Abstract

This paper presents a comprehensive review of research on sulfurized polyacrylonitrile (SPAN) for rechargeable batteries which was firstly reported by Jiulin Wang in July 2002. Spanning over two decades (2002–2025), this review cites over 600 publications, covering various aspects of SPAN-based battery systems. These include SPAN chemical structure, structural evolution during synthesis, redox reaction mechanism, synthetic conditions, cathode, electrolyte, binder, current collector, separator, anode, SPAN as additive, SPAN as anode, and high-energy SPAN cathodes. As this field continues to advance rapidly and garners significant interest, this review aims to provide researchers with a thorough and in-depth overview of the progress made over the past 23 years. Additionally, it highlights emerging trends and outlines future directions for SPAN research and its practical applications in energy storage technologies.

1. Introduction

Metal–sulfur batteries (MSBs, M: Li, Na, K, Mg, Al, etc.) are widely regarded as a promising alternative for energy storage, offering the potential for high energy density and cost-effectiveness [,]. Sulfur, the key active material in MSBs, boasts an impressive theoretical specific capacity of 1675 mAh g−1, achieved through a 16-electron transfer redox reaction of crown-shaped sulfur (S8). This enables lithium–sulfur batteries (LSBs) to achieve an exceptionally high theoretical energy density of up to 2600 Wh kg−1, significantly exceeding those of currently commercially available lithium-ion batteries (LIBs) []. Sulfur is also naturally abundant, economically viable, environmentally benign, and free from supply chain constraints []. In addition to lithium–metal anodes, other metallic anodes—such as sodium (Na), potassium (K), magnesium (Mg), and aluminum (Al)—have also been explored for use in MSBs. These alternatives may offer promising solutions to challenges associated with lithium, including its limited availability and rising cost. These attributes position MSBs as compelling candidates to address the growing demand for extended-range electric vehicles (EVs) and to meet the need for affordable, large-scale energy storage solutions.

Conventional MSBs typically consist of a C/S composite cathode made from a composite of elemental sulfur, conductive additives, and binders, paired with a metallic anode. Taking LSBs for an example, during discharge, S8 undergoes a “two-stage” reduction process, first converting to soluble lithium polysulfide species Li2Sn (4 ≤ n ≤ 8), which are then further reduced to insoluble Li2S2 or Li2S []. This process involves a “solid–liquid–solid” transition and is characterized by a dual-voltage plateau (ca. 2.4 V and 2.1 V) in the discharge profile. The charging process essentially reverses these steps. Although traditional LSBs hold the promise of high theoretical energy density and low cost, several intrinsic drawbacks have hindered their practical implementation []. Firstly, the poor electrical and ionic conductivity of elemental sulfur, Li2S2, and Li2S results in sluggish reaction kinetics and low utilization of the active materials. Secondly, the sulfur cathode undergoes significant volume changes during cycling due to the density difference between elemental sulfur (2.03 g cm−3) and the discharge product Li2S (1.66 g cm−3) []. These substantial volume changes can cause the pulverization of active materials and disintegration of the electrode. Thirdly, the long-chain polysulfide intermediates Li2Sn (4 ≤ n ≤ 8) are soluble in conventional ether-based electrolytes []. Under the influence of concentration and electric field gradients, these intermediates shuttle between the cathode and anode, a phenomenon known as the “shuttle effect”. This leads to the loss of active materials, anode deterioration, internal energy inefficiencies, and rapid capacity decay. These issues collectively hinder the performance of traditional MSBs.

To overcome the challenges of conventional MSBs, sulfurized polyacrylonitrile (SPAN) has emerged as a promising cathode material, gaining significant research attention since its initial reports by Wang et al. during 2002 and 2004 [,,]. Unlike traditional C/S composites, SPAN features sulfur covalently bonded to a conductive polymer backbone in short-chain configurations (–Sn–, where 2 ≤ n ≤ 4), ensuring atomic-level dispersion []. The polypyrrole conductive framework in SPAN exhibits significantly higher electrical conductivity (10−5 to 10−7 S cm−1) compared to insulating elemental sulfur (10−30 S cm−1). A key advantage of SPAN is its “solid–solid” conversion mechanism during cycling, eliminating the issues associated with the solid–liquid–solid transition seen in C/S composites. This unique behavior grants SPAN several advantages: (1) compatibility with carbonate-based electrolytes, unlike C/S composites []; (2) minimal “shuttle effect”, enabling high sulfur utilization and superior cycling stability; and (3) improved performance under lean electrolyte conditions due to the absence of liquid-phase conversion process. However, SPAN still faces limitations that hinder its practical application: (1) low sulfur (typically 35–50 wt%, with up to ~56 wt%); (2) substantial volume expansion during cycling; (3) sluggish reaction kinetics; and (4) irreversible capacity loss in the first cycle. Despite these challenges, Metal||SPAN batteries hold great potential to outperform conventional LIBs, offering a theoretical energy density exceeding 1000 Wh kg−1 (based on cathode + metaillic lithium anode mass) compared to ~800 Wh kg−1 for Li||NMC batteries, while leveraging low-cost raw materials []. Continued advancements in Metal||SPAN batteries could position them as a viable high-energy, cost-effective alternative to conventional LIBs.

In this paper, the author presents a comprehensive review of all peer-reviewed research studies (available in the Scopus database and Google Scholar) on SPAN and its applications in rechargeable batteries from 2002 to 2025. This review begins with outlining the methodology for literature collection and analyzing the key research trends over the past two decades. Subsequently, it provides a systematic and in-depth discussion on the following critical aspects: synthesis, characterization and mechanism studies, cathode design, electrolytes, solid-state batteries, binders, current collectors, separators, anodes, cell configurations, and theoretical studies. By consolidating two decades of research, this review not only summarizes the advancements in SPAN research but also identifies key challenges and proposes possible future research directions to accelerate the development of high-energy, long-lasting, and commercially viable SPAN-based batteries.

2. Dataset Construction and Research Progress

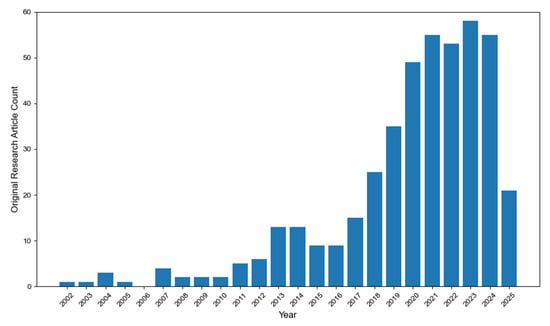

The methodology for compiling the comprehensive dataset of SPAN-related studies is detailed in the Supporting Information and graphically summarized in Figure 1 and Figure S1. This dataset encompasses all peer-reviewed literature on SPAN-based rechargeable batteries from its first report in 2002 through 6 May 2025. As of the latest update, the database includes 437 original research articles and 160 non-original publications (reviews, perspectives, etc.). The dataset is kept and maintained periodically in the author’s GitHub repository []. Figure 1 illustrates the evolving research trends, revealing a notable surge in SPAN-related studies beginning in 2018, with sustained growth through 2022. Since 2021, annual publication rates have stabilized at approximately 50–60 original research papers per year, reflecting sustained interest in SPAN as a promising cathode material. This review systematically examines every peer-reviewed study on SPAN-based batteries published between 2002 and 2025, ensuring a thorough analysis of the field’s progression. By mapping historical developments, we identify key milestones, emerging trends, and future opportunities to advance SPAN technology toward commercialization.

Figure 1.

Number of publications of original research articles on SPAN for rechargeable batteries from 2002 to 6 May 2025.

3. Chemical Structure

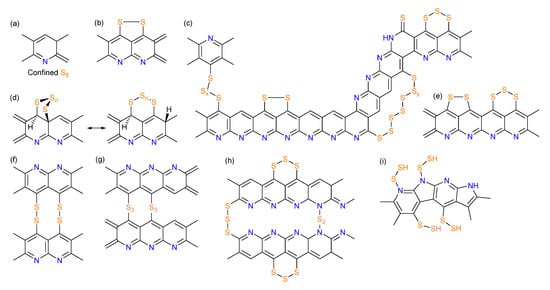

Since the groundbreaking work by Wang et al. [], numerous studies have explored the possible chemical structure of SPAN. In their initial studies published in 2002 and 2003 [,], Wang et al. synthesized SPAN by heating a mixture of polyacrylonitrile (PAN) and sulfur at 280–300 °C for 6 h under argon, followed by comprehensive characterization. Elemental analysis (EA) reveals a composition of 53.41 wt% S, 10.73 wt% N, 30.92 wt% C, and 0.89 wt% H. Solid-state 13C nuclear magnetic resonance (NMR) spectra indicate the formation of double bonds due to the cyclization of -CN groups, while Fourier transform infrared (FT-IR) and Raman spectroscopy rules out C-S bond formation. X-ray photoelectron spectroscopy (XPS) confirms the presence of elemental sulfur. Based on these findings, the authors proposed that PAN undergoes dehydrogenation and cyclization during vulcanization, resulting in a conjugated polypyridine skeleton encapsulating elemental nano sulfur (Figure 2a).

In 2004, Yu et al. proposed, for the first time, that sulfur is covalently incorporated into the backbone as -C-S-S-C- linkages in SPAN synthesized temperatures ranging from 250 to 800 °C [] (Figure 2b). Elemental sulfur was detected in SPAN synthesized at 250 °C but diminished with increasing temperature and nearly disappeared above 450 °C.

Fanous et al. employed time-of-flight secondary ion mass spectrometry (TOF-SIMS) in 2011 to investigate the sulfur bonding modes in SPAN []. Fragments such as CNS (CNS−, C3NS−, C5NS−), CS (C2S−), Sx (S2−, S3−) were detected while no SN fragments were observed, suggesting sulfur binds exclusively to carbon (not nitrogen) and oligosulfide structures exist. The strong CNS− signal indicated that sulfur primarily bonds to carbon adjacent to nitrogen. XPS and FT-IR spectra further excluded the presence of elemental S8, leading to a revised SPAN structural model (Figure 2c). In a follow-up study (2012), Fanous et al. demonstrated that higher synthesis temperatures reduce sulfur content and enhance graphitization of the polymer backbone, improving rate capability and cycling stability [].

Doan et al. investigated the binding mechanism of sulfur and PAN in the SPAN composite by heating PAN-sulfur mixtures at 300 °C for 0.5–4 h []. They concluded that S8 was embedded between heterocyclic rings of dehydrogenated PAN, which was similar to the structure proposed by Wang et al. []. Zhang et al. (2014) consolidated prior findings with their own data, proposing a structure where short -Sx- chains covalently attach to cyclized, partially dehydrogenated PAN backbones [] (Figure 2d). Wei et al. (2015) further suggested that sulfur existed as S3/S2 units bonded to pyridinic-N-containing carbon backbones, retaining this configuration throughout redox processes [] (Figure 2e).

In 2018, Wang et al. employed solid-state NMR, electron paramagnetic resonance (EPR), EA, and simulations to deduce a repeating C3N1S1 unit in SPAN, with PAN chains linked by -S2- bridges [] (Figure 2f). Jin et al. proposed a similar structure but with -Sx- (2 ≤ x ≤ 4) bridging adjacent polypyridine rings [] (Figure 2g).

The existence of N-S bonds in the SPAN structure was firstly evidenced and proposed by Weret et al. in 2020 [] (Figure 2h). From the high-resolution cross-polarization/magic angle spinning (CP-MAS) 15N solid-state NMR, XPS, and FT-IR spectra, they identified N-S and N=C-S bonds, which contribute to the high initial discharge capacity. Huang et al. (2021) provided new via CP-MAS solid-state NMR, XPS, and density functional theory (DFT) calculations [], proposing a vicinal pyridinic/pyrrolic nitrogen structure that attracts S2 during synthesis and facilitates N-S bond formation (Figure 2i). In a subsequent study, Huang et al. proposed an energetically favorable -N-Sx-N- (x < 4) configuration on the SPAN backbone, supported by Raman spectroscopy and computational results [].

Theoretical studies have further elucidated SPAN’s structure. Zhu et al. used DFT to identify stable motifs in PAN and SPAN []. It is found that backbone structures with multiple stair-like configurations are energetically favored for PAN. For PAN, stair-like backbone configurations are energetically favored, while SPAN stabilizes S=C double bonds at kink/edge sites and sulfur bridges between backbones. S-N bonds were found to be unstable, and larger Sn rings (reducing internal stress) are more stable than smaller ones.

Figure 2.

Proposed chemical structures of SPAN in previous papers by (a) Wang et al., reproduced with permission []. Copyright © 2002, Wiley-VCH; (b) Yu et al., reproduced with permission []. Copyright © 2004, Elsevier; (c) Fanous et al., reproduced with permission []. Copyright © 2011, American Chemical Society; (d) Resonated structures proposed by Zhang et al., reproduced with permission []. Copyright © 2014, MDPI; (e) Wei et al., reproduced with permission []. Copyright © 2015, American Chemical Society; (f) Wang et al. reproduced with permission []. Copyright © 2018, American Chemical Society; (g) Jin et al., reproduced with permission []. Copyright © 2018, Elsevier; (h) Weret et al., reproduced with permission []. Copyright © 2020, Elsevier; (i) Huang et al., reproduced with permission []. Copyright © 2021, American Chemical Society.

4. Structural Evolution During Synthesis

SPAN is typically synthesized by heating a mixture of PAN and sulfur at elevated temperatures for an extended duration under an inert atmosphere [,]. The structural evolution from PAN to SPAN, along with the associated chemical transformations, has been extensively investigated. Key findings are summarized below.

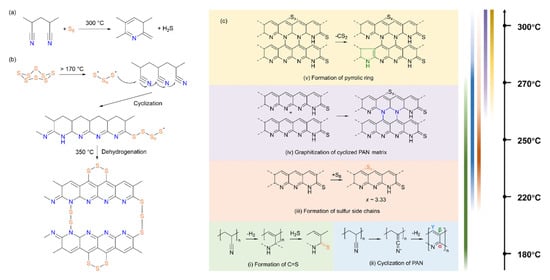

In their pioneering 2002 study, Wang et al. proposed that sulfur acts as an effective dehydrogenating agent, removing hydrogen from PAN to produce H2S during heat treatment [] (Figure 3a). Simultaneously, the -CN groups undergo cyclization, forming a conjugated heterocyclic chain. He et al. (2008) later employed thermogravimetry (TG) and differential scanning calorimetry (DSC) to analyze PAN and sulfur mixtures heated to 600 °C []. Their DSC data revealed exothermic peaks near 320 °C for sulfur/PAN ratios below 3.5:1, transitioning to endothermic peaks at ratios above 4:1, suggesting a critical reaction threshold at this temperature.

