Abstract

Developing countries in Asia widely use manual seed broadcasting methods due to a lack of appropriate seeding machinery. The agricultural sector is currently facing labor shortages and high labor costs, especially seasonal labor shortages for broadcasting and transplanting operations. However, the primary constraint in adopting existing broadcasting seeders for small-scale farmers in developing countries is the high initial purchase costs. Therefore, developing locally commercial accessible technology for small-scale farmers is an urgent requirement. In this regard, attempt was taken to develop a new low-cost 3D printed seeder that can be used for multi-crop seed broadcasting operations when integrated with an autonomous terrain vehicle. A new seed metering mechanism was proposed for seed broadcasting that can be controlled electronically from the autonomous terrain vehicle. Positional sensors based on the real time kinematics—global navigation satellite system (RTK-GNSS) were used to record positional information. The best observation was noted at a vehicle operational speed of 0.351 ms−1 and had a coefficient of variation (CV) referring to the distribution uniformity of seeds of 19% for green peas, 22% for cowpeas, and 25% for chickpeas. The developed seeder could spread multi-crop seeds and adjust the seed rates electronically at the different ranges of rotational speeds. Therefore, the use of 3D printed fabricated prototype seed broadcasting units with small-scale autonomous vehicles can be implemented to help in labor supplements and perform the broadcasting of different seeds.

1. Introduction

Open-field cultivation usually involves several farming operations in the process of producing agricultural products. These operations include land preparation, nursery management, planting, sowing, harvesting, and postharvest handling [1]. Among these management practices, broadcasting or seed sowing should be carried out in a timely manner to ensure high productivity by considering several factors, such as rainfall and irrigation schedule. Broadcasting of seeds and transplanting operations are performed with machines in developed countries; however, in developing countries, especially in Southeast Asia, these operations are performed manually in most areas [2]. Most developing countries widely use the broadcasting method rather than the transplanting and machine-operated seed sowing methods, thus overcoming constraints such as a lack of machinery, difficulties in the dry season or less rainfall, and difficulties in machine hiring for preliminary operations [3]. The broadcasting method has been used in both dryland farming and wetland farming, which saves labor and time and reduces production risks [4]. However, broadcasting has become popular and common in developing countries. Thus, manual broadcasting is a conventional technique that requires a higher skilled labor force, is imprecise, and finally leads to low crop productivity [4,5].

Mechanical broadcasting in a precise manner can reduce the usage of seasonal labor, avoid poor distribution of seeds, and finally lead to higher productivity. A seed broadcaster was fabricated locally with available materials to sow soybean, guinea corn, and paddy. The net weight of the device was 6.25 kg, which was easy to carry in higher ground agricultural fields; the discharge efficiency and broken efficiency of the device was 92%, 91.7%, and 97.5%, and 10%, 8.3%, and 2.7% for guinea corn, rice, and soybean, respectively [6]. The seed sizes and shapes were different, the fabricated unit depended on the crop type and the variety, and the metering mechanism was limited to few seeds. However, for the broadcasting operation, farmers use simple, lightweight, and cheap seed, which usually requires a shallow sowing depth. Thus, to achieve equal distribution in broadcasting, farmers tend to mix the seed with sand, the ratio of sand to seed being 7:1. Moreover, broadcasting can lead to uneven distribution of plants, and the wide spaces between crop plants lead to weed growth, which is one of the disadvantages. Thus, increasing the density and even distribution can overcome this challenge. Most of the crops need the correct time period for high yield and the time required for planting can be reduced through the use of small-scale intelligent agricultural terrain vehicles [5]. Thus, no-drill planting creates suitable growing conditions for crops, resulting in an increase in yield from 10% to 30% [7]. In addition, the parameters of grain drills for subsoil and no-drill cultivation were also reported. The optimal parameters for the seed drill coulter depend on the diffuser and the height of the pendulum spreader.

However, increasing seed density via broadcasting improves biomass production and cover crop standards, which helps nutrient scavenging, weed suppression, and erosion control [8]. Thus, when compared to drilling, broadcasting results in earlier planting, and the success of broadcasting basically relies on adequate and timely rainfall, with a lack of rainfall resulting in slow growth [9].

Even though four-wheel tractors with attachments can spread the seeds, the machines require skilled operator, more attention, and the overlapping of seed layers, with difficulty in accessing higher terrain fields also an issue, especially in Asian countries. Moreover, investigation of automatic driving to support in agricultural operations has potential and can be one of the key factors that determine agricultural machinery intelligence [10]. Agricultural vehicle operations need skilled laborers; however, by incorporating autonomous intelligence systems, operational efficiency can be improved without skilled labor [11]. Positional data on agricultural vehicles could provide a more accurate understanding of agricultural operations based on a real-time kinematics—global navigation satellite system (RTK-GNSS) [12]. Furthermore, there are opportunities to improve intelligence using visual navigation [13], inertial navigation (INS) [14], and GNSS [15] technologies for agricultural vehicle navigation.

Moreover, 3D printing of agricultural small parts for vehicles becomes convenient due to low cost, less weight, and ease of maintenance and replacing locally. In Southeast Asian countries, farmers face difficulties in terms of access to suppliers. Therefore, replacing damaged parts of small-scale vehicles can be undertaken by local repair stations using 3D printed materials. A study has also been performed regarding the impregnation of machinery parts using 3D printing systems [16]. Thus, 3D scanning the agricultural machinery parts and 3D printing them for replacement becomes an easy and reliable technology. Another study also reported that reverse engineering software can be integrated in surface model design studies in order to print 3D parts with correct dimensions [17].

Lightweight vehicles that can be operated autonomously can resolve most of the skilled labor problems for seed broadcasting, increase productivity, and minimize seed waste. By considering all these factors, this study has been carried out to develop a new 3D printed seed broadcasting system that can be integrated with a lightweight small-scale autonomous vehicle for broadcasting operations.

