Abstract

Due to environmental concerns, plastic recycling and natural fiber composites have been given more attention lately. In Malaysia, mengkuang leaf fiber (MLF) has been identified as a potential candidate to be used as a reinforcing fiber. The combination of recycled polypropylene (r-PP) and MLF could result in an inexpensive and sustainable composite. However, the mechanical properties of this composite have not been fully studied. The aim of this work was to evaluate tensile, flexural and impact properties of r-PP/MLF composites with and without sodium hydroxide (NaOH) treatment and maleic anhydride-grafted polypropylene (MAPP). The composite consisted of 60 wt.% of r-PP and 40 wt.% of MLF. The composite was compounded by twin-screw extruder and test specimens were fabricated using an injection molding process. Generally, the tensile and flexural properties showed improvements, especially those with MAPP and alkaline treatment, compared to neat r-PP. Improvements in tensile strength and modulus of approximately 28% and 224% were achieved for r-PP/Treated MLF/MAPP composite respectively. However, an adverse effect was observed in the impact strength of the composite, which was expected due to the nature of short fiber employed in this work.

1. Introduction

In recent decades, a significant amount of attention has been focused on plastic recycling and natural fiber composites, primarily due to economic and environmental concerns [1]. Recycling is well-known for its economic and environmental benefits, which include reduction in greenhouse gas emissions, and resource and energy conservation. It is an important segment of the economy which creates jobs and saves money from waste generation.

Plastics are used in wide variety of applications such as packaging, the automotive industry, construction materials and microelectronics processing. For example, polypropylene (PP) is one of the main polymers used in the production of single-use plastics, which generate a high environmental impact. Single-use plastics made from PP include microwave dishes, ice cream tubs, potato chip bags and bottle caps. Consequently, the amount of waste generated is increasing and causing environmental issues. Recycling of materials and replacement of traditional composites with less environmentally harmful options have become more important. These efforts also have significant economic benefits, many of which are often overlooked [2].

Composites are combinations of two or more materials in which one of the materials is a matrix (polymer, ceramic or metal) phase and the other is a reinforcing phase (particles, fibers or sheets). For fiber reinforced plastic (FRP), the matrix may be made from thermoplastic or thermoset polymers while the reinforcing fibers can be synthetic or natural fibers. The fiber serves as the constituent that gives the composite strength and stiffness, while the polymer matrix holds everything together and effectively transfers stresses to the fiber.

Natural fibers are preferred due to their advantages such as sufficient mechanical properties, low weight, low energy consumption, low cost, ecological sustainability, biodegradability and carbon dioxide neutrality [3,4,5,6]. Natural fibers have been used widely in many industries such as automotive, medical, sport and construction [7]. The advantages in terms of economic and ecological perspectives [8,9] are well-established especially in the automotive [10] and construction industries [11].

Non-wood plant fibers, such as the various parts of plants comprising of stem, leaf, core and fruit, can be used as natural fibers, which are alternative sources for wood fibers [12]. The application of non-wood fiber as a reinforcing fiber is an important way to preserve the natural forest, since excessive utilization of wood fiber would lead to deforestation. So far, researchers have worked with sisal [13], abaca [14], banana [15] and pineapple leaf fiber [16]. Mengkuang leaf fiber (MLF) is a relatively new material as the reinforcing fiber.

Mengkuang or its scientific name Pandanus tectorius is a fibrous plant that is available in abundance in tropical countries like Malaysia and Indonesia. Traditionally, mengkuang leaf is used to produce handcrafted products, mats, hats and rope. The full potential of MLF as a reinforcing fiber could not be accessed easily since it is limited in the literature. Sheltami et al. [17] discovered that MLF consisted of 37% cellulose, 34.4% hemicellulose, 15.7% pentosans and 24% lignin and ash. Fourier-transform infrared spectroscopy (FTIR) analysis revealed that mengkuang leaf contained the same functional group as found in natural fiber such as kenaf, jute and flax, suggesting its amazing potential as the reinforcing fiber [18]. Fauzi et al. [19] found that the MLF was a good reinforcement in polyester.

Hashim et al. [20] used thermoplastic elastomer composite of ethylene vinyl acetate (EVA)/natural rubber (NR)/MLF to study the effect of MLF loading (from 10 wt.% to 40 wt.% with an increment of 10 wt.%) on tensile properties. They concluded that an increase in MFL loading resulted in an increase in Young’s modulus but a decrease in tensile strength. In another work, Halim et al. [21] studied the flexural and impact properties of low density polyethylene reinforced with MLF. The fiber weight percentage used were 10%, 20% and 30% with fiber length of less than 0.5 mm, 0.5–1 mm and 1–2 mm. Extrusion and compression molding were used to fabricate the specimens. They stated that flexural strength and modulus were increased with the increase in fiber content and fiber length. However, the impact strength increased with fiber length but decreased with the increase of fiber content.

Due to its hydrophilic nature, natural fiber composites can cause several problems, such as swelling, dimension changes and voids [22]. To remove excessive content of hemicellulose, pectin, lignin and ash, alkaline treatment such as sodium hydroxide (NaOH) can be applied, which is a common surface treatment for MLF [19,23]. The clean surface of the fiber could significantly improve the adhesion between the fiber and matrix [24]. Another way to improve fiber-matrix interfacial adhesion is through introduction of a coupling agent. The presence of maleic anhydride polyethylene (MAPE) or maleic anhydride polypropylene (MAPP) could enhance the interfacial bonding between the fiber and matrix [25,26]. Using the same range of fiber weight percentage and fiber length as Halim et al. [21], Hamdan et al. [27] investigated tensile, flexural and impact properties with and without MAPE. They concluded that both volume fraction and fiber length did not improve tensile properties but improve flexural strength significantly. Impact strength increased with an increase of fiber length but decreased with an increase of volume fraction. Flexural properties showed good progress with higher MAPE content, while tensile and impact properties were increased with 2 wt.% and 4 wt.% of MAPE, respectively.

