Abstract

Background: the advent of Industry 4.0 (I4.0) innovations has revolutionized supply chain management through technologies like the Internet of Things (IoT) and Artificial Intelligence (AI) integrated into procurement processes. Methods: this study addresses a critical knowledge gap by conducting a comprehensive review of 111 papers sourced from the Scopus database. These papers are classified into seven sub-themes encompassing I4.0 or procurement 4.0 (P4.0), big data, IoT, additive manufacturing, blockchain, e-procurement, and AI. Results: the investigation reveals that I4.0 technologies, particularly e-procurement and blockchain, have garnered substantial attention. Such technologies offer diverse value propositions, encompassing streamlined supplier evaluation, lead time reduction, cost optimization, and enhanced data security. Conclusion: the paper underscores pivotal trends and insights for the evolution of Procurement 4.0, illuminating a path toward more efficient supply chain management.

1. Introduction

The 4th Industrial Revolution, or Industry 4.0 (I4.0), represents generally the convergence of information and communication technologies (ICT), and the automation of machinery and infrastructure [1,2]. In manufacturing, it stands for the digitalization of factories and their related supply chain processes. As a result of advanced digitalization in manufacturing, a new concept known as ‘smart manufacturing’ has come into existence. Smart manufacturing revolutionizes the coordination of manufacturing elements by leveraging an integrated data chain system facilitated by the Internet, which made a critical improvement in strategic supply chain management [3]. Procurement is considered a critical part of the supply chain since it affects directly the overall performance of the whole supply chain.

Procurement is defined broadly in terms of any form of the buying process, whether it is in the form of purchasing, leasing, renting, or otherwise acquiring supplies, services, or construction from external suppliers [4,5]. This concept includes all management responsibilities which the managers are supposed to follow such as identifying, sourcing, accessing, and managing resources outside the company. Also, it suggests fulfilling of strategic objectives of the company to make significant business value and impact profit. From the perspective of supply chain management, the role of procurement is considered indispensable, as it plays a crucial role in highlighting the importance of ongoing enhancements within the procurement division [1].

Procurement 4.0 (P4.0), which is a term that encompasses a component of I4.0, introduces a network between all supply chain upstream partners, enabling dynamic and quick cooperation and coordination beyond organizational frontiers [6]. Companies have increasingly embraced P4.0 techniques in their supply chain (SC) operating models, offering valuable support to procurement managers in overcoming purchasing challenges. This is made possible through the utilization of cutting-edge technologies such as the Internet of Things, e-procurement, big data, additive manufacturing (AM) or 3D printing, blockchain, artificial intelligence, and modularity. Table 1 provides a brief definition for each I4.0 component. These technologies affect every aspect of the value chain and empower procurement managers to optimize their processes and enhance decision-making capabilities for more efficient and effective procurement operations, including supplier sourcing, distribution, transportation, warehousing, and most importantly, customer satisfaction. Moreover, they have the potential to contribute to effectiveness, efficiency, cost reduction, and shorter lead times in the supply chain, thereby providing significant benefits for the supply chain industry [7].

Table 1.

Brief definition for each I4.0 component [8].

In procurement, the three primary components of I4.0 that play a pivotal role are automation, connectivity, and advanced analytics. With these evolving capabilities, procurement processes can be almost further automated, and decision-making processes can be supported through advanced analytics tools [9]. Although information technology systems have been in use to support procurement functions for many years, their emerging holistic use in each stage of the procurement process in the supply chain at present is unique and constitutes Procurement 4.0. It is believed that the scope of procurement processes will be even more expanded in the future as a result of new technological advancements. For instance, the development of modern intelligent systems, which will have the computing power, connectivity, and autonomy to be able to analyze historical and future-oriented data may bring newer mechanics to procurement processes. This will be capable of offering holistic, autonomous, and real-time task completions. Electronic procurement (e-procurement), for example, can offer electronic solutions to procurement processes. This is the first step for digitalization that gives procurement departments smart support for operational and tactical decisions [10]. However, these advantages of procurement are not well taken into the companies’ operations. Bogaschwesky and Müller [11] point out, in a survey made for procurement managers in different German companies, the majority of the interviewees (56%) are still reluctant to proceed with digitalization in their procurement department and this attitude must be overcome to adopt these developments.

There is an increasing trend for procurement decision-makers to invest in digital technologies in their quest for greater access to global markets to obtain competitive advantages through the interconnection between buyers and suppliers [12]. Executives in procurement anticipate cost reductions without losing efficiency throughout the whole supply chain. However, many of them opt for digitalization in order to avoid being outdated [13]. In fact, a study by the European Economic and Social Committee states that people work more efficiently due to procurement digitalization [14]. Digitalization brings forth innovations and economic growth that create new methods and technologies. In short, one could argue that digitalization has multiple consequences as it creates and reduces jobs but its overall impact is yet to be determined [15].

The adoption of a P4.0 program requires an essential restructuring of business organizations. It calls for a new organizational strategy because several operational processes have to be modified in this new stage [16]. Through this restructuring, many processes of the companies such as procurement, production, logistics, and IT departments were connected to each other in terms of accounting and controlling their activities. Therefore, it is important to restructure interactions within supply chain management completely [17]. I4.0 is widely acknowledged as having the ability to provide new capabilities to procurement functions [9]. By using automated and internally integrated systems, a completely autonomous operational procurement system can be enabled. In p4.0, interactions between internal and external shareholders would be increased and more reliable data would be generated in which advanced analytics offer up-to-date information and new ways of analysis supporting decision-making processes.

To demonstrate the paradigm-shifting influence of I4.0 technologies on procurement procedures, the following few leading examples from diverse industries can be illustrated. In the manufacturing domain, Toyota emerges as a paradigmatic case. The seamless integration of I4.0 elements such as the IoT and AI has endowed Toyota with a streamlined supply chain marked by enhanced efficiency, minimized downtime, and amplified productivity. In the service sector, Amazon exemplifies the transformative potential of I4.0. Skillful application of advanced data analytics, automation, and AI-driven decision-making has not only expedited order fulfillment from 80% to 90% but also cultivated tailor-made customer experiences, epitomizing the burgeoning importance of these technologies in the contemporary consumer landscape [18]. Shifting the focus to the public sphere, the World Health Organization (WHO) magnifies the pivotal role of I4.0 technologies in global health management. Through data-driven insights and predictive analytics, WHO proactively addresses disease outbreaks, optimizes medical supply chains, and refines resource allocation [19]. In the private sphere, Walmart’s adroit integration of I4.0 technologies has ushered in a new era of astute procurement. Capitalizing on the potential of IoT and real-time analytics, Walmart deftly manages inventory levels, augments demand forecasting accuracy, and mitigates stockouts, thereby augmenting customer satisfaction and operational seamlessness [20]. These tangible examples demonstrate the undeniable pertinence and urgency of I4.0 technologies in the realm of procurement, motivating small and medium enterprises (SMEs) across industries to expertly employ these tools for strategic advantage.

Given the transformative potential of I4.0 technologies, the correlation between I4.0 and procurement demands further clarification. I4.0 introduces intelligent automation, data-driven insights, and enhanced connectivity, all of which can significantly enhance procurement processes. The significance lies in the amplified efficiency, strategic agility, and value-driven decision-making that these technologies facilitate. By harnessing I4.0 tools, procurement can achieve enhanced transparency, sustainability, and innovation, ultimately contributing to the overarching success of organizations.