2. Materials and Methods

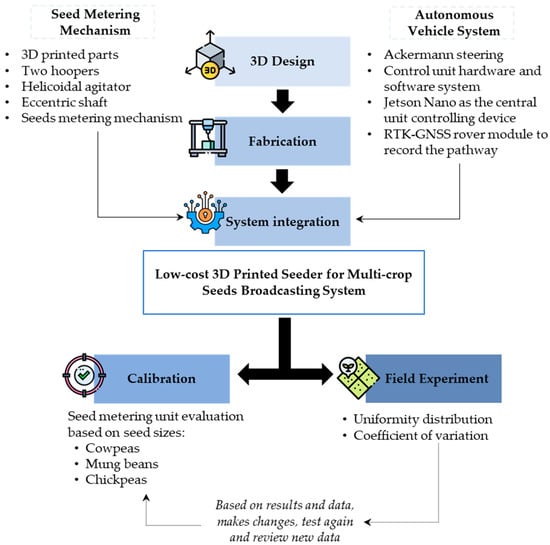

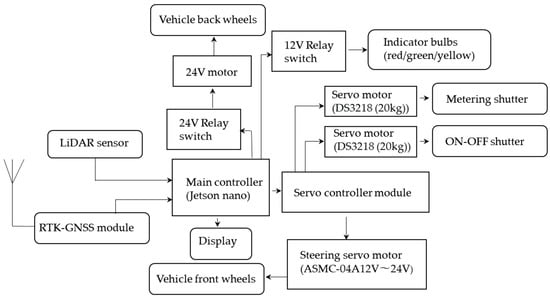

The developed autonomous seed broadcaster consisted of two main parts. The main focus was the development of a seed metering mechanism using low-cost plastic materials and an autonomous vehicle system in which to install a seed metering system that can be navigated along a pre-determined path using RTK-GNSS coordinates. The overall workflow of the technical roadmap is given to show the integration of seed metering mechanism and autonomous vehicle system (Figure 1).

Figure 1.

Overall workflow for development of the seed metering system for the autonomous system.

2.1. Design and Development of the Seed Broadcasting Device

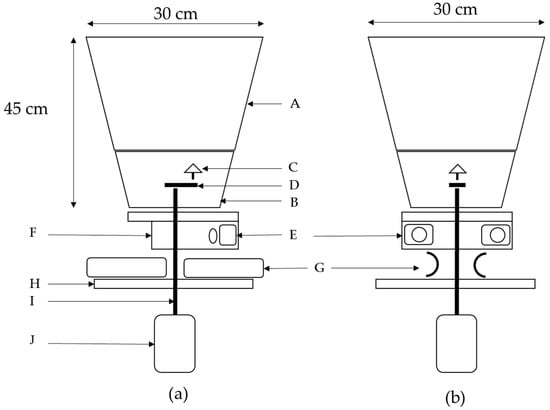

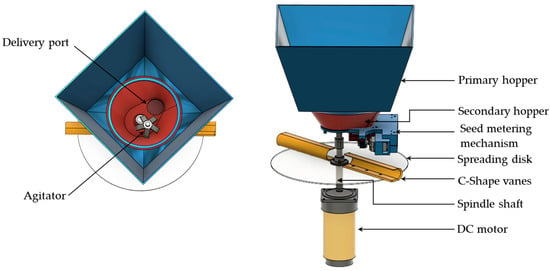

The seed broadcasting device was designed to be attached to the bottom part of the seeder, which was composed of a combination of two hoppers (primary and secondary), a helicoidal agitator, an eccentric shaft, and the seed metering mechanism (Figure 2). The components were designed using the software Autodesk® Fusion 360™ version 13.1.1.12, (Autodesk Headquarters, San Francisco, CA, USA).

Figure 2.

Two-dimensional drawing of the seed broadcasting device: (a) side view of the device; (b) front view of the device. A: Primary hopper. B. Secondary hopper. C: Agitator. D: Eccentric shaft. E: Servo motors. F: Seed metering mechanism. G: Vanes. H: Spreading disk. I: Spindle shaft. J: DC motor.

2.2. Seed Metering Mechanism

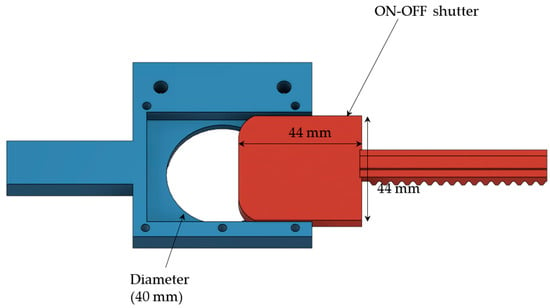

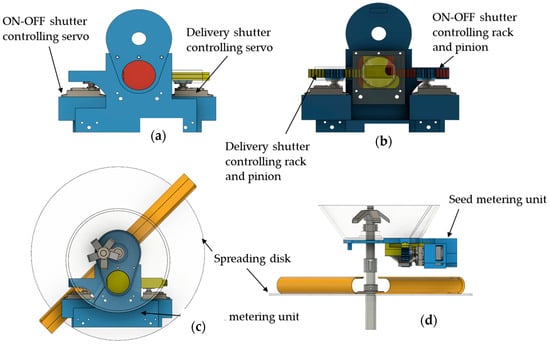

The seed metering mechanism was designed and developed based on two shutters: an ON–OFF shutter with a dimension of 44 × 44 mm (Figure 3) and a metering shutter. The main function of the ON–OFF shutter was to open and close the delivery port. Rack and pinion methods were used to move this shutter.

Figure 3.

ON–OFF shuttering system for seed broadcasting.