The objective of this work was to study the tensile, flexural and impact properties of recycled PP (r-PP) reinforced with MLF. At the same time, the effects of NaOH treatment and/or MAPP on the mechanical properties of r-PP/MLF composite were evaluated. Performing this research is useful and necessary to understand the actual potentials of recycled PP/MLF composites in terms of their mechanical properties, leading to possible future applications for the composites.

2. Materials and Methods

MLF was acquired from a local village in Kuala Kangsar, Perak, Malaysia. The MLF was dried in the sun and cut into smaller pieces with average length of 7.5 mm and width of 1 mm. The matrix of the composite, r-PP, was obtained in pellet form from a local plastic recycling company, Sheng Foong Plastic Industries Sdn. Bhd., Perak, Malaysia. NaOH for alkaline treatment was manufactured by R and M Chemicals, Essex, UK and supplied by Avantis Laboratory Sdn. Bhd., Ipoh, Malaysia. The MLF that went through alkaline treatment was soaked in 5% concentration of NaOH for 24 h. Then, the MLF was washed with distilled water and dried under the sunlight for 3 days. The coupling agent used here was MAPP with the commercial name of Dupont™ Fusabond® P613. As recommended by the manufacturer (Dupont, Wilmington, NC, USA), 5 wt.% of the MAPP was added to the composite.

The compounding process of the composite was done using a twin-screw extruder (Leistritz Advanced Technologies, Allendale, NJ, USA) at 25 rpm with die diameter of 4 mm, pressure of 39 bar and temperature of 166 °C. The extrudate composite was cooled by forced air. Test specimens were fabricated using injection molding with temperature of 185 °C, pressure of 66.9 bar and screw velocity of 95 mm/s. Tensile, flexural and notched Izod impact tests were carried out according to ASTM D638, D790 and D256, respectively.

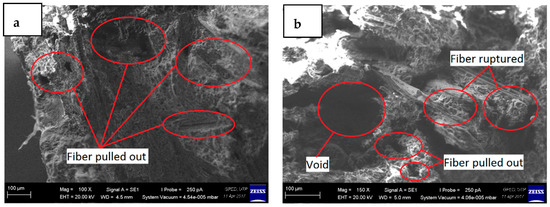

The morphologies of r-PP/MLF composites were studied using a scanning electron microscope (SEM, Phenom-World B.V., Eindhoven, The Netherlands). Prior to SEM examination, the tensile fractured surface of the sample was mounted onto aluminium stub and sputter-coated with a thin layer of gold to prevent electrostatic charging while obtaining information on fiber dispersion, fiber-matrix interaction and the mode of failure.

