Abstract

By integrating cathodic arc evaporation (CAE) with magnetron sputtering (MS) or high-power impulse magnetron sputtering (HiPIMS), hard coatings with diverse multicomponent compositions can be fabricated. Depending on the deposition conditions, the coatings with nano-composite or nano-multilayered microstructures are produced. During the mixing deposition conditions, nano-composite coatings are fabricated, which can be tailored to possess combining properties of super hardness, low friction coefficient, and excellent thermal/chemical stability. For the deposition with larger rotating periods, layer-by-layer deposition was observed. By the nano-multilayered coating design, superior mechanical properties (hardness ≥ 35 GPa), modulated residual stresses, and enhanced high-temperature properties can be obtained. In addition, lubricious elements, low friction (friction coefficient < 0.4), and low wear (<10−5 mm3/N∙m) both at ambient temperature and high temperature can be realized. Among these coatings, some have been specifically designed to achieve outstanding cutting performance in high-speed cutting applications. Several nitride and oxide hard coatings, such as AlTiN, TiAlN/TiSiN, AlCrN/Cu, and AlCrO, were deposited using a hybrid industrial physical vapor deposition (PVD) coating system. The microstructure, mechanical properties, and cutting performance of these coatings will be discussed.

1. Introduction

To enhance the lifetime and performance of cutting tools, there is a growing demand for high-performance coatings. Cutting tool coatings must possess a combination of properties, including relatively high hardness, excellent adhesion, wear resistance, and oxidation resistance [1,2]. To meet these requirements, it is necessary to develop new coating materials and advanced synthesis methods. CAE, with its high ionization rate, is the most commonly used technique to fabricate hard nitride coatings. These coatings exhibit strong adhesion to various substrates and a dense microstructure with stoichiometric composition [3,4,5]. However, on one hand, the formation of macro-particles during deposition, which increases the surface roughness and defects in the coatings, is inevitable and limits the high-precision applications of arc-evaporated nitride coatings [6,7]. Although magnetically-filtered CAE can suppress the macro-droplet defect to a certain extent, the deposition rate and production scale are significantly limited [8,9,10]. On the other hand, the relatively high residual stress generated during CAE, primarily resulting from the bombardment of energetic particles during deposition, limits the deposition of adherent and thick nitride coatings [11,12,13]. Excessive residual compressive stress can cause coating delamination and chipping failure during machining or other applications [14]. MS is another vapor deposition technique used to prepare coatings with excellent surface quality and a controllable residual stress state. However, sputtered nitride coatings exhibit low deposition rates and low compactness due to their low ionization rates [15]. HiPIMS technique excites high-density plasma through high-power pulses, yielding sputtered particles ionization rates above 70%, and substantially improving coating density and adhesion [16,17]. Traditional sputtering, limited by gas ion dominated bombardment, which has shortcomings in momentum transfer efficiency and inhibition of gas incorporation. In contrast, HiPIMS technique optimizes coating performance at a lower acceleration energy through bombardment of ionized species [18,19].

Although HiPIMS, filament ion sources, microwave assistance, and similar techniques have markedly boosted the ionization of both gas-phase and metal plasmas in MS, yielding coatings with superior microstructure and properties, their high capital cost and cumbersome integration continue to restrict widespread adoption [20,21].

The hybrid PVD approach that synergistically couples CAE with MS has emerged as a highly promising route for synthesizing high-performance hard coatings. Coatings prepared using the hybrid techniques exhibit high deposition rates and compactness (arising from CAE) and low residual stress levels (arising from MS), making them highly suitable for industrial applications [22,23,24]. In this paper, we will describe the efforts to develop hybrid coatings, including nitride hard coatings with nano-composite and nano-multilayered microstructures and Al-Cr-O oxide coatings. The hybrid deposition techniques, microstructure, and mechanical/machining properties of the coatings will be summarized.

2. Origins of the Hybrid PVD Deposition Technology

In 1986, B. Window and N. Savvides [25,26,27] invented unbalanced magnetron sputtering (UBMS). Teer [28] subsequently optimized the technology and the UBMS coaters. UBMS generates no macroparticles, delivers an ultrasmooth finish, and excels at sputtering alloy targets with wide melting-point spreads such as TiAl, TiZr, and TiNb, etc. During the same period, cathodic-arc technology advanced into steered arc through the external magnetic steering of cathode spots. The steered arc process yielded dense, well-adhered films, yet ejected macroparticles still compromised surface finish and structural integrity. The UBMS and steered arc were the two dominant industrial processes for nitride hard coatings.

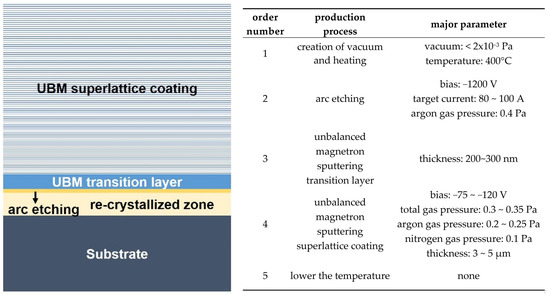

In April 1991, Hultman and co-workers at Linköping University reported that stainless-steel substrates pre-etched at −1200 V bias in an Ar/Ti arc plasma formed a 10–20 nm Ti–Fe intermetallic layer that diffused 120–160 nm into the substrate, generating a recrystallized, compositionally graded interface [29]. Subsequent TiN deposition on this interface exhibited markedly higher adhesion. Identical etching in a sputtering discharge produced neither the intermixed layer nor the adhesion enhancement. Recognizing the complementary strengths of steered arc and UBMS, Hauzer launched the HTC 1000-4 arc-bond sputter (ABSTM) hybrid coater in 1991 [29,30]. The sequence (Figure 1) begins with arc pre-etching for superior adhesion, followed by UBMS deposition for defect-free, high-quality surface layers. Exploiting the symmetrical cathode array of the HTC 1000-4, Hauzer and Sheffield Hallam University produced superlattice multilayers with nanometer-scale precision. Donohue et al. [31,32,33] systematically mapped the influence of pressure, bias, bilayer period, and duty ratio for TiAlN/ZrN and TiAlN/TiNbN stacks (sputtered TiAlN alternated with arc-deposited ZrN or TiNbN), defining a robust process window for industrial-scale manufacture. Sheffield Hallam University researchers produced TiAlN/CrN/TiAlYN [34], TiAlN/VN [35,36], and CrN/NbN [37] superlattice coatings that excel in dry milling of Ti alloys, high-speed machining of aerospace Al 7010-T7651 and automotive AlSi9Cu1 alloys, and in extending die life for Ti-alloy landing-gear components hot-formed at 850 °C [38].

Figure 1.

Typical structure and production process of the hybrid ABSTM coating.

In the above ABSTM hybrid PVD attempts, the role of CAE is only for etching the substrate during the pretreatment stage. After that, closed-field UBMS coatings were undertaken. To fabricate hard coatings with multicomponent compositions, nano-composite, and nano-multilayered microstructures, researchers further explored the depositions combining steered arc and MS simultaneously. Kim et al. successfully deposited a variety of multicomponent and nano-composite coatings, including TiSiN [39] and AlTiSiN [40], using a hybrid CAE and MS deposition technique in a lab-scale PVD setup. Fox-Rabinovich et al. developed AlTiN/Cu [41] and TiAlCrN/NbN [42] nano-multilayer coatings for application as tribologically adaptive coatings on cutting tools using the industrial hybrid arc/sputter coating machine (Kobelco AIP®+UBMS® hybrid coater, Kobelco, Kobe, Japan) [43]. These coatings were successfully applied to milling tools used for machining H13 tool steel (hardness range of 55–57 HRC). Researchers at Oerlikon Balzers utilized the HI3 technology to deposit AlTiN coatings (CAE) and SiBCN coatings (HiPIMS) in a composite manner [44,45]. This process enabled a structural transition of the coating from the columnar crystals of the base layer to the nano-crystalline structure in the composite deposition zone and, finally, to the amorphous structure of the functional top layer. The AlTiN/SiBCN coating combines high hardness with excellent toughness, demonstrating a significant advantage in tool life when machining difficult-to-cut materials compared to its competitors [46]. In the subsequent chapters, we will describe the details of the hybrid PVD methods for fabricating nano-composite and nano-multilayered coatings.

3. Hybrid PVD Technique for Synthesizing Nano-Composite Coatings

Beginning in 1995, Vepřek and co-workers at TU Munich unveiled superhard (>40 GPa) nano-crystalline/amorphous nano-composites, introducing a three-dimensional network in which an amorphous “tissue” encapsulates nano-crystalline grains [47,48,49]. TiSiN, the archetype, couples super-high hardness with low friction and excellent chemical stability [50,51,52]. Initially synthesized by PECVD [53,54,55] or sputtering [56,57,58] in the early 2000s, TiSiN was later refined by Kim’s group at Pusan National University, which co-deposited Ti via cathodic arc and Si via UBMS while rotating the substrates at 25 rpm [59]. Increasing Si content (0–12.7 at.%) progressively reduced surface roughness and room-temperature friction, peaking in hardness at 45 GPa for 7.7 at.% Si. Relative to single-arc TiN, the hybrid TiSiN coatings exhibited markedly improved mechanical and tribological performance; in dry machining of AISI D2 tool steel (62 HRC), tool life doubled and surface finish improved significantly [60,61].

