Abstract

The exponential growth of digitalisation and the continuous increase in sustainability needs are currently reshaping the European manufacturing industry through its entire value chain. Industrial sectors have undergone significant changes globally in recent years, and they will continue to face this deep transformation. The manufacturing sectors, more specifically, companies, need to develop a relevant strategy that can support their organisation to handle the upcoming future technological developments and sustainability requirements properly. In order to implement the strategy effectively and achieve an adequate digital and green transformation, their main focus should be the development of a multi-skilled workforce. This competent workforce can only be built by foreseeing the changes in the needed skills for the manufacturing industry and then updating the skills of the current workforce accordingly. As an answer to this need, we developed an automated skill database for the manufacturing industry, particularly transversal occupations of this sector related to the industrial symbiosis (IS) and energy efficiency (EE). Differently from the conventional ones, the generated database incorporated not only the current but also the future skill needs for each profile. During the development of the future skills for each occupation in the database, we identified the foreseen skill needs for the manufacturing industry through detailed desk research. Therefore, this paper presents a valuable perspective on the subject. Our work aimed to fill the gap for a database specifically developed for the manufacturing industry, which provides the end-users with data about the new skills requirements resulting from industrial changes and sustainability needs. We believe that companies, education and training institutions and policymakers can make use of the generated database as a complementary tool for developing their training programmes or strategy roadmaps to cover the emerging changes in each individual industrial sector.

1. Introduction

The manufacturing industry is the key sector in many countries, especially in Europe. It forms the basis of many national economies [1,2]. The manufacturing industry is a vital component of the European economy, producing 24 percent of GDP (Gross Domestic Product) and employing almost 50 million people, contributing to one out of every five jobs in the EU [2]. The manufacturing industry is defined by the OECD (Organisation for Economic Co-operation and Development) as a cyclical sector due to its sensitivity to many external and internal factors and the cyclical changes caused by these factors [2]. It is critical for any country to understand the cyclical relationship between manufacturing industry indicators, particularly in terms of the industry’s most essential variables, such as sales, salaries, and employment [2]. Among some of the most important manufacturing industries are those that include steel, chemicals, engineering, minerals, ceramics, water, etc. They all obtain products from different types of raw materials by the use of manual labour or machinery [3]. Industrial companies, who have a great impact on not only the European but also the global economy, are currently seeking to develop new strategies that can help their growth in a sustainable way, both technologically and economically [1,3,4]. The industry’s competitiveness is constantly improving in EU countries, particularly with the support of European initiatives [2].

Commerce and worldwide competition, the access to raw materials that enable manufacturing processes and, more pertinently nowadays, energy and guidelines for their more efficient use, the skill framework of the labour force, technology and innovations, etc., all influence the condition and evolution of the manufacturing sectors [2]. Moreover, processes of globalisation and, what is crucial nowadays, technological developments generate new kinds of business models, services and goods [2].

For the performance of industrial companies, the interaction between the industry and the environment is crucial [3,5,6]. Environmental consequences have intensified the pressure on industrial enterprises because manufacturing sectors have a considerable impact on every component of sustainable development (social, environmental, economic and institutional) [7].

Furthermore, upcoming consumer societies and the exceptional growth of industrial activity have led to increasing environmental emissions, solid waste generation and landfills [1]. The demand for exponential economic and demographic growth cannot be realised since resources are limited [1,7,8].

In these circumstances, the threat of environmental contamination is becoming more severe, in addition to the worldwide scarcity of resources [5,9]. The European Commission (EUCOM) has reaffirmed its goal of being at the forefront of the battle against climate change and achieving a greenhouse-neutral continent by 2050 as a key step toward resolving environmental issues [1,2,6]. To fulfil the commitments made in the Paris Agreement, EU members have made an exemplary shift from an adaptive reduction to a proactive promotion of a climate-neutral economy [9].

In terms of making the shift to a more sustainable industry in a softer and easier manner, recently, the management of the manufacturing companies has been focused on, particularly, the digitalisation of the sector and its development in the direction of zero emissions (decarbonisation) and sustainable development [9,10].

The manufacturing industry is also working towards the implementation of solutions that are innovative in the field of renewable energy sources and the transformation of the activities of companies to ensure that they operate with respect to energy efficiency [11]. The increasing use of renewable energy sources and energy-efficient technologies is one of the climate transition and sustainable development trends observed in the industrial sector [12].

As a result, in addition to its daily operations, the manufacturing industry must deal with the pressures of environmental regulations, the obstacles of resource price volatility and resource supply threats [1]. The development and deployment of digital technologies in manufacturing is a critical factor in overcoming obstacles and speeding up the transition to a more sustainable and energy-efficient European industry [11,13].

The ongoing demand for effective methods, procedures and measurements that allow flexibility for constantly changing circumstances drives the current digitalisation of the manufacturing industry [14,15,16,17].

The digitalisation of the industry, often known as Industry 4.0, is acknowledged as new production processes that are partially or completely managed by technology and tools that interact autonomously across the value chain [18,19]. Hence, it is primarily dependent on intelligent computational systems, electrical machinery and current information technologies (ITs) that enable process optimisation and growth in productivity [16]. As a result, digitalisation has become a critical component of the current industrial revolution, which is resulting in a smart manufacturing revolution in conventional industries [17].

Three major technologies that have initiated this revolution are Big Data analytics, the Internet of Things (IoT) and cyber-physical systems [18,19].

