Performance and Preparation of Styrene-Butadiene Copolymer Modified Polypropylene Matte Films

Abstract

1. Introduction

2. Materials and Sample Preparation

2.1. Materials

2.2. Sample Preparation

3. Characterization/Testing Methods

3.1. Rheological Properties

3.2. Crystallization Behavior

3.3. Optical Performance Characterization

3.4. Mechanical Performance Testing

3.5. Micromorphological Observations

3.6. Heat-Sealing Properties

4. Results and Discussion

4.1. Processing Properties

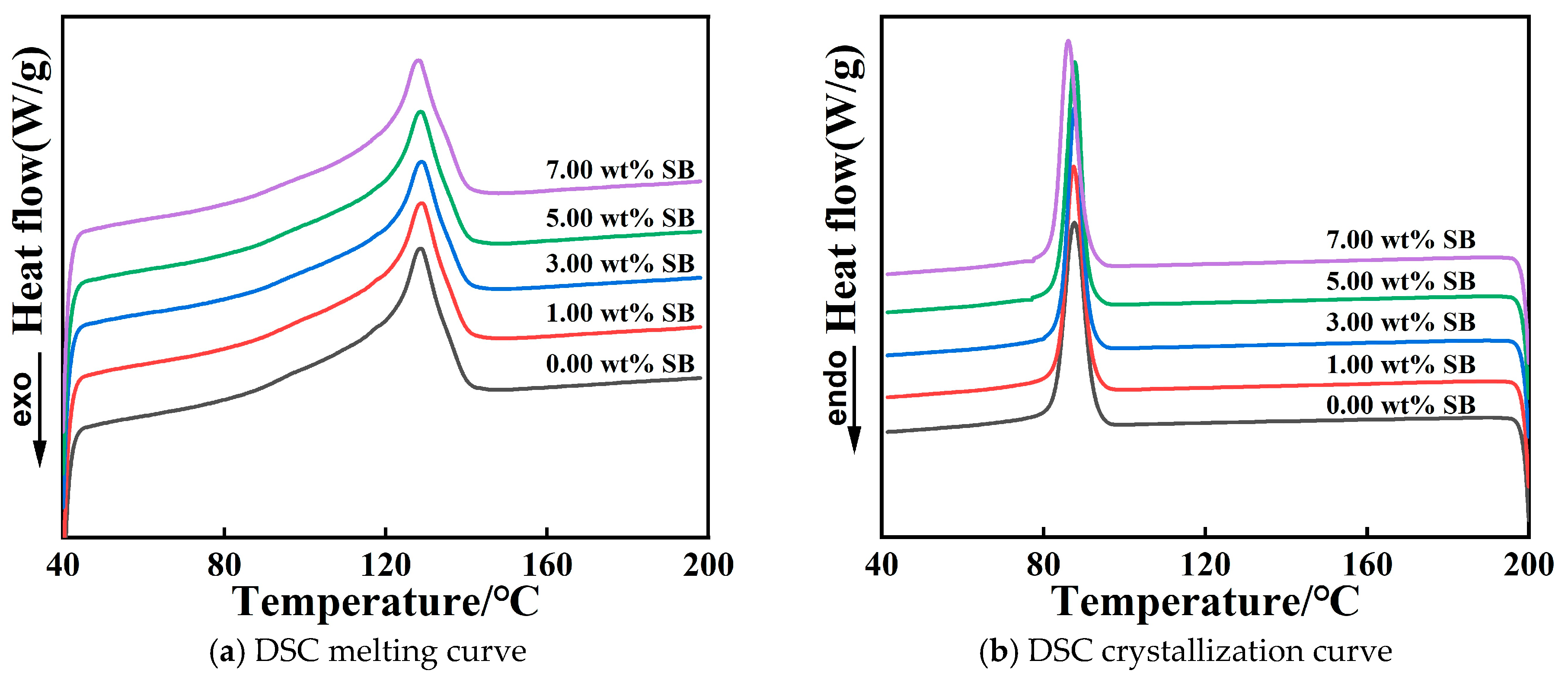

4.2. Crystallization and Melting Behaviors

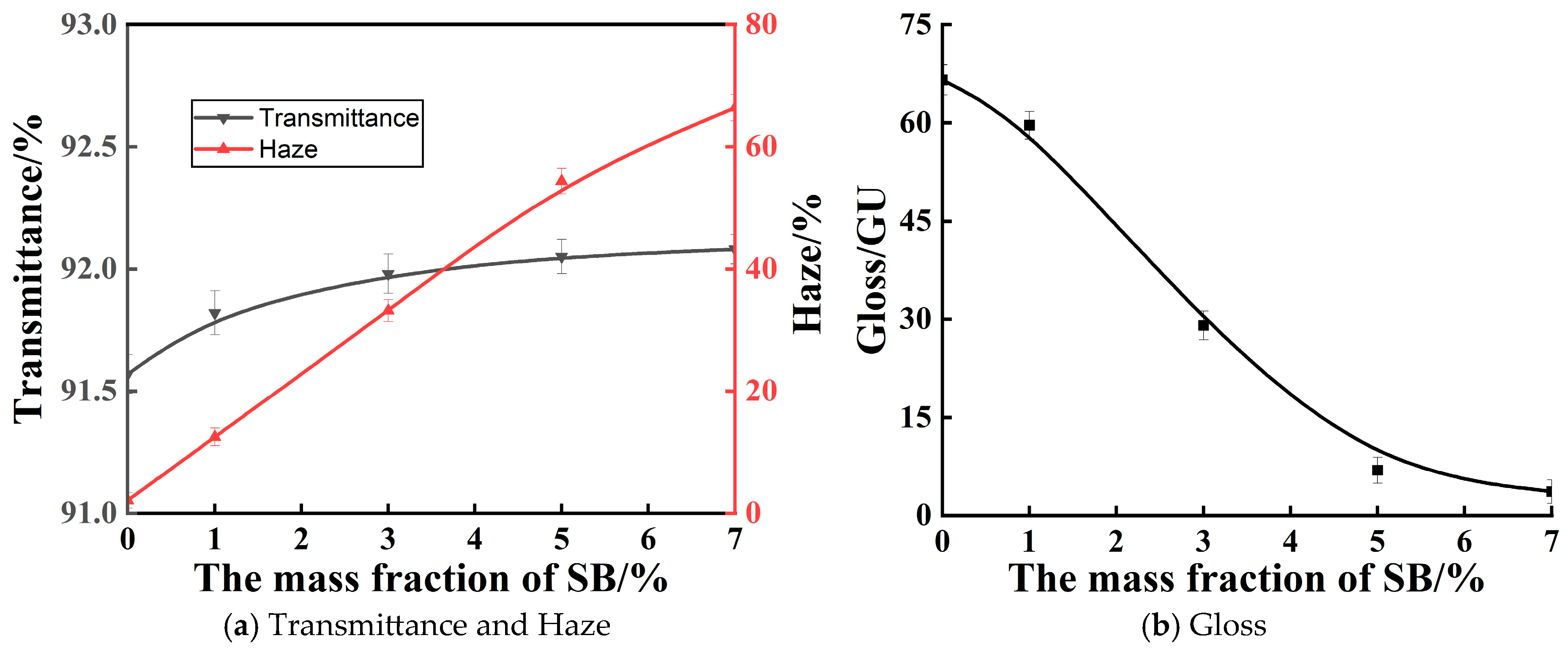

