The Production of Gypsum Materials with Recycled Citrogypsum Using Semi-Dry Pressing Technology

Abstract

:1. Introduction

2. Results

2.1. Appearance of Experimental Mixes

2.2. Properties of Experimental Mixes

3. Discussion

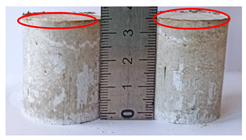

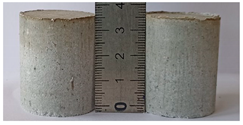

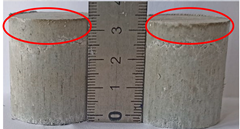

3.1. Influence of Formulation and Molding Pressure on the Appearance of Samples

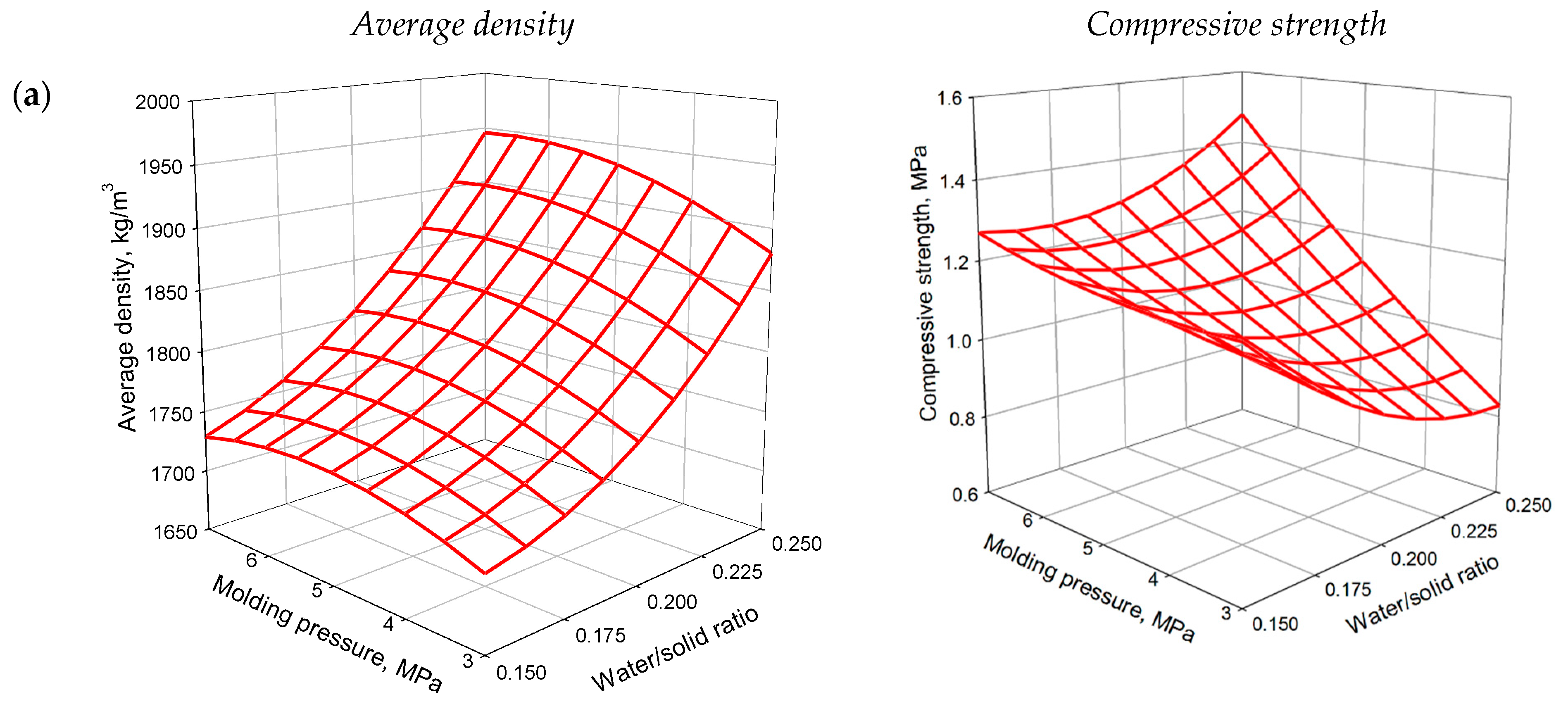

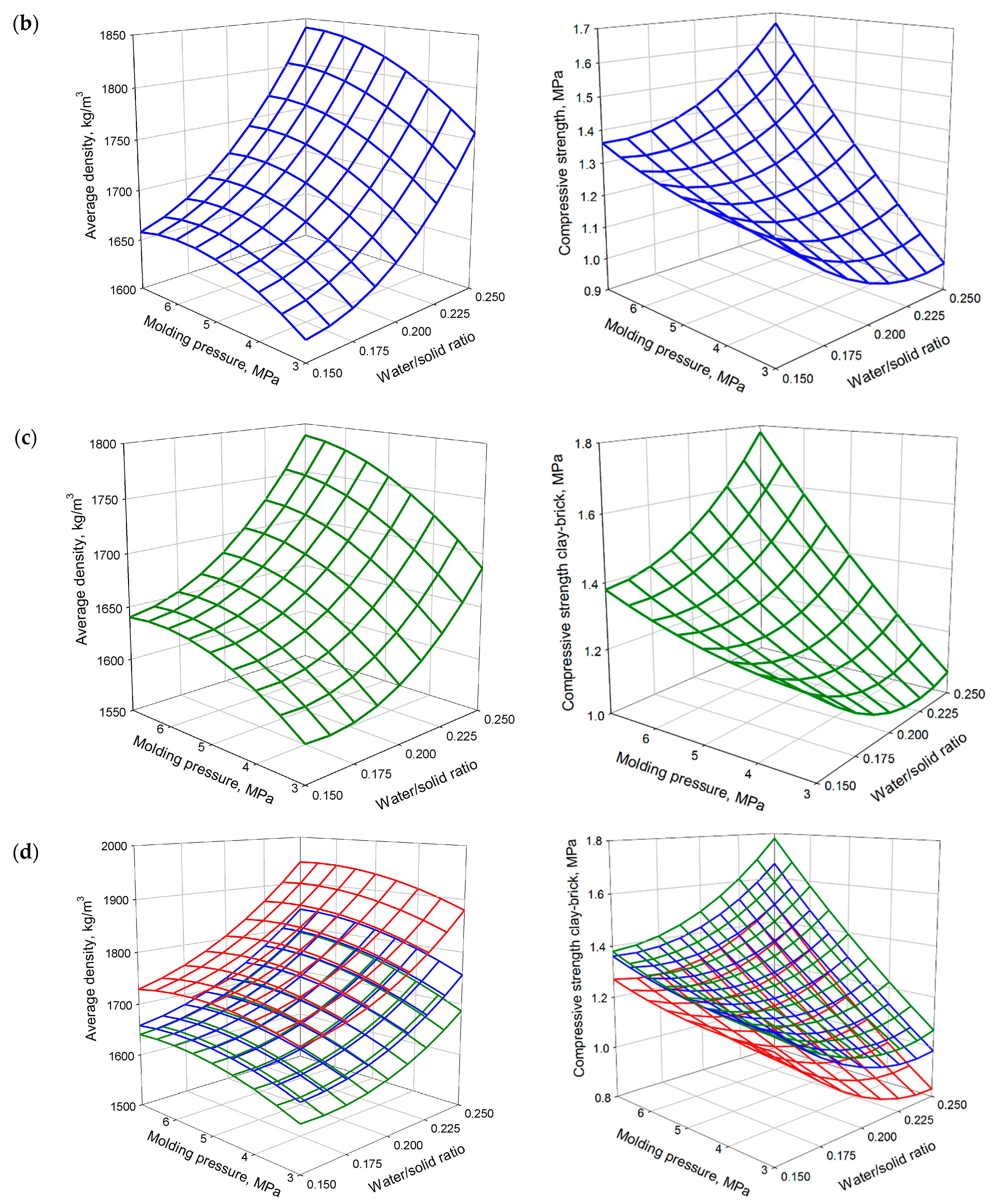

3.2. Influence of Formulation and Molding Pressure on the Physical and Mechanical Characteristics of Samples

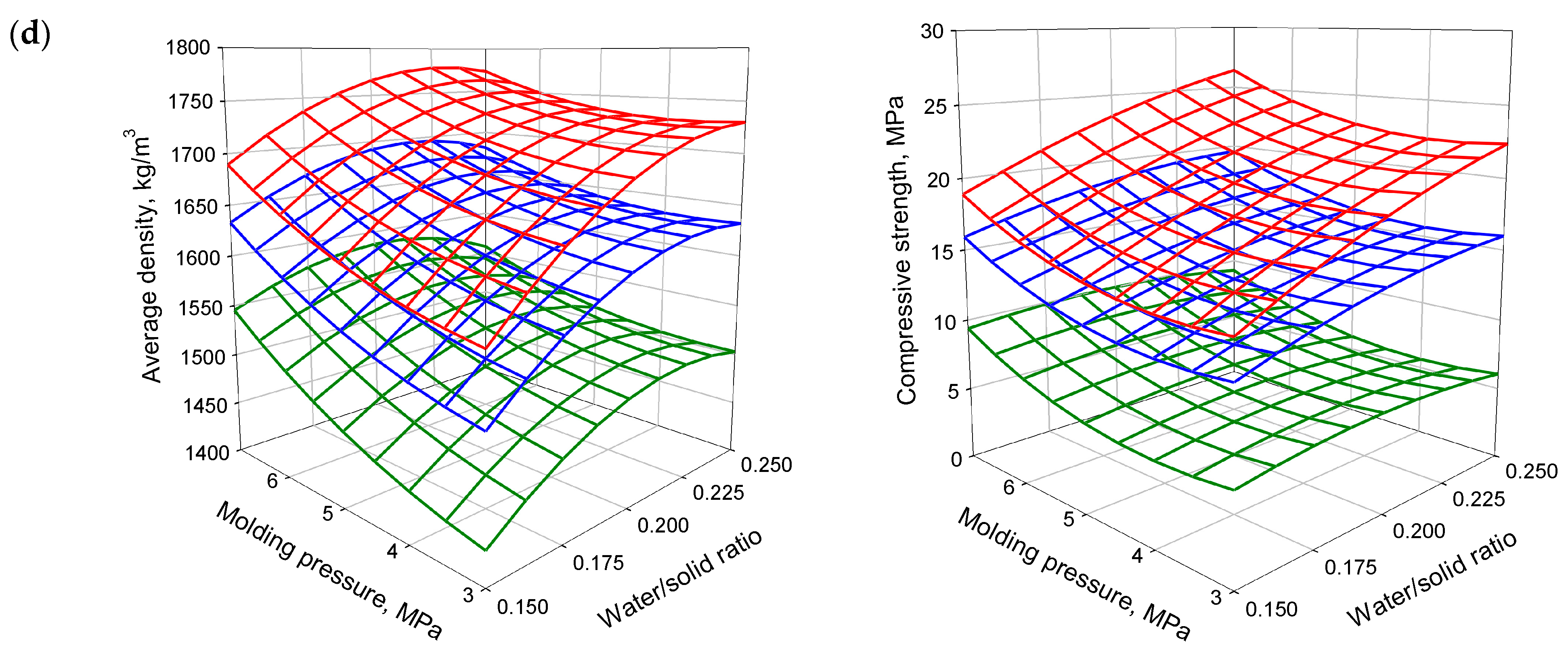

3.3. Influence of Formulation and Molding Pressure on the Physical and Mechanical Characteristics of Samples at Two Days after Demolding

