Abstract

In this study, we investigated the tribological properties of various additives (lubricity, friction modifiers, anti-wear and extreme pressure) in a highly volatile paraffinic base oil formulated for stamping applications, using a newly developed methodology for tribological testing. The investigation focused on the short-term (10 cycles) and long-term (10,000 cycles) effects of the different additive mixtures on friction and wear behaviour. It was found that the performance of the additive mixtures evolves with sliding time, which is due to changes in contact conditions: the transfer of the Fe film from the steel sheet to the WC-Co surface increases the contact area, which in turn leads to a significant reduction in contact pressure and changes the activation of tribofilm formation. The presence of tribofilms influences the amount and size of the contact area and reduces the adhesion between the contact surfaces. Among the conventional additives, sulphurised additive mixtures show stable performance under both short and long-term conditions, while more aggressive chlorinated additive mixtures perform well in the short term, but their performance decreases with prolonged sliding. Importantly, the additives with a decreasing environmental impact outperformed the conventional additives under long-term conditions: the less harmful phosphorus-based mixture outperformed the sulphurised mixtures in terms of wear properties, while the performance of environmentally acceptable polyol ester was particularly encouraging, exhibiting the lowest friction coefficient (~0.11, compared with ~0.12 for S-oil and 0.14 for S-ester) and the second lowest wear coefficient (~1.1 × 10−1 mm3/Nm compared with ~1.5 × 10−1 mm3/Nm for S-ester). Overall, the polyol ester reduced the coefficient of friction by approximately 8 to 21% compared to sulphurised additive mixtures, and its wear coefficient was also about 27% lower.

Keywords:

stamping; steel sheet; additives; friction; wear; Fe-transfer film; P-based additives; S-based additives 1. Introduction

Stamping is one of the most basic and widely used manufacturing processes for the mass production of components in various industries. It involves a series of metal-forming operations, each of which contributes to the complexity of a single stamping cycle, often involving multiple contact points—including the punch, die, blank holder, and other elements [1,2,3]. These operations usually take place under very demanding conditions, such as high contact pressures and sliding speeds, localised temperature peaks, and high shear rates. As a result, there is often high friction at the tool–sheet interface and severe tool wear, which ultimately reduces the service life of dies and tooling [4,5]. The use of appropriate lubrication technology has been shown to effectively mitigate these issues and extend tool life [6,7,8].

In recent years, increasingly stringent national and international regulations for the use of high-performance lubricants in metal forming (Metalworking fluids—MWFs) have increased the demand for continuous tribological evaluation of new, more sustainable, and environmentally acceptable lubricants, including base fluids and additives. This task is particularly complex, as it requires not only the integration of environmentally acceptable lubricants and novel materials, but also a deep understanding of their interactions with the contact surfaces under a range of operating conditions, including varying pressures and temperatures, as different additives are activated under different tribochemical conditions [9,10,11,12]. In addition, the development of reliable laboratory test methods tailored to these evolving systems is required.

Despite the growing interest in sustainable lubrication, many of the most effective conventional MWFs still rely on additives containing sulphur, phosphorus, and chlorine—components known for their environmental impact [13]. Chlorinated paraffin oils, for instance, are still used to prevent galling [14], especially in certain regions where the medium- (C14–C17) and long-chain (>C18) variants have not yet been discontinued [15]. Although numerous studies have investigated environmentally acceptable MWF formulations, most have focused on specific metal-forming processes [13,14,16,17,18,19,20,21,22] and have often overlooked the unique tribological requirements of stamping processes, which require highly customised lubricant solutions due to the individual nature of these operations [23].

Existing tribological studies on stamping lubricants have primarily focused on fully formulated lubricants [24,25,26], while investigations on base components, such as pure base fluid [27] or fluids with a single additive, are relatively scarce. Moreover, most of these studies examine only one formulation at a time—either the specific additive mixture or a single fully formulated fluid—leaving a gap in comprehensive analyses that compare different additive types (e.g., lubricity, extreme pressure and anti-wear additives, and friction modifiers) and their distinct (specific) functions and effects. Experimental evaluations are typically conducted using either standard lab-scale devices, such as the four-ball tester [28] or the pin-on-disc tribometer [5,13,29,30,31,32], or with customised and bench-type setups intended to better replicate real-scale applications [4,5,13,18,22,25,33,34,35,36,37,38]. However, none of these approaches (methods) are specifically adapted to the conditions encountered in punching stamping. Conventional lab-scale tribology tests often fail to simulate the high contact pressures (pin-on-disc), rapid single-pass deformation, and the reciprocating motion of the tools that are typical of stamping operations [39]. These tests are based on repeated sliding over the same surface and unidirectional movement, which lead to different surface conditions and wear mechanisms than those seen in punching stamping [40]. On the other hand, customised and bench-type tests (e.g., strip-draw or cup-draw) provide a better simulation of forming processes, but they are mainly designed for drawing and do not fully capture the specific tribological demands of punching and blanking. Moreover, they are costly, have limited throughput, and often do not provide control over critical parameters such as temperature and localised tool–workpiece interactions.

To address these limitations, in our recent work we developed a reliable lab-scale methodology based on a 10,000 cycle reciprocating sliding test on a model tribological device [41]. This method enabled clear differentiation in friction and wear performance between base fluids, fully formulated MWFs, and mixtures with individual additives under conditions that were representative of stamping. The differences in friction became apparent after just 10 cycles and continued to increase with further testing, while differences in wear became significant only after 10,000 cycles. In that study, these results were used exclusively for the development and validation of the testing methodology.

In this study, we apply this methodology to investigate the tribological performance of different additives in MWFs over both short-term (10 cycles) and long-term (10,000 cycles) operation. The aim is to elucidate the mechanisms responsible for these differences and to determine whether environmentally acceptable additives can match or surpass the performance of conventional sulphurised and chlorinated additives under the conditions of punching-stamping operations. To achieve this goal, we used a reciprocating sliding tribometer, scanning white light interferometry, scanning electron microscopy, and energy dispersive X-ray spectroscopy.

2. Materials and Methods

2.1. Specimens and Lubricants

To study the effect of different additives on lubrication performance in the punching-stamping production process, the electrical steel and WC-Co were selected as contact materials used in real punching-stamping operations. The electrical steel was commercially available (Isovac 800–65 K, Voestalpine, Linz, Austria) in the shape of sheets with a thickness of 0.65 mm and Sa roughness of 1.5 μm. In addition to Fe as a balance, the metal sheet also contains 0.037% of C, 0.179% of Si, 0.306% of Mn, 0.035% of P, 0.006% of S and 0.064% of Al. The countersurface (acting as a punching tool) was WC-Co ball (ISO K40, Meusburger, Wolfurt, Austria), with a diameter of 10 mm and Sa roughness of 10 nm, and consists of 86.6% WC and 11.8% Co.

The base lubricant was a highly volatile paraffinic oil (Isopar-M, Exxon Mobil, Houston, TX, USA) with a kinematic viscosity of 1.14 mm2/s at 25 °C, which was used as a reference lubricant (further denoted in text and figures as ‘Base’). Such base oils are commonly employed in steel-sheet stamping because they evaporate readily after stamping, leaving the surfaces free of residues and eliminating the need for additional cleaning. To this base lubricant, different types of commercially available stamping additives were introduced at 2 wt.% and stirred for at least two hours to achieve homogeneity of oil-additive mixtures. In this way, 8 different oil-additive mixtures were prepared. The additives used are reported in Table 1, along with the labels used later in the text and figures. Additives were selected in a wide range, in terms of their type (see Table 1), as well as in terms of their environmental impact (from environmentally acceptable additives like esters to conventional ones based on sulphur and chlorine). The viscosity of the oil-additive mixtures is slightly higher compared to the reference base lubricant (Base): namely, from 1.44 to 1.66 mm2/s at 25 °C.

Table 1.

Additives used in this study.

