Abstract

Brewer’s spent grain (BSG), a by-product originating from the brewing industry, contains substantial amounts of fibers, proteins, and bioactive compounds; however, its utility is restricted by anti-nutritional factors. Solid-state fermentation (SSF) presents a viable method for improving the nutritional and functional properties of BSG. Microorganisms such as Rhizopus oligosporus have been demonstrated to enhance nutrient bioavailability, facilitate the degradation of complex carbohydrates, and improve protein digestibility while simultaneously reducing anti-nutritional components. Furthermore, this fermentation process yields bioactive compounds that exhibit antioxidant, anti-inflammatory, and prebiotic properties, thereby contributing to improved gut health, the prevention of metabolic disorders, and enhanced nutritional outcomes. Additionally, SSF seeks sustainability by repurposing agro-industrial by-products, reducing waste, and promoting the principles of a circular economy. Collectively, these advantages underscore the transformative potential of SSF in converting BSG into a functional food ingredient, effectively addressing contemporary health and environmental challenges and offering innovative solutions for food security and sustainable development.

1. Introduction

Brewers’ spent grain (BSG) is the most significant by-product of the brewing industry, accounting for approximately 85% of the total solid by-products generated during brewing and 30% of the malt weight [1]. Global annual BSG production is estimated to range between 3.4 and 4.5 million tons. Despite being a cereal by-product without starch and sugars and its remaining nutritional richness—comprising fibers, proteins, lipids, vitamins, and minerals—BSG is often undervalued due to its low market price, high moisture content, and susceptibility to microbial contamination. These challenges present a compelling opportunity to explore effective valorization strategies to transform BSG into value-added products [2].

The brewing process involves a sequence of complex steps designed to maximize the utilization of raw materials, primarily barley grains. Key stages include malting, milling, mashing, lautering, boiling, wort cooling, and fermentation. During mashing, starch is extracted from barley grains, leaving behind insoluble solid residues referred to as BSG. The sugary liquid by-product, known as wort, is subsequently fermented to produce beer [3].

The chemical composition of BSG is influenced by several factors, including the type of barley, the season of harvest, the brewing methodology employed, and the conditions under which processing occurs. On a dry-weight basis, BSG typically comprises approximately 70% lignocellulosic fibers and 20% proteins [4]. These fibers primarily consist of hemicellulose (28%), cellulose (16%), and lignin (7%), which collectively contribute to the resistance of BSG to degradation. Furthermore, BSG contains carbohydrates such as glucose, xylose, arabinose, oligosaccharides, and polysaccharides. The predominant proteins present in BSG are hordeins, glutelins, globulins, and albumins, while the lipid content constitutes approximately 10%, primarily in the form of triglycerides and free fatty acids [5].

BSG is also rich in amino acids, including essential ones like phenylalanine, lysine, tryptophan, histidine, and methionine, as well as non-essential amino acids such as alanine, glycine, proline, and serine. Furthermore, it contains vitamins like biotin, choline, pantothenic acid, folic acid, niacin, riboflavin, thiamine, and pyridoxine, along with minerals such as phosphorus, calcium, potassium, iron, magnesium, and selenium. Phenolic compounds, notably ferulic acid and p-coumaric acid, are also abundant in BSG [6].

Despite its nutritional and biochemical potential, the high moisture content of BSG (approximately 80%) renders it highly susceptible to microbial activity, limiting its shelf life to about 7–10 days. Environmentally, the disposal of BSG contributes to significant greenhouse gas emissions, producing over 513 kg of CO2 equivalents per ton when sent to landfills [7]. Logistically, its high moisture content increases transportation and storage costs, further complicating its utilization. Currently, around 70% of BSG is used as livestock feed, 10% is converted to biogas, and the remaining 20% is discarded in landfills [7]. BSG has also been dried and milled, and BSG powder produced by ReGrained in California [8] is being used in nutritional bars, bakery, and pasta products, and has been evaluated by our research team and considered to have potential health benefits in human diets [9].

Solid-state fermentation (SSF) has emerged as a promising strategy for managing agro-industrial by-products like BSG. SSF enables the production of enzymes and secondary metabolites with diverse industrial applications, including pharmaceuticals. Unlike submerged liquid fermentation (SmF), SSF offers advantages such as lower energy requirements, more stable products, compact fermenters, and simplified downstream processes [10].

While significant research has focused on using BSG as a substrate for the microbial production of enzymes and secondary metabolites, studies exploring its fermentation for functional food applications remain limited. Some investigations have examined the use of fermented BSG as a functional food or enriched animal feed, but its potential for targeted fermentation and broader industrial applications has yet to be fully realized [11].

The growing interest in leveraging agro-industrial waste for health and technological benefits has been driven by factors such as increasing environmental awareness, rising waste management costs, and the commercial potential of bioactive components. Regulatory frameworks now encourage the valorization of by-products by extracting high-value compounds for functional foods, food processing aids, or medicinal applications [12].

This review explores the biotechnological valorization of BSG through SSF by various microbial species, emphasizing its implications for consumer nutrition and health. Additionally, it highlights key factors that influence fermentation processes, compares submerged fermentation to solid-state fermentation, and examines the industrial potential of BSG valorization.

This narrative review was conducted by following a structured literature search in PubMed, Scopus, Web of Science, and Google Scholar, prioritizing open-access articles published in English. The search strategy employed the following keywords and their combinations: “brewer’s spent grain”, “solid-state fermentation”, “Rhizopus oligosporus”, “dietary fiber”, and “functional food”. Literature screening was carried out in two stages: (1) title and abstract review to identify articles addressing BSG composition, SSF processes, nutritional and functional improvements, or health effects; and (2) full-text evaluation to confirm relevance and methodological rigor. Inclusion criteria comprised studies that: (1) investigated BSG composition and/or modifications through SSF; (2) evaluated the functional or nutritional properties of fermented BSG; and (3) reported potential applications in human of functional food development. Exclusion criteria included: (1) studies unrelated to BSG; (2) research focused solely on liquid fermentation processes; and (3) articles lacking sufficient methodological detail or scientific rigor. The selected literature was qualitatively analyzed to identify key trends, technological approaches, and functional implications of BSG fermentation with R. oligosporus. No meta-analysis was performed.

2. Valorization of Brewer’s Spent Grain: A Sustainable Approach to Food, Feed, and Biotechnology

This section aims to provide a comprehensive overview of the importance and potential of valorizing BSG within the context of sustainable food systems, waste reduction, and circular economy strategies. A major by-product of beer production, BSG offers environmental, nutritional, economic, and technological value when appropriately repurposed.

Beer is the fifth most consumed beverage globally, with production reaching 1.89 billion hectoliters in 2022 [13,14,15], generating approximately 20 kg of BSG per hectoliter (100 L) of beer. This translates into vast quantities of underutilized biomass that, if discarded, contribute to environmental waste. However, BSG can be redirected toward productive applications in food, feed, and biotechnology, illustrating its role in circular economy models, which emphasize recycling and reusing sources to minimize environmental impact and support sustainable development [11,13,14,15,16].

Despite its potential, the high moisture content of fresh BSG presents challenges in handling, storage, and transportation due to spoilage risks. To overcome these barriers and extend shelf life, preservation strategies such as drying, fermentation, and ensiling have been explored [5,17].

Nutritionally, BSG is rich in dietary fiber, proteins, and lipids, making it a valuable ingredient for various food and feed applications. Its composition, however, depends on grain type and brewing method; for instance, barley-based BSG is generally higher in fiber, while wheat-based BSG may contain more protein [12,18,19]. These variations must be considered when formulating targeted nutritional products.

In food systems, incorporating BSG has been shown to improve fiber content and contribute to functional benefits, such as enhanced texture and moisture retention. Moreover, BSG serves as a substrate for extracting bioactive compounds (e.g., phenolics and peptides), which possess antioxidant activity useful in food preservation and packaging applications [18,19,20,21]. Biotechnologically, BSG can support microbial fermentation, enabling the production of enzymes, metabolites, and other compounds valuable to industrial and pharmaceutical sectors [6].

From an ecological standpoint, diverting BSG from waste streams reduces methane emissions and decreases the carbon footprint of the brewing industry. These environmental gains, in turn, indirectly support public health by improving air quality and conserving ecosystems [7].

Economically, BSG valorization reduces disposal costs and creates new revenue opportunities for breweries and food producers. Its abundance and low cost make it an appealing raw material for developing affordable and sustainable food and feed products, particularly in places with high beer production.

In summary, the valorization of BSG offers a multifaceted opportunity-linking environmental sustainability, food and feed innovation, and industrial biotechnology. This positions BSG as a strategic ingredient for developing greener and more resilient production systems.

