Abstract

The objective of this study was to evaluate the nutritional value of dried Kishk-like products using burghal of wheat, oat, and fenugreek with cow’s milk, camel’s milk, and goat’s milk. Kishk is an artisanal product that is popular in Egypt and the Middle East. This product is made primarily with wheat; however, to our knowledge, no research has used fenugreek seeds in making it. Changes in the physicochemical, microbial, and sensory properties of Kishk samples were followed over 90 days of storage at room temperature. The proximate analysis of fenugreek–Kishk samples (CF, AF, and GF) revealed the levels of moisture content (4.05–7.86%), protein (21.49–22.66%), fat (22.07–26.07%), fiber (13.59–14.19%), carbohydrate (22.16–28.37%), and ash (8.00–9.03%), and acidity ranged from 3.00% to 5.98%. Notably, the GF sample displayed the highest a*, b*, dC*, and ΔE values, along with the lowest L* value among all samples. Counts of coliform, yeasts and molds, Staphylococci, and spore-forming bacteria were not detected at detection limit < log CFU/g for any prepared Kishk-like samples. This was due to the combined levels of organic acids, high acidity, and low moisture content in Kishk samples that resulted in a safe food with a long shelf life. The Kishk-like samples thus could provide a complementary diet for infants up to six months, as well as a suitable option for children and elderly individuals requiring specialized care, offering an alternative to commercially available extracts.

1. Introduction

Historically, the process of fermenting food has been used to improve shelf life and product quality. Many countries have produced traditional, dried fermented milk products for centuries using various manufacturing techniques, raw materials, and microorganisms [1]. Consequently, dried, fermented milk products play an important role in the diets of consumers in these countries [2].

Kishk is a dried mixture of fermented milk and parboiled cracked cereal (Burghul) that is widely consumed in the region spanning the Eastern Mediterranean and the Indian subcontinent [2]. Various other products exist that resemble the characteristics of Kishk. These products include Tarhana in Turkey, Kushuk in Iraq, Atole in Scotland and Greece, and Tahonya/Talkuna in Finland and Hungary [2]. Egyptian Kishk is one of the traditional foods in Upper Egypt. Its ingredients typically include Laban Zeer, which refers to fermented milk, along with boiled, dried, and crushed whole wheat grains [3]. Kishk can be made from various types of milk, including cow’s milk and buffalo milk. Kishk is a balanced food as minor constituents that are deficient in milk are supplemented by cereals and vice versa. Moreover, Kishk is highly valued for its nutritional content and contributes significantly to a healthy diet. Additionally, dried Kishk has a remarkable shelf life as it is not prone to moisture absorption. It can be stored in an open jar for up to two years without spoiling, making it a convenient and food option [4,5,6]. The properties of Kishk can be altered by using various types of cereals, starter cultures, and dairy ingredients in its formulation [7].

Camel’s milk is known for its rich nutritional composition. It is abundant in beneficial components such as volatile acids, particularly linoleic acids, and polyunsaturated acids [8]. Additionally, camel’s milk is a good source of essential minerals such as potassium, magnesium, zinc, copper, sodium, and iron, along with vitamins C and B [9]. Camel’s milk has significant biological value due to its abundant antimicrobial factors such as lysozyme, the lactoperoxidase system, and immunoglobulins [7,10]. Studies have suggested that camel’s milk possesses medicinal properties that may help to regulate and ameliorate some of the complications associated with type 1 diabetes such as high cholesterol levels, liver and kidney diseases, reduced oxidative stress, and slower wound healing [11,12,13].

Goat’s milk is widely recognized for its nutritional qualities as it contains vital nutrients and bioactive substances that promote good health. Compared to cow’s milk, goat’s milk has higher levels of essential nutrients, such as 25% more vitamin B6, 47% more vitamin A, and 13% more calcium [9,14]. These nutritional advantages are particularly beneficial for individuals with cow’s milk allergies [15]. Additionally, goat’s milk is employed as a therapeutic measure for various conditions, including gastrointestinal and respiratory issues [9,16]. In addition to its therapeutic benefits, goat’s milk is also effective in addressing malabsorption illnesses. This is due to its elevated content of short- and medium-chain triglycerides, which provide ample energy for growing children [16].

Over the past few years, cereals and their components have gained recognition as functional foods and nutraceuticals. This is because cereals offer essential dietary fiber, protein, energy, minerals, antioxidants, and vitamins that are necessary for maintaining human health. Additionally, cereals can serve as fermentable substances to support the proliferation of probiotic microorganisms [17,18]. For example, oats are a globally cultivated and consumed food crop and ancient grain that is increasing in popularity due to its nutritional composition and the multifunctional benefits provided by certain bioactive compounds [19]. Oats have significant quantities of dietary fibers (with 55% soluble fiber and 45% insoluble fiber), proteins (particularly rich in lysine), unsaturated fatty acids (including linoleic, oleic, and linolenic acids), vitamins (such as A, E, D, and B12), minerals (including calcium, phosphorus, and iron), and bioactive compounds such as phenolic compounds and β-glucan [19,20,21,22]. The consumption of oats has been associated with numerous health benefits, including antioxidant and anti-inflammatory effects, potential anticancer properties, the ability to reduce blood cholesterol and blood glucose levels, and the improvement of the gut microbiota [20,21,22].

Fenugreek (Trigonella foenum-graecum) is a leguminous herb cultivated in India and North African countries [23]. The historical use of fenugreek seeds and leaves spans both culinary and medicinal purposes, demonstrating its longstanding presence in human traditions [24]. It is widely known for its high fiber, gum, and other phytochemical components. With approximately 25% of its composition consisting of dietary fiber, fenugreek seeds offer digestive benefits and can even alter the texture of food. Moreover, fenugreek seeds are believed to contain key bioactive components, including polyphenols such as rhaponticin and isovitexin [25], as well as flavonoids, alkaloids, amino acids, coumarins, vitamins, saponins, and other antioxidants. These elements are considered to be the primary contributors to the seeds’ beneficial properties [24,26]. Numerous studies have demonstrated that fenugreek possesses significant medicinal properties, including antidiabetic, antioxidant, anticarcinogenic, hypoglycemic, and hypocholesterolemic activities [27,28]. Based on these several health benefits, fenugreek can be suggested as a beneficial addition to our daily dietary intake, as well as a valuable ingredient for creating functional foods [29]. Moreover, in modern food technology, fenugreek is utilized as a food stabilizer, adhesive, and emulsifying agent, primarily due to its fiber, protein, and gum content [28].

