Abstract

Escalating environmental concerns have dictated the need to develop innovative methods for efficiently desulfurizing marine fuels (heavy fuel oils). In this work, the oxidative desulfurization method using deep eutectic solvents (DESs) was applied to reduce the sulfur content in a commercially available heavy fuel oil (HFO) below 0.5 wt.%, as current regulations demand. Initially, the S-compounds in the fuel were oxidized using an oxidative mixture of H2O2 with carboxylic acid (either acetic or formic acid). Subsequently, the oxidized S-compounds were extracted from the fuel using a series of environmentally friendly deep eutectic solvents (DESs), the best of which was proven to be a mixture of choline chloride with ethylene glycol at a 1/2 molar ratio. The process was optimized by investigating the effect of several process parameters on the desulfurization efficiency, namely, the H2O2/S molar ratio, the H2O2/acid molar ratio, the acid type, the oxidation temperature and oxidation time, the solvent/fuel mass ratio, the extraction time, and the extraction temperature. A desulfurization efficiency of 75.7% was achieved under the optimized conditions, reducing the S content in the fuel to 0.33 wt.%. Furthermore, different methods to recycle the DESs were investigated, and consecutive desulfurization and solvent regeneration cycles were performed. The most efficient recycling method was determined to be the anti-solvent addition of excess water, which resulted in 89.5% DES purification by causing precipitation of the dissolved solids. After three cycles of desulfurization and regeneration using different recycling routes, it was found that the regeneration degree declines gradually; however, it is more than 79.3% in all cases.

1. Introduction

1.1. The Presence of Sulfur in Fuels

Crude oil contains a significant amount of sulfur, which usually ranges between 1–4 wt.% [1]. Sulfur is present in a variety of sulfur compounds (S-compounds) that can be either inorganic (such as H2S) or organic, in which sulfur is bound to a hydrocarbon molecule as a heteroatom [1,2].

Although most of these compounds are removed during crude oil refining, a small percentage remains in commercial fuels. These S-compounds are a source of concern because they are associated with a series of detrimental effects on human health [2]. In addition, SO2 is released into the atmosphere during commercially available marine fuel combustion, contributing to the formation of photochemical smog and acid rain [2]. Furthermore, corrosion in tanks and pipelines could be attributed to S-species, while refining process catalysts can also be poisoned by S-compounds [2].

These serious adverse effects have led many competent authorities and international organizations to apply stringent regulations for the concentration of sulfur in commercially available marine fuels. Currently, the regulations set by the European Union allow a maximum sulfur content of 10 ppm for gasoline and diesel [3]. Furthermore, the International Marine Organization (IMO) has recently lowered the maximum sulfur content allowed in marine fuels (heavy fuel oil, HFO) to 0.5 wt.% for ships operating outside designated emission control areas [4]. In addition, there is an even lower limit of 0.1 wt.% within emission control areas, including the entire Mediterranean Sea starting from 2025 [4].

1.2. Technologies for Sulfur Removal from Fuels

The most common process for the removal of S-compounds from petroleum distillates in refineries is hydrodesulfurization (HDS) [5]. It is a catalytic process, in which the distillate is processed in a reactor with an excess of H2 gas at a high temperature range of 300–400 °C and pressure range of 50–100 bar [6]. Hence, it is an energy-intensive, environmentally unfriendly process. Hydrodesulfurization is very efficient at removing light S-compounds (sulfides, thiols), but the efficiency of this process is limited in the case of aromatic thiophenes such as dibenzothiophene and 4,6-dimethyl dibenzothiophene, which require extreme operating conditions [5]. These heavier compounds are termed refractory S-compounds [5]. S-compounds in the heaviest petroleum distillates, such as HFO, consist mainly of these heavy refractory compounds [2].

In recent years, alternative processes for the deep desulfurization of petroleum distillates have been proposed, aiming to replace HDS for the removal of heavy S-compounds under mild operating conditions. Adsorptive desulfurization, bio-desulfurization, extractive desulfurization, and oxidative desulfurization are the most eminent [6,7,8].

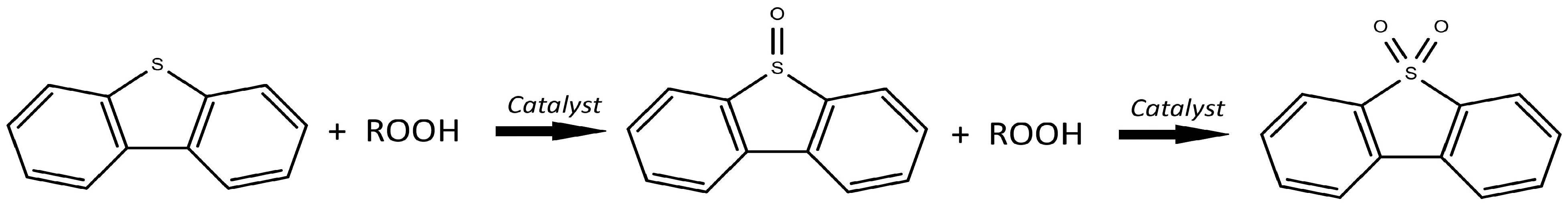

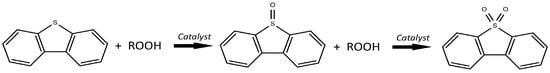

Oxidative desulfurization (ODS) is based on the oxidation of S-compounds by mixing fuel with appropriate oxidants and catalysts under mild operating conditions. Typical oxidants include H2O2, peroxy salts, NO2, O3, and KMnO4, while acetic acid and formic acid are common catalysts [6,8]. During oxidation, S-compounds are converted to sulfoxides and sulfones, which are more polar than their unoxidized form (Figure 1) [9]. Subsequently, the sulfoxides and sulfones are extracted using an appropriate polar solvent. In addition to common polar organic solvents such as acetonitrile, methanol, and N,N-dimethylformamide, other ionic liquids and deep eutectic solvents can also be applied [8]. After extraction, the mixture is spontaneously separated into a non-polar phase (the raffinate fuel) and a polar one (the solvent containing the oxidized S-compounds).

Figure 1.

The conversion of S-compounds to sulfoxides and sulfones during the ODS process.

The challenges of ODS include the selectivity for S-compounds, the use of environmentally friendly solvents, and their efficient regeneration. Nevertheless, it has significant advantages compared to the traditional HDS process. S-compounds are relatively easy to convert to sulfoxides and sulfones with oxidation, which is much more efficient in the removal of refractory S-compounds such as dibenzothiophene, and finally, it takes place at mild operating conditions, so it is not as energy-intensive as HDS [10,11].

1.3. Oxidative Desulfurization of Heavy Petroleum Distillates

The heaviest petroleum distillates such as fuel oil, vacuum distillates, and bitumen occupy a large proportion of total hydrocarbon product. A study on Iranian refineries revealed that this proportion amounts to 32 wt.%, while 60% of these products are fuel oil [12]. HFO, also known as bunker oil, is a broad term covering different residual fuels and mixed distillate diluents to achieve desired characteristics such as viscosity and density [13]. It comprises a mixture of high molecular weight hydrocarbons (boiling point > 400 °C) with high specific gravity and high carbon-to-hydrogen ratios [8,12]. It also contains many impurities such as heavy metals, asphaltenes, and approximately 3–4 wt.% of sulfur [8,12]. Since HFO is mainly used as a marine fuel, there is a demand to develop an efficient process that can lower its sulfur content to the limits set by the IMO.

Previous studies on the desulfurization of heavy distillates are limited because model fuels were mostly used instead of commercial ones. Nevertheless, there are some citations in the literature demonstrating the promising potential of ODS for this purpose [11,12,14,15,16,17,18,19,20]. Table 1 summarizes the most important aspects of these studies.

Table 1.

ODS of heavy petroleum distillates: summary of the literature.

1.4. Regeneration of Deep Eutectic Solvents

Deep eutectic solvents (DESs) are mixtures of Lewis/Brønsted acids and bases, the melting points of which are lower than their counterpart compounds [21,22]. They consist of trivial, low-cost constituents such as lactic acid, glucose, urea, ethylene glycol, and choline chloride. They are non-toxic and easily biodegradable. These solvents consist of a mixture of two or more compounds that act as hydrogen-bond donors (HBDs) and hydrogen-bond acceptors (HBAs). According to the nature of HBDs and HBAs, deep eutectic solvents are classified into four distinct categories. Type I DESs consist of a quaternary ammonium salt with a metal halide, and type II DESs consist of a quaternary ammonium salt with a hydrated metal halide. Type III DESs are formed by a quaternary ammonium salt and an HBD such as alcohols and carboxylic acids, and finally, type IV refers to eutectic mixtures of ZnCl2 with an HBD such as urea or acetamide [21,22]. The mixtures between HBAs and HBDs are represented based on their molar ratios [22].

In the case of oxidative desulfurization, there have been several studies that use a DES for the extraction of oxidized S-compounds from fuels [23,24,25,26,27,28,29,30,31]. The applicability of these solvents in ODS is justified by their tendency to form hydrogen bonds with the oxidized S-compounds, which results in the extraction of the latter from the nonpolar fuel [28,29]. It has been demonstrated that DESs are efficient solvents for this purpose, while they have the crucial advantage of being non-toxic and more environmentally friendly than common organic solvents [23,24,25,26,27,29]. In addition, it has been reported that an acidic HBD can catalyze the oxidation of S-compounds, as in the case of a DES consisting of acetamide/glutaric acid with a molar ratio of 1/2 [29].

However, a crucial issue for the viability of the complete process is the regeneration of a DES. The oxidized S-compounds must be removed from the deep eutectic solvent so that it can be reused multiple times to treat different batches of HFO. The regeneration of a DES after its use in various processes has been a subject of study in the literature, and several methods have been proposed including anti-solvent addition, membrane filtration, crystallization, liquid–liquid extraction, and supercritical fluid extraction [32]. The efficiency of each method strongly depends on the DES nature and the chemical nature of the sulfur compounds aimed to be removed.

In the case of using DESs in oxidative desulfurization, the regeneration is carried out using anti-solvent addition, and in most studies, the anti-solvent is water [23,24,25,26]. Particularly, excess water is added to the DES under room temperature so that the oxidized S-compounds precipitate and can be filtered out. Then, the water is removed with evaporation and the regenerated DES is reused for another cycle of oxidative desulfurization. Moreover, purifying the DES with diethyl ether has been reported as an alternative regeneration method [8]. Carbon tetrachloride (CCl4) has been used as an anti-solvent [27] as well, but generally, the use of this dangerous solvent should be avoided.

In this work, deep eutectic solvents are used in the oxidative desulfurization (ODS) process of commercially available heavy fuel oil (HFO). Particularly, HFO undergoes an initial oxidation step, where the oxidation of aromatic sulfur compounds (S-compounds) occurs. Subsequently, several DESs are tested for the efficient extraction of these oxidized compounds from HFO. To the best of our knowledge, this is the first time that these solvents have been used for the oxidative desulfurization of commercial heavy petroleum distillates. Considering the environmentally benign nature of these solvents, the results reported in the following sections can pave the way for a new, sustainable industrial process for highly efficient desulfurization.

2. Materials and Methods

Marine heavy fuel oil (HFO) was supplied by a local refinery. Hydrogen peroxide (35%, PanReac AppliChem, Darmstadt, Germany) was used as the oxidant. Formic acid (99.8%, PanReac AppliChem, Darmstadt, Germany) and acetic acid (99.8%, PanReac AppliChem, Darmstadt, Germany) were tested as catalysts for oxidation. For the preparation of deep eutectic solvents, choline chloride (ChCl) (98%, GHW Eurochemicals, Bratislava, Slovakia), lactic acid (LA) (90%, ISOLAB, Schweitenkirchen, Germany), citric acid (CA) (food grade, PENTA, Prague, Czech Republic), ethylene glycol (EG) (reagent grade, TEKKIM, Bursa, Turkey), and polyethylene glycol 400 (PEG400) (extra pure, TEKKIM, Bursa, Turkey) were used. Acetone (A.G. PENTA, Prague, Czech Republic) and Toluene (99.5%, Sordalab, Etampes, France) were used for the recycling process as received, without further process.

2.1. Oxidation and Extraction

For the oxidation process, the necessary quantity of HFO was poured into a glass beaker and placed under magnetic stirring with simultaneous heating on a hotplate and continuous monitoring of the temperature (beaker I). The appropriate quantities of H2O2 and catalyst (acetic acid or formic acid) were mixed in a separate beaker (beaker II). When the HFO reached a certain temperature (beaker I), the oxidation reaction was initiated with the dropwise addition of the oxidizing mixture (beaker II in beaker I) under continuous stirring. Then, the mixture was left under magnetic stirring at 300 rpm for a certain time. Finally, the beaker was removed from the hotplate, and the extraction step followed.

For the extraction process, seven different deep eutectic solvents (DESs) were developed by varying the molar ratios between their constituents: ChCl/EG (1/2), ChCl/LA (1/2 and 1/4), ChCl/LA/CA (1/2/1 and 1/4/1), ChCl/PEG400 (1/6), and ChCl/PEG400 (1/6) mixed with an equal mass of deionized water. In the first step, the appropriate quantity of HFO and the oxidizing agents (as received from the previous stage) were poured into a glass beaker (beaker I) and placed under magnetic stirring with simultaneous heating at the extraction temperature. The temperature was monitored and carefully controlled. Then, a certain amount of DES (beaker III) was added slowly, according to the predetermined solvent-to-HFO mass ratio (beaker III in beaker I). The mixture was left under vigorous stirring for a certain time.

After the completion of the extraction process, all mixtures were allowed to settle overnight at room temperature. Finally, when the extraction process was complete, two phases were formed: a more polar phase at the bottom, which consisted of the DES and the dissolved sulfones, and a less polar raffinate HFO phase on top. The two phases were separated and stored in different containers.

Inductively coupled plasma-optical emission spectroscopy (ICP-OES) (Thermo Scientific, Thermo iCAP 6500 duo, Waltham, MA, USA) was used for determining the concentration of the sulfur content in the initial HFO and in the raffinate HFO after the desulfurization process. The desulfurization efficiency for each sample was calculated according to Equation (1):

where Sinitial is the initial S concentration (ppm) in the starting HFO and Sfinal is the final S concentration (ppm) in the raffinate fuel. The sulfur content in the initial HFO was measured at 1.36 wt.% using ICP-OES.

2.2. Recycling DESs

Choline chloride/ethylene glycol (ChCl/EG) with a 1/2 molar ratio is the DES that was used in all recycling experiments as it yielded the highest extraction degree of oxidized S-compounds. Deionized water and ethanol were tested as anti-solvents. Acetone and toluene were used for liquid–liquid extraction. In all the recycling experiments, the DES and the solvent were placed under vigorous stirring in a glass beaker at room temperature for a certain time.

In the case of liquid–liquid extraction, the mixture was allowed to settle overnight for phase separation. The DES has a higher density than acetone and toluene; hence, it was recovered as the bottom phase. The density of ChCl/EG with a 1/2 molar ratio was previously estimated to be 1.12 g/mL [33]. Either acetone or toluene was decanted, and the recycled DES was recovered. In the case of anti-solvent addition, there was no phase separation, and the mixture was heated for anti-solvent removal. All the experimental conditions are displayed in Section 3.3.

