Valorization of Natural Byproducts Through Additive Manufacturing for Ecologically Sustainable Composite Materials: A Literature Review

Highlights

- The integration of sawdust, wood chips, and bark into polymer matrices through AM can enhance thermal stability. Filler contents up to 30 wt.% maintain uniform dispersion while higher concentrations could result in nozzle clogging and degraded mechanical strength.

- Surface modification via coupling agents and controlled fiber morphology can significantly improve interfacial adhesion. These treatments can enhance mechanical performance by 25–30%, provide thermal stability, and improve dimensional accuracy due to improved interfacial bonding.

- Valorization of wood byproducts for the production of polymer-based composites with the aid of additive manufacturing resulted in 30–35% lower energy consumption and 65–70% reduced CO2 emissions compared to the conventional thermoplastic systems.

- Demonstrated large-scale applications such as the BioHome3D project, confirming the feasibility of translating those findings into industrial applications. The incorporation of smart technologies can lead to efficient sustainable closed loop systems in alignment with the global environmental goals.

Abstract

1. Introduction

2. Feedstock Analysis, Treatment, and Manufacturing Processes

2.1. Different Types of Raw Materials

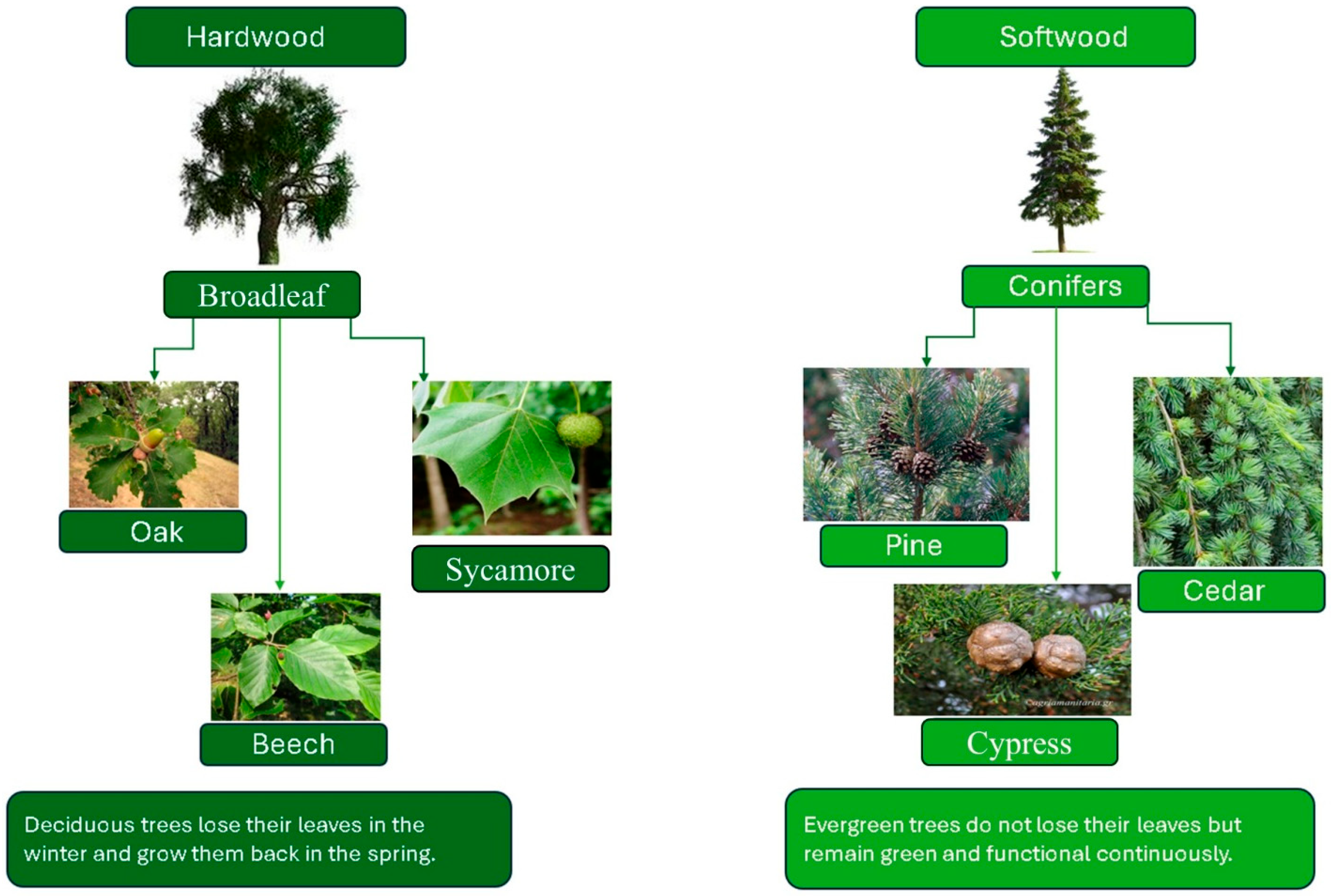

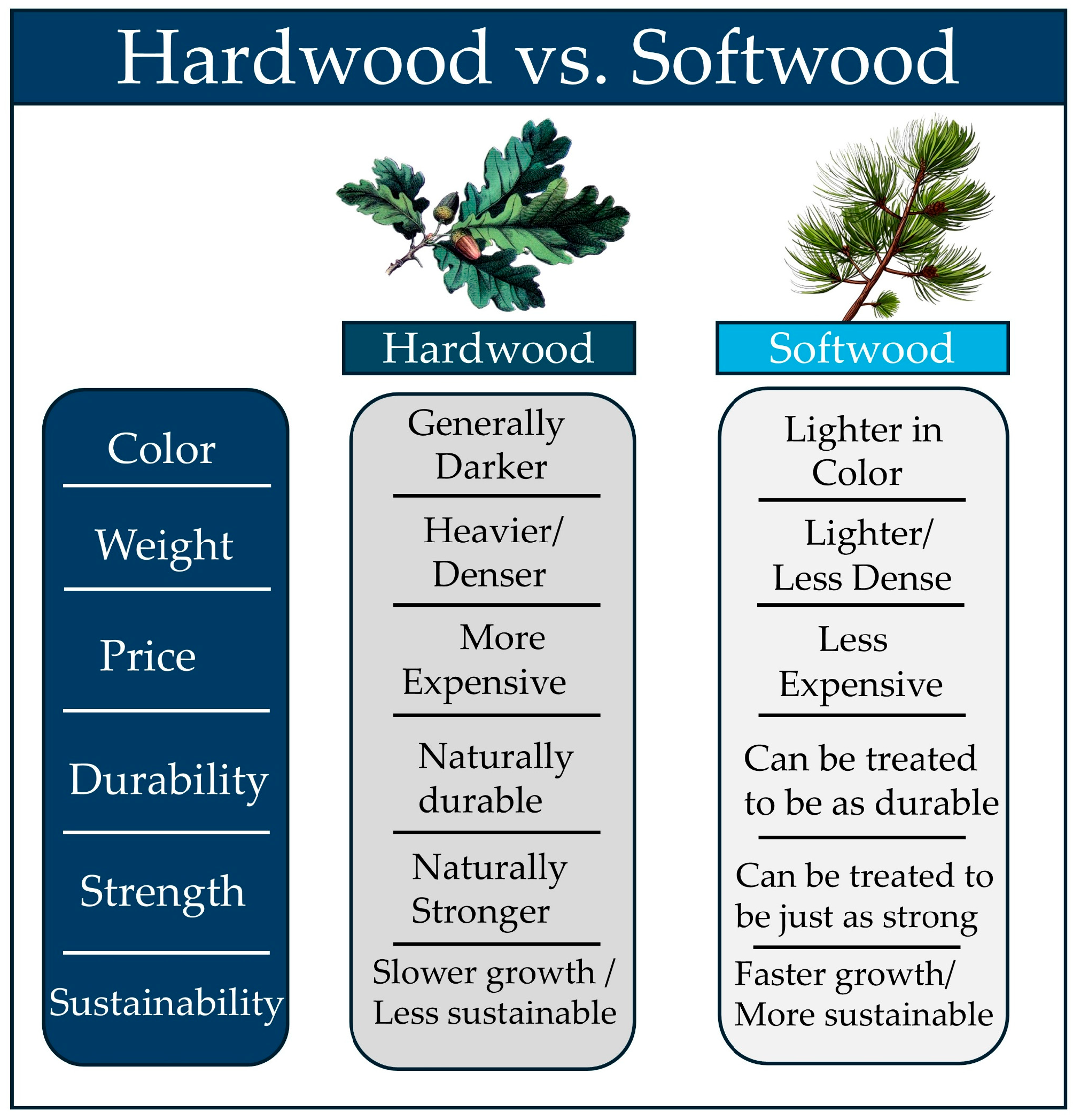

2.1.1. Acquisition Source

2.1.2. Structural Characterization of Wood Byproducts

2.2. Treatment Methods of Wood Byproducts

2.3. Utilization of Wood Byproducts in Manufacturing Processes—The Case of 3D Printing

