Abstract

Vinyl, such as those in the form of mulching and vinyl houses, is used to improve agricultural productivity. It is generated as an agriculture waste vinyl (AWV) after use. The collected AWV is transported to a recycling facility and shredded, washed, and compressed to be recycled. Recycled materials can contribute to the circular economy of agriculture as they are used again as an agricultural plastic product. However, in Korea, there are concerns about the illegal disposal (landfill, incineration) of AWV. So, a new management model is needed in which stakeholders voluntarily establish an AWV management system. In this study, a sustainable management strategy was proposed. This strategy is reinforcing the responsibility of the producers of AWV and forms a value chain in the proper discharge after consumption by applying the deposit system proposed to recover AWV. Local governments and the National Agricultural Cooperative Federation (NH) proposed education to curb the illegal disposal of AWV, and for managing areas where a collection system has not yet been established, biodegradable mulching vinyl (BMV) was proposed to minimize the environmental pollution caused by AWV. It was calculated that the EPR contribution was 0.16 USD/kg, and the introduction of BMV was 0.42 USD/kg in Korea. This study will provide a new alternative in countries struggling with AWV management.

1. Introduction

In the agricultural sector, plastics are categorized into packaging and non-packaging, accounting for 3.4% of demand [1]. Agricultural plastics (Film) are mainly used for houses, mulching and low tunnels, silage, and bale wraps [2]. Agricultural vinyl (AV) and pesticides are used to increase the yield of crops in agriculture and are considered essential products [3]. After being used, it is known as agricultural waste vinyl (AWV).

Not recycling AWV means financial loss and environmental damage, for example, the loss of potential financial benefits from recycled materials. AWV are composed of a limited range of resins such as low-density polyethylene (LDPE) or linear LDPE (LLDPE), making them a suitable input for mechanical recycling [4]. Implementing a circular economy (CE) model can economically and environmentally improve the production system, which will reduce the need for virgin materials in the production system [5].

According to figures from 2020, 310,000 tons of AWV are generated annually in Korea. A total of 70,000 tons of high-quality AWV for vinyl houses was collected by the private sector, and 190,000 tons of low-quality AWV for mulching was collected from the K-eco (Korea Environment Corporation). The remaining 60,000 tons have not been recovered and are illegally disposed of (landfill, Incineration) [6]. Uncollected AWV poses a threat to environmental pollution, rural landscape conservation, and the safety of harvested crops [7,8]. When AWV is incinerated, it can generate a large amount of dioxin, which is a carcinogen, and dust that induces respiratory diseases. It may adversely affect the health of farmers [9]. It is an environmental problem that can cause water [10,11,12] and production issues [13]. Issues related to AW are not limited to Korea. In rural areas of Africa, India, and China, human waste disposal is a major concern besides household and agricultural waste [14]; the monitoring of illegal dumping is crucial either in high-income countries affecting public lands, roadsides, or water bodies [15,16]. The expansion of waste collection services across rural municipalities should be a priority in many countries [17].

Looking at the prior research on the problems and improvements for AWV in Korea, AWV is rarely sanctioned, even if the farmers who are the discharger do not comply with the discharge obligation in a drop-off site, and it can be discharged for free [18]. Additionally, it does not apply to the polluter pays principle (PPP), and illegal disposals such as the incineration and landfilling of AWV is widespread. So, incentives need to be provided for resident education and rural areas in order to solve illegal disposals [19]. It is reported that it is necessary to provide appropriate drop-off sites and incentives for collection on a village-by-village basis for waste collection. Since it is difficult to expand the collection and treatment system because AWV is generated in a concentrated manner in the rural region, a private sector-led collection system for abandoned agricultural waste, which is mainly composed of large farmers, was proposed [20]. Additionally, to increase the collection rate, there is a study result showing that the increase in the unit price of collection compensation and the number of collections is effective in increasing the collection rate [21].

Analyzing prior research, the reasons why AWV cannot be collected are as follows: (1) absence of stakeholder responsibility and obligation [6], (2) insufficient drop-off site [18], (3) stakeholder education [22], and (4) insufficient incentive for collecting AWV [21], and (5) the division of roles of stakeholders to collect AWV and not enough effort by the public sector [19].

In prior research, the focus is on the fact that AWV is household waste, so there is a proposal that efforts in the public sector should strengthen the management of the public sector via the expansion of drop-off sites and collection compensation. However, it is difficult for the MOE and local governments to set a budget for the treatment of AWV, and neglect and improper treatment continue to occur. Therefore, it is time to analyze the current management system of AWV and improve the management system most suitable for the treatment of AWV.

The purpose of this study is to examine the agricultural plastic waste management system in Korea and to devise a strategy for establishing a resource circulation system, consider the legal system, the generation and disposal status of AWV, and the derived problems of management in Korea, to investigate cases in foreign Europe and Japan, and to suggest a sustainable management system for AWV. The results of this study can be considered as benchmarking models for countries that are experiencing problems like Korea or have waste management systems.

2. Results

2.1. Agricultural Vinyl Management System

2.1.1. Law and Policy

The Waste Control Act is a basic law that regulates matters related to waste management in Korea. Waste is divided into household waste (Municipal solid waste) and industrial waste. AWV is managed as household waste, and the national and local governments have the responsibility for disposal. Dischargers of household waste must be discharged separately; if this is not performed, a fine will be imposed.

However, AWV is unlike general household waste and is generated from agricultural activities. In addition, since it is generated widely in rural areas, a lot of costs are incurred for collection and transportation. Nevertheless, it discharges of AWV for free. This is a kind of incentive to maintain agriculture and recognize the aging of the countryside. Therefore, Korea’s Waste Control Act does not induce proper treatment because AWV is household waste, and thus consideration for agriculture continues.

A fare system based on distance is a system in which to efficiently carry out the AWV collection work being carried out by K-eco, where private consignment collection is being implemented. The amount of consignment collected by private business groups is limited to 1500 tons/year. The collection and transportation costs increased continuously from 0.034 USD/kg in 2005 to 0.040 USD/kg in 2020. Additional transportation costs were added if the collection distance is 100 km or more. This system is to support the cost of collecting and transporting AWV. However, the cost is not realistic, and due to problems such as rising oil prices and labor costs, it is more economical to collect only AWV from nearby areas. As a result, a large amount of generation and selective collection from AWV treatment facilities and nearby areas is taking place.

The collection grade system is improving the quality of waste vinyl by paying a difference in collection compensation costs after grade determination according to the foreign matter content at the time of collection of AWV [23]. It is classified into four grades (A, B, C, D) according to the degree of the foreign matter content of AWV. If the quality (class D) contains foreign substances (metal fittings, agricultural materials, iron wires, waste, etc.) excluding soil, water, and plant residues, collection can be refused, and proper separation and discharge are induced. The guideline suggests that the collection compensation should be USD 0.11 for A class, USD 0.076 for B class, and USD 0.046 for C class, but the collection compensation is paid at USD 0.038–0.25/kg depending on the financial conditions of the local government. However, as mentioned earlier, the amount that private contractors can collect is 1500 tons/year. Therefore, it is more economical to collect only grade A. As a result, B, C, and D grades are reluctantly collected, even if they are discharged to the drop-off site and are accumulated.

The waste charge system is the disposal cost of waste that products, materials, and containers that contain harmful substances or toxic substances are difficult to recycle and may cause problems of waste management borne by the manufacturer or importer of the container. It is a system to control the generation of waste from the production stage and prevent the waste of resources. AV is classified as a synthetic resin product; producers must pay a waste burden but can be exempted if vinyl is made of biodegradable resin. The collected waste contribution will be used as compensation by local governments for collecting AWV. Although this system has the advantage of charging producers for disposal costs, it cannot induce recycling. In addition, since the waste charge is added to the user, it is not used practically as it is an economic pressure on companies.

