chin. Soc. Agric. Eng. 2022, 38, 21–30. [Google Scholar]

- Liu, W.J.; Zeng, S.; Chen, X.G. Design and Experiment of Adaptive Profiling Header Based on Multi-Body Dynamics-Discrete Element Method Coupling. Agriculture 2024, 14, 105. [Google Scholar] [CrossRef]

- Xu, L.Z.; Ma, Z.; Li, Y.M. Test and Analyses of the Reciprocal Friction Properties between the Rapeseeds Threshing Mixture and Non-smooth Bionic Surface. Ama-Agric. Mech. Asia Afr. Lat. Am. 2016, 47, 17–23. [Google Scholar]

- Mesquita, C.M.; Hanna, M.A.; Costa, N.P. Self-propelled prototype soybean harvester. Trans. Asae 2005, 48, 1301–1310. [Google Scholar] [CrossRef]

- Hu, Y.F.; Tang, Z.; Wang, S.G.; Li, B.; Guo, X.H.; Chen, S.R. The Influence of the Distribution Law and Uniformity of a Threshed Mixture with the Working Parameters of a Soybean Threshing Device. Agronomy 2024, 14, 1581. [Google Scholar] [CrossRef]

- Wang, S.G.; Li, B.; Chen, S.R.; Tang, Z.; Zhou, W.W.; Guo, X.H. Design and Performance Test of Soybean Profiling Header Suitable for Harvesting Bottom Pods on Film. Agriculture 2024, 14, 1058. [Google Scholar] [CrossRef]

- Liu, S.F.; Tang, Z.; Shen, C.; Wang, T.; Liang, Y.Q. Effect Of Rice Stubble On Soil Compaction Properties Of A Crawler Undergoing Combine Harvester Harvesting. Eng. Agric. 2023, 43, e20230057. [Google Scholar] [CrossRef]

- Gao, Q.M.; Cheng, L.; Shen, H.Y.; Chen, Y.C.; Zhao, W.S.; Wang, Z.W.; Chen, M.J. Experimental research on shear mechanical properties of tomato stem. Int. Agrophysics 2024, 38, 13–20. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Z.Z.; Pan, B.; Cui, Q.L.; Zhang, L.L.; Qiu, S.J.; Zhang, Y.Q. Study on the Shear and Bending Mechanical Properties of Millet Stem. Agriculture 2024, 14, 923. [Google Scholar] [CrossRef]

- Peng, Z.H.; Yang, F.Z.; Li, Y.H.; Li, X.; Li, B.G.; Xu, G.L. Design and Testing of a Whole-Row Top-Loosening Stem-Clamping Seedling Extraction Device for Hole Tray Seedlings. Agriculture 2025, 15, 165. [Google Scholar] [CrossRef]

- Zhao, Y.F.; Tang, Z.; Chen, S.R. Loading Model and Mechanical Properties of Mature Broccoli (Brassica oleracea L. Var. Italica Plenck) Stems at Harvest. Agriculture 2022, 12, 1519. [Google Scholar] [CrossRef]

- Hidalgo-Cordero, J.F.; Nemec, M.; Castro, P.H.; Hájková, K.; Castro, A.O.; Hysek, S. Macromolecular Composition of Totora (Schoenoplectus californicus. C.A. Mey, Sojak) Stem and Its Correlation with Stem Mechanical Properties. J. Nat. Fibers 2023, 20, 2282049. [Google Scholar] [CrossRef]

- Wójtowicz, T.; Grabowska-Joachimiak, A.; Zielinski, A. Analysis of morpho-anatomical stem properties determining its mechanical strength in selected rye cultivars. Int. Agrophysics 2020, 34, 123–131. [Google Scholar] [CrossRef]

- Han, D.D.; Li, W.; Cui, T.; Wang, Q.; Tang, C.; Chen, L.; Xu, L.J. Biomechanical features and parametric calibration of a bilayer bonded particle model for the cornstalk during harvest. Sci. Rep. 2024, 14, 20198. [Google Scholar] [CrossRef]

- Gianinetti, A.; Baronchelli, M. The Pulvinus Is the Weak Point for Stem Lodging Resistance in Ripe Barley. Plants 2024, 13, 3172. [Google Scholar] [CrossRef]

- Zargar, O.; Pharr, M.; Muliana, A. Modeling and simulation of creep response of sorghum stems: Towards an understanding of stem geometrical and material variations. Biosyst. Eng. 2022, 217, 1–17. [Google Scholar] [CrossRef]

- Kaminski, R.; Speck, T.; Speck, O. Adaptive spatiotemporal changes in morphology, anatomy, and mechanics during the ontogeny of subshrubs with square-shaped stems. Am. J. Bot. 2017, 104, 1157–1167. [Google Scholar] [CrossRef]

- Wu, W.C.; Hu, Y.G.; Jiang, Z.H. Investigation on the Bending Behavior of Tea Stalks Based on Non-Prismatic Beam with Virtual Internodes. Agriculture 2022, 12, 370. [Google Scholar] [CrossRef]

- Wu, S.; Wei, X.H. Mechanical interaction between a canopy opener and rice stalks based on the transient dynamic analysis. Biosyst. Eng. 2019, 178, 256–263. [Google Scholar] [CrossRef]

- Li, Z.Y.; Wang, G.Q.; Jia, W.D.; Ou, M.X.; Dong, X.; Zhang, T.; Wang, C.Y. Effects of cutting parameters on the ultimate shear stress and specific cutting energy of Canadian goldenrod stem. Eur. J. Hortic. Sci. 2024, 89, 32. [Google Scholar] [CrossRef]

- Wang, W.; Lv, X.L.; Yi, Z.Y. Parameter Optimization of Reciprocating Cutter for Chinese Little Greens Based on Finite Element Simulation and Experiment. Agriculture 2022, 12, 2131. [Google Scholar] [CrossRef]

