Abstract

Multi-arm caliper logging tools provide a high-precision technology for monitoring tubing and casing integrity. However, due to the wellbore structure of horizontal wells and the self-weight of the instrument, the multi-arm caliper logging data of horizontal wells typically exhibit obvious eccentricity, resulting in a high misjudgment probability in the quantitative evaluation of oil and casing pipe damage. In this manuscript, simulation experiments were conducted using the 5.5-inch casing under laboratory conditions. The experiments clarified the response characteristics of forty-arm caliper logging tools in centered and eccentric states within intact and damaged casing. An equivalent model combining the instrument and the horizontal pipe structure was established, and a new method for correcting instrument eccentricity based on the forty-arm caliper logging data in horizontal wells was developed through theoretical analysis. The proposed model effectively overcomes the limitations of existing correction methods under casing damage conditions, reducing the relative error by up to 0.53% and 1.16% in intact and damaged well sections, respectively, compared to the ellipse-fitting algorithm. This effectively improves the correction coincidence rate for eccentricity influence of multi-arm caliper logging tools under various conditions in horizontal well. Applying this established method to the processing and interpretation of forty-arm caliper logging data in horizontal wells provides robust technical support for the high-precision quantitative evaluation, damage location identification, and repair of horizontal well casing.

1. Introduction

Global demand for oil and natural gas continues to surge, making the exploitation and development of unconventional oil and gas reservoirs increasingly important for petroleum engineers [1,2,3]. Due to the poor physical properties of these unconventional reservoirs, horizontal wells and volume fracturing technology have emerged as effective development strategies [4,5]. However, several factors during development—such as hydraulic fracturing, corrosive fluid, and changes in crustal stress—can damage tubing and casing. Common types of damages include corrosion, misalignment, deformation, and perforation, and these damages significantly impair normal oil and gas production [6,7,8]. By 2021, Chinese oil fields reported over 30,000 wells with tubing and casing damage, with major fields all experiencing damage rates exceeding 20%. Globally, some oil fields face alarming casing failure rates of up to 50% [9,10,11]. Consequently, accurate detection and quantification of tubing and casing damage have become crucial for effective repair operations.

Monitoring tubing and casing damage presents major challenges, particularly in horizontal wells. The complexity of wellbore structure makes it challenging to transport logging instruments downhole and maintain proper centering, especially compared to vertical wells. Current casing damage monitoring technologies include multi-finger imaging tool, e.g., MIT [12,13,14,15], ultrasonic testing technology [16,17,18,19,20,21] and electromagnetic detection technology [22,23,24,25], e.g., MTT (Magnetic Thickness Tool) [16,17,18,19,20,21,22,23,24,25,26,27,28], MID-K/S (Magnetic Inspection Device-K/S) [29,30,31,32], TEM (Transient Electromagnetic Tool) [33,34,35], etc. Among these techniques, the MIT stands out as the most widely used method for wellbore integrity monitoring due to its effectiveness and cost efficiency. This mechanical device consists of equiangular-spaced tungsten carbide-tipped arms that expand until they contact the inner casing surface. The logging system detects the damage by recording voltage signal variations caused by arm extension and retraction when contacting damaged inner surfaces. When measuring arm pass through the perforations, they extend; conversely, they retract when encountering scaling. To maximize coverage of the casing shaft section, MIT designs include varying numbers of arms (24, 40, 64, 80, and 120) suitable for different casing sizes. Despite this range, defects shorter than the circumferential distance between adjacent arms may remain undetected. Furthermore, the instrument’s relatively simple mechanical structure makes it susceptible to various influences, especially in horizontal wells. In horizontal well sections, the instrument’s gravity often causes eccentricity during measurement, even when stabilizers are installed [36,37,38]. This eccentricity phenomenon will finally cause the measured caliper values of each arm to differ from one another, and seriously impact the final interpretation and mislead casing damage identification. Therefore, it is necessary to perform eccentricity correction and then provide accurate information for the integrity evaluation of the casing in horizontal wells.

Existing MIT eccentricity correction methods include opposite side compensation method [39], circle-fitting algorithm [38,40,41,42,43,44,45,46], ellipse-fitting algorithm [43], center of mass method [43,47], chord approach [44,46,47,48,49,50], and confined best-fit circle method [47]. However, these methods all have significant application limitations and cannot fully adapt to the complex working conditions of horizontal wells (such as casing perforation, large key-seats, and severe eccentricity). The opposite side compensation method is only suitable for vertical direction arm correction and wells with deviation angle less than 45° and no asymmetric damage [39]. The circle-fitting algorithm works for undamaged sections but produces numerous erroneous judgments in damaged casing sections [40,41,47]. The ellipse-fitting method improves adaptability to elliptical boreholes but fails in casing perforation or multi-arm key-seat scenarios [44,46,47,49]. The center of mass method and chord approach have defects such as systematic offset and poor adaptability to non-circular boreholes [43,47]. The confined best-fit circle method is only applicable to open-hole logging without borehole shrinkage and cannot address casing damage scenarios [43,46,47]. Currently, no single method can achieve optimal eccentricity correction across all situations, especially in horizontal well casing damage monitoring. The limitations of existing methods lead to insufficient correction accuracy, which affects the reliability of damage location and evaluation results.

Currently, no single method provides optimal decentralization corrections for an MIT across all situations. For undamaged tubing and casing, all methods are applicable, except for the center of mass method. The chord method shows best performance in a small key-seat scenario [43], while the circular algorithm provides satisfactory results [44]. For a large key-seat scenario, the ellipse-fitting method calculates tool centers accurately, though with a greater offset than the actual tool centers. Among the primary algorithms, ellipse-fitting and chord methods deliver the best tool for eccentricity corrections. However, methods that fit well diameter curves from instrument monitoring, including circle-fitting, ellipse-fitting, and chord approaches, often fail to detect localized casing damage.

A new eccentricity correction method is needed for a MIT used in horizontal wells. Our proposed method aimed to perform corrections under various conditions, providing effective technical support for monitoring and evaluating tubing and casing damage in horizontal wells, precisely locating damage, and guiding repair operations.

The paper is organized as follows: the design of physical simulation experiments and the experimental results are elaborated in Section 2. In Section 3 we present the eccentricity correction method, which is implemented through three different working conditions. Finally, Section 4 and Section 5 are devoted to the presentation of the discussion and conclusion, respectively.

2. Experiments and Results

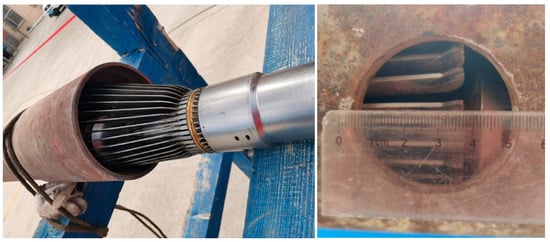

To simulate MIT response in horizontal wells, we conducted experiments using a 40-arm caliper logging tool at the Xinjiang Branch of China National Logging Group Co., Ltd., Karamay District, Xinjiang Uygur Autonomous Region, China. The experimental system consists of the ground information acquisition system, signal control and transmission system, 40-arm caliper logging tool, casing with different inner diameters, and damage designs. The 40-arm caliper logging tool (Figure 1) (WELL-SUN Company, Xi’an Shanxi, China) features an outside diameter of 2.875 in (73.03 mm) and a length of 61.97 in (1574.04 mm). The tool measurement range spans from 2.9 to 7.5 in (73.66–190.5 mm), with a radius measurement accuracy of ±0.03 in (±0.762 mm), and a resolution of 0.005 in (0.127 mm).

Figure 1.

The forty-arm caliper logging tool used in this study.