3. Results and Discussions

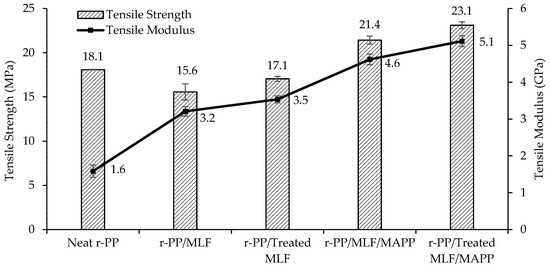

3.1. Tensile Properties

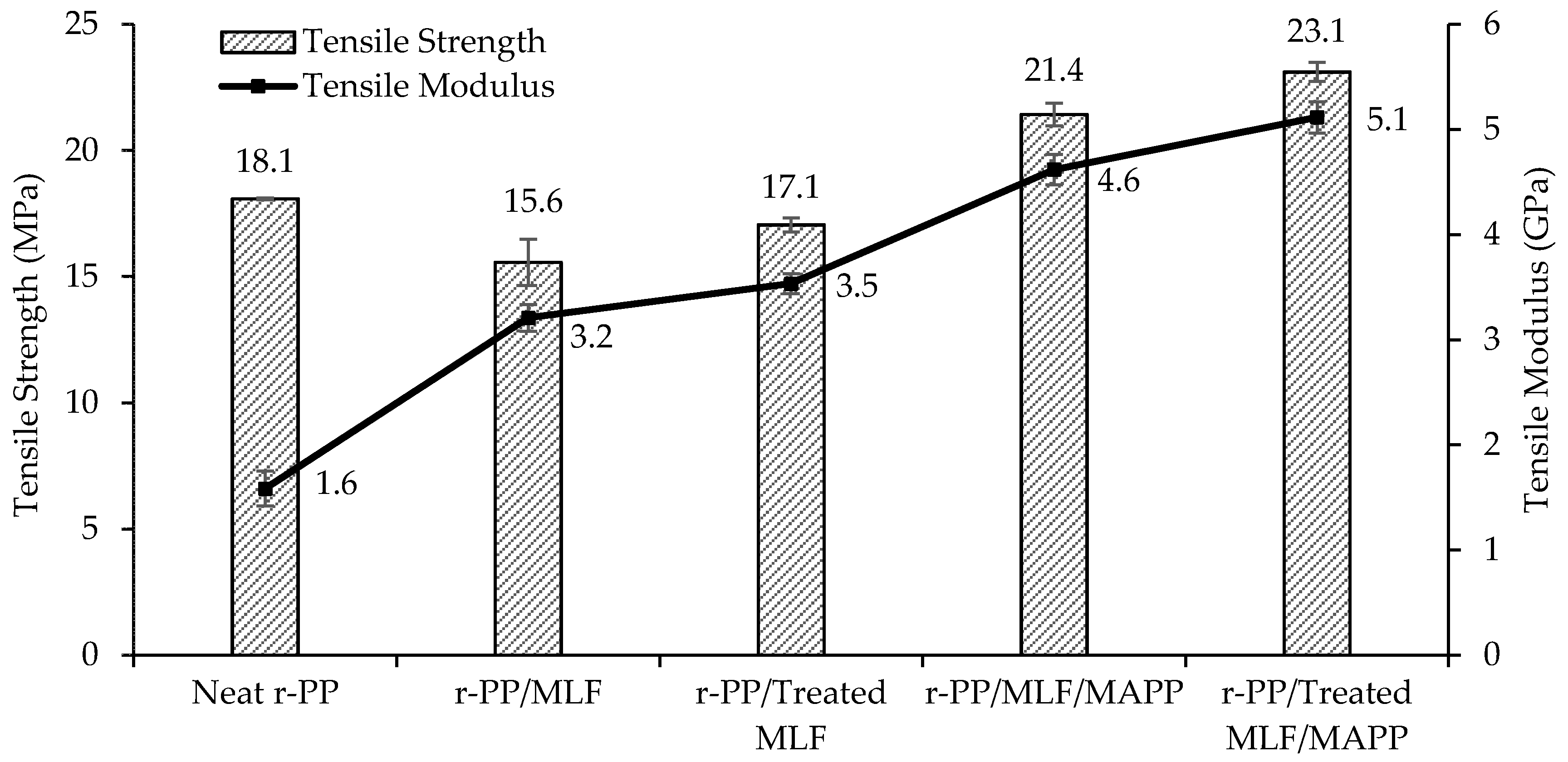

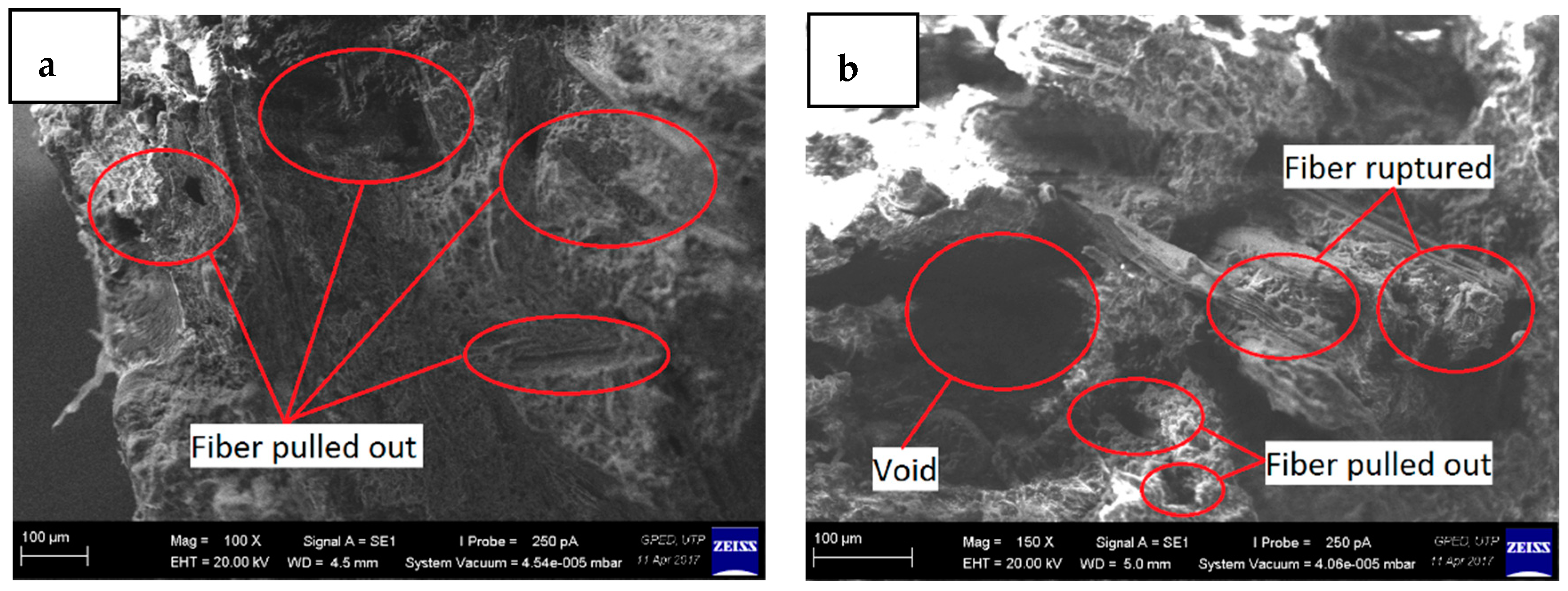

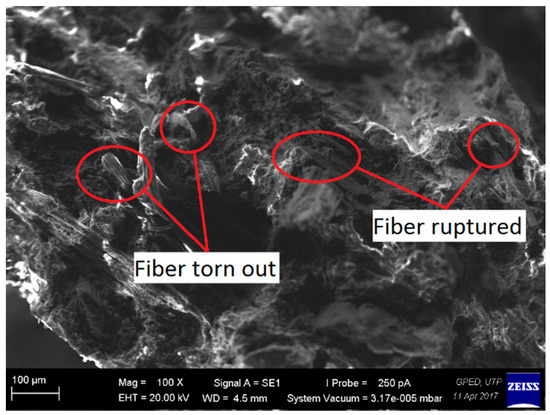

Figure 1 shows the tabulated data of tensile strengths and moduli of neat r-PP and r-PP/MLF composites. An increasing trend was observed from r-PP/MLF to r-PP/Treated MLF/MAPP. However, tensile strengths of r-PP/MLF and r-PP/NaOH treated MLF (i.e., r-PP/Treated MLF) were lower compared to neat r-PP. The main reason for the reduction of tensile strengths in both r-PP/MLF and r-PP/Treated MLF is due to weak fiber-matrix interfacial bonding, as indicated by fiber pulled out (shown in Figure 2). The tensile strength of r-PP/Treated MLF slightly improved due to stronger fiber without impurities, lignin and minimal hemicellulose.

Figure 1.

Tensile strengths and moduli of neat recycled polypropylene (r-PP) and r-PP/mengkuang leaf fiber (MLF) composites.

Figure 2.

Scanning electron microscope (SEM images of: (a) r-PP/MLF composite; (b) r-PP/Treated MLF composite.