- Jin, C.; Liu, G.; Ni, Y.; Yang, T.; Wang, T.e.; Qi, Y. Design and experiment of header profiling mechanism for combine harvester based on MBD-DEM coupling. Trans. Chin. Soc. Agric. Eng. 2022, 38, 1–10. [Google Scholar]

- Ni, Y.; Jin, C.; Chen, M.; Yuan, W.; Qian, Z.; Yang, T.; Cai, Z. Computational model and adjustment system of header height of soybean harvesters based on soil-machine system. Comput. Electron. Agric. 2021, 183, 105907. [Google Scholar] [CrossRef]

- Leng, Y.C.; Fu, Y.; Liu, K.Y.; Tang, P.; Tang, J.L.; Wang, R.Q.; Lv, X.R. Design and test of reel speed control system for soybean combine harvester in the strip intercropping mode. Sci. Rep. 2024, 14, 25133. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Chen, S.; Wang, S.; Tang, Z.; Li, B.; Guo, X. Design of soybean header suitable for single-film harvesting in Xinjiang and analysis of grain-sweeping process. Agric. Res. Arid Areas 2024, 42, 294–300. [Google Scholar]

- Li, Z.R. Design and Development of a Soybean Profiling Header and Control System for a Multi-Crop Crawler Combine Harvester. Master’s Thesis, Gansu Agricultural University, Lanzhou, China, 2022. [Google Scholar]

- Liu, G.W.; Ni, Y.L.; Yang, T.X.; Qi, Y.D.; Jin, C.Q. Design and experiment of an automatic height control system for a soybean harvester header. J. Chin. Agric. Mech. 2023, 44, 155–160. [Google Scholar]

- Huang, C.Y.; Wang, S.S.; Wang, Y.F.; Liu, Y.; Song, H.M. Design and simulation of a soybean header profiling device based on electro-hydraulic control. Tract. Farm Transp. Veh. 2025, 52, 40–46. [Google Scholar]

- Xie, H.R. Design and Experiment of a Uniform Flow Conveying Header for a Soybean Combine Harvester. Master’s Thesis, Shandong University of Technology, Zibo, China, 2019. China National Knowledge Infrastructure. [Google Scholar]

- Li, Z.R.; Xu, L.Z.; Xu, X.Q.; Xu, L.; Chai, X.Y. Design and simulation of a mechanical-hydraulic combined soybean header profiling device. J. Agric. Mech. Res. 2024, 46, 60–65. [Google Scholar]

- Jin, S.S.; Zhang, C.Y.; Huang, X.F.; Guan, J.W. Analysis and design of the all-directional leveling system fortracked intelligent chassis in hilly and mountainous areas. J. Anhui Sci. Technol. Univ. 2025. Available online: https://link.cnki.net/urlid/34.1300.n.20250523.1502.002 (accessed on 20 October 2025).

- Liu, P.Y.; Peng, F.J.; Li, H.T.; Wang, Z.Z.; Wei, W.J.; Zhao, J.P. Design and experiment of an agricultural adaptive leveling chassis for hilly areas. Trans. Chin. Soc. Agric. Mach. 2017, 48, 42–47. [Google Scholar] [CrossRef]

- Mu, X.D.; Yang, F.Z.; Duan, L.J.; Liu, Z.J.; Song, Z.Y.; Li, Z.L.; Guan, S.Q. Research advances and development trend of mountainous tractor leveling and anti-rollover system. Smart Agric. 2024, 3, 1–16. [Google Scholar] [CrossRef]

- Pang, J.; Li, Y.M.; Ji, J.T.; Xu, L.Z. Vibration excitation identification and control of the cutter of a combine harvester using triaxial accelerometers and partial coherence sorting. Biosyst. Eng. 2019, 185, 25–34. [Google Scholar] [CrossRef]

- Wang, R.C.; Jiang, Y.Y.; Ding, R.K.; Sun, Z.Y.; Xu, K. Omnidirectional leveling control of an electromechanical working machine based on BP neural network PID. Trans. Chin. Soc. Agric. Eng. 2024, 41, 155–162. [Google Scholar] [CrossRef]

- Zhang, F.G.; Lü, X.L.; Yang, H.B.; Du, L.H.; Liu, Z.; Tang, P.; Lü, X.R. Design of a leveling control system for a mountain tractor based on fuzzy PID. J. Hunan Agric. Univ. (Nat. Sci.) 2023, 49, 121–126. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, Y.L.; Wu, Z.P.; Traore, S.N.; Chen, D.; Xing, L.C. BP neural network model for material distribution prediction based on variable amplitude anti-blocking screening DEM simulations. Int. J. Agric. Biol. Eng. 2023, 16, 190–199. [Google Scholar] [CrossRef]

- Zhang, J.H.; Li, Y.M.; Qi, W.C.; Liu, C.L.; Yang, F.Z.; Li, Z.P. Attitude synchronous control system for a hilly and mountainous tractor based on neural network PID. Trans. Chin. Soc. Agric. Mach. 2020, 51, 356–366. [Google Scholar] [CrossRef]

- Peng, H. Research on the Automatic Leveling Control Method for the Body Posture of Tractors in Hilly and Mountainous Areas. Doctoral Dissertation, Jilin University, Changchun, China, 2024. [Google Scholar]

- Zhu, Z.H.; Chai, X.Y.; Xu, L.Z.; Quan, L.; Yuan, C.C.; Tian, S.C. Design and performance of a distributed electric drive system for a series hybrid electric combine harvester. Biosyst. Eng. 2023, 236, 160–174. [Google Scholar] [CrossRef]

- Zhu, Z.; Yang, Y.P.; Wang, D.Q.; Cai, Y.F.; Lai, L.H. Energy Saving Performance of Agricultural Tractor Equipped with Mechanic-Electronic-Hydraulic Powertrain System. Agriculture 2022, 12, 436. [Google Scholar] [CrossRef]

