Unraveling the Friction and Wear Mechanisms of a Medium-Carbon Steel with a Gradient-Structured Surface Layer

Abstract

1. Introduction

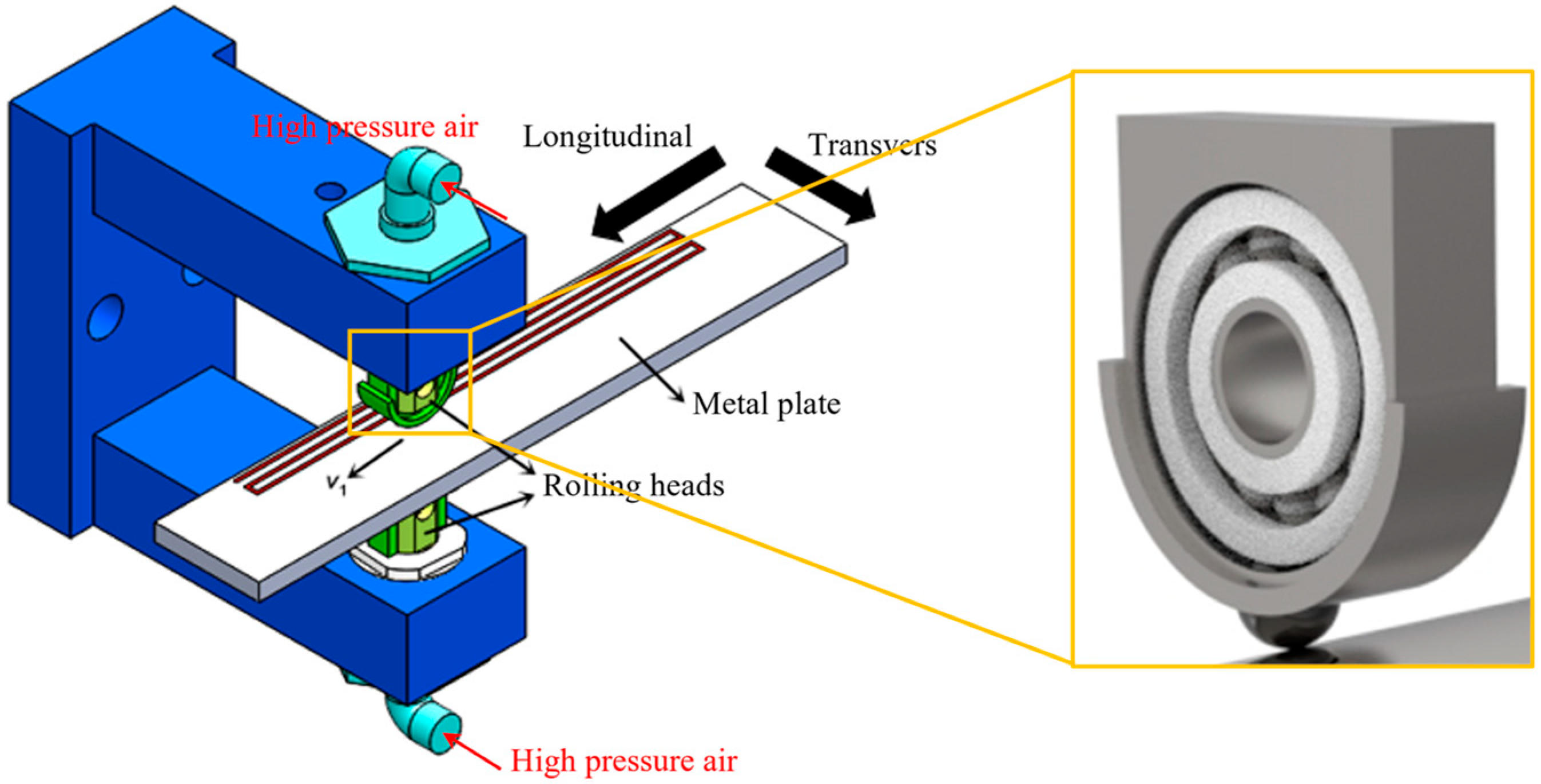

2. Materials and Methods

2.1. Materials

2.2. Characterization Techniques

2.3. Hardness Measurement

2.4. Tribological Tests

3. Results

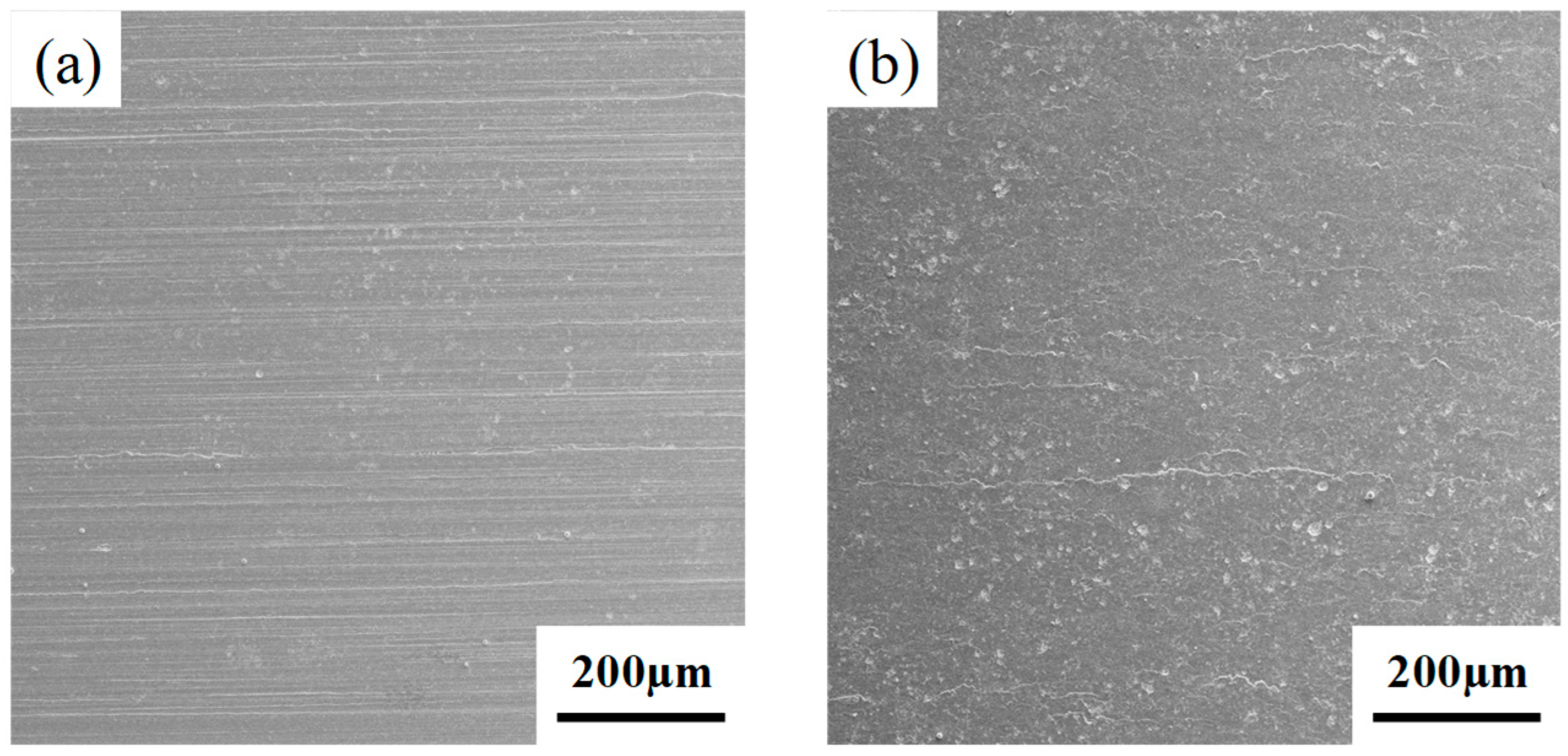

3.1. Surface Morphology

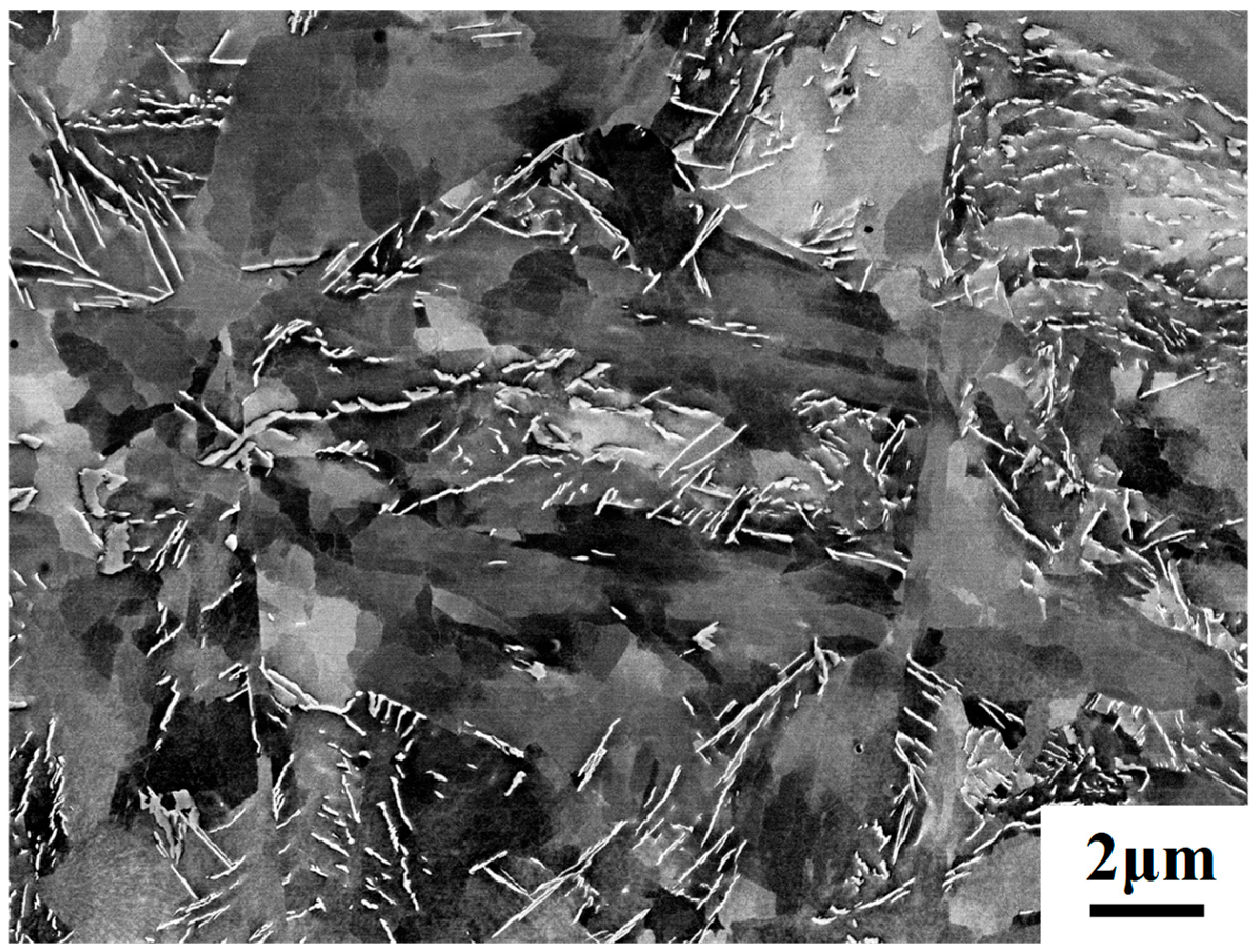

3.2. Microstructural Analysis

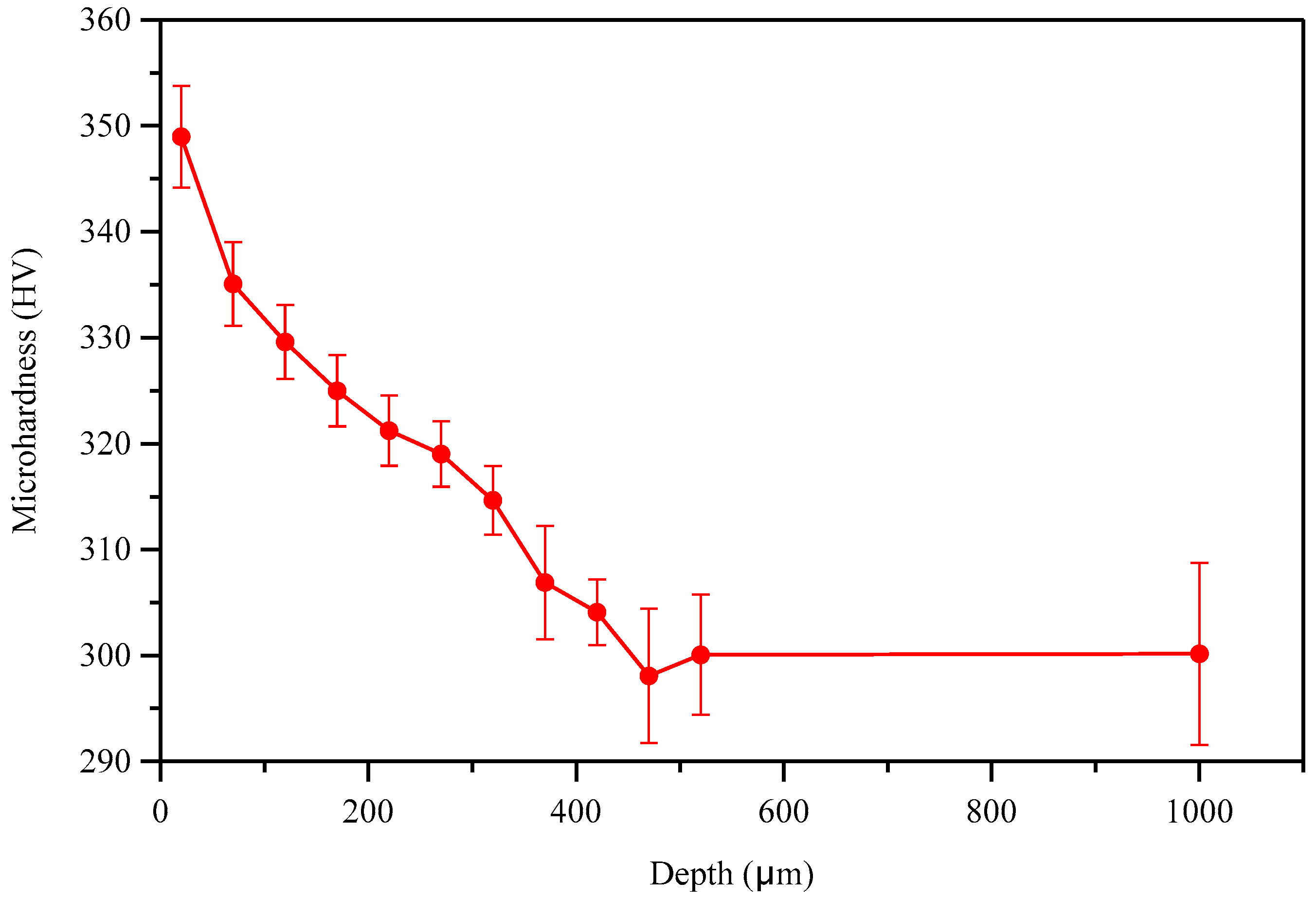

3.3. Hardness

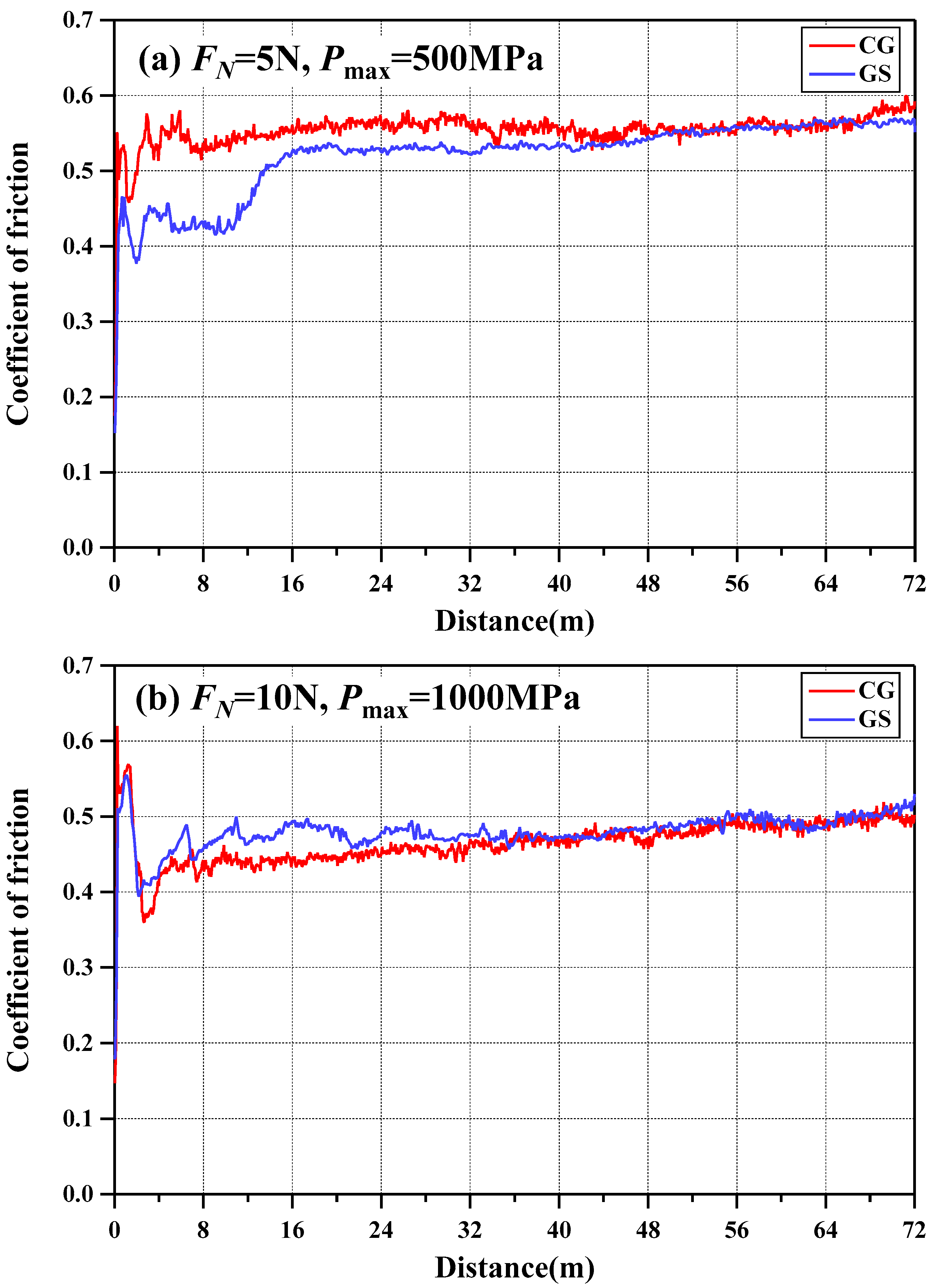

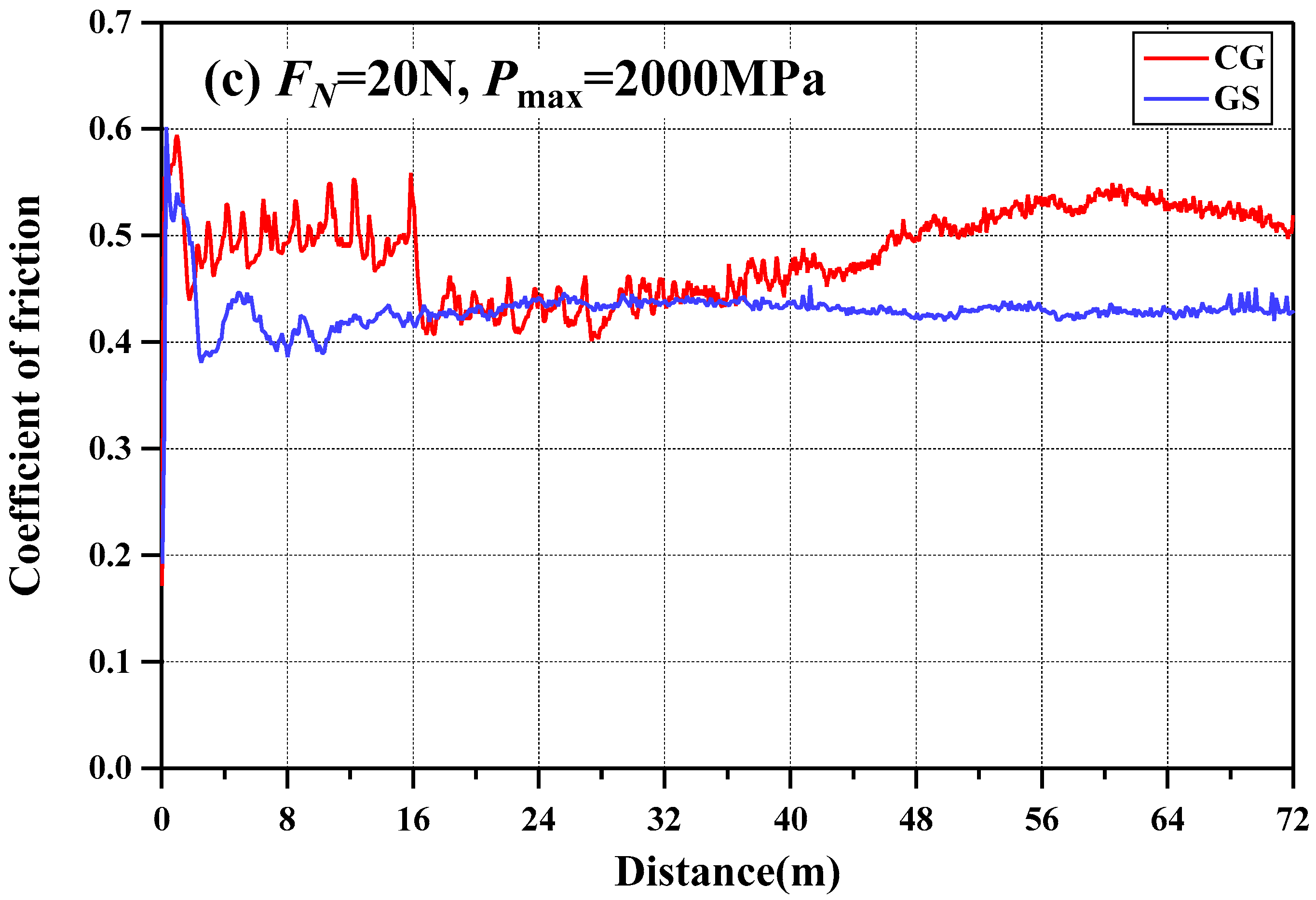

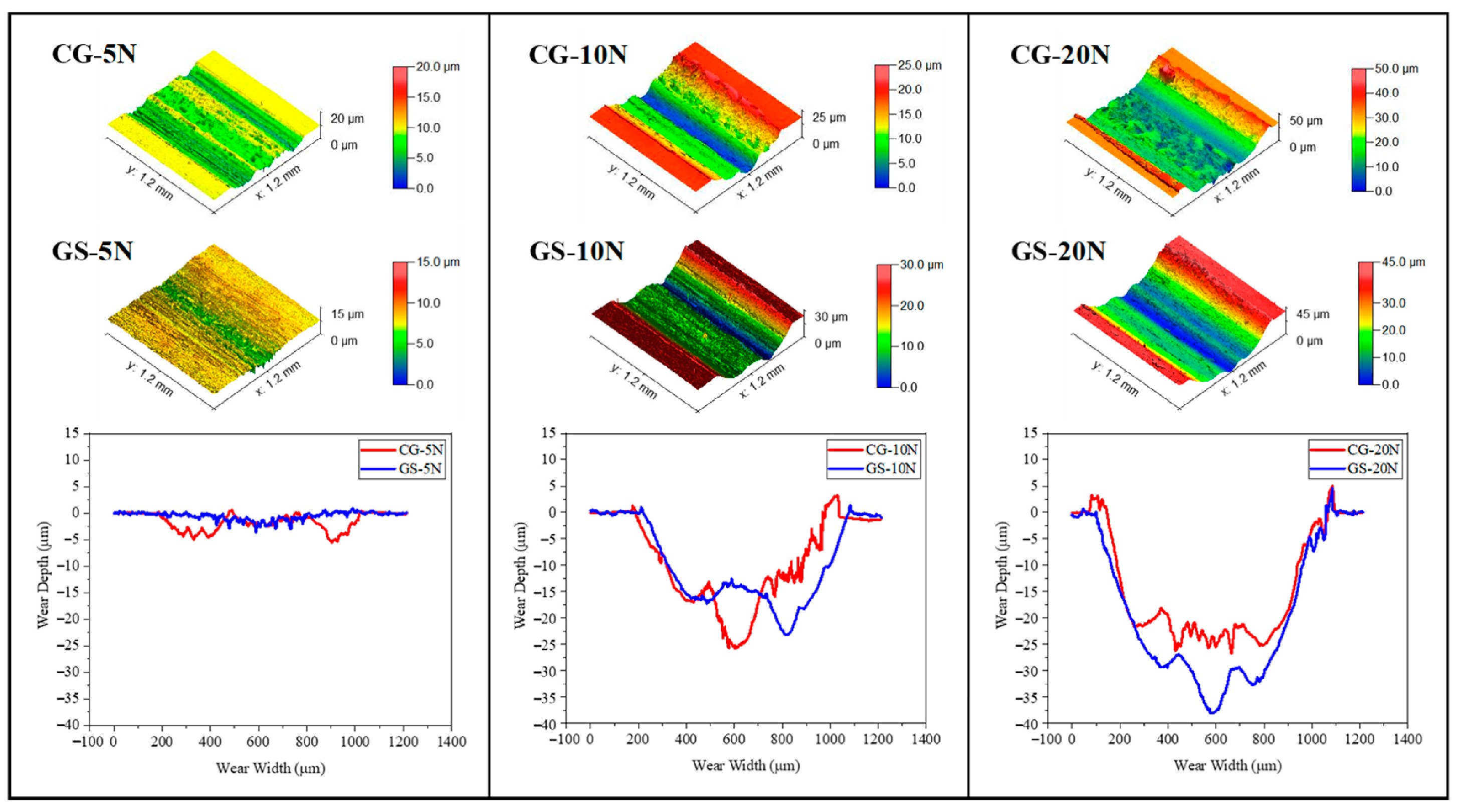

3.4. Tribological Performance Analysis

4. Discussion

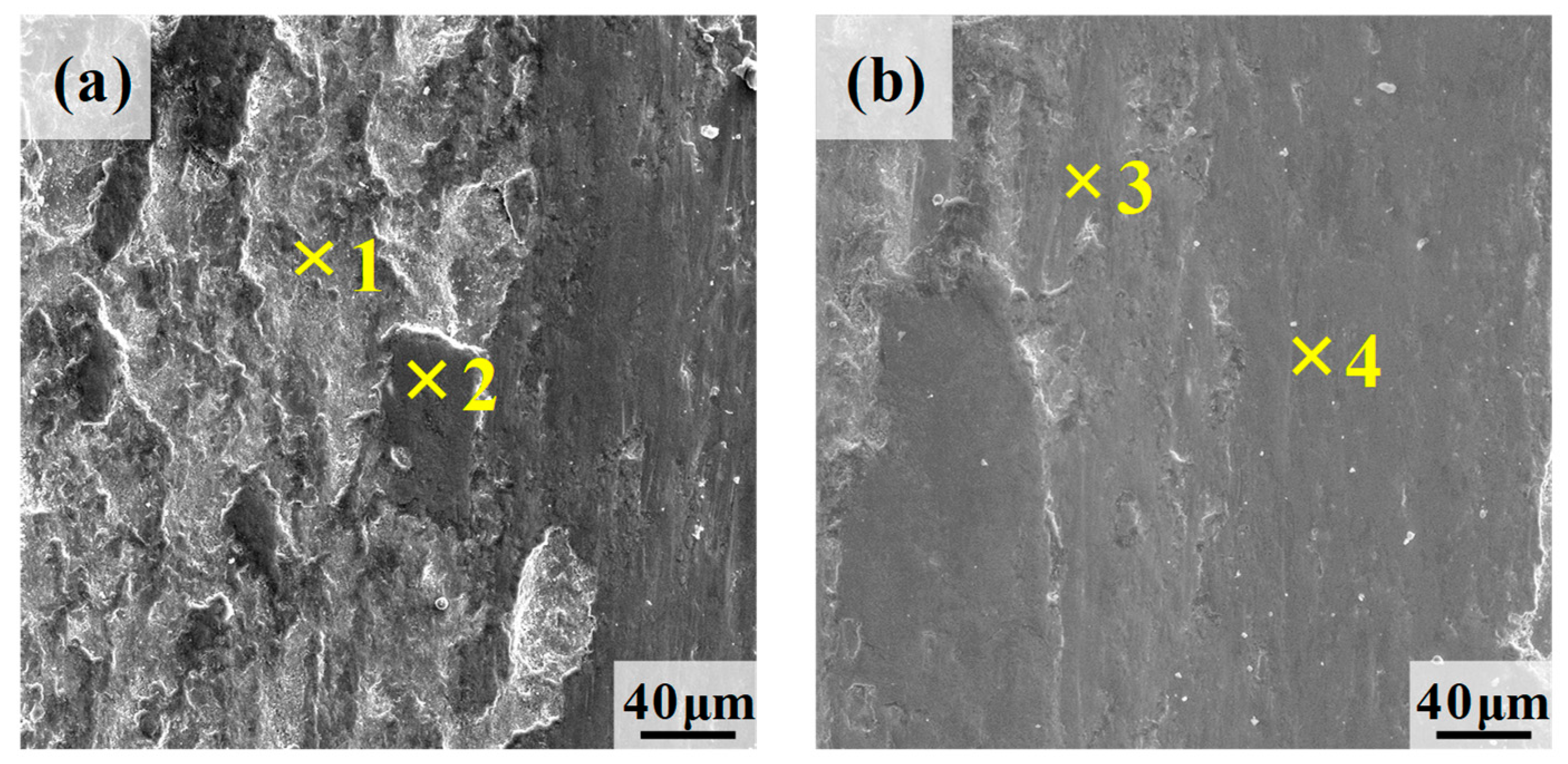

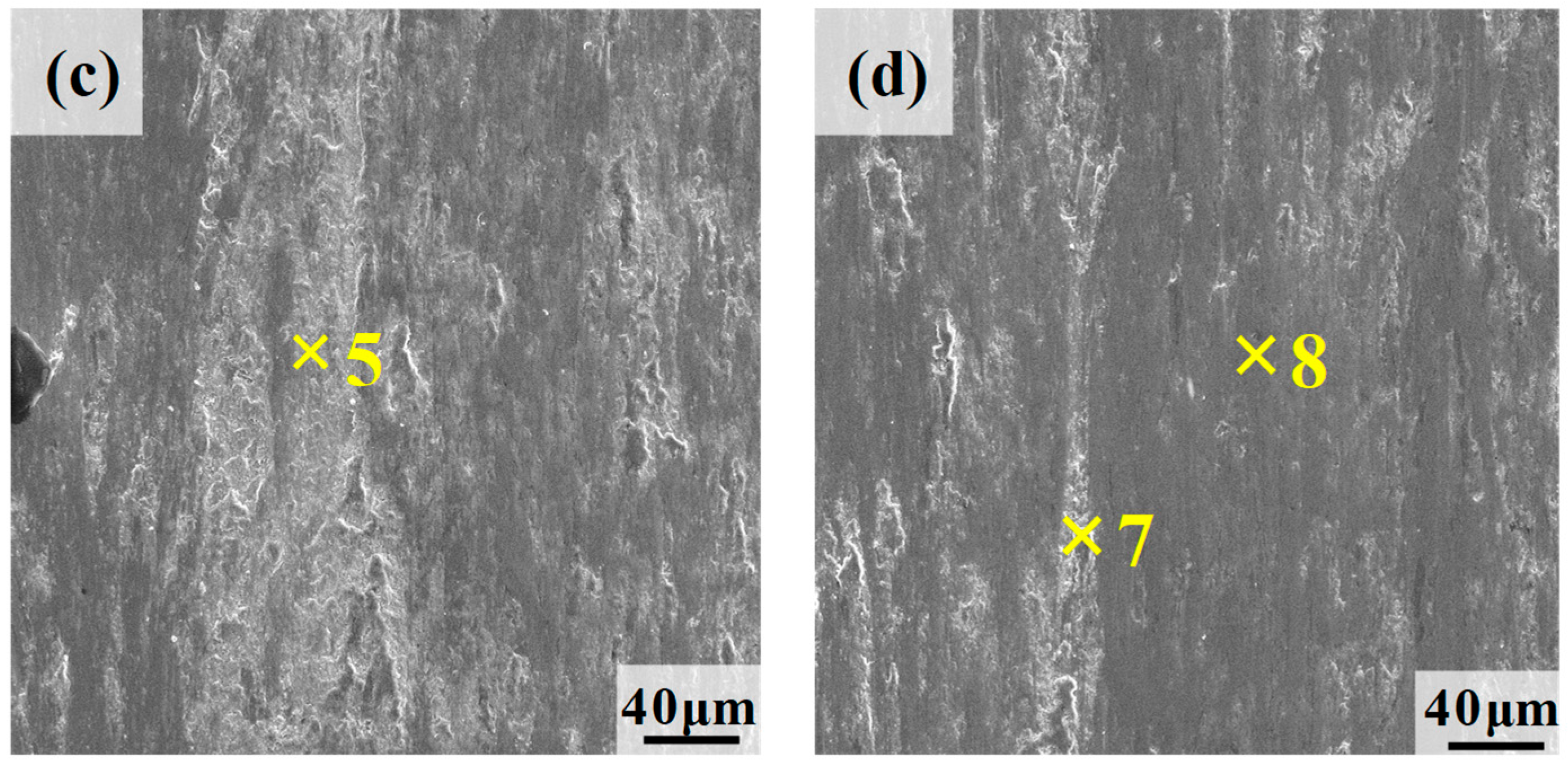

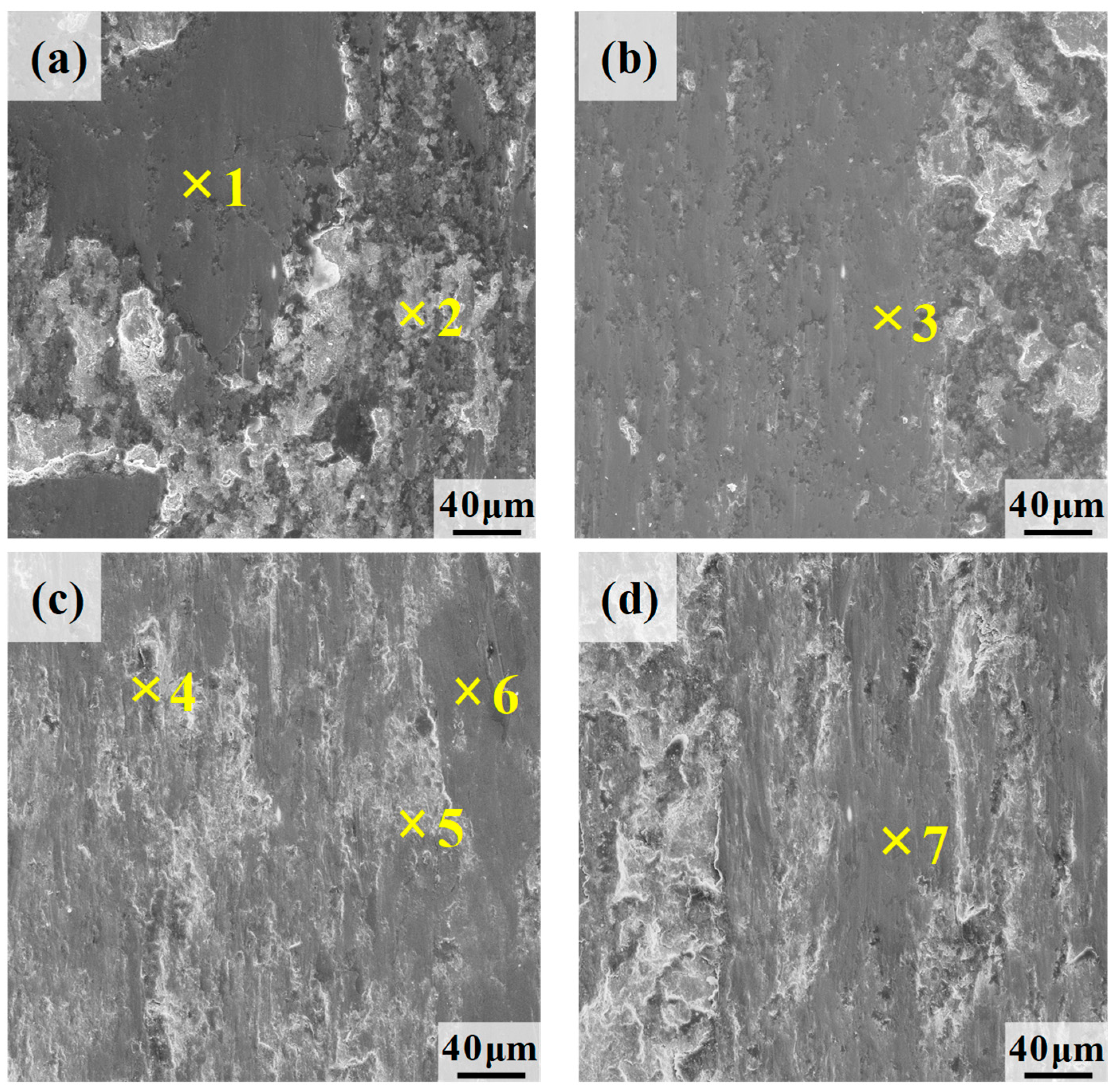

