- Article

Experimental Comparison of Unstratified and Stratified Drag Wakes of a Dimpled Sphere at Reynolds Number 105

- Maddie C. Samuell,

- Nerion Zekaj and

- Scott Wunsch

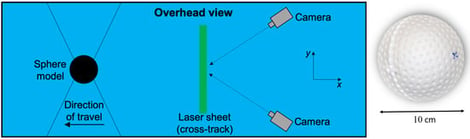

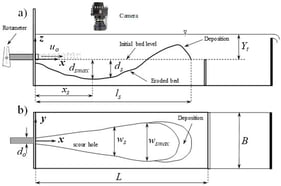

The drag wake of a dimpled sphere is studied experimentally using stereo particle image velocimetry at a Reynolds number of in both unstratified and stratified (Froude number ) fluids at downstream distances of

6 February 2026