- Zheng, S.Q.; Xu, S.L.; Rai, R. Trailer-referenced autonomous navigation of agricultural tractor-trailer systems. Comput. Electron. Agric. 2025, 237, 110514. [Google Scholar] [CrossRef]

- Han, J.Y.; Liu, H.Y.; Tang, H. Research on Obstacle Avoidance Path Planning for Wheeled Tractor-Trailer System. Int. J. Automot. Technol. 2025, 26, 1067–1076. [Google Scholar] [CrossRef]

- Guo, C.K.; Mu, J.Q.; Zhang, J.Y.; Heng, L. Model Predictive Control Based Path Planner Design for On-road Autonomous Tractor Trailer Vehicles. In Proceedings of the 8th IFAC Conference on Nonlinear Model Predictive Control (NMPC), Kyoto, Japan, 21–24 August 2024. [Google Scholar]

- Jia, B.B.; Gao, L.; Li, D.W.; Yang, Y.; Fu, M.Y.; Xie, S.S. Trajectory Planning Method for Tractor-trailer System Based on Nonlinear Model Predictive Control. In Proceedings of the 43rd Chinese Control Conference (CCC), Kunming, China, 28–31 July 2024. [Google Scholar]

- Hellander, A. On Optimal Integrated Task and Motion Planning with Applications to Tractor-Trailers; Linkoping University Electronic Press: Linkoping, Sweden, 2023. [Google Scholar]

- Hellander, A.; Bergman, K.; Axehill, D. On Integrated Optimal Task and Motion Planning for a Tractor-Trailer Rearrangement Problem. In Proceedings of the 62nd IEEE Conference on Decision and Control (CDC), IEEE Control Syst Soc, Singapore, 13–15 December 2023. [Google Scholar]

- Kolahi, P.M.; Nazemizadeh, M. Nonlinear dynamic modeling of tractor-trailer mobile robots with consideration of wheels inertia and their optimal point-to point path planning. Meccanica 2023, 58, 245–253. [Google Scholar] [CrossRef]

- Zhang, J.; Chen, D.; Wang, S.M.; Yu, Z.J.; Wei, L.G.; Jia, Q. Heading information fusion method for an INS/GNSS integrated navigation system in agricultural machinery. Trans. Chin. Soc. Agric. Mach. 2015, 46 (Suppl. 1), 1–7. [Google Scholar]

- Chang, N.J.; Yan, X.H.; Chen, B.X.; Wu, Y.W.; Xu, L.Y. Research on autonomous obstacle avoidance of mountainous tractors based on semantic neural network and laser SLAM. PLoS ONE 2025, 20, e0323631. [Google Scholar] [CrossRef] [PubMed]

- Xu, N.; Li, Z.H.; Guo, N.; Wang, T.; Li, A.J.; Song, Y.M. Global Path Planning for Articulated Steering Tractor Based on Multi-Objective Hybrid Algorithm. Sensors 2024, 24, 4832. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.P.; Li, Y.; Wang, H.; Wang, C.S.; Zhang, J.; Wang, T.W.; Yang, F.Z. Path planning of greenhouse electric crawler tractor based on the improved A and DWA algorithms. Comput. Electron. Agric. 2024, 227, 109596. [Google Scholar] [CrossRef]

- Guo, H.P.; Li, Y.; Wang, H.; Wang, T.W.; Rong, L.R.; Wang, H.Y.; Guo, S.M. Research on autonomous navigation system of greenhouse electric crawler tractor based on LiDAR. Front. Plant Sci. 2024, 15, 1377269. [Google Scholar] [CrossRef]

- Yang, L.; Tang, X.; Wu, S.; Wen, L.; Yang, W.; Wu, C. Local path planning for autonomous agricultural machinery on farm road. Trans. Chin. Soc. Agric. Eng. 2024, 40, 27–36. [Google Scholar]

- Zhou, M.K.; Wang, W.W.; Shi, S.Q.; Huang, Z.; Wang, T. Research on Global Navigation Operations for Rotary Burying of Stubbles Based on Machine Vision. Agriculture 2025, 15, 114. [Google Scholar] [CrossRef]

- Chen, H.T.; Xie, H.; Sun, L.M.; Shang, T.S. Research on Tractor Optimal Obstacle Avoidance Path Planning for Improving Navigation Accuracy and Avoiding Land Waste. Agriculture 2023, 13, 934. [Google Scholar] [CrossRef]

- Liang, C.D.; Pan, K.; Zhao, M.; Lu, M. Multi-Node Path Planning of Electric Tractor Based on Improved Whale Optimization Algorithm and Ant Colony Algorithm. Agriculture 2023, 13, 586. [Google Scholar] [CrossRef]

- Li, S.; Li, J.; Zhao, L.; Ji, J.; Ren, Y. Path planning for field full coverage operation in hilly and mountainous farmlands based on the enhanced whale optimization algorithm. Trans. Chin. Soc. Agric. Eng. 2024, 40, 61–70. [Google Scholar]

- Liu, L.; Chen, T.; Gao, S.J.; Liu, Y.; Yang, S.G.; Wang, X.L. Optimization of Agricultural Machinery Allocation in Heilongjiang Reclamation Area Based on Particle Swarm Optimization Algorithm. Teh. Vjesn.-Tech. Gaz. 2021, 28, 1885–1893. [Google Scholar] [CrossRef]

- Xu, S. Vision-Based Autonomy Stacks for Farm Tractors and Intelligent Spraying Systems in Orchards. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2024. [Google Scholar]