To the best of our knowledge, an up-to-date, comprehensive review of the literature on the role of I4.0 in procurement management has yet to be explored. This work introduces a novel perspective by comprehensively synthesizing the existing literature on the integration of I4.0 technologies in procurement. While previous studies have explored individual applications of these technologies, this review uniquely consolidates diverse research to present a comprehensive understanding of the enhanced efficiency in supply chain management through the P4.0 process. This study seeks to explore the profound impact of I4.0 technologies on procurement processes, identify crucial drivers and challenges for adoption, and assess how these technologies can optimize procurement efficiency, reduce costs, and revolutionize supply chain management. Additionally, we aim to unveil the current trend in smart procurement and anticipate its future direction, providing valuable insights into the evolving landscape of modern procurement practices. As such, we propose the following three research questions as primary motivators for presenting and discussing this structured review:

- Which procurement processes are predominantly impacted by Industry 4.0 technologies?

- What are the primary enablers and challenges in the adoption of Industry 4.0 technologies?

- What is the current trend in smart procurement and the future direction?

The purpose of this work is to give a thorough and well-structured review of the literature and explore the role of I4.0 technologies on P4.0 to address the aforementioned research questions. The article’s primary contribution is to describe the existing state-of-the-art literature on this topic.

The article is outlined as follows. Section 2 presents a brief on the journey to Procurement 4.0. Section 3 draws the specified methodology used to conduct the literature review and the criteria utilized to gather the listed publications. The review is broken down in Section 4 where the proposed categories are offered and discussed in Section 5. Section 6 provides the reflections and a conclusion.

2. Procurement Journey

Procurement, sourcing, and purchasing are essential activities for acquiring goods and services in a company. While often used interchangeably, it is crucial to understand their differences and develop effective procedures for each process. Strohmer et al. [21] emphasize the importance of recognizing the distinctions, especially considering the demographic range of operations, where purchasing and sourcing may vary. Procurement encompasses the entire procedure from identifying the need to payment, purchasing refers to acquiring goods or services, and sourcing involves evaluating potential providers.

Procurement entails acquiring goods or services and encompasses activities such as purchasing, transportation, quality control, and inspection. Supplier selection decisions are influenced by the total cost of ownership (TCO), making procurement relevant in project environments [22,23].

Sourcing is a strategic process that involves managing supplier relationships to gain a competitive advantage. It includes decisions on supplier quantity, relationship type, contract duration, negotiation type, and local or global sourcing. Strategic sourcing aims to reduce costs, ensure long-term supply stability, and minimize supply risk [24]. It involves building relationships, allocating business, and making decisions on terms, often guided by tools like Portfolio Analysis for segmenting suppliers and products based on their strategic importance and risk profile [25].

Purchasing focuses on identifying user requirements, finding suppliers, developing agreements, ensuring prompt payment, and evaluating effectiveness. It does not include responsibilities for materials planning, scheduling, inventory management, or quality control. Procurement refers to the transactional aspect and should be streamlined [26].

Table 2 provides a concise overview of the main differences between procurement, sourcing, and purchasing [21]. It outlines key criteria such as the definition of each term, the scope of their focus, the main activities involved, decision-making considerations, the aims pursued, and the relationships established.

Table 2.

Brief on main differences between Procurement, Sourcing, and Purchasing.

Before exploring the role of I4.0 in procurement processes, this section briefly discusses the previous procurement stages that laid the foundation for P4.0. Historically, the evolving methods for procurement processes started along with the industrial revolutions. While procurement or purchasing was almost a clerical process in earlier times, it became a separate but crucial part of production as a result of mass production followed by the Industrial Revolution. Traditionally, procurement has been understood as a cost-reducing mechanism by ensuring goods are at the lowest possible cost for production. But now it has grown to a proactive and strategic one as a result of advanced digital integration into procurement processes. In effect, purchasing, which has been hitherto understood as an important part of this process, has become just one part of a larger procurement operation today. This section aims to present a brief historical journey of procurement and its evolution from Procurement 1.0 to Procurement 4.0 (Smart Procurement) [2].

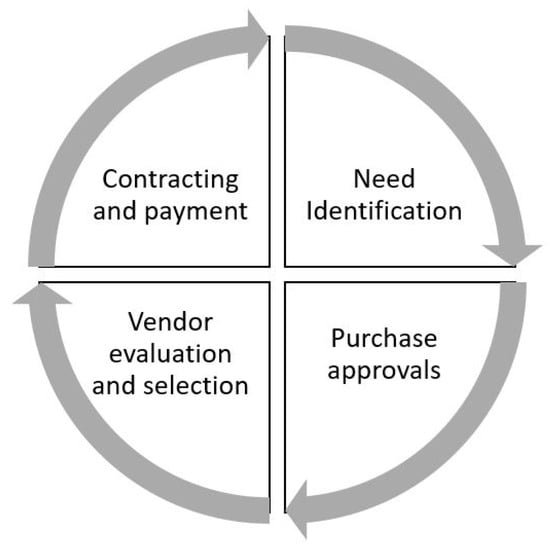

Based on the Institute for Supply Management in India [27], the traditional procurement cycle can be summarized in the following main dimensions as illustrated in Figure 1: (1) Identify the needs, a business recognizes a required product or service for its own operational purposes; (2) Purchase approvals, making a purchase request and seeking approvals required from the appropriate stakeholders; (3) Vendor evaluation and selection, supply chain professionals solicit proposals from vendors, negotiate possible working relationships, and select their final supplier; (4) Contracting and payment, the purchase order will be approved by the vendor, at which point the relationship becomes one of the vendor relationship management processes.

Figure 1.

Main procurement dimensions.

Procurement management has developed in tandem with every successive technological advancement. There is a progression in the attention paid to and the strategy used by the procurement processes and practices at each stage as summarized in Table 3.

Table 3.

Key characteristics and technological emphasis of each procurement stage.

2.1. Procurement 1.0: Tactical Procurement

This stage refers to an early form of procurement processes when procurement was understood as synonymous with purchasing. This stage is characterized by an emphasis on cost reduction and operational efficiency. Procurement is predominantly regarded as a tactical function, with a transactional approach serving as the predominant mode of operation, in which obtaining products and services at the lowest possible price while keeping procurement costs to a minimum level is the main objective at this stage [28]. Although procurement management works as a supporting function with a focus on cost containment, this basic form of procurement has been adopted by the vast majority of companies today [29]. In addition, in this conventional procurement phase, the focus is on the execution of tactical tasks including dealing with contract requests, operating RFXs (requests for information, requests for qualification, and requests for proposal), and facilitating communications and relationships with suppliers [30]. Therefore, it also can be called tactical procurement where procurement professionals are assigned to take care of multiple functions in a reactive and transaction mode.

With more automation options in the interaction between both ends of the supply chain, procurement has turned away from cost containment to deliver accelerated and broader value. It is a holistic process, that consists of risk mitigation strategies, supplier innovation, demand management, global perspectives, sustainability, and more.

2.2. Procurement 2.0: From Cost Containment to Value Creation

Historically, procurement pursued a singular strategy of obtaining the best price, product, and situation available. However, with the advent of advanced internet technologies, procurement become able to create more complex and nuanced strategies [31]. This development is known as Procurement 2.0, where enterprises began to exert greater control over the flow of information, beyond basic informational tools. Procurement 2.0 is no longer solely focused on cost management [32] but instead emphasizes category management, a cross-functional approach, and supplier relationship management [33]. These enhancements mark a significant shift from the previous iteration of procurement, Procurement 1.0.

Recently, there has been a growing recognition of the potential value that procurement can bring to an organization through technological collaboration. By leveraging advanced technologies such as big data analytics and software tools, procurement can add value by addressing several key areas of concern, including working capital management, risk mitigation, and exploring new markets or business lines. The increased information flow and automation capabilities provided by these technologies can improve collaboration with suppliers and drive greater efficiency throughout the procurement process. This shift in focus from cost management to value creation is a central feature of Procurement 2.0. As a result, it has become necessary for organizations to re-evaluate the procurement function itself and consider how it can be optimized to better support broader business objectives [34]. Businesses are recognizing the important impact that procurement can have on various business models and their competitive advantages [35]. By effectively communicating the value of procurement to various departments and business functions, organizations can better align their procurement strategies with overall business objectives and drive greater value creation.

