Abstract

Global objectives to mitigate climate change in the construction industry have led to increasing geopolymer development as an alternative to carbon-intensive cement. Geopolymers can have similar mechanical properties and a lower carbon footprint. However, geopolymer production is not as homogeneous as cement because it is produced by synthesizing alkali solutions with different aluminosilicate precursors. This study assessed the feasibility of using conventional (fly ash, blast furnace slag, and metakaolin) and alternative precursors (steel slag, mine tailings, glass waste, sewage sludge ashes, and municipal solid waste incineration bottom ashes (MSWI BA)) in geopolymer mixes for different European regions (Belgium and Finland) from a sustainability perspective, using environmental, economic, and resource availability indicators as the criteria. A multi-objective optimization technique was applied to identify optimal precursors for geopolymer mixes using two scenarios: (1) considering both conventional and alternative precursors; (2) only considering alternative precursors. The results from the first scenario show that one of the most optimal precursor combinations for the geopolymer mix is 50% fly ash, 25% MSWI BA, and 25% sewage sludge ash for Belgium. For Finland, it is 19% fly ash, 27% mine tailings, and 45% MSWI BA. For the second scenario, one of the most optimal precursor combinations for Belgium is 87% MSWI BA and 13% steel slag. For Finland, it is 25% mine tailings and 75% MSWI BA. Subsequently, linear regression analysis was applied to predict the compressive strength of the identified optimal mixes, and the results for Belgium and Finland were between 31–55 MPa and 31–50 MPa for the first scenario and between 50–59 MPa and 50–55 Mpa for the second scenario, respectively.

1. Introduction

Geopolymer composites are considered as a more environmentally sustainable alternative to Portland cement (PC) concrete due to the latter being the second-largest CO2 emitter (4–8% of global CO2 emissions) and the third-largest consumer of energy [1,2]. These concerns have led to increasing research into and the development of geopolymers in recent times [1,3,4,5,6]. Geopolymers can be used for other applications including replacing natural aggregates [7], adsorbents for wastewater treatment [8], the immobilization of toxic metals [9], thermal insulators [10], as a precursor for advanced ceramics [11], etc. However, most research on geopolymers has focused on its application as an alternative to PC concrete and has based the development of geopolymer composites mix designs on precursors such as coal fly ash (CFA), granulated blast furnace slag (GBFS), and metakaolin, making these precursors conventional in the development of geopolymer composites. Many of these studies have reported that improving the environmental profile of geopolymers will require using industrial by-products (CFA and GBFS) as precursors compared to virgin raw materials such as metakaolin [5,12,13]. However, conventional precursors from industrial by-products, CFA and GBFS, are in decline.

CFA has seen a decline due to targets to cease energy production from the combustion of coal in the European Union (EU). Hard coal production has declined from 277 million tons in 1990 to 56 million tons in 2020 in EU-27 countries and hard coal and inland consumption has seen a decline of 389 million tons in 1990 to 143 million tons in 2020 [14]. GBFS on the other hand has declined 22% in production between 2016 and 2018 [15]. In addition to the decline in the production of the abovementioned precursors, they are also already competitively used in other industries, including the cement industry. On the other hand, metakaolin being a virgin raw material calcined from kaolin is not the most environmentally sustainable option compared to CFA and GBFS [1,16,17]. However, it is still commonly used in geopolymer development but not produced as much in Europe with an estimated production of 35 million tons in Europe as of 2019 [18]. Due to the decline in the production and availability of these precursors, an option might be importing them from neighboring countries or countries with higher availability such as China which has about 550 million tons of CFA production with only a 60% utilization rate as of 2018 [19]. The utilization rate has led to an accumulation of up to 3 billion tons of CFA in China [19]. However, improving the environmental profile of geopolymers will depend on the availability of local materials to avoid additional emissions from transportation. Based on these different concerns, the large scale and long-term development of geopolymers within Europe is put to question.

To overcome these limitations, studies have expanded their outlook from conventional precursors to other types of materials with pozzolanic properties to be used as precursors in the development of geopolymer composites. These alternative precursors can include mine tailings [12,20,21], sewage sludge ash [22,23], municipal solid waste incineration bottom ash (MSWI BA) [24,25], steel slag [21,26,27], and glass waste [28,29,30], all of which are locally available materials in different European regions. The referenced studies have focused on the technical aspect of geopolymer development with little focus on the environmental sustainability perspective.

Systematically assessing the environmental impacts of geopolymers with alternative precursors instead of conventional precursors aids in developing geopolymers with a better environmental profile. Furthermore, a framework including different sustainability criteria could be used in the development of geopolymer composite mix design. To support this, [31] created a systematic evaluation framework for developing a sustainable geopolymer composite mix design using a single industrial by-product (CFA) as a precursor while optimizing costs and associated environmental impacts. In addition, [32] presented a generic framework for concrete mixture optimization incorporating environmental, financial, and mechanical properties. However, to our knowledge there has not been a systematic way to optimize the development of geopolymer mix designs with different combinations of precursors based on environmental, economic, and resource availability criteria.

Thus, this study applies a 3D multi-objective optimization framework for sustainable precursor selection in developing geopolymer composite mix designs in two European countries: Belgium and Finland. The objective is to identify which combination of precursors is suitable for geopolymer development in both countries. Pareto-optimization is the employed multi-objective optimization method because it provides non-dominant solutions over other solutions. The optimization is conducted to find sets of optimum precursors for geopolymer composite mix designs with minimal economic costs, minimal environmental impacts, and maximized resource use. This can be applied in practical situations to assist decisionmakers when considering different precursors in geopolymer development. To validate the results, linear regression analysis was conducted to predict the compressive strength of the optimized mix designs to investigate their relative potential mechanical properties.

2. Results—Obtain the Optimized Set of Mix Designs

The next stage of the framework, after developing objective functions and defining major optimization problems and constraints, is to obtain a set of Pareto optimized solutions. The optimization problem was run 100 times for both Belgium and Finland. Subsequently, the environmental, economic, and resource availability indicators were compared to ensure satisfactory savings in the environmental and economic indicators and maximization of the resource availability indicator. Afterwards, several mixes out of the 100 optimized mixes identified for each country were selected and investigated in detail to show the diversity of the different precursor combinations.