The public interest direct payment system subsidies to farmers to promote public interest functions such as environmental conservation and the maintenance of rural communities by agricultural activities [24]. It sets out the obligations for the proper disposal of AWV. The discharger is instructed: “Do not leave farm waste voluntarily, store it in a drop-off site in the village and manage the farmland and its surroundings cleanly” and “Landfill farm waste, domestic waste in the farmland, not be incinerated”. The local government is obliged to “operate and collect waste collected from the village by operating a village patrol collection vehicle.” This system is being evaluated positively. However, since it is an incentive system, there is no disadvantage to farmers, even if it is not implemented. Therefore, it is not possible to urge active change in the behavior of farmers.

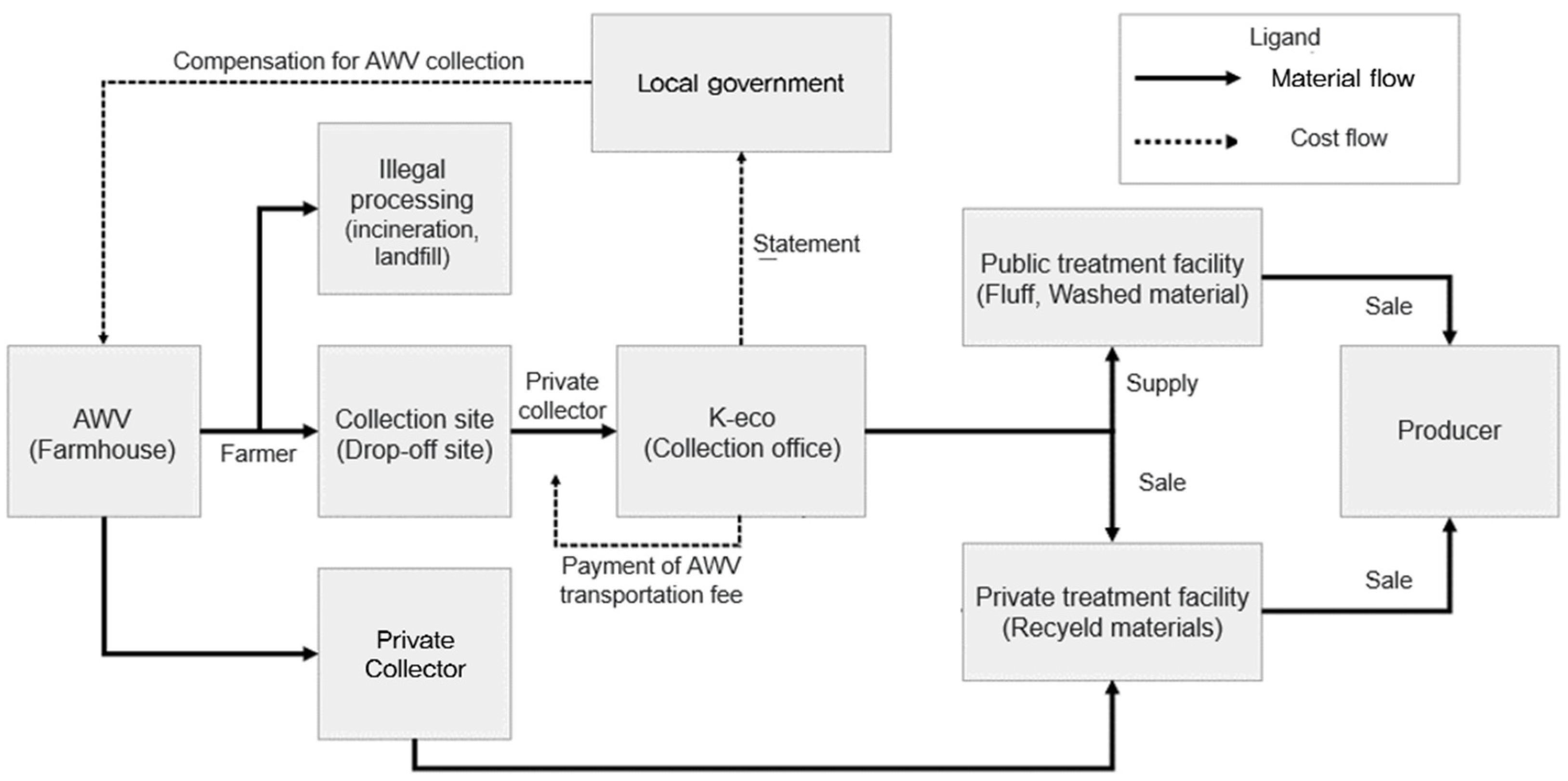

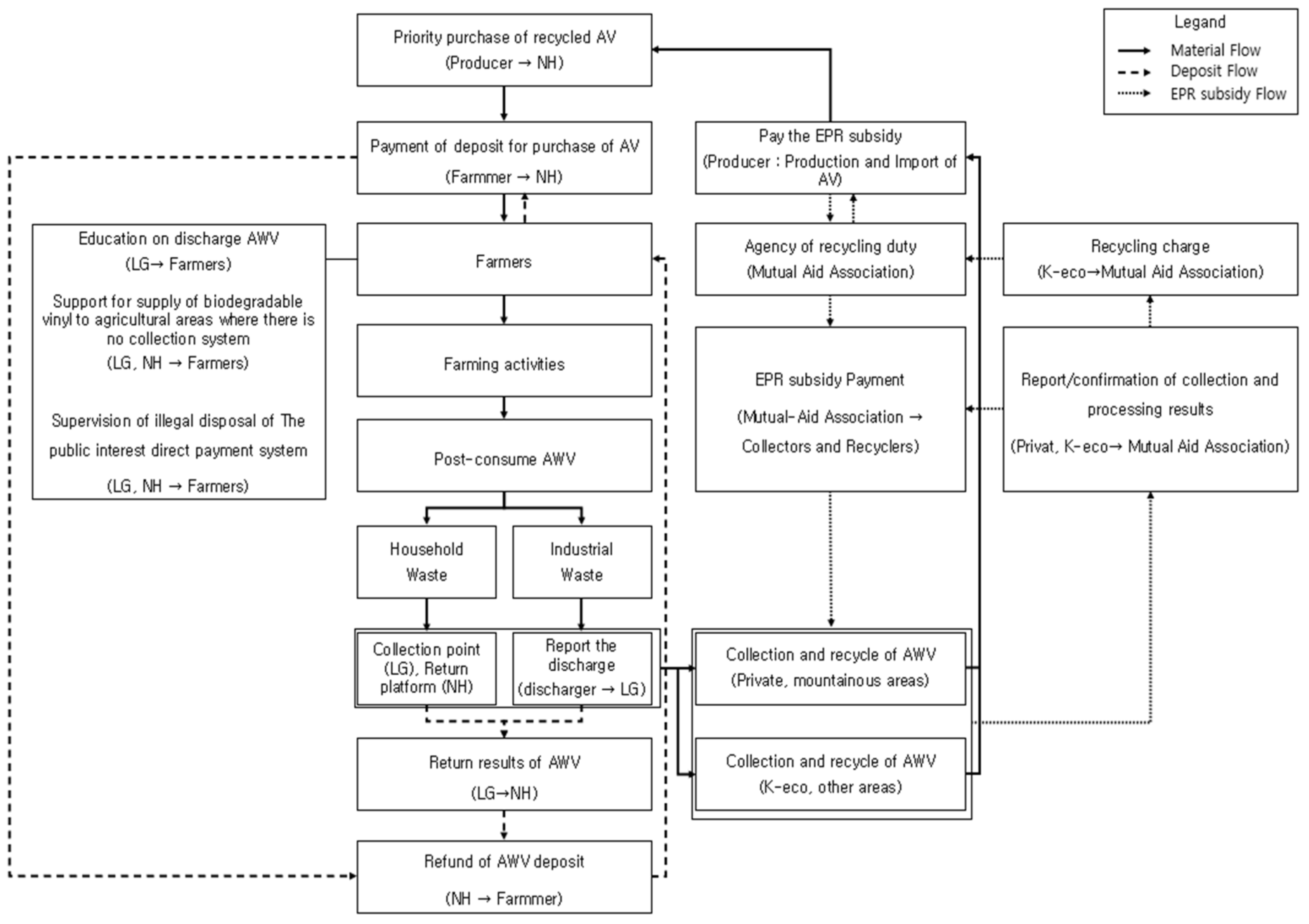

Figure 1 shows the management system for AWV in Korea. AWV is two main streams, except for illegal disposal. The K-eco plays a central role in the disposing of AWV, which is relatively low in profitability. On the other hand, profitable house vinyl is being collected and recycled by private recycling companies. Local governments support the efficient separation of collection by education, publicity, and the collection grading system, and they manage and operate a common collection point. Dischargers are transported to the drop-off site and discharged separately. The AWV loaded at the drop-off point is directly transported to a collection office operated by the K-eco, a joint consignment treatment facility, or a private treatment facility. When AWV is brought into the collection office, the regional headquarters of the K-eco uses the video management device to check the properties and weight of the waste vinyl; after confirmation, a collection slip is issued. The collected AWV is recycled using recycling facilities and supplied to domestic and foreign recycling companies.