In 2020, Weret et al. proposed a mechanistic pathway for SPAN synthesis based on spectroscopic evidence [] (Figure 3b). They hypothesized that thermally initiated ring-opening of S8 generates polysulfane diradicals, which subsequently attack nitrile carbons, initiating heterocycle formation and sulfur incorporation into the PAN backbone.

A more detailed thermodynamic analysis was provided by Xie et al. in 2025, who utilized X-ray absorption spectroscopy (XAS) to probe bonding interactions during SPAN synthesis with element-specific resolution (C, N, S) [] (Figure 3c). During the synthetic process, the formation of C=S bonds begins at around 180 °C, where sulfur bonds to the carbon adjacent to the nitrogen in the matrix. In 180–220 °C, PAN cyclization occurs, but not significantly. Major reactions, including cyclization of PAN and the formation of C-S bonds occur predominantly between 220 and 270 °C. Sulfur tends to bond with the γ-site of the six-membered ring and connect two carbon rings with C-Sx-C bonds. Above 250 °C, pyrrolic rings and graphitic structures start to form. At 300 °C, the average length of x of sulfur chains in C-Sx-C is approximately 3.33. This work underscores the utility of XAS in elucidating reaction pathways for organic cathode materials and provides a foundation for optimizing SPAN’s electrochemical cyclability.

Figure 3.

The proposed structural evolution mechanisms of the synthesis of SPAN by (a) Wang et al., reproduced with permission []. Copyright © 2002, Wiley−VCH; (b) Weret et al., reproduced with permission []. Copyright © 2020, Elsevier; (c) Xie et al., reproduced with permission []. Copyright © 2025, American Chemical Society.

5. Electrochemical Properties

Extensive research into the electrochemical behavior of SPAN cathodes has revealed several consistent characteristics as understanding of its chemical structure has advanced. These include high initial discharge capacity with accompanying voltage hysteresis, a “solid–solid” conversion mechanism during charge/discharge processes, significant volume expansion during cycling, relatively stable cycling performance, compatibility across a wide temperature range, and sluggish reaction kinetics. These properties have been systematically investigated through numerous studies.

Initially, Wang et al. assembled Li||SPAN batteries with polyvinylidenefluoride-hexafluoropropylene (PVDF-HFE) gel electrolyte system containing 1 M LiPF6 in ethylene carbonate (EC) and dimethyl carbonate (DMC) (1:1, v/v) [,,]. The Li||SPAN batteries delivered an initial discharge capacity of 850 mAh g−1SPAN and retained above 600 mAh g−1SPAN after 50 cycles. This corresponded to approximately 90% sulfur utilization, with Li2S identified as the discharge product through subsequent analysis. Cyclic voltammetry studies revealed two closely spaced reduction peaks centered around 1.85 V versus Li+/Li during discharge, and a single oxidation peak at approximately 2.27 V during charge.

Further investigations by He et al. between 2007 and 2009 provided additional insights into the charge/discharge characteristics of SPAN cathodes [,,]. Their work established important operational limits, showing that while SPAN cathodes suffer irreversible degradation when charged above 4.0 V, they maintain excellent reversibility even when deeply discharged to 0 V. The temperature resilience of SPAN was clearly demonstrated through capacity measurements of 854 mAh g−1SPAN at 60 °C and 632 mAh g−1SPAN at −20 °C. In addition, these studies first documented the substantial volume changes occurring during cycling, revealing a 22% increase in cathode thickness during discharge associated with Li+ insertion and accompanying structural rearrangements.

The importance of electrode engineering parameters on electrochemical properties of SPAN has been thoroughly examined in multiple studies. Wang et al. demonstrated in 2010 that compaction pressure significantly affects electrochemical behavior, with optimal performance achieved at 8 MPa and notable degradation occurring at higher pressures of 24 MPa due to pore structure collapse and reduced ionic accessibility []. Niesen et al. systematically investigated the relationship between electrode density and electrochemical performance of SPAN cathodes []. The results shows that while calendaring reduced the electrical resistance, compressing the electrodes to densities higher than 1.05 g cm−3 led to a reduction in rate capability due to the loss of active reaction sites and a poor wettability of the electrode. Moschner et al. further advanced this understanding by characterizing the springback phenomenon in compressed SPAN electrodes and its detrimental effects on long-term cycling stability []. Their comprehensive analysis combining experimental and simulation approaches identified maintenance of homogeneous electronic networks as critical for sustained performance, suggesting several optimization strategies including improved binder systems and incorporation of advanced conductive additives such as carbon nanotubes or graphene.

The kinetic limitations and interfacial phenomena of SPAN cathodes were elucidated through detailed electrochemical impedance spectroscopy (EIS) studies by Wang et al. in 2011 []. Their work tracking impedance evolution at various states of charge revealed dynamic changes in both interfacial impedance (Rsf) and charge transfer resistance (Rct) during cycling, with values increasing during delithiation and decreasing during lithiation. Notably, the Li+ diffusion coefficient was found to reach its maximum value after the initial formation cycle, while both Rsf and Rct decreased following the first complete lithiation, indicating improved electrode kinetics and reversibility after this activation process.

6. Redox Reaction Mechanism

The distinctive electrochemical behavior of sulfurized polyacrylonitrile (SPAN) has motivated comprehensive investigations into its redox reaction mechanism, with researchers employing increasingly sophisticated analytical techniques to unravel the complex structure-property relationships. The evolving understanding of this mechanism has progressed through several key stages of discovery.

Initial studies by Wang et al. established fundamental observations regarding SPAN’s electrochemical behavior, noting both the remarkably high initial discharge capacity and the characteristic low voltage plateau [,,]. Their proposed mechanism implicated strong electronic interactions between sulfur heteroatoms and nitrogen centers within the polypyridine framework, suggesting that the energetic requirements for sulfur dissociation contributed to the observed discharge potential. This work first proposed the structural modifications occurring during the initial cycle, particularly the change of nitrogen environments that accounted for subsequent more positive discharge potentials in electrochemical behavior.

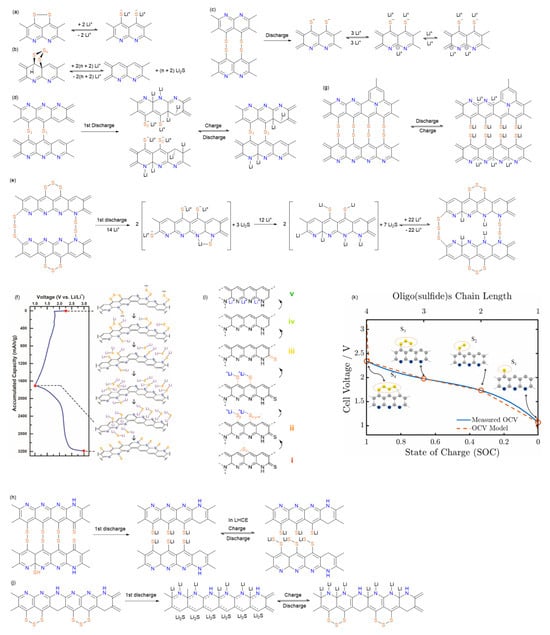

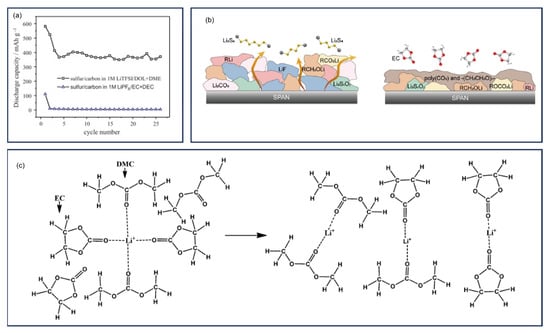

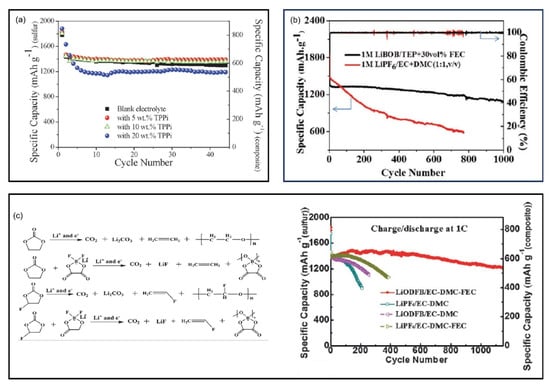

Yu et al. advanced this understanding by proposing a multi-origin capacity contribution model [] (Figure 4a): (1) conventional sulfur redox chemistry involving embedded nano-sized elemental sulfur, (2) cleavage and reformation of S-S linkages within the polymer matrix, and (3) Faradaic processes associated with lithium intercalation/deintercalation in the layered structure. This mechanism explained SPAN’s exceptional capacity while accounting for its unique voltage profile.

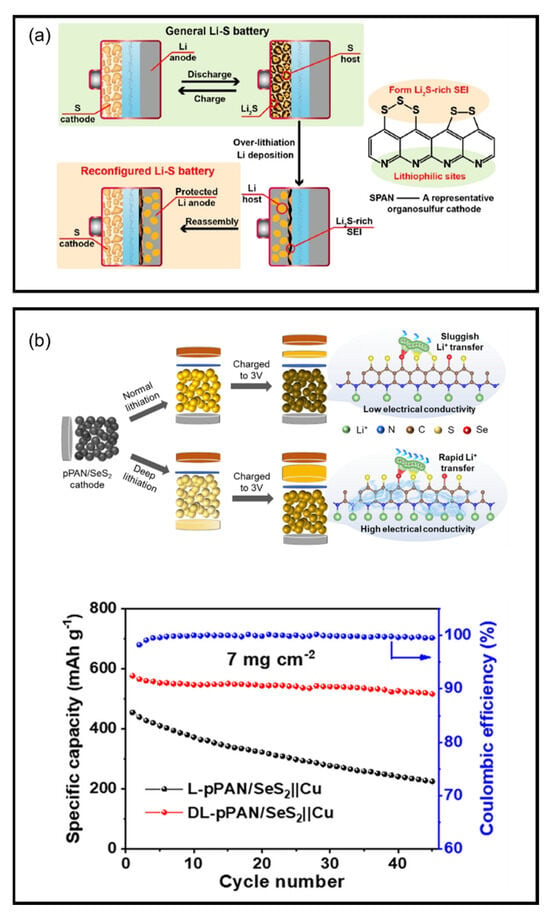

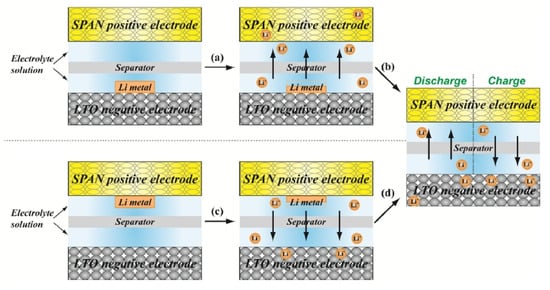

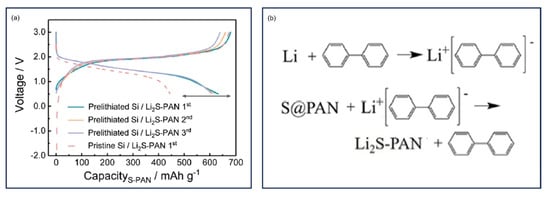

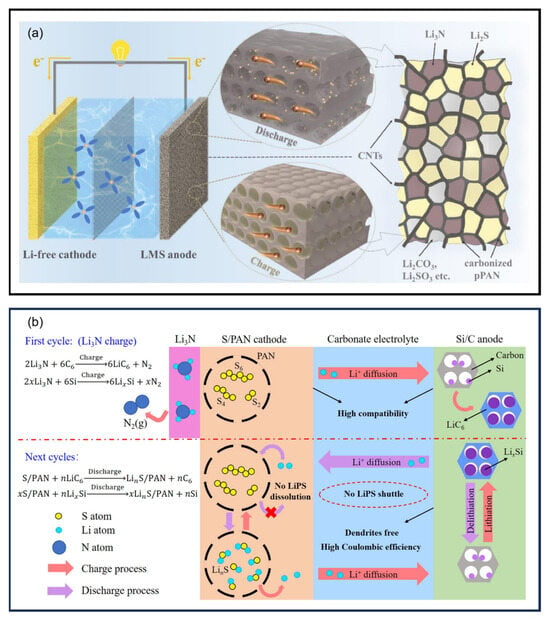

Subsequently, Fanous et al. conducted electrolyte studies and found that the Li||SPAN cells prepared from LiTFSI in 1,3-dioxolane (DOL) and dimethoxyethane (DME) displayed a shoulder peak in the discharge profile, indicating the formation of elemental sulfur []. They proposed that in ether-based electrolytes, the sulfur of the polysulfides that was not bound to carbon but to the sulfur was first released from the backbone and further reduced to Li2S. In addition, the authors proposed that the polymer backbone contributes to an additional ~100 mAh g−1cathode to the capacity only in the first discharge cycle. Complementary investigations into the electroactivity of the SPAN backbone within expanded charge–discharge windows by Wang et al. revealed an ultra-high lithium storage capacity at low potentials (0–1 V vs. Li+/Li) corresponding to four-electron transfer per C3NH unit []. The reversible capacity of SPAN could reach 1750 mAh g−1sulfur in the charge–discharge range of 0–3 V. This finding was further elucidated by Jiang et al. who employed several in situ characterization techniques to study the over-lithiation process in SPAN via in situ Raman spectroscopy and in situ electrochemical atomic force microscopy (EC-AFM) []. It is revealed that the S-S/C-S bonds gradually break during the initial over-lithiation stage and C-Li bonds generate.