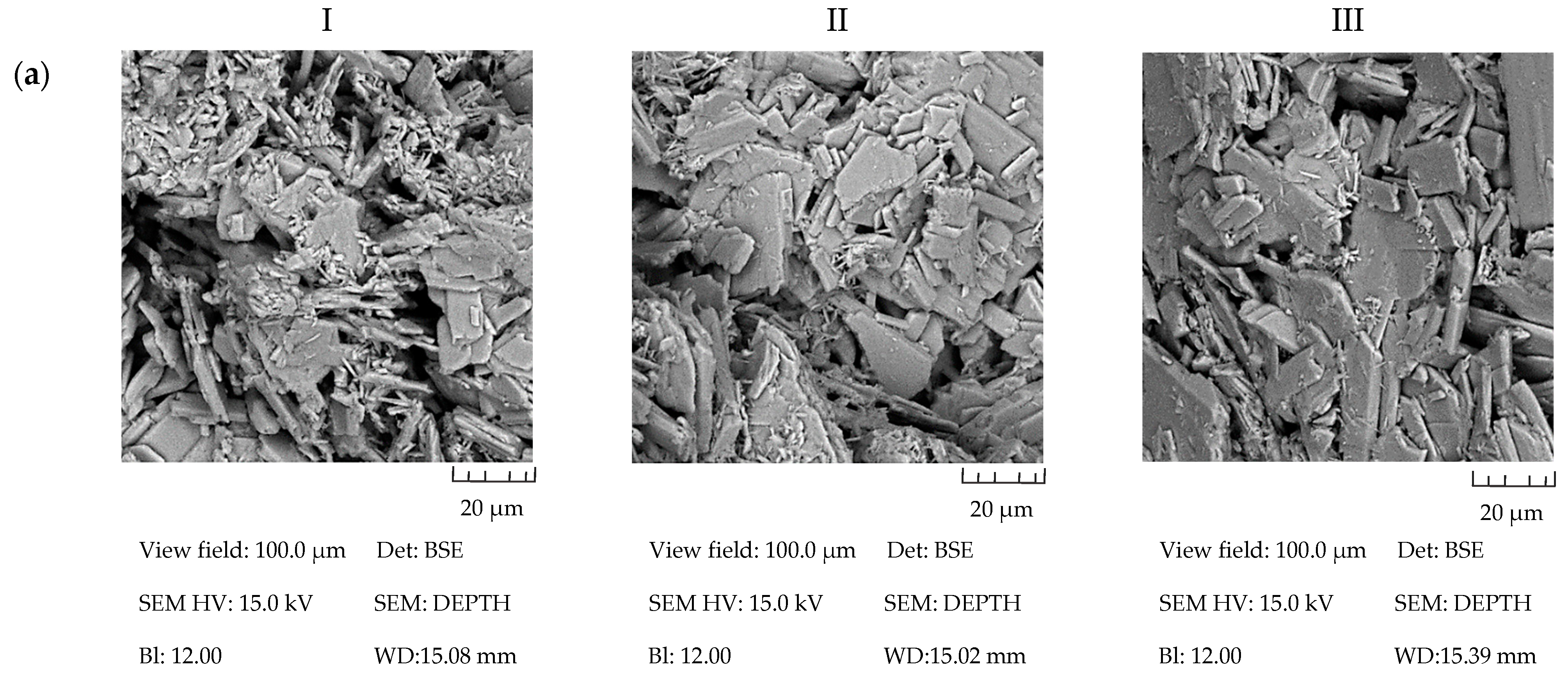

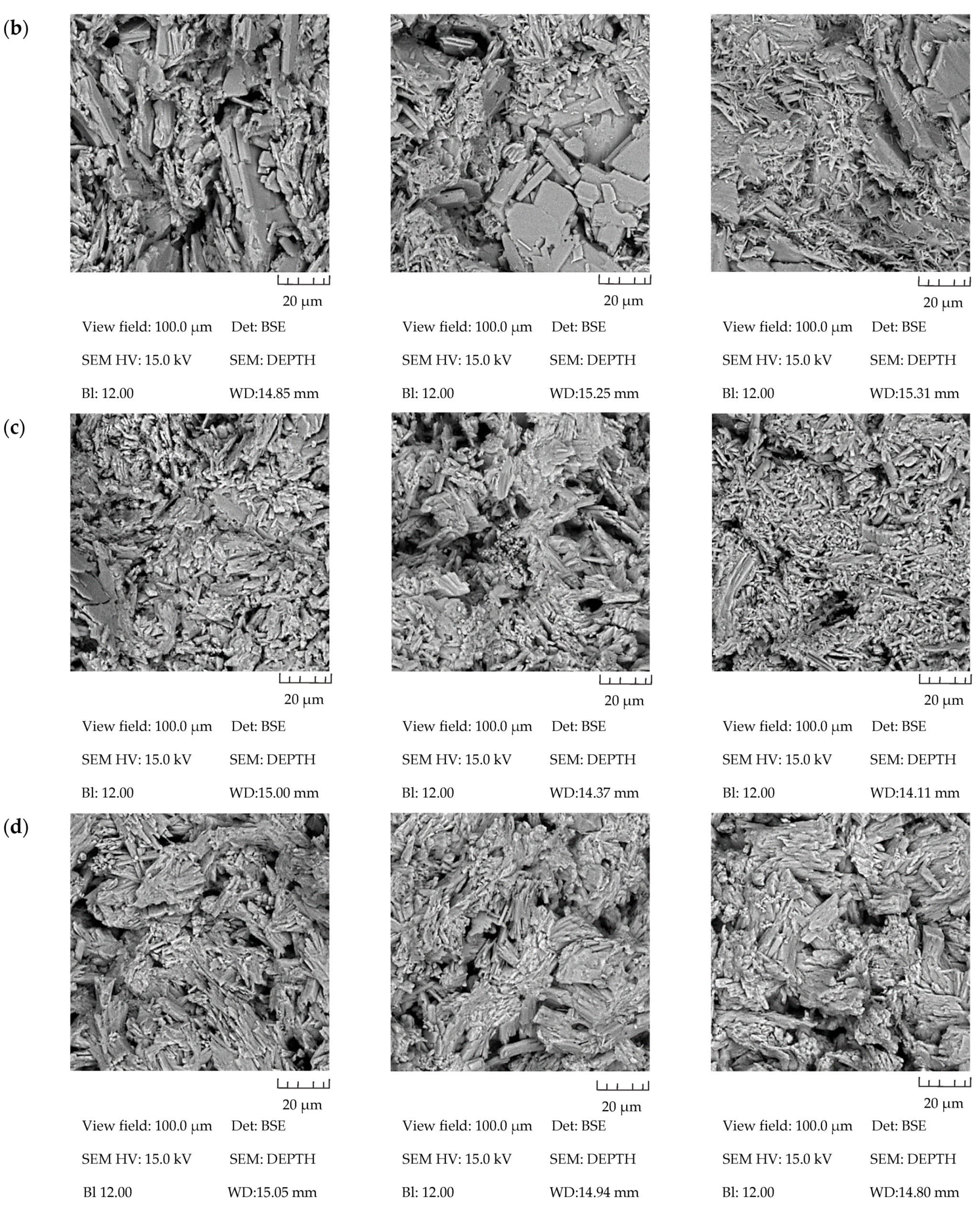

3.4. Effect of Formulation and Molding Pressure on the Microstructure of the Samples at Two Days after Demolding

4. Materials and Methods

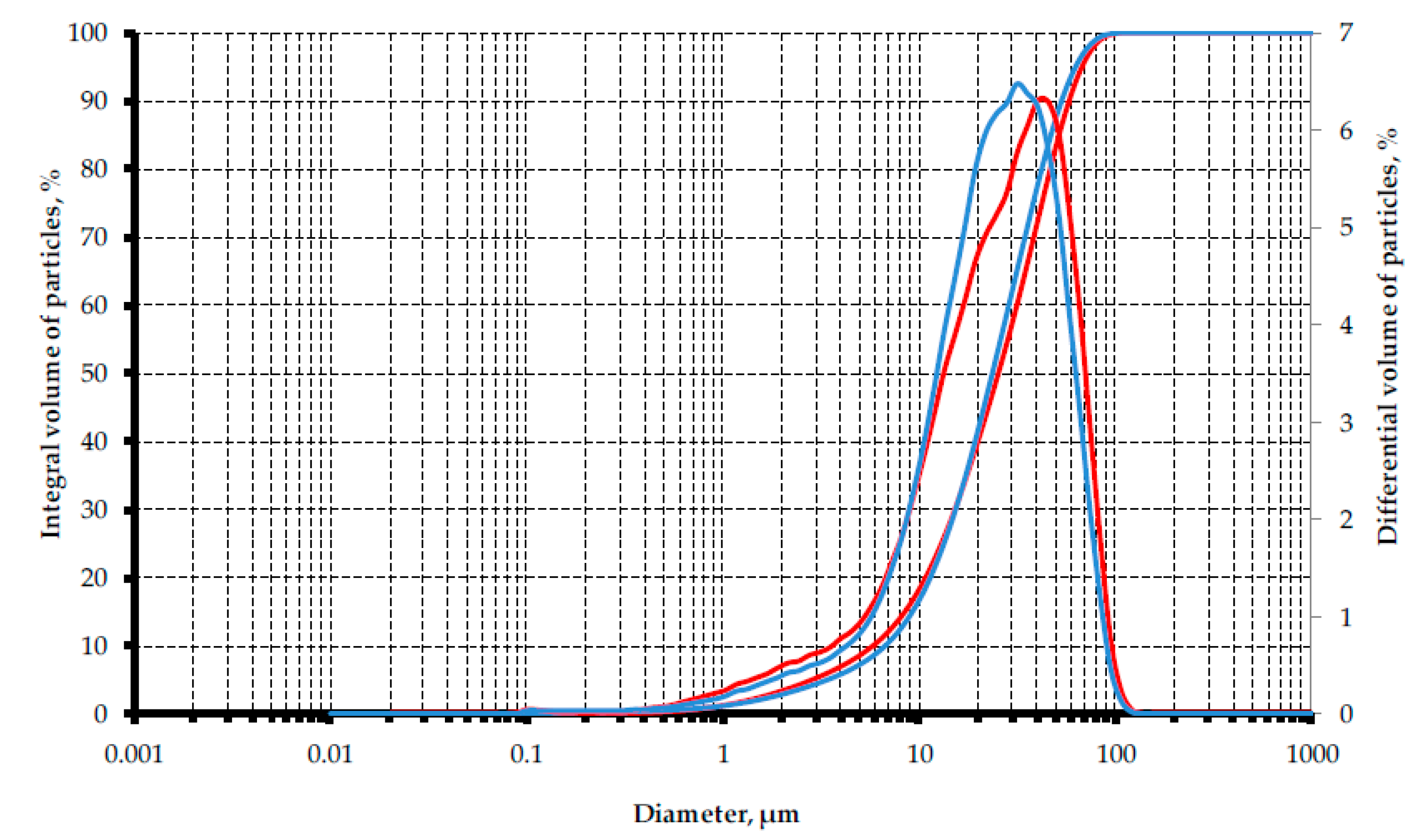

4.1. Materials

4.2. Methods

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rashad, A.M. Phosphogypsum as a construction material. J. Clean. Prod. 2017, 166, 732–743. [Google Scholar] [CrossRef]

- Yang, J.; Liu, W.; Zhang, L.; Xiao, B. Preparation of load-bearing building materials from autoclaved phosphogypsum. Constr. Build. Mater. 2009, 23, 687–693. [Google Scholar] [CrossRef]

- Guan, B.; Yang, L.; Wu, Z.; Shen, Z.; Ma, X.; Qingqing, Y. Preparation of a-calcium sulfate hemihydrate from FGD gypsum in K, Mg-containing concentrated CaCl2 solution under mild conditions. Fuel 2009, 88, 1286–1293. [Google Scholar] [CrossRef]

