A Systematic Review of Glove Construction Based on Hand Anthropometric Measurements and Finite Element Simulations

Abstract

1. Introduction

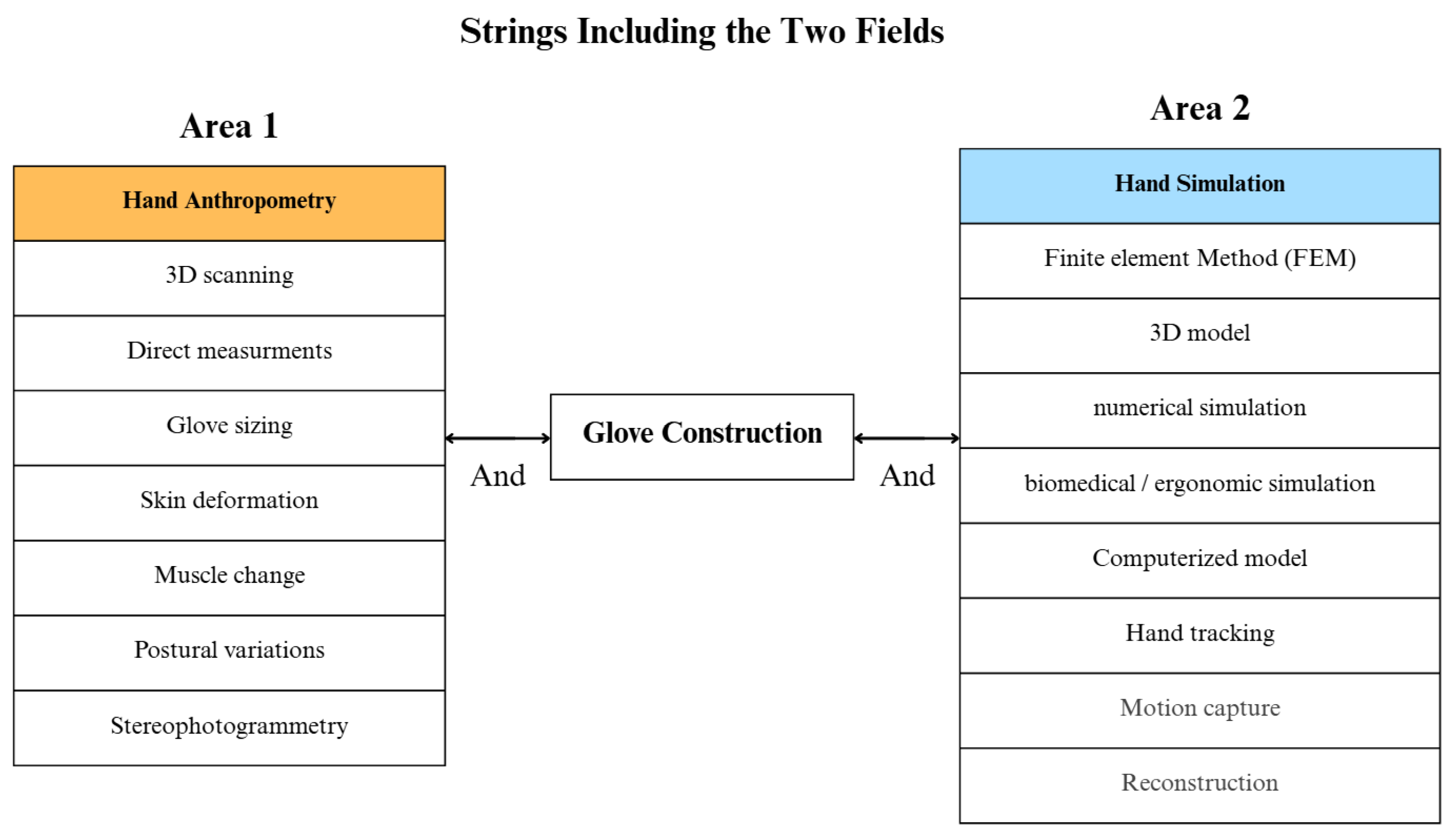

2. Materials and Methods

3. Results and Discussion

3.1. Hand Anthropometry Measurements by 3D Scanning

| Scanners | Relative Error (%) | Price (USD) | Resolution | Scanning Speed | Handheld Supportive | References |