2.2. Tribological Tests

Tribological tests were performed on a reciprocating sliding tribometer (Bruker, Billerica, MA, USA), using electrical steel sheet—WC-Co ball contact configuration. Testing conditions were selected to simulate contact conditions similar to those in real punching-stamping operations: normal load of 185 N (resulting in the initial Hertzian contact pressure of 3.3 GPa and thus, plastic deformation of the steel sheet), sliding speed of 0.05 m/s, stroke length of one cycle of 10 mm and temperature of 25 ± 2 °C. Two different lengths of tribological tests were employed, namely with 10 cycles and with 10,000 cycles [42]. In this way, we simulated the initial (10 cycles), and long-term (10,000 cycles) effects of the additives studied. During testing, the studied lubricants (base oil and oil-additive mixtures) were supplied into the contact in small, manually pulsed doses (20 μL), ensuring consistent lubrication with a limited quantity of lubricant, which is characteristic of metal-sheet stamping. At least three repetitions were performed for each combination of the lubricant type and number of cycles. During the tribological tests, the coefficient of friction was measured continuously, and the steady-state value and standard deviation of the coefficient of friction are reported in the Section 3.

2.3. Surface Analyses

After the tribological tests (10 cycles and 10,000 cycles), both contact surfaces (electrical steel sheet and WC-Co ball) were analysed to evaluate the effect of the additives studied on the wear properties, by employing two different surface analysis techniques. The scanning white light interferometry (SWLI, Bruker—ContourGT-K0, Bruker, Billerica, MA, USA) was used to determine the wear volume of the steel sheets and, subsequently, to calculate the wear coefficient. The wear coefficient,

, was calculated according to Archard’s equation:

, where

is the wear volume,

is the applied load, and

is the total sliding distance. The wear volume was determined by multiplying the average cross-sectional area of the wear track by its length. For each wear track, the cross-sectional area was measured using scanning white light interferometry (SWLI) in three different positions, and the average value was used to calculate the wear volume. For each additive mixture, three independent wear tracks were analysed. On the other hand, there was no wear observed on the WC-Co balls, but only the Fe transferred films from the steel sheet and tribofilms within the contact area. For this reason, the surfaces of WC-Co balls were analysed with a scanning electron microscope (SEM) (JEOL JSM IT100, JEOL, Tokio, Japan), utilising both SED and EDS detectors. For each additive mixture, EDS analyses were conducted on at least three distinct regions within the contact area. In this paper, we report the results from the region considered the most representative.

3. Results

3.1. Friction

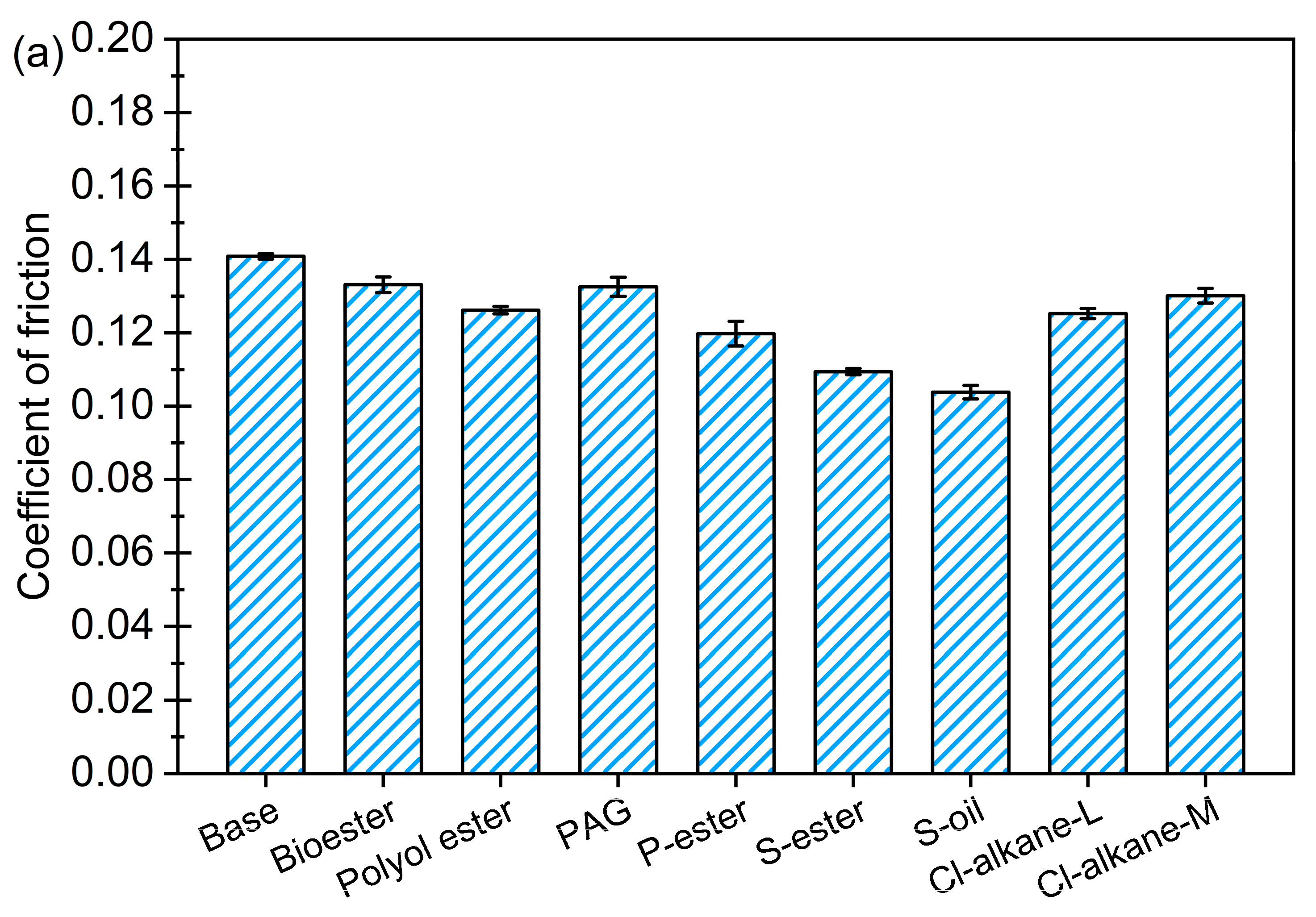

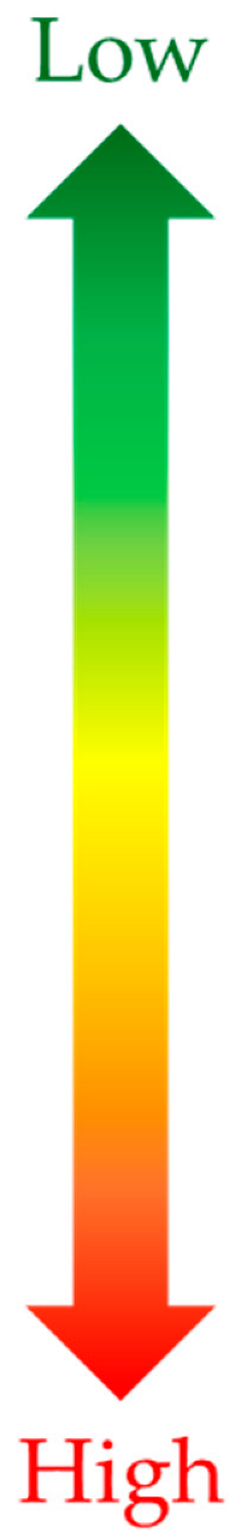

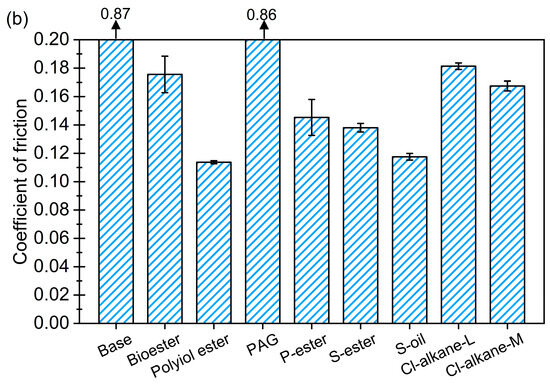

Figure 1 presents the steady-state coefficients of friction after 10 cycles (Figure 1a) and 10,000 cycles (Figure 1b). After 10 cycles (Figure 1a), noticeable differences already emerge between additive mixtures. In addition, all additives reduce the coefficient of friction compared to the pure base lubricant. The lowest values are observed for mixtures with S-oil (~0.10) and S-ester (~0.11), followed by the mixture with P-ester (~0.12). Mixtures with completely organic additives—polyol ester, PAG, and bioester—have similar coefficients of friction as the mixtures with chlorinated additives (Cl-alkane-L and Cl-alkane-M): namely, around 0.13.