Building on the TiSiN foundation, Kim’s team extended the system to TiAlSiN and TiSiCN nano-composites. At ~9 at.% Si, (Ti,Al,Si)N nano-crystals (~8 nm) are uniformly dispersed within an amorphous Si3N4 matrix, yielding 55 GPa hardness and a 650 GPa elastic modulus [40]. This architecture fuses the thermal stability of TiAlN with the super-hard character of TiSiN, extending tool life by 30–50% over TiAlN when dry- or MQL-machining D2 tool steel [62]. Similarly, TiSiCN (8.9 at.% Si) comprises nano-crystalline (Ti,C)N grains embedded in an amorphous Si3N4/SiC network. Tribochemical interaction with ambient moisture generates self-lubricating SiO2 and Si(OH)2 films, decreasing the friction coefficient to ~0.6 (cf. 0.75 for TiCN and 0.8 for TiSiN) while preserving the 55 GPa superhardness [63].

CrN-based coatings have also been alloyed with Ti [64], Al [65], B [66,67,68], C [69], Ta [70], etc. Using arc/sputter hybrid deposition, Kim’s group synthesized CrSiN [71], CrSiON [72], CrCN [73], CrSiCN [74,75,76], CrAlN [77], CrAlSiN [77], CrMoN [73], and CrMoSiN [78,79], demonstrating superior performance in high-speed dry micro-machining of high-strength brass (HBsC3) [80,81,82] and AISI W1-8 die steel (52 HRC) [23,83]. In CrSiN, 9.3 at.% Si produced nano-composite CrN grains in amorphous Si3N4, maximizing hardness (~34 GPa) and lowering friction [71]. During oxidation (800–1000 °C in air), Si outward diffusion and formation of amorphous SiO2 retarded further oxidation. A joint study optimized arc/sputter parameters controlling CrSiN nanostructure and elucidated the evolution mechanism via thermodynamics and molecular dynamics [71]. CrSiON with 16 at.% O formed CrN nano-crystals encapsulated by amorphous SiO2 and Si3N4, reaching 47 GPa hardness and 0.22 friction coefficient; higher O (>25 at.%) caused Cr2O3 segregation and hardness loss [72].

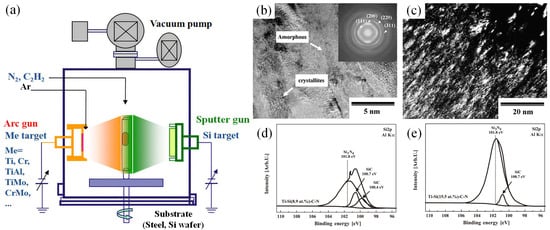

The key factor of synthesizing nano-composite hard coatings is the utilization of a hybrid PVD technique combining arc and sputtering lies in the mixed deposition conditions. As shown in Figure 2, the mixing deposition is realized by a small vacuum chamber with a diameter of around 400 mm and a high-speed substrate rotation of 25 rpm. The incident deposition species of the arc plasma and sputtering plasma reach the substrates almost simultaneously. By varying the compositions of the arc/sputter targets, ratio of the arc/sputter power, and deposition parameters such as nitrogen gas pressure, bias voltage, and deposition temperatures, the composition and energy of the deposition species can be precisely tuned [84,85,86]. Therefore, multicomponent nano-composite coatings with optimized microstructures and properties can be synthesized. Figure 2 shows the TEM structure and XPS results of the TiSiCN coatings. The images reveal the nano-composite microstructure with TiCN face-centered cubic (FCC) nano-crystals, and amorphous SiCN tissue phase (Si3N4 and SiC) was synthesized. By introducing more metallic elements into the coatings, the combined effect of solid-solution hardening by alloying atoms (C [76], Al [87], Cr [88], and Mo [89,90]) and the grain boundary hardening with strong cohesive energies of interphase boundaries induced by nano-composite microstructures can produce superior hard coatings [91]. By the basic concept on multi-component coatings based on alloying plus nano-composite design, many excellent hybrid-function coatings composed of nano-crystalline grains of nitrides or carbides ((Ti, Cr, Mo, Al)(C, N)x, etc.) are surrounded by an amorphous hard matrix (SiNx) [92,93,94,95]. These types of nano-composite films possess superhardness (>40 GPa), while also exhibiting a high stiffness (elastic modulus) and a sufficient stability against environmental attack [96,97]. Table 1 presents some selected hardness, friction coefficients, and applications of the hybrid ABSTM coatings. The doping of Si significantly increases the coating hardness and reduces the friction coefficient. However, the hardness decreases further when silicon is excessively doped [39,40,59,63,71,74,78,79,95].

Figure 2.

(a) Typical structure and production process of the hybrid ABSTM coating; (b,c) cross-sectional HRTEM and SAED and dark-field image for Ti–Si–C–N coating; (d,e) XPS spectra of Si 2p for Ti–Si–C–N coating. Adapted from [63].

Table 1.

Performance and applications of coatings deposited using hybrid PVD technique. Data from [39,40,59,63,71,74,78,79,95].

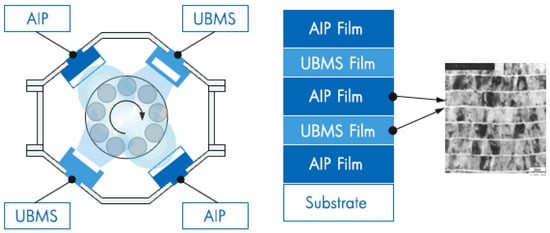

4. Hybrid PVD Technique for Synthesizing Nano-Multilayered Coatings

As for the industrial applications, most PVD coating systems have large chamber sizes that are unsuitable for hybrid arc and sputtering deposition. As shown in Figure 3, the deposited coatings form nano-multilayers composed of alternating arc-deposited layers and sputter-deposited layers. The microstructure and properties of the coatings depend on the deposition configuration and process parameters. To clearly characterize nano-multilayered coatings deposited by hybrid PVD coating techniques, the deposition details and three kinds of hybrid coatings are described in the following four parts.

Figure 3.

Typical structure and production process of the hybrid Kobelco AIP®+UBMS® coating.

4.1. Optimization of Hybrid PVD Deposition Parameters

To achieve highly efficient hybrid deposition, the optimization of process parameters is a prerequisite. Firstly, the challenge of combining CAE and MS deposition lies in the significant differences between their process parameters, especially in terms of total deposition pressure and nitrogen partial pressure [98,99]. MS is particularly sensitive to nitrogen partial pressure. When depositing nitride coatings, an excessively high nitrogen partial pressure may lead to the formation of a nitride layer on the metal target surface, causing “target poisoning”. This can reduce the sputtering rate and even trigger arcing or extinguishing of the glow discharge [100,101,102]. Since both arc and sputtering targets are operated simultaneously during arc/sputtering hybrid deposition, optimizing the nitrogen partial pressure to avoid target poisoning is crucial for successful composite deposition [103].

Taking the hybrid arc/sputtering deposition of AlTiN coatings as an example, the total deposition pressure was maintained at 0.8 Pa during the deposition process. The growth morphology of the coatings deposited under four different nitrogen partial pressures (0.4 Pa, 0.5 Pa, 0.6 Pa, and 0.7 Pa) was compared. The surface quality of the coating deposited at the optimized nitrogen partial pressure (0.6 Pa) was significantly better than that of the coating deposited at the initial nitrogen partial pressure (0.4 Pa). Within a certain range, as the nitrogen partial pressure increases, the probability of “droplets” emitted from the arc target colliding with gas molecules in the vacuum chamber also increases. This creates a filtering effect, thereby improving the surface quality of the coating. However, continuously increasing the nitrogen partial pressure will cause the nitriding reaction to occur in the vacuum path between the target material and the substrate, rather than on the substrate surface. This leads to a decrease in plasma density and a weakening of the ion bombardment effect, resulting in a decline in the surface quality and even the mechanical properties of the coating [104,105,106].