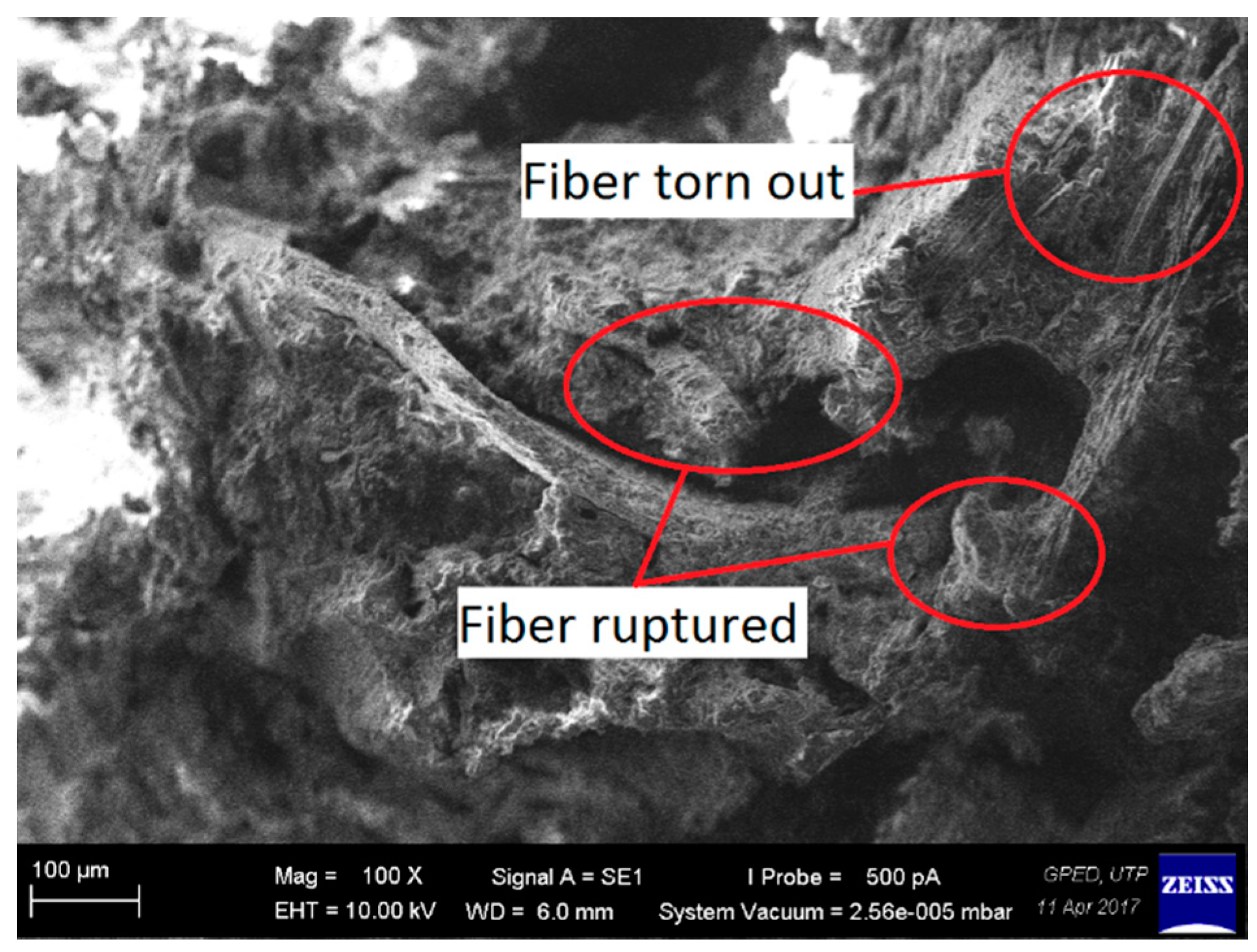

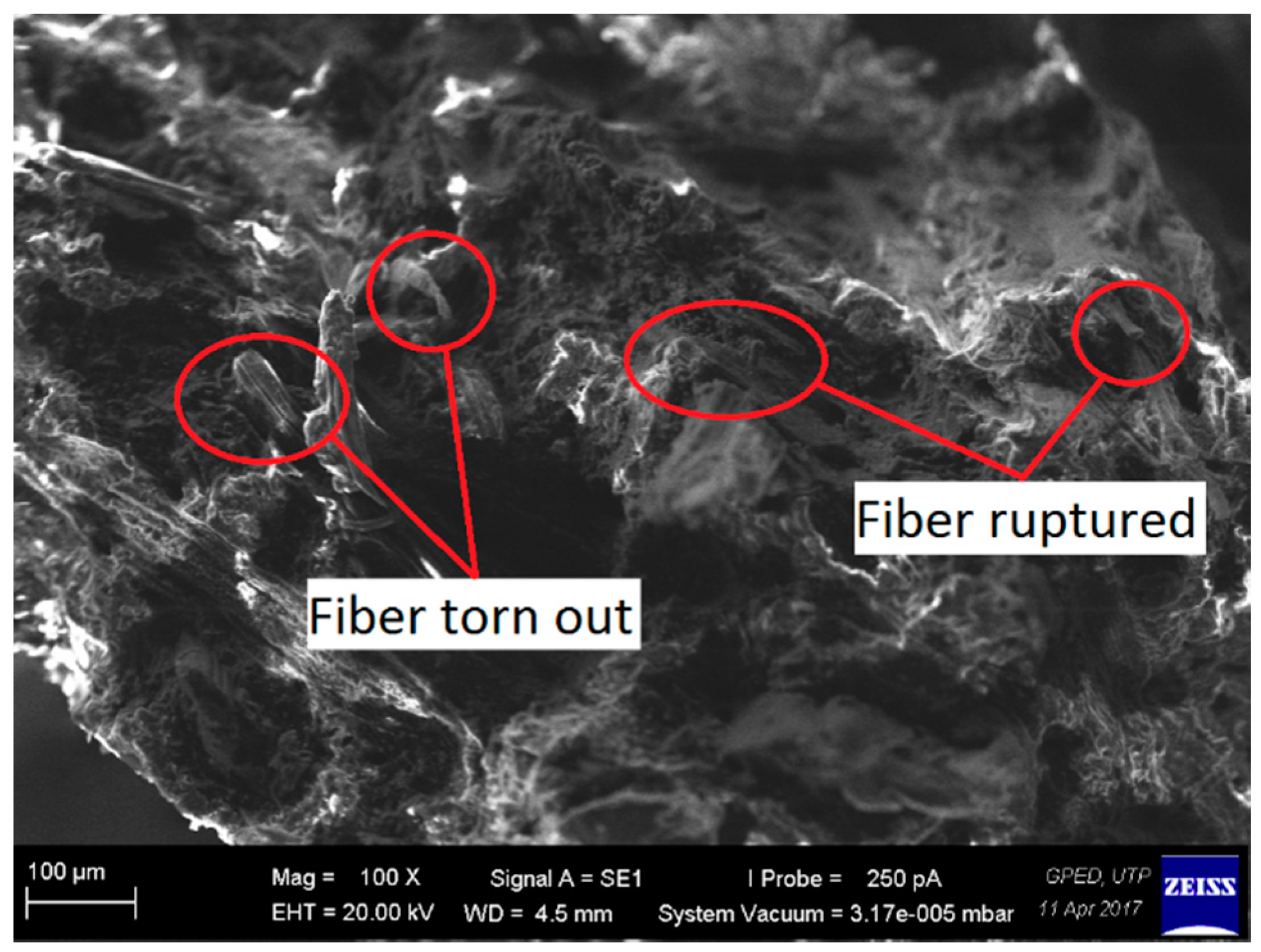

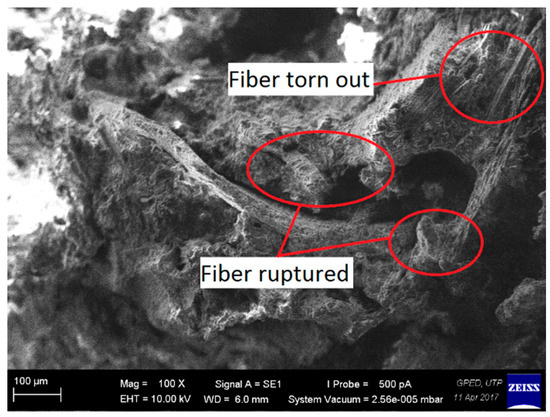

When MAPP was added to the composite, the most significant improvement was observed. The coupling agent, that is, MAPP, was used to provide compatibility between fiber and immiscible polymer matrix through reduction of the interfacial tension. Tensile strength of the composite with MAPP was enhanced by 37% compared to that of without MAPP. This is due to an improvement in interfacial bonding between fiber and matrix, as indicated by the ruptured fiber shown in Figure 3. The highest tensile strength was achieved when MAPP was added to r-PP/treated MLF composite. With stronger fibers and better fiber-matrix interfacial bonding, tensile strength of r-PP/Treated MLF/MAPP improved by 27.6% compared to neat r-PP. The ruptured fiber shown in Figure 4 indicates that this composite employs the strength of stronger and cleaner fiber due to NaOH treatment.

Figure 3.

SEM image of r-PP/MLF/MAPP composite.

Figure 4.

SEM image of r-PP/Treated MLF/ maleic anhydride-grafted polypropylene (MAPP) composite.

Tensile modulus is another property that can be extracted from tensile test. All moduli of the composites were higher than neat r-PP, suggesting that the MLF provides stiffness to the composites. The highest tensile modulus was observed in r-PP/Treated MLF/MAPP, which was an improvement of 224% compared to neat r-PP. A similar trend to tensile strength is observed here, indicating that better fiber-matrix interaction due to the presence of MAPP and stronger fiber due to NaOH treatment contribute towards the increasing trend of tensile modulus.

