Abstract

This study explores the development of 4D-printed smart structures based on PLA/PETG (75/25) polymer blends reinforced with nanocellulose (0–3 wt%), processed using fused filament fabrication (FFF). Both conventional U-shaped specimens and anti-tri-chiral auxetic architectures were fabricated to evaluate the effects of nanocellulose on mechanical performance and shape memory behavior. Tensile tests demonstrated that nanocellulose reinforcement enhanced both strength and stiffness, with the highest values observed at 2 wt% (tensile strength of 56 MPa and Young’s modulus of 3.3 GPa). In standard U-shaped samples, all compositions showed excellent shape fixity and recovery (100%). For auxetic structures, shape memory behavior and deformation response varied with nanocellulose content. Notably, 2 wt% nanocellulose yielded the highest shape recovery ratio (90.8%) and fixity (99.8%), indicating improved elasticity and structural responsiveness. Meanwhile, 1 wt% nanocellulose resulted in the highest energy absorption and more controlled deformation under compression, suggesting enhanced energy dissipation and stress distribution. A slight decrease in performance at 3 wt% is attributed to nanocellulose agglomeration and reduced polymer chain mobility. These findings highlight nanocellulose as a multifunctional additive that enables fine-tuning of mechanical and functional properties in 4D-printed structures. Depending on the intended application whether focused on energy absorption, mechanical strength, or shape recovery nanocellulose content can be strategically adjusted. This approach opens pathways for designing responsive materials suited for biomedical engineering, adaptive devices, and advanced environmental technologies.

1. Introduction

The consideration of time as a fourth dimension in additive manufacturing resulted in the introduction of 4D printing, a type of technology by which the printed objects can be programmed to change shape or property upon exposure to environmental stimuli like heat, light, or water [1,2,3,4,5,6,7,8,9]. This type of dynamic behavior is extremely attractive for smart materials and responsive structures [10,11]. Although shape memory polymers (SMPs) are already the basis material for this application, they have poor mechanical properties and are currently receiving considerable attention as targets for reinforcement using high performance fillers such as nanocellulose, a renewable material with high mechanical performance, high surface area to volume ratio, and capacity to form strong hydrogen-bonded networks. It has become a promising reinforcement filler in polymer matrix [12].

Recent developments in the 3D printing of nanocellulose polymer-based composites show notable enhancements in mechanical property, printed resolution and biocompatibility. For instance, Latif et al. [13] also showed that resin-infused nanocellulose architectures had more than 40% higher bending strength and higher thermal stability than unmodified epoxy composites. Similarly, Ma et al. [14] grafted nanocellulose with PLA and PCL to get PLA/PCL NCC-based bionanocomposites suitable for 3D printing and exhibiting tensile strength over 50 MPa, high shape retention of printed objects. Zhou et al. [15] reported gelatin–oxidized nanocellulose hydrogels with compression strength of 20–35 kPa, yet they were verified to be biocompatible for biomedical applications. In SLA printing, Barkane et al. [16] has demonstrated that the incorporation of nanocellulose as low as 0.1 wt% into a bio-based acrylate resin raised the modulus to 160 MPa and increased glass transition temperature by 15 °C, highlighting the functional impact of nanocellulose at ultra-low concentrations. When comparing bacterial and pulp-derived nanocellulose in cartilage bioprinting, Jovic et al. [17] demonstrated that formulations including bacterial nanocellulose had better print fidelity and higher cell survival (>90%). The production of high-performance, sustainable, and bioactive composite materials for structural, biomedical, and environmental applications is made possible by the versatility and functional advantages of nanocellulose in 3D printing, as demonstrated by these works taken together.

The potential of nanocellulose-reinforced polymer composites in intelligent and adaptable systems is demonstrated by recent developments in 4D printing of these materials. For example, Gu et al. [18] used PCL/PBAT reinforced with cellulose nanofibers (CNFs) to create thermally sensitive shape memory composites, which resulted in stable deformation and great printability for soft grippers. Like this, Zhang et al. [19] showed that PVA/CNC composites’ mechanical strength, thermal stability, and water resistance were greatly increased by hydrogen bonding and coordination interactions, opening the door to direct ink writing 3D/4D printing. These results demonstrate that nanocellulose is a crucial enabler for high-performance, sustainable, and programmable 4D-printed structures because it can improve mechanical performance, shape memory behavior, and interfacial bonding in thermally or photothermally sensitive composite systems.

Superior mechanical flexibility and energy absorption qualities are provided by auxetic structures, which are distinguished by a negative Poisson’s ratio. These qualities are further improved by 4D printing and the use of intelligent reinforcements such as nanocellulose. According to a recent assessment, fiber-reinforced auxetic structures made with 4D printing have the potential to be used in robotics and aerospace because they can produce scalable, controllable form changes in response to stimuli [20]. Although there are currently no direct studies on nanocellulose in auxetic 4D-printed structures, related research on cellulose nanofiber (CNF)-reinforced shape memory polymers has demonstrated that minor additions of 1 part per hundred (phr) of polymer mass improve printability and mechanical performance while permitting dependable self-deforming behaviors like winding in soft grippers inspired by plants [18]. A further study that used La0.7Sr0.3MnO3 nanoparticles in shape memory polymers for auxetic structures showed that the shape recovery rate was improved (179.5%/min compared to 124.3%/min baseline) although fixity remained at about 100% and the recovery ratio only slightly decreased (from 88% to 81%) [21]. According to these results, nanocellulose can also improve the actuation efficiency, thermal responsiveness, and structural integrity of auxetic 4D-printed materials due to its natural hydrogen-bonding potential and mechanical reinforcement ability. This could lead to new applications in biomedical scaffolds, adaptive wearables, and responsive filtration systems.

The optimization of 3D-printed auxetic composites relies heavily on finite element modeling (FEM). Reducing the cell angle doubles the negative Poisson’s ratio and increases stiffness, according to ABAQUS/Standard nonlinear static analyses of re-entrant lattices as reported by Zhang et al. [22]. Saleh et al. [23] showed a 25% increase in energy absorption predicted by ANSYS Workbench quasi-static 3D simulations of CF-reinforced TPMS lattices, and auxetic ligament rotation was confirmed by ABAQUS/Explicit models of tetrachiral metals validated by DVC [24]. On the other hand, Foam-filled composites’ LS-DYNA dynamic crash analyses revealed an energy absorption increase of over 50% as suggested by Li et al. [25]. All things considered, FEM using ABAQUS, ANSYS, and LS-DYNA allows for the effective design of high-performance, lightweight auxetic composites [26,27].

This study examines the mechanical and shape memory properties of nanocellulose-reinforced PLA/PETG polymer composites that are 4D printed into auxetic anti-tri-chiral structures. The goal of the research is to develop smart materials with reversible transformations and structural flexibility by utilizing the reinforcing qualities of nanocellulose and the distinct deformation behavior of auxetic geometries. Biomedical devices, adaptive actuators, and environmental systems are just a few of the many possible uses for these materials. In particular the natural adsorption ability of nanocellulose and the porosity of auxetic structures can be used in concert for filtration and heavy metal adsorption applications.

2. Materials and Methods

2.1. Samples Preparation

2.1.1. Materials

The nanocellulose utilized in this study was obtained from CelluForce. The producer has reported some properties: It appears white to off-white, with a moisture content ≤ 6%, bulk density of 0.5–0.8 g/cm3, and powder particle size ranging from 1 µm to 50 µm. When dispersed at 2 wt%, the NC exhibits nanoparticle dimensions below 150 nm, a pH between 5 and 8, conductivity under 350 µS/cm, and viscosity greater than 5 cP. The material shows 70–90% crystallinity. Some researchers had studied the NCC from the same sources [28,29,30]. Polylactic acid (PLA) and polyethylene terephthalate glycol-modified (PETG) resin pellets from Push Plastic were selected as the polymer matrices for developing the Nanocellulose-reinforced 4D printing blends. PLA pellets, with a density of 1.24 g/cm3, and PETG pellets, with a density of 1.27 g/cm3, were sourced from Push plastics and served as the base materials for the composites.

2.1.2. Preparation of Blends and Nanocomposite

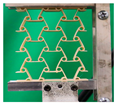

To prepare PLA, PETG, and nanocellulose for nanocomposite fabrication, all components were pre-dried in a vacuum oven at 60 °C for 24 h to remove residual moisture, as illustrated in Figure 1.

Figure 1.

Schematic representation of the preparation and processing of nanocellulose-reinforced PLA/PETG nanocomposites for 3D Printing.

First, a binary polymer blend of PLA and PETG was prepared at a 75/25 weight ratio by mixing their pellets in a beaker immediately before extrusion. This specific composition was selected based on our previous studies, which demonstrated its superior shape memory properties [3,31]. Nanocellulose powder was then incorporated at concentrations of 0%, 1%, 2%, and 3% w/w by blending it with the PLA-PETG pellets.