The horizontal well bore simulation employed a 32.38 ft (9.87 m) long, 5.5-inch (139.7 mm) diameter casing section with a 0.304 in (7.72 mm) wall thickness. Each casing section has a total length of 32.38 ft (9.87 m), with damage (i.e., holes and cracks) distributed over 8.300 ft (2.53 m) (Figure 2 and Figure 3). Holes of varying diameters (1.949 in (49.5 mm) and 1.173 in (29.8 mm)) were designed, spaced at ~7.677 in (195 mm) intervals. The cracks were designed in vertical and horizontal structures, measuring 1 and 3 cm in width, respectively. These diverse damage patterns allowed us to comprehensively evaluate the 40-arm caliper logging tool’s response under both centralization and eccentricity conditions.

Figure 2.

Simulation experiment platform used in this study.

Figure 3.

Images of artificially made holes and cracks used in this study.

The experiment steps are as follows:

First, the casing was horizontally fixed to simulate the horizontal wellbore. The 40-arm caliper logging tool was connected with the ground information acquisition equipment via a power cable and powered on to ensure a normal operation. Prior to formal measurement, the tool was calibrated against a standard graduated cylinder featuring five reference scales (3.125, 4, 5, 6, and 7 inches) to eliminate systematic errors and establish a baseline for accurate measurement in the centered wellbore position (Figure 4).

Figure 4.

Calibration of the multi-caliper logging tool used in this study.

Secondly, we inserted the 40-arm caliper logging tool into the casing and positioned it at the toe of the casing. All measurement data were recorded during the uniform lifting process. We conducted measurements in both intact and damaged casings, and repeated both continuous logging and fixed-point measurement twice to ensure data stability and accuracy. For experiments with the damaged casing, we simulate eccentricity by omitting the centralizer from the multi-arm caliper logging tool string. After installation, we recorded continuous measurements during uniform upward tool movement, with repeated trials ensuring data reliability (Figure 5 and Figure 6). We then performed stationary point measurements under eccentric conditions at multiple depth positions under identical experimental parameters. Subsequently, we installed centralizers on the multi-arm caliper tool to achieve centralization, enabling comparative continuous and point measurements in both centralized and eccentric configurations for damaged casing evaluation. The continuous logging and discrete point measurements were followed by centralized measurements with centralizers during both constant-velocity tool movement and stationary acquisition phases (Figure 7). All experimental configurations incorporated repeated measurement principles to validate measurement repeatability and ensure experimental reliability. This comprehensive approach allowed us to establish the response characteristics of the 40-arm caliper logging tool under varying centralization conditions for both intact and damaged casing geometries.

Figure 5.

Eccentric passage of the caliper logging tool through the test casing (total length: 32.38 ft (9.87 m)) and holes (typical example: 1.949 in (49.5 mm)).

Figure 6.

The initial and repeated measurement curves in the intact casing when the instrument is under a centralized condition.

Figure 7.

The initial and repeated measurement curves in the intact casing when the instrument is under an eccentric condition.

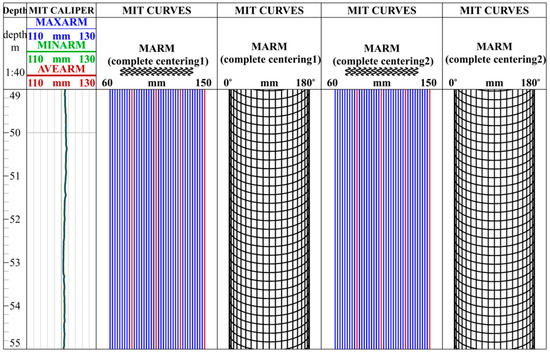

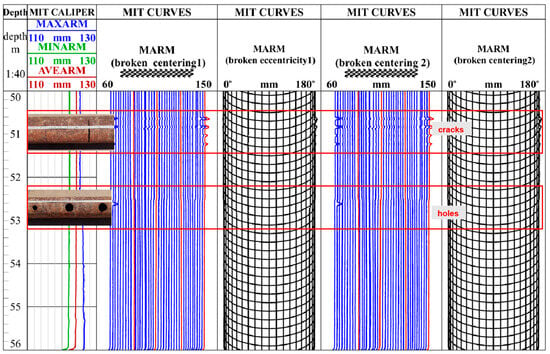

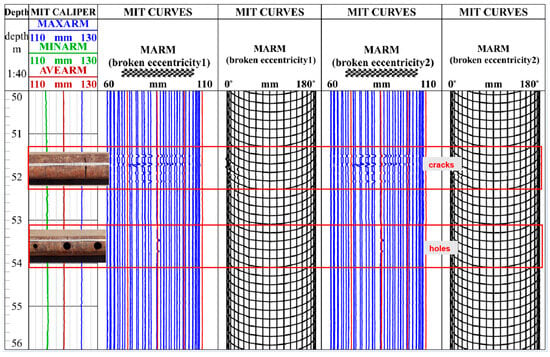

The instrument response curves obtained from centering and eccentric measurements in both intact and damaged casings are shown in Figure 6, Figure 7, Figure 8 and Figure 9. Figure 6 and Figure 7 display measurement curves under central and eccentric conditions in an intact casing, respectively. In these figures, the first track indicates the hole and crack positions; the second track shows maximum, minimum, and average wellbore diameter values; and the third through sixth tracks present raw multi-caliper values from the first to second continuous measurements.

Figure 8.

The initial and repeated measurement curves in the damaged casing with different holes and cracks when the instrument is under a centralized condition.

Figure 9.

The initial and repeated measurement curves in the damaged casing with different holes and cracks when the 40-arm caliper logging tool is under an eccentric condition.

Figure 8 and Figure 9 illustrate the measurement curves of the instrument under central and eccentric conditions in a damaged casing. These curves demonstrate the extension of multi-caliper arms when the instrument passes through cracks and holes. At 51–52 m, the MIT curves of “broken eccentricity 1” and “broken eccentricity 2” on both sides present extensive extrusion signs, while the curve in the middle shows a pronounced increase, indicating casing damage at this position (Figure 8).

A detailed analysis of the results reveals several key observations. The first and repeated measurement curves acquired in the intact casing under central conditions appear as straight lines with nearly identical values, demonstrating excellent measurement repeatability (Figure 6). This consistency occurs as the centralized instrument maintains stable positioning within the undamaged casing. Despite the instrument being in an eccentric position, the “complete eccentricity 1” and “complete eccentricity 2” curves remain relatively straight without obvious deformation (Figure 7). Furthermore, a calculation of the relative deviation based on the measurement 40 arms at different depths shows that the relative deviation for damaged central conditions ranges in 0.011~0.179%, and for damaged eccentric conditions ranges 0.017~1.298%, indicating excellent repeatability. This stability can be attributed to the intact casing, which enables the tool to maintain a stable eccentric state within the wellbore. During monitoring, the measurement signals exhibit minimal fluctuations, resulting in logging curves that appear as essentially straight lines.

However, several potential sources of variation in measurement signals during repeated tests should be noted. Firstly, slight fluctuations in power supply voltage may affect signal transmission. Secondly, mechanical wear of the caliper arm tips after repeated contact with the inner surface of the casing could introduce errors. Thirdly, temperature variations in the laboratory environment may impact the instrument’s electronic components. Lastly, subtle differences in lifting speed during continuous logging measurements might also influence the results. These factors should be considered in future studies to further refine the measurement accuracy and robustness of the method.

The logging responses in the damaged casing with the instrument under central and eccentric conditions are shown in Figure 8 and Figure 9. Under central conditions, the MIT curves exhibit a relatively uniform overall distribution, with localized responses indicating cracks and holes. At crack locations, the logging curves display a serrated pattern, while at holes, the curves show partial subsidence forming single or double sharp tooth-like features. The most significant difference between central and eccentric conditions is the pronounced extrusion deformation under eccentric conditions, manifested as uneven curve distribution. The compressed sections of the curves are relatively densely packed and darker in color, while the stretched sections are relatively sparsely distributed and lighter in color. This phenomenon occurs because the instrument, under the combined influence of its own gravity and eccentric placement, causes the lower measuring arms to compress inward, resulting in underestimated caliper values, while the upper arms stretch outward, leading to overestimated caliper values. Comparing the logging data under central and eccentric conditions in Figure 8 and Figure 9, it is clear that eccentricity extensively impacts logging response. Meanwhile, significant differences in the maximum, minimum, and average inner diameter values are observed between the damaged and intact casing conditions depicted in these figures. When the casing is damaged, the instrument arms extend into holes and fractures, causing the caliper curves to vary in shape; when the casing is intact, the maximum, minimum, and average inner curves essentially overlap.