2.4. Environmental Perspective of the Valorization of Wood Byproducts via 3D Printing

3. Evaluation of the Wood Byproducts Composites via Additive Manufacturing Processes

3.1. Physicochemical Evaluation

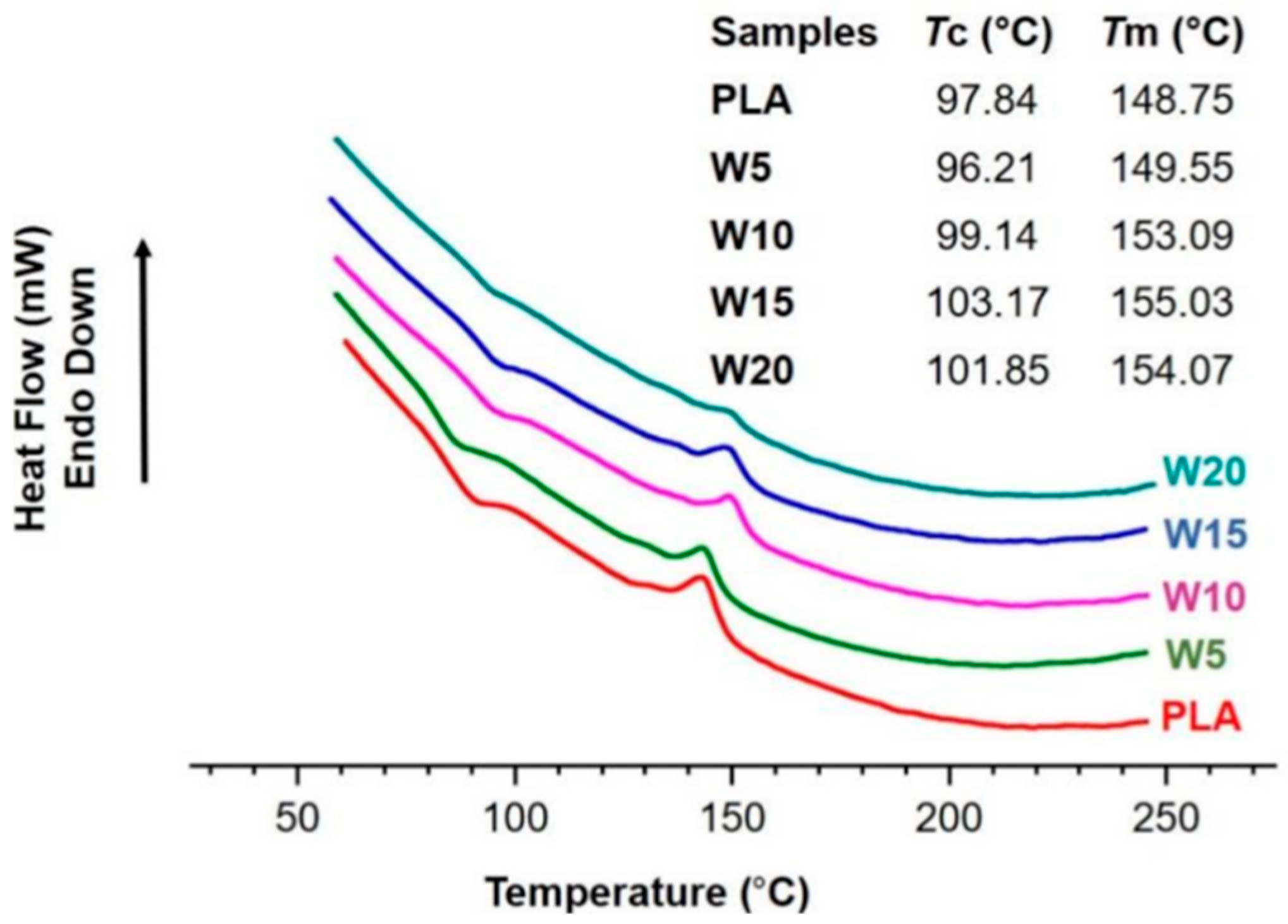

3.1.1. Glass Transition and Melting Temperatures

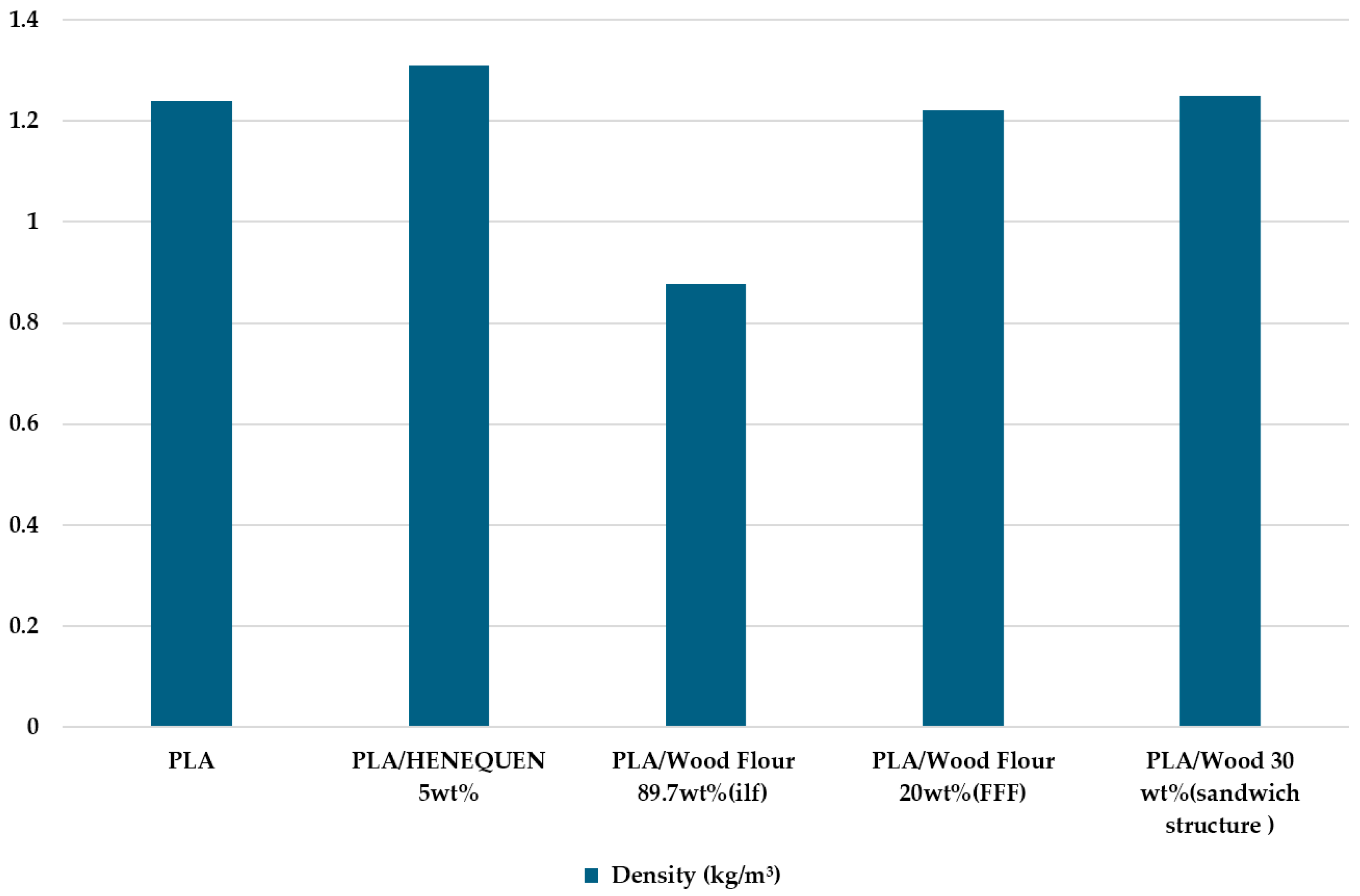

3.1.2. Composites’ Density and Infill Density’s Influence on Printability

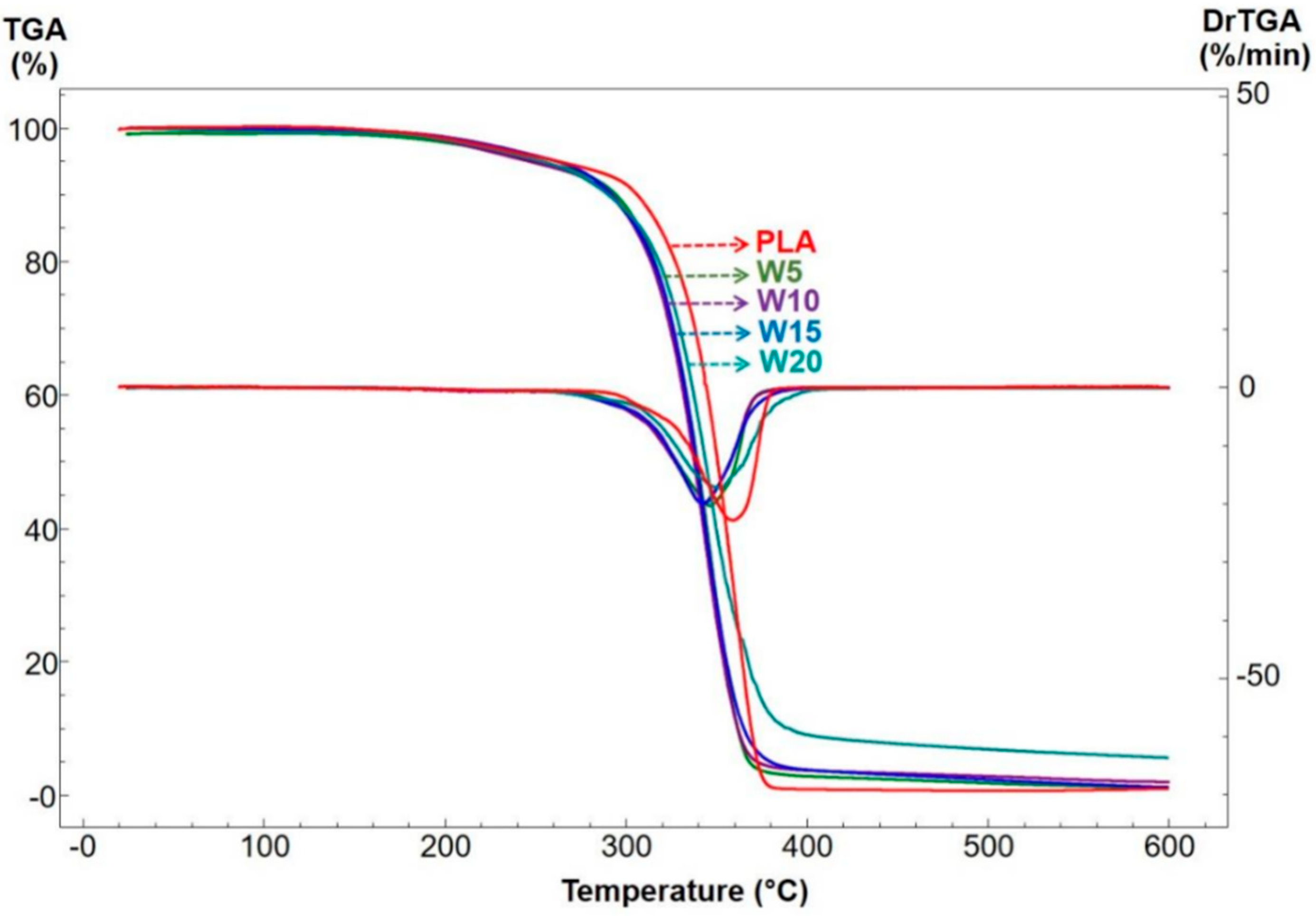

3.1.3. Thermal Stability

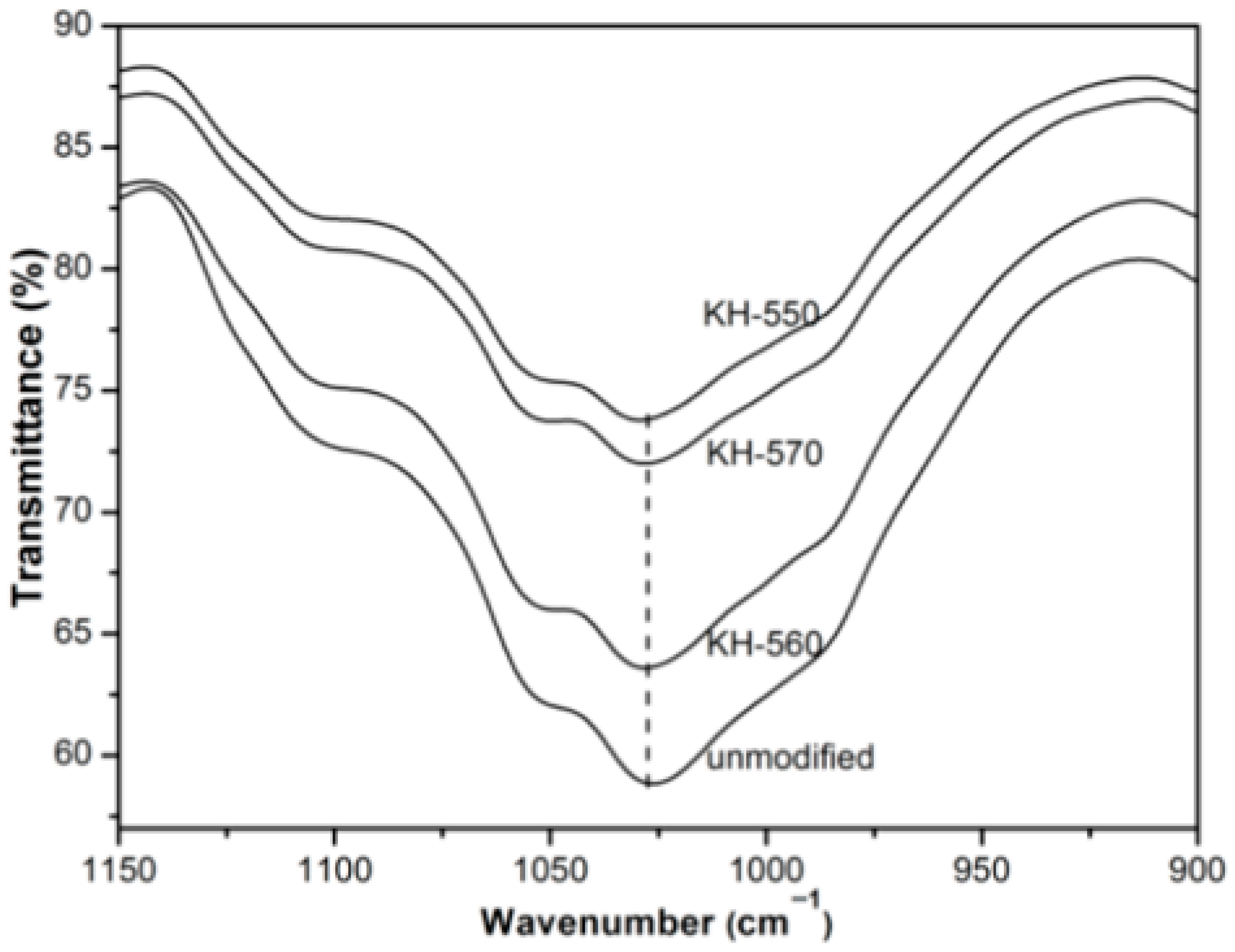