The purity of the recycled DES and the solvents was assessed with a UV-Vis spectrophotometer (double beam, Drawell DU-8800D, Shanghai, China) using deionized water as the reference sample.

The regeneration degree for each cycle of DES regeneration was calculated as:

where the % impurity was assessed using the UV-Vis spectra of the samples, as described in Section 3.3.3.

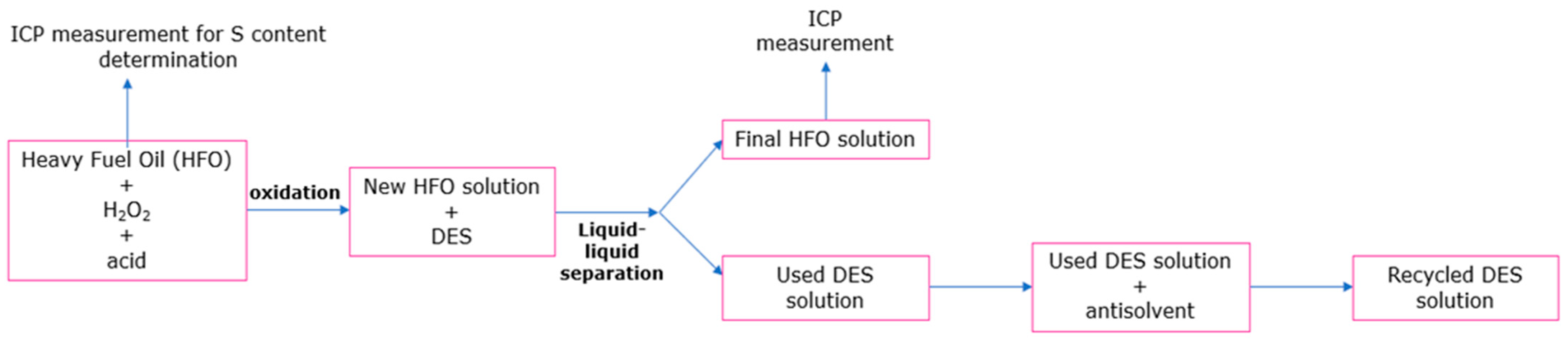

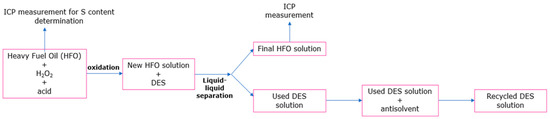

The complete experimental process that was followed is summarized in Scheme 1.

Scheme 1.

Oxidative desulfurization process steps.

3. Results and Discussion

3.1. The Effect of Oxidation Conditions on the Desulfurization Efficiency of HFO

Different parameters that affect the oxidation stage of the process were systematically investigated. Table 2 summarizes the set of experiments that were performed for the optimization of the oxidation reaction. The optimization of oxidation conditions was based on preliminary screening experiments. The range of temperatures (45–80 °C) and the duration of the process (90–180 min) were set based on relevant studies in the literature, which are summarized in Table 1. The extraction process was performed as the second stage of the ODS process after the completion of each oxidative step/experiment included in Table 2. The extraction conditions were kept identical to properly screen the effect of the studied parameters. Particularly, the used DES was choline chloride with ethylene glycol with a molar ratio of 1/2, while the solvent/oil mass ratio was equal to 5/1, which represents the mass ratio between DES and HFO in the extraction mixture. The extraction reaction was performed at 60 °C, and the duration was 90 min.

Table 2.

Investigation of the oxidation process parameters: summary of experiments.

In Table 2, the ratio H2O2/S refers to the molar ratio between H2O2 and sulfur in the oxidation mixture. The ratio H2O2/acid refers to the molar ratio between H2O2 and acid (formic or acetic) in the oxidation mixture. In the fourth column, the mass ratio of either acetic (A) or formic (F) acid in the oxidation mixture is presented. In one additional sample (No. 8), extractive desulfurization was performed without the initial oxidation step. In this case, the HFO and the DES were placed under vigorous stirring into the same beaker at 60 °C for 90 min. The last column displays the desulfurization efficiency of each experiment (% S removal) that was determined using ICP-OES measurement of the derived raffinate HFO.

3.1.1. Effect of the H2O2/S Molar Ratio

To investigate the range of conditions for the oxidation stage, preliminary screening experiments with a high excess of H2O2 were conducted. The molar ratio of H2O2 to S ranged from 4.7/1 to 9.9/1, which is much higher than the stoichiometric ratio (2/1). In these preliminary experiments, it was observed that the viscosity of the mixture increased soon after the start of the oxidation reaction, hindering proper magnetic stirring. This could be attributed to a polymerization phenomenon that was reported in similar studies, which is triggered by the formation of free radicals according to the following reaction cascade [10] that includes Equations (3)–(8):

Olefins can be partially oxidized with the addition of free radicals to their double bonds. Moreover, the presence of asphaltenes in HFO exacerbates the phenomenon. Asphaltenes are solid, dark-brown substances with an aromatic structure. They consist mostly of carbon and hydrogen, but their molecules also contain sulfur at a considerable mass ratio, which can amount to more than 7 wt.% [34]. Asphaltenes are not defined based on their chemical structure but on their solubility, as petroleum components are soluble in aromatic solvents and insoluble in n-alkanes [35].

A. Mortezaee et al. [10] showed that the presence of asphaltenes contributes to the polymerization of HFO, but they demonstrated that the addition of n-heptane suppressed this phenomenon. However, the molar ratios of H2O2 to sulfur and formic acid to sulfur were relatively high in that case, namely, 5/1 and 40/1, respectively [10]. As a result, the process was hindered by excessive polymerization reactions [10]. On the other hand, in the present work, the molar ratio of H2O2 to S was kept at low levels (2.5/1) to prevent this phenomenon. In addition, the maximum acid concentration in the mixture was 28.24 wt.%, which corresponds to a molar ratio of 19.6/1 with respect to sulfur (Experiment No. 2). Hence, it was feasible to avoid the formation of viscous gum, and the magnetic stirring remained unhindered during oxidation under these conditions.

The results of this study suggested that a molar ratio of H2O2 to S equal to 2.5/1 was optimum for the investigated process, and it was used for all the experiments presented in Table 2. Furthermore, the S removal degree was very low when no oxidant was used (Experiment No. 8); therefore, it was concluded that oxidation is necessary for the efficient desulfurization of the fuel.

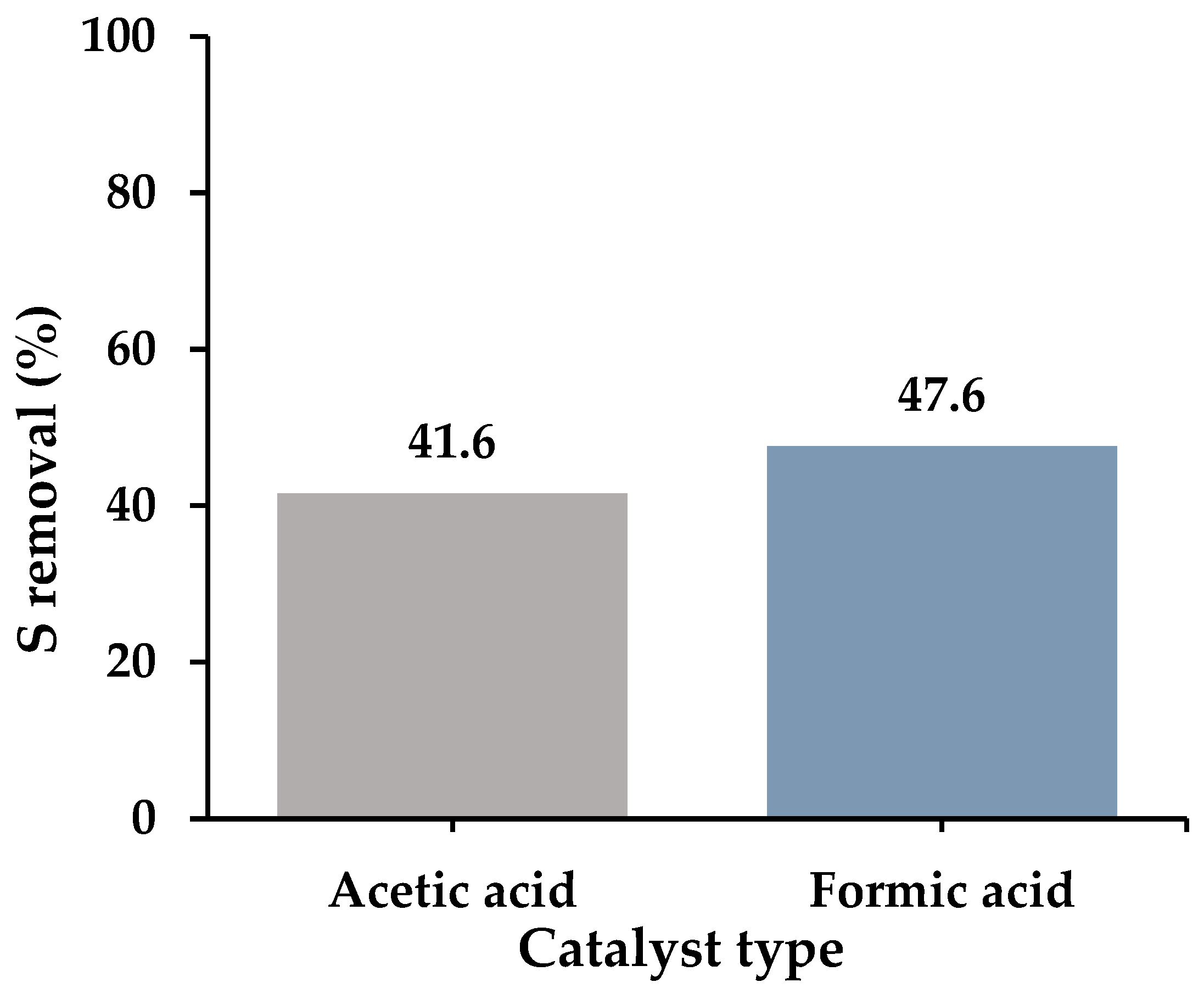

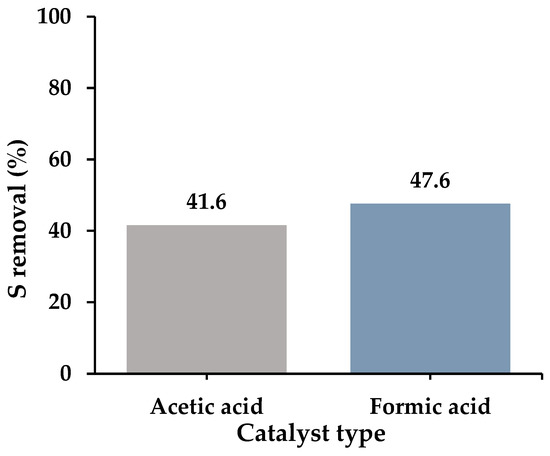

3.1.2. Effect of Catalyst Type

The impact of acetic or formic acid addition on the oxidative desulfurization process of HFO was investigated to determine the optimum acid for the studied process. Oxidation with acetic acid as the catalyst was milder, and the temperature of the reaction could be easily regulated. On the contrary, the addition of formic acid into the system (Experiment Νο. 7) led to a rapid increase in the reaction temperature (>85 °C), especially at high formic acid concentrations. In this case, the system was allowed to cool down, and the reaction was resumed when the temperature reached the desired levels. This chemical behavior resembled the auto-acceleration phenomenon during free-radical polymerization (Trommsdorff effect), which is due to localized increases in viscosity that hinder termination reactions [25]. Lowering the formic acid concentration in the system did not limit these phenomena.

The occurrence of uncontrollable oxidation reactions in heavy fuel triggered with formic acid has been reported before [10,20]. In those research studies, the concentration of formic acid in the process was relatively high. The molar ratio of formic acid to sulfur was reported to be 40/1 in the study by A. Mortezaee et al. [10], while the concentration of formic acid in the mixture ranged between 8 and 50 wt.% in the work by A. Farshi et al. [20]. In contrast, the concentration of formic acid in the present work was kept at a relatively low level of 3.2 wt.%. Nevertheless, uncontrollable oxidation reactions still occurred.

The efficiency of each catalyst in the removal of S from the HFO was compared between Experiments No. 3 and 7, which were carried out under identical conditions of oxidation and extraction, and in which the same molar ratio of H2O2/acid (3/1) was applied. The results are presented in Figure 2, which shows that the use of formic acid led to a slightly higher removal of S (47.6% vs. 41.6%). Nevertheless, due to the rapid oxidation reactions triggered with formic acid, which led to an uncontrollable temperature increase and to partial evaporation of the catalyst, and due to a low desulfurization efficiency, the use of acetic acid as a catalyst appeared to be more suitable to the experimental protocol since the high viscosity of the resulting raffinate fuel prevents its usability.

Figure 2.

The effect of catalyst type on the desulfurization efficiency of HFO. In both cases, the H2O2/acid molar ratio was 3, the reaction temperature was 60 °C. and the reaction time was 90 min (Experiments No. 3 and 7).