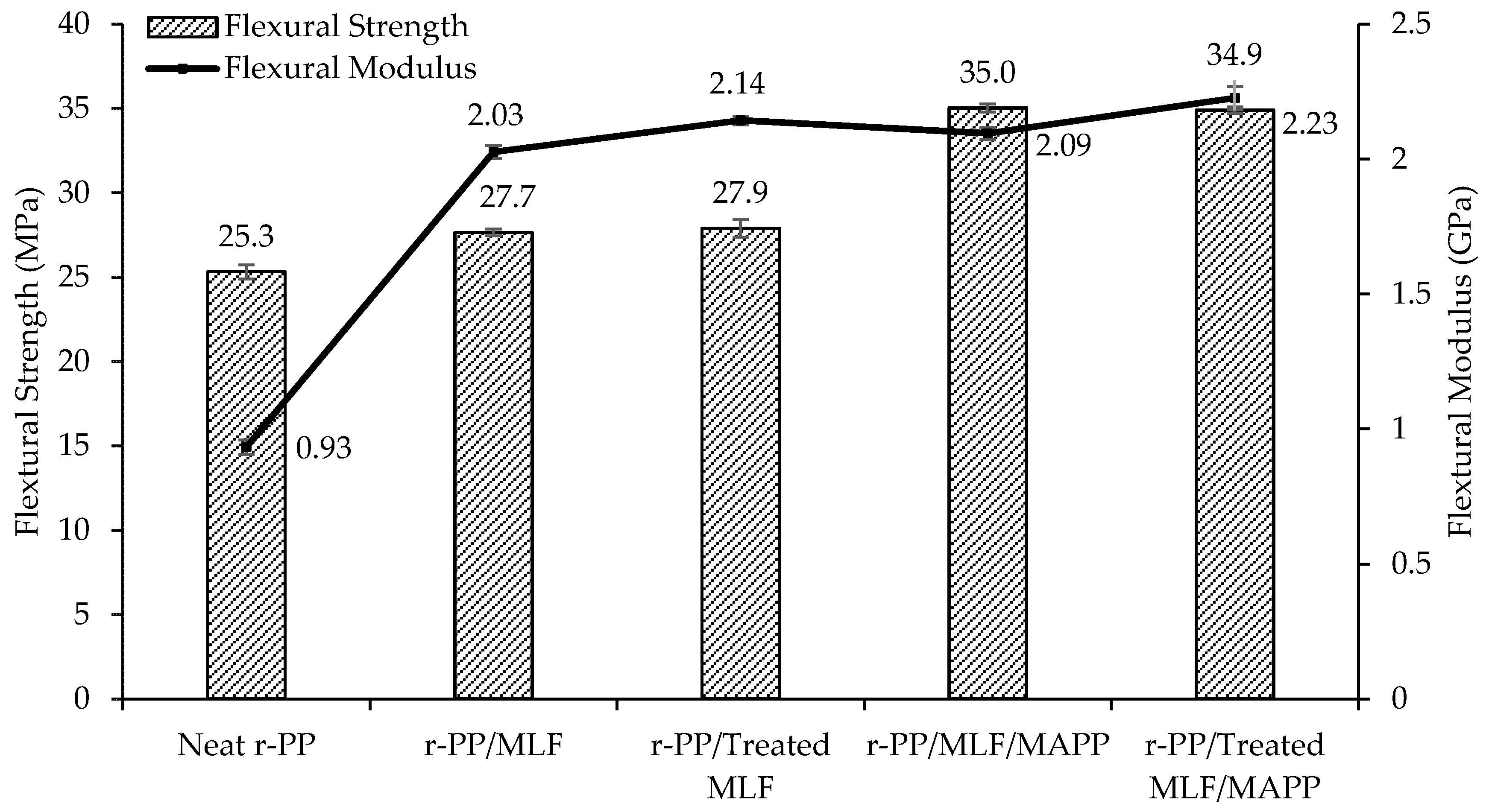

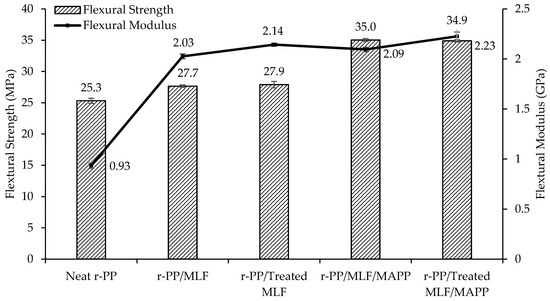

3.2. Flexural Properties

Flexural strengths and moduli of neat r-PP and r-PP/MLF composites are summarized in Figure 5. Flexural strengths of the composites generally showed an increasing trend compared to neat r-PP. Besides the contribution of MLF, MAPP was a major contributor to flexural strength, even though virtually no improvement due to NaOH treatment was observed. The improvement due to MAPP was approximately 26%, signifying the importance of fiber-matrix adhesion in achieving high mechanical properties. An improvement of approximately 38% was observed for both r-PP/MLF/MAPP and r-PP/Treated MLF/MAPP compared to neat r-PP.

Figure 5.

Flexural strengths and moduli of neat r-PP and r-PP/MLF composites.

The tendency for a material to resist bending can be explored through flexural modulus data. Similar to flexural strength, all of the composite data show substantial improvements compared to neat r-PP. However, the trend indicates that MAPP and alkaline treatment do not play a major role in improving the flexural modulus. The addition of 40 wt.% of MLF to r-PP is enough to increase the flexural modulus significantly. The highest value of flexural modulus was achieved by r-PP/Treated MLF/MAPP with an improvement of 140% compared to neat r-PP.