3. The Brewing Process: From Malted Barley to Brewer’s Spent Grain

Beer production begins with carefully selecting essential ingredients: malted barley, hops, and yeast. The process starts with malting the barley, where the grains are soaked in water for an extended period to ensure proper hydration. The hydrated grains are then spread in thin layers and kept under controlled temperature and humidity conditions to facilitate germination. During germination, enzymes become active and break down stored starches into simpler sugars. Once the desired germination stage is reached, the process is stopped by drying the grains. The drying time and temperature influence the type of malt produced, each characterized by unique flavors, colors, and aromas. In some beer recipes, the malt undergoes additional curing at higher temperatures, enhancing its flavor profile and contributing to darker hues. Subsequently, the dried malt is milled to optimize sugar extraction during the mashing process. In this step, the milled malt is mixed with hot water, allowing enzymes to convert starches into fermentable sugars. This process typically takes place at temperatures between 65 °C and 70 °C for approximately 60 to 90 min. At the same time, soluble compounds such as sugars and proteins are released. Malt proteins are partially hydrolyzed into peptides and amino acids, facilitated by the degradation of the barley grain’s cell walls [1].

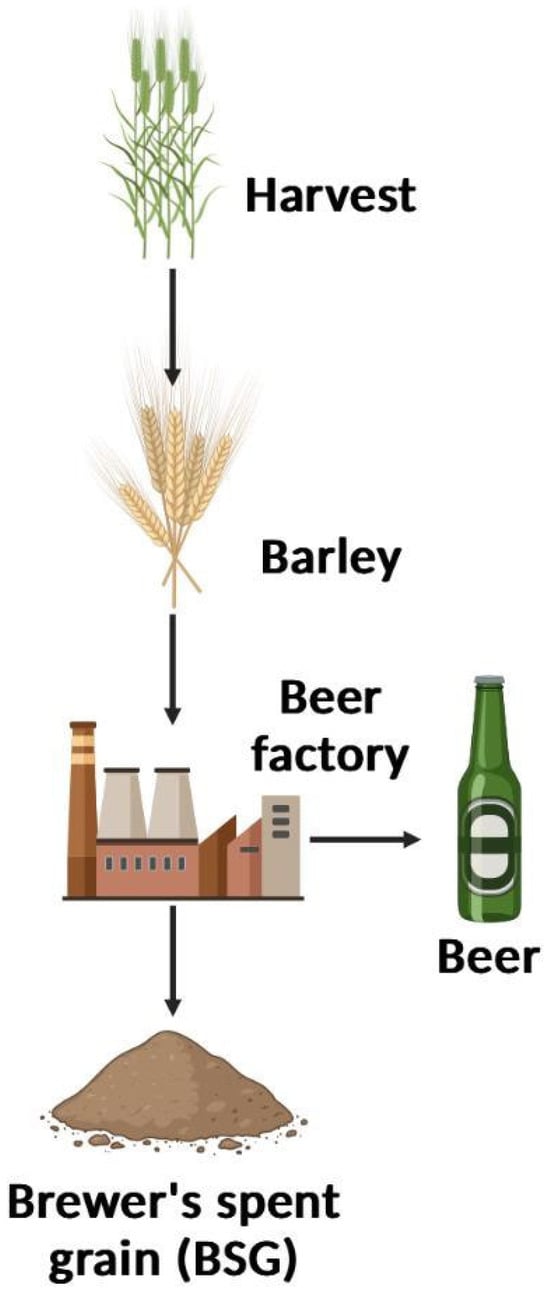

After mashing, the resulting liquid, known as wort, is separated from the solid by-products, the BSG, through filtration. The wort is collected and transferred to fermentation tanks to continue the brewing process, while the BSG is set aside as a by-product [16], as shown in Figure 1.

Figure 1.

Beer brewing process for the generation of brewer’s spent grain (BSG) as a by-product from barley processing.

Several factors influence the quality and composition of BSG, including mashing temperature, duration, and the yeast strain used. For instance, higher mashing temperatures or extended mashing times can enhance starch breakdown, altering the nutrient profile of BSG. Similarly, different yeast strains impact BSG composition by fermenting sugars in varying ways. Barley, the primary ingredient in beer production, comprises three main components: germ (embryo), endosperm (including aleurone layer and starchy endosperm), and grain coverings. Grain coverings consist of the seed coat, pericarp layers, and husk, arranged from inner to outermost layers. In traditional brewing methods that utilize a lauter tun, BSG plays a critical role by forming a filtration bed that separates the wort from the mash. For this reason, malt must be milled carefully to preserve the integrity of grain coverings, ensuring effective filtration. In modern large-scale breweries, mash filters are often employed, reducing reliance on BSG’s filtration properties and allowing for finer milling of the malt. However, many small and craft breweries continue to embrace traditional filtration methods, which rely on BSG to maintain wort clarity and quality [2].

4. Nutritional Composition of Brewer’s Spent Grain

BSG primarily consists of the husks of barley malt grains, along with portions of the pericarp and seed coat layers. It is well known for its richness in sugars, proteins, and minerals, although the chemical composition of BSG can vary significantly. The composition of BSG varies significantly due to multiple factors, including the variety of materials used, the harvest date, the growing conditions, as well as the stages of the beer production process [5]. BSG is distinguished by a macronutrient profile marked by its high fiber content, moderate protein levels, and remaining carbohydrates, which make it a beneficial by-product in nutritional uses. Several studies have examined its composition and have noted differences in the amounts of protein, fiber, lipids, and carbohydrates [2]. Table 1 presents a summary of macronutrients from different authors, illustrating the variability and potential use of BSG in food formulations.

Table 1.

Chemical composition of BSG reported by different authors.

The dietary fiber content in BSG is especially remarkable, ranging from 30% to 70% [6]. This fiber is predominantly insoluble, comprising cellulose, hemicellulose, and lignin, which classifies BSG as a lignocellulosic material [5,9]. Insoluble fiber plays a crucial role in human digestive health by promoting bowel regularity and preventing constipation [24]. Furthermore, it enhances feelings of fullness and satiety, potentially providing benefits for weight management and obesity prevention [25,26]. The soluble fiber fraction of BSG, particularly arabinoxylans, exhibits prebiotic properties, supporting beneficial gut microbiota such as Bifidobacteria and Lactobacillus, which contribute to overall gut health [6,24]. Furthermore, studies indicate that the consumption of BSG can improve lipid profiles and reduce fat absorption, positively impacting metabolic health [25].

Beyond its fiber content, BSG is a significant source of protein, containing levels that range from 15 to 30% on a dry weight basis. This characteristic highlights its potential to meet the increasing demand for macronutrient-rich ingredients in the development of functional foods [27]. The protein in BSG is noted for its diverse amino acid profile, which is vital for various physiological functions in humans. Incorporating BSG-derived protein into food matrices elevates their nutritional value and contributes to enhancing their techno-functional properties, such as texture, emulsification, and water retention capacity, thus conferring distinct advantages which are essential for ensuring product quality in the resulting food formulations [6,25,28,29]. The protein quality of BSG can vary based on the malting and brewing processes, which may influence both the digestibility and bioavailability of these proteins [29]. In addition, protein content in BSG differs across various batches and brewing methods, influenced by the type of malt and fermentation conditions used. It has been observed that fermentation substantially improves the protein digestibility of BSG, consequently enhancing its biological value and in vivo bioavailability. Furthermore, fermentation converts complex proteins into bioactive peptides, which exhibit antioxidant, antimicrobial, and blood pressure-regulating properties [30].

Amino acid composition can differ based on diverse factors, including the type of barley, malting conditions, and brewing process parameters. Compared to whole barley, BSG frequently exhibits higher levels of specific amino acids due to the partial degradation of protein that occurs during mashing [22]. Table 2 illustrates the comparative analysis of amino acid content between BSG and barley.

Table 2.

Amino acid composition of BSG and barley.

Essential amino acids, including methionine, phenylalanine, tryptophan, histidine, and lysine, play a crucial role in human health, enhancing the nutritional quality of ingredients and supporting functions such as protein synthesis, enzyme production, and muscle maintenance [26]. Histidine, in particular, boosts the antioxidant capacity of BSG by facilitating the formation of melanoidins during the Maillard reaction, which adds functional benefits in food applications [20]. Lysine, often limited in cereal-based diets, makes BSG a valuable supplement for improving overall amino acid balance. Notably, the classification of essential amino acids in the table is based on the nutritional requirements of adult mammals, specifically humans. The amino acid profile of BSG is therefore a key indicator of its nutritional quality and potential dietary benefits. Moreover, processing methods such as fermentation can further enhance protein digestibility and amino acid bioavailability, maximizing its nutritional potential. Overall, the amino acid composition and protein content of BSG position it as a promising ingredient for addressing dietary deficiencies and enriching food formulations [31].

The lipid content of BSG is relatively low, typically around 10%. However, it contains fatty acids that play a crucial role in various metabolic processes. Lipid profile can vary depending on the brewing process and the specific barley varieties used, thus influencing its potential applications in food products [6,29].

BSG is rich in essential minerals such as potassium, magnesium, calcium, and phosphorus, all of which play crucial roles in various physiological functions within the human body. The mineral content may vary depending on the brewing process and the raw materials utilized; however, studies show that BSG can provide a significant amount of these nutrients. For instance, BSG derived from malted barley may supply over 20% of the daily potassium and magnesium requirements, depending on the fermentation conditions and type of grain used. Furthermore, research has demonstrated that the nutrient content in BSG can be enhanced or optimized through processing techniques such as germination and fermentation [6,26].

