Comparison Study on the Microstructure, Hardness and Wear Properties of Ti Alloy Composites Reinforced by Carbon Nanomaterials

Abstract

1. Introduction

2. Results and Discussion

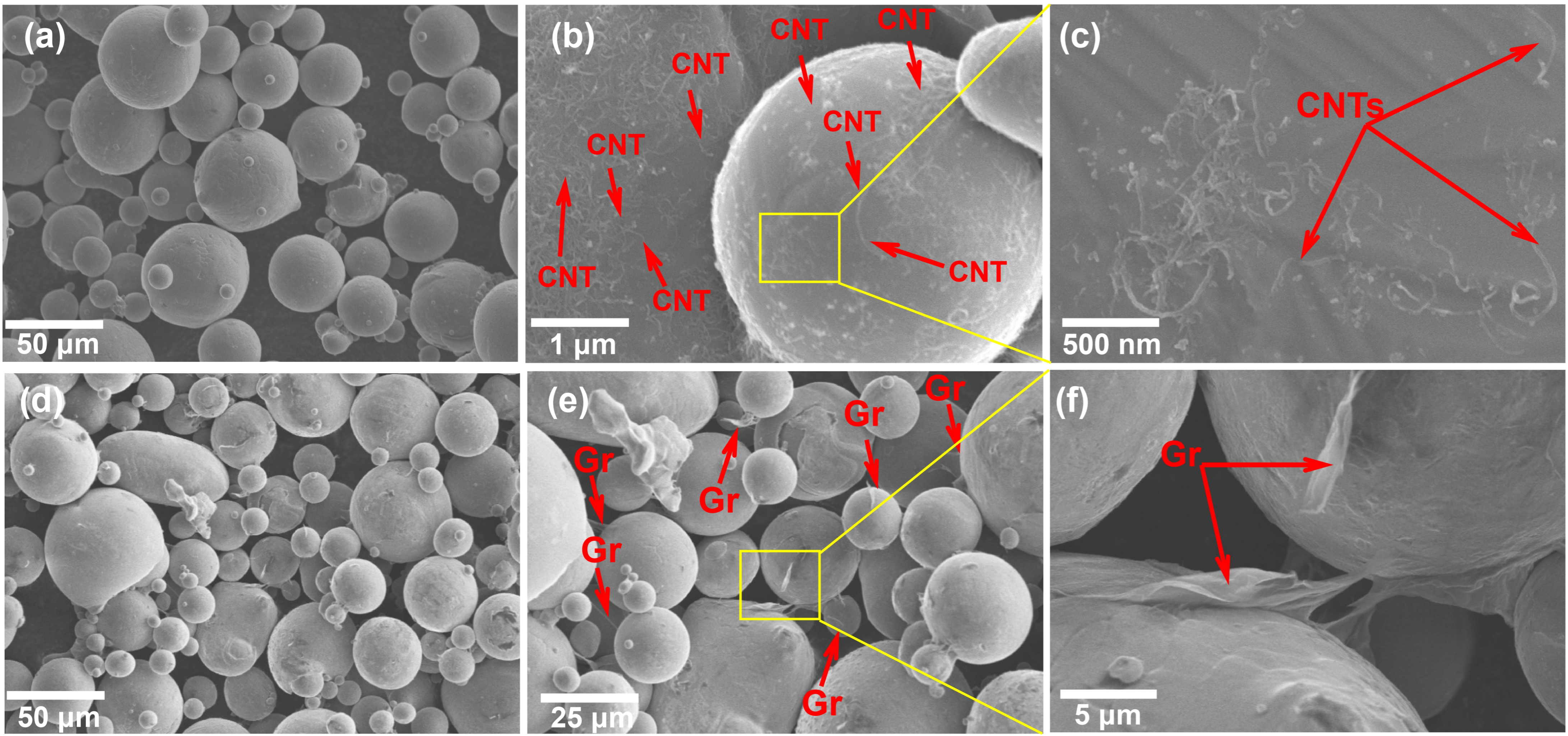

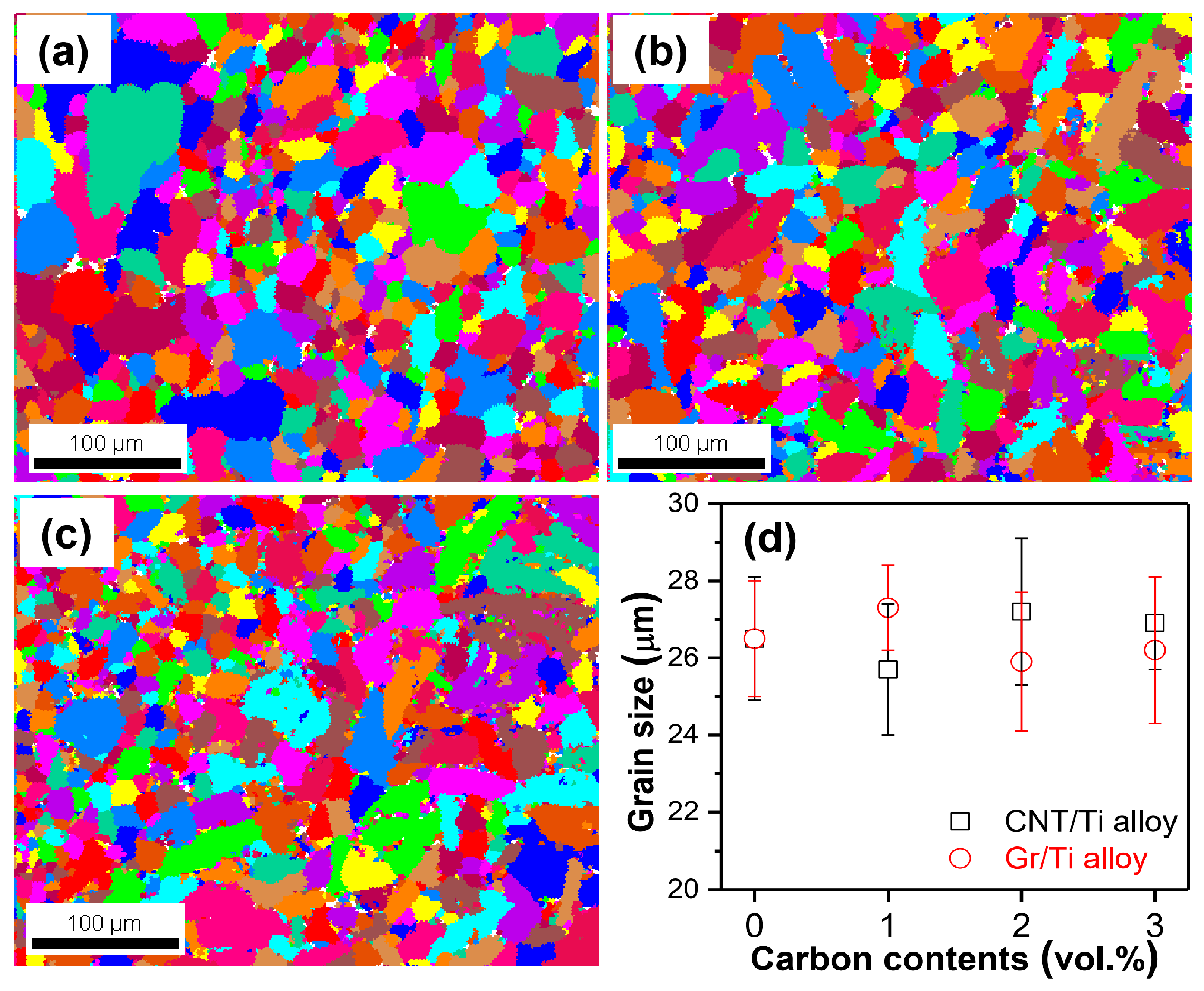

2.1. Microstructure

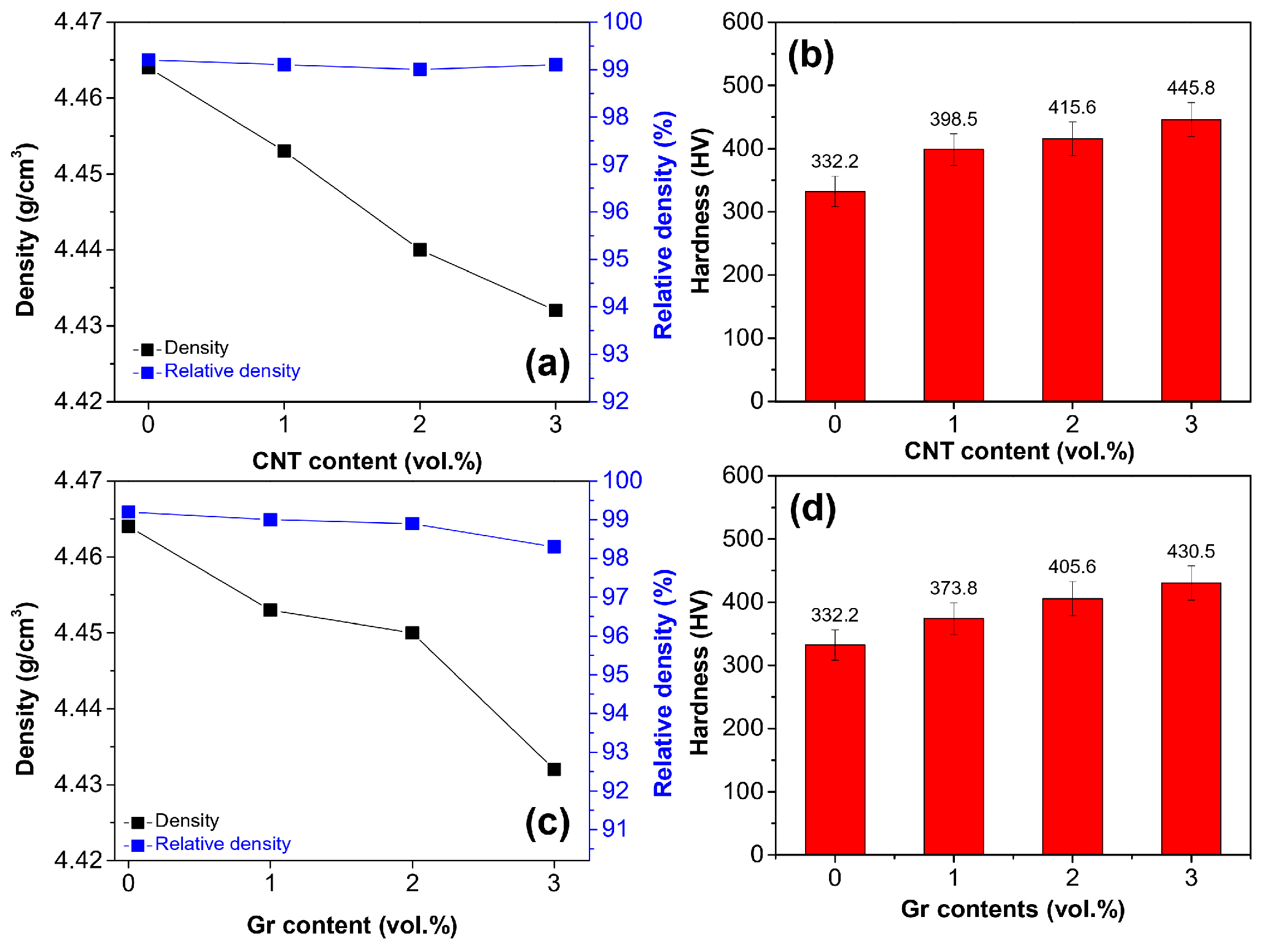

2.2. Density and Hardness

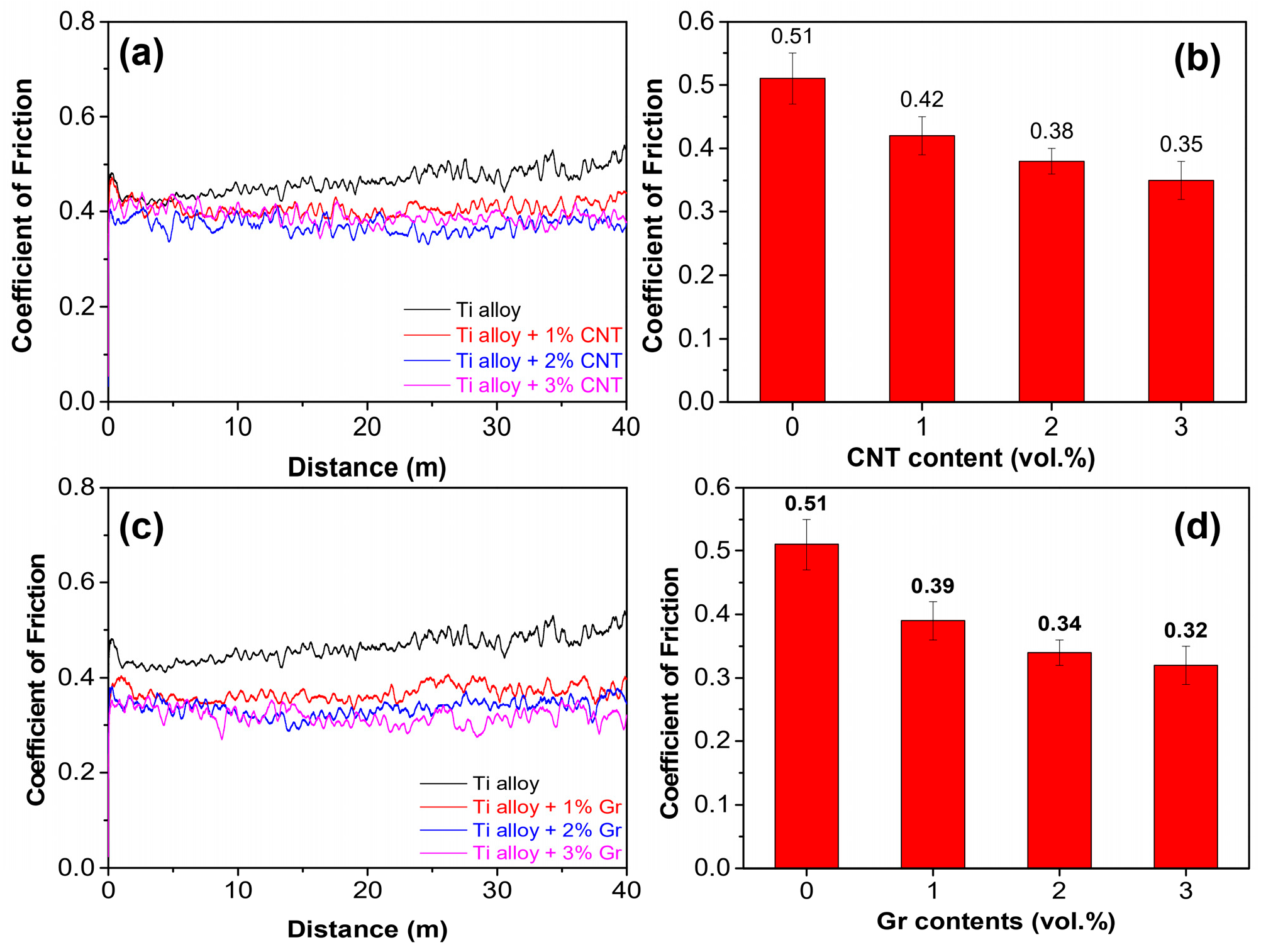

