Abstract

The industrial processing of innovative packaging papers with enhanced barrier properties has become ever more challenging due to the more stringent regulations on single-use plastics (SUPs), with an extended applicability to coated papers. Although the traditional packaging papers are based on renewable sources, they do not provide water and oil resistance and traditionally require the deposition of extruded polymer films or dispersion coatings that interfere with the paper recycling process. In this study, an alternative method has been investigated through the impregnation of papers with various types of biowax, including a synthetic PE wax, palm oil wax, sunflower wax, rice bran wax, rapeseed wax, castor wax, rice bran wax, and candelilla wax. The close control of processing conditions in an industrial pilot-line is critical to produce an optimized product quality with enhanced water and oil contact angles. In particular, the variations in wax type and wax loadings after single- or dual-side impregnation and the control of processing temperatures have been related to the oil and water contact angles. The stable water contact angles in the range of 100 to 120° were obtained depending on the biowax type. Meanwhile, the increase in oil contact angles up to 60° is in line with the enhanced grease resistance. The good recyclability scores of biowax-impregnated papers were demonstrated following the “Harmonized European laboratory test method to generate parameters enabling the assessment of the recyclability of paper and board products in recycling mills with conventional process (Part I)”, version February 2024.

Keywords:

paper; packaging; biowax; impregnation; contact angles; water resistance; oil resistance; recyclability 1. Introduction

The growing restrictions on single-use plastics and increasing consumer demand for sustainable packaging have accelerated the transition toward fiber-based materials in the food and consumer goods sectors. Paper is inherently renewable, recyclable, and biodegradable; however, its hydrophilic nature and porous structure limit its resistance to water, oil, and grease, necessitating barrier enhancements for practical applications. Conventional polymer coatings, such as polyethylene or fluorinated compounds, provide effective barriers [1], but they hinder recyclability and introduce environmental concerns due to their persistence and toxicity [2].

Wax barrier coatings have gained attention as alternatives to synthetic polymer barriers in paper packaging [3]. Natural waxes such as carnauba, candelilla, and rice bran wax provide hydrophobic and oleophobic properties [4,5]. Studies report water contact angles above 100° for wax-coated papers, reducing liquid penetration compared to untreated substrates [6]. Oil resistance also improves, with KIT values reaching appropriate levels for food-contact applications [7]. Beeswax and carnauba wax coatings have demonstrated reductions in water vapor transmission rates by up to 77%, enhancing shelf-life performance [8]. However, the mechanical properties are influenced by the penetration of heavy wax coatings and may lead to a reduction in tensile strength [9]. Dispersion-based wax coatings combined with biopolymers can further improve flexibility and surface uniformity [10,11]. However, excessive wax loading may impair heat-sealability and cause surface defects, requiring precise process control [12]. Moreover, the presence of synthetic wax coatings may reduce the recyclability of the paper [13]. Therefore, a novel method through biowax impregnation is explored in this study, employing a lower wax loading as compared to traditional paper coatings.

2. Materials and Methods

2.1. Materials

An overview of the impregnated paper samples evaluated in this study is provided in Table 1. As a reference material, a standard packaging-grade paper was selected: Flexpack Smooth (Starkraft, Pöls, Austria), which is a commercially available bleached kraft paper produced entirely from virgin fibers. The base paper has a grammage of 35 g/m2, which is typical for lightweight flexible packaging applications. The paper is industrially manufactured using a high-quality kraft pulping process, ensuring excellent mechanical strength and surface smoothness. Its uniform fiber distribution and low porosity make it suitable for subsequent impregnation. The choice of this reference material allows for a consistent comparison in terms of barrier performance, compatibility with bio-based impregnation agents, and recyclability.

Table 1.

Overview of impregnated paper samples with different types of (bio)wax and impregnation sides.

