1. Introduction

Carbon-Fiber-Reinforced Polymers (CFRPs) are extensively employed in aerospace, wind energy, and automotive sectors owing to their outstanding mechanical properties, particularly their high strength-to-weight ratio. Modern aircraft, such as the Boeing 787 and Airbus A350, make extensive use of CFRP components, which constitute more than 50% of their structural mass, thereby enhancing fuel efficiency and enabling lightweight design [

1]. Beyond aerospace, the adoption of CFRP composites in automotive structures and high-pressure storage vessels is rapidly expanding. These materials provide significant weight savings and superior crashworthiness, with energy absorption capacities reaching up to 250 kJ/kg—far exceeding the ~20 kJ/kg typical of steel. Such advantages have driven their increasing use in compressed natural gas (CNG) and hydrogen storage systems, particularly in filament-wound pressure vessels designed for vehicles and industrial transport applications [

2,

3].

As high-performance composites gain industrial traction, global market projections forecast growth from USD 27.6 billion in 2024 to USD 56.9 billion by 2034 [

4]. With CFRP waste from the aviation and wind energy sectors expected to surpass 840,000 tons annually by 2050 and European composite waste nearing 683,000 tons per year, the current global recycling capacity of under 100,000 tons highlights a critical gap, prompting regulatory pressure and urgent demand for sustainable end-of-life solutions [

5]. Recent studies have further emphasized the need to align composite recycling with the circular economy and sustainability assessment, particularly in aerospace applications, to support environmentally responsible material recovery [

6,

7]. This trend increases the need for efficient end-of-life recycling. Thermoset-based CFRPs, unlike thermoplastics, cannot be remelted due to permanent cross-linking in their resin, posing a challenge to traditional recycling methods [

8].

Several recycling strategies have been developed over the past decades. Mechanical recycling, which involves shredding or grinding composites into smaller particles, is cost-effective but lowers the fiber quality [

9]. Thermal methods, such as pyrolysis, can recover fibers but involve high infrastructure costs and produce harmful byproducts. Chemical recycling, on the other hand, offers high retention of material properties through effective resin removal using solvent systems [

10]. Among recent advancements, plasma-assisted solvolysis, a hybrid approach combining oxidative chemicals and plasma, has shown promise in degrading matrix material while protecting fiber structure [

11].

The significance of recycling CFRPs lies not only in addressing environmental challenges but also in the ability to recover fibers with properties suitable for reuse in high-performance applications. Notably, mechanical recycling was evaluated by reinforcing polymer composites with recycled carbon fibers (rCFs). The composites showed 208% higher stiffness and 105% tensile strength [

12]. In addition, a process involving microwave pyrolysis followed by oxidation was used to recover clean carbon fibers, and the rCFs retained tensile strength at 73% relative to virgin carbon fibers (vCFs) [

13]. In a recent study, model composites were recycled three times via pyrolysis and partial oxidation. While the stiffness of the rCFs increased up to 130.9% of that of vCFs, tensile strength decreased progressively with each cycle, retaining only 25% with rapid heating [

14]. However, mechanical recycling faces limitations such as poor interfacial adhesion between rCFs and the new polymer matrix, caused by fiber surface damage and shortening during processing [

9]. Pyrolysis can produce gas and liquid feedstocks; however, char formation negatively impacts the mechanical properties of the fibers [

15].

Recently, chemical recycling of CFRPs has shown promising advances. A comparative study involving methanesulfonic acid (MSA), acetic acid, and nitric acid found MSA most effective, reducing residual resin to 5%. The rCFs experienced a 27.6% reduction in tensile strength, a 19.2% loss in Young’s modulus, and a 10.5% reduction in elongation at break, indicating moderate mechanical degradation [

16]. Similarly, a one-step oxidative solvolysis method using peracetic acid achieved full resin removal with more than 90% recovery of solvents while preserving the tensile strength of the rCFs [

17]. Additionally, using a special catalyst in a dimethylacetamide solvent enabled nearly complete resin degradation without visible surface damage. However, mechanical evaluation showed that the recycled fibers retained 82.8% of their original strength [

18]. In another environmentally friendly approach, CFRPs were immersed in nitric acid followed by sodium bicarbonate, both at 80 °C. Interfacial shear strength (IFSS) and tensile strength increased by 2.7 and 1.6 times, respectively, while maintaining a comparable elastic modulus [

19]. Furthermore, energy-efficient solvolysis using meta-Chloroperoxybenzoic acid (mCPBA) at 40 °C decomposed resin in 6 h; rCFs retained 93.6% of their strength and showed 26% higher IFSS [

20]. A catalytic method employing a monoethanolamine–potassium hydroxide (MEA–KOH) solvent achieved 99% decomposition. Tensile testing, analyzed using Weibull statistics, showed that tensile strength and modulus were retained at 96% and 95%, respectively [

21]. Recently, rCFs recovered through microwave-assisted chemical recycling retained 98.3% of their original tensile strength, 94.1% of Young’s modulus, and 96.2% of the elongation at break [

22]. A semi-continuous flow process using near- and supercritical water and water/ethanol mixtures demonstrated that the tensile strength of rCFs was statistically comparable to unsized virgin fibers [

23]. Moreover, supercritical solvolysis using n-propanol achieved, despite the elevated temperature, rCFs showing no significant deviation in tensile properties; however, there was a reduction in IFSS [

24]. Additionally, a two-step method employing H

2O

2 and N,N-dimethylformamide enabled over 90% matrix decomposition, with the recovered fibers retaining up to 97% [

25]. A hybrid approach combining chemical swelling and electrochemical oxidation in dimethyl sulfoxide at ambient conditions achieved resin removal of over 90.3%. The rCFs maintained 93.6% of their tensile strength, while their IFSS improved significantly, reaching 118.76% of the original values [

26]. Further, supercritical 1-propanol with a catalyst improved resin breakdown, while the rCFs retained 95% of their tensile strength at temperatures up to 330 °C, but at 340 °C, strength retention dropped to 88.6%, highlighting the process’s temperature sensitivity [

27]. Superheated steam was used to recycle CFRPs, yielding recycled fibers with lower tensile strength. Tensile modulus was nearly the same, and Weibull analysis showed that strength decreased with longer gauge lengths [

28]. An optimized recovery method using supercritical acetone enabled nearly complete matrix removal. Carbon fibers treated at 300 °C for 60 min retained and even exceeded the tensile strength of vCFs [

29]. Finally, in a preliminary study using water- and acetone-based solvolysis under subcritical and supercritical conditions, resin decomposition reached 90–100%. Equally important, rCFs retained over 70% of their tensile strength and 61% of their Young’s modulus [

30], consistent with findings from water/ethanol-based solvolysis, where comparable mechanical retention was reported under optimized conditions [

31].

In the evolving field of solvolysis, assisted techniques such as sonication and plasma treatment have shown promise in enhancing resin removal efficiency under milder conditions. For instance, sonochemical treatment using diluted nitric acid and hydrogen peroxide significantly increased the decomposition rate up to 95%, while preserving the tensile strength of recovered fibers. This approach reduces the need for harsh chemicals and high temperatures or pressures [

32]. Plasma-assisted solvolysis using nitric acid has demonstrated complete epoxy matrix decomposition, independent of composite geometry, without the use of extreme thermal and pressure conditions. Treatment time was reduced to under 180 min, while morphological analyses confirmed clean fiber surfaces. The rCFs retained 70% of their tensile strength, 74% strain at break, and 95% of Young’s modulus, indicating strong structural preservation [

33,

34]. This aligns with a study showing that plasma-enhanced nitric acid accelerates matrix dissolution by enhancing oxidation and mass transport, with mass transport remaining the main rate-limiting step [

35].