The resulting mixtures were fed into a single-screw extruder(ÉRIMA, Trois riviéres, Canada) to produce 3D printing filaments. Key processing parameters, including extrusion temperature, extrusion rate, line speed, and oven temperature, were carefully optimized to ensure high filament quality with minimal defects and consistent diameter. Extrusion temperatures were precisely maintained between 180 °C and 185 °C, as detailed in Table 1, to accommodate the distinct thermal and flow properties of each composition. A 3 mm nozzle was used to extrude filaments with a target diameter of 2.80 mm.

Table 1.

Compositions, extrusion temperatures, and 3D printing parameters of PLA/PETG blend and nanocellulose-reinforced PLA/PETG nanocomposites.

Following extrusion, the filaments were cooled and wound onto spools using a filament winding system, preparing them for 3D printing.

2.2. Three-Dimensional Printing by Fused Filament Fabrication (FFF)

The PLA/PETG polymer blend and nanocomposite filaments were used to print 100 mm × 20 mm × 1 mm samples for U-shape memory testing, following the ASTM D638 Type IV standard [32] and anti-tri-chiral auxetic structures. The specimens were designed using CAD software (Version: 5.2.1, Ultimaker B.V., Stationsplein 32, 3511 ED Utrecht, The Netherlands) and printed using an Ultimaker S5 printer (Ultimaker B.V., Stationsplein 32, 3511 ED Utrecht, The Netherlands).

For the PLA/PETG polymer blend and nanocellulose-reinforced polymer blend, a 0.4 mm AA nozzle was used. Printing parameters were optimized to ensure consistent performance across all samples, including a layer height of 0.2 mm, 100% infill density, an infill line width of 0.45 mm, and a printing speed of 20 mm/s. The bed temperature was maintained at 100 °C [33,34].

The nozzle temperature was tailored for each sample to optimize print quality, with specific values listed I, Table 1. This systematic approach ensured uniform filament quality and reliable print performance for both the PLA/PETG blends and nanocellulose-based nanocomposites.

2.3. Characterization

2.3.1. Tensile Test

Mechanical testing was performed under standard ambient conditions using an MTS universal testing machine (MTS, Eden Prairie, MN, USA) equipped with a 20 kN load cell. Five specimens per composition, conforming to ASTM D638 Type IV standards, were 3D-printed with a 0° raster orientation to ensure consistency in loading direction. This setup enabled a comprehensive evaluation of the tensile behavior of the materials, including the determination of ultimate tensile strength (UTS) and Young’s modulus (E). The obtained data provide valuable insights into the influence of nanocellulose reinforcement on the structural integrity and mechanical performance of the PLA-75/PETG-25 polymer blends.

2.3.2. Compression of Auxetic Anti-Trichiral Structures

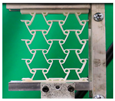

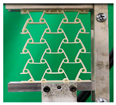

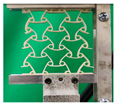

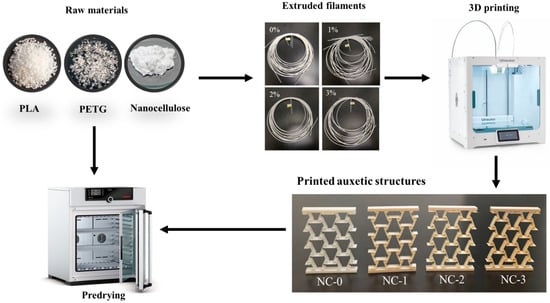

Mechanical compression tests were performed on three 3D-printed anti-tri-chiral auxetic specimens fabricated from a PLA/PETG (75/25) blend with different nanocellulose reinforcements. The tests were carried out using an MTS universal testing machine under standard ambient conditions, with a constant crosshead speed of 5 mm/min. Each specimen was designed based on a repeating anti-tri-chiral unit cell geometry consisting of circular ligaments with a radius of 2.5 mm connected by straight beams 10 mm wide as reported in Table 2, forming a triangular lattice pattern as seen in Figure 2a. The full 3D-printed structures measured 105 mm in height, 85 mm in width, and had a thickness of 15 mm, as shown in Figure 2b,c.

Table 2.

Geometic parameters of anti-tri-chiral unit cell.

Figure 2.

Schematic sketch of the unit cells for the anti-trichiral auxetic structure, illustrating the geometric parameters. The parameter r represents the mean radius of the circular node, l/2 denotes half the ligament length, and t indicates the ligament thickness (a) 3D design (b), and dimensions of the anti-trichiral auxetic structure specimen (c).

2.3.3. Finite Element Modeling (FEM)

Abaqus/Standard was used in this study to simulate the mechanical compression behavior of the auxetic structure under a Static, General step with nonlinear geometry (NLGEOM), which allowed for the accurate capture of large deformations. Since the goal was to separate and assess the impact of geometric auxeticity rather than material nonlinearity, the base material was modeled as linear elastic. This simplification makes it possible to observe directly how the structural topology controls the compression-induced energy absorption properties and negative Poisson’s ratio response. A quasi-static loading condition was guaranteed by the Static, General step, which allowed for stable convergence while taking into consideration nonlinear contact and deformation effects inside the lattice.

2.3.4. Infrared Spectroscopy (FTIR)

Fourier Transform Infrared Spectroscopy (FTIR) (Thermo Fisher Scientific, Madison, WI, USA) was performed in Attenuated Total Reflectance (ATR) mode with a resolution of 4 cm−1, covering the spectral range of 4000–400 cm−1.

2.3.5. X-Ray Diffraction (XRD)

X-ray diffraction (XRD) (Bruker AXS Inc, Madison, WI, USA) analysis was performed to examine the structural characteristics of the PLA/PETG nanocomposites. The measurements were carried out using a diffractometer with a Cu Kα radiation source (λ = 1.5406 Å), operating at 30 kV and 30 mA. Scans were recorded over a 2θ range of 5–40°, with a step size of 0.02° and a counting time of 1 to 2 s per point. These conditions provided clear and detailed diffraction patterns suitable for evaluating the effect of nanocellulose on the material structure.

2.3.6. Shape Memory Test

Three U-shaped 3D-printed samples per composition measuring 100 mm × 20 mm × 1 mm and printed at a 0° orientation were subjected to shape programming and recovery tests to evaluate their shape memory properties. The samples were first heated to the designated programming temperature (Tp) and then deformed to fit a 20 mm-thick mold. While held in the mold, they were cooled to room temperature to stabilize the temporary shape. After cooling, the mold was removed, and the fixed angle (θfixed) was measured to quantify the shape fixation stage.

For recovery evaluation, the samples were reheated to a constant temperature, and the bending angle (θi) was carefully measured. Shape fixity (Sf) and shape recovery (Sr) were calculated using the following equations:

These measurements provided quantitative insights into the efficiency of the shape memory behavior in the studied composites. Detailed experimental procedures and previous results can be found in our earlier work [31].

3. Results and Discussions

3.1. Infrared Spectroscopy (FTIR)

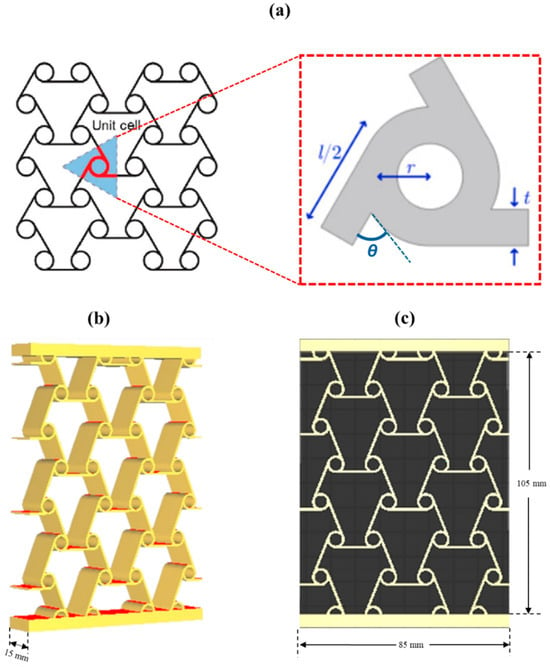

The structural features and chemical interactions of PLA/PETG blends with different amounts of nanocellulose (NC) are depicted in the FTIR spectrum shown in Figure 3. Key functional groups that correspond to the polymer matrix and nanocellulose are visible in the spectrum data, which sheds light on how they interact.

Figure 3.

FTIR analysis of PLA/PETG nanocomposites with increasing nanocellulose content.

The spectrum clearly shows the distinctive peaks of PETG and PLA. The C=O stretching vibration from ester bonds, a characteristic that distinguishes both PLA and PETG, is represented by the prominent absorption peak at about 1750 cm−1. C–O stretching vibrations also show up between 1200 and 1100 cm−1, which supports the polyester structure even more.

The presence of aromatic groups is indicated by the benzene ring vibrations from PETG, which emerge around 1600 cm−1 and 1500 cm−1, whereas the CH3 asymmetric and symmetric stretching vibrations of PLA are seen in the range of 2995–2945 cm−1 [3,35,36].