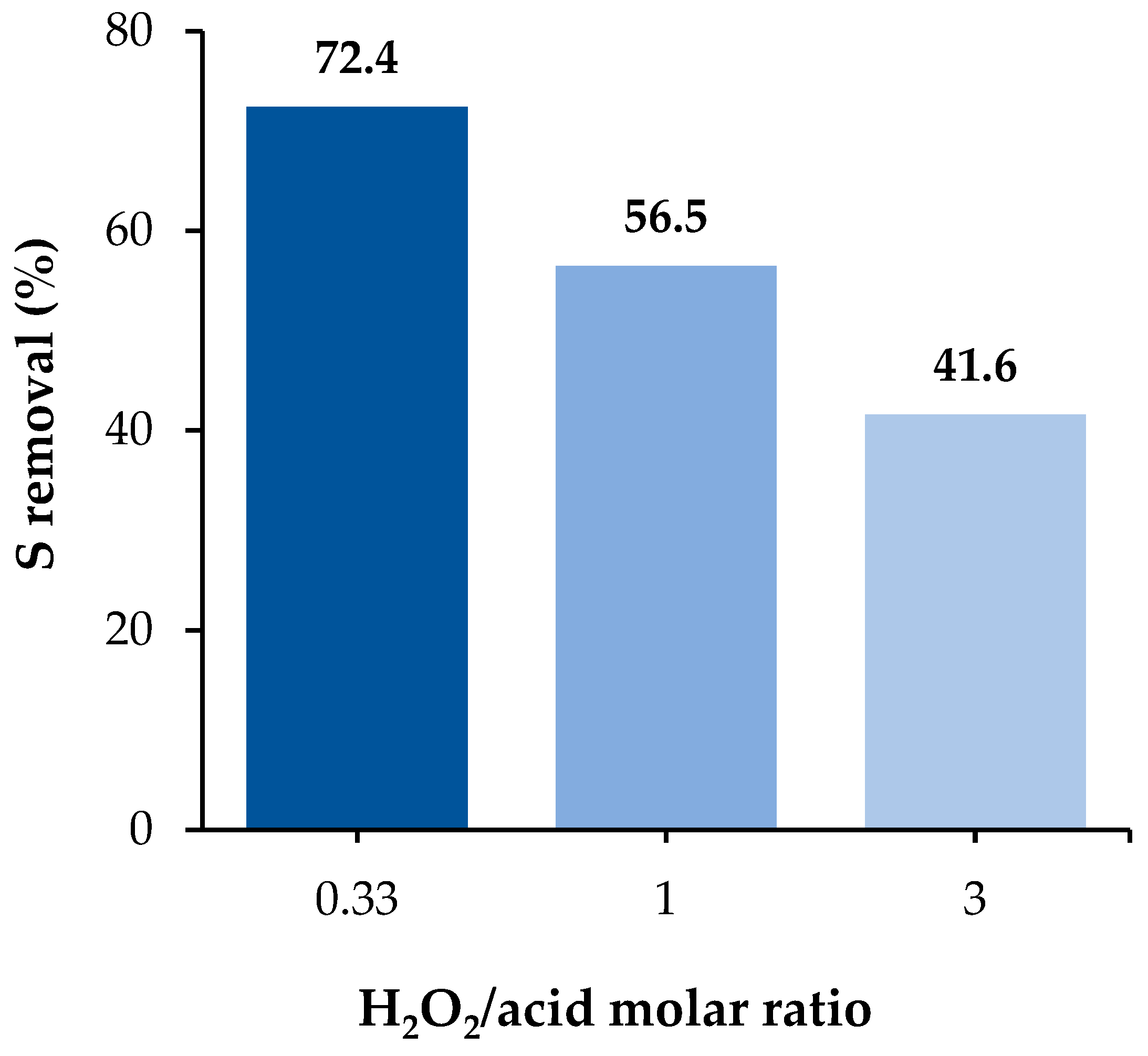

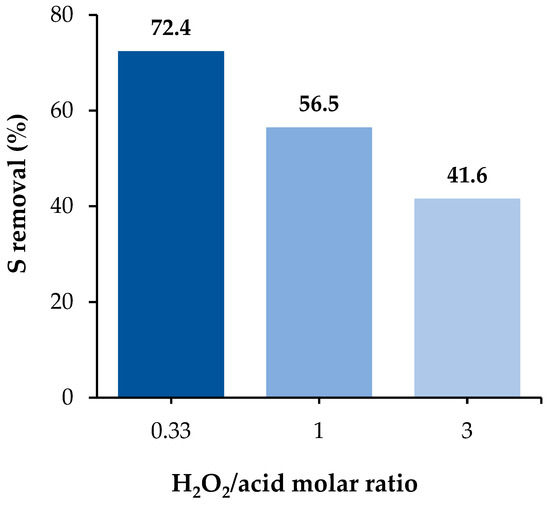

3.1.3. Effect of the H2O2/Acid Molar Ratio

The effect of the molar ratio between H2O2 and carboxylic acid (either acetic or formic acid), which varied from 0.33 to 3 (Table 2), was also evaluated. Since the stoichiometric ratio is 1/1, a lower (0.33) molar ratio was expected to result in a more intense oxidation reaction.

The impact of the molar ratio between H2O2 and acetic acid on desulfurization efficiency was tested (Experiments No. 1–3), and the results are presented in Figure 3. The smallest molar ratio (0.33) induced higher S removal (72.4%) as it resulted in higher catalyst mass concentration in the system (28.24 wt.%) and thus in a larger extent of oxidation.

Figure 3.

The effect of H2O2/acetic acid molar ratio on the desulfurization efficiency of HFO. In all three cases, the reaction temperature was 60 °C and the reaction time was 90 min (Experiments No. 1, 2, and 3).

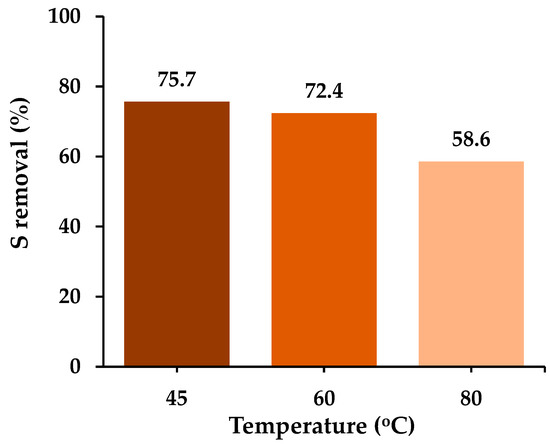

3.1.4. Effect of Oxidation Temperature and Time

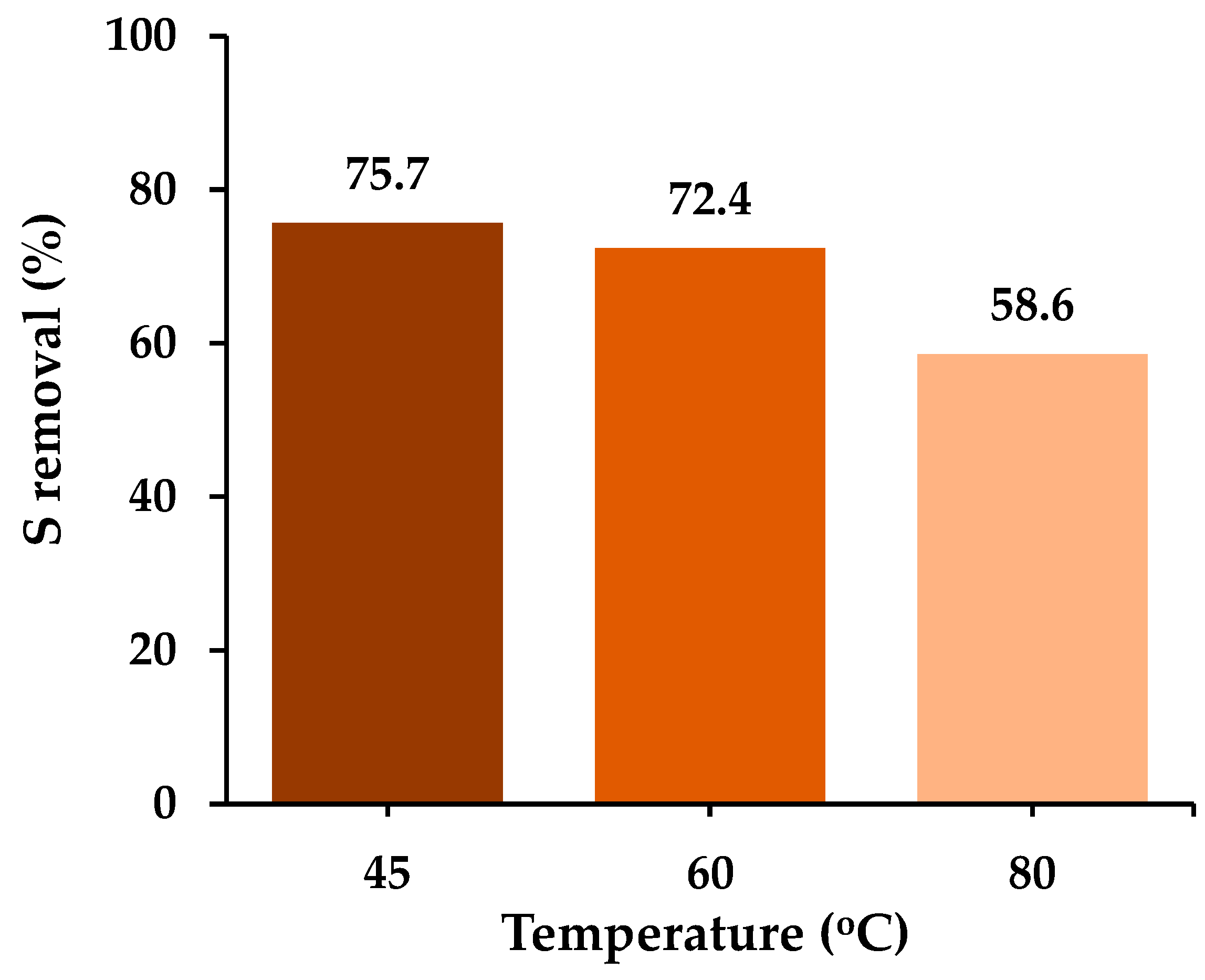

The range of oxidation temperatures that was studied for the determination of the optimum oxidation temperature varied between room temperature and 80 °C. When no heating was applied to the system, difficulties in magnetic stirring were confronted due to the fuel’s high viscosity; hence, the oxidation temperature tests varied between 45 and 80 °C (Experiments No. 2, 4, and 5), while the other experimental parameters did not change. The impact of oxidation temperature on the desulfurization efficiency of HFO is presented in Figure 4. With increasing oxidation temperature, the liquid catalyst evaporation rate was increased. As a result, the catalyst concentration in the solution decreased, as well as the S removal. It is possible that a partial decomposition of peroxides also took place [10]. The removal of S from the fuel amounted to 75.7% at 45 °C and 72.4% at 60 °C. This optimum range of temperatures is in agreement with the recommended oxidative desulfurization temperatures listed in the literature when a mixture of H2O2 and acetic acid was applied [10,20,36]. In these research studies, oxidative desulfurization yielded the highest sulfur removal degree at 60 °C. For the commercially available marine heavy fuel oil used in this work, the optimum oxidation temperature was found to be 45 °C, presenting a more energy-efficient process compared to the literature.

Figure 4.

The effect of oxidation temperature on the desulfurization efficiency of HFO. In all three cases, acetic acid was used as a catalyst at a H2O2/acid molar ratio of 0.33/1, and the reaction time was 90 min (Experiments No. 2, 4, and 5).

The desulfurization degrees achieved in this study resulted in raffinate fuels with a final sulfur content of 3305 ppm (0.33 wt.%) and 3754 ppm (0.37 wt.%), respectively. It became clear that the S content in the marine HFO can be reduced to lower than 0.5 wt.%, complying with IMO regulation. Moreover, the desulfurization efficiency reported here is amongst the highest that have been reported for the oxidative desulfurization of heavy petroleum distillates and commercial marine fuels (Table 1).

The impact of oxidation time on the desulfurization efficiency of HFO was assessed using time settings of 90 min and 180 min while keeping the other parameters identical (Experiments No. 2 and 6). The increase in the oxidation time at 180 min did not significantly affect the desulfurization efficiency (72.4% vs. 74.5%). Therefore, the oxidation step with 90 min duration was considered to be preferable, taking into account the sustainability of the process.

3.2. The Effect of Extraction Conditions on the Desulfurization Efficiency of HFO

Table 3 includes the experiments that were designed and performed for the optimization of sulfone extraction from HFO. The effect of four process parameters (the nature of the DES, the solvent/oil mass ratio, the extraction temperature, and the extraction time) on the desulfurization efficiency was investigated and hereby reported. The oxidation process conditions in all the extraction experiments were 56.5 wt.% HFO with 15.26 wt.% H2O2 and acetic acid as the catalyst (28.24 wt.%). The total mass of the experiments was 33 g with a H2O2/S molar ratio equal to 2.5 and a H2O2/acid molar ratio equal to 0.33/1. The oxidation reaction temperature was kept at 60 °C, and the oxidation time was 90 min. The sample obtained under these oxidation conditions is presented here to demonstrate the optimization methodology for the extraction.

Table 3.

Investigation of the extraction process parameters: summary of experiments.

In Table 3, the molar ratio between each DES component is presented. The solvent/oil mass ratio represents the mass ratio between DES and HFO in the extraction mixture.

After each extraction process, the mixture was left to settle overnight at room temperature. Finally, separation of the two phases was observed in most samples; the more polar phase was at the bottom, which consisted of the DES and the dissolved sulfones, and the less polar raffinate HFO phase was on top. The two phases were separately retrieved and stored in different containers. In several samples (Νo. 11, 12, 15, and 16), there was no clear phase separation. For these samples, the conditions of extraction were considered unsuccessful, and the measurement of S concentration was not carried out (noted with the symbol “X” in Table 3).

3.2.1. Effect of the Type of DES on the Desulfurization Efficiency of HFO

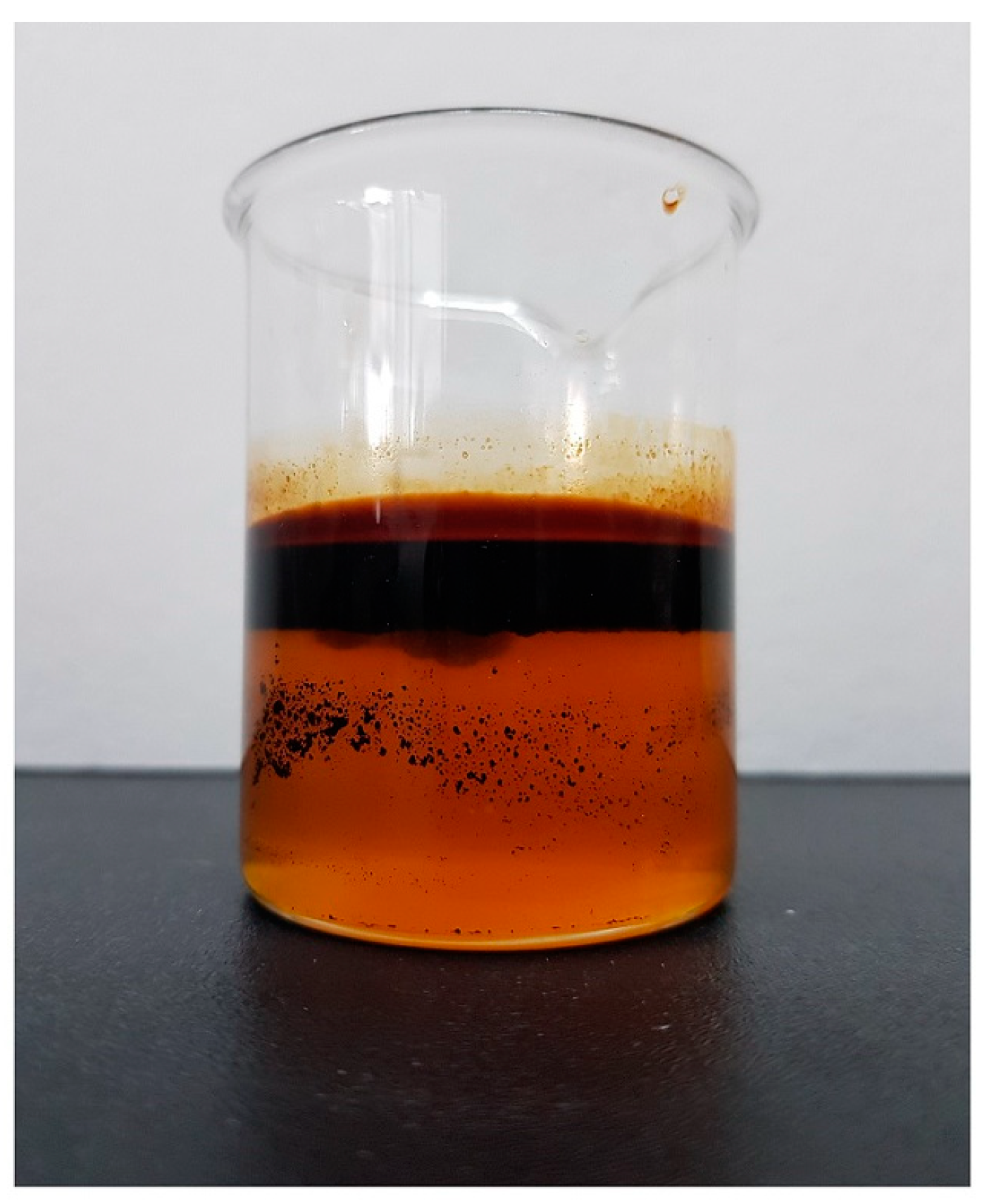

Several deep eutectic solvents were used for the extraction of oxidized S-compounds from HFO. After phase separation, the color of the DES was either deep brown or orange, depending on the sample (Figure 5). A pure DES is colorless; hence, it was assumed that various oxidized compounds from HFO were finally dissolved in the DES. The significant color change was probably not because of the S-compounds, which are generally white, but due to the oxidized asphaltenes, which have a deep brown color. Finally, the color intensity of the DES was indicative of the oxidation extent in various HFO compounds. If more asphaltenes were oxidized, then they would have been easily dissolved in the DES, and thus, their color would have been darker at the end of the phase separation.