Overall, previous studies demonstrate that solvolysis methods—and plasma-assisted solvolysis in particular—can recover carbon fibers with minimal loss of mechanical performance and, in some cases, even enhance properties. The present work evaluates the extent to which the mechanical properties of carbon fibers are preserved after plasma-assisted solvolysis, compared with their virgin counterparts. Multiple CFRP batches were recycled under different plasma-solvolysis conditions, and the recovered fibers were subjected to mechanical characterization. Single-fiber tension tests were conducted to measure tensile strength, Young’s modulus, and elongation at break, while microbond tests were performed to assess the interfacial shear strength (IFSS). Statistical analyses were applied to examine property retention across processing conditions. By investigating how plasma-assisted solvolysis influences fiber mechanics, this study addresses key challenges in CFRP recycling. The present study performs a parametric assessment linking plasma power, acid concentration, and gas composition to the quantitative mechanical retention of carbon fibers. Through detailed tensile, interfacial, and Weibull statistical analyses, it establishes a comprehensive correlation between processing conditions and mechanical reliability of recycled fibers. The results advance understanding of hybrid chemical–plasma recycling processes, supporting the development of circular economy strategies for advanced composites and promoting the sustainable expansion of CFRP applications.

2. Experimental Section

2.1. Materials

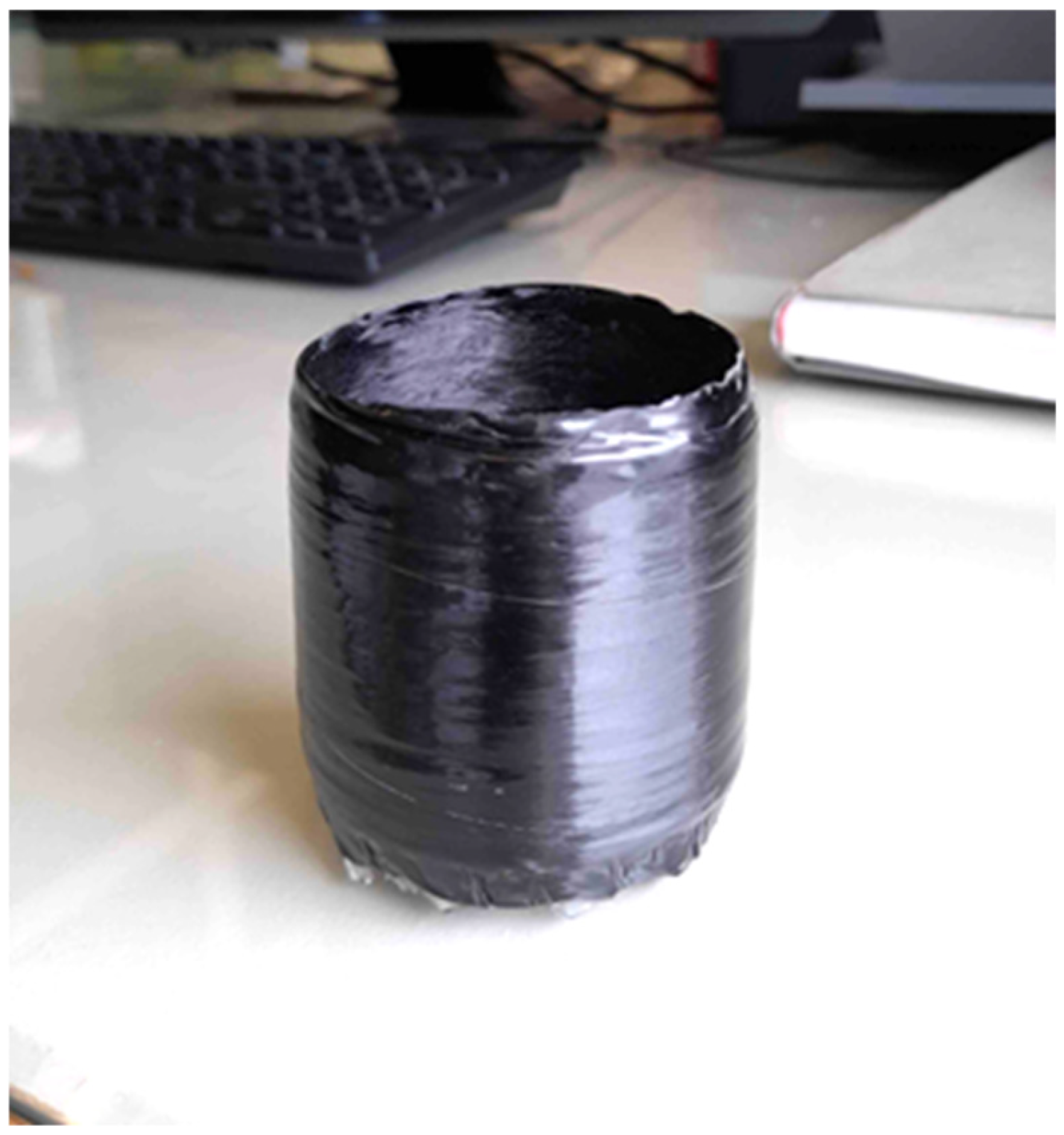

The CFRPs examined in this study were sourced from composite cylinders produced by filament winding (

Figure 1), a technique widely employed for fabricating cylindrical structures. The cylinders were custom-manufactured by Β&Τ Composites, Florina, Greece, using the filament winding method. Each specimen measured 6.4–6.5 cm in height, with an internal diameter of 5.5 cm and an external diameter of 6.0 cm, yielding a wall thickness of approximately 0.25 cm.

The reinforcement material used in this study comprised virgin carbon fibers supplied by Fibermax Ltd. (Volos, Greece), specifically the TR30S grade in 3K and 24K tow configurations. The designations 3K and 24K indicate tows containing approximately 3000 and 24,000 individual filaments, respectively, corresponding to small- and large-bundle fiber formats. These fibers are recognized for their high tensile strength and uniform structural quality, making them a standard choice in performance-critical applications. The total fiber mass was 1.80 kg, corresponding to an overall fiber length of approximately 5000 m [

36].

The polymer matrix employed in this study was the high-performance epoxy laminating system SR 1700, supplied by Sicomin Epoxy Systems (Châteauneuf-les-Martigues, France), a bisphenol-A-based resin widely used in the automotive, naval, and aerospace industries. This resin system is characterized by its high modulus, excellent stiffness, low water absorption after curing, and strong adhesion to various reinforcements, including carbon fibers. The curing process incorporated the SD 2803 and SD 2806 amine hardeners, supplied by the same manufacturer, mixed with the resin at the recommended 100:39 (

w/

w) ratio. The resulting composite structure demonstrated good mechanical integrity, with a service temperature capability of up to 60–70 °C. The key properties of the resin system, as provided in the technical datasheet, are summarized in

Table 1 [

37].