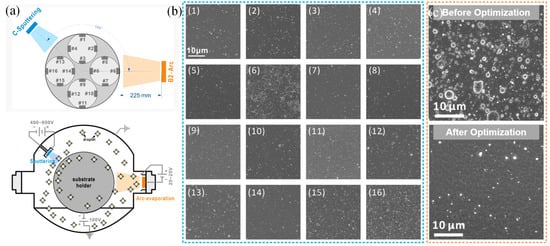

Bias voltage is another important deposition parameter affecting coating quality. Negatively charged droplets are repelled toward the substrate due to the high voltage of the sputtering target and are further repelled by the substrate with even higher voltage in front of the arc target [107,108]. Increasing bias voltage results in fewer macroparticles and a surface with fewer defects. The sample loading method also has a significant impact on the deposition of large particles on the coating surface [6,7,109]. As shown in Figure 4, during the coating deposition process, the specimens are periodically rotated in front of the arc and sputtering targets. The plasma density varies at different positions. In front of the arc target, the plasma density is higher, and the bombardment and purification effects on large particles are stronger. Therefore, fewer large particles are deposited on the sample surface at this position. At other positions, where the plasma density is lower, more large particles are deposited on the sample surface. Samples were mounted at the 16 positions to detect macroparticle deposition on the coating surface, showing different densities of macroparticles on the specimens. By optimizing the deposition gas parameters and loading fixture, dense and adherent coatings with significantly fewer macroparticles were obtained.

Figure 4.

(a) Schematic diagram of hybrid PVD deposition; (b) surface morphology of AlTiN coatings at different positions; (c) comparison of droplet distribution on AlTiN coating surface before and after optimization.

4.2. Hybrid Nitride Coatings with Similar Crystalline Lattices

Arc-sputtering hybrid coatings are effectively a multilayer superposition of arc-evaporated sublayers and sputtered sublayers [110,111]. In hybrid hard coatings composed of one material or two materials with similar crystalline lattices, sublayers may stack with the same lattice structure, or one material may grow on another in a metastable crystal structure. As the modulation period changes, epitaxial growth of one modulation layer on another may occur [112,113,114]. On the other hand, due to the different plasma densities in the arc and sputtering processes, the coating microstructure and, therefore, the properties of the hybrid coatings can be tuned by the ratio of arc and sputtering deposition [115,116].

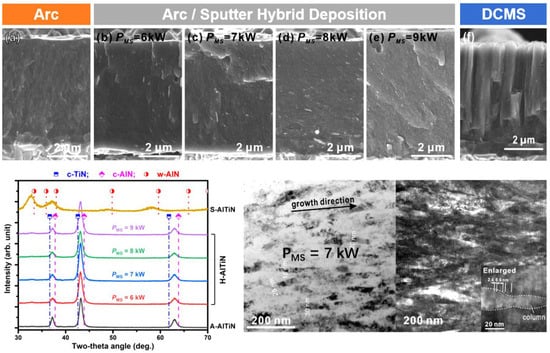

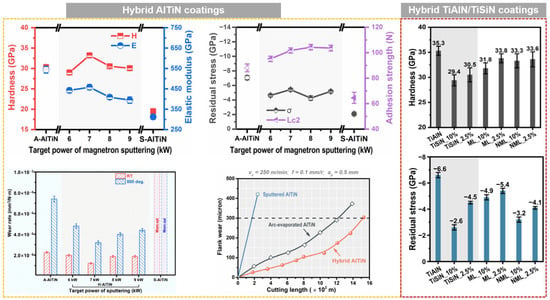

Using hybrid AlTiN coatings as an example [117], Figure 5 illustrates that AlTiN coatings deposited via arc-sputtering hybrid deposition exhibit a dense microstructure similar to that of arc coatings. Specifically, the hybrid coatings display an FCC phase structure of cubic TiN (c-TiN) and cubic AlN (c-AlN) akin to arc coatings, whereas sputtered coatings exhibit a hexagonal phase of w-AlN. At the SEM level, a dense coating structure is observed. TEM analysis shows that the arc-sputtering hybrid deposition results in a nano-lamellar structure. The bright-field image reveals that the coating consists of fine columnar grains extending along the growth direction, with a column width of less than 50 nm. These single columnar grains are assembled from alternating CAE and MS sublayers with nano-sized thicknesses.

Figure 5.

Microstructure, phase structure, and lattice details of the hybrid AlTiN coatings at various sputtering AlTiN powers (a) arc-AlTiN; (b–e) hybrid-AlTiN with different PMS; (f) DCMS-AlTiN. Adapted from [117].

As shown in Figure 6, hybrid AlTiN coatings can be optimized to possess superior mechanical properties, including higher hardness, lower residual stress, better adhesion, and lower wear rates [117]. The hybrid AlTiN coating deposited at an MS power of 7.0 kW exhibited significantly higher hardness (33.2 GPa) and elastic modulus (457.9 GPa) compared to arc-evaporated and sputtered AlTiN coatings. Simultaneously, the hybrid AlTiN coatings demonstrated a compressive stress level of −4.3 to −5.4 GPa, which is intermediate between the arc AlTiN (−7.1 GPa) and sputter AlTiN (−2.1 GPa) coatings. The higher hardness and moderate compressive stress result in significantly reduced wear rates and enhanced cutting performance for the tools. The minimum wear rates observed for the hybrid AlTiN coating (PMS = 7.0 kW) were 1.2 × 10−6 and 3.2 × 10−6 mm3/N∙m, which were 1/5 and 1/2 of the wear rates of the arc AlTiN coatings at room temperature (RT) and 800 °C, respectively. In contrast, the sputter AlTiN coating exhibited wear at both RT and 800 °C. The hybrid AlTiN coating achieved a much higher cutting life, with approximately a 1/4 increase compared to arc coatings and a 9-fold increase compared to sputter coatings.

Figure 6.

Mechanical properties, wear resistance, and cutting performance of the hybrid AlTiN and TiAlN/TiSiN coatings. Adapted from [117].

In hybrid coatings composed of two different materials with similar crystalline lattices, the coating tuning is similar to that of hybrid AlTiN coatings. The modulation period and modulation ratio of the arc layer and sputtered layer critically influence the microstructure and properties of the coatings. Figure 6 shows the hardness and residual stress of the hybrid TiAlN/TiSiN coatings by tuning the stacking micro- and nano-laminates [117]. Arc TiAlN coating exhibits high hardness of 35.3 GPa but with high compressive residual stress of −6.6 GPa. By periodically inserting HIPIMS TiSiN into the TiAlN coatings with a specific modulation period and modulation ratio, the hybrid coatings can achieve similar high hardness while maintaining substantially reduced compressive stresses. The toughness of the coatings is also affected. Similar cases include AlTiN/AlCrN [118,119,120], AlTiN/WN [121,122], etc. By periodically adding WN into the AlTiN crystals, the residual compressive stress can be tuned from −1.7 GPa to −4.7 GPa, while the coating hardness remains in the range of 32.6–38.8 GPa.

4.3. Hybrid Nitride Coatings with Dissimilar Crystalline Lattices

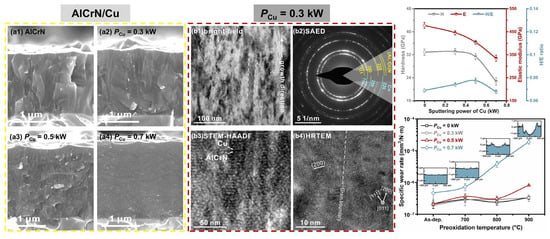

When two materials with dissimilar crystalline lattices are combined into a single hybrid hard coating, the growth of the crystals is disrupted, leading to the renucleation of the crystals. For example, consider the AlCrN/Cu hybrid coating (Figure 7) [123]. The Cu-free AlCrN coating exhibits typical columnar grain growth. In contrast, the hybrid AlCrN-Cu coatings show denser structures with diminished micro-columns when the Cu power (PCu) is set at 0.3 kW and 0.5 kW. At a PCu of 0.7 kW, the columnar grain growth is completely disrupted. In the TEM images, the AlCrN/Cu coating with PCu = 0.3 kW displays a spindly columnar structure. The STEM image reveals alternating partially epitaxial growth of Cu sublayers with AlCrN sublayers, with discontinuous Cu sublayers. Further increasing the Cu content in the hybrid coatings results in the complete loss of epitaxial laminating growth. Instead, a nano-composite microstructure is obtained, with Cu dispersed in the reduced nano-sized or even amorphous AlCrN crystals. Similar microstructural evolution has been observed in hybrid TiSiN and TiAlSiN films by Kim et al. [39,40].

Figure 7.

Microstructure, mechanical properties, and wear performance of the hybrid AlCrN/Cu coatings. Adapted from [123].