- Zhou, X.Y.; Chen, W.M.; Wei, X.H. Improved Field Obstacle Detection Algorithm Based on YOLOv8. Agriculture 2024, 14, 2263. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, K.; Wu, S.X.; Wen, L.; Chen, Z.B.; Dong, L.; Wu, C.C. An obstacle avoidance path planner for an autonomous tractor using the minimum snap algorithm. Comput. Electron. Agric. 2023, 207, 107738. [Google Scholar] [CrossRef]

- Kachappilly, A.; Devanna, R.; Torres-Torriti, M.; Cheein, F.A. A cloud point methodology for evaluating the integrity risk of arboreal crop during field coverage of agricultural machinery. Comput. Electron. Agric. 2025, 231, 109844. [Google Scholar] [CrossRef]

- Soitinaho, R.; Väyrynen, V.; Oksanen, T. Heuristic cooperative coverage path planning for multiple autonomous agricultural field machines performing sequentially dependent tasks of different working widths and turn characteristics. Biosyst. Eng. 2024, 242, 16–28. [Google Scholar] [CrossRef]

- Fu, H.T.; Li, Z.; Zhang, W.J.; Feng, Y.X.; Zhu, L.; Long, Y.Z.; Li, J. Path Planning for Agricultural UAVs Based on Deep Reinforcement Learning and Energy Consumption Constraints. Agriculture 2025, 15, 943. [Google Scholar] [CrossRef]

- Liang, X.H.Z.; Chen, B.Q.; Wei, C.J.; Zhang, X.C. Inter-row navigation line detection for cotton with broken rows. Plant Methods 2022, 18, 90. [Google Scholar] [CrossRef]

- Takai, R.; Yang, L.; Noguchi, N. Development of a crawler-type robot tractor using RTK-GPS and IMU. Eng. Agric. Environ. Food 2014, 7, 143–147. [Google Scholar] [CrossRef]

- Yang, L.; Noguchi, N.; Takai, R. Development and application of a wheel-type robot tractor. Eng. Agric. Environ. Food 2016, 9, 131–140. [Google Scholar] [CrossRef]

- Yu, S.; Yan, M.; Wang, P.; Zhu, J.; Yang, X. 3D path planning of plant protection UAVs in hilly mountainous orchards. Journal of Zhejiang University. Eng. Sci. 2025, 59, 635–642. [Google Scholar]

- Chen, S.X.; Noguchi, N. Remote safety system for a robot tractor using a monocular camera and a YOLO-based method. Comput. Electron. Agric. 2023, 215, 108409. [Google Scholar] [CrossRef]

- Chai, X.; Zhu, J.; Yao, W.; Chen, C. A Study on path planning for field roads in hilly and mountainous areas based on low-altitude remote sensing. J. Agric. Univ. Hebei 2025, 48, 97–106. [Google Scholar]

- Wang, B.; Du, X.X.; Wang, Y.N.; Mao, H.P. Multi-machine collaboration realization conditions and precise and efficient production mode of intelligent agricultural machinery. Int. J. Agric. Biol. Eng. 2024, 17, 27–36. [Google Scholar] [CrossRef]

- Liu, W.; Zhou, J.H.; Zhang, T.F.; Zhang, P.C.; Yao, M.J.; Li, J.H.; Hu, J.P. Key Technologies in Intelligent Seeding Machinery for Cereals: Recent Advances and Future Perspectives. Agriculture 2025, 15, 8. [Google Scholar] [CrossRef]

- Wang, Q.; Qin, W.C.; Liu, M.N.; Zhao, J.J.; Zhu, Q.Z.; Yin, Y.X. Semantic Segmentation Model-Based Boundary Line Recognition Method for Wheat Harvesting. Agriculture 2024, 14, 1846. [Google Scholar] [CrossRef]

- Lv, R.Y.; Hu, J.P.; Zhang, T.F.; Chen, X.X.; Liu, W. Crop-Free-Ridge Navigation Line Recognition Based on the Lightweight Structure Improvement of YOLOv8. Agriculture 2025, 15, 942. [Google Scholar] [CrossRef]

- Kong, X.Y.; Guo, Y.B.; Liang, Z.W.; Zhang, R.; Hong, Z.T.; Xue, W.X. A method for recognizing inter-row navigation lines of rice heading stage based on improved ENet network. Measurement 2025, 241, 115677. [Google Scholar] [CrossRef]

- Chen, Z.; Yang, Y.; Zhang, H.; Li, C.; Pu, Y.; Yang, M. Extracting navigation line after segmenting the field scene of green Sichuan peppers. Trans. Chin. Soc. Agric. Eng. 2024, 40, 217–226. [Google Scholar]

- He, S.; Hu, J.; He, Z.; Li, Q.; Wang, S. IRCF-based unmanned aerial vehicle low altitude remote sensing field boundary extraction method. J. South. Agric. 2025, 56, 111–123. [Google Scholar]

- Liu, W.; Hu, J.P.; Liu, J.X.; Yue, R.C.; Zhang, T.F.; Yao, M.J.; Li, J. Method for the navigation line recognition of the ridge without crops via machine vision. Int. J. Agric. Biol. Eng. 2024, 17, 230–239. [Google Scholar] [CrossRef]

- Li, X.; Zhao, W.; Zhao, L. Extraction algorithm of the center line of maize row in case of plants lacking. Trans. Chin. Soc. Agric. Eng. 2021, 37, 203–210. [Google Scholar]

- Pan, S.; Chen, K.; Xie, Y.; Mo, J. Detection of the wheat-harvesting boundary in wheat field based on multi-texture fusion. Trans. Chin. Soc. Agric. Eng. 2023, 39, 123–131. [Google Scholar]

- Yu, S.S.; Huang, X.Y.; Wang, L.; Chang, X.H.; Ren, Y.; Zhang, X.R.; Wang, Y. Qualitative and quantitative assessment of flavor quality of Chinese soybean paste using multiple sensor technologies combined with chemometrics and a data fusion strategy. Food Chem. 2023, 405, 134859. [Google Scholar] [CrossRef]