2.2. The Plasma-Assisted Solvolysis Process

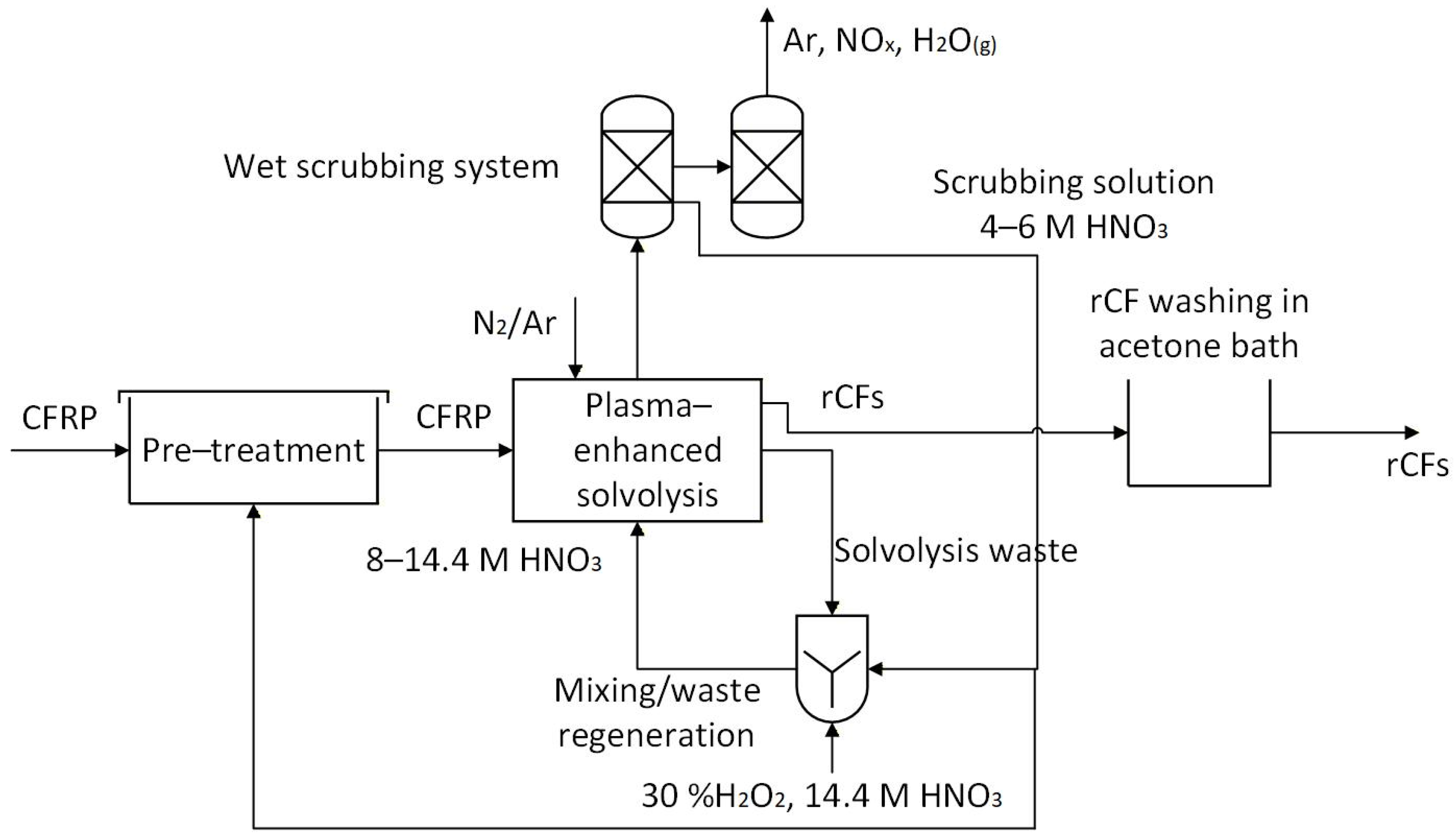

The plasma-assisted solvolysis process consists of five sequential stages: (a) material pre-treatment, (b) solvolysis in a plasma reactor, (c) fiber cleaning, (d) liquid waste regeneration, (e) flue gas scrubbing.

Figure 2 illustrates the integrated process flow chart.

The recycling process begins with pre-treatment, swelling the composite in a low-concentration nitric acid solution, typically 4–6 M. This step enhances the accessibility of the resin matrix, improving its sensitivity to oxidative degradation during the plasma-assisted phase. The pre-treatment is essential for facilitating uniform plasma exposure and efficient resin breakdown.

Following pre-treatment, the composite is transferred to a 2 L glass reactor and is submerged in 1.2 L of a higher-concentration nitric acid solution, about 10–14 M. The reactor is mounted on a stainless-steel baseplate, which serves as the grounded electrode. Four vertically oriented cylindrical electrodes, referred to as plasma heads, are inserted into the solution. Each electrode is surrounded by a glass tube that delivers a controlled flow of inert gases, argon (Ar) and nitrogen (N2), in a fixed 2:0.5 volumetric ratio, forming bubbles within the solution to support plasma generation. The electrodes are powered by an alternating current (AC) generator (IGBT143, Martignoni Elettrotecnica, Milano, Italy) operating at 30 kHz, with a maximum output of 2 kW. Under these conditions, plasma is generated within the liquid medium, initiating oxidative decomposition of the polymer matrix. During treatment, the applied voltage is ~30 kV peak-to-peak and is monitored using a high-voltage 1000:1 passive probe (P6015A, Tektronix, Beaverton, OR, USA). Current flow is ~2–3 A peak-to-peak, and it is measured via the voltage drop across a 47 Ω precision resistor (HS300 47R J ±5%, Arcol) connected between the stainless-steel bottom electrode and ground, using a 100:1 passive voltage probe (Hameg HZ53, Mainhausen, Germany).

Plasma treatment accelerates resin degradation, enabling the release of clean carbon fibers. Throughout the process, solution temperature can reach 110 °C within 60 min due to plasma-induced heating. Real-time monitoring of process voltage, via passive high-voltage probes, ensures consistent control of input power. Upon completion of the plasma treatment, the recovered carbon fibers are mechanically separated from the solution and washed with acetone to remove residual matrix and acid contaminants. Around 1 L of acetone is sufficient for cleaning 1 kg of fibers.

During the solvolysis process, nitrogen oxide (NO

x) gases are generated as byproducts. These emissions are directed into a wet scrubbing system, where fraction of the NO

x is converted into nitric acid. This recovered solution is then reused in the pre-treatment stage, forming part of a closed-loop chemical cycle. These emissions are directed into a wet scrubbing system of 0.06 M H

2O

2 and 0.01 M HNO

3, where a fraction of the NO

x is converted into nitric acid. Specifically, a two-stage wet scrubber is employed, involving 2 × 1.5 L wet scrubbing solutions connected in series. Typically, during operation 0.3–0.4

of emissions are led into the wet scrubber. After 50 h of operation, NO

x recovery stabilizes at ~82%, while the concentration of the first-in-series wet scrubbing solution starts plateauing at 5–6 M HNO

3. This recovered solution is replaced with fresh scrubbing solution and then reused in the pre-treatment stage, forming part of a closed-loop chemical cycle. In addition, the residual liquid remaining in the reactor undergoes a regeneration process involving the addition of fresh nitric acid, hydrogen peroxide (H

2O

2), and the scrubber-derived acid. This mixture restores the reactivity of the solution, allowing its reuse for 4 operation cycles before replacing it with fresh HNO

3 [

38].