New spectrum characteristics are introduced by the addition of nanocellulose, which are mostly linked to hydroxyl (–OH) groups. The development of hydrogen bonds between nanocellulose and the polymer matrix is suggested by a broad band in the 3300–3400 cm−1 range that corresponds to O–H stretching vibrations. These vibrations become more noticeable as the NC concentration increases. Furthermore, cellulose’s C–O–C stretching vibrations occur between 1100 and 1000 cm−1 and frequently coincide with PLA/PETG’s ester groups [37,38].

The spectra show that nanocellulose significantly affects the structure of the polymer. Peak intensity variations and broadening in the O-H stretching region suggest improved intermolecular interactions, which could result in better adhesion and dispersion in the composite.

Hydrogen bonding between PLA and nanocellulose has been demonstrated to improve structural stability and mechanical qualities [39,40]. Strong interfacial adhesion between nanocellulose and polymers is indicated by the expansion of the O–H stretching peak, which has been widely documented [41].

Finally, with discernible interactions between the constituents, the FTIR measurement validates the effective incorporation of nanocellulose into the PLA/PETG matrix. Improved compatibility and structural alterations within the composite are indicated by changes in peak intensity and position, especially in the O–H and C=O stretching areas. These results demonstrate nanocellulose’s potential to improve polymer characteristics and are consistent with earlier research on nanocellulose-reinforced polymer systems.

3.2. X-Ray Diffraction (XRD)

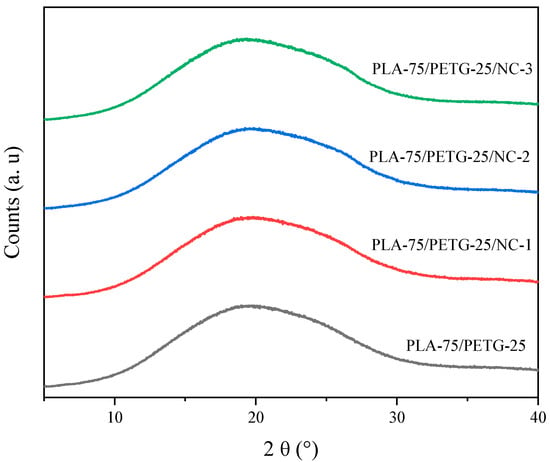

The X-ray diffraction (XRD) patterns of PLA-75/PETG-25 composites reinforced with varying nanocellulose contents (0%, 1%, 2%, and 3%) seen in Figure 4 reveal characteristic amorphous halos centered around 2θ° ≈ 16–25°, indicating a predominantly amorphous microstructure across all samples [42]. This broad diffraction band is typical of PLA and PETG blends, which are known to exhibit low crystallinity due to their molecular structure and the thermal history imposed by the 3D printing process [43].

Figure 4.

XRD of 3D printing of PLA-75/PETG-25 polymer blend and Nanocellulose-reinforced polymer composites.

Upon incorporation of NC at 1%, 2%, and 3%, the overall intensity of the diffraction pattern gradually increases without the appearance of sharp crystalline peaks. This indicates that NC enhances local ordering within the matrix but does not induce new crystalline phases or change the fundamental amorphous character of the system. These results align well with the FTIR analysis, which showed no new characteristic absorption bands attributable to crystalline structures, but rather an intensification of existing peaks particularly in the hydroxyl (–OH) and carbonyl (C=O) regions suggesting enhanced hydrogen bonding and polymer chain interactions.

FTIR and XRD findings suggest that nanocellulose acts primarily as a nucleating agent at the molecular level, promoting intermolecular interactions and possible local ordering, but not to the extent of forming detectable crystalline domains. Similar behavior has been reported in previous studies where NCC led to improved molecular packing and hydrogen bonding in PLA-based systems without significantly modifying the bulk crystalline structure [42,44,45].

In summary, the XRD analysis demonstrates that while nanocellulose marginally enhances structural organization in PLA/PETG blends, it does not change their amorphous nature or introduce new crystalline phases, consistent with previous findings in PLA/NC nanocomposites.

3.3. Mechanical Properties

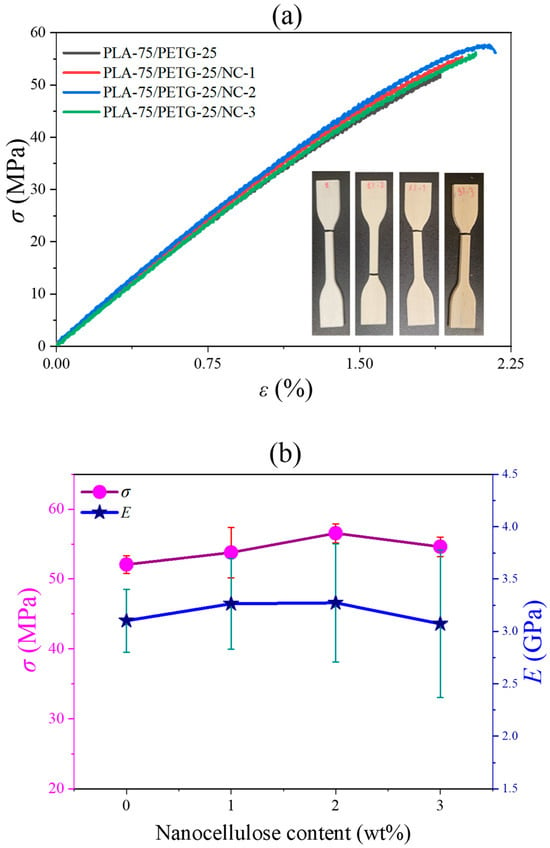

Fused Deposition Modeling (FDM) 3D-printed samples were utilized to assess the mechanical characteristics of PLA/PETG mixes with nanocellulose (NC) reinforcement. All samples show similar elastic behavior at low strain levels (<1%), according to the stress–strain curves (Figure 5a), indicating that the addition of NC does not appreciably change the initial stiffness. With varying NC concentrations, however, differences in ultimate tensile strength (UTS) are noted. With a strength of above 55 MPa, the PLA-75/PETG-25/NC-2 sample exhibits the maximum strength, with a little drop at 3 wt% NC. This pattern suggests that enhanced interfacial bonding and stress transmission increase mechanical performance at an ideal NC concentration of 2 wt%. At 3 wt% NC, however, potential nanocellulose agglomeration might serve as stress concentrators, decreasing efficacy [33].

Figure 5.

Mechanical properties of PLA/PETG nanocomposite with different nanocellulose content (a) stress–strain curves and (b) comparison of ultimate tensile strength (σ) and elastic modulus (E) for PLA-75/PETG-25 blends with varying nanocellulose (NC) content.

The change in UTS (σ, in MPa) and elastic modulus (E, in GPa) with NC concentration is quantified by the bar chart in Figure 5b. The average UTS and E of the control sample (0 wt% NC) are approximately 52 MPa and ~3 ± 0.3 GPa, respectively. At 2 wt% NC, the strength reaches its maximum (~56 MPa), and at 3 wt% NC, it slightly decreases to ~54 MPa. The elastic modulus has a similar trend, peaking at around 3.3 ± 0.6 GPa for 2 wt%, suggesting increased stiffness as a result of NC reinforcement [46]. The bar chart’s error bars indicate mechanical property variability, which is probably caused by irregular layer deposition and the intrinsic anisotropy of FDM-printed parts [47].

The FDM process has a significant impact on mechanical performance. Local weak regions of FDM-printed objects are introduced by the layering process, especially when subjected to tensile pressure. Strength and stiffness are increased by improved layer adhesion, which is facilitated by nanocellulose. However, excess NC might cause nozzle blockage or uneven dispersion at higher NC loadings (3 wt%), which would impair mechanical performance [48]. Previous studies have demonstrated that nanocellulose reinforcement enhances the characteristics of the polymer matrix at low concentrations; however, excessive filler might result in flaws, diminishing the mechanical benefits [49].

In summary, PLA-75/PETG-25 used in FDM 3D printing showed a maximum tensile strength (~56 MPa) and stiffness (~3.3 GPa) when the NC content is 2 wt%. Although it exhibits declining results at increasing concentrations, nanocellulose reinforcement improves mechanical characteristics by strengthening polymer connections. To maximize the mechanical performance of printed items, the intrinsic limits of FDM, such as interlayer adhesion and NC dispersion, must be adjusted.