Figure 1.

Steady-state coefficient of friction after (a) 10 and (b) 10,000 cycles.

After 10,000 cycles (Figure 1b), the differences in friction become more pronounced and the performance ranking changes notably. The mixture with polyol ester, an environmentally acceptable additive, exhibits the lowest coefficient of friction (~0.11), followed by the mixtures with sulphurised additives: S-oil (~0.12) and S-ester (~0.14). A mixture with P-ester shows a moderate increase to ~0.15. In contrast, both mixtures with chlorinated additives—traditionally considered highly effective under extreme stamping conditions—perform less favourably. Friction stabilises at ~0.17 for Cl-alkane-M and ~0.18 for Cl-alkane-L—values like those of the bioester mixture (~0.18). The worst performance was observed for the mixture with the PAG additive, which fails under these severe conditions, and reaches ~0.86 after 10,000 cycles—comparable to the pure base lubricant.

3.2. Wear

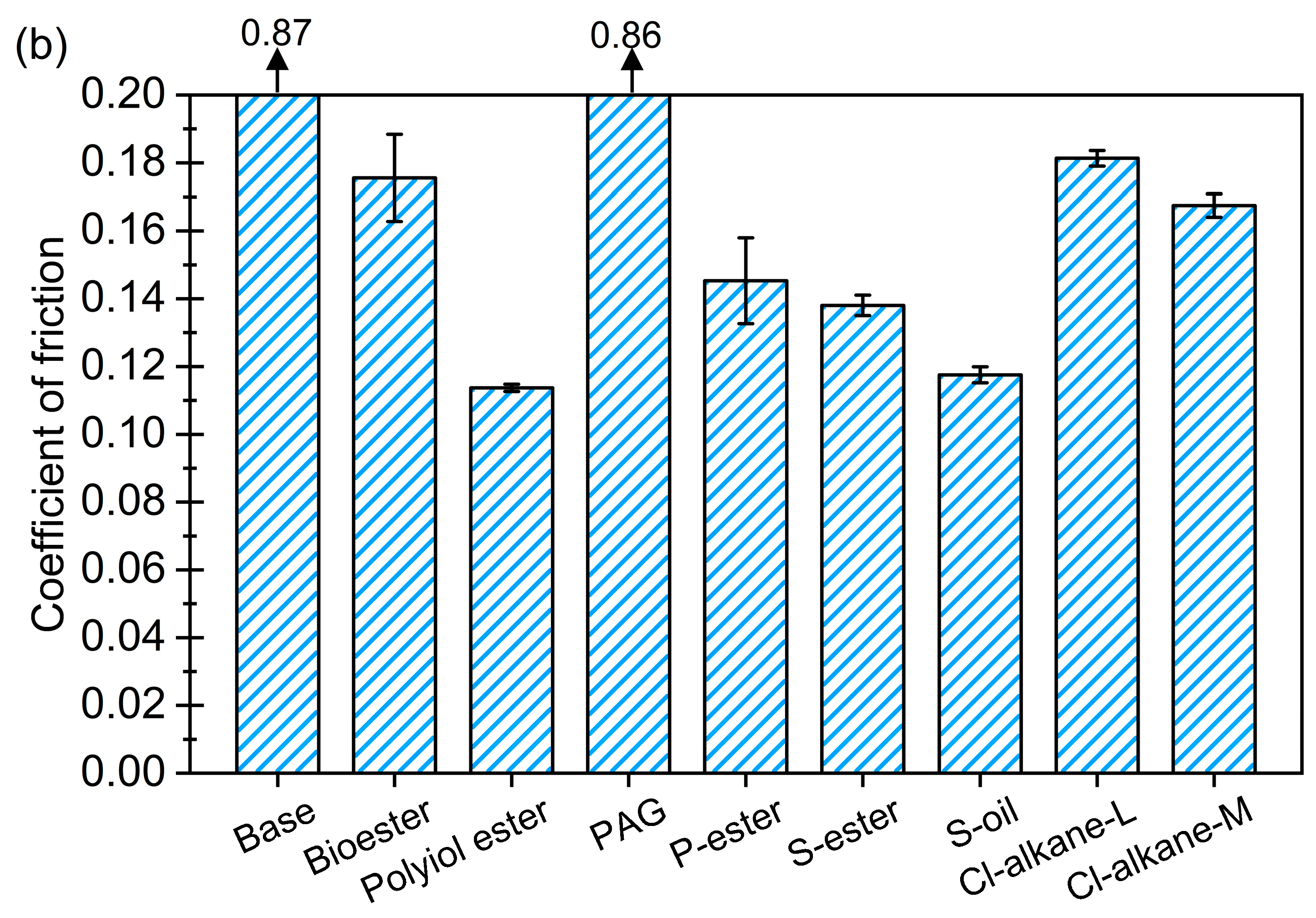

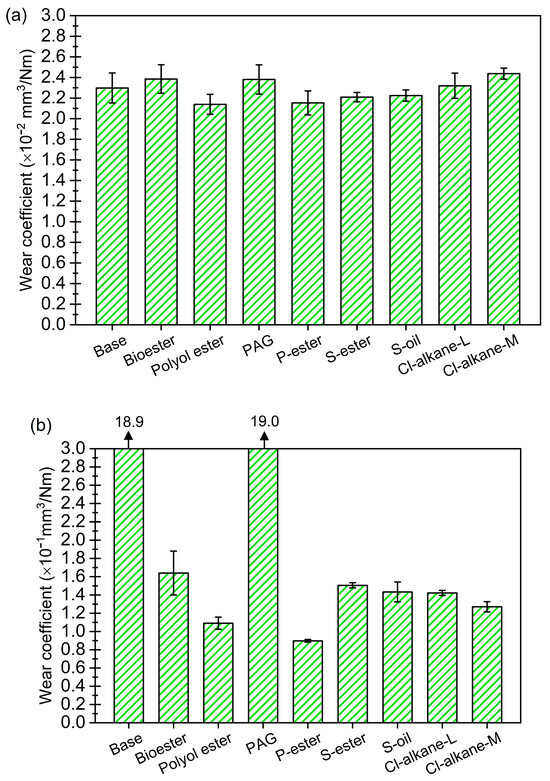

After 10 cycles (Figure 2a), there are no clear differences in the wear coefficient between the additive mixtures or the base lubricant. The differences become clear after 10,000 cycles (Figure 2b), where the lowest wear coefficient was observed for the mixture with P-ester (~0.9 × 10−1 mm3/Nm), followed by the mixture with polyol ester (~1.1 × 10−1 mm3/Nm). Mixtures with sulphurised and chlorinated additives exhibit similar anti-wear properties, with the wear coefficient ranging from ~1.3 × 10−1 mm3/Nm for Cl-alkane-M to ~1.5 × 10−1 mm3/Nm for S-ester. Lubricity additives (bioester and PAG) show the poorest anti-wear performance, with a particularly high wear coefficient observed for PAG (~19.0 × 10−1 mm3/Nm).

Figure 2.

Wear coefficient of the steel sheet after (a) 10 and (b) 10,000 cycles.