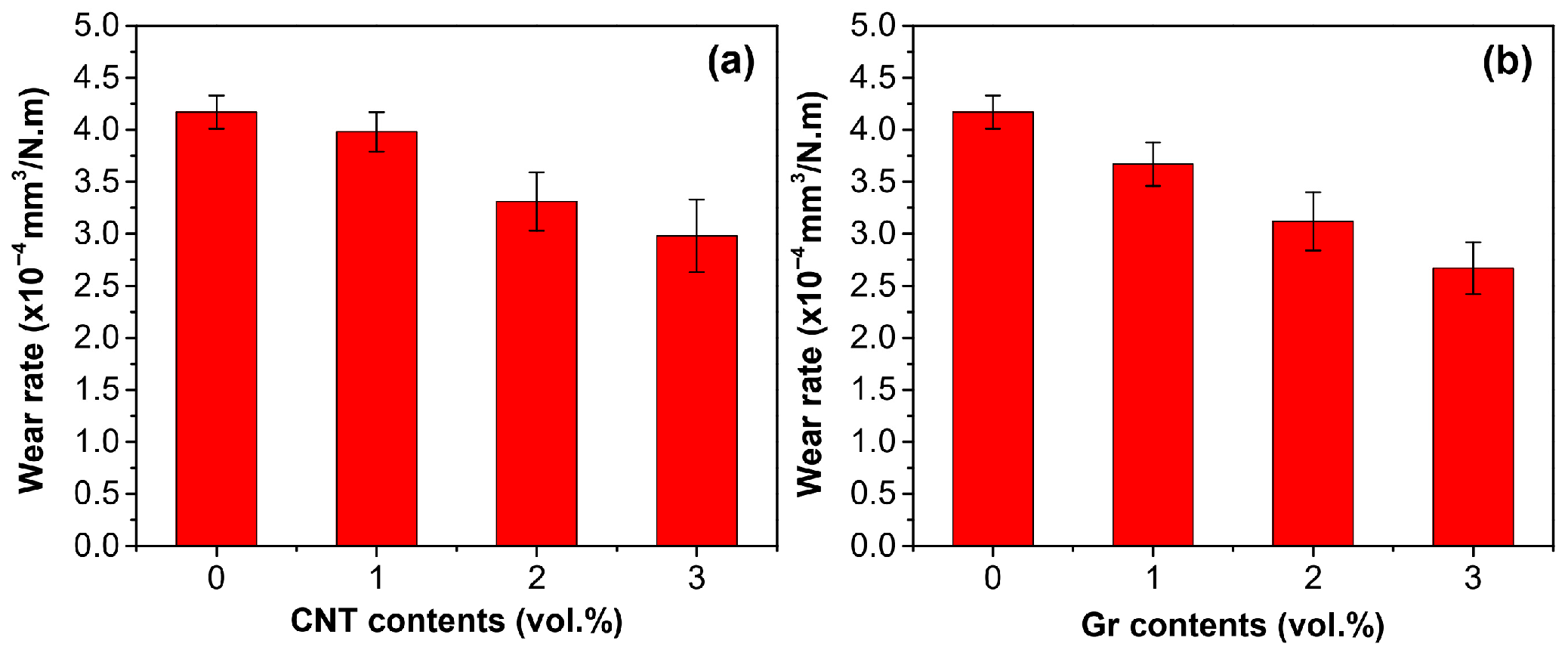

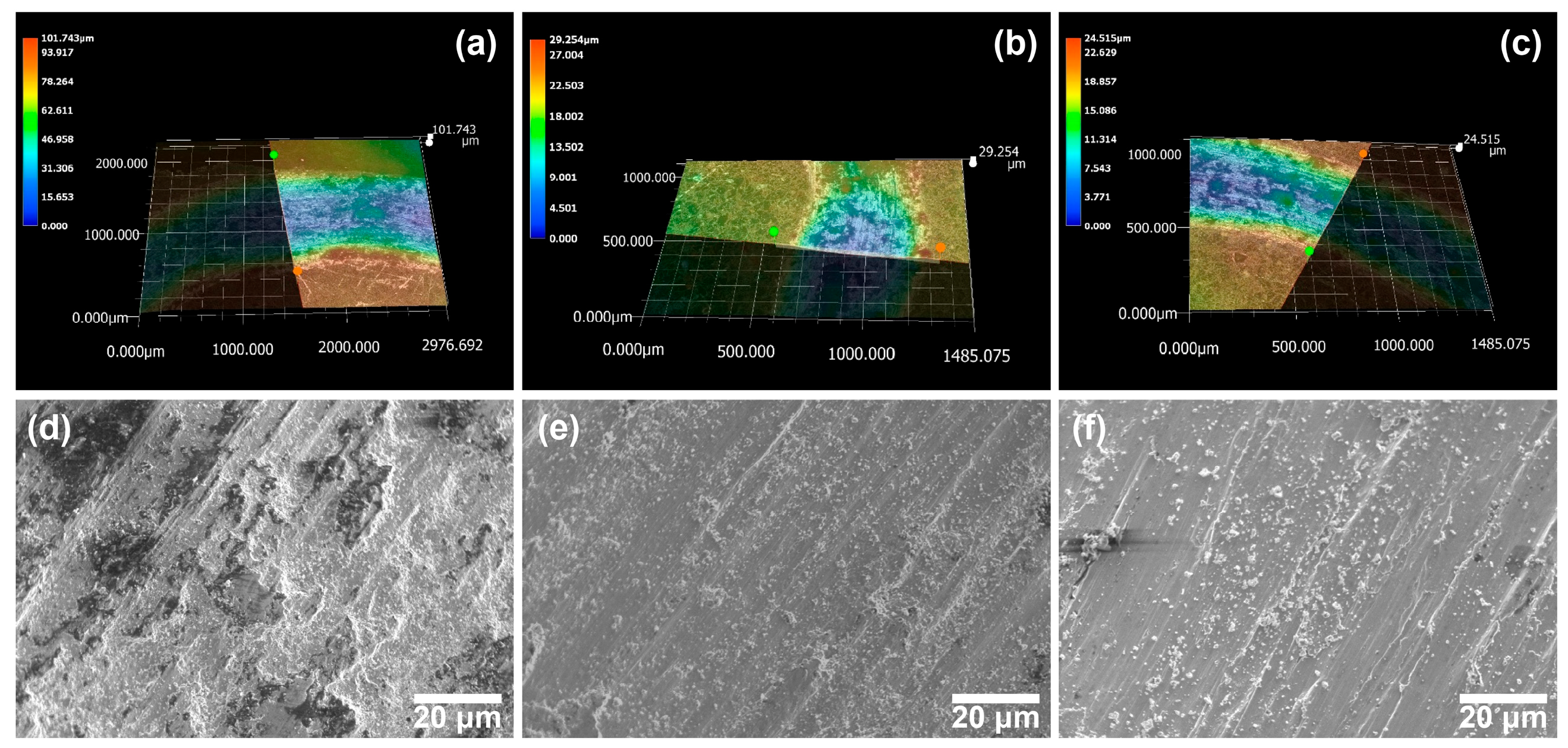

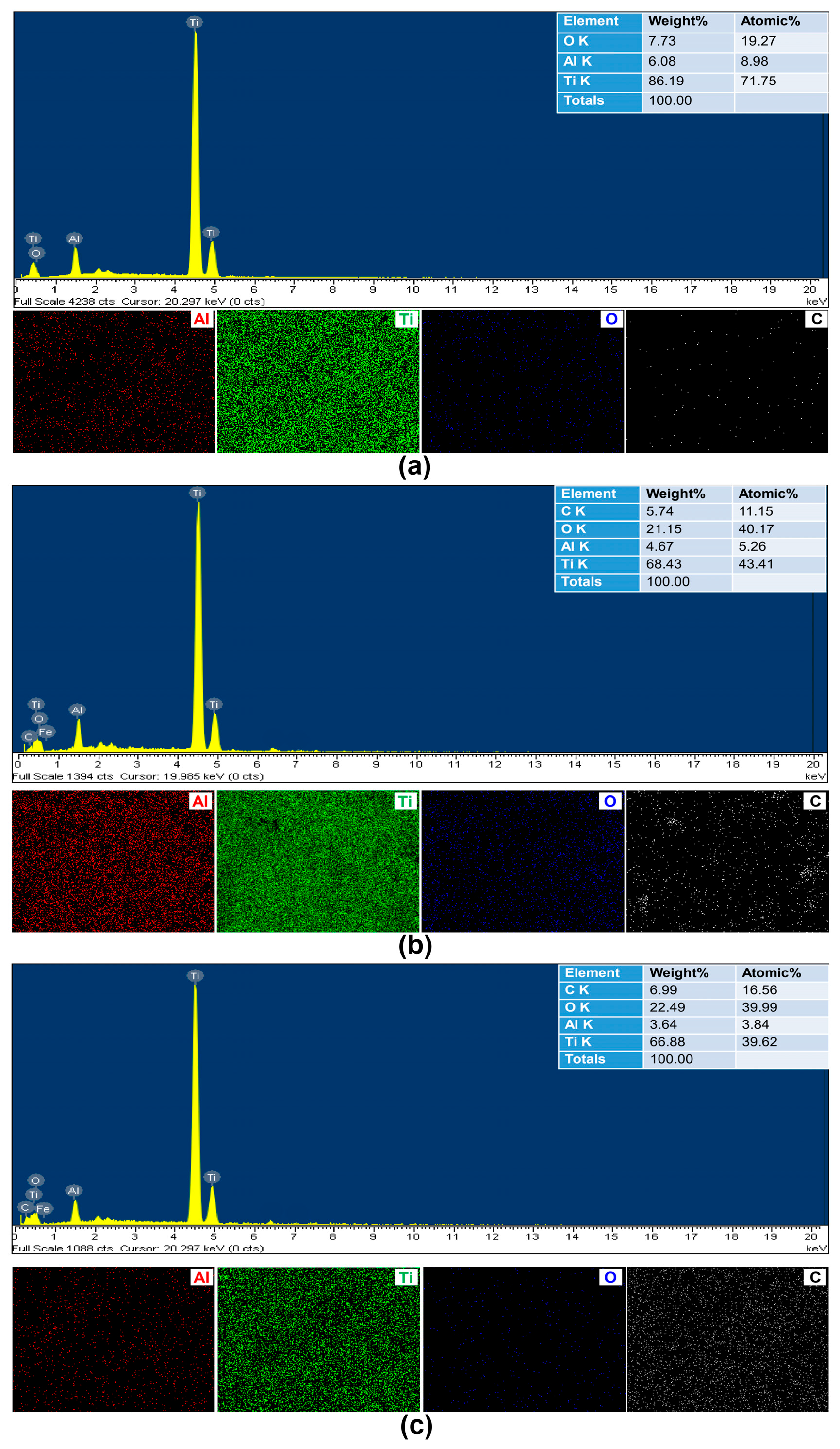

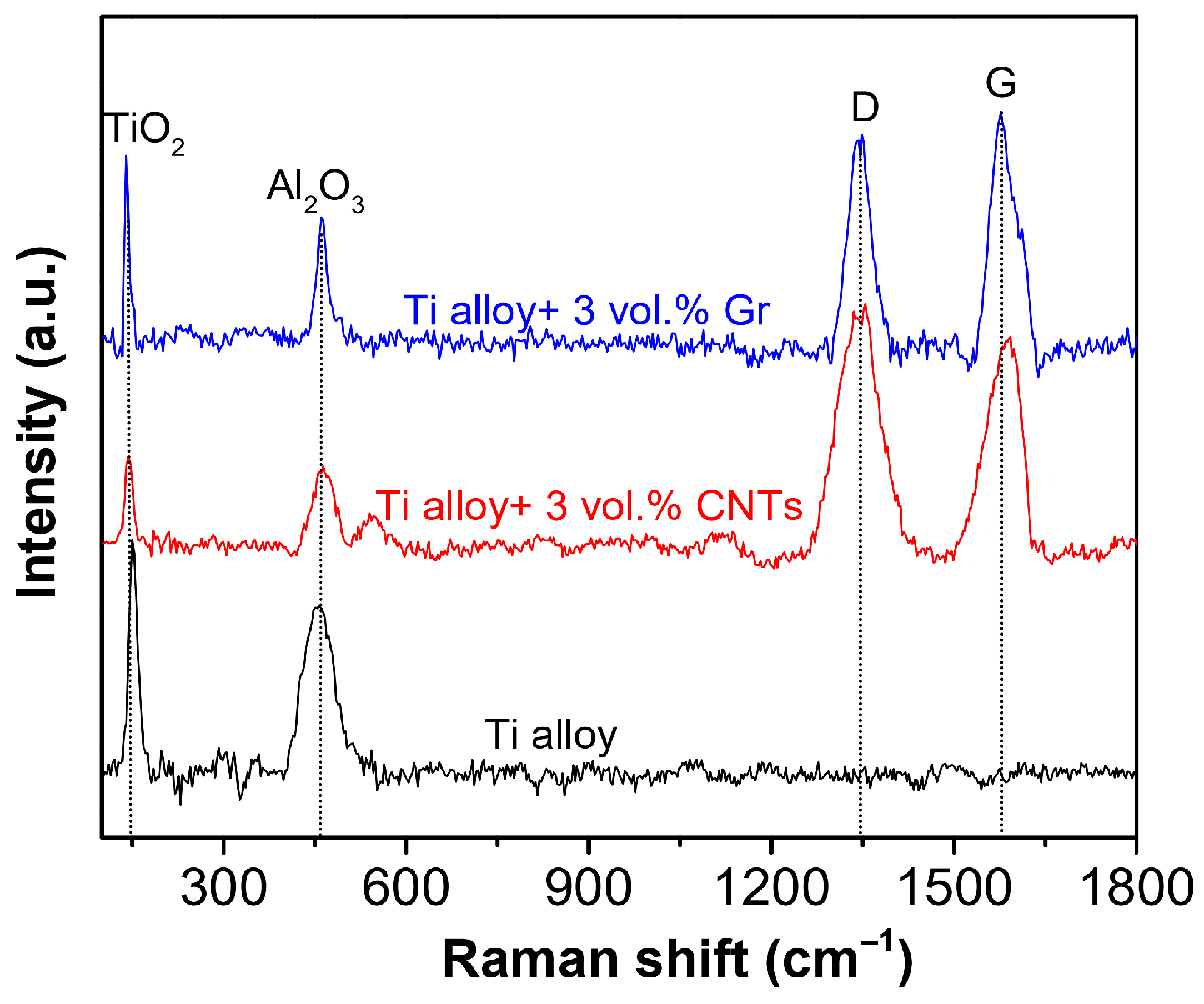

2.3. Wear Property

3. Materials and Methods

3.1. Materials

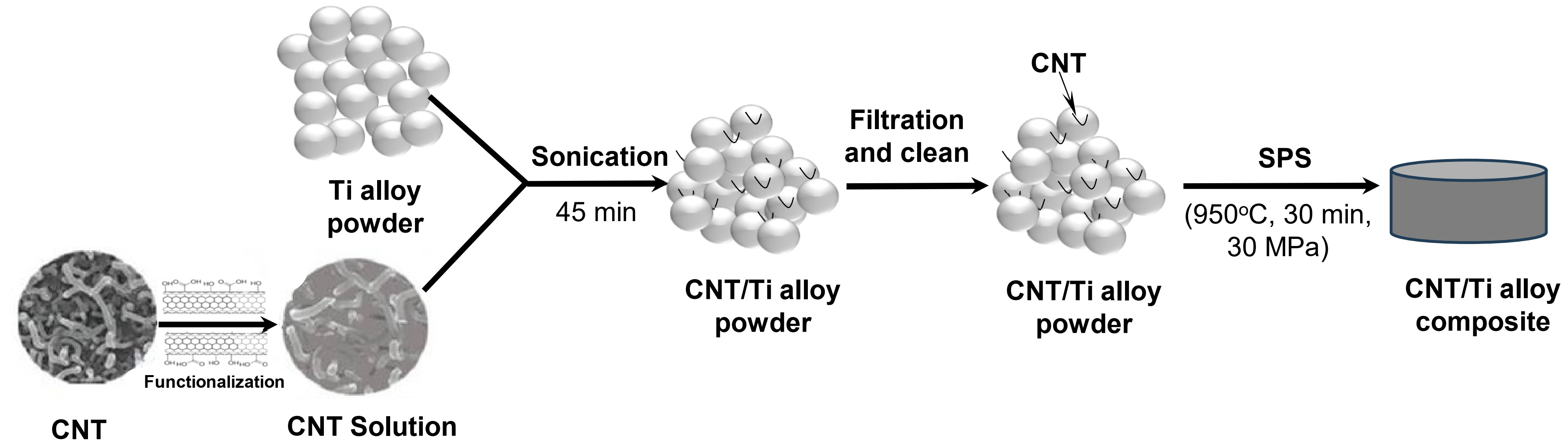

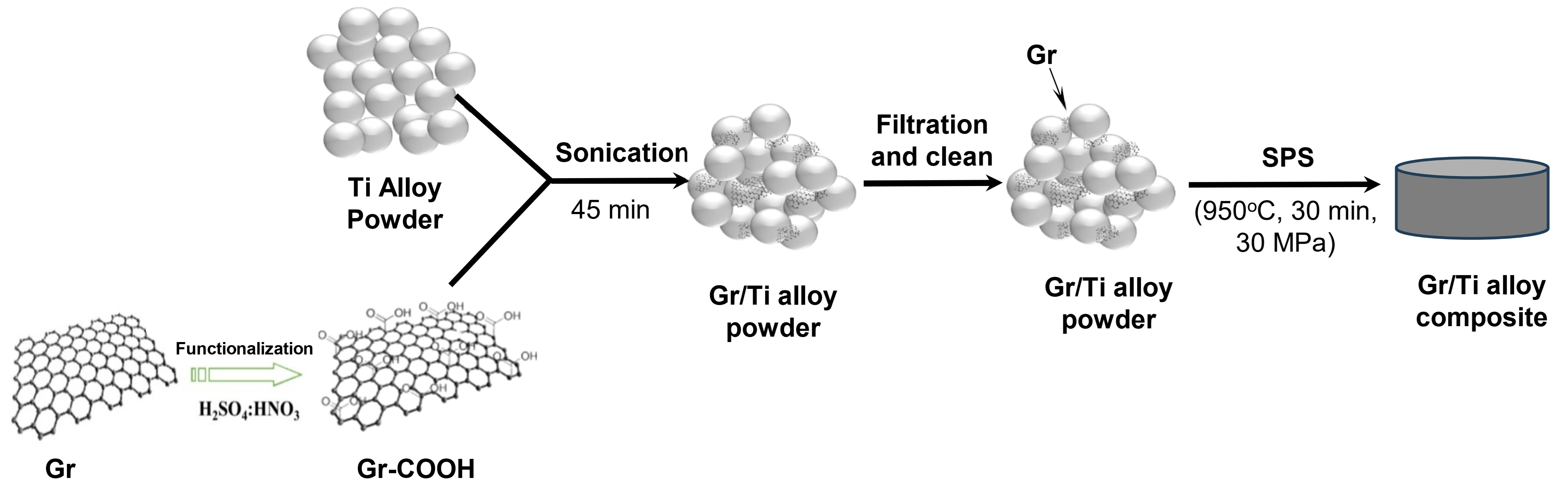

3.2. Fabrication of Ti Alloy Composites

- ❖

- Fabrication of CNT/Ti Alloy Composites