In addition to its mineral content, BSG is rich in several vitamins, particularly B vitamins like niacin, riboflavin, and folate, which are crucial for energy metabolism and maintenance of healthy skin and nerves. Notably, folate and riboflavin are key to cellular health and brain function, making BSG a valuable ingredient in food products aimed at supporting brain health and preventing neurodegenerative diseases [26].

Notably, BSG contains several bioactive compounds, including phenolic acids such as ferulic acid and p-coumaric acid, which are recognized for their antioxidant properties [20,24]. These compounds are primarily located in the cell walls of barley and are associated with various health benefits, including anti-inflammatory and anti-carcinogenic effects [32]. The antioxidant activity of these phenolic acids helps neutralize free radicals in the body, thereby reducing oxidative stress that is linked to numerous chronic diseases, including cardiovascular diseases and cancer. These antioxidants can enhance the health benefits of BSG-enriched products, making it a valuable ingredient in functional foods. Research has indicated that the bioavailability of phenolic compounds in BSG can be improved through various processing methods, such as fermentation and thermal treatment. These processes can release compounds from their bound forms, leading to increased bioavailability, which in turn can enhance the functional properties of BSG when used in food formulations. This makes BSG a promising ingredient for health-focused products [24].

5. Health Benefits of Brewer’s Spent Grain

The composition of BSG significantly influences its nutritional characteristics, with particular emphasis placed on its fiber and phenolic compound content [9,33]. Arabinoxylans (AXs) represent the predominant hemicellulose present in BSG, contributing to its substantial dietary fiber content. AXs may constitute up to 28% of the dry weight of BSG, surpassing equivalent values found in barley and wheat. These compounds are composed of xylopyranosyl residues that possess arabinofuranose side chains, which enhance their solubility and functional properties [34]. The water-extractable form of AXs functions as a prebiotic, being fermented by gut bacteria such as Bifidobacteria and Lactobacillus. A healthy population of these bacteria is critical for maintaining gut health, as their fermentation activity leads to the production of beneficial short-chain fatty acids (SCFAs) such as butyrate [35,36]. The production of SCFAs is generally recognized as advantageous, given their role in protecting the host from pathogens, inducing immune responses, reducing cholesterol synthesis, stimulating colonic blood flow, enhancing muscular contractions, and safeguarding the colon against carcinogenesis [35,36]. Consumption of AXs has been demonstrated to regulate postprandial blood sugar levels by increasing the viscosity of gastrointestinal contents [5,37]. This effect slows gastric emptying and intestinal transit, resulting in a gradual release of glucose and a moderated insulin response, thereby assisting in the modulation of postprandial glycemic responses. Lignin, another important fiber component of BSG, promotes bifidobacterial growth in the gut and may exhibit antioxidant properties due to its partial degradation by gut microbiota [38]. The presence of lignin in dietary fiber is noteworthy not only because it is indigestible but also due to its interactions with other dietary components, influencing their absorption and metabolic pathways. Lignin possesses potential health benefits, including antioxidant capabilities and the ability to bind bile acids, which may contribute to cholesterol management. Moreover, the structural properties of lignin facilitate the formation of complexes with other nutrients, potentially enhancing their bioavailability and efficacy within the gastrointestinal tract. The interaction of lignin with gut microbiota warrants further investigation, as a thorough understanding of these dynamics could lead to improved applications of BSG in functional foods aimed at enhancing digestive health [35,38]. β-glucans, although present in smaller quantities, provide cardiovascular advantages, including cholesterol reduction. The beneficial effects of β-glucans on health are attributed to their ability to dissolve and form a gel-like consistency that increases gastrointestinal viscosity. This heightened viscosity reduces the reabsorption of bile acids and stimulates the synthesis of bile acids from cholesterol, effectively lowering cholesterol levels [39]. A daily intake of at least 3 g of barley-derived β-glucans is recommended [40,41], making BSG a valuable source of soluble fiber. While the precise mechanisms by which dietary fibers influence immune modulation remain to be fully elucidated, it is known that specialized M cells in the gut can absorb these fibers, triggering cytokine production [42]. The dietary fibers present in BSG, particularly AXs and β-glucans, provide significant health benefits, including enhanced gut health, effective cholesterol management, and potential prebiotic effects [9,11].

The protein content of BSG typically ranges from 15% to 30% of its dry weight, making it noteworthy due to its rich lysine content—a vital amino acid often lacking in other cereals. This characteristic positions BSG as a promising protein source, particularly for the creation of plant-based protein isolates and hydrolysates that offer health benefits. Research has underscored the potential of proteins derived from BSG for their antioxidant, antihypertensive, and immunomodulatory properties. Enzymatically produced hydrolysates have shown promise in managing conditions such as diabetes and hypertension [33,43]. While dairy products have largely dominated the field of bioactive peptide research, BSG is emerging as a valuable plant-derived alternative. Protein hydrolysates from various crops have been noted for their significant antioxidant and blood pressure-lowering effects. Although BSG hydrolysates exhibit lower antioxidant activity, they effectively inhibit the pro-inflammatory cytokine IFN-γ [11].

Phenolic compounds, particularly hydroxycinnamic acids such as ferulic acid and p-coumaric acid, are found in abundance in BSG and possess antioxidant, anti-carcinogenic, and immunomodulatory properties. Research highlights the protective effect of these compounds against oxidative DNA damage and inflammation, a known contributor to chronic diseases such as colorectal cancer. Ferulic acid and p-coumaric acid are two of the predominant phenolic compounds in BSG [24], both exhibiting strong antioxidant activity that aids in defending against oxidative stress [20]. Their effectiveness can be further enhanced through various treatments and enzymatic hydrolysis.

These phenolic compounds have also been shown to inhibit acetylcholinesterase and butyrylcholinesterase, enzymes linked to neurodegenerative diseases. They offer additional protection against oxidative DNA damage and counteract neurotoxic effects, underscoring their potential role in neuroprotection [44]. Emerging studies emphasize the anti-inflammatory and anti-carcinogenic attributes of ferulic acid and p-coumaric acid. These compounds can inhibit the formation of carcinogenic nitrosamines and mitigate oxidant-induced DNA damage, indicating their possible applications in cancer prevention [33].

Furthermore, research highlights their lipid-lowering and cardioprotective properties, particularly in preventing the oxidation of low-density lipoprotein (LDL) cholesterol, a critical factor for cardiovascular health [45]. Continued exploration into the extraction, detailed characterization, and practical applications of these compounds could pave the way for the development of innovative functional foods and nutraceuticals [46].

6. Strategies to Improve the Bioavailability of Nutrients in Brewer’s Spent Grain

BSG is a substantial by-product of the brewing industry, constituting a valuable source of nutrients, including proteins, dietary fibers, vitamins, and phenolic compounds. However, the bioavailability of these nutrients is often limited by the structural complexity of BSG and the presence of anti-nutritional factors. To optimize nutrient bioavailability, a variety of strategies, such as physical processing, fermentation, and integration into different food matrices, have been explored [9,11].

Incorporating BSG into various food matrices is one of the promising approaches to enhance nutrient bioavailability. Blending BSG with other flours such as sorghum or groundnut cake can produce functional food products that not only preserve BSG’s nutritional value but also improve the sensory attributes of the final products [26,44]. This integration not only promotes BSG utilization in human nutrition but also contributes to the circular economy by reducing food waste [47].

Additionally, optimizing the processing conditions, including temperature and moisture content, during the preparation of BSG-enriched products significantly affects the final nutrient profile and consumer acceptance [48]. For instance, adjusting the moisture content during baking can improve the texture and palatability of BSG-enriched products, making them more appealing to consumers [29,49].

7. Physical Processing to Enhance BSG Nutrient Bioavailability

BSG, which accounts for approximately 85% of brewery solid waste, contains significant quantities of dietary fiber (soluble and insoluble), proteins, essential amino acids, complex carbohydrates, and bioactive compounds such as phenolic acids and prebiotic oligosaccharides. However, its lignocellulosic structure limits nutrient digestibility and absorption, necessitating physical treatments to unlock its full nutritional potential.

This section outlines how thermal, mechanical, and enzymatic processes, especially extrusion, milling, and hydrothermal treatment, enhance the bioavailability of specific nutrients in BSG.

7.1. Thermal Processing to Enhance BSG Nutrient Bioavailability

Thermal processing methods (e.g., extrusion, autohydrolysis, subcritical water hydrolysis) improve the release of amino acids (e.g., lysine, leucine), soluble sugars (e.g., glucose, xylose), and phenolic compounds, while also enhancing prebiotic formation, particularly arabinoxylan-oligosaccharides (AXOSs) [50]. Extrusion and hydrothermal treatments significantly improve the digestibility and bioavailability of its nutrients. High temperatures and mechanical shear involved in extrusion promote starch gelatinization and the breakdown of complex polymers, releasing bound nutrients [27,49]. Extruded BSG has been successfully incorporated into various food products such as bread, increasing fiber content and improving the overall nutritional profile [51].