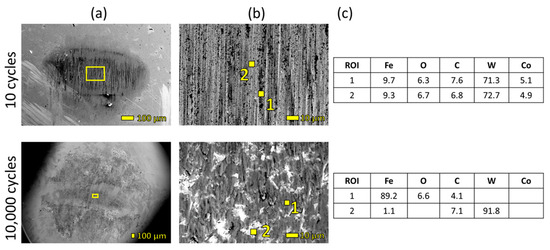

3.3. Surface Analysis

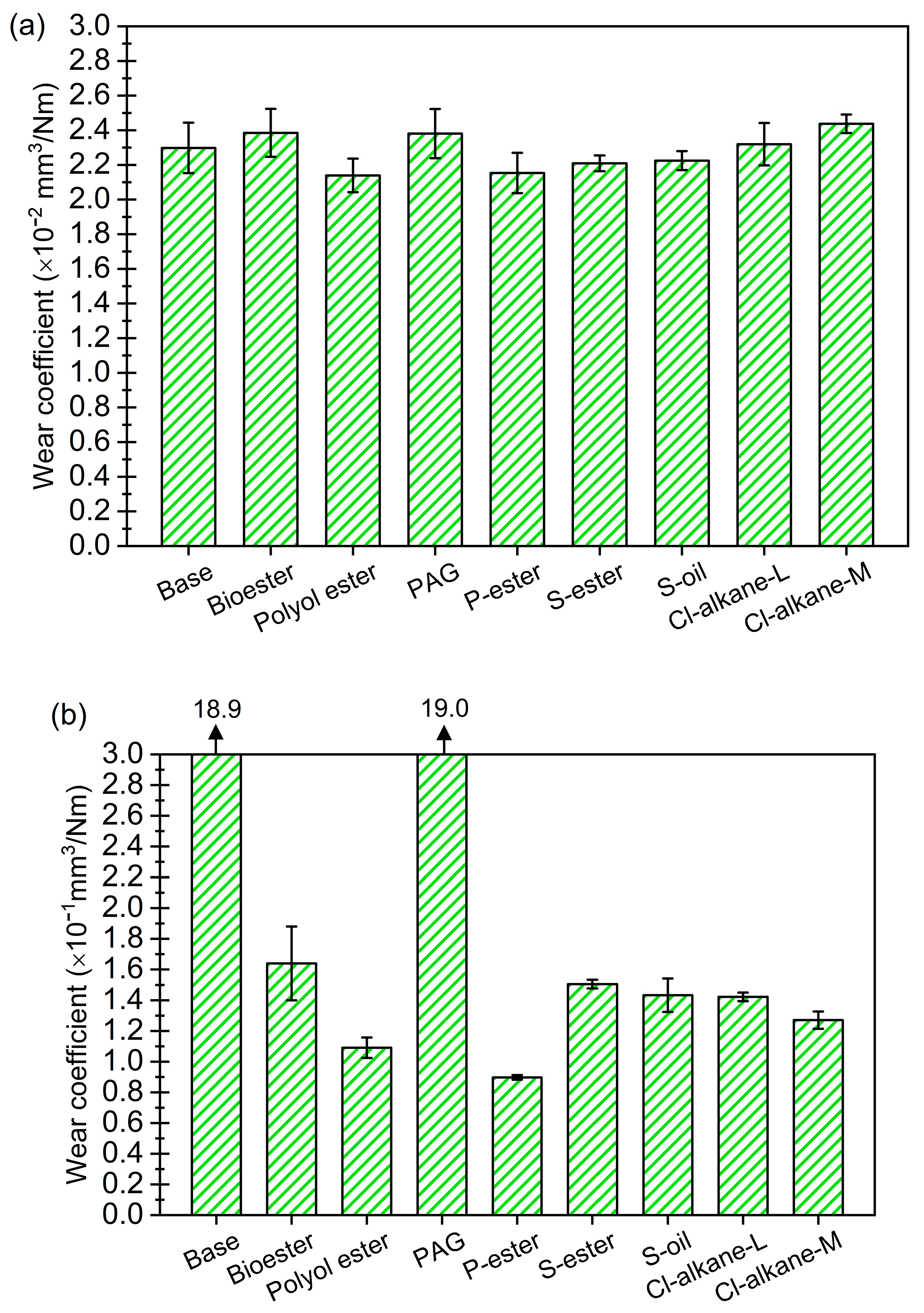

Figure 3 shows SEM images of the contact area on a WC-Co ball after the 10 and 10,000 cycle tests with the base lubricant. Panel (a) provides a low-magnification view of the overall contact area, while panel (b) offers a high-magnification view highlighting representative surface morphology, and panel (c) presents the corresponding EDS analysis of the selected regions in (b). Notably, an Fe transfer film was observed after only 10 cycles. This film appears smooth and aligned with the sliding direction. After 10,000 cycles, both the contact area and the Fe transfer film increase significantly. The film’s morphology also changes—it becomes multilayered and significantly rougher than the smoother film seen after only 10 cycles.

Figure 3.

SEM images of the contact area on the WC-Co ball after 10 and 10,000 cycle tests in the presence of base lubricant at (a) lower and (b) higher magnification, and (c) the corresponding EDS analyses on the marked areas in (b).

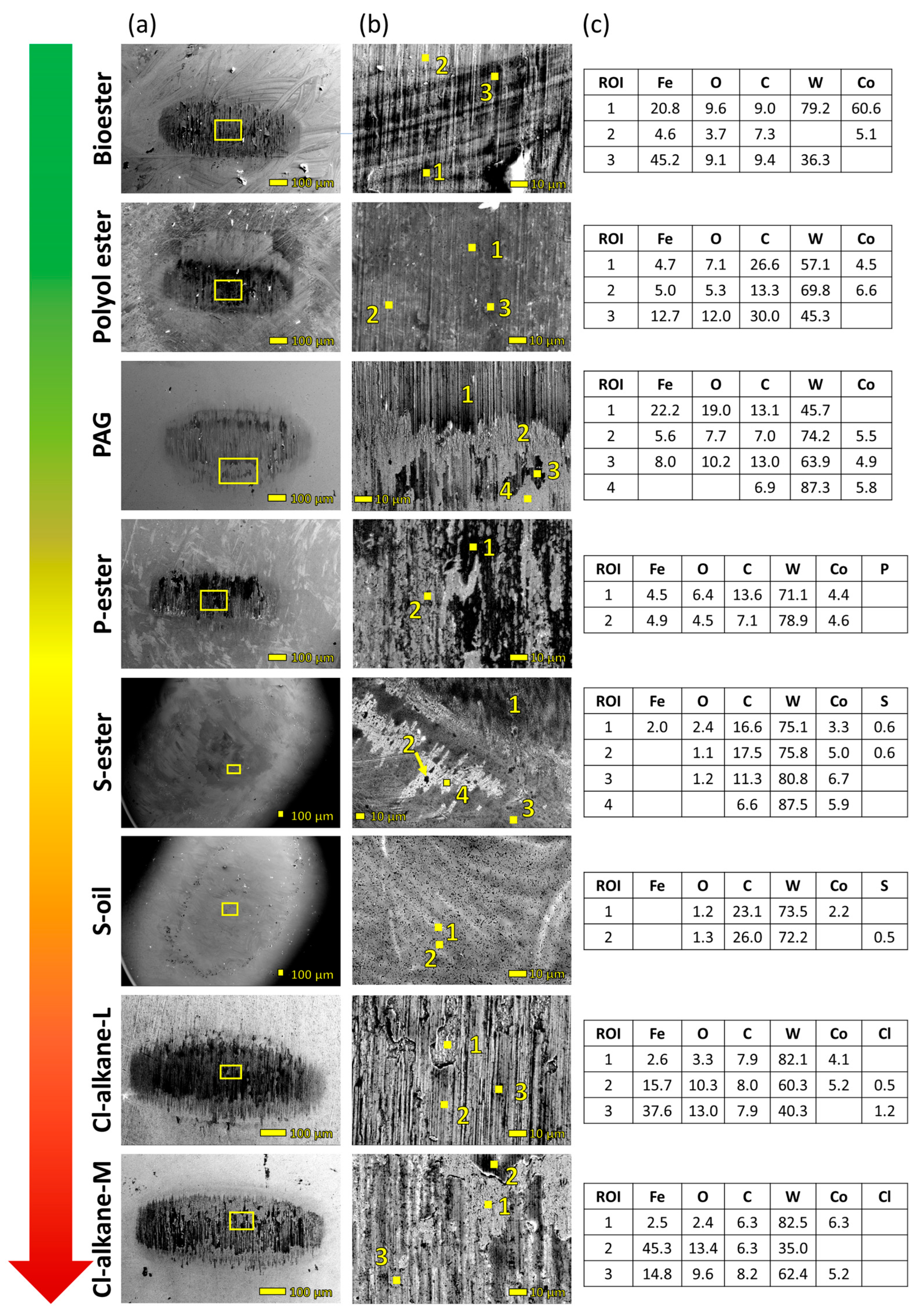

Figure 4 shows SEM images of the contact area on a WC-Co ball after a 10 cycle test in the presence of different additives mixtures. Panel (a) shows a low magnification view of the entire contact surface, while panel (b) provides a high magnification view highlighting the representative surface morphology, and panel (c) shows the corresponding EDS analysis of the selected regions in (b). Only a mixture with the S-oil additive was able to prevent the transfer of the Fe film to the WC-Co ball. Similar protection of the contact surfaces was also achieved with the mixture with the S-ester additive, as only a small portion of the contact area was covered with a small amount of the Fe transfer film (~2 wt%). In contrast, for all other additive mixtures, a much larger part of the contact area was covered with the Fe transfer film, which has a similar morphology to that after the 10 cycle test in the presence of the base lubricant, i.e., a uniform coverage with orientation in the sliding direction. It is noteworthy that small amounts of sulphur (S) were found in both mixtures with sulphurised additives (S-oil and S-ester), indicating the formation of a protective tribofilm. In contrast, no or only very small amounts of phosphorus (P) and chlorine (Cl) were found in the case of mixtures with P-ester and chlorinated additives. These observations are consistent with the best available protection against the transfer of the Fe film in the case of the two mixtures with sulphurised additives.