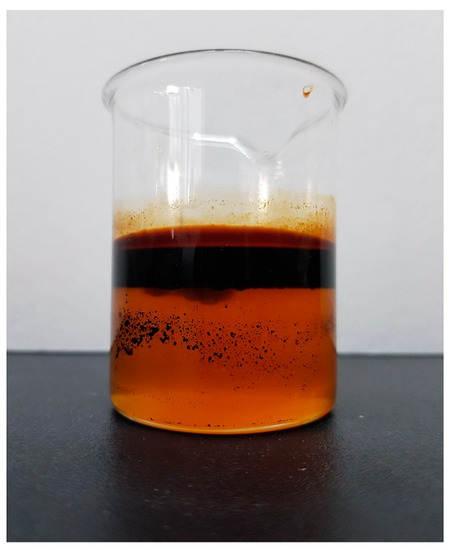

Figure 5.

Phase separation after extraction (Experiment No. 17).

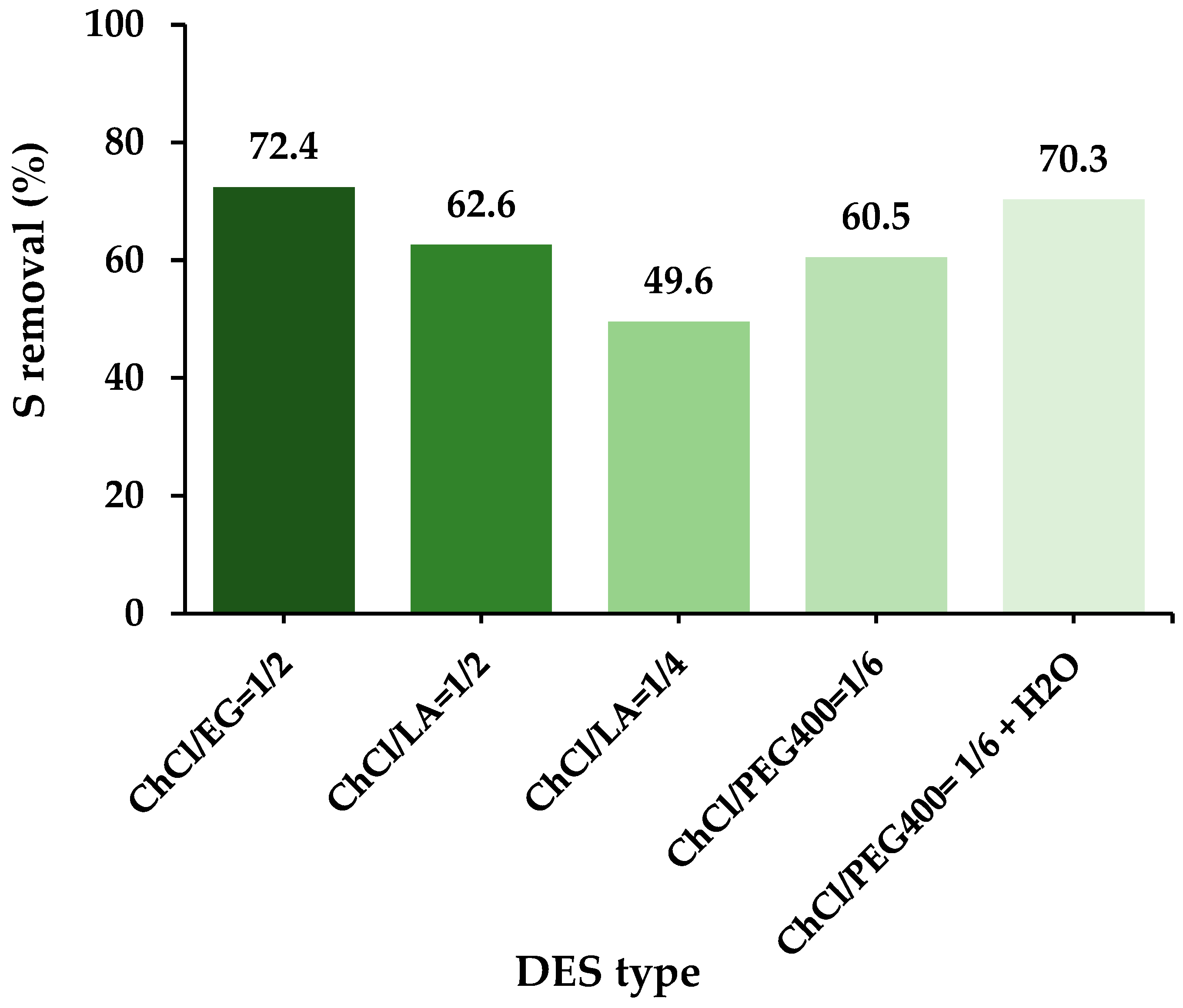

The extraction process with ChCl/LA (Experiments No. 9 and 10) resulted in a clear phase separation and a DES with deep brown color (Figure S1 in the Supplementary Material). On the other hand, the DES appeared to be more viscous in the presence of CA, and there was no visible phase separation when the process was completed due to the formation of a stable emulsion (Experiments No. 11 and 12) (Figure S2). Thus, it is assumed that CA promotes flocculation between different components. The presence of asphaltenes contributes to this flocculation, as it has been reported that they are relatively polar and can form hydrogen bonds with water or other polar substances [10]. Furthermore, the DES containing PEG400 (Experiment No. 13) was highly viscous, and after extraction, its color was very dark brown (Figure S3). In principle, low viscosity is preferable to facilitate the mass transfer of sulfones; thus, EG is preferable compared to PEG400. The addition of H2O to ChCl/PEG400 (1/6) lowered the viscosity of the DES and improved its hydrogen bonding capacity (Experiment No. 14). This resulted in improved desulfurization efficiency, which, however, was lower than the samples extracted with ChCl/EG (Figure 6).

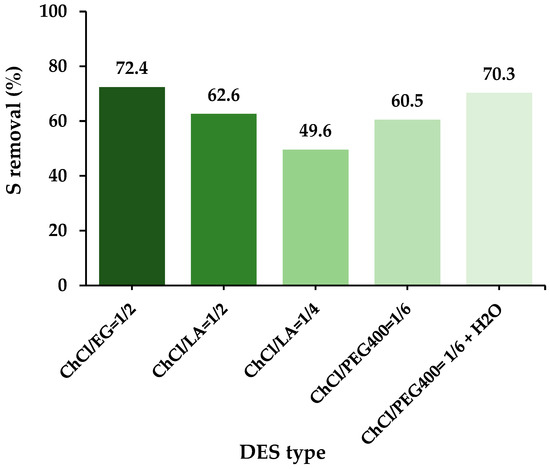

Figure 6.

The effect of the type of DES on the desulfurization efficiency of HFO.

The effect of solvent type on the desulfurization efficiency was monitored by testing the above-mentioned deep eutectic solvents for the extraction of sulfones from HFO while keeping all the other process parameters identical. The results shown in Figure 6 reveal that ChCl/EG with a molar ratio of 1/2 provided the highest removal of S (72.4%). This result is of high importance, as the commonly reported solvents used for the extraction of sulfones from heavy fuel oils are organic solvents such as methanol, acetonitrile, and N,N-dimethylformamide [15,16,18,20], the extensive use of which should be avoided for environmental reasons. On the contrary, in the present study, it is reported that a very high desulfurization efficiency is feasible using a more environmentally benign deep eutectic solvent.

It is well-known that density influences the extraction of S-compounds in similar processes because it affects the mass transfer between different phases. Ethylene glycol has a lower density (1.11 g/mL) than lactic acid (1.21 g/mL); thus, it is expected to facilitate the mass transfer of sulfones from HFO. A DES consisting of choline chloride with ethylene glycol was used elsewhere for the desulfurization of a model fuel, and the S removal was reported to be less than 50% in the specific conditions of that process [25]. In contrast, this study is the first time that this DES was used for commercial marine fuels instead of model marine fuel, and the present work reports a significant desulfurization efficiency under the optimized conditions.

The removal of oxidized S-compounds from fuels is based on favorable molecular interactions, and it has been described using molecular simulations [28,29,33]. Firstly, the strong interaction between ChCl and EG is attributed to hydrogen bonds that form between the oxygen atoms of EG and the methyl protons of the choline cation (C-H⋯O), and it is also based on the electrostatic interactions between the hydrogen atoms of EG and the Cl- ion (O-H⋯Cl-) [28]. Hence, a stable geometry and multiple hydrogen bonds are formed between the molecules of ChCl and EG. In the presence of unoxidized S-compounds, it was established that ChCl and EG tend to retain the geometry of their bonds, and there are only weak noncovalent interactions between the aromatic rings in the S-compounds and either ChCl or EG (C-H⋯π, O-H⋯π) [28]. Therefore, the clusters of the DES molecules do not form favorable interactions with the unoxidized S-compounds contained in the fuel [28].

In contrast, when the S-compounds convert to sulfones and sulfoxides after oxidation, the presence of O atoms bound to sulfur gives rise to new hydrogen bonds with the DES constituents (-C-H⋯Os and O-H⋯Os). In addition, calculations based on the free energies of solvation (ΔGosolv) for the unoxidized and the oxidized S-compounds reveal that oxidized S-compounds have a very high tendency to transfer to the more polar DES phase because of their increased tendency to form hydrogen bonds with DES constituents [28]. Furthermore, interactions between ChCl and S-compounds appear to be more significant than the interactions between EG and S-compounds [33]. The polar interactions between the oxidized S-compounds and the DES phase are also justified by taking into consideration the Hansen solubility parameters of each compound, particularly the δp and δh parameters, which indicate the tendency for polar and hydrogen-bonding interactions, respectively. Hydrocarbons are generally non-polar and both their δp and δh are close to zero [37]. On the contrary, the set of these two parameters (δp, δh) are (19.5, 18.4) for ChCl and (11.0, 26.0) for EG, respectively [37,38]. The highest magnitude of these parameters exhibits the propensity of the DES constituents for polar interactions. For tetramethylene sulfide (tetrahydrothiophene), these parameters are (6.7, 9.1), respectively, showing their moderately non-polar character [37]. When this compound is oxidized though, it is converted to tetramethylene sulfone, for which the Hansen solubility parameters increase to (18.2, 10.9), respectively. This large increase in δp indicates that the oxidized S-compound becomes much more polar, and, therefore, can be favorably dissolved into a polar phase (DES) instead of a non-polar hydrocarbon phase.

For the solvents consisting of ChCl/LA, after increasing the proportion of LA from ChCl/LA = 1/2 to ChCl/LA = 1/4, the S removal is decreased. This could be explained by the fact that a higher concentration of choline chloride is a determinant for the extraction of S-compounds [33].