2.1. Optimal Mixes in Belgium

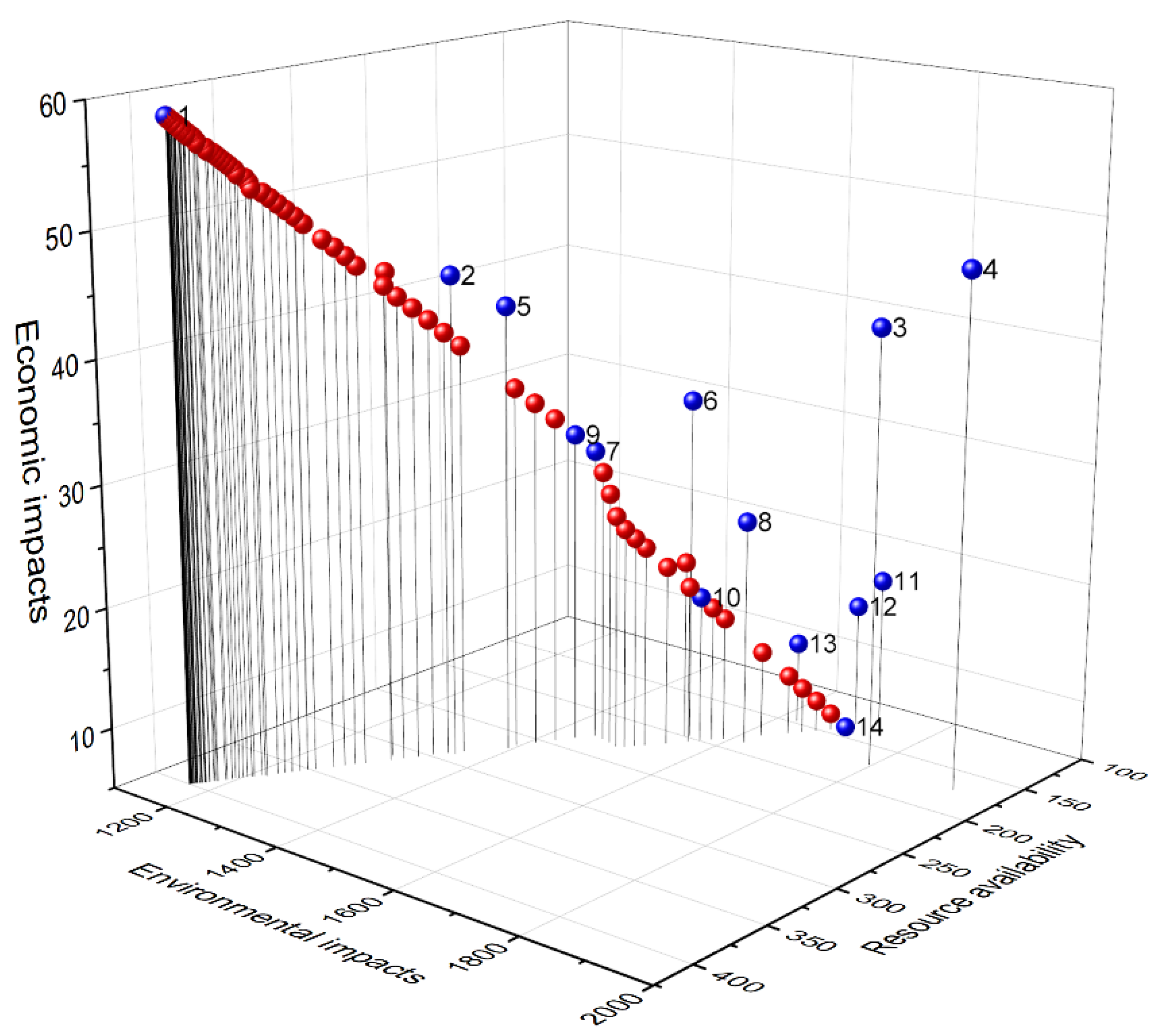

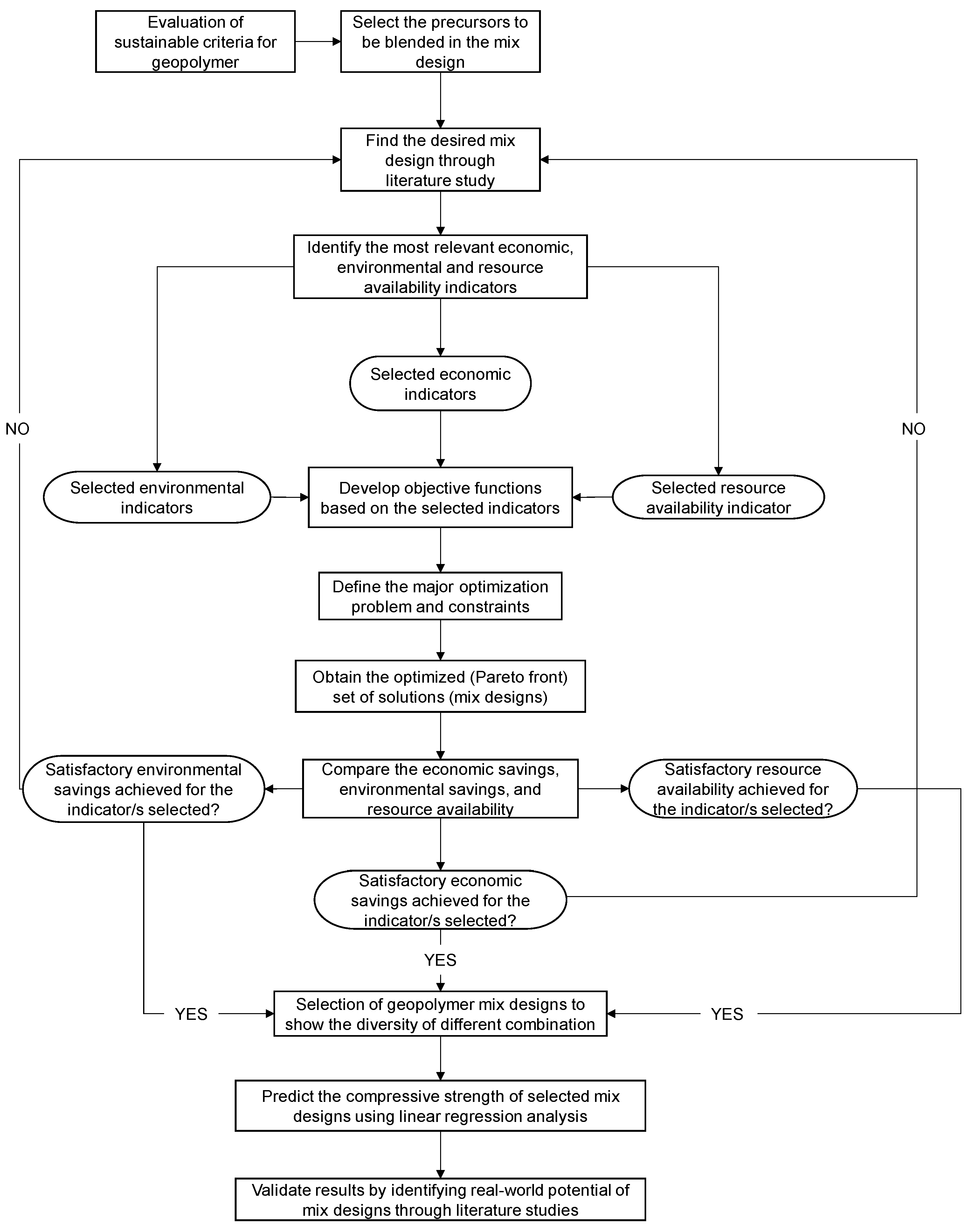

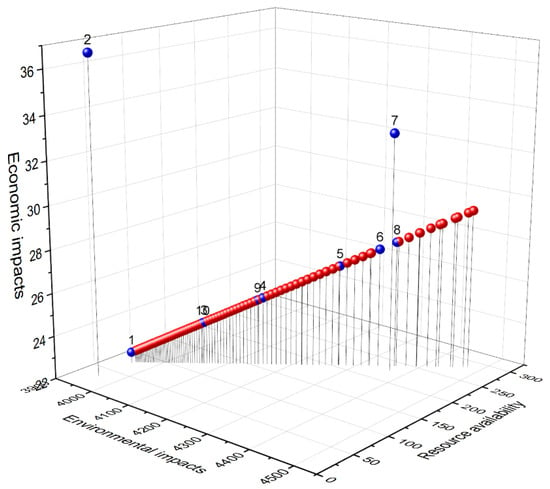

The results of the three function (environment, resource availability, and economic) optimization presented as the Pareto front are illustrated in the 3D graph in Figure 1. As shown, some selected mixes among the many optimized solutions were further investigated to illustrate the diversity of the different precursor combinations that led to local Pareto optimal solutions. These selected mixes are highlighted in the blue color while the rest of the mixes are in the red color in Figure 1. From the highlighted mixes in the blue color, mix 1 has the lowest environmental impact and the highest availability of resources to be produced in Belgium, whereas the costs of EUR 59/m3 are also high compared to the other mixes. On the other hand, mix 14 has the lowest costs but high environmental impacts, with limited availability of resources for geopolymer production. The performance of mix 9 across the impact categories is close to the average, indicating a trade-off among the environmental, economic, and resource availability indicators. Details of the selected mixes are further presented in Table 1.

Figure 1.

Optimal mixes in Belgium.

Table 1.

Selected optimal mixes in Belgium.

The Results in Table 1 shows the optimal mixes in Belgium, such as mix 1 containing 100% CFA as a precursor, whereas mix 9 contains 50% CFA, 25% MSWI BA, and 25% sewage sludge ash. The lowest costs were observed for mix 14, which contains 98% MSWI BAs and 2% CFA. A few mixes contain small amounts of glass waste and steel slag. This shows that CFA, MSWI BA, and sewage sludge ash are the optimal precursors in Belgium from a sustainability perspective.