|---|---|---|---|---|---|---|

| Artec Eva 3D | - | 19,800 | 1.3 megapixels, up to 0.1 mm | 16 FPS | Yes | [7,9,11,12,20] |

| Artec Leo 3D | 1.16–1.46 | 34,800 | 2.3 megapixels, up to 0.1 mm | 80 FPS | Yes | [17,18] |

| Infoot | - | - | up to 0.5 mm | Not disclosed | No | [6] |

| Occipital Structure Sensor | 5.08 | 527–995 | VGA (640 × 480)/1.3 megapixels, up to 1 mm | 30–60 FPS | Yes | [17] |

| Gemini Structured Light Scanning | 3.94 | - | up to 0.05–0.1 mm | Not disclosed | No | [8] |

| Techniques | Hand Posture (s) | Machines | Sample Size | Paper Focus/Topic | References |

|---|---|---|---|---|---|

| 26 landmarks on the palm | Grasping, fingers splayed, fingers closed | Occipital structure sensor attached to a tablet, Anthroscan | 15 male and 15 female university students, no hand injuries | Hand anthropometry under motion | [13] |

| Fingers splayed | 30 females, no limits on age | Fitting of certain sports gloves in 4 sizes for females | [1] | ||

| 24 landmarks on the hand scanned with plaster hand models | Fingers splayed | Gemini structured light scanning system, computed tomography (CT) scanning, direct measurement | 6 male and 4 female age 26–35, no hand injuries | Efficiency and precision of 3D scanning compared to CT scanning and direct measurement | [8] |

| 47 landmarks on palm (joints and finger web) | Fingers splayed, relaxed, ball grasp | Artec Eva 3D scanner and Rapidform XOR software | 20 females and males, age 18–40, no hand injuries | Tracking the hand measurements and skin deformation in dynamic poses for designing gloves | [12] |

| A few landmarks placed near the finger web | Fingers closed | Artec Eva 3D scanner, with CloudCompare and MeshLab | One female aged 25, no hand injuries | Determination of dimensional allowances by comparison between gloved and bare hand | [7] |

| No landmarks, take hand length and hand breadth metacarpals, according to ISO 7250 [21] | Fingers closed | Harpenden Anthropometer, measuring tape, Artec Eva 3D scanner, Brother 2D scanner | 13 males and 12 females, age 25–45 | Precision, reliability, cost, and complexity among direct measurements, 2D and 3D scanning | [9] |

| 17 landmarks on the dorsal palm and wrist | Fingers splayed, slight grasping, power grasping | INFOOT scanner, with calculations performed by Geomagic Studio 12 | 13 females, age 40–65, M size, no hand injuries | Skin deformation behavior during dynamic hand poses | [6] |

| 14 landmarks on a plaster hand | Fingers splayed | Bone calipers, measuring tape, Occipital Structure Sensor, Artec Leo 3D scanner | 12 subjects, no limits on age or gender | Precision of different 3D scanning methods compared to direct measurement | [17] |

| 50 landmarks on the dorsal side of the hand with scanning | Fingers splayed, cylinder grasped | Artec Eva 3D scanner with Geomagic Studio | 111 females, age 18–26, no hand injuries | Relationship between grasping and hand skin deformation | [11] |

| No landmarks, stain left on cotton gloves after grasping objects with splayed hand is scanned | 52 objects grasped | EinScan 3D scanner, with the painted areas separated by mapping texture and point clouds, which will be marked on 3D-printed hands | 8 males and 4 females, age 20–30, no hand injuries | Development of technique of Ti3D-contact to obtain hand contact areas | [14] |

| Landmarks in ISO 7250 [21] | Fingers splayed, fingers closed | Artec Eva 3D scanner with Geomagic Wrap | 468 males and 469 females, age 22–60 | Collection of hand dimension of large-scale Chinese population | [20] |

| 23 landmarks on the hands, which represent 7 specific measurements | No specific poses are mentioned | Artec Leo 3D scanner, with 7 measurements, auto/semi-auto measured by Anthroscan | 15 of 800 subjects, no limits on age or gender | Precision of the auto/semi-auto measurement of the hand by 3D hand scanning | [18] |

| No specific landmarks with a 3D printed hand model (age 19, male) | Finger splayed | Structure Sensor Pro for iPad, with 3D models shown with Meshmixer program | 42 untrained and 45 trained university students | Precision of acquiring hand measurements between trained and untrained students | [19] |