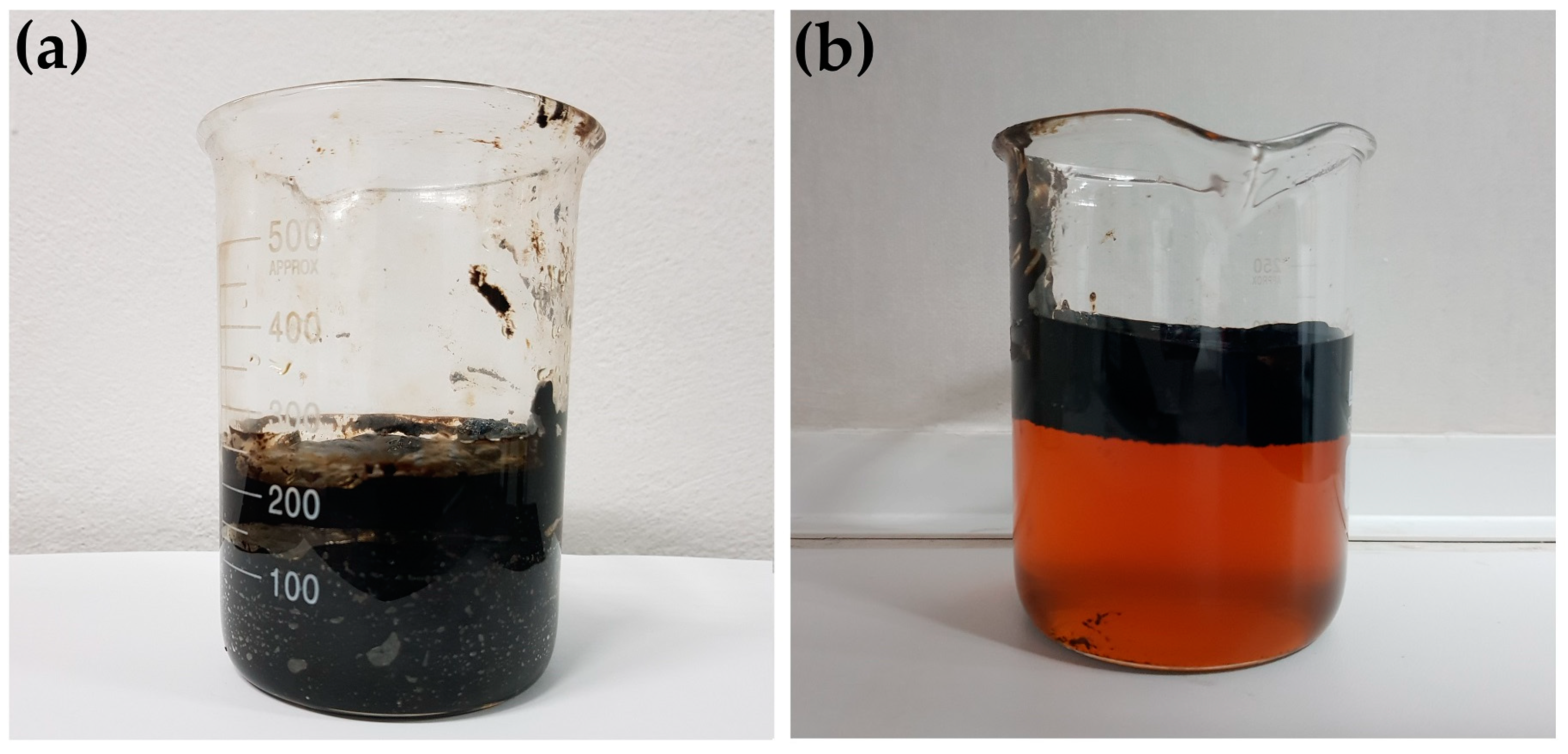

3.2.2. Effect of Solvent/Oil Mass Ratio

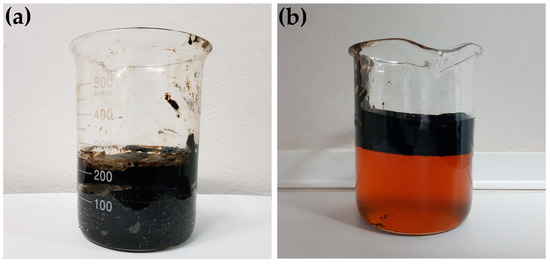

In the experiments aiming to determine the optimum extraction temperature, time, and solvent/oil mass ratio, the DES with ChCl/EG (1/2) was parametrically optimized. Three different mass ratios of solvent (DES) to oil (HFO) were tested: 5/1, 2/1, and 0.5/1 (Experiments No. 2, 15, and 16, respectively). At low mass ratios (2/1 and 0.5/1), no phase separation was observed at the end of the process (Figure 7), and the raffinate HFO could not be recovered. On the contrary, obvious phase separation occurred at a 5/1 mass ratio (Figure 7). Therefore, it was determined that an excess of the DES is required for efficient fuel/DES phase separation and raffinate HFO recovery.

Figure 7.

Extraction with ChCl/EG = 1/2 using two different solvent/oil mass ratios: (a) 2/1 (Experiment No. 15) and (b) 5/1 (Experiment No. 2).

3.2.3. Effect of Extraction Temperature and Time

The effect of temperature on the extraction of sulfones was investigated by conducting the process at two different temperatures (60 °C and 80 °C) (Experiments No. 2 and 18, respectively). According to the results, there is no enhancement in the desulfurization efficiency after increasing the temperature from 60 °C to 80 °C. Moreover, increasing the temperature higher than 80 °C is not recommended because the solvent will probably be evaporated at a much higher rate. Therefore, it is preferable to keep the extraction temperature at 60 °C. The effect of extraction time was investigated by conducting the extraction for 90 min and 180 min while keeping all the other parameters stable (Experiments No. 2 and No. 17, respectively). According to the obtained results, increasing the duration of extraction does not result in an efficiency increase in desulfurization. Hence, it can be concluded that the extraction of sulfones is completed within the first 90 min of the process.

3.3. DES Recyclability

Table 4 summarizes the experiments that were performed for the recycling of the DES, which was recovered after the oxidative desulfurization of HFO, as described in Section 3.1 and Section 3.2. In all cases, the DES recovered from Experiment No. 2 was used. The recycling of DES was performed using two different approaches, namely, liquid–liquid extraction using either acetone or toluene and anti-solvent addition using either ethanol or deionized water. Moreover, consecutive cycles of oxidative desulfurization with simultaneous DES regeneration were carried out, following the methodology of anti-solvent addition with excess water.

Table 4.

Summary of experiments for the recycling of the DES.

3.3.1. Liquid–Liquid Extraction

In liquid–liquid extraction, a non-miscible solvent is added to the DES in order for the species of interest to be extracted, due to the lack of miscibility and polarity deviation [32]. Therefore, the solute is extracted from the DES, and it is transferred into the additional solvent. The two phases are immiscible and easily separated.

Acetone addition was examined as a possible additive for the regeneration of the DES after sulfone extraction (Experiment No. 19). Acetone has been previously applied for the regeneration of ChCl/EG used in biodiesel production, with a DES/acetone ratio of 1/2 w/v [39]. In that case, 70 wt.% of the DES was recovered by extracting the dissolved glycerol.

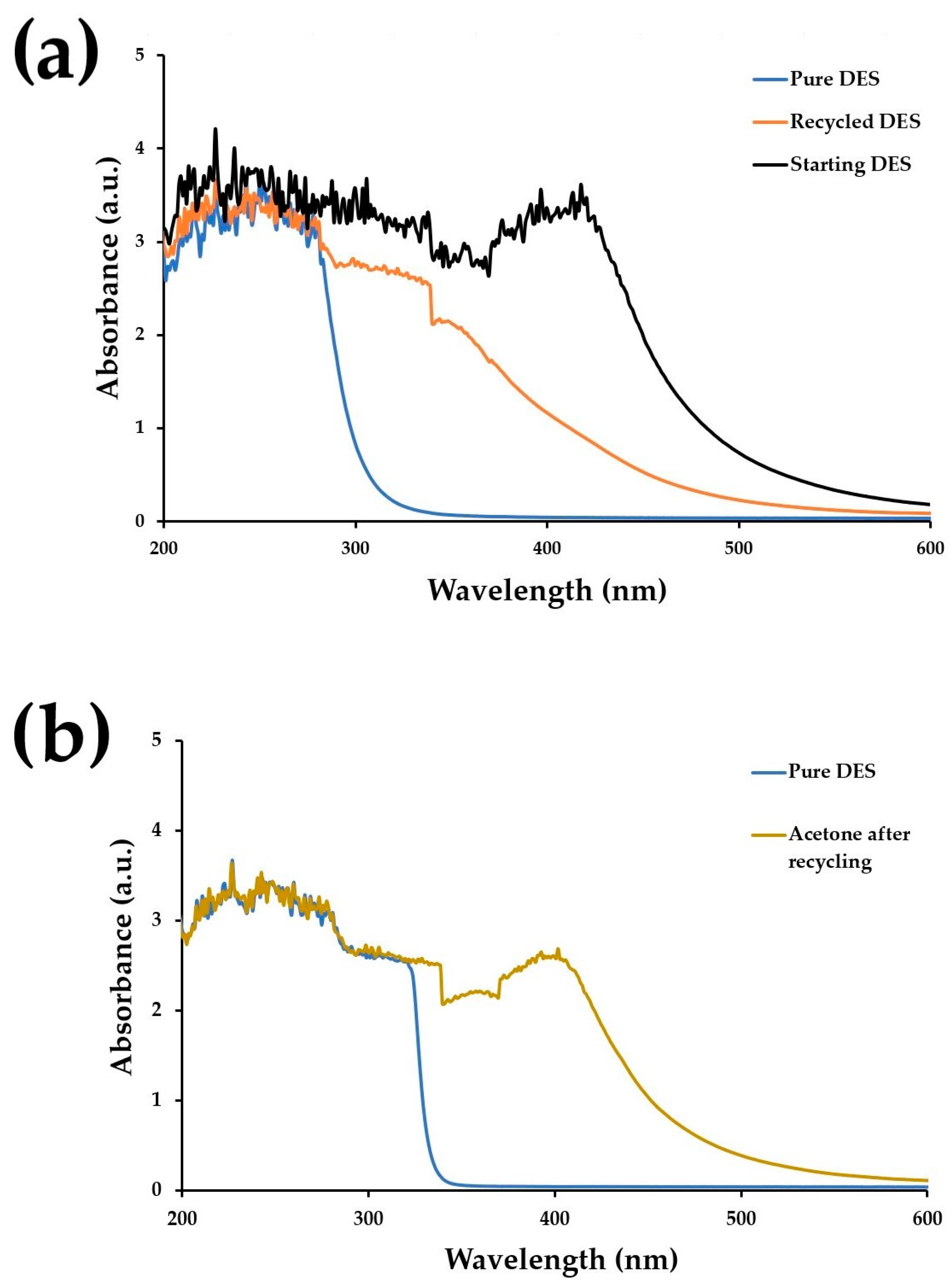

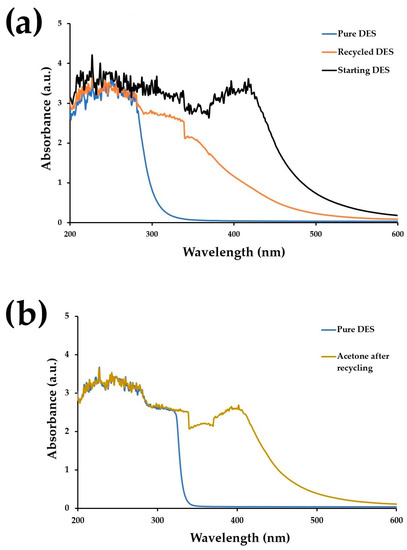

After mixing the used DES with acetone and stirring vigorously, the two phases separated spontaneously, and the DES was easily obtained (Figure S4). In this case, the color in the DES was lighter compared to the starting DES before recycling (shown in Figure 7b), and, simultaneously, the acetone phase obtained an orange color. The UV-Vis spectra of these samples are presented in Figure 8, and they reveal that the absorbance of the recycled DES in the range of 380–450 nm was significantly lower compared to the absorbance of the starting DES in the same range. This implies that a significant amount of the initially dissolved solids has been removed during recycling.

Figure 8.

(a) UV-Vis spectra of recycled DES from Experiment No. 19, of the pure DES, and of the starting impure DES before recycling. (b) UV-Vis spectra of acetone recovered from Experiment No. 19 and of pure acetone.

According to the literature, aromatic S-compounds are expected to absorb in the region between 300 and 400 nm [40]. However, asphaltenes absorb in this region as well [41]. It is expected that during the initial oxidation of HFO, a part of asphaltenes and maltenes are oxidized and extracted by the DES. Hence, the UV absorption peaks in these substances overlap with the UV absorption peaks of oxidized S-compounds as they are both transferred from the starting DES to the regenerating solvent. Moreover, the aromatic S-compounds are white powders, while asphaltenes are deep brown [35,40]. Hence, the brown color is mainly attributed to the dissolution of oxidized asphaltenes and maltenes in the various phases.

The UV-Vis spectrum of the acetone phase was collected, as well, and it was compared to the spectrum of pure acetone (Figure 8). The spectra comparison confirms the transfer of dissolved solid species from the DES to acetone, especially those containing species that exhibit absorption peaks in the area of 400 nm.

Consecutive cycles of oxidative desulfurization and DES regeneration were conducted for the DES recyclability studies. Furthermore, consecutive cycles of oxidative desulfurization and DES regeneration using acetone were performed. For this purpose, the DES recovered after Experiment No. 2 was recycled with acetone, reused for the desulfurization of HFO, recycled for a second time, and reused again for another cycle of oxidative desulfurization. Nevertheless, in the second cycle of oxidative desulfurization, an emulsion between the DES and the HFO formed, and there was no phase separation at the end of the cycles, indicating that DES recycling with acetone can be applied no more than two times.

In addition to acetone, the impure DES recovered from Experiment No. 2 was also recycled by mixing with toluene, a non-polar solvent (Experiment No. 20). Following the previously described pathway, two phases were separated in the end: the recycled DES on the bottom and the recovered toluene on top (Figure S5a). In this case, however, the UV-Vis spectrum of the recycled DES exhibited similar levels of absorption as the starting impure DES, while there was no significant change in color. Therefore, this recycling process was considered unsuccessful.

3.3.2. Anti-Solvent Addition

In this DES recycling approach, a solvent is added that is miscible with the DES but does not dissolve the solutes of interest. So, the dissolved solids precipitate, and they are recovered with filtration. The anti-solvent addition approach is amongst the most common methods for DES regeneration after oxidative desulfurization, particularly with the addition of water [23,24,25,26]. By applying this regeneration process, it has been reported that DES can be recycled and reused in oxidative desulfurization for up to seven consecutive cycles [8,23,26]. The amount of water needed for efficient regeneration is usually not specified in the literature. In this work, deionized water was used, but we also attempted to recycle the DES by mixing it with ethanol. Ethanol has also been used extensively for the regeneration of various types of DESs because it is a low-cost, non-toxic solvent that can be easily recycled with evaporation and condensation [32].

In the recycling attempt with ethanol (Experiment No. 21), the starting impure DES was mixed with ethanol at a 1/1 w/w ratio, and it was kept under vigorous stirring for 1 h. Finally, a homogeneous solution was formed without any precipitation phenomena (Figure S6a). The UV-Vis spectrum of the DES/ethanol mixture was recorded, and it was compared to the spectrum of the starting impure DES (Figure S6b). Based on the results of Figure S6a,b, the main absorbance peaks are preserved, except for a broad band above 400 nm. The absorbance peaks only appear smaller, which can be attributed to the dilution of the DES with the addition of ethanol. Although it has been reported that various types of DESs can be regenerated using ethanol for up to three consecutive cycles [32], in this work, it was established that ethanol is not suitable for the regeneration of the used DES that included the compounds extracted from the marine HFO. The crucial parameter that hindered the effective DES regeneration is the dissolved sulfones that do not precipitate with the addition of ethanol.

To determine the performance of DES recycling with water addition (Experiment No. 22), deionized water was mixed with the used DES at a 1/1 mass ratio. Before stirring initiation, the mixture was opaque with a brownish color. Progressively, it became clearer and lighter as the stirring proceeded. Simultaneously, there was obvious precipitation of solids on the walls of the beaker and the magnet.