3.1.4. Intermolecular Interactions

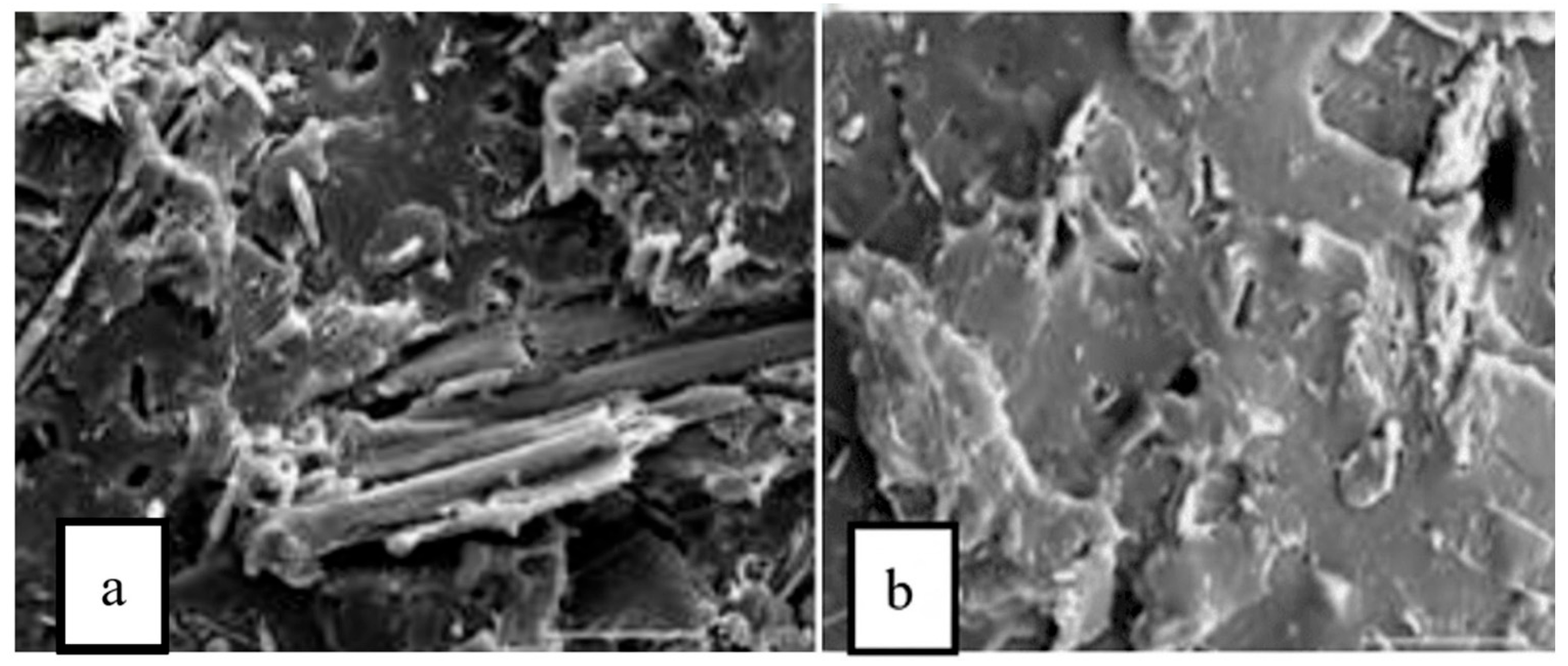

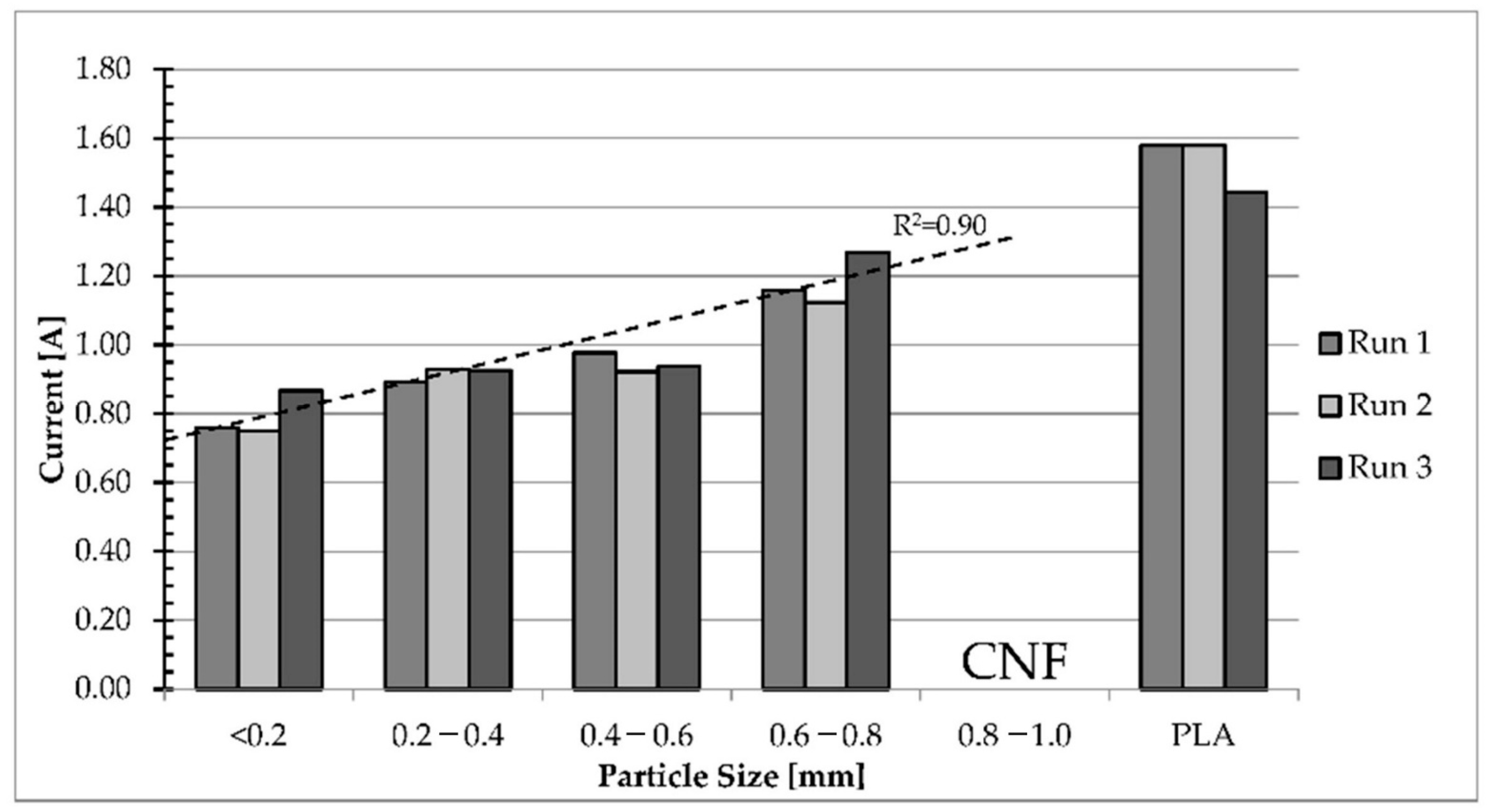

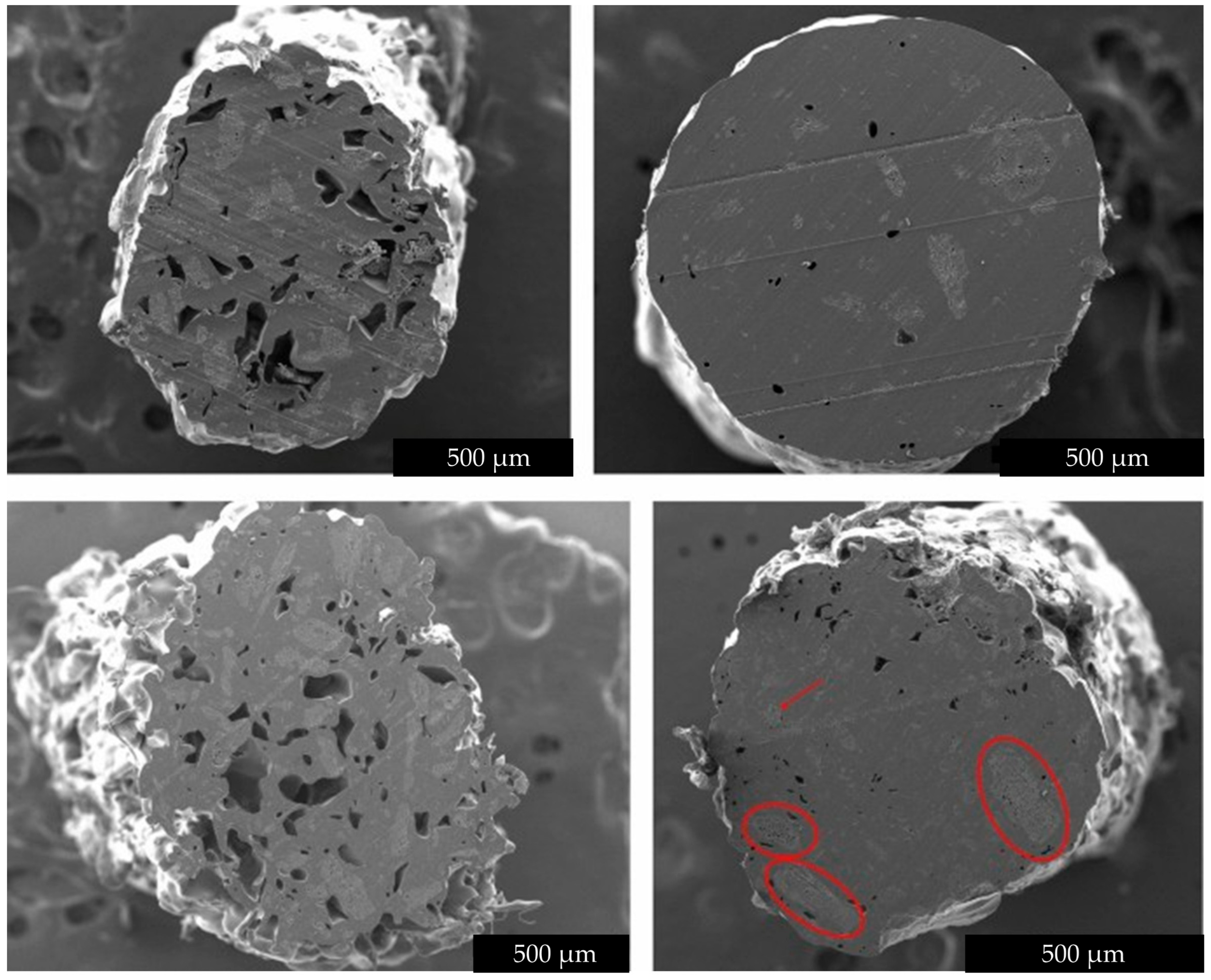

3.2. Influence of Size and Morphology on Printability

3.3. Static Mechanical Evaluation

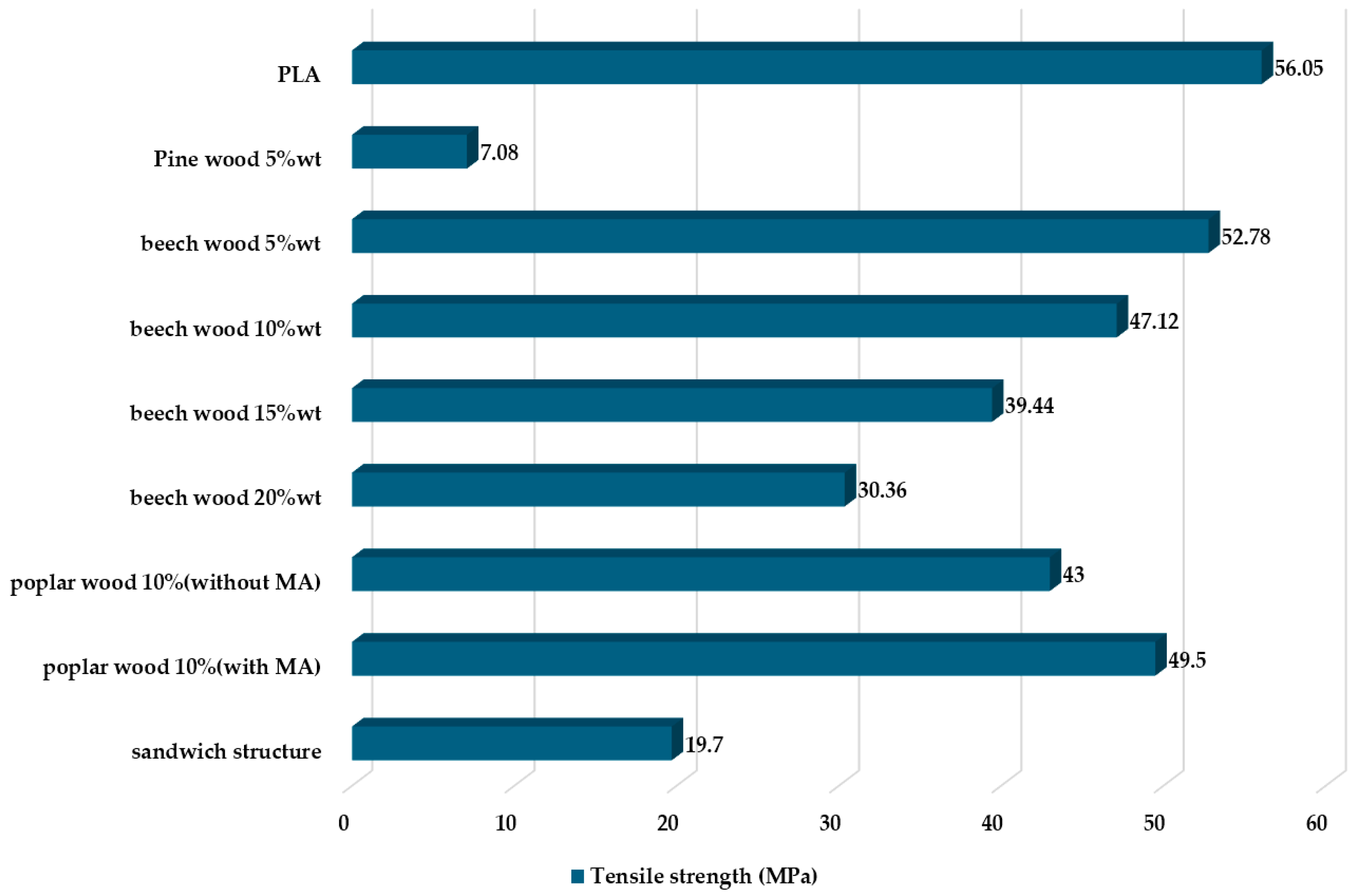

3.3.1. Tensile Strength

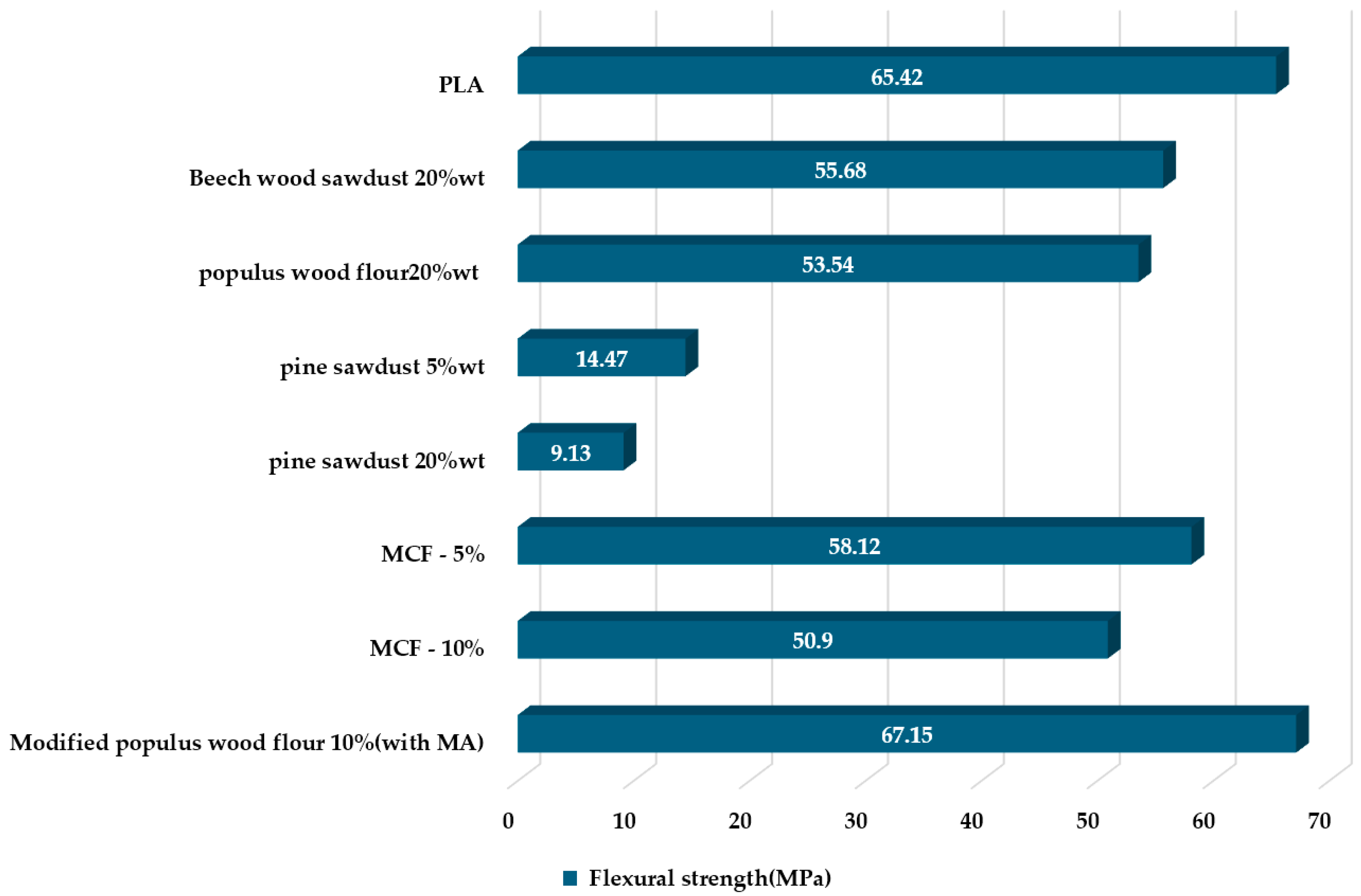

3.3.2. Flexural Strength

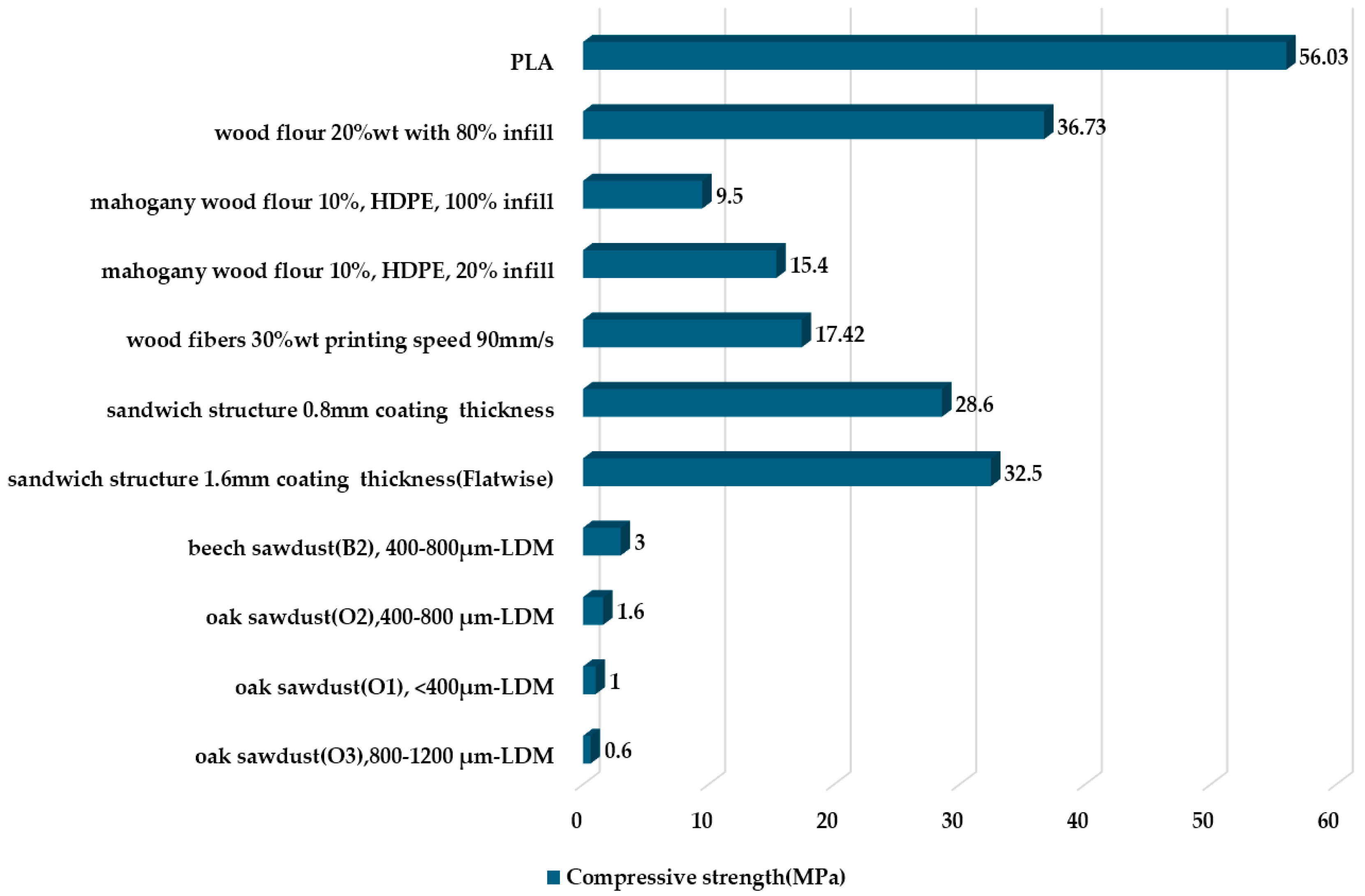

3.3.3. Compressive Strength

3.4. Dynamic Mechanical Evaluation

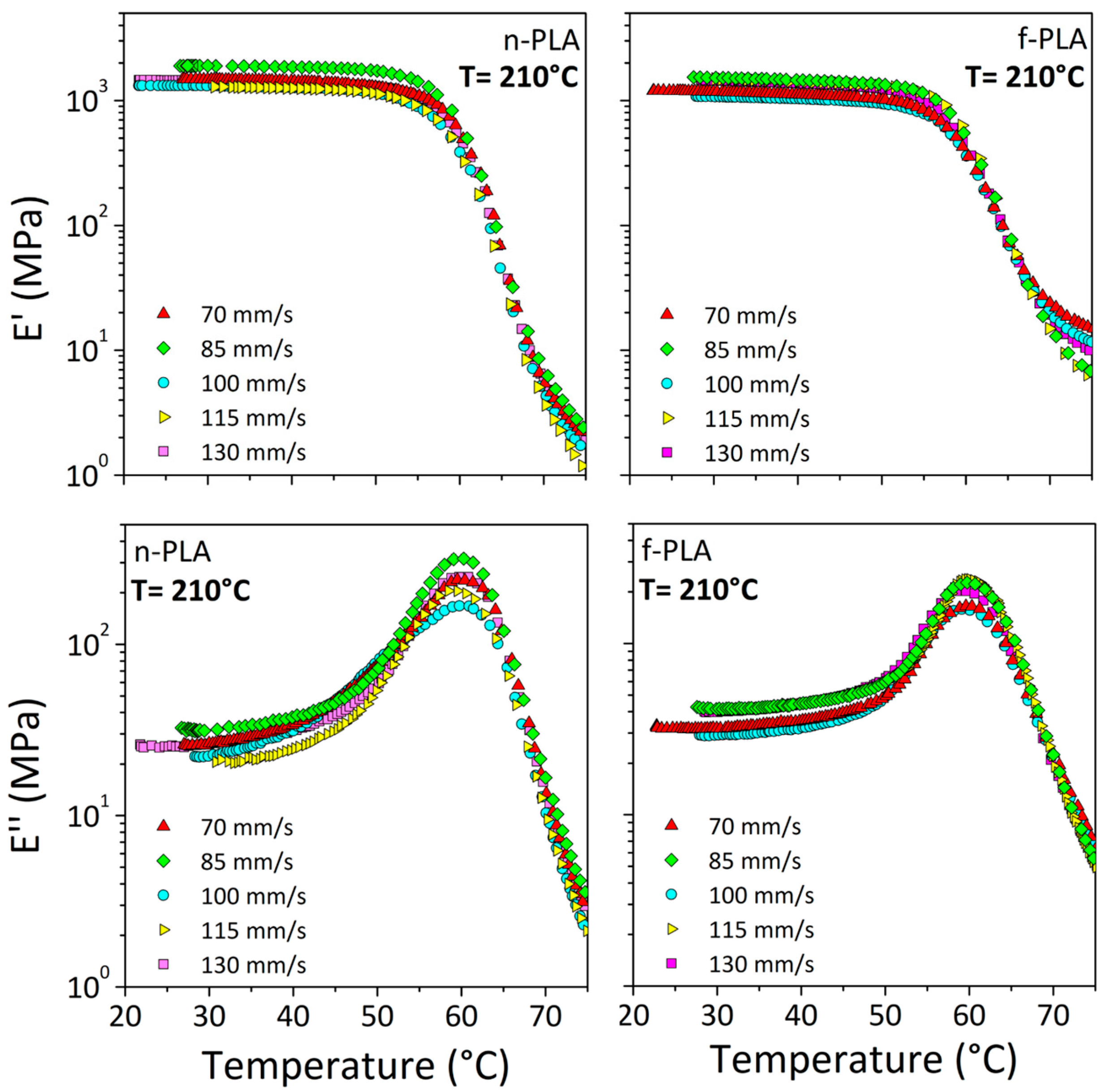