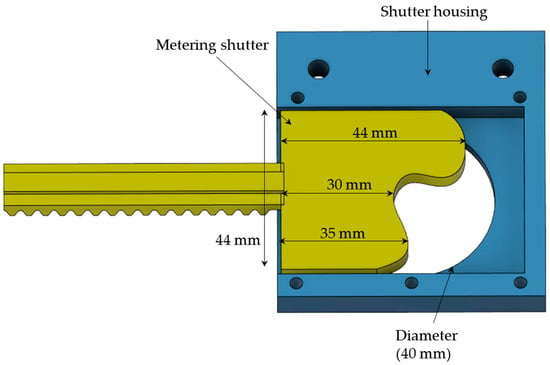

The metering shutter was placed below the ON–OFF shutter (Figure 4). The function of the metering shutter was to allow for the flow of seeds according to the size of seeds. Moreover, a metering shutter could adjust the seed flow. Thus, the delivery shutter could control the equal distribution of the seeds in the system. Both shutters were controlled by programmable digital servo motors (DS-3218 MG-20 kg/cm, AOELEC Technology Co., Ltd., Dongguan City, Guangdong Province, China).

Figure 4.

Seed metering mechanism.

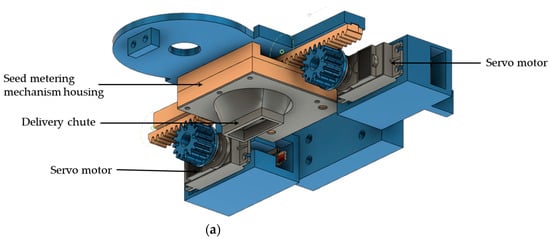

As indicated in Figure 1, the primary hopper was the main storage unit for the seeds and was fitted on top of the seed broadcasting device. The hopper body was made of sheet aluminum, and a hinged-type sliding cover was fitted at the top of the hopper. The secondary hopper was fitted under the primary hopper. The material of this hopper was polylactic acid (PLA) plastic. The 3D printed seed metering mechanism was controlled by these two shutters, and the opening and closing angles of the shutters could be changed based on the specifications of seed size and rate of application. A 3D design of the overall seed metering mechanism is shown in Figure 5.

Figure 5.

Metering design and fabrication: (a) 3D Design; (b) 3D printed seed metering mechanism assembly.

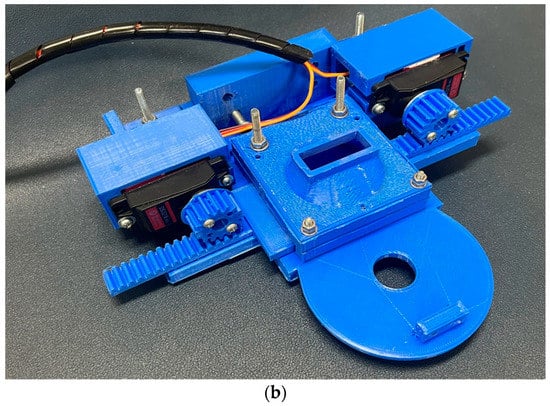

The top view of the seed metering unit shows the arrangement of rack and pinion servomotors, which was also fabricated from 3D printing materials (Figure 6a); the bottom-view arrangement (Figure 6b), the top view placement of the seed metering unit in the total broadcasting system (Figure 6c), and the side-view arrangement of the fabricated unit of the seed metering mechanism system (Figure 6d) are also displayed.

Figure 6.

Operational procedure of the seeding metering unit: (a) top view of the seed metering unit; (b) bottom view of the seed metering unit; (c) top view of the broadcasting unit and arrangement of the seed metering unit; (d) Side view of the broadcasting unit and arrangement of the seed metering unit.

2.3. Broadcasting System for Autonomous Vehicles

The secondary hopper was square-top- and oval-bottom-shaped. The delivery chute was fitted under the seed metering mechanism, and the outlet was rectangular loft-shaped. The design of the delivery chute used bristled ropes that prevented the turbulence of the seeds from affecting the spreading disk. The main spindle served as the rotation source of the seed broadcasting mechanism and was connected to a DC motor. A circular plastic disk 30 cm in diameter was connected to the main spindle (Table 1). Two C-shaped vanes were fitted on the spreading disk, and the C-shaped vanes could carry the seeds over the spreading disk and spread the seeds to the surroundings. The top view of the broadcasting unit shows the rotating agitator used to agitate the seeds near the seed outlet of the hopper, which helped to prevent clogging and avoid the formation of a cone-shaped airgap when seeds moved down through the outlet (Figure 7).

Table 1.

Seed broadcasting device specification.

Figure 7.

Three-dimensional design of the seed broadcasting device.

2.4. Small-Scale Vehicles for Autonomous Operation

2.4.1. Vehicle Modification

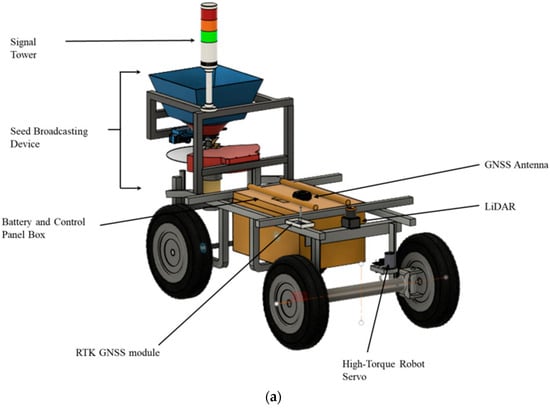

The seeder chassis was modified from the electric carrier. The original design of the electric carrier had one electric motor axle drive with wheels, two caster wheels, two DC 12 V/32 A batteries, a toolbox, supports, and a frame (Power Tiger HQ-PT2015, Shantou Chenghai Crafts Factory, Shantou City, Guangdong Province, China). For the modification, the front wheels were changed for Ackermann steering, where the vehicle was powered by the rear-wheel drive system. The toolbox was converted to the control box of the newly modified vehicle.