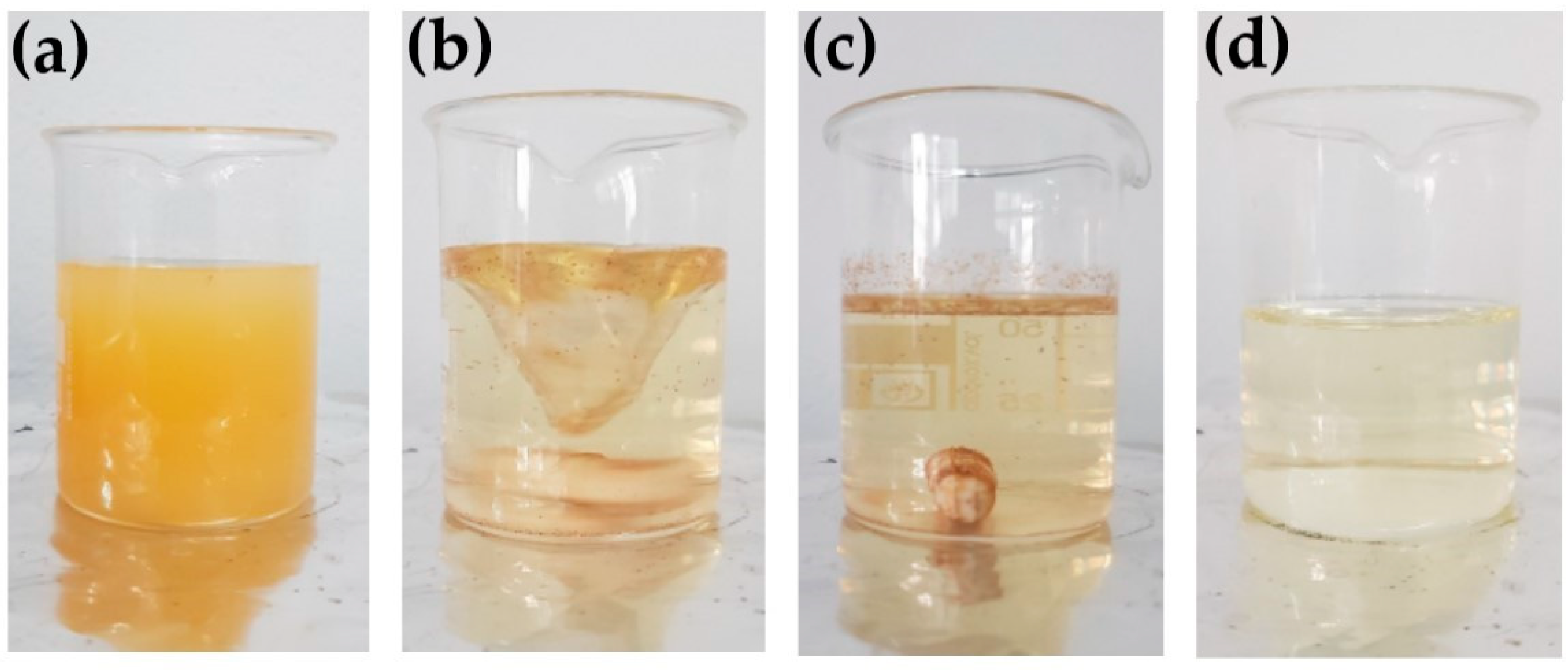

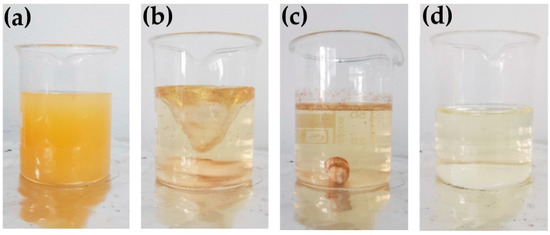

Despite the evident clearance of the solution, it still retained a slight yellow color, indicating the existence of a considerable concentration of dissolved solids. Therefore, regeneration with water was carried out at more extreme conditions. The deionized water was mixed with DES at a 5/1 mass ratio, and vigorous stirring took place for 2 h (Experiment No. 23). Photographic captures of the mixture evolution during regeneration are depicted in Figure 9. At the recycling process initiation, the DES/water mixture was opaque, but it gradually became clearer as the recycling proceeded. When the regeneration was complete, the mixture was rather clear, and it was filtered under vacuum for the removal of precipitated solids. The regeneration of DESs using water is attributed to the strong hydrogen bonds formed between the water molecules and the DES constituents (choline chloride and ethylene glycol), which are stronger than the bonds between the DES and sulfones. Consequently, this method was used to carry out consecutive cycles of oxidative desulfurization and DES regeneration.

Figure 9.

Mixing water with the used DES (after extraction) at a 5/1 mass ratio for 2 h. From left to right: (a) the beginning of mixing, (b) the gradual clearing, (c) the mixture at the end of the process, and (d) the mixture after filtration.

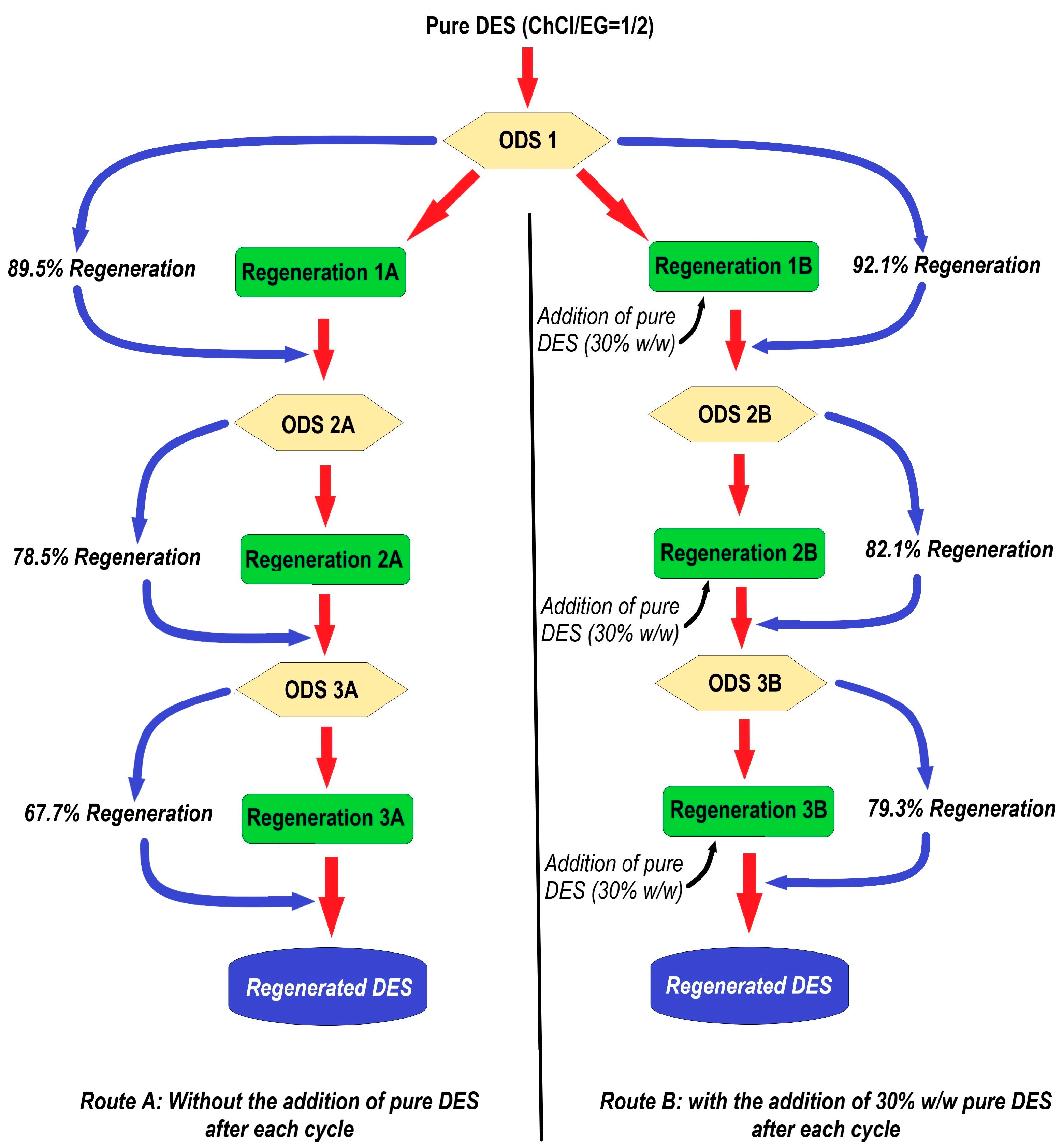

3.3.3. Consecutive Cycles of Oxidative Desulfurization and Solvent Regeneration

For the consecutive cycles of desulfurization and recycling, the impure DES was regenerated with excess deionized water addition, according to the conditions described for Experiment No. 23 in Table 4, namely, the addition of deionized water at a 5/1 mass ratio of water/DES and vigorous stirring for 2 h at RT. Two distinct routes were followed for this process, and they are both depicted in Figure 10. In route A (left branch), there was no addition of pure DES after each cycle. In route B (right branch), 30% w/w of pure DES was added to the regenerated DES after each recycling cycle. The conditions for oxidative desulfurization (ODS) at each stage were the same as those described for Experiment No. 2 in Table 2 and Table 3.

Figure 10.

Consecutive cycles of oxidative desulfurization and regeneration of the solvent: two separate routes.

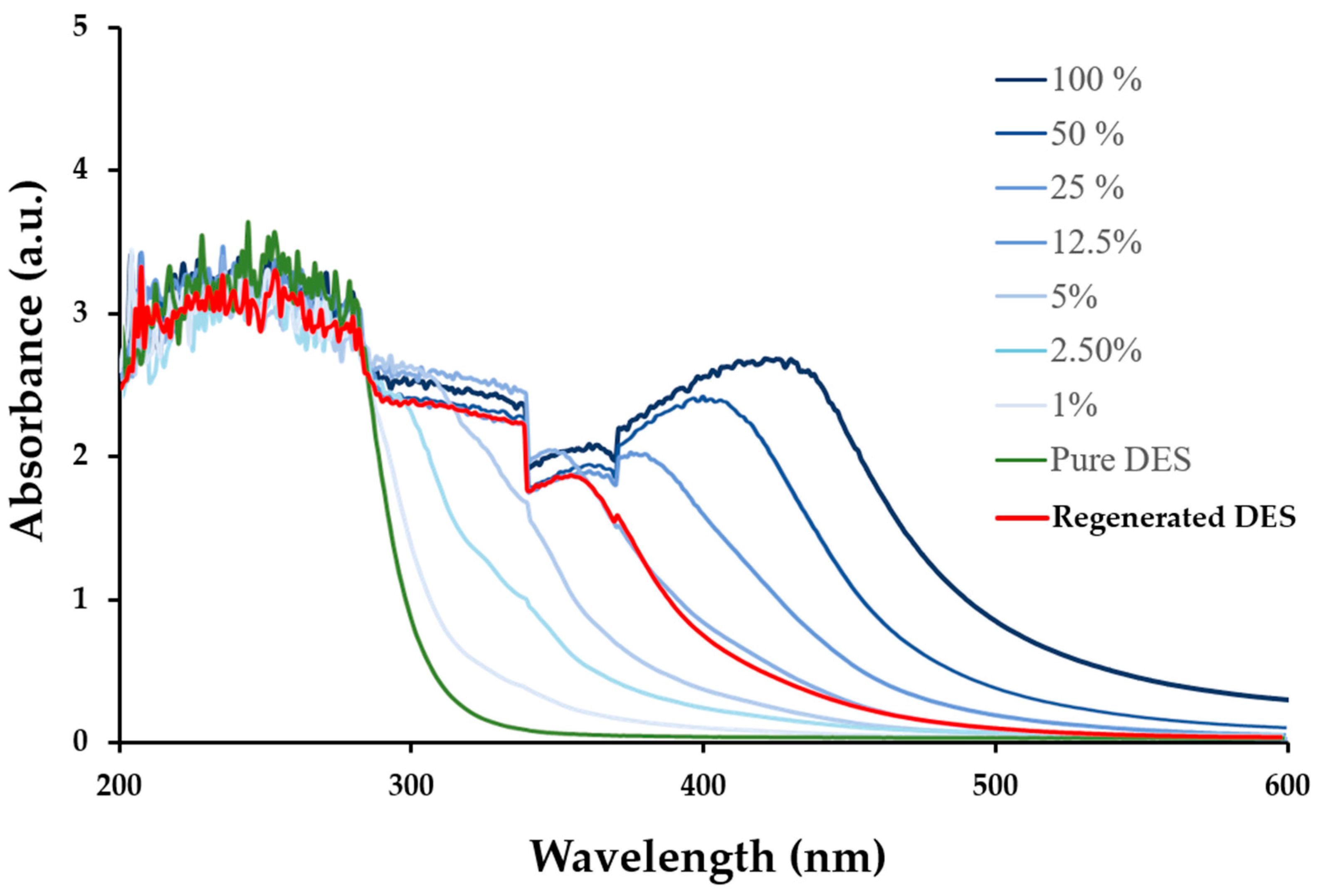

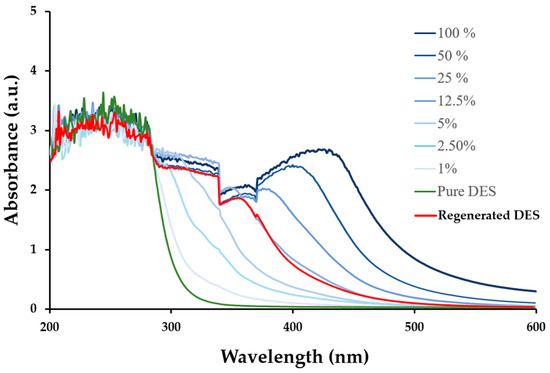

For the initial oxidative desulfurization of HFO (ODS 1), the synthetic protocol used in Experiment No. 2 was repeated, and pure DES was used (ChCl/EG = 1/2) for the initial ODS. The impure DES recovered after this extraction was divided into two equal portions, and each of them was used for the consecutive cycles in route A or route B, respectively. After each regeneration step, the degree of DES regeneration was estimated using UV-Vis spectroscopy measurements after a calibration curve was developed.

For the calibration performance, the initial impure DES recovered from ODS 1 was diluted with pure DES at varying mass ratios, namely, 50%, 25%, 12.5%, 5%, 2.5%, and 1% w/w. The UV-Vis spectra of these solutions are presented in Figure S7. The spectrum of the starting DES (100% w/w concentration of impure DES), which is the DES after the extraction step, is also included in this graph. All the solutes diluted in the starting DES are also soluble in pure DES, so, the progressive dilutions with pure DES lower the concentration of these solutes accordingly, and they result in UV-Vis spectra of progressively lower absorbance (Figure S7). In Figure S7, the spectrum of pure DES is included for comparison. It should be noted that the dissolved solutes are not only sulfones but oxidized asphaltenes and other compounds from the initial fuel. The starting DES has the highest concentration of these dissolved solutes. Efficient regeneration of the DES implies the removal of not only the sulfones but also of all the dissolved solutes. Hence, this starting DES is considered to represent the 100% impure sample, and all the regenerated solvents in the following paragraphs are compared to this DES sample for the determination of their level of impurity.

The UV-Vis spectra in Figure S7 indicate that the progressive dilutions cause a displacement in the curves to the left and a convolution of the peaks. Hence, the wavelength at which the absorbance equals 1 for each curve was used as the measure for the determination of the impurity level degree (%). The selected wavelengths are demonstrated in Table S1.

Based on this set of data, a calibration curve was produced to correlate the % impurity with the wavelength at absorbance = 1, which is presented in Figure S8 in the Supplementary Material. The data were fit to a power-law function: , where y is the wavelength (nm) at absorbance = 1 and x is the % level of impurity, as it has been previously established. Hence, the impurity of each regenerated DES was calculated by recording its UV-Vis spectrum, determining at which wavelength the absorbance was equal to 1, and comparing it with the calibration curve.