The procurement landscape has undergone a significant transformation, largely driven by the increasing share of revenue attributed to procurement. To align procurement with corporate objectives, companies have developed category strategies [36]. This transformation has led to an increased role of procurement role in cross-organizational collaboration, which has been facilitated by technological advancements connecting all departments across the business. To streamline supply chain processes and achieve greater operational efficiency, a movement to centralize purchases and reorganize vendors has emerged [37]. This has resulted in procurement playing an increasingly important role in managing working capital and identifying risks to business performance. Through enhanced information flow and the development of software to identify risks, the efficiency of these areas has been greatly improved [38].

2.3. Procurement 3.0 (Supply-Side Optimization)

Procurement 3.0 is all about supply-side optimization. It is more than just an advanced digitalization in the procurement process. It signifies a drastic change in procurement structure and the use of high-edge technologies for procurement purposes. The E-Commerce revolution of the 1990s, which laid the foundation for Procurement 2.0, had facilitated a shift from on-premise toward cloud-based tools. It also formed the basis for emerging Procurement 3.0 technologies by making advancements in categorial improvement in functional efficiency. In this phase, the application of digital technology is more focused on automation and recording of the process: a transaction executed, an invoice paid, an item purchased, and a contract signed. A system of record-keeping (in the form of software) has been used in the procurement process which helps to understand contextual reasons by probing into what happened and why. This recording is important: it makes a foundation for AI-enabled predictive models which will make progress in future decision making. A fully matured application of such a technology can be seen in the next stage of procurement, which is known as Procurement 4.0.

The key objective of Procurement 3.0 is to optimize the supply side. In this stage, business stage, business strategy has been linked to the enterprise by ensuring that a good supplier base under the right commercial agreements and delivering the right goods and services. There are clear building blocks required to accomplish this evolution.

With the emergence of Procurement 3.0, procurement and business were connected to the information existing outside of their own data ecosystem and leveraging intelligent capabilities that do more than execute transactions to guide business decisions. Most of these emerging technologies effectuated enhancing the value of legacy systems which consider small investments, have low requirements for integration, and have payback periods measured in months not years [27]. Scholars like Mavidis and Folinas [39] have vividly discussed the e-procurement journey in the public sector and its results in improving access to information and transparency in management. In this study, they evaluate comparatively the challenges and problems between procurement technologies 3.0 and 4.0 and lay down a roadmap for achieving new procurement management in Industry 4.0.

3. Methodology

The approach that is used in this research draws relevant works from an online citation index (Scopus) that is easily accessible. These works have been published in peer-reviewed journals along with other reliable sources. This section describes the search strategy used to identify relevant works and discusses how those works were categorized in relation to I4.0 in the context of procurement management.

3.1. Literature Survey Process

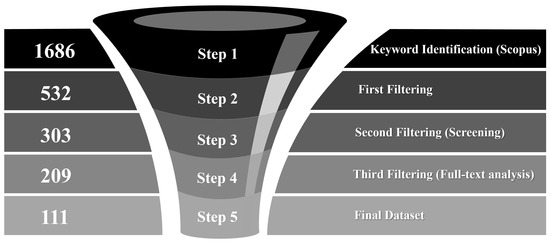

This work comprises a literature review of the published papers on the role of I4.0 technologies in procurement processes, aiming (1) to collect information about unveiling the current trend in smart procurement and (2) to identify crucial drivers and challenges for adoption, and assess how these technologies can optimize procurement efficiency, reduce costs, and revolutionize supply chain management. The present study adhered to the rigorous PRISMA (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) guidelines [40] to ensure transparency and methodological robustness. It involves formulating research questions, conducting comprehensive database searches, applying strict inclusion/exclusion criteria, analyzing and extracting data from selected studies, synthesizing and interpreting findings, and producing a comprehensive review report analysis. Five stages are conducted in the identification, screening, and eligibility of works, as shown in Figure 2, which summarizes the stages in the review process.

Figure 2.

Literature review process–Funnel approach.

In Step 1, keywords included in the title, abstract, and keywords (TITLE-ABS-KEY) relevant to the topic are identified as, TITLE-ABS-KEY((procurement AND 4.0) OR (procurement AND (“additive manufacturing” OR “3D print*” OR print*)) OR (procurement AND blockchain) OR (procurement AND digit*) OR (“digital procurement”), (procurement AND digitalization) OR (procurement AND “digital transformation”) OR (“agile procurement”) OR (e-procurement) OR (“smart procurement”) OR (procurement AND auto*) OR (procurement AND (“smart contract” OR “digital contract”)) OR (procurement AND “big data”) OR (procurement AND “artificial intelligence”) OR (procurement AND “Internet of Things”) OR (procurement AND (price* OR cost*)) OR (procurement AND risk*) OR (procurement AND suppl*) OR (procurement AND data)). These keywords are used for literature retrieval from the Scopus database, since this web search engine is globally recognized as the primary source of peer-reviewed literature, and its effectiveness as an index database has been demonstrated. Running the aforementioned research query resulted in a total of 1686 documents. In Step 2, the initial stage of filtering search criteria can be described as (a) the language of the article should be in English, (b) the timeframe should cover the range of years (2012–2022) as this range is considered to be the flourishing start of the fourth industrial revolution applications in manufacturing systems and supply chains, (c) document type chosen to include only articles or review articles, (d) published in journals only. The dataset after the first filtering procedure is comprised of 532 papers. The second filtering criterion, Step 3, represented in reading the titles and abstracts of the papers found and then selecting only the most relevant ones to the field of engineering management and decision sciences, e.g., engineering, business, management, decision science, economics, finance, and accounting. The pool of papers selected after this step amounted to 303 papers, which undergo a third filtering procedure, Step 4, that aims to ensure that all works to be reviewed are meaningful contributions to the topic and add significant value to the literature scope, which results in 209 papers. The third filtering criterion goes for in-depth full-text reading of the papers to ensure they are relevant to the proposed scope. Table 4 and Table 5 present the inclusion and exclusion criteria and the final data set in Step 5 consists of 111 papers as a total number of articles.

Table 4.

Inclusion criteria (IC).

Table 5.

Exclusion criteria (ExC).

3.2. Literature Review Classifications

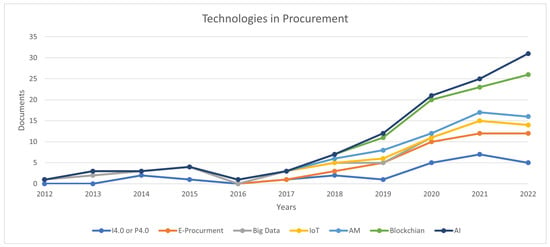

Figure 3 summarizes the distribution of the selected papers per technology and per publication year. As shown, the number of publications has been rapidly growing over the last three years, which confirms the high interest in the use of I4.0 technologies in the procurement area.

Figure 3.

Distribution of the data set per technology and publication year.