4.1. Surface Analysis of Steel Balls

4.2. Analysis of Wear Mechanisms

5. Conclusions

- 1.

- The frictional behavior of the specimens exhibited distinct load-dependent characteristics. The coefficient of friction (COF) of the CG specimens initially decreased and then increased with rising normal load, whereas that of the GS specimens decreased continuously. This trend can be attributed to the progressive formation of protective oxide films at the sliding interface due to enhanced oxidative reactions.

- 2.

- A clear transition in wear mechanisms was observed with increasing load. The CG specimens transitioned from oxidative/abrasive wear at lower loads (5 and 10 N) to abrasive/fatigue wear at 20 N. In contrast, the GS specimens underwent a more progressive shift: from oxidative/abrasive wear at 5 N to adhesive/abrasive wear at 10 N and finally to adhesive wear accompanied by significant plastic deformation at 20 N.

- 3.

- The wear resistance of the GS specimen degraded with increasing load. It showed 63.16% less mass loss than the CG specimen at 5 N, but 45.65% more at 20 N. This performance reversal, confirmed by the Archard wear coefficients, demonstrates the limitation of the gradient structure under high load.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.P.; Luo, Y.C.; Mo, Q.Y.; Huang, B.; Wang, S.Y.; Mao, X.F.; Zhou, L. Failure analysis and improvement of a 42CrMo crankshaft for a heavy-duty truck. Eng. Fail. Anal. 2023, 153, 107567. [Google Scholar] [CrossRef]