Regarding the mechanical properties, the pure AlCrN coating exhibits a hardness of 32.9 GPa and an elastic modulus of 477.3 GPa. When Cu is introduced at contents of 2.6 at.% and 7.9 at.% (corresponding to PCu values of 0.3 and 0.5 kW), the hardness shows comparable values at 31.3–33.1 GPa. Notably, when the Cu content is further increased to 13.8 at.% (PCu = 0.7 kW), the hardness drops significantly to 22.7 GPa. The incorporation of the metallic Cu phase enhances the deformation capacity under the applied load, thereby improving the toughness of the hard coatings. The AlCrN/Cu coating with PCu = 0.5 kW exhibits the highest H/E ratio of 0.078, indicating superior toughness. Moreover, when oxidized at 800 °C, the AlCrN/Cu coatings form CuO. The formation of fine-grained, shearable CuO contributes to a reduced coefficient of friction. Specifically, AlCrN/Cu coatings with PCu values of 0.3 kW and 0.5 kW exhibit a lower coefficient of friction of approximately 0.4 after oxidation at 800 °C. However, further increasing the Cu content deteriorates the wear resistance of the coatings. Overall, the incorporation of a second phase through hybrid coating fabrication is advantageous for designing coatings with multifunctional properties. With these kinds of hybrid coating methods, AlTiN/MoCuN and AlTiN/MoCuVN hard coatings with high hardness, high wear resistance, and low friction coefficients at a wide temperature range are attained [124].

4.4. Hybrid Hard Oxide Coatings with Template Lattices

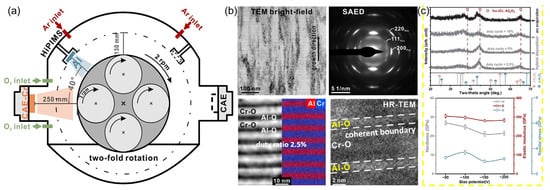

Arc-evaporated (Cr, Al)2O3 coatings, known for their high hardness and excellent chemical inertness, hold great promise as protective layers for cutting tools. However, their high surface roughness limits their application in advanced machining processes [125]. By employing a hybrid deposition technique that combines CAE and HiPIMS, it is possible to deposit Cr-O/Al-O hard coatings with significantly fewer growth defects [126].

Due to the high sensitivity of HiPIMS to O2 pressure, a suitable gas inlet strategy is necessary for the reliable preparation of oxide coatings. Specifically, when O2 is introduced near the CAE Cr target, the oxygen flow rate can be adjusted within a wider range without causing significant arcing in the HiPIMS Al target. This approach enables the stable synthesis of Cr-O/Al-O coatings with an oxygen content exceeding 50 at.% and achieves a remarkable hardness enhancement of 12 GPa. Adjusting the HiPIMS duty cycle from 10.0% to 2.5% enhances the crystallinity of the Al-O crystals, thereby increasing the hardness of the Cr-O/Al-O hybrid coatings from 16.6 GPa to 24.7 GPa. As illustrated in Figure 8, the hybrid Cr-O/Al-O coatings exhibit a compositionally modulated multilayer structure, originating from the alternating deposition of CAE and HiPIMS layers [126]. The template effect allows the Al-O sublayers to fully crystallize, using the Cr-O sublayers as nucleation templates. Typically, Al-O coatings are challenging to crystallize at low deposition temperatures below 650 °C. However, the epitaxial growth between the arc-evaporated Cr-O and sputtered Al-O sublayers results in a dominant and metastable FCC structure. The hybrid CAE/HiPIMS technique shows great promise for depositing hard oxide coatings with low surface roughness and high hardness under optimized deposition parameters. Further research is needed to explore the structural control related to modulation geometry, phase structure, and thermal stability of Cr-O/Al-O multilayer coatings.

Figure 8.

(a) Schematic diagram of hybrid pvd system; (b) cross-sectional TEM microstructure of Cr-O/Al-O coating; (c) GIXRD pattern and mechanical properties of Cr-O/Al-O coating. Adapted from [126].

5. Conclusions and Perspectives

By integrating CAE with MS or HiPIMS, it is possible to fabricate hard coatings with a diverse range of multicomponent compositions. These hybrid coatings can be precisely tuned in surface and cross-sectional microstructure, surface morphology, crystalline defects, phase structure, residual stress, and related mechanical, wear and machining properties. Through periodic modulation of composition or structure using alternating hard sublayers, the hybrid coatings achieve superior properties, including synergistic improvements in hardness, toughness, and wear resistance. While coatings deposited by CAE typically exhibit high hardness, the bombardment of high energy particles often results in the accumulation of interfacial defects, leading to elevated residual stresses. In contrast, nano-composite coatings, synthesized through hybrid techniques that tailor the interfacial structure, can achieve high mechanical performance and interfacial adhesion while effectively reducing stresses. Compared to single deposition techniques, hybrid deposition combines the high ionization rate and strong coating-substrate adhesion of CAE with the wide range of target material selection and adjustable internal stress of MS. This integration overcomes the inherent limitations of single deposition methods and obtains coatings with outstanding properties without relying on costly HiPIMS or radio frequency sputtering equipment, thereby significantly reducing both capital and operating expenditures and creating favorable conditions for industrial production. Owing to low residual stress, hybrid PVD can achieve thick coating deposition, overcoming the high porosity of laser cladding, the high cost and potential pollution of chemical vapor deposition, and the porosity and residual stress inherent to thermal spraying, thereby achieving superior overall performance. Moreover, by designing nano-lamellar and nano-composite structures, high-performance hard coatings can be developed, which significantly enhance the cutting performance of tools.

Author Contributions

R.Z.—original draft preparation; Q.W.—conceptualization, writing, reviewing and editing; Y.X.—Review and draft editing; L.L.—Review and editing; K.H.K.—Review and editing. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the National Natural Science Foundation of China (52375173, 52401083), the Guangdong Basic and Applied Basic Research Foundation (2023B151520033), and the Major Science and Technology Projects in Dongguan(DGKJ2401).

Conflicts of Interest

Author L.L. was employed by Guangdong Huasheng Nanotechnology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PVD | Physical vapor deposition |

| CAE | Cathodic arc evaporation |

| MS | Magnetron sputtering |

| HiPIMS | High-power impulse magnetron sputtering |

| UBMS | Unbalanced magnetron sputtering |

| ABSTM | Arc-Bond Sputter |

| FCC | Face-centered cubic |

References

- Dabees, S.; Mirzaei, S.; Kaspar, P.; Holcman, V.; Sobola, D. Characterization and evaluation of engineered coating techniques for different cutting tools-review. Materials 2022, 15, 5633. [Google Scholar] [CrossRef] [PubMed]

- Seenath, A.A.; Sarhan, A.A.D. A State-of-the-Art review on cutting tool materials and coatings in enhancing the tool performance in machining the superior nickel-based superalloys. Arab. J. Sci. Eng. 2024, 49, 10203–10236. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Tarnowska, M. The surface assessment and the properties of selected multilayer coatings. Lubricants 2023, 11, 371. [Google Scholar] [CrossRef]

- Petrović, B.; Mitić, D.; Miličić Lazić, M.; Lazarević, M.; Trajkovska Petkoska, A.; Nasov, I.; Živković, S.; Jokanović, V. TiN-Ag multilayer protective coatings for surface modification of AISI 316 stainless steel medical implants. Coatings 2025, 15, 820. [Google Scholar] [CrossRef]

- Tang, V.-T.; Chang, Y.-Y.; Chen, Y.-R. Enhancement of a magnetically controlled cathodic arc source for the deposition of multi-component hard nitride coatings. Materials 2025, 18, 2276. [Google Scholar] [CrossRef]

- Akhter, R.; Bendavid, A.; Munroe, P. The influence of substrate bias on the surface morphology, microstructure and mechanical behaviour of TiNiN coatings. Appl. Surf. Sci. 2022, 590, 153107. [Google Scholar] [CrossRef]

- Kheyrodin, M.; Mahboubi, F.; Elmkhah, H. The effect of negative bias voltage on the microstructure and hot corrosion behavior of heat-treated NiCoCrAlY coatings applied via the cathodic arc evaporation physical vapor deposition method. J. Mater. Eng. Perform. 2024, 33, 283–300. [Google Scholar] [CrossRef]

- Kuprin, A.S.; Ovcharenko, V.D.; Gilewicz, A.; Tolmachova, G.N.; Kolodiy, I.V.; Vasilenko, R.L.; Kuznetsova, T.; Lapitskaya, V.; Warcholinski, B. Structural, mechanical and tribological properties of Cr-V-N coatings deposited by cathodic arc evaporation. Tribol. Int. 2022, 165, 107246. [Google Scholar] [CrossRef]

- Xian, L.; Fan, H.; Xian, G.; Li, L.; Luo, Y.; Zhao, H. Comparison study of the microstructure, mechanical and tribological properties of TiAlN, AlCrBN and TiAlN/AlCrBN coatings by cathodic arc evaporation. Int. J. Refract. Met. Hard Mater. 2025, 128, 107017. [Google Scholar] [CrossRef]

- Gilewicz, A.; Kuznetsova, T.; Aizikovich, S.; Lapitskaya, V.; Khabarava, A.; Nikolaev, A.; Warcholinski, B. Comparative investigations of AlCrN coatings formed by cathodic arc evaporation under different nitrogen pressure or arc current. Materials 2021, 14, 304. [Google Scholar] [CrossRef]