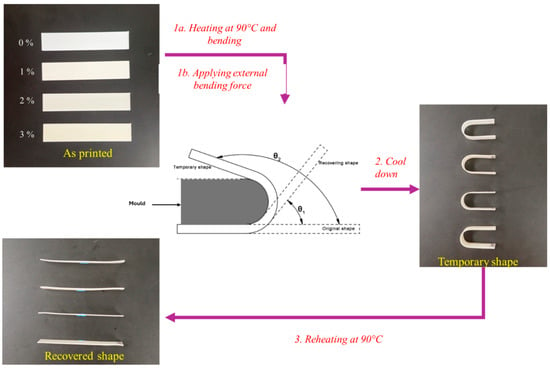

3.4. U-Shape Memory Performances

The shape memory behavior of 3D-printed PLA/PETG nanocomposite samples with various levels of nanocellulose (0%, 1%, 2%, and 3%) is shown in Figure 6. There is a discernible color shift, with an opaquer look resulting from a higher nanocellulose concentration. The images additionally illustrate excellent printing quality, with smooth surfaces and distinct shapes. The as-printed flat state, deformation into a U-shape following heating over the glass transition temperature (Tg = 90 °C) with an applied external force, and subsequent chilling to maintain the temporary shape are the three primary steps in the shape memory process. Regardless of the amount of nanocellulose present, all samples completely regain their initial flat shape when heated to 90 °C. This suggests that while adding nanocellulose may affect other mechanical properties, it does not impair the shape memory effect. These findings demonstrate the potential of PLA/PETG composites reinforced with nanocellulose for use in biomedical devices, smart actuators, and self-healing materials. Additional quantitative research may shed more light on how nanocellulose affects mechanical performance and recovery kinetics.

Figure 6.

Shape memory behavior of 3D-Printed PLA/PETG nanocomposite with different nanocellulose contents.

The impact of nanocellulose content on form fixity (Sf), shape recovery (Sr), and shape recovery time can be observed in Figure 7. Nanocellulose content has no detrimental effect on the material’s capacity to hold and regain its shape because shape fixity and recovery are always 100%. This implies that for all evaluated compositions, the polymer matrix offers adequate structural integrity and flexibility. The small difference in shape recovery time, however, suggests that the concentration of nanocellulose affects recovery speed but has no effect on recovery capabilities. This pattern may be explained by how nanocellulose alters the matrix’s viscoelastic characteristics, which in turn alters how responsive it is to outside stimuli.

Figure 7.

Shape memory performance of PLA/PETG composites as a function of nanocellulose content.

Strong hydrogen bonds seen in nanocellulose, as shown by FTIR data, may be one reason. These bonds increase network rigidity and limit polymer chain mobility, which may impede shape recovery. Furthermore, the presence of nanocellulose may change the material’s thermal conductivity as reported by Shrestha et al. [50], which indicates that nanocellulose exhibits higher intrinsic thermal conductivity than most polymer matrices. For example, nanocellulose has been reported to reach thermal conductivity values up to ~1 W/m·K, compared to <0.2 W/m·K for PLA or PETG. This facilitates faster heat distribution during thermal triggering, promoting faster transition through the glass transition temperature of PLA. These changes could impact heat distribution and shape recovery kinetics. Additionally, nanocellulose may function as a plasticizer, changing the mechanisms of stress transmission, or as a reinforcement, increasing stiffness and viscosity, depending on how it is dispersed. While too much nanocellulose could limit polymer mobility and slow recovery, the trend in the time recovery curve might suggest an ideal concentration of nanocellulose at which the fastest recovery occurs.

According to previous studies on nanocellulose-reinforced shape-memory polymers (SMPs), although nanocellulose improves mechanical characteristics, its higher crystallinity and intermolecular interactions may also have an impact on recovery speed [37]. Based on this research, a low concentration of nanocellulose can speed up recovery by enhancing stress transfer and heat conductivity [51], while a higher concentration could hinder recovery by decreasing polymer mobility. Because poor dispersion can result in heterogeneous structures that either delay or localize form recovery, the degree of filler-matrix interaction is crucial [52].

In summary, nanocellulose amount has a slight impact on recovery time but has no effect on shape fixity or recovery % in standard U-shape memory test. The significance of striking a balance between reinforcement and flexibility to maximize recovery speed is highlighted by this behavior, which is probably caused by variations in matrix stiffness, thermal conductivity, and viscoelastic behavior.

3.5. Anti-Tri-Chiral Auxetic Structures

3.5.1. Mechanical Performance Under Compression

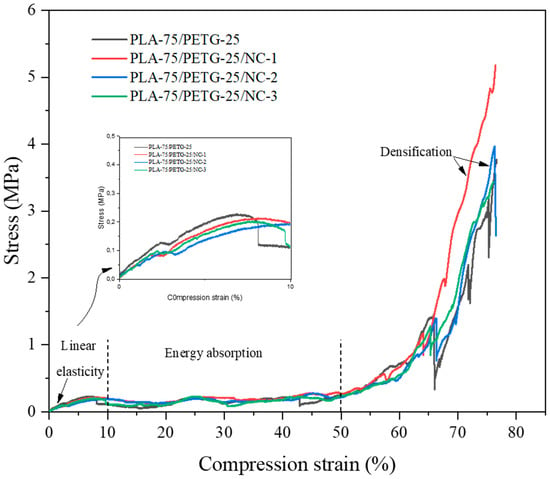

The compression behavior of anti-tri-chiral auxetic structures based on PLA-75/PETG-25 reinforced with 0, 1, 2, and 3 wt% nanocellulose was analyzed in different stages, focusing on mechanical performance and energy absorption as shown in Figure 8. Both the tabulated data and the associated stress–strain curves can be used to analyze the mechanical response of 3D-printed anti-tri-chiral auxetic structures. The findings point to three primary stages of deformation: elastic deformation, buckling and auxetic behavior, and densification.

Figure 8.

Compression behavior and energy absorption of anti-tri-chiral auxetic structures based on PLA-75/PETG-25 blend reinforced with nanocellulose.

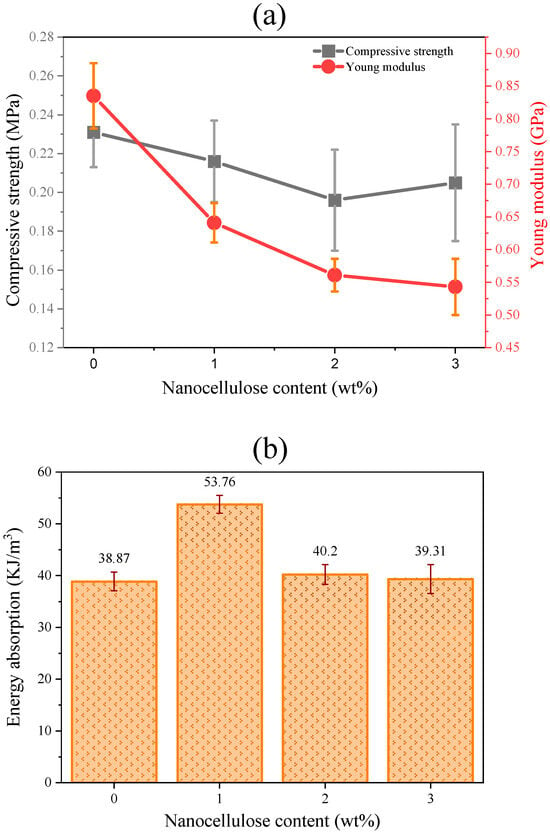

Compressive strength and Young’s modulus inside the elastic zone noticeably drop when the nanocellulose content in PLA/PETG-based anti-tri-chiral auxetic structures is increased from 0 to 3 wt%, as shown in Figure 9a. Compressive strength decreases from about 0.24 MPa at 0 wt% to about 0.195 MPa at 2 wt%, then slightly increases to about 0.205 MPa at 3 wt%, indicating a partial recovery of load-bearing capacity at higher reinforcement levels. Young’s modulus, on the other hand, continuously decreases across the same range, from roughly 0.87 GPa to 0.55 GPa, suggesting a significant decrease in initial stiffness. The rupture of the polymer matrix and possible agglomeration of nanocellulose at larger levels are responsible for this behavior, which reduces stiffness and impedes effective stress transfer. Although nanocellulose is known to improve toughness and shape memory performance in later stages of deformation, its presence in the elastic zone seems to impair compressive resistance and structural stiffness, particularly at higher concentrations, which is consistent with earlier research on nanocellulose-filled polymer composites [53,54].

Figure 9.

Effect of nanocellulose content on compressive strength and elastic modulus in the elastic deformation stage (a). Energy absorption of the auxetic anti-tri-chiral structures (b).

During the densification stage, which occurs after a strain of over 50%, all the samples exhibit a sharp increase in stress because of the closing up of internal voids. However, this reaction is more consistent in structures reinforced with nanocellulose. More specifically, NC-1 and NC-2 show smoother stress increases with fewer fluctuations, indicating enhanced energy absorption and delayed structural collapse. Although NC-1 reaches the highest stress levels, it also shows more variability, suggesting that the localized stiffness induced by nanocellulose may disrupt uniform deformation under extreme compression. This is further supported by the data in Figure 9b, where energy absorption is measured. The unreinforced PLA/PETG structure absorbs 38.87 KJ/m3 J, while the NC-1 sample (with 1 wt% nanocellulose) achieves the highest energy absorption of 53.76 KJ/m3, a significant improvement of almost 39%. This superior performance can be attributed to the optimal dispersion and bonding of nanocellulose, enhancing energy dissipation mechanisms like ligament bending and node rotation. At 2 wt% (NC-2), energy absorption decreases to 39.31 KJ/m3, possibly due to nanocellulose clumping or reduced flexibility. Interestingly, energy absorption rises again to 40.2 KJ/m3 at 3 wt% (NC-3), indicating some recovery in mechanical synergy but still not reaching the level of NC-1. These findings underscore a nonlinear correlation between nanocellulose content and energy absorption, underscoring the importance of precise filler loading to balance stiffness, toughness, and auxetic response.