- Pan, D.; Zhao, Y.G.; Wang, Y.T.; Xu, X.F.; Yin, P.L.; Chong, X.Y. Formation of ultrafine pearlites in tempered 42CrMo steel induced by electro-pulsing. Mater. Lett. 2019, 251, 73–77. [Google Scholar] [CrossRef]

- Zhang, J.T.; Liu, Z.H.; Sun, J.X.; Zhao, H.L.; Shi, Q.Y.; Ma, D.W. Microstructure and mechanical property of electropulsing tempered ultrafine grained 42CrMo steel. Mater. Sci. Eng. A 2020, 782, 139213. [Google Scholar] [CrossRef]

- Lv, Y.F.; Xu, P.; Liang, R.; Wang, L.; Pang, C. Corrosion resistance of VC-reinforced Fe-based SMA coatings by laser cladding. Surf. Coat. Technol. 2024, 478, 130457. [Google Scholar] [CrossRef]

- Khare, S.; Singh, O.P.; Dora, K.B.; Sasun, C. Spalling investigation of connecting rod. Eng. Fail. Anal. 2012, 19, 77–86. [Google Scholar] [CrossRef]

- Wang, K.; Yin, L.Y.; Long, Z.L.; Liang, N.; Zhu, D.D.; Zhang, S.H. Effect of copper-rich precipitations on the adaptive behavior of low carbon martensitic steels during dry sliding wear. Wear 2025, 576–577, 206136. [Google Scholar] [CrossRef]

- Zhang, W.; Li, L.; Gao, J.; Liu, J.; Gong, H.; Wang, Q. Theoretical calculation and experimental verification of wear prediction during the tightening process of bolted joint. Tribol. Lett. 2024, 73, 17. [Google Scholar] [CrossRef]

- Liu, B.G.; Lu, X.W.; Li, W.; Jin, X.J. Enhanced wear resistance of nanotwinned austenite in higher Si nanostructured bainitic steel. Wear 2018, 398–399, 22–28. [Google Scholar] [CrossRef]

- Sun, L.G.; Wu, G.; Wang, Q.; Lu, J. Nanostructural metallic materials: Structures and mechanical properties. Mater. Today 2020, 38, 114–135. [Google Scholar] [CrossRef]

- Kumar, K.S.; Van Swygenhoven, H.; Suresh, S. Mechanical behavior of nanocrystalline metals and alloys. Acta Mater. 2003, 51, 5743–5774. [Google Scholar] [CrossRef]

- Jeong, D.H.; Erb, U.; Aust, K.T.; Palumbo, G. The relationship between hardness and abrasive wear resistance of electrodeposited nanocrystalline Ni–P coatings. Scripta Mater. 2003, 48, 1067–1072. [Google Scholar] [CrossRef]

- Sun, D.Y.; Feng, X.Y.; Zhang, P.; Sun, X.W.; Yang, Z.N.; Long, X.Y.; Zhang, F.C. Effects of two-step austempering processes on the wear resistance and fatigue lifetime of high-carbon nanostructured bainitic steel. J. Mater. Res. Technol. 2024, 30, 4739–4749. [Google Scholar] [CrossRef]

- Shah, M.; Bakshi, S.D. Three-body abrasive wear of carbide-free bainite, martensite and bainite-martensite structure of similar hardness. Wear 2018, 402–403, 207–215. [Google Scholar] [CrossRef]