- ❖

- Fabrication of Gr/Ti Alloy Composites

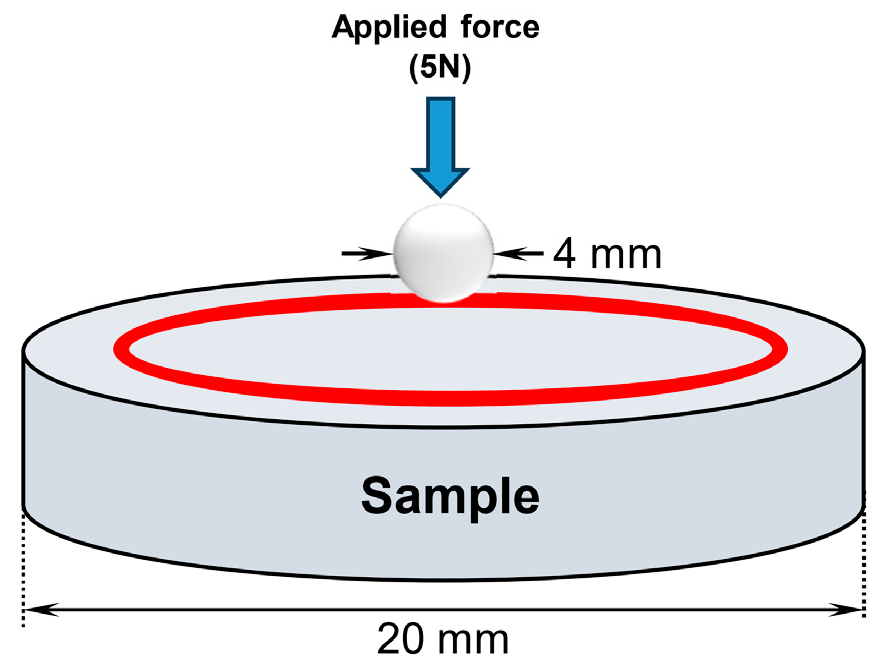

3.3. Characterizations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- da Silva, L.R.R.; Pereira, A.C.; Monteiro, S.N.; Kuntoğlu, M.; Binali, R.; Khan, A.M.; Unune, D.R.; Pimenov, D.Y. Review of Advances and Challenges in Machining of Metal Matrix Composites. J. Mater. Res. Technol. 2025, 37, 1061–1085. [Google Scholar] [CrossRef]