- Shen, Z.X.; Guan, B.H.; Fu, H.L.; Yang, L. Effect of Potassium Sodium Tartrate and Sodium Citrate on the Preparation of a-Calcium Sulfate Hemihydrate from Flue Gas Desulfurization Gypsum in a Concentrated Electrolyte Solution. Am. Ceram. Soc. 2009, 92, 2894–2899. [Google Scholar] [CrossRef]

- Sevim, U.K.; Ozturk, M.; Onturk, S.; Bankir, M.B. Utilization of boron waste borogypsum in mortar. J. Build. Eng. 2019, 22, 496–503. [Google Scholar] [CrossRef]

- Kavas, T.; Olgun, A.; Erdogan, Y. Setting and hardening of borogypsum—Portland cement clinker–fly ash blends. Studies on effects of molasses on properties of mortar containing borogypsum. Cem. Concr. Res. 2005, 35, 711–718. [Google Scholar] [CrossRef]

- Sverguzova, S.V.; Tarasova, G.I.; Chernysheva, N.V.; Shamshurov, A.V. Theoretical substantiation of the possibility of non-firing dehydration of citrogypsum. Bull. BSTU Im. V. G. Shukhov 2010, 2, 117–121. [Google Scholar]

- Kozhukhova, N.I.; Shurakov, I.M.; Titenko, A.A.; Alfimova, N.I.; Zhernovskaya, I.V.; Bukovtsova, A.I. Effect of the curing conditions on the characteristics of citrogypsum-containing alkali-activated binders. Constr. Mater. Prod. 2021, 4, 24–34. [Google Scholar] [CrossRef]

- Silva, L.F.O.; Oliveira, M.L.S.; Crissien, T.J.; Santosh, M.; Bolivar, J.; Shao, L.; Dotto, G.L.; Gasparotto, J.; Schindler, M. A review on the environmental impact of phosphogypsum and potential health impacts through the release of nanoparticles. Chemosphere 2022, 286, 131513. [Google Scholar] [CrossRef]

- Men, J.; Li, Y.; Cheng, P.; Zhang, Z. Recycling phosphogypsum in road construction materials and associated environmental considerations: A review. Heliyon 2022, 8, e11518. [Google Scholar] [CrossRef]

- Wang, J.; Yang, P. Potential flue gas desulfurization gypsum utilization in agriculture: A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 1969–1978. [Google Scholar] [CrossRef]

- Voropaev, V.; Alfimova, N.; Nikulin, I.; Nikulicheva, T.; Titenko, A.; Nikulichev, V. Influence of Gypsum-Containing Waste on Ammonia Binding in Animal Waste Composting. Agriculture 2021, 11, 1153. [Google Scholar] [CrossRef]

