Abstract

The movement to digitally transform Saudi Arabia in all sectors has already begun under the “Vision 2030” program. Consequently, renovating and standardizing production and manufacturing industries to compete with global challenges is essential. The fourth industrial revolution (Industry 4.0) triggered by the development of information and communications technologies (ICT) provides a baseline for smart automation, using decentralized control and smart connectivity (e.g., Internet of Things). Industrial engineering graduates need to have acquaintance with this industrial digital revolution. Several industries where the spirit of Industry 4.0 has been embraced and have already implemented these ideas yielded gains. In this paper, a roadmap containing an academic term course based on the concept of Industry 4.0, which our engineering graduates passed through, is presented. At first, an orientation program to students elaborating on the Industry 4.0 concept, its main pillars, the importance of event-driven execution, and smart product manufacturing techniques. Then, various tasks in developing a learning factory were split and assigned among student groups. Finally, the evaluation of student potential in incorporating the Industry 4.0 concept was analyzed. This methodology led to their professional skill development and promoted students’ innovative ideas for the manufacturing sector.

1. Introduction

The fourth industrial revolution (Industry 4.0) gains global attention from several production sectors. Therefore, decision-makers in different countries have launched several research projects to support their manufacturing sectors in their transformation process into Industry 4.0 to enhance their competitive advantages [1]. Since Germany announced Industry 4.0 and promised to bring remarkable benefits to the manufacturing industry worldwide, many countries have rushed to launch similar initiatives [2]. For example, the United States of America has launched a similar initiative called Smart manufacturing [3]. In 2014, China revealed a national 10-year vision called “Made in China 2025” to transform China into a world manufacturing power [4,5]. In 2016, Japan went far beyond Industry 4.0 [6], and they shared the vision of what is called Society 5.0. Society 5.0 focuses on the digitalization of all life sectors of Japanese society [6]. To be aligned with the latest technological innovation, the government of the Kingdom of Saudi Arabia (KSA) has launched “vision 2030” to upgrade existing industries (refinery, petrochemical, fast-moving consumer goods, etc.) [7]. Therefore, it is vital to modulate and upgrade the current educational curriculums to educate and familiarize future generations of students with new technological innovations to support their societies’ welfare. This article proposes a new methodology for upgrading the current curriculum program at the Industrial Engineering Department (IED) at King Saud University (KSU) to reflect the latest technological innovations in Industry 4.0.

1.1. Integrating Industry 4.0 into the Engineering Study Programs

Industry 4.0 was initially introduced at the Hannover exhibition in 2011 [8]. It was one project of German 10-point high-tech Strategy 2020. Industry 4.0 revolves around creating a smart manufacturing environment through interconnecting smart production entities such as smart products, movable and stationary machines, tools, robots, storage and retrieval systems, material handlings and other production entities by utilizing the powerful features of latest advancements in Information and Communication Technologies (ICT) and Cyber-Physical Systems (CPS). A real-time data capturing system, such as radio-frequency identification (RFID), sensors, and digital cameras, is utilized to control the production processes [9,10,11] and react to any incident or situation through complex and elaborated algorithms that control the interaction between all smart entities [12,13,14,15,16,17]. Industry 4.0 is the digital transformation of manufacturing systems (i.e., digitalization) to smart manufacturing systems [18].

One of the significant promising benefits of Industry 4.0 in manufacturing systems is enabling individualized and customized products within a mass production chain and addressing the technical aspects of these requirements by applying the generic concepts of CPS and Industrial Internet of Things (IIoT) to the industrial production systems [19,20]. Connections of CPS in Industry 4.0 and Manufacturing Execution System (MES) are based on building blocks. These blocks are embedded systems with decentralized control and advanced connectivity that collect and exchange real-time information to identify, locate, track, monitor, and optimize the production processes [21].

Strategically, the trend of Industry 4.0 adaptation is increasing, which resulted in a high demand for highly skilled engineers who can effectively contribute to the conversion process to Industry 4.0. Therefore, integrating Industry 4.0 concepts in engineering curriculums has become one of the main priorities of the universities and academic institutions [22]. Such literature promoted us to imply that undergraduate students need to acquire new skills or competencies to cope with the future of Industry 4.0. Therefore, some universities started to upgrade their engineering programs to integrate the concepts of Industry 4.0 in their engineering curriculums to qualify their graduates with the required skills to implement Industry 4.0 solutions [23]. Industry 4.0 implementation is based on multi-disciplinary teams on various technologies and techniques [24,25], where the undergraduates must deepen and strengthen their skills.

These emerging technologies include the Internet of Things (IoT), CPS, cloud computing, big data, blockchain, industrial information technology, and other related technologies [26,27,28,29]. Based on the [30], 10 Industry 4.0 transformation pillars can be counted as follows: Internet of Things, cloud computing, cyber-physical system, big data, autonomous robots, simulation, horizontal and vertical integration, additive manufacturing, augmented reality, and blockchain.

For example, CPS is the core foundation of Industry 4.0 [31,32]. CPS enhances and secures the integration between smart physical entities and computational level through complex control algorithms [33]. The infrastructure of the interconnected smart physical entities represents the Internet of Things (IoT) system. RFID and sensors are considered as the significant enablers of the IoT network [34]. Therefore, the IoT can be described as a network of devices with local intelligence, enabling communication between facilities, machines, finished, and unfinished products. It incorporates machine learning, big data technology, data collection from sensors, machine-to-machine communication, and automation technologies. Compared to humans, intelligent machines, when connected, can collect and process large data sets with more accuracy and consistency [35]. The research increased the vital role of using blockchain in the manufacturing systems. The potential use of blockchain in Industry 4.0 includes supporting, scalability, autonomy, resilience, and security [36].

Through the aforementioned 10 Industry 4.0 pillars, the new skills and competencies required by the digital transformation of Industry 4.0 can be identified. Therefore, this can be a starting point for the integration between Industry 4.0 and engineering programs. So it is highly recommended to change the direction of higher education. For instance, in addition to the typical hard and soft skills, the academic institutes and universities must add another category of skills, i.e., digitalization skills. This should bridge the gap between academia and industry for new required skills and knowledge.

To accurately identify the required Industry 4.0 skills to be delivered in academic institutes and universities, further investigation must be carried out. For instance, [37] investigated the necessary skills of junior engineers that must be required to be ready for Industry 4.0 solutions. The results show that there is a need to create and provide skills about the basic concepts of Industry 4.0.

1.2. Research Objectives

Going beyond the limits of the existing systems requires structural innovation or breakthrough solutions to enhance students’ skills and performance. The ultimate aim of undergraduate engineering students is to be competitive in their field. Initially, they have to familiarize themselves with the basic engineering principles and approaches. Secondly, from practical lab sessions to training workshops, they get hands-on experience with the conventional machinery equipment. Thirdly, they have to be able to cope up with recent advancements in engineering fields. Therefore, after the emergence of Industry 4.0, different academic institutions have built Industry 4.0-based learning factories (LF) to transfer the new concepts of Industry 4.0 to their students. LFs create opportunities for students to be updated about the latest advancements in Industry 4.0 and to make them aware of the powerful results of the manufacturing and ICT integration [38]. LFs offer a realistic environment to test the basic engineering principles of Industry 4.0 environment [39]. Moreover, smart LFs give the students the ability to understand the behavior of real production systems by applying different scenarios based on different production approaches and exploring different improvement scenarios [40,41].

However, the recently built smart LFs train the students on how the real Industry 4.0-based smart factory operates rather than teach the core concepts and the transformation process to achieve Industry 4.0-based smart factory through upgrading the student’s skills on the aforementioned Industry 4.0 main pillars. So they become prepared and skilled for transformation and upgrading the conventional production systems to become smart production systems. In this regard, [23,42] investigated the impacts of the emergence of Industry 4.0 on industrial engineering (IE) curriculum and suggested enhancements to IE curriculums in universities of South Africa. The results indicate that industrial engineers’ roles might be diminished if the curriculum will not be revised, developed, and upgraded to cope with the required skills of Industry 4.0. An Industry 4.0 industrial engineering learning factory didactic model was formulated by [42]. The model was built based on the learning factory as the learning platform for the Industry 4.0 concepts. They mentioned that only one university in South Africa has made considerable progress toward integrating Industry 4.0 concepts with their IE curriculum. Another methodology was introduced by [43] to integrate Industry 4.0 with the current university curriculums, where several technical study programs will be evaluated concerning Industry 4.0 related topics. The evaluation process is based on the Reference Architecture Model for Industry 4.0 (RAMI 4.0). A case study was done based on the built methodology where some academic syllabi within engineering study programs at the Emden/Leer Applied Sciences University were evaluated. The results show that Industry 4.0 topics must be covered through specific courses or lectures in the university’s current academic curriculum.

Recently, since Industry 4.0 covers multidisciplinary topics in engineering fields, [44] built a platform at Emden/Leer Applied Sciences University to teach different Industry 4.0 related topics. The built platform is called “Automated Class Room”. This platform consists of different modules from different specialization. Therefore, the work describes how this platform was used through different departments to teach their students the concepts of Industry 4.0 from their perspectives. The platform allows students from different departments to work together and learn how to implement Industry 4.0 technologies. Similarly, [45] discussed the applicability of integrating Industry 4.0 concepts into the teaching of engineering programs and accordingly proposed a blended teaching model that explains how the integration between Industry 4.0 related concepts and teaching of engineering courses can be realized. The model contains self-education teaching methods to create lifelong learners who can adapt to the latest technological advancements in the rapidly changing world.

Therefore, it is important to embed the concepts of Industry 4.0 engineering curriculums where the contents of some course must be revised and updated according to the 10 pillars of Industry 4.0.

Undoubtedly, a dedicated academicians’ team here at IED/KSU has seriously taken this concern. To some extent, the industrial engineering program can be considered as a multidisciplinary study program, and almost none of the recent articles discussed a model for integrating Industry 4.0 into the industrial engineering program. Therefore this article introduces a new short-term course to upgrade the industrial engineering syllabus at IED/KSU to integrate the new concepts of Industry 4.0 with industrial engineering courses and proposed a few policy implications that have to be implemented after the approval of all syndicate members of the university. Depending on that, we upgraded our syllabus and redefined ourselves to enhance our teaching potential. We are indeed ready to render a recent educational methodology to make our undergraduate engineering students excel in their technical skills. In this article, we establish the importance of delivering the concept of Industry 4.0, and its necessity to be included in the engineering syllabus (Section 1).

In this proposed course, we explained in Section 2 the educational process and a case study that enables the students to handle miniload operations. An evaluation method was then designed to evaluate the contribution of students as per the course design was introduced in Section 3 and followed by a discussion in Section 4 to analyze the advantages of the new Industry 4.0 teaching method and its impacts on undergraduate students. Finally, conclusions and specified several future research directions are drawn.