Figure 4.

SEM images of the contact area on the WC-Co ball after 10 cycle tests in the presence of different additive mixtures at (a) lower and (b) higher magnification, and (c) the corresponding EDS analyses on the marked areas in (b). The arrow indicates the order of the additives according to their environmental impact.

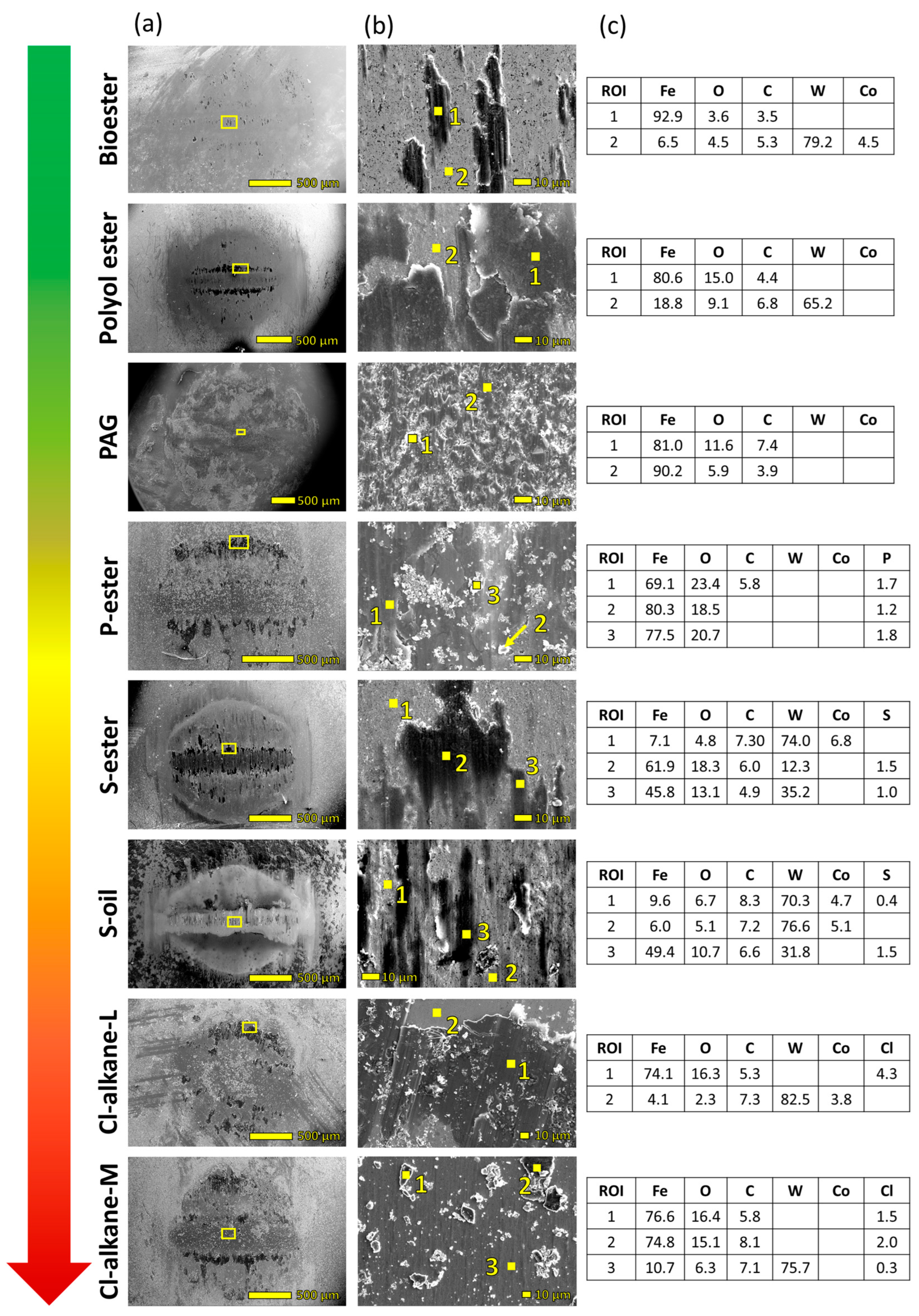

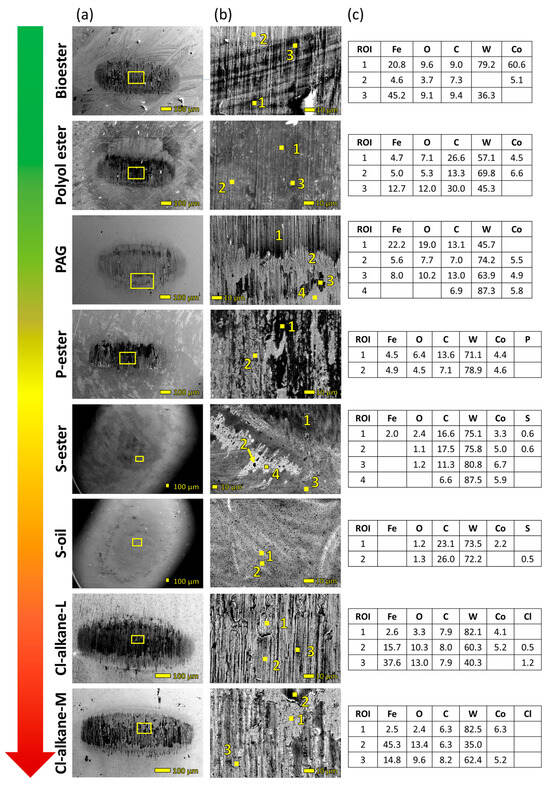

Figure 5 shows SEM images of the contact area on a WC-Co ball after a 10,000 cycle test in the presence of different additive mixtures. Panel (a) shows a low magnification view of the entire contact surface, while panel (b) shows a high magnification view, highlighting the representative surface morphology, and panel (c) shows the corresponding EDS analysis of the selected regions in (b). For all additive mixtures, the Fe transfer film was observed on the WC-Co ball, with the iron content generally decreasing as additive severity increases. The two environmentally acceptable mixtures, containing bioester and polyol ester additives, produce thick, Fe-rich stripes (80–93 wt%), although significant amounts of iron can also be detected outside of these regions (7–19 wt%). A mixture with the PAG additive has the largest contact area covered with a significant amount of Fe transfer film (81–90 wt%), reflecting both the morphology and the Fe content of the base lubricant (as seen in Figure 3). A mixture with the P-ester additive results in a uniform Fe transfer film over the entire contact area, with abundant wear debris. Phosphorus (P) was also detected over the entire contact area, indicating a well-distributed film formed by the additive. Mixtures with sulphurised additives (S-oil and S-ester) exhibit Fe film characteristics and a similar surface morphology to the most environmentally acceptable additives (bioester and polyol ester), but with lower iron concentrations (around 50–60 wt% on thick stripes/islands), and significantly less iron outside these regions (~6–10 wt%). The detection of sulphur (S) confirms the formation of an additive-derived tribofilm, although less uniformly than with P-ester. Mixtures with chlorinated additives behave differently: Cl-alkane-L forms Fe-rich islands (>70 wt% Fe) only at the edge of the contact area, whereby chlorine (Cl) was also detected on these islands. A minimal concentration of iron (<5 wt%) and no chlorine was observed outside those islands. In contrast, the mixture with the Cl-alkane-M additive shows a low overall amount of iron (~10 wt%), but a very high amount of iron (>70 wt%) on sharp wear particles within the contact area. Chlorine was detected on the entire contact area, indicating a more evenly distributed additive-derived tribofilm.

Figure 5.