- Mileiko, S. Carbon-Fibre/Metal-Matrix Composites: A Review. J. Compos. Sci. 2022, 6, 297. [Google Scholar] [CrossRef]

- Fu, Z.; Pang, A.; Luo, H.; Zhou, K.; Yang, H. Research Progress of Ceramic Matrix Composites for High Temperature Stealth Technology Based on Multi-Scale Collaborative Design. J. Mater. Res. Technol. 2022, 18, 2770–2783. [Google Scholar] [CrossRef]

- Karadimas, G.; Salonitis, K. Ceramic Matrix Composites for Aero Engine Applications—A Review. Appl. Sci. 2023, 13, 3017. [Google Scholar] [CrossRef]

- Abd-Elaziem, W.; Khedr, M.; Abd-Elaziem, A.E.; Allah, M.M.A.; Mousa, A.A.; Yehia, H.M.; Daoush, W.M.; El-Baky, M.A.A. Particle-Reinforced Polymer Matrix Composites (PMC) Fabricated by 3D Printing. J. Inorg. Organomet. Polym. Mater. 2023, 33, 3732–3749. [Google Scholar] [CrossRef]

- Makhesana, M.; Sankhla, A.; Pawar, A.; Patel, K. A Comprehensive Review of Metal Matrix Composites: Manufacturing Techniques, Mechanical Properties, and Industrial Applications. In Advances in Sustainable Materials: Fundamentals, Modelling and Characterization; Elsevier: Amsterdam, The Netherlands, 2025; pp. 413–429. [Google Scholar] [CrossRef]