- Stewart, S.B.; Fedrigo, M.; Levick, S.R.; O’Grady, A.P.; Mendham, D.S. Multi-sensor modelling of woody vegetation and canopy cover across natural and modified ecosystems. Int. J. Appl. Earth Obs. Geoinf. 2025, 141, 104635. [Google Scholar] [CrossRef]

- Lv, J.; Liu, Y.Y.; Jin, R.; Zhu, W.H. Forested Swamp Classification Based on Multi-Source Remote Sensing Data: A Case Study of Changbai Mountain Ecological Function Protection Area. Forests 2025, 16, 794. [Google Scholar] [CrossRef]

- Xiong, S.T.; Baltezar, P.; Crowley, M.A.; Cecil, M.; Crema, S.C.; Baldwin, E.; Estes, L. Probabilistic Tracking of Annual Cropland Changes over Large, Complex Agricultural Landscapes Using Google Earth Engine. Remote Sens. 2022, 14, 4896. [Google Scholar] [CrossRef]

- He, J.; Dong, W.H.; Tan, Q.N.; Li, J.N.; Song, X.W.; Zhao, R.M. A Variable-Threshold Segmentation Method for Rice Row Detection Considering Robot Travelling Prior Information. Agriculture 2025, 15, 413. [Google Scholar] [CrossRef]

- Su, Z.Q.; Zou, W.; Zhai, C.Y.; Tan, H.R.; Yang, S.; Qin, X.Y. Design of an Autonomous Orchard Navigation System Based on Multi-Sensor Fusion. Agronomy 2024, 14, 2825. [Google Scholar] [CrossRef]

- Hu, X.T.; Zhang, X.; Chen, X.; Zheng, L. Research on Corn Leaf and Stalk Recognition and Ranging Technology Based on LiDAR and Camera Fusion. Sensors 2024, 24, 5422. [Google Scholar] [CrossRef]

- Ban, C.; Wang, L.; Chi, R.J.; Su, T.; Ma, Y.Q. A Camera-LiDAR-IMU fusion method for real-time extraction of navigation line between maize field rows. Comput. Electron. Agric. 2024, 223, 109114. [Google Scholar] [CrossRef]

- Liu, Y.; Ji, J.; Pan, D.; Zhao, L.; Li, M. Localization Method for Agricultural Robots Based on Fusion of LiDAR and IMU. Smart Agric. 2024, 6, 94–106. [Google Scholar]

- Kang, H.W.; Wang, X. Semantic segmentation of fruits on multi-sensor fused data in natural orchards. Comput. Electron. Agric. 2023, 204, 107569. [Google Scholar] [CrossRef]

- Luo, H.; Wang, J. ICDO-RBFNN multi-sensor data fusion for agricultural greenhouse environment. Trans. Chin. Soc. Agric. Eng. 2024, 40, 184–191. [Google Scholar]

- Tong, R.; Jiang, Q.; Zou, Z.Q.; Hu, T.; Li, T.H. Embedded System Vehicle Based on Multi-Sensor Fusion. IEEE Access 2023, 11, 50334–50349. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, Q.S.; Xu, L.Z.; Xu, X.Q.; Liang, Z.W. Wheat Lodging Direction Detection for Combine Harvesters Based on Improved K-Means and Bag of Visual Words. Agronomy 2023, 13, 2227. [Google Scholar] [CrossRef]

- Long, D.S.; McCallum, J.D. On-combine, multi-sensor data collection for post-harvest assessment of environmental stress in wheat. Precis. Agric. 2015, 16, 492–504. [Google Scholar] [CrossRef]

- Yuan, W.A.; Li, J.T.; Bhatta, M.; Shi, Y.Y.; Baenziger, P.S.; Ge, Y.F. Wheat Height Estimation Using LiDAR in Comparison to Ultrasonic Sensor and UAS. Sensors 2018, 18, 3731. [Google Scholar] [CrossRef]

- Schirrmann, M.; Hamdorf, A.; Garz, A.; Ustyuzhanin, A.; Dammer, K.H. Estimating wheat biomass by combining image clustering with crop height. Comput. Electron. Agric. 2016, 121, 374–384. [Google Scholar] [CrossRef]

- Chen, B.; Gu, S.H.; Huang, G.M.; Lu, X.J.; Chang, W.S.; Wang, G.T.; Zhao, C.J. Improved estimation of nitrogen use efficiency in maize from the fusion of UAV multispectral imagery and LiDAR point cloud. Eur. J. Agron. 2025, 168, 127666. [Google Scholar] [CrossRef]

- Xu, R.; Li, C.Y.; Bernardes, S. Development and Testing of a UAV-Based Multi-Sensor System for Plant Phenotyping and Precision Agriculture. Remote Sens. 2021, 13, 3517. [Google Scholar] [CrossRef]

- Rilling, S.; Nielsen, M.; Milella, A.; Jestel, C.; Fröhlich, P.; Reina, G. A Multisensor Platform for Comprehensive Detection of Crop Status: Results from two Case Studies. In Proceedings of the 14th IEEE International Conference on Advanced Video and Signal Based Surveillance (AVSS), Lecce, Italy, 29 August–1 September 2017. [Google Scholar]

- Cui, L.F.; Le, F.X.; Xue, X.Y.; Sun, T.; Jiao, Y.X. Design and Experiment of an Agricultural Field Management Robot and Its Navigation Control System. Agronomy 2024, 14, 654. [Google Scholar] [CrossRef]

- Tan, M.K.; Zhuang, Z.W.; Chen, S.T.; Li, R.; Jia, K.; Wang, Q.C.; Li, Y.Q. EPMF: Efficient Perception-Aware Multi-Sensor Fusion for 3D Semantic Segmentation. Ieee Trans. Pattern Anal. Mach. Intell. 2024, 46, 8258–8273. [Google Scholar] [CrossRef] [PubMed]