Other digital technologies, such as Artificial Intelligence (AI) and Blockchain, allow for improvements in renewable resources and even the establishment of smart grids and new modes of energy transfer, all of which contribute to the manufacturing sector’s long-term sustainability [1,20]. Technological solutions such as the newest versions of sensors, Artificial Intelligence (AI), the Internet of Services (IoS), advanced robotics, machine learning, the Internet of Things (IoT), cloud computing, cyber-physical systems, Machine-to-Machine Interaction (M2M) and others are continuing to evolve manufacturing concepts [13,16,20,21]. These vital technologies are assisting in shaping the future of automation, leading to more efficient and innovative goods, methodologies and services in the manufacturing sectors [4,13,22]. They can be used in either new and existing plants, transforming conventional manufacturing operations into smart manufacturing systems known as “smart factories” [23]. This notion involves the integration of communication, manufacturing, computational and control processes into digitalised, automated and context-aware manufacturing systems in order to optimise business models [16,23,24]. This improvement will have a significant impact on the business model, allowing for higher-quality output in less time and at a lower cost [11,16,25].

Because of the disruptive changes throughout the evolving digitalisation, the working environment within many manufacturing sectors will radically change over the next twenty years [26].

Taking everything into account, the manufacturing sectors urgently require a plan to guide them through the development of a more sustainable, symbiotic, energy-efficient and digitalised industry.

Therefore, in order to promote the growth of the European manufacturing industry and maintain its competitiveness during the digital and green transformation, the industry is in need of preparing the workforce for the future. Additionally, it is possible through upgrading its qualifications [3,11,25,27].

Continuously upgrading qualifications, skills and knowledge is the only way to build a highly trained and multi-skilled workforce that can cope with all technological and green changes and can adapt to the new manufacturing processes, the majority of which are related to sustainability, energy efficiency, industrial symbiosis and computer science [14,17,28].

Updating the skills of the current workforce is only possible by determining the current skill needs and foreseeing the skill changes in the manufacturing industry [3,21,24,25,29,30,31,32]. In order to respond to this need, we created an automated skill database for the manufacturing industry. This database was generated to incorporate not only current skill requirements but also future ones in order to provide a capable tool for establishing the skill gaps for each job profile.

During the development of the database, first of all, we carefully analysed the transversal occupations related to IS and EE in the sector and selected the most relevant ones. Afterwards, we determined their current skills needs. The main source used to identify and select not only the manufacturing-industry-related occupations but also their current needed skills was ESCO’s database (European Skills, Competences, Qualifications and Occupations) [33]. Then, we created an automated database that incorporates the definition of the job profiles as well as their skill requirements in the excel format. Then, in order to develop the future skills of the selected profiles, we carried out detailed desktop research to identify the anticipated skill needs of the manufacturing industry (presented in Section 2: Identifying the Future Skills Requirements for the Manufacturing Industries). This chapter provides deep and particularised insight into the subject. After completing the literature review, we analysed each of the chosen occupations individually and evaluated how they would be influenced by the industrial demands resulting from IS, EE and digitalisation. Finally, we identified the skills they would require in the future. Consequently, we incorporated all the information into our database and finalised the development process of the automated database.

The fundamental distinction of our database from conventional ones, such as ESCO, is that ours incorporates the foreseen skill requirements for each selected job profile. The ESCO database is a very useful and broad source for classifying the skills, competences, qualifications and occupations. Therefore, for the development of the current skills of our selected profiles, we used it efficiently. Nevertheless, it needs to be enriched regarding future skills due to the ongoing evolution of occupations. Therefore, in this work, we aimed to fill that gap and create a specific database for the manufacturing industry that provides the users with data about the new skills needed as a result of not only general but also sector-specific industrial changes, sustainability needs and innovations. This paper demonstrates not only the methodology of the development of the database but also provides insight into and a detailed analysis of the future skill needs of the manufacturing industry due to the ongoing technological changes and sustainability needs. We believe that this database will be a critical tool for the manufacturing industry, guiding the companies, universities, training centres and policymakers who are responsible for offering training programmes that deliver the needed qualifications to the manufacturing workforce and building the upskilled workforce that is really needed.

2. Identifying the Future Skill Requirements for the Manufacturing Industry

In this chapter, we focused on determining the manufacturing workforce’s future skill requirements. For this aim, firstly, we needed to identify the skill trends influencing the manufacturing sectors. To this end, we conducted extensive desk research, analysing related scientific papers, reports, sectorial and cross-sectorial guidelines and projects, previous studies of our research team [17,18,25,27,31] and, lastly, the work carried out by the experts of the SPIRE-SAIS project [32] (a team of experienced academics and industrial practitioners of at least 7 countries). Section 2.1 presents the general skill trends for the industry, and Section 2.2 tackles the future skill needs of its workforce. We used the captured findings in the development of the automated database, as presented in Section 3.2. Results and Discussion.

2.1. General Skill Trends for Manufacturing Sectors

The most crucial factor for determining the expected evolution of skill requirements is to have a broad picture of the future manufacturing sectors.

We can accomplish this by exploring the industrial developments brought on by Industry 4.0 and the sectorial requirements caused by sustainability, energy efficiency and environmental measures.

Industry 4.0 is a key factor for energy efficiency and industrial symbiosis. If the aim of Industry 4.0 is understood precisely and the current technological developments can be implemented accurately, these technologies can be utilised as an effective solution for the achievement of a circular economy, sustainability, industrial symbiosis and energy efficiency [27].