The impregnation of the paper was conducted with different wax types at one side or two sides of the paper. Besides different biowaxes, a PE wax with medium melting point was used (Proquiwax 56–58). The processing was performed on industrial pilot-scale roll-to-roll equipment by guiding the paper through a bath of molten wax, followed by the guidance over different rolls under confidential conditions of pressure, temperature speed, and contact times. The controlled take-up of the wax allowed for the determination of the loading of the wax.

2.2. Characterization and Testing Procedures

The microscopic pictures of impregnated papers were made using confocal laser scanning microscopy with a VK-X3000 microscope (Keyence, Mechelen, Belgium) at objective magnification ×50. The contact angles with water, sun oil, and olive oil were determined through contact angle measurements with a OCA 50 system (Dataphysics Instruments GmbH, Filderstadt, Germany). The measurements were conducted through the deposition of a droplet with a volume of 3 µL, followed by the spreading of the droplet over the substrate over 2 s. The contact angles are averaged over five measurements and reported as a value with standard deviation. The KIT values were determined through the deposition of a series of grease-like liquids that become increasingly aggressive, reporting the highest number of a solution that does not stain the paper (TAPPI Method T599).

The recyclability evaluation of impregnated papers was performed according to the protocol published by CEPI (February 2004), “Harmonized European laboratory test method to generate parameters enabling the assessment of the recyclability of paper and board products in recycling mills with conventional process (Part I)” [14]. The repulping was performed in a disintegrator at 2.5%, 40 °C, and pH = 7 over 30,000 revolutions. The screening of coarse rejects (CRs) was performed through a filtration of the repulped fiber over a plate with 5 mm diameter slots (8.6 L/min, 5 min). The screening of fine rejects (FRs) was performed through the filtration of the coarse accepts over a plate with 150 µm slots (8.6 L/min, 5 min). Based on weight measurements after drying, the CR and FR fractions were calculated as a percentage of the dry sample weight. From the experimental data, the parameters were calculated for total rejects TR = CR + FR a (with correction factor a = 1), and fiber yield Y = 100% − TR. After making the hand sheets of the fine accept fiber fraction, visual inspection was performed to determine the visual impurity score (VI) and sheet adhesion score (SA).

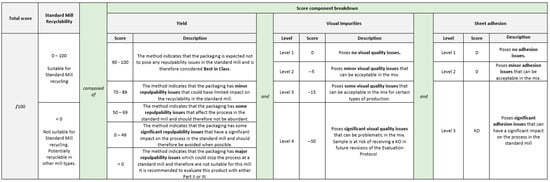

Finally, the technical recyclability score T was calculated as expressed in Equation (1), with the score breakdown and interpretation of the scores shown in Figure 1 [14].

Figure 1.

Assessment criteria for recyclability of impregnated papers through different scores [14].

3. Results and Discussion

3.1. Materials Characterization

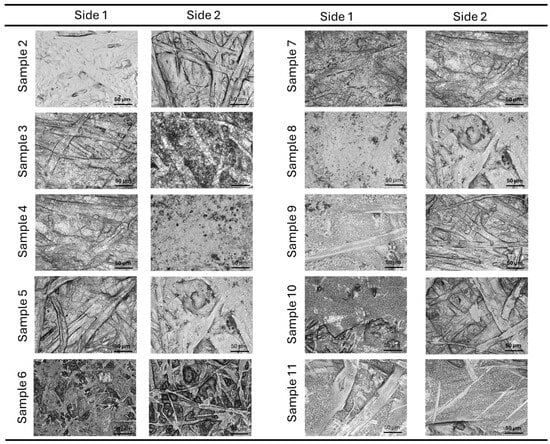

The microscopic surface evaluation of impregnated papers at both sides of the paper is shown in Figure 2. Given the type of wax and loading, different degrees of fiber coverage are observed. The wax rarely forms a continuous film that fully covers the fibers, in contrast with traditional paper coatings. The embedment of fibers into a wax film is most prominent for the impregnation with synthetic wax, while a certain degree of porosity or fiber exposure at the surface is observed for the papers impregnated with biowax. The optical observations may also be correlated to various degrees of accessibility of the fibers during repulping and recyclability. Alternatively, the partial surface coverage will be sufficient to form a locally protective film on the fibers, introducing barrier properties.