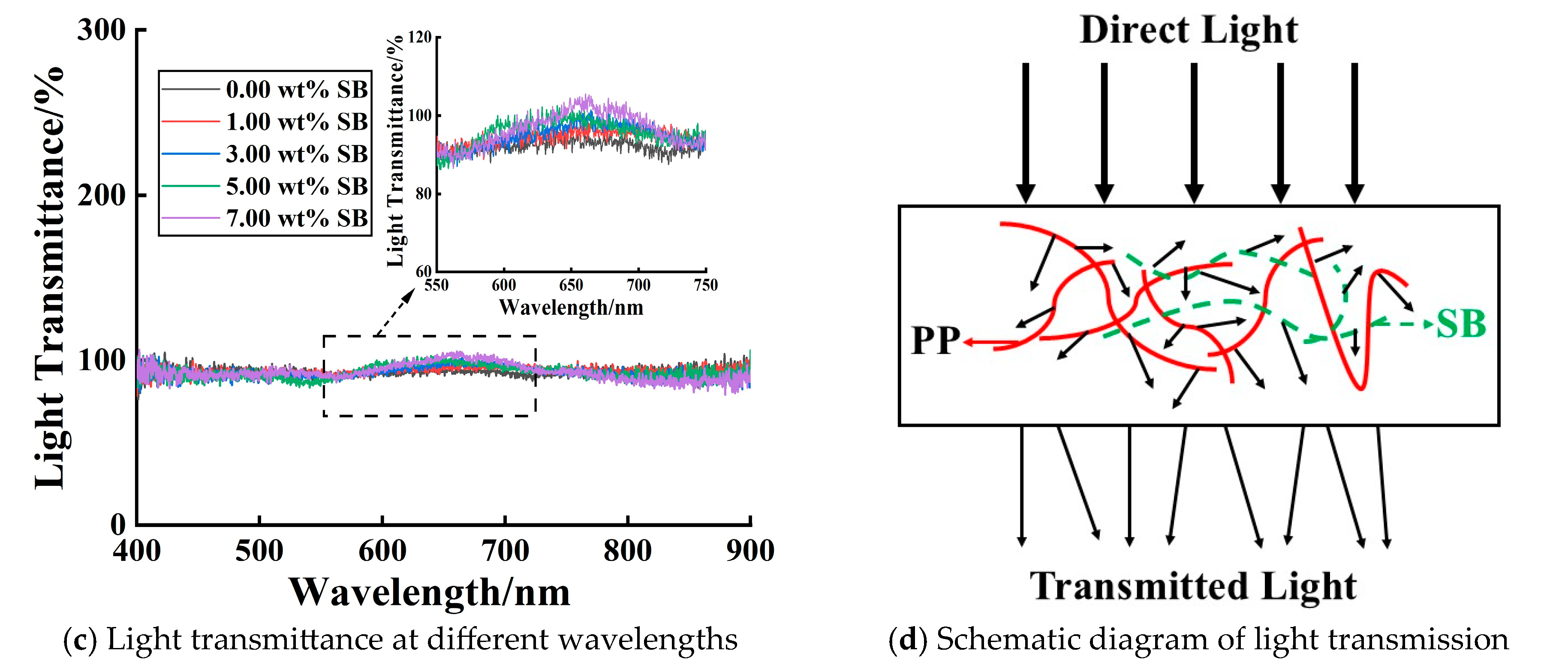

4.3. Optical Properties

4.4. Mechanical Properties

4.5. Observation on Microstructure

4.6. Heat-Sealing Performance

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, M.W. Research on the Technology and Market of Cast Polypropylene (CPP) Matte Film for Chinese Household Paper. Plast. Plast. 2023, 33, 1–5. [Google Scholar]

- Ping, W. Performance of Polypropylene Cast Film and Development Status of Special Materials. Chem. Pharm. Eng. 2023, 44, 67–70. [Google Scholar]

- Dziadowiec, D.; Matykiewicz, D.; Szostak, M.; Andrzejewski, J. Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications. Materials 2023, 16, 1071. [Google Scholar] [CrossRef] [PubMed]

- Ambroise, B.; Sheppard, R.M.; H Tt, D.; Marchal, A.; Guillaume, C. Co-Extruded, Biaxially Oriented, Matte, Hdpe Films. EP3986713A1, 27 April 2022. [Google Scholar]

- Gahleitner, M.; Paulik, C. Polypropylene and other polyolefins. In Brydson’s Plastics Materials; Butterworth-Heinemann: Oxford, UK, 2017; pp. 279–309. [Google Scholar]

- Lee, W.; Kim, K.; Seo, H.; Park, Y.; Won, J.; Kang, H. Effect of different polyolefin film haze rates on cultivation environment and lettuce growth. J. Agric. Life Environ. Sci. 2022, 34, 264–273. [Google Scholar]