3.2. Hand Simulation by FEM

| Type of Image-Based Approach | FEM Reconstructions on Hand | Material Parameters (Young’s Modulus, Poisson Ratio (P)/Ogden Hyper-Elastic Model (µ and α)) | Sample Sizes | Paper Focus/ Topic | References |

|---|---|---|---|---|---|

| 3D imaging, 3D laser scanner (NextEngineInc.) | Four-node linear tetrahedron (>2.3 mm), static | Bone: 17 GPa, 0.3 P Skin: 177 kPa, 0.4 P | One female, age 25, fingers splayed, bare hand | Simulate the glove-skin interface pressure of therapy gloves | [4] |

| Open-source 3D anatomical digital hand model | Four-node linear tetrahedron (2 mm for bones, 1 mm for soft tissues), static | Bone: 14–20 GPa, 0.3 P Soft Tissues: 177 kPa, 0.4 P | 5 male subjects, age 21–24, no hand injuries, fingers splayed, cylindrical grasping gloved hand | Simulate the contact data of gloved hands grasping cylindrical objects | [5] |

| 2D CT imaging, then 3D modeling with Geomagic Studio | Linear tetrahedron (1 mm for bones, 0.5 mm for cartilage, 3 mm for soft tissues), static | Cortical and Canellous Bones: 18,000 and 100 MPa, 0.20/0.25 P RA Cortical and Canellous Bones: 12,000 and 33 MPa, 0.20/0.25 P Soft Tissue: 177 kPa, 0.4 P | One male with no hand injuries, fingers splayed. One male with rheumatoid arthritis, fingers splayed, bare hand/hand with orthosis | Compare the stress and displacement of the normal hand, the hand with RA, and the hand with RA and orthosis | [27] |

| 2D CT imaging, then 3D modeling with Scan2Mesh | Eight-node brick elements (7 mm for bones); four-node shell elements (2 mm for skin and flesh), dynamic | Bone: 15,000 MPa, 0.2 P Flesh: 0.5 MPa, 0.3 P Skin: 16.7 MPa, 0.4 P | One adult subject, no limits on age or gender, no hand injuries, cylindrical grasping, bare hand | Simulate the contact pressure of bare hands grasping cylindrical objects | [31] |

| 2D CT images, then 3D models by Geomagic Studio | Four-node linear tetrahedron for the entire hand, quasi-static | Bone: 17 GPa, 0.3 P Nail: 170 MPa, 0.3 P Soft Tissues: −0.0759–0.0657µ, 4.712–4.941α, 0.45 P | One subject, no limits on age or gender, fingers splayed and grasping, bare hand | Simulate the hand reactions (tissue strain, pressure, vibration) in actions like grasping | [33] |

| 3D model from human model database | Four-node solid tetrahedron elements (5 mm for bones and skin); three-node triangular shell elements (5 mm for soft tissue), dynamic | Bone: Rigid Skin: 80 kPa, 0.48 P Soft tissues: (−)9.32/(−)15.7µ, −1.21/9.34α, 0.48 P | 54 males, age 30–51, calculated and represented as 3 hand dimensions, cylindrical grasping, bare hand | Simulate the contact pressure, tactile comfort of bare hands grasping cylindrical objects | [32] |

| 3D model from human model database | Tetrahedron solid elements for bones and soft tissue; triangular shell elements for skin, quasi-static | Bone: 17 GPa, 0.3 P Skin: 0.014 GPa, 0.3 P Soft tissues: 0.014 GPa, 0.3 P | One subject, no limits on age or gender, cylindrical grasping, bare hand | Simulate the contact pressure, tactile comfort of bare hands grasping cylindrical objects | [25] |

| Open-source MR images, then 3D model by open-source software | Hexahedron elements for ligaments, tendon, tissue, and nerve; tetrahedral elements for bone, static | Bone: 10,000 MPa, 0.3 P Soft tissues: 24.9/37.6/12.5/12.9µ, 10.9/8.89/4.51/6.5α | One subject, no limits on age or gender, fingers splayed, bare hand | Diagnose carpal tunnel syndrome of the hand by analyzing the relationships between compression of the median nerve and finger flexion | [28] |

| 2D CT/MR images, then 3D models by Creo | Four-node solid tetrahedron elements for the entire hand, quasi-static | Bone: 17 GPa, 0.3 P Skin: −0.0759–0.0657µ, 4.941–6.425α Soft tissues: −0.0489–0.0396µ, 5.262–6.751α | One male, aged 23, fingers splayed, grasping, gloved hand | Define and simulate loading and boundary conditions, and predict contact pressure under different contact patterns | [24] |