According to the complex scenarios related to Industry 4.0, in the near future, operators will be able to make more smart choices in less time thanks to real-time data from intelligent and automated production environments. Cooperative robotic systems will take over simple and monotonous tasks as workers perform highly skilled tasks and make critical decisions as a result of cutting-edge robotic technology [28]. Automated technologies will also enhance employee safety by allowing them to stay far away from machines [22].

Furthermore, with technological advances, upskilling the workforce will be necessary for concepts such as AI, human–robot collaboration, cybersecurity, digital twin, intelligent material and IoT [4,14,15,18,29,30,33].

Industrial businesses will adopt a more team-oriented strategy as artificial intelligence tools are integrated, and old top-down hierarchical systems will lose their strength. Collaboration between co-workers will become more important, as will collaboration between employees and support systems [34]. Job profiles will be expected to carry out jobs with a significantly greater range of responsibilities. As a result, individuals will be expected to have a broad range of knowledge and experience in a variety of fields [28].

The major perceived consequence of the changes in technology is the rapidly growing demand for technological skills [18,35]. These technological skills include basic and advanced digital skills, such as programming [11]. As a result of the increasing demand, security and data protection knowledge will become more crucial [30]. ICT skills will be required for lower-skilled occupations, such as technicians, to replace previously dangerous occupations and contribute to risk mitigation.

The quick rise in demand for social and emotional skills (something that machines are still far from learning) as a result of greater technology use is a crucial element to consider because the demand for these talents will rise [18]. Creativity, critical thinking, lifelong learning and other higher cognitive abilities, such as teamwork, problem-solving and decision-making, will be essential [16,18,29,36]. Regarding social skills, entrepreneurship, business and consumer awareness, as well as financial and legal skills, will additionally be necessary for occupations such as managers or engineers [37,38,39,40]. As previously stated, as industrial processes become increasingly automated and digitised, the workforce will be asked to carry out more complex tasks. Strong reading, numeracy, information and communication abilities, problem solving and certain soft skills, such as teamwork, coordination and autonomy, will be required to complete these tasks [35,40,41].

The demand for cognitive abilities will shift primarily from basic to higher cognitive skills as machines become more automated, reducing the number of tasks requiring fundamental thinking abilities (such as basic data processing) [38].

In addition, to achieve a simplified depiction of the larger picture, the workforce of the future will require abilities such as complexity management, complicated information processing and abstraction [35].

Moreover, the demand for management, communication and organisational abilities will rise dramatically [28]. Physical and manual abilities required for job profiles will be reshaped in response to the variety of automated work activities. These abilities will be in high demand for the foreseeable future, even though they will remain the most essential category of labour abilities [16,18].

Because of the impact of Industry 4.0, it is expected that in the near future, the workforce will demand more pronounced social, emotional, advanced cognitive and technological abilities than previously required basic cognitive, physical and mechanical skills [38,42].

The general trend also indicates that technological skills are in higher demand than administrative and technical abilities [16].

Apart from the transformation caused by Industry 4.0, as previously stated in Section 1, Europe’s goal to remain a competitive force in the industrial manufacturing sectors requires the construction of green skills as a way of boosting the focus on environmental concerns, sustainability and energy efficiency. Green skills will be highly critical for the future manufacturing sectors, and the workers will be expected to dominate skills related to Energy Efficiency (EE) and Industrial Symbiosis (IS) [43]. Concepts such as material reutilisation, waste reduction and management, recycling and reducing, and circular business models will be key skills for the upcoming future job profiles [3,6,8,15,20,42]. A master’s degree will be required in the European manufacturing business [6].

In general, workers from traditional manufacturing industries, such as chemicals, ceramics, cement, nonferrous metals, ceramics, minerals, steel, water, etc., will be continuously upgrading their skills to meet these skill trends [32].

2.2. Determination of Future Skill Requirements of the Sector

After determining the general skill trends and the manufacturing sector’s future scenario in the previous chapter, we can define the future skill requirements taking into account the changes brought on by digitalisation, as well as the concepts of sustainability, energy efficiency and industrial symbiosis.

The findings from all prior studies have been analysed and categorised into three groups: technological, green and social skills. Then, they were compiled into a database that covers future skill requirements for professional profiles in the manufacturing industry (presented in Section 3.2 Results and Discussion). The database will eventually act as a guide for occupations and competencies in the industrial industries.

After defining all future skills, the skills gaps among present and future industry demands are identified, and the final stage will be to recruit a highly competent labour force that can meet the expectations of the industrial sector. By supporting appropriate talent acquisition and recruitment, the sector will be able to include experts who are well-suited to the problems that digitalisation brings.

3. Development of the Sectorial Skills Database

This section presents the establishment of a database for the professional profiles of the manufacturing industry, incorporating both their present and future skill requirements. This database was created to be utilised as a guide for the subsequent creation of educational and training courses. This section discusses the methodology’s development and the findings of the conducted research.

3.1. Materials and Methods

During the creation of the database, to identify the transversal, IS- and EE-related occupations in the manufacturing industries and also define their current skills needs, we used one main reference: the ESCO database (European Classification of Skills, Competences, Qualifications and Occupations, developed by the European Commission).