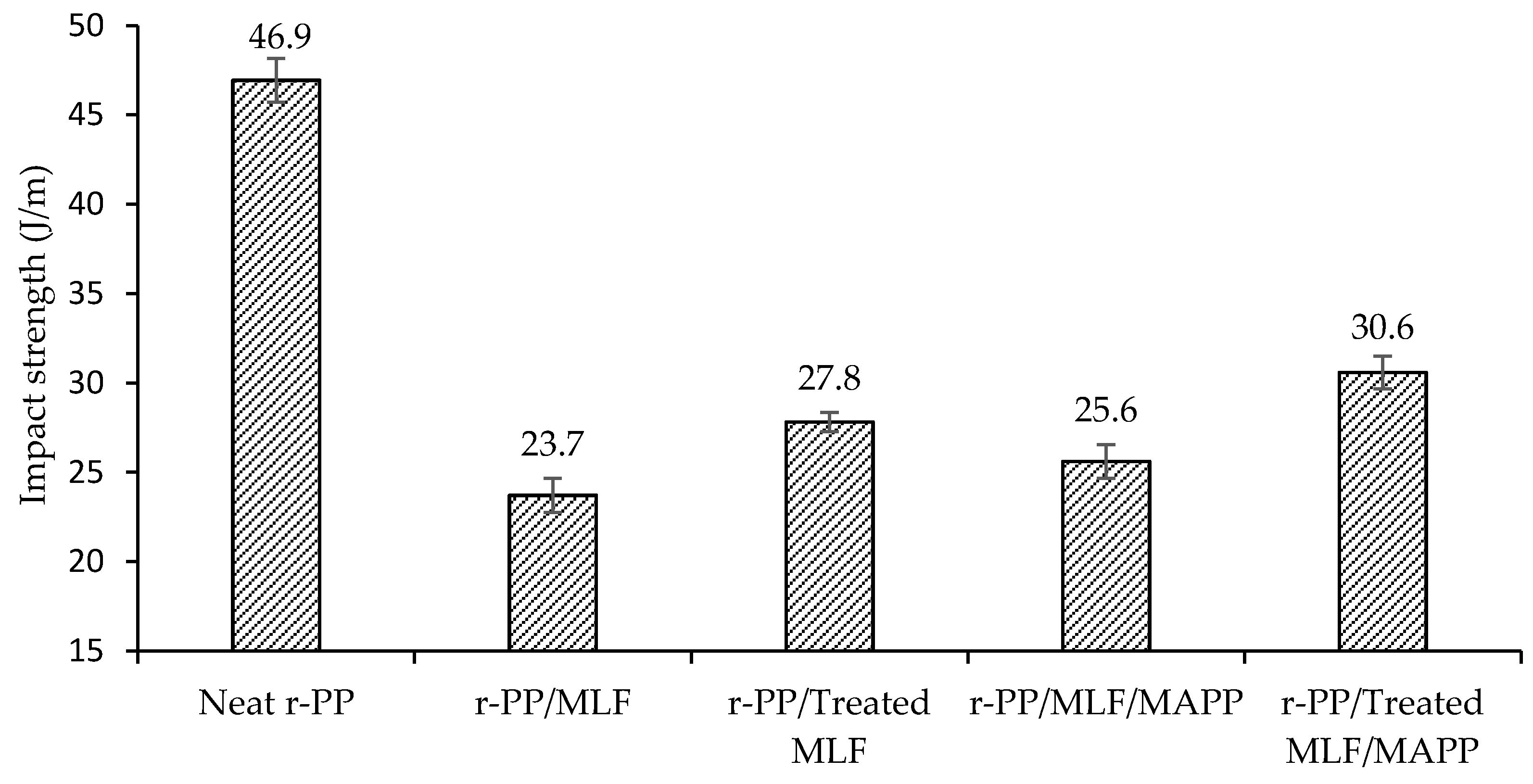

3.3. Impact Strength

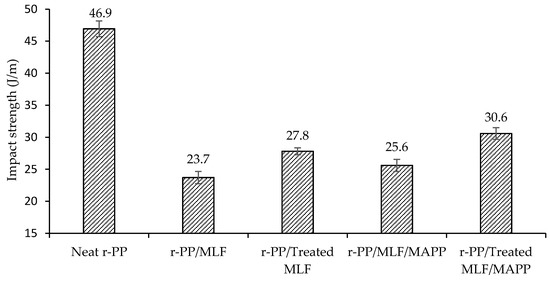

Impact strength is the ability of the material to resist fracture under stress applied at high speeds. The absorbance of energy in composite strength against a strike occurs by the combination of the creation and development of cracks. The notched Izod impact test specifies the energy required to propagate a crack to the breaking point, but not to initiate it. Resistance to the growth of a macroscopic crack is often regarded as a more functional parameter. A crack starts in a high stress concentration area with a defect such as an area where the connection between the two phases of the composite is very weak.

Figure 6 exhibits Izod impact strengths of neat r-PP and r-PP/MLF composites. The impact strengths of all composites were significantly lower than neat r-PP. The addition of 40 wt.% of MLF to r-PP causes a reduction in impact strength. This is due to the nature of short fiber used in this work, which presents a weak connection between fiber and matrix phases. The impact strength increases when the length of fiber increases. As highlighted by Pickering et al. [28], the longer fiber offers more efficient and better stress transfer compared to the shorter fiber. The shorter fiber makes the materials more brittle and incapable of disrupting the crack propagation. The short fiber most likely will be pulled out from the matrix rather than broken, allowing a crack to pass through the composite. Even though NaOH treatment and MAPP slightly improved the impact strength of the composite, the strength never came close to that of neat r-PP.

Figure 6.

Izod impact strengths of neat r-PP and r-PP/MLF composites.

4. Conclusions

Tensile, flexural and impact properties of r-PP/MLF composites with and without alkaline treatment and MAPP were successfully studied. Generally, improvements were observed in tensile and flexural properties. While NaOH treatment contributed to the increase of mechanical properties, MAPP showed very significant influence in tensile strength, tensile modulus and flexural strength. The composite with both alkaline treatment and MAPP achieved the highest improvement in most categories. Improvements of 27.6%, 224%, 38% and 140% were observed in tensile strength, tensile modulus, flexural strength and flexural modulus, respectively, compared to neat r-PP. Morphological study of the fractured samples had indicated an enhancement in fiber-matrix adhesion with the addition of MAPP through ruptured fiber as compared to pulled out fiber without MAPP. However, impact strengths of the composites were reduced significantly, which was expected because short fiber most likely would be pulled out from the matrix rather than ruptured under stress applied at high speed, allowing a crack passed through the composite.

Author Contributions

Conceptualization, M.Z.A.; Investigation, N.H.C.A.; Resources, N.H.C.A.; Supervision, M.Z.A.; Writing—Original Draft, N.H.C.A.; Writing—Review & Editing, M.Z.A.

Funding

This research was funded by YAYASAN UNIVERSITI TEKNOLOGI PETRONAS, grant number YUTP 0153AA-E25. The APC was funded by YUTP 0153AA-E2.

Acknowledgments

The authors would like express their appreciation to Universiti Teknologi PETRONAS for supporting this work under YUTP 0153AA-E25.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ferrão, P.; Amaral, J. Assessing the economics of auto recycling activities in relation to European Union Directive on end of life vehicles. Technol. Forecast. Soc. Chang. 2006, 73, 277–289. [Google Scholar] [CrossRef]

- Akçaözoğlu, S. Evaluation of waste plastics as recycled plastic composite materials. Edorium J. Waste Manag. 2015, 1, 16–19. [Google Scholar] [CrossRef]

- Kengkhetkit, N.; Amornsakchai, T. A new approach to “Greening” plastic composites using pineapple leaf waste for performance and cost effectiveness. Mater. Des. 2014, 55, 292–299. [Google Scholar] [CrossRef]

- Leao, A.L.; Fouza, S.F.; Cherian, B.M.; Frollini, E.; Thomas, S.; Pothan, L.A.; Kottaisamy, M. Agro-based biocomposites for industrial applications. Mol. Cryst. Liq. Cryst. 2010, 522, 318–327. [Google Scholar] [CrossRef]

- Uma Devi, L.; Joseph, K.; Munikandan Nair, K.C.; Thomas, S. Ageing studies of pineapple leaf fiber-reinforced polyester composites. J. Appl. Polym. Sci. 2004, 94, 503–510. [Google Scholar] [CrossRef]