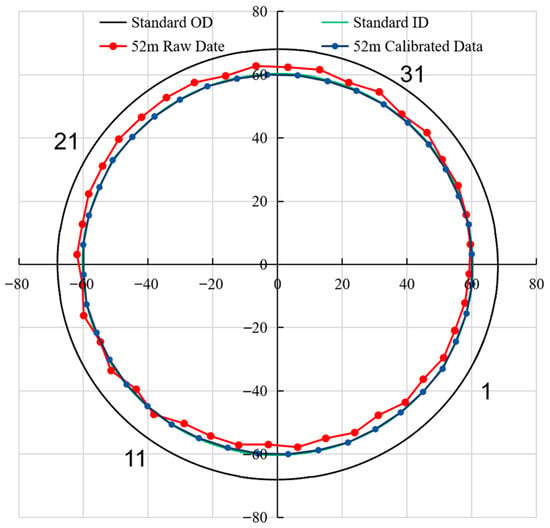

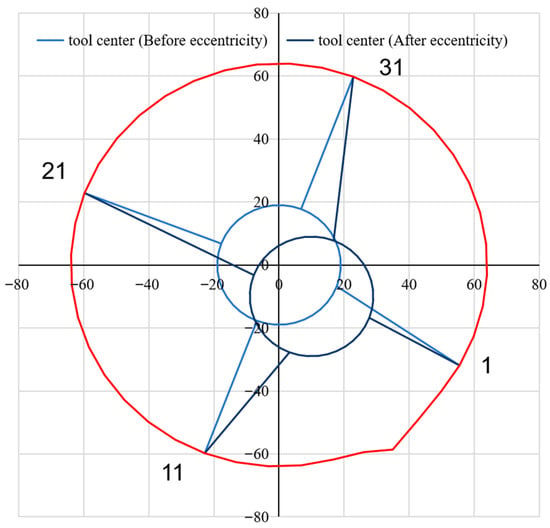

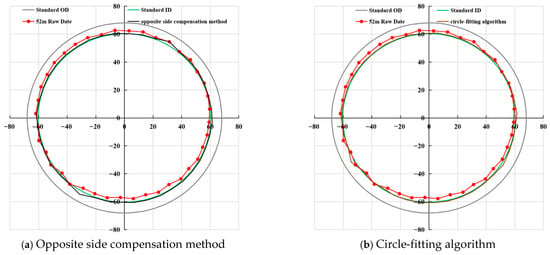

The cross-sectional views before and after eccentricity correction at a depth of 52 m under the condition of a damaged casing with a crack, are shown in Figure 10. When comparing the logging data before and after eccentricity correction, the 52 m raw data reveal an eccentric phenomenon (Figure 10). Instrument eccentricity can substantially cause misjudgment in the quantitative evaluation of oil and casing pipe damage. Therefore, establishing an accurate eccentricity correction method is crucial.

Figure 10.

Cross-sectional views of before and after eccentricity correction.

3. Method

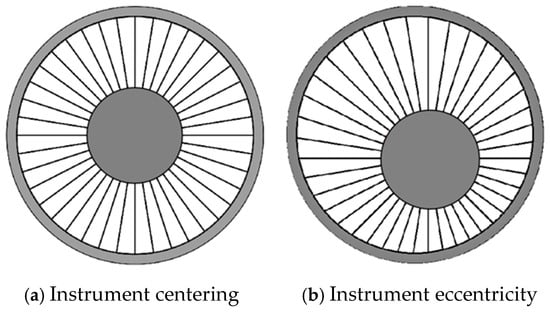

For multi-arm caliper logging tools in the horizontal wells (Figure 11), measurement accuracy is heavily dependent on tool positioning. When the instrument is centrally positioned within the wellbore (Figure 11a), its accuracy reflects the true casing radius. However, when the instrument deviates from the center of the wellbore (Figure 11b), the measured data no longer reflect the true radius even in intact wellbores. Typically, measuring arms near the bottom of the wellbore are compressed, resulting in a decrease in caliper values, while arms near the top extend, causing increased measurements. Given the fixed length of each caliper arm, we can establish an equivalent model combining wellbore structure and instrument positioning. By placing this equivalent model into a two-dimensional coordinate system, we can determine the coordinates of the contact position between the multi-arms and the inner surface of the wellbore could be obtained, then the main task is to obtain the correct center position coordinates of the instrument.

Figure 11.

Schematic diagram of the position of the instrument in the wellbore before and after the horizontal well eccentricity.

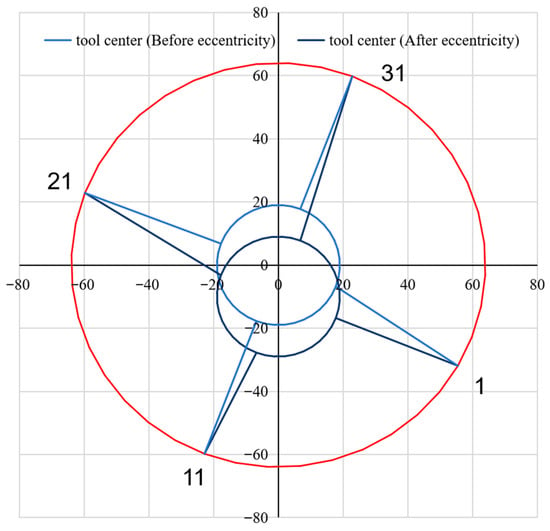

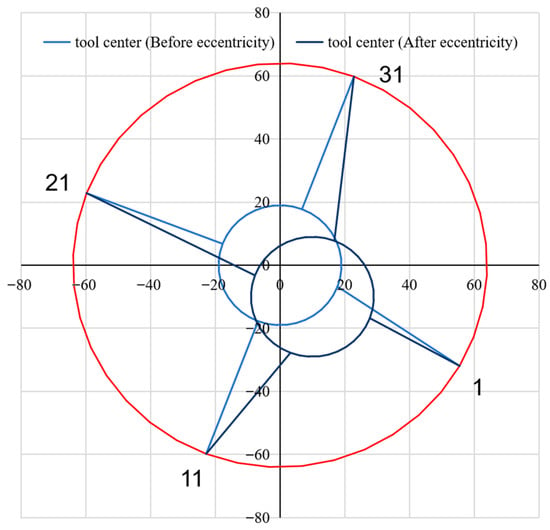

The measured value of a forty-arm caliper logging instrument monitoring is Li (where i represents the arm serial number of the clockwise multi-arm caliper logging tool, with i = 1,2,3,…, 40). The rotation azimuth of arm 1 is ROT1, with adjacent arm angles at 9-degree intervals. Using arm 1 as the x axis and arm 11 as the y axis, the center point of the instrument after eccentricity is taken as the origin of the rectangular coordinate system (0,0). The coordinates of the center wellbore cross-section points are represented by (x0, y0). In Figure 12, Figure 13, Figure 14 and Figure 15, the red circle denotes the inner wall of the wellbore, while the light-blue circle indicates the central position of the instrument before eccentricity and the gray-blue circle signifies its central position after eccentricity.

Figure 12.

Schematic of vertical deviation of the caliper logging instrument.

Figure 13.

Schematic of the axial and horizontal deviation of 40-arm caliper logging instrument (no damage).

Figure 14.

Schematic diagram of axial and horizontal offset of 40-arm caliper logging instrument (broken).

Figure 15.