Unlike wheat and oat, which are deeply studied and incorporated in several forms into Kishk formulations, fenugreek seeds have not yet been incorporated into Kishk formulations. Consequently, the primary objective of this study was to develop a functional Kishk-like products made from fenugreek seed burghul with various types of milk such as cow’s milk, camel’s milk, and goat’s milk, and, for comparative purposes, Kishk formulations made with various type of milk and wheat and oat burghuls. The Kishk-like samples were then assessed for their physicochemical, microbiological, and sensory characteristics during and after 90 days of storage at room temperature.

2. Materials and Methods

2.1. Materials

Two different commercial cereals, namely wheat (Triticum spp.) and oat (Avena spp.), as well as fenugreek seed (Trigonella foenum graecum), were purchased from the local market in Alexandria, Egypt. The milk of cows and goats used for making dried Kishk was sourced from a farm in El-Beheira Governorate, Egypt. Camels’ milk, on the other hand, was obtained from a herd situated in the Maruot Research Station, which is part of the Desert Research Center located in Alexandria Governorate, Egypt. The commercial freeze-dried DVS-mixed bacterial starters of CH-1 (containing Lactobacillus delbrueckii ssp. bulgaricus and Streptococcus thermophilus) as yoghurt starter (from Chr. Hansen Laboratory Copenhagen, Denmark) were used in the fermentation process. Freeze-dried bacterial starter was propagated separately as mother cultures in autoclaved (121 °C/20 min) skim milk. The cultures were incubated at 40 °C, until the curding of milk. Cultures were prepared 24 h before use.

Preparation of Wheat, Oat, and Fenugreek Burghuls

The polished grains (0.5 kg), consisting of wheat, oat, and fenugreek, were manually cleaned by removing any foreign grains or impurities. Next, they were placed in a stainless-steel sieve and washed thoroughly under a strong stream of tap water while being continuously stirred for 2 min. Afterward, they were rinsed with distilled water. The cleaned and washed polished wheat, oat, and fenugreek were then cooked in a stainless-steel pot that contained 1.5 L of distilled water. It took between 2530 min for the grains to cook and absorb the water from the beginning of boiling. Once cooked, the grains were left to cool and then blended to break them up to obtain burghul.

2.2. Methods

2.2.1. Manufacturing of Dried Kishk-like Samples

Various Kishk-like samples were created using cow, goat, or camel milk along with wheat, oat, or fenugreek burghuls. The dried Kishk-like samples were assigned abbreviation codes, which can be found in Table 1.

Table 1.

Abbreviation codes of different prepared dried Kishk-like samples.

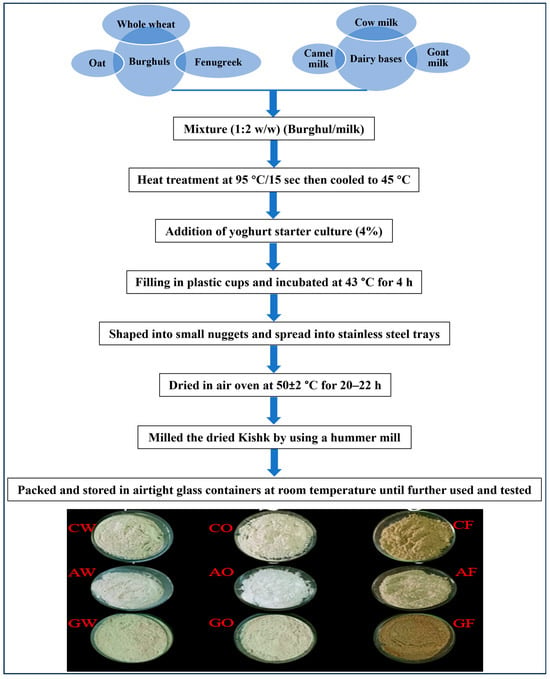

Each type of burghul was mixed with a dairy base (cow, camel, or goat milk) in a ratio of 1:2 (w/w) as described in Table 1. The mixture was then heated to 95 °C for 15 s and rapidly cooled to 45 °C. Additionally, 4% of yoghurt starter culture was added to the mixture. The resulting paste was filled into polystyrene cups and covered, then incubated at 43 °C for 4 h. After that, the fermented paste was formed into nuggets (3–5 cm), placed on stainless steel trays, and dried in an air oven at 50 ± 2 °C for 20–22 h. The dried nuggets were milled by using a hammer mill. The dehydrated Kishk was then transferred to airtight glass containers and stored at ambient temperature for 90 days, with samples being tested every 30 days during this period (Figure 1).

Figure 1.

Flow diagram of preparation steps of dried Kishk-like samples and images of final products. Product codes (CW, AW, GW, CO, AO, GO, CF, AF, and GF) match formulas in Table 1.

2.2.2. Chemical Analysis of Different Types of Milk and Burghul

The total solids, protein, ash, titratable acidity (% lactic acid), and total carbohydrate content of cow, camel, and goat milk were examined using the Association of Official Analytical Chemists standard methods [30] (Table 2). In addition, the nutritional composition of burghul made from whole wheat, oat, and fenugreek seeds was determined by analyzing their total solids, fat, protein, ash, total carbohydrate, and crude fiber content, using the methods of the American Association of Cereal Chemists (AACC) [31], and the Association of Official Analytical Chemists (AOAC) [32] (Table 2).

Table 2.

Characteristics of the raw materials used in the manufacture of dried Kishk-like samples.

2.2.3. Dried Kishk Analysis

Proximate Composition

The dried Kishk-like samples were analyzed at four different storage periods, which were 0, 30, 60, and 90 days from the start of storage. The nutritional composition of the samples was determined by following the procedures described by AOAC [33], including the analysis of total solids, protein, ash, and crude fiber content. The fat content and titratable acidity (as a percentage of lactic acid) were determined [34]. Finally, the total carbohydrate content of the samples (on a dry weight basis) was calculated using the difference (total solids − (% protein + % lipid + % ash + % crude fiber). The calorific value of dried Kishk-like samples was determined by employing the proximate analysis results and a specific equation, which is as follows:

Kcal/100 g = (% protein × 4) + (% fat × 9) + (% carbohydrate × 4)

Enumeration of Microorganisms

Different prepared dried Kishk-like samples were microbiologically analyzed after preparation. Ten grams of each sample were weighted, and transferred to sterilized flasks, containing 90 mL of 2% sodium citrate solution. Then, samples were homogenized with a Stomacher (Seward, Model 400, West Sussex, UK) for 30 s, and serial dilutions using sterilized saline solution (0.1% sodium chloride) were carried out [34].