| 3D image, 3D scanner (Artec 3D); Bone data from CT | Ten-node quadratic tetrahedron solid elements (5 mm for bone, fat, and skin), static | Bone: 15 GPa, 0.3 P Fat: 0.034 MPa, 0.45 P Skin: 0.177 MPa, 0.4 P | One male, no limits on age, slightly grasping hand with orthosis | Simulate the level and distribution of pressure perceived by the hand under orthosis | [26] |

| Open-source 3D hand model | Four-node linear tetrahedron solid elements (2 mm for bone, 1 mm for soft tissue), dynamic | Bone: 15 GPa, 0.3 P Soft tissues: −0.0489–0.0396µ, 5.262–6.751α | One male, cylindrical grasping, sphere grasping, three-finger pinching, bare hand | Simulate the contact pressure in grasping for designing exoskeleton gloves | [34] |

| 2D MR images, then 3D models by LS-Dyna | Tetrahedron elements (1 mm for isotropic/anisotropic muscle), dynamic | Isotropic muscle: 22.4 kPa (not activated), 338.8 kPa (MAX), 0.499 P Anisotropic muscle: 338.8 kPa, 0.499 P (longitudinal), 25.2 kPa, 0.963 P (transversal) | One male, aged 28, cylindrical grasping and pushing, bare hand | Analyze the vibratory behavior of hand muscles in cylindrical grasping and pushing actions | [29] |

| 2D CT images, then 3D models by MIMICS 19.0; muscle-tendon displacements measured by ultrasound imaging | Four-node linear tetrahedron elements (for bone, tendon, and ligament), dynamic | Bone: 17,000 MPa, 0.3 P Tendon: 68–125.31 MPa, 0.45 P Ligament: 20–114.03 MPa, 0.45 P | One male, aged 30, no hand injuries, fingers lifting with different forces and fingers splayed | Analyze the force applied in different muscles and their roles during fine hand movements | [30] |

| Model Used | Motion State | Element Size (mm) | Element Numbers | Relative Error (%) | Image-Based Approach | References |

|---|---|---|---|---|---|---|

| Linear | Dynamic | 2 | 50,400 | 24.95 | 2D CT images | [31] |

| Linear | Dynamic | - | 326,427 | 10.82 | 2D CT with ultrasonic | [30] |

| Hyper-elastic | Quasi-static | - | 375,514 | 10.85 | Open-source 3D model | [33] |

| Linear | Static | 0.5, 1, 3 | 1,262,481 | 7.87 | 2D CT images | [27] |

4. Limitations and Future Directions

4.1. Limitations of 3D Scanning and FEM

4.1.1. Standards of Data Collection Simulation

4.1.2. Convenience with Accessibility

4.1.3. Data Retrieval

4.2. Future Directions

4.2.1. Enhanced Image Collection Through 3D Scanning

4.2.2. Standardization or Comparison of Data Retrieval

4.2.3. Extension of FEM to Different Areas

4.2.4. Possible Applications with AI and ML

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| FEM | Finite element method |

| CT | Computed tomography |

| MR | Magnetic resonance |

| AI | Artificial intelligence |

| ML | Machine learning |

| WoS | Web of Science |

| ICC | Intraclass correlation coefficient |

| RA | Rheumatoid arthritis |

| FDP | Flexor digitorum profundus |

| FDS | Flexor digitorum superficialis |

References

- Griffin, L.; Sokolowski, S.L.; Savvateev, E.; Bhuyan, A.U.I.A. Comparison of Glove Specifications, 3D Hand Scans, and Sizing of Sports Gloves for Athletes. In Proceedings of the 3DBODY.TECH 2019—10th International Conference and Exhibition on 3D Body Scanning and Processing Technologies, Lugano, Switzerland, 22–23 October 2019; pp. 109–118. [Google Scholar]

- Kovacs, K.; Splittstoesser, R.; Maronitis, A.; Marras, W.S. Grip Force and Muscle Activity Differences Due to Glove Type. AIHA J. 2002, 63, 269–274. [Google Scholar] [CrossRef] [PubMed]