2. Industry 4.0 Curriculum Zone

2.1. Student Orientation Program

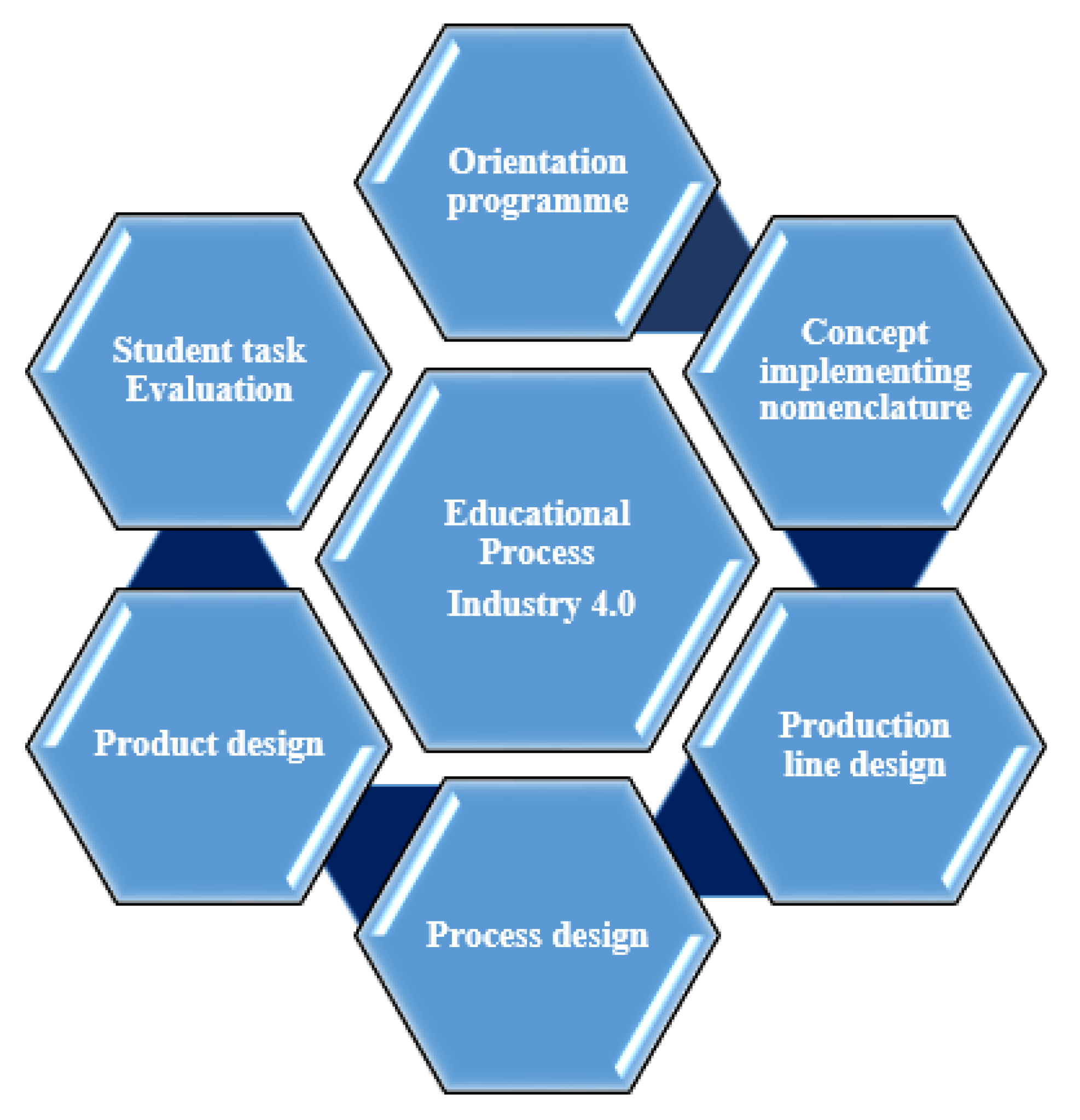

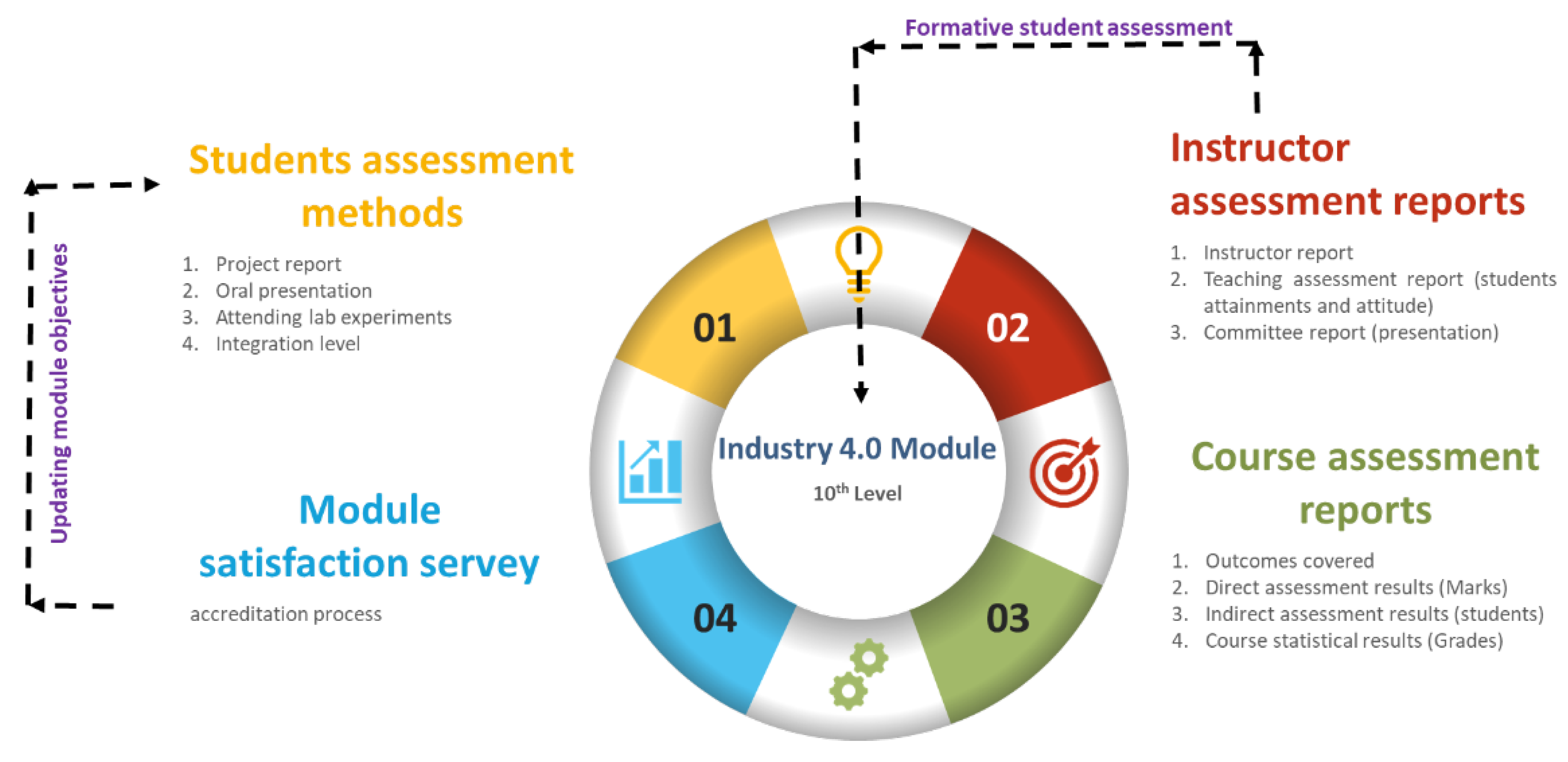

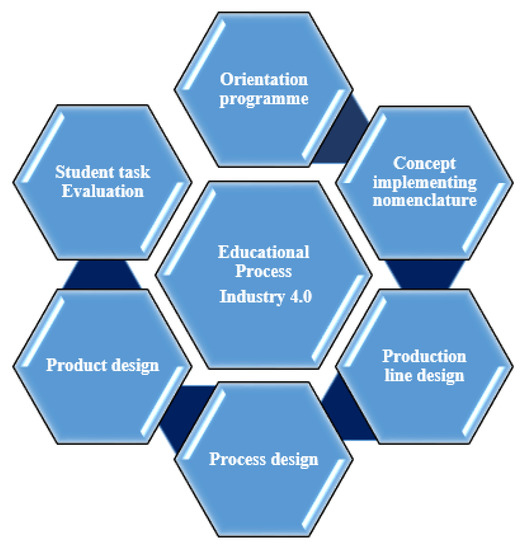

The educational process of implementing the concept of Industry 4.0 is a computer-based educational system (Figure 1), and it started with an orientation program where both the faculty members and participants can express their emotions. Faculty members of various streams attended this event and had substantial outcomes. Then we organized an advanced level orientation course about the concept of Industry 4.0 and included it in our curriculum. The intention was to train upcoming industrial engineering graduates to face the challenges of new industry innovations and to gear them for flexible advanced technologies. So a nomenclature to implant concept Industry 4.0 was laid by faculty members and based on feedback to familiarize students to translate technologies into design principles and operational solutions. After the discussion, a team of students designed a suitable prototype production line. The other team completed the process design, and so the product design. Finally, student task evaluation occurred based on their quality of work and documentation of their project. This undertaken initiative was to ease and fill the gap in an educational training institution. The concept Industry 4.0 for IE graduates is an exclusive arena that will trigger them about new emerging demands in the manufacturing sector. We introduced them to the concepts of Industry 4.0 and elaborated its influence in the industrial environment creating a big space of opportunity. We stressed the need for highly skilled, knowledgeable engineers, and their need to drive future industrial innovations. Moreover, additive manufacturing (3D printing) is also a field for inspiring graduates to explore more.

Figure 1.

Educational process.

Confidently, when implementing Industry 4.0, we say that demand in need of technically sound engineering graduates will enhance research and development in all sectors. We expect such developments to solve issues on both local and global manufacturing systems.

2.2. Teaching and Training Methodology

The teaching and training methodology used in this paper is inspired by Jungmann’s research cycle, synchronized with Kolb’s learning cycle [46]. It is a unique methodology for engineering graduates to find solutions for real-time issues in industries. In this short-term course, we adopted this learning methodology. A proposed methodology is a direct approach (i.e.,) an expository method which eases students to adapt themselves to the modern techniques and skills related to Industry 4.0. The additional benefit of adapting Jungmann’s research cycle synchronized with Kolb’s learning cycle helped us achieve a guided approach of methodology, which was immensely an exploratory method. The student delegator smartness adapted in our methodology was favorable in peer feedback activities of a Smart LFs. This unique educational method proposed to deliver skilled Industrial engineering graduates who are aware of the recent advanced developments had been tranquil than expected—this facilitated student problem-solving techniques while programming our industrial prototype bearing in mind real-time issues. Indeed, it is a challenge for an undergraduate student of a single engineering stream to understand all the main pillars of Industry 4.0 deeply. Our minimum expectation was to create awareness for all students about Industry 4.0 (i.e.,) an Industrial revolution of this modern era, which is not as present in their engineering syllabus. In this course, anticipated industrial engineering students had to choose a single pillar in Industry 4.0 and directed them to startup in building up small real-time industrial prototypes. The Jungmann’s research cycle synchronized with Kolb’s learning cycle is a blended style that combines requisite student’s skill and focused supervisory vision on assigning the Industry 4.0 concept. It explained how students could approach real-time issues, apply their theoretical knowledge, and find solutions for the future industrial challenges.