2.4.2. Vehicle Driving and Steering Systems

The driving motor in the electric cart was attached to the back wheel (24 V DC SCT1-040A, Shenzhen Senchuang Technology Co., Ltd., Shenzhen, China). The electromagnetic relay was used to control the motor, as indicated in the circuit diagram (Figure 8). A single-board computer (NVIDIA® Jetson NanoTM Developer Kit B01-4GB, NVIDIA Corporation Santa Clara, Santa Clara, CA, USA) was the central unit controlling device, which sent and received signals to a double pole double throw (DPDT) relay (JQY-13F(LY2N-J), PEOTR, Wenzhou, Zhejiang Province, China) linked to the motor.

Figure 8.

Flow chart for electric component assembly and actuators.

The total power was provided by a portable power supply unit, and there were three AC 100 V to DC (5 V, 12 V, 24 V) power converters used (SKY TOPPOWER® PS2103, Shenzhen, China, MF320A24AG MOONS® Industries (Jiangsu) Co., Ltd., Changzhou, Jiangsu Province, China, and VTC03A, Shenzhen V&T Technologies Co., Ltd., Shenzhen, China).

The seeder’s spindle shaft was connected to a 12 V motor, and a voltage regulator was used to control the speed of rotation. The servo motors were controlled using an I2C Adafruit 16-Channel 12-bit PWM/Servo Driver (Rasbee® PCA9685, SunFounder, Shenzhen, China), two 5 V servo motors were attached to the seed metering unit, and the 24 V servo was used to manage the steering. An RTK-GNSS rover module (U-blox® C94-M8P Application Kit, Thalwil, Switzerland) was attached to the vehicle after the rover and connected with the base station established at the Tsukuba-Plant Innovation Research Center (T-PIRC) located inside the University of Tsukuba (Japan). GNSS signals were used to record the pathway of the moving autonomous seeder during the designed pathway of the experiments, which was pre-programmed.

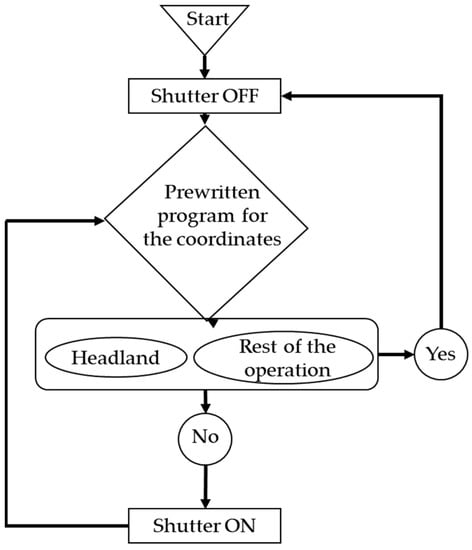

The steering system of this seeder was of the Ackermann steering type. This steering system has been used in mobile robots [18]. A 24 V high-torque robot servo motor (RCmall ASMC-04A, China) was used to control the steering. The 12 V signal tower (PATLITE® LE-01P, Komaki, Japan) was mounted on the vehicle frame to enhance the visibility of the seeder underworking conditions. A 10-inch portable monitor (ROADOM, Shenzhen Shinho Electronic Technology Co., Ltd., Shenzhen, China.) was used as the display, which was used for system configuration of the single-board computer. Figure 9 shows a flow diagram of the working principle of the seeder.

Figure 9.

Working principle of the seeder.

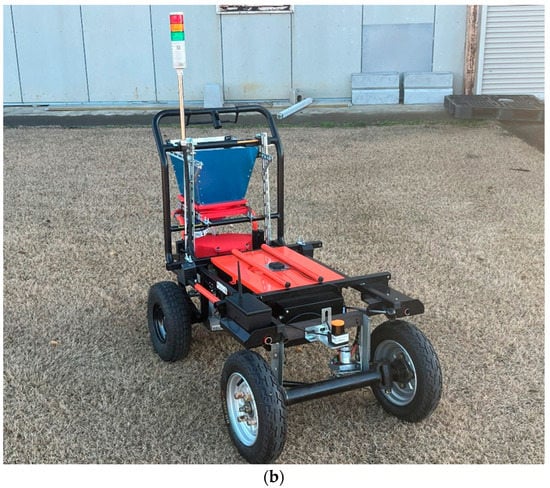

2.4.3. Structure of the Seeder

The 3D design of the multi-crop seeder and fabrication work was completed after all design works and necessary components were set up in the autonomous vehicle for broadcasting the seeds (Figure 10a,b). Field level calibration for the seed metering systems was conducted from the autonomous vehicle (Figure 11).

Figure 10.

Design and fabrication of the multi-crop seeder in the modified vehicle based on Ackermann steering: (a) 3D design of the multi-crop seeder; (b) autonomous multi-crop seeder after fabrication.

Figure 11.

Evaluation of the seeding mechanism and autonomous vehicle: (a) spreading disk; (b) mung bean; (c) cowpea; (d) chickpea.

2.5. Seed Broadcaster Calibration and Data Collection

2.5.1. Seed Metering Unit Evaluation

Cowpeas (Vigna unguiculata), mung beans (Vigna radiata), and chickpeas (Cicer arietinum) were used to evaluate the seed metering mechanism according to size. In the experiment, chickpeas were the largest (8 mm average diameter), followed by cowpeas (6.5 mm average diameter) and green peas (4.5 mm average diameter) (Table 2). Average seed size was used to calibrate the opening and closing angles of the ON–OFF shutter and metering shutter. The seed rates were controlled by the metering mechanism and could be adjusted according to the requirements. The two shutters were controlled using two servo motors, which could be controlled by changing the angle values sent via the main controller. In this study, we set the opening and closing angles and operating time delays based on experimental observations, with 186 rpm used for the spreading disk’s rotational speed. The opening and closing time and the opening angles were found based on trial and error, with tests conducted on grids to find out the distribution and the continuous flow through the seed metering mechanism for three seed types.