- Yu, A.; Yick, K.L.; Ng, S.P.; Yip, J. 2D and 3D anatomical analyses of hand dimensions for custom-made gloves. Appl. Ergon. 2013, 44, 381–392. [Google Scholar] [CrossRef]

- Yu, A.; Yick, K.L.; Ng, S.P.; Yip, J.; Chan, Y.F. Numerical simulation of pressure therapy glove by using Finite Element Method. Burns 2016, 42, 141–151. [Google Scholar] [CrossRef]

- Zhang, Y.; Xie, H.; Lake, M.J. Accuracy prediction of wearable flexible smart gloves. AUTEX Res. J. 2024, 24, 20230008. [Google Scholar] [CrossRef]

- Nasir, S.H.; Troynikov, O.; Watson, C. Skin Deformation Behavior during Hand Movements and Their Impact on Functional Sports Glove Design. Procedia Eng. 2015, 112, 92–97. [Google Scholar] [CrossRef]

- Szkudlarek, J.; Zagrodny, B.; Zarychta, S.; Zhao, X. 3D Hand Scanning Methodology for Determining Protective Glove Dimensional Allowances. Int. J. Environ. Res. Public Health 2023, 20, 2645. [Google Scholar] [CrossRef]

- Yu, F.; Zeng, L.; Pan, D.; Sui, X.; Tang, J. Evaluating the Accuracy of Hand Models Obtained from Two 3D Scanning Techniques. Sci. Rep. 2020, 10, 11875. [Google Scholar] [CrossRef]

- Filho, P.C.A.; da Silva, L.; Castellucci, H.I.; Rodrigues, M.; Pereira, E.; Pombeiro, A.; Colim, A.; Carneiro, P.; Arezes, P.; Guedes, J.C.; et al. Comparison Between Anthropometric Equipment and Scanners in Hand Measurement. In Occupational and Environmental Safety and Health V; Arezes, P.M., Melo, R.B., Carneiro, P., Castelo Branco, J., Colim, A., Costa, N., Costa, S., Duarte, J., Guedes, J.C., Perestrelo, G., et al., Eds.; Springer: Cham, Switzerland, 2024; Volume 492, pp. 43–58. [Google Scholar]

- Paoli, A.; Neri, P.; Razionale, A.V.; Tamburrino, F.; Barone, S. Sensor Architectures and Technologies for Upper Limb 3D Surface Reconstruction: A Review. Sensors 2020, 20, 6584. [Google Scholar] [CrossRef]

- Zhai, Y.; Wu, S.; Hu, Q.; Zhou, W.; Shen, Y.; Yan, X.; Ma, Y. Influence of Grasping Postures on Skin Deformation of Hand. Sci. Rep. 2023, 13, 21416. [Google Scholar] [CrossRef] [PubMed]

- Kwan, M.; Yick, K.; Chow, L.; Yu, A.; Ng, S.; Yip, J. Impact of Postural Variation on Hand Measurements: Three-Dimensional Anatomical Analysis. PLoS ONE 2021, 16, e0250428. [Google Scholar] [CrossRef] [PubMed]

- Griffin, L.; Kim, N.; Carufel, R.; Sokolowski, S.; Lee, H.; Seifert, E. Dimensions of the Dynamic Hand: Implications for Glove Design, Fit, and Sizing. In Advances in Interdisciplinary Practice in Industrial Design, 2nd ed.; Shin, C.S., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018; Volume 790, pp. 38–48. [Google Scholar]

- Chen, Z.; Chen, H.; Ouyang, Y.; Cao, C.; Gao, W.; Hu, Q.; Jin, H.; Zhang, S. A High-Resolution and Whole-Body Dataset of Hand-Object Contact Areas Based on 3D Scanning Method. Sci. Data 2025, 12, 451. [Google Scholar] [CrossRef]

- Sanseverino, G.; Schwanitz, S.; Krumm, D.; Odenwald, S.; Lanzotti, A. Understanding the Effect of Gloves on Hand-Arm Vibrations in Road Cycling. Proceedings 2020, 49, 70. [Google Scholar] [CrossRef]

- Zare Bidoki, F.; Ezazshahabi, N.; Mousazadegan, F.; Latifi, M. Objective and Subjective Evaluation of Various Aspects of Hand Performance Considering Protective Glove’s Constructional Parameters. J. Ind. Text. 2022, 51 (Suppl. S4), 6533S–6562S. [Google Scholar] [CrossRef]