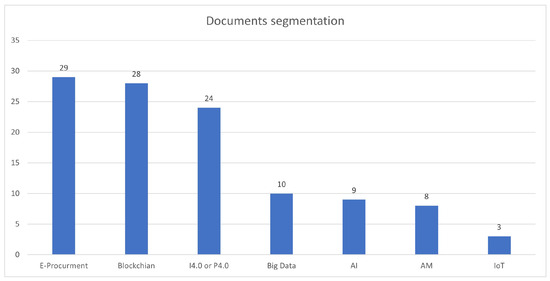

Figure 4 depicts the final number of papers (n = 111) included in the review, highlighting the prominence of e-procurement, blockchain, and I4.0 or P4.0 technologies in the literature. After diagnosing the data set, it becomes evident that e-procurement, blockchain, and I4.0 or P4.0 technologies have the highest number of published papers. These technologies have attracted significant attention and research interest in the field of procurement. The bar representing e-procurement stands out prominently, indicating a substantial body of literature dedicated to this area. It signifies the importance of e-procurement in the context of I4.0, as organizations seek to automate and digitize their procurement processes for improved efficiency and effectiveness. Similarly, the bar representing blockchain technology is notable, highlighting the growing interest in leveraging blockchain for secure and transparent transactions in procurement. Lastly, the bar representing I4.0 or P4.0 technologies demonstrates the significance of I4.0 in shaping the future of procurement. The inclusion of papers related to I4.0 or P4.0 indicates the recognition of its transformative potential and the need to understand its implications for procurement practices.

Figure 4.

Distribution of Papers Included in the Review.

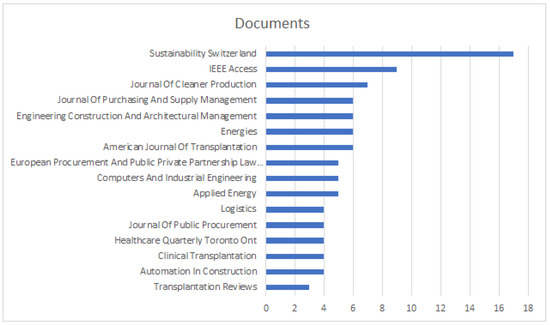

Figure 5 illustrates the title and the number of journals utilized in this study. The top three journals with the highest number of related selected articles are Sustainability Switzerland, IEEE Access, and the Journal of Cleaner Production. This figure provides an overview of the distribution of articles among different journals, highlighting the journals that have contributed significantly to the research in this field.

Figure 5.

Titles and Number of Journals Used in the Study.

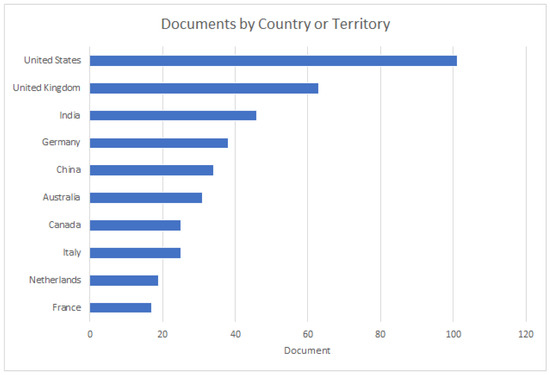

The current distribution of articles per country is visually presented in Figure 6, highlighting that the United States has the highest number of publications related to the topic, followed by the United Kingdom and India.

Figure 6.

Distribution of Articles Per Country.

3.3. Relevant Literature

Table 6 exhibits the most relevant literature related to the procurement topic. The papers are classified into seven sub-themes, which include I4.0 or P4.0, E-procurement, big data, Internet of Things (IoT), Additive Manufacturing (AM), Blockchain, and Artificial Intelligence (AI). Most of the literature overlaps these sub-themes. However, they are classified differently for analytical purposes. Detailed reviews of these papers are discussed in the following section.

Table 6.

Thematic division of the reviewed literature.

4. Literature Review

In this section, we present a comprehensive review of previous research papers related to the use of I4.0 technologies for enhancing and improving procurement processes. The literature review covers most of the I4.0 technologies and their applications in procurement. Although the implications of I4.0 concepts have been discussed individually in different industrial contexts, a limited number of studies have discussed the use of emerging technologies in procurement processes comprehensively. Therefore, this work is meant to potentially provide a comprehensive picture of the application of such technologies and offer some value propositions in order to enhance the procurement processes in a wide variety of industries.

The collected articles are divided into sub-themes, including I4.0 or P4.0, e-procurement, big data, IoT, additive manufacturing, blockchain, and AI. By analyzing separately the literature related to these themes, this study discusses the impact of different I4.0 technologies in the procurement processes and their roles within various areas of supply chain management.

Supply chain resilience has emerged as a key element in I4.0 to manage risk during out-of-stock conditions at a time of crisis. It has been used to optimize supply chains from end to end, leading to major impacts on value delivery. Researchers have discussed various ways in which supply chain resilience could be improved during crisis periods. In their insightful paper, Pereira et al. [148] discuss how procurement plays a significant role in detecting and dealing with intra- and inter-organizational problems to impact supply chain resilience. Using a systematic literature review, based on 30 published papers between 2000 and 2013, they revealed that achieving resilience in the supply chain requires efforts from both internal and external elements of the extended enterprise.

4.1. Industry 4.0 (I4.0) and Procurement 4.0 (P4.0)

Needless to say, digital transformation is a key component of the fourth industrial revolution, and it has increasingly grown overall in industrial sectors. According to Lasi et al. [51], I4.0 means advanced digitalization within industrial factories. As a result, it facilitates cyber-physical systems that describe the merger of digital with physical workflow [55]. It stands for a combination of internet technologies with future-oriented technologies in the field of “smart” objects (machines and products). Thus, it equips the industrial manufacturing system in such a way that products can control their manufacturing process. With the high-level digitalization in the industrial field, new ways of production have been created through the interactions between multiple technologies [52]. Scholars have discussed how the application of such technologies transformed the overall business management structure, and individual aspects of companies including the value chain model, e.g., [59].

To shed light on the applications of I4.0 technologies in various contexts, it is essential to provide a concise overview of the relevant literature. In this regard, Chou and Liao [63] contribute to the field by presenting a procurement decision-making model specifically designed for the food processing machinery sector. The food processing industry has witnessed a significant influx of smart manufacturing equipment with advanced and fully automated technologies, enabled by technological advancements. Within this context, I4.0 serves as an integrating force, leveraging high-equipped technological innovations to harmonize demands, sales, and manufacturing resources in the procurement process. Employing such a tool in the food processing industry offers benefits such as accuracy, reliability, real-time applications, and a reduction in uncertainties associated with human-based decision-making [63]. I4.0’s emphasis on procuring subsystems for assembly into other manufactured parts is a critical feature that aligns with the evolving needs of modern manufacturing. It allows for modular production, customization, rapid prototyping, and collaborative supply chain practices. This approach empowers manufacturers to be more agile, innovative, and efficient, ultimately leading to increased competitiveness and improved customer satisfaction.

The advent of I4.0 has given rise to a paradigm shift in the realm of procurement, leading to the emergence of what is known as Procurement 4.0. This transformative development has introduced a range of significant advantages for companies, particularly in the domain of supply chain management [44]. It has been made possible through the implementation of advanced digitalization techniques within organizational structures and supply chain operations. Within an organization, the procurement division has assumed a pivotal role in driving this transformation. By transcending its traditional cost-centric approach, procurement has adopted a profit-centric perspective, thereby redefining not only what is procured but also how these acquisitions are made. This shift has prompted the procurement function to explore novel business models, enabling them to unlock untapped opportunities and enhance their strategic contributions to the organization. By embracing the principles of P4.0, companies can leverage the potential of digital technologies and data-driven insights to optimize their procurement processes, enhance supply chain efficiency, and achieve sustainable competitive advantages in the dynamic business landscape. Such a transition holds the promise of reshaping procurement practices and revolutionizing the way organizations approach their purchasing strategies and supplier relationships.