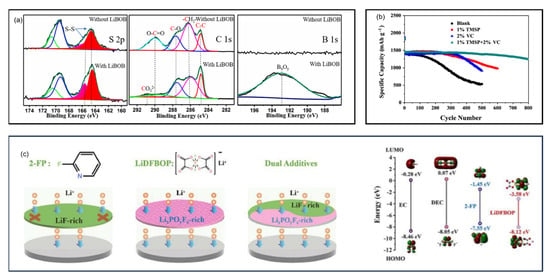

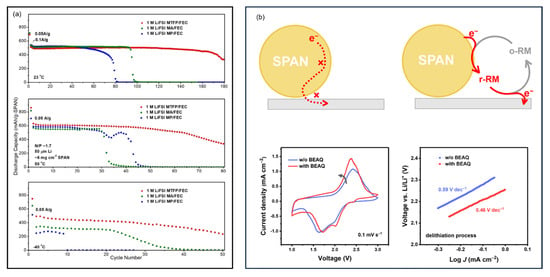

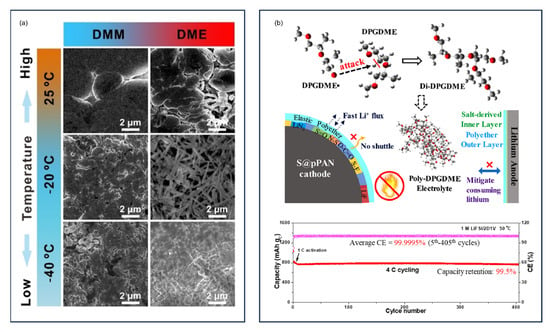

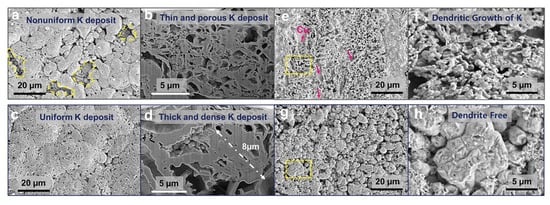

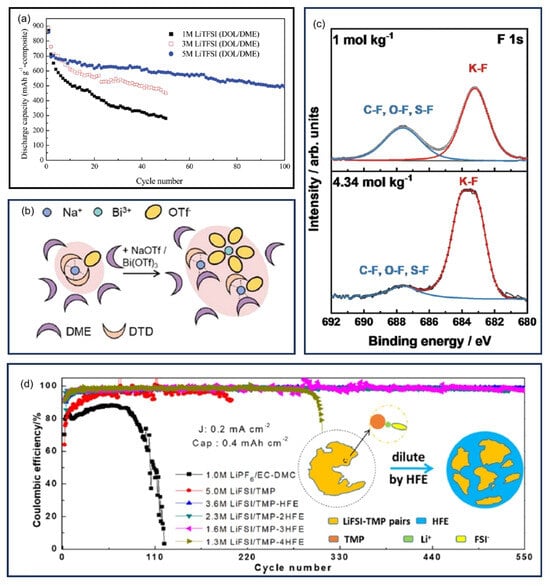

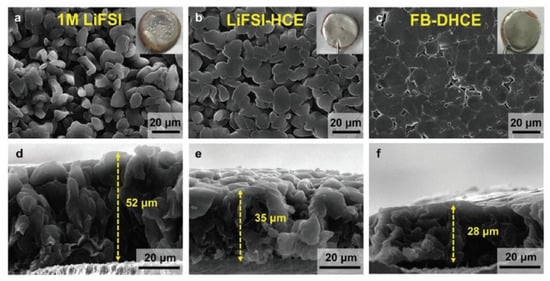

The origin of the voltage hysteresis and the initial irreversible capacity was systematically investigated by Zhang et al., who identified two primary contributors []: (1) interfacial resistance at SPAN-conductive carbon particle boundaries and (2) irreversible reduction in short conjugated carbon bonds. Their proposed “solid–solid” conversion mechanism, involving direct transformation between SPAN and Li2S without soluble lithium polysulfides (LiPSs) intermediates, provided a coherent explanation for the minimal shuttle effect and outstanding cycle life out SPAN cathodes (Figure 4b). Several researchers investigated the electrolyte-dependent behavior of the formation of LiPSs during the redox process. Wei et al. proposed that Li2S was the only discharge product in carbonated-based electrolytes, while LiPSs could form and shuttle in ether-based electrolytes []. Dominko et al. analyzed the electrochemical behavior of the SPAN cathode by in operando UV-Vis spectroscopy and 4-electrode Swagelok setup cell setup []. No LiPSs or elemental sulfur was observed during the redox process in the sulfolane electrolyte. Warneke et al. reported no long chain polysulfides were observed during discharge for the SPAN cathode in carbonate and ether mixed electrolytes [].

Wang et al. confirmed the presence of the thiyl radical after the cleavage of the S-S bond in the first cycle through the characterization of 7Li solid-state NMR, EPR, and simulations []. Their comprehensive characterization revealed that Li+ participate in reversible binding interactions with anionic sites localized on both sulfur and nitrogen atoms, which was fundamentally responsible for SPAN’s exceptional cycle life and rate performance characteristics (Figure 4c). Complementing these findings, Jin et al. conducted detailed investigations of SPAN’s lithium storage mechanism using solid-state NMR and XPS [] (Figure 4d). During the electrochemical process, other than the conventional sulfur redox reactions, C=N and C=C groups also react with lithium to form Li-C-N-Li and Li-C-C-Li groups and afford additional capacity. After the first charge, a portion of these lithiated carbon species remain permanently reduced. This partial irreversibility was correlated with the observed first-cycle capacity loss in SPAN electrodes.

Building upon the identification of N-S and N=C-S bonds in SPAN’s structure alongside S-S and C-S bonds, Weret et al. proposed a comprehensive SPAN redox mechanism [] (Figure 4e). During the first discharge, electrochemical cleavage of the covalent bonds results in the irreversible formation of Li-C and Li-N bonds, contributing the high initial discharge capacity. The electron-donating effect of Li-C and Li-N species increases the electron density of the conjugated structure and benefits the decrease in the voltage hysteresis after the second cycle. Huang et al. further elucidated the critical role of N-S bonds in mediating the “solid–solid” transformation, identifying a stepwise process where N-Sx-N and C-S3-C linkages cleave to form N/C-Sy-Li, N/C-Li, and Li2S species [] (Figure 4f). Their studies revealed that during full lithiation, Li2S preferentially aligns along nitrogen-rich edges of the SPAN matrix through Li-N interactions. While N/C-S bond reformation occurs during charging, the re-establishment of bridge-type N-Sx-N and C-S3-C configurations is energetically disfavored, leading instead to stabilized thiyl radical formation within the conjugated system. Kappler et al. provided comparative evidence for nitrogen’s essential role through studies of nitrogen-free sulfurized poly(vinylacetylene) (SPVac) [], conclusively demonstrating that the nitrogen-rich aromatic backbone in SPAN is prerequisite for achieving both high sulfur utilization and reversible binding.

In 2023, Wang et al. studied the structural transformation in SPAN during the first cycle and proposed a post-thermal treatment strategy to reduce the first cycle irreversible capacity loss [] (Figure 4g). The authors believed that the loss of nonaromatic functional groups such as C-S, C=S, and N-H was responsible for the irreversible capacity loss during the first cycle and conductive carbon was found to actively participate in the conversion of SPAN intermediates to the discharge products. Therefore, the authors developed a post-thermal treatment by annealing SPAN at 350 °C for 24 h to reduce the nonaromatic groups. As a result, SPAN with post-treatment exhibited nearly identical reversible capacity of 520 mAh g−1SPAN as the pristine SPAN while reducing the first-cycle irreversible capacity loss from 225 to ~100 mAh g−1SPAN.

Advanced characterization by Tan et al. using synchrotron-based pair distribution function (PDF) and soft X-ray absorption spectroscopy (sXAS) provided atomic-scale insights into cycling-induced interphasial changes in SPAN [] (Figure 4h). PDF analysis of pristine SPAN identified C-S bonds and S-S dimers connecting pyridine networks, while discharged states showed S-S cleavage and -S-Li formation. During the first discharge, the S-S dimer is replaced by short sulfur chains (-S-S-S-), accompanied by the breaking of nonaromatic C-S and C=S bonds which supplies the sulfur needed in forming short sulfur chains. The short sulfur chains are actively involved in the following reversible cycling. The study further demonstrated electrolyte-dependent interphase formation, with localized high concentration electrolyte (LHCE: 1.8 M LiFSI in diethyl ether (DEE)/bis-(2,2,2-trifluorosulfonyl)imide (BTFE)) producing stable FSI−-derived interphases, while DOL/DME led to unstable cathode-electrolyte interfaces (CEI) and polysulfide dissolution. In Xie et al.’s work, they identified the role of the bonding interactions of SPAN, including S-S, C-S, and C=S bonds, in the electrochemical reactions by tracking the evolution of XAS features of intermediate states [] (Figure 4i).

Pereira et al. investigated the redox mechanism of SPAN in LiNO3-containing ether electrolytes by a combination of post-mortem analysis with XPS and in-operando FT-IR study []. The in-operando FT-IR spectra reveal that C-S bonds reform during cycling despite breaking in the initial cycle in ether electrolytes with concentrated LiNO3. However, this reformation does not occur in ether electrolytes without LiNO3. Additionally, soluble polysulfide species exist in both systems during the first discharge but only persist in ether electrolytes without LiNO3. XPS analysis reveals the formation of a stable LiF-rich CEI in ether electrolytes with concentrated LiNO3. Based on the results, the authors proposed that a quasi-solid–solid conversion of sulfur occurred in electrolytes with sulfur enabled by a robust CEI coupled with C-S bond reformation during cycling.

Hu et al. studied the molecular structure and electrochemical reaction mechanism of SPAN by various techniques including in situ Raman, ex situ XPS, and EPR [] (Figure 4j). As it is consistent with several previous studies, the authors proposed that the reversible capacity came from the reversible S-S and C-S bond cleavage and reformation; and the initial irreversible capacity came from the irreversible reaction between C=N and Li+. The residual Li+ on the carbon matrix enhances the conductivity of the SPAN skeleton and results in the reduction in voltage hysteresis after the second cycle. The authors proposed a novel insight, where a conjugate aromatic structure with radical was formed after the C-S bond cleavage. And during the charge process, sulfur prioritizes to combine with the C radical on the aromatic ring, resulting in elimination of polysulfides generation over long cycles. Liu et al. investigated the role of the polymer backbone of SPAN from multiple aspects, including electrochemistry, spectroscopy, microscopy, and theoretical calculations []. The results revealed four critical backbone functions: (1) sulfur anchoring sites, (2) conductive π-network with narrowed HOMO-LUMO gap by sulfur-doping, (3) irreversible Li+ binding affecting first-cycle efficiency, and (4) pyridinic nitrogen-mediated Li2S stabilization.

The redox mechanism of Na||SPAN batteries was studied by Kappler et al. in 2023 []. They reported a high-performance Na||SPAN battery with a simple commercially available carbonated-based electrolyte and investigated the SPAN redox chemistry. The in situ EIS and XAS at different depths of charge and discharge revealed that the formation of Na2S2 or Na2S occurs abruptly close to the lower voltage cut-off, not gradually over discharge as that in Li||SPAN batteries.

Computational studies have been dedicated to investigating the redox reaction mechanism of SPAN and significantly advanced its understanding. In 2017, Zhu et al. employed DFT calculation to study the interactions between Li+ and SPAN with sulfur chain lengths varying from one to eight and proposed a hypothetical mechanism for the charge–discharge process []. Their study revealed that in both discharging and charging process, Li+ preferentially coordinates with N atoms. In addition, spatially separating a dissociated SnLi fragment from the backbone is difficult, which provides a plausible explanation for the minimal polysulfides shutting problem in SPAN cathodes. Based on these findings, the authors proposed a mechanism for the discharging process: First, a Li+ approaches the SPAN backbone where the Li+ simultaneously coordinates with the free end of the S-chain and the N atoms on the backbone. Then, a second Li+ attacks the end of the backbone attached to the S-chain, cleaving the S-chain, and leaving behind a single S or a S2 unit attached to the backbone and forming Li2Sy intermediate. The detached Li2Sy can be further reduced to Li2S or reattach at another location on the backbone. In 2022, Bertolini et al. investigated the discharge process of SPAN via ab initio molecular dynamics []. The simulation suggests that Li+ tends to coordinate with the nitrogen in the polymer backbone at low lithiation degree. As the lithiation progresses, Li+ coordinates with sulfur, indicating that the nitrogen plays an important role in capturing PSs.

Beltran et al. used ab initio molecular dynamics to study the electrochemical lithiation processes in a multiplayer graphene nanosheet-based sulfur-carbon composite model embedded in DOL solvent []. Their calculation showed that a strong C-S interaction, which is evidenced in SPAN composites, not only contributes to eliminate the sulfur dissociation into the solvent but also leads to an “all in-solid-state” sulfur reduction pathway, skipping the formation of long-chain LiPSs. In another one of their studies, they addressed and explained the lithiation of SPAN via first-principles computational approaches []. Their model indicated that during the lithiation process above 1.0 V vs. Li/Li+, the Li+/electrons first reduce sulfur in intermediate positions that are not interacting with the graphitized backbone directly and then attack sulfur atoms engaged in C-S bonding, leading to the C-S cleavage. Below 1.0 V, the reduction in the graphitized backbone dominates via C-Li and N-Li interactions, which accounts for the irreversible capacity loss observed in the first two discharge cycles. The effect of electrochemical lithiation on the SPAN mechanical integrity was investigated by Beltran et al. via uniaxial tensile loading tests using molecular dynamics with the ReaxFF potential []. Volume expansion, Young’s modulus, yield strength, and ultimate tensile strength with increasing lithium contents were evaluated. The results showed that the SPAN lithiation leads to a volume expansion which barely changes with a higher graphitization degree, increase YM modulus, and decreased ductility.