- Seifert, E.; Griffin, L. Comparison and Validation of Traditional and 3D Scanning Anthropometric Methods to Measure the Hand. In Proceedings of the 11th Int. Conference and Exhibition on 3D Body Scanning and Processing Technologies, Lugano, Switzerland, 17–18 November 2020; p. 41. [Google Scholar]

- Bhuyan, A.U.I.; Griffin, L. Make It Easy: Reliability of Automatic Measurement for 3D Hand Scanning. In Proceedings of the 11th International Conference and Exhibition on 3D Body Scanning and Processing Technologies, Lugano, Switzerland, 17–18 November 2020; p. 38. [Google Scholar]

- Glazer, C.; Oravitan, M.; Pantea, C.; Almajan-Guta, B.; Jurjiu, N.-A.; Marghitas, M.P.; Avram, C.; Stanila, A.M. Evaluating 3D Hand Scanning Accuracy Across Trained and Untrained Students. Bioengineering 2025, 12, 777. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, H.; Liu, K. Anthropometric Hand Dimensions of Chinese Adults Using Three-Dimensional Scanning Technique. In Design, User Experience, and Usability: Design for Emotion, Well-Being and Health, Learning, and Culture; Soares, M.M., Marcus, A., Rosenzweig, E., Eds.; Springer International Publishing: Cham, Switzerland, 2022; Volume 13322, pp. 377–387. [Google Scholar]

- ISO 7250; Basic Human Body Measurements for Technological Design. ISO: Geneva, Switzerland, 2017.

- Mena, A.; Wollstein, R.; Baus, J.; Yang, J. Finite Element Modeling of the Human Wrist: A Review. J. Wrist Surg. 2023, 12, 478–487. [Google Scholar] [CrossRef]

- Cei, G.; Artoni, A.; Bianchi, M. A Review on Finite Element Modelling of Finger and Hand Mechanical Behaviour in Haptic Interactions. Biomech. Model. Mechanobiol. 2025, 24, 895–917. [Google Scholar] [CrossRef]

- Wei, Y.; Zou, Z.; Wei, G.; Ren, L.; Qian, Z. Subject-Specific Finite Element Modelling of the Human Hand Complex: Muscle-Driven Simulations and Experimental Validation. Ann. Biomed. Eng. 2020, 48, 1181–1195. [Google Scholar] [CrossRef]

- Hokari, K.; Arimoto, R.; Pramudita, J.A.; Ito, M.; Noda, S.; Tanabe, Y. Palmar Contact Pressure Distribution During Grasping a Cylindrical Object: Parameter Study Using Hand Finite Element Model. Adv. Exp. Mech. 2019, 4, 135–140. [Google Scholar]

- Tan, X.; Ahmed-Kristensen, S.; Zhu, Q.; Han, T.; Zhu, L.; Chen, W.; Cao, J.; Nanayakkara, T. Identification of Excessive Contact Pressures under Hand Orthosis Based on Finite Element Analysis. Prosthet. Orthot. Int. 2025, 49, 119–126. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Yang, J.; Feng, P.; Li, X.; Chen, W. Biomechanical Analysis of Rheumatoid Arthritis of the Hand and the Design of Orthotics: A Finite Element Study. Bioengineering 2025, 12, 462. [Google Scholar] [CrossRef] [PubMed]

- Peshin, S.; Karakulova, Y.; Kuchumov, A.G. Finite Element Modeling of the Fingers and Wrist Flexion/Extension Effect on Median Nerve Compression. Appl. Sci. 2023, 13, 1219. [Google Scholar] [CrossRef]

- Vauthier, S.; Noël, C.; Settembre, N.; Ngo, N.H.P.; Gennisson, J.; Chambert, J.; Foltête, E.; Jacquet, E. Factoring Muscle Activation and Anisotropy in Modelling Hand-Transmitted Vibrations: A Preliminary Study. Proceedings 2023, 86, 12. [Google Scholar] [CrossRef]

- Lv, Y.; Zheng, Q.; Chen, X.; Hou, C.; An, M. Analysis on Synergistic Cocontraction of Extrinsic Finger Flexors and Extensors during Flexion Movements: A Finite Element Digital Human Hand Model. PLoS ONE 2022, 17, e0268137. [Google Scholar] [CrossRef]