In a similar vein, Gottge et al. [5] underscore the importance of I4.0 technologies, such as big data, business intelligence, and the IoT, in the procurement process. Their study specifically focuses on the practical implications of these technologies on the purchasing activities of automotive manufacturers, employing a transaction cost economic approach to examine both theoretical and practical impacts. The authors adopt a multiple-case study methodology, utilizing qualitative content analysis and cross-case synthesis. The findings reveal that strategic purchasing processes benefit from the co-creation of specifications, parameter-based negotiations, an additional sub-process, and automated pre-qualification. Notable changes in operative purchasing processes include interactive call-offs and proactive troubleshooting. Through the application of these technologies, transaction costs decrease as uncertainty and supplier specificity are minimized, alongside reduced information search, monetary costs, and negotiations.

Ghadge and Goswami [62] delve into the impact of I4.0 implementation on the supply chain, offering a comprehensive framework to enhance its application across various industries. Through a critical literature review, the study investigates key drivers and barriers across organizational, strategic, technological, legal, and ethical dimensions. Building upon these identified factors, they develop a systematic assessment system to evaluate the impact of I4.0 on supply chain processes. Raja et al. [50] support the study and both shed light on the challenges encountered during implementation and put forward a novel framework aimed at facilitating the effective integration of I4.0 concepts into the supply chain, including the procurement function as an integral part of these processes.

Rane and Narvel [41] examine the utilization of I4.0 technologies to enhance the agility of project procurement management (PPM) processes. Given the growing market demands and shorter time-to-market requirements, the existing PPM encounters challenges in responding with agility. To address this, the authors propose strategies for implementing I4.0 tools and leveraging selective critical success factors to enhance the agility of executive PPM processes. Furthermore, they explore the use of additional tools such as IoT, mobility, business intelligence, blockchain, and robotic process automation (RPA) to further improve agility in PPM.

Digitalization has ushered in a new era for procurement, enabling the utilization of data analytics to meet evolving business requirements. Referred to as Industry 4.0, this transformative paradigm offers promising opportunities and a host of capabilities to enhance procurement processes [42]. The continuous development and refinement of various technologies and tools have significantly bolstered procurement, fostering improvements in efficiency, effectiveness, and overall performance [57]. However, it is crucial to acknowledge the substantial costs associated with the development, acquisition, and implementation of these technologies. Therefore, meticulous analyses are indispensable to determine the potential impact, scope, and applicability of investments [6]. To cultivate a competitive environment, organizations endeavor to establish digitized procurement systems that prioritize customer preferences and exhibit the necessary agility to meet growing customer satisfaction. In this context, scholars have engaged in discussions concerning the systematic application of digitalization in procurement and its consequential effects on supply chain dynamics.

Rejeb and Appolloni [54] and Bag and Sivarajah [46], delve into the role of procurement digitalization in manufacturing operations and the circular economy. Through the analysis of survey data collected from working professionals in South Africa, the latter study identifies key resources required in a P4.0 environment to enhance remanufacturing operations and circular economy performance in emerging economies. Drawing on the resource-based view theory, the researchers explore the influence of resources on P4.0 and its impact on productivity in remanufacturing operations. They argue that improving the performance of remanufacturing operations can contribute to achieving circular economic outcomes. In a similar vein, Bag et al. [46] and Bag et al. [43] investigate the effects of digital transformation on P4.0 processes in terms of productivity within a circular economy context. Findings from a survey conducted among South African manufacturers suggest that P4.0 can be leveraged to optimize the buyer’s intentions and enhance circular economy performance.

Rejeb et al. [61], Pires et al. [53], and Richnak [56] investigate the utilization of emerging technologies in procurement processes to address the complexity of exchanging data and information in procurement logistics. Their study highlights the significance of digitalization and the adoption of technologies such as big data analytics, robotics, IoT, blockchain, and smart contracts in enhancing industrial procurement functions and tools. These technologies offer benefits such as improved predictability, transactional automation, and proactive supplier relationship management. The authors also discuss the potential of emerging technologies in procurement activities, as well as organizational barriers that impede their widespread implementation and suggest possible remedies.

Klünder et al. [58] examine the impact of digitalization on procurement costs, highlighting its potential to further reduce costs by ensuring supplies at a lower cost. Through empirical examination, explanatory surveys, and survey-based studies, the authors investigate the effects of digitalization on procurement costs, specifically material and commodity costs, and support the implementation of I4.0 technologies to achieve cost reduction in the procurement process. In a related study, Lorentz et al. [47] propose a procurement digitalization strategy, focusing on key drivers, technology interventions, and mechanisms. Based on data collected from interviews and workshops involving 48 digital intervention projects, the study reveals the significant influence of internal-external dynamics on procurement digitalization. The findings indicate that internal complexity facilitates digitalization by enabling communication support and process structuring interventions, while external dynamism drives interventions for information processing and decision-making, particularly related to supply market knowledge, strategic alignment, and supplier capability assessment.

Hallikas et al. [60] delve into the role of data analytics in the digitalization of procurement and supply chains, specifically examining the relationship between digital procurement processes and supply chain performance. The analysis of survey data reveals several significant findings. First, there is a direct and positive association between digital procurement processes and supply chain performance. Second, the study demonstrates that data analytics capabilities play a crucial role in enhancing a firm’s competitiveness in procurement and supply chain management. However, it is important to note that the impact of data analytics differs when considering internal versus external sources. Internal data analytics have a positive influence on supply chain performance, whereas external data analytics directly enhance digital procurement capabilities, which in turn mediate their impact on supply chain performance. These findings highlight the importance of investing in data analytics capabilities to improve supply chain performance and optimize the digital procurement process.

Flechsig et al. [49] and Schiele [48] shed light on the application of Robotic Process Automation (RPA) in purchasing and supply management. While RPA has gained significant attention in digital transformation, its potential within purchasing and supply management, particularly in the public sector, remains relatively unexplored. Drawing upon multiple case studies encompassing both the public and private sectors, the authors offer valuable insights into the challenges, appropriate processes, and effective strategies for implementing RPA. The findings underscore the importance of organizations’ digital procurement readiness and maturity in determining the success of RPA adoption.

To classify and describe the many digital technologies and techniques used in building procurement, Ibem and Laryea [45] conduct a thorough literature survey. Their research highlights 36 unique digital technologies and solutions, such as web-based applications that improve construction supply chain interactions among different stakeholders in real time. The study highlights the need for a consolidated digital solution that integrates and unites all main construction procurement processes, providing purchasers with a full-fledged platform from which to oversee the whole procurement lifecycle.

4.2. e-Procurement

The increasing demand for automation in the business sector has led to the emergence of e-procurement as a vital component of digitalized procurement processes [89]. Chan et al. [84] provide a comprehensive overview of the evolution and development of e-procurement, highlighting its significance in optimizing the supply chain by reducing costs and improving efficiency. E-procurement encompasses various elements, such as e-sourcing, e-coordination, and e-communities [85]. In the context of public procurement, the application of e-procurement has been instrumental in promoting good governance [88,90] and reducing corruption within organizations [91].

Within this context, Basak [69] highlights the significance of e-procurement in the aviation industry’s maintenance, repair, and overhaul (MRO) sector by comparing it with traditional procurement methods. E-procurement offers advantages, such as simplified processes and increased transparency, making it a valuable tool for maximizing supply chain performance. It reduces costs throughout the value chain and enhances efficiency. In a highly agile supply chain, Chibani et al. [71] demonstrate the use of e-procurement for dynamic optimization. The buyer-supplier interactions in this context are volatile, requiring decisions on the quantity and selection of products based on price and capacity variations. Traditional optimization approaches are inadequate for addressing these dynamic challenges.

Kim et al. [70] investigate the influence of strategic sourcing and e-procurement on firm performance. Through a structured survey of 137 managers in US manufacturing firms, the study employs partial least squares-based structural equation modeling for data analysis. The findings reveal a positive impact of strategic sourcing and e-procurement on firm performance. Additionally, the study demonstrates that business characteristics and environmental factors, such as competition, market turbulence, firm size, and product life cycle stage, moderate these relationships. This research contributes to theory and practice by examining the effects of e-procurement on firm performance.