Bertolini et al. made significant contributions to understanding the dynamic behavior of uncoordinated carbon (Cuc) on the SPAN backbone through a series of computational studies. It was revealed that Cuc is able to not only capture a polysulfide (PS) from the electrolyte but also decompose and bind to the solvent and/or remove lithium from the PS []. In 2022, Bertolini et al. further investigated the role of Cuc in the SPAN backbone using DFT [,]. The simulation suggested that Cuc can be thermodynamically created due to lithiation. Furthermore, Cuc can react with the solvent on the polymer backbone through different mechanisms which are affected by the interaction between the solvent and Cuc. These findings provided insights into how SPAN’s structure governs lithiation of sulfur chains and revealed previously unrecognized reaction pathways between electrolytes and host materials containing a Cuc. Further investigations by Bertolini et al. using ab initio molecular dynamics simulations elucidated overpotential-driven side reactions during charging []. The simulation indicated that under high-potential conditions, electron-deficient polymer backbones become susceptible to nucleophilic attack by hydrogen atoms from electrolyte solvents, with preferential reaction sites at sulfur chains and nitrogen centers in SPAN. These parasitic reactions were shown to progressively degrade battery performance through both active material consumption and interface destabilization.

Recently, Simanjuntak et al. advanced the theoretical understanding of SPAN electrodes through a novel continuum model []. The discharge mechanism of SPAN and the impact of different parameters and processes on cell behavior were investigated (Figure 4k). The simulations identified current collector-cathode interface resistance as the dominant factor underlying large overpotentials at elevated current densities, rather than bulk electrolyte transport limitations. For cell designs targeting high energy densities, the simulation demonstrated that the morphology and microstructure of the SPAN cathode is crucial.

Figure 4.

The proposed redox reaction mechanisms of SPAN by (a) Yu et al., reproduced with permission []. Copyright © 2004, Elsevier; (b) Zhang et al., reproduced with permission []. Copyright © 2014, MDPI; (c) Wang et al., reproduced with permission []. Copyright © 2018, American Chemical Society; (d) Jin et al., reproduced with permission []. Copyright © 2018, Elsevier; (e) Weret et al., reproduced with permission []. Copyright © 2020, Elsevier; (f) Huang et al., reproduced with permission []. Copyright © 2021, Elsevier; (g) Wang et al., reproduced with permission []. Copyright © 2023, American Chemical Society; (h) Tan et al., reproduced with permission []. Copyright © 2023, American Chemical Society; (i) Xie et al., reproduced with permission []. Copyright © 2025, American Chemical Society; (j) Hu et al., reproduced with permission []. Copyright © 2024, Elsevier; (k) Simanjuntak et al., reproduced with permission []. Copyright © 2024, Elsevier.

7. SPAN Synthetic Conditions

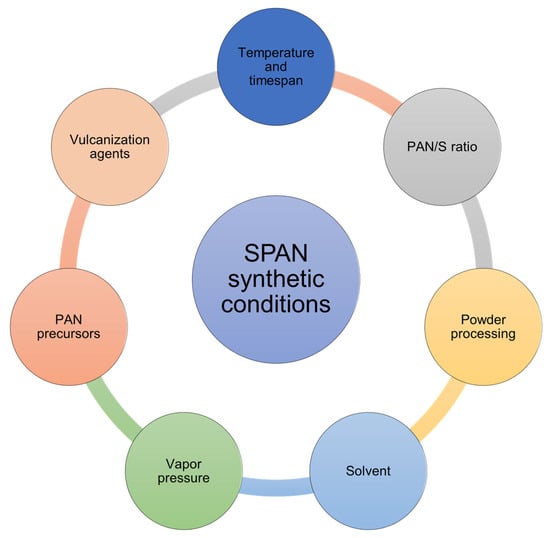

The chemical structure and the properties of SPAN are dependent on synthetic conditions. Various synthetic parameters including temperature, timespan, PAN/S ratio, powder processing, solvent, vapor pressure, PAN precursors, and vulcanization agents have been investigated by researchers to understand the correlation between the chemical structure and the property of SPAN and to optimize the synthetic procedure (Scheme 1). A comprehensive discussion is provided below.

Scheme 1.

Schematic diagram of SPAN synthetic conditions.

7.1. Temperature and Timespan

The synthesis temperature critically determines SPAN’s structural and electrochemical properties, with most studies identifying 300–450 °C as the optimal range for achieving high-performance materials [,,]. The performance of SPAN synthesized at different temperatures is summarized in Table 1. Initially, Wang et al. synthesized SPAN by heating the mixture of polyacrylonitrile (PAN) and sulfur at 280–300 °C for 6 h under argon [,,], yielding SPAN with 53.41 wt% of sulfur. The Li||SPAN battery exhibited an initial discharge capacity of 850 mAh g−1SPAN and retained above 600 mAh g−1SPAN at 0.3 mA cm−2 after 50 cycles.

Table 1.

Summary of cycling performance of SPAN synthesized at different temperatures.

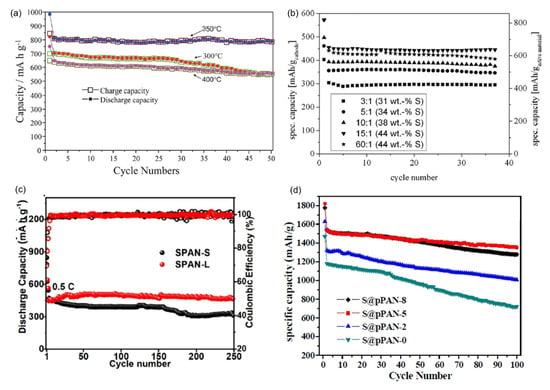

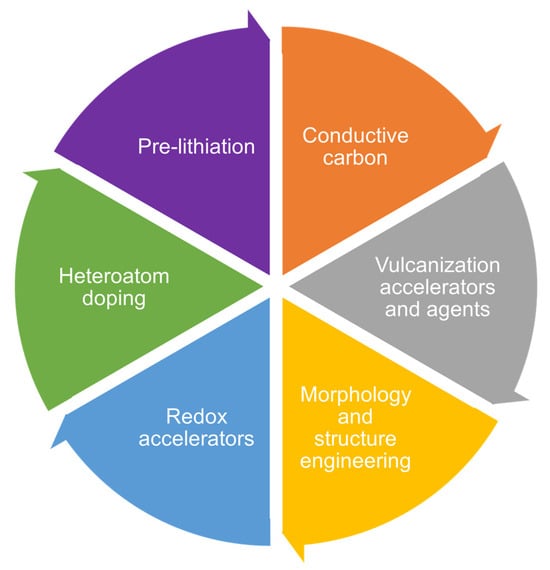

Yu et al.’s systematic investigation demonstrated that SPAN synthesized at 450 °C exhibited exceptional cyclability (90.4% capacity retention after 380 cycles) []. Wang et al. synthesized SPAN at 300, 350, and 400 °C and compared the electrochemical performances [] (Figure 5a). They identified the optimal temperature for the SPAN synthesis as 350 °C, with which the Li||SPAN battery delivered a reversible capacity of about 795 mAh g−1SPAN and a capacity retention of 98.1% after 50 cycles based on the 2nd discharge capacity. These findings were corroborated by Langrud et al., who showed complete sulfurization at 350 °C/3 h enabled 97% capacity retention over 100 cycles []. Fanous et al. also studied the influence of the synthesis temperature on the chemical structure and electrochemical performance of SPAN []. Higher synthesis temperature leads to lower sulfur content and higher degree of graphitization of the polymer backbone in SPAN, eventually resulting in higher rate capability and cycle stability. They concluded that SPAN prepared at temperatures > 450 °C showed a structural degradation, rendering 390–460 °C the optimal temperature range for synthesis. There observations were confirmed by Pan et al., who identified 300–400 °C for 12 h reaction time as producing SPAN with optimal electrochemical performance [].

Figure 5.

The cycling performance of SPAN cathodes prepared via different synthetic conditions. (a) Cycling performance of SPAN cathodes prepared at different temperatures (red: 300 °C; blue: 350 °C; purple: 400 °C). Reproduced with permission []. Copyright © 2012, Royal Society of Chemistry; (b) Cycling performance of SPAN cathodes with different sulfur content. Reproduced with permission. Copyright © 2013, IOP Publishing, Ltd.; (c) Long−term cycling performance of SPAN cathodes prepared via conventional solid−phase synthesis (SPAN−S) and liquid-phase cyclization method (SPAN−L). Reproduced with permission []. Copyright © 2024, American Chemical Society; (d) Cycling performance of SPAN cathodes prepared at different vapor pressures. The number x in S@pPAN−x is the vapor pressure during the synthesis of SPAN. Reproduced with permission []. Copyright © 2016, Royal Society of Chemistry.

Jerez et al. reported a novel two-stage synthesis process for SPAN [], involving initial heating at 150 °C to melt elemental sulfur followed by 300 °C treatment for complete vulcanization of PAN. The yielded SPAN composite contains 38.3% of sulfur. The as-assembled Li||SPAN battery delivered high capacity and stable cycling performance, with above 1000 mAh g−1sulfur after 150 cycles at 0.1 C.

While reaction time has a relatively smaller effect on the chemical and electrochemical properties of SPAN, a critical timespan of around 3–6 h is required for most SPAN synthesis to ensure the complete transformation of the PAN matrix and the covalent binding between sulfur and PAN []. The performance of SPAN synthesized at different timespan is summarized in Table 2. Doan et al.’s investigation of heating duration (0.5–4 h at 300 °C) determined 56 wt% as the upper limit for sulfur content while maintaining good cycle performance []. Lower temperatures generally require longer reaction times to achieve complete vulcanization as demonstrated by Pan et al. [].

Table 2.

Summary of cycling performance of SPAN synthesized at different timespan.

These collective findings reveal several fundamental structure-property relationships. The 300–350 °C range optimizes sulfur incorporation (50–55 wt%) while preserving the conjugated polymer structure, whereas 350–450 °C promotes enhanced graphitization that improves electronic conductivity at the expense of reduced sulfur content. Temperatures below 300 °C result in incomplete sulfurization and poor cycling performance, while exceeding 450 °C causes excessive carbonization and electrochemical activity degradation. These temperature-dependent behaviors originate from complex interplay between sulfur bonding configuration evolution (S-S versus C-S), backbone conjugation length, nitrogen environment preservation, and domain size/crystallinity development. The preponderance of evidence indicates that 350–450 °C for 3–6 h represents the optimal synthesis window, effectively balancing sulfur content, structural integrity, and electrochemical performance in SPAN materials.

7.2. PAN to Sulfur Ratio

The available binding sites for sulfur on the PAN matrix is limited, which restricts the final sulfur content in the SPAN (typically ranges from 30 to 56 wt%), and consequently affects the energy density of the SPAN cathode. The ratio of PAN and sulfur in the starting materials directly impacts the sulfur content in the SPAN. The performance of SPAN synthesized with different PAN/S ratio is summarized in Table 3. Fanous et al. conducted a comprehensive study examining SPAN synthesized at 550 °C with PAN/S ratio varying from 1/3 to 1/60 [] (Figure 5b). Their work demonstrated that while increasing sulfur content in the precursor mixture generally enhances sulfur incorporation, a saturation point exists beyond which additional sulfur does not increase the final sulfur content. Specifically, both 1:15 and 1:60 PAN/S ratios yielded SPAN with identical sulfur content of 44 wt%. Complementary research by Pan et al. explored PAN/S ratio ranging from 1/1 to 1/2, producing SPAN with sulfur content between 37.5 and 56.7 wt% []. The authors concluded that SPAN synthesized from PAN/S ratio of 1/1.5 delivered the optimal electrochemical performance.

Table 3.

Summary of cycling performance of SPAN synthesized with different PAN/S ratio.

7.3. Powder Processing

The preparation of SPAN typically involves mechanical processing of PAN and sulfur powder mixtures prior to thermal treatment. Conventional methods employ high-energy ball milling to achieve homogeneous mixing. In 2014, Konarov et al. used manual mixing followed by heat treatment at 300 °C (SPAN-m) []. Compared to SPAN prepared by high-energy ball milling mixing (SPAN-b), the authors claimed that manual mixing was less time and energy consuming and could avoid the breakage of PAN chains. Morphological results suggested the presence of protected uniform nanoscopic particles in SPAN-m, which exhibits better capacity retention and rate capability then SPAN-b. Further optimization of mechanical processing was investigated by Cho et al., who examined the effects of ball milling time on pre-heated PAN/S mixtures []. They found that pre-heated PAN/S mixtures with 5 h ball milling time yielded SPAN cathodes with the best electrochemical properties.

7.4. Solvent

While conventional SPAN synthesis typically employs dry powder mixtures of PAN and sulfur, alternative solvent-based methods have emerged as promising routes to enhance material homogeneity and electrochemical performance. These "wet" synthesis strategies enable molecular-level control over sulfur distribution and polymerization reactions.

In 2016, Du et al. pioneered an innovative solvent-mediated approach using dimethyl sulfoxide (DMSO) as the reaction medium []. Their method involved direct reaction of PAN with sulfur in DMSO solution followed by thermal treatment at 500 °C. This liquid-phase process achieved unprecedented uniformity in sulfur distribution throughout the polymer matrix, as confirmed by spectroscopic and microscopic characterization. The resulting SPAN cathode exhibited exceptional electrochemical performance, delivering a reversible capacity of 1304 mAh g−1sulfur maintained over 100 cycles at 0.5 C. More recently, Shi et al. developed a liquid-phase cyclization method employing SOCl2 as both solvent and sulfur source []. This two-step process first converts PAN to cyclized PAN (cPAN-L) at a relatively low temperature of 130 °C, followed by thermal treatment at 300 °C to produce SPAN-L. The reaction temperature is significantly lowered for the preparation of cPAN-L precursor, thereby inhibiting side reactions, and improving the structural regularity in SPAN-L. Conventional SPAN (SPAN-S) synthesized via solid-phase reaction was also prepared and tested. As a result, the Li||SPAN-L battery delivered a reversible capacity of 607.4 mAh g−1 after 100 cycles at 0.1 C, corresponding to a capacity retention of 89.4% (Figure 5c), whereas the Li||SPAN-S battery only retained 64.1% of the capacity.

7.5. Vapor Pressure

The vapor pressure conditions during SPAN synthesis have emerged as a critical parameter influencing both the material’s chemical structure and electrochemical performance. While most preparations occur under ambient pressure or in open systems, controlled vapor pressure environments can significantly enhance the resulting material properties. The performance of SPAN synthesized at different vapor pressure is summarized in Table 4.