The ESCO database allows the user to search by occupation, skill, competence or qualification that are considered relevant for the European Union labour market. The ESCO database involves 3008 occupations and 13,890 skills [43]. In our study, ESCO was the primary source for locating and selecting job profiles and their current skill requirements. For the selection of IS- and EE-related, transversal job profiles in the manufacturing sectors, a set of keywords was determined by the research group shown in Table 1. The defined keywords to identify the profiles that are directly related to IS and EE were “environment/al”, “waste”, “water”, “energy”, “recycling”, “contamination”, “renewable”, “pollution” and “energy efficiency”. In addition, “trainer” and “teacher” keywords were defined to include the trainer profiles. To find out the manufacturing-related profiles that would be directly affected by IS and EE, “maintenance” and “industrial production” keywords were used. These keywords were searched in the title of the profiles in the ESCO database. After analysing the job profiles with the aforementioned keywords, only the most relevant and representative job profiles at managerial and operational levels (manager, supervisor, technician and engineer) were selected in order to keep the number of the profiles low and increase the quality of our work.

Table 1.

The keywords to identify IS- and EE-related transversal job profiles in the manufacturing industry in the ESCO database.

Once we selected the most representative profiles, we used the ESCO database to define their present skill demands. The ESCO occupational profiles were then integrated into an Excel spreadsheet, along with their descriptions and current skills needs. Since the skill needs of each profile have two categories in the ESCO database—essential and optional—this categorisation was kept the same way in the new spreadsheet. After incorporating all the data in the spreadsheet, the second and key step in building the automated database for the selected job profiles of the manufacturing industry was applying Excel’s automated VBA (Visual Basic for Applications) method to the document.

Then, as mentioned above, we had to determine future competence needs of the selected profiles in order to create a database with the data of the future skill needs of the industry. For this aim, we conducted detailed desk research—presented in Section 2—in order to analyse and identify the future skill requirements of the manufacturing sectors. This study, which is basically a thorough literature review about the subject, has been our main source during the development of the future skill requirements. Another major reference for the development of future competences was the work carried out by our research team [17,18,21,25,27]. Therefore, after analysing these sources, we identified the general foreseen skill needs for the manufacturing sectors due to the ongoing technological changes and sustainability, IS and EE needs. After, we categorised them as technical, green and social skills in order to simplify them. The next step was to analyse how each selected job profile would transform in the future as a result of the industrial requirements related to sustainability, energy efficiency and industrial symbiosis and digitalisation concepts. After, we examined and determined which future skills were demanded by each profile. Whenever we detected a future skill need for an occupation, we evaluated if it is an essential or optional demand for the same occupation in the future and categorised it accordingly. After the analysis, the future skill needs for each job profile were entered manually into the created database and the process for the development of the automated sectorial database was completed.

In this work, we assumed that the current skill needs will be maintained in the future, even though we are aware of the fact that in some cases, the required level of mastery for each skill may evolve in time. Although new occupations in the manufacturing industry may appear in the future, this research has not considered the inclusion of possible future jobs. It has, therefore, been assumed that the selected profiles, with the established future competences, will be able to meet the skill needs of the manufacturing sectors.

Additionally, in the case of some of the occupations in our database, we detected that several current skill needs that had been categorised as “optional” by ESCO could be “essential” in the future for the same occupation. For this reason, this kind of current competences (in the optional category) was highlighted in red and introduced again in the future essential skills category, as they will gain importance in the near future.

Furthermore, in order to simplify and improve the quality of the developed database and make the future skills as compatible as possible with the ESCO database, whenever we identified a new future skill needed for the job profile, before introducing it to our database, we verified whether a similar competence had already been defined by the ESCO in their database. In the positive case, we replaced the identified future skill with its ESCO version and avoided repetitions.

In Table 2, the initial definition of the skills we identified and the definition of the same skills suggested by the ESCO database are presented as examples.

Table 2.

Identified skills and their ESCO version.

3.2. Results and Discussion

The purpose of our research was to create and automate a database of present and future skill requirements for transversal IS- and EE-related job profiles in the manufacturing industry.