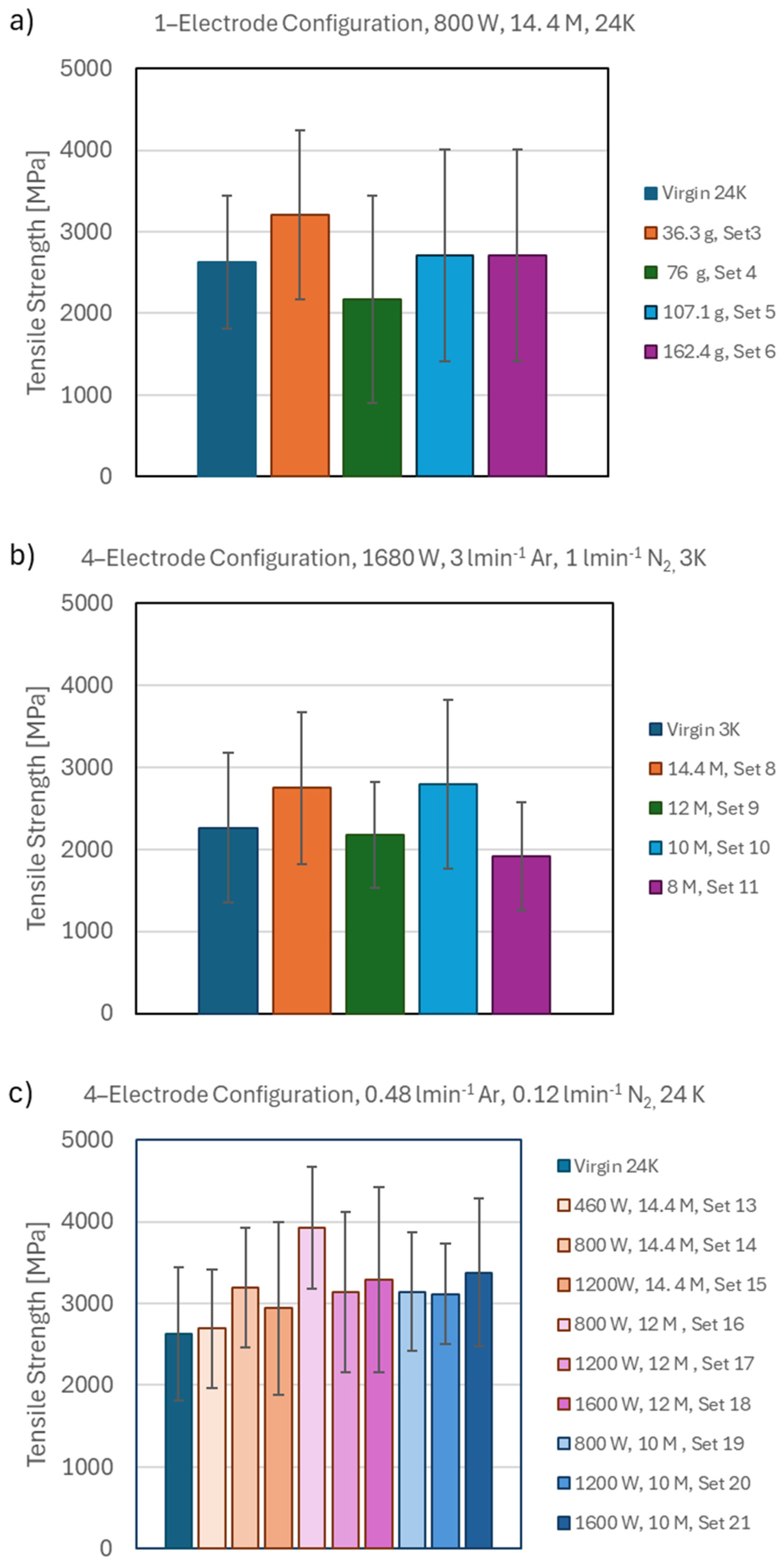

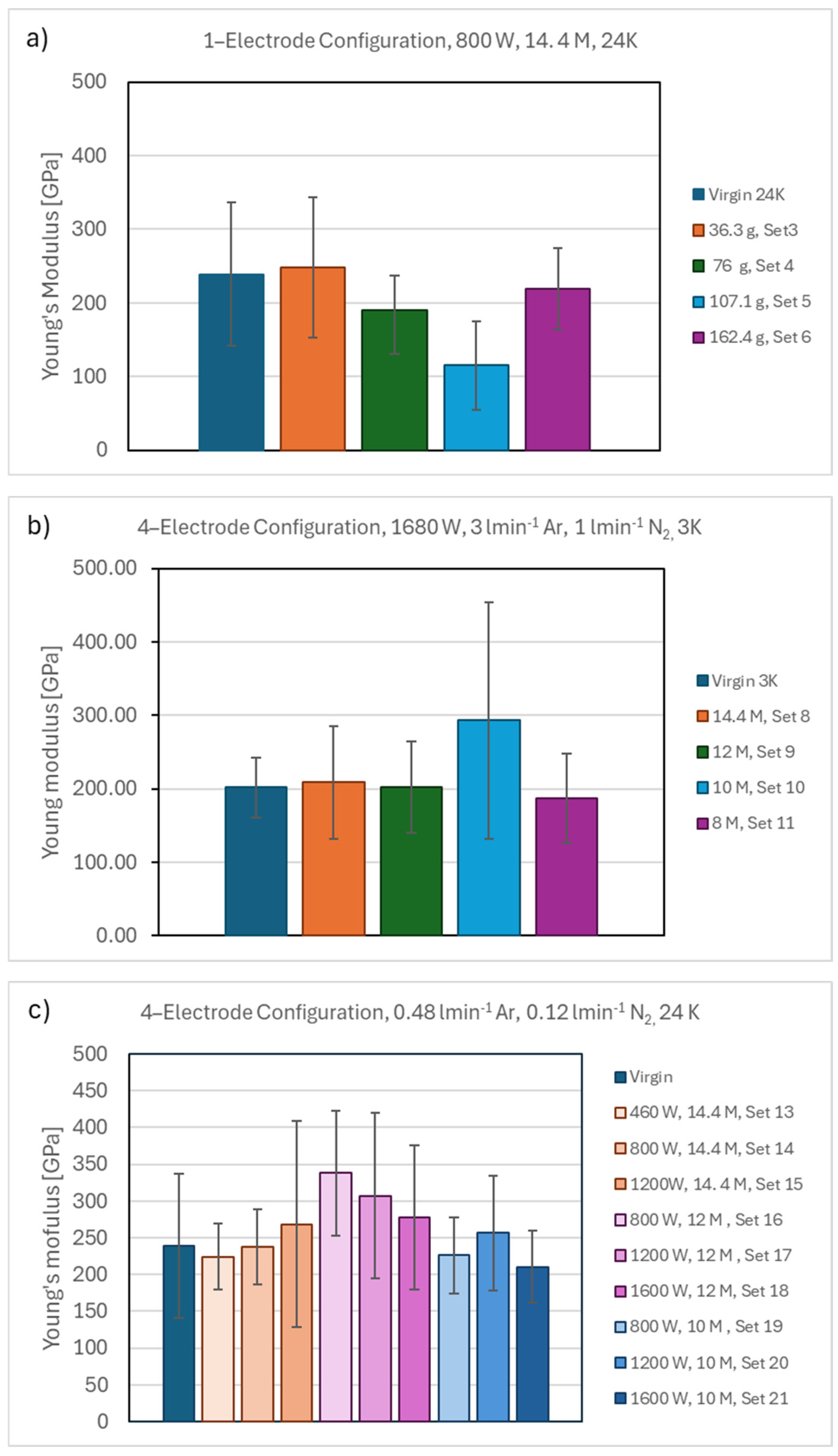

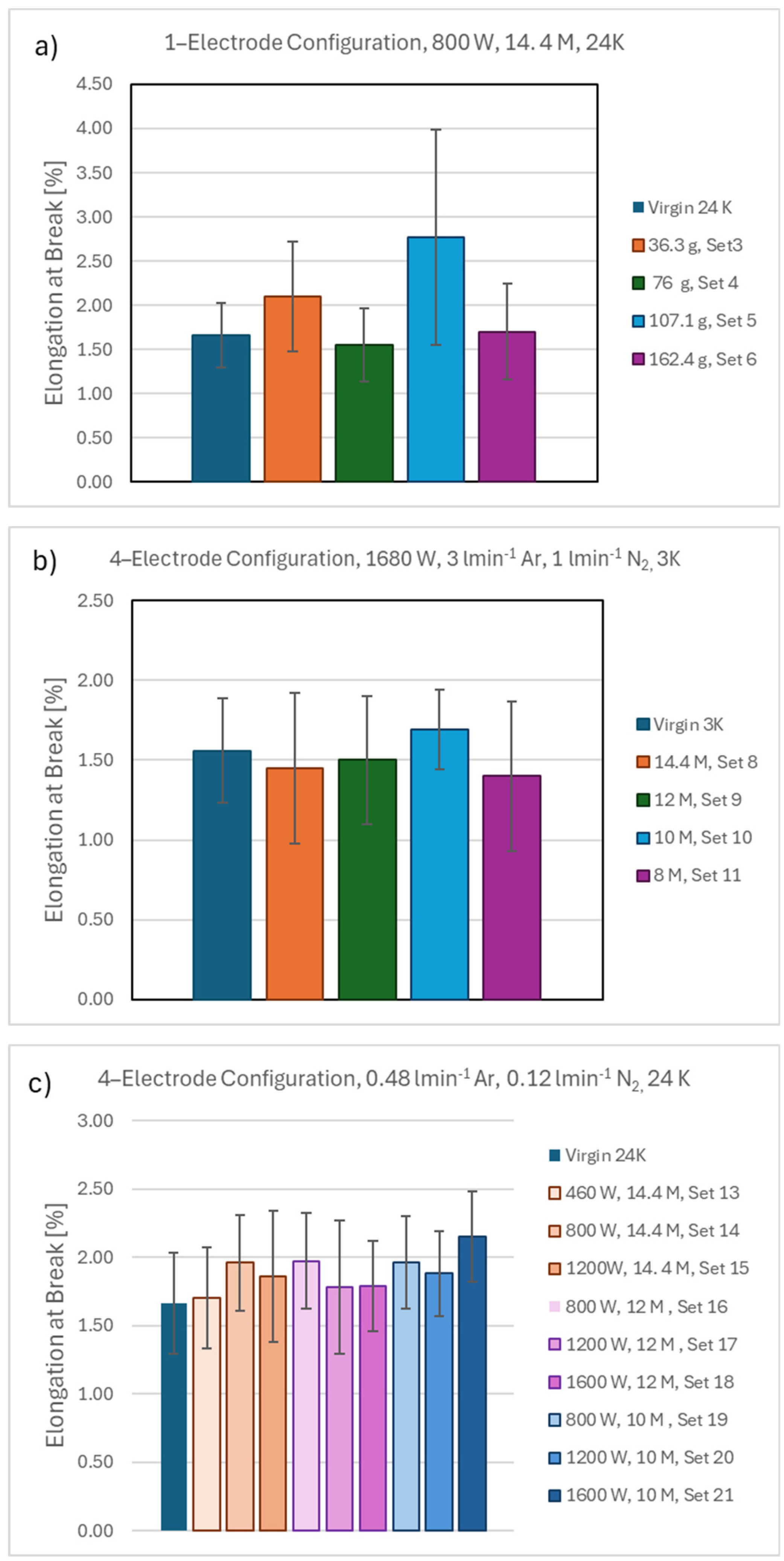

To systematically assess the recycling performance of carbon fibers, several experiments were conducted by varying the plasma-enhanced solvolysis parameters. First, a one-electrode configuration using pure N2 and 14.4 M HNO3 was tested by increasing the composite mass loaded in the reactor and keeping a constant power input (800 W). In this case, low treatment times (<6 h) for complete resin degradation were achieved. However, high HNO3 losses and thus high NOx emissions were observed. To minimize the environmental impact, a four-plasma-head configuration and N2/Ar mixtures were selected and the effect of solvent concentration, power input, and N2 and Ar flow rate on the materials’ mechanical properties were tested. The adjustment of the parameters was performed considering the generator power, the reactor materials’ properties, and solvent losses. It is wort noting that the reaction time was kept equal to 6 h unless complete resin dissolution was achieved.

Table 2 summarizes the experimental conditions for each sample (Set 1 and Set 2 stand for 3K and 24K virgin fibers, while Set 7 stands for conventional HNO

3 solvolysis).

2.3. Characterization of Fibers

2.3.1. Single-Fiber Tension Test

Recycled carbon fiber batches obtained from plasma-assisted solvolysis were visually inspected prior to mechanical testing.

Figure 3 shows a typical batch, with fibers retaining a linear structure and appearing largely free of visible resin residues. The fibers’ surfaces were further investigated by SEM imaging (JEOL 6300, Zhubei City, Taiwan).

The mechanical properties of the recycled carbon fibers were assessed using a Minimat 2000 material tester (Rheometric Scientific, Piscataway, NJ, USA) in accordance with ASTM C1557–14 [

39]. A gauge length of 25 mm and a crosshead speed of 2 mm/min were selected following ASTM C1557–14, which recommends this length for single-fiber tensile testing. Similar parameters have also been adopted in studies on recycled PAN-based carbon fibers obtained from epoxy composites [