The descending peaks observed in the densification region of the compression stress–strain curves as seen in Figure 8 are primarily attributed to the progressive collapse and subsidence of unit cells within the auxetic anti-tri-chiral structures, rather than to testing setup artifacts. As compression increases, localized buckling and folding of the interconnected circular nodes and ligaments occur, resulting in sudden stress drops that manifest as descending peaks in the curves. This behavior is typical of auxetic lattice architectures, where the unique geometry allows for large deformation and energy dissipation through sequential cell collapse; A phenomenon consistent with previous studies on auxetic metamaterials under compression [55,56]. Visual evidence from the compression sequence images were reported in Table 3 supports this. Indeed, as strain increases, individual rows or sections of the structure sequentially deform and collapse, particularly during the densification phase.

Table 3.

Mechanical response of anti-tri-chiral auxetic structures based on PLA/PETG polymer blends reinforced with different amount of nanocellulose under compression.

Due to their negative Poisson’s ratio, auxetic structures have been shown to have higher energy absorption and enhanced mechanical stability under compression [57]. Like the findings of this investigation, it was discovered that auxetic deformation and buckling play a major role in energy dissipation and structural integrity in metamaterials [58]. The typical three-stage deformation pattern seen in previous studies on chiral-based auxetic designs is followed by the stress–strain response of the pure PLA/PETG anti-tri-chiral auxetic structure [59]. However, this study differs from other research that only focused on pure polymer auxetic structures because the addition of nanocellulose reinforcement improves energy absorption and structural stability.

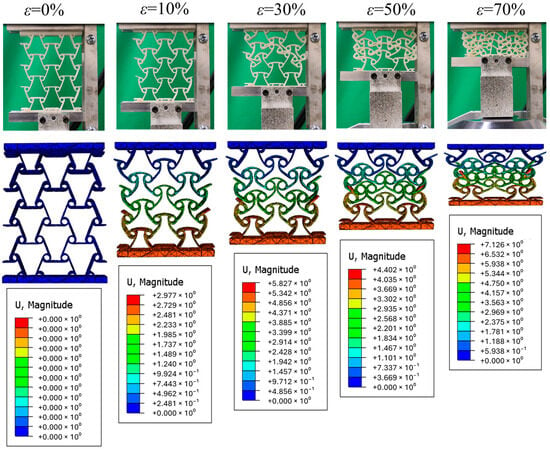

The experimental deformation and the finite element modeling (FEM) using Abaqus (Figure 10) of an anti-tri-chiral auxetic structure made from a PLA/PETG (75/25) polymer blend under progressive compressive strain ranging from 0% to 70% are contrasted in the accuracy of the numerical model in the initial, unloaded state is confirmed by the fact that both the experimental and simulated structures show very little stress at 0% strain. The auxetic behavior is demonstrated by the central nodes’ rotation and lateral contraction for strains of 10% and 30%. These deformation patterns are well captured by the simulation, which shows corresponding stress concentrations at the ligament junctions, primarily highlighted in green and yellow. At higher strain levels (50% and 70%), the structure exhibits pronounced central compression, while the outer boundaries remain relatively intact. While the simulations capture the general trends of stress concentration particularly the localization in triangular nodes and curved ligaments indicated by orange and red zones; They tend to predict a more symmetric deformation pattern than what is observed experimentally. This discrepancy likely stems from real-world imperfections such as slight geometric irregularities, uneven material distribution, or frictional effects during testing, which are not accounted for in the idealized finite element model. These asymmetries in the experimental response may also contribute to the descending stress peaks observed in the densification region of the compression curves (Figure 8), as local instabilities or asymmetric unit cell collapse trigger sudden stress drops. Nonetheless, the simulations remain valuable in qualitatively predicting local stress distribution and overall deformation behavior, in agreement with previous FEM validations for auxetic designs [60]. Similarly, the model’s predictive capability aligns with observations from Zhou et al. [61], confirming its relevance for guiding the design and optimization of complex auxetic structures, despite some limitations in capturing experimental asymmetries.

Figure 10.

Deformation behavior and stress distribution of interlocking auxetic structure under compression (no nanocellulose reinforcement).

Table 3 presents the deformation behavior of PLA/PETG-based anti-tri-chiral auxetic structures under compressive strain ranging from 0% to 70%, highlighting the significant impact of nanocellulose reinforcement on their mechanical response. The reference structure without nanocellulose (0 wt%) displays the expected auxetic behavior characterized by node rotation and lateral contraction; however, it shows signs of early instability at high strain levels. With the addition of 1 wt% nanocellulose, the deformation becomes more uniform and controlled. This formulation exhibits the most optimal auxetic performance, marked by smooth, coordinated deformation and excellent structural integrity. This enhancement reflects the effective reinforcement of the matrix and improved load transfer, facilitated by hydrogen bonding and interfacial interactions between nanocellulose and the polymer chains [62,63]. At 2 wt%, the structure still performs well but begins to show signs of reduced flexibility, and at 3 wt%, the auxetic response slightly deteriorates. This decline is likely due to nanocellulose agglomeration, which can impair polymer mobility and create local stress concentrations, as observed in previous studies on nanocellulose-filled composites [64]. These results confirm that nanocellulose, when optimally integrated at 1 wt%, serves as a valuable functional additive in 4D-printed auxetic structures, enabling tunable mechanical behavior and improved shape programmability.

The observed tension–compression asymmetry in our experimental results can be attributed to the intrinsic differences in mechanical behavior under tensile and compressive loading in both the polymer blend and the auxetic geometry used for compression testing. Indeed, tensile tests were conducted using ASTM D638, which evaluates standard dog-bone-shaped specimens in uniaxial loading, providing uniform stress distribution. In contrast, compression tests were performed on 3D-printed trichiral auxetic structures, which are architected to deform nonlinearly and exhibit auxetic behavior (negative Poisson’s ratio). Auxetic lattices often show direction-dependent mechanical responses due to their geometry, which leads to tension-compression asymmetry, as confirmed in the literature [65].

The PLA-75/PETG-25/NC-1 sample likely shows the highest energy absorption under compression due to a synergy between improved interfacial bonding (enabled by nanocellulose) and optimal stiffness for structural deformation. At 1 wt% nanocellulose, dispersion is ideal in the structure and avoids agglomeration, enhancing stress distribution and deformation uniformity. This aligns with findings that small amounts of reinforcement can improve mechanical damping and energy dissipation in auxetic lattices [66].

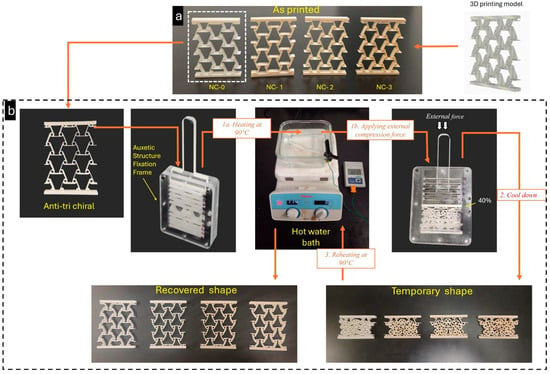

3.5.2. Shape Memory Behavior Process

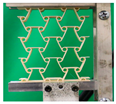

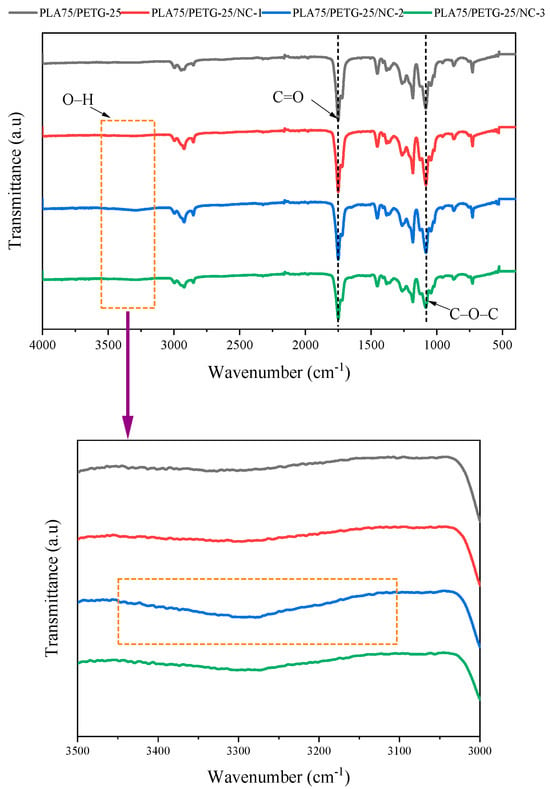

The 3D-printed auxetic structures in Figure 11a are of the highest quality because they can display the negative Poisson’s ratio behavior that is typical of auxetic materials. High deformation capacity and better energy absorption are made possible by this special characteristic as demonstrated in the above section, which improves structural performance. The improved shape memory and mechanical performance is a result of careful material selection and printing. To further illustrate these functionalities, Supplementary Video S1 presents the experimental shape recovery of the auxetic structure under thermal activation, while Supplementary Video S2 shows the numerical simulation of the recovery process, confirming the deformation mechanisms and the auxetic behavior predicted by the model.