Thermal treatments such as autohydrolysis and subcritical water hydrolysis further enhance nutrient extraction from BSG, particularly soluble sugars and amino acids [52]. These treatments also promote the formation of prebiotic compounds such as arabinoxylan-oligosaccharides (AXOSs), beneficial for gut health [53]. Enzymatic hydrolysis has also been shown to increase BSG digestibility, making it more suitable for human food applications [6,54].

The valorization of BSG through thermal processing aligns with circular economy principles by reducing waste and converting BSG into high-value ingredients for human and animal nutrition [6,47].

7.2. Milling to Enhance BSG Nutrient Bioavailability

Milling increases the surface area of BSG particles, improving the release of dietary fibers, amino acids, and fermentable sugars. When combined with enzymatic pretreatment, milling enhances the liberation of monosaccharides like glucose and xylose, boosting BSG’s digestibility and fermentability [3,55].

Milling is another key physical process that enhances the bioavailability of nutrients in BSG by altering its structural characteristics. For example, milling and drying BSG before incorporating it into bakery products have been shown to increase fiber content and improve nutritional benefits [51]. Partial substitution of wheat flour with milled BSG significantly improved the nutritional value of bread, demonstrating the effectiveness of milling in facilitating BSG’s integration into food matrices [55].

BSG’s composition, primarily the husk, pericarp, and aleurone layers of barley, is rich in proteins and dietary fibers [56]. Milling breaks down these structures, making nutrients more accessible. Enzymatic pretreatment of milled BSG further increases the release of nutrients such as glucose and xylose [3], potentially making BSG a more accessible substrate for microbial fermentation and other biotechnological applications.

7.3. Extrusion Processing to Enhance BSG Nutrient Bioavailability

Extrusion is a highly effective method for enhancing the bioavailability of key nutrients in BSG. Through the combined effects of heat, pressure, and shear, extrusion breaks down complex macromolecules, facilitating starch gelatinization and the release of bound proteins, phenolic compounds, and dietary fibers. These transformations improve protein digestibility, boost the absorption of essential amino acids and antioxidants, and increase the content of soluble dietary fiber, contributing to prebiotic activity [27,51,53,57].

Optimizing extrusion parameters, such as moisture content and screw speed, can further enhance the concentration of bioactive compounds and the formation of AXOSs, reinforcing BSG’s potential as a functional food ingredient [27,53].

8. Fermentation and Enzymatic Hydrolysis to Enhance BSG Nutrient Bioavailability

Fermentation has been classified into submerged fermentation (SmF) and Solid-State Fermentation (SSF) based on the level of water used during the fermentation process [54]. Both fermentation methods can increase the bioavailability of BSG’s proteins, fibers, and bioactive compounds while also reducing anti-nutritional factors [2,16]. In addition, SSF presents advantages over SmF for processing agricultural residues like BSG, including higher productivity, better oxygen circulation, and use of low-cost media, and it resembles the natural habitat for several microorganisms [55]. SSF using specific microbial strains, such as Rhizopus oligosporus, Bacillus subtilis, and Pleurotus ostreatus, has been shown to improve BSG’s protein content and produce beneficial metabolites [7,30].

Fermentation also increases the release of phenolic compounds and vitamins, enhancing BSG’s functional properties [24]. Enzymatic hydrolysis breaks down complex carbohydrates and proteins into more bioavailable forms, further improving BSG’s nutritional value [56]. Enzymatic hydrolysis post-thermal treatment produces more digestible protein hydrolysates, further enhancing the nutritional value of BSG [17,56]. Overall, fermentation and enzymatic hydrolysis represent promising approaches to valorize BSG by enhancing its bioavailability and functional properties.

9. Solid-State Fermentation of Brewer’s Spent Grain: Advancing Nutritional and Functional Applications

SSF is a bioprocess involving the growth of microorganisms on solid substrates with minimal free water, making it particularly suitable for agro-industrial residues like BSG, which is rich in lignocellulosic materials [50]. Unlike SmF, SSF offers lower water usage, minimal effluent generation, and efficient conversion of low-value by-products into functional ingredients. Many microorganisms are involved in SSF and SmF processes, and the main ones are summarized in Table 3.

Table 3.

Main groups of microorganisms involved in solid-state fermentation (SSF) and submerged liquid fermentation (SmF) processes.

The SSF process involves substrate preparation, microbial inoculation, and incubation under controlled conditions. During fermentation, microorganisms metabolize complex macromolecules such as polysaccharides and proteins into simple, more digestible forms. This transformation improves nutrient bioavailability, enhances antioxidant capacity, and reduces anti-nutritional factors, contributing to the overall nutritional and functionality of the substrate [57,58,59].

One well-studied microorganism in SSF is Rhizopus oligosporus, a fungus recognized for its ability to increase protein digestibility and degrade anti-nutritional compounds in BSG [60] without producing undesirable metabolites [45]. The resulting biomass exhibits elevated levels of protein and phenolic compounds, along with improved antioxidant capacity than unfermented BSG [60].

Beyond its nutritional impact, SSF contributes to environmental sustainability by valorizing agricultural by-products, minimizing food waste, and reducing processing costs. It also enables the production of enzymes, antibiotics, and other bioactive compounds, highlighting its versatility across food, feed, and pharmaceutical industries [61,62]. Recent advancements further underscore SSF’s potential to integrate nutrient-rich residues like BSG into food systems [58], aligning with circular economy principles and sustainable development goals [63,64].

10. Valorization of BSG Through Solid-State Fermentation

SSF on BSG has emerged as a valuable approach for the targeted valorization of BSG, focusing on its integration into food systems. Unlike general descriptions of SSF processes, this section emphasizes how fermentation-driven biotransformation improves BSG’s techno-functional and bioactive properties, positioning it as a resource for functional food development.

Key outcomes of BSG fermentation include the generation of bioactive peptides with emulsifying and foaming properties [9], increased levels of soluble dietary fiber with prebiotic effects, and the reduction in anti-nutritional factors such as tannins. These changes enhance BSG’s applicability inf food matrices aimed at gut health support and metabolic disorder prevention [5]. The main nutritional modifications brought by SSF are summarized in Table 4.

Table 4.

Nutritional enhancement of BSG through SSF by diverse microorganisms.

Fermentation with Rhizopus oligosporus, in particular, significantly enriches BSG’s amino acid bioavailability [24], B vitamin content, and phenolic acid concentration [30], contributing antioxidant potential and chronic disease prevention benefits [24]. These bioactive compounds strengthen BSG’s profile as a functional ingredient for health-promoting diets.

Importantly, SSF-driven valorization supports circular economy objectives by repurposing agro-industrial waste streams into nutrient-rich, high-value products. This include potential development of high-fiber supplements, protein-enriched flours, or functional food additives, reducing food system losses while contributing to food security and sustainability goals [32].

11. Key Factors Influencing Solid-State Fermentation

SSF of BSG is influenced by several key factors that affect the efficiency and effectiveness of the fermentation process. These factors include substrate characteristics, microorganism selection, fermentation conditions, and intended applications of the final fermented product [32].

In terms of substrate characteristics, BSG is a lignocellulosic by-product from the brewing industry, primarily composed of cellulose, hemicellulose, and lignin. This unique and complex structure makes it a suitable substrate for microbial fermentation. Notably, the carbohydrate content of BSG can reach as high as 50%, offering a rich source of fermentable sugars [78].

The high carbohydrate content of BSG, combined with its rich array of nutrients—including proteins, vitamins, and minerals—enhances its potential as a substrate for SSF [78]. However, the structural complexity of BSG necessitates pre-treatment, such as mechanical, chemical, or enzymatic methods, to improve its digestibility and facilitate microbial access to the polysaccharides [32]. The high lignin content can considerably impede microorganisms’ ability to effectively decompose biomass without any of the previously discussed pre-treatments.

Moreover, water activity (Aw) and moisture content of the substrate are crucial factors in SSF. BSG features a high moisture content, rendering it suitable for fermentation in solid-state conditions. Nevertheless, careful adjustment of moisture levels is essential to avoid excess water that could disrupt the fermentation process. Proper moisture levels are critical for ensuring optimal enzyme activity and allowing microbial strains to effectively metabolize the available nutrients. Both microbial growth and production of enzymes and metabolites are directly influenced by Aw. Imbalances in moisture content—either too low or too high—can impede microbial growth and diminish fermentation efficiency. Therefore, achieving a balance between moisture content and Aw is vital for successful SSF [79].

The duration of fermentation plays a crucial role in SSF. It dictates the length of time microorganisms must degrade the substrate and generate desired metabolites. Extended fermentation periods can foster the accumulation of bioactive compounds such as antioxidants and peptides, which can enhance the functional properties of BSG. However, if fermentation is prolonged excessively, it may lead to the breakdown of beneficial compounds or a loss of enzymatic activity, thereby diminishing the overall nutritional value and efficacy of the process [24]. While the ideal fermentation time varies depending on the microorganism utilized and the specific objectives of SSF, it generally falls within the range of 24 to 96 h. To prevent over-fermentation, it is crucial to monitor the process at regular intervals.