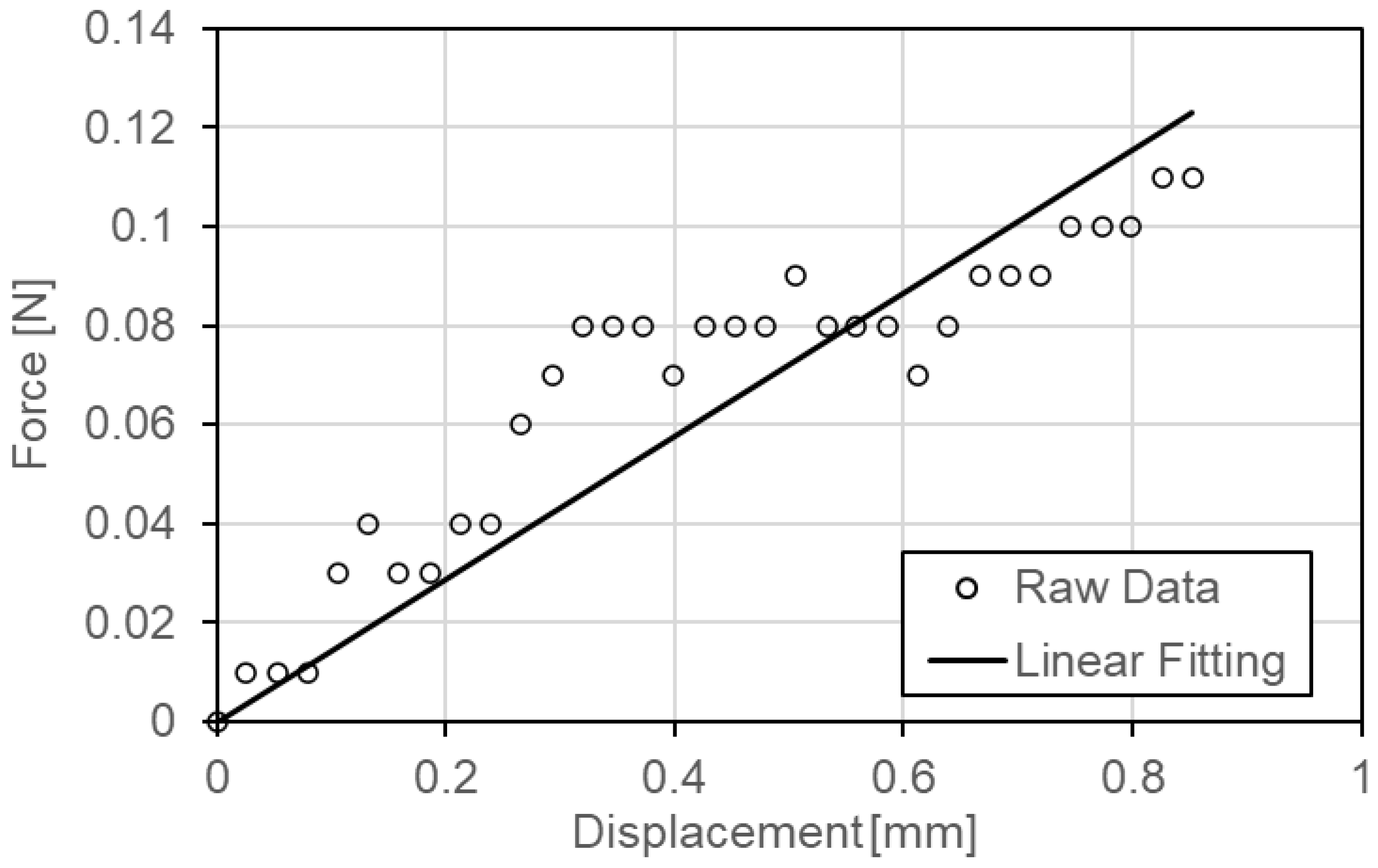

24], confirming the suitability of this range. Preliminary trials at different speeds showed that 2 mm/min provided stable elongation and fracture within 30 s, in accordance with the standard. For sample preparation, individual fibers were carefully mounted on paper frames using a two-part epoxy adhesive applied at both ends. The fibers were aligned carefully to avoid any pre-tension, ensuring reliable test results. The fiber diameter was determined by scanning electron microscopy (the mean of ten random measurements per set) prior to tensile testing. Tensile strength, Young’s modulus, and elongation at break of each fiber were then calculated based on the recorded force and displacement data. These properties were derived using the following equations:

where is the force to failure and is the fiber cross-sectional area at the fracture plane.

where

is the gage length, which is equal to 0.025 m,

is the record crosshead displacement, and

is the system compliance, equal to 0.0012 m/N.

A representative force–displacement curve obtained from the tensile testing is shown in

Figure 4, illustrating the raw output from the testing machine used to extract mechanical properties.

Data collection focused exclusively on specimens that were fractured within the gauge length, excluding any tests where failure occurred outside this region. Each reported value represents the average from at least 25 valid tests. The instrument was calibrated before each testing series following the manufacturer’s instructions. The installed load beam had a maximum capacity of 200 N, and the tear force limit was 5% of the load beam capacity. The raw force offset was confirmed to remain below this limit and was automatically zeroed via the system software prior to loading each specimen. Prior to calculating the mean values of the mechanical properties, interquartile range (IQR) analysis was employed to remove outliers caused by slipping or grinding problems, providing a statistically robust dataset. This approach identifies values lying outside the range defined by

and

, where

and

are the first and third quartiles of the dataset, respectively. Data points outside this range were considered statistical outliers and excluded from the final averages. A summary of tested and accepted fibers after filtering is provided in

Appendix B. From these measurements, tensile strength, Young’s modulus, and elongation at break were calculated to evaluate the effect of plasma-assisted solvolysis on the mechanical performance of the rCFs compared to vCFs. All results are reported as means ± standard deviation in

Appendix A.

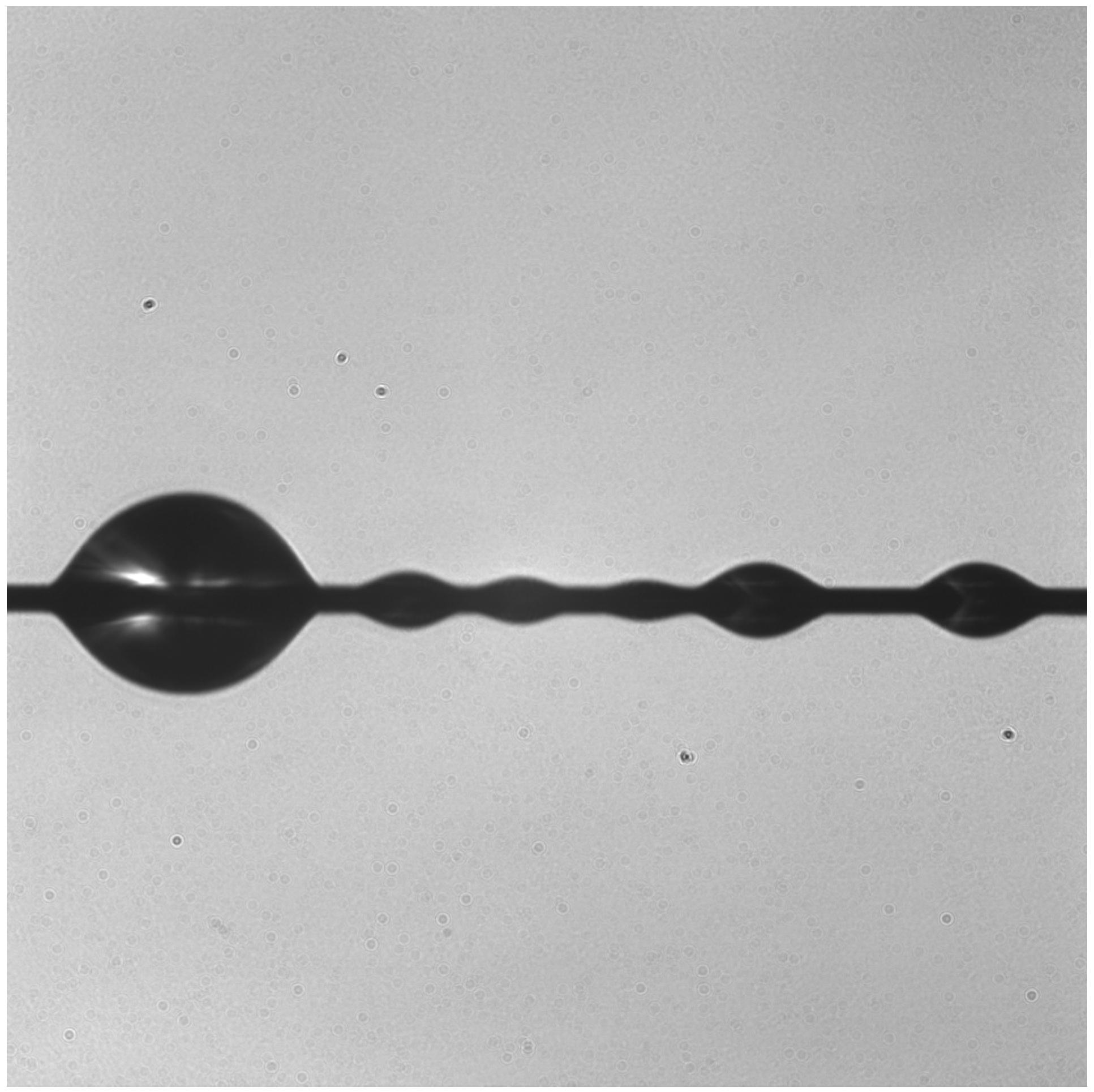

2.3.2. Microbond Test

To evaluate the fiber–matrix interfacial properties, microbond tests were conducted. For each fiber type, both virgin and recycled, three independent tests were performed, with each test comprising at least 25 single-fiber droplet measurements. The parameters that recorded were fiber diameter, embedded length, droplet area, and maximum debonding force. The droplet area,

, was calculated assuming a cylindrical shape using the formula

where

is the fiber diameter and

is the embedded length of the droplet.

Interfacial shear strength was determined by calculating the slope of the linear fit between the applied force

and the embedded droplet area, providing a more reliable metric than maximum load alone. Mean IFSS

values were computed for each test to ensure statistical robustness. It is important to note that the microbond test is highly sensitive to the accurate measurement of droplet dimensions and the resin curing conditions, and variability in results often reflects differences in fiber–matrix interactions rather than experimental error. The resin droplets were prepared from Araldite

®LY5052 epoxy and Aradur

®5052 hardener (Huntsman Advanced Materials, Basel, Switzerland). The resin droplets were deposited within 30 min after mixing to maintain consistent viscosity and embedded lengths of approximately 50–150 µm. Curing was performed at 80 °C for 2 h followed by post-curing at 120 °C for 1 h, ensuring reproducible polymerization across all samples. Force and strain data were collected at a sampling frequency of 50 Hz using a FIBRObond microdroplet tester (Fibrobotics, Tampere, Finland) [

40].