- Lothrop, A.; Yang, Q.; Huang, X.; Wu, X. Characterization of (AlCrTiVZr)N high-entropy coating produced by cathodic arc evaporation. J. Mater. Eng. Perform. 2024, 33, 7240–7252. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Myslinski, P.; Dobruchowska, E.; Murzynski, D.; Kochmanski, P.; Rokosz, K.; Raaen, S. Effect of nitrogen pressure and substrate bias voltage on the properties of Al–Cr–B–N coatings deposited using cathodic arc evaporation. Tribol. Int. 2021, 154, 106744. [Google Scholar] [CrossRef]

- Ali, M.; Hamzah, E.; Hamid, M.A.; Hashim, A.H. Whether macro-droplets generate or develop in depositing hard coatings by cathodic arc evaporation technique. Int. J. Refract. Met. Hard Mater. 2023, 115, 106296. [Google Scholar] [CrossRef]

- He, Q.; Saciotto, V.; DePaiva, J.M.; Guimaraes, M.C.; Kohlscheen, J.; Martins, M.M.; Veldhuis, S.C. Enhancing tool performance in high-speed end milling of Ti-6Al-4V alloy: The role of AlCrN PVD coatings and resistance to chipping wear. J. Manuf. Mater. Process. 2024, 8, 68. [Google Scholar] [CrossRef]

- Rao, A.U.; Tiwari, S.K.; Goyat, M.S.; Chawla, A.K. Recent developments in magnetron-sputtered silicon nitride coatings of improved mechanical and tribological properties for extreme situations. J. Mater. Sci. 2023, 58, 9755–9804. [Google Scholar] [CrossRef]

- Bai, H.; Li, J.; Gao, J.; Ni, J.; Bai, Y.; Jian, J.; Zhao, L.; Bai, B.; Cai, Z.; He, J.; et al. Comparison of CrN Coatings Prepared Using High-Power Impulse Magnetron Sputtering and Direct Current Magnetron Sputtering. Materials 2023, 16, 6303. [Google Scholar] [CrossRef]

- Zin, V.; Montagner, F.; Deambrosis, S.M.; Miorin, E.; Comisso, N.; Rancan, M.; Paradisi, E.; Mortalò, C. High power impulse magnetron sputtering plasma nitriding of biomedical grade CoCrMo alloy. Mater. Des. 2025, 252, 113802. [Google Scholar] [CrossRef]

- Lu, X.; Yang, L.; Lu, Y.; Yan, Z.; Hao, J.; Liu, W. Enhanced mechanical and tribological properties of high-entropy alloys reinforced molybdenum nitride coatings via high power impulse magnetron sputtering. J. Alloys Compd. 2025, 1038, 182789. [Google Scholar] [CrossRef]

- Kapran, A.; Ballage, C.; Hubička, Z.; Minea, T. Effect of magnetron configuration on the spatial distribution of sputtered species in high-power impulse magnetron sputtering (HiPIMS) plasmas. Vacuum 2025, 238, 114324. [Google Scholar] [CrossRef]

- Krýsová, H.; Cichoň, S.; Kapran, A.; Volfová, L.; Chvostová, D.; Imrich, T.; Neumann-Spallart, M.; Krýsa, J.; Hubička, Z. Deposition of Fe2O3:Sn semiconducting thin films by reactive pulsed HiPIMS + ECWR co-sputtering from Fe and Sn targets. J. Photochem. Photobiol. A Chem. 2024, 454, 115676. [Google Scholar] [CrossRef]

- Castro, J.D.; Ans, M.; Cavaleiro, D.; Carvalho, S. Tribological and mechanical properties of ZrxNy films obtained by HiPIMS in DOMS mode. Tribol. Int. 2023, 189, 108960. [Google Scholar] [CrossRef]

- Kiryukhantsev-Korneev, P.V.; Sytchenko, A.D.; Gorshkov, V.A.; Loginov, P.A.; Sheveyko, A.N.; Nozhkina, A.V.; Levashov, E.A. Complex study of protective Cr3C2–NiAl coatings deposited by vacuum electro-spark alloying, pulsed cathodic arc evaporation, magnetron sputtering, and hybrid technology. Ceram. Int. 2022, 48, 10921–10931. [Google Scholar] [CrossRef]

- Fredebeul-Beverungen, N.; Steinhorst, M.; Roch, T. Comparison of magnetron-sputtered and cathodic arc-deposited Ti and Cr thin films on stainless steel for bipolar plates. Materials 2024, 17, 2864. [Google Scholar] [CrossRef]

- Lun, W.; Chen, G.; Wu, Z.; Li, H.; Lin, Y.; Lin, L.; Zheng, A.; Liu, C.; Zeng, Z.; Zhu, D. Conductivity and corrosion resistance of TiSiC/MeN multilayer films. Ceram. Int. 2024, 50, 48064–48073. [Google Scholar] [CrossRef]

- Window, B.; Savvides, N. Unbalanced dc magnetrons as sources of high ion fluxes. J. Vac. Sci. Technol. A 1986, 4, 453–456. [Google Scholar] [CrossRef]

- Savvides, N.; Window, B. Unbalanced magnetron ion-assisted deposition and property modification of thin films. J. Vac. Sci. Technol. A 1986, 4, 504–508. [Google Scholar] [CrossRef]

- Window, B.; Savvides, N. Charged particle fluxes from planar magnetron sputtering sources. J. Vac. Sci. Technol. A 1986, 4, 196–202. [Google Scholar] [CrossRef]

- Yang, S.; Li, X.; Cooke, K.E.; Teer, D.G. A study of TiMoN nano-multilayer coatings deposited by CFUBMSIP using DC and HIPIMS power. Appl. Surf. Sci. 2012, 258, 2062–2067. [Google Scholar] [CrossRef]

- Münz, W.D.; Hurkmans, T.; Keiren, G.; Trinh, T. Comparison of TiAlN coatings grown by unbalanced magnetron and arc bond sputtering techniques. J. Vac. Sci. Technol. A 1993, 11, 2583–2589. [Google Scholar] [CrossRef]

- Sproul, W.D. Ion-assisted deposition in unbalanced-magnetron sputtering systems. Mater. Sci. Eng. A 1993, 163, 187–192. [Google Scholar] [CrossRef]

- Luo, Q.; Rainforth, W.M.; Donohue, L.A.; Wadsworth, I.; Münz, W.D. Tribological investigation of TiAlCrN and TiAlN/CrN coatings grown by combined steered-arc/unbalanced magnetron deposition. Vacuum 1999, 53, 123–126. [Google Scholar] [CrossRef]

- Paritong, H.; Wadsworth, I.; Donohue, L.A.; Münz, W.D. Corrosion resistant Nb coatings grown by combined steered arc/unbalanced magnetron deposition. Trans. IMF 1998, 76, 144–148. [Google Scholar] [CrossRef]

- Donohue, L.A.; Cawley, J.; Brooks, J.S.; Münz, W.D. Deposition and characterization of TiAlZrN films produced by a combined steered arc and unbalanced magnetron sputtering technique. Surf. Coat. Technol. 1995, 74–75, 123–134. [Google Scholar] [CrossRef]

- Lembke, M.I.; Titchmarsh, J.M.; Lewis, D.B.; Münz, W.D. Investigation of the oxidation behaviour of A TiAlCrYN pvd hard coating. MRS Online Proc. Libr. 2011, 648, 657. [Google Scholar] [CrossRef]

- Luo, Q.; Zhou, Z.; Rainforth, W.M.; Hovsepian, P.E. TEM-EELS study of low-friction superlattice TiAlN/VN coating: The wear mechanisms. Tribol. Lett. 2006, 24, 171–178. [Google Scholar] [CrossRef]

- Luo, Q. Temperature dependent friction and wear of magnetron sputtered coating TiAlN/VN. Wear 2011, 271, 2058–2066. [Google Scholar] [CrossRef]

- Lewis, D.B.; Hovsepian, P.E.; Schönjahn, C.; Ehiasarian, A.; Smith, I.J. Industrial scale manufactured superlattice hard PVD coatings. Surf. Eng. 2001, 17, 15–27. [Google Scholar] [CrossRef]

- Münz, W.D. Manufacturing of nanoscale multilayered hard coatings deposited by cathodic arc/unbalanced magnetron sputtering. MRS Bull. 2003, 28, 173–179. [Google Scholar] [CrossRef]

- Kim, K.H.; Choi, S.-r.; Yoon, S.-y. Superhard Ti–Si–N coatings by a hybrid system of arc ion plating and sputtering techniques. Surf. Coat. Technol. 2002, 161, 243–248. [Google Scholar] [CrossRef]

- Park, I.-W.; Choi, S.R.; Suh, J.H.; Park, C.-G.; Kim, K.H. Deposition and mechanical evaluation of superhard Ti–Al–Si–N nanocomposite films by a hybrid coating system. Thin Solid Film. 2004, 447–448, 443–448. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G. Hierarchical adaptive nano-structured PVD coatings for extreme tribological applications: The quest for non-equilibrium states and emergent behavior. Sci. Technol. Adv. Mater. 2012, 13, 043001. [Google Scholar] [CrossRef]

- Ning, L.; Veldhuis, S.C.; Yamamoto, K. Investigation of wear behavior and chip formation for cutting tools with nano-multilayered TiAlCrN/NbN PVD coating. Int. J. Mach. Tools Manuf. 2008, 48, 656–665. [Google Scholar] [CrossRef]

- Takahara, K.; Akari, K.; Kawaguchi, H.; Tamagaki, H. Current and future PVD systems and coating technologies. Kobelco Technol. Rev. 2005, 55, 81–85. Available online: https://api.semanticscholar.org/CorpusID:138619728 (accessed on 14 August 2025).