- Nega, A.; Worku, A. Composite manufacturing from recycled medical gloves reinforced with jute fiber. J. Text. Sci. Eng. 2018, 8, 369–371. [Google Scholar] [CrossRef]

- Yang, Y.; Ota, T.; Morii, T.; Hamada, H. Mechanical property and hydrothermal aging of injection molded jute/polypropylene composites. J. Mater. Sci. 2010, 46, 2678–2684. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, M.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Al-Oqla, F.M.; Sapuan, S.M. Natural fiber reinforced polymer composites in industrial applications: Feasibility of date palm fibers for sustainable automotive industry. J. Clean. Prod. 2014, 66, 347–354. [Google Scholar] [CrossRef]

- Saba, N.; Paridah, M.T.; Jawaid, M. Mechanical properties of kenaf fibre reinforced polymer composite: A review. Constr. Build. Mater. 2015, 76, 87–96. [Google Scholar] [CrossRef]

- Tye, Y.Y.; Lee, K.T.; Abdullah, W.N.W.; Leh, C.P. The world availability of nonwood lignocellulosic biomass for the production of cellulosic ethanol and potentialpretreatments for the enhancement of enzymatic saccharification. Renew. Sustain. Energy Rev. 2016, 60, 155–172. [Google Scholar] [CrossRef]

- Joseph, K.; Thomas, S.; Pavithran, C.; Brahmakumar, M. Tensile properties of short sisal fiber-reinforced polyethylene composites. J. Appl. Polym. Sci. 1993, 47, 1731–1739. [Google Scholar] [CrossRef]

- Shibata, M.; Takachiyo, K.I.; Ozawa, K.; Yosomiya, R.; Takeishi, H. Biodegradable polyester composites reinforced with short abaca fiber. J. Appl. Polym. Sci. 2002, 85, 129–138. [Google Scholar] [CrossRef]

- Paul, S.A.; Boudenne, A.; Ibos, L.; Candau, Y.; Joseph, K.; Thomas, S. Effect of fiber loading and chemical treatments on thermophysical properties of banana fiber/polypropylene commingled composite materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1582–1588. [Google Scholar] [CrossRef]

- Sapuan, S.; Mohamed, A.; Siregar, J.; Ishak, M. Pineapple Leaf Fibers and PALF-reinforced Polymer Composites. In Cellulose Fibers: Bio-and Nano-Polymer Composites; Kalia, S., Kaith, B., Kaur, I., Eds.; Springer: Berlin, Germany, 2011; pp. 325–343. ISBN 978-3-642-17370-7. [Google Scholar]

- Sheltami, R.M.; Abdullah, I.; Ahmad, I.; Dufresne, A.; Kargarzadeh, H. Extraction of cellulose nanocrystals from mengkuang leaves (Pandanus tectorius). Carbohydr. Polym. 2012, 88, 772–779. [Google Scholar] [CrossRef]

- Piah, M.R.M.; Baharum, A.; Abdullah, I. Mechanical properties of bio-composite natural rubber/high density polyethylene/mengkuang fiber (NR/HDPE/MK). Polym. Polym. Compos. 2016, 24, 767–774. [Google Scholar] [CrossRef]

- Fauzi, F.A.; Ghazalli, A.; Siregar, J.P.; Tezara, C. Investigation of thermal behaviour for natural fibres reinforced epoxy using thermogravimetric and differential scanning calorimetric analysis. MATEC Web Conf. 2016, 78, 1042. [Google Scholar] [CrossRef]

- Hashim, F.; Ismail, H.; Rusli, A. Properties and characterization of ([mengkuang leaf fiber]-filled ethylene vinyl acetate)/(natural rubber) blend: Effects of blending sequences and mengkuang leaf fiber loading. J. Vinyl Addit. Technol. 2018, 24, 109–115. [Google Scholar] [CrossRef]

- Halim, N.A.; Siregar, J.P.; Mathivanan, D.; Bachtiar, D.; Ghazali, Z.; Rejab, M.R.M.; Tezara, C. The performance of mengkuang leaf fiber reinforced low density polyethylene composites. J. Mech. Eng. Sci. 2018, 12, 3645–3655. [Google Scholar] [CrossRef]

- Das, G.; Biswas, S. Physical, mechanical and water absorption behaviour of coir fiber reinforced epoxy composites filled with Al2O3 particulates. IOP Conf. Ser. Mater. Sci. Eng. 2016, 115, 12012. [Google Scholar] [CrossRef]

- Hamizol, M.S.; Megat-Yusoff, P.S.M. Tensile strength of single continuous fiber extracted from mengkuang leaves. J. Teknol. 2015, 76, 101–107. [Google Scholar] [CrossRef]

- Liu, M.; Meyer, A.S.; Fernando, D.; Silva, D.A.S.; Daniel, G.; Thygesen, A. Effect of pectin and hemicellulose removal from hemp fibres on the mechanical properties of unidirectional hemp/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 724–735. [Google Scholar] [CrossRef]

- Zulkifli, N.I.; Samat, N. Mechanical Properties of Green Recycled Polypropylene Composites: Effect of Maleic Anhydride Grafted Polypropylene (MAPP) Coupling Agent. Adv. Mater. Res. 2013, 812, 187–191. [Google Scholar] [CrossRef]

- Zulkifli, N.I.; Samat, N.; Anuar, H.; Zainuddin, N. Mechanical Properties and failure modes of recycled polypropylene/microcrytalline cellulose composites. Mater. Des. 2015, 69, 114–123. [Google Scholar] [CrossRef]

- Hamdan, M.H.M.; Siregar, J.P.; Bachtiar, D.; Bachtiar, D.; Rejab, M.R.M.; Tezara, C. Mechanical properties of mengkuang leave fiber reinforced low density polyethylene composites. In Natural Fiber Reinforced Vinyl Ester and Vinyl Polymer Composites; Sapuan, S.M., Ismail, H., Zainudin, E.S., Eds.; Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Cambridge, UK, 2018; pp. 181–196. [Google Scholar]

- Pickering, K.L.; Efendy, M.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).