Table 2.

Experimental crops and their dimensions.

2.5.2. Kinematic Approach for Seed Distribution

The rotational disk used for the distribution of seeds was the main key factor that determined the travelling distance and uniformity of seeds. The parameters of designing the spreading disk were based on the plane curvilinear motion of the seeds as well as the principle of circular motion.

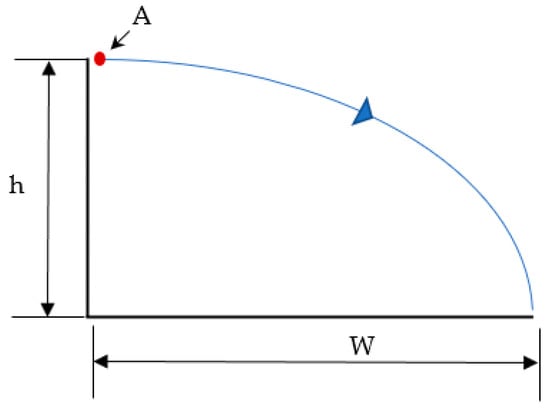

The distribution of seeds via the spreading disk is indicated in Figure 12. The velocity of individual seed A can be expressed using Equation (1).

where V is the velocity of the seed (ms−1), ω is the angular velocity in rad/min, N is the spreading disk (rpm), and r is the length of the blade (m). The seed at the corner of the spreading disk, which can travel longer distances, is shown in Figure 13.

Figure 12.

Seed movements from the spreading disk using curvilinear motion.

Figure 13.

The curvilinear motion of seed A distributed at a distance of W.

Seed A would travel a distance of W, and V is the velocity due to the impact of the rotating blade fixed to the disk. The horizontal distance or swath width W (m) are calculated using Equation (2), where h is the height of the spreading disk (m) from the ground and g is gravity (ms−2).

The calculated values are discussed in Section 4 (h = 0.3m, N = 180 rpm, and r = 0.15 m). Equation (3) can be obtained after combining Equations (1) and (2) [19]. The calculated W values are represented in Table 1.

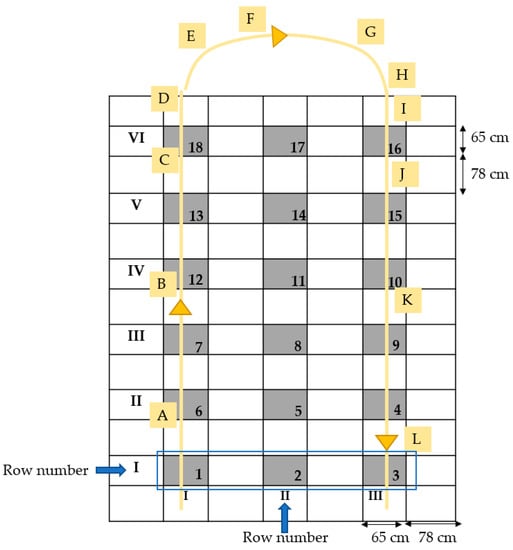

The broadcasting system was evaluated using two rotational spinner speeds along with four different vehicle speeds. The lower rotating speed of the spreading disc was 41 rpm and the maximum was 332 rpm, which was measured using an AD5172 digital optical tachometer (© 2023 MONET ASIA Co., Ltd.). The rpm values were selected based on motor performance and analysis of seed distribution based on seed covering area (based on seed distribution in the grids), which is explained in the performance evaluation. Since the seed rates to the rotational disks depended on the seed metering mechanism, we kept similar rates over the experiments based on a trial-and-error method and compared them with theoretical calculated values, which indicated that the seed distribution on grids was more even between these two rpm values. Finally, 186 rpm was selected for the experiment due to better distribution capacity, and the theoretical maximum for this speed was 72.2 cm, which was enough to overlap the middle grid columns in the experimental design (Figure 14). Moreover, within the rpm value ranges, once the rpm value increases, the seed coverage distribution area also increases. The rpm value lower than 100 had aggregation of seed on the disks (seed not distributed to the next column), and over 200 rpm the seeds tended to travel higher distances and had more uneven distribution. The experiments were carried out using three different seed types and the small-scale autonomous vehicle.

Figure 14.

Experimental design for evaluation of the seed metering mechanism’s performance (A–L represent the position of the seeder at each location of the grid).

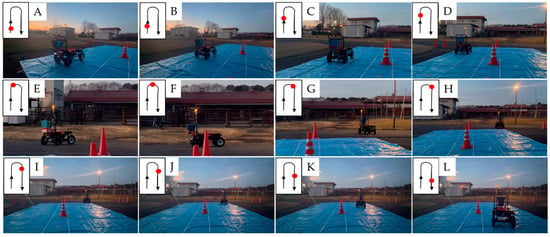

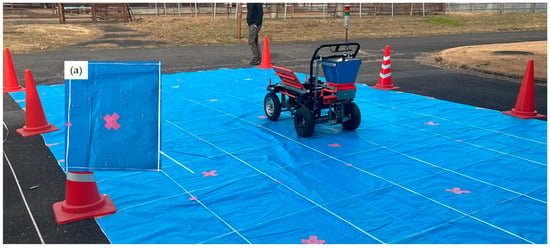

2.6. Field Experiments

In the field experiments, we performed evaluation of the seed metering mechanism based on grid systems (Figure 14, Figure 15 and Figure 16). Field evaluation was not conducted since we had several limitations related to the design that need to be addressed in Southeast Asian field conditions for broadcasting. For grid experiments, the machine was operated along a pre-determined path for three observations.