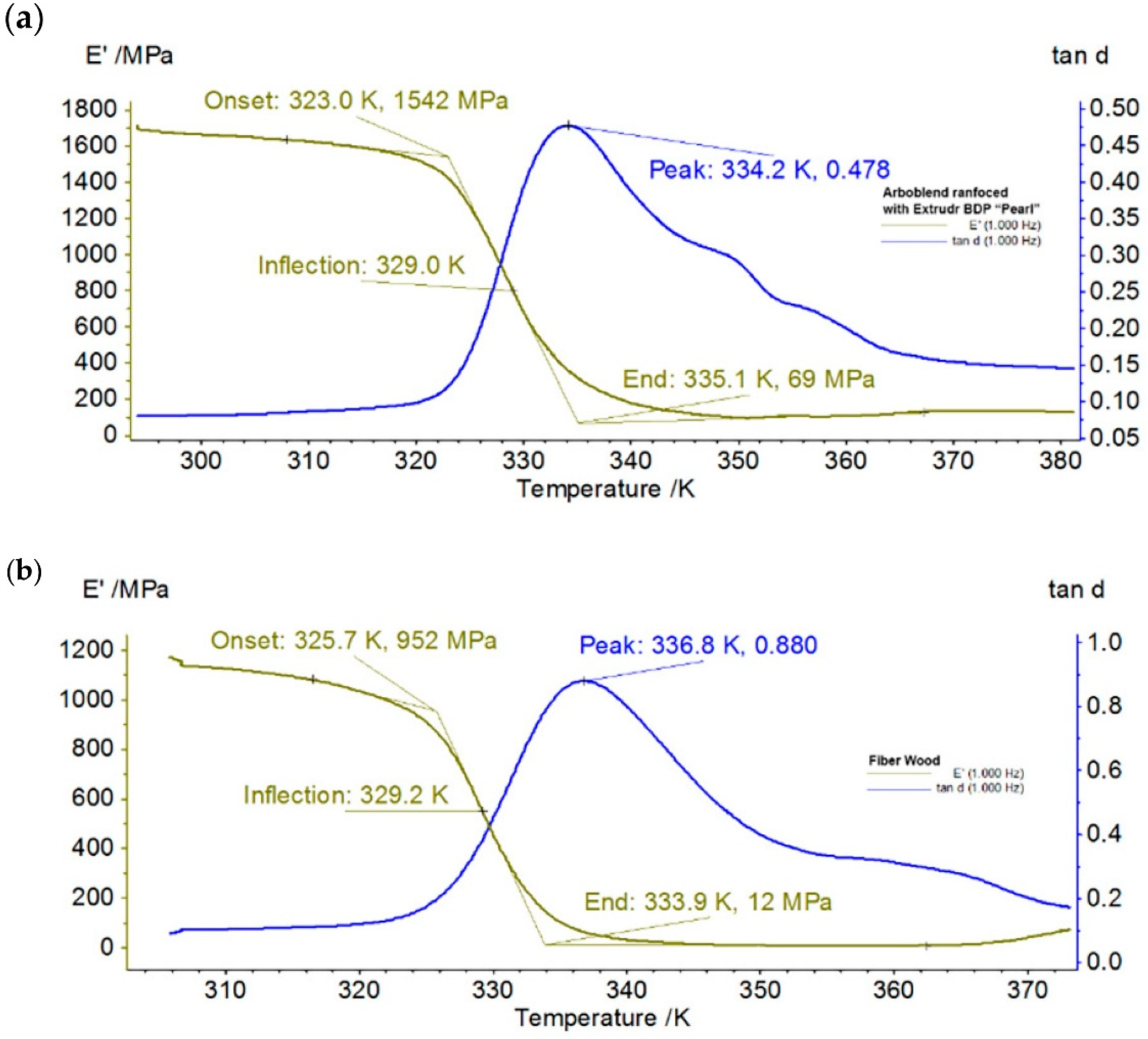

3.4.1. Dynamic Mechanical Analysis (DMA)—Thermomechanical Response

3.4.2. Fatigue Response

3.4.3. Impact Response

3.5. Life Cycle Assessment (LCA) Analysis

4. Large-Scale Applications

5. Research Gaps and Solutions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Consumption of Primary Processed Wood Products Predicted to Grow 37 Percent by 2050. Available online: https://www.fao.org/newsroom/detail/consumption-of-primary-processed-wood-products-predicted-to-grow-37-percent-by-2050/en (accessed on 16 July 2025).