- Maddah, H.A. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Gillis, G.G. Multilayer Matte Biaxially Oriented Polypropylene Film with Ultra Low Seal Initiation Temperature. U.S. Patent 10,022,941(P), 17 July 2018. [Google Scholar]

- Ammar, L.B.; Fakhfakh, S. Optical and dielectric properties of polypropylene/montmorillonite nanocomposites. Funct. Compos. Struct. 2020, 2, 045003. [Google Scholar] [CrossRef]

- Kloziński, A.; Szczepańska, M.; Jakubowska, P.; Samujło, B.; Barczewski, M.; Lota, G. The influence of calcium carbonate and its modifications on the extrusion process and selected functional properties of polypropylene cast films. Polimery 2022, 67, 509–521. [Google Scholar] [CrossRef]

- Ramazanov, M.A.; Shirinova, H.A.; Nuriyeva, S.G.; Jafarov, M.A.; Hasanova, M.R. Structure and optic properties of the nanocomposites based on polypropylene and amorphous silica nanoparticles. J. Thermoplast. Compos. Mater. 2023, 36, 1762–1774. [Google Scholar] [CrossRef]

- Li, L.; Chen, L.; Bruin, P.; Winnik, M.A. Morphology evolution and location of ethylene–propylene copolymer in annealed polyethylene/polypropylene blends. J. Polym. Sci. Part B Polym. Phys. 2015, 35, 979–991. [Google Scholar] [CrossRef]

- Chen, X.; Yu, P.; Kostromin, S.; Bronnikov, S. Minor-phase particles evolution in a polyethylene/ethylene–propylene copolymer (80/20) blend across mixing: Breakup and coalescence. J. Appl. Polym. Sci. 2014, 130, 3421–3431. [Google Scholar] [CrossRef]

- Elkoun, S.; Huneault, M.; McCormick, K.; Puterbaugh, F.; Kale, L. LLDPE-based mono- and multilayer blown films: Effect of processing parameters on properties. Polym. Eng. Sci. 2010, 45, 1214–1221. [Google Scholar] [CrossRef]

- Johnson, M.B.; Wilkes, G.L.; Sukhadia, A.M.; Rohlfing, D.C. Optical properties of blown and cast polyethylene films: Surface versus bulk structural considerations. J. Appl. Polym. Sci. 2000, 77, 2845–2864. [Google Scholar] [CrossRef]

- Liao, T.C.; Chen, C.L.; Wu, W.Y. Matte Synthetic Paper. US10774206B2, 23 April 2020. [Google Scholar]

- Boydağ, F.Ş.; Mamedov, S.V.; Alekperov, V.A.; Özcanli, Y.L. Optical characterization of weakly absorbing PP, PE, and PP/PE films. Opt. Spectrosc. 2003, 95, 225–229. [Google Scholar] [CrossRef]

- Luo, S.; Yi, P.; Xiong, Y.; Shen, J.; Guo, S. Light-scattering capacity of ethylene–vinyl acetate copolymers in polypropylene: Toward high haze and transmittance. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Chen, X.Y.; Xiang, M. Formulating of a novel polyolefin hazy film and the origins of haze thereof. Polym. Bull. 2010, 64, 925–937. [Google Scholar] [CrossRef]

- Chen, X.W.; Chen, S.T.; Meng, L.W. Mechanism of woven structure formation in polypropylene polyethylene extinction film system. Polym. Mater. Sci. Eng. 2019, 35, 13–19. [Google Scholar]

- Gray, A.P. Polymer crystallinity determinations by DSC. Thermochim. Acta 1970, 1, 563–579. [Google Scholar] [CrossRef]

- Scoti, M.; De Stefano, F.; Di Girolamo, R.; Malafronte, A.; Talarico, G.; De Rosa, C. Model of Crystallization Behavior of Isotactic Polypropylene: The Role of Defects. Macromol. Chem. Phys. 2023, 224, 2200262. [Google Scholar] [CrossRef]

- Addeo, A. Polypropylene Handbook; Hanser: Munich, Germany, 2005. [Google Scholar]

- Henderson, J.N. Styrene-butadiene rubbers In Rubber Technology; Boston, MA: Springer US: Boston, MA, USA, 1987; pp. 209–234. [Google Scholar]