Table 4.

Summary of cycling performance of SPAN synthesized at different vapor pressure.

In 2016, Liu et al. conducted systematic investigations in 2016 by synthesizing SPAN under precisely controlled vapor pressures of 0, 2, 5, and 8 MPa []. Their comprehensive characterization revealed that SPAN prepared at 5 MPa (SPAN-5MPa) exhibited the highest degree of graphitization, indicating formation of an optimal conductive molecular architecture. As a result, SPAN-5MPa delivered an optimal electrochemical performance, with about 1542 mAh g−1sulfur in the second cycle, and a capacity retention of 88% after 100 cycles at 200 mA g−1 (Figure 5d). Pan et al. demonstrated that vapor pressure manipulation through reactor volume adjustment in sealed hydrothermal systems could improve SPAN’s cycle stability []. Their findings suggested that moderate pressure increases promote more complete vulcanization reactions while preserving the polymer backbone’s structural integrity. In 2024, Sarode et al. reported a novel synthesis method for SPAN with high sulfur content (53.62%) by heating PAN, sulfur, and CoCl2 mixture at elevated temperature in an alumina ceramic boat closed with an alumina plate []. The synthesis method resulted in an 18% increase in sulfur incorporation, compared to the traditional open-system synthetic method.

7.6. PAN Precursors

The selection and characteristics of PAN precursors play a pivotal role in determining the structural and electrochemical properties of SPAN. While most studies employ commercial PAN homopolymers (average Mw ≈ 150,000 g mol−1), emerging research demonstrates that precursor molecular engineering can significantly impact SPAN performance.

Innovative synthetic strategies have explored direct polymerization of acrylonitrile (AN) monomers in the presence of sulfur. Zhu et al. developed a suspension polymerization method combining AN and elemental sulfur, yielding SPAN with 400 mAh g−1 reversible capacity over 30 cycles at 0.1 C []. Zhang et al. reported an in situ polymerization of acrylonitrile with nano-sulfur particles followed by vulcanization as a synthetic route to prepare SPAN []. The Li||SPAN battery demonstrated enhanced reversibility, with a second-cycle discharge capacity of 1177 mAh g−1sulfur and retained about 100% after 100 cycles at 0.5 C.

The molecular weight of the PAN precursors influences directly on the chemical composition and the properties of SPAN. Pu et al. identified distribution of the molecular weight and purity of the PAN precursor as critical factors affecting the electrochemical performance of the SPAN []. Lei et al. demonstrated that higher molecular weight PAN (555 kDa) yields SPAN with 55 wt% sulfur content and outstanding cycling stability (710 mAh g−1SPAN after 200 cycles at 1 C) [] (Figure 6a). Later, Liu et al. and Wang et al. also employed the “high-molecular-weight PAN precursor” strategy to synthesize SPAN with high sulfur content [,]. Liu et al. incorporated high molecular weight PAN (360 kDa) with reduced graphene oxide (rGO), creating bamboo-structured SPAN fibers with 53 wt% sulfur content. Wang et al. achieved breakthrough performance using ultra-high molecular weight PAN (1000 kDa), obtaining 54.5 wt% sulfur content and exceptional rate capability (695 mAh g−1SPAN at 5 C).

The chemical composition of PAN precursors plays an important role in the chemical and electrochemical properties of SPAN. According to Yi et al.’s report [] and several reports on the carbon fiber industry [,], it is a common practice to introduce copolymeric monomers, such as itaconic acid, methacrylate, acrylic acid, or acrylamide, into the PAN polymerization system to improve the mechanical properties of the carbon fiber which is a product of PAN. Yi et al. found that the introduction of even a small amount of a second monomer into the PAN structure could lead to a significantly worse electrochemical performance of the resulting SPAN (Figure 6b). Much earlier than Yi et al.’s work, Wei et al. successfully developed a SPAN/MWCNT composite as cathode materials by ball-milling S, PAN, and MWCNT followed by pyrolysis at 300 °C in N2 atmosphere in 2011 []. Instead of using homopolymer PAN, they used copolymer PAN composed of 92 wt% acrylonitrile and 8 wt% of methylacrylate, which is extensively used in textile industry and thus cheaper and more available, for the synthesis of SPAN and SPAN/MWCNT. The Li||SPAN/MWCNT battery delivered a capacity retention rate of 96.5% after 100 cycles at 0.5 C and exhibited excellent rate capability up to 7 C.

Figure 6.

The cycling performance of SPAN cathodes prepared via different synthetic conditions. (a) Cycling performance of SPAN of different molecular weights (where the number following S@PAN indicates its molecular weight). Reproduced with permission []. Copyright © 2020, American Chemical Society; (b) Cycling performance of SPAN with different PAN precursors. Blue: SPANM (Macklin PAN precursor, early product); black: SPANNM (Macklin PAN precursor, recent product); red: SPANA (Sigma-Aldrich PAN precursor, early product); purple: SPANNA (Sigma-Aldrich PAN precursor, recent product). Reproduced with permission []. Copyright © 2024, Springer Nature; (c) Cycling performance of SPAN cathodes prepared from different vulcanization agents (S2Cl2: SPAN−SCl; sulfur: SPAN−S). Reproduced with permission []. Copyright © 2022, American Chemical Society.

7.7. Vulcanization Agents

Vulcanization agents other than elemental sulfur have been proposed to lower the vulcanization temperature and optimize the SPAN structure. In 2022, Shi et al. reported a highly efficient vulcanization agent, S2Cl2, for the SPAN synthesis with low reaction temperature []. It was found that S2Cl2 could promote PAN cyclization, reduce the cyclization reaction temperature, and prevent the loss of nitrogen atoms and the agglomeration of SPAN primary particles at elevated temperatures. As a result, SPAN prepared using S2Cl2 has a more regular structure and smaller particle size, and the Li||SPAN battery delivered better electrochemical performance, with a second and 200th discharge capacity of 580 and 487 mAh g−1 at 0.1 A g−1, respectively, corresponding to a capacity retention of 84% (Figure 6c).

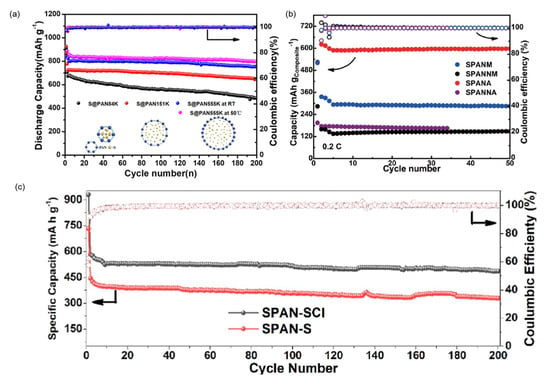

8. Cathode Modification

Researchers have developed many effective strategies for SPAN cathode modification to improve the electrochemical performance. These strategies could be categorized into six primary research directions: conductive carbon additives, vulcanization accelerators, morphology and structure engineering, redox accelerators, heteroatoms doping, and pre-lithiation of SPAN (Scheme 2). The details are presented below.

Scheme 2.

Schematic diagram of cathode modifications.

8.1. Conductive Carbon Additives

The intrinsically low electrical conductivity of SPAN represents a fundamental limitation that researchers have addressed through strategic incorporation of various carbon-based conductive additives. These materials form percolating networks that dramatically improve charge transport while maintaining the advantageous properties of SPAN. The most extensively studied carbon additives include carbon nanotubes (CNTs), graphene, porous carbon, graphite, carbon fibers, dense carbons, and their derivatives. In this section, research works that feature the modification of the SPAN cathode with conductive carbon additives will be discussed.

8.1.1. Carbon Nanotubes

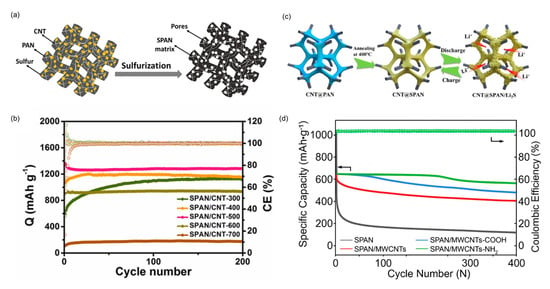

Carbon nanotubes (CNTs) have emerged as a transformative conductive additive for SPAN cathodes, leveraging their exceptional electrical conductivity, high aspect ratio, and mechanical flexibility to overcome the intrinsic conductivity limitations of SPAN materials [,]. The integration of CNTs into SPAN cathodes has been achieved through several innovative approaches, each offering distinct advantages in terms of electrochemical performance and structural stability. The performance of SPAN cathode with CNTs additives is summarized in Table 5.

Table 5.

Summary of cycling performance of SPAN cathode with CNTs additives.

In 2011, Yin et al. developed a novel SPAN@MWCNTs core–shell composite by the in situ co-polymerization of AN and itaconic acid (IA) on the surface of MWCNTs followed by vulcanization []. This approach enabled homogeneous CNT distribution throughout the SPAN matrix, establishing continuous conductive networks that significantly enhanced both cycle life and rate capability compared to conventional SPAN cathodes. Parallel work by Wei and Kim demonstrated that mechanical ball-milling of PAN, sulfur, and MWCNTs followed by pyrolysis could produce composite cathodes with similarly improved cyclability and rate performance [,].

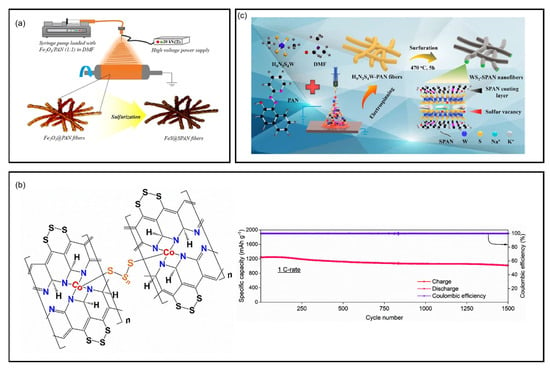

CNTs have been extensively used in the construction of freestanding SPAN electrodes. In 2019, Razaaq et al. reported a freestanding thin-film SPAN/CNTs cathode fabricated via electrospinning method by co-spinning sulfur, PAN, and CNTs followed by vulcanization [] (Figure 7a). The pre-added sulfur creates a conductive pathway in the nanofiber structure upon vaporization. The interconnected CNTs network also provide a conductive pathway for fast Li+ diffusion and electronic charge transfer. As a result, the freestanding SPAN/CNTs cathode delivered a high initial discharge capacity of 1610 mAh g−1sulfur at 0.2 C and cycle stability of 1106 mAh g−1sulfur for over 500 cycles at 1 C. In later works, Razzaq et al. reported a freestanding and fibrous CoS2/SPAN/CNTs composite cathode [] and Co10/SPAN/CNTs composite cathode []. While CNTs dramatically enhance the fiber conductivity and generate mesoscopic porosity for charge and mass transport, the atomically dispersed Co effectively enhances the electronic conductivity and facilitates the redox kinetics of SPAN. The as-assembled Li||CoS2/SPAN/CNTs pouch cell with a high cathode areal capacity (8.1 mAh cm−2) delivered a reversible discharge capacity of 1322 mAh g−1sulfur after 17 cycles. And the Li||Co10/SPAN/CNTs coin cell delivered an initial capacity of 1252 mAh g−1sulfur and retained 1020 mAh g−1sulfur after 1500 cycles at 1 C.

Further innovations in freestanding SPAN/CNTs electrode design have focused on improving electrolyte compatibility and charge transport. Wang et al. developed a freestanding fibrous SPAN/CNTs cathode compatible with both ether and carbonate electrolytes []. The interwoven SPAN/CNTs network not only accelerates charge transfer but also supplies fast Li+ transport channels. The SPAN/CNTs cathode delivered a reversible capacity of 1180 mAh g−1sulfur with no capacity decay over 1000 cycles at 800 mA g−1 in ether electrolytes, demonstrating its potential for practical applications. Li et al. also reported a flexible and freestanding SPAN/CNTs nanofibrous cathode prepared via electrospinning followed by the vulcanization process []. The SPAN/CNTs nanofiber prepared at 500 °C showed a low charge transfer resistance and the optimal cell performance, delivering reversible capacity of 1280 mAh g−1 over 200 cycles at 400 mA g−1, corresponding to a capacity decay rate of 0.02% per cycle (Figure 7b).

Recent advances have focused on three-dimensional porous architectures to support high active material loadings. Hu et al. reported a high-loading three-dimensional holey CNT@SPAN freestanding cathode fabricated by a one-step phase inversion method followed by vulcanization []. The 3D porous framework facilitates fast transport of ions and electrons, accommodates volume expansion during cycling, and mitigates the shuttle effect (Figure 7c). In addition, it was revealed that during the first discharge process, the lithium ions occupy the carbon skeleton irreversibly, enhancing the conductivity of the composite. As a result, the Li||CNT@SPAN battery with a high cathode loading (sulfur loading = 7.5 mg cm−2) exhibited 10.21 mAh cm−2 and delivered stable cycling for over 30 cycles at 0.1 C. In 2024, Shao et al. reported a self-supporting CNT-interpenetrating hierarchically porous SPAN (CIHP-SPAN) electrode prepared via a facile phase separation method []. The unique porous CIHP-SPAN cathode exhibits exceptional electron and ion conductivity. With a V2O5-anchored carbon fiber as the interlayer, the Li||ICIHP-SPAN battery delivered an initial capacity of 614.8 mAh g−1sulfur and retained 500 mAh g−1sulfur after 500 cycles at 5 C. Inspired by mussel and cobweb, Zuo et al. reported a high-loading SPAN cathode (PDA@SPAN/SWCNTs) enabled by the combination of polydopamine (PDA) coating and a bimodal SWCNTs slurry dispersed in polyvinylpyrrolidone (PVP) []. The cobweb-structured SWCNTs networks and the interactions between PDA and PVP not only improve the electrode integrity but also promote charge transport. In addition, the dynamic N-H…O hydrogen bond effectively prevents the electrode from cracking even under a high active material ratio of 95%. As a result, the Li||PDA@SPAN/SWCNTs battery with a high active material loading (7.16 mg cm−2, 5.16 mAh cm−2) retained 92.0% and 87.2% of capacity in 80 and 160 cycles at 0.1 C, respectively. Furthermore, the Li||PDA@SPAN battery with an ultra-high active material loading (16.24 mg cm−2) and lean electrolyte (E/SSPAN = 4.8) exhibited stable cycling over 60 cycles at 0.1 C.