Figure 1.

Schemes of AWV management in Korea [19].

2.1.2. Generation and Disposal

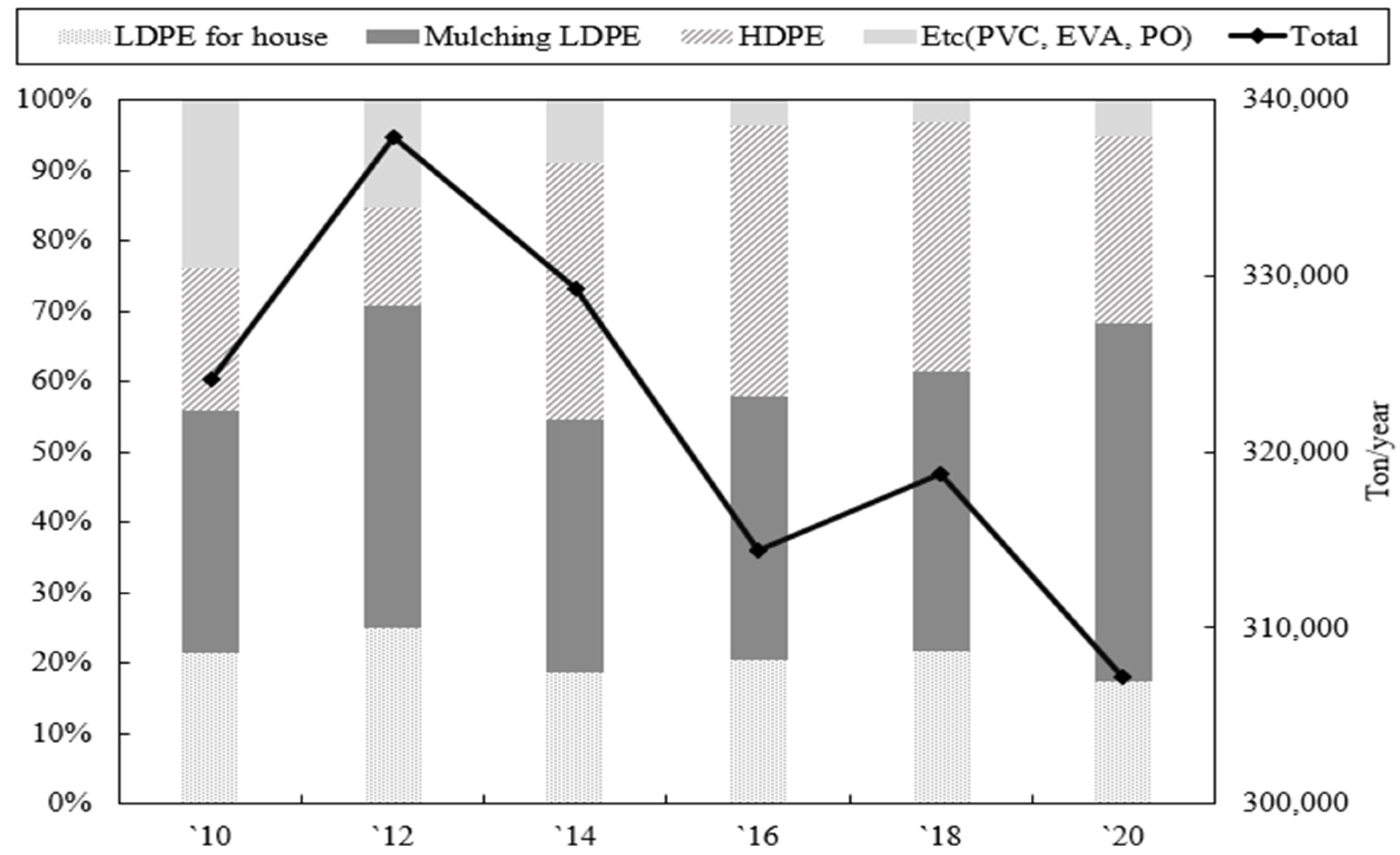

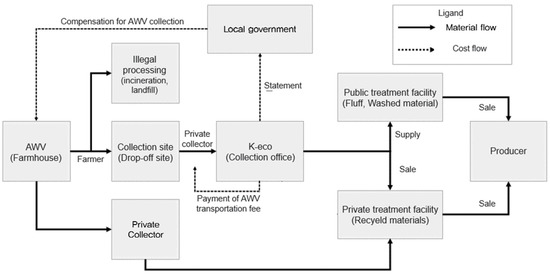

Figure 2 shows the generation amount of agricultural plastic waste and the generation rate by material. The generation of AWV was 307,159 tons in 2020, on a declining trend [25]. It is presumed that the number of farm households and illegal treatment due to an aging population had major impacts on the decline. By material, about 53,589 tons of LDPE for houses, 156,422 tons of LDPE for mulching, 81,517 tons of HDPE (High-Density Polyethylene), and 15,631 tons of other AWV (PVC (Polyvinyl chloride), EVA (Ethylene Vinyl Acetate), and PO (Poly Olefin)) were generated. HDPE is mostly used for multi-purpose applications; even foreign substances are counted in discharged AWV. In addition, considering that the discharge of AWV from other materials decreased by 80% (77,346 tons (`10)→15,631 tons (`20)), the aging of rural areas in Korea is progressing very rapidly (67%(`10)→79%(`20)), while there is a diminishment in the reduction in plastic use in farmland (0.44 ton/ha(`10)→0.41 ton/ha(`20). The abovementioned reason causes a decrease in agricultural plastic waste.

Figure 2.

The generation amount of agricultural plastic waste and the generation rate by material [25].

In the results of a fact-finding survey by the Ministry of Agriculture in Korea [26], it is estimated that more than 20% of farmers incinerated agricultural waste such as plastic waste (2019), and the reasons for incineration was because it was ‘difficult to throw away and troublesome’ (54.2%) and the ‘prevention of pollution due to neglect’ (35.5%) was high.