- Zbieć, M.; Franc-Dąbrowska, J.; Drejerska, N. Wood Waste Management in Europe through the Lens of the Circular Bioeconomy. Energies 2022, 15, 4352. [Google Scholar] [CrossRef]

- Wood Products—Production and Trade. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Wood_products_-_production_and_trade (accessed on 17 July 2025).

- Garg, M.; Rani, R.; Meena, V.K.; Singh, S. Significance of 3D Printing for a Sustainable Environment. Mater. Today Sustain. 2023, 23, 100419. [Google Scholar] [CrossRef]

- Saidin, W.; Wagiman, A.; Ibrahim, M. Development of Wood-Based Composites Material for 3D Printing Process. Appl. Mech. Mater. 2013, 315, 987–991. [Google Scholar] [CrossRef]

- Kartal, F.; Kaptan, A. Sustainable Reinforcement of PLA Composites with Waste Beech Sawdust for Enhanced 3D-Printing Performance. J. Mater. Eng. Perform. 2024, 34, 15248–15259. [Google Scholar] [CrossRef]

- Sustainable Development Goals. Available online: https://commission.europa.eu/strategy-and-policy/sustainable-development-goals_en (accessed on 17 July 2025).

- Kyriakidis, I.F.; Kladovasilakis, N.; Pechlivani, E.M.; Tsongas, K. Mechanical Performance of Recycled 3D Printed Sustainable Polymer-Based Composites: A Literature Review. J. Compos. Sci. 2024, 8, 215. [Google Scholar] [CrossRef]

- View of Circular Economy: A Bibliometric Review of Research in Emerging Economies (2010–2024). Available online: https://www.econjournals.com/index.php/ijeep/article/view/17021/8445 (accessed on 17 July 2025).

- Friant, M.C.; Vermeulen, W.J.V.; Salomone, R. Transition to a Sustainable Circular Society: More than Just Resource Efficiency. Circ. Econ. Sustain. 2023, 4, 23–42. [Google Scholar] [CrossRef]

- Liampas, S.; Kladovasilakis, N.; Tsongas, K.; Pechlivani, E.M. Recent Advances in Additive Manufacturing of Fibre-Reinforced Materials: A Comprehensive Review. Appl. Sci. 2024, 14, 10100. [Google Scholar] [CrossRef]

- Zanuttini, R.; Negro, F. Wood-Based Composites: Innovation towards a Sustainable Future. Forests 2021, 12, 1717. [Google Scholar] [CrossRef]

- Miseljic, M.; Olsen, S.I. Life Cycle Assessment of Functionally Enhanced Polymers—Engineered Nanomaterials or Conventional Additives. J. Nanosci. Nanotechnol. 2016, 16, 8007–8018. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; De Carolis, V.; Montagna, F.; Palumbo, E.; Corcione, C.E. Development and Characterization of Sustainable PLA/Olive Wood Waste Composites for Rehabilitation Applications Using Fused Filament Fabrication (FFF). J. Build. Eng. 2022, 56, 104673. [Google Scholar] [CrossRef]

- Angiosperms vs. Gymnosperms. Available online: https://www.diffen.com/difference/Angiosperms_vs_Gymnosperms (accessed on 19 July 2025).

- Ross, R. Wood Handbook: Wood as an Engineering Material. Available online: https://research.fs.usda.gov/treesearch/62200 (accessed on 19 July 2025).

- Asante, B.; Appelt, J.; Yan, L.; Krause, A. Influence of Wood Pretreatment, Hardwood and Softwood Extractives on the Compressive Strength of Fly Ash-Based Geopolymer Composite. J. Mater. Sci. 2023, 58, 5625–5641. [Google Scholar] [CrossRef]

- Konofalska, E.; Kozakiewicz, P.; Buraczyk, W.; Szeligowski, H.; Lachowicz, H. The Technical Quality of the Wood of Scots Pine (Pinus sylvestris L.) of Diverse Genetic Origin. Forests 2021, 12, 619. [Google Scholar] [CrossRef]

- Bayat, M. Types of Engineered Wood and Their Uses. In Current Applications of Engineered Wood; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Lyubenova, A.; Baranowska, M.; Menkis, A.; Davydenko, K.; Nowakowska, J.; Borowik, P.; Oszako, T. Prospects for Oak Cultivation in Europe Under Changing Environmental Conditions and Increasing Pressure from Harmful Organisms. Forests 2024, 15, 2164. [Google Scholar] [CrossRef]

- Chikri, R.; Elhadiri, N.; Benchanaa, M.; Maguana, Y.E. Efficiency of Sawdust as Low-Cost Adsorbent for Dyes Removal. J. Chem. 2020, 2020, 8813420. [Google Scholar] [CrossRef]

- Šćiban, M.; Radetić, B.; Kevrešan, Ž.; Klašnja, M. Adsorption of Heavy Metals from Electroplating Wastewater by Wood Sawdust. Bioresour. Technol. 2006, 98, 402–409. [Google Scholar] [CrossRef] [PubMed]

- Horisawa, S.; Sunagawa, M.; Tamai, Y.; Matsuoka, Y.; Miura, T.; Terazawa, M. Biodegradation of Nonlignocellulosic Substances II: Physical and Chemical Properties of Sawdust before and after Use as Artificial Soil. J. Wood Sci. 1999, 45, 492–497. [Google Scholar] [CrossRef]

- Vusić, D.; Vujanić, F.; Pešić, K.; Šafran, B.; Jurišić, V.; Zečić, Ž. Variability of Normative Properties of Wood Chips and Implications to Quality Control. Energies 2021, 14, 3789. [Google Scholar] [CrossRef]

- Moskalik, T.; Gendek, A. Production of Chips from Logging Residues and Their Quality for Energy: A Review of European Literature. Forests 2019, 10, 262. [Google Scholar] [CrossRef]

- Feng, S.; Cheng, S.; Yuan, Z.; Leitch, M.; Xu, C. Valorization of Bark for Chemicals and Materials: A Review. Renew. Sustain. Energy Rev. 2013, 26, 560–578. [Google Scholar] [CrossRef]

- Using Bark as a Heat Insulation Material. BioResources. Available online: https://bioresources.cnr.ncsu.edu/resources/using-bark-as-a-heat-insulation-material/ (accessed on 20 July 2025).

- Sims, R.E.H.; Mabee, W.; Saddler, J.N.; Taylor, M. An Overview of Second Generation Biofuel Technologies. Bioresour. Technol. 2009, 101, 1570–1580. [Google Scholar] [CrossRef]

- Shibu, C.; Chandel, S.; Vats, P. Scaling up of Wood Waste Utilization for Sustainable Green Future. In Handbook of Research on Sustainable Consumption and Production for Greener Economies; IGI Global: Hershey, PA, USA, 2023; pp. 358–383. [Google Scholar]

- Mishra, K.; Siwal, S.S.; Saini, A.K.; Thakur, V.K. Recent Update on Gasification and Pyrolysis Processes of Lignocellulosic and Algal Biomass for Hydrogen Production. Fuel 2022, 332, 126169. [Google Scholar] [CrossRef]

- Bütün, F.Y.; Sauerbier, P.; Militz, H.; Mai, C. The Effect of Fibreboard (MDF) Disintegration Technique on Wood Polymer Composites (WPC) Produced with Recovered Wood Particles. Compos. Part A Appl. Sci. Manuf. 2019, 118, 312–316. [Google Scholar] [CrossRef]