Jungmann’s research cycle is supposed to be one of the circular ways to synchronize the research and the learning experience laid on a robust platform. The cycle also gives a clear roadmap for engineering students to utilize our experienced faculty team and lab facilities.

This modern research methodology is applied to utilize the faculty team’s concrete experience to formulate a smart production line properly. They learn to develop a production line by unique instruments and field devices available in our IED/KSU Labs.

2.3. Course Design Procedure

After introducing the new genre of Industry 4.0 to the students, we decided to mine their exciting topic related to the concept. We assigned students into four groups and wanted them to get back with their innovative ideas to develop a smart production line. A prerequisite set to students was to go through the path of Jungmann’s Research Cycle synchronized with Kolb’s cycle.

A time frame was set up for students to complete their tasks involving production line design, process design, performance assessment, and system evaluation. The student teams received their schedule for this short-term course in the IED automation and control laboratory. A pattern of six students in four teams was combined based on the exciting subjects they have undertaken so far. The limitation of four teams was assigned specific tasks, and one student had to coordinate these tasks in each group—a total of 24 students per classroom (section) maintained as per university accreditation norms. The team formation was based on the marks obtained by students in their previous examinations, all teams had a combination of slower learners, average runners, and toppers.

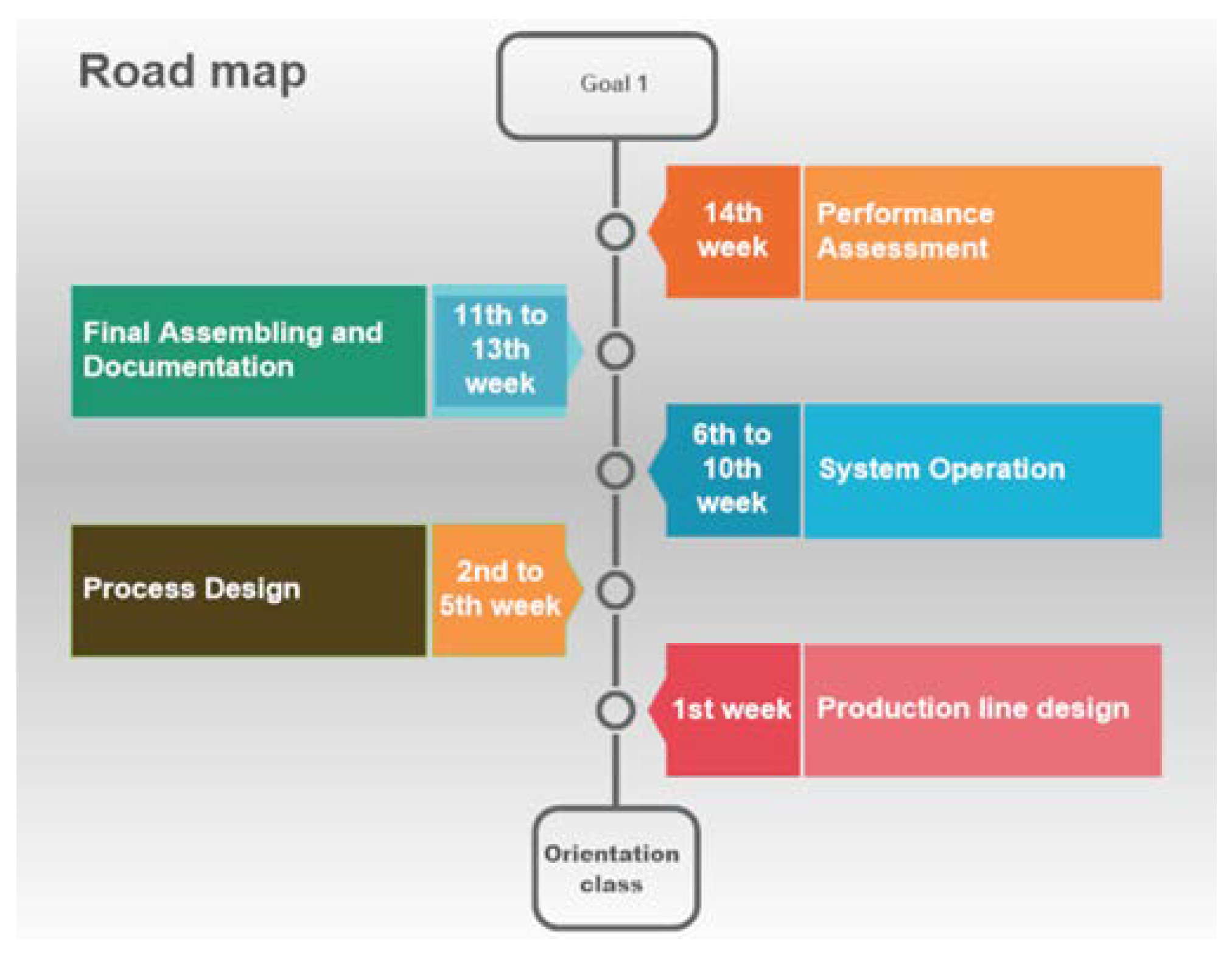

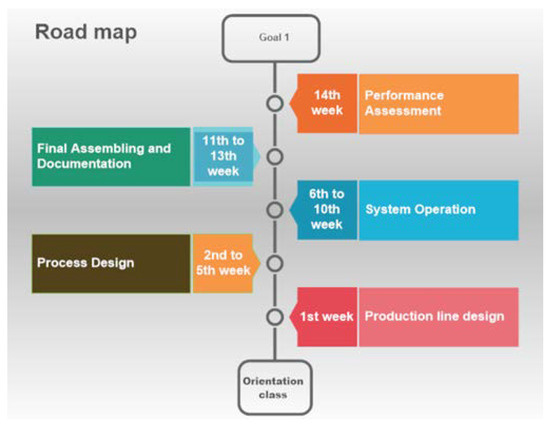

The course roadmap (Figure 2) directs the student team to attain their interim goals and plan the required activities. This course is at the final year (10th level) of the Industrial Engineering curriculum and aims to teach students and boost their engagement with trending topics, such as smart connectivity, smart monitoring, and smart design in the first phase. To achieve this goal within a fifteen-week timeframe, each group had to go through five activities (production line design, process design, system operation, final assembly and documentation, and finally, performance assessment). At the end of this course, all students get familiarized with defined topics in Industry 4.0, understand its relative pillars and importance of event-driven execution by developing a smart production line. By the end, students had to report to their supervisor at every stage of completion. The below scheme also ensured that each student at the end of this course familiarized themselves with a specific concept in Industry 4.0, understanding its relative pillars and importance of event-driven execution by developing a smart production line.

Figure 2.

Industry 4.0 short-term course milestones.