- Vlček, J.; Potocký, Š.; Čížek, J.; Houška, J.; Kormunda, M.; Zeman, P.; Peřina, V.; Zemek, J.; Setsuhara, Y.; Konuma, S. Reactive magnetron sputtering of hard Si–B–C–N films with a high-temperature oxidation resistance. J. Vac. Sci. Technol. A 2005, 23, 1513–1522. [Google Scholar] [CrossRef]

- Vlček, J.; Hřeben, S.; Kalaš, J.; Čapek, J.; Zeman, P.; Čerstvý, R.; Peřina, V.; Setsuhara, Y. Magnetron sputtered Si–B–C–N films with high oxidation resistance and thermal stability in air at temperatures above 1500 °C. J. Vac. Sci. Technol. A 2008, 26, 1101–1108. [Google Scholar] [CrossRef]

- Vetter, J. Innovative PVD processes for advanced coatings based on HiPIMS and arc: Scalable pulsed power plasma and high ionization triple. In Proceedings of the Functional Coatings and Surface Engineering, Montreal, QC, Canada, 2–5 June 2014; pp. 1–20. [Google Scholar]

- Vepřek, S.; Reiprich, S. A concept for the design of novel superhard coatings. Thin Solid Film. 1995, 268, 64–71. [Google Scholar] [CrossRef]

- Procházka, J.; Karvánková, P.; Vepřek-Heijman, M.G.J.; Vepřek, S. Conditions required for achieving superhardness of ≥45 GPa in nc-TiN/a-Si3N4 nanocomposites. Mater. Sci. Eng. A 2004, 384, 102–116. [Google Scholar] [CrossRef]

- Zhang, R.F.; Veprek, S. Phase stabilities of self-organized nc-TiN/a-Si3N4 nanocomposites and of Ti1−xSixNy solid solutions studied by ab initio calculation and thermodynamic modeling. Thin Solid Film. 2008, 516, 2264–2275. [Google Scholar] [CrossRef]

- Yang, J.; Cao, H.; Li, Y.; Liu, F.; Tang, Y.; Zhao, N.; Qi, F.; Ouyang, X. Microstructure, mechanical properties, and corrosion resistance of TiSiN coating prepared by FCVA technique with different N2 flow rates. Vacuum 2023, 209, 111811. [Google Scholar] [CrossRef]

- Schalk, N.; Moritz, Y.; Nayak, G.K.; Holec, D.; Hugenschmidt, C.; Burwitz, V.V.; Mathes, L.; Schiester, M.; Saringer, C.; Czettl, C.; et al. Nanocomposite versus solid solution formation in the TiSiN system. Acta Mater. 2024, 275, 120063. [Google Scholar] [CrossRef]

- Maksakova, O.; Smyrnova, K.; Ludrovcová, B.; Sahul, M.; Haršáni, M.; Truchlý, M.; Sahul, M.; Vopát, T.; Pašák, M.; Kozak, A.; et al. Tribological and micromechanical performance of hard yet tough TiSiN/WN coatings: An experimental analysis of multilayer effects. Int. J. Refract. Met. Hard Mater. 2025, 131, 107212. [Google Scholar] [CrossRef]

- Lu, C.-H.; Hao, D.; Yeh, N.-C. A perspective of recent advances in PECVD-grown graphene thin films for scientific research and technological applications. Mater. Chem. Phys. 2024, 319, 129318. [Google Scholar] [CrossRef]

- Almaev, A.V.; Yakovlev, N.N.; Chernikov, E.V.; Erzakova, N.N.; Mochalov, L.A.; Kudryashov, M.A.; Kudryashova, Y.; Nesov, S.N. Gas sensitivity of PECVD β-Ga2O3 films with large active surface. Mater. Chem. Phys. 2024, 320, 129430. [Google Scholar] [CrossRef]

- Pham, D.P.; Kim, H.; Choi, J.; Oh, D.; Chung, Y.-B.; Jeon, W.-S.; Jo, J.; Dao, V.-A.; Dhungel, S.K.; Yi, J. In-situ PECVD-based stoichiometric SiO2 layer for semiconductor devices. Opt. Mater. 2023, 137, 113536. [Google Scholar] [CrossRef]

- Ma, Y.; Li, L.; Qian, J.; Qu, W.; Luo, R.; Wu, F.; Chen, R. Materials and structure engineering by magnetron sputtering for advanced lithium batteries. Energy Storage Mater. 2021, 39, 203–224. [Google Scholar] [CrossRef]

- Pan, Y.; Wang, J.; Lu, Z.; Wang, R.; Xu, Z. A review on the application of magnetron sputtering technologies for solid oxide fuel cell in reduction of the operating temperature. Int. J. Hydrogen Energy 2024, 50, 1179–1193. [Google Scholar] [CrossRef]

- Atta, S.; NarendraKumar, U.; Kumar, K.V.A.N.P.S.; Yadav, D.P.; Dash, S. Recent developments and applications of TiN-based films synthesized by magnetron sputtering. J. Mater. Eng. Perform. 2023, 32, 9979–10015. [Google Scholar] [CrossRef]

- Lee, D.K.; Kang, D.S.; Suh, J.H.; Park, C.-G.; Kim, K.H. Synthesis and mechanical evaluation of quaternary Ti–Cr–Si–N coatings deposited by a hybrid method of arc ion plating and sputtering techniques. Surf. Coat. Technol. 2005, 200, 1489–1494. [Google Scholar] [CrossRef]

- Kang, I.S.; Kim, J.S.; Kang, M.C.; Lee, K.Y. Tool condition and machined surface monitoring for micro-lens array fabrication in mechanical machining. J. Mater. Process. Technol. 2008, 201, 585–589. [Google Scholar] [CrossRef]

- Kang, I.S.; Kim, J.S.; Kim, J.H.; Kang, M.C.; Seo, Y.W. A mechanistic model of cutting force in the micro end milling process. J. Mater. Process. Technol. 2007, 187–188, 250–255. [Google Scholar] [CrossRef]

- Safin Kaosar Saad, K.; Saba, T.; Bin Rashid, A. Application of PVD coatings in medical implantology for enhanced performance, biocompatibility, and quality of life. Heliyon 2024, 10, 35541. [Google Scholar] [CrossRef]

- Jeon, J.-H.; Choi, S.R.; Chung, W.S.; Kim, K.H. Synthesis and characterization of quaternary Ti–Si–C–N coatings prepared by a hybrid deposition technique. Surf. Coat. Technol. 2004, 188–189, 415–419. [Google Scholar] [CrossRef]

- Genzel, C.; Reimers, W. Depth-resolved X-ray residual stress analysis in PVD (Ti, Cr) N hard coatings. Int. J. Mater. Res. 2003, 94, 655–661. [Google Scholar] [CrossRef]

- Aktarer, S.M.; Sert, Y.; Küçükömeroğlu, T. Investigation of structural, hardness, adhesion, and tribological properties of CrN and AlCrN coatings deposited on cylinder liner. Mater. Des. 2025, 253, 113972. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, X.; Cai, H.; Huang, Z.; Xue, Y.; Pei, L.; Kang, B. Effect of B element doping on high-temperature tribological properties of WS2-based composite coatings. Lubricants 2025, 13, 332. [Google Scholar] [CrossRef]

- An, J.; Zhang, X. Crbn-based molecular Glues: Breakthroughs and perspectives. Bioorganic Med. Chem. 2024, 104, 117683. [Google Scholar] [CrossRef]

- Petzold, G.; Gainza, P.; Annunziato, S.; Lamberto, I.; Trenh, P.; McAllister, L.A.; DeMarco, B.; Schwander, L.; Bunker, R.D.; Zlotosch, M.; et al. Mining the CRBN target space redefines rules for molecular glue–induced neosubstrate recognition. Science 2025, 389, 6736. [Google Scholar] [CrossRef]

- Kumar, S.; Charoo, M.S. Combined effect of laser surface texturing and CrCN coating on the friction between piston ring and cylinder liner interface. J. Mater. Eng. Perform. 2025, 1–13. [Google Scholar] [CrossRef]

- Kainz, C.; Tkadletz, M.; Stark, A.; Schell, N.; Czettl, C.; Pohler, M.; Schalk, N. Thermal stability of a cathodic arc evaporated Cr0.74Ta0.26N coating. Materialia 2022, 22, 101434. [Google Scholar] [CrossRef]