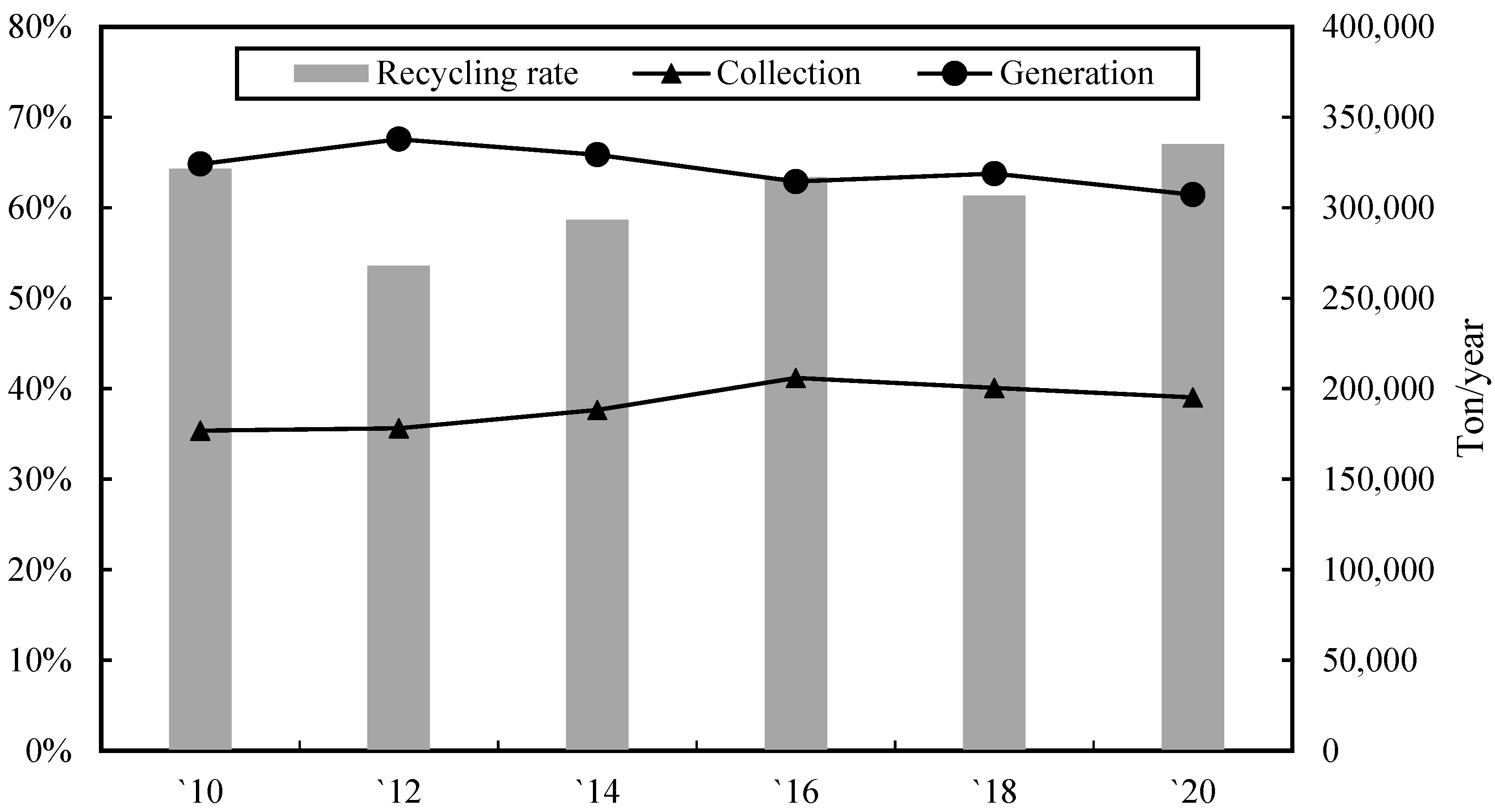

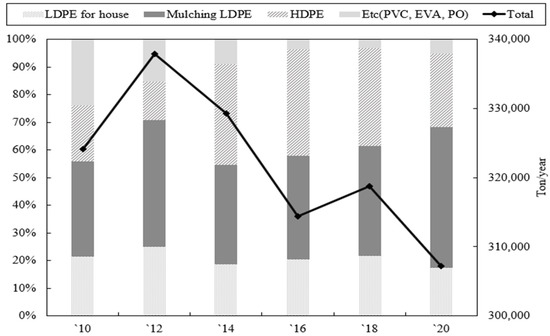

Figure 3 shows status of collection and recycling of AWV in Korea. According to the public collection status of AWV in 2020, the HDPE collection rate was 118.7%, the LDPE collection rate for mulching was 62.8%, the LDPE for the house was 0.01%, and the others were 1.09%. This is because HDPE and LDPE for multi-purpose use are less profitable in the private sector, so the reason for the collection rate exceeding 100% is that waste vinyl that has not been discharged is recovered or mixed with foreign substances. On the other hand, the public collection rate of LDPE for houses and others is very low, but this is because LDPE for the house is discharged cleanly and profitably, so it is the preferred method of collection in private areas.

Figure 3.

Current status of collection and recycling of AWV [25].

AWV which is not collected by the public sector is collected and recycled in the private sector. It is difficult to transport to the drop-off site, resulting in landfill or illegal incineration. Considering that the rate of the collection has stagnated at around 50–60% for several years, it is considered that there is a limit to the expectation that private collection will be activated under the current system.