Figure 15.

Broadcasting of seeds using the autonomous vehicle in the experimental field (A–L represent the position of the seeder at each location of the grid).

Figure 16.

Grid arrangement and data collection: (a) 65 cm × 65 cm grid seed distribution.

The proposed autonomous small-scale vehicle was used with different forward speeds in a grid-shaped field designed with a determined distance interval considering crop practices (Figure 14). The data were collected from the parcels of the grids after the operation. The number of broadcasted seeds was counted after performing experiments at three variations of vehicle speed (0.351 ms−1, 0.443 ms−1, and 0.521 ms−1), and the rotating disk for seed distribution was set to 186 rpm during the experiments. The vehicle speeds were determined based on a human working rate (manual broadcasting) since the aim was to develop an autonomous machine able to mimic field workers’ operations, with three speeds chosen accordingly. These vehicle speeds were controlled by changing the voltage on the DC power supply.

The machine was commanded by a single Python programing language code including the navigation system, seed metering, and broadcasting mechanism. At first, the servo controlling the ON–OFF shutter was programmed in an open position at the start of the operation and a closed position at the end of the operation. The following sections discuss the performance parameters that were measured during the seed broadcasting experiment. The positions and the movement patterns of the vehicle are indicated in Figure 15.

The row numbers in Figure 14 are linked with Table 3, Table 4 and Table 5. In the tables, each row number represents the average number of seeds distributed in the shaded grids. For example, row 1 in Table 3 indicates the average number of seeds was 23, 22, and 22 in shaded grids 1, 2, and 3, respectively, for mung bean, cowpea, and chickpea at the vehicle speed of 0.351 ms−1.

Table 3.

Experimental results of seed distribution at the grid (6V ≅ 0.351 ms−1).

Table 4.

Experimental results of seed distribution at the grid (7V ≅ 0.443 ms−1).

Table 5.

Experimental results of seed distribution at the grid (8V ≅ 0.521 ms−1).

- Uniformity of Distribution

A grid arrangement was used to collect the seeds delivered from the seeder according to the standard method system provided by the American Society of Agricultural Engineers (ASAE, 1997). The dimension of each numbered grid plot was 65 × 65 cm, with plots in six rows, 87 cm apart, and perpendicular to the direction of travel. The delivered seeds in the numbered grid were counted after each repetition (Figure 16).

- Coefficient of Variation (CV)

A CV can be used to determine and express the uniformity of the distribution of applications. The mean value, standard deviation, and CV are determined from the following expressions:

where σ is the standard deviation, μi is the individual reading of the seed count, μ is the mean reading of the seed, and n is the total number of seed readings.

3. Results

The seed broadcasting experiment was performed with three replications of vehicle speeds. The metering shutter was operated in the reciprocating motion (fully open and closed position) throughout the operation. The data were collected from the numbered grid plots of the experiment after each of the operations. There were eighteen numbered grid plots in the experimental layout areas. Statistical calculations were then performed for seed distribution performance using Microsoft® Excel software (Microsoft 365®, version 2303). Redmond, WA, USA: Microsoft Corporation. For seed distribution uniformity, referring to each type, broadcasted seeds were collected again from the grids and seed distribution uniformity was observed (Table 3, Table 4 and Table 5).

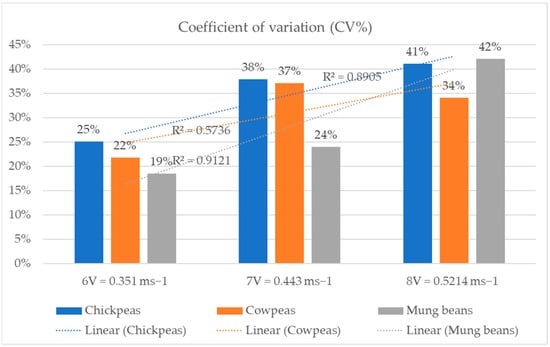

For chickpeas, the observations showed the effect of vehicle travel speed on the distribution of seeds across the swath on the ground. Seed distributions were more equal at the speed of 0.521 ms−1 than at the other two speeds. It was clear that the effective swath of the seed distribution increased as the speed of the vehicle increased in combination with the constant rotational speed of the spreading disk. For cowpeas, seed distributions were more equal at the speeds of 0.521 ms−1 and 0.443 ms−1 than at 0.351 ms−1. The effective swath of the seed distribution was increased as the speed of the vehicle increased in combination with the constant rotation speed of the spreading disk. For the mung beans, seed distributions were more equal at the speed of 0.351 ms−1 than at the other two speeds of 0.521 ms−1 and 0.443 ms−1. Furthermore, a corresponding decrease in CV was observed in relation to the speed of operation and each type of seed. CV at the vehicle traveling speed of 0.351 ms−1 was observed to be 25%, 22%, and 19% for chickpeas, cowpeas, and mung beans, respectively (Figure 17, Table 3). The CV was 38%, 37%, and 24% for chickpeas, cowpeas, and mung beans, respectively, at a vehicle speed of 0.443 ms−1 (Figure 17, Table 4). Finally, the vehicle speed was raised to 0.521 ms−1, and the CV of seed distribution was 41%, 34%, and 42% for chickpeas, cowpeas, and mung beans, respectively (Figure 17, Table 5). Chickpeas had the lowest coefficient of variation values while conducting the experiments using the listed autonomous vehicle speeds. The uniformity of seed distribution is considered one of the most important factors for spreading. Meanwhile, the outward seed dispersion increased the coefficient of variation that was observed with high vehicle traveling speed.

Figure 17.

Coefficient of variation for three types of seed distribution.