2.2. Optimal Mixes in Finland

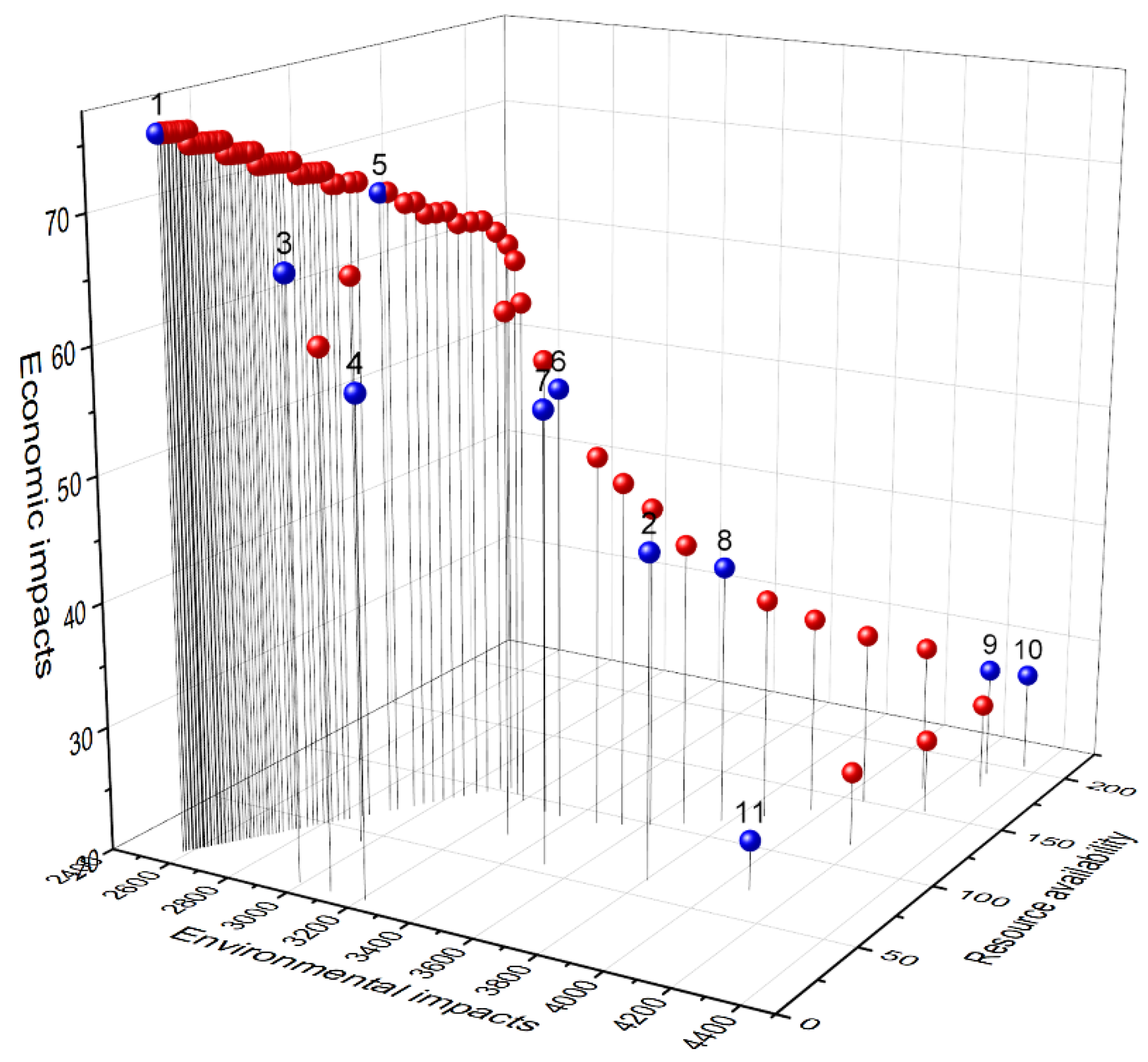

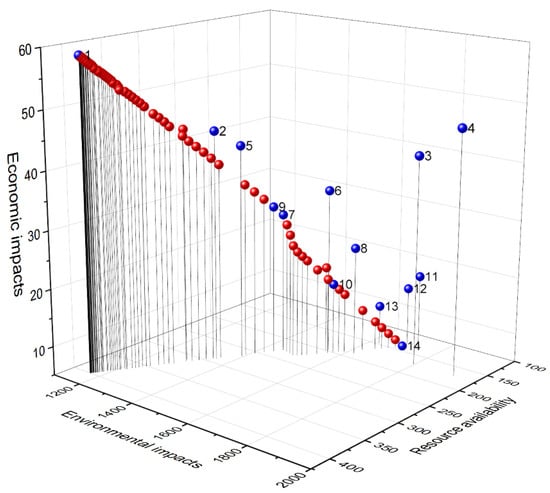

On the other hand, for Finland, the results of the three function (environment, resource availability, and economy) Pareto front optimization are illustrated in the 3D graph in Figure 2. While mix 1 has the lowest environmental impacts, it has the highest costs and low resource availability. Mix 11 has the lowest costs with medium availability, but high environmental impacts. The trade-off between the impact indicators can be represented by mix 8. The diversity of the different precursor combination solutions is detailed and investigated in Table 2.

Figure 2.

Optimal mixes in Finland.

Table 2.

Selected optimal mixes in Finland.

The mixes presented in Table 2 were selected (the blue color in the graph) among the many optimized solutions (the red color in the graph) to illustrate the combinations of different precursors that make up the local Pareto optimal solutions. The optimal mix combinations are the following: mix 1 contains 100%FA; mix 8 contains 19% CFA, 27% mine tailings and 45% MSWI BA, while mix 11 contains 16% mine tailings and 85% MSWI BA. A few mixes contain glass waste, sewage sludge ash, and steel slag.