Figure 11.

Shape memory process of Tri-Chiral auxetic structures reinforced with nanocellulose. (a) 3D printed Tri-chiral auxetic structures based on PLA-75/PETG-25 polymer blend reinforced with 1, 2, and 3 wt% of nanocellulose. (b) Shape memory programming and recovery process: The auxetic structure is placed in an Auxetic Structure Fixation Frame and heated above the glass transition temperature (T > Tg, 90 °C) in a hot water bath while an external force is applied to deform the structure. After cooling, the temporary shape is maintained. Upon reheating at 90 °C, the structure recovers its original form, demonstrating its shape memory behavior.

Following external stimuli or deformation, Figure 11b illustrates the final fixation of the temporary shape, demonstrating the stability and dependability of the 3D-printed structure. A key feature of shape memory polymers is fixing, in which the structure maintains its transient state even after being exposed to different mechanical or environmental stresses. The figure clearly demonstrates the printed material’s superior functional performance, highlighting its appropriateness for applications needing regulated shape transitions and the maintenance of a programmed form.

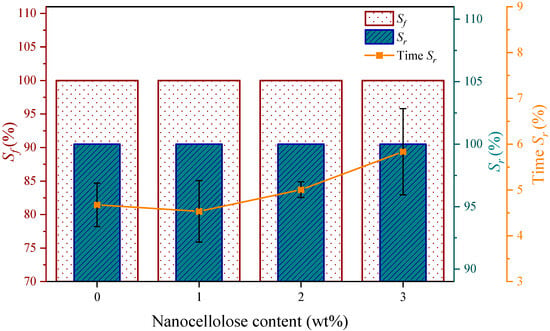

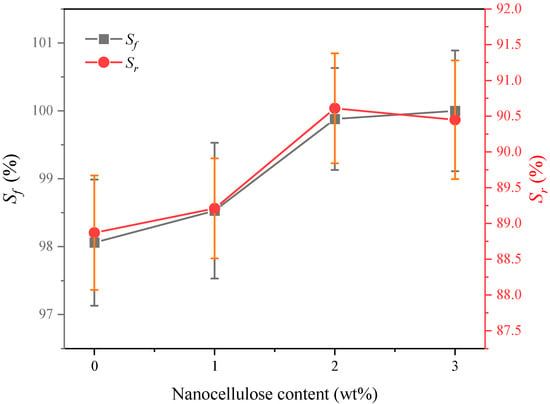

As illustrated in Figure 12, the performance of shape memory is much improved by the addition of nanocellulose to anti-tri-chiral PLA/PETG auxetic structures. According to the figure, the shape recovery ratio (Sr) peaks at 90.8% with 2% nanocellulose before somewhat declining to 90.4% at 3%, while the shape fixity ratio (Sf) grows from 98.1% to over 99.8% as the nanocellulose content increases to 3%. According to FTIR studies, this enhancement is attributed to nanocellulose’s capacity to create a hydrogen-bonded network inside the polymer matrix, improving crystallinity and fostering mechanical and thermal stability. Higher concentrations, however, may cause nanocellulose agglomeration to impair soft segments’ elasticity, which would lessen form recovery. These trends are in line with the findings of Salama et al. [63], who emphasized the role of nanocellulose as a thermal trigger in shape memory materials, Fu & Tian [67], who highlighted its contribution to temporary phase stabilization and enhanced shape memory performance, and Auad et al. [68], who reported recovery rates above 95% with only 1–2% nanocellulose in TPU composites. The usefulness of nanocellulose as a functional additive in 4D-printed polymer systems for intelligent applications is supported by these findings.

Figure 12.

Evolution of the shape fixity ratio (Sf) and the shape recovery ratio (Sr) as a function of nanocellulose content (0–3 wt%) in PLA/PETG-based anti-tri-chiral auxetic structures.

A clear relationship can be observed between the shape memory behavior and the compression properties of anti-tri-chiral structures in PLA/PETG reinforced with nanocellulose. With the increase in nanocellulose content, the shape memory performance significantly improves, with a shape recovery rate reaching a maximum of 90.8% at 2% by weight and a shape fixation rate steadily increasing from 98.1% to over 99.8% at 3% by weight. This improvement is attributed to the formation of a hydrogen-bonded network within the polymer matrix, which enhances crystallinity and promotes both thermal and mechanical stability, as confirmed by FTIR analysis. However, this improvement in functional performance is accompanied by a reduction in compressive strength and Young’s modulus in the elastic region. The initial stiffness decreases with the addition of nanocellulose, indicating a disruption in the continuity of the matrix and reduced stress transfer efficiency, particularly at higher reinforcement levels. This suggests that the improved shape recovery is facilitated by increased chain mobility, which, while beneficial for shape programming and recovery, compromises the elastic mechanical response. At 3 wt%, a slight decline in Sr and minor recovery in compressive strength suggest the onset of nanocellulose agglomeration, which limits polymer mobility and introduces localized stress concentrations. These findings highlight the dual role of nanocellulose as both a structural modifier and a functional additive.

4. Conclusions

This study aimed to develop intelligent, responsive 4D-printed anti-tri-chiral auxetic structures using PLA-75/PETG-25 blends reinforced with nanocellulose. By leveraging the reinforcing capability of this sustainable nanofiller, both tensile strength and stiffness were improved. The highest performance was achieved at 2 wt% nanocellulose, with an elastic modulus of 3.3 GPa and a tensile strength of 56 MPa.

The addition of nanocellulose notably enhanced the shape memory performance of the auxetic structures, achieving a maximum recovery ratio of 90.8% and a fixity ratio exceeding 99.8% at 2 wt%. This improvement results from hydrogen bonding between nanocellulose and the polymer matrix, which strengthens the internal network and stabilizes the temporary shape. A slight decrease at 3 wt% was attributed to reduced chain mobility and filler agglomeration, indicating that a moderate nanocellulose content allows precise tuning of the material’s mechanical and functional behavior.

Under compression, auxetic structures exhibit three deformation stages: elastic, auxetic buckling, and densification. The addition of nanocellulose slightly lowers stiffness but enhances energy absorption and delays failure, with 1 wt% providing the highest absorption (53.76 kJ/m2) due to improved stress distribution and smoother deformation. At 3 wt%, agglomeration reduces flexibility.

These auxetic structures offer shape adaptability, energy absorption, and durability, making them suitable for soft robotics, biomedical, and protective applications. Their porosity and nanocellulose content also support environmental uses such as water purification. Overall, this work unites materials science, additive manufacturing, and sustainability to develop bio-based, programmable 4D-printed structures with intelligent and adaptive performance.

Supplementary Materials

The following supporting information can be download at: https://www.mdpi.com/article/doi/sl. Video S1: Auxetic-experimental shape recovery; Video S2: Auxetic-numerical simulation of shape recovery.

Author Contributions

Conceptualization, K.B.; methodology, K.B. and M.H.; software, A.M.; validation, M.H. and L.L.; formal analysis, K.B. and D.M.; investigation, K.B. and D.M.; resources, M.H. and L.L.; data curation, K.B.; writing—original draft preparation, K.B.; writing—review and editing, M.H., L.L. and D.M.; supervision, M.H. and L.L.; project administration, M.H. and L.L.; funding acquisition, K.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Natural Sciences and Engineering Research Council of Canada (NSERC) grant number [RGPIN-2021-02846].