- Lu, J.; Wang, K.; Sui, X.M.; Zhang, J.; Wang, H.H.; Qin, Q.M.; Song, Z.F.; Ren, X.L.; Yang, J.X.; Long, F.Q. Rapid synthesis of ultra-wear-resistant nanocrystallite stainless steel via electron beam direct irradiation. Surf. Coat. Technol. 2024, 483, 130714. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, G.; Han, Z.; Lu, K. Grain size effect on wear resistance of a nanostructured AISI52100 steel. Scr. Mater 2008, 58, 445–448. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Wu, X.L. Heterostructured materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Cao, Z.Y.; Cui, L.Q.; Luo, S.H.; Su, H.; Pang, Z.C.; Zhao, W.; Zhang, L.Y.; He, W.F.; Liang, X.Q. Superior fretting wear resistance of titanium alloys from stable gradient nanostructures induced by laser shock peening. Int. J. Plast. 2025, 188, 104293. [Google Scholar] [CrossRef]

- Duan, C.F.; Qu, S.G.; Sun, P.F.; Li, X.Q. Effect of heating-assisted ultrasonic surface rolling on the microstructure evolution and wear behavior of martensitic steel. Surf. Coat. Technol. 2024, 483, 130759. [Google Scholar] [CrossRef]

- Luo, J.S.; Sun, W.T.; Duan, R.X.; Yang, W.Q.; Chan, K.C.; Ren, F.Z.; Yang, X.S. Laser surface treatment-introduced gradient nanostructured TiZrHfTaNb refractory high-entropy alloy with significantly enhanced wear resistance. J. Mater. Sci. Technol. 2022, 110, 43–56. [Google Scholar] [CrossRef]

- Lavakumar, B.; Prasad, M.J.N.V.; Phani, P.S.; Wasekar, N.P. Influence of compositional and microstructural gradient on the wear performance of nanocrystalline Ni-W coatings. Wear 2023, 530–531, 205039. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, B.; Li, D.; Zeng, X.; Lu, J. Wear behavior of nanocrystalline structured magnesium alloy induced by surface mechanical attrition treatment. Surf. Coat. Technol. 2015, 261, 219–226. [Google Scholar] [CrossRef]

- Sun, Y. Sliding wear behaviour of surface mechanical attrition treated AISI 304 stainless steel. Tribol. Int. 2013, 57, 67–75. [Google Scholar] [CrossRef]

- Ralls, A.M.; Leong, K.; Liu, S.C.; Wang, X.G.; Jiang, Y.Y.; Menezes, P.L. Unraveling the friction and wear mechanisms of surface nanostructured stainless-steel. Wear 2024, 538–539, 205185. [Google Scholar] [CrossRef]

- Li, M.Y.; Dang, X.F.; Ning, L.Z.; Liu, D.R.; Geng, Y.F.; Cheng, F.Y.; Dong, J.Y.; Liang, R.Y.; Tian, Z.; Zhou, G.N.; et al. Post-processing of laser-directed energy deposited IN718 superalloys through combined heat treatment and shot peening: Microstructural evolution and wear resistance enhancement. Surf. Coat. Technol. 2025, 509, 132209. [Google Scholar] [CrossRef]

- Hu, H.B.; Tang, G.B.; Cheng, Z.T.; Pan, Y.T.; Huang, Z.B.; Ding, W.F.; Liang, Z.W. Co-Cr3C2 coating incorporating grain refinement and dislocation density gradient to enhance wear resistance of 24CrNiMo steel. Wear 2025, 546, 205752. [Google Scholar] [CrossRef]

- Pape, F.; Maiss, O.; Denkena, B.; Poll, G. Enhancement of roller bearing fatigue life by innovative production processes, Ind. Lubr. Tribol. 2019, 71, 1003–1006. [Google Scholar] [CrossRef]

- Zou, Y.; Li, J.K.; Liu, X.; He, T.T.; Lu, J.S.; Li, D.L.; Li, Y. Effect of multiple ultrasonic nanocrystal surface modification on surface integrity and wear property of DZ2 axle steel. Surf. Coat. Technol. 2021, 412, 127012. [Google Scholar] [CrossRef]

- Wang, P.F.; Han, Z. Friction and wear behaviors of a gradient nano-grained AISI 316L stainless steel under dry and oil-lubricated conditions. J. Mater. Sci. Technol. 2018, 34, 1835–1842. [Google Scholar] [CrossRef]

- Wang, Y.J.; Jia, Z.; Ji, J.J.; Cheng, Q.Q.; Chan, L.; Lu, X.Z.; Lai, C.P.; Liu, D.X. Surface mechanical rolling treatment-introduced gradient nanostructured Inconel 625 alloy with enhanced high-temperature wear resistance. Tribol. Int. 2025, 201, 110187. [Google Scholar] [CrossRef]

- Wang, C.; Liu, X.; Hu, X.Y.; Fei, S.H.; Li, B.K.; Deng, H.S.; Shen, G.; Wang, X.G. Gradient-structured 1060 aluminum by air pressure-driven surface mechanical rolling treatment and its effects on the friction performance. J. Manuf. Process. 2023, 108, 804–819. [Google Scholar] [CrossRef]

- Tang, Y.H.; Ji, P.F.; Li, B.; Zhang, G.F.; Ma, W.; Wang, F.; Zhang, X.Y.; Ma, M.Z.; Liu, R.P. Effect of loading on microstructure and friction and wear behavior of an austenite lightweight steel. Tribol. Int. 2023, 177, 108006. [Google Scholar] [CrossRef]

- Wang, H.B.; Song, G.L.; Tang, G.Y. Enhanced surface properties of austenitic stainless steel by electropulsing-assisted ultrasonic surface rolling process. Surf. Coat. Technol. 2015, 282, 149–154. [Google Scholar] [CrossRef]

- Yang, H.W.; Zhang, Z.C.; Shu, J.; Han, Y. Gradient nanostructure, enhanced surface integrity and fatigue resistance of Ti-6Al-7Nb alloy processed by surface mechanical attrition treatment. J. Mater. Sci. Technol. 2024, 188, 252–269. [Google Scholar] [CrossRef]

- Zong, H.J.; Kang, N.; Mansori, M.E. Impact of applied loads on wear mechanisms in H13 steel at various preheating temperatures during laser powder bed fusion additive manufacturing. Wear 2024, 556–557, 205538. [Google Scholar] [CrossRef]

- GB/T 18254-2016; High-Carbon Chromium Bearing Steel. Standardization Administration of the People’s Republic of China: Beijing, China, 2016.

- Li, J.; Yan, H.Z.; Li, S.B.; Lei, M.T. Microstructure and wear behavior of arc-shaped 40CrNiMo steel after laser hardening. J. Mater. Res. Technol. 2023, 24, 5743–5754. [Google Scholar] [CrossRef]

- Derelizade, K.; Rincon, A.; Venturi, F.; Wellman, R.G.; Kholobystov, A.; Hussain, T. High temperature (900 °C) sliding wear of CrNiAlCY coatings deposited by high velocity oxy fuel thermal spray. Surf. Coat. Technol. 2022, 432, 128063. [Google Scholar] [CrossRef]

- Wei, M.X.; Wang, S.Q.; Wang, L.; Cui, X.H.; Chen, K.M. Effect of tempering conditions on wear resistance in various wear mechanisms of H13 steel. Tribol. Int. 2011, 44, 898–905. [Google Scholar] [CrossRef]

- Syniuta, W.D.; Corrow, C.J. A scanning electron microscopy fractographic study of rolling-contact fatigue. Wear 1970, 15, 187–199. [Google Scholar] [CrossRef]

- Suh, N.P. The delamination theory of wear. Wear 1973, 25, 111–124. [Google Scholar] [CrossRef]