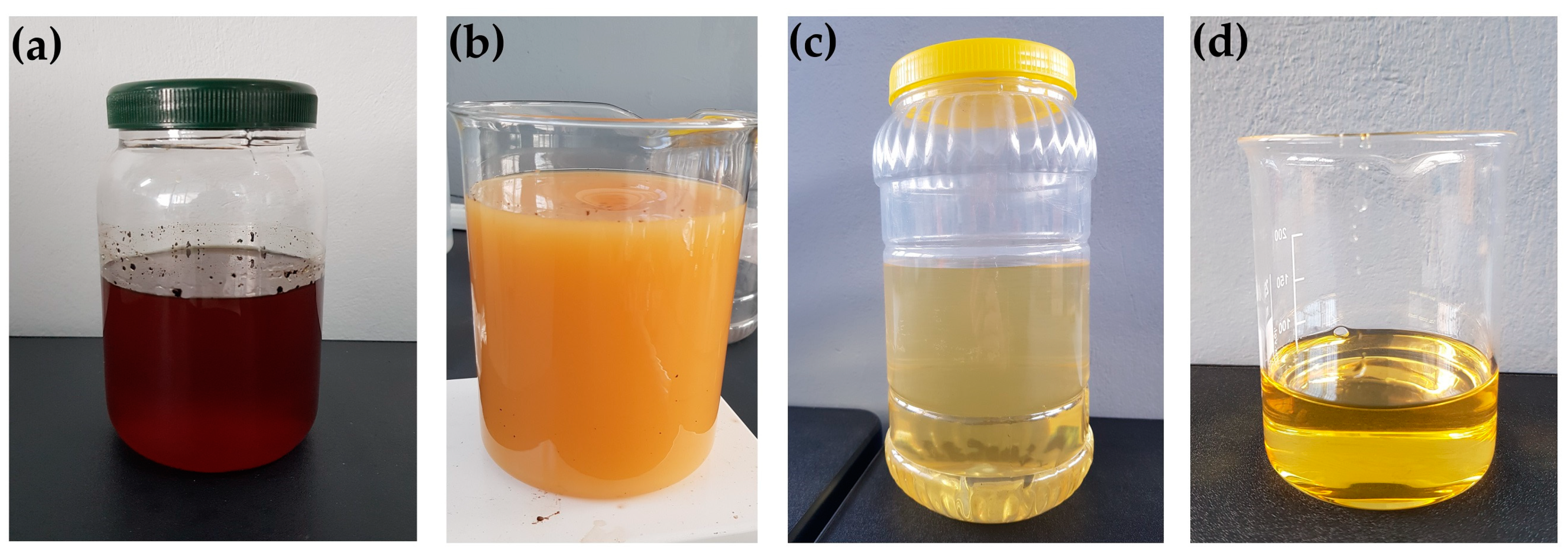

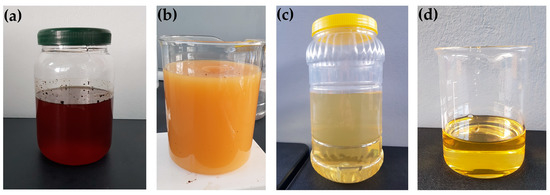

During recycling, most of the dissolved solids precipitate due to the addition of excess water in the DES. After the water evaporation with heated stirring at 80 °C, the regenerated DES was obtained in each case. The molar ratio between ChCl and EG was not examined after the regeneration process; however, no significant changes were expected. The evaporation temperature is much lower than the boiling point of ethylene glycol (197 °C), while the melting point of ChCl is 302 °C, and there was no observed precipitation of ChCl after each process. The complete Regeneration 1A process is demonstrated in Figure 11.

Figure 11.

The recycling of DES obtained from ODS 1 with excess water: (a) the starting impure DES; (b) mixing with water and stirring; (c) the final mixture of DES with water after filtration; and (d) the regenerated DES after water evaporation.

In route A, the UV-Vis spectrum of the sample recovered after Regeneration 1A revealed that it is 89.5% pure (Figure 12).

Figure 12.

The UV-Vis spectrum of the regenerated DES recovered after the Regeneration 1A process (red line) compared to the spectra of the samples with varying impurity levels.

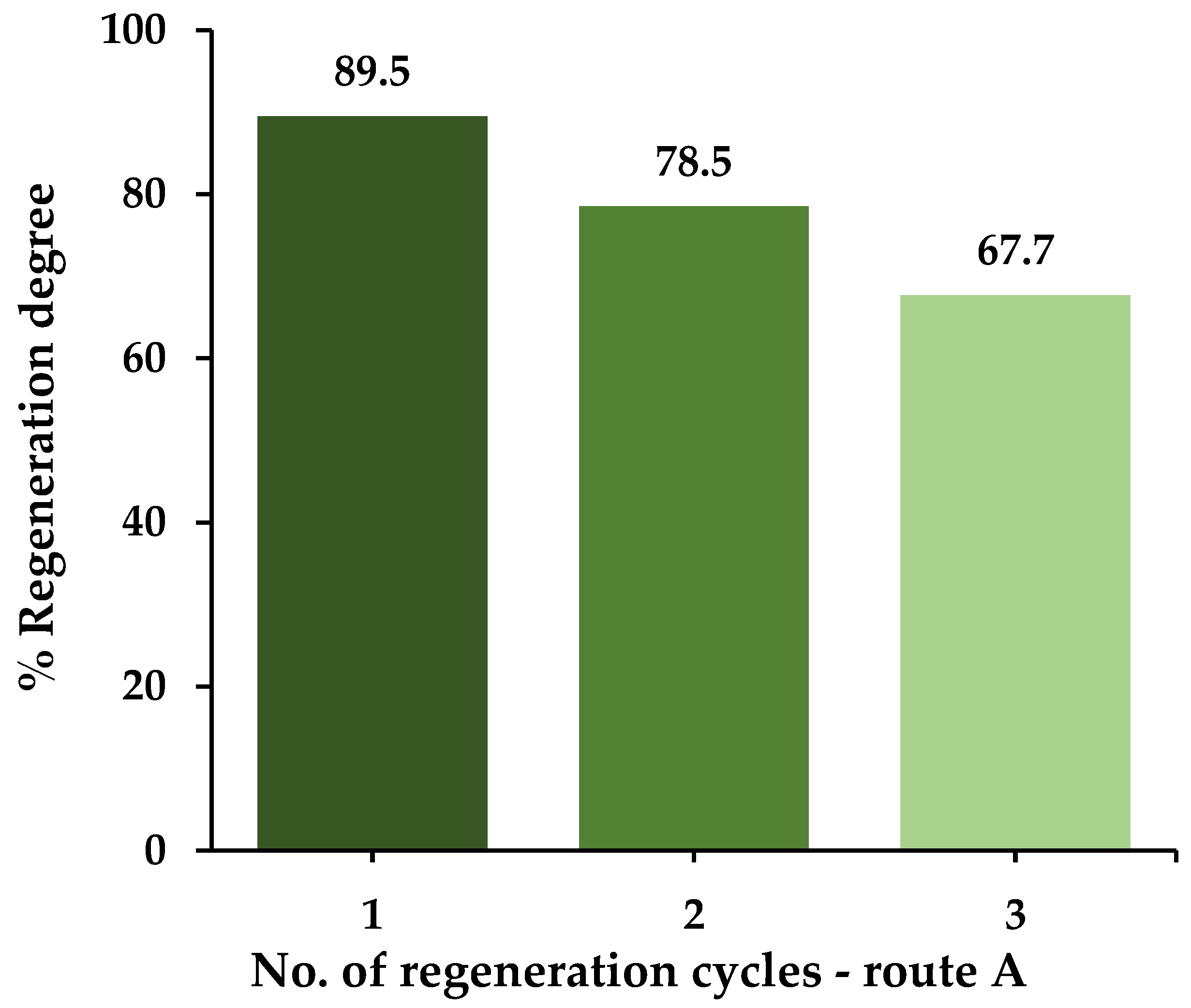

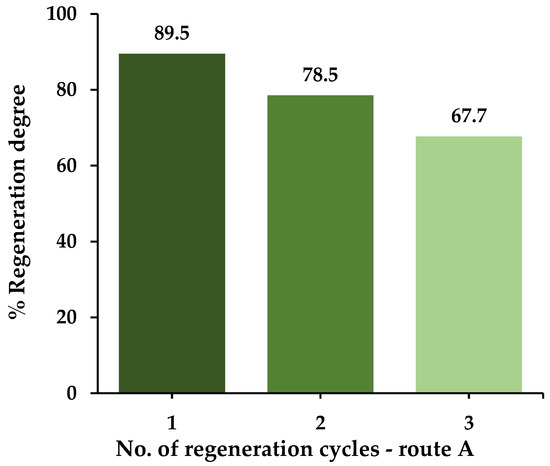

The regeneration degree of the other two cycles of route A was calculated accordingly, and they are presented concisely in Figure 10 and Figure 13. A gradual decrease in the regeneration degree was observed; however, the recycling of the DES was feasible to a considerable extent. Relevant studies published in the literature have also reported a gradual decrease in the regeneration degree [8,24,27].

Figure 13.

The DES regeneration degree after each regeneration cycle of route A.

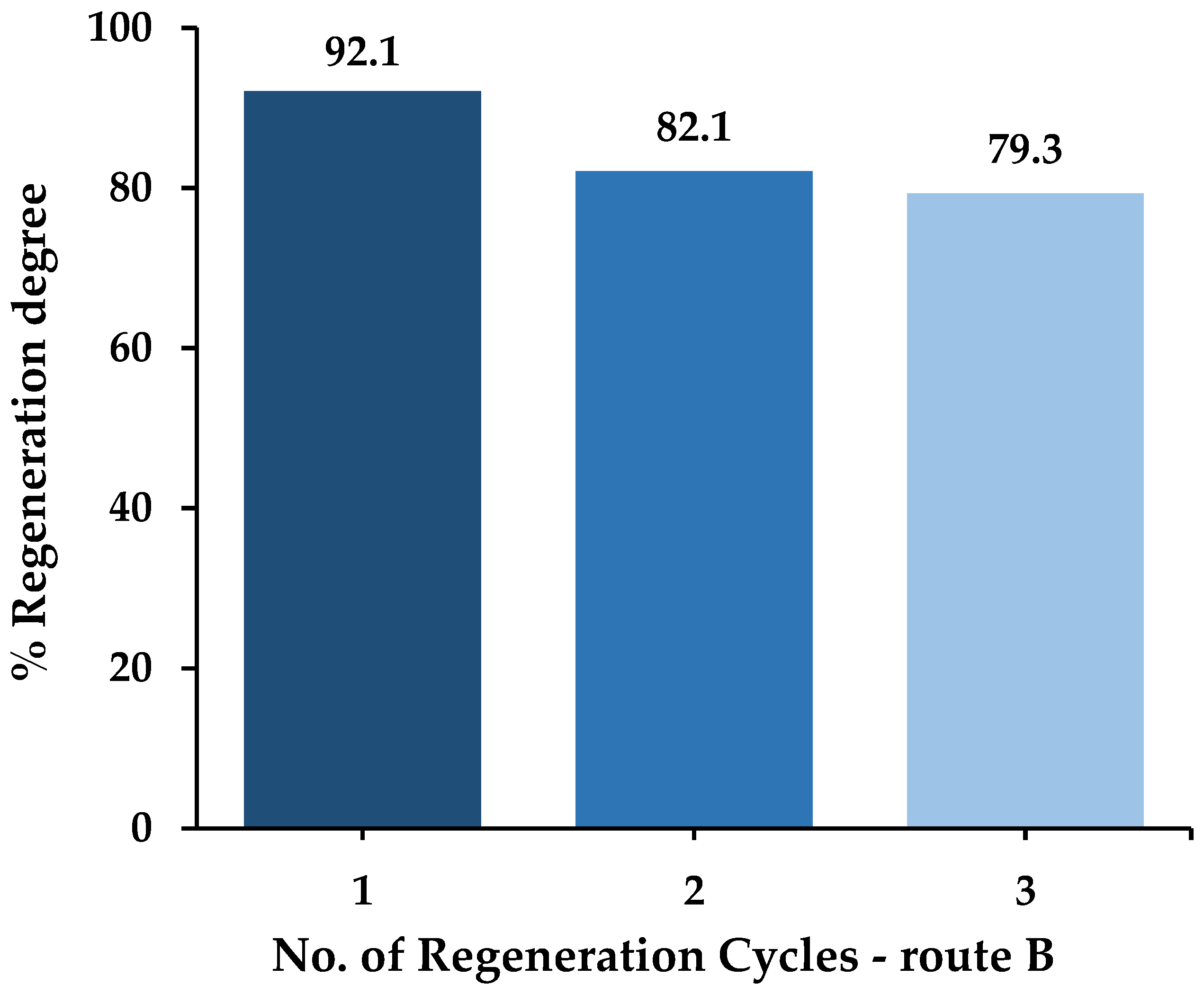

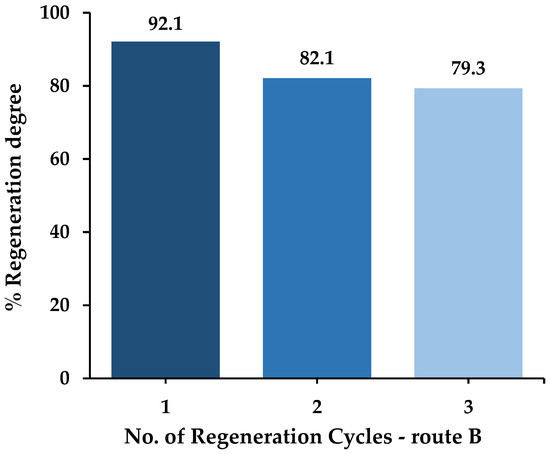

In the consecutive cycles of route B, 30% w/w of the pure DES (ChCl/EG = 1/2) was added after each regeneration step. The regeneration degree of each recycling step was calculated considering this added amount, and according to the obtained results, they are considerably higher than the cycles of route A (Figure 13 and Figure 14). In route B, the regeneration degree reaches a considerable 79.3% after three cycles of ODS and recycling. The enhancement in the recycling process could be attributed to the increase in the recycled DES purity, due to the addition of fresh DES.

Figure 14.

The DES Regeneration degree after each regeneration cycle of route B.

The results reported in this section indicate the feasible and efficient application of DES in consecutive cycles of oxidative desulfurization of heavy fuel oil. However, the use of excess water and the evaporation of DES should be taken into account when an industrial scale-up is considered. The use of water and the power consumption for its evaporation can affect the operating expenses of an industry. Nevertheless, water can be designed to circulate in a closed loop, which is common practice for various industrial processes. After evaporation, steam can be condensed with simple cooling at room temperature and then reused for another cycle of DES regeneration. Thus, no water addition is required after each cycle, and water circulation and evaporation are the only steps in which energy would be consumed. In addition, filtration of the recycled DES for the removal of precipitated solids is a process that can be easily scaled up since no volatile toxic organic solvents are used. Therefore, the process proposed here occurs at mild conditions of oxidation and extraction, and it is feasible to have recycling loops of the streams involved in the process at an industrial scale. These conditions can be compared to hydrodesulfurization (HDS), which is the most widely used desulfurization process in refineries. HDS is a very energy-consuming process since it requires very high temperatures (300–400 °C) and pressures (50–100 bar), while it involves the consumption of large volumes of H2 and the use of catalysts that demand recurrent regeneration [5,6]. Thus, ODS with the use of DES is less energy-consuming and more environmentally benign.