Figure 2.

Microscopic evaluation of impregnated papers with different types of biowax: side 1 (impregnated side) and side 2 (non-impregnated side).

3.2. Barrier Performance Testing

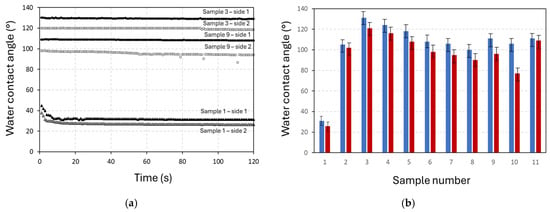

The results for water contact angles on both sides of the impregnated paper samples are presented in Figure 3. As shown in Figure 3a, the water contact angles on a non-coated paper strongly drop as a function of measuring time due to the absorption of the water into the paper structure. The water contact angles on impregnated papers remain stable over time and are higher compared to the base paper. The increase in hydrophobicity for papers impregnated with biowax is higher compared to synthetic PE wax, with values between 100° and 132° depending on the biowax type. The hydrophobicity of the biowax-impregnated paper may depend on the interplay of a number of factors, including the presence of long non-polar hydrocarbon chains from fatty acids and esters, the crystallization properties of the wax, and the resulting surface roughness of the impregnated paper. In general, the presence of non-polar fatty acids particularly improves the hydrophobic properties of the biowax, as observed for impregnated papers, with palm oil wax providing the highest contact angles. Alternatively, the water contact angles do not uniquely correspond with the degree of saturation or polarity of the biowax, as the particular molecular structures of sunflower wax, rapeseed wax, and castor oil wax are more polar and give reasonable water contact angles in the hydrophobic range.

Figure 3.

Water contact angles as an indication of hydrophobic barrier performance of biowax-impregnated papers: (a) illustration of water contact angles measured over time after deposition of a 3 µL droplet; (b) stabilized static water contact angle on side 1 (blue bar) and side 2 (red bar).

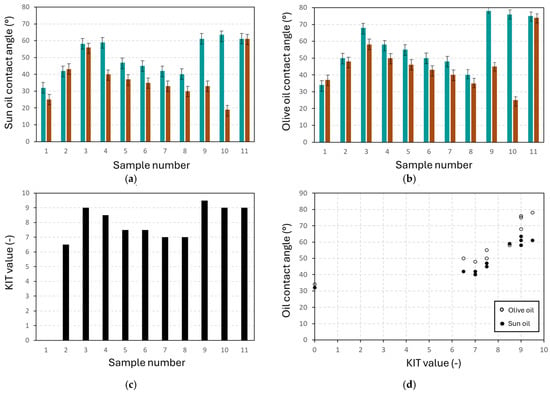

The properties corresponding with the oil resistance of the impregnated papers are presented in Figure 4, including the contact angle measurements with sun oil (Figure 4a) and olive oil (Figure 4b). The values are compared to the fat resistance determination of KIT values (Figure 4c), which are directly correlated to the oil contact angles (Figure 4d). The contact angles for olive oil are evidently higher compared to sun oil, in parallel with the surface tension of the oil, but similar trends amongst the different samples are observed. The maximum oil contact angles occur for papers with castor oil wax, as it has a more saturated molecular structure, hence making it better at repelling oils and grease.

Figure 4.

Oil contact angles and fat resistance of biowax-impregnated papers,: (a) sun oil contact angles on side 1 (green bar) and side 2 (brown bar); (b) olive oil contact angles on side 1 (green bar) and side 2 (brown bar); (c) KIT values; (d) relation between oil contact angles and KIT values.