- Pooja, K.; Tarannum, N.; Chaudhary, P. Metal Matrix Composites: Revolutionary Materials for Shaping the Future. Discov. Mater. 2025, 5, 35. [Google Scholar] [CrossRef]

- Najafizadeh, M.; Yazdi, S.; Bozorg, M.; Ghasempour-Mouziraji, M.; Hosseinzadeh, M.; Zarrabian, M.; Cavaliere, P. Classification and Applications of Titanium and Its Alloys: A Review. J. Alloys Compd. Commun. 2024, 3, 100019. [Google Scholar] [CrossRef]

- Hill, D.; Banerjee, R.; Huber, D.; Tiley, J.; Fraser, H.L. Formation of Equiaxed Alpha in TiB Reinforced Ti Alloy Composites. Scr. Mater. 2005, 52, 387–392. [Google Scholar] [CrossRef]

- Ogunmefun, O.A.; Bayode, B.L.; Jamiru, T.; Olubambi, P.A. A Critical Review of Dispersion Strengthened Titanium Alloy Fabricated through Spark Plasma Sintering Techniques. J. Alloys Compd. 2023, 960, 170407. [Google Scholar] [CrossRef]

- Shang, C.; Zhang, F.; Wang, J.; Chen, F. Interface Configuration Effect on Mechanical and Tribological Properties of Three-Dimension Network Architectural Titanium Alloy Matrix Nanocomposites. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106981. [Google Scholar] [CrossRef]

- Sun, G.; Zhuang, S.; Jia, D.; Pan, X.; Sun, Y.; Tu, F.; Lu, M. Facile Fabricating Titanium/Graphene Composite with Enhanced Conductivity. Mater. Lett. 2023, 333, 133680. [Google Scholar] [CrossRef]

- Liu, L.; Li, Y.; Zhang, H.; Cheng, X.; Mu, X.; Fan, Q.; Ge, Y.; Guo, S. Simultaneously Enhancing Strength and Ductility in Graphene Nanoplatelets Reinforced Titanium (GNPs/Ti) Composites through a Novel Three-Dimensional Interface Design. Compos. B Eng. 2021, 216, 108851. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Li, J.S. Super-High-Strength Graphene/Titanium Composites Fabricated by Selective Laser Melting. Carbon 2021, 174, 451–462. [Google Scholar] [CrossRef]

- Munir, K.S.; Kingshott, P.; Wen, C. Carbon Nanotube Reinforced Titanium Metal Matrix Composites Prepared by Powder Metallurgy—A Review. Crit. Rev. Solid State Mater. Sci. 2015, 40, 38–55. [Google Scholar] [CrossRef]

- Ayanda, O.S.; Mmuoegbulam, A.O.; Okezie, O.; Durumin Iya, N.I.; Mohammed, S.E.; James, P.H.; Muhammad, A.B.; Unimke, A.A.; Alim, S.A.; Yahaya, S.M.; et al. Recent Progress in Carbon-Based Nanomaterials: Critical Review. J. Nanoparticle Res. 2024, 26, 106. [Google Scholar] [CrossRef]

- Srinivasan, V.; Kunjiappan, S.; Palanisamy, P. A Brief Review of Carbon Nanotube Reinforced Metal Matrix Composites for Aerospace and Defense Applications. Int. Nano Lett. 2021, 11, 321–345. [Google Scholar] [CrossRef]

- Guler, O.; Bagci, N. A Short Review on Mechanical Properties of Graphene Reinforced Metal Matrix Composites. J. Mater. Res. Technol. 2020, 9, 6808–6833. [Google Scholar] [CrossRef]

- Carneiro, Í.; Simões, S. Strengthening Mechanisms in Carbon Nanotubes Reinforced Metal Matrix Composites: A Review. Metals 2021, 11, 1613. [Google Scholar] [CrossRef]

- Jalali, M.; Hassanzadeh, N.; Alizadeh, R.; Langdon, T.G. Graphene-Reinforced Metal Matrix Composites Produced by High-Pressure Torsion: A Review. J. Mater. Sci. 2024, 59, 20900–20928. [Google Scholar] [CrossRef]

- Xiong, N.; Bao, R.; Yi, J.; Fang, D.; Tao, J.; Liu, Y. CNTs/Cu-Ti Composites Fabrication through the Synergistic Reinforcement of CNTs and in Situ Generated Nano-TiC Particles. J. Alloys Compd. 2019, 770, 204–213. [Google Scholar] [CrossRef]

- Dong, S.; Chen, T.; Fu, H.; Chen, X.; Zhou, C. Mechanical Response and Interface Properties of Graphene-Metal Composites: A Review. J. Mater. Res. Technol. 2025, 36, 398–416. [Google Scholar] [CrossRef]

- Fonseca, A.F.; Liang, T.; Zhang, D.; Choudhary, K.; Phillpot, S.R.; Sinnott, S.B. Titanium-Carbide Formation at Defective Curved Graphene-Titanium Interfaces. MRS Adv. 2018, 3, 457–462. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, F.; Saba, F.; Shang, C. Graphene-TiC Hybrid Reinforced Titanium Matrix Composites with 3D Network Architecture: Fabrication, Microstructure and Mechanical Properties. J. Alloys Compd. 2021, 859, 157777. [Google Scholar] [CrossRef]

- Guiderdoni, C.; Estournès, C.; Peigney, A.; Weibel, A.; Turq, V.; Laurent, C. The Preparation of Double-Walled Carbon Nanotube/Cu Composites by Spark Plasma Sintering, and Their Hardness and Friction Properties. Carbon 2011, 49, 4535–4543. [Google Scholar] [CrossRef]

- Van Trinh, P.; Lee, J.; Kang, B.; Minh, P.N.; Phuong, D.D.; Hong, S.H. Mechanical and Wear Properties of SiCp/CNT/Al6061 Hybrid Metal Matrix Composites. Diam. Relat. Mater. 2022, 124, 108952. [Google Scholar] [CrossRef]

- Van Trinh, P.; Van Luan, N.; Minh, P.N.; Phuong, D.D. Effect of Sintering Temperature on Properties of CNT/Al Composite Prepared by Capsule-Free Hot Isostatic Pressing Technique. Trans. Indian Inst. Met. 2016, 70, 947–955. [Google Scholar] [CrossRef]

- Mohammed, S.M.A.K.; Chen, D.L. Carbon Nanotube-Reinforced Aluminum Matrix Composites. Adv. Eng. Mater. 2020, 22, 1901176. [Google Scholar] [CrossRef]