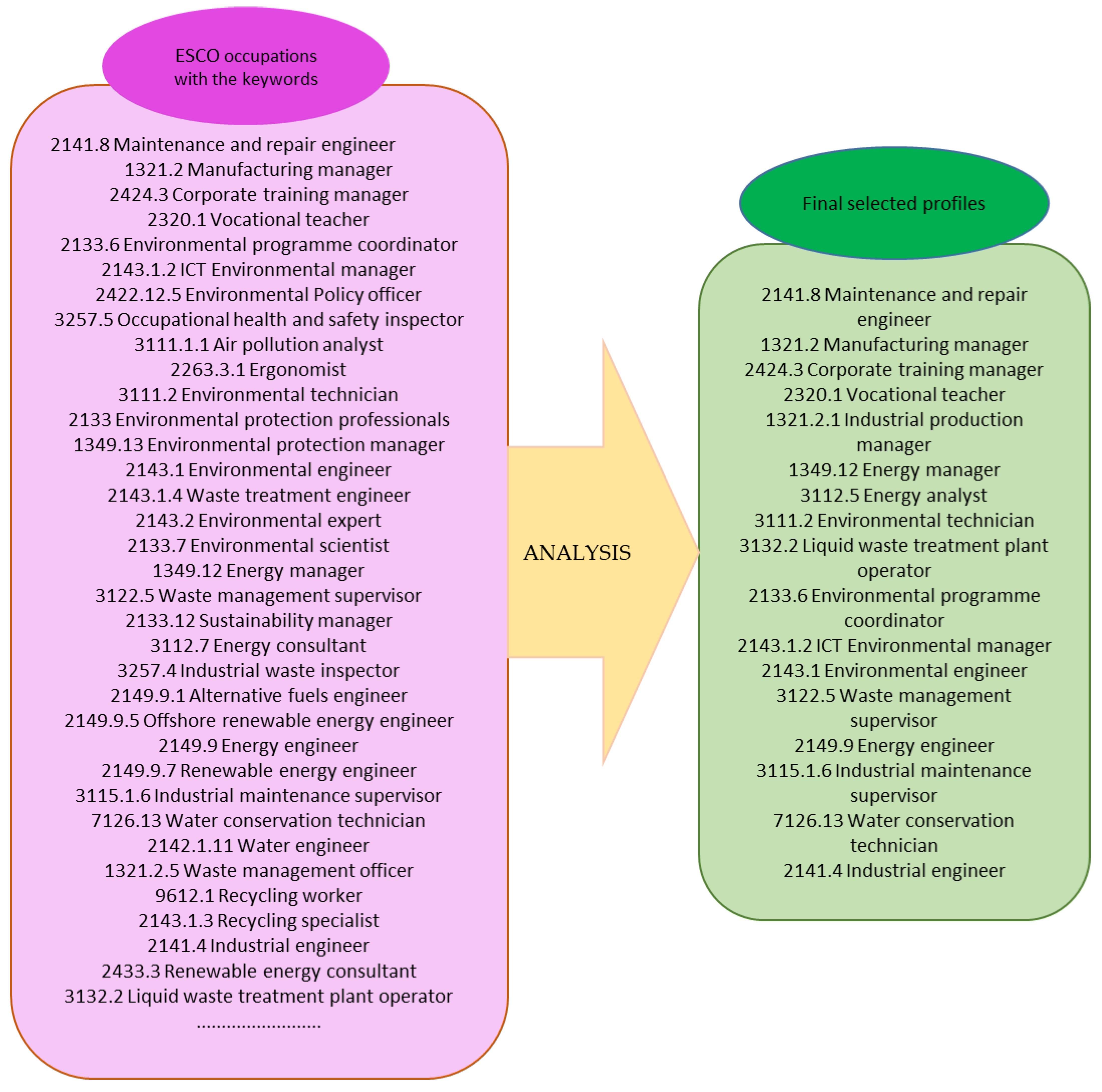

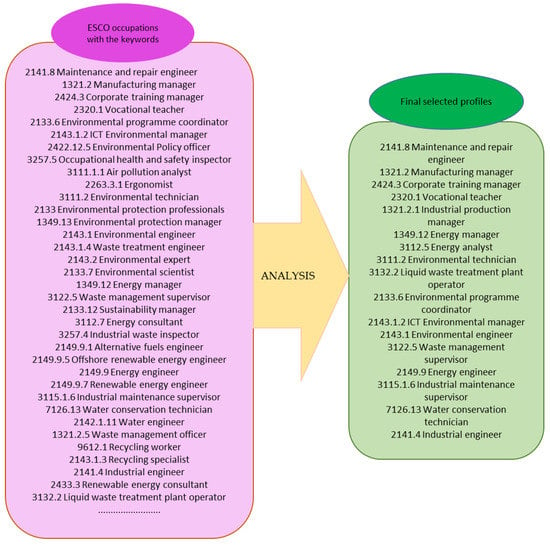

In order to identify the transversal job profiles of the manufacturing industry that are related with IS and EE, we introduced the IS- and EE-related keywords presented in the Methodology section (in Table 1) into the ESCO database. We gathered more than 70 occupations using these keywords. Through a detailed analysis applying the criteria demonstrated in the Methodology section, we selected 17 sector-related occupations among the first results. They were tagged as “technician”, “operator”, “manager” or “engineer”.

Figure 1 summarises the methodology and results of the process of identifying the most representative IS-, EE- and sustainability-related job profiles in the manufacturing industry.

Figure 1.

The process of selecting the relevant IS- and EE-related job profiles of the manufacturing industry and the final 17 ESCO profiles selected after the analysis (on the right).

We used ESCO’s research as the major source to identify current job profiles relevant to the manufacturing industry and the competencies required for each profile, as indicated in the Methodology Section. Therefore, profile descriptions and the current skill needs of each selected profile (presented in Figure 1) were taken directly from ESCO and incorporated into the created database. Table 3 provides us with a view of the database, showing the profile description, weblink, alternative labels and ISCO number of four selected occupations in the manufacturing industry. In addition, Table 4 presents another view of the created database: the current skill needs of these profiles. Additionally, in Table 4, the (optional) current skills highlighted in red are the ones that will become more important in the future and appear in the essential future skills category in Table 6. The full versions of Table 3 and Table 4 (with the selected job profiles) can be found in the Supplementary Materials.

Table 3.

An overview of the generated database: name of the job profile, weblink for ESCO, alternative labels for the profile, profile description and ISCO code.

Table 4.

An overview of the generated database: current skills needs of the selected job profiles, categorised as essential and optional.

The ESCO database is a very efficient and broad data source for classifying the skills, competences, qualifications and occupations. That is the main reason why we could use it effectively for the development of the current skill needs of the selected manufacturing industry occupations. However, ESCO could not provide us with predicted skill requirements for the same occupations, and we needed these data in order to generate our sectorial database. Therefore, the focus of our study has been to identify the future skill needs of the sector in general and of each specific occupation to complete the database. As mentioned in the methodology, through detailed research, we determined the new skill needs of the manufacturing industry caused by both general and sector-specific technological changes as well as environmental and sustainability requirements.