The dried Kishk-like samples were examined after 90 days for total viable bacterial counts at 30 °C for 24–48 h using plate count agar (oxide) [3], yeasts and molds at 25 °C for 3–4 days using sabouraud dextrose agar medium (oxide) [35], coliforms at 37 °C for 24 h using violet red bile agar medium [36], Staphylococci at 35 °C for 18–24 h using Staphylococcus medium No. 110 (Difco), and spore-forming bacterial count at 32 °C for 24 h using mannitol salt agar medium after the samples were heated at 80 °C for 20 min in a water bath and then cooled at room temperature [37]. After incubation, the colonies (30–300 colonies) developed on agar plates were counted. Each value represents the mean of duplicates and the results are expressed as log colony-forming units per gram (log CFU/g).

Color Attribute Determination

The color of the dried Kishk-like samples was assessed after they were stored at room temperature for 90 days. This evaluation was carried out using a portable Hunter Lab Color Quest XE Spectrophotometer (Birstall, Leicestershire, UK). Before measurement, the instrument was calibrated with a standard plate. Three measurements were taken from each sample to ensure accuracy. The color characteristics of the Kishk-like samples were determined by measuring the following attributes: L* (lightness), a* (red/green coordinates), b* (yellow/blue coordinates), dC* (the difference between the chroma of the sample and the chroma of the standard), and ΔΕ (a single value that takes into account the differences between the L*, a* and b* of the sample and standard).

d = difference between sample and standard.

Organic Acid Determination

The concentrations of organic acids (lactic, acetic, and formic) in various dried Kishk-like samples, following 90 days of storage, were determined using the HPLC method described by Tamime et al. [38]. To extract the organic acids, five grams of dried Kishk-like samples were mixed with a water–acetonitrile solution (1:4, v/v) in a 50 mL beaker (analytical-grade, BDH Chemicals Ltd., Poole, UK). The extract after filtration through a Whatman No. 1 filter paper (Whatman Ltd., Maidstone, UK) was injected (20 μL) into the HPLC column (Aminex HPX–87H column (300 × 7.8 mm, Bio–Rad, Hercules, CA, USA). The flow rate of the solvent was 0.7 μL min−1 at 65 °C and the wavelength of the detector was 220 nm [34]. The organic acid standards were prepared in the mobile phase (0.01 M KH2PO4 with 0.0025 M sodium hexane sulfonate (ion pair reactive, Sigma, St Louis, MO, USA) solution adjusted to pH 3.1), and the chromatograph was calibrated using this standard solution. Peaks were verified by adding the standard organic acid solutions into a number of samples, and each peak area was calculated from its standard organic acid peak area. The results were calculated on a dry-weight basis.

Sensory Evaluation

The prepared Kishk-like samples (two replicates for each sample) were randomly assigned codes and then evaluated by 8 semi-trained panelists (7 women and 1 man, aged between 25 and 45 years old) at the Food and Dairy Science and Technology Department, Faculty of Agriculture, Damanhour University, Egypt. The samples were prepared as soups by mixing dried Kishk (20 g) with 170 mL of water. Then, samples were heated with stirring to boiling for a few mins, and cooled to 40 °C. The samples were served in identical glass containers to the panelists and presented at a temperature of 40 °C for sensory evaluation. Sensory descriptive analysis of soup was performed using the profiling method (BS ISO 13299:2003). The scoring system for sensory attributes was as follows: the flavor (1–45 points), body and texture (1–30 points), appearance and color (1–15 points), and acidity (1–10 points) were scored, according to the method of Abou-Donia et al. [39]. The sensory panel also defined each one of the sensory attributes. During the evaluation process, the panelists rinsed their mouths with warm water between samples to ensure the accuracy of the experimental data.

Statistical Analysis

Measurements were performed in triplicate for each sample and mean values and standard deviations are reported. Statistical analyses were carried out using CoStat software, version 6.400 (CoHort software, Monterey, CA, USA). Two- and three-way analysis of variance (ANOVA) and the least significant difference (LSD) test were used to establish the significance of differences among the treatments. Significant differences were defined at p ≤ 0.05.

3. Results and Discussion

3.1. Chemical Composition of Dried Kishk-like Samples

The chemical composition of the dried Kishk-like samples over the storage time for 90 days at 25 ± 2 °C is shown in Table 3. Significant differences were noticed in the chemical compositions among dried Kishk-like samples. The data in Table 3 indicate that the chemical composition of the dried Kishk-like samples is within the following ranges: moisture content (4.05–7.86%), protein (16.14–22.66%), fat (15.03–26.07%), fiber (7.75–14.19%), carbohydrate (22.16–44.16%), and ash (6.32–9.03%). Lowering the moisture content of Kishk-like products (ranging between 4.05 and 7.86%) extends their shelf life by inhibiting microbial activities, as well as enzymatic and nonenzymatic reactions, which are responsible for causing spoilage [40]. The findings also indicated that the influence of milk types (cow, camel, and goat) and grain types (wheat, oat, and fenugreek) on the proximate analysis of the dried Kishk-like products was significantly stronger (p ≤ 0.05) compared to the impact of storage time. In general, the dried Kishk-like samples experienced a slight decrease in total solids, fat, ash, crude fibers, protein, and carbohydrate contents over the storage period (90 days) (Table 3). These results are in agreement with previous studies [34,41].

Table 3.

Chemical composition of different dried Kishk-like samples stored for 90 days at ambient temperature.

Use of fenugreek burghul with various types of milk (cow, camel, and goat milks) resulted in Kishk-like products with elevated levels of moisture, protein, fat, ash, and crude fiber. In contrast, these products exhibited lower carbohydrate content when compared to other Kishk-like samples made using wheat and oat burghuls. On the other hand, the proximate analysis of CF, AF, and GF samples was within ranges of moisture content (4.05–7.86%), protein (21.49–22.66%), fat (22.07–26.07%), fiber (13.59–14.19%), carbohydrate (22.16–28.37%), and ash (8.00–9.03%) (Table 3). Thus, this minor variance in the proximate content is foremost linked to the composition of the ingredients used in Kishk-like formulations (Table 2) and the drying technique employed, as mentioned in previous studies [6,7,34].

According to Table 3, the dried Kishk-like samples made from oat burghul, when combined with various types of milk (CO, AO, and GO), displayed the highest values of fat (18.54–22.20%) and ash (6.55–7.92%), as well as carbohydrates (40.83–44.65%). On the other hand, these samples exhibited the lowest values of protein (16.14–16.93%) and crude fiber (7.75–7.92%) when compared to CW, AW, and GW samples, which were made using wheat burghul. These results are consistent with the findings of previous research, as reported [12,42].