- Cánovas, C.R.; Macías, F.; Pérez-López, R.; Basallote, M.D.; Millán-Becerro, R. Valorization of wastes from the fertilizer industry: Current status and future trends. J. Clean. Prod. 2018, 174, 678–690. [Google Scholar] [CrossRef]

- Liu, S.; Liu, W.; Jiao, F.; Qin, W.; Yang, C. Production and resource utilization of flue gas desulfurized gypsum in China—A review. Environ. Pollut. 2021, 288, 117799. [Google Scholar] [CrossRef] [PubMed]

- Qin, X.; Cao, Y.; Guan, H.; Hu, Q.; Liu, Z.; Xu, J.; Hu, B.; Zhang, Z.; Luo, R. Resource utilization and development of phosphogypsum-based materials in civil engineering. J. Clean. Prod. 2023, 387, 135858. [Google Scholar] [CrossRef]

- Emrullahoglu Abi, C.B. Effect of borogypsum on brick properties. Constr. Build. Mater. 2014, 59, 195–203. [Google Scholar] [CrossRef]

- Guan, B.; Kong, B.; Fu, H.; Yu, J.; Jiang, G.; Yang, L. Pilot scale preparation of α-calcium sulfate hemihydrate from FGD gypsum in Ca–K–Mg aqueous solution under atmospheric pressure. Fuel 2012, 98, 48–54. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q.; Shen, Z.; Li, L.; Li, X.; Ma, S. L-aspartic acid: A crystal modifier for preparation of hemihydrate from phosphogypsum in CaCl2 solution. J. Cryst. Growth 2019, 511, 48–55. [Google Scholar] [CrossRef]

- Alfimova, N.I.; Pirieva, S.Y.; Elistratkin, M.Y.; Kozhuhova, N.I.; Titenko, A.A. Production methods of binders containing gypsum-bearing wastes: A review. Bull. BSTU Named After V.G. Shukhov 2020, 11, 8–23. [Google Scholar] [CrossRef]

- Calderón-Morales, B.R.S.; García-Martínez, A.; Pineda, P.; García-Tenório, R. Valorization of phosphogypsum in cement-based materials: Limits and potential in eco-efficient construction. J. Build. Eng. 2021, 44, 102506. [Google Scholar] [CrossRef]

- Ozkul, M.H. Utilization of citro- and desulphogypsum as set retarders in Portland cement. Cem. Concr. Res. 2000, 30, 1755–1758. [Google Scholar] [CrossRef]

- Caillahua, M.C.; Moura, F.J. Technical feasibility for use of FGD gypsum as an additive setting time retarder for Portland cement. J. Mater. Res. Technol. 2018, 7, 190–197. [Google Scholar] [CrossRef]

- Vaičiukyniene, D.; Nizevičienė, D.; Kiele, A.; Janavičius, E.; Pupeikis, D. Effect of phosphogypsum on the stability upon firing treatment of alkali-activated slag. Constr. Build. Mater. 2018, 184, 485–491. [Google Scholar] [CrossRef]

- Kozhukhova, N.I.; Shurakov, I.M.; Kozhukhova, M.I.; Elistratkin, M.Y.; Alfimova, N.I. Understanding the relationship between composition and rheology in alkali-activated binders. J. Phys. Conf. Ser. Link Is Disabl. 2021, 2124, 012004. [Google Scholar] [CrossRef]

- Pirieva, S.; Alfimova, N.; Levickaya, K. Citrogypsum as a Raw Material for Gypsum Binder Production. Constr. Unique Build. Struct. 2022, 100, 10007. [Google Scholar] [CrossRef]

- Ma, B.; Jin, Z.; Su, Y.; Lu, W.; Qi, H.; Hu, P. Utilization of hemihydrate phosphogypsum for the preparation of porous sound absorbing material. Constr. Build. Mater. 2020, 234, 117346. [Google Scholar] [CrossRef]

- Lu, W.; Ma, B.; Su, Y.; He, X.; Jin, Z.; Qi, H. Preparation of a-hemihydrate gypsum from phosphogypsum in recycling CaCl2 solution. Constr. Build. Mater. 2019, 214, 399–412. [Google Scholar] [CrossRef]

- Zhou, J.; Sheng, Z.; Li, T.; Shu, Z.; Wang, Y. Preparation of hardened tiles from waste phosphogypsum by a new intermittent pressing hydration. Ceram. Int. 2016, 42, 7237–7245. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Zhao, Y.; Shu, Z.; Wang, Y.; Zhang, Y.; Shen, X. Preparation of paper-free and fiber-free plasterboard with high strength using phosphogypsum. Constr. Build. Mater. 2020, 243, 118091. [Google Scholar] [CrossRef]

- Mirsaev, R.N.; Babkov, V.V.; Nedoseko, I.V.; Yunusova, S.S.; Akhmadulina, I.I.; Shayakhmetov, U.S. Structural formation and hardening of pressed compositions based on calcium sulfate dehydrate. Build. Mater. 2009, 6, 6–9. [Google Scholar]

- Petropavlovskii, K.; Novichenkova, T.; Petropavlovskaya, V.; Salman, M.; Fediuk, R.; Amran, M. Faience waste for the production of wall products. Materials 2021, 14, 6677. [Google Scholar] [CrossRef] [PubMed]