- Park, J.H.; Chung, W.S.; Cho, Y.-R.; Kim, K.H. Synthesis and mechanical properties of Cr–Si–N coatings deposited by a hybrid system of arc ion plating and sputtering techniques. Surf. Coat. Technol. 2004, 188–189, 425–430. [Google Scholar] [CrossRef]

- Lee, J.D.; Wang, Q.M.; Kim, S.-H.; Wang, T.-G.; Shin, D.-W.; Kim, K.H. Microstructure and mechanical properties of quaternary Cr–Si–O–N films by a hybrid coating system. Surf. Coat. Technol. 2012, 206, 3721–3727. [Google Scholar] [CrossRef]

- Choi, E.Y.; Kang, M.C.; Kwon, D.H.; Shin, D.W.; Kim, K.H. Comparative studies on microstructure and mechanical properties of CrN, Cr–C–N and Cr–Mo–N coatings. J. Mater. Process. Technol. 2007, 187–188, 566–570. [Google Scholar] [CrossRef]

- Jeon, J.-H.; Jang, C.S.; Yoon, S.-Y.; Shin, B.-C.; Kim, K.H. Effects of Si addition on the characteristic evolution and syntheses of nanocomposite Cr–Si–C–N coatings prepared by a hybrid coating system. Surf. Coat. Technol. 2005, 200, 1635–1639. [Google Scholar] [CrossRef]

- Cai, F.; Yang, Q.; Huang, X.; Wei, R. Microstructure and corrosion behavior of CrN and CrSiCN coatings. J. Mater. Eng. Perform. 2010, 19, 721–727. [Google Scholar] [CrossRef]

- Li, Q.; Jiang, F.-q.; Leng, Y.-x.; Wei, R.-h.; Huang, N. Microstructure and tribological properties of Ti(Cr)SiCN coating deposited by plasma enhanced magnetron sputtering. Vacuum 2013, 89, 168–173. [Google Scholar] [CrossRef]

- Park, I.-W.; Kang, D.S.; Moore, J.J.; Kwon, S.C.; Rha, J.J.; Kim, K.H. Microstructures, mechanical properties, and tribological behaviors of Cr–Al–N, Cr–Si–N, and Cr–Al–Si–N coatings by a hybrid coating system. Surf. Coat. Technol. 2007, 201, 5223–5227. [Google Scholar] [CrossRef]

- Hong, S.G.; Shin, D.-W.; Kim, K.H. Syntheses and mechanical properties of quaternary Cr-Mo-Si-N coatings by a hybrid coating system. Mater. Sci. Eng. A 2008, 487, 586–590. [Google Scholar] [CrossRef]

- Heo, S.J.; Kim, K.H.; Kang, M.C.; Suh, J.H.; Park, C.-G. Syntheses and mechanical properties of Mo–Si–N coatings by a hybrid coating system. Surf. Coat. Technol. 2006, 201, 4180–4184. [Google Scholar] [CrossRef]

- Krella, A. Resistance of PVD coatings to erosive and wear processes: A review. Coatings 2020, 10, 921. [Google Scholar] [CrossRef]

- Maros, M.B.; Siddiqui, S.A. Tribological study of simply and duplex-coated CrN-X42Cr13 tribosystems under dry sliding wear and progressive loading scratching. Ceramics 2022, 5, 1084–1101. [Google Scholar] [CrossRef]

- Klocke, F.; Nobel, C.; Veselovac, D. Influence of tool coating, tool material, and cutting speed on the machinability of low-leaded brass alloys in turning. Mater. Manuf. Process. 2016, 31, 1895–1903. [Google Scholar] [CrossRef]

- Yang, T.; Yin, J.; Ying, P.; Lin, C.; Zhang, P.; Wu, J.; Kovalev, A.; Huang, M.; Wang, T.; Grigoriev, A.Y.; et al. Influence of molybdenum addition on the structure, mechanical properties, and cutting performance of AlTiN coatings. Lubricants 2024, 12, 429. [Google Scholar] [CrossRef]

- Singh, A.; Ghosh, S.; Aravindan, S. Investigation of oxidation behaviour of AlCrN and AlTiN coatings deposited by arc enhanced HIPIMS technique. Appl. Surf. Sci. 2020, 508, 144812. [Google Scholar] [CrossRef]

- Chang, C.-L.; Luo, G.-J.; Yang, F.-C.; Tang, J.-F. Effects of duty cycle on microstructure of TiN coatings prepared using CAE/HiPIMS. Vacuum 2021, 192, 110449. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, S.; Lin, J.; Cao, F.; Liu, Y.; Xue, R.; Wang, T. Microstructure, mechanical and tribological properties of gradient CrAlSiN coatings deposited by magnetron sputtering and arc ion plating technology. Thin Solid Film. 2022, 760, 139490. [Google Scholar] [CrossRef]

- Kameneva, A.; Kichigin, V.; Bublik, N. Structure and electrochemical behavior of AlN, AlTiN, and AlTiSiN physical vapor deposition coatings in 3% NaCl solution. J. Mater. Eng. Perform. 2022, 31, 10402–10411. [Google Scholar] [CrossRef]

- Chung, H.; Kim, D.W.; Cho, W.J.; Han, H.N.; Ikeda, Y.; Ishibashi, S.; Körmann, F.; Sohn, S.S. Effect of solid-solution strengthening on deformation mechanisms and strain hardening in medium-entropy V1-xCrxCoNi alloys. J. Mater. Sci. Technol. 2022, 108, 270–280. [Google Scholar] [CrossRef]

- Huang, J.; Xue, J.; Li, M.; Cheng, Y.; Lai, Z.; Hu, J.; Zhou, F.; Qu, N.; Liu, Y.; Zhu, J. Exploration of solid solutions and the strengthening of aluminum substrates by alloying atoms: Machine learning accelerated density functional theory calculations. Materials 2023, 16, 6757. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, P.; Yu, J.; Ying, P.; Yang, T.; Wu, J.; Wang, T.; Myshkin, N.; Levchenko, V. Tribological properties of MoN/TiN multilayer coatings prepared via high-power impulse magnetron sputtering. Lubricants 2025, 13, 319. [Google Scholar] [CrossRef]

- Yu, Z.-H.; Cao, S.; Yang, R.; Hu, Q.-M. Enhanced solid solution hardening by off-center substitutional solute atoms in α-Ti. Mater. Des. 2025, 251, 113709. [Google Scholar] [CrossRef]

- Zhou, X.; Fang, H.; Li, R.; Yuan, T.; Yan, Q. Joint effect of Mo and Cr on microstructure and properties of Ti–Al–Mo–Cr–B alloys. Mater. Chem. Phys. 2024, 313, 128715. [Google Scholar] [CrossRef]

- Zhang, M.; Zhou, F.; Wang, Q.; Fu, Y.; Zhou, Z. Tribocorrosion characteristics of CrMoSiCN/Ag coatings on Ti6Al4V alloys in seawater. Ceram. Int. 2021, 47, 31780–31797. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, F.; Zhang, M.; Wang, Q.; Zhou, Z. Structure and tribocorrosion behavior of CrMoSiCN nanocomposite coating with low C content in artificial seawater. Friction 2021, 9, 1599–1615. [Google Scholar] [CrossRef]

- Ji Hwan, Y.; Kwon, S.H.; Choi, J.; Wang, Q.M.; Kim, K. Synthesis and mechanical properties of Cr-Mo-Si-C-N coatings by a hybrid coating system. J. Ceram. Process. Res. 2009, 10, S112–S115. [Google Scholar]

- Wolfe, D.E.; Ryan, C.J.; DeSalle, C.M.; Stepanoff, S.P.; Aronson, B.I.; Boring, Z.M.; Reiss, J.A.; Albert, P.E.; Nicastro, J.K.; Fjeldsted, A.P. A comprehensive review of modern engineered ceramics coatings for optimised resistance to wear and corrosion. Adv. Appl. Ceram. 2023, 122, 81–100. [Google Scholar] [CrossRef]

- Hassan, A.; Wołoszyk, K.; Krata, P. FRP-based reinforcement coatings of steel with application prospects in ships and offshore structures: A review. Ships Offshore Struct. 2024, 20, 740–754. [Google Scholar] [CrossRef]

- Horikawa, N.; Guennec, B.; Kashi, T.; Miyajima, T.; Kinoshita, T.; Okamura, S.; Sakaida, A.; Kawano, Y.; Iwai, Y. Industrial arc ion plating and unbalanced magnetron sputtering coating deposition: Static and fatigue performances of TiAlN-Coated SKH51 tool steel. J. Mater. Eng. Perform. 2022, 31, 8808–8822. [Google Scholar] [CrossRef]