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge Yasmine Abdin and Rachel Cummings, Department of Materials Engineering, The University of British Columbia, Vancouver, Canada.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Ding, A.; Tang, F.; Alsberg, E. 4D printing: A comprehensive review of technologies, materials, stimuli, design, and emerging applications. Chem. Rev. 2025, 125, 3663–3771. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, D.; Liu, J.; Xu, S.; Qiu, F.; Hu, L.; Liu, Y.; Ke, C.; Ruan, C. 4D printing polymeric biomaterials for adaptive tissue regeneration. Bioact. Mater. 2025, 48, 370–399. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. Designing advanced 4D printing thermo-sensitive shape memory polymer blends for enhanced mechanical and shape memory performances. Prog. Addit. Manuf. 2025, 10, 6507–6526. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. Advanced 4D Printing of Flax Fiber-Reinforced PLA/PETG Blends for Enhanced Mechanical, Thermal, and Shape Memory Properties. Polymer 2025, 333, 128587. [Google Scholar] [CrossRef]

- Kouka, M.A.; Abbassi, F.; Habibi, M.; Chabert, F.; Zghal, A.; Garnier, C. 4D printing of shape memory polymers, blends, and composites and their advanced applications: A comprehensive literature review. Adv. Eng. Mater. 2023, 25, 2200650. [Google Scholar] [CrossRef]

- Megdich, A.; Habibi, M.; Laperrière, L. A review on 4D printing: Material structures, stimuli and additive manufacturing techniques. Mater. Lett. 2023, 337, 133977. [Google Scholar] [CrossRef]

- Megdich, A.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. Advanced nanocomposites for 4D printing: High-performance electroactive shape memory polymers for smart applications. Appl. Mater. Today 2025, 44, 102702. [Google Scholar] [CrossRef]

- Saska, S.; Pilatti, L.; Blay, A.; Shibli, J.A. Bioresorbable polymers: Advanced materials and 4D printing for tissue engineering. Polymers 2021, 13, 563. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D printing of polymers: Fused deposition modelling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Franco Urquiza, E.A. Advances in additive manufacturing of polymer-fused deposition modeling on textiles: From 3D printing to innovative 4D printing—A review. Polymers 2024, 16, 700. [Google Scholar] [CrossRef]

- Sajjad, R.; Chauhdary, S.T.; Anwar, M.T.; Zahid, A.; Khosa, A.A.; Imran, M.; Sajjad, M.H. A review of 4D printing–technologies, shape shifting, smart polymer based materials, and biomedical applications. Adv. Ind. Eng. Polym. Res. 2024, 7, 20–36. [Google Scholar] [CrossRef]

- Shen, Z.; Qin, M.; Xiong, F.; Zou, R.; Zhang, J. Nanocellulose-based composite phase change materials for thermal energy storage: Status and challenges. Energy Environ. Sci. 2023, 16, 830–861. [Google Scholar] [CrossRef]

- Latif, M.; Jiang, Y.; Kumar, B.; Kim, J. 3D printing of nanocellulose structures infused Epofix resin with improved mechanical properties. In Proceedings of the 2022 2nd International Conference on Digital Futures and Transformative Technologies (ICoDT2), Rawalpindi, Pakistan, 24–26 May 2022; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Latif, M.; Jiang, Y.; Kumar, B.; Kim, J. One-pot cellulose nanofibrillation, surface-modification and grafting by deep eutectic solvent towards high performance 3D printing nanocellulose-enriched bionanocomposites. Ind. Crops Prod. 2024, 210, 118134. [Google Scholar]

- Zhou, S.; Han, C.; Ni, Z.; Yang, C.; Ni, Y.; Lv, Y. Gelatin-oxidized nanocellulose hydrogels suitable for extrusion-based 3D bioprinting. Processes 2022, 10, 2216. [Google Scholar] [CrossRef]

- Barkane, A.; Jurinovs, M.; Briede, S.; Platnieks, O.; Onufrijevs, P.; Zelca, Z.; Gaidukovs, S. Biobased resin for sustainable stereolithography: 3D printed vegetable oil acrylate reinforced with ultra-low content of nanocellulose for fossil resin substitution. 3D Print. Addit. Manuf. 2023, 10, 1272–1286. [Google Scholar] [CrossRef]

- Jovic, T.H.; Nicholson, T.; Arora, H.; Nelson, K.; Doak, S.H.; Whitaker, I.S. A comparative analysis of pulp-derived nanocelluloses for 3D bioprinting facial cartilages. Carbohydr. Polym. 2023, 321, 121261. [Google Scholar] [CrossRef]

- Jovic, T.H.; Nicholson, T.; Arora, H.; Nelson, K.; Doak, S.H.; Whitaker, I.S. Design and development of 4D-printed cellulose nanofibers reinforced shape memory polymer composites: Application for self-deforming plant bionic soft grippers. Addit. Manuf. 2023, 70, 103544. [Google Scholar]

- Bai, H.; Li, Y.; Zhang, S.; Ma, P.; Dong, W. Photo-crosslinkable poly (vinyl alcohol)/nanocrystalline cellulose composites with controllable performance and exceptional water vapor barrier property for packaging application. Cellulose 2022, 29, 7721–7734. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L. 4D printing of fiber-reinforced auxetic structures: The building blocks: A review. Smart Mater. Struct. 2024, 33, 063001. [Google Scholar] [CrossRef]

- Yousuf, M.H.; Abuzaid, W.; Egilmez, M. 4D Printing of Magnetic Shape Memory Polymer—La0.7Sr0.3MnO3 Nanocomposite. Adv. Eng. Mater. 2025, 27, 2402423. [Google Scholar] [CrossRef]

- Zhang, W.; Yan, Z.; Zhang, J.; Wang, H.; Han, F.; Jiang, P.; Wu, T.; Qin, Q. On in-plane crushing behavior of an improved double-arrow auxetic metamaterial with two-step deformation mode. Eng. Struct. 2024, 303, 117482. [Google Scholar] [CrossRef]

- Saleh, M.; Anwar, S.; Al-Ahmari, A.M.; Alfaify, A. Compression performance and failure analysis of 3D-printed carbon fiber/PLA composite TPMS lattice structures. Polymers 2022, 14, 4595. [Google Scholar] [CrossRef]

- Etemadi, E.; Hosseinabadi, M.; Gholikord, M.; Abbaslou, M.; Imani, M.; Hu, H. Dynamic performance of arc-shaped auxetic structures through split Hopkinson pressure bar tests. Smart Mater. Struct. 2025, 34, 085022. [Google Scholar] [CrossRef]

- Li, Z.; Yu, Q.; Zhao, X.; Yu, M.; Shi, P.; Yan, C. Crashworthiness and lightweight optimization to applied multiple materials and foam-filled front end structure of auto-body. Adv. Mech. Eng. 2017, 9, 1687814017702806. [Google Scholar] [CrossRef]

- Galea Mifsud, R.; Muscat, G.A.; Grima-Cornish, J.N.; Dudek, K.K.; Cardona, M.A.; Attard, D.; Farrugia, P.S.; Gatt, R.; Evans, K.E.; Grima, J.N. Auxetics and FEA: Modern materials driven by modern simulation methods. Materials 2024, 17, 1506. [Google Scholar] [CrossRef]

- Garg, A.; Sharma, A.; Zheng, W.; Li, L. A review on artificial intelligence-enabled mechanical analysis of 3D printed and FEM-modelled auxetic metamaterials. Virtual Phys. Prototyp. 2025, 20, e2445712. [Google Scholar] [CrossRef]

- Wojno, S.; Ahlinder, A.; Altskär, A.; Stading, M.; Abitbol, T.; Kádár, R. Percolation and phase behavior in cellulose nanocrystal suspensions from nonlinear rheological analysis. Carbohydr. Polym. 2023, 308, 120622. [Google Scholar] [CrossRef] [PubMed]

- Wojno, S.; Fazilati, M.; Nypelö, T.; Westman, G.; Kádár, R. Phase transitions of cellulose nanocrystal suspensions from nonlinear oscillatory shear. Cellulose 2022, 29, 3655–3673. [Google Scholar] [CrossRef]

- Gupta, A.; Mekonnen, T.H. Cellulose nanocrystals enabled sustainable polycaprolactone based shape memory polyurethane bionanocomposites. J. Colloid Interface Sci. 2022, 611, 726–738. [Google Scholar] [CrossRef]

- Bouguermouh, K.; Habibi, M.; Laperrière, L.; Li, Z.; Abdin, Y. 4D-printed PLA-PETG polymer blends: Comprehensive analysis of thermal, mechanical, and shape memory performances. J. Mater. Sci. 2024, 59, 11596–11613. [Google Scholar] [CrossRef]

- ASTM D638-22; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022.

- Abdelhamid, Z.; Mohamed, H.; Kelouwani, S. The use of machine learning in process–structure–property modeling for material extrusion additive manufacturing: A state-of-the-art review. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 70. [Google Scholar] [CrossRef]

- Ziadia, A.; Habibi, M.; Kelouwani, S. Machine learning study of the effect of process parameters on tensile strength of FFF PLA and PLA-CF. Eng 2023, 4, 2741–2763. [Google Scholar] [CrossRef]

- Vinyas, M.; Athul, S.J.; Harursampath, D.; Nguyen Thoi, T. Mechanical characterization of the Poly lactic acid (PLA) composites prepared through the Fused Deposition Modelling process. Mater. Res. Express 2019, 6, 105359. [Google Scholar] [CrossRef]

- Thirugnanasambandam, A.; Dutta, H.; Gnanasagaran, C.L.; Kechagias, J.D. Development of 3D printed novel multi-polymer component based on blended filaments of polylactic acid and polyethylene terephthalate glycol. Prog. Addit. Manuf. 2024, 10, 1147–1160. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, F.; Yang, Z.; Hu, X.; Pan, Y.; Lu, Y.; Jiang, M. 3D printing of polyurethane/nanocellulose shape memory composites with tunable glass transition temperature. Ind. Crops Prod. 2022, 182, 114831. [Google Scholar] [CrossRef]