The dispersity and chemical properties of CNTs can be altered by the chemical functionalization. Liu et al. investigated the dispersion behavior of functionalized MWCNTs within a PAN matrix and subsequently elucidated their impacts on electrochemical performance via computational and experimental studies []. It was found that aminated MWCNTs (MWCNTs-NH2), which possess lower mixing free energy and the closet Hansen solubility parameters to PAN, exhibit the optimal dispersion characteristics. Consequently, the Li||SPAN/MWCNTs-NH2 battery delivered initial discharge capacities of 907.4 and 842.4 mAh g−1 and retained 92.4% and 90.0% after 200 and 400 cycles at 0.2 and 1.0 C, respectively (Figure 7d).

Figure 7.

SPAN cathodes composited with CNTs. (a) Synthesis of the freestanding thin−film SPAN/CNTs cathode. Reproduced with permission []. Copyright © 2019, Elsevier; (b) Cycling performance of SPAN/CNT composite cathodes prepared at different temperatures. The number followed by the “−“ sign is the temperature at which the SPAN/CNT is prepared. Reproduced with permission []. Copyright © 2021, Elsevier; (c) Schematic representation of the synthesis and charge/discharge behavior of CNT@SPAN cathode. Reproduced with permission []. Copyright © 2023, American Chemical Society. (d) Cycling performance of different SPAN/MWCNT composites. Reproduced with permission []. Copyright © 2023, American Chemical Society.

8.1.2. Graphene

Graphene is a two-dimensional carbon material with a single layer of carbon atoms in a honey-comb lattice []. Graphene has been used as a carbon additive in the SPAN cathode. The performance of SPAN cathode with graphene additives is summarized in Table 6.

Table 6.

Summary of cycling performance of SPAN cathode with graphene additives.

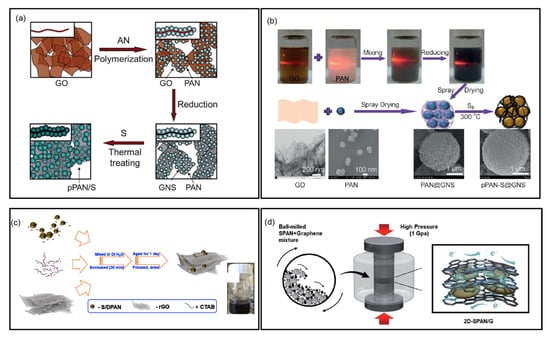

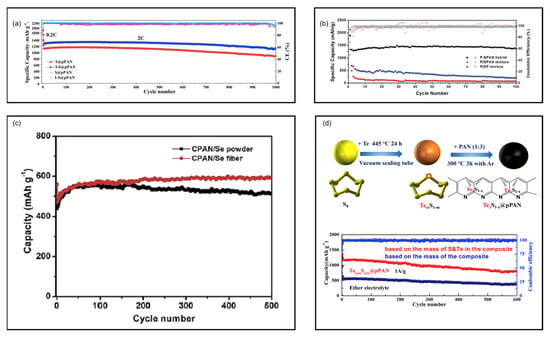

In 2012, Yin et al. reported the preparation of SPAN/graphene nanosheet (GNS) composite via in situ polymerization of AN at the presence of graphene oxide, followed by reduction by hydrazine hydrate and pyrolysis with sulfur []. The resulting composite cathode with 4 wt% graphene demonstrated significantly improved cycle life and rate capacity (Figure 8a). In the same year, the same group reported a dual-mode SPAN/mildly reduced graphene oxide nanosheets composite as cathode materials []. In this composite, sulfur is both covalently bonded with the PAN matrix and non-covalently dispersed in the mildly reduced graphene oxide nanosheets, achieving a high sulfur content of 65.1 wt%. The composite cathode exhibited about 900 mAh g−1composite discharge capacity and 650 mAh g−1composite reversible capacity for 50 cycles. Zhang et al. prepared a SPAN/graphene composite via ball milling of PAN, sulfur, and graphene, followed by heat treatment at 350 °C []. The cell displayed stable cycling across various current densities between 0.5 and 4 C, demonstrating improved electrochemical properties. Li et al. synthesized graphene oxide (GO) via a modified Hummer’s method and fabricated SPAN/GO composite with a simple physical blending method [].

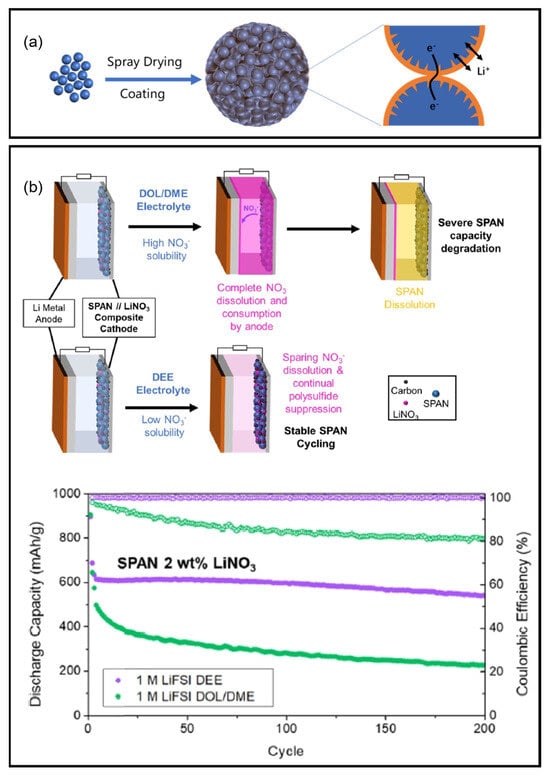

With further studies of graphene for SPAN cathodes, different preparation methods have been employed to tailor SPAN/graphene composite with different morphologies and chemical structures. Wang et al. reported a microspherical-structured SPAN/GNS composite cathode prepared via spray drying PAN nanoparticles and GNS, followed by vulcanization [] (Figure 8b). Scanning electron microscopy (SEM) and TEM revealed that PAN nanoparticles are uniformly and loosely wrapped by GNS. The SPAN/GNS composite cathode exhibited a high reversible capacity of 681.2 mAh g−1composite in the second cycle and retained 88.8% capacity after 300 cycles at 0.2 C.

Konarov et al. developed a SPAN/rGO composite prepared through self-assembling modification of rGO on SPAN, enhancing the electric conductivity of the composite to ~10−4 S cm−1 []. This SPAN/rGO cathode exhibited an initial discharge capacity of 1490 mAh g−1sulfur and retained 92% capacity after 100 cycles at 0.2 C (Figure 8c). Similarly, Krishnaveni et al. fabricated a SPAN/GO composite via solution processing []. Morphological study showed that SPAN is wrapped by highly conductive wrinkled layers of GO which not only suppress the shuttling issue but also help accommodating volume changes during cycling. The resulting Li||SPAN battery delivered an initial discharge capacity of 1402 mAh g−1sulfur and retained 1096 mAh g−1sulfur after 50 cycles at 0.1 C.

For high-mass-loading SPAN cathodes, Wang et al. designed a three-dimensional holey graphene/SPAN (SPAN/3DHG) composite []. The 3D holey graphene framework ensures fast electron and ion transport within the thick electrode and affords space to mitigate the volume expansion during cycling. The as-assembled Li||SPAN/3DHG battery with a cathode loading of 15.2 mg cm−2 delivered 581.6 mAh g−1sulfur after 1500 cycles at 2 C, corresponding to a capacity retention of 81.5%. A compact and high-mass-loading two-dimensional SPAN/graphene (2D-SPAN/G) cathode was prepared via a high-pressure pelletization method by Kim et al. [] (Figure 8d). The graphene nanosheets function as a robust and conductive scaffold, encapsulating SPAN nanoparticles, providing structural integrity, and enabling high utilization of sulfur. The Li||2D-SPAN/G battery with a high areal capacity of 11 mAh cm−2 exhibited a capacity retention of 79.0% after 300 cycles at 4 mA cm−2. In addition, the Li||2D-SPAN/G pouch cell with an area capacity of 6 mAh cm−2 retained 69.1% capacity after 150 cycles at 4 mA cm−2.

Liu et al. developed a bamboo-shaped SPAN/rGO composite with SPAN as the bamboo stalk and rGO as the bamboo joint []. The SPAN/rGO composite is fabricated by the free radical polymerization of AN in the presence of rGO followed by electrospinning and vulcanization. In 2025, Lu et al. reported a freestanding SPAN/rGO cathode with nacre-like architecture fabricated by high-speed dispersion and coating []. The graphene nanosheets provide a conductive framework and the dense layered structure effectively alleviates the volume expansion during cycling. As a result, the Li||SPAN/rGO batteries with high SPAN loadings of 8.0 and 10.0 mg cm−2 delivered 670.2 and 525.5 mAh g−1 after 60 cycles at 0.1 C, respectively.

Figure 8.

SPAN cathodes composited with graphenes. (a) Schematic illustration of the in situ polymerization and synthesis of SPAN/graphene composites. Reproduced with permission []. Copyright © 2012, Royal Society of Chemistry; (b) Schematic illustration of the synthetic process of SPAN/graphene composite via spray drying and heat treatment. Reproduced with permission []. Copyright © 2014, Wiley−VCH; (c) Schematic illustration of rGO attachment to SPAN by self-assembly. Reproduced with permission []. Copyright © 2017, Elsevier; (d) Schematic illustration of the fabrication of 2D−SPAN/G. Reproduced with permission []. Copyright © 2022, Royal Society of Chemistry.

8.1.3. Porous Carbon

Porous carbon is one of the most representative carbon materials which possesses pores of various sizes []. Porous carbons such as acetylene black (AB), Ketjen black (KB), Super P, etc., and their derivatives have been used as a conductive additive for the SPAN electrodes in many works. This subsection focuses on studies featuring the use of porous carbon in SPAN cathodes are discussed. The performance of SPAN cathode with porous carbon additives is summarized in Table 7.

Table 7.

Summary of cycling performance of SPAN cathode with porous carbon additives.

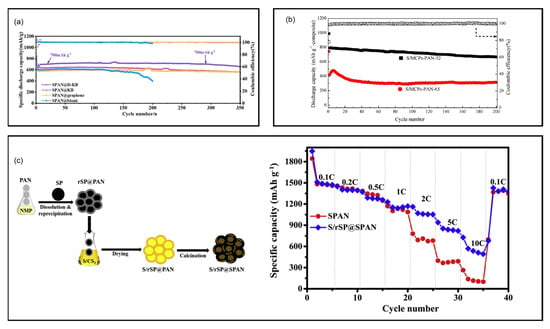

In 2013, Wen et al. reported the preparation of SPAN/porous carbon composite by the heat diffusion method, where porous carbon was synthesized from pyrolyzed phenol resin by hydrothermal reaction []. The SPAN/porous carbon composite cathode retained 658.8 mAh g−1SPAN after 50 cycles at 0.1 C, 95% of the second cycle charging capacity.

A dual-mode SPAN/KB composite was developed by Sohn et al. where sulfur was both covalently bonded to the SPAN matrix and noncovalently dispersed in the composite []. In 2024, Xu et al. engineered defective Ketjen Black (D-KB) as the matrix of SPAN by a dissolution-precipitation process to construct the internal conductive network of SPAN (SPAN@D-KB) []. Compared to pristine KB, D-KB has the advantages of high active site density and high specific surface area (1446.3 m2 g−1), therefore the conductivity and reaction kinetics of the obtained SPAN@D-KB is improved. The Li||SPAN@D-KB battery delivered a reversible discharge capacity of 700 mAh g−1composite and retained 653 mAh g−1composite after 350 cycles at 0.2 C (Figure 9a).

Chang et al. reported an interconnected core–shell pyrolyzed polyacrylonitrile@sulfur/carbon nanocomposites for LSBs [], in which the conductive porous carbon structure acted as nanoreactors and restricted the polysulfides dissolution. The composite cathode delivered an initial capacity of 1269 mAh g−1sulfur at 0.5 C. Zhang et al. developed novel microporous carbon polyhedrons (MCPs) encapsulated PAN nanofibers for fabricating sulfur composite cathodes [] (Figure 9b). The S/MCPs-PAN composite was prepared by electrospinning MCPs and PAN followed by co-heating MCPs-PAN with sulfur. The MCPs provide a sufficient sulfur loading area and PAN offers the structure stability and a conductive path. Consequently, the S/MCPs-PAN cathode with 52 wt% sulfur content delivered an initial discharge capacity of 789.7 mAh g−1composite and 666.2 mAh g−1composite after 200 cycles at 160 mA g−1 current density. Kuo et al. reported a SPAN wrapped porous carbon-sulfur composite (S/rSP@SPAN) as cathode materials for LSBs [] (Figure 9c). S/rSP@SPAN was synthesized using a dissolution-reprecipitation method followed by the thermal treatment. The dissolution-reprecipitation process augments the surface area of the composite which provides high sulfur loading area, improved active materials-electrolytes contact, and high conductivity. The resulting Li||S/rSP@SPAN battery delivered an excellent rate performance with 492 mAh g−1sulfur at 10 C and stable cycling with 1251 mAh g−1sulfur over 100 cycles at 0.1 C. A new Li+-conductive porous carbon (PANC@BP) for SPAN electrodes was proposed by Zhang et al. []. PANC@BP was prepared by coating Black Pearls 2000 with 10% PAN pyrolysis carbon. It was demonstrated that PANC@BP could inhibit the polysulfides dissolution during cycling. The Li||PANC@BP-SPAN battery delivered a second cycle discharge capacity of about 700 mAh g−1composite and maintained 661 mAh g−1composite after 300 cycles at 100 mA g−1. A novel composite material, SPAN confined in macro-porous carbon (MaPC), was firstly reported as the cathode material to improve the cycle stability of Li||SPAN batteries []. MaPC provides an interconnected electron conductive network and the space to accommodate active materials. The Li||SPAN coin cell delivered a discharge capacity of 806 mAh g−1sulfur after 150 cycles at 1050 mA g−1. A 0.8 Ah Li||SPAN pouch cell with high cathode loading of 10 mgcomposite cm−2 and lean electrolyte (3 mL Ah−1) maintained stable cycling for 25 cycles at 0.5 C.