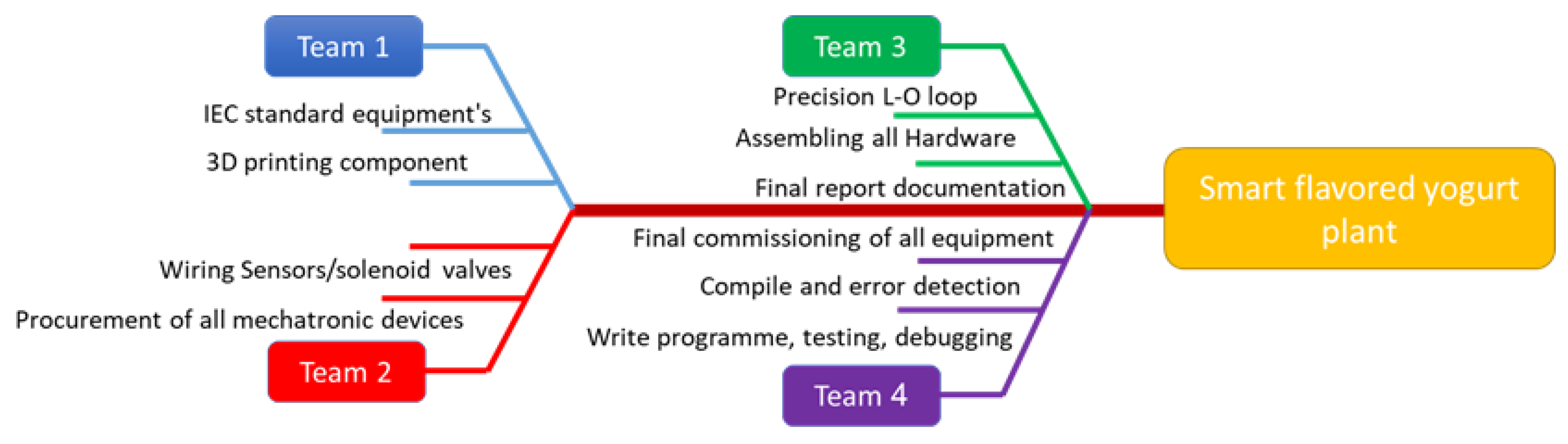

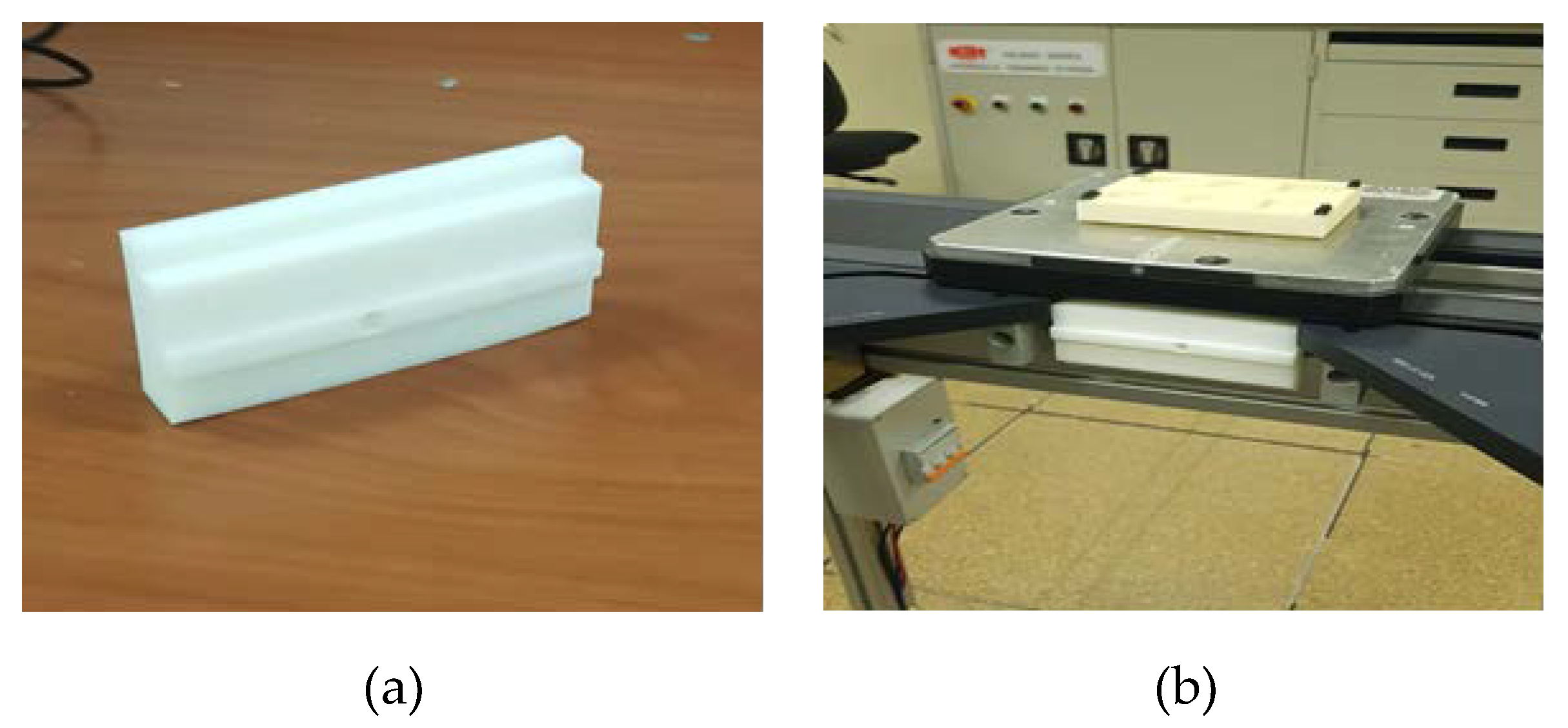

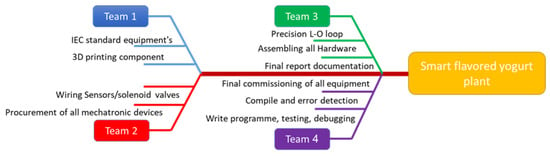

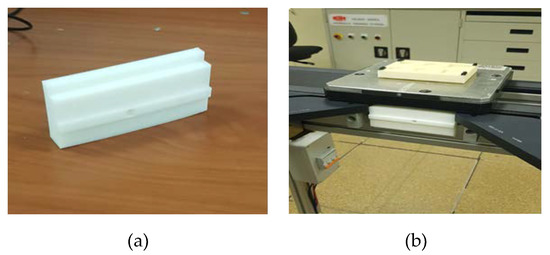

2.4. Production Design

In the manufacturing system, to obtain a professional design, it is essential to consider the evolution of production lines to deliver an effective solution. The highlighted topics were discussed among the students’ groups, and the workload was equally distributed among them to deliver their contributions. Figure 3 represents the plan of student allotment in groups where the first team had identified all International Electrotechnical Commission (IEC) standard equipment required for our production line, consulting project supervisor. Firstly, with 3D printing, they had successfully printed the base plate, which was missing (Figure 4) with polylactic acid (PLA) plastic.

Figure 3.

Course design based on project management methodology.

Figure 4.

Defective conveyor object: (a) 3D printed item; (b) installed 3D Printed item in the conveyor system.

The second team, who underwent a detailed study, had chosen an appropriate communication subsystem, i.e., Ethernet IP, with a futuristic approach. They had completed all Autocad designs and worked on CATIA software required for the 3D printer. This team also completed the procurement of all required mechatronic equipment. The 3rd team had rearranged the existing conveyor loop system from the L loop to the desired O loop. As per their designed project sequence activities, they were assembling production lines, especially the pneumatic piston stoppers’ installation at their precise positions. All related documentation and final report submission tasks assigned for them. Finally, the 4th team using e-Cockpit software configured the WAGO PFC (WAGO Kontakttechnik GmbH & Co. KG, Minden, Germany), and in it, they had written the ladder logic program as per operation sequence. The testing, debugging, and completed commissioning of the production line were completed by this team. Students vivid in industrial automation had programmed the Programmable Field Controller (PFC) referring the existing curriculum at IED/KSU. The second challenge was the selection of appropriate field devices such as sensors, solenoid valves, and pneumatic pistons. A variety of sensor types such as photoelectric, photo reflective, proximity, induction, contrast, and color sensors are opted for, which are regarded the eyes of the system.

System Hardware

The WAGO 750-880 Programmable Fieldbus Controller (PFC) combines the functionality of an ETHERNET-based Fieldbus Coupler with the functionality of a Programmable Logic Controller (PLC). The controller used for applications in an individual machine, plant construction, the process industry, and building technologies.

The two Ethernet interfaces and the integrated switch make possible the wiring of the Fieldbus in a line topology. Thus additional infrastructure elements such as switches or hubs can be void. With the dual in-line package (DIP) switch, the last byte of the IP address, as well as the assignment of the IP address (dynamic host configuration protocol (DHCP), BootP, firm setting) can be given. Also, we allotted new IP Addresses (static configuration) for individual station PFC with unique MAC (Media Access Control Identity) addresses [47].