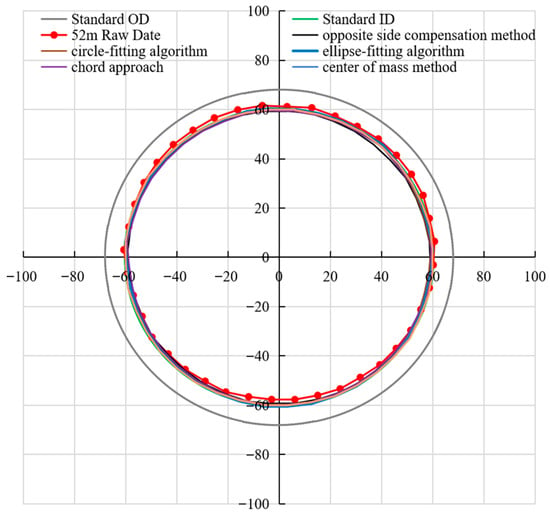

Comprehensive results of various eccentric correction methods under intact casing and instrument centering conditions.

3.1. Eccentricity Correction for Intact Casing (Vertical Deviation Only)

When there is no damage to the casing and an arm is located in the due north direction of the shaft section (Figure 12), the corresponding arm number is,

when no instrument arm is precisely at the top position of the shaft, a decision needs to be made on determining the number of the instrument arm that is closest to the top.

Then obtain the maximum offset distance of the symmetry arm,

the coordinates of the wellbore center are represented by (x0, y0) = (0, Δmax).

The spatial coordinates of each arm before eccentricity are expressed as (xi, yi), the later eccentric coordinates are expressed as (xi′, yi′), which corresponds to a geometric analytical operation; NO is the arm number of the top arm; ROT1 is the azimuth angle of arm 1 monitored by multi-arm well diameter logging instrument, max is the maximum offset distance, mm; Li is the measured well diameter value, mm.

Finally, the eccentricity correction is completed according to the relationship between the coordinate points (0, 0) of the center point of the instrument and the shaft section (0, Δmax) and the coordinates (xi′, yi′), and whether the set loss is judged according to the radius before the eccentricity and the radius after correction.

3.2. Eccentricity Correction for Intact Casing (Vertical and Horizontal Deviation)

When the instrument undergoes both vertical and horizontal deviations (Figure 13), we determine the maximum deviation direction by analyzing the difference values between symmetrical arms. The maximum offset distance of the symmetry arm is

the maximum offset azimuth calculation is as follows:

When ,

Then the central dot coordinates (x0, y0) are expressed as:

When ROTm ≤ 180,

when ROTm > 180,

when ,

then the central dot coordinates (x0, y0) are expressed as:

When ROTm ≤ 180,

when ROTm > 180,

the spatial coordinates of each arm before eccentricity are expressed as (xi, yi), while post- eccentric coordinates are expressed as (xi′, yi′), Δmax is the maximum offset distance, mm; Li is the measured caliper value of the i-th arm, mm; Li+20 is the measured caliper value of the (i + 20)-th arm, mm; ROT1 is the azimuth angle of arm number 1 monitored by the multi-arm caliper logging tool; ROTm is the azimuth angle substituting the azimuth angle of the longest arm when calculating the offset azimuth angle, in degrees; Lm is the measured caliper value of the longest arm when calculating the offset azimuth angle, mm; ROTi is the azimuth angle of the i-th arm monitored by the multi-arm caliper logging tool; x0 is the abscissa value of the center point of the wellbore cross-section, and y0 is the ordinate value of the center point of the wellbore cross-section.

Finally, the eccentricity correction is completed based on the relationship between the coordinate points (0,0) of the center point of the eccentric instrument and the central dot coordinates (x0, y0) of the shaft section, and the eccentric coordinates (xi′, yi′). Casing loss is determined by comparing the radius before the eccentricity and the radius after correction.

3.3. Eccentricity Correction for Damaged Casing

For damaged casings with horizontal and vertical instrument deviation (Figure 14), we employ two complementary methods to determine the shaft section center coordinates, then average the results.

Using Method 1, we calculated the difference in casing symmetry arms and then sorted the resulting values.

If the sorted Δi decreases from the arm with the maximum difference and the decreasing difference is relatively uniform, there is no casing damage; when the inversion of one arm and the decreasing difference is abnormal, the serial position of the arm is damaged.

After determining the maximum offset direction of the instrument by sorting the subtraction value of the symmetry arm, the maximum offset distance of the symmetry arm is,

The maximum offset direction of the instrument is determined by the subtraction value of the symmetry arm, and the maximum offset distance of the symmetry arm is,

the calculation process of the maximum offset arm azimuth angle and the central dot coordinates is the same as Equations (6)–(11).

In the equation, Δmax is the maximum offset distance, mm. Sort is the difference sorting function; Δi is the offset of the i-number arm from the symmetry arm, mm; Li is the measured well diameter value of arm i, mm; Li+20 is the measured well diameter value of arm i + 20 mm;

Method 2, it is known that the rotation azimuth angle of arm 1 is ROT1, and the angle between any adjacent arms is a constant 9 degrees. Using the difference in wall thickness to calculate the corresponding offset distance, and then the central dot coordinates of the shaft section (x0′, y0′) are obtained, the arm number of the top arm is,

taking the arm i as the maximum offset distance, coordinates of the circular circle at the center of the wellbore section (x0′, y0′) are obtained,

the coordinate position of the center of the final shaft section can be expressed as (,y)

the spatial coordinates before eccentricity are expressed as (xi, yi), while the post-eccentric coordinates are expressed as (xi′, yi′). NO is the serial number of the top arm; ROT1 is the azimuth of arm 1 monitored by multi-arm caliper logging, Li is the observed value of arm i, mm; Li+20 is the measured value of arm i + 20, mm; (x0′, y0′) is the center point coordinates of the wellbore section obtained by two perpendicular arms; (x0, y0) is the coordinates of the center obtained by two perpendicular arms; and () is the coordinates of the final wellbore section from Method 1 and Method 2.

Finally, the eccentricity correction is completed based on the relationship between the tool center point coordinate (0, 0), the shaft center coordinates (), and the eccentric coordinate (xi′, yi′). Casing loss assessment is based on comparing the radius before eccentricity and the radius after correction.

The proposed method was coded in C++ (Visual Studio 2022) and deployed on the Lead 4.0 platform. It has been successfully applied to nearly 100 field well logging datasets, with all computations being performed within this integrated environment. By establishing the new eccentricity correction method of horizontal well diameter logging data, we obtained corrected multi-arm caliper logging response values that accurately reflect the structural characteristics and damage position of horizontal oil well casing. This approach effectively supports high-precision evaluation of multi-arm diameter monitoring data, ultimately enhancing oil well integrity assessment and repair planning.