As indicated in Figure 14, Figure 15 and Figure 16, the total system was tested on a blue sheet with a grid system and the number of seeds at each section was counted, which is represented in Table 3, Table 4 and Table 5. During the experiment, the rpm of the motor was kept at 186 and the seed metering mechanism’s opening and closing shutter angles were not changed. As indicated in Table 3, the vehicle’s forward movement speed was 0.351 ms−1, and the seeds were collected from six rows marked on the blue color sheet with three respective columns. As an example, for mung bean, the first row’s first column (grid 1) had 23 seeds, and the third row’s third column (grid 9) had 30 seeds. The seeder started moving from row I, column I and moved forward until row VI before then taking the headland turn and coming back to column III, row VI, finally stopping at row I, column III. Column II had overlapped seeds (Figure 14 and Figure 15). As observed for column II, the overlapping seeds were slightly higher than for column I and column III for mung beans and cowpeas at the three speeds. Since the size of chickpeas was larger than the other two seed types, the amount that came out from the seed metering mechanism was lower. This explains why there were fewer reported; however, in the case of distribution, it was similar to the other two rows, and we observed that the metering mechanism in this case could be adjusted to allow for the flow of more seeds. We need to improve the prototype to allow for seed selection input which can adjust the opening of seed metering mechanisms automatically to lead to an equal number of seeds on the spreading disk.

The tables represent three different speeds, and the minimum CV% was found at the speed of 0.351 ms−1. Once the speed was increased, the number of seeds in the given area were decreased. However, there were limitations in terms of counting the number of seeds in the given area automatically and adjusting the seed metering mechanism accordingly.

4. Discussion

In seed broadcasting, it was observed that the effective swath of the seed distribution was increased at the lower vehicle speed with the constant rotational speed of the spreading disk. The CVs for the three types of seeds were related to the seeding rate corresponding to the vehicle’s traveling speed. In the experiments, large seeds (chickpeas and cowpeas) had less delivery than small seeds (mung beans). In this experiment, we observed that automatic adjustment of spindle speed was required while broadcasting large seeds since we set the speed to 186 rpm during the experiments. This rpm value was recommended based on seed particle travel information. Besides theoretical aspects of travel, a trial-and-error method was used to finalize the selection of spinning disk speed. We conducted our experiments on a plastic sheet kept on concrete, which also caused the slippage of seeds from the grid. This limitation needs to be overcome through further experiments on soil. A real-time seed counting system was absent, which also needs to be improved through the embedding of a high-quality image processing system.

In this regard, further improvements to the machine will be implemented, such as the utilization of an image-based system to determine the size of seeds and automatic adjustment of the spindle’s rotational speed with larger seeds to avoid overthrowing distances. CVs at a vehicle traveling speed of 0.351 ms−1 were recorded, with the best performance for chickpeas, cowpeas, and mung beans being 25%, 22%, and 19%, respectively. Therefore, it can be concluded that the proposed small-scale autonomous vehicle at lower speeds of operation can be adjusted to the farming level. In addition, seeder distribution displayed good performance in terms of broadcasting. Furthermore, the developed 3D printed new seeder is low-cost, light, has higher potential in reducing soil compaction in fields, and can be used in zero-tillage operations for multi-crop autonomous broadcasting systems. However, there are some limitations on the rotational speed of the seeder as only one fixed rpm was used based on trial-and-error adjustments, which were then compared with theoretical observations. Further experiments will be conducted with variable rotational speeds for different sizes of seeds for uniform seed distribution. Most seeding machines, including broadcasters, cannot recognize field boundaries or turning points automatically, which causes the loss of seeds. In this regard, deep learning-based intelligence can be added based on a Deep SORT system for detecting seeding lines to allow the number of seeds to be tracked [20], which can be applied to reduce the number of seeds per given area.

5. Conclusions

Seed broadcasting in a timely and efficient manner is important to achieve higher crop production. The following conclusions can be drawn for the further development of seed metering systems with autonomous vehicles:

- (1)

- A new 3D printed seed metering mechanism system for broadcasting seeds was developed for integration with small-scale autonomous vehicles.

- (2)

- An autonomous small vehicle was converted so that a seed metering system could be attached, and a low-cost RTK-GNSS positioning system was equipped to allow for tracking of the vehicle’s position during broadcasting.

- (3)

- The broadcasting system was tested to identify seed distribution, and results show that at the speed of 0.351 ms−1 the coefficient of variation for cowpea, mung bean, and chickpea was 22%, 19%, and 25%, respectively.

The new broadcasting unit can be further modified to perform simultaneous operations involving seed distribution, with variable disk rotational speeds based on the machine’s vision control system. Further improvements will be carried out using deep learning approaches for variability in the application for seeds, including the use of fertilizers for higher productivity.

Author Contributions

Conceptualization, A.M. and T.A.; methodology, R.M.R.D.A.; software, A.M. and V.M.N.; validation, A.M., V.M.N. and R.M.R.D.A.; formal analysis, A.M., V.M.N. and R.M.R.D.A.; investigation, A.M., V.M.N. and R.M.R.D.A.; resources, T.A.; data curation, A.M., V.M.N. and R.M.R.D.A.; writing—original draft preparation, A.M.; writing—review and editing, T.A.; visualization, A.M.; supervision, T.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that were generated and analyzed during this study are available from the corresponding author upon reasonable request; however, restrictions apply to data reproduction and commercially confidential details.