2.5. Process Design

2.5.1. Process Flow

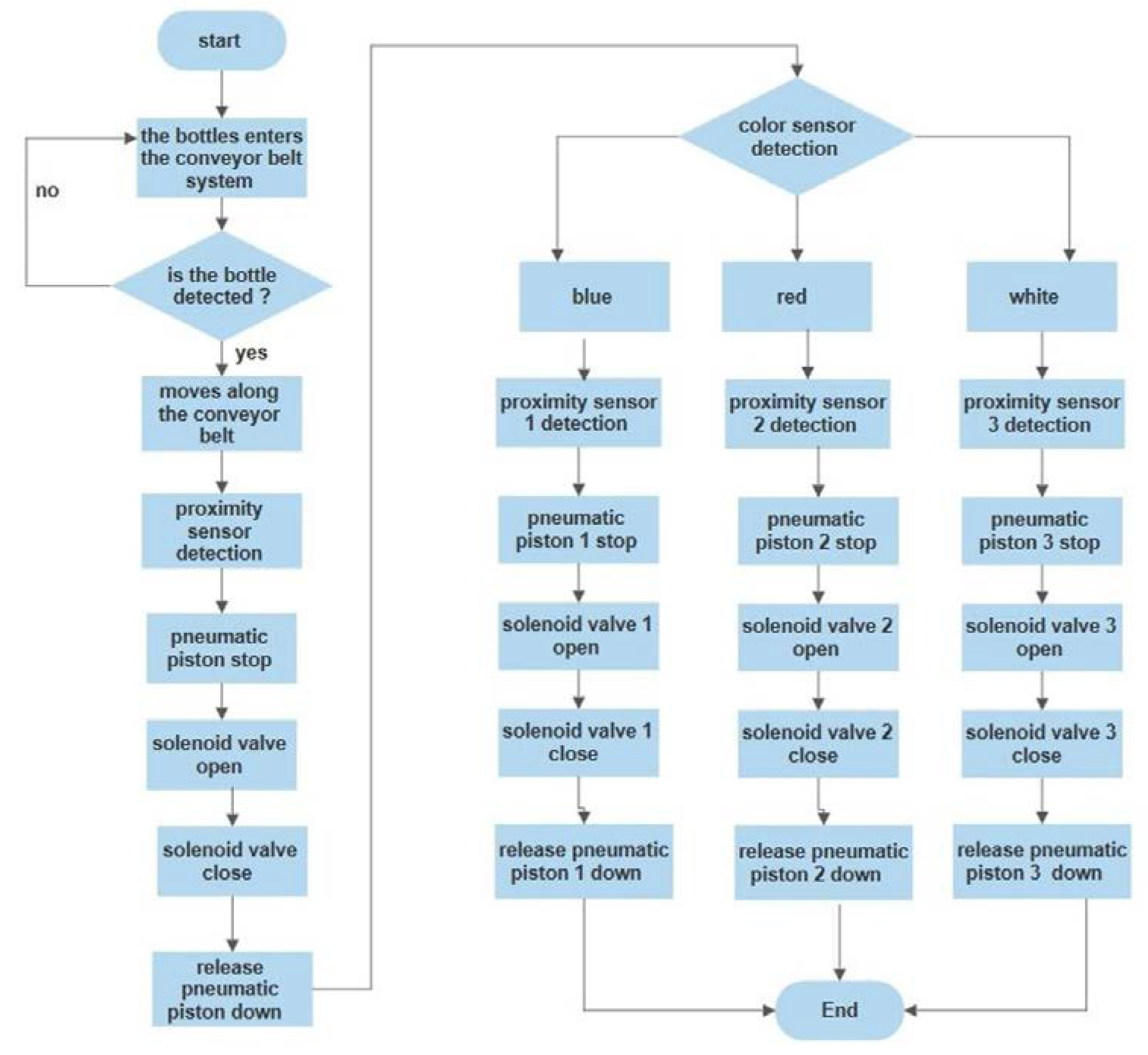

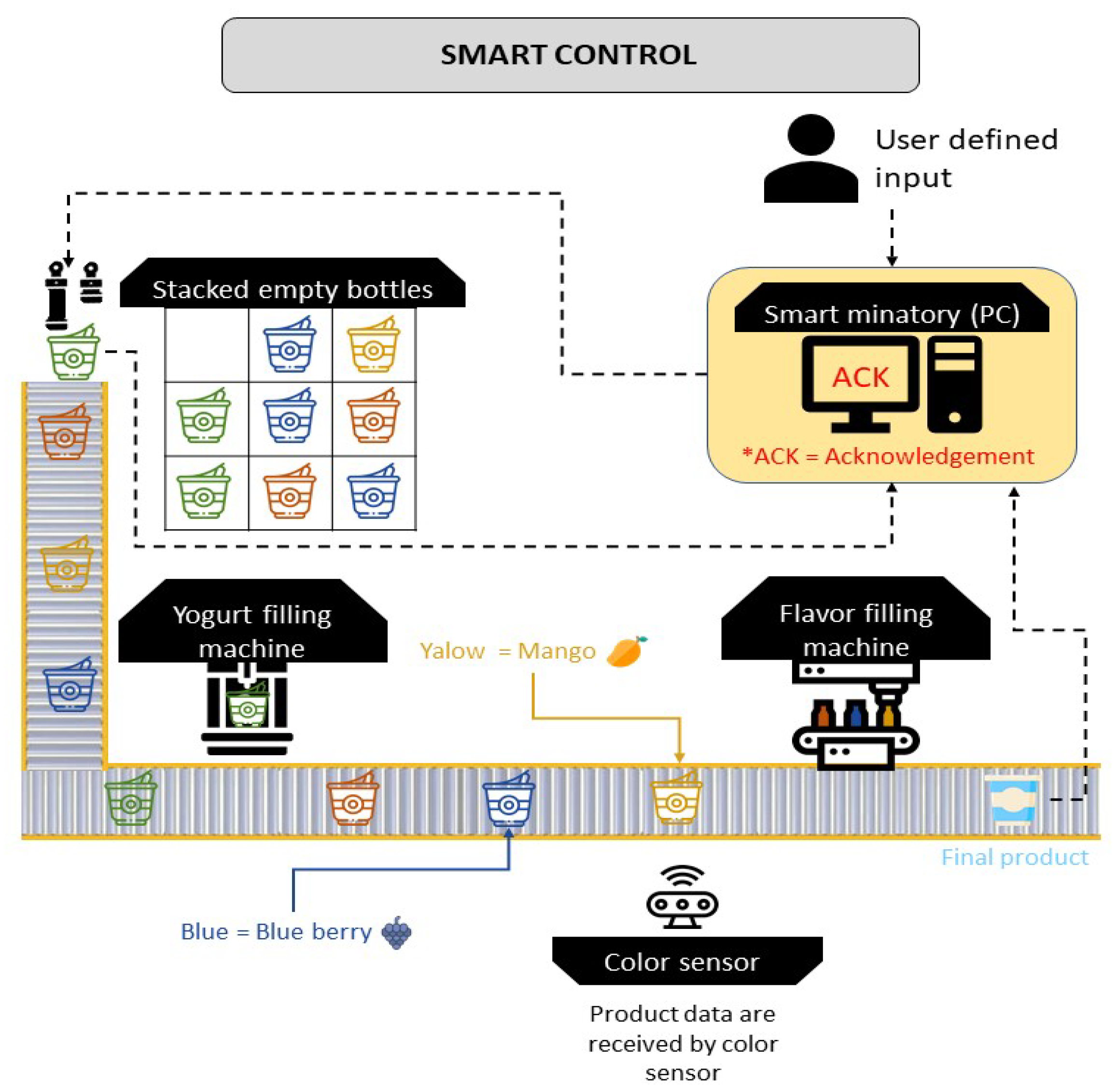

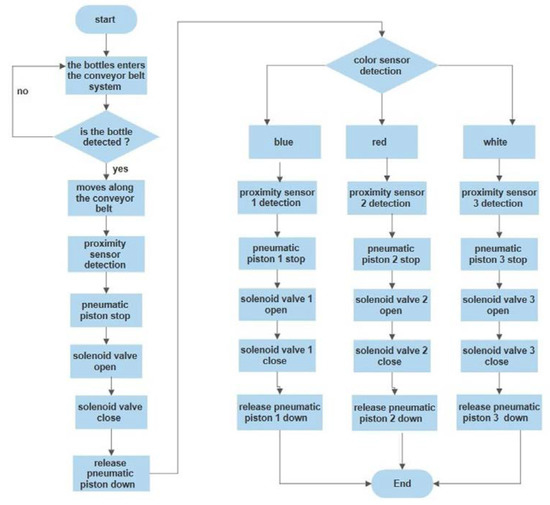

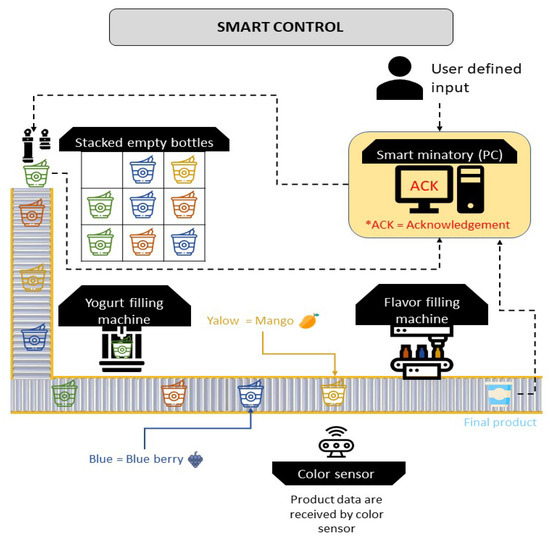

The conveyor belt is loaded with unfilled bottles and undergoes various changes [48]. The pneumatic pistons push the unfilled bottles in the conveyor track one by one. The unfilled bottles kept on the base plate reach the initial filling position after “START” is hand-pressed, as represented in Figure 5. The three-action sequence launched (i.e.,) the first event is triggered when the proximity sensor detects the unfilled bottles and stops at base yogurt flushing nozzle. In the first action, the unfilled bottle is halted by the pneumatic stopper in a proper position. The second action, the base yogurt, flushed into the unfilled container for a user-defined time by opening the nozzle valve. In the third task, a photoelectric contrast sensor detects the entering container. The information collected by the photoelectric contrast sensor triggers the next sequence to fill the desired flavor (i.e.,) topping over the base yogurt. This information is mutually used as a global variable to trigger the upcoming filling stages. Now the piston drops down to transfer the base yogurt container to execute the next event. The subsequent event depends on the information received from the photoelectric contrast sensor. The customized flavor is to be filled in the container after halting it in an accurate position. Mango, blueberry, and strawberry are the customized options. Next, by the opening nozzle valve of customized essence, the topping upon base yogurt is completed. After the filling process, the corresponding pneumatic piston goes down, and the filled container driven to the end of the conveyor belt. After the container is occupied with customized yogurt topping, the conveyor carries it to the end of the line. A proximity sensor that triggers the successive event was yogurt containers to reach a consistent point to be stowed, frosted, and later transferred by a robotic arm.

Figure 5.

Flow chart of customized yogurt filling system.

2.5.2. Prototype Narration

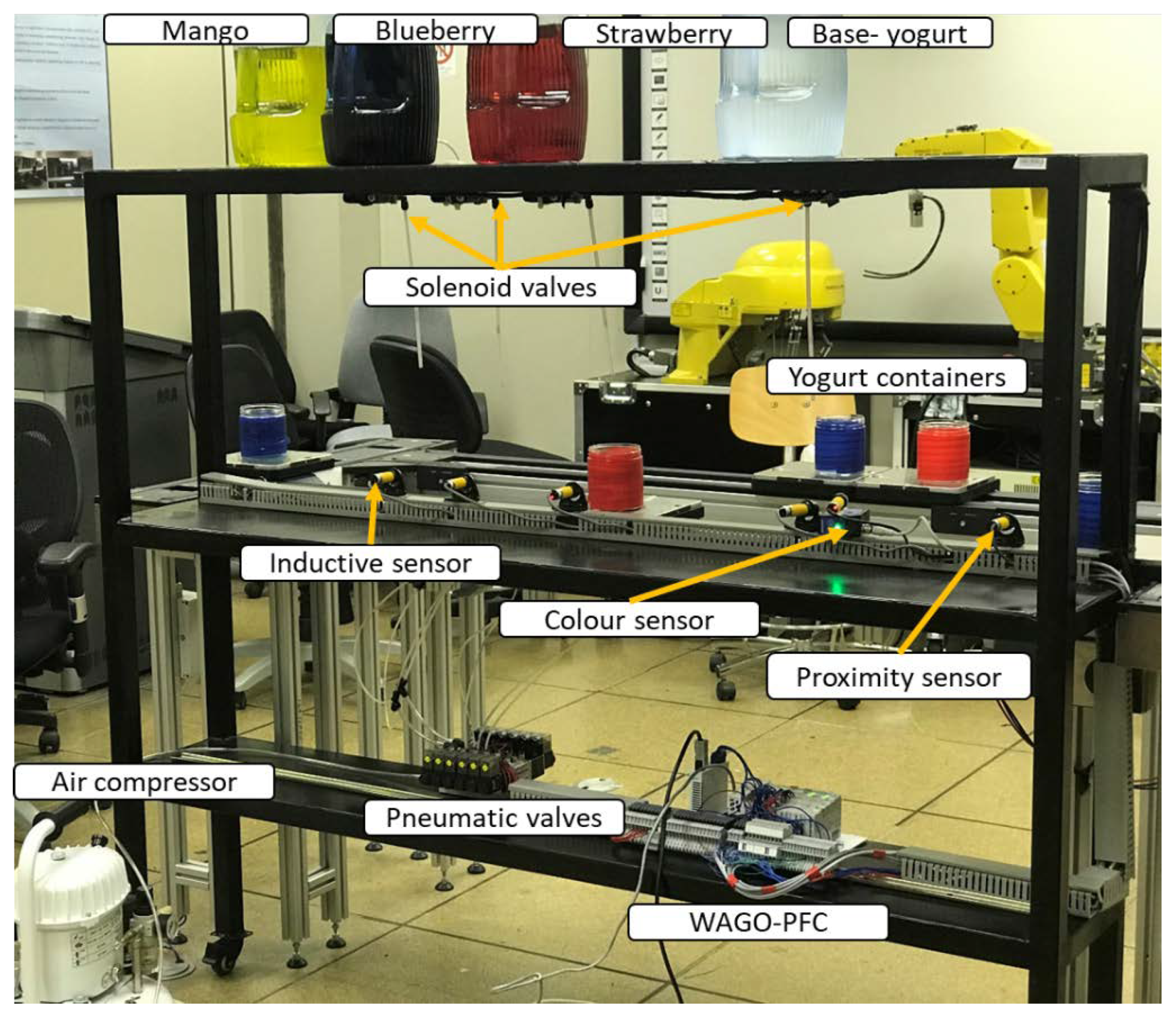

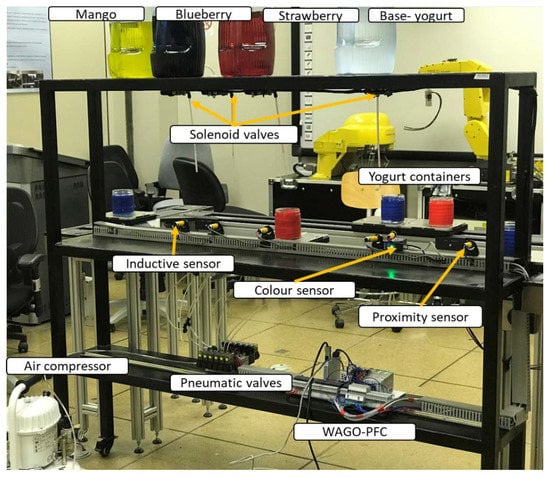

The IED/KSU’s inventiveness to attain familiarity in the Industry 4.0 concept had to begin from scratch. A realistic approach, such as mass customization by filling different flavors. The production line has different stages comprising typical applications such as conveying, passing over the base plate, identification, categorizing products planned to implement. A controller from WAGO Kontakttechnik GmbH & Co. KG, which is a German company in Minden that manufactures components for decentralized automation. Programmed in e-Cockpit software in compliance with standard IEC 61131 and WAGO 750-8202 programmable field bus controllers (PFC 200). To achieve an independent smart production line synchronizing various tasks from different controllers, this prework study showed that a sophisticated control software was required because the initial goal was to establish a completely automated plant. All safety steps and counteractive steps added as a programming function to stop product development and to sidestep any misfortunes when carried out in industry. The feasibility of integrating the concept of Industry 4.0 has demonstrated by developing different scenarios to be applied to our Industry 4.0 lab. Figure 6 shows our testing scheme in the Industry 4.0 lab at KSU. It is also a smart reconfigurable manufacturing system (RMS) developed step by step from scratches [48]. The latest development was done by [49], where a virtual reality system was integrated with it; thus, students can anticipate the RMS design, interact with, and understand its operations, and evaluate its performance.