Initial microbial load and inoculum concentration are critical factors influencing the success of SSF. The type and quantity of microorganisms introduced into the substrate directly affect the efficiency of the fermentation process. An inadequate inoculum or an imbalance in microbial populations can lead to suboptimal fermentation outcomes. Moreover, the selection of microbial strains is vital in SSF, as different microorganisms possess varying abilities to degrade lignocellulosic materials and produce desired metabolites. Filamentous fungi, such as Rhizopus oryzae, Rhizopus oligosporus, and various species of Aspergillus, are commonly utilized due to their capacity to thrive in low-moisture environments and their proficiency in producing hydrolytic enzymes such as cellulases, hemicellulases, and ligninases. These enzymes are essential for breaking down complex polysaccharides. Some of these fungal strains also generate bioactive compounds during fermentation, including antioxidant peptides, which enhance the functional properties of the final product. Furthermore, specific bacteria can be employed for their ability to produce metabolites like organic acids, which facilitate the breakdown of substrate and improve nutrient bioavailability [80].

Fermentation conditions, including temperature, pH, and oxygen availability, play a crucial role in the success of SSF. For instance, Rhizopus species thrive at temperatures ranging from 25 °C to 35 °C, which fosters optimal growth and enzyme production [36]. Furthermore, maintaining a pH range of 5.5 to 7.5 is essential for ensuring the enzymatic activity of microorganisms and preserving the nutrient integrity within BSG.

Adequate ventilation and oxygenation are vital in SSF, particularly during aerobic fermentation, where both fungi and bacteria depend on oxygen to produce enzymes and other bioactive compounds. Insufficient oxygen levels can lead to diminished microbial growth and a reduced yield of desired metabolites. Effective ventilation ensures a consistent supply of oxygen to these microorganisms, which is critical for their metabolic processes. In certain SSF setups, ventilation is meticulously managed to prevent CO2 accumulation, which can hinder microbial development. Oxygen control is especially important for filamentous fungi, as they require aerobic conditions to grow and produce hydrolytic enzymes effectively [81].

The SSF process in BSG is affected by various factors, such as the substrate properties, choice of microorganisms, fermentation conditions, and the desired uses of the fermented product. Grasping these factors is essential for optimizing SSF techniques for different applications, thus increasing the value of this plentiful by-product [81,82].

12. Microbial Diversity in Solid-State Fermentation: Role of Fungi and Bacteria and Their Impact on Brewer’s Spent Grain

Microbial diversity present in SSF plays a vital role in enhancing the nutritional and functional properties of BSG. Various microorganisms, including fungi such as Aspergillus, Rhizopus, and Fusarium, decompose complex polysaccharides like cellulose and arabinoxylans, thereby releasing bioavailable nutrients and increasing antioxidant capacity [83]. These fungi produce enzymes, including cellulases, xylanases, and amylases, which significantly improve digestibility [84,85].

For instance, Aspergillus niger has demonstrated its ability to produce high levels of xylanase, which significantly aids the hydrolysis of hemicellulose in BSG, leading to increased sugar availability for subsequent fermentation processes [86]. Similarly, the use of Rhizopus oligosporus has been shown to enhance the protein content of BSG through fermentation, resulting in a product that is better suited for animal feed [70]. Furthermore, the filamentous fungus Neurospora intermedia has been found to improve the nutritional composition of BSG by boosting protein levels and enriching essential amino acids, vitamins, and minerals during the fermentation process. This transformation enhances BSG value for both human consumption and animal feed [78]. Likewise, Trametes versicolor has been employed to produce laccase, an enzyme with applications in food processing, while also increasing BSG phenolic content, which is linked to various health benefits [24,76].

Bacteria play a crucial role in BSG fermentation. Notably, lactic acid bacteria, such as Lactobacillus rhamnosus, are effective for fermenting sugars found in BSG, resulting in the production of lactic acid [87]. This acidification not only helps to preserve the fermented product by inhibiting spoilage organisms but also enhances its flavor profile, making it more appealing for human consumption [88]. Also, the fermentation process improves BSG digestibility, rendering it a more suitable feed ingredient for livestock [84]. Furthermore, the use of Saccharomyces carlsbergensis in BSG fermentation has been explored for its potential to produce bioethanol, which can act as a preservative for fruits and vegetables [89]. This application underscores the versatility of BSG as a substrate for various microbial processes, contributing to waste reduction and resource recovery within the brewing industry.

The interaction between fungi and bacteria creates a synergistic effect during SSF. Fungi decompose complex macromolecules, while bacteria enhance the bioavailability of health-promoting metabolites. This collaboration elevates the nutritional and functional quality of BSG, increasing its bioeconomic potential [47]. The synergistic relationship between fungi and bacteria in SSF promotes a more complex microbial community, optimizing the bioconversion of BSG into high-value products and improving nutrient conversion and bioactive compound production. This microbial synergy not only enhances the sensory attributes of the final product but also aids in preserving BSG by lowering pH levels and inhibiting spoilage organisms [82]. Furthermore, the fermentation process can produce bioactive compounds such as phenolic acids, which are linked to various health benefits, including antioxidant and anti-inflammatory properties [78,82].

Selecting and balancing the appropriate microorganisms for SSF is crucial for optimizing BSG fermentation. By strategically choosing specific fungi and bacteria, it is possible to customize the fermentation process to enhance bioactive compound production, thereby improving the nutritional and functional qualities of BSG. This microbial balance plays a significant role in the success of SSF and can lead to the development of valuable products for a range of applications, from animal feed to functional foods [26,62].

13. Hindrance Factors and Technical Challenges in Brewery Spent Grain Upcycling

Upcycling BSG holds considerable promises for promoting sustainability within the brewing industry. However, its effective utilization is hindered by various challenges that can be broadly categorized into technical, economic, and regulatory dimensions.

Considering the technical challenges, BSG is primarily composed of cellulose, hemicellulose, and lignin, which can complicate its processing for applications such as biopolymer production or animal feed [90,91]. For instance, the presence of lignin can hinder BSG digestibility when used as animal feed, potentially leading to health issues in livestock, such as diarrhea and bloating [92]. Moreover, the variability in the moisture content and microbiota of BSG can affect its stability and safety as a feedstock or ingredient in food products [51]. The need for pre-treatment processes such as enzymatic hydrolysis to enhance the digestibility and nutrient availability of BSG further complicates its upcycling [56]. BSG microbiological quality is crucial, as improper storage and conservation techniques can lead to increased fungal contamination, which may result in mycotoxins production. For instance, the soaking method of conservation was found to correlate with higher fungal counts, indicating that storage conditions significantly affect the safety of BSG for animal consumption [93].

BSG’s chemical composition, including its lipid content, has been explored for its potential to serve as a source of valuable phytochemicals [94]. However, the presence of pesticide residues in BSG is an area of concern, as these contaminants can affect both animal health and the quality of products derived from BSG, such as fermented foods or bioproducts [24]. The degradation of these residues through bioremediation processes using BSG has shown promise, suggesting that BSG can play a dual role in waste management and as a substrate for microbial activity [95].

The presence of heavy metals in BSG poses a considerable constraint to its valorization. Heavy metals can originate from various sources, including the brewing process itself, agricultural practices, and environmental contamination. Their presence not only affects the safety and quality of BSG but also limits its applications in food products and animal feed due to potential toxicity and bioaccumulation risks. Heavy metals such as cadmium, arsenic, and lead have been identified in BSG, raising concerns about their bioavailability and mobility in the environment. The chemical speciation of these metals is crucial for understanding their potential risks; for instance, certain forms may be more toxic or bioavailable than others [47]. The adsorption capacity of BSG for heavy metals has been studied, revealing that while BSG can act as an adsorbent for some toxic metals, the presence of these contaminants can limit its use in applications where food safety is primordial [96,97]. Moreover, heavy metal content can significantly impact the BSG nutritional profile. Studies have indicated that the presence of heavy metals can interfere with the bioavailability of essential nutrients, potentially leading to adverse health effects when BSG is consumed by livestock or humans. The interaction between heavy metals and nutrients can also affect fermentation processes used in the valorization of BSG, as certain metals may inhibit microbial activity, thereby reducing the efficiency of bioconversion processes [6].

To mitigate the risks associated with heavy metals in BSG, various strategies have been proposed. These include pre-treatment methods such as washing or chemical treatment to reduce heavy metal concentrations before BSG is used in food or feed applications [3,96]. Notably, the development of biochar from BSG has been explored to sequester heavy metals, thus enhancing the safety of BSG for agricultural use [20,98]. However, the effectiveness of these methods can vary based on the specific heavy metals present and their concentrations, needing further research to optimize treatment processes [96,97].