4. Conclusions

In this work, the oxidative desulfurization process of a commercially available marine fuel was validated at the lab scale by optimizing the main experimental parameters that influence each step in the process. The highest desulfurization efficiency was achieved by oxidizing the fuel with a combination of H2O2 and acetic acid for 90 min at 45 °C. The molar ratio of H2O2/S was kept at 2.5/1, while a relatively low molar ratio of H2O2/acetic acid (0.33/1) was essential for the efficient oxidation of S-compounds to sulfones. The highest extraction degree of sulfones from the fuel was accomplished using an environmentally friendly deep eutectic solvent (DES) consisting of choline chloride and ethylene glycol at a molar ratio of 1/2. The most favorable extraction conditions were found to be a 90 min duration at 60 °C and a 5/1 mass ratio of solvent/fuel. Furthermore, it was established that the anti-solvent addition of excess water is the most efficient recycling method for the used DES amongst the ones tested since it contributed to achieving a very high regeneration degree after consecutive cycles of oxidative desulfurization and DES regeneration.

Under the optimized conditions, the yield of the ODS process was 75.7%, which was correlated to an S content of 3305 ppm for the raffinate fuel (0.33 wt.%). This S content complies with the limit set by the International Marine Organization for marine fuels (0.5 wt.%). Therefore, the scalable process that was demonstrated here can pave the way for the desulfurization of commercial fuels in a sustainable and energy-efficient manner.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/separations10080445/s1. Figure S1. The phase separation after extraction with ChCl/LA (1/2) (Experiment No. 9). Figure S2. No phase separation after extraction with ChCl/LA/CA (1/4/1) (Experiment No. 12). Figure S3. The ChCl/PEG (1/6) recovered from Experiment No. 13. Figure S4. Recycling DES with acetone (Experiment No. 19); (a) stirring the mixture of DES with acetone; (b) phase separation and (c) recovery of the two phases. The recycled DES is in the right bottle. Figure S5. Recycling DES with toluene; (a) the phase separation between recycled DES (bottom phase) and the recovered toluene (top phase); (b) the UV-Vis spectrum of the recycled DES compared to the spectra of the pure DES and of the starting impure DES. Figure S6. Recycling DES with ethanol; (a) the mixture of the impure DES with ethanol and (b) the UV-Vis spectrum of the mixture between ethanol and recycled DES compared to the spectrum of the starting impure DES. Figure S7. UV-Vis spectra of the solutions of impure, used DES diluted with pure DES at varying concentrations. The solutions represent DES samples with varying impurity levels, where “100%” represents the starting impure DES. Figure S8. The calibration curve for the correlation between % level of impurity and wavelength at absorbance = 1. Table S1. Data for the calibration curve used to estimate the level of impurity of recycled DES.

Author Contributions

Conceptualization, K.M.S., A.M.M. and I.Y.; methodology, E.S. and O.T.; validation, E.S., O.T. and A.M.M.; formal analysis, E.S.; investigation, E.S. and O.T.; resources, K.M.S. and I.Y.; data curation, O.T. and A.M.M.; writing—original draft preparation, E.S., O.T. and A.M.M.; writing—review and editing, O.T. and A.M.M.; supervision, O.T., A.M.M. and I.Y.; project administration, A.M.M., K.M.S. and I.Y.; funding acquisition, A.M.M., K.M.S. and I.Y. All authors have read and agreed to the published version of this manuscript.

Funding

This investigation was funded by the European Regional Development Fund and the Republic of Cyprus for the “RESTART 2016–2020” Programmes for Research, Technological Development and Innovation (RTDI) within the framework of the research project Sulfaway: Innovative approach for the desulfurization of heavy oil (RPF proposal number: CONCEPT-HYDRO/0421/0011).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are contained within this article and the Supplementary Material.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Fahim, M.A.; Al-Sahhaf, T.A.; Elkilani, A.S. Refinery Feedstocks and Products. In Fundamentals of Petroleum Refining; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Ahmad, W. Sulfur in Petroleum. In Applying Nanotechnology to Desulfurization Process in Petroleum Engineering, 1st ed.; Saleh, T.A., Ed.; IGI Global: Hershey, PA, USA, 2016. [Google Scholar]

- European Union Law. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32009L0030 (accessed on 31 May 2023).

- International Maritime Organization. Available online: https://www.imo.org/en/MediaCentre/PressBriefings/pages/34-IMO-2020-sulphur-limit-.aspx (accessed on 2 June 2023).

- Song, C.; Turaga, U.; Ma, X. Desulfurization. In Encyclopedia of Chemical Processing, 1st ed.; Lee, S., Ed.; Taylor & Francis: Abingdon, UK, 2006. [Google Scholar]

- Saleh, T.A. Characterization, determination and elimination technologies for sulfur from petroleum: Toward cleaner fuel and a safe environment. Trends Environ. Anal. Chem. 2020, 25, e00080. [Google Scholar] [CrossRef]

- Abro, R.; Kiran, N.; Ahmed, S.; Muhammad, A.; Jatoi, A.S.; Mazari, S.A.; Salma, U.; Plechkova, N.V. Extractive desulfurization of fuel oils using deep eutectic solvents—A comprehensive review. J. Environ. Chem. Eng. 2022, 10, 107369. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, D.; Wu, F.; Wei, X.; Zhang, J. Deep desulfurization of fuels with cobalt chloride-choline chloride/polyethylene glycol metal deep eutectic solvents. Fuel 2018, 225, 104–110. [Google Scholar] [CrossRef]

- Houda, S.; Lancelot, C.; Blanchard, P.; Poinel, L.; Lamonier, C. Oxidative Desulfurization of Heavy Oils with High Sulfur Content: A Review. Catalysts 2018, 8, 344. [Google Scholar] [CrossRef]

- Mortezaee, A.; Movahedirad, S.; Sobati, M.A. Challenges of oxidative/extractive desulphurization of heavy fuel oil. Can. J. Chem. Eng. 2023, 101, 1802–1814. [Google Scholar] [CrossRef]

- Imtiaz, A.; Waqas, A.; Muhammad, I. Desulfurization of liquid fuels using air-assisted performic acid oxidation and emulsion catalyst. Chin. J. Catal. 2013, 34, 1839–1847. [Google Scholar] [CrossRef]

- Fritt-Rasmussen, J.; Wegeberg, S.; Gustavson, K.; Sørheim, K.R.; Daling, P.S.; Jørgensen, K.; Tonteri, O.; Holst-Andersen, J.P. Heavy Fuel Oil (HFO); TemaNord; 2018:549; Nordic Council of Ministers: Copenhagen, Denmark, 2018; ISBN 978-92-893-5851-4. [Google Scholar]

- Mirshafiee, F.; Movahedirad, S.; Sobati, M.A.; Alaee, R.; Zarei, S.; Sargazi, H. Current status and future prospects of oxidative desulfurization of naphtha: A review. Process. Saf. Environ. Prot. 2023, 170, 54–75. [Google Scholar] [CrossRef]

- Faramarzi, R.; Darian, J.T.; Ghaedian, M.; Shafeghat, A.; Safavi, M. Desulfurization of Heavy Oil by Using Combination of Oxidation and Mild Thermolysis. J. Jpn. Pet. Inst. 2019, 62, 136–140. [Google Scholar] [CrossRef]

- Vedachalam, S.; Dalai, A.K. Hydrotreating and Oxidative Desulfurization of Heavy Fuel Oil into Low Sulfur Marine Fuel over Dual Function NiMo/γ–Al2O3 Catalyst. Catalysis Today 2023, 407, 165–171. [Google Scholar] [CrossRef]

- Fan, J.; Saxena, S.; Xiao, C.; Mei, J.; Wang, G.; Chen, A.; Zhang, W.; Li, H.; Duan, A.; Roberts, W.L. Molecular characteristics of sulfur compounds in oxidative desulfurization for heavy fuel oil based on APPI FT-ICR MS analysis. Catal. Today 2022, 404, 262–268. [Google Scholar] [CrossRef]

- Ogunlaja, A.S.; Alade, O.S.; Tshentu, Z.R. Vanadium(IV) catalysed oxidation of organosulfur compounds in heavy fuel oil. Comptes Rendus Chim. 2017, 20, 164–168. [Google Scholar] [CrossRef]

- Mitra, S.; Racha, S.M.; Shown, B.; Mandal, S.; Das, A.K. New insights on oxidative desulfurization for low sulfur residual oil production. Sustain. Energy Fuels 2023, 7, 270–279. [Google Scholar] [CrossRef]

- Vedachalam, S.; Boahene, P.E.; Dalai, A.K. Oxidative Desulfurization of Heavy Gas Oil over a Ti–TUD-1-Supported Keggin-Type Molybdenum Heteropolyacid. Energy Fuels 2020, 34, 15299–15312. [Google Scholar] [CrossRef]

- Farshi, A.; Shiralizadeh, P. Sulfur reduction of heavy fuel oil by oxidative desulfurization (ODS) method. Pet. Coal 2015, 57, 295–302. [Google Scholar]

- Chandran, D.; Khalid, M.; Walvekar, R.; Mubarak, N.M.; Dharaskar, S.; Wong, W.Y.; Gupta, T.C.S.M. Deep eutectic solvents for extraction-desulphurization: A review. J. Mol. Liq. 2019, 275, 312–322. [Google Scholar] [CrossRef]

- Lima, F.; Branco, L.C.; Silvestre, A.J.; Marrucho, I.M. Deep desulfurization of fuels: Are deep eutectic solvents the alternative for ionic liquids? Fuel 2021, 293, 120297. [Google Scholar] [CrossRef]

- Hao, L.; Wang, M.; Shan, W.; Deng, C.; Ren, W.; Shi, Z.; Lü, H. L-proline-based deep eutectic solvents (DESs) for deep catalytic oxidative desulfurization (ODS) of diesel. J. Hazard. Mater. 2017, 339, 216–222. [Google Scholar] [CrossRef]

- Jiang, W.; Zhu, K.; Li, H.; Zhu, L.; Hua, M.; Xiao, J.; Wang, C.; Yang, Z.; Chen, G.; Zhu, W.; et al. Synergistic effect of dual Brønsted acidic deep eutectic solvents for oxidative desulfurization of diesel fuel. Chem. Eng. J. 2020, 394, 124831. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, W.; Zhu, W.; Zhu, W.; Li, H.; Guo, T.; Zhu, W.; Li, H. Oxidative desulfurization of fuels promoted by choline chloride-based deep eutectic solvents. J. Mol. Catal. A Chem. 2016, 424, 261–268. [Google Scholar] [CrossRef]

- Jin, D.; Yu, G.; Li, X.; Li, T.; Zhang, F.; Tian, S.; Zhou, Z.; Ren, Z. One-pot extractive and oxidative desulfurization of fuel with ternary dual-acid deep eutectic solvent. Fuel 2022, 329, 125513. [Google Scholar] [CrossRef]

- Mao, C.; Zhao, R.; Li, X.; Gao, X. Trifluoromethanesulfonic acid-based DESs as extractants and catalysts for removal of DBT from model oil. RSC Adv. 2017, 7, 12805–12811. [Google Scholar] [CrossRef]

- Wagle, D.V.; Zhao, H.; Deakyne, C.A.; Baker, G.A. Quantum Chemical Evaluation of Deep Eutectic Solvents for the Extractive Desulfurization of Fuel. ACS Sustain. Chem. Eng. 2018, 6, 7525–7531. [Google Scholar] [CrossRef]

- Sun, L.; Zhu, Z.; Su, T.; Liao, W.; Hao, D.; Chen, Y.; Zhao, Y.; Ren, W.; Ge, H.; Lü, H. Novel acidic eutectic mixture as peroxidase mimetics for oxidative desulfurization of model diesel. Appl. Catal. B Environ. 2019, 255, 117747. [Google Scholar] [CrossRef]

- Mohammed, M.Y.; Ali, A.M.; Albayati, T.M. Choline chloride-based deep eutectic solvents for ultrasonic-assisted oxidative desulfurization of actual heavy crude oil. Chem. Eng. Res. Des. 2022, 182, 659–666. [Google Scholar] [CrossRef]

- Lim, C.Y.; Majid, M.F.; Rajasuriyan, S.; Zaid, H.F.M.; Jumbri, K.; Chong, F.K. Desulfurization Performance of Choline Chloride-Based Deep Eutectic Solvents in the Presence of Graphene Oxide. Environments 2020, 7, 97. [Google Scholar] [CrossRef]

- Isci, A.; Kaltschmitt, M. Recovery and recycling of deep eutectic solvents in biomass conversions: A review. Biomass Convers. Biorefinery 2022, 12, 197–226. [Google Scholar] [CrossRef]

- Słupek, E.; Makoś, P. Absorptive Desulfurization of Model Biogas Stream Using Choline Chloride-Based Deep Eutectic Solvents. Sustainability 2020, 12, 1619. [Google Scholar] [CrossRef]

- Calemma, V.; Rausa, R.; D’Anton, P.; Montanari, L. Characterization of Asphaltenes Molecular Structure. Energy Fuels 1998, 12, 422. [Google Scholar] [CrossRef]

- Groenzin, H.; Mullins, O.C. Asphaltene Molecular Size and Structure. J. Phys. Chem. A 1999, 103, 11237. [Google Scholar] [CrossRef]

- Sengupta, A.; Kamble, P.D.; Basu, J.K.; Sengupta, S. Kinetic Study and Optimization of Oxidative Desulfurization of Benzothiophene Using Mesoporous Titanium Silicate-1 Catalyst. Ind. Eng. Chem. Res. 2012, 51, 147–157. [Google Scholar] [CrossRef]

- Hansen, C.M. Table A.1. In Hansen Solubility Parameters: A User’s Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Mokhtarpour, M.; Shekaari, H.; Zafarani-Moattar, M.T.; Golgoun, S. Solubility and solvation behavior of some drugs in choline based deep eutectic solvents at different temperatures. J. Mol. Liq. 2020, 297, 111799. [Google Scholar] [CrossRef]

- Homan, T.; Shahbaz, K.; Farid, M.M. Improving the production of propyl and butyl ester-based biodiesel by purification using deep eutectic solvents. Sep. Purif. Technol. 2017, 174, 570–576. [Google Scholar] [CrossRef]

- Abdi, G.; Ashokkumar, M.; Alizadeh, A. Ultrasound-assisted oxidative-adsorptive desulfurization using highly acidic graphene oxide as a catalyst-adsorbent. Fuel 2017, 210, 639. [Google Scholar] [CrossRef]

- Evdokimov, I.N.; Losev, A.P. On the Nature of UV/Vis Absorption Spectra of Asphaltenes. Pet. Sci. Technol. 2007, 25, 55–66. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).