2.3. Scenario Analysis

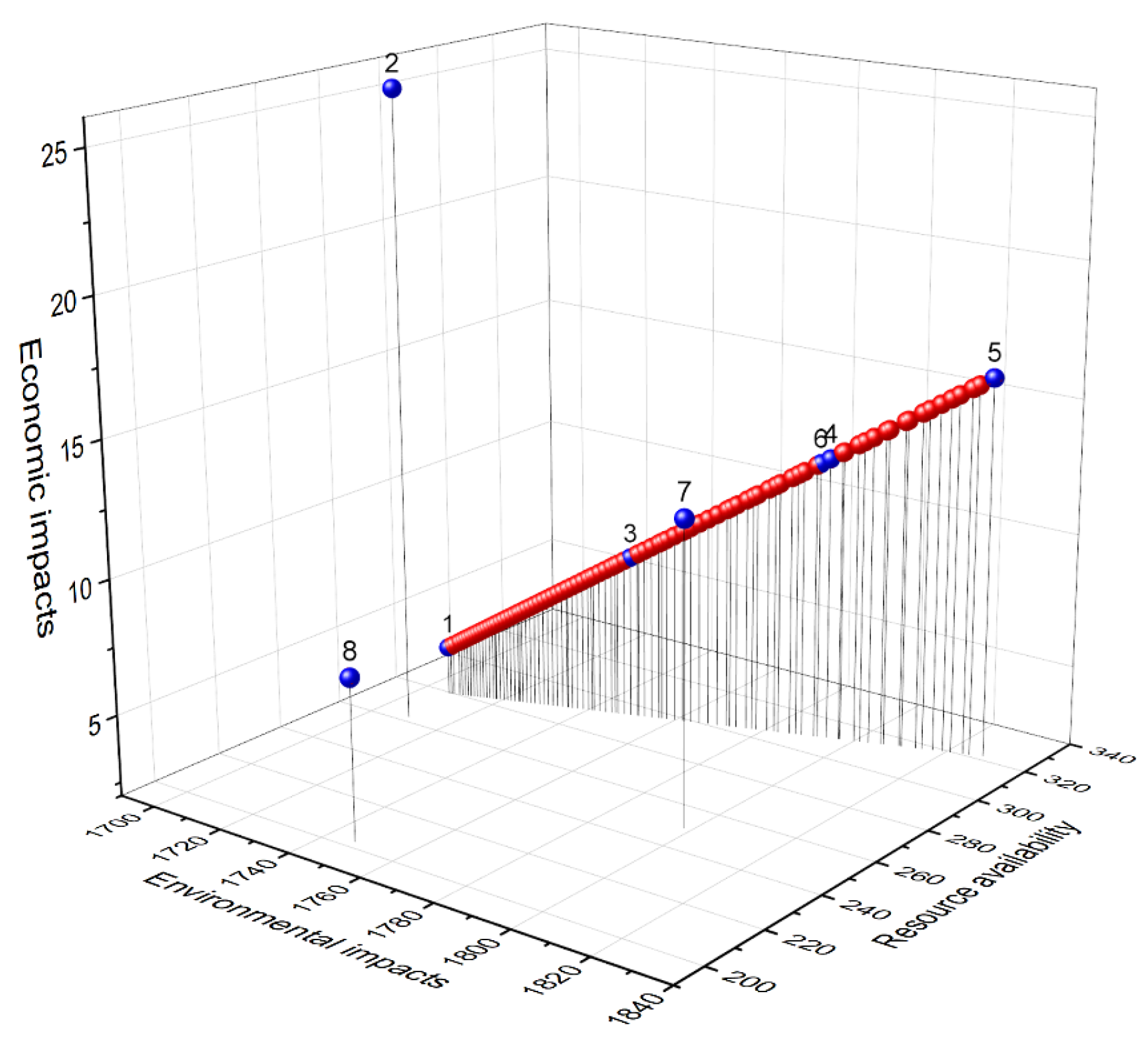

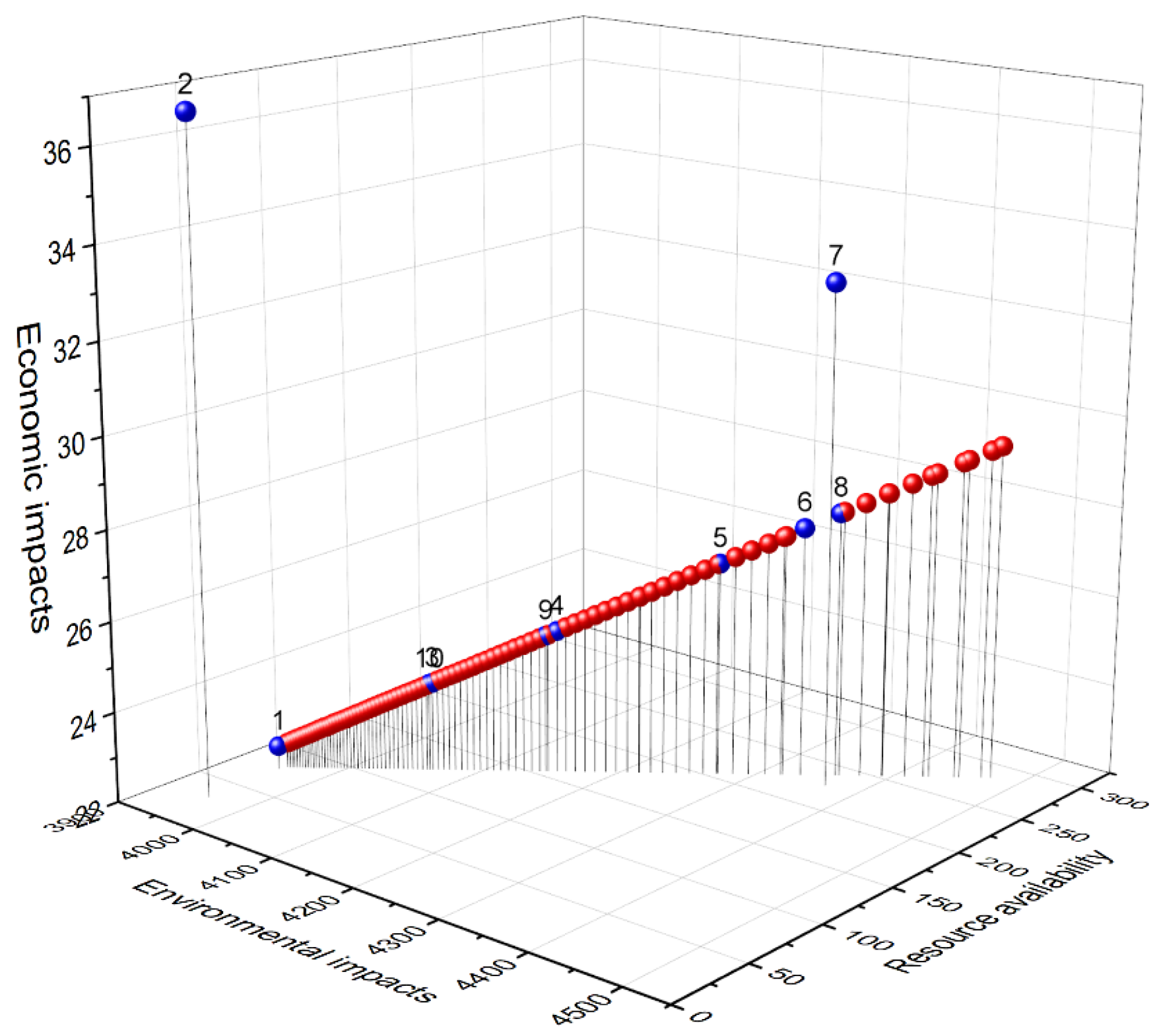

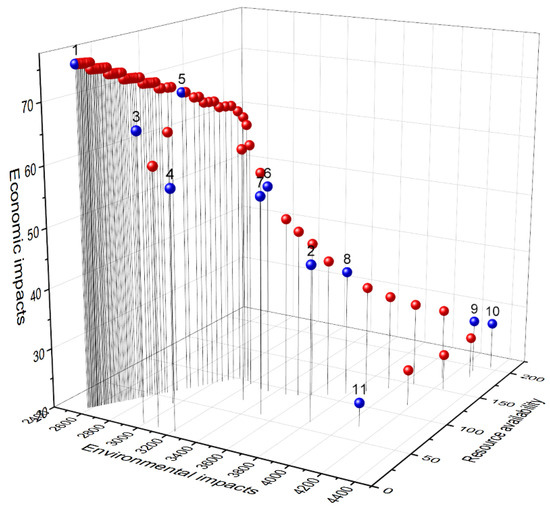

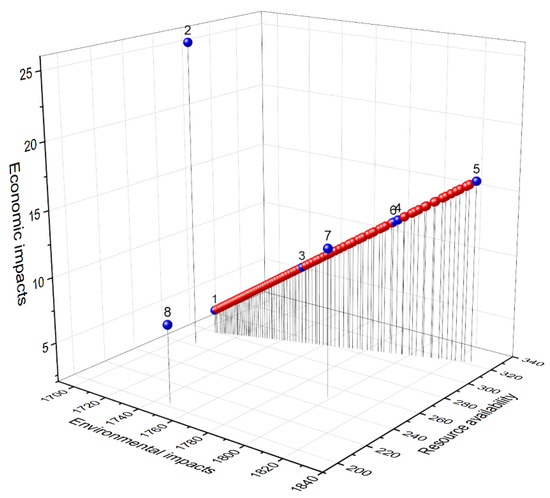

After obtaining different mixes to show the diversity of the different precursor combinations, a scenario analysis was conducted where conventional precursors (CFA, GBFS, and metakaolin) were excluded from the set of available precursors and only alternative materials, such mine tailings, sewage sludge ash, MSWI BA, steel slag and glass waste, were considered. This was carried out to determine the optimal mixes when alternative precursors are used. Figure 3 and Figure 4 illustrate combinations of optimal mix designs for Belgium and Finland, respectively, without conventional precursors. The diversity of the different precursor combination solutions is detailed and investigated in Table 3 and Table 4.

Figure 3.

Optimal mixes with alternative materials in Belgium.

Figure 4.

Optimal mixes with alternative materials in Finland.

Table 3.

Selected optimal mixes using only alternative materials in Belgium.

Table 4.

Selected optimal mixes using only alternative precursors in Finland.

For Belgium, the lowest environmental impacts, costs, and above-average resource availability are observed for mix 1, which contains 100% MSWI BAs. Mix 5 which contains 65% MSWI Bas and 26% steel slag has the highest availability of resources, but at the same time, it has 7% higher environmental impacts and four times higher costs than mix 1. For Finland, the lowest environmental impacts and costs are observed for mix 1, which contains 96% MSWI BAs and 4% sewage sludge ashes in its precursors content, while mix 8 which contains equal amounts of mine tailings and MSWI BAs is associated with an increased availability of resources; its environmental impacts and costs are 10% and 24% higher, respectively, than those of mix 1.

For Belgium, the optimal mix combinations for alternative precursors as shown in Table 3 are mixes containing MSWI BA and steel slag with some mixes also containing sewage sludge ashes and glass waste. The MSWI BA content across the selected mixes is between 48% and 99%. While for Finland, the most optimal mix combinations are MSWI BA and mine tailings, with a few mixes including sewage sludge ash and glass waste. This is detailed in Table 4.

2.4. Predicted Compressive Strength

To validate the study, some characteristics of the geopolymer mix designs were investigated by predicting the compressive strength of the mixes as discussed in Section 5.4.4. Based on the linear regression model (Equation 12), the predicted compressive strengths of the optimal mixes are shown in Table 1, Table 2, Table 3 and Table 4. To ensure feasible comparison among the mixes, the compressive strength was estimated based on the precursor and activator quantities and their chemical composition using the results of regression analysis. For structural applications, the recommended minimum compressive strength is 20 MPa (BS-EN 197-1, 2011). For the optimized mixes, their predicted compressive strength varies between 31 MPa and 59 MPa. The results of the regression analysis indicate the relationship between the chemical composition of the mix constituents and their compressive strength. However, the adjusted R2 of 0.72 indicates that variability in compressive strength cannot be fully explained by variation in the examined variables. Therefore, the real compressive strength should be verified through laboratory tests.

3. Verification through Literature Studies

To further validate the results of this study, the identified optimal mixes were verified through a literature review (Table 5). This is to show the possibility of using these precursor combinations that are available in the literature. As many studies do not present detailed information regarding the tested mix designs, the exact content of precursors inside mixes has not been presented. However, it can be observed from the literature that the combination of precursors identified in this paper (Table 1, Table 2, Table 3 and Table 4) can be potentially used for developing geopolymer composites or alkali-activated materials.

Table 5.

Mixes examined in the literature. X depicts the materials that make up the geopolymer mix design.

4. Discussion

The consideration of CFA and GBFS as sometimes waste or by-products creates an assumption that they are sustainable alternatives as precursors. However, local availability and pre-treatment costs can be a predetermining factor of their overall sustainability. Addressing the issues of availability, cost, and environmental impact through the application of a sustainable criteria framework enables optimization of precursors to minimize environmental, economic, and social impacts. The current availability of precursors in Belgium and Finland is reflected in the resource availability indicator. However, in the future, the availability of conventional precursors such as GBFS and CFA might decrease due to the phasing out of coal power plants in Europe, as well as shift from blast furnaces towards electric arc furnaces in the steel industry. Thus, a scenario analysis was conducted where only mixes with alternative precursors such as mine tailings, MSWI BA, sewage sludge ashes, steel slag, and glass waste are considered, of which their supply will be stable in the future [39]. On the other hand, the utilization of glass waste and steel slag in other industries, such as in the closed loop recycling of glass waste and the use of steel slag as a supplementary cementitious material in concrete might increase, leading to competition for resources between industries and this corresponding to a higher cost of materials. This might also affect the results of Pareto optimization.

Multi-objective optimization showed that GBFS and metakaolin are not optimal materials to be used in both countries, meaning that alternative materials such as MSWI BA, mine tailings, steel slag, and sewage sludge ash have higher potential in these regions. From the two respective scenarios (Section 2.1, Section 2.2 and Section 2.3), the result of the multi-objective optimization show that using alternative precursors (MSWI BA, steel slag, sewage sludge ash, and mine tailings) instead of a conventional precursor (CFA) has reduced economic impacts and more consistent resource availability. However, the environmental impacts from the alternative precursors are slightly higher. This is because CFA does not require as high a level of additional pre-treatment as the former, which means less energy consumption and a reduced environmental impact. Although, this is part of what makes CFA a go-to precursor, the context of this study is to determine locally available alternative precursors for geopolymers due to the declining availability of CFA in the future. If on the other hand, CFA is imported, transportation emissions increase the impact associated with the material. Thus, exploring alternative precursors will require more efficient treatment processes to reduce the associated environmental impacts.