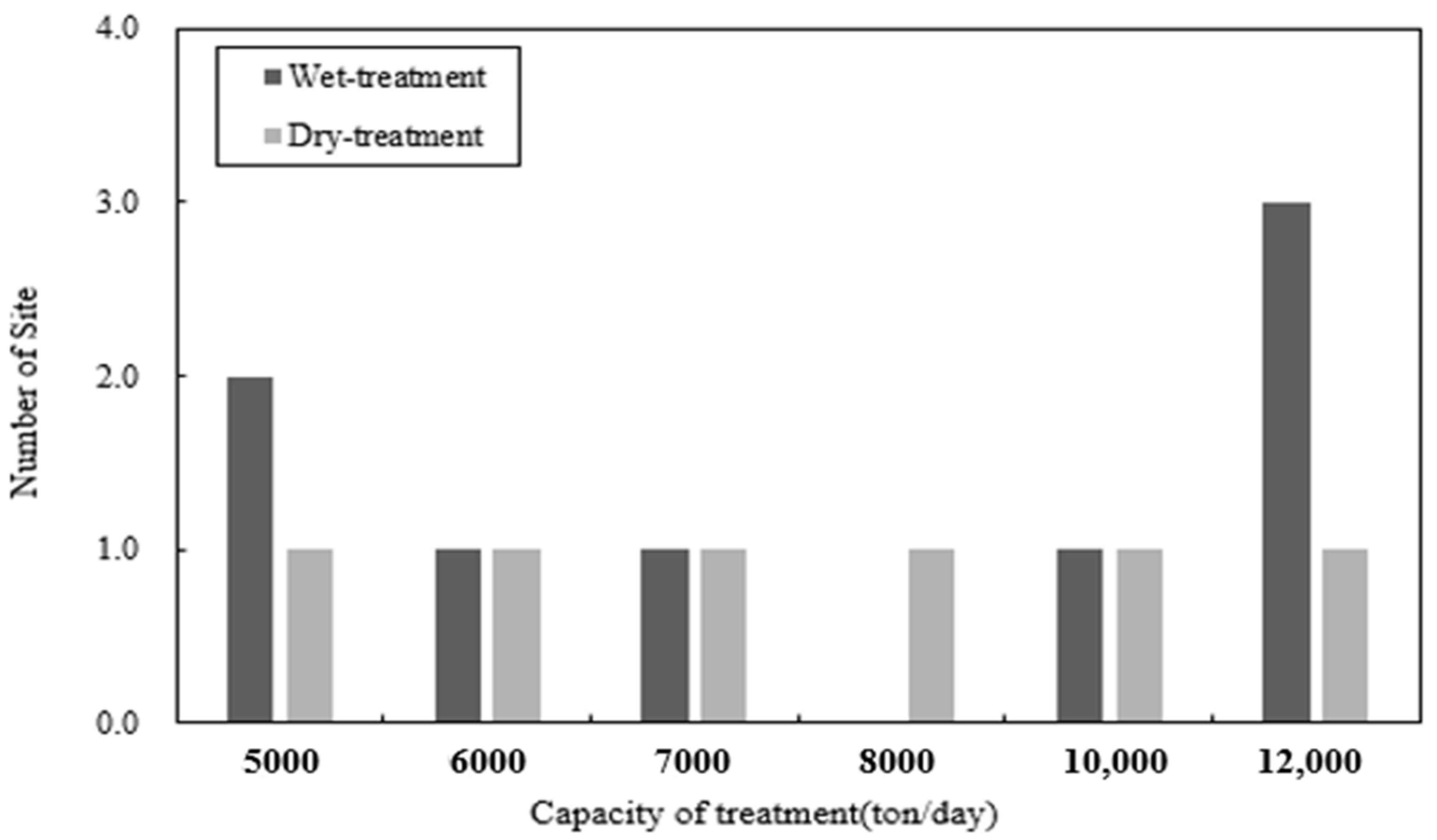

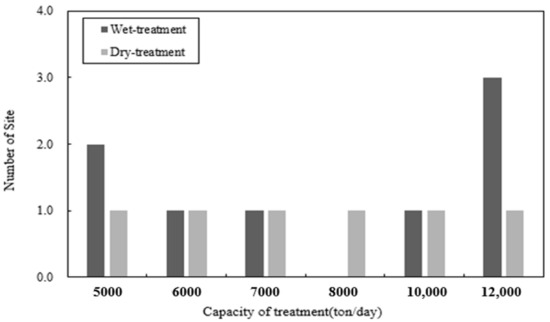

Figure 4 is showing the facility status of AWVTFs (AWV treatment facilities), with a total of 14 AWVTFs in Korea (as of 2020). Only 10 AWVTF has operated, nine are wet-treated (washing) facilities, and the other one is a dry-treated (hitting) facility. The total capacity of the AWVTF in operation is 84,000 tons/year, and only 43% of the total collected AWV can be processed. The wet treatment for the recycling of AWV goes through a washing process two to three times to remove foreign substances, so the treatment cost is high and there is a problem with wastewater treatment. However, it is thought that the number of facilities converting to wet-treated is increasing because dry treatment has a lot of foreign substances, and the quality of recycled products is lower as a result. The properties of the recycled material of AWV are not as appropriate as the virgin material for AV [27], and use of the former would considerably increase production costs while requiring a greater number of additives and slowing down the production process [28].

Figure 4.

Current status of farming waste plastic treatment facility (Use of k-eco’s internal data).

2.2. Agricultural Vinyl Management System of EU

In the European case, it was found that the recycling of AWV was managed according to the Extended Producer Responsibility (EPR). EPR was imposed on all stakeholders, and it is notable that the public sector felt the difficulty of managing agricultural plastics alone and therefore the private sector tried to activate waste management and treatment. Therefore, there is a need to introduce a system that builds partnerships between stakeholders.

In Spain [29], a new association MAPLA (Environmental Agriculture and Plastics) has recently been formed to manage agricultural plastic waste. The purpose of MAPLA is to increase the collection and recycling rates. MAPLA engages farmers, cooperatives, sales representatives, and distributors. The circular economy in Spain consists of nine stages. Agricultural vinyl is produced, and used vinyl is decontaminated and discharged separately, then discharged to a designated area using a dedicated collection vehicle and finally collected by a collection company, undergoing pre-treatment and packaging and becoming plastic obtained via material recycling.

In France [30], AWV is legally classified as non-hazardous waste, and all producers of agricultural waste vinyl must follow the principle of producer-responsible recycling. Storage of agricultural waste can only be done in facilities classified, and landfill or incineration is strictly prohibited. Farmers have the responsibility and duty to separate discharge waste, and producers and distributors must collect and dispose of waste. A notable example is Adivalor, an industrial, private organization for the treatment of agricultural plastics in France. Adivalor is a non-profit organization established to contribute to the development of sustainable agriculture via agricultural waste collection and recycling. Adivalor is supported by stakeholders such as farmers, countries, the federation of agricultural unions, and the agricultural distributor. Adivalor has 330 producers and 1300 distributors (cooperatives and merchants organizing collection systems everywhere in the region), 300,000 farmers (returning agricultural waste), and receives support from government agencies. There are 7000 collection points in operation nationwide. Adivalor’s collection service is available only to agricultural enterprises, public institutions, and administrations, and only the packaging materials of participants with Adivalor’s mark are collected. As of 2015, 70,000 tons of agricultural plastic packaging waste out of 116,000 tons were estimated to be agricultural plastic vinyl, with a collection rate of 73% and a recycling rate of 98%.

In Germany [31], a voluntary collection system called ERDE (Erntekunststoffe Recycling Deutschland—Together for the environment) with manufacturers and merchants to increase the collection rate and recycling of agricultural plastics has been established. The discharge site is supported by agricultural plastics manufacturers and distributors for installation and operation, while farmers, contractors, and disposal companies operate ERDE collection points. Farmers contact RIGK (the recovery system for the agricultural field) directly to return AWV or check the discharge site and discharge it cleanly. Discharge sites are supported in installation and operation by agricultural plastics manufacturers and distributors, and trade, machinery, farmers, contractors, and processing companies operate ERDE collection points. At the collection site, personnel conduct on-site inspections to see if all manual work standards, such as the removal of foreign substances from the discharged collection, have been met. The plastic is compressed and transported to recycling partners. Recycling companies are building a system in which plastics are pulverized and produced as recycled materials and products. ERDE aims to recycle 65% of silage vinyl in Germany by 2022, collecting and compressing factory vinyl from agriculture and using it to make vinyl or other products. Currently, nearly 35% of waste silos and stretch vinyl are collected and 100% are recycled as renewable materials.

2.3. Agricultural Vinyl Management System of Japan

In Japan [32], AWV is classified as industrial waste by law, and according to the polluter pays principle, farmers are required to bear the cost of collection and disposal, and local governments and producers bear the cost together. By the application of the polluter pays principle, farmers remove foreign substances in the discharge stage and roll them to a certain size. It is possible to reduce the generation of AWV from farming and produce discharge waste of high-quality.

Waste plastic is based on suppressing its occurrence and using it as a renewable material for the reduction of the environmental load and effective use of resources. In addition, polyolefin vinyl such as Agricultural PO and Agricultural Poly have the same amount of heat as fossil fuels and are being used as fuel substitutes in cement plants, paper mills, and power plants. Exports were also made; the recycling rate was 74.5% in 2019 [32].

Proper treatment of agricultural waste plastics utilizes a regional collection and treatment system. Councils are organized by administrative agencies such as prefectures and municipalities, agricultural cooperatives, agricultural material sellers, and agricultural production associations to share their roles.

The government is working with organizations across the country to dispose of agricultural plastic waste, providing information to municipalities and making efforts for proper disposal nationwide. Support is provided for the research and development of new technologies and for new materials or the expansion of demand for recycled products. Prefectures establish prefectural councils composed of municipal councils, private recycling and processing companies, and distributors in their respective municipalities, and formulate appropriate treatment promotion plans.

There are 47 LCs (local councils) in operation nationwide. LCs make amendments to relevant laws and regulations, and roles and requirements for proper treatment are communicated to municipalities, and then the management companies and treatment facilities are informed of the costs. They are also responsible for the collection and provision of information. MCs (Municipal councils) play a practical role in the collection of waste plastics and provide information on proper treatment to farmers. The manufacturing company makes efforts to use recycled agricultural waste vinyl products, develop new recycled products, demonstrate them, and prepare new plastic treatment methods. By providing information on the prepared treatment method to interested parties, they oversee making it easier to recycle and process agricultural waste plastics and are in charge of ensuring that proper treatment is not hindered, and that distributors help farmers in proper collection and treatment. We are actively providing information to this end. Recycling and processing companies contribute to collection and treatment by contracting with prefectures and municipalities and work to develop new uses for recycled materials in cooperation with agricultural vinyl manufacturers.

Table 1 shows compares the legal status and management, collection, and recycling systems of AWV in the EU, Japan, and Korea. For the efficient collection and recycling of AWV, the role of farmers, the cause of the occurrence, is essential. Waste vinyl generated in self-cultivation fields must be discharged by farmers to a designated place after removing foreign substances. However, as discussed above, it is presumed that due to the lack of responsibility on the part of the farmers who are obligated to discharge plastic waste, the farmers do not discharge it to a certain place, and instead incinerate, landfill, or neglect it in cultivated land.