3.3. Recyclability Testing

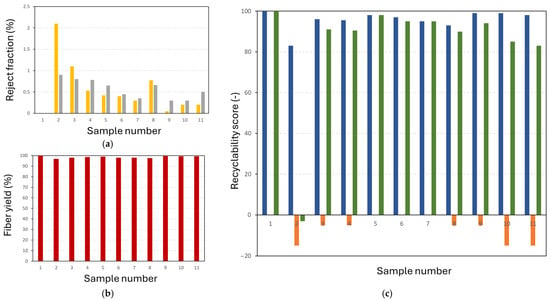

After repulping, the results of relevant assessment parameters are given in Figure 5. According to the reject fractions in Figure 5a, a reduction in both CR and FR is observed for the biowax-impregnated papers compared to the papers with a synthetic PE wax. In particular, the CR is highly reduced for biowax-impregnated papers due to the lack of formation of fiber agglomerates during the repulping process. A synthetic PE wax is generally considered to be more adherent to cellulose fibers than a biowax. Indeed, cellulose is a polar, hydrophilic material, while both synthetic PE waxes and biowaxes are non-polar and hydrophobic (composed primarily of long-chain hydrocarbons). Adhesion between non-polar waxes and polar cellulose is generally based on mechanical interlocking and weaker van der Waals forces, rather than strong chemical bonding. During impregnation, however, the PE wax more effectively penetrates the porous cellulose structure, creating a strong barrier and bonding. The PE wax is typically softer and less viscous than a biowax, resulting in a superior adherence to the cellulose fibers. During repulping, the accessibility of the fibers for disintegration plays a critical role. While comparing the two-sided impregnation with the one-sided impregnation of papers with castor oil wax, the former gives rise to a higher amount of CR and FR, owing to the reduced accessibility of the fibers. As a result of the calculated fiber yield Y in Figure 5b, all samples show a value Y above the threshold value (Y > 80), whereas the highest value of Y = 99.7 corresponds to the impregnated papers with castor oil wax.

Figure 5.

Results of recyclability assessment with indication of parameters resulting from the testing protocol: (a) fraction of coarse rejects (CRs, yellow) and fine rejects (FRs, gray); (b) fiber yield Y; (c) recyclability scores, including yield score (blue), visual impurity score (VI, orange), and technical recyclability score (T, green).

When comparing the different recyclability scores in Figure 5c, the occurrence of visual impurities in paper samples with a negative VI score (i.e., VI = −5 or −15) is mainly attributed to the presence of translucent wax particles. The sheet adhesion scores (SA = 0) are not plotted, as no sheet adhesion issues were noticed. The total recyclability scores T > 0 are acceptable, except for the impregnated paper with synthetic PE wax. A good recyclability of all biowax-impregnated papers was noticed, with the best performance of castor oil wax.

4. Conclusions

This study demonstrates that biowax impregnation significantly enhances the water and oil barrier properties of packaging papers without compromising recyclability. Depending on the selected type of biowax, the stable water contact angles of 100 to 120° are obtained together with oil contact angles up to 60°, in parallel with the improvements in grease resistance. Recyclability tests confirm a high fiber yield and low reject fractions, supporting a compatibility with conventional recycling processes for biowax-impregnated papers. In contrast to the papers impregnated with synthetic wax, the reduction in recyclability was mainly related to the high fraction of coarse rejects and fiber clogging.

Overall, biowax impregnation offers a sustainable and effective solution without compromising the performance and circularity of future fiber-based packaging materials. Future work should focus on long-term performance under real packaging conditions, life-cycle analysis, and the development of standardized industrial guidelines for the optimization of the biowax impregnation process.