Furthermore, from the results of the environmental impact of the standard CFA-based geopolymer concrete which in our reference mix is based on (Table 6), the GWP of the standard CFA geopolymer is 45% less than the equivalent Portland cement (PC) concrete [5]. When considering the scenarios with alternative precursors, the GWP will be 43–45% lower than the PC concrete. This makes the use of the alternative precursors still a better option for geopolymers. While activators provide a high contribution towards the environmental impacts and costs of geopolymer mixes, in this study, the amount of activator was kept the same as in the reference mix. However, little research has been performed so far on the variability of precursors while keeping the amounts of activators constant. Therefore, regression analysis was applied to predict the compressive strength of the examined mixes. The results indicate that optimized combinations of precursors with constant amounts of activator would achieve a compressive strength suitable for structural applications. However, other factors besides the examined variables might determine variation in compressive strength, therefore affecting the actual mechanical properties of the optimized mixes. For the end-of-life of these geopolymer mix designs, it was assumed that geopolymer composites using different combinations of precursors will have similar recyclability potential. Future laboratory tests will be required to verify and examine the durability properties of the optimized mix designs.

Table 6.

Reference geopolymer mix design [5,40].

5. Methodology

Sustainability has a broad definition which can include environmental, economic, and social aspects [41]. The criteria to assess sustainability can be defined taking into consideration both the goal of the study and the nature of material under evaluation [31,42]. In the case of the geopolymer composites in this study, sustainability is evaluated based on the environmental impacts and economic impacts, as well as the local availability of materials which we consider as a resource availability indicator. As mentioned earlier, the local availability of materials in the examined regions not only allows to minimize transportation emissions and thereby lower environmental impacts, but also implies the security of domestic supply and reduces the reliability on importation. Furthermore, by considering the environmental, economic, and resource availability in the optimization framework, the external stakeholders concerns are considered [31], which aids in better decision-making in geopolymer composite mix design development.

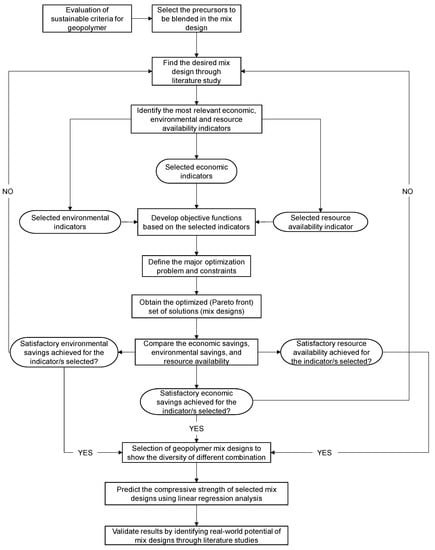

In this study, the framework presented by [31] has been further developed to evaluate sustainability of optimized geopolymer mix designs with different combinations of precursors while also extending the framework to include a third dimension, namely resource availability. Furthermore, the influence of activators on the optimized geopolymer mixes were considered and their predicted compressive strengths were examined. Figure 5 gives more details on the framework.

Figure 5.

Optimized blended mix design selection procedure (framework adapted and further developed from [31].

As a first step in the proposed optimization framework, materials with pozzolanic properties that can be used as precursors in geopolymers were selected. These selected precursors include both conventionally used materials in the development of geopolymers (CFA, GBFS, and metakaolin), as well as other aluminosilicate materials that can be sourced in the EU. Then, a mix design was chosen from literature studies to serve as a reference mix design in the development of the new optimized mix designs with the different precursors. This reference mix design as shown in Table 6 was chosen because of its lower amount of alkali-activator compared to the other mix designs in the literature [5,40]. Several literature sources have highlighted alkali activators to be the main contributing material to the environmental impact of geopolymers [3,5,43,44,45]. As such, special attention was paid to the quantity of alkali activator when choosing the reference mix design while ensuring the adequate compressive strength of the mix design. Subsequently, relevant indicators were selected for the environmental, economic, and resource availability criteria to assess the geopolymers from a sustainability perspective. These indicators were used to develop objective functions to define major optimization problems and constraints. The optimization problem was set up in MATLAB software and as an outcome, a Pareto optimal frontier with several mix designs was built. Then, several sets of optimal mix designs were selected from the Pareto frontier to illustrate and assess the diversity of different precursors in the geopolymer mix designs. Additionally, a scenario analysis was conducted to determine the optimal precursor mixes when conventional precursors are excluded. The scenario analysis explores the potential of using only alternative precursors in geopolymer development. As an additional step to the framework, the compressive strength of these optimized mix designs was predicted by conducting a linear regression analysis and these were supported by mix designs found in the existing literature to identify their real-world potential.

5.1. Precursors Selection for Blended Mix Design (Evaluation of Precursors for Geopolymer Potential)

Based on the optimization framework in Figure 5, the first step is to select aluminosilicate precursors to be blended in developing geopolymer mix designs. Since the framework is based on multi-objective genetic algorithms, the precursor selection can be a single material or several materials. Accordingly, conventional precursors in geopolymer such as CFA, GBFS, and metakaolin and alternative precursors that are locally available across Europe and specifically in Finland and/or Belgium, such as mine tailings, sewage sludge ash, municipal solid waste incineration (MSWI) bottom ash, steel slag, and glass waste, were examined.

5.2. Find the Desired Mix Design through Literature Studies

Since the focus of this study is optimizing geopolymer mix designs primarily by using different precursors, other parameters in a geopolymer mix design such as an alkali activator (sodium silicate and sometimes sodium hydroxide) were kept constant in the optimization. However, as mentioned earlier, the alkali activator is also known to be the major contributing factor to the environmental impact of geopolymers. Thus, a reference geopolymer mix design [40] with a suitable amount of alkali activator and compressive strength was chosen (see Table 6). The reference mix design was chosen because its environmental profile has been analyzed in comparison to PC concrete in literature studies and has shown to be an environmentally sustainable geopolymer mix design with a 45% lower global warming potential (GWP) when compared to PC concrete of the same equivalence [4,5]. Thus, choosing this mix design and keeping the alkali activator constant in the optimization allowed a more analytical focus on the precursors and compressive strength that can be achieved from the optimized mix designs with different precursors. The range of 400 kg to 408 kg was set for the different precursors. The range acted as a constraint in setting a lower and upper limit for the precursors in the optimization calculation. Details pertaining to the constraints will be further discussed in Section 5.4.2.

5.3. Identify the Most Relevant Economic, Environmental, and Social Indicators

After finding the desired reference mix design through the literature study, the most relevant sustainability indicators (environmental, economic, and resource availability) were identified following the framework in Figure 5. These indicators were identified based on a literature review [31,33,42,46] and the relevance in assessing the selected precursors for the geopolymer mix design. The indicators are presented in Table 7.

Table 7.

Most relevant economic, environmental, and social indicators.

The relevant environmental indicators identified are production emissions, pretreatment emissions, and transportation emissions [31] for the different precursors. The different environmental impact categories considered for the emissions include abiotic depletion potential (ADP), acidification potential (AP), eutrophication potential (EP), global warming potential (GWP), freshwater ecotoxicity potential (FAETP), human toxicity potential (HTP), marine ecotoxicity potential (MAETP), ozone depletion potential (ODP), photochemical ozone creation potential (POCP), and terrestrial toxicity potential (TETP). The environmental impacts are quantified for the indicators (precursor production, pre-treatment, and transportation to the geopolymer composite production site). Transportation was estimated based on the shortest distances between material sourcing facilities and geopolymer composite manufacturing sites (existing concrete plants) in Belgium and Finland using geographic information system (QGIS) software. The results from the environmental impact assessment of the different precursors were normalized and weighted for each environmental indicator. Further explanation can be found in Section 5.4.1, and the weighted result is presented in the Supplementary Material (Table S3).

The relevant social indicator identified is resource availability [42,46]. This indicator considers the quantity of the respective precursors locally available in Belgium and Finland. The results were also normalized. This is described more in Section 5.4.1 and in the Supplementary Material (Table S7).

Lastly, the economic indicators identified are the procurement costs of the precursors, the costs associated with pretreatment of these precursors if needed, as well as costs associated with transportation from the sourcing site to the concrete production site which is estimated to be EUR 0.228/km/ton [47]. The total costs of transportation depend on the estimated distances. Furthermore, for materials that are currently being landfilled, the avoided costs of landfill are also included. The cost for procurement, pretreatment, and avoided landfill of each precursor were sourced either locally where available or otherwise from the literature. This is expatiated more in Section 5.4.1 and in the Supplementary Material (Tables S5 and S6).

5.4. Define Objective Functions Based on the Selected Indicators

After identifying the most relevant environmental, resource availability, and economic indicators, the objective functions were developed based on these indicators. Here, the major optimization problem and constraints were defined which are further elaborated in the section below.

5.4.1. Objective Functions

The three objective functions follow the sustainability concept and aim to minimize the environmental, social, and economic impacts of the geopolymers to investigate their potential as a substitute for PC concrete. The following objective functions are defined, where x is the precursor variable vector.

Objective function 1: Minimize total environmental impacts (EIs) of precursors, where PE is the weighted environmental impacts associated with material production, PTE is the weighted environmental impacts associated with material pretreatment, and TE is the weighted environmental impacts associated with transportation. The environmental impacts categories (Section 5.3) of each precursor x are collected for PE, PTE, and TE. Then, the results were normalized and weighted according to normalization factors of CML 2001–January 2016, Europe. Afterwards, the total EIs were summed up as shown in the Equation (1) below.