Figure 6.

Designed smart production plant/system design and implementation.

The student had to deploy these configurations on the shop floor. Therefore, each group had to develop control modules using PLCs to interconnect equipment and allow system communication. Control modules developed using a system engineering methodology based on the new version of IEC 61131. They support Object Orientation [50] so that the control modules can be reused and deployed several times on similar modules with reduced customization.

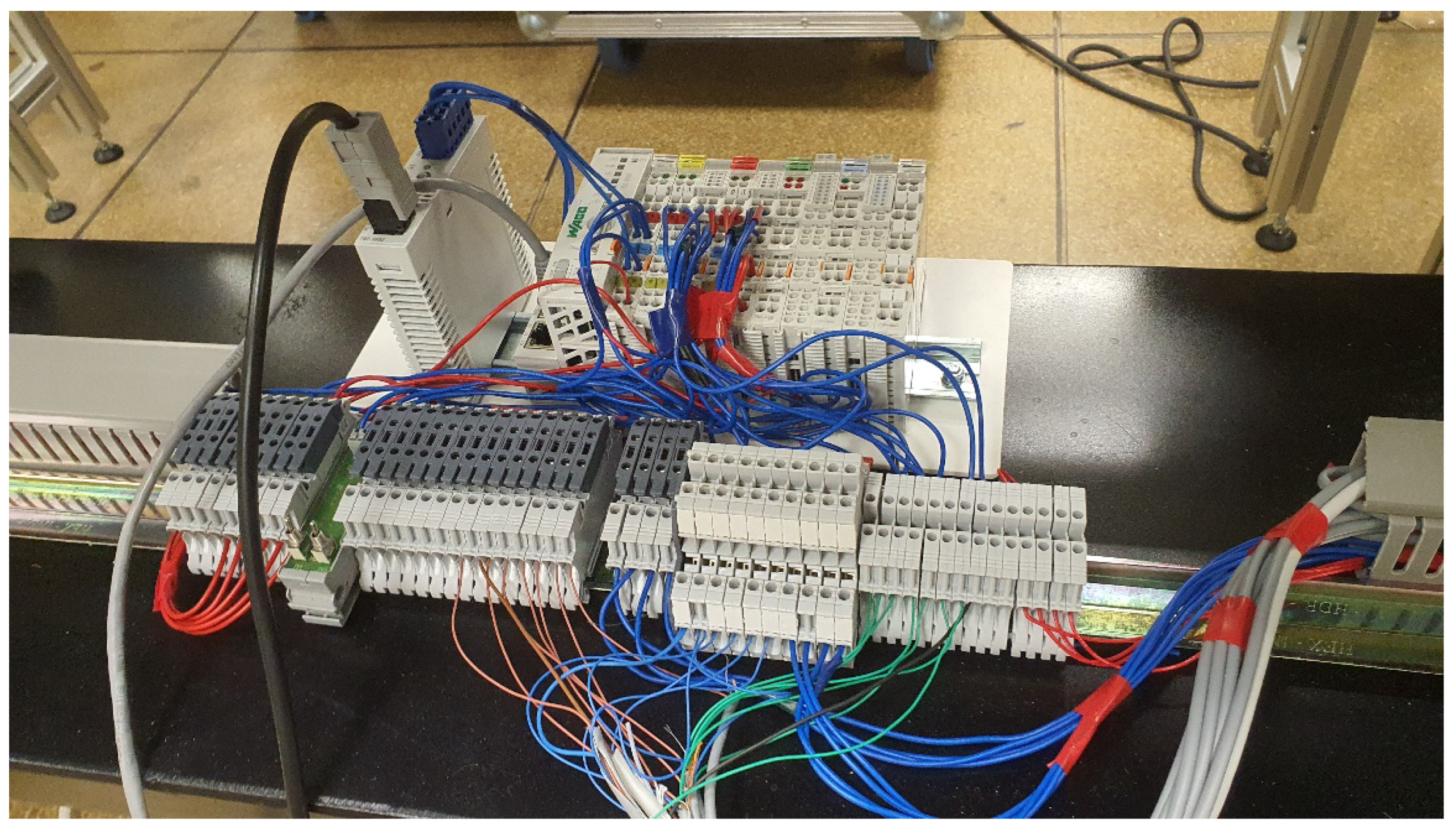

2.5.3. System Design and Implementation

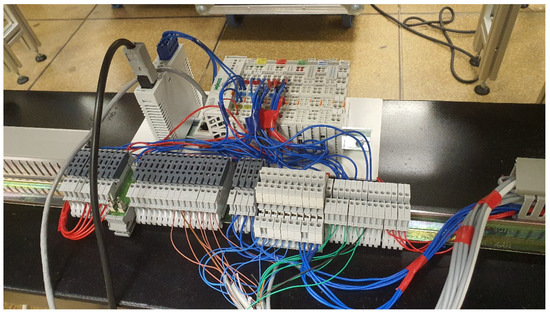

Security features and IT infrastructure in remote applications supported, firewall, web server, data processing at high speed, made us choose a WAGO Programmable Field Controller (PFC) 750-8100 (Figure 7). Both devices were located in the same subnet to ensure that the host personal computer (PC) could communicate with the controller via Ethernet. The IP address that adapts the system structure ensures the PC and the controller communicate with one another using the Web-Based Management (WBM) configuration tool.

Figure 7.

WAGO programmable field controller (PFC) 750-8100.

In a customized sequential task, active information received from sensors execute several sequence tasks. Students, by uploading the written program from e-Cockpit software (ladder logic) to the PFC accomplish the software work. The completion of hardware installation, including all sensors, solenoid valves, and the WBM configuration to monitor operational status were achieved. At each step of the filling process, the crucial information from the photoelectric sensor is essential—an independent product to get interconnected via operational data to the controller. To finally finish product coordination of information from the product itself is mandatory to achieve mass customization. The complexities of system design, monitoring, operation, and control of the production line included in this short-term course, especially a product (i.e.,) desired yogurt filling with different flavors supported students in understanding concepts. We can access PFC with the Internet via remote access to view product development from any location. An automatic yogurt filling machine in Figure 8, developed by a layout from students with existing lab equipment, demonstrates practical operation in industry complications. Inspired by RMS and within a smart factory, the intention was that products could share information or essential data. Increased flexibility by splitting value-oriented responsibilities and its complexity of coordination can reduce. Experiments are also determined on whether the process is time-driven execution or whether event-driven executions are to be performed.

Figure 8.

Production design layout.

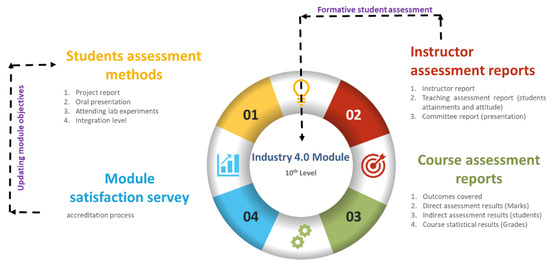

3. Course Evaluation Process

With the purpose of measuring the teaching effectiveness, the proposed evaluation process (Figure 9) had been adapted for the industrial engineering students in 10th-level based on four elements: (1) project report, (2) oral presentation, (3) attending lab experiments (4), and course instructor evaluation report.

Figure 9.

Curricular evaluation process designed and implemented by the University of King Saud-College of Engineering.

3.1. Student Direct Assessment

Student’s academic performance was measured based on a variety of methods of semester work. The course outcomes are aligned with IED/KSU outcomes, which fall within four domain categories: (1) knowledge, (2) cognitive skills, (3) interpersonal skills and responsibility (4) communication, information technology, and numerical skills. The course outcomes are numbered and listed in Table 1 where the results of the student direct assessment for the three groups are presented in Table 2.

Table 1.

Course learning outcomes.

Table 2.

Direct assessment results.