Pesticides, often used in the cultivation of barley and other grains, can be accumulated in BSG, potentially hindering its utilization in various applications, including animal feed, biopolymer production, and food products. The implications of pesticide contamination are multifaceted, affecting not only the health of livestock but also the safety and quality of end products derived from BSG.

14. Economic and Regulatory Dimensions of BSG Upcycling

The economic viability of upcycling BSG is influenced by costs associated with processing and market demand for resulting products. Many breweries, particularly smaller craft operations, may lack the financial resources to invest in necessary technology for effective upcycling [63,99]. Furthermore, the competition with established uses of BSG, primarily as animal feed, can limit the incentive for breweries to explore alternative valorization pathways [100]. Fluctuating prices of raw materials and the economic feasibility of converting BSG into high-value products such as bioplastics or biofuels can deter investment in upcycling initiatives [47].

Regulatory frameworks surrounding food safety and waste management can pose significant barriers to BSG upcycling. Approving non-standard materials for use in food products or construction can be challenging due to stringent safety regulations [63]. Furthermore, the need for compliance with environmental regulations regarding waste disposal can limit the options available for breweries to manage their spent grains sustainably [101]. The lack of standardized protocols for processing and utilization of BSG can create uncertainty for breweries considering upcycling as a viable option [102].

While the potential of upcycling spent grain from breweries is recognized, it is crucial to tackle the technical, economic, and regulatory hurdles that need to be overcome to foster sustainable practices in the brewing industry. Cooperation among stakeholders—like breweries and researchers—is vital for developing effective strategies to address these challenges and increase the value of BSG [103].

15. Food Applications and Future Perspectives of Brewer’s Spent Grain Fermentation

BSG, a by-product of the brewing process, has attracted considerable interest for its potential applications in food products owing to its rich nutritional profile and functional properties. BSG primarily consists of cellulose, hemicellulose, lignin, and proteins, thus representing a significant source of dietary fiber and bioactive compounds that can enhance the nutritional quality of various food products [1,45]. BSG valorization not only helps in waste reduction within the brewing industry but also presents opportunities for the development of functional foods that can appeal to health-conscious consumers.

One of the most promising applications of BSG is in the formulation of baked goods such as bread, biscuits, and snacks. Incorporating BSG into these products has been shown to significantly improve their nutritional content. For example, studies have demonstrated that adding BSG to biscuits increases their total phenolic content (TPC) and antioxidant capacity, which are beneficial for human health [45]. Recent advancements in fermentation techniques, particularly SSF, have demonstrated promise in enhancing the nutritional and sensory properties of BSG. The inclusion of filamentous fungi such as Rhizopus oligosporus during SSF has been shown to improve BSG digestibility by breaking down anti-nutritional factors and enhancing protein digestibility [19,45].

In the context of bread production, BSG has been utilized to create high-fiber bread that satisfies the increasing consumer demand for functional foods. The inclusion of BSG has been associated with enhancements in the bread’s techno-functional properties such as dough viscosity and crumb structure, which are crucial for achieving desirable textural characteristics [19,103]. Moreover, incorporating BSG has been linked to a decrease in crumb hardness, likely due to the improved dough rise during fermentation, which contributes to a softer texture [19].

The sensory properties of BSG-enriched baked goods deserve attention. Research shows that while adding BSG can change the color and flavor profile of bread, these alterations do not adversely affect the overall sensory quality [103].

Beyond baked goods, BSG has potential applications in pasta production. Studies have shown that incorporating BSG into fresh pasta formulations can create fiber-rich products, even at relatively low inclusion levels [1,19]. Using BSG in pasta not only enhances its nutritional profile but also contributes to the development of functional foods that support digestive health due to their high fiber content [104].

BSG’s versatility extends to its role in producing fermented beverages. BSG can act as a substrate for fermentation processes, resulting in drinks rich in phenolic compounds and other bioactive components. Fermentation serves as a transformative process for BSG, enhancing its nutritional value and functional characteristics. For example, fermentation can revitalize BSG, thereby improving its techno-functional properties and nutritional value in high-fiber bread formulations. The dietary fiber in BSG is important as it contributes to health benefits such as a reduced risk of cardiovascular disease and improved digestive health [19].

Moreover, the fermentation process can increase the solubility of proteins in BSG, which is crucial for its use in food products. It has been noted that BSG protein isolate exhibits high solubility, likely due to the breakdown of proteins into smaller peptides during brewing, which can boost the protein content of food formulations. The incorporation of BSG into food products has been shown to improve their nutritional profiles. For example, studies suggest that substituting part of the flour with BSG in pasta can enhance both protein and dietary fiber content while maintaining acceptable sensory characteristics. Furthermore, it highlights that BSG can provide a significant amount of lysine, an essential amino acid often lacking in plant-based diets, thus improving the overall amino acid profile of foods when paired with other protein sources [104].

In addition to its use in food products, BSG has been explored for its potential in bioprocessing and biofuel production. Sugars released from BSG during enzymatic hydrolysis can be fermented to produce ethanol, providing an alternative energy source that aligns with sustainability goals [1].

Despite the historical sensory challenges for BSG in food applications, recent fermentation technology developments offer an opportunity to raise its nutritional value while improving the sensory quality of final products, boosting consumer acceptance. By effectively leveraging the advantages of SSF and various fermentation techniques, BSG can transform into a valuable component for a wide variety of food products, promoting health benefits and sustainability in the food sector [83,103].

The increasing emphasis on the valorization of agro-industrial by-products highlights their considerable economic and environmental potential. BSG, a by-product generated in significant quantities by breweries worldwide, represents a valuable yet largely underutilized resource. Although BSG possesses great promise as a functional ingredient in food applications and as a source of bioactive compounds, its current usage is primarily limited to animal feed and landfill disposal. There is an urgent need to investigate advanced processing techniques and innovative applications that could enhance the functional properties of BSG, thereby broadening its role within the food industry and supporting more sustainable waste management practices.

16. Limitations of Current Knowledge

Although the valorization of BSG using solid-state fermentation has presented substantial potential, the current literature shows multiple limitations and unaddressed barriers. First, a major part of the existing literature focuses on positive outcomes, often failing to consider negative results, unsuccessful fermentation attempts, or differences in microbial strain and fermentation substrates. This lack of published unsuccessful or suboptimal trials hampers a comprehensive understanding of both the potential and constraints of SSF applications.

Additionally, variability in fermentation results due to differences in microbial species, inoculum concentration, substrate composition, moisture content, and environmental factors hinder the reproducibility and scalability of SSF processes. For example, despite the promising results associated with Rhizopus oligosporus, its performance can vary considerably based on the source of BSG, pre-treatment strategies, and fermentation duration. Moreover, inconsistencies in study design, absence of standardized protocols, and insufficient in vivo or clinical evaluations also limit the applicability of current findings.

Furthermore, issues such as mycotoxin contamination, accumulation of heavy metals and pesticide residues in BSG, along with regulatory challenges related to BSG for food-grade applications, remain unresolved and under-discussed in most studies. Future research should adopt more critical and comparative approaches, include rigorous risk assessments, and transparently report limitations and unsuccessful outcomes to allow a more comprehensive and realistic evaluation of BSG valorization through SSF.

Brewer’s spent grain (BSG), a nutrient-rich by-product of the brewing industry, represents a highly promising yet underutilized resource for food and health applications. Through SSF, BSG can be effectively transformed into a value-added ingredient with enhanced nutritional, functional, and techno-functional characteristics. SSF not only improves the protein digestibility, amino acid profile, and fiber solubility, but also facilitates the release of bioactive compounds such as phenolic acids and prebiotic fibers, as a result increasing the health-promoting potential of BSG-derived products. Likewise, the application of SSF also addresses social issues related to carbon footprints and by-product waste, promoting a circular economy by converting agro-industrial waste into high-value ingredients for the food, feed, and biotechnological sectors.

17. Final Recommendations

In conclusion, BSG fermentation by Rhizopus oligosporus offers significant opportunities for enhancing both economic viability and environmental sustainability. Its potential as a functional and bioactive ingredient with increased protein content underscores the need for continued research and development to fully harness its capabilities within the food and health industries. This sustainable strategy reduces environmental impact, reduces greenhouse emissions from waste disposal, and enhances resource efficiency. Despite its benefits, implementation still faces challenges regarding standardization of fermentation conditions, inconsistencies in microbial performance, and potential contamination risk. More interdisciplinary research is warranted to optimize SSF protocols, guarantee safety and regulatory compliance, and test consumer acceptability in diverse food matrices.

Unlocking the potential for BSG through SSF requires coordination among food researchers, microbiologists, industry, and policymakers. With targeted innovation and thorough evaluation, SSF can contribute significantly to global goals for sustainability, waste reduction, and public health through functional foods.

Future research should focus on optimizing specific processing techniques that enhance the functional and nutritional properties of BSG. For example, fermentation of BSG with Rhizopus oligosporus has demonstrated commercial potential for the development of protein-enriched snacks, due to its ability to improve protein digestibility and increase the concentration of free amino acids. This represents a promising direction for creating value-added, plant-based food products targeted at health-conscious consumers.