Acknowledgments

The authors would like to acknowledge the Japanese International Cooperation Agency (JICA) and Development of Core Human Resources in Agricultural Sector in Myanmar (Phase-2) for their support through graduate program sponsorship at the University of Tsukuba. The authors would like to thank the Tsukuba-Plant Innovation Research Center (T-PIRC), University of Tsukuba, for providing facilities for this research to be conducted.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lin, H.-C.; Fukushima, Y. Rice Cultivation Methods and Their Sustainability Aspects: Organic and Conventional Rice Production in Industrialized Tropical Monsoon Asia with a Dual Cropping System. Sustainability 2016, 8, 529. [Google Scholar] [CrossRef]

- Hossen, M.A.; Talukder, M.R.A.; Al Mamun, M.R.; Rahaman, H.; Paul, S.; Rahman, M.M.; Miaruddin, M.; Ali, M.A.; Islam, M.N. Mechanization Status, Promotional Activities and Government Strategies of Thailand and Vietnam in Comparison to Bangladesh. AgriEngineering 2020, 2, 489–510. [Google Scholar] [CrossRef]

- Belton, B.; Win, M.T.; Zhang, X.; Filipski, M. The rapid rise of agricultural mechanization in Myanmar. Food Policy 2021, 101, 102095. [Google Scholar] [CrossRef]

- Pandey, S.; Mortimer, M.; Wade, L.; Tuong, T.P.; Lopez, K.; Hardy, B. (Eds.) Direct seeding: Research issues and opportunities. In Proceedings of the International Workshop on Direct Seeding in Asian Rice Systems: Strategic Research Issues and Opportunities, Bangkok, Thailand, 25–28 January 2000; International Rice Research Institute: Los Baños, PH, USA, 2002. 383p. [Google Scholar]

- Awulu, J.O.; Audu, J.; Nuhu, G. Development and Evaluation of Manually Operated Seed Broadcaster. J. Agric. Eng. Biotechnol. 2014, 2, 13. [Google Scholar] [CrossRef]

- Sudake, R.D.; Andhale, Y.C.; Kothavade, A.K.; Gunjal, P.B.; Niketan, V. Design and Development of SeedSowing Machine for Agriculture Purpose. Int. J. Res. Anal. Rev. (IJRAR) 2019, 10, 549–551. Available online: www.Ijrar.Org (accessed on 15 February 2023).

- Nukeshev, S.O.; Kakabaev, N.; Romanyuk, N.N.; Troyanovskaya, I.P.; Smelik, V.A.; Voinash, S.A. Design and rationale for parametres of the seed-fertilizer seeder coulter for subsoil broadcast seeding. IOP Conf. Ser. Earth Environ. Sci. 2021, 677, 052010. [Google Scholar] [CrossRef]

- Brennan, E.B.; Leap, J.E. A comparison of drill and broadcast methods for establishing cover crops on beds. HortScience 2014, 49, 441–447. [Google Scholar] [CrossRef]

- Fisher, K.A.; Momen, B.; Kratochvil, R.J. Is broadcasting seed an effective winter cover crop planting method? Agron. J. 2011, 103, 472–478. [Google Scholar] [CrossRef]

- RShamshiri, R.; Weltzien, C.; Hameed, I.A.; Yule, I.; Grift, T.; Balasundram, S.K.; Pitonakova, L.; Ahmad, D.; Chowdhary, G. Research and development in agricultural robotics: A perspective of digital farming. Int. J. Agric. Biol. Eng. 2018, 11, 1. [Google Scholar]

- Ayerdi Gotor, A.; Marraccini, E.; Leclercq, C.; Scheurer, O. Precision Farming Uses Typology in Arable Crop-Oriented Farms in Northern France. Precis. Agric. 2020, 21, 131–146. [Google Scholar] [CrossRef]

- Landau, H.; Chen, X.; Klose, S.; Leandro, R.; Vollath, U. Trimble’s RTK and DGPS solutions in comparison with precise point positioning, observing our changing earth. In Proceedings of the International Association of Geodesy Symposia, Perugia, Italy, 2–13 July 2007; pp. 709–718. [Google Scholar]

- Wang, T.; Chen, B.; Zhang, Z.; Li, H.; Zhang, M. Applications of machine vision in agricultural robot navigation: A review. Comput. Electron. Agric. 2022, 198, 107085. [Google Scholar] [CrossRef]

- Titterton, D.H.; Weston, J.L. Strapdown Inertial Navigation Technology Aerospace & Electronic Systems Magazine; IEEE: Piscataway, NJ, USA, 2004. [Google Scholar]

- Ponnambalam, V.R.; Bakken, M.; Moore, R.J.D.; Gjevestad, J.G.O.; From, P.J. Autonomous Crop Row Guidance Using Adaptive Multi-ROI in Strawberry Fields. Sensors 2020, 20, 5249. [Google Scholar] [CrossRef] [PubMed]

- Kazberov, R.Y.; Tuzhilin, S.P. The Quality of Strengthening Impregnation of 3D-Printed Parts for Agricultural Machinery. Agric. Mach. Technol. 2022, 16, 48–54. (In Russian) [Google Scholar] [CrossRef]

- Verim, Ö.; Sen, O. Application of Reverse Engineering Method on Agricultural Machinery Parts. Int. Adv. Res. Eng. J. 2023, 7, 35–40. [Google Scholar] [CrossRef]

- Jurišić, M.; Plaščak, I.; Željko, B.; Radocaj, D.; Zimmer, D. Sensors and Their Application in Precision Agriculture. Teh. Glas. 2017, 15, 529–533. [Google Scholar] [CrossRef]

- Ziauddin, A.T.M.; Hussain Khan, F. BAUZIA Seed-Fertilizer Distributor—A Novel Technology Ready for Commercial Use. In Proceedings of the 4th International Conference on Mechanical Engineering, Dhaka, Bangladesh, 26–28 December 2001; pp. 117–122. Available online: https://me.buet.ac.bd/icme/icme2001/cdfiles/Papers/Applied%20Mechanics/serial21.pdf (accessed on 5 May 2023).

- Abeyrathna, R.M.; Nakaguchi, V.M.; Minn, A.; Ahamed, T. Recognition and Counting of Apples in a Dynamic State Using a 3D Camera and Deep Learning Algorithms for Robotic Harvesting Systems. Sensors 2023, 23, 3810. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).