Objective function 2: Resource availability (RA) is associated with maximizing the use of resources, in this case so that local materials that are abundant and available are prioritized more than scarce materials. Here, the RA indicator was normalized by applying the min–max normalization method, where materials were ranked from lowest domestic supply (0) to the highest domestic supply (1).

Objective function 3: Minimize economic impacts (CIs), where PC is procurement cost, PT is pretreatment cost, TC is transportation cost, and LC is avoided landfill cost. The costs were measured in euros per kg of precursor.

The coefficients are weighting factors indicating the priority of variables in defined objective functions. In this study, all of the variables are considered to have equal importance inside objective functions; therefore, coefficients are equal to 1. The variables inside the objective Function (1) are represented as follows:

where is the mass of precursor y, EFy is the weighted emission factor associated with the production of precursor y, EFe is the weighted emission factor associated with energy consumption My during the pretreatment process of this material, EFt is the emission factor for transportation, and dt is the average transportation distance between different material sourcing sites and geopolymer composite plants.

The resource availability indicator defined in Equation (2) is represented by the following variables:

where MFy is the annual material flow of material y in tons, normalized across materials, thus 0 ≤ MFy ≤ 1.

The economic impacts defined in Equation (3) are represented by the following equations:

Cy is procurement cost of the precursor which is assumed to be 0 if the material is considered as waste, Ce is the unit cost of energy used for pre-treatment, Ct is the unit transportation cost, and Cl is the cost of landfilling expressed in euros per kg of material.

5.4.2. Constraints

The quantity of precursors was estimated based on the desired reference mix design in Table 6 (Section 5.2). This reference mix design indicated that the total amount of precursors in 1 m3 of concrete is 408 kg. Therefore, this was used to estimate the boundaries for the quantity of precursors in the geopolymer mix designs. Thus, the constraint is formulated such that the sum of quantities of precursor used in the objective function is within the range 400 to 408 (400 ≤ Q1 + Q2 + Q3 + Q4 + Q5 + Q6 + Q7 + Q8 (=Qmax) ≤ 408). Once the optimal mixes are identified, we estimate the predicted compressive strength of each mix design based on the chemical composition and quantity of precursors and activator. This is further described in Section 5.4.4.

5.4.3. Weights

To find the Pareto optimal solution, the different weightings of objective functions are considered. As we have three objective functions, each function is allocated a weight inside the optimization problem. The Hardy–Weinberg principle weight distribution method was used, resulting in the following weights being randomly allocated to three functions: t2; 2t(1 − t); (1 − t)2, where 0 < t < 1. However, if the decisionmaker considers one of the objective functions more important over the two others, the results of this optimization might change with one precursor becoming more favorable over the others. For example, if more weight is allocated to economic indicators than to environmental or resource availability.

5.4.4. Prediction of Compressive Strength

Linear regression analysis was applied to estimate the compressive strength of the examined geopolymer composite mixes available in the literature [40,48,49,50,51], using the following factors as explanatory variables: Na2O/SiO2, SO2/Al2O4, H2O/Na2O, water to binder ratio, Na2O/Al2O3, binder to aggregates ratio, reactivity modulus (RM), hydraulic modulus, (HM), lime modulus (LM), and silica modulus (SM), as well as basicity index. Both the chemical composition of the precursors as well as the alkali activator was taken into consideration to determine the abovementioned ratios. The geopolymer mixes were assumed to be cured at an ambient temperature and this is the reason why curing was not taken into consideration. The outputs of the regression analyses are presented in the Supplementary Material (Table S9). According to the results, the variables that determine 72% variation (R2 = 0.72) in the compressive strength of the geopolymer mixes are Na2O/SiO2, H2O/Na2O, water to binder ratio, hydraulic modulus, and basicity index. Therefore, these variables were used to predict the compressive strength of the optimized mixes that were identified based on the three objective functions.

6. Conclusions

The aim of this study was to identify the most sustainable precursors for geopolymer mix designs using 3D multi-objective optimization. The investigated combinations of precursors in the mix designs provided optimized solutions according to three stated objective functions which are based on environmental, economic, and resource availability indicators. In addition, regional differences across Europe (Belgium and Finland) were considered in this selection. Two scenarios are considered: when conventional precursors (CFA, GBFS, and metakaolin) and only when alternative precursors (MSWI BA, steel slag, sewage sludge ash, and mine tailings) are considered in the list of optimized precursors. To validate the results, linear regression analysis was conducted to predict the compressive strength of the optimized mix designs to investigate their relative potential mechanical properties.

Using the 3D multi-objective optimization mathematical model, the optimal materials to be used as precursors in geopolymer mix designs were identified. The country-specific analysis illustrates that the optimal precursors selected for geopolymer composites are different across the regions. While mine tailings are available in Finland, there is limited availability of this material in Belgium. MSWI BA has a high potential to be used in both countries. Glass waste is available in both Belgium and Finland and can be used as an additional precursor. Steel slag, although produced in both countries, is only optimal for use in Belgium and only when alternative precursors are considered. The optimal precursors in which the objective functions are close to the average, indicating a trade-off among the environmental economic and resource availability, include:

When conventional precursors are considered in the list of optimized precursors:

- ○

- 50% CFA, 25%, MSWI BA and 25% sewage sludge ash—Belgium

- ○

- 19% CFA, 27%, mine tailings and 45% MSWI BA—Finland

When only alternative precursors are considered:

- ○

- 87% MSWI BA and 13% steel slag—Belgium

- ○

- 25% mine tailings and 75% MSWI BA—Finland

Thus, when considering alternative precursors, the most optimal precursor for geopolymer composites in Belgium is MSWI BA and steel slag, while for Finland, it is mine tailings and MSWI BA with an estimated 43–45% lower GWP than PC concrete.

To evaluate the real-world feasibility of the precursors in geopolymer composites, the compressive strength was predicted based on the precursor and activator quantities and their chemical composition using the results of the linear regression analysis. The predicted compressive strengths for Belgium and Finland when conventional precursors were considered is between 31–55 MPa and 31–50 MPa, respectively, while the predicted compressive strength for the alternative precursors is between 50–59 MPa and 50–55 MPa for Belgium and Finland, respectively. To prove the feasibility of the identified precursor combinations, the optimal mix designs were verified through literature studies. However, the next steps of the research can focus on examination of the mechanical properties of the optimized mixes at a laboratory scale. The long-term durability aspects should also be taken into consideration.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/recycling8020032/s1, Table S1. Energy requirement for pre-treatment; Table S2. Electricity costs; Table S3. Weighted Environmental impacts of precursors & transportation, estimated using Gabi software; Table S4. Transportation distances in km; Table S5. Procurement and transportation costs and landfill costs in Finland; Table S6. Procurement and transportation costs and landfill costs in Belgium; Table S7. Availability of materials in Finland; Table S8. Availability of materials in Belgium; Table S9. Results of linear regression analyses. References [1,14,47,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76] are cited in the supplementary materials.

Author Contributions

Conceptualization, M.A., A.K., J.H., G.H. and M.H.; methodology, M.A. and A.K.; software, M.A. and A.K.; validation, M.A. and A.K.; formal analysis, M.A. and A.K.; investigation, M.A. and A.K.; re-sources, J.H., G.H. and M.H.; data curation, M.A. and A.K.; writing—original draft preparation, M.A. and A.K.; writing—review and editing, M.A., A.K., J.H., G.H. and M.H.; visualization, M.A. and A.K.; supervision, J.H., G.H. and M.H.; project administration, J.H., G.H. and M.H.; funding acquisition, A.K. and G.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Union’s Horizon 2020 research and innovation programme grant number 813596 DuRSAAM.

Data Availability Statement

No new data were created.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Heath, A.; Paine, K.; McManus, M. Minimising the global warming potential of clay based geopolymers. J. Clean. Prod. 2014, 78, 75–83. [Google Scholar] [CrossRef]

- IEA. Cement—Analysis—IEA [WWW Document]. 2022. Available online: https://www.iea.org/reports/cement (accessed on 15 February 2023).