Sánchez-Rodríguez et al. [92] investigate the impact of e-procurement on small and medium-sized enterprises (SMEs), focusing on facilitators and obstacles that affect business performance. The study examines data from 199 managers in the manufacturing sector and identifies significant relationships between SMEs and factors, such as support of executive management, information technology obstacles, and strategic procuring. Furthermore, the research reveals positive associations between e-procurement, procurement efficiency, and overall business performance. These findings highlight the importance of e-procurement in enhancing the performance of SMEs.

Belisari et al. [73] investigate the positive and negative impacts of e-procurement adoption in the Italian market, encompassing both the public and private sectors. Through an examination of two Italian companies that have implemented over 150 e-procurement projects, the study highlights the effects of e-procurement solutions. The findings demonstrate that the adoption of e-procurement leads to improved purchasing performance and compliance with the procurement code. However, the manifestation of these benefits differs between the public and private sectors.

Hung [68] investigates the effects of a Web-based e-procurement system on companies’ organizational performance within the supply chain. Their model incorporates various contextual factors and was tested through a survey of 105 manufacturing firms in Taiwan. Utilizing the partial least-squares regression method, the study finds that e-purchasing activities significantly improve organizational and inter-organizational efficiency. Additionally, an enhanced partnership approach positively affects supplier and buyer performance. These findings highlight the positive impact of web-based e-procurement on organizational performance.

Kamarulzaman et al. [66,67] investigate the utilization of e-procurement technologies in the Malaysian Palm Oil Industry (MPOI). Through in-depth interviews and comprehensive analysis, the authors in both articles highlight the potential of e-procurement in enhancing purchasing efficiency by streamlining the search process, providing material information, and reducing human errors. However, the study reveals that certain products, such as fresh fruit bunch, crude palm oil, and crude palm kernel oil, face limitations in adopting e-procurement tools due to established suppliers’ limited utilization of such technologies in their purchasing activities.

Gupta [64] examines the impact of information technology (IT) on e-procurement in Indian organizations. Based on a survey conducted among 36 organizations, the author highlights the positive effects of IT usage, including improved business process efficiency, such as enhanced inventory control, cost and time reduction, and improved customer service. However, the study also identifies persistent security concerns that hinder the widespread adoption of IT infrastructure for e-procurement. Specifically, issues related to internet security, loss of information sharing, and legal legitimacy must be effectively addressed to establish trust in online transactions.

Adowo et al. [65] investigate the potential of e-procurement in combating corruption and unethical practices in construction project delivery in Nigeria. While e-procurement has been widely adopted to enhance supply chain management in various sectors, its role in addressing corruption has received limited attention. This is particularly significant in sub-Saharan countries where corruption levels are substantial. Through 759 cross-sectional surveys conducted across different fields in Nigeria, the researchers identify 18 anti-corruption capabilities associated with e-procurement in construction project delivery. These capabilities focus on ensuring inventory management, accountability, and reducing human involvement during the bidding process. Transparency in bidding fosters competition and aids in curbing corruption within construction procurement activities. Also, the same author, Aduwo et al. [77] investigate the presence of critical gray areas in the public procurement process and highlight the potential of e-procurement’s digital solutions to combat corrupt practices. Public procurement plays a vital role in developing and maintaining city infrastructure to enhance citizens’ quality of life. However, corrupt practices hinder its success. Through a survey of 759 construction stakeholders across Nigeria’s six geopolitical zones, this study identifies e-procurement technologies utilized for project announcement, information exchange, tendering, proposal submission, progress monitoring, and payment. The findings emphasize the importance of digitalization in eliminating corruption within procurement processes. Thus, this paper explores digital solutions for enhancing public procurement in the Nigerian construction sector.

Ibem et al. [79] investigate the impact of e-procurement on the user experience within the Nigerian construction industry. While e-procurement adoption is widespread in developing countries like Nigeria, its influence on construction stakeholders and their experiences remains understudied. This survey-based study includes 759 stakeholders and reveals that e-procurement tools are extensively used for information exchange and expanding tender opportunities. However, their utilization for tracking construction site progress is limited. Factors such as internet infrastructure adequacy, operational environment, technology benefits, and system accessibility directly influence user experiences, emphasizing the need for their consideration to ensure sustainable e-procurement implementation in the construction sector.

Ramkumar et al. [75] emphasize the significance of the Technology Acceptance Model (TAM) and Quality-TAM (Q-TAM) in e-procurement services. Through an analysis of data from organizational buyers, The research shows how organizational purchasers’ perceptions of procurement services are affected by information flow and logistical fulfillment. This research introduces a quality technology acceptance model that predicts organizational buyers’ intentions to continue using e-procurement services, focusing on user satisfaction within a mandated usage setting. It distinguishes itself from existing literature by exclusively focusing on user intentions of organizational buyers, rather than firm-level adoption issues. Furthermore, the application of e-procurement in SMEs is crucial for developing competitive advantages. E-procurement systems facilitate connections between SMEs and other business activities, such as supply chain integration, resulting in rapid development in a globalized world. Madzimure et al. [76] investigate the relationship between e-procurement, supplier integration, and supply chain performance in retail SMEs through case studies in South Africa. Their quantitative research approach evaluates various e-procurement components, highlighting the impact of e-design and e-negotiation on supply chain integration. Additionally, the study demonstrates that supply chain integration positively influences supply chain performance.

Mélon et al. [80] examine the impact of large-scale e-procurement adoption on institutional quality in Denmark, the Netherlands, and Portugal, comparing it with other countries. Using data from 108 countries between 1996 and 2017, the study employs a differences-in-differences policy analysis approach. The findings indicate that the effects of e-procurement reform on institutional quality are not uniform. While Denmark and the Netherlands experience substantial improvements in the rule of law and government effectiveness post-reform, the overall impact on institutional quality is less pronounced. This paper highlights the contributions of e-procurement to institutional quality, revealing variations in its effects across different countries.

Masudin et al. [81] and Susantya et al. [86] investigate the effects of e-procurement adoption in Indonesian manufacturing companies by examining the relationships between top management support, information quality, e-procurement implementation, and company performance. Through two surveys administered to staff members, the study finds that the support of senior management and information reliability significantly influence e-procurement implementation, leading to enhanced business performance.

It is well-established that prior experience in e-procurement platforms enhances project performance. To gain deeper insights into the effectiveness of prior experience, Hong and Shao [82] explore the moderating factors that influence the impact of buyer-supplier experience in these platforms. Specifically, they examine the role of temporal distance, language difference, and routine tasks in determining the success of the prior experience. Their findings shed light on the significance of prior experience in e-procurement platforms.

Sanchez et al. [72] conducted a study to explore the impact of digital transformation (DT) on supply chain procurement (SCP) and competitive advantage (CAD). Through a survey of 221 supply chain professionals, the researchers determined that DT positively influences both SCP and CAD, with SCP mediating the relationship between DT and CAD. The findings suggest that digital procurement has the potential to revolutionize competitive markets, and the study offers preliminary recommendations for shifting from standard to smart procurement practices.

Chen et al. [83] conducted a study to explore the relationship between procurement complexity, government structure, and e-procurement adoption in local governments. Analyzing survey data from over 400 cities, the researchers found that a centralized government structure increases the likelihood of e-procurement adoption in response to procurement complexity. In contrast, governments with a coordinated structure are less likely to adopt e-procurement due to their reliance on intra-organizational collaboration and information-sharing to manage complex procurements. These findings shed light on how different government structures can effectively handle complex administrative operations and enhance the adoption of e-procurement.