Table 3 presents the gross energy values of dried Kishk-like samples. Notably, there were significant differences observed in the gross energy values between the Kishk samples when processed fresh and during storage. Undoubtedly, carbohydrates, proteins, and fats found in foods serve as energy sources for various bodily functions and physical activities. It is acknowledged that these macronutrients are considered fuel for all organisms, contributing to approximately 55–75%, 10–15%, and 15–30% of the energy required by the organisms [41]. The gross energy values of the CO, AO, and GO samples, ranging from 408.73 to 427.25 kcal/100 g, were higher than those of the other samples made from fenugreek and wheat burghuls. These differences in energy values could be attributed to the higher carbohydrate content in the CO, AO, and GO samples, whereas the fenugreek and wheat burghul milk samples had higher levels of protein and fat, respectively (Table 3). Our findings align with the results of a previous study conducted by Darwish et al. [41], in which they noted that the energy content increased in Oat–Kishk flake formulas as the proportion of oats used as a replacement increased.

In conclusion, the addition of milk to grain improves the nutritional value of Kishk powder by increasing its amino acid content. This is particularly important because plant proteins typically have lower nutritive value compared to animal proteins [12]. As a result, combining these two protein sources creates complementary proteins, with milk proteins providing lysine, which is lacking in wheat, and other essential amino acids that are beneficial for consumers [40]. This balanced protein profile offers enhanced benefits to consumers. Additionally, the higher ash and crude fiber contents observed in dried Kishk samples indicate a higher mineral content, and fiber intake is known to reduce cholesterol levels and contribute to maintaining human health [41].

3.2. The Acidity Values of Dried Kishk-like Samples

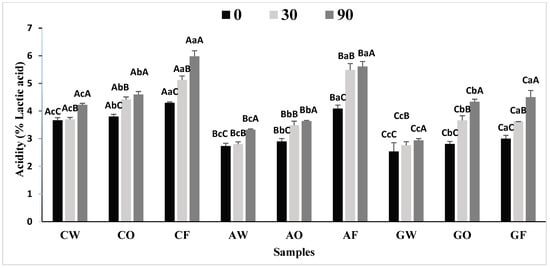

The values of titratable acidity (% as lactic acid) of prepared dried Kishk-like samples during the storage period (90 days) at room temperature were determined and the data are illustrated in Figure 2. Overall, the acidity rates of all Kishk samples demonstrated a significant and consistent increase (p ≤ 0.05) from the initial day of storage throughout the entire 90-day storage period.

Figure 2.

Acidity (%) of dried Kishk-like samples during a 90-day storage period at ambient temperature. Results are the average of 3 independent experiments, error bars represent ± standard deviation and letters of significant effects of factors (type of milk, type of grains, storage time), respectively. Data points with different letters are significantly different from each other (p ≤ 0.05). Sample codes (CW, AW, GW, CO, AO, GO, CF, AF, and GF) match formulas in Table 1.

According to the milk type used for manufacturing Kishk-like samples, the acidity values were higher in dried Kishk-like samples produced with whole cow milk (CW, CO, and CF) than camel and goat milk samples when processed fresh and up to the end of storage (90 days) (Figure 2). This could be attributed to the variations in the used milk composition in Kishk manufacture. Specifically, whole cow milk had the highest carbohydrate content (4.01%), as indicated in Table 2. This higher carbohydrate content likely promoted the growth of lactic acid bacteria during the fermentation step, leading to increased acidity in the Kishk-like samples produced with whole cow milk compared to those made with other types of milk. The present findings are in general agreement with those previously reported by Ferweez et al. [6], which indicated that Saidy Kishk prepared from cow’s milk had the highest carbohydrate content (58.25%) compared to other types of kishk made with different types of milk.

Furthermore, during the 90-day storage period, it is worth noting that the Kishk-like samples produced using goat milk experienced the most significant increase in acidity rate when compared to those made with cow and camel milk. Indeed, the acidity rate in the 0-to-90-day period exhibited the following increments: 0.40% for GW, 1.52% for GO, and 1.54% for GF samples (Figure 2). The observed trends in the results align with findings from previous studies [42,43]. This trend may be attributed to the lower buffering capacity of goat milk compared to cow milk [44]. Additionally, the different types of milk may affect the acidification rate of different lactic acid bacteria and therefore some of them may be more active in cow milk, while others may be more active in goat milk [44]. For instance, in goat milk, there is an observed increase in the microbial growth of Lactobacillus delbrueckii ssp. bulgaricus, resulting in enhanced acidity development [45].

On the other hand, based on the grain types used, the acidity rates of the dried Kishk-like samples were higher when fenugreek burghul (CF, AF, and GF) was used as the grain type compared to the samples made with oat and wheat burghuls during fresh processing and up to the end of the storage period (90 days) (Figure 2). Indeed, over the 90 days, the acidity value of the CF sample increased from 4.20% to 5.98%, while the AF and GF samples increased from 4.09% to 5.61% and from 3% to 4.54%, respectively (Figure 2). The observed outcomes could be attributed to the fenugreek seed burghul components, which have a high protein content (9.10%, Table 2), and can serve as fermentation substrates for yoghurt starter cultures. For instance, during fermentation, lactic acid bacteria might hydrolyze the fenugreek proteins, promoting their growth and metabolic activity, leading to the release of organic acids during the storage period and thus, higher acidity levels in the samples [46]. At the same time, Figure 2 illustrates that oat Kishk-like samples (CO, AO, and GO) had significantly higher acidity values when compared to wheat Kishk-like samples (CW, AW, and GW). These findings agree with previous studies [3,34,47].

In conclusion, the high acidity content of all Kishk-like samples, caused by the release of organic acids generated due to the fermentation process of milk and grain components (carbohydrate and protein), leads to a bacteriostatic effect of spoilage and pathogenic microorganisms, in which the shelf life of the final product increases [3,7,41,48].

3.3. Microbiological Analysis of Prepared Dried Kishk-like Samples

The production of healthy and safe dried Kishk is based on critical control points during the making of Kishk: cooking, fermentation, drying, and storage [49]. The microbiological analysis findings for the dried Kishk-like samples following a 90-day storage period are outlined in Table 4. It can be seen that total bacterial counts for different samples of Kishk ranged from 4.01 to 5.94 log CFU/g. These findings align with a prior study as reported [3]. On the other hand, counts of coliform, yeasts and molds, Staphylococci, and spore-forming bacteria were not detected at the detection limit < log CFU/g for any prepared Kishk-like samples. These results were in concordance with those of previous studies [3,7,34,50]. The results are mainly associated with the characteristics of Kishk, which is a highly acidic food with low water activity. The high acidity (2.54–5.98%, Figure 2) generated due to fermentation, release of organic acids, and low moisture content (4.05–7.86%, Table 3) leads to a hard environment (bacteriostatic effect) for pathogenic microorganisms, which may no cause food spoilage and shelf life increasing [49]. Hence, we can deduce that our findings indicate that the Kishk-like products exhibited favorable hygiene and sanitation standards throughout both their manufacturing and storage processes.