- Abdulkareem, M.; Havukainen, J.; Nuortila-Jokinen, J.; Horttanainen, M. Environmental and economic perspective of waste-derived activators on alkali-activated mortars. J. Clean. Prod. 2021, 280, 124651. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Habert, G.; D’Espinose De Lacaillerie, J.B.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. An overview of geopolymers derived from industrial by-products. Constr. Build. Mater. 2016, 127, 183–198. [Google Scholar] [CrossRef]

- Xu, L.Y.; Huang, B.T.; Lao, J.C.; Yao, J.; Li, V.C.; Dai, J.G. Tensile over-saturated cracking of Ultra-High-Strength Engineered Cementitious Composites (UHS-ECC) with artificial geopolymer aggregates. Cem. Concr. Compos. 2023, 136, 104896. [Google Scholar] [CrossRef]

- El Alouani, M.; Saufi, H.; Moutaoukil, G.; Alehyen, S.; Nematollahi, B.; Belmaghraoui, W.; Taibi, M. Application of geopolymers for treatment of water contaminated with organic and inorganic pollutants: State-of-the-art review. J. Environ. Chem. Eng. 2021, 9, 105095. [Google Scholar] [CrossRef]

- Hossain, M.U.; Wang, L.; Chen, L.; Tsang, D.C.W.; Ng, S.T.; Poon, C.S.; Mechtcherine, V. Evaluating the environmental impacts of stabilization and solidification technologies for managing hazardous wastes through life cycle assessment: A case study of Hong Kong. Environ. Int. 2020, 145, 106139. [Google Scholar] [CrossRef]

- Frattini, D.; Occhicone, A.; Ferone, C.; Cioffi, R. Fibre-reinforced geopolymer concretes for sensible heat thermal energy storage: Simulations and environmental impact. Materials 2021, 14, 414. [Google Scholar] [CrossRef]

- Ren, X.; Zhang, L.; Ramey, D.; Waterman, B.; Ormsby, S. Utilization of aluminum sludge (AS) to enhance mine tailings-based geopolymer. J. Mater. Sci. 2015, 50, 1370–1381. [Google Scholar] [CrossRef]

- Niu, H.; Abdulkareem, M.; Sreenivasan, H.; Kantola, A.M.; Havukainen, J.; Horttanainen, M.; Telkki, V.V.; Kinnunen, P.; Illikainen, M. Recycling mica and carbonate-rich mine tailings in alkali-activated composites: A synergy with metakaolin. Miner. Eng. 2020, 157, 106535. [Google Scholar] [CrossRef]

- Abdulkareem, M.; Havukainen, J.; Horttanainen, M. How environmentally sustainable are fibre reinforced alkali-activated concretes? J. Clean. Prod. 2019, 236, 117601. [Google Scholar] [CrossRef]

- Eurostat. Coal Production and Consumption Statistics. 2021; ISSN 2443-8219. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Coal_production_and_consumption_statistics#Consumption_and_production_of_hard_coal (accessed on 5 April 2021).

- Euroslag. Iron and Steel Mining Slags (Ferrous Slags) Statistics 2018 [WWW Document]. 2019. Available online: https://www.euroslag.com/products/statistics/statistics-2018/ (accessed on 5 April 2021).

- Abdulkareem, M.; Havukainen, J.; Nuortila-Jokinen, J.; Horttanainen, M. Life cycle assessment of a low-height noise barrier for railway traffic noise. J. Clean. Prod. 2021, 323, 129169. [Google Scholar] [CrossRef]

- Komkova, A.; Habert, G. Environmental impact assessment of alkali-activated materials: Examining impacts of variability in constituent production processes and transportation. Constr. Build. Mater. 2023, 363, 129032. [Google Scholar] [CrossRef]

- Euromines. Production by Mineral|Euromines [WWW Document]. 2019. Available online: http://www.euromines.org/mining-europe/production-mineral#Kaolin (accessed on 5 April 2021).

- Luo, Y.; Wu, Y.; Ma, S.; Zheng, S.; Zhang, Y.; Chu, P.K. Utilization of coal fly ash in China: A mini-review on challenges and future directions. Environ. Sci. Pollut. Res. 2021, 28, 18727–18740. [Google Scholar] [CrossRef]

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900. [Google Scholar] [CrossRef]

- Küçük, M.E.; Kinnarinen, T.; Timonen, J.; Mulari, O.; Häkkinen, A. Characterisation of Industrial Side Streams and Their Application for the Production of Geopolymer Composites. Minerals 2021, 11, 593. [Google Scholar] [CrossRef]

- Istuque, D.B.; Soriano, L.; Akasaki, J.L.; Melges, J.L.P.; Borrachero, M.V.; Monzó, J.; Payá, J.; Tashima, M.M. Effect of sewage sludge ash on mechanical and microstructural properties of geopolymers based on metakaolin. Constr. Build. Mater. 2019, 203, 95–103. [Google Scholar] [CrossRef]

- Sitarz, M.; Zdeb, T.; Gomes, J.C.; Soares, E.G.; Hager, I. The immobilisation of heavy metals from sewage sludge ash in geopolymer mortars. MATEC Web Conf. 2020, 322, 01026. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Zhang, L.; Li, J.; Hou, Z. Advances in understanding and analyzing the anti-diffusion behavior in complete carbonation zone of MSWI bottom ash-based alkali-activated concrete. Constr. Build. Mater. 2018, 186, 1072–1081. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Li, J.; Hou, Z.; Jin, C. Use of slaked lime and Portland cement to improve the resistance of MSWI bottom ash-GBFS geopolymer concrete against carbonation. Constr. Build. Mater. 2018, 166, 290–300. [Google Scholar] [CrossRef]

- Guo, X.; Pan, X. Effects of Steel Slag on Mechanical Properties and Mechanism of Fly Ash–Based Geopolymer. J. Mater. Civ. Eng. 2019, 32, 04019348. [Google Scholar] [CrossRef]

- Hafez, H.; Kassim, D.; Kurda, R.; Silva, R.V.; de Brito, J. Assessing the sustainability potential of alkali-activated concrete from electric arc furnace slag using the ECO2 framework. Constr. Build. Mater. 2021, 281, 122559. [Google Scholar] [CrossRef]

- El-Naggar, M.R.; El-Dessouky, M.I. Re-use of waste glass in improving properties of metakaolin-based geopolymers: Mechanical and microstructure examinations. Constr. Build. Mater. 2017, 132, 543–555. [Google Scholar] [CrossRef]

- Sethi, H.; Bansal, P.P.; Sharma, R. Effect of Addition of GGBS and Glass Powder on the Properties of Geopolymer Concrete. Iran. J. Sci. Technol. Trans. Civ. Eng. 2019, 43, 607–617. [Google Scholar] [CrossRef]

- Zhang, L.; Yue, Y. Influence of waste glass powder usage on the properties of alkali-activated slag mortars based on response surface methodology. Constr. Build. Mater. 2018, 181, 527–534. [Google Scholar] [CrossRef]

- Sandanayake, M.; Gunasekara, C.; Law, D.; Zhang, G.; Setunge, S.; Wanijuru, D. Sustainable criterion selection framework for green building materials—An optimisation based study of fly-ash Geopolymer concrete. Sustain. Mater. Technol. 2020, 25, e00178. [Google Scholar] [CrossRef]

- Shobeiri, V.; Bennett, B.; Xie, T.; Visintin, P. A generic framework for augmented concrete mix design: Optimisation of geopolymer concrete considering environmental, financial and mechanical properties. J. Clean. Prod. 2022, 369, 133382. [Google Scholar] [CrossRef]

- Marinković, S.; Dragaš, J.; Ignjatović, I.; Tošić, N. Environmental Assessment of Green Concretes for Structural Use. J. Clean. Prod. 2017, 154, 633–649. [Google Scholar] [CrossRef]

- Krishna, R.S.; Shaikh, F.; Mishra, J.; Lazorenko, G.; Kasprzhitskii, A. Mine Tailings-Based Geopolymers: Properties, Applications and Industrial Prospects. Ceram. Int. 2021, 47, 17826–17843. [Google Scholar] [CrossRef]

- Wongsa, A.; Boonserm, K.; Waisurasingha, C.; Sata, V.; Chindaprasirt, P. Use of Municipal Solid Waste Incinerator (MSWI) Bottom Ash in High Calcium Fly Ash Geopolymer Matrix. J. Clean. Prod. 2017, 148, 49–59. [Google Scholar] [CrossRef]

- Krausova, K.; Cheng, T.W.; Gautron, L.; Dai, Y.S.; Borenstajn, S. Heat Treatment on Fly and Bottom Ash Based Geopolymers: Effect on the Immobilization of Lead and Cadmium. Int. J. Environ. Sci. Dev. 2012, 3, 350–353. [Google Scholar] [CrossRef]

- Kastiukas, G.; Zhou, X.; Asce, M.; Castro-Gomes, J. Preparation Conditions for the Synthesis of Alkali-Activated Binders Using Tungsten Mining Waste. J. Mater. Civ. Eng. 2017, 29, 04017181. [Google Scholar] [CrossRef]

- Adesanya, E.; Ohenoja, K.; Kinnunen, P.; Illikainen, M. Alkali Activation of Ladle Slag from Steel-Making Process. J. Sustain. Metall. 2017, 3, 300–310. [Google Scholar] [CrossRef]

- Scarlat, N.; Fahl, F.; Dallemand, J.F. Status and Opportunities for Energy Recovery from Municipal Solid Waste in Europe. Waste Biomass Valorization 2019, 10, 2425–2444. [Google Scholar] [CrossRef]

- Hardjito, D.; Rangan, B.V. Development and Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete, Research Report GC. Curtin University of Technology 2005. Research Report, 94. Available online: https://www.geopolymer.org/wp-content/uploads/curtin-flyash-GP-concrete-report.pdf (accessed on 27 April 2018).

- UNDP. Sustainable Development Goals [WWW Document]. 2018. Available online: http://www.undp.org/content/undp/en/home/sustainable-development-goals.html (accessed on 27 April 2018).