- Li, M.L.; Hu, Y.H.; Zhao, N.X.; Qian, Q.S. One-Stage Multi-Sensor Data Fusion Convolutional Neural Network for 3D Object Detection. Sensors 2019, 19, 1434. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Sun, Q.X.; Zhang, N.; Chai, X.J.; Sun, T. PodNet: Pod real-time instance segmentation in pre-harvest soybean fields. Plant Phenomics 2025, 7, 100052. [Google Scholar] [CrossRef]

- Jia, X.F.; Hua, Z.L.; Shi, H.T.; Zhu, D.; Han, Z.Z.; Wu, G.X.; Deng, L.M. A Soybean Pod Accuracy Detection and Counting Model Based on Improved YOLOv8. Agriculture 2025, 15, 617. [Google Scholar] [CrossRef]

- Xie, Q.Z.; Du, H.B.; Yang, Q.; Liu, Z.; Jin, X.; Li, C.F.; Wei, Y.; Tang, F.; Tao, P.; Yan, L. A Novel Tool for Soybean Pods and Branches Recognition by Deep Learning Based Approach. Plant Breeding 2024, 0, 1–12. [Google Scholar] [CrossRef]

- Yu, Z.H.; Wang, Y.X.; Ye, J.X.; Liufu, S.J.; Lu, D.L.; Zhu, X.L.; Yang, Z.; Tan, Q.J. Accurate and fast implementation of soybean pod counting and localization from high-resolution image. Front. Plant Sci. 2024, 15, 1320109. [Google Scholar] [CrossRef]

- Guo, Y.X.; Pan, J.C.; Wang, X.Y.; Deng, H.; Yang, M.L.; Liu, E.L.; Chen, Q.; Zhu, R.S. DLML-PC: An automated deep learning and metric learning approach for precise soybean pod classification and counting in intact plants. Front. Plant Sci. 2025, 16, 1583526. [Google Scholar] [CrossRef]

- Liu, F.; Liu, H.; Wu, Q.; Han, Z.; Pang, S.; Wang, S.; Zhao, L. Pod-pose: An efficient top-down keypoint detection model for fine-grained pod phenotyping in mature soybean. Plant Methods 2025, 21, 82. [Google Scholar] [CrossRef]

- Jiang, T.Y.; Shao, M.S.; Zhang, T.Y.; Liu, X.Y.; Yu, Q. Soybean Pod and Seed Counting in Both Outdoor Fields and Indoor Laboratories Using Unions of Deep Neural Networks. In Proceedings of the 18th European Conference on Computer Vision (ECCV), Milan, Italy, 29 September–4 October 2024. [Google Scholar]

- Yu, H.; Weng, L.; Wu, S.Q.; He, J.J.; Yuan, Y.L.; Wang, J.; Xu, X.; Feng, X.Z. Time-Series Field Phenotyping of Soybean Growth Analysis by Combining Multimodal Deep Learning and Dynamic Modeling. Plant Phenomics 2024, 6, 158. [Google Scholar] [CrossRef]

- Zhou, L.Y.; Zhang, Y.; Chen, H.C.; Sun, G.Y.; Wang, L.; Li, M.X.; Sun, X.; Feng, P.; Yan, L.; Qiu, L.; et al. Soybean yield estimation and lodging classification based on UAV multi-source data and self-supervised contrastive learning. Comput. Electron. Agric. 2025, 230, 109822. [Google Scholar] [CrossRef]

- Lu, J.; Fu, H.K.; Tang, X.H.; Liu, Z.; Huang, J.J.; Zou, W.L.; Chen, H.; Sun, Y.; Ning, X.; Li, J. GOA-optimized deep learning for soybean yield estimation using multi-source remote sensing data. Sci. Rep. 2024, 14, 7097. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Lu, X.L.; He, L.; Xu, R.X.; Yang, Y.; Qiu, J. Research on soybean leaf disease recognition in natural environment based on improved Yolov8. Front. Plant Sci. 2025, 16, 1523633. [Google Scholar] [CrossRef] [PubMed]

- Bevers, N.; Sikora, E.J.; Hardy, N.B. Soybean disease identification using original field images and transfer learning with convolutional neural networks. Comput. Electron. Agric. 2022, 203, 107449. [Google Scholar] [CrossRef]

- Pang, L.; Wang, Z.; Mi, S.Y.; Li, H. Feasibility Study on Identifying Seed Variety of Soybean With Hyperspectral Imaging and Deep Learning. J. Chemom. 2025, 39. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Sun, L.J.; Jin, X.L.; Zhao, X.G.; Li, S.J. DAFFnet: Seed classification of soybean variety based on dual attention feature fusion networks. Crop J. 2025, 13, 619–629. [Google Scholar] [CrossRef]

- Zhu, S.L.; Zhang, J.Y.; Chao, M.N.; Xu, X.J.; Song, P.W.; Zhang, J.L.; Huang, Z.W. A Rapid and Highly Efficient Method for the Identification of Soybean Seed Varieties: Hyperspectral Images Combined with Transfer Learning. Molecules 2020, 25, 152. [Google Scholar] [CrossRef]

- Nie, J.S.; Luo, H.Z.; Zhou, Y.; Li, Q.Q.; Qiu, Q.Y.; Zhang, L.H. Design and Test of a Low-Loss Soybean Header Based on Synchronous Profiling. Agriculture 2023, 13, 1580. [Google Scholar] [CrossRef]

- Cao, Z.P.; Li, Q.Q.; Chen, L.F.; Zhou, Y.; Nie, J.S.; Chen, Q.; Zhang, L.H. Structural Design and Testing of a Corn Header for Soybean-Corn Intercropping. Agriculture 2025, 15, 123. [Google Scholar] [CrossRef]