Table 4.

Microbiological analysis of different samples of dried Kishk prepared from various sources.

3.4. Color Parameters of Dried Kishk-like Samples

The color of food is a significant attribute influenced by the color and properties of the raw materials and the processing conditions. The L* (lightness), a* (redness), b* (yellowness), dC* (the difference between the chroma of the sample and the chroma of the standard), and ΔΕ (a single value that takes into account the differences between the L*, a*, and b* of the sample and standard) of dried Kishk-like samples after 90 days of storage were determined and the obtained results are tabulated in Table 5.

Table 5.

Color parameters of dried Kishk prepared from different sources.

The dried Kishk-like samples made with oat burghul (CO, AO, and GO) exhibited the highest L* values of 77.54, 81.96, and 76.19, respectively. On the other hand, the fermented milk samples with fenugreek burghul (CF: 60.62, AF: 68.92, and GF: 56.66) had the lowest L* values, as indicated in Table 5. Simultaneously, the use of goat milk in the Kishk-like samples (GW, GO, and GF) resulted in a decrease in L* values compared to the samples prepared using cow and camel milk. These results are in agreement with [3,12].

Table 5 further demonstrates that the fenugreek burghul fermented milk samples (CF, AF, and GF) exhibited higher a*, b*, dC*, and ΔE values compared to the other samples, with the GF sample recording 9.79, 23.78, 25.60, and 49.93 for a*, b*, dC*, and ΔE, respectively. These outcomes can be attributed to the relatively dark color of the fenugreek burghul used, which can be linked to its higher ash content (Table 2) and the presence of phenolic pigments [23], which evidently led to a considerable rise in the a*, b*, dC*, and ΔE values in the fermented milk samples.

Depending on the milk types used in Kishk-like preparation, the a*, b*, dC*, and ΔE values of camel milk samples were lower compared to the samples made with cow and goat milk. Specifically, the AO sample displayed an a* value of 1.58, b* value of 15.74, dC* value of 15.70, and ΔE value of 23.57 (Table 5).

To sum up, the GF sample showed the highest a*, b*, and ΔE values while having the lowest L* value among all the samples. Conversely, the AO sample had the lowest a*, b*, and ΔE values and the highest L* value compared to the other samples. The variations in color parameters can be attributed to the formation of Maillard reaction products during the drying process [51], the influence of phenolic compounds found in burghuls [52], and the presence of free minerals like Fe, Cu, and Sn, which can catalyze nonenzymatic browning reactions in Kishk-like powders [41,53].

3.5. Organic Acids of Dried

Organic acids are produced during the metabolism of fermentable sugars or carbohydrates. Depending on the microorganisms involved, the fermentation of milk proceeds via the glycolysis pathway with the almost exclusive formation of lactic acid, and via the pentose phosphate pathway with the formation of lactic and acetic acids [54]. During the fermentation of milk, some organic acid concentrations (lactic, propionic, acetic) increase, while the concentration of other organic acids (hippuric, orotic, citric) decreases [55]. Nevertheless, their role as natural preservatives is very important for increasing the quality of fermented milk products, especially for extending their shelf life [56].

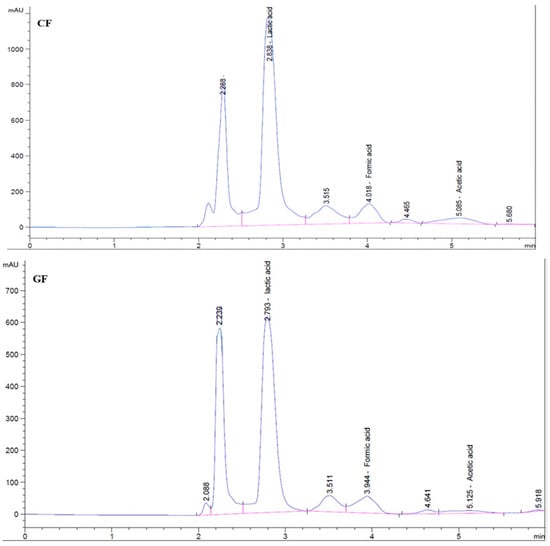

Figure 3 shows a typical HPLC chromatogram of organic acids (lactic, formic, and acetic acids) for CF, AF, and GF samples after 90 days of storage. On the other hand, the concentrations (ppm) of lactic acid, formic acid, and acetic acid for all Kishk-like samples after storage ending are presented in Table 6.

Figure 3.

HPLC chromatograms of organic acids for dried Kishk-like samples (CF, AF, and GF) after 90 days of storage time at λ= 220 nm. Numbers over peaks indicate lactic, formic, and acetic acids.

Table 6.

Organic acids of dried Kishk prepared from different sources.

In general, the amount of lactic acid was significantly (p ≤ 0.05) affected by the grain additive type (wheat, oat, and fenugreek burghuls), for all Kishk treatments. At the same time, lactic acid, formic acid, and acetic acid amounts for all Kishk-like samples were not affected (p > 0.05) by the type of milk (cow milk, camel milk, and goat milk) used for manufacturing them (Table 6). In dried Kishk-like samples after 90 days, lactic acid was found in the highest concentration (between 2400 and 32,700 ppm), while acetic was the lowest concentration (between 100 and 3100 ppm). This is related to lactic acid bacteria, which primarily derive their energy from lactose during the process of lactic acid production; meanwhile, acetic acid and other acids are produced in minor amounts [56]. According to Tamime et al. [38], the acidity of Kishk produced in the Middle East is due firstly to lactic acid, secondly to propionic acid, and thirdly to acetic acid. Nassar et al. [34] similarly observed that, following a 90-day storage period, Kishk samples prepared using wheat, barley, and freek burghuls with skim milk exhibited elevated levels of lactic acid, propionic acid, and acetic acid, with relatively minimal amounts of formic acid.