- Chamoret, D.; Bodo, M.; Roth, S. A First Step in Finite-Element Simulation of a Grasping Task. Comput. Assist. Surg. 2016, 21 (Suppl. S1), 22–29. [Google Scholar] [CrossRef]

- Hokari, K.; Pramudita, J.A.; Okada, K.; Ito, M.; Tanabe, Y. Development of a Gripping Comfort Evaluation Method Based on Numerical Simulations Using Individual Hand Finite Element Models. Int. J. Hum. Factors Ergon. 2023, 10, 187–206. [Google Scholar] [CrossRef]

- Harih, G. Development of a Tendon Driven Finger Joint Model Using Finite Element Method. In Advances in Human Factors in Simulation and Modeling; Cassenti, D.N., Ed.; Springer International Publishing: Cham, Switzerland, 2018; Volume 780, pp. 463–471. [Google Scholar]

- Zhang, Y.; Xie, H.; Newton, M.A.A. Enhancing Assistive Technology Design: Biomechanical Finite Element Modeling for Grasping Strategy Optimization in Exoskeleton Data Gloves. Med. Eng. Phys. 2025, 137, 104308. [Google Scholar] [CrossRef] [PubMed]

- Reyes-Santias, F.; Antelo, M. Explaining the Adoption and Use of Computed Tomography and Magnetic Resonance Image Technologies in Public Hospitals. BMC Health Serv. Res. 2021, 21, 1278. [Google Scholar] [CrossRef] [PubMed]

- Wald, L.L.; McDaniel, P.C.; Witzel, T.; Stockmann, J.P.; Cooley, C.Z. Low-Cost and Portable MRI. J. Magn. Reson. Imaging 2020, 52, 686–696. [Google Scholar] [CrossRef] [PubMed]

- Andersson, H.; Tamaddon, A.; Malekian, M.; Ydström, K.; Siemund, R.; Ullberg, T.; Wasselius, J. Comparison of Image Quality between a Novel Mobile CT Scanner and Current Generation Stationary CT Scanners. Neuroradiology 2023, 65, 503–512. [Google Scholar] [CrossRef]

- Heckel, R.; Jacob, M.; Chaudhari, A.; Perlman, O.; Shimron, E. Deep Learning for Accelerated and Robust MRI Reconstruction. Magn. Reson. Mater. Phy. 2024, 37, 335–368. [Google Scholar] [CrossRef]

| Inclusion Criterion | Value |

|---|---|

| Papers that focus on hand anthropometry, but not specifically gloves | Include |

| Papers that focus on the FEM of hands, but not specifically for gloves | Include |

| Title includes at least two searched keywords | Include |

| Papers that compare hand anthropometric measurement methods | Include |

| Papers that focus on the collection of the inner structures of the hand, but not outer surfaces, with no 3D hand reconstructions | Include |

| Papers related to hand anthropometry, but focus on external objects (e.g., tools) | Exclude |

| Studies that examine body anthropometry, but not the hand | Exclude |

| Articles that focus on the material of gloves | Exclude |

| Articles that focus on posture or motion capturing, but not anthropometry or hand reconstruction | Exclude |

| Articles that use 2D FEM instead of 3D FEM for hands | Exclude |

| Articles that only produce the FEM of fingers instead of the entire hand | Exclude |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chan, C.-Y.; Hung, S.-C.; Kwan, M.-Y.; Yick, K.-L. A Systematic Review of Glove Construction Based on Hand Anthropometric Measurements and Finite Element Simulations. Technologies 2025, 13, 560. https://doi.org/10.3390/technologies13120560

Chan C-Y, Hung S-C, Kwan M-Y, Yick K-L. A Systematic Review of Glove Construction Based on Hand Anthropometric Measurements and Finite Element Simulations. Technologies. 2025; 13(12):560. https://doi.org/10.3390/technologies13120560

Chicago/Turabian StyleChan, Chi-Yin, Sik-Cheung Hung, Mei-Ying Kwan, and Kit-Lun Yick. 2025. "A Systematic Review of Glove Construction Based on Hand Anthropometric Measurements and Finite Element Simulations" Technologies 13, no. 12: 560. https://doi.org/10.3390/technologies13120560

APA StyleChan, C.-Y., Hung, S.-C., Kwan, M.-Y., & Yick, K.-L. (2025). A Systematic Review of Glove Construction Based on Hand Anthropometric Measurements and Finite Element Simulations. Technologies, 13(12), 560. https://doi.org/10.3390/technologies13120560