4. Discussion

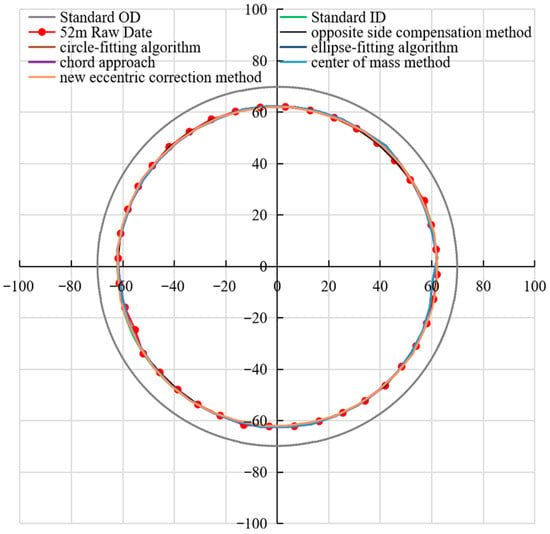

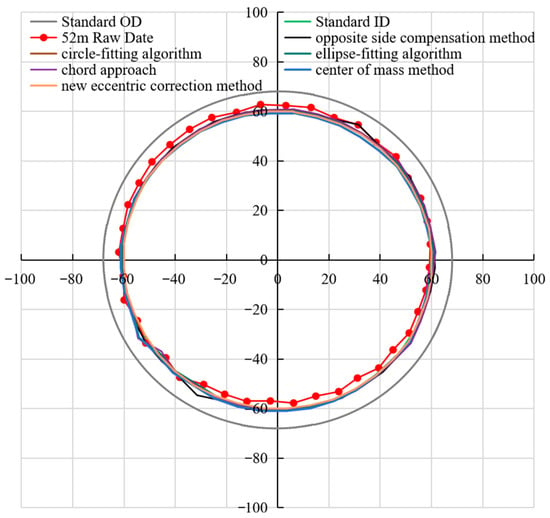

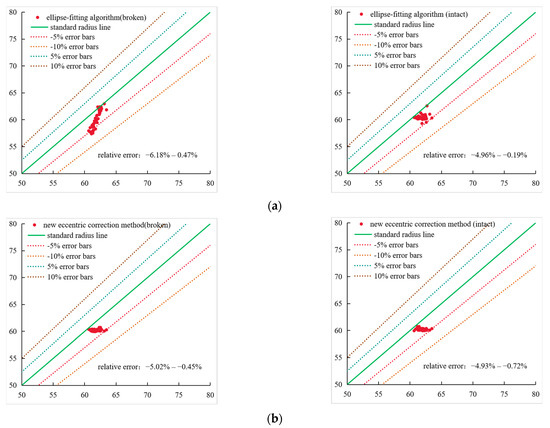

This study systematically validated the newly proposed eccentric correction method using experimental data and conducted a comprehensive comparative analysis with existing eccentric correction approaches. The results demonstrate that under intact casing conditions, all eccentric correction methods achieved satisfactory correction outcomes. However, in the presence of casing damage, our proposed method exhibited superior correction accuracy and stability compared to existing techniques. This superiority is thoroughly demonstrated by multiple sets of comparative experimental data (Figure 15, Figure 16, Figure 17 and Figure 18).

Figure 16.

Comprehensive results of various eccentric correction methods under intact casing and instrument eccentricity conditions.

Figure 17.

Comprehensive results of various eccentric correction methods under damaged casing and instrument centering conditions.

Figure 18.

Comprehensive results of various eccentric correction methods under damaged casing and instrument eccentricity conditions.

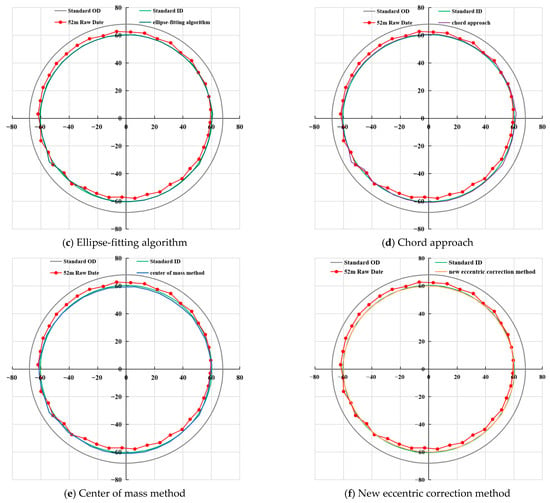

In Figure 15, Figure 16, Figure 17, Figure 18 and Figure 19, the gray solid line represents the standard casing outer diameter, the green solid line represents the standard casing inner diameter, and the red curve denotes the measured raw caliper data. Specifically, the opposite-side compensation method, circle-fitting algorithm, ellipse-fitting algorithm, chord method, center of mass method, and new eccentric correction method in the study are denoted by black, brown, teal, purple, light blue, and yellow, respectively. Under intact casing and instrument centering conditions (Figure 15), the measured caliper with the green standard inner diameter line requires no eccentricity correction. Figure 16 demonstrates the correction effects of each eccentric correction method under intact casing conditions with the instrument in an eccentric state. The raw caliper data only slightly deviate from the green standard inner diameter line, showing no obvious eccentric characteristics. This is because under single casing conditions, the cable exerts an upward force on the instrument, effectively counteracting the downward deviation caused by its gravity. Under these conditions, both the newly proposed eccentric correction method and the existing eccentric correction methods exhibit favorable correction effects.

Figure 19.

Result diagrams of different eccentric correction methods under the scenarios of casing damage and instrument eccentricity (a–f).

Comprehensive result diagrams of various eccentricity correction methods under instrument eccentricity and centering conditions in a damaged casing are shown in Figure 17 and Figure 18. In Figure 17, each method displays an excellent correction performance under the condition of instrument centering in a damaged casing, the correction curves match the standard inner diameter. However, under eccentric conditions (Figure 18), a pronounced upward deviation of the original data curve from the standard inner diameter is evident. Specifically, the caliper measurements on the upper side exceed the standard inner diameter, whereas those on the lower side fall short. This phenomenon also indicates that there is a significant eccentricity in the instrument. This observation aligns precisely with the eccentric condition illustrated in Figure 10. Our systematic study of the fitting correction methods reveals major differences in their effectiveness. In areas with normal well conditions, all the tested correction techniques align with the standard inner diameter with high precision, resulting in excellent fitting outcomes. However, in damaged casing areas, the chord method, the opposite side compensation method, the circle-fitting algorithm, and even the relatively advanced ellipse-fitting algorithm all exhibit obvious limitations. These methods struggle to accurately identify damage features, which appear as sharp peaks in the fitting curves and ultimately lead to the omission of damaged areas. In contrast, the newly established eccentric correction method completely avoids these problems.

To present the differences among various correction methods, we conducted a comprehensive analysis for cases where the casing is damaged and the instrument is eccentric (Figure 19a–f).

Through a systematic comparative analysis, we found major performance differences among eccentricity correction methods. In normal well conditions, various methods achieve a good fit with the standard inner diameter, demonstrating an ideal correction effect. However, when applied to areas with damaged casings, traditional methods such as the chord method, the center of mass method, the opposite side compensation method, the circle-fitting algorithm, as well as the currently widely used ellipse-fitting algorithm, all reveal obvious limitations. The phenomenon is primarily attributed to the specialized measurement environment. In the damaged casing areas, when logging arms encounter holes, the measured data exhibit abnormal peaks, manifested as sharp protrusions in the fitting curves. Due to the algorithm limitations, traditional correction methods struggle to effectively identify and accurately process such abnormal data features. This often leads to the omission of this key damage information during the fitting process, thus affecting the accurate judgment of the actual condition of the casings. In sharp contrast, the newly proposed eccentric correction method demonstrates outstanding comprehensive performance advantages. Relying on its innovative algorithm design, this method not only maintains a high-precision fitting level in conventional areas but also, even when faced with complex scenarios of damaged casings, can accurately capture the damage features and achieve a high degree of consistency with the actual casing morphology, providing a more reliable technical support for detecting casing damage.

To further quantify performance disparities among correction methods and validate the advantages of the newly proposed method, this study conducted a systematic relative error analysis for each eccentric correction method. The results accurately reflect the differences in measurement accuracy and reliability among the methods, provide an important basis for evaluating their effectiveness in practical applications. The detailed data and analytical conclusions have been presented in Figure 20.

Figure 20.

Error analysis diagrams of each eccentric correction processing under the condition that casing is damaged and instrument is eccentric (a–f).

In-depth analysis of the relative error diagrams reveals that, under the conditions of both casing damage and instrument eccentricity, traditional correction methods exhibit notably wide relative error margins. Specifically, the opposite side compensation method shows a relative error range of −1.69% to 3.37%, the circle-fitting algorithm has a range of −1.72% to 3.60%, the chord approach yields a range of −1.69% to 3.63%, and the center of mass method demonstrates an even broader range, spanning from −1.92% to 3.71%. The conventional ellipse-fitting algorithm, while offering some improvement in correction efficacy, has managed to constrict its relative error range to −0.88% to 3.53%. In stark contrast, the newly proposed eccentric correction method significantly outperforms existing techniques. Its relative error range is confined to a much narrower interval of −0.61% to 0.66%, which represents a reduction of 0.27% to 2.87% compared to the ellipse-fitting algorithm. These findings unequivocally demonstrate that, in the challenging context of damaged casings and eccentric instrument positions, the new eccentric correction method attains the highest measurement precision and stability levels, thereby providing powerful technical support for the high-precision quantitative evaluation, damage location, and repair of the multi-arm caliper logging data of horizontal wells.