Table 1.

Compares the legal status and management, collection, and recycling systems of AWV in the EU, Japan, and Korea.

2.4. Strategies for Sustainable Agricultural Waste Vinyl Management Systems in South Korea

Inappropriate treatment of AWV is for the convenience of the discharger. From the perspective of PPP, there is a need for stronger responsibility. For example, economic incentives to induce environmentally friendly deposits. A structure is needed in which the deposit is returned when they return to the drop-off site or the NH. Farmers are classified into individual union members and corporate union members, and all these union members are closely connected to the regional NH and related companies. Therefore, since members of the farming community purchase agricultural materials from the NH distribution network, it is possible to build a reverse collection system for neglected AWV by utilizing these distribution networks.

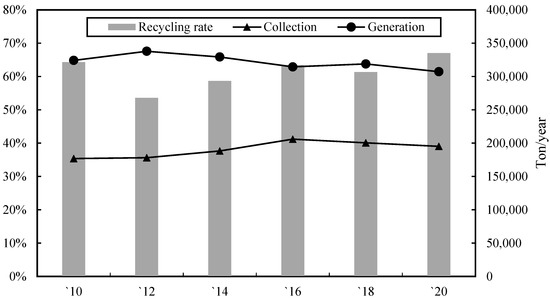

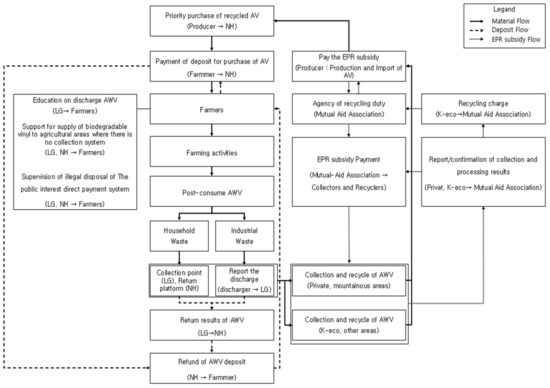

Figure 5 is shows the proposed model. It largely presented discharge and treatment systems and shows the flow of support in the form of money and materials.

Figure 5.

Scheme of suggested sustainable management model of AWV in Korea.

In the discharge system, the management system was divided into household waste and industrial waste according to the subject of plastic farming waste, and the responsibility of the public and private sectors was clarified. It is expected that the money that has been spent from the national treasury on handling the private sector will be able to be reduced. In common, when individuals and farmers purchase agricultural vinyl, they purchase it at a price that includes a deposit and receive a refund of the deposit from the deposit management center according to the discharge performance. A reverse collection system was established by adding the NH as a base for domestic waste discharge, and support was provided in cases where a joint collection site was not established, or when the NH was too far away or difficult to discharge. In addition, in the case of islands and mountainous regions where collection systems are not equipped, a plan to supply biodegradable vinyl in cooperation between local governments and agricultural cooperatives was proposed.

In the treatment system, the EPR system was introduced. Farming material producers paid the EPR contribution and replaced the cost of existing public funds, thereby reducing the money spent via the national treasury and strengthening producers’ responsibilities. Instead, a compensation system was proposed to require the NH to undergo compulsory purchases to promote resource circulation when obligatory producers sell recycled AWV. In addition, to strengthen management of illegal processing, local governments and agricultural cooperatives supervised illegal processing, proposed a reward system for reporting illegal processing, and made it mandatory for the private sector to report the results of collection and processing.

The strategy model and roles of each stakeholder in the model are as follows (Figure 5):

- Discharge and collection

First, local governments should extend drop-off sites and educate regularly on the prevention of the illegal disposal of AWV. The discharger must recognize that AWV should be discharged at a clean drop-off site. Considering rural residents were likely to dump waste at drop-off sites if those public services were provided, multiple collection points should be encouraged in areas where the distance from a disposal site is over 2 km [32].

The existing system has the responsibility in the public sector. However, the proposed model has the effect of strengthening the responsibility of the discharger and producer. There is a deposit system among the methods of fulfilling the discharger’s responsibility for disposal, and it can be used to efficiently recover waste in rural areas [33].

So, a deposit system is introduced to fulfill their discharge responsibilities from the discharge source to drop-off site. So, when farmers purchase AV, they purchase a price that includes a deposit, and the deposit is refunded from the NH according to the return performance. Considering the economic structure, in which most farmers are members of the NH and purchase AV from the NH, it would be reasonable for the NH to oversee the parts related to the purchase of AV. Additionally, the NH is a base for discharging waste, and if there is no drop-off site and it is difficult to dispose of it, collection can be supported.

- Recycling

EPR would be more likely to be adopted by small–medium AV producers [34]. AV producers pay the EPR contribution for the produce and imported products. This system replaces the cost of existing public finances, thereby reducing the financial burden on the national treasury and strengthening the responsibility of producers. In addition, there are many problems with the quality of the recycled products of AWV. As such, there is a need to develop a technology capable of producing high-quality renewable materials from agricultural waste vinyl. There is a need to develop advanced recycling technology using the financial resources of the EPR system. Instead, a compensation system has been established that requires the NH to undergo compulsory purchases to promote resource circulation. In addition, to strengthen the management of illegal processing, local governments and the NH supervised illegal disposals and proposed a reward system for reporting illegal disposals, while the private sector reports the collection and disposal results.

For the operation of the EPR system, producers of vinyl for farming materials are included as obligatory producers, and after collecting contributions, collection subsidies are given to civilians, and recycling subsidies are paid to processing facilities (public corporations and private recycling companies), expanding producers’ responsibilities.

Table 2 shows result of cost to introducing EPR. An amount of USD 0.06/kg was provided for collection support, USD 0.09/kg was provided for recycling, and USD 0.01/kg was provided for cooperative and center operation costs, resulting in a total contribution of USD 0.16/kg. These costs are higher than the USD 0.04/kg previously paid to private collectors and are expected to contribute to the improvement of the collection rate.

Table 2.

Cost of introducing EPR for AWV.

- Introducing of biodegradable vinyl

If it is difficult to collect and recycle AWV, it is necessary to introduce BMV. The tensile nature and strength of biodegradable vinyl are greater than those of neat agricultural recycled plastic [35]. It is an essential material for farming, providing warmth, a weeding effect, and pest prevention, but it is difficult to collect and causes environmental problems due to the soil environment and illegal incineration due to uncollected waste vinyl. As for BMV, there is also an argument that the supply of BMV should be expanded in accordance with the emergence of an aging society [36]. It is very valuable in agriculture because it can be used, and there is no worry about waste disposal, so it is emerging as a new way to replace AV. BMV is mainly composed of polyester and starch, and after harvesting crops, it is covered with soil via a grinding process using a rotary operation and is finally decomposed into water and carbon dioxide or methane gas by microorganisms in the soil. There are also research results that indicate that it is a way to respond not only to the environment, but also to the aging of rural areas, and that it is more economical than using existing PE. However, the indiscriminate use of biodegradable vinyl should be limited because vinyl production can increase crop production costs [37]. In the case of remote islands and mountainous areas where a collection system is not equipped, a plan to distribute biodegradable vinyl was necessarily proposed in cooperation with local governments and the NH.

In Korea, to encourage biodegradable resin, annual reductions in packaging waste, exclusions from disposable product use regulation, and exemptions from waste charge are being implemented, which can promote production, but the price between domestic general mulching and biodegradable mulching vinyl is about a difference of 1.2 to 1.5 times, so it is difficult to induce farmers to purchase it. In Japan, the supply of biodegradable resin was about 1150 tons in 2006, but it had increased to about 3420 tons by 2018. This is because it is difficult and expensive to take out vinyl buried in the soil and remove the soil and take it out of the site, and it is considered practically difficult to collect waste vinyl generated in remote mountainous areas Japan supports the purchase cost of BVM, and this support contributes to the spread of BVM general mulching [38].