Figure 5 presents an optical micrograph showing an ellipsoidal resin droplet formed around an embedded fiber during sample preparation.

2.4. Preliminary Statistical Analysis

After calculating the mechanical properties for each set of rCFs, a statistical evaluation was performed using a two-tailed

t-test. This method was selected to determine whether the observed differences in properties between recycled and virgin fibers were statistically significant, or simply due to random variation. The

t-test is a well-established statistical tool that helps assess whether the difference between two groups is likely due to actual changes, from the recycling process. Each rCF batch was compared to the virgin fiber reference group, and the corresponding

p-values were computed. A

p-value less than 0.05 was considered statistically significant, indicating that the recycling process had a measurable effect on the fibers [

41].

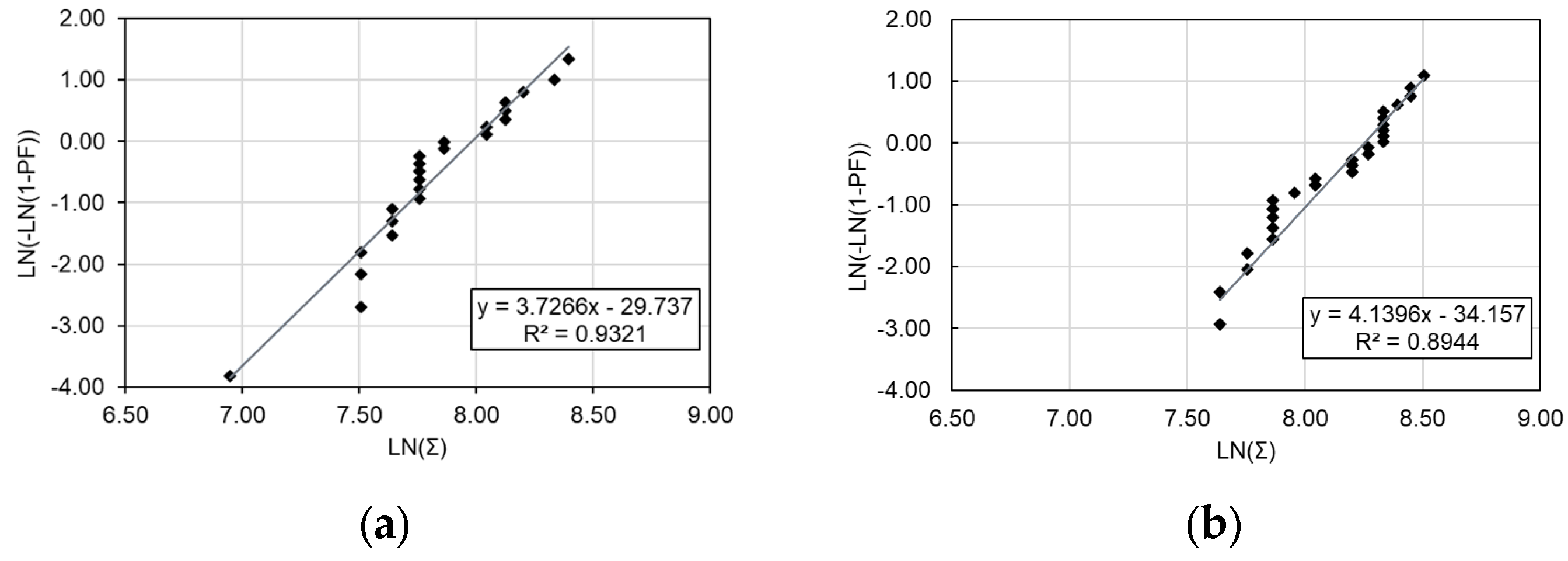

Due to variability in surface condition, mainly from uneven resin removal during solvolysis, rCFs often show significant scatter in tensile strength measurements. Residual epoxy clusters can act as micro-defects, subtly alter fiber geometry, and cause localized stress concentrations under load. These irregularities affect how individual fibers deform, leading to performance differences within the same batch.

To interpret this scatter and assess the reliability of tensile data, a two-parameter Weibull distribution was applied, commonly used for brittle materials where failure is governed by surface flaws. The failure probability

for a given stress

and gauge length

, relative to a reference length

, is described by the Weibull expression:

Here, is the scale parameter (characteristic strength) at which 63.2% of fibers are expected to fail, and is the shape parameter (Weibull modulus), which indicates strength consistency—a higher value means lower scatter.

To calculate these, tensile strength values for each rCF set were ranked in ascending order. The failure probability for each value

was estimated using

where

is the total number of samples. A linearized form of the Weibull equation

was used to extract the slope

and intercept

. This analysis helps quantify how uniformly the recycled fibers perform under tensile stress and offers insight into the presence of defects introduced during the recycling process [

42,

43].

4. Discussion

Plasma-assisted solvolysis integrates plasma treatment with chemical depolymerization, enabling efficient matrix removal from CFRPs within a closed-loop system. Plasma-assisted solvolysis enables efficient carbon fiber recovery from CFRPs while implementing environmental controls through NOx emission capture and chemical reusability. During the process, NOx byproducts are captured in a two-stage wet scrubbing system. The scrubbing solution is later used in (a) the pre-treatment step, (b) the regeneration of the plasma reactor’s solution. The regenerated reactor liquid maintains reactivity for four consecutive operation cycles.