Figure 9.

SPAN cathodes composited with porous carbon. (a) Cycling performance of SPAN@D−KB, SPAN@KB, SPAN@graphene, and SPAN@blank. Reproduced with permission []. Copyright © 2024, Elsevier; (b) Cycling performance of the S/MCPs−PAN composite. Reproduced with permission []. Copyright © 2017, American Chemical Society; (c) Schematic illustration of the synthetic procedure of S/rSP@SPAN and rate capabilities of the S/rSP@SPAN and the reference SPAN cathode. Reproduced with permission []. Copyright © 2019, Elsevier.

8.1.4. Graphite

Graphite (Gr), a naturally occurring crystalline carbon allotrope, is the most commercially successful anode material for LIBs due to its excellent conductivity and structural stability []. Its role has expanded to SPAN cathodes as a conductive additive.

In 2021, Zhang et al. demonstrated the effectiveness of KS6 graphite in SPAN cathodes []. The SPAN composite containing 10 wt% KS6 exhibited exceptional electrochemical performance, delivering an initial discharge capacity of 1700 mAh g−1sulfur and maintaining 1050 mAh g−1sulfur after 50 cycles at 100 mA g−1. This highlights graphite’s potential not only as an anode material but also as a versatile conductive agent for high-performance SPAN-based cathodes.

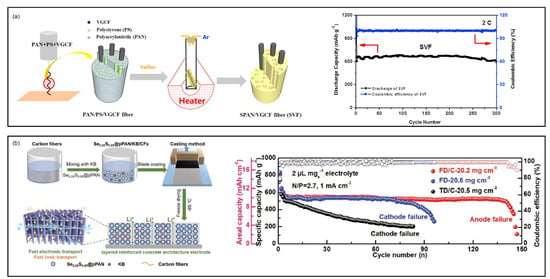

8.1.5. Carbon Fibers

Carbon fibers have emerged as promising conductive frameworks for SPAN cathodes, offering both ionic conductive pathways and enhanced electrochemical performance. In 2019, Liu et al. reported a freestanding porous SPAN/vapor grown carbon fiber composite (VGCF) as cathode materials for Li||SPAN batteries [] (Figure 10a). SPAN/VGCF was prepared by electrospinning PAN, polystyrene (PS), and VGCF suspension followed by vulcanization. During vulcanization, PS decomposed to create parallel channels in the fibers, enabling rapid ion transfer and complete utilization of the active materials. As a result, the freestanding SPAN/VGCF cathode demonstrated excellent cycling stability and rate performance, delivering 903 mAh g−1 sulfur after 150 cycles at 1 C and 600 mAh g−1 sulfur after 300 cycles at 2 C.

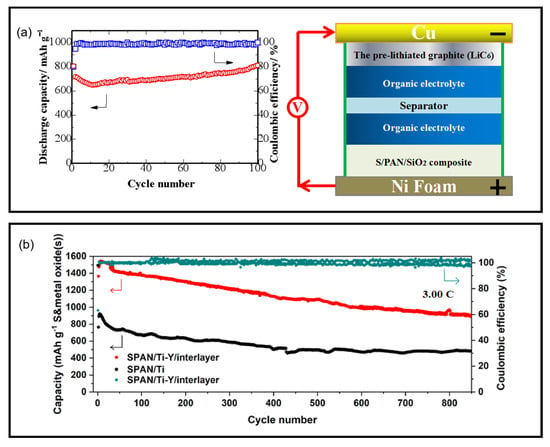

Han et al. reported a high-mass-loading Se0.05S0.95PAN cathode with a layered reinforce concrete structure (LRCS) by integrating an ice-template method with incorporated carbon fibers (CFs) [] (Figure 10b). The LRCS enables aligned through-channel structure and intertwined conductive network, leading to fast electron and ion transport and enhanced electrode integrity. Consequently, the Li||Se0.05S0.95PAN battery with a high cathode mass loading (20.2 mg cm−2), low E/S ratio of 2, and limited Li (N/P = 2.7) delivered an areal capacity of 10 mAh cm−2 and a capacity retention of 80.8% after 140 cycles at 1 mA cm−2. A 40 mAh Li||Se0.05S0.95PAN pouch cell (cathode loading of 20.2 mg cm−2, N/P = 2.7, E/S = 2) showed stable cycling over 15 cycles with slight capacity decay.

Figure 10.

SPAN cathodes composited with carbons. (a) Schematic illustration of the fabrication steps for the SVF composite and cycling performance of SVF. Reproduced with permission []. Copyright © 2019, Elsevier; (b) Schematic illustration of the electrode fabrication process via lyopholization and incorporating carbon fibers and cycling performance of thick SPAN electrodes. Reproduced with permission []. Copyright © 2021, John Wiley and Sons.

8.1.6. Dense Carbon

Recent advances in SPAN composites have explored dense carbon architectures to enhance electrode density and conductivity. In 2022, Jo et al. reported a novel SPAN/dense carbon composite material (CS-DPAN) prepared by adding terephthalic acid (TPA) to the conventional SPAN synthesis []. CS-DPAN is composed of dense carbon and SPAN, resulting in higher tap density (≈1.02 g cm−3), conductivity, and surface area than the conventional SPAN. As a result, the Na||CS-DPAN battery delivers an initial discharge capacity of 1628 mAh g−1sulfur and retained 77% after 300 cycles at 0.5 C.

8.2. Vulcanization Accelerators and Vulcanization Agents

The energy density of SPAN cathodes is intrinsically limited by their sulfur content. To address this, researchers have adapted vulcanization accelerators (VAs) from rubber industry practices, where these additives are known to promote crosslinking and improve material properties []. Typical VAs include thiocarbamates, thiazoles, sulfenamides, thiuram disulfides, etc. When incorporated into SPAN synthesis, these compounds not only increase sulfur incorporation but also enhance the electrochemical performance of the resulting cathodes. The performance of SPAN cathode with different VA additives is summarized in Table 8.

Table 8.

Summary of cycling performance of SPAN cathode with different VA additives.