- Li, M.; Yu, Y.; Zou, C.; Tian, C.; Xiang, Y. Tribological and Corrosion Performance of CrAlN/CrN Coatings in Artificial Seawater under Varied Nitrogen Pressures. Coatings 2023, 13, 2090. [Google Scholar] [CrossRef]

- Roy, A.; Wang, S.; Komvopoulos, K. A review of plasma-assisted deposition methods for amorphous carbon thin and ultrathin films with a focus on the cathodic vacuum arc technique. J. Mater. Res. 2023, 38, 586–616. [Google Scholar] [CrossRef]

- Kosari Mehr, A.; Kosari Mehr, A. Magnetron sputtering issues concerning growth of magnetic films: A technical approach to background, solutions, and outlook. Appl. Phys. A 2023, 129, 662. [Google Scholar] [CrossRef]

- Borowski, P.; Myśliwiec, J. Recent advances in magnetron sputtering: From fundamentals to industrial applications. Coatings 2025, 15, 922. [Google Scholar] [CrossRef]

- Tien, C.; Chiang, C.; Lin, S. Optimization of electron-beam evaporation process parameters for ZrN thin films by plasma treatment and taguchi method. Plasma 2023, 6, 478–491. [Google Scholar] [CrossRef]

- Wang, J.; Cai, F.; Fang, L.; Zheng, J.; Zhang, S. Investigations on microstructure and mechanical properties of AlCrB(O)N coatings deposited under various nitrogen partial pressures. Vacuum 2022, 196, 110726. [Google Scholar] [CrossRef]

- Xue, L.; Hu, X.; Xi, Y.; Qiu, L.; Pan, X.; Zhang, Y. Effect of N2 partial pressure on ZrN coating orientation and tribocorrosion behavior and mechanism. Ceram. Int. 2024, 50, 24847–24863. [Google Scholar] [CrossRef]

- Aissani, L.; Fellah, M.; Chadli, A.H.; Samad, M.A.; Cheriet, A.; Salhi, F.; Nouveau, C.; Weiß, S.; Obrosov, A.; Alhussein, A. Investigating the effect of nitrogen on the structural and tribo-mechanical behavior of vanadium nitride thin films deposited using R.F. magnetron sputtering. J. Mater. Sci. 2021, 56, 17319–17336. [Google Scholar] [CrossRef]

- Ju, Y.; Ai, L.; Qi, X.; Li, J.; Song, W. Review on hydrophobic thin films prepared using magnetron sputtering deposition. Materials 2023, 16, 3764. [Google Scholar] [CrossRef]

- Muhammed, M.; Javidani, M.; Ebrahimi Sadrabadi, T.; Heidari, M.; Levasseur, T.; Jahazi, M. A comprehensive review of cathodic arc evaporation physical vapour deposition (CAE-PVD) coatings for enhanced tribological performance. Coatings 2024, 14, 246. [Google Scholar] [CrossRef]

- Ji, L.; Liu, H.; Huang, C.; Liu, X.; Chu, D.; Liu, Y.; Yao, P. Effect of arc deposition process on mechanical properties and microstructure of TiAlSiN gradient coatings. Ceram. Int. 2024, 50, 40014–40029. [Google Scholar] [CrossRef]

- Poplavsky, A.; Kudriavtsev, Y.; Kolpakov, A.; Pilyuk, E.; Manokhin, S.; Goncharov, I. The effect of vacuum annealing on the structure and properties of the electrically conductive a-CN coating. Vacuum 2021, 184, 109919. [Google Scholar] [CrossRef]

- Devarajan, D.K.; Rangasamy, B.; Amirtharaj Mosas, K.K. State-of-the-Art developments in advanced hard ceramic coatings using PVD techniques for high-temperature tribological applications. Ceramics 2023, 6, 301–329. [Google Scholar] [CrossRef]

- Dorri, S.; Nyqvist, O.; Palisaitis, J.; Vorobiev, A.; Devishvili, A.; Sandström, P.; Persson, P.O.Å.; Ghafoor, N.; Eriksson, F.; Birch, J. Artificial superlattices with abrupt interfaces by monolayer-controlled growth kinetics during magnetron sputter epitaxy, case of hexagonal CrB2/TiB2 heterostructures. Mater. Des. 2025, 251, 113661. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.D.; Pelenovich, V.; Wan, Q.; Guo, J.L.; Chen, Y.M.; Zhang, J.; Xue, L.J.; Li, Z.G.; Yang, B. Influences of modulation period on structure and properties of AlTiSiN/AlCrSiN nanocomposite multilayer coatings. Vacuum 2021, 193, 110516. [Google Scholar] [CrossRef]

- Zhou, S.Y.; Yan, S.J.; Han, B.; Yang, B.; Lin, B.Z.; Zhang, Z.D.; Ai, Z.W.; Pelenovich, V.O.; Fu, D.J. Influence of modulation period and modulation ratio on structure and mechanical properties of TiBN/CrN coatings deposited by multi-arc ion plating. Appl. Surf. Sci. 2015, 351, 1116–1121. [Google Scholar] [CrossRef]

- Mahajan, U.; Dhonde, M.; Sahu, K.; Ghosh, P.; Shirage, P. Titanium nitride (TiN) as a promising alternative to plasmonic metals: A comprehensive review of synthesis and applications. Mater. Adv. 2024, 5, 846–895. [Google Scholar] [CrossRef]

- Peng, Y.; Peng, J.; Wang, Z.; Xiao, Y.; Qiu, X. Diamond-like carbon coatings in the biomedical field: Properties, applications and future development. Coatings 2022, 12, 1088. [Google Scholar] [CrossRef]

- Zhang, Q.; Wu, Z.; Xu, Y.X.; Wang, Q.; Chen, L.; Kim, K.H. Improving the mechanical and anti-wear properties of AlTiN coatings by the hybrid arc and sputtering deposition. Surf. Coat. Technol. 2019, 378, 125022. [Google Scholar] [CrossRef]

- Fan, Q.; Guo, M.; Wu, Z.; Hao, X.; Cao, F.; Liu, Y.; Wang, T. Effects of bias voltage on the microstructure and properties of AlCrN/AlTiN nanoscale multilayer coatings. Vacuum 2023, 215, 112327. [Google Scholar] [CrossRef]

- Varghese, V.; Akhil, K.; Ramesh, M.R.; Chakradhar, D. Investigation on the performance of AlCrN and AlTiN coated cemented carbide inserts during end milling of maraging steel under dry, wet and cryogenic environments. J. Manuf. Process. 2019, 43, 136–144. [Google Scholar] [CrossRef]

- Orjuela, F.A.; Vallejo, F.F.; Hahn, H.; Olaya, J.J.; Alfonso, J.E.; Velasco, L. Nitrogen flux effect on the mechanical properties of AlCrTiN Nanostructured coatings obtained by R.F. magnetron sputtering. Ceram. Int. 2023, 49, 17867–17875. [Google Scholar] [CrossRef]

- Biksa, A.; Yamamoto, K.; Dosbaeva, G.; Veldhuis, S.C.; Fox-Rabinovich, G.S.; Elfizy, A.; Wagg, T.; Shuster, L.S. Wear behavior of adaptive nano-multilayered AlTiN/MexN PVD coatings during machining of aerospace alloys. Tribol. Int. 2010, 43, 1491–1499. [Google Scholar] [CrossRef]

- Lin, L.; Zhang, S.; Wu, Z.; Lin, Y.; Zheng, A.; Liu, C.; Tu, R.; Wang, Q. Fabrication of self-lubricative AlTiN/WNx films for Ti-6Al-4V machining by HiPIMS. Vacuum 2025, 238, 114337. [Google Scholar] [CrossRef]

- Geng, D.; Li, H.; Chen, Z.; Xu, Y.X.; Wang, Q. Microstructure, oxidation behavior and tribological properties of AlCrN/Cu coatings deposited by a hybrid PVD technique. J. Mater. Sci. Technol. 2022, 100, 150–160. [Google Scholar] [CrossRef]

- Mei, H.; Wang, R.; Geng, D.; Yan, K.; Shen, Y.; Zhu, Q.; Ding, J.C.; Zou, C.; Gong, W.; Wang, Q. Microstructure and mechanical properties of AlTiN/MoVCuN nano-multilayered coatings deposited by BPMS. J. Mater. Res. Technol. 2025, 35, 2547–2557. [Google Scholar] [CrossRef]

- Ma, J.; Xing, L.; Tan, J.; Wang, H.; He, X.; Yin, X. Temperature-dependent degradation of Al2O3—CrAl-O—Cr-O—Al-O multilayer coatings on ferritic-martensitic steels in oxygen-saturated lead–bismuth eutectic. Mater. Des. 2025, 254, 114101. [Google Scholar] [CrossRef]

- Geng, D.; Xu, Y.X.; Wang, Q. Hybrid deposition of Cr–O/Al–O hard coatings combining cathodic arc evaporation and high power impulse magnetron sputtering. Surf. Coat. Technol. 2023, 456, 129235. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).