The identified future skills were divided into three categories: technological, green and personal. These categories and some skills that are part of each one can be seen in the following table (Table 5). The main contribution of our study to the database and the outcome of this research is the identified future skills. Only after having them identified could we analyse which future skills were demanded by each profile, evaluate if it is essential or optional and integrate them into the database. We finalised the generation of the database by this last step. Table 6 shows the identified future skill needs of the job profiles, both essential and optional, which were chosen from Table 5. The full versions of Table 6 (with the selected job profiles) can be found in the Supplementary Materials.

Table 5.

List of the identified future skills for the manufacturing industry.

Table 6.

An overview of the generated database: identified future skill needs of the selected job profiles, categorised as essential and optional.

In addition, the results of our work, the automated database and all the related data, were validated by the partners of the SPIRE-SAIS project.

Table 7 shows an example data sheet from the created database. In this table, we can see the “Maintenance and repair engineer” job profile as an example. The initial five rows in the table show the hierarchical order of the ESCO occupation groups that the “Maintenance and repair engineer” job profile belongs to; the first row, “professionals”, includes the second row, “the biggest”, and the fourth row, “engineering professionals”, and so on. The table also incorporates a direct link to ESCO’s webpage, where all the data in the table related to the job profile are available. In addition, we can find alternative names for the job profile. The ISCO number of the occupation, which can be defined as an international code, is provided by the database. Furthermore, the table shows the current skill requirements of the “Maintenance and repair engineer” profile (extracted from the database of ESCO), where the skills highlighted in red are the ones that will gain importance and be considered essential in the future. Finally, the table incorporates the future skill needs defined by this work.

Table 7.

The view of an example sheet from the database: “Maintenance and repair engineer”.

If we change the “Maintenance and repair engineer” occupation to another job profile, all the aforementioned data related to the new job profile will show up on the table automatically, replacing the previous information about the “Maintenance and repair engineer”. Thus, we call it a smart table, and the automation of the database makes this technology possible. This method makes the database a much more helpful and user-friendly tool since it allows the user to perform an instant search and achieve the result with only a short statement in a short period of time. Therefore, the database can be used very efficiently by companies, training developers, education centres and policymakers.

We also believe that the generated database with future skills could support the evolution and upgrades of the current ESCO database.

4. Conclusions

Over the last few years, emerging digitalisation and transformations towards a more sustainable and energy-efficient industry has profoundly affected the manufacturing sectors. These sectors’ processes are undergoing considerable changes from the implementation of smart technologies and newly introduced environmental regulations. Therefore, the industry needs a multi-skilled labour force that handles the challenges arising from the industry’s digital and green transformation and converts them into opportunities. This competent workforce can be generated by foreseeing the skill changes in the manufacturing industry and upskilling and reskilling the current labour force correspondingly.

In order to deal with this need, we developed an automated skill database for the most representative IS- and EE-related occupations in the manufacturing sectors. This database was created to incorporate not only current skill needs but also future ones in order to be an efficient tool for identifying the skill gaps for each profile. To determine the current skill needs and descriptions of the selected occupation, we used the ESCO database. However, we did not have any concrete database for future skill needs. Therefore, we needed to develop future skills in the database. For this aim, we performed detailed desktop research to identify foreseen skill requirements (presented in Section 2). After analysing the information, we incorporated it into the database. Therefore, our main contribution to the generated database is the development of future skills.

The main difference between our database and conventional ones, such as ESCO, is that ours includes the foreseen skill needs for each job profile. ESCO is a very well-developed and efficient database; however, it needs to be enhanced with respect to future skills due to the continuous evolution of job profiles. Our work aimed to fill that gap, and we generated a specific database for the manufacturing sectors that provides the end-users with information about the new skill requirements resulting from industrial changes and sustainability needs. In addition, the validation of the results was performed by the partners of the SPIRE-SAIS project.

The developed database can be used as a fundamental tool for manufacturing sectors, training and education programmes, universities or policymakers. It can be a guide for training programmes and, by applying the right training, for the sector. It will help to bridge the skill gap between what is expected of the industry and what currently exists. The results of the research are able to contribute to the continuous improvement of ESCO since the outcomes are compatible with the ESCO structure.

This study can also serve as a blueprint for future research on this subject.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/recycling7030032/s1, Table S1: An overview of the generated database: name of the job profile, weblink for ESCO, alternative labels for the profile, profile description and ISCO code; Table S2: An overview of the generated database: current skill needs of the selected job profiles, categorised as essential and optional; Table S3: An overview of the generated database: identified future skill needs of the selected job profiles, categorised as essential and optional.

Author Contributions

T.A., P.d.V. and A.G. took part in the writing, conceptualisation, methodology and investigation stages; A.O. took part in the conceptualisation and investigation stages. All authors have read and agreed to the published version of the manuscript.

Funding

The research described in the present paper was developed within the projects entitled “Skills and Competences Needed for the Maximization of Energy Efficiency and Industrial Symbiosis (S4SYMB)” and “Blueprint “New Skills Agenda Steel”: Industry-driven sustainable European Steel Skills Agenda and Strategy (ESSA)”. The S4SYMB project is funded by the Euskampus foundation and Siemens Gamesa Renewable Energy, whereas the ESSA project is funded by the Erasmus Plus Programme of the European Union, Grant Agreement No 2018-3019/001-001, Project No. 600886-1-2018-1-DE-EPPKA2-SSA-B. The sole responsibility for the issues treated in the present paper lies with the authors; the Commission is not responsible for any use that may be made of the information contained therein.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

All data generated in this research have been publicly posted as Supplementary Material.