Fu et al. [74] present a case study on the implementation of a green e-procurement system using a cloud model. The study focuses on private hospitals in Taiwan and highlights the challenges associated with conventional systems, including high resource requirements, regular updates of green specifications, and system crashes affecting procurement efficiency. To address these issues, the authors propose a cloud-based e-procurement system that improves efficiency and reduces information maintenance costs. The results demonstrate the successful optimization of resource allocation and timely understanding of user needs, enabling the development of tailored marketing strategies. The cloud-green e-procurement model proves beneficial for enhancing procurement activities in a sustainable manner.

E-procurement has revolutionized public procurement systems, enhancing government administration and governance [87]. Micea et al. [78] explore the impact of an integrated model of Blockchain and the Internet of Things, known as (BIoT) on achieving sustainable and smart procurement in the public sector. Additionally, Chen et al. [83] investigate the adoption of e-procurement systems in local government. They argue that the complex structure of local government procurement can be effectively addressed through the implementation of an e-procurement system. The study findings highlight the potential of different local government structures in handling complex managerial tasks and facilitating e-procurement adoption.

4.3. Big Data

Big data is an emerging and relevant topic for industrial operations. In the supply chain, the application of big data will bring benefits like higher visibility, enhanced bargaining position in negotiations, better risk management, and better decision-making. Big data helps to control spending with data analysis and reduce risks by identifying potential supply chain disruptions [93]. Therefore, it plays a significant role in enhancing the procurement process.

In a recent review essay, Lee and Mangalaraj [100] discuss the uses of big data analytics in various business functions particularly in the context of the rapid expansion of machine learning and technological infrastructure. The role of big data in supply chain management (SCM) for handling customer preferences, visibility improvements, and resilience has been emphasized in the paper but, interestingly, from the vantage point of an interdisciplinary perspective, which will offer an increased and holistic understanding of its functions. By combining existing perspectives in big data research in SCM, namely organizational and technical, and holding together a bottom-up approach, i.e., using bibliometric analysis in classifying those studies, and a top-down approach, i.e., employing a framework to classify findings, this paper analyzes prominent theories used in the study of big data and SCM. Moreover, a focus has been given to sustainability within this research domain, which has not been given due attention in previous studies.

Zeisel et al. [101] present a conceptual architecture for implementing big data applications in the procurement function. The architecture facilitates the integration of diverse data sources, skilled teams, and big data analytics. Additionally, the authors identify and discuss a comprehensive range of both existing and innovative use cases for big data in procurement.

Moretto et al. [94] analyze the value of big data technology in supporting the procurement process and the implementation of procurement practices. Using a focus group discussion among procurement professionals and experts and analyzing four case studies supported by secondary data analysis, this work illustrates how big data technology influences different procurement processes and what kind of benefits can be expected from adopting this technology for procurement performance. Big data technology is shown to have the greatest potential impact on strategic sourcing phases, mainly in strategy configuration, reverse marketing, spend analysis, supplier evaluation, negotiation, and selection. In short, the application of the technology enables better data management and improves the quality of the business environment.

Tiwari et al. [95] illustrate the implications of big data in the procurement process of various industries and businesses and argue that the application of big data technology assists companies in making informed decisions by analyzing massive amounts of data in a short time. More specifically, the author explores the implication of big data for purchasing and supply purposes that enhance companies’ visibility in the supply market. Data gathered from interviews suggest that big data technologies enhance companies’ ability to identify new suppliers, manage risks, and analyze suppliers. In addition, predictive analytics techniques can be used in market analyses and negotiations.

Song et al. [96] discuss the significance of a big-data-driven approach for emergency drug procurement planning. In the context of uncertainty of diseases, traditional approaches to drug procurement planning are inefficient, which often causes overstocking or understocking in hospitals. Consequently, public health care services are negatively affected. Thus, the authors use a heuristic optimization algorithm based on a deep neural network to predict morbidities of acute gastrointestinal infections based on a massive amount of environmental data. Two case studies illustrate that such methodology provides quick and efficient solutions, which are better than the methods currently used in drug procurement.

Narwane et al. [102] investigate the role of big data analytics in mediating the relationship between Supply Chain 4.0 company performance and various performance parameters. The study employs a two-stage hybrid approach combining statistical assessment and an artificial neural network (ANN) algorithm, based on data obtained from 321 responses from 40 Indian industrial organizations. The findings highlight the significant impact of organizational performance characteristics, ecologically conscious procurement and sourcing, endogenous and exogenous factors, shipping and distribution, operation-related aspects, technical expertise, and collaboration on the adoption of big data analytics.

Kuo et al. [98] discuss the implementation of the smart support system of material procurement based on big data and predictive analytics in order to reduce waste and thereby make sustainable enterprises. In this system, an intelligent event-driven feedback control method is used for controlling process plans. A decision support system is also designed to reduce material usage based on usage data. Moreover, data science and predictive analytics techniques have been applied to make better procurement decisions. The authors argue that the application of the system is highly effective in semiconductor manufacturing.

Focusing on big data’s impacts on supply chain activities, Murad et al. [99] analyzes optimizing procurement as an intermediate factor in which big data’s impacts on the supply chain’s sustainability performance could be measured. They argue that the benefits of having big data capabilities are neither visible immediately nor achievable straightforwardly, instead, they have to be sought in intermediate factors such as procurement optimization. By analyzing existing literature, they offer a conceptual framework to examine procurement optimization with big data capabilities, specifically focusing on healthcare-sustainable supply chains.

It is an already acknowledged fact that green procurement is a necessary component in any organization to attain higher environmental performance. However, this is not an easy task because of the potential risks such absence of appropriate information, tools, and training. Alnuami et al. [97] demonstrate that big data technology is a solution to this problem. Its concept can transform the traditional e-procurement system into green procurement and ensure better environmental performance. By analyzing resource orchestration theory, the authors argue that if organizations reorganize resources and capabilities in terms of the big data e-procurement method, a higher environmental performance is achievable. Empirical samples of 216 procurement professionals indicate that big data analytic capabilities provide enhanced environmental performance and sustainability.

4.4. Internet of Things

IoT provides useful capabilities for achieving better procurement with more efficient operations. IoT refers to the interconnection of information with the help of sensing and actuating devices that facilitate a platform so that information may be exchanged across systems in an integrated manner, leading to a unified framework that can be used to power cutting-edge applications [103]. Scholars have discussed the significance of IoT as an enabler, empowering companies to gain real-time data and continuous evaluation for better decision-making by identifying consumers’ consumption patterns.

Fang et al. [104] illustrate an integrated three-stage model based on IoT for the optimization of procurement, production, and product recovery. Due to increasing environmental concerns worldwide, the recovery of end-of-use products has become an important part of the manufacturing industry today. In this context, manufacturers must develop proper strategies to reduce waste, raw material usage, and production costs by recycling and refurbing used items. The authors propose the use of IoT to address the questions of how to collect end-of-use items from customers and acquire knowledge about each item. The products can be identified with codes and monitored and tracked using wireless sensor networks. A particle swarm optimization algorithm is used, and there are three recovery options for increasing product demand in each stage of the product life cycle. IoT facilitates manufacturers to collect and share data for providing products that are functional and less expensive. By doing so, manufacturers can make a global chain comprising suppliers, factories, and recyclers, which help them assemble products at a lower cost. In this context, manufacturers are forced to select appropriate suppliers for specific components, ensuring lower procurement costs of greenhouse gas emission-contained materials.

Jemmali et al. [105] present an intelligent algorithm aimed at addressing supplier selection challenges. The proposed algorithm utilizes a set of determinants and sophisticated formulas to convert predefined preferences into quantitative measurements. These measurements enable the differentiation between suppliers and their proposals. Experimental results confirm the effectiveness of the D3S model in selecting the most suitable offer from a range of proposals provided by various vendors.