Moreover, the effects of combined treatments—such as fermentation followed by extrusion or enzymatic hydrolysis—on bioactive compound release and product functionality should be further explored. Industry stakeholders are encouraged to invest in pilot-scale applications and sensory studies to evaluate consumer acceptance and scalability. Regulatory considerations, shelf-life stability, and cost-effectiveness are also key factors that must be addressed to facilitate the integration of BSG into mainstream food systems.

Overall, BSG represents a valuable resource for the circular bioeconomy, and interdisciplinary collaboration will be essential to unlock its full commercial and nutritional potential.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mussatto, S.I. Brewer’s spent grain: A valuable feedstock for industrial applications: Brewer’s spent grain and its potential applications. J. Sci. Food Agric. 2014, 94, 1264–1275. [Google Scholar] [CrossRef] [PubMed]

- Lynch, K.M.; Steffen, E.J.; Arendt, E.K. Brewers’ spent grain: A review with an emphasis on food and health. J. Inst. Brew. 2016, 122, 553–568. [Google Scholar] [CrossRef]

- Patel, A.; Mikes, F.; Bühler, S.; Matsakas, L. Valorization of Brewers’ Spent Grain for the Production of Lipids by Oleaginous Yeast. Molecules 2018, 23, 3052. [Google Scholar] [CrossRef] [PubMed]

- Cooray, S.T.; Chen, W.N. Valorization of brewer’s spent grain using fungi solid-state fermentation to enhance nutritional value. J. Funct. Foods 2018, 42, 85–94. [Google Scholar] [CrossRef]

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Appl. Sci. 2020, 10, 5619. [Google Scholar] [CrossRef]

- Mitri, S.; Salameh, S.-J.; Khelfa, A.; Leonard, E.; Maroun, R.G.; Louka, N.; Koubaa, M. Valorization of Brewers’ Spent Grains: Pretreatments and Fermentation, a Review. Fermentation 2022, 8, 50. [Google Scholar] [CrossRef]

- Eliopoulos, C.; Arapoglou, D.; Chorianopoulos, N.; Markou, G.; Haroutounian, S.A. Conversion of brewers’ spent grain into proteinaceous animal feed using solid state fermentation. Environ. Sci. Pollut. Res. 2022, 29, 29562–29569. [Google Scholar] [CrossRef]

- Thai, S.; Avena-Bustillos, R.J.; Alves, P.; Pan, J.; Osorio-Ruiz, A.; Miller, J.; Tam, C.; Rolston, M.R.; Teran-Cabanillas, E.; Yokoyama, W.H.; et al. Influence of drying methods on health indicators of brewers spent grain for potential upcycling into food products. Appl. Food Res. 2022, 2, 100052. [Google Scholar] [CrossRef]

- Inzunza-Soto, M.; Avena-Bustillos, R.-J.; Thai, S.; Roman, V.; Whitehill, L.; Tam, C.; Rolston, M.-R.; Alemán-Hidalgo, D.-M.; Terán-Cabanillas, E.; Yokoyama, W.; et al. Health Benefits of High Protein and Dietary Fiber Dry-Fractioned Brewery Spent Grain Fines. ACS Food Sci. Technol. 2022, 2, 1870–1878. [Google Scholar] [CrossRef]

- Robinson, T.; Singh, D.; Nigam, P. Solid-state fermentation: A promising microbial technology for secondary metabolite production. Appl. Microbiol. Biotechnol. 2001, 55, 284–289. [Google Scholar] [CrossRef]

- Chin, Y.L.; Chai, K.F.; Chen, W.N. Upcycling of brewers’ spent grains via solid-state fermentation for the production of protein hydrolysates with antioxidant and techno-functional properties. Food Chem. X 2022, 13, 100184. [Google Scholar] [CrossRef]

- Nazzaro, F.; Fratianni, F.; Ombra, M.N.; d’Acierno, A.; Coppola, R. Recovery of biomolecules of high benefit from food waste. Curr. Opin. Food Sci. 2018, 22, 43–54. [Google Scholar] [CrossRef]

- Lao, E.J.; Dimoso, N.; Raymond, J.; Mbega, E.R. The prebiotic potential of brewers’ spent grain on livestock’s health: A review. Trop. Anim. Health Prod. 2020, 52, 461–472. [Google Scholar] [CrossRef]

- Santos, D.; Barreiros, L.; Jesus, Â.; Silva, A.L.; Martins, J.P.; Oliveira, A.I.; Pinho, C. Beer with Probiotics: Benefits and Challenges of Their Incorporation. Beverages 2024, 10, 109. [Google Scholar] [CrossRef]

- Wang, S.-M.; Wu, J.-X.; Gunawan, H.; Tu, R.-Q. Application of Life Cycle Assessment in Beer Production: Systematic Review. Beverages 2024, 10, 86. [Google Scholar] [CrossRef]

- Ravanal, M.C.; Doussoulin, J.P.; Mougenot, B. Does sustainability matter in the global beer industry? Bibliometrics trends in recycling and the circular economy. Front. Sustain. Food Syst. 2024, 8, 1437910. [Google Scholar] [CrossRef]

- Shen, Y.; Abeynayake, R.; Sun, X.; Ran, T.; Li, J.; Chen, L.; Yang, W. Feed nutritional value of brewers’ spent grain residue resulting from protease aided protein removal. J. Anim. Sci. Biotechnol. 2019, 10, 78. [Google Scholar] [CrossRef]

- Chu, H.-Y.I.; Miri, T.; Onyeaka, H. Valorization of Bioactive Compounds Extracted from Brewer’s Spent Grain (BSG) for Sustainable Food Waste Recycling. Sustainability 2025, 17, 2477. [Google Scholar] [CrossRef]

- Neylon, E.; Arendt, E.K.; Zannini, E.; Sahin, A.W. Fermentation as a Tool to Revitalise Brewers’ Spent Grain and Elevate Techno-Functional Properties and Nutritional Value in High Fibre Bread. Foods 2021, 10, 1639. [Google Scholar] [CrossRef]

- Hejna, A.; Marć, M.; Kowalkowska-Zedler, D.; Pladzyk, A.; Barczewski, M. Insights into the Thermo-Mechanical Treatment of Brewers’ Spent Grain as a Potential Filler for Polymer Composites. Polymers 2021, 13, 879. [Google Scholar] [CrossRef]

- García, D.C.; Villalba, I.; Savino, N.; Nazareno, M.A. Nutritional and functional characterization of different types of brewer’s spent grain flours. Food Biosci. 2025, 64, 105890. [Google Scholar] [CrossRef]

- Nyhan, L.; Sahin, A.W.; Schmitz, H.H.; Siegel, J.B.; Arendt, E.K. Brewers’ Spent Grain: An Unprecedented Opportunity to Develop Sustainable Plant-Based Nutrition Ingredients Addressing Global Malnutrition Challenges. J. Agric. Food Chem. 2023, 71, 10543–10564. [Google Scholar] [CrossRef]

- Nagy, V.; Diósi, G. Using brewer’s spent grain as a byproduct of the brewing industry in the bakery industry. Élelmiszervizsgálati Közlemények 2021, 67, 3339–3350. [Google Scholar] [CrossRef]

- Verni, M.; Pontonio, E.; Krona, A.; Jacob, S.; Pinto, D.; Rinaldi, F.; Verardo, V.; Díaz-de-Cerio, E.; Coda, R.; Rizzello, C.G. Bioprocessing of Brewers’ Spent Grain Enhances Its Antioxidant Activity: Characterization of Phenolic Compounds and Bioactive Peptides. Front. Microbiol. 2020, 11, 1831. [Google Scholar] [CrossRef]

- Anisha, A.; Kaushik, D.; Kumar, M.; Kumar, A.; Esatbeyoglu, T.; Proestos, C.; Rizwan-Khan, M.; Elobeid, T.; Kaur, J.; Oz, F. Volarisation of Brewer’s spent grain for noodles preparation and its potential assessment against obesity. Int. J. Food Sci. Technol. 2023, 58, 3154–3179. [Google Scholar] [CrossRef]

- Tankem, T.; Ndasi- Ngwasiri, P.; Awganande-Ambindei, W.; Calister-Wingang, M.; Martin-Ngwabie, N.; Benoit-Ngassoum, M.; Richard-Aba, E. Production and Evaluation of the Nutritional and Functional Qualities of “Adakwa” Enriched with Waste Biomass of Traditional Brewer’s Spent Grain as a Functional Staple Food. Adv. Chem. Eng. Sci. 2023, 13, 265–288. [Google Scholar] [CrossRef]

- Gutierrez-Barrutia, M.B.; Cozzano, S.; Arcia, P.; Del Castillo, M.D. In Vitro Digestibility and Bioaccessibility of Nutrients and Non-Nutrients Composing Extruded Brewers’ Spent Grain. Nutrients 2022, 14, 3480. [Google Scholar] [CrossRef] [PubMed]