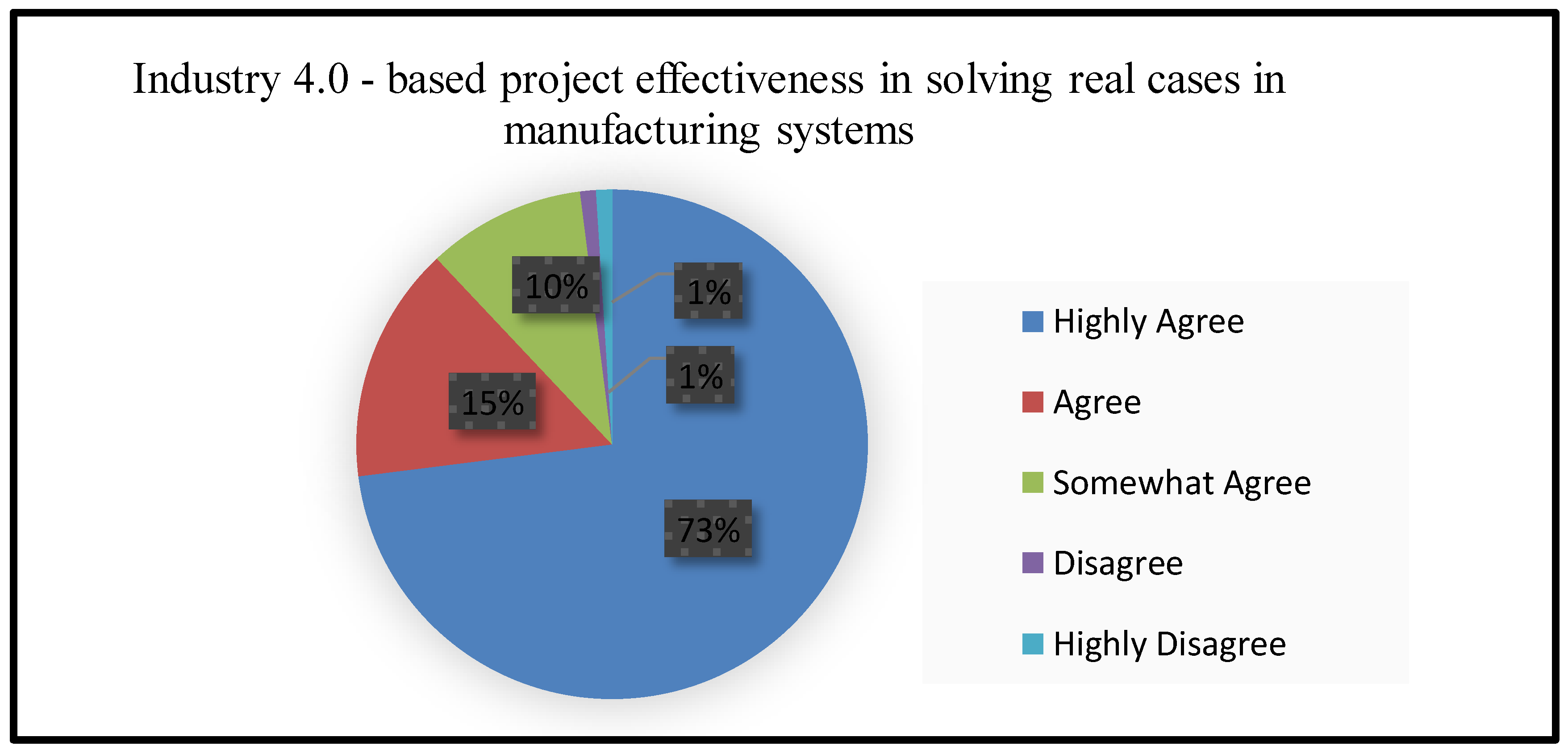

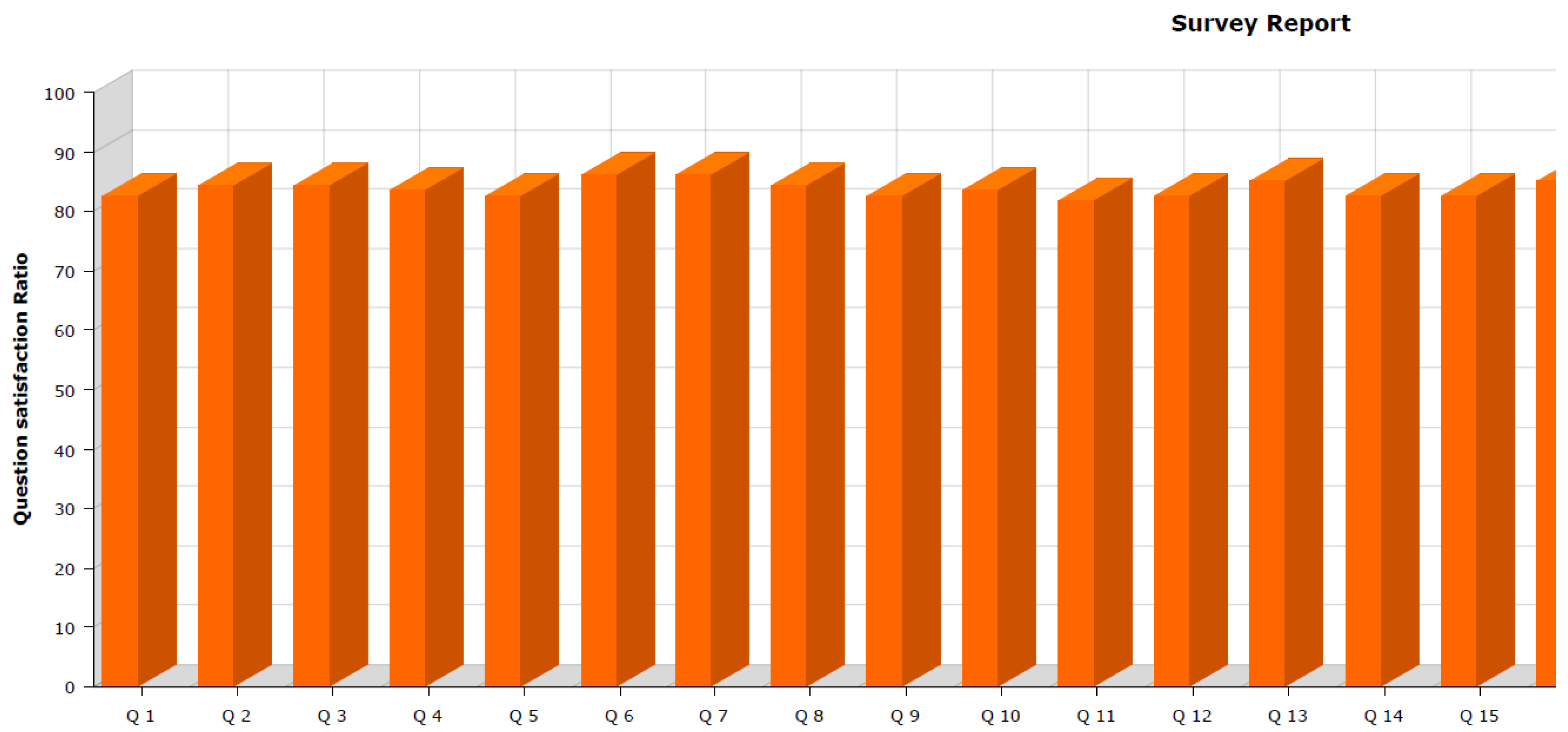

3.2. Student Indirect Assessment

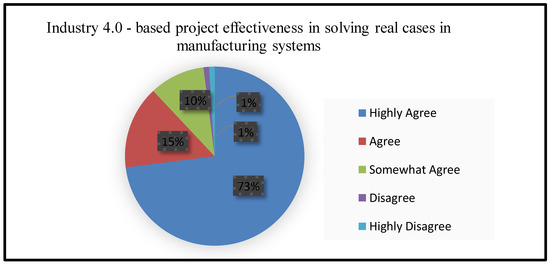

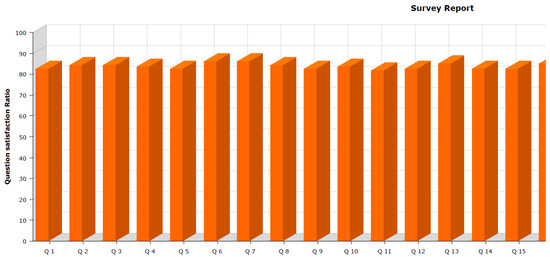

A survey has been designed and distributed to a sample of 48 graduates (two sections) to obtain their response scores related to course organization, methodology, supervisors, and acquired skills. The survey was distributed during the final examination period to obtain a full response. The results shown in (Figure 10) indicates that most of the graduates believe in the effectiveness of Industry 4.0-based projects in solving real cases in manufacturing systems. Finally, (Figure 11) shows the overall results of the students distributed surveys (48 graduated), and the average rating scores of the level of achievement of all questions are above the target benchmark of 75%. Therefore, the student’s satisfaction ration satisfaction ratio was acceptable and above the benchmark.

Figure 10.

Percentages of graduates respond to their effectiveness in solving real cases in the manufacturing system.

Figure 11.

Course satisfaction ratio.

4. Discussion and Conclusions

This paper emphasizes the learning methodology for engineering graduates to upgrade their knowledge about Industry 4.0 and boost their potential by illuminating the facts about the concept Industry 4.0. In this systematic way, we had achieved our first phase in establishing a platform to develop and imply one of the Industry 4.0 pillar concepts. This procedural way of evaluating students concerning the tasks they had accomplished in an orderly logical arrangement, as advised by their supervisor, was highly appreciated. This methodology had translated student’s potential from their theoretical background from applied instrumentation harmonizing the cyber-physical system by direct, deductive, and demonstrative technique is proposed below in an elaborated manner. By this methodology, we expect to induce a robust engineering curriculum that consists of mechatronics and digitalized instrumentation related to pillars of Industry 4.0 in scope. In the future, our Industrial Engineering syllabus shall focus on the results obtained from our evaluation reports obtained by implementing the above-prescribed methods. We strongly recommended specific policy implications in our department that had been highly appreciated by the syndicate members of our University. Specifically, the need to have a skilled faculty development program, strengthen research collaboration, enhanced research quality, and increased research funding to promote and enhance the department’s research culture.

Moreover, we had built the production line to be continuously self-optimizing and supportive of any concrete actions. In this phase, we have attained three significant objectives based on the adopted research methodology. By bypassing conventional methods and utilizing smart design (additive manufacturing), 3D printed the missing mechanical component of the conveyor system was the first objective. Smart monitoring using WAGOWebVisu (a user-friendly interface) was the second objective. To support detecting and monitoring various atypical events in pneumatic piston stoppers, solenoid valves, sensors during the filling process of yogurt containers. The third objective, smart control of the production line, with the help of WAGO Web-based management, such as controlling the operations online via the Internet, was accomplished. More specifically, our concept with the concept Industry 4.0 states and supports our argument that it is just not replacing humans with robotics equipment or advanced technologies. However, it obliges the need for highly skilled (technically sound) human resources to design, program, monitor, manage, and maintain the smart factory.

This paper provides an authentic case study to demonstrate how engineering technology could benefit from the concept of Industry 4.0 and how to educate young graduates about the new Industrial 4.0 era. Future improvements to the course directed towards more formal and practical rapprochement with systems engineering methodologies [49]. Also, we have the intention to evaluate and assess the course outcomes with industrial partners, collect their opinions and suggestions, and include them to improve the course content. Thus, for our engineering graduates, this short-term course about Industry 4.0 created valuable and provoking awareness. By the long stretch, this paper will establish the core ideas required for industrial engineering graduates to excel in Industry 4.0.

Author Contributions

Conceptualization B.S.; data creation S.K.; formal analysis B.S., and S.K.; funding acquisition, B.S.; investigation S.K.; methodology B.S., and S.K.; project administration B.S.; resources B.S.; software S.K.; supervision B.S.; validation S.K. and N.G.; visualization S.K.; writing—original draft B.S., S.K. and M.R.; writing—review and editing M.R. and N.G.; All authors have read and agreed to the published version of the manuscript.

Funding

This study received funding from King Saud University through researchers supporting project number (RSP-2020/145). And the APC was funded by King Saud University through researchers supporting project number (RSP-2020/145).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Thoben, K.D.; Wiesner, S.A.; Wuest, T. “Industrie 4.0” and Smart Manufacturing—A Review of Research Issues and Application Examples. Int. J. Autom. Technol. 2017, 11, 8100. [Google Scholar] [CrossRef]

- Andulkar, M.; Le, D.T.; Berger, U. A multi-case study on Industry 4.0 for SME’s in Brandenburg, Germany. In Proceedings of the 51st Hawaii International Conference on System Sciences, Hilton Waikoloa Village, HI, USA, 3–6 January 2018. [Google Scholar]

- Posada, J.; Toro, C.; Barandiaran, I.; Oyarzun, D.; Stricker, D.; De Amicis, R.; Pinto, E.B.; Eisert, P.; Dollner, J.; Vallarino, I. Visual Computing as a Key Enabling Technology for Industrie 4.0 and Industrial Internet. IEEE Comput. Graph. Appl. 2015, 35, 26–40. [Google Scholar] [CrossRef] [PubMed]

- Li, L. Technological Forecasting & Social Change China’s manufacturing locus in 2025: With a comparison of “Made-in-China” and “Industry 4.0”. Technol. Forecast. Soc. Chang. 2018, 135, 66–74. [Google Scholar]

- Xu, L.D.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar] [CrossRef]

- Society 5.0: The Big Societal Transformation Plan of Japan. Available online: https://www.i-scoop.eu/industry-4-0/society-5-0/ (accessed on 21 March 2020).