- Petropavlovskaya, V.B.; Belov, V.V.; Novichenkova, T.B.; Buryanov, A.F.; Poleonova, Y.Y.; Petropavlovsky, K.S. Resource-saving non-fired gypsum composites. Build. Mater. 2015, 6, 79–81. [Google Scholar]

- Petropavlovskaya, V.B.; Novichenkova, T.B.; Buryanov, A.F. Improving the technological properties of non-fired hyper-pressed gypsum products. Bull. BSTU Named After V.G. Shukhov 2013, 6, 75–78. [Google Scholar]

| Sample ID | Evaluation of Sample Appearance | |

|---|---|---|

| Sample Appearance | Comments | |

| mix 1 |  | Smooth surface without delamination easy demolding; slight water release was observed |

| mix 2 |  | Smooth surface; slight delamination in the form of a surface crack at a distance of 5–10 mm from the top of the sample; easy demolding |

| mix 3 |  | Smooth surface without flaking; easy demolding; slight water release was observed |

| mix 4 |  | Easy demolding; in the upper part of the sample, a surface delamination 4–10 mm high is observed |

| mix 5 |  | Easy demolding; there was a slight release of water; in the upper part of the sample, surface delamination 2–5 mm high is observed |

| mix 6 |  | Demolding was difficult; in the upper part of the sample, there is a significant delamination and a wedge with a height of 5–7 mm and a depth of 1 mm |

| mix 7 |  | Demolding was difficult; in the upper part of the sample, there is a slight delamination and a wedge with a height of 2–7 mm and a depth of 1 mm |

| mix 8 |  | Demolding was difficult, in the upper part of the sample there is a significant delamination and a wedge with a height of 5–10 mm, and with a depth of 1–2 mm |

| mix 9 |  | Smooth surface without delamination; easy demolding; there was a slight release of water |

| mix 10 |  | Demolding was difficult; in the upper part of the sample, there is a slight delamination and a wedge with a height of 3–5 mm and a depth of 1–2 mm |

| mix 11 |  | Easy demolding; in the upper part of the sample, a slight delamination of the surface up to 10 mm high is observed |

| mix 12 |  | Easy demolding; in the upper part of the sample, there is a slight delamination of the surface with a height of 3–10 mm |

| mix 13 |  | Smooth surface, slight delamination in the form of a surface crack at a distance of 7–11 mm from the top of the sample; easy demolding |

| mix 14 |  | Demolding was difficult; there is a delamination and a slight wedge in the upper part of the sample with a height of 3–7 mm and a depth of 1 mm |

| mix 15 |  | Demolding was difficult; there is a delamination and a slight wedge in the upper part of the sample with a height of 1–10 mm, and a depth of 1 mm |

| Samples of Reference Mixes | ||

| mix 16 |  | Demolding was difficult, in the upper part of the sample there is a significant delamination and a wedge with a height of 7–14 mm, and with a depth of 1–2 mm |

| mix 17 |  | Demolding was difficult, in the upper part of the sample there is a significant delamination and a wedge with a height of 2–8 mm, and with a depth of 1–2 mm |

| mix 18 |  | In the upper part of the sample, surface delamination 1–5 mm high is observed |

| Mix ID | Average Values of Controlled Output Parameters | |||

|---|---|---|---|---|

| Immediately after Demolding | At 2 Days after Demolding | |||

| Average Density, kg/m3 | Compressive Strength, MPa | Average Density, kg/m3 | Compressive Strength, MPa | |