- Luo, H.; Jiang, X.; Qin, D.; Zuo, P.; Zhang, F.; Zhang, L. Design and experiment of narrow row spacing and low-damage corn picking header. J. Northeast Agric. Univ. 2021, 52, 66–76. [Google Scholar]

- Hou, J.; Xie, F.; Wang, X.; Liu, D.; Ji, B. Design and test of multi-crop harvester header. J. Hunan Agric. University. Nat. Sci. 2023, 49, 223–230. [Google Scholar]

- Cortez, J.W.; Syrio, M.G.; Rodrigues, S.A. Types of Header, Operating Speed, and Geometry of Collection Frames on the Total Losses of Soybean Harvest. Eng. Agric. 2019, 39, 482–489. [Google Scholar] [CrossRef]

- de Menezes, P.C.; da Silva, R.P.; Carneiro, F.M.; Girio, L.A.D.; de Oliveira, M.F.; Voltarelli, M.A. Can combine headers and travel speeds affect the quality of soybean harvesting operations? Rev. Bras. De Eng. Agric. E Ambient. 2018, 22, 732–738. [Google Scholar] [CrossRef]

- Ni, Y.; Jin, C.; Chen, M.; Qian, Z.; Yang, T.; Xu, J.; Liu, G. Soybean crushing forms by mechanical harvesting and factors affecting the proportions of different forms. Food Sci. Technol. 2023, 43, e111822. [Google Scholar] [CrossRef]

- Liu, Y.B.; Li, Y.M.; Ji, K.Z.; Yu, Z.W.; Ma, Z.; Xu, L.Z.; Niu, C.H. Development of a hydraulic variable-diameter threshing drum control system for combine harvester part I: Adaptive monitoring method. Biosyst. Eng. 2025, 250, 174–182. [Google Scholar] [CrossRef]

- Kang, J.; Wang, X.; Xie, F.; Hou, J.; Li, Q.; Liu, A. Design and test of the independently-adjustable concave plate screen for a multi-crop combine harvester. Trans. Chin. Soc. Agric. Eng. 2025, 41, 11–21. [Google Scholar]

- Kang, J.; Wang, X.; Xie, F.; Luo, Y.; Li, Q.; Huang, X. Experiments and analysis of the differential threshing cylinder for soybean with different maturities. Trans. Chin. Soc. Agric. Eng. 2023, 39, 38–49. [Google Scholar]

- Kang, J.; Wang, X.; Xie, F.; Luo, Y.; Li, Q.; Chen, Z. Design and experiment of symmetrical adjustable concave for soybean combine harvester. Trans. Chin. Soc. Agric. Eng. 2022, 38, 11–22. [Google Scholar]

- Tan, Y.; Chen, L.; Hu, S.; Wang, J.; Chen, Z.; Lyu, X. Design and experiment of longitudinal-axial flow flexible bent-tooth soybean thresher. Acta Agric. Zhejiangensis 2023, 35, 2954–2965. [Google Scholar]

- Jin, C.; Kang, Y.; Guo, H.; Wang, T.e.; Yin, X. Experimental research on the influence of threshing roller structures on the quality of mechanically-harvested soybeans. Trans. Chin. Soc. Agric. Eng. 2021, 37, 49–58. [Google Scholar]

- Hussain, S.; Hu, J.J.; Yong, C.; Ali, A.; Song, H.Y.; Zheng, D.C.; Ahmed, M. CFD study of self-cleaning system of multi-stage tangential roller threshing unit for precise buckwheat breeding. Heliyon 2024, 10, e27180. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Tao, G.; Dai, Z.; Zhang, Z.; Cheng, T. Factor analysis of soybean harvest losses and experimental research on machine harvesting parameters: A case study of Beidahuang Group Heilongjiang Heshan Farm. J. China Agric. Univ. 2024, 29, 209–217. [Google Scholar]

- Chen, Y.X.; Tang, Z.; Li, B.; Wang, S.G.; Liu, Y.; Zhou, W.W.; He, X.Y. Analysis of Damage Characteristics and Fragmentation Simulation of Soybean Seeds Based on the Finite-Element Method. Agriculture 2025, 15, 780. [Google Scholar] [CrossRef]

- Dun, G.; Li, H.; Yu, C.; Yang, Y.; Gao, Z.; Mao, N.; Zhang, S. Simulation collision analysis of soybean seed based on finite element method. J. Henan Agric. Univ. 2020, 54, 620–629. [Google Scholar]

- Gun-Ho, L.; Eun, M.B.; Kumar, B.J.; Na-Eun, K.; Bhola, P.; Seong-Woo, J.; Tae, K.H. Assessment of Load on Threshing Bar During Soybean Pod Threshing. J. Biosyst. Eng. 2023, 48, 478–486. [Google Scholar] [CrossRef]

- Tan, Y.; Chen, L.; Hu, S.; Wang, J.; Chen, Z.; Liu, X. Discrete element modeling method and parameter calibration of Nanxia Dou 25 at harvest stage. J. Northeast Agric. Univ. 2023, 54, 77–87. [Google Scholar]

- Ho, L.G.; Eun, M.B.; Kim, N.-e.; Tae, K.H. The Effect of Soybean’s Moisture Content on Ultimate Strength. J. Agric. Life Sci. 2022, 56, 113–118. [Google Scholar]

- Qiu, Q.Y. Design and Experiment of a Dual-Use Cleaning Device and Loss Monitoring Device for Soybean and Maize. Master’s Thesis, Sichuan Agricultural University, Chengdu, China, 2023. [Google Scholar]

- Guo, D.F.; Wang, L.Z.; Du, Y.F.; Wu, Z.K.; Zhang, W.R.; Zhi, Q.; Ma, R.F. Online optimization of adjustable settings for agricultural machinery assisted by digital twin. Comput. Electron. Agric. 2024, 227, 109504. [Google Scholar] [CrossRef]