According to previous studies [6], even if there is economic feasibility for farmers, it is difficult to feel the immediate benefits to farmers, so there is a need to review only the direct benefits. Therefore, to reduce the cost of BMV, the government should induce the introduction of BMV by adjusting product prices via eco-friendly farming material support projects and waste sharing fees and subsidizing the purchase of agricultural materials from NH and local governments.

Table 3 shows support cost for extending BVM. As the waste quota is applied, the vinyl for general mulching is charged about USD 0.16/kg as a collection and recycling subsidy, whereas the difference in unit price can be partially mitigated as BMV is not subject to the quota. NH needs to support agricultural material support via cooperation projects with local governments, and it is necessary to support the supply of BMV to farmers’ agricultural material support projects.

Table 3.

Comparison of purchase price between general mulching and biodegradable mulching.

BMV is reasonable in terms of economic and environmental friendliness. However, when the use of BMV begins to increase, it may adversely affect the AW resource circulation system. Looking at the priority of waste management in Korea, it is managed in the order of generation reduce > reuse > material recycling > energy recovery > disposal. This is because biodegradable vinyl can be regarded as appropriate disposal. It may cause problems in the quality of the recycled products due to its different material and characteristics compared to plastic.

3. Methods

3.1. Analysis of AWV’s Management System in Korea

To analyze the management system of AWV in Korea, we investigated the laws and systems related to agricultural waste and the current state of generation and disposal. Agricultural waste-related laws and systems, such as the Waste control act, Collection grade system, “Fare system based on distance”, “Waste Charge System”, and “Public interest direct payment system”, were examined (Table 4).

Table 4.

Law and policy-related AWV management.

The current data on the generation, collection, and treatment of AWV has used the agricultural waste statistical survey (a sample survey of approximately 2000 by a farmhouse visit survey targeting farmhouses cultivating crops using plastic among farmhouses and growing crops in fields among farmhouses) of the MOE [25]. The problem of AWV management was derived by comprehensively examining the agricultural waste vinyl-related system examined above and the current state of generation, collection, and treatment.

3.2. Analysis of AWV’s Management System in EU and Japan

To devise a better strategy, there is a need to consider advanced AWV management systems abroad. In European countries, a significant amount of agricultural plastic waste is concentrated in some countries. Spain, which discharge the most agricultural plastic waste, has a large share in four countries: Italy, Germany, France, and the United Kingdom [40]. In Asia, Japan’s agricultural waste management system is known to be advanced [41]. To get the implications of the foreign AWV management system, we investigated the AWV management system of EU countries and Japan.

3.3. Determination of EPR Contributions

To build an advanced model, the cost part should also be analyzed. There is a need to calculate the subsidy that should be provided to private collectors of agricultural plastic waste and public collectors. To this end, the appropriate vehicle and personnel required for the collection were set to 1 vehicle equipped with a 2.5-ton crane and 253 working days per year by referring to the recruitment guidelines for private agricultural waste consignment companies [42]. As for the recycling cost of AWV, the treatment facility is a 12,000-ton wet treatment facility, because the cleaning process is required to deal with impurities such as soil, organic matter, dust, or metals [43]. The treatment cost was investigated by K-eco. So, the recycling cost is USD 106.1/ton, the yield of the recycled products is 25%, and the unit price of the recycled products per ton is USD 208.3; the sales revenue of the recycled products is calculated as USD 52.1. For the detailed cost of items, the legal basis used for cost calculation in Korea was applied, and the cost is shown in Table 5. The calculation of the EPR contribution was applied using the following formulas.

Table 5.

Collection and transportation unit price of AWV.

Extended Producer Responsibility (EPR) contribution (USD/year) = packaging materials/product shipment volume (kg/year) × mandatory recycling rate × unit price of EPR contribution (USD/kg)*.

※ Unit price for EPR contribution (USD/kg) = Unit price for collection/recycling support (USD/kg) + Union/center operation cost (USD/kg).

※ Unit price of collection/recycling subsidy (USD/kg) = cost of collection/recycling (USD/kg) + profit (USD/kg) ± adjustment of the joint operating committee.

4. Conclusions

In the European case, it was found that a collection system was secured and managed by the EPR system for the responsible recycling of AWV. In Japan, AWV is classified as industrial waste. According to the PPP, farmers are required to bear the cost of collection and treatment. Local governments and producers bear the cost together. Farmers must remove foreign substances in the discharge stage, roll them into a certain size, and discharge them. The proposed model in this study covers both the EU’s EPR and Japan’s responsible discharge and can contribute to the establishment of the AWV circulation system.

The important thing is that cultivated land is scattered and there are many small-scale and old farms. It is difficult that proper treatment of AWV depends only on the willingness of farmers. So, the role of farmhouses and local governments is primarily important.

It is for the convenience of the farmer that AWV is discharge-free, and there is a need to strengthen the regulation rather than consider the discharger. Therefore, when a producer purchases AWV, a deposit is charged to induce farmers to undertake proper discharging procedures with economic incentives, and in connection with the public interest direct payment system, illegal disposal can be managed by checking the use and return of AWV. In addition, since members of farm households purchase agricultural materials from the distribution network of the NH, it was proposed to build a reverse collection system for agricultural wastes left unattended by using these distribution networks.

For the operation of the EPR system, producers of AV were included in the mandatory producers, collected the contribution, and the collection subsidy was given to the collecting company, and the recycling subsidy was paid to the recycling company. Local governments and the NH contributed to the illegal disposal of AWV and the establishment of a collection system in the island and mountainous areas. NH ordered the priority purchase of AV that recycled AWV, so that mandatory producers could participate in promoting recycling and maintaining a stable supply system. It is possible to supplement the producer’s responsibility and economic feasibility of treatment and establish a circulation system that recycles recycled materials into AV.

BMV is disposed of in the soil, and it is inconsistent with the aspect of encouraging material recycling and resource circulation in domestic waste management, which can make the management of AWV more difficult. Therefore, it is suggested to introduce BMV only in areas where the collection is difficult.

Author Contributions

Writing—original draft preparation, D.K., E.K.; writing—review and editing, C.P. All authors have read and agreed to the published version of the manuscript.

Funding

This study was supported by the Human Resource Development Programs for Green Convergence Technology; funded by the Korea Ministry of Environment(MOE) and Basic Science Research Program through the National Research Foundation of Korea (NRF); funded by the Ministry of Education (Grants No. NRF-2020R1A6A1A03042742).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Erälinna, L.; Järvenpää, A.M. Maatalousmuovijätteen Keräys Ja Kierrätys; University of Turku: Turku, Finland, 2018; pp. 18–22. Available online: https://maatalousmuovijate.fi/ (accessed on 25 December 2021).

- Briassoulis, D.; Hiskakis, M.; Babou, E.; Antiohos, S.K.; Papadi, C. Experimental investigation of the quality characteristics of agricultural plastic wastes regarding their recycling and energy recovery potential. Waste Manag. 2012, 32, 1075–1090. [Google Scholar] [CrossRef]

- Orzolek, M. A Guide to the Manufacture, Performance, and Potential of Plastics in Agriculture, 1st ed.; William Andrew: Norwich, NY, USA, 2017. [Google Scholar]

- Borreani, G.; Tabacco, E. Silomais, come e quando raccogliere la qualità. L’Informatore Agrar. 2008, 64, 28–31. [Google Scholar]

- Nasir, M.H.A.; Genovese, A.; Acquaye, A.A.; Koh, S.C.L.; Yamoah, F. Comparing linear and circular supply chains: A case study from the construction industry. Int. J. Prod. Econ 2017, 183, 443–457. [Google Scholar] [CrossRef]

- Kim, K.H.; Kim, K.M. Agricultural Waste Vinyl Discharge Status and Implications. In Agricultural Waste Vinyl discharge Status and Implications; National Assembly Research Service: Sejong, Republic of Korea, 2020. [Google Scholar]