| mix 1 | 1772 ± 1.50% | 1.99 ± 2.11% | 1550± 2.11% | 9.37 ± 4.10% |

| mix 2 | 1639 ± 0.98% | 1.24 ± 1.50% | 1564 ± 1.50% | 9.24 ± 2.11% |

| mix 3 | 1696 ± 1.10% | 0.99 ± 2,70% | 1512 ± 1.37% | 6.16 ± 4.17% |

| mix 4 | 1594 ± 1.30% | 1.49 ± 2.6% | 1418± 2.53% | 6.16 ± 4.17% |

| mix 5 | 19378 ± 1.78% | 1.24 ± 2.7% | 1786 ± 1.61% | 26.11 ± 3.13% |

| mix 6 | 1721 ± 0.79% | 1.37 ± 0.98% | 1680 ± 0.46% | 18.8 ± 0.34% |

| mix 7 | 1883 ± 0.5% | 0.99 ± 2.52% | 1711 ± 0.31% | 22.52 ± 4.09% |

| mix 8 | 1727 ± 0.98% | 0.99 ± 2.95% | 1594± 0.82% | 14.18± 6.60% |

| mix 9 | 1662 ± 2.11% | 0.99 ± 1.44% | 1520 ± 1.44% | 6.29 ± 4.20% |

| mix 10 | 1799 ± 0.86% | 1.24 ± 2.15% | 1721 ± 1.28% | 20.15 ± 3.83% |

| mix 11 | 1750 ± 0.77% | 1.49 ± 2.41% | 1678 ± 0.65% | 18.8 ± 2.12% |

| mix 12 | 1617 ± 1.98% | 0.87 ± 1.69% | 1627± 0.19% | 14.37 ± 1.46% |

| mix 13 | 1823 ± 1.27% | 1.24 ± 1.77% | 1646 ± 0.03% | 16.04 ± 3.60% |

| mix 14 | 1641 ± 0.98% | 1.24 ± 2.53% | 1557± 2.16% | 12.45 ± 5.28% |

| mix 15 | 1722 ± 1.78% | 1.37 ± 3.60% | 1634 ± 0.19% | 15.01 ± 4.11% |

| Reference Mixes | ||||

| mix 16 | 1790 ± 2.80% | 0.75 ± 2.57% | 1655 ± 1.89% | 10.78 ± 4.78% |

| mix 17 | 1806 ± 2.00% | 1.12 ± 2.32% | 1778 ± 2.14% | 26.75 ± 3.51% |

| mix 18 | 1944 ± 2.01% | 1.24 ± 2.48% | 1785 ± 1.99% | 29.77 ± 2.42% |

| Oxide | m/m% | Elements | m/m% |

|---|---|---|---|

| SO3 | 55.47 | S | 22.22 |

| CaO | 43.36 | Ca | 30.99 |

| SiO2 | 0.54 | Si | 0.25 |

| Fe2O3 | 0.15 | Fe | 0.12 |

| SrO | 0.14 | Sr | 0.12 |

| Al2O3 | 0.13 | Al | 0.06 |

| MgO | 0.06 | Mg | 0.03 |

| Na2O | 0.04 | Na | 0.03 |

| P2O5 | 0.08 | P | 0.04 |

| K2O | 0.03 | K | 0.02 |

| O | 46.12 |

| Parameters | Values |

|---|---|

| Bulk density, kg/m3 | 690 |

| Specific surface area, m2/kg | 290–300 |

| Standard consistency (Russian standard GOST 23789-2018), % | 123 |

| Initial setting (Russian standard GOST 23789-2018), min | 18 |

| Final setting (Russian standard GOST 23789-2018), min | 30 |

| Compressive strength (Russian standard GOST 23789-2018), MPa | 0.7 |

| Parameters | Variation Levels of Studied Parameters | Variability Interval | |||

|---|---|---|---|---|---|

| Original Form | Coded Form | −1 | 0 | +1 | |

| FCG content, wt.% | X1 | 10 | 30 | 50 | 20 |

| Molding pressure, MPa | X2 | 3 | 5 | 7 | 2 |

| W/S ratio | X3 | 0.15 | 0.20 | 0.25 | 0.05 |

| No | Input Parameters | |||||

|---|---|---|---|---|---|---|

| Coded Form | Original Form | |||||

| X1 | X2 | X3 | FCG Content, wt.% | Molding Pressure, MPa | W/S Ratio | |

| 1 | +1 | +1 | +1 | 50 | 7 | 0.25 |

| 2 | +1 | +1 | −1 | 50 | 7 | 0.15 |

| 3 | +1 | −1 | +1 | 50 | 3 | 0.25 |

| 4 | +1 | −1 | −1 | 50 | 3 | 0.15 |

| 5 | −1 | +1 | +1 | 10 | 7 | 0.25 |

| 6 | −1 | +1 | −1 | 10 | 7 | 0.15 |

| 7 | −1 | −1 | +1 | 10 | 3 | 0.25 |

| 8 | −1 | −1 | −1 | 10 | 3 | 0.15 |

| 9 | +1 | 0 | 0 | 50 | 5 | 0.20 |

| 10 | −1 | 0 | 0 | 10 | 5 | 0.20 |

| 11 | 0 | +1 | 0 | 30 | 7 | 0.20 |

| 12 | 0 | −1 | 0 | 30 | 3 | 0.20 |

| 13 | 0 | 0 | +1 | 30 | 5 | 0.25 |

| 14 | 0 | 0 | −1 | 30 | 5 | 0.15 |

| 15 | 0 | 0 | 0 | 30 | 5 | 0.20 |

| Reference mixes | ||||||

| 16 | – | −1 | −1 | – | 3 | 0.15 |

| 17 | – | 0 | 0 | – | 5 | 0.20 |

| 18 | – | +1 | +1 | – | 7 | 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfimova, N.; Pirieva, S.; Levickaya, K.; Kozhukhova, N.; Elistratkin, M. The Production of Gypsum Materials with Recycled Citrogypsum Using Semi-Dry Pressing Technology. Recycling 2023, 8, 34. https://doi.org/10.3390/recycling8020034

Alfimova N, Pirieva S, Levickaya K, Kozhukhova N, Elistratkin M. The Production of Gypsum Materials with Recycled Citrogypsum Using Semi-Dry Pressing Technology. Recycling. 2023; 8(2):34. https://doi.org/10.3390/recycling8020034

Chicago/Turabian StyleAlfimova, Nataliya, Sevda Pirieva, Ksenia Levickaya, Natalia Kozhukhova, and Mikhail Elistratkin. 2023. "The Production of Gypsum Materials with Recycled Citrogypsum Using Semi-Dry Pressing Technology" Recycling 8, no. 2: 34. https://doi.org/10.3390/recycling8020034

APA StyleAlfimova, N., Pirieva, S., Levickaya, K., Kozhukhova, N., & Elistratkin, M. (2023). The Production of Gypsum Materials with Recycled Citrogypsum Using Semi-Dry Pressing Technology. Recycling, 8(2), 34. https://doi.org/10.3390/recycling8020034