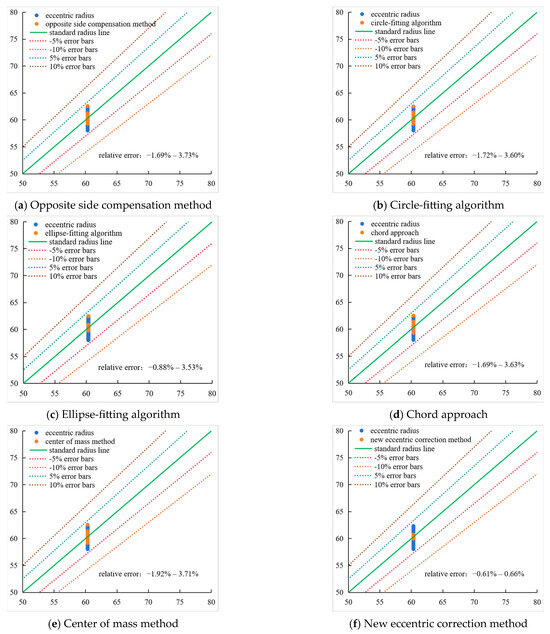

Based on the overall analysis, the eccentricity correction effects of the newly established eccentric correction method and the elliptical fitting correction method are relatively good. Therefore, an error analysis was conducted on the eccentric and centered data of the damaged and intact well sections for these two methods (Figure 21).

Figure 21.

Error analysis diagrams of eccentric and centered measurement methods under damaged casing and intact casing conditions (a,b). (a) Error analysis diagram for the data after the ellipse-fitting correction and centralization measurements (left: damaged well section; right: intact well section). (b) Error analysis diagram for the data after correction by the new eccentric correction method and centralization measurements (left: damaged well section; right: intact well section).

Experimental data comparisons indicate that the relative eccentric correction errors for intact casings are substantially lower than those for damaged casings. The new eccentric correction method demonstrates superior performance compared to the traditional ellipse-fitting algorithm. Specifically, for intact well sections, the relative error between the response values of eccentric and centered measurements, after applying the new correction method, ranges from −4.93% to −0.72%. This range reflects a 0.03–0.53% reduction in post-correction relative errors compared to the conventional ellipse-fitting algorithm. Conversely, for damaged well sections, the new method exhibits a relative error range of −5.02% to −0.45%, resulting in a 0.92–1.16% decrease in relative errors post-correction when compared with the traditional algorithm. Confirmed by statistical t-tests, the p-value of the newly established method is approximately 0.0011 for damaged casings and about 0.0032 for intact casings. Whether the casing is intact or damaged, the p-values of the newly established method are both far less than 0.05, which further verifies the superiority of this method. These findings highlight that the proposed method effectively enhances the consistency of correcting the eccentric effects of multi-arm caliper logging tools for tubing and casing in horizontal wells across diverse damage scenarios, thereby contributing to more reliable well integrity assessments.

The practicality of our method has been validated through the successful processing and interpretation of numerous field datasets. The design of the forty-arm caliper tool, whose arms maintain continuous contact with the borehole wall, renders its measurements largely insensitive to borehole fluids and temperature variations. The primary environmental influence is, therefore, tool gravity. It is important to note that the method remains applicable across a broad range of wellbore conditions, provided that the tool itself does not experience significant signal distortion under extreme temperatures.

Our findings revealed that the newly proposed eccentric correction method, developed from the monitoring data of the forty-arm caliper logging tool, demonstrates remarkable technical advantages. This method excels in measurement precision and stability, and effectively addresses the issue of missing information in damaged well sections, a common drawback of traditional correction methods. As a result, it significantly expands the applicable scope. Whether under conventional or complex well conditions, this method is capable of accurately correcting the measurement deviations caused by eccentricity in multi-arm caliper logging data. It provides a solid and reliable technical guarantee for the efficient monitoring and evaluation of damage to the oil casing in horizontal wells, as well as for the precise location and scientific repair of such damage.

As the proposed method has been implemented in C++ and integrated into the Lead 4.0 platform, the computational efficiency of the C++ code enables practical real-time processing within the logging software suite. The method maintains its applicability even under conditions of extreme eccentricity, though such scenarios are uncommon in practice. Regarding data integrity, measurements from one or two distorted arms are typically discarded; however, datasets with excessive invalid readings are excluded entirely to ensure result reliability.

A relevant case analysis was conducted based on the newly proposed eccentric correction method (Figure 22). It illustrates the 3D correction diagrams of well sections before and after eccentricity correction. In the 3D imaging diagrams of typical well sections such as 3475–3500 m, 3640–3660 m, and 3835–3865 m, uncorrected data show major color differences in the 3D diagrams. Red regions represent casing damage, with caliper measurements exceeding the green-referenced standard inner diameter, while blue areas indicate borehole diameters smaller than the standard. This is because the eccentricity of the instrument and the casing damage lead to differences in the measured values of the borehole diameter. In contrast, corrected images show uniform color distribution dominated by the green reference, with substantially reduced red and blue regions, demonstrating regular morphological characteristics. This consistency intuitively confirms that the eccentricity correction effectively mitigates tool eccentricity effects. These results further validate the feasibility of the proposed method, which is of great significance for guiding casing damage detection and eccentric correction in field applications.

Figure 22.

Three-dimensional correction diagrams of well sections before and after eccentricity correction. (a) X well 3D imaging at 3475–3500 m in depth (left: before correction, right: after correction). (b) X well 3D imaging at 3640–3660 m in depth (left: before correction, right: after correction). (c) X well 3D imaging Figure 3835–3865 m in depth (left: before correction, right: after correction).

5. Conclusions

- (1)

- This research provides valuable methodological advancements to horizontal well logging technology. Through a comprehensive comparative analysis of various eccentricity correction methods, a new eccentricity correction method was proposed and developed. Following data processing and correction, the results indicate that the newly proposed method exhibits the lowest relative error, showcasing its superior performance compared to existing techniques.

- (2)

- The new method significantly enhances measurement accuracy, achieving high precision across both intact and damaged casing sections with substantially reduced relative error. A critical advancement is its ability to accurately identify and faithfully preserve localized damage features, which are often overlooked by conventional algorithms.

- (3)

- The practical application of the eccentricity correction method significantly enhances the reliability of forty-arm caliper logging interpretation in horizontal wells. By extensively enhancing eccentricity correction accuracy, this method provides robust technical support for high-precision quantitative evaluation, precise damage localization, and efficient repair of horizontal well multi-arm wellbore logging data.

Future work will focus on demonstrating that the method is adaptable to tools with different arm geometries (e.g., 24-arm, 64-arm caliper tools), and this adaptability can be achieved simply by adjusting the symmetry arm interval and coordinate calculation parameters. Additionally, field validation in multiple oilfields with varying well conditions (e.g., high-temperature reservoirs, heavy oil wells) will be conducted to further verify the method’s practicality and reliability.

Author Contributions

Conceptualization, X.J.; methodology, X.J.; software, M.C.; validation, X.J.; M.C., X.L., G.Y. and H.Y.; formal analysis, X.J. and H.Y.; investigation, X.J., M.C., X.L., G.Y. and H.Y.; resources, M.C., X.L. and Y.Z.; data curation, M.C., X.L. and Y.Z.; writing—original draft preparation, X.J. and M.C.; writing—review and editing, X.J., M.C., X.L., G.Y., H.Y. and Y.Z.; visualization, X.J. and H.Y.; supervision, M.C., X.L., G.Y. and Y.Z.; project administration, M.C.; funding acquisition, M.C. and Y.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This project was supported by the Natural Science Foundation of Sichuan Province of China (No. 2024NSFSC1998) and the National Natural Science Foundation of China (No. 41804141). This work was also supported by the Open Fund (PLN 201933) of State Key Laboratory of Oil and Gas Reservoir Geology and Exploitation (Southwest Petroleum University) and the China Postdoctoral Science Foundation (NO. 2018M643525).