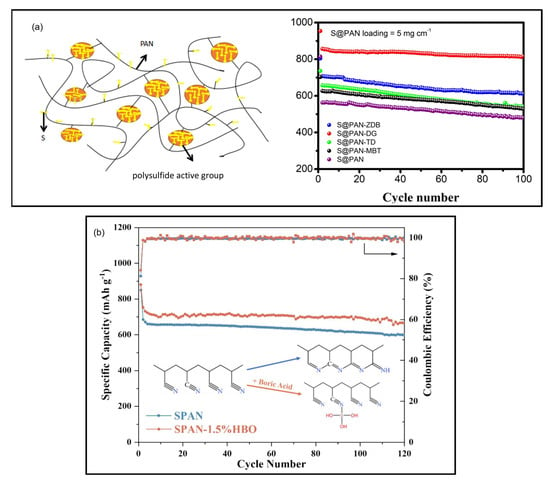

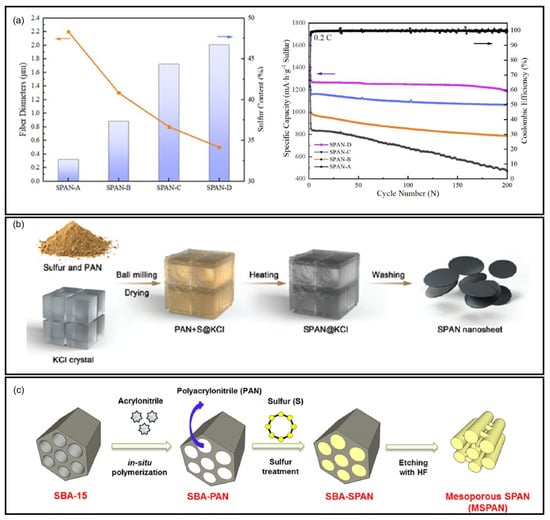

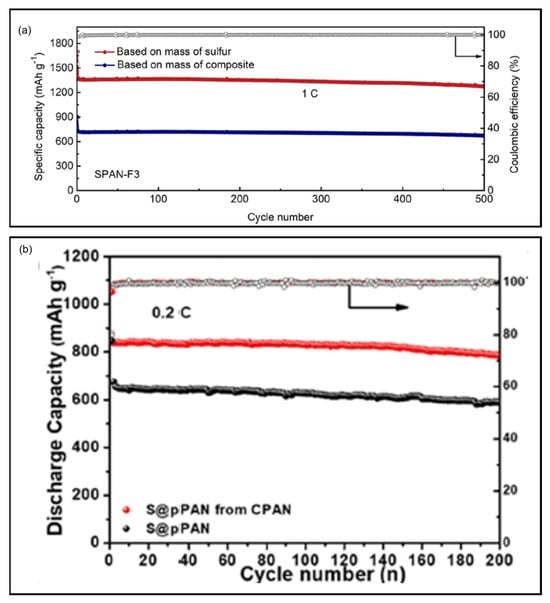

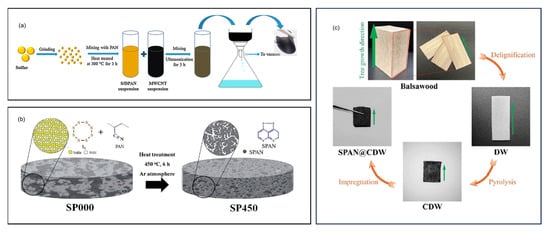

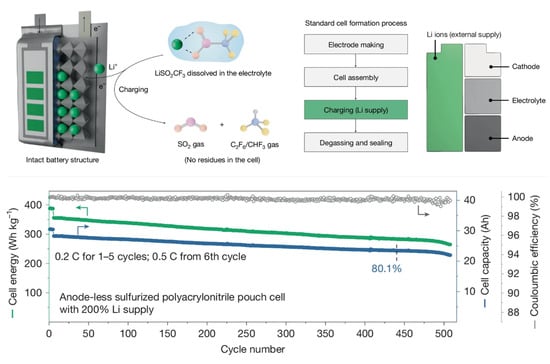

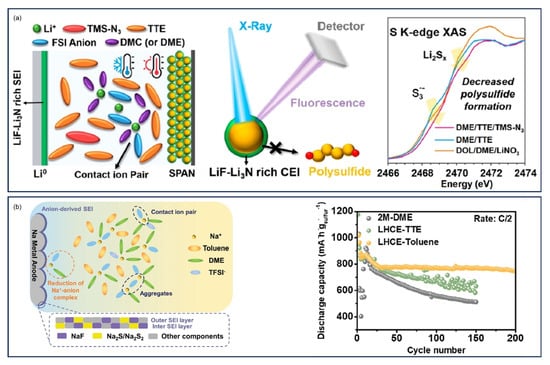

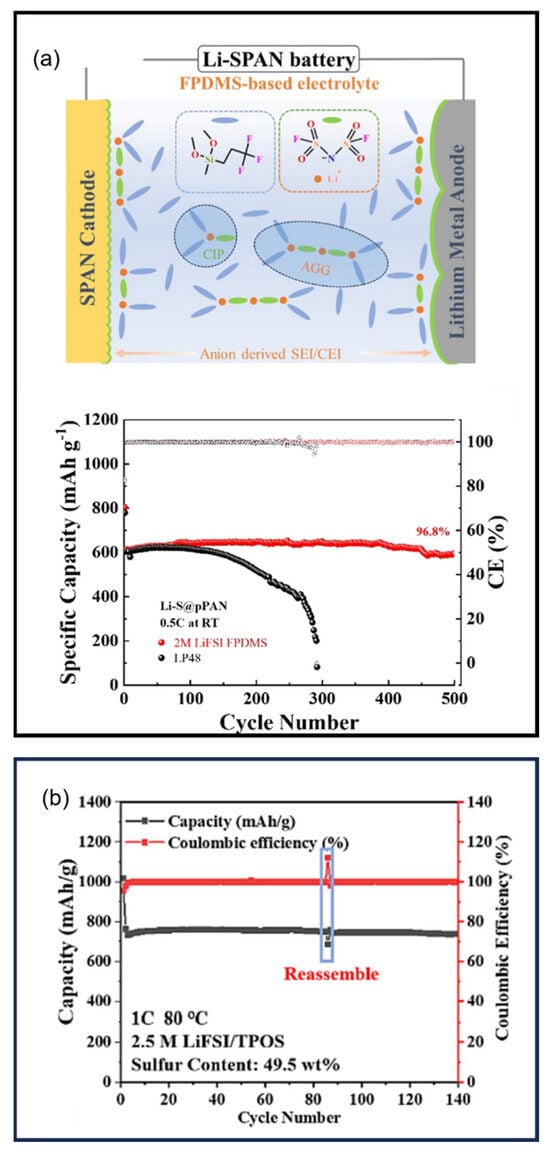

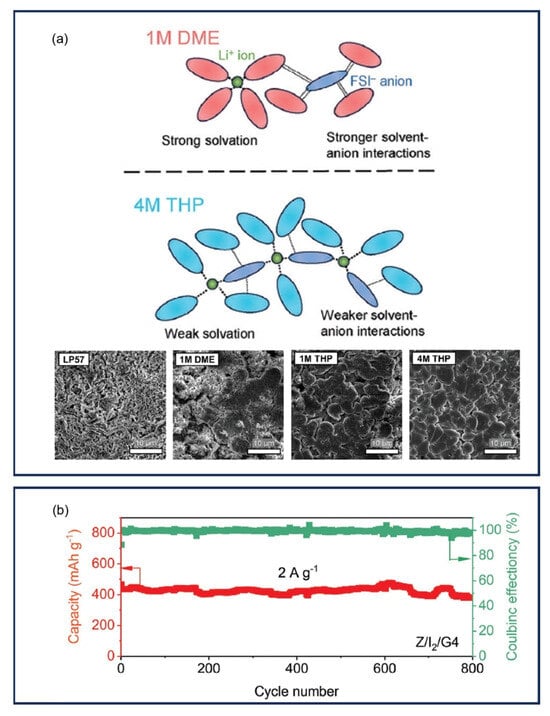

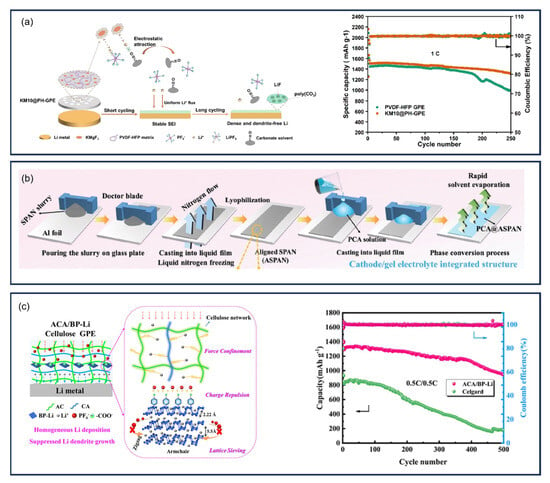

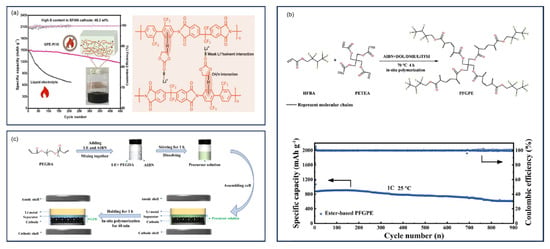

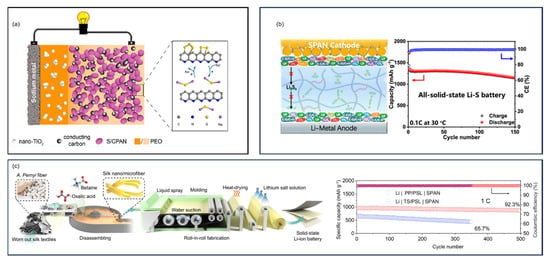

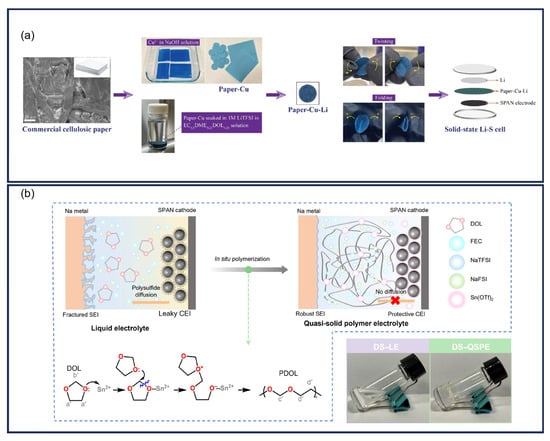

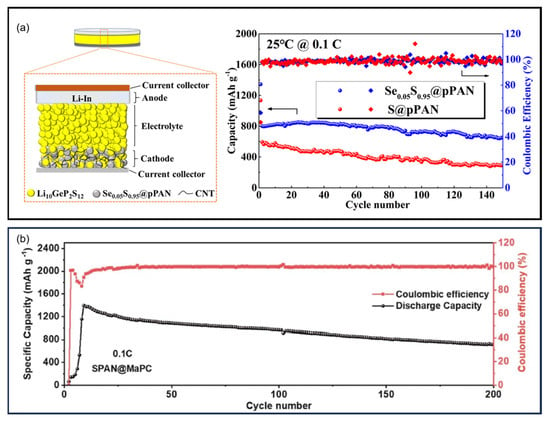

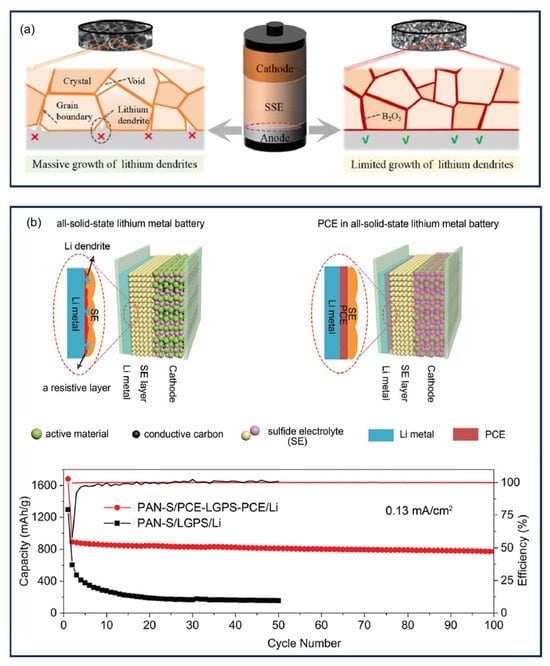

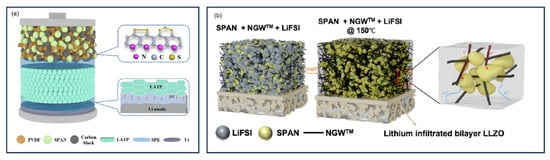

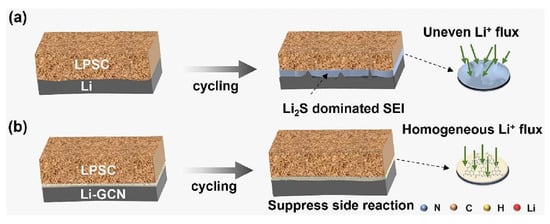

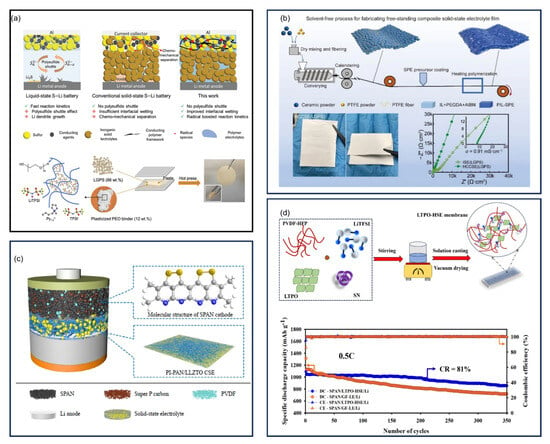

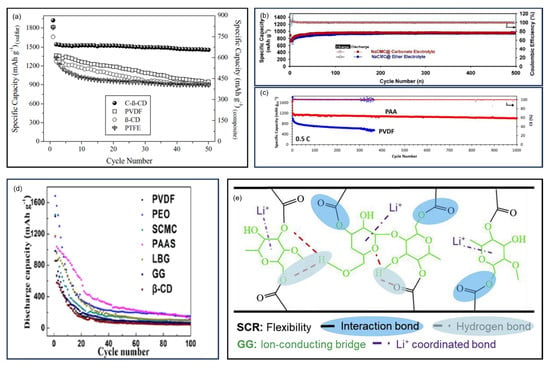

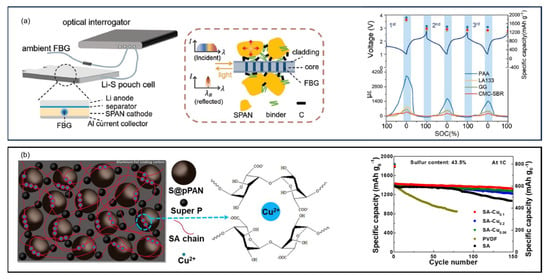

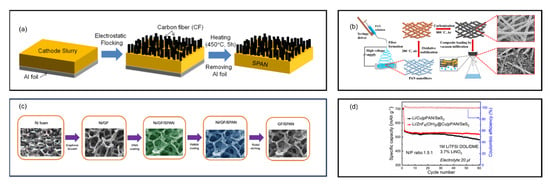

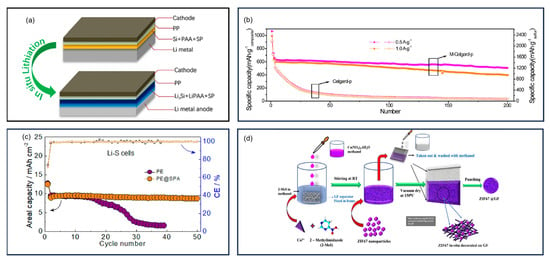

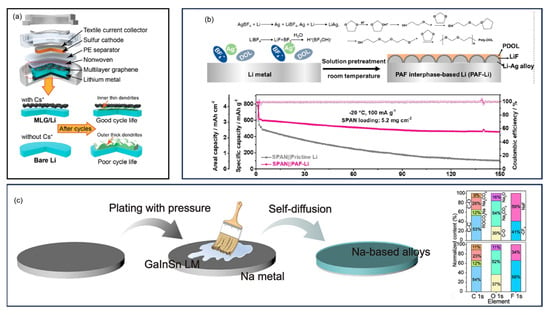

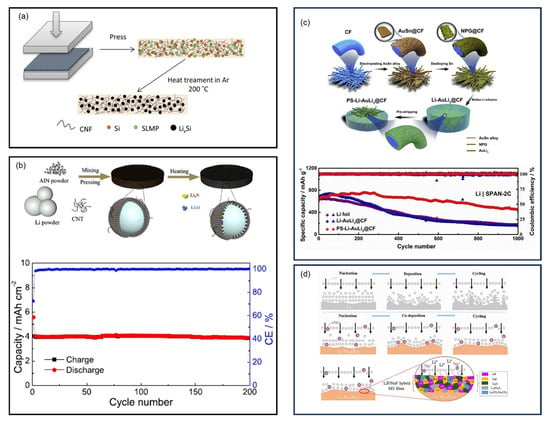

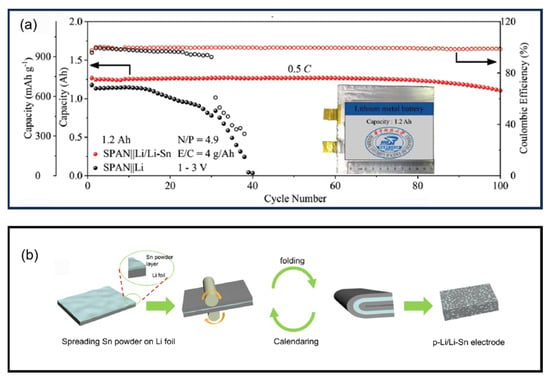

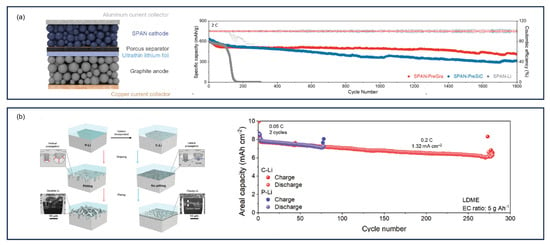

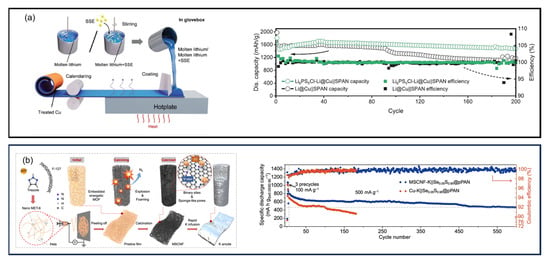

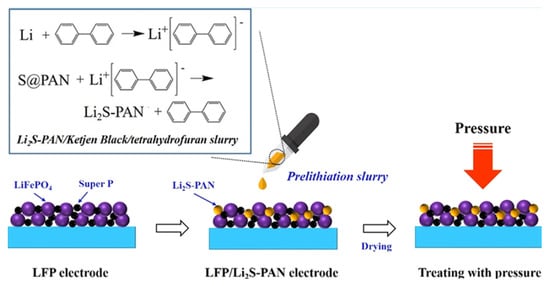

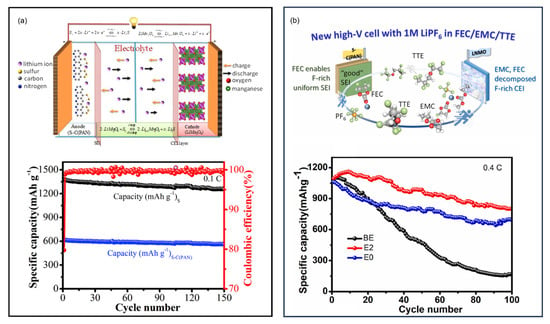

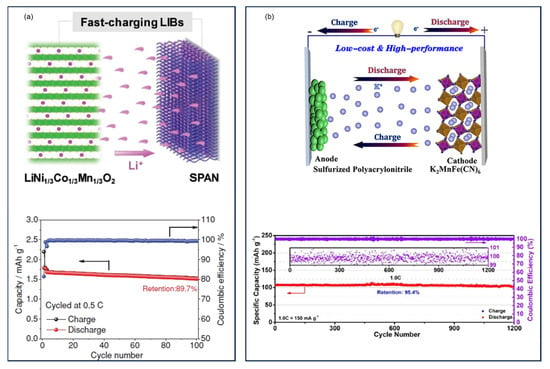

The pioneering work by Chen et al. in 2015 first demonstrated the effectiveness of this approach by employing 2-mercaptobenzothiazoles (MBT) as a VA []. Through a process involving ball milling with PAN and sulfur followed by thermal treatment at 280 °C, they achieved an 8 wt% increase in sulfur content and a corresponding 120 mAh g−1 improvement in discharge capacity compared to conventional SPAN. This breakthrough prompted further systematic investigations into VA effects. Wang et al. conducted a comparative study on the effect of different VAs on the electrochemical performance of SPAN cathodes [] (Figure 11a). Diphenyl guanidine (DG), zinc N-ethyl-N-phenyldithiocarbamate (ZDB), tetrathylthiuruam disulfide (TD), MBT, 2,2-dithiobis(benzothiazole) (DBB), and ethlenethiourea (ET) were selected and tested. Among these, the low-speed DG can effectively expand the space of the crosslinking of PAN chain and provide more vacancies and time for the sulfurization, resulting in an improvement of sulfur content in SPAN by 14 wt% and a remarkable discharge capacity of 897 mAh g−1composite at 0.1 C. The beneficial effect of DG and MBT on the electrochemical performance of SPAN is also confirmed in other works [,,].