- Steinmetz, Z.; Wollmann, C.; Schaefer, M.; Buchmann, C.; David, J.; Troger, J.; Munoz, K.; Fror, O.; Schaumann, G.E. Plastic mulching in agriculture. Trading short-term agronomic benefits for long-term soil degradation. Sci. Total Environ. 2016, 550, 690–705. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Chen, G.; Wang, W.; Wang, J. Microplastic pollution research methodologies, abundance, characteristics and risk assessments for aquatic biota in China. Environ. Pollut. 2020, 266, 115098. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.J. Discharge of Dioxins by Open-air Burning of Domestic and Agricultural Wastes. J. Korea Soc. Waste Manag. 2008, 25, 66–72. [Google Scholar]

- Briassoulis, D.; Babou, E.; Hiskakis, M.; Scarascia-Mugnozza, G.; Picuno, P.; Guarde, D.; Dejean, C. Review, mapping and analysis of the agricultural plastic waste generation and consolidation in Europe. Waste Manag. Res. 2013, 31, 1262–1278. [Google Scholar] [CrossRef]

- Picuno, P. Innovative Material and Improved Technical Design for a Sustainable Exploitation of Agricultural Plastic Film, Polymer-Plastics. Technol. Eng. 2014, 53, 1000–1011. [Google Scholar]

- Vox, G.; Loisi, R.V.; Blanco, I.; Mugnozza, G.S.; Schettini, E. Mapping of Agriculture Plastic Waste. Agric. Agric. Sci. Procedia 2016, 8, 583–591. [Google Scholar] [CrossRef]

- Hernández-Arenas, R.; Beltrán-Sanahuja, A.; Navarro-Quirant, P.; Sanz-Lazaro, C. The effect of sewage sludge containing microplastics on growth and fruit development of tomato plants. Environ. Pollut. 2020, 268, 115779. [Google Scholar] [CrossRef]

- Epstein, E. Disposal and Management of Solid Waste. In Pathogens and Diseases, 1st ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Mazza, A.; Piscitelli, P.; Neglia, C.; Rosa, G.D.; Iannuzzi, L. Illegal dumping of toxic waste and its effect on human health in Campania. Int. J. Environ. Res. Public Health 2015, 12, 6818–6831. [Google Scholar] [CrossRef]

- Kim, G.; Chang, Y.; Kelleher, D. Unit pricing of municipal solid waste and illegal dumping: An empirical analysis of Korean experience. Environ. Econ. Policy Stud. 2008, 9, 167–176. [Google Scholar] [CrossRef]

- Mihai, F.C.; Taherzadeh, M.J. Introductory Chapter: Rural Waste Management Issues at Global Level. In Solid Waste Management in Rural Areas; InTech: London, UK, 2017. [Google Scholar]

- Heo, J.; Moon, S.C.; Song, M.R. A Study on the Problem of Rural Sohd Waste in Korea. Korean Assoc. Environ. Sociol. 2001, 9, 92–121. [Google Scholar]

- Kang, C.Y. A Study on Establishing Effective Management System for Equipped Agricultural Input Wastes; Korea Rural Economic Institute: Sejong, Republic of Korea, 2004. [Google Scholar]

- Yi, W.E.; Ahn, D.H. An Analysis of the Determinants of the Collection Rate of Agricultural Plastic Waste. J. Korean Soc. Rural. Plan. 2019, 25, 11–18. [Google Scholar] [CrossRef]

- Han, J.H.; Kim, J.Y.; Kim, T.I.; Park, K.B. A Study on The Residential Environment and Landscape Improvement in Rural area: Focused on the Actual Condition of rural household’s garbage and farming wastes. J. Korean Soc. Rural. Plan. 2020, 151, 151–159. [Google Scholar]

- The Waste Control Act, Article 4 Paragraph 1. Available online: https://www.law.go.kr/ (accessed on 26 February 2021).

- Available online: https://www.keco.or.kr/kr/business/resource/contentsid/1559/index.do (accessed on 21 February 2021).

- Ministry of Agriculture, Food and Rural Affairs. Guidelines for the Public Interest Direct Payment System; Ministry of Agriculture, Food and Rural Affairs: Sejong, Republic of Korea, 2020. [Google Scholar]

- Ministry of Environment. Agricultural Waste Statistical Survey. Sejong, Republic of Korea. 2010–2020. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatList.do?menuNo=M13020303 (accessed on 27 February 2021).

- Available online: http://www.krdf.or.kr/_subpage/kor/reference/content5.php?viewMode=view&idx=174&ca (accessed on 12 February 2022).

- European Commission. A European Strategy for Plastics in a Circular Economy; COM: Brussels, Belgium, 2018; pp. 1–19. [Google Scholar]

- BASF Introduces IrgaCycle™, New Additive Solutions for Mechanical Recycling of Plastics. Available online: https://www.basf.com/tw/en/media/news-releases/asia-pacific/2021/09/basf_introduces_irgacycle_mechanical_recycling.html (accessed on 19 February 2022).

- Anaip, La Plasticultura en España. Madrid, Espana, 2015. pp. 2–7. Available online: https://www.anaip.es/images/Divisiones/Agricultura/Catlogo-La-Plasticultura-en-Espaa-ANAIP-3-Mb.pdf (accessed on 2 December 2021.).

- Available online: https://www.adivalor.fr/en/filiere/presentation/index.html (accessed on 15 December 2021).

- Available online: https://www.erde-recycling.de/ (accessed on 24 December 2021).

- Available online: http://www.noubi-rc.jp/agriculture/ (accessed on 25 December 2021).

- Feng, W.; Zhihua, C.; Ann, R.; Ying, L. Compliance with household solid waste management in rural villages in developing countries. J. Clean. Prod. 2018, 202, 293–298. [Google Scholar]

- Komwit, S. An optimal deposit-refund system for mitigating hazardous packaging waste in Thailand’s agricultural sector. Fac. Manag. Sci. 2021, 16, 23–31. [Google Scholar]

- Carlos, G.S.; Alvar, M.A.; Beatriz, P.G.; Joaquín, M.U.; María, U.O.; Carmen, F.V. Use of residual agricultural plastics and cellulose fibers for obtaining sustainable eco-composites prevents waste generation. J. Clean. Prod. 2014, 83, 228–237. [Google Scholar]

- Bher, A.; Mayekar, P.C.; Auras, R.A. Biodegradation of Biodegradable Polymers in Mesophilic Aerobic Environments. Int. J. Mol Sci. 2022, 23, 12165. [Google Scholar] [CrossRef] [PubMed]

- Castillo-Díaz, F.J.; Belmonte-Ureña, L.J.; Batlles-delaFuente, A.; Francisco, C.F. Impact of the new measures related to the circular economy on the management of agrochemical packaging in Spanish agriculture and the use of biodegradable plastics. Environ. Sci. Eur. 2022, 34, 94. [Google Scholar] [CrossRef]

- Available online: https://www.maff.go.jp/j/supply/hozyo/nousan/221215_150-1.html (accessed on 1 February 2023).

- Available online: https://www.keco.or.kr/kr/business/resource/contentsid/1562/index.do (accessed on 15 February 2021).

- Le, M. A Contribution to an Intensive Ecological Agriculture; Plasticulture: Levallois-Perret, France, 2015. [Google Scholar]

- Hiroyuki, T. Collection, disposal and exchange of waste agricultural plastics in Japan, Korea, and China. Tech Monit. 2009, 50–54. [Google Scholar]

- Available online: https://www.keco.or.kr/kr/open/communityid/1/view.do?p=2&idx=30610&FAQCATGORY_ID=&f=1&q=%EC%98%81%EB%86%8D%ED%8F%90%EA%B8%B0%EB%AC%BC (accessed on 10 February 2021).

- Briassoulis, D.; Hiskakis, M.; Babou, E. Technical specifications for mechanical recycling of agricultural plastic waste. Waste Manag. 2013, 33, 1516–1530. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).