- Reihanian, M.; Bavi, M.A.; Ranjbar, K. CNT-Reinforced Al-XZr (x = 0.25, 0.5 and 1 Wt.%) Surface Composites Fabricated by Friction Stir Processing: Microstructural, Mechanical and Wear Characterisation. Philos. Mag. 2022, 102, 1011–1041. [Google Scholar] [CrossRef]

- Chen, H.; Mi, G.; Sun, Y.; Li, P. Unique Grain Refinement Mechanism of Graphene Oxide Reinforced High-Temperature Titanium Alloy Matrix Composite. Mater. Today Commun. 2024, 41, 110803. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, Z.; Luo, Y.; Xiao, Y.; Tan, F.; Liu, K. Understanding the Influencing Mechanism of CNTs on the Microstructures and Wear Characterization of Semi-Solid Stir Casting Al-Cu-Mg-Si Alloys. Metals 2022, 12, 2171. [Google Scholar] [CrossRef]

- Gholami-Kermanshahi, M.; Hsiao, Y.C.; Lange, G.; Chang, S.H. Effects of Carbon Nanotube Addition on the Microstructures, Martensitic Transformation, and Internal Friction of Cu–Al–Ni Shape-Memory Alloys. Sci. Rep. 2023, 13, 21181. [Google Scholar] [CrossRef]

- Azarniya, A.; Safavi, M.S.; Sovizi, S.; Azarniya, A.; Chen, B.; Hosseini, H.R.M.; Ramakrishna, S. Metallurgical Challenges in Carbon Nanotube-Reinforced Metal Matrix Nanocomposites. Metals 2017, 7, 384. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, Z.; Bai, P.; Du, W.; Li, Y.; Yang, X.; Wang, Q. In-Situ Synthesis of TiC/Graphene/Ti6Al4V Composite Coating by Laser Cladding. Mater. Lett. 2020, 270, 127711. [Google Scholar] [CrossRef]

- Wang, N.; Choi, Y.; Oue, K.; Matsugi, K. Fabrication of In-Situ Rod-like TiC Particles Dispersed Ti Matrix Composite Using Graphite Power Sheet. Sci. Rep. 2022, 12, 19154. [Google Scholar] [CrossRef] [PubMed]

- Su, L.; Sun, J.; Ding, F.; Gao, Y.; Gao, X.; Zheng, L. Molecular Insight into the Reversible Dispersion and Aggregation of Graphene Utilizing Photo-Responsive Surfactants. Appl. Surf. Sci. 2021, 567, 150840. [Google Scholar] [CrossRef]

- Han, X.; Kong, H.; Chen, T.; Gao, J.; Zhao, Y.; Sang, Y.; Hu, G. Effect of π–π Stacking Interfacial Interaction on the Properties of Graphene/Poly(Styrene-b-Isoprene-b-Styrene) Composites. Nanomaterials 2021, 11, 2158. [Google Scholar] [CrossRef]

- Adegbenjo, A.O.; Olubambi, P.A.; Westraadt, J.E.; Lesufi, M.; Mphahlele, M.R. Interface Analysis of Spark Plasma Sintered Carbon Nanotube Reinforced Ti6Al4V. JOM 2019, 71, 2262–2271. [Google Scholar] [CrossRef]

- Dash, T.; Rout, T.K.; Palei, B.B.; Bajpai, S.; Kundu, S.; Bhagat, A.N.; Satpathy, B.K.; Biswal, S.K.; Rajput, A.; Sahu, A.K.; et al. Synthesis of α-Al2O3–Graphene Composite: A Novel Product to Provide Multi-Functionalities on Steel Strip Surface. SN Appl. Sci. 2020, 2, 1147. [Google Scholar] [CrossRef]

- El-Deen, S.S.; Hashem, A.M.; Abdel Ghany, A.E.; Indris, S.; Ehrenberg, H.; Mauger, A.; Julien, C.M. Anatase TiO2 Nanoparticles for Lithium-Ion Batteries. Ionics 2018, 24, 2925–2934. [Google Scholar] [CrossRef]

- Van Trinh, P.; Anh, N.N.; Hong, N.T.; Hong, P.N.; Minh, P.N.; Thang, B.H. Experimental Study on the Thermal Conductivity of Ethylene Glycol-Based Nanofluid Containing Gr-CNT Hybrid Material. J. Mol. Liq. 2018, 269, 344–353. [Google Scholar] [CrossRef]

- Van Thanh, D.; Li, L.J.; Chu, C.W.; Yen, P.J.; Wei, K.H. Plasma-Assisted Electrochemical Exfoliation of Graphite for Rapid Production of Graphene Sheets. RSC Adv. 2014, 4, 6946–6949. [Google Scholar] [CrossRef]

- Van Trinh, P.; Anh, N.N.; Tam, N.T.; Hong, N.T.; Hong, P.N.; Minh, P.N.; Thang, B.H. Influence of Defects Induced by Chemical Treatment on the Electrical and Thermal Conductivity of Nanofluids Containing Carboxyl-Functionalized Multi-Walled Carbon Nanotubes. RSC Adv. 2017, 7, 49937–49946. [Google Scholar] [CrossRef]

- ASTM G-99; Standard Test Method for Wear and Friction Testing with a Pin-on-Disk or Ball-on-Disk Apparatus. ASTM International: West Conshohocken, PA, USA, 2023.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, N.B.; Hau, T.V.; Trung, T.B.; Trinh, P.V.; Phuong, D.D. Comparison Study on the Microstructure, Hardness and Wear Properties of Ti Alloy Composites Reinforced by Carbon Nanomaterials. Inorganics 2025, 13, 405. https://doi.org/10.3390/inorganics13120405

An NB, Hau TV, Trung TB, Trinh PV, Phuong DD. Comparison Study on the Microstructure, Hardness and Wear Properties of Ti Alloy Composites Reinforced by Carbon Nanomaterials. Inorganics. 2025; 13(12):405. https://doi.org/10.3390/inorganics13120405

Chicago/Turabian StyleAn, Nguyen Binh, Tran Van Hau, Tran Bao Trung, Pham Van Trinh, and Doan Dinh Phuong. 2025. "Comparison Study on the Microstructure, Hardness and Wear Properties of Ti Alloy Composites Reinforced by Carbon Nanomaterials" Inorganics 13, no. 12: 405. https://doi.org/10.3390/inorganics13120405

APA StyleAn, N. B., Hau, T. V., Trung, T. B., Trinh, P. V., & Phuong, D. D. (2025). Comparison Study on the Microstructure, Hardness and Wear Properties of Ti Alloy Composites Reinforced by Carbon Nanomaterials. Inorganics, 13(12), 405. https://doi.org/10.3390/inorganics13120405