Data Availability Statement

The data generated or analyzed during this study are available from the corresponding author upon reasonable request.

Acknowledgments

We would like to extend our heartfelt thanks to all those who provided support throughout the process of this work. Their contributions, whether in administrative assistance, technical help, or other forms, have been invaluable to the completion of this manuscript.

Conflicts of Interest

Author Yaning Zhao was employed by the company Changqing Branch, China National Logging Corporation. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The company had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results. All authors declare that there are no relationships or interests that could inappropriately influence or bias the work presented in this manuscript.

Abbreviations

The following abbreviations are used in this manuscript:

| MIT | Multi-arm caliper logging tool |

| MTT | Magnetic Thickness Tool |

| MID-K/S | Magnetic Inspection Device-K/S |

| TEM | Transient Electromagnetic Tool |

References

- Jia, A.; Yan, H.J.; Tang, H.F.; Wang, Z.N.; Liu, Q.M. Key technologies and countermeasures for deep and ultra-deep gas reservoir development in China. Nat. Gas Ind. 2021, 44, 119–127. [Google Scholar]

- Dengfa, H.E.; Chengzao, J.I.A.; Wenzhi, Z.H.A.O.; Fengyin, X.U.; Xiaorong, L.U.O.; Wenhui, L.I.U.; Yong, T.; Shanlin, G.; Xiujuan, Z.; Di, L.; et al. Research progress and key issues of ultra-deep oil and gas exploration in China. Pet. Explor. Dev. 2023, 50, 1333–1344. [Google Scholar] [CrossRef]

- Li, M.; Liu, J.; Xia, Y. Risk Prediction of Gas Hydrate Formation in the Wellbore and Subsea Gathering System of Deep-Water Turbidite Reservoirs: Case Analysis from the South China Sea. Reserv. Sci. 2025, 1, 52–72. [Google Scholar] [CrossRef]

- Liao, Q.Z.; Wang, B.; Chen, X.; Tan, P. Reservoir stimulation for unconventional oil and gas resources: Recent advances and future perspectives. Adv. Geo-Energy Res. 2024, 13, 7–9. [Google Scholar] [CrossRef]

- Yin, H.; Zhao, X.W.; Li, Q.; Gao, J.J.; Tang, Z.Q.; Dai, L.M. Effect of fracture-induced stress on casing integrity during fracturing in horizontal wells. Adv. Mech. Eng. 2022, 14, 1–9. [Google Scholar] [CrossRef]

- Su, Y.; Shilong, Z.; Fu, J.; Shen, X.; Yang, Z.; Guo, J.; Xiong, Y.; Li, B.; Peng, C. Analysis of casing stress during multistage fracturing of shale gas horizontal wells considering thermo-hydro-mechanical coupling. Energy Sci. Eng. 2023, 11, 2851–2865. [Google Scholar]

- Cao, L.; Lv, M.; Li, C.; Sun, Q.; Wu, M.; Xu, C.; Dou, J. Effects of Crosslinking Agents and Reservoir Conditions on the Propagation of Fractures in Coal Reservoirs During Hydraulic Fracturing. Reserv. Sci. 2025, 1, 36–51. [Google Scholar] [CrossRef]

- Wu, T.J.; Li, M.; Liu, N.N.; Zhang, T.; Su, J.W. Research on mechanism of non-uniform in-situ stress induced casing damage based on finite element analysis. Appl. Sci. 2024, 14, 5987. [Google Scholar] [CrossRef]

- Wu, J.; Ansari, U. From CO2 Sequestration to Hydrogen Storage: Further Utilization of Depleted Gas Reservoirs. Reserv. Sci. 2025, 1, 19–35. [Google Scholar] [CrossRef]

- Zhang, J.Q.; Wu, L.; Jia, D.L.; Wang, L.M.; Chang, J.H.; Li, X.N.; Cui, L.N.; Shi, B.B. A machine learning method for the risk prediction of casing damage and its application in waterflooding. Sustainability 2022, 14, 14733. [Google Scholar] [CrossRef]

- Pan, Y.M. Study on the current situation and influencing factors of casing damage in S oilfield, Springer Series in Geomechanics and Geoengineering. In Proceedings of the International Field Exploration and Development Conference, Chengdu, China, 23–25 September 2020; pp. 2001–2006. [Google Scholar]

- Mohamed, H.; Osama, S.; Abdulhussein, F.; Lazăr, A. Pipe integrity analysis and evaluation using Multi Finger Imaging Tool (MIT)-field case studies. Pet. Coal 2021, 63, 455–466. [Google Scholar]

- Zeng, B.; Zhang, H.Z.; Zhou, X.J.; Yang, X.; Song, Y.; Chen, Z. Microseismic characteristics of shale gas wells with casing deformation in Sichuan Basin. In Proceedings of the 55th U.S. Rock Mechanics/Geomechanics Symposium, Virtual, 20–23 June 2021. [Google Scholar]

- Al-Haddad, S.M.; Shuber, H.H.; Alaryan, A.M.; Iqbal, P.; Nuriyev, O. Individual barriers corrosion monitoring using electromagnetic measurements. In Proceedings of the SPE Thermal Well Integrity and Production Symposium, Kuala Lumpur, Malaysia, 22–23 November 2022. [Google Scholar]

- Zhang, X.W.; Liu, J.D.; Cheng, W.; Jiang, W.D.; Jin, J.; Shen, L.H. New type of casing deformation rising in Weiyuan Changning shale gas play. In Proceedings of the International Petroleum Technology Conference, Riyadh, Saudi Arabia, 21–23 February 2022. [Google Scholar]

- Ajgou, N.; Graba, B.; Sayah, L.; Ismail, M.; Yakupov, A.; Saada, M.; Rourke, M.; Abdelmoula, M. Effective solutions to well integrity management using multi finger caliper and electromagnetic tool. In Proceedings of the SPE Gas & Oil Technology Showcase and Conference, Dubai, United Arab Emirates, 21–23 October 2019. [Google Scholar]

- Chen, H.H.; Sun, Z.F.; Liu, X.E.; Qiu, A. Multifunctional ultrasound imaging logging tool design for casing wells of offshore oilfield in China. In Proceedings of the Twenty-fourth International Ocean and Polar Engineering Conference, Busan, Republic of Korea, 15–20 June 2014. [Google Scholar]

- Benayad, S.; Baouche, R.; Chaouchi, R.; Mitra, S.; Sen, S.; Benmamar, S. In-situ stress state and geomechanical modeling of the paleozoic clastic reservoirs in Hassi Terfa field, Algeria. In Proceedings of the International Geomechanics Conference, Kuala Lumpur, Malaysia, 18–20 November 2024. [Google Scholar]

- Lu, J.; Han, J.; Wu, J.; Che, X.; Qiao, W.; Wang, J.; Chen, X. Physical simulation of ultrasonic imaging logging response. Sensors 2022, 22, 9422. [Google Scholar] [CrossRef] [PubMed]

- Hamadani, A.; Sawafi, S.A.; Taher, A. Acquiring high-resolution images while drilling in a fast logging environment utilizing a new ultrasonic sensor. In Proceedings of the SPE Conference at Oil and Gas West Asia, Muscat, Oman, 22–24 April 2024. [Google Scholar]

- Wang, J.; Liu, F.; Xu, H.H. Oil and gas casing 3D visualization technology based on multi-frequency ultrasonic scanning. Pet. Sci. Technol. 2023, 41, 1328–1348. [Google Scholar] [CrossRef]