SEM images of the contact area on the WC-Co ball after 10,000 cycle tests in the presence of different additive mixtures at (a) lower and (b) higher magnification, and (c) the corresponding EDS analyses on the marked areas in (b). The arrow indicates the order of the additives according to their environmental impact.

4. Discussion

In this work, we present a comprehensive study on the effects of different additive types in metalworking fluids (MWFs), including lubricity, extreme pressure, anti-wear, and friction modifier additives. The focus is on understanding their specific functions and how they influence tribological performance under varying conditions. The detailed effects of these additives are discussed in the following subsections.

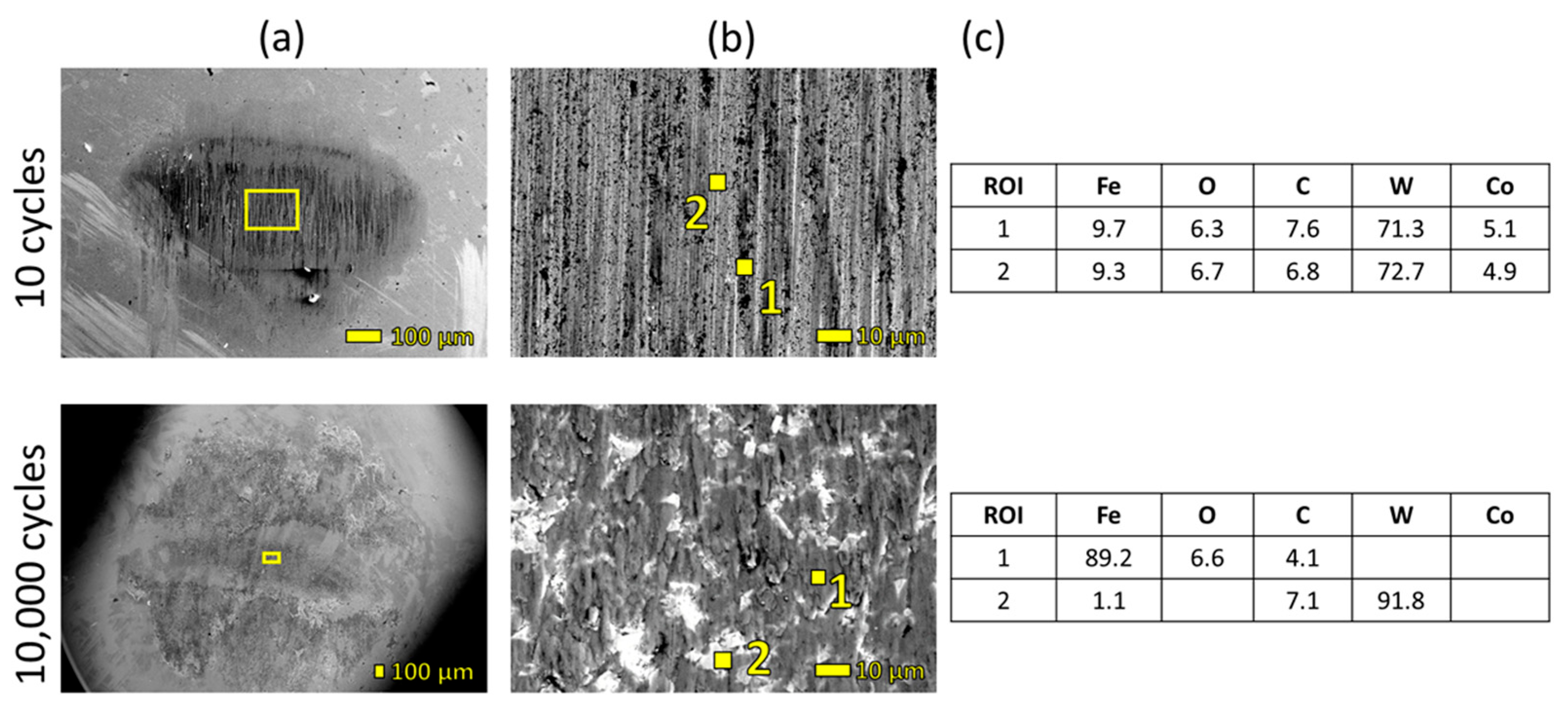

4.1. Short vs. Long Term Effect

The differences between the short-term (10 cycles) and long-term (10,000 cycles) behaviour of the additive mixtures on tribological properties (compare Figure 1a,b and Figure 2a,b) can be largely attributed to a significant increase in contact area (compare Figure 4a and Figure 5a), which in turn leads to a reduction in contact pressure. To explicitly show the differences in contact area between short-term and long-term tests, the contact area values were extracted from Figure 4a and Figure 5a and are jointly reported in Table 2. The increase in contact area arises from the high deformability of the steel sheet and the transfer of an Fe film from the steel sheet to the WC-Co ball. The presence of this Fe film ultimately determines the size of the contact area.

Table 2.

Contact areas with Fe transfer films on WC-Co ball after 10 and 10,000 cycles.

Different type of additive mixtures require different tribochemical conditions (contact pressure, temperature, and shear stresses) to activate and form protective surface tribofilms [9,10,11]. Friction modifiers typically activate under milder contact conditions (lower temperatures and contact pressures) than anti-wear additives, and significantly milder conditions than EP additives [9,10,11,43,44,45]. The formation of these tribofilms under varying tribochemical conditions was found to affect the rate and amount of the Fe transfer film to the WC-Co counter surface.

After 10 cycles, the Fe transfer film was either absent or negligible for mixtures with sulphurised additives (S-oil and S-ester, Figure 5), indicating no significant change in the initial contact area and contact pressure. Other additive mixtures exhibited more substantial Fe transfer, with resulting contact areas of about 2.0–2.7 × 10−7 m2, which are an order of magnitude larger than the initial Hertzian contact area (Table 2). This led to a substantial reduction in contact pressure. A slight deviation was observed for the PAG additive, which produced a larger contact area of around 3.5 × 10−7 m2 and thus, a greater reduction in contact pressure. These variations contributed to differences in the coefficient of friction, but not in the wear coefficient. After 10 cycles, the amount of the Fe transfer film is apparently not yet sufficient to significantly increase the adhesion with the steel sheet and so to enhance its wear. Namely, the differences in contact area between different additive mixtures remained under a factor of two (Table 2). The lowest coefficient of friction was observed for the mixtures with sulphurised additives, followed by the mixtures with P-ester, polyol ester, and chlorinated additives, and the others, in that order. The lowest coefficient of friction observed for both sulphurised additive mixtures aligns with the absence of an Fe transfer film. This absence is likely due to a protective tribofilm formed under high initial contact pressure (~3.3 GPa), as evidenced by the sulphur detected on the WC-Co surface (Figure 4). In contrast, although a chlorine-based tribofilm is present in the case of the Cl-alkane-L additive mixture (Figure 4), it fails to prevent Fe-film transfer onto the WC-Co surface. Moreover, EDS analysis suggests that the tribofilm forms on the pre-existing Fe film—only after the Fe film has transferred.

After the 10,000 cycle test, Fe transfer film was observed for all additive mixtures (Figure 5). At this stage, the contact areas were an order of magnitude larger than after the 10 cycle test, and two orders of magnitude larger than the initial Hertzian contact area (Table 2). The differences between additive mixtures became more pronounced, i.e., by more than a factor of four. This further reduced the contact pressure and changed the ranking of additive effectiveness in terms of friction and wear performance.

The polyol ester, classified as a friction modifier, generally operates most effectively under lower pressure conditions. Accordingly, after 10,000 cycles—when the pressure had significantly decreased—it exhibited a lower coefficient of friction than after 10 cycles: in fact, the lowest among all tested mixtures (Figure 1). This additive also provided strong surface protection, as evidenced by its relatively small contact area (Table 2), which corresponded to the second-lowest wear coefficient (Figure 2).

On the other hand, the Cl-alkane-M additive, which is considered the most aggressive additive and typically performs well under high-contact pressure conditions, no longer provides the same level of protection after long-term use, resulting in a significant increase in the coefficient of friction (from 0.130 to 0.167). A similar coefficient of friction value was also obtained in other studies using MWFs for cutting applications [12], as well as its increase with the number of cycles [36].