4.5. Additive Manufacturing

Additive manufacturing (AM), also called 3D printing [106], is yet another technological advancement that takes a transformative approach to industrial production by facilitating the creation of lighter, stronger parts and systems. It employs a method of data-driven computer-aided design that has a huge potential for developing novel product concepts and enhancing the performance of existing ones. It also facilitates better design freedom and functional benefits such as weight reduction.

Revilla et al. [107] discuss the significance of AM technology and its potential to alter and disrupt a wide range of industrial sectors. AM technology is not only used for new product designs but also for redesigning production networks. The buyer uses AM technology to produce parts with data provided by suppliers. Using supplier-provided data, the client (buyer) could manufacture parts using additive manufacturing. This is one manner in which AM technology is influencing the future of business partnerships between buyers and suppliers. However, studies examining the effects of AM on industrial procurement are still limited. AM technologies potentially allow the decentralization of the manufacturing and restructuring of logistical aspects of supply chains that were never explored well.

Sgarbossa et al. [108] examine the logistical considerations and challenges associated with AM and decentralization. The study also investigates the potential of AM as a solution for strategic sourcing in procurement. Moreover, the authors explore the application of AM technologies in spare parts management and provide decision trees to assist industrial managers and practitioners in their decision-making processes.

The effects of using AM in spare parts procurement are investigated by Bhattacharyya et al. [112], in particular in terms of supply chain resilience and effective inventory management for spare parts. The results of the research show that using AM might lessen reliance on original equipment manufacturers (OEMs) for acquiring some replacement components. The study also found that using AM might save costs in production and lead times significantly.

The adoption of AM technologies has increased the freedom of design by expanding the possibility of producing unconventional geometrics. However, such decisions are complex since optimizing AM requires integrating data from several disciplines. For instance, to make unique and challenging products, there must be a proper assessment of the qualities of printed materials and their compatibility with a certain application, redesign forms with respect to AM’s limitations, and so on. Moreover, procurement and logistics evaluation must be included in this process. In this regard, Raffaeli et al. [109] investigate the adoption of AM technology in production design. The study examines the various factors involved in this decision-making process and proposes a systematic approach that guides designers through structured algorithm procedures. This approach enables designers to evaluate the suitability of AM adoption and to develop optimal designs considering the constraints of AM technology.

Muhammad et al. [110] examine the application of AM in enhancing the resilience of the automotive supply chain network and addressing disruptions. The global supply system, particularly the automotive sector, has faced significant challenges due to the COVID-19 pandemic. To assess the potential of AM in strengthening the automotive supply chain, the authors focus on the Indian automotive industry as a case study. They identify key barriers to widespread AM adoption, such as insufficient government regulations, limited management support, restricted availability of raw materials, and workforce constraints. The study also discusses mitigation strategies that leverage AM in the upstream automotive supply chain.

Chowdhury et al. [111] present an innovative optimization framework for the design and operation of an integrated AM supply chain network. This framework considers the interdependencies among flow networks, resource limitations, and costs at the process and system levels within a unified decision framework. A two-stage stochastic programming model is proposed, where the first stage focuses on minimizing facility site selection and capacity decisions before any customer demand information is known. Once demand information is available, second-stage decisions are made, including determining the optimal layer thickness for AM products, production planning, post-processing, procurement, storage, and transportation.

Knofius et al. [113] conduct a comprehensive analysis of the total costs associated with consolidation using AM, encompassing logistics, manufacturing, and repair expenses. Their findings indicate that consolidation with AM often leads to higher overall costs, primarily due to a loss of flexibility. In contrast to conventionally constructed components that allow for partial replacements, consolidated components require complete replacement in the event of failure. Moreover, the perceived advantage of shorter lead times for resupplying consolidated spare parts proves to be insignificant. These conclusions highlight the necessity of considering a holistic cost perspective when evaluating the outcomes of design enhancements using AM. Neglecting such an approach may result in unintended consequences that cast doubt on the viability of design changes, even in the presence of significant functionality improvements.

4.6. Blockchain

Blockchain is yet another important I4.0 technology that has been predominantly used in procurement for making smart contracts. Smart Contracts play an essential role in procurement and they have been increasingly used in many industries due to many features, including automatic execution, nontempering in the blockchain environment, and transparency [4]. However, blockchain technology and its recent developments in applications are moderately well explored in the literature.

In 2017, the initial scholarly publications on the application of blockchain technology in the construction industry were introduced, comprising a total of three articles. Over the span of a few years, a body of literature has emerged with an average annual expansion rate of 184%, resulting in a cumulative count of 121 documents by early 2021. To explore the topic’s growth and advancement, all 121 papers were reviewed. A literature study and scientometric analysis were used in a mixed methods approach to examine the present environment [133]. In total, 33 blockchain application categories in construction were identified and organized into seven subject areas: (1) procurement and supply chain, (2) design and construction, (3) operations and life cycle, (4) smart cities, (5) intelligent systems, (6) energy and carbon footprint, and (7) decentralized organizations.

The possibilities of blockchain technology in making a digitalized supply chain (DSC) have been explored and multiple models are experimented with in different procurement fields [114]. Dutta et al. [115] explore industrial sectors such as shipping, automotive, aviation, manufacturing energy, healthcare, etc., in which the use of blockchain technology can enhance efficiency in business process management. Similarly, another study pointed out a blockchain-enabled smart contract system has been used to mitigate unethical practices of bid shopping and peddling during the subcontractor procurement process [116].

One of the important qualities of blockchain technology is its capacity to record data in a predetermined way, in a cryptographic mode. Many enterprises employ this technology in their respective fields in order to make their procurement processes more efficient and cost-effective. In this context, Hofbauer and Sangl [117] present a comprehensive analysis of blockchain technology’s application potential in digitizing transaction processes. They delve into the underlying principles and implications of blockchain in transaction activities. Through an examination of statistical data on users’ expectations and requirements, the authors highlight how blockchain can meet these needs. By integrating theoretical foundations with practical applications, this study effectively showcases the transformative possibilities of blockchain technology in the digitalization of transaction processes.

A methodology for green procurement using blockchain and Internet of Things integration is proposed by Rane and Thakker [118]. By reviewing extensive literature and analyzing interviews conducted among procurement managers from different industries, they identify challenges in green procurement and then discuss how the integration of blockchain and IoT technologies provides capabilities to overcome procurement challenges, making a sustainable business model. The authors argue that the proposed architecture can create a green supply chain, and such green initiatives enhance the competitiveness of the industries at the global level. Also, a successful green procurement will contribute to saving energy consumption and efficient waste disposal, thereby realizing a sustainable business model.

Government agencies and companies widely use computing solutions because of the ease of use of procurement processes. However, the security of cloud file storage has always been a threat. Pinheiro et al. [119] designed a new method to monitor the integrity of files stored in cloud storage using smart contracts in the blockchain network, symmetric encryption, and computational trust. This consists of a protocol that provides important features such as confidentiality, decentralization, audit availability, etc. The proposed method is feasible and accurate in detecting corrupted files. Therefore, it has the potential to improve the e-procurement process in various stages of a business.

Guo et al. [127] present the significance of blockchain technology in contract management that offers better security to the traditional electronic contract system. Industries have generally been adopting the e-contract system in modern times because it reduces time and human labor and improves contract management efficiency. However, since it has a centralized database-based storage schema in the e-contract system, there is a high possibility of data hacking and information draining; therefore, it raises serious security concerns. In this context, this study proposes a blockchain technology integrated contract management system. It develops a process-oriented contract management system (BE contractor) and discusses its implementation with a focus on Hangzhou (in China) power grid enterprise.