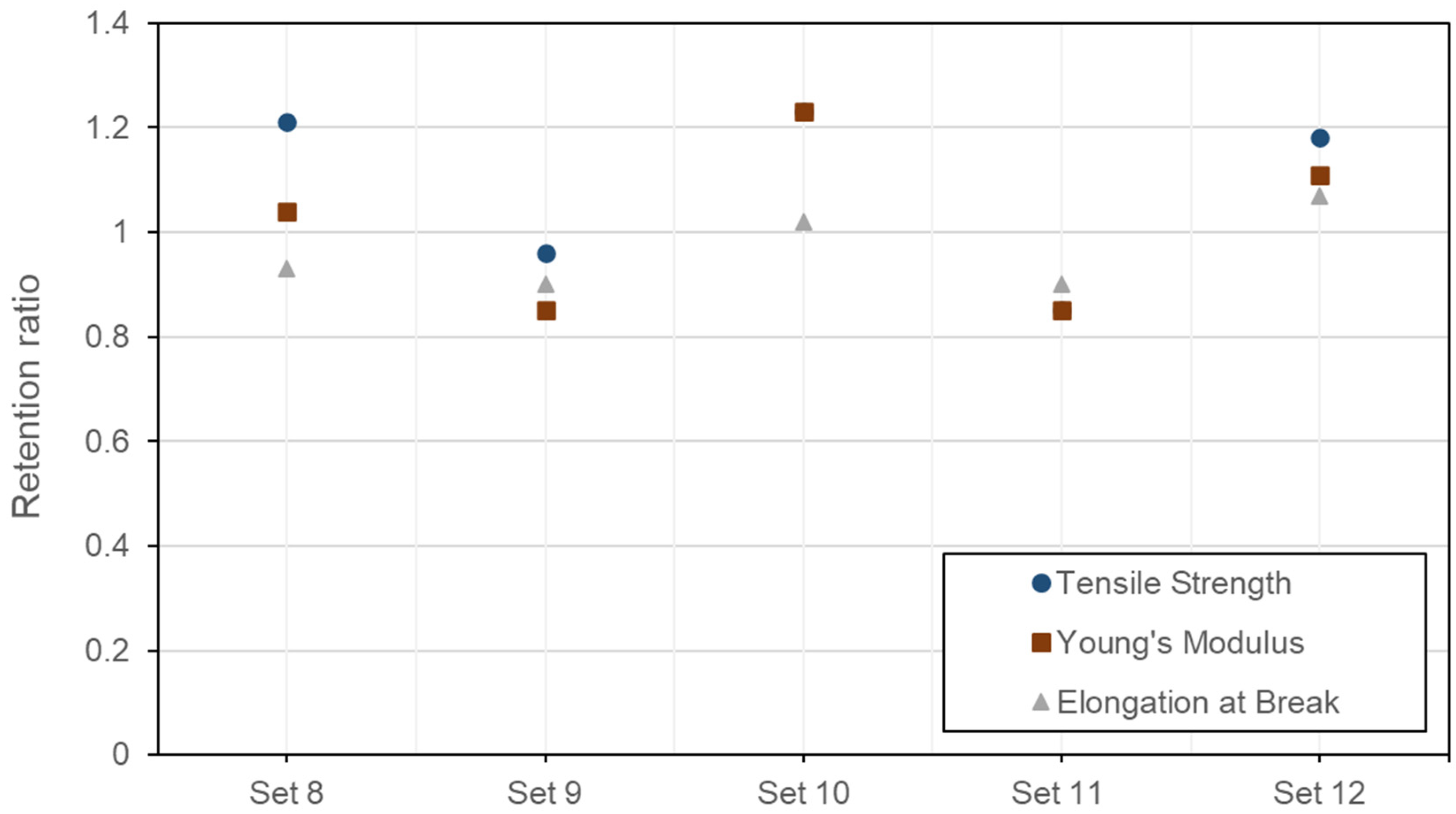

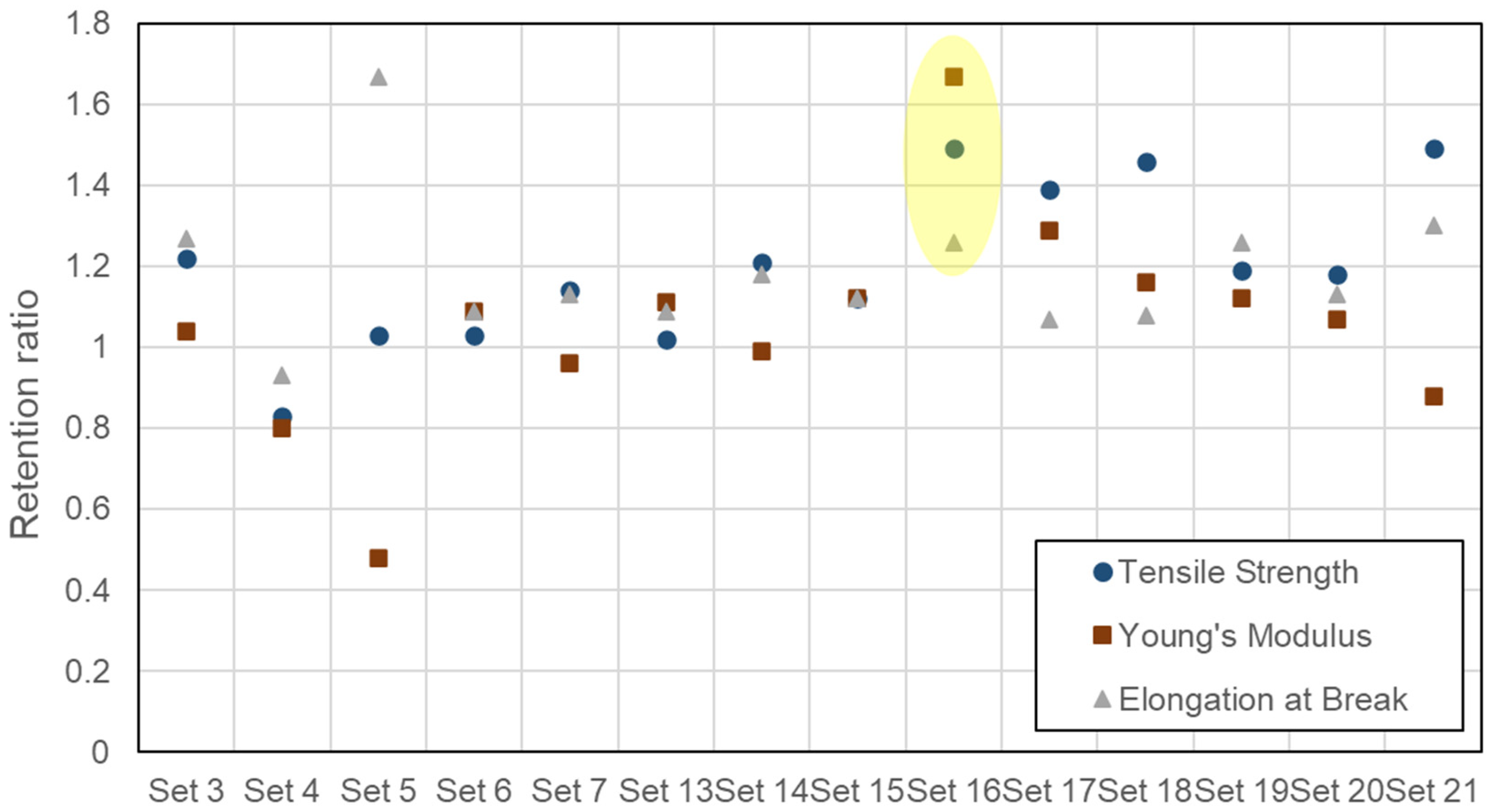

Different properties responded differently. The tensile strength of most recycled fibers was well retained, with several sets showing comparable or even improved values relative to virgin fibers, demonstrating that plasma-assisted solvolysis can preserve structural integrity under certain conditions. In particular, strength was robust under moderate plasma power (800–1200 W), combined with balanced acid concentrations (10–12 M) and lower composite-to-acid ratios (2.1–2.3 g/mol). Compared with data summarized from solvolysis recycling studies of CFRPs [

55], where recovered fibers generally retained 80–95% of their original strength, the best-performing conditions in this work achieved equal or superior retention, indicating more effective preservation of fiber integrity.

Young’s modulus exhibited greater variability, leading to both reductions and notable increases in some cases. The modulus benefited from a 12 M acid concentration and 2.3 g/mol ratio. It is worth noting that virgin 3K and 24K fibers exhibited nearly identical properties, with only a slight difference in Young’s modulus. Although the sizing was effectively removed, the observed improvements in stiffness could be partially explained by increased oxygen content and the formation of new surface functional groups, factors previously reported to influence modulus, depending on fiber type and treatment conditions [

56].

Elongation at break generally increased, particularly in 24K fiber sets, suggesting greater surface ductility due to microstructural smoothing during treatment.

These observations also highlight the importance of surface condition in maintaining interfacial performance, with the 3K recycled fibers showing consistency and retention of IFSS values. Overall, IFSS remained relatively insensitive to processing variations.

Weibull analysis confirmed that sets with higher shape factors exhibited more consistent mechanical behavior across recycled batches. However, input power resulted in lower Weibull shape factors, indicating more scatter and reduced reliability. This observed scatter in lower-performing batches may be linked to morphological inconsistencies, such as fiber twisting or localized degradation from plasma exposure.

In a potential next phase, a multi-objective optimization approach could be employed to identify process conditions that balance all the tensile properties. Based on the existing mechanical dataset, a model may be developed to simultaneously maximize performance, constrained within experimentally validated parameter ranges to ensure feasibility. The predicted optimal parameters could then guide future solvolysis trials to support model validation.