Furthermore, Table 6 illustrates that the dried Kishk samples prepared using fenugreek burghul exhibit the highest lactic acid concentration compared to the other samples. Specifically, the lactic acid content in CF, AF, and GF samples was recorded as 32,700, 27,100, and 21,000 ppm, respectively. Interestingly, these findings have coincided with those of % acidity (Figure 2), where we found the acidity rates of the dried Kishk-like samples were higher when fenugreek burghul was used compared to the samples made with oat and wheat burghuls during fresh processing and up to 90 days of storage. Therefore, it can be concluded that the dried Kishk-like samples are safe due to the combined levels of organic acids or high levels of lactic acid and low pH.

3.6. Sensory Evaluation of Dried Kishk-like Samples

Consumer rejection of any of the sensory characteristics could negatively influence the overall perception of food. The organoleptic characteristics of dried Kishk-like samples after 90 days of storage time are shown in Table 7. Panelists evaluated the flavor, body and texture, appearance, and color, as well as the acidity, of Kishk soup samples. We noticed that there were significant differences (p ≤ 0.05) between the soup samples of Kishk in flavor scores. However, there were no significant differences in the scores of body and texture, appearance, color, and acidity for the various Kishk soup samples (Table 7). These findings are in rather close accordance with those reported by Nassar et al. [34].

Table 7.

Organoleptic properties of dried Kishk-like samples prepared from different sources.

The results of the overall sensory analysis show that the utilization of wheat burghul in Kishk powder preparation resulted in highly acceptable soup properties in terms of sensory properties. At the same time, the soup samples of Kishk manufactured from fenugreek burghul with different types of milk had the lowest values of overall acceptability in the sensory analysis, for which CF, AF, and GF samples were scored 81, 85, and 77, respectively (Table 7). These results agree with [24], which found that yoghurt samples fortified with fenugreek seed flour had the lowest scores in terms of overall acceptability in the sensory analysis when compared to both plain yoghurt and yoghurt samples fortified with moringa. Finally, we can conclude that these products could be used to feed infants aged up to 6 months as a complementary diet, or used for children and elderly persons who need special care instead of commercial extracts, because the nutritive value of cereal-fermented milk is higher than of milk or cereal alone.

4. Conclusions

Fermented dairy products represent one category of fermented foods that are widely consumed, contributing to socio-economic development and food security. In this study, the Kishk-like samples we created exhibited elevated acidity, which was attributed to the fermentation process of milk and grain components, leading to the release of organic acids with bacteriostatic effects against spoilage and pathogenic microorganisms. Furthermore, these samples demonstrated low water content. These properties resulted in the final Kishk products being a safe food with a long shelf life that is easy to store at ambient temperature. Dried Kishk-like samples prepared from fenugreek burghul with cow’s milk, camel’s milk, and goat’s milk contained the highest contents of protein, fat, ash, crude fiber, and lactic acid compared to the samples made with oat and wheat burghuls. These products can function as a supplementary diet for infants up to six months old, and they also present a viable choice for children and elderly individuals in need of specialized care, providing an alternative to commercially produced extracts. Moreover, in economically challenged regions such as Africa, fermented products could help to address various challenges such as nutrient deficiencies (proteins, vitamins, and minerals), enhancing food security and mitigating the double burden of chronic and infectious diseases faced by the countries in the region. Additional research via biological evaluation such as in vivo studies and human clinical trials is warranted in order to confirm and establish the health benefits and consequent public health impact following the consumption of these products.

Author Contributions

Conceptualization, K.S.N. and E.S.R.; methodology, K.S.N.; software, K.S.N. and I.A.; validation, T.E., S.A.I. and S.A.K.; formal analysis, K.S.N., T.E. and S.A.K.; investigation, K.S.N., T.E. and S.A.K.; resources, E.S.R., I.A. and S.A.I.; data curation, E.S.R., K.S.N., T.E. and S.A.K.; writing—original draft preparation, K.S.N. and E.S.R.; writing—review and editing, K.S.N., S.A.I., T.E. and S.A.K.; visualization, K.S.N. and S.A.K.; supervision, K.S.N.; project administration, E.S.R., S.A.I., K.S.N., T.E. and S.A.K.; funding acquisition, K.S.N., S.A.I., T.E. and S.A.K. All authors have read and agreed to the published version of the manuscript.

Funding

The work was supported by the Open Access Fund of Leibniz Universität Hannover, with additional partial support from the Department of Family and Consumer Sciences and the Agriculture Research Station at North Carolina Agriculture and Technical State University, as well as the Dairy Microbiology Laboratory at Alexandria University, Egypt.

Institutional Review Board Statement

Reference number DUFA–2023–7.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data exhibited in this study are available and contained within the article.

Acknowledgments

The authors are grateful to all cooperating university research departments for their valuable efforts, which proved resourceful and beneficial for the outcomes of these trials.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Blandino, A.; Al-Aseeri, M.E.; Pandiella, S.S.; Cantero, D.; Webb, C. Cereal-Based Fermented Foods and Beverages. Food Res. Int. 2003, 36, 527–543. [Google Scholar] [CrossRef]

- Tamime, A.Y.; O’connor, T.P. Kishk—A Dried Fermented Milk/Cereal Mixture. Int. Dairy J. 1995, 5, 109–128. [Google Scholar] [CrossRef]

- Gadallah, M.G.E.; Hassan, M.F.Y. Quality Properties of Kishk (a Dried Fermented Cereal-Milk Mixture) Prepared from Different Raw Materials. J. Saudi Soc. Agric. Sci. 2019, 18, 95–101. [Google Scholar] [CrossRef]

- Abou-Donia, S.A. Origin, History and Manufacturing Process of Egyptian Dairy Products: An Overview. Alexandria J. Food Sci. Technol. 2008, 5, 51–62. [Google Scholar]

- Abou-Zeid, N.A. Review of Egyptian Cereal-Based Fermented Product (Kishk). Int. J. Agric. Innov. Res. 2016, 4, 600–609. [Google Scholar]

- Ferweez, H.; Mohran, M.; Tammam, A.A.; Ismail, H.; Farag, A. Increasing of Nutritional and Added Values of Functional Kishk by Replacing Burghul with Broken Seeds of Faba Bean (Vicia faba, L.) as Innovative Dairy Product. New Val. J. Agric. Sci. 2021, 1, 76–88. [Google Scholar] [CrossRef]

- Abd-Rabou, H.S.; Shehata, M.G.; El Sohaimy, S.A.; Awad, S.A. Functional Probiotic Quinoa Camel Milk Kishk. J. Food Process. Preserv. 2020, 44, e14681. [Google Scholar] [CrossRef]

- Mullaicharam, A.R. A Review on Medicinal Properties of Camel Milk. World J. Pharm. Sci. 2014, 2, 237–242. [Google Scholar]