- Alzahrani, A. Markets and language policy in saudi arabia: How the english language can contribute to the success of the Saudi Vision 2030. Int. J. Engl. Lang. Linguist. Res. 2017, 5, 1–12. [Google Scholar]

- Drath, R.; Horch, A. Industrie 4.0—Hit or hype? IEEE Ind. Electron. Mag. 2014, 8, 56–58. [Google Scholar] [CrossRef]

- Zhong, R.Y. RFID data driven performance evaluation in production systems. Procedia CIRP 2019, 81, 24–27. [Google Scholar] [CrossRef]

- Tang, L.; Cao, H.; Theng, L.; Huang, N. Value-driven uncertainty-aware data processing for an RFID-enabled mixed-model assembly line. Int. J. Prod. Econ. 2015, 165, 273–281. [Google Scholar] [CrossRef]

- Gjeldum, N.; Salah, B.; Aljinovic, A.; Khan, S. Utilization of Industry 4.0 Related Equipment in Assembly Line Balancing Procedure. Processes 2020, 8, 864. [Google Scholar] [CrossRef]

- Buer, S.V.; Strandhagen, J.O.; Chan, F.T.S. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Kagermann, H.; Wahlster, W.; Helbig, J. Recommendations for Implementing the Strategic Initiative INDUSTRIE 4.0—Securing the Future of German Manufacturing Industry’, Technical Report; Acatech—National Academy of Science and Engineering: München, Germany, 2013. [Google Scholar]

- MacDougall, W. Industry 4.0 Smart Manufacturing for the Future; German Trade and Invest: Berlin, Germany, 2014. [Google Scholar]

- Gorecky, D.; Schmitt, M.; Loskyll, M.; Zühlke, D. Human-machine-interaction in the industry 4.0 era. In Proceedings of the 12th IEEE International Conference on Industrial Informatics (INDIN), Porto Alegre, Brazil, 27–30 July 2014; pp. 289–294. [Google Scholar]

- Yue, X.; Cai, H.; Yan, H.; Zou, C.; Zhou, K. Cloud-assisted industrial cyber-physical systems: An insight. Microprocess. Microsyst. 2015, 39, 1262–1270. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of Industry 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 1–10. [Google Scholar] [CrossRef]

- Industry 4.0: The Fourth Industrial Revolution Guide to Industrie 4.0. Available online: https://www.i-scoop.eu/industry-4-0/ (accessed on 11 June 2020).

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2018, 101, 1–12. [Google Scholar] [CrossRef]

- Ramadan, M.; Salah, B. Smart Lean Manufacturing in the Context of Industry 4.0: A Case Study. Int. J. Ind. Manuf. Eng. 2019, 13, 174–181. [Google Scholar]

- Rojko, A. Industry 4.0 Concept: Background and Overview. Int. J. Interact. Mob. Technol. 2017, 11, 77–90. [Google Scholar] [CrossRef]

- Leiden, A.; Posselt, G.; Bhakar, V.; Singh, R.; Sangwan, K.S.; Hermann, C. Transferring Experience Labs for Production Engineering Students to Universities in Newly Industrialized Countries. In Proceedings of the IOP Conference Series: Materials Science and Engineering, 297, TSME-International Conference on Mechanical Engineering (TSME-ICoME 2017), Bangkok, Thailand, 12–15 December 2018. [Google Scholar]

- Sackey, S.M.; Bester, A. Industrial engineering curriculum in Industry 4.0 in a South African context. S. Afr. J. Ind. Eng. 2016, 27, 101–114. [Google Scholar] [CrossRef]

- Khan, R.; Khan, S.U. Design and implementation of an automated network monitoring and reporting back system. J. Ind. Inf. Integr. 2018, 9, 24–34. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Al-Ahmari, A.; Salah, B.; Alkhalefah, H. Requirements of the smart factory system: A survey and perspective. Machines 2018, 6, 23. [Google Scholar] [CrossRef]

- Arnold, C.; Kiel, D.; Voigt, K. How the Industrial Internet of Things Changes Business Models in Different Manufacturing Industries. Int. J. Innov. Manag. 2016, 20, 1–25. [Google Scholar] [CrossRef]

- Wan, J.; Cai, H.; Zhou, K. Industrie 4.0: Enabling technologies. In Proceedings of the 2015 International Conference on Intelligent Computing and Internet of Things, Harbin, China, 17–18 January 2015; pp. 135–140. [Google Scholar]

- Moeuf, A.; Pellerin, R.; Lamouri, S.; Tamayo-Giraldo, S.; Barbaray, R. The industrial management of SMEs in the era of Industry 4.0. Int. J. Prod. Res. 2018, 56, 1118–1136. [Google Scholar] [CrossRef]

- Frank, A.G.; Dalenogare, L.S.; Ayala, N.F. Industry 4.0 technologies: Implementation patterns in manufacturing companies. Int. J. Prod. Econ. 2019, 210, 15–26. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; Boston Consulting Group (BCG): Boston, MA, USA, 2015. [Google Scholar]

- Mladineo, M.; Veza, I.; Gjeldum, N. Solving partner selection problem in cyber-physical production networks using the HUMANT algorithm. Int. J. Prod. Res. 2017, 55, 2506–2521. [Google Scholar] [CrossRef]

- Zhou, K.; Liu, T.; Liang, L. From cyber-physical systems to Industry 4.0: Make future manufacturing become possible. Int. J. Manuf. Res. 2016, 11, 167–188. [Google Scholar] [CrossRef]

- Gürdür, D.; El-Khoury, J.; Seceleanu, T.; Lednicki, L. Making Interoperability Visible: Data Visualization of Cyber-physical Systems Development Tool Chains. J. Ind. Inf. Integr. 2016, 4, 26–34. [Google Scholar] [CrossRef]

- Liu, F.; Tan, C.; Lim, E.; Choi, B. Traversing Knowledge Networks: An Algorithmic Historiography of Extant Literature on the Internet of Things (IoT). J. Manag. Anal. 2017, 4, 3–34. [Google Scholar] [CrossRef]

- The Nine Pillars of Industry 4.0. Available online: http://enovect.com/the-nine-pillars-of-industry-4-0/ (accessed on 17 July 2020).

- Blockchain Meets Industry 4.0—What Happened Next? Available online: https://www.allerin.com/blog/5659-2 (accessed on 14 July 2020).

- Motyl, B.; Baronio, G.; Uberti, U.; Speranza, D.; Filippi, S. How will change the future engineers’ skills in the Industry 4.0 framework? A questionnaire survey. Procedia Manuf. 2017, 11, 1501–1509. [Google Scholar] [CrossRef]

- Abele, E.; Metternich, J.; Tisch, M.; Chryssolouris, G.; Sihn, W.; ElMaraghy, H.; Hummel, V.; Ranz, F. Learning factories for research, education, and training. Procedia CIRP 2015, 32, 1–6. [Google Scholar] [CrossRef]

- Krückhans, B.; Morlock, F.; Prinz, C.; Freith, S.; Kreimeier, D.; Kuhlenkötter, B. Learning Factories qualify SMEs to operate a smart factory. In Proceedings of the COMA’16 Proceedings: International Conference on Competetive Manufacturing, Wallenber centre, Stellenbosch, South Africa, 27–29 January 2016; pp. 457–460. [Google Scholar]

- Kreimeier, D.; Morlock, F.; Prinz, C.; Krückhans, B.; Bakir, D.C.; Meier, H. Holistic learning factories. Procedia CIRP 2014, 17, 184–188. [Google Scholar] [CrossRef]

- Steffen, M.; May, D.; Deuse, J. The Industrial Engineering Laboratory. In Proceedings of the 2012 IEEE Global Engineering Education Conference (EDUCON), Marrakech, Morocco, 17–20 April 2020. [Google Scholar]

- Sackey, S.M.; Bester, A.; Adams, D. Industry 4.0 learning factory didactic design parameters for industrial engineering education in South Africa. S. Afr. J. Ind. Eng. 2017, 28, 114–124. [Google Scholar] [CrossRef]

- Götting, M.; Gosewehr, F.; Müller, M.; Wermann, J.; Zarte, M.; Colombo, A.W.; Pechmann, A.; Wings, E. Methodology and case study for investigating curriculums of study programs in regard to teaching industry 4.0. In Proceedings of the 15th International Conference on Industrial Informatics (INDIN) IEEE, Emden, Germany, 24–26 July 2017; pp. 533–538. [Google Scholar]

- Wermann, J.; Colombo, A.W.; Pechmann, A.; Zarte, M. Using an interdisciplinary demonstration platform for teaching Industry 4.0. Procedia Manuf. 2019, 31, 302–308. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Chin, J.; Show, P.L.; Yang, T.C.K.; Huang, C.-M. Integration of 3D printing and Industry 4.0 into engineering teaching. Sustainability 2018, 10, 3960. [Google Scholar] [CrossRef]

- Frerich, S.; Meisen, T.; Richert, A.; Petermann, M.; Jeschke, S.; Wilkesmann, U.; Tekkaya, A.E. Engineering Education 4.0 Excellent Teaching, and Learning in Engineering Sciences, 1st ed.; Springler International Publishing AG: Cham, Switzerland, 2016. [Google Scholar]

- 3S—Smart Software Solutions GmbH. User Manual for PLC Programming with Codesys 2.3, 11th ed.; 3S—Smart Software Solutions GmbH: Kempten, Germany, 2010. [Google Scholar]

- Salah, B.; Khan, S.; Gjeldum, N. An Automatic Yogurt Filling System Built from Scratch Based on Industry 4.0 Concept. Trans. Famena. 2020, 44, 59–70. [Google Scholar] [CrossRef]

- Salah, B.; Abidi, M.H.; Mian, S.H.; Krid, M.; Alkhalefah, H.; Abdo, A. Virtual reality-based engineering education to enhance manufacturing sustainability in industry 4.0. Sustainability 2019, 11, 1477. [Google Scholar] [CrossRef]

- Thramboulidis, K.A. Framework for the Implementation of Industrial Automation Systems Based on PLCs. arXiv 2014, arXiv:1402.3920. Available online: https://arxiv.org/abs/1402.3920 (accessed on 13 January 2014).

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).