Finally, the friction and wear properties of the steel sheet/WC-Co tribological pair are governed primarily by adhesion rather than abrasion. This predominance results from the boundary lubrication regime and the material contrast between the very hard, smooth WC-Co and the rougher, softer steel sheet. Tribofilms formed by different additive mixtures have two critical roles: (i) the formation of tribofilm on the WC-Co surface to prevent or at least reduce the transfer of the Fe film, either by minimising its extent or by confining it to smaller areas, and (ii) the formation of the tribofilm on the transferred Fe film, which at least partially decreases the adhesion between the WC-Co and the steel sheet surfaces.

4.2. Conventional vs. Environmentally Acceptable Additive Mixtures

The long-term effects of additives on tribological properties are of crucial importance, because only after prolonged use can the actual performance of each additive be evaluated in terms of protecting the WC–Co surface against the Fe transfer film in WC–Co/steel sheet contacts. This has a direct impact on both the quality of the stamped products and the lifetime of the WC–Co stamping tools.

Our study showed that mixtures containing sulphur-based additives performed equally well in terms of wear (Figure 2b), and even better in terms of the coefficient of friction (Figure 1b) compared to mixtures with more aggressive chlorinated additives (Cl-alkane-M and Cl-alkane-L). In addition, the sulphurised mixtures also provided a better WC–Co surface morphology after the test (Figure 5). In particular, the Fe transfer film formed with the sulphurised additives was more rounded in shape and did not consist of sharp wear particles, as observed with the Cl-alkane-M additive. Such sharp particles could have a negative impact on product quality, further emphasising the advantage of sulphurised additive mixtures. Overall, these results confirm that sulphurised additives, which are already widely used as substitutes for chlorinated paraffins [9,46], represent an appropriate and effective choice for current industrial applications. Nevertheless, it should be noted that sulphurised additives occupy a middle position on the environmental impact scale of lubricant additives [9] (Table 1), which makes the search for more environmentally acceptable alternatives desirable.

In this regard, our results show that the mixture containing the P-ester additive, which is less harmful than sulphurised additives, exhibited significantly better wear properties and equally favourable friction properties compared to S-oil and S-ester mixtures (Figure 1b and Figure 2b). This result suggests that phosphorus-based additives are a promising replacement for sulphurised formulations. Particularly encouraging is our observation that an environmentally acceptable polyol ester additive mixture can compete directly with sulphurised mixtures. In the long-term tests, the polyol ester achieved the lowest coefficient of friction (Figure 1b) and the second lowest wear coefficient (Figure 2b). The morphology of the Fe transfer film in this case was also very similar to that produced by the sulphurised additives, underpinning its potential as a sustainable and effective lubricant additive.

5. Conclusions

- The changing contact conditions can either enhance or weaken (diminish) the effectiveness of additives, depending on their type, in forming protective tribofilms. Such tribofilms serve two primary roles: (i) reducing the transfer of the Fe film to WC–Co, either by limiting its extent or confining it to smaller regions, and (ii) decreasing adhesion between the WC–Co and the steel sheet surfaces.

- Sulphurised additives (S-oil and S-ester) perform well under both short- and long-term conditions, in contrast to the more aggressive chlorinated additives (Cl-alkane-M and Cl-alkane-L), whose performance deteriorates significantly as contact pressure decreases. Although chlorinated additives are typically used as high-pressure additives under extreme stamping conditions, they are among the less effective additives in this study. After 10,000 cycles, mixtures containing chlorinated additives exhibited a coefficient of friction of ~0.18, ~29 to 50% higher than that of sulphurised additive mixtures (~0.14 S-ester and ~0.12 S-oil). Their wear coefficient of ~1.3 × 10−1 mm3/Nm, however, was ~13% lower than that of sulphurised additive mixtures (~1.5 × 10−1 mm3/Nm).

- The P-ester additive outperformed both types of sulphurised additives in terms of long-term wear resistance, as the wear coefficient was ~0.9 × 10−1 mm3/Nm, which is approximately 40% lower than that of the sulphurised additive mixtures.

- Among the environmentally acceptable additives, polyol ester demonstrates the best overall tribological performance. After 10 cycles, its effectiveness is only slightly lower than that of the sulphur-based additives. However, after 10,000 cycles, the polyol ester mixture achieved the lowest coefficient of friction and the second lowest wear coefficient. The coefficient of friction of ~0.11 was ~8 to 21% lower than that of the sulphurised additives, while the wear coefficient of ~1.1 × 10−1 mm3/Nm was ~27% lower. These results highlight the strong potential of polyol ester formulations as safe and effective multifunctional alternatives to conventional additives.

Author Contributions

Conceptualization, M.K.; methodology, M.P., L.Č. and M.K.; validation, L.Č. and M.P.; formal analysis, M.P. and L.Č.; investigation, L.Č. and M.P.; resources, M.K.; data curation, L.Č. and M.P.; writing—original draft preparation, L.Č.; writing—review and editing, L.Č., M.P. and M.K.; visualization, L.Č. and M.P.; supervision, M.K.; project administration, M.K.; funding acquisition, M.K. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the company Hidria Lamtec d.o.o. and the Slovenian Research Agency as part of research project No. L2-9244 and research core funding No. P2-0231.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AW | Anti-Wear Additive |

| EP | Extreme Pressure Additive |

| FM | Friction Modifier Additive |

References

- Schmid, S.R.; Kalpakjian, S. Manufacturing Engineering and Technology; Pearson Prentice Hall: Upper Saddle River, NJ, USA, 2006. [Google Scholar]

- Stephenson, D.A.; Agapiou, J.S. Metal Cutting Theory and Practice; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Byers, J.P. Metalworking Fluids; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Kim, H.; Altan, T.; Yan, Q. Evaluation of Stamping Lubricants in Forming Advanced High Strength Steels (AHSS) Using Deep Drawing and Ironing Tests. J. Mater. Process. Technol. 2009, 209, 4122–4133. [Google Scholar] [CrossRef]

- Harwood, B.; Altan, T. Forming Trends in the Automotive Industry and Their Impact on Lubrication. Tribol. Lubr. Technol. 2015, 71, 46. [Google Scholar]

- Kraemer, A.; Stoll, J.; Blickle, D.; Lanza, G.; Boeker, B. Analysis of Wear Behavior of Stamping Tools in the Production of Electrical Steel Sheets. In Proceedings of the 2015 5th International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 15–16 September 2015; IEEE: Washington, DC, USA, 2015; pp. 1–7. [Google Scholar]

- Trzepieciński, T. Approaches for Preventing Tool Wear in Sheet Metal Forming Processes. Machines 2023, 11, 616. [Google Scholar] [CrossRef]

- Čoga, L.; Polajnar, M.; Samodurova, A.; Kalin, M. Tribological Properties of Steel Sheet with Epoxy-Based Enamel Coating under Dry and Lubricated Conditions for Stamping Applications. J. Mater. Res. Technol. 2025, 36, 7666–7675. [Google Scholar] [CrossRef]

- Saini, V.; Lodhi, A.P.S. Surface Protectants Additives. In Lubricant Technology; CRC Press: Boca Raton, FL, USA, 2025; pp. 42–54. [Google Scholar]

- Minami, I. Molecular Science of Lubricant Additives. Appl. Sci. 2017, 7, 445. [Google Scholar] [CrossRef]

- Fang, L.; Korres, S.; Lamberti, W.A.; Webster, M.N.; Carpick, R.W. What Stress Components Drive Mechanochemistry? A Study of ZDDP Tribofilm Formation. Faraday Discuss. 2023, 241, 394–412. [Google Scholar]

- Pape, F.; Poll, G.; Ellersiek, L.; Denkena, B.; Liu, H. Tribological Effects of Metalworking Fluids in Cutting Processes. Lubricants 2023, 11, 224. [Google Scholar] [CrossRef]

- Buteri, A.; Borgeot, M.; Roizard, X.; Lallemand, F.; Melot, J.M.; Morand, L. Tribological Behavior of a New Green Industrial Lubricant for Stamping Operations-Application to Stainless Steels. IOP Conf. Ser. Mater. Sci. Eng. 2016, 159, 012018. [Google Scholar] [CrossRef]

- Schmid, S.R.; Saha, P.K.; Wang, J.; Schmitz, T. Developments in Tribology of Manufacturing Processes. J. Manuf. Sci. Eng. 2020, 142, 110803. [Google Scholar] [CrossRef]

- Nussbaumer, J. Alternatives for Chlorinated Paraffins in Metalworking Applications. Tribol. Lubr. Technol. 2012, 68, 48. [Google Scholar]