- Tawfek, M.A.; Baker, E.A.; El-Sayed, H.A. Study Properties of Fermented Camels’ and Goats’ Milk Beverages Fortified with Date Palm (Phoenix dactylifera L.). Food Nutr. Sci. 2021, 12, 418–428. [Google Scholar]

- El-Agamy, E.I. Camel Milk. In Handbook of Milk of Non-Bovine Mammals; Wiley: Hoboken, NJ, USA, 2006; pp. 297–344. [Google Scholar]

- Shori, A.B. Camel Milk as a Potential Therapy for Controlling Diabetes and Its Complications: A Review of in Vivo Studies. J. Food Drug Anal. 2015, 23, 609–618. [Google Scholar] [CrossRef]

- El-Gendy, M.H.; El-Sisy, T.T.; Ali, S.A. Production of Dried Fermented Camel Dairy Product Mixed with Some Cereals. World J. Dairy Food Sci. 2016, 11, 121–130. [Google Scholar]

- Shamsia, S.M. Nutritional and Therapeutic Properties of Camel and Human Milks. Int. J. Genet. Mol. Biol. 2009, 1, 52–58. [Google Scholar]

- Getaneh, G.; Mebrat, A.; Wubie, A.; Kendie, H. Review on Goat Milk Composition and Its Nutritive Value. J. Nutr. Heal. Sci. 2016, 3, 401. [Google Scholar]

- Nayik, G.A.; Jagdale, Y.D.; Gaikwad, S.A.; Devkatte, A.N.; Dar, A.H.; Ansari, M.J. Nutritional Profile, Processing and Potential Products: A Comparative Review of Goat Milk. Dairy 2022, 3, 622–647. [Google Scholar] [CrossRef]

- Navamniraj, K.N.; Sivasabari, S.; Ankitha Indu, J.; Krishnan, D.; Anjali, M.R.; Akhil, P.R.; Pran, M.; Firzan, N.; Praveen, S.V.; Prachi, S.; et al. Beneficial Impacts of Goat Milk on the Nutritional Status and General Well-Being of Human Beings: Anecdotal Evidence. J. Exp. Biol. Agric. Sci. 2023, 11, 1–15. [Google Scholar] [CrossRef]

- Charalampopoulos, D.; Wang, R.; Pandiella, S.S.; Webb, C. Application of Cereals and Cereal Components in Functional Foods: A Review. Int. J. Food Microbiol. 2002, 79, 131–141. [Google Scholar] [CrossRef]

- El-Batawy, O.I.; Mahdy, S.M.; Gohari, S.T. Development of Functional Fermented Oat Milk by Using Probiotic Strains and Whey Protein. Int. J. Dairy Sci. 2019, 14, 21–28. [Google Scholar] [CrossRef]

- Paudel, D.; Dhungana, B.; Caffe, M.; Krishnan, P. A Review of Health-Beneficial Properties of Oats. Foods 2021, 10, 2591. [Google Scholar] [CrossRef]

- Abdelshafy, A.M.; El-Naggar, E.A.; Kenawi, M.N. Morenga Leaves for Promotion the Healthy Benefits of Oat Fermented by Probiotic Bacteria: The First Investigation. Appl. Food Res. 2022, 2, 100166. [Google Scholar] [CrossRef]

- Yu, Q.; Qian, J.; Guo, Y.; Qian, H.; Yao, W.; Cheng, Y. Applicable Strains, Processing Techniques and Health Benefits of Fermented Oat Beverages: A Review. Foods 2023, 12, 1708. [Google Scholar] [CrossRef]

- Mykhalevych, A.; Polishchuk, G.; Nassar, K.; Osmak, T.; Buniowska-Olejnik, M. β-Glucan as a Techno-Functional Ingredient in Dairy and Milk-Based Products—A Review. Molecules 2022, 27, 6313. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, K. Fenugreek (Trigonella foenum-graecum): A Review of Health Beneficial Physiological Effects. Food Rev. Int. 2006, 22, 203–224. [Google Scholar] [CrossRef]

- Dhawi, F.; El-Beltagi, H.S.; Aly, E.; Hamed, A.M. Antioxidant, Antibacterial Activities and Mineral Content of Buffalo Yoghurt Fortified with Fenugreek and Moringa Oleifera Seed Flours. Foods 2020, 9, 1157. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Ding, C.; Wang, X.; Wang, H.; Suo, Y. Using Response Surface Methodology to Optimize Countercurrent Chromatographic Separation of Polyphenol Compounds from Fenugreek (Trigonella foenum-graecum L.) Seeds. J. Liq. Chromatogr. Relat. Technol. 2015, 38, 29–35. [Google Scholar] [CrossRef]

- Ouzir, M.; El Bairi, K.; Amzazi, S. Toxicological Properties of Fenugreek (Trigonella Foenum Graecum). Food Chem. Toxicol. 2016, 96, 145–154. [Google Scholar] [CrossRef]

- Syed, Q.A.; Rashid, Z.; Ahmad, M.H.; Shukat, R.; Ishaq, A.; Muhammad, N.; Rahman, H.U.U. Nutritional and Therapeutic Properties of Fenugreek (Trigonella foenum-graecum): A Review. Int. J. Food Prop. 2020, 23, 1777–1791. [Google Scholar] [CrossRef]

- Srivastava, A.; Singh, Z.; Verma, V.; Choedon, T. Potential Health Benefits of Fenugreek with Multiple Pharmacological Properties. In Research Anthology on Recent Advancements in Ethnopharmacology and Nutraceuticals; IGI Global: Hershey, PA, USA, 2022; pp. 672–687. [Google Scholar]

- Dhull, S.B.; Punia, S.; Sandhu, K.S.; Chawla, P.; Kaur, R.; Singh, A. Effect of Debittered Fenugreek (Trigonella foenum-graecum L.) Flour Addition on Physical, Nutritional, Antioxidant, and Sensory Properties of Wheat Flour Rusk. Legum. Sci. 2020, 2, e21. [Google Scholar] [CrossRef]

- Agricultural Chemicals, Contaminants. In Official Methods of Analysis of AOAC International; Horwitz, W. (Ed.) AOAC International: Gaithersburg, MD, USA, 2010; Volume 1. [Google Scholar]

- Approved Methods of the American Association of Cereal Chemists, 8th ed.; American Association of Cereal Chemists: St. Paul, MN USA, 2000; pp. 15–46.

- Official Methods of Analysis of the Association of Official Analytical Chemists; Association of Official Analytical Chemists: Washington, DC, USA, 2000; Volume 17, ISBN 0935584676.

- Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2007; Volume 222.

- Nassar, K.S.; Shamsia, S.M.; Attia, I.A. Improvement of the Nutritional Value of a Cereal Fermented Milk: 2-Dried Kishk Like. J. Food Process. Technol. 2016, 7, 2. [Google Scholar]

- Standard 94B 1990; IDF Milk and Milk Products: Enumeration of Yeasts and Moulds—Colony Count Technique at 25 °C. IDF: Schaerbeek, Belgium, 1990.

- APHA. Standard Methods for the Examination of Water and Wastewater, 18th ed.; APHA: Washington, DC, USA, 1992. [Google Scholar]

- Nassar, K.S.; Shamsia, S.M.; Attia, I.A. Improvement of the Nutritional Value of Cereal Fermented Milk: 1-Soft Kishk Like. J. Food Process. Technol. 2016, 7, 9. [Google Scholar]

- Tamime, A.Y.; Barclay, M.N.I.; Amarowicz, R.; McNulty, D. Kishk—A Dried Fermented Milk/Cereal Mixture. 1 Composition of Gross Components, Carbohydrates, Organic Acids and Fatty Acids. Lait 1999, 79, 317–330. [Google Scholar] [CrossRef]

- Abou-Donia, S.A.; Attia, I.A.; Khattab, A.A.; El-Shenawi, Z. Formulation of Dried Cereal Fermented Milks with Prolonged Storage Life. Egypt. J. Dairy Sci. 1991, 19, 283–299. [Google Scholar]

- Darwish, S.M.; Darwish, A.M. Preparation and Evaluation of Oat-Kishk Flakes as a New Product. World J. Dairy Food Sci. 2017, 12, 19–24. [Google Scholar] [CrossRef]

- Ismail, H.A.; Rayan, A.M. Preparation and Evaluation of Quinoa-Kishk as a Novel Functional Fermented Dairy Product. J. Food Sci. Technol. 2022, 59, 1063–1074. [Google Scholar] [CrossRef] [PubMed]

- Tamime, A.Y.; Muir, D.D.; Barclay, M.N.I.; Khaskheli, M.; McNulty, D. Laboratory-Made Kishk from Wheat, Oat and Barley: 2. Compositional Quality and Sensory Properties. Food Res. Int. 1997, 30, 319–326. [Google Scholar] [CrossRef]

- Dimitrellou, D.; Salamoura, C.; Kontogianni, A.; Katsipi, D.; Kandylis, P.; Zakynthinos, G.; Varzakas, T. Effect of Milk Type on the Microbiological, Physicochemical and Sensory Characteristics of Probiotic Fermented Milk. Microorganisms 2019, 7, 274. [Google Scholar] [CrossRef]

- Serhan, M.; Mattar, J.; Debs, L. Concentrated Yogurt (Labneh) Made of a Mixture of Goats’ and Cows’ Milk: Physicochemical, Microbiological and Sensory Analysis. Small Rumin. Res. 2016, 138, 46–52. [Google Scholar] [CrossRef]

- Varga, L.; Süle, J.; Nagy, P. Survival of the Characteristic Microbiota in Probiotic Fermented Camel, Cow, Goat, and Sheep Milks during Refrigerated Storage. J. Dairy Sci. 2014, 97, 2039–2044. [Google Scholar] [CrossRef]

- Setti, K.; Kachouri, F.; Hamdi, M. Improvement of the Antioxidant Activity of Fenugreek Protein Isolates by Lactococcus lactis Fermentation. Int. J. Pept. Res. Ther. 2018, 24, 499–509. [Google Scholar] [CrossRef]

- El-Aidie, S.A.A.; El-Dieb, S.M.; El-Nawawy, M.; Emara, E.; Sobhy, H. Nutraceutical Food Based on Cereal and Probiotic Fermented Milk. Int. J. Dairy Sci. 2017, 12, 377–384. [Google Scholar] [CrossRef]

- Hajj, E.; Dib, H.; Yaacoub, R.; Mohyeddin, O.; Al-Amin, M.; Mcheik, Z. Effect of Modified Manufacturing Procedure on the Overall Quality Attributes and Safety of Kishk. Leban. Sci. J. 2019, 20, 215. [Google Scholar] [CrossRef]

- Mashak, Z.; Sodagari, H.; Mashak, B.; Niknafs, S. Chemical and Microbial Properties of Two Iranian Traditional Fermented Cereal-Dairy Based Foods: Kashk-e Zard and Tarkhineh. Int. J. Biosci. 2014, 4, 124–133. [Google Scholar]

- Tamime, A.Y.; Muir, D.D.; Khaskheli, M.; Barclay, M.N.I. Effect of Processing Conditions and Raw Materials on the Properties of Kishk 1. Compositional and Microbiological Qualities. LWT–Food Sci. Technol. 2000, 33, 444–451. [Google Scholar] [CrossRef]

- Erbaş, M.; Certel, M.; Uslu, M.K. Microbiological and Chemical Properties of Tarhana during Fermentation and Storage as Wet—Sensorial Properties of Tarhana Soup. LWT–Food Sci. Technol. 2005, 38, 409–416. [Google Scholar] [CrossRef]

- Rodríguez, H.; Curiel, J.A.; Landete, J.M.; de las Rivas, B.; de Felipe, F.L.; Gómez-Cordovés, C.; Mancheño, J.M.; Muñoz, R. Food Phenolics and Lactic Acid Bacteria. Int. J. Food Microbiol. 2009, 132, 79–90. [Google Scholar] [CrossRef]

- Bilgiçli, N.; İbanoğlu, Ş. Effect of Pseudo Cereal Flours on Some Physical, Chemical and Sensory Properties of Bread. J. Food Sci. Technol. 2015, 52, 7525–7529. [Google Scholar] [CrossRef]

- Urbienė, S.; Leskauskaitė, D. Formation of Some Organic Acids during Fermentation of Milk. Pol. J. Food Nutr. Sci 2006, 15, 277–281. [Google Scholar]

- Horlacher, N.; Oey, I.; Agyei, D. Learning from Tradition: Health-Promoting Potential of Traditional Lactic Acid Fermentation to Drive Innovation in Fermented Plant-Based Dairy Alternatives. Fermentation 2023, 9, 452. [Google Scholar] [CrossRef]

- Erbaş, M.; Uslu, M.K.; Erbaş, M.O.; Certel, M. Effects of Fermentation and Storage on the Organic and Fatty Acid Contents of Tarhana, a Turkish Fermented Cereal Food. J. Food Compos. Anal. 2006, 19, 294–301. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).