- Zain, N.M.; Yusop, S.M.; Ahmad, I. Preparation and characterization of cellulose and nanocellulose from pomelo (Citrus grandis) albedo. J. Nutr. Food Sci. 2014, 5, 334. [Google Scholar]

- Yakkan, E.; Uysalman, T.; Atagür, M.; Sever, K.; Seydibeyoğlu, M.Ö. Nanocellulose-polypropylene nanocomposites enhanced with coupling agent. Bartın Orman Fakültesi Derg. 2018, 20, 491–502. [Google Scholar]

- Wei, L.; Luo, S.; McDonald, A.G.; Agarwal, U.P.; Hirth, K.C.; Matuana, L.M.; Sabo, R.C.; Stark, N.M. Preparation and Characterization of the Nanocomposites from Chemically Modified Nanocellulose and Poly (lactic acid). J. Renew. Mater. 2017, 5, 410–422. [Google Scholar] [CrossRef]

- Mukherjee, T.; Tobin, M.J.; Puskar, L.; Sani, M.A.; Kao, N.; Gupta, R.K.; Pannirselvam, M.; Quazi, N.; Bhattacharya, S. Chemically imaging the interaction of acetylated nanocrystalline cellulose (NCC) with a polylactic acid (PLA) polymer matrix. Cellulose 2017, 24, 1717–1729. [Google Scholar] [CrossRef]

- Mukherjee, T.; Tobin, M.J.; Puskar, L.; Sani, M.A.; Kao, N.; Gupta, R.K.; Pannirselvam, M.; Quazi, N.; Bhattacharya, S. Properties of polylactic acid reinforced by hydroxyapatite modified nanocellulose. Polymers 2019, 11, 1009. [Google Scholar] [CrossRef]

- Park, J.Y.; Hwang, S.Y.; Yoon, W.J.; Yoo, E.S.; Im, S.S. Compatibility and physical properties of poly (lactic acid)/poly (ethylene terephthalate glycol) blends. Macromol. Res. 2012, 20, 1300–1306. [Google Scholar] [CrossRef]

- Chi, K.; Catchmark, J.M. Enhanced dispersion and interface compatibilization of crystalline nanocellulose in polylactide by surfactant adsorption. Cellulose 2017, 24, 4845–4860. [Google Scholar] [CrossRef]

- Wang, Q.; Ji, C.; Sun, J.; Zhu, Q.; Liu, J. Structure and properties of polylactic acid biocomposite films reinforced with cellulose nanofibrils. Molecules 2020, 25, 3306. [Google Scholar] [CrossRef]

- Ambone, T.; Torris, A.; Shanmuganathan, K. Enhancing the mechanical properties of 3D printed polylactic acid using nanocellulose. Polym. Eng. Sci. 2020, 60, 1842–1855. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Tian, C.; Xue, H.; Fang, K.; Zhang, K.; Tian, G. Multi-material 3D-printing nozzle design based on the theory of inventive problem solving and knowledge graph. Designs 2023, 7, 103. [Google Scholar] [CrossRef]

- Sztorch, B.; Brząkalski, D.; Pakuła, D.; Frydrych, M.; Špitalský, Z.; Przekop, R.E. Natural and synthetic polymer fillers for applications in 3D printing—FDM technology area. Solids 2022, 3, 508–548. [Google Scholar] [CrossRef]

- Shrestha, S. Effect of Nanocellulose Reinforcement on the Properties of Polymer Composites. Doctoral Dissertation, Purdue University, West Lafayette, IN, USA, 2019. [Google Scholar]

- Uetani, K.; Hatori, K. Thermal conductivity analysis and applications of nanocellulose materials. Sci. Technol. Adv. Mater. 2017, 18, 877–892. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Fabrication, properties and applications of polymer composites additively manufactured with filler alignment control: A review. Compos. Part B Eng. 2023, 256, 110661. [Google Scholar] [CrossRef]

- Gorbunova, M.; Anokhin, D.; Badamshina, E. Recent advances in the synthesis and application of thermoplastic semicrystalline shape memory polyurethanes. Polym. Sci. Ser. B 2020, 62, 427–450. [Google Scholar] [CrossRef]

- Ma, X.; Tian, S.; Li, X.; Fan, H.; Fu, S. Combined polyhexamethylene guanidine and nanocellulose for the conservation and enhancement of ancient paper. Cellulose 2021, 28, 8027–8042. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Ren, X.; Zhang, Y.; Xie, Y.M. A novel auxetic metamaterial with enhanced mechanical properties and tunable auxeticity. Thin-Walled Struct. 2022, 174, 109162. [Google Scholar] [CrossRef]

- Li, Y.; Chen, Z.; Xiao, D.; Wu, W.; Fang, D. The Dynamic response of shallow sandwich arch with auxetic metallic honeycomb core under localized impulsive loading. Int. J. Impact Eng. 2020, 137, 103442. [Google Scholar] [CrossRef]

- Lakes, R.S. Negative-Poisson’s-ratio materials: Auxetic solids. Annu. Rev. Mater. Res. 2017, 47, 63–81. [Google Scholar] [CrossRef]

- Yang, C.; Vora, H.D.; Chang, Y. Behavior of auxetic structures under compression and impact forces. Smart Mater. Struct. 2018, 27, 025012. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, W.Z.; Jiang, W.; Zhang, X.Y.; Dong, J.; Xie, Y.M.; Evans, K.E.; Ren, X. Recent advances of auxetic metamaterials in smart materials and structural systems. Adv. Funct. Mater. 2025, 35, 2421746. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Yang, Z.; Lu, Z. Novel auxetic structures with enhanced mechanical properties. Extrem. Mech. Lett. 2019, 27, 59–65. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, Y.; Jiang, D.; Chen, Y.; Xie, Y.M.; Jia, L.J. In-plane impact behavior of 3D-printed auxetic stainless honeycombs. Eng. Struct. 2022, 266, 114656. [Google Scholar] [CrossRef]

- Salama, A.; Abouzeid, R.; Leong, W.S.; Jeevanandam, J.; Samyn, P.; Dufresne, A.; Bechelany, M.; Barhoum, A. Nanocellulose-based materials for water treatment: Adsorption, photocatalytic degradation, disinfection, antifouling, and nanofiltration. Nanomaterials 2021, 11, 3008. [Google Scholar] [CrossRef] [PubMed]

- Salama, A.; Abouzeid, R.; Leong, W.S.; Jeevanandam, J.; Samyn, P.; Dufresne, A.; Bechelany, M.; Barhoum, A. Nanocellulose-based thermoplastic polyurethane biocomposites with shape memory effect. J. Compos. Sci. 2023, 7, 168. [Google Scholar] [CrossRef]

- Aranguren, M.I.; Auad, M.L.; Richardson, T.; Adanur, S.; Orts, W.J.; Medeiros, E.S.; Mattoso, L.H.C.; Mosiewicki, M.A.; Marcovich, N.E. Polyaniline Modified Nanocellulose as Reinforcement of a Shape Memory Polyurethane. 2008. Available online: https://d1wqtxts1xzle7.cloudfront.net/81414383/2629-libre.pdf?1645923003=&response-content-disposition=inline%3B+filename%3DPolyaniline_Modified_Nanocellulose_as_Re.pdf&Expires=1762829933&Signature=L1JZMANJcBzh3D~hykJmfTpttl5qEVlFnet7Wmt7Ddlll1B8faM1qPwt~-SGsIswseb5pun8RuxvmPW1iQEU~hF4SBCXxWBfPaDdLv3CcECMEIBfSWhHUKD0bWsz9of6N1haFHZajY~0tpdwlQRZ0eJjdQjtMOFAzRJ3bQDPIC8RwVwtS5MAj48LLWYHfbaHj0H9gFPrrUGz~NX4rm67vPyfxFsopGAI8FM59azT~iq2lzwGoH2LfChbMECZbkk1cboecL40aLBZJqaE3TKuwQOFlzRdRZjHej9wSfKWoHpix8Mp6M1utzPr9lyBaJrM37YqGol-MOtnIUQ-5cGCdg__&Key-Pair-Id=APKAJLOHF5GGSLRBV4ZA (accessed on 19 October 2025).

- Peng, X.-L.; Bargmann, S. A design method for metamaterials: 3D transversely isotropic lattice structures with tunable auxeticity. Smart Mater. Struct. 2021, 31, 025011. [Google Scholar] [CrossRef]

- Günaydın, K.; Rea, C.; Kazancı, Z. Energy absorption enhancement of additively manufactured hexagonal and re-entrant (auxetic) lattice structures by using multi-material reinforcements. Addit. Manuf. 2022, 59, 103076. [Google Scholar]

- Fu, S.; Tian, C. Nanocellulose and its application for shape-memory materials. In Eco-Friendly Polymer Nanocomposites: Chemistry and Applications; Springer: New Delhi, India, 2015; pp. 101–135. [Google Scholar]

- Auad, M.L.; Contos, V.S.; Nutt, S.; Aranguren, M.I.; Marcovich, N.E. Characterization of nanocellulose- reinforced shape memory polyurethanes. Polym. Int. 2008, 57, 651–659. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).