- Teplukhin, V.K. The development of theoretical foundations for electromagnetic flaw detection of oil and gas wells. Russ. J. Nondestruct. Test. 2004, 40, 834–843. [Google Scholar] [CrossRef]

- Bo, D.; Mengmeng, P.; Bowen, R.; Ling, Y. A signal reconstruction method for memory-type transient electromagnetic detection systems in horizontal wells. In Proceedings of the 2021 IEEE 3rd International Conference on Intelligent Control, Measurement and Signal Processing and Intelligent Oil Field (ICMSP), Xi’an, China, 23–25 July 2021; pp. 63–67. [Google Scholar]

- Xie, Y.; Fan, L.H.; Yang, L.; Zhao, Y.; Hao, X.N.; Dang, B. Depth-time dimension signal reconstruction of transient electromagnetic logging using compressed sensing. In Proceedings of the 2022 IEEE 4th International Conference on Intelligent Control, Measurement and Signal Processing (ICMSP), Hangzhou, China, 8–10 July 2022. [Google Scholar]

- Ma, X.H. Integrity of gas reservoir storage facilities during the operation phase. In Handbook of Underground Gas Storages and Technology in China; Springer: Singapore, 2021; pp. 1145–1170. [Google Scholar]

- Zou, H.L.; Wang, X.G.; Kang, J.L.; Deng, M.M.; Wang, Q.H.; Zhu, H.S.; Gao, C.W. Integrated workover and re-completion techniques to successfully restore productivity for sour gas field, Turkmenistan. In Proceedings of the SPE Production and Operations Symposium, Oklahoma City, OK, USA, 27–29 March 2011. [Google Scholar]

- Elendu, C.; Nwamara, N.; Alinnor, C.; Enekhai, H.; Ojukwu, I.; Ayoo, J.; Abolarin, O. The diagnostics and recompletion strategy of a well with sustained casing pressure. In Proceedings of the SPE Nigeria Annual International Conference and Exhibition, Lagos, Nigeria, 1–3 August 2022. [Google Scholar]

- Aliko, E.; Casciaro, D.; Conte, A.; Busollo, C.; Baronio, E.; Abdo, E.A. Optimizing well integrity with accurate forecasting of casing and tubing resistance reduction trends through innovative numerical modeling techniques. SPE J. 2025, 30, 127–143. [Google Scholar] [CrossRef]

- Zhao, Y.G.; Song, L.Z. Casing defect detection logging and its application. Nat. Gas Ind. 2008, 28, 52–54. [Google Scholar]

- Li, Q.W.; Yang, Q.A.; Dong, X.H.; Li, M.X.; Xi, Y.T. Development of double layer metal thermal spray: Novel external corrosion mitigation method for gas well tubing. In Proceedings of the SPE International Oilfield Corrosion Conference and Exhibition, Aberdeen, UK, 28–29 May 2012. [Google Scholar]

- Xingfu, Z.; Yingxiang, W.; Qiang, L.; Xiwei, Y. Multi-pipe string electromagnetic detection tool and its applications. In Proceedings of the 2007 IEEE 8th International Conference on Electronic Measurement and Instruments, Xi’an, China, 16–18 August 2007. [Google Scholar]

- Golovatskaya, G.; Potapov, A.; Xie, M.J.; Shumilov, A. The technology of magnetic-pulse flaw detection-thickness measurement of multistring wells by the transient method. In Proceedings of the SPWLA 65th Annual Logging Symposium, Rio de Janeiro, Brazil, 18–22 May 2024. [Google Scholar]

- Zhu, Y.L.; Chen, W.Y.; Song, W.T.; Han, S.X. New fast imaging techniques for electrical source transient electromagnetic data: Approaches and application. Comput. Geosci. 2025, 194, 105770. [Google Scholar] [CrossRef]

- Dutta, S.; Olaiya, J. Analysis and interpretation of multi-barrier transient electromagnetic measurements. In Proceedings of the SPWLA 61st Annual Logging Symposium, Virtual Online Webinar, 20–24 June 2020. [Google Scholar]

- Xue, G.Q.; Li, H.; He, Y.M.; Xue, J.J.; Wu, X. Development of the inversion method for transient electromagnetic data. IEEE Access 2020, 8, 146172–146181. [Google Scholar] [CrossRef]

- Dang, B.; Yang, L.; Liu, C.Z.; Zheng, Y.H.; Li, H.; Dang, R.R.; Sun, B.Q. A uniform linear multi-coil array-based borehole transient electromagnetic system for non-destructive evaluations of downhole casings. Sensors 2018, 18, 2707. [Google Scholar] [CrossRef]

- Arshad, W.; Khan, K. Understanding the key factors affecting well integrity in horizontal well multistage hydraulic fracturing. In Proceedings of the Middle East Oil and Gas Show and Conference, Manama, Bahrain, 19–21 February 2023. [Google Scholar]

- Li, H.Q.; Wang, R.H. Research on a measurement method for downhole drill string eccentricity based on a multi-sensor layout. Sensors 2021, 21, 1258. [Google Scholar] [CrossRef]

- Ning, W.D.; Hou, Y.W.; Liu, R.F.; Ma, L.J.; Liu, J.K. Multiarm well bore log correction evaluation technique. In Proceedings of the 2015 International Conference on Oil and Gas Field Exploration and Development, Dubai, United Arab Emirates, 16–18 November 2015. [Google Scholar]

- Bäßler, H. Dezentrierungskorrektur von BHTV-Daten angewandt auf die Tiefbohrung VGS, Rußland: Hochauflösende Kaliberauswertung am Beispiel der KTB. Ph.D. Thesis, University of Karlsruhe, Karlsruhe, Baden-Württemberg, Germany, 1995. [Google Scholar]

- Barton, C.A. Development of in Situ Stress Measurement Techniques for Deep Drillholes. Ph.D. Thesis, Stanford University, Stanford, CA, USA, 1988. [Google Scholar]

- Lysne, P. Determination of borehole shape by inversion of televiever data: The log analyst. Log Anal. 1986, 27, 64–71. [Google Scholar]

- Wagner, D.; Müller, B.; Tingay, M. Correcting for tool decentralization of oriented six-arm caliper logs for determination of contemporary tectonic stress orientation. Petrophysics 2004, 45, 530–539. [Google Scholar]

- Han, Z.Q.; Wang, C.Y.; Wang, Y.T.; Wang, C. Borehole cross-sectional shape analysis under in situ stress. Int. J. Geomech. 2020, 20, 1–6. [Google Scholar] [CrossRef]

- Assanelli, A.P.; Turconi, G.L. Effect of measurement procedures on estimating geometrical parameters of pipes. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2001. [Google Scholar]

- Sawaryn, S.J.; Pattillo, P.D.; Brown, C.; Schoepf, V. Assessing casing wear in the absence of a baseline caliper log. SPE Drill. Complet. 2015, 30, 152–163. [Google Scholar] [CrossRef]

- Yang, Z.T.; Fang, X.D.; Huang, L. A robust approach for determining borehole shape from six-arm caliper logs. Geophysics 2018, 83, 203–215. [Google Scholar] [CrossRef]

- Chandrasekhar, S.V.; Anjos, J.L.; Frazão, L.E.; Bonelli, R.C.; Percy, J.G.; Dos Santos, C.M.; Gasparetto, D.; Lima, L.B.; Pilisi, N. Casing wear estimation without a baseline log-a distorted ellipse methodology. In Proceedings of the Annual Offshore Technology Conference, Houston, TX, USA, 6–9 May 2019. [Google Scholar]

- Sawaryn, S.J.; Jamieson, A.L.; McGregor, A.E. Explicit calculation of expansion factors for collision avoidance between two co-planar survey error ellipses. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 8–10 October 2012. [Google Scholar]

- Markley, M.E.; Last, N.; Mendoza, S.; Mujica, S. Case studies of casing deformation due to active stresses in the andes cordillera, Colombia. In Proceedings of the IADC/SPE Drilling Conference and Exhibiton, Dallas, TX, USA, 26–28 February 2002. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).