- Devnani, B.; Moran, G.C.; Grossmann, L. Extraction; Composition; Functionality, and Utilization of Brewer’s Spent Grain Protein in Food Formulations. Foods 2023, 12, 1543. [Google Scholar] [CrossRef]

- Ikram, S.; Huang, L.; Zhang, H.; Wang, J.; Yin, M. Composition and Nutrient Value Proposition of Brewers Spent Grain. J. Food Sci. 2017, 82, 2232–2242. [Google Scholar] [CrossRef]

- Tan, Y.X. Brewers’ Spent Grains as Potential Novel Functional Food Ingredients for Food Security. Ph.D. Thesis, Nanyang Technological University, Singapore, 2020. [Google Scholar] [CrossRef]

- Jaeger, A.; Zannini, E.; Sahin, A.W.; Arendt, E.K. Barley Protein Properties, Extraction and Applications, with a Focus on Brewers’ Spent Grain Protein. Foods 2021, 10, 1389. [Google Scholar] [CrossRef]

- Bianco, A.; Budroni, M.; Zara, S.; Mannazzu, I.; Fancello, F.; Zara, G. The role of microorganisms on biotransformation of brewers’ spent grain. Appl. Microbiol. Biotechnol. 2020, 104, 8661–8678. [Google Scholar] [CrossRef]

- McCarthy, A.L.; O’Callaghan, Y.C.; Piggott, C.O.; FitzGerald, R.J.; O’Brien, N.M. Brewers’ spent grain; bioactivity of phenolic component, its role in animal nutrition and potential for incorporation in functional foods: A review. Proc. Nutr. Soc. 2013, 72, 117–125. [Google Scholar] [CrossRef]

- Liu, L.; Chen, M.; Coldea, T.E.; Yang, H.; Zhao, H. Modified structural and functional properties of arabinoxylan derived from brewers’ spent grain by ultrasound-assisted extraction. Rs.3.rs 2022. [Google Scholar] [CrossRef]

- Ohra-aho, T.; Niemi, P.; Aura, A.-M.; Orlandi, M.; Poutanen, K.; Buchert, J.; Tamminen, T. Structure of Brewer’s Spent Grain Lignin and Its Interactions with Gut Microbiota in Vitro. J. Agric. Food Chem. 2016, 64, 812–820. [Google Scholar] [CrossRef] [PubMed]

- Reis, S.F.; Gullón, B.; Gullón, P.; Ferreira, S.; Maia, C.-J.; Alonso, J.-L.; Domingues, F.-C.; Abu-Ghannam, N. Evaluation of the prebiotic potential of arabinoxylans from brewer’s spent grain. Appl. Microbiol. Biotechnol. 2014, 98, 9365–9373. [Google Scholar] [CrossRef] [PubMed]

- Ullah, H.; Espotio, C.; Piccinochi, R.; De Lellis, L.F.; Santarcangelo, C.; Minno, A.D.; Baldi, A.; Buccato, D.G.; Khan, A.; Piccinocchi, G.; et al. Postprandial Glycemic and Insulinemic Response by a Brewer’s Spent Grain Extract-Based Food Supplement in Subjects with Slightly Impaired Glucose Tolerance: A Monocentric, Randomized, Cross-Over, Double-Blind, Placebo-Controlled Clinical Trial. Nutrients 2022, 14, 3916. [Google Scholar] [CrossRef]

- Niemi, P.; Aura, A.-M.; Maukonen, J.; Smeds, A.-I.; Mattila, I.; Niemela, K.; Tamminen, T.; Faulds, C.-F.; Buchert, J.; Poutanen, K. Interactions of a Lignin-Rich Fraction from Brewer’s Spent Grain with Gut Microbiota in Vitro. J. Agric. Food Chem. 2013, 61, 6754–6762. [Google Scholar] [CrossRef]

- Gupta, M.; Abu-Ghannam, N.; Gallaghar, E. Barley for Brewing: Characteristic Changes during Malting, Brewing and Applications of its By-Products. Compr. Rev. Food Sci. Food Saf. 2010, 9, 318–328. [Google Scholar] [CrossRef]

- Ivanova, K.; Denkova, R.; Kostov, G.; Petrova, T.; Bakalov, I.; Ruscova, M.; Penov, N. Extrusion of brewers’ spent grains and application in the production of functional food. Characteristics of spent grains and optimization of extrusion: Extrusion of brewers’ spent grains and application in the production of functional food. Characteristics of spent grains and optimization of extrusion. J. Inst. Brew. 2017, 123, 544–552. [Google Scholar] [CrossRef]

- Steiner, J.; Procopio, S.; Becker, T. Brewer’s spent grain: Source of value-added polysaccharides for the food industry in reference to the health claims. Eur. Food Res. Technol. 2015, 241, 303–315. [Google Scholar] [CrossRef]

- Volman, J.J.; Ramakers, J.D.; Plat, J. Dietary modulation of immune function by β-glucans. Physiol. Behav. 2008, 94, 276–284. [Google Scholar] [CrossRef]

- Crowley, D.; O’Callaghan, Y.; McCarthy, A.; Connolly, A.; Piggott, A. FitzGerald, R.; O’Brien, N.-M. Immunomodulatory potential of a brewers’ spent grain protein hydrolysate incorporated into low-fat milk following in vitro gastrointestinal digestion. Int. J. Food Sci. Nutr. 2015, 66, 672–676. [Google Scholar] [CrossRef]

- Oh, D.-R.; Kim, M.J.; Choi, E.J.; Kim, Y.; Lee, H.S.; Bae, D.; Choi, C. Protective Effects of p-Coumaric Acid Isolated from Vaccinium bracteatum Thunb. Leaf Extract on Corticosterone-Induced Neurotoxicity in SH-SY5Y Cells and Primary Rat Cortical Neurons. Processes 2021, 9, 869. [Google Scholar] [CrossRef]

- Wang, X.; Xu, Y.; Teo, S.-Q.; Heng, C.-W.; Shan-Lee, D.-P.; Gan, A.-X.; Kim, J.-E. Impact of solid-state fermented Brewer’s spent grains incorporation in biscuits on nutritional, physical and sensorial properties. LWT 2023, 182, 114840. [Google Scholar] [CrossRef]

- Cao, H.; Saroglu, O.; Karadag, A.; Diaconeasa, Z.; Zoccatelli, G.; Conte-Junior, C.-A.; Gonzalez-Aguilar, G.-A.; Ou, J.; Bai, W.; Zamarioli, C.M.; et al. Available technologies on improving the stability of polyphenols in food processing. Food Front. 2021, 2, 109–139. [Google Scholar] [CrossRef]

- Zeko-Pivač, A.; Tisma, M.; Znidarsic-Plazl, P.; Kulisic, B.; Sakellaris, G.; Hao, J.; Planinic, M. The Potential of Brewer’s Spent Grain in the Circular Bioeconomy: State of the Art and Future Perspectives. Front. Bioeng. Biotechnol. 2022, 10, 870744. [Google Scholar] [CrossRef]

- Korzeniowska, J.N.Y.M. Brewers’ spent grain in food systems: Processing and final products quality as a function of fiber modification treatment. J. Food Sci. 2021, 86, 1532–1551. [Google Scholar] [CrossRef]

- Makowska, A.; Mildner-Szkudlarz, S.; Obuchowski, W. Effect of Brewer’s Spent Grain Addition on Properties of Corn Extrudates with an Increased Dietary Fibre Content. Pol. J. Food Nutr. Sci. 2013, 63, 19–24. [Google Scholar] [CrossRef]

- Olawoye, B.T.; Gbadamosi, S.O.; Yildiz, F. Effect of different treatments on in vitro protein digestibility, antinutrients, antioxidant properties and mineral composition of Amaranthus viridis seed. Cogent Food Agric. 2017, 3, 1296402. [Google Scholar] [CrossRef]

- Onofre, S.B.; Bertoldo, I.C.; Abatti, D.; Refosco, D. Chemical Composition of the Biomass of Saccharomyces cerevisiae-(Meyen ex E. C. Hansen, 1883) Yeast obtained from the Beer Manufacturing Process. Int. J. Adv. Eng. Res. Sci. 2018, 5, 351–355. [Google Scholar] [CrossRef]

- Sganzerla, W.G.; Viganó, J.; Nochi-Castro, L.-E.; Maciel-Silva, F.-W.; Rostagno, M.-A.; Mussatto, S.-I.; Forster-Carneiro, T. Recovery of sugars and amino acids from brewers’ spent grains using subcritical water hydrolysis in a single and two sequential semi-continuous flow-through reactors. Food Res. Int. 2022, 157, 111470. [Google Scholar] [CrossRef]

- Gómez, B.; Míguez, B.; Veiga, A.; Parajó, J.C.; Alonso, J.L. Production, Purification, and in Vitro Evaluation of the Prebiotic Potential of Arabinoxylooligosaccharides from Brewer’s Spent Grain. J. Agric. Food Chem. 2015, 63, 8429–8438. [Google Scholar] [CrossRef]