Funding

This research was funded by Flanders Innovation and Entrepreneurship Agency (VLAIO) grant HBC.2022.0944 (Nada).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available from the author upon request.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Ying, H.; Qi, L.; Malotky, D.; Harris, J.; Kainz, B.; Drumright, R.; Liechty, W.; Mason, J. Coatings for sustainable paper-based flexible packaging: Barrier properties and processability. TAPPI J. 2022, 11, 617–622. [Google Scholar] [CrossRef]

- Kathuria, A.; Zhang, S. Sustainable and repulpable barrier coatings for fiber-based materials for food packaging: A review. Front. Mater. 2022, 9, 929501. [Google Scholar] [CrossRef]

- Liu, D.; Duan, Y.; Wang, S.; Gong, M.; Dai, H. Improvement of oil and water barrier properties of food packaging paper by coating with microcrystalline wax emulsion. Polymers 2022, 14, 1786. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Svendström, K.; Lepo, A. Biowaxes used as a barrier formulation material in coating fibre-based substrates. Packaging Technol. Sci. 2024, 37, 1095–1105. [Google Scholar] [CrossRef]

- Jahangiri, F.; Mohanty, A.; Pal, A.K.; Clemmer, R.; Gredori, S.; Misra, M. Wax coatings for paper packaging applications: Study of the coating effect on surface, mechanical, and barrier properties. ACS Environ. Au 2024, 5, 165–182. [Google Scholar] [CrossRef] [PubMed]

- Yadav, S.; Khan, A.; Hamdani, S.S.; Rabnawaz, M. Degradable polymeric waxes for paper coating. ACS Appl. Polym. Mater. 2024, 6, 3263–3272. [Google Scholar] [CrossRef]

- Basak, S.; Dangate, M.S.; Sany, S. Oil- and water-resistance paper coatings: A review. Prog. Org. Coat. 2024, 186, 107938. [Google Scholar] [CrossRef]

- Zhang, W.; Xiao, H.; Qian, L.Y.E. Enhanced water vapour barrier and grease resistance of paper bilayer-coated with chitosan and beeswax. Carbohydrate Polym. 2014, 101, 401–406. [Google Scholar] [CrossRef] [PubMed]

- Marzbani, P.; Azadfallah, M.; Yousefzadeh, M.; Najafi, F.; Pourbabaee, A.A.; Koivula, H.; Ritala, M. Effect of polyethylene wax/soy protein-based dispersion barrier coating on the physical, mechanical, and barrier characteristics of paperboards. J. Coat. Technol. Res. 2021, 18, 247–257. [Google Scholar] [CrossRef]

- Morgado, F.; Conceicao, R.; Barroso, S.; Pinto, F.R.; Gil, M.M.; Novo, P.J.; Alves, N.; Valente, J.F.A. Advances in biocoatings for paper and cardboard food packaging. Prog. Org. Coat. 2025, 208, 109491. [Google Scholar] [CrossRef]

- Woch, J.; Małachowska, E.; Korasiak, K.; Lipkiewicz, A.; Dubowik, M.; Chrobak, J.; Iłowska, J.; Przybysz, P. Barrier dispersion-based coatings containing natural and paraffin waxes. Molecules 2022, 27, 930. [Google Scholar] [CrossRef] [PubMed]

- Andersson, C.; Ernstsson, M.; Järnström, L. Barrier properties and heat sealability/failure mechanisms of dispersion-coated paperboard. Packaging Technol. Sci. 2003, 15, 209–224. [Google Scholar] [CrossRef]

- Khan, A.; Hamdani, S.S.; Duncan, E.; Rabnawaz, M. High-performance synthetic waxes for a sustainable packaging ecosystem. ACS Sus. Chem. Eng. 2024, 12, 12188–12199. [Google Scholar] [CrossRef]

- Leberle, U.; Georgiadou, M. Harmonised European Laboratory Test Method to Generate Parameters Enabling the Assessment of the Recyclability of Paper and Board Products in Recycling Mills with Conventional Process (Part I), Confederation of European Paper Industries (CEPI). 2025. Available online: https://www.cepi.org/cepi-recyclability-test-method-version-3/ (accessed on 3 November 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).