- Guo, D.; Du, Y.; Li, X.; Li, G.; Chen, D.; Song, Z. Digital Twin System for Agricultural Machinery with Cloud-Fog-Edge-Terminal Architecture. Trans. Chin. Soc. Agric. Mach. 2023, 54, 133–141. [Google Scholar]

- Li, X.; Du, Y.; Liu, L.; Mao, E. Design and experiment of the automatic control system for low damage corn grain direct harvesters. Trans. Chin. Soc. Agric. Eng. 2023, 39, 34–42. [Google Scholar]

- Li, Y.; Xu, L.Z.; Li, Y.M.; Lv, L.Y.; Shi, M.L. Modeling and control methods of a multi-parameter system for threshing and cleaning in grain combine harvesters. Comput. Electron. Agric. 2024, 225, 109251. [Google Scholar] [CrossRef]

- Wu, L.F.; Chen, D.G.; Xu, X.Q.; Wu, Y.Q. Experimental Design and Validation of an Adjustable Straw Guide Structure for a Grain Combine Harvester Thresher Based on a Material Movement Model. Appl. Sci. 2023, 13, 8476. [Google Scholar] [CrossRef]

- Zhang, D.M.; Yi, S.J.; Li, H.Y.; Gu, J.; Zhang, F.F.; Feng, T. Optimization of Millet Axial Flow Threshing and Separation Device Based on Discrete Element Method. Teh. Vjesn. -Tech. Gaz. 2021, 28, 1877–1884. [Google Scholar] [CrossRef]

- Wang, S.Z.; Lu, B.C.; Cao, J.R.; Shen, M.W.; Zhou, C.Q.; Feng, Y. Research on a method for diagnosing clogging faults and longitudinal axial flow in the threshing cylinders of drum harvesters. Noise Control Eng. J. 2021, 69, 209–219. [Google Scholar] [CrossRef]

- Wang, J.W.; Xu, C.S.; Xu, Y.A.; Qi, X.; Liu, Z.M.; Tang, H. Vibration Analysis and Parameter Optimization of the Longitudinal Axial Flow Threshing Cylinder. Symmetry 2021, 13, 571. [Google Scholar] [CrossRef]

- Ni, Y.; Jin, C.; Wang, T.e.; Zhou, L.; Liu, Z. Design and experiments of the 4LZ-1.5 soybean combine harvester. Trans. Chin. Soc. Agric. Eng. 2022, 38, 1–11. [Google Scholar]

- Chen, M.; Ni, Y.; Jin, C.; Xu, J.; Zhang, G. Online Monitoring Method of Mechanized Soybean Harvest Quality Based on Machine Vision. Trans. Chin. Soc. Agric. Mach. 2021, 52, 91–98. [Google Scholar]

- Jin, C.; Liu, S.; Chen, M.; Yang, T.; Xu, J. Online quality detection of machine-harvested soybean based on improved U-Net network. Trans. Chin. Soc. Agric. Eng. 2022, 38, 70–80. [Google Scholar]

- Wang, R.C.; Zhang, K.Q.; Ding, R.K.; Jiang, Y.; Jiang, Y.Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.Z.; Lv, L.Y.; Shi, Y.; Yu, X. Study on Modeling Method of a Multi-Parameter Control System for Threshing and Cleaning Devices in the Grain Combine Harvester. Agriculture 2022, 12, 1483. [Google Scholar] [CrossRef]

- Liu, Y.B.; Li, Y.M.; Chen, L.P.; Zhang, T.; Liang, Z.W.; Huang, M.S.; Su, Z. Study on Performance of Concentric Threshing Device with Multi-Threshing Gaps for Rice Combines. Agriculture 2021, 11, 1000. [Google Scholar] [CrossRef]

- Liang, Z.W.; Li, Y.M.; De Baerdemaeker, J.; Xu, L.Z.; Saeys, W. Development and testing of a multi-duct cleaning device for tangential-longitudinal flow rice combine harvesters. Biosyst. Eng. 2019, 182, 95–106. [Google Scholar] [CrossRef]

- Wang, F.Z.; Liu, Y.B.; Li, Y.M.; Ji, K.Z. Research and Experiment on Variable-Diameter Threshing Drum with Movable Radial Plates for Combine Harvester. Agriculture 2023, 13, 1487. [Google Scholar] [CrossRef]

- Li, L.Q.; Xie, S.M.; Ning, J.M.; Chen, Q.S.; Zhang, Z.Z. Evaluating green tea quality based on multisensor data fusion combining hyperspectral imaging and olfactory visualization systems. J. Sci. Food Agric. 2019, 99, 1787–1794. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, X.; Tang, Z.; Wang, B. Sensor-Centric Intelligent Systems for Soybean Harvest Mechanization in Challenging Agro-Environments of China: A Review. Sensors 2025, 25, 6695. https://doi.org/10.3390/s25216695

Gu X, Tang Z, Wang B. Sensor-Centric Intelligent Systems for Soybean Harvest Mechanization in Challenging Agro-Environments of China: A Review. Sensors. 2025; 25(21):6695. https://doi.org/10.3390/s25216695

Chicago/Turabian StyleGu, Xinyang, Zhong Tang, and Bangzhui Wang. 2025. "Sensor-Centric Intelligent Systems for Soybean Harvest Mechanization in Challenging Agro-Environments of China: A Review" Sensors 25, no. 21: 6695. https://doi.org/10.3390/s25216695

APA StyleGu, X., Tang, Z., & Wang, B. (2025). Sensor-Centric Intelligent Systems for Soybean Harvest Mechanization in Challenging Agro-Environments of China: A Review. Sensors, 25(21), 6695. https://doi.org/10.3390/s25216695