Acknowledgments

The authors gratefully acknowledge the European Union for the opportunity granted, which has made the development of the present work possible. The authors also wish to thank all partners of the project for their support and the fruitful discussion that led to the successful completion of the present work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lieder, M.; Rashid, A. Towards Circular Economy Implementation: A Comprehensive Review in Context of Manufacturing Industry. J. Clean. Prod. 2016, 115, 36–51. [Google Scholar] [CrossRef]

- Behun, M.; Gavurova, B.; Tkacova, A.; Kotaskova, A. The Impact of the Manufacturing Industry on the Economic Cycle of European Union Countries. J. Compet. 2018, 10, 23–39. [Google Scholar] [CrossRef] [Green Version]

- European Commission. SETIS Magazine Digitalisation of the Energy Sector Looking Back 10 Years of Forward Thinking Set Plan Funding Low-Carbon Technologies Energy Systems Modelling Low-Carbon Heating and Cooling the Relevance of the Water-Energy Nexus for EU Policies Digitalis; European Commission: Brussels, Belgium, 2016. [Google Scholar]

- Bongomin, O.; Ocen, G.G.; Nganyi, E.O.; Musinguzi, A.; Omara, T. Exponential Disruptive Technologies and the Required Skills of Industry 4.0. J. Eng. 2020, 2020, 4280156. [Google Scholar] [CrossRef] [Green Version]

- International Renewable Energy Agency. Innovation Landscape for a Renewable-Powered Future: Solutions to Integrate Variable Renewables; IRENA: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- International Labour Organization. Skills for a Greener Future: A Global View Based on 32 Country Studies; International Labour Organization: Geneva, Switzerland, 2019. [Google Scholar]

- Ciliberto, C.; Szopik-Depczyńska, K.; Tarczyńska-Łuniewska, M.; Ruggieri, A.; Ioppolo, G. Enabling the Circular Economy Transition: A Sustainable Lean Manufacturing Recipe for Industry 4.0. Bus. Strategy Environ. 2021, 30, 3255–3272. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. World Energy Transitions Outlook 1.5 °C Pathway; IRENA: Abu Dhabi, United Arab Emirates, 2021. [Google Scholar]

- Eirini, S.; Nikos, R.; Konstantinos, K. Environmental Productivity Growth and Convergence of European Manufacturing Industries. Are They under Pressure? MPRA: Munich, Germany, 2022. [Google Scholar]

- Kueppers, M.; Pineda, S.N.P.; Metzger, M.; Huber, M.; Paulus, S.; Heger, H.J.; Niessen, S. Decarbonization Pathways of Worldwide Energy Systems—Definition and Modeling of Archetypes. Appl. Energy 2021, 285, 116438. [Google Scholar] [CrossRef]

- Borowski, P.F. Digitization, Digital Twins, Blockchain, and Industry 4.0 as Elements of Management Process in Enterprises in the Energy Sector. Energies 2021, 14, 1885. [Google Scholar] [CrossRef]

- Forum Energii. Energy Boost for Poland over Pln 580 Bn (Eur 132.2 Bn) and 240 000 New Jobs Will Lift Poland from the Recession, Modernise Its Economy, and Increase the Welfare of Poles; Forum Energii: Warsaw, Poland, 2020. [Google Scholar]

- Freddi, D. Digitalisation and Employment in Manufacturing Pace of the Digitalisation Process and Impact on Employment in Advanced Italian Manufacturing Companies. AI Soc. 2017, 33, 393–403. [Google Scholar] [CrossRef]

- Ghobakhloo, M. The Future of Manufacturing Industry: A Strategic Roadmap toward Industry 4.0. J. Manuf. Technol. Manag. 2018, 29, 910–936. [Google Scholar] [CrossRef] [Green Version]

- Akyazi, T.; Goti, A.; Oyarbide, A.; Alberdi, E.; Bayon, F. A Guide for the Food Industry to Meet the Future Skills Requirements Emerging with Industry 4.0. Foods 2020, 9, 492. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akyazi, T.; Goti, A.; Oyarbide-Zubillaga, A.; Alberdi, E.; Carballedo, R.; Ibeas, R.; Garcia-Bringas, P. Skills Requirements for the European Machine Tool Sector Emerging from Its Digitalization. Metals 2020, 10, 1665. [Google Scholar] [CrossRef]

- European Commission. Economic and Social Committee, the Committee of the Regions and the European Investment Bank Investing in a Smart, Innovative and Sustainable Industry a Renewed EU Industrial Policy Strategy; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- Jacques, B.; Eric, H.; Susan, L.; Peter, D.; Anna, W.; Subramaniam, A. Automation and the Workforce of the Future; McKinsey: New York, NY, USA, 2018. [Google Scholar]

- Hernandez, D.M.; Peralta, G.; Manero, L.; Gomez, R.; Bilbao, J.; Zubia, C. Energy and Coverage Study of LPWAN Schemes for Industry 4.0. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and Their Application to Mechatronics (ECMSM), Donostia, Spain, 24–26 May 2017. [Google Scholar] [CrossRef]

- Arcelay, I.; Goti, A.; Oyarbide-Zubillaga, A.; Akyazi, T.; Alberdi, E.; Garcia-Bringas, P. Definition of the Future Skills Needs of Job Profiles in the Renewable Energy Sector. Energies 2021, 14, 2609. [Google Scholar] [CrossRef]

- Faheem, M.; Shah, S.B.H.; Butt, R.A.; Raza, B.; Anwar, M.; Ashraf, M.W.; Ngadi, M.A.; Gungor, V.C. Smart Grid Communication and Information Technologies in the Perspective of Industry 4.0: Opportunities and Challenges. Comput. Sci. Rev. 2018, 30, 1–30. [Google Scholar] [CrossRef]

- Market Prospects the History of Industry 4.0 and How to Changing Machine Tools|Market Prospects. Available online: https://www.market-prospects.com/articles/industry-4-0-how-to-changing-machine-tools (accessed on 5 April 2022).