- Wei, L.L.; Wang, Y.G.; Misra, R.D.K.; Chen, J. Understanding the high-temperature oxidation resistance of heat-resistant austenitic stainless steel with gradient nanostructure. Corros. Sci. 2024, 231, 111966. [Google Scholar] [CrossRef]

- Singh, D.; Cemin, F.; Jimenez, M.J.M.; Antunes, V.; Alvarez, F.; Orlov, D.; Figueroa, C.A.; Hosmani, S.S. High-temperature oxidation behaviour of nanostructure surface layered austenitic stainless steel. Appl. Surf. Sci. 2022, 581, 152437. [Google Scholar] [CrossRef]

- Rai, A.K.; Biswal, R.; Gupta, R.K.; Rai, S.K.; Singh, R.; Goutam, U.K.; Ranganathan, K.; Ganesh, P.; Kaul, R.; Bindra, K.S. Enhancement of oxidation resistance of modified P91 grade ferritic-martensitic steel by surface modification using laser shock peening. Appl. Surf. Sci. 2019, 495, 143611. [Google Scholar] [CrossRef]

- Menezes, P.L.; Kishore; Kailas, S.V. Influence of roughness parameters and surface texture on friction during sliding of pure lead over 080 M40 steel. Int. J. Adv. Manuf. Technol. 2009, 43, 731–743. [Google Scholar] [CrossRef]

- Jiang, J.; Stack, M.M. Modelling sliding wear: From dry to wet environments. Wear 2006, 261, 954–965. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and rubbing of flat surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

| Cr | Si | Mn | Ni | Mo | P | C | Fe |

|---|---|---|---|---|---|---|---|

| 1.150 | 0.274 | 0.570 | 0.031 | 0.719 | 0.017 | 0.420 | Balance |

| Case | 5 N | 10 N | 20 N |

|---|---|---|---|

| CG | 7.87 ∗ 10−5 | 2.26 ∗ 10−4 | 1.74 ∗ 10−4 |

| GS | 3.03 ∗ 10−5 | 2.77 ∗ 10−4 | 2.66 ∗ 10−4 |

| Case | Point | Fe | O | C | Cr | Mn | Mo |

|---|---|---|---|---|---|---|---|

| CG-5N | 1 | 94.79 | 0.52 | 4.08 | 0.61 | - | - |

| GS-5N | 2 | 93.19 | 0.28 | 4.84 | 1.28 | 0.41 | - |

| CG-10N | 3 | 92.36 | 0.34 | 6.26 | 0.83 | 0.21 | - |

| 4 | 89.80 | 2.37 | 5.67 | 1.33 | 0.58 | 0.26 | |

| GS-10N | 5 | 94.88 | 0.39 | 3.39 | 1.04 | 0.17 | 0.13 |

| 6 | 93.63 | 0.78 | 3.70 | 0.97 | 0.36 | 0.57 | |

| CG-20N | 7 | 93.55 | 0.35 | 5.29 | 0.81 | - | - |

| 8 | 85.23 | 1.58 | 11.92 | 1.01 | 0.25 | - | |

| GS-20N | 9 | 93.49 | 1.80 | 3.20 | 1.13 | 0.18 | 0.19 |

| 10 | 81.00 | 14.19 | 2.78 | 1.12 | 0.43 | 0.48 |

| Case | Point | Fe | O | C | Cr | Mn | Mo |

|---|---|---|---|---|---|---|---|

| CG-5N | 1 | 84.56 | 0.63 | 13.10 | 0.92 | 0.43 | 0.36 |

| 2 | 65.37 | 27.54 | 5.62 | 1.13 | 0.25 | 0.09 | |

| 3 | 61.93 | 31.39 | 5.53 | 0.90 | 0.25 | - | |

| 4 | 89.36 | 0.56 | 8.69 | 0.98 | 0.45 | - | |

| GS-5N | 5 | 93.42 | 0.53 | 4.02 | 0.92 | 0.91 | 0.23 |

| 6 | 65.97 | 29.68 | 3.26 | 0.83 | 0.14 | 0.12 | |

| 7 | 67.56 | 25.59 | 5.41 | 0.85 | 0.31 | 0.29 | |

| 8 | 87.31 | 0.50 | 10.77 | 1.01 | 0.41 | - |

| Case | Point | Fe | O | C | Cr | Mn | Mo |

|---|---|---|---|---|---|---|---|

| CG-10N | 1 | 77.09 | 0.75 | 20.62 | 0.75 | 0.27 | 0.51 |

| 2 | 59.79 | 29.36 | 9.90 | 0.74 | 0.20 | - | |

| 4 | 66.40 | 26.96 | 5.50 | 0.62 | 0.18 | 0.34 | |

| 5 | 87.95 | 0.50 | 10.77 | 1.01 | 0.41 | - | |

| GS-10N | 5 | 73.88 | 15.46 | 9.56 | 0.77 | 0.33 | - |

| 6 | 80.64 | 3.36 | 13.97 | 0.99 | 0.60 | 0.44 | |

| 7 | 77.39 | 3.97 | 16.86 | 0.85 | 0.37 | 0.57 | |

| 8 | 83.34 | 0.42 | 14.64 | 0.88 | 0.35 | 0.37 |

| Case | Point | Fe | O | C | Cr | Mn | Mo |

|---|---|---|---|---|---|---|---|

| CG-20N | 1 | 88.46 | 3.32 | 6.55 | 1.22 | 0.45 | - |

| 2 | 88.69 | 2.25 | 7.28 | 1.08 | 0.69 | - | |

| 3 | 86.07 | 2.67 | 9.51 | 0.94 | 0.51 | 0.31 | |

| GS-20N | 4 | 79.77 | 2.46 | 16.19 | 0.64 | 0.45 | 0.48 |

| 5 | 80.47 | 0.45 | 17.48 | 0.75 | 0.52 | 0.33 | |

| 6 | 81.96 | 0.67 | 15.82 | 0.82 | 0.72 | - | |

| 7 | 89.89 | 0.48 | 8.12 | 0.84 | 0.43 | 0.24 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Que, B.; Dong, L.; Li, Z.; Cheng, Y.; Wang, X. Unraveling the Friction and Wear Mechanisms of a Medium-Carbon Steel with a Gradient-Structured Surface Layer. Lubricants 2025, 13, 448. https://doi.org/10.3390/lubricants13100448

Zhang H, Que B, Dong L, Li Z, Cheng Y, Wang X. Unraveling the Friction and Wear Mechanisms of a Medium-Carbon Steel with a Gradient-Structured Surface Layer. Lubricants. 2025; 13(10):448. https://doi.org/10.3390/lubricants13100448

Chicago/Turabian StyleZhang, Huaming, Baoyan Que, Li Dong, Zhenling Li, Yang Cheng, and Xiaogui Wang. 2025. "Unraveling the Friction and Wear Mechanisms of a Medium-Carbon Steel with a Gradient-Structured Surface Layer" Lubricants 13, no. 10: 448. https://doi.org/10.3390/lubricants13100448

APA StyleZhang, H., Que, B., Dong, L., Li, Z., Cheng, Y., & Wang, X. (2025). Unraveling the Friction and Wear Mechanisms of a Medium-Carbon Steel with a Gradient-Structured Surface Layer. Lubricants, 13(10), 448. https://doi.org/10.3390/lubricants13100448