- Wypych, G. Handbook of Polymers; Elsevier: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Jang, B.Z.; Uhlmann, D.R.; Sande, J.B.V. Rubber-toughening in polypropylene. J. Appl. Polym. Sci. 1985, 30, 2485–2504. [Google Scholar] [CrossRef]

| Samples/wt% | Tm/°C | Tc/°C | ΔHm/(J·g−1) | ΔHc/(J·g−1) | Xc/% |

|---|---|---|---|---|---|

| 0.00 | 128.52 ± 0.12 | 87.60 ± 0.10 | 64.92 ± 0.09 | 69.83 ± 0.10 | 31.06 ± 0.03 |

| 1.00 | 128.96 ± 0.11 | 87.35 ± 0.11 | 62.70 ± 0.10 | 66.69 ± 0.10 | 30.00 ± 0.02 |

| 3.00 | 128.92 ± 0.12 | 87.67 ± 0.10 | 59.40 ± 0.10 | 62.70 ± 0.09 | 28.42 ± 0.03 |

| 5.00 | 128.62 ± 0.12 | 87.72 ± 0.10 | 64.65 ± 0.09 | 64.65 ± 0.09 | 30.93 ± 0.03 |

| 7.00 | 128.14 ± 0.11 | 86.10 ± 0.11 | 65.73 ± 0.10 | 64.51 ± 0.10 | 31.45 ± 0.02 |

| Samples/wt% | Tensile Strength/MPa | Elongation at Break/% | Falling Dart Impact Strength/g | Puncture Strength/(N/mm) | ||

|---|---|---|---|---|---|---|

| MD | TD | MD | TD | |||

| 0.00 | 37.72 ± 0.75 | 34.00 ± 0.76 | 1030.71 ± 55.61 | 1186.52 ± 65.23 | 105.00 ± 1.40 | 7.82 ± 0.19 |

| 1.00 | 36.63 ± 0.59 | 33.12 ± 0.79 | 1163.04 ± 56.32 | 1249.72 ± 66.45 | 123.50 ± 1.31 | 8.41 ± 0.20 |

| 3.00 | 35.06 ± 0.53 | 32.63 ± 0.72 | 1307.83 ± 57.33 | 1376.92 ± 64.28 | 134.00 ± 1.28 | 9.52 ± 0.18 |

| 5.00 | 32.72 ± 0.61 | 31.63 ± 0.65 | 1466.82 ± 54.35 | 1489.93 ± 67.36 | 146.50 ± 1.26 | 10.83 ± 0.19 |

| 7.00 | 31.03 ± 0.57 | 30.13 ± 0.58 | 1484.31 ± 55.45 | 1519.72 ± 69.62 | 148.00 ± 1.33 | 11.13 ± 0.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Ma, Y.-L.; Lv, J.-L.; Yi, Z.; Zeng, S.; Wang, J.-H.; Huang, X.-X. Performance and Preparation of Styrene-Butadiene Copolymer Modified Polypropylene Matte Films. J. Compos. Sci. 2025, 9, 566. https://doi.org/10.3390/jcs9100566

Yang K, Ma Y-L, Lv J-L, Yi Z, Zeng S, Wang J-H, Huang X-X. Performance and Preparation of Styrene-Butadiene Copolymer Modified Polypropylene Matte Films. Journal of Composites Science. 2025; 9(10):566. https://doi.org/10.3390/jcs9100566

Chicago/Turabian StyleYang, Kang, Yu-Long Ma, Jin-Long Lv, Zhang Yi, Shu Zeng, Ju-Heng Wang, and Xiao-Xiao Huang. 2025. "Performance and Preparation of Styrene-Butadiene Copolymer Modified Polypropylene Matte Films" Journal of Composites Science 9, no. 10: 566. https://doi.org/10.3390/jcs9100566

APA StyleYang, K., Ma, Y.-L., Lv, J.-L., Yi, Z., Zeng, S., Wang, J.-H., & Huang, X.-X. (2025). Performance and Preparation of Styrene-Butadiene Copolymer Modified Polypropylene Matte Films. Journal of Composites Science, 9(10), 566. https://doi.org/10.3390/jcs9100566