- Djordjevic, M.; Aleksandrovic, S.; Arsić, D.; Lazic, V.; Milosavljevic, D.; Nikolic, R. Comparative Study of an Environmentally Friendly Lubricant with Conventional Lubricants in Strip Ironing Test. J. Balk. Tribol. Assoc. 2016, 22, 947–958. [Google Scholar]

- Ramezani, M.; Schmid, S.R. Bio-Based Lubricants for Forming of Magnesium. J. Manuf. Process. 2015, 19, 112–117. [Google Scholar] [CrossRef]

- Pereira, M.P.; Yan, W.; Rolfe, B.F. Sliding Distance, Contact Pressure and Wear in Sheet Metal Stamping. Wear 2010, 268, 1275–1284. [Google Scholar] [CrossRef]

- Bay, N.; Azushima, A.; Groche, P.; Ishibashi, I.; Merklein, M.; Morishita, M.; Nakamura, T.; Schmid, S.; Yoshida, M. Environmentally Benign Tribo-Systems for Metal Forming. CIRP Ann. 2010, 59, 760–780. [Google Scholar] [CrossRef]

- Lovell, M.; Higgs, C.F.; Deshmukh, P.; Mobley, A. Increasing Formability in Sheet Metal Stamping Operations Using Environmentally Friendly Lubricants. J. Mater. Process. Technol. 2006, 177, 87–90. [Google Scholar] [CrossRef]

- Ike, H. Report on Metal Forming Tribology Research in Japan with Special Focus on Environmental Aspects. In Proceedings of the 2nd International Conference on Tribology in Manufacturing Processes (ICTMP 2004), Nyborg, Denmark, 15–18 June 2004. [Google Scholar]

- Bay, N.; Olsson, D.D.; Andreasen, J.L. Lubricant Test Methods for Sheet Metal Forming. Tribol. Int. 2008, 41, 844–853. [Google Scholar] [CrossRef]

- McGuire, N. Minding the Metalworking Fluids. Tribol. Lubr. Technol. 2016, 72, 32. [Google Scholar]

- Lovell, M.R.; Deng, Z. Characterization of Interfacial Friction in Coated Sheet Steels: Influence of Stamping Process Parameters and Wear Mechanisms. Tribol. Int. 2002, 35, 85–95. [Google Scholar] [CrossRef]

- Kim, H.; Sung, J.H.; Sivakumar, R.; Altan, T. Evaluation of Stamping Lubricants Using the Deep Drawing Test. Int. J. Mach. Tools Manuf. 2007, 47, 2120–2132. [Google Scholar] [CrossRef]

- Chandrasekharan, S.; Palaniswamy, H.; Jain, N.; Ngaile, G.; Altan, T. Evaluation of Stamping Lubricants at Various Temperature Levels Using the Ironing Test. Int. J. Mach. Tools Manuf. 2005, 45, 379–388. [Google Scholar] [CrossRef]

- Polajnar, M.; Čoga, L.; Kalin, M. Base Lubricants for Green Stamping: The Effects of Their Structure and Viscosity on Tribological Performance. Friction 2023, 11, 1741–1754. [Google Scholar] [CrossRef]

- Peña-Parás, L.; Taha-Tijerina, J.; García, A.; Maldonado, D.; González, J.A.; Molina, D.; Palacios, E.; Cantú, P. Antiwear and Extreme Pressure Properties of Nanofluids for Industrial Applications. Tribol. Trans. 2014, 57, 1072–1076. [Google Scholar] [CrossRef]

- Marzouki, M.; Kowandy, C.; Richard, C. Experimental Simulation of Tool/Product Interface during Hot Drawing. Wear 2007, 262, 235–241. [Google Scholar] [CrossRef]

- Ghiotti, A.; Sgarabotto, F.; Bruschi, S. A Novel Approach to Wear Testing in Hot Stamping of High Strength Boron Steel Sheets. Wear 2013, 302, 1319–1326. [Google Scholar] [CrossRef]

- Klocke, F.; Raedt, H.-W. Formulation and Testing of Optimised Coating Properties with Regard to Tribological Performance in Cold Forging and Fine Blanking Applications. Int. J. Refract. Met. Hard Mater. 2001, 19, 495–505. [Google Scholar] [CrossRef]

- Ramadan, M.K.; Lashin, M.M.A.; Gaafer, A.M. Mechanical and Tribological Properties of Coated Steel Blanking Punch. J. Egypt. Soc. Tribol. 2020, 17, 27–35. [Google Scholar]

- Schwingenschlögl, P.; Merklein, M. Characterization of Tribological Conditions within Direct Hot Stamping. J. Mater. Process. Technol. 2020, 278, 116535. [Google Scholar]

- Uda, K.; Azushima, A.; Yanagida, A. Development of New Lubricants for Hot Stamping of Al-Coated 22MnB5 Steel. J. Mater. Process. Technol. 2016, 228, 112–116. [Google Scholar] [CrossRef]

- Decrozant-Triquenaux, J.; Pelcastre, L.; Courbon, C.; Prakash, B.; Hardell, J. Effect of Surface Engineered Tool Steel and Lubrication on Aluminium Transfer at High Temperature. Wear 2021, 477, 203879. [Google Scholar] [CrossRef]

- Yanagida, A.; Azushima, A. Evaluation of Coefficients of Friction in Hot Stamping by Hot Flat Drawing Test. CIRP Ann. 2009, 58, 247–250. [Google Scholar] [CrossRef]

- Bogatu, L.; Dragomir, R. Suitable Compositions for Efficient Deep Stamping Lubricants. Rev. Chim. 2015, 66, 722–726. [Google Scholar]

- Li, X.; Yan, X.; Zhang, Z.; Ren, M.; Jia, H. Determination of Hot Stamping Friction Coefficient of 7075 Aluminum. Metals 2021, 11, 1111. [Google Scholar] [CrossRef]

- Fernandes, L.; Silva, F.J.G.; Andrade, M.F.; Alexandre, R.; Baptista, A.P.M.; Rodrigues, C. Improving the Punch and Die Wear Behavior in Tin Coated Steel Stamping Process. Surf. Coat. Technol. 2017, 332, 174–189. [Google Scholar] [CrossRef]

- Kohutiar, M.; Krbata, M.; Escherova, J.; Eckert, M.; Mikus, P.; Jus, M.; Polášek, M.; Janík, R.; Dubec, A. The Influence of the Geometry of Movement during the Friction Process on the Change in the Tribological Properties of 30CrNiMo8 Steel in Contact with a G40 Steel Ball. Materials 2024, 17, 127. [Google Scholar] [CrossRef]

- Polajnar, M.; Čoga, L.; Sharma, S.K.; Kalin, M. Laboratory Tribological Screening Test Methodologies to Evaluate the Performance of Metalworking Lubricants for Punching Stamping. Tribol. Int. 2025, 211, 110815. [Google Scholar] [CrossRef]

- Krbata, M.; Ciger, R.; Kohutiar, M.; Sozańska, M.; Eckert, M.; Barenyi, I.; Kianicova, M.; Jus, M.; Beronská, N.; Mendala, B.; et al. Effect of Supercritical Bending on the Mechanical & Tribological Properties of Inconel 625 Welded Using the Cold Metal Transfer Method on a 16Mo3 Steel Pipe. Materials 2023, 16, 5014. [Google Scholar] [CrossRef] [PubMed]

- Spikes, H. Friction Modifier Additives. Tribol. Lett. 2015, 60, 5. [Google Scholar] [CrossRef]

- Alves, S.M.; Schroeter, R.B.; Bossardi, J.C.D.S.; Andrade, C.L.F.D. Influence of EP Additive on Tool Wear in Drilling of Compacted Graphite Iron. J. Braz. Soc. Mech. Sci. Eng. 2011, 33, 197–202. [Google Scholar] [CrossRef]

- Srinivas, V.; Thakur, R.N.; Jain, A.K. Antiwear, Antifriction, and Extreme Pressure Properties of Motor Bike Engine Oil Dispersed with Molybdenum Disulfide Nanoparticles. Tribol. Trans. 2017, 60, 12–19. [Google Scholar] [CrossRef]

- Canter, N. Special Report: Trends in Extreme Pressure Additives. Tribol. Lubr. Technol. 2007, 63, 10. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).