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2018, 6, 6505–6519. [Google Scholar] [CrossRef]

- Rafael, L.D.; Jaione, G.E.; Cristina, L.; Ibon, S.L. An Industry 4.0 Maturity Model for Machine Tool Companies. Technol. Forecast. Soc. Chang. 2020, 159, 120203. [Google Scholar] [CrossRef]

- Akyazi, T.; Oyarbide, A.; Goti, A.; Gaviria, J.; Bayon, F. Creating a Roadmap for Professional Skills in Industry 4.0. Hydrocarb. Process. 2020, 99, 50–51. [Google Scholar]

- Hecklau, F.; Orth, R.; Kidschun, F.; Orth, R.; Kohl, H. Human Resources Management: Meta-Study-Analysis of Future Competences in Industry 4.0. In Proceedings of the 3th European Conference on Management, Leadership and Governance, London, UK, 11–12 December 2017. [Google Scholar]

- Vella, K.; Reines, R.; Gontarz, A.; Group, C.T.M. The European Machine Tool Sector and the Circular Economy; CECIMO: Brussels, Belgium, 2019. [Google Scholar]

- European Commission. European Commission; European Commission: Brussels, Belgium, 2019. [Google Scholar]

- Czako, V. Employment in the Energy Sector Status Report 2020; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar] [CrossRef]

- Del Castillo Vera, E.P.P.P.; Jens Geier, S.S. BRIEFING EU Legislation in Progress Proposal for a Regulation Establishing the European Cybersecurity Industrial, Technology and Research Competence Centre and the Network of National Coordination Centres; EPRS European Parliamentary Research Service: Brussels, Belgium, 2021. [Google Scholar]

- Akyazi, T.; Alvarez, I.; Alberdi, E.; Oyarbide-Zubillaga, A.; Goti, A.; Bayon, F. Skills Needs of the Civil Engineering Sector in the European Union Countries: Current Situation and Future Trends. Appl. Sci. 2020, 10, 7226. [Google Scholar] [CrossRef]

- Spire-Sais Skills Alliance for Industrial Symbiosis—A Cross-Sectoral Blueprint for a Sustainable Process Industry|SPIRE. Available online: https://www.aspire2050.eu/sais (accessed on 14 April 2022).

- Accenture Building Greater Cyber Resilience in Renewables|Accenture. 2020. Available online: https://www.accenture.com/_acnmedia/PDF-125/Accenture-Cybersecurity-Renewables-Services.pdf#zoom=50 (accessed on 16 April 2022).

- Lindzon, J. How AI Is Changing the Way Companies Are Organized. Available online: https://www.fastcompany.com/3068492/how-ai-is-changing-the-way-companies-are-organized (accessed on 4 April 2022).

- Deming, D.J.; Barrera-Osorio, F.; Chandra, A.; Khwaja, A.; Manning, A.; Michaels, G.; Miratrix, L.; Muralid-haran, K.; Pager, D.; Rogers, T.; et al. The Growing Importance of Social Skills in the Labor Market. Q. J. Econ. 2017, 132, 1593–1640. [Google Scholar] [CrossRef] [Green Version]

- ISCO. International Standard Classification of Occupations; ILO: Geneva, Switzerland, 2012. [Google Scholar]

- Chan, S.W.; Zaman, I.; Ahmad, M.F.; Zaman, I.; Ko, W.S. Employers’ Perception on Important Employability Skills in the Manufacturing Industry E-Procurement Technology for Sustainable Procurement View Project Supply Chain Development for Entrepreneurship and Business View Project Employers’ Perception on Important Employability Skills in the Manufacturing Industry. Int. J. Eng. Technol. 2018, 7, 170–175. [Google Scholar] [CrossRef]

- Hecklau, F.; Orth, R.; Kidschun, F.; Orth, R.; Kohl, H. Human Resources Management: Meta-Study-Analysis of Future Competences in Industry 4.0. In Proceedings of the International Conference on Intellectual Capital, Knowledge Management & Organizational Learning, Hong Kong, China, 7–8 December 2017; pp. 163–174. [Google Scholar]

- Froy, F.; Giguère, S.; Meghnagi, M. Skills for Competitiveness: A Synthesis Report; OECD: Paris, France, 2012. [Google Scholar]

- Overton, T.; Mcgarvey, D.J. Development of Key Skills and Attributes in Chemistry. Chem. Educ. Res. Pract. 2017, 18, 401. [Google Scholar] [CrossRef]

- Grundke, R.; Jamet, S.; Kalamova, M.; Squicciarini, M. Having the Right Mix: The Role of Skill Bundles for Comparative Advantage and Industry Performance in GVCs; OECD: Paris, France, 2017. [Google Scholar] [CrossRef]

- University of Cambridge Institute for Sustainability Leadership (CISL). Working towards a Climate Neutral Europe: Jobs and Skills in a Changing World; CISL: Cambridge, UK, 2020. [Google Scholar]

- Esco. Available online: https://esco.ec.europa.eu/en/classification/occupation_main (accessed on 8 April 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).