- Akadiri, P.O.; Olomolaiye, P.O.; Chinyio, E.A. Multi-criteria evaluation model for the selection of sustainable materials for building projects. Autom. Constr. 2013, 30, 113–125. [Google Scholar] [CrossRef]

- Passuello, A.; Rodríguez, E.D.; Hirt, E.; Longhi, M.; Bernal, S.A.; Provis, J.L.; Kirchheim, A.P. Evaluation of the potential improvement in the environmental footprint of geopolymers using waste-derived activators. J. Clean. Prod. 2017, 166, 680–689. [Google Scholar] [CrossRef]

- Teh, S.H.; Wiedmann, T.; Castel, A.; de Burgh, J. Hybrid life cycle assessment of greenhouse gas emissions from cement, concrete and geopolymer concrete in Australia. J. Clean. Prod. 2017, 152, 312–320. [Google Scholar] [CrossRef]

- Weil, M.; Dombrowski, K.; Buchwald, A. Life-cycle analysis of geopolymers. In Geopolymers: Structures, Processing, Properties and Industrial Applications; Elsevier: Amsterdam, The Netherlands, 2009; pp. 194–210. [Google Scholar] [CrossRef]

- Khoshnava, S.M.; Rostami, R.; Valipour, A.; Ismail, M.; Rahmat, A.R. Rank of green building material criteria based on the three pillars of sustainability using the hybrid multi criteria decision making method. J. Clean. Prod. 2018, 173, 82–99. [Google Scholar] [CrossRef]

- Van der Meulen, S.; Grijspaardt, T.; Mars, W.; van der Geest, W.; Roest-Crollius, A.; Kiel, J. Cost Figures for Freight Transport—Final report, Research to Progress. Panteia. 2020. Available online: https://www.kimnet.nl/binaries/kimnet/documenten/formulieren/2020/05/26/cost-figures-for-freight-transport/Cost+figures+for+freight+transport+-+final+report.pdf (accessed on 27 April 2018).

- Albidah, A.; Alghannam, M.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Characteristics of metakaolin-based geopolymer concrete for different mix design parameters. J. Mater. Res. Technol. 2021, 10, 84–98. [Google Scholar] [CrossRef]

- Bellum, R.R.; Muniraj, K.; Madduru, S.R.C. Investigation on modulus of elasticity of fly ash-ground granulated blast furnace slag blended geopolymer concrete. Mater. Today Proc. 2020, 27, 718–723. [Google Scholar] [CrossRef]

- Marathe, S.; Mithanthaya, I.R.; Shenoy, R.Y. Durability and microstructure studies on Slag-Fly Ash-Glass powder based alkali activated pavement quality concrete mixes. Constr. Build. Mater. 2021, 287, 123047. [Google Scholar] [CrossRef]

- Sarker, P.K.; Haque, R.; Ramgolam, K.V. Fracture behaviour of heat cured fly ash based geopolymer concrete. Mater. Des. 2013, 44, 580–586. [Google Scholar] [CrossRef]

- Fatec. Utilizing Material Side Streams in Manufacturing of for Example Concrete, Mortars, and Cementitious Materials. Fatec Oy, 2020. Available online: https://fatec.fi/ (accessed on 12 May 2021).

- Marceau, M.; Van Geem, M.G. Life Cycle Inventory of Slag Cement Manufacturing Process CTL Project No. 312012, 2003. In Proceedings of the Eighth CANMET/ACI International Conference on Fly Ash, Silica Fume, Slag and Natural Pozzolans in Concrete, Las Vegas, NV, USA, 23–29 May 2004; American Concrete Institute Farmington Hills: Farmington Hills, MI, USA, 2004; pp. 1–26. Available online: https://www.ecocem.ie/wp-content/uploads/2016/08/ECL009_Life_Cycle_Inventory_of_GGBS_Cement_Concrete.pdf (accessed on 29 January 2023).

- De Bakker, J. Energy Use of Fine Grinding in Mineral Processing. Met. Mater. Trans. E 2014, 1, 8–19. [Google Scholar] [CrossRef]

- Vinai, R.; Soutsos, M. Production of sodium silicate powder from waste glass cullet for alkali activation of alternative binders. Cem. Concr. Res. 2018, 116, 45–56. [Google Scholar] [CrossRef]

- Torelli, D. Use of Waste Material in AAM Concrete: Application in Circular Economy, ETH Zurich. 2020. Available online: https://sc.ibi.ethz.ch/en/education/stundent-theses/master-projects/abgeschlossene-masterprojektarbeiten1.html (accessed on 29 January 2023).

- Eurostat, Statistics|Electricity Prices for Non-Household Consumers—Bi-Annual Data (from 2007 onwards). 2022. Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_pc_205/default/table?lang=en (accessed on 14 April 2022).

- Abdollahnejad, Z.; Pacheco-Torgal, F.; Félix, T.; Tahri, W.; Aguiar, J.B. Mix design, properties and cost analysis of fly ash-based geopolymer foam. Constr. Build. Mater. 2015, 80, 18–30. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.; Ventura, A. LCA allocation procedure used as an incitative method for waste recycling: An application to mineral additions in concrete. Resour. Conserv. Recycl. 2010, 54, 1231–1240. [Google Scholar] [CrossRef]

- NLK, Ecosmart Concrete Project: Metakaolin Pre-Feasibility Study, Report EA2860, Vancouver, British Columbia. 2002. Available online: http://ecosmartconcrete.com/docs/trnlkmk02.pdf (accessed on 29 January 2023).

- Van Oss, H.G. SLAG-IRON AND STEEL, Semantic Scholar. 2002. Available online: https://www.semanticscholar.org/paper/SLAG%E2%80%94IRON-AND-STEEL-Oss/061992ba0485caa0719e49377d8a6bdf3c380e9a (accessed on 29 January 2023).

- Eurostat, Recycling—Secondary Material Price Indicator. 2021, pp. 1–10. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Recycling_%E2%80%93_secondary_material_price_indicator (accessed on 29 January 2023).

- European Commission—Taxation and Customs Union, Taxes in Europe Database, v.3. 2017. Available online: https://ec.europa.eu/taxation_customs/tedb/taxDetails.html?id=252/1577833200 (accessed on 14 April 2022).

- Kijlstra. Aanvullende Prijslijst. 2019. Available online: https://www.betonmortelnederland.nl/Portals/0/Documenten/Aanvullende tarieven - 2019.pdf (accessed on 14 April 2022).

- CEWEP. CEWEP—The Confederation of European Waste-to-Energy Plants. 2021. Available online: https://www.cewep.eu/wp-content/uploads/2017/12/Landfill-taxes-and-bans-overview.pdf (accessed on 14 April 2022).

- Belgium Ecotax Rates. General tax-Base Specific Tax-Base Tax Rate Euro Levy on Energy Tax. 2009. Available online: https://foes.de/pdf/Belgium%20Ecotax%20Rates.pdf (accessed on 14 April 2022).

- LUKE, Biomass Atlas. 2017. Available online: https://biomassa-atlas.luke.fi/?lang=en (accessed on 26 April 2021).

- Suopajärvi, H.; Haapala, A. SMARCTIC WP4—Zero-Waste Integrates of Metallurgical Industry and Bioeconomy. 2014. Available online: https://www.researchgate.net/publication/318275778_SMARCTIC_WP4_-_Zero-waste_integrates_of_metallurgical_industry_and_bioeconomy (accessed on 14 April 2022).

- Niemelin, T.; Autiola, M.; Jyrävä, H.; Lindroos, N.; Kulmala, A.; Österbacka, J.; Helaakoski, M. UTILISATION OF BY-PRODUCTS AND ALTERNATIVE CONSTRUCTION MATERIALS IN NEW MINE CONSTRUCTION. 2020. Available online: https://projektit.ramboll.fi/life/upacmic/matsku/deliverables/Other_deliverables/WASCON2018_UPACMIC_extended_abstract_2-5-2018.pdf (accessed on 14 April 2022).

- Havukainen, J.; Nguyen, M.T.; Hermann, L.; Horttanainen, M.; Mikkilä, M.; Deviatkin, I.; Linnanen, L. Potential of phosphorus recovery from sewage sludge and manure ash by thermochemical treatment. Waste Manag. 2016, 49, 221–229. [Google Scholar] [CrossRef]

- Suomen Erityisjäte Oy, MSWI Bottom Ash as a Part of National Decree: Reducing Environmental Permit Requirements|Suomen Erityisjäte Oy. 2021. Available online: https://www.erityisjate.fi/research-and-future/innovations-and-technologies/mswi-bottom-ash-as-a-part-of-national-decree-/ (accessed on 14 April 2022).

- Eurostat. Generation of Waste by Waste Category, Hazardousness and NACE Rev. 2 Activity. 2022. Available online: http://appsso.eurostat.ec.europa.eu/nui/submitViewTableAction.do (accessed on 14 April 2022).

- Eurofer. Map of EU Steel Production Sites. 2021. Available online: https://www.eurofer.eu/assets/Uploads/Slide1.PNG (accessed on 14 April 2022).

- Eurostat. Statistics|Sewage Sludge Production and Disposal from Urban Wastewater (in Dry Substance (d.s)). 2022. Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00030/default/table?lang=en (accessed on 14 April 2022).

- Joseph, A.M.; Snellings, R.; Heede, P.V.D.; Matthys, S.; De Belie, N. The Use of Municipal Solid Waste Incineration Ash in Various Building Materials: A Belgian Point of View. Materials 2018, 11, 141. [Google Scholar] [CrossRef]

- Statbel. Packaging Waste. Génération de Déchets D’emballages (Tonnes). 2020. Available online: https://statbel.fgov.be/en/themes/environment/waste-and-pollution/packaging-waste#figures (accessed on 14 April 2022).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).