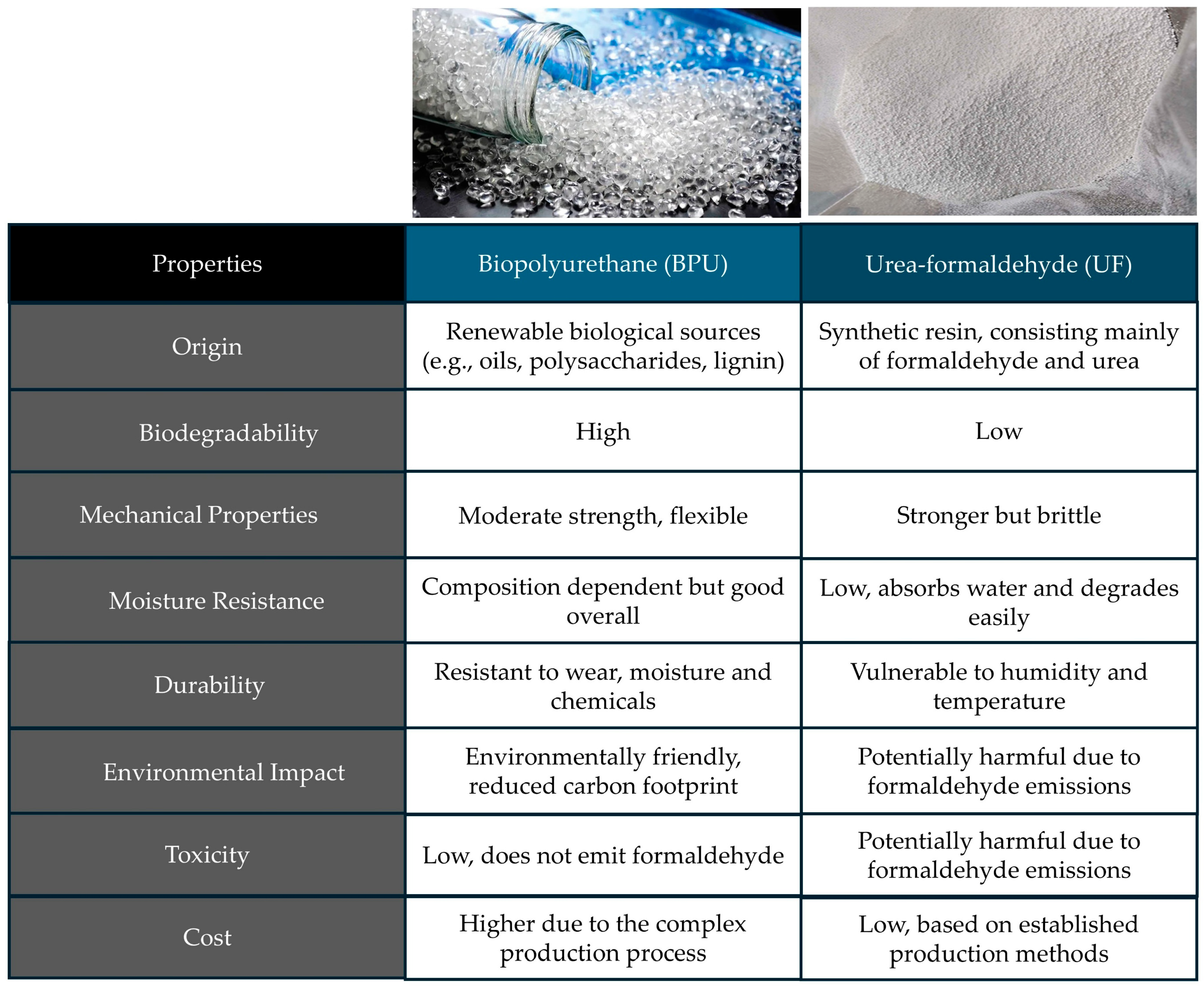

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from Agricultural Biomass and Recycled Wood Waste: A Review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Barbirato, G.H.A.; Junior, W.E.L.; Hellmeister, V.; Pavesi, M.; Fiorelli, J. OSB Panels with Balsa Wood Waste and Castor Oil Polyurethane Resin. Waste Biomass Valorization 2018, 11, 743–751. [Google Scholar] [CrossRef]

- Mo, Y.; Huang, X.; Hu, C. Recent Advances in the Preparation and Application of Bio-Based Polyurethanes. Polymers 2024, 16, 2155. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Xu, Q.; Jiang, G.; Teng, D. Preparation and Properties of Lignin-Based Polyurethane Materials. Arab. J. Chem. 2023, 17, 105471. [Google Scholar] [CrossRef]

- Park, S.; Jeong, B.; Park, B.-D. A Comparison of Adhesion Behavior of Urea-Formaldehyde Resins with Melamine-Urea-Formaldehyde Resins in Bonding Wood. Forests 2021, 12, 1037. [Google Scholar] [CrossRef]

- Tohmura, S.-I.; Hse, C.-Y.; Higuchi, M. Formaldehyde Emission and High-Temperature Stability of Cured Urea-Formaldehyde Resins. J. Wood Sci. 2000, 46, 303–309. [Google Scholar] [CrossRef]

- Kaur, R.; Singh, P.; Tanwar, S.; Varshney, G.; Yadav, S. Assessment of Bio-Based Polyurethanes: Perspective on Applications and Bio-Degradation. Macromol 2022, 2, 284–314. [Google Scholar] [CrossRef]

- Suwan, A.; Sukhawipat, N.; Uthaipan, N.; Saetung, A.; Saetung, N. Some Properties of Experimental Particleboard Manufactured from Waste Bamboo Using Modified Recycled Palm Oil as Adhesive. Prog. Org. Coat. 2020, 149, 105899. [Google Scholar] [CrossRef]

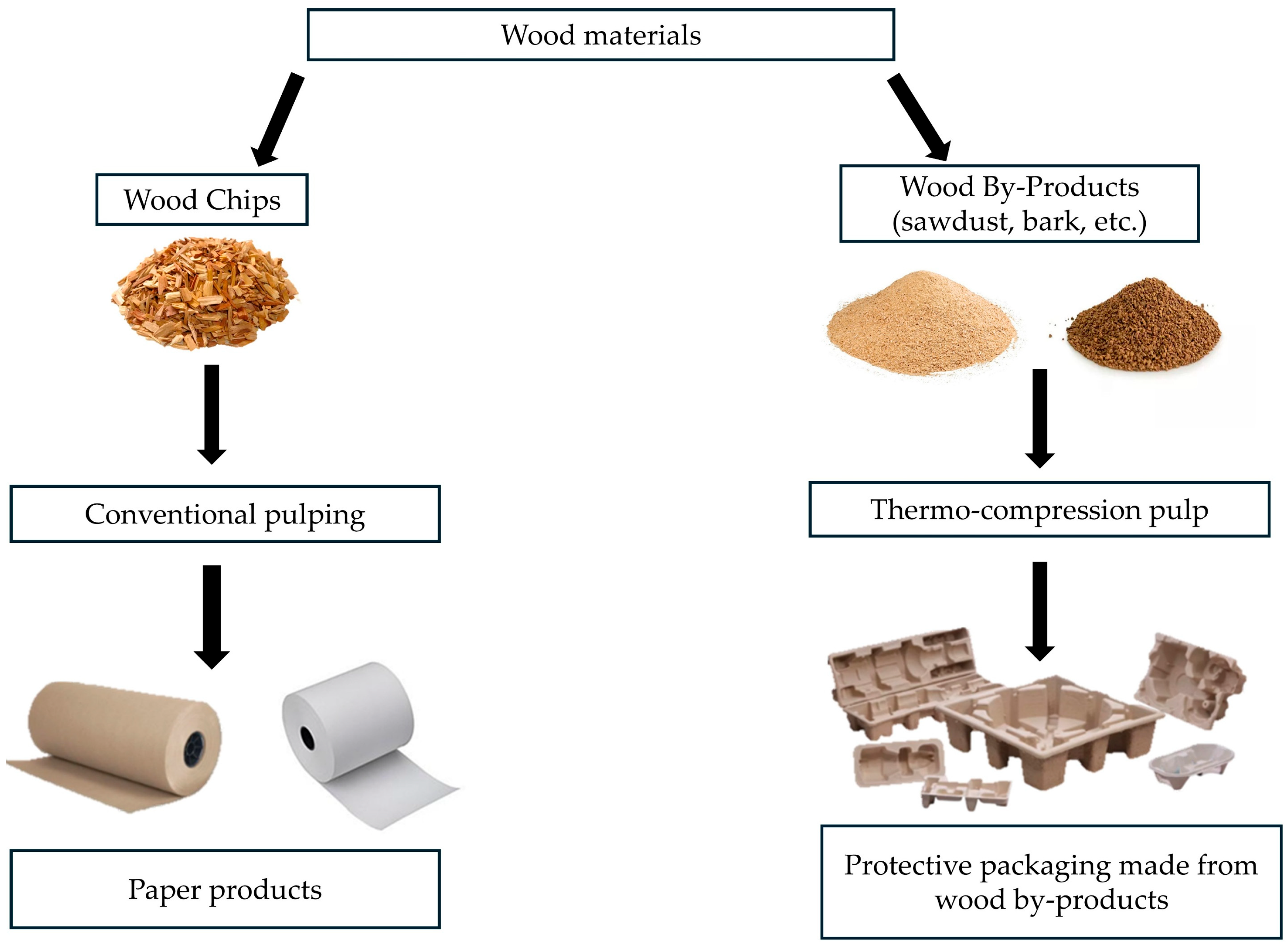

- Fuller, W. PULPING|Chip Preparation. In Encyclopedia of Forest Sciences; Elsevier: Amsterdam, The Netherlands, 2004; pp. 883–899. [Google Scholar] [CrossRef]

- Lehr, M.; Miltner, M.; Friedl, A. Removal of Wood Extractives as Pulp (Pre-)Treatment: A Technological Review. SN Appl. Sci. 2021, 3, 886. [Google Scholar] [CrossRef]

- Ruwoldt, J.; Opedal, M.T. Green Materials from Added-Lignin Thermoformed Pulps. Ind. Crops Prod. 2022, 185, 115102. [Google Scholar] [CrossRef]

- Revolutionizing Packaging Solutions: Thermoformed Molded Pulp for Sustainable Future|Hanson. Available online: https://www.hspulpmolding.com/revolutionizing-packaging-solutions-thermoformed-molded-pulp-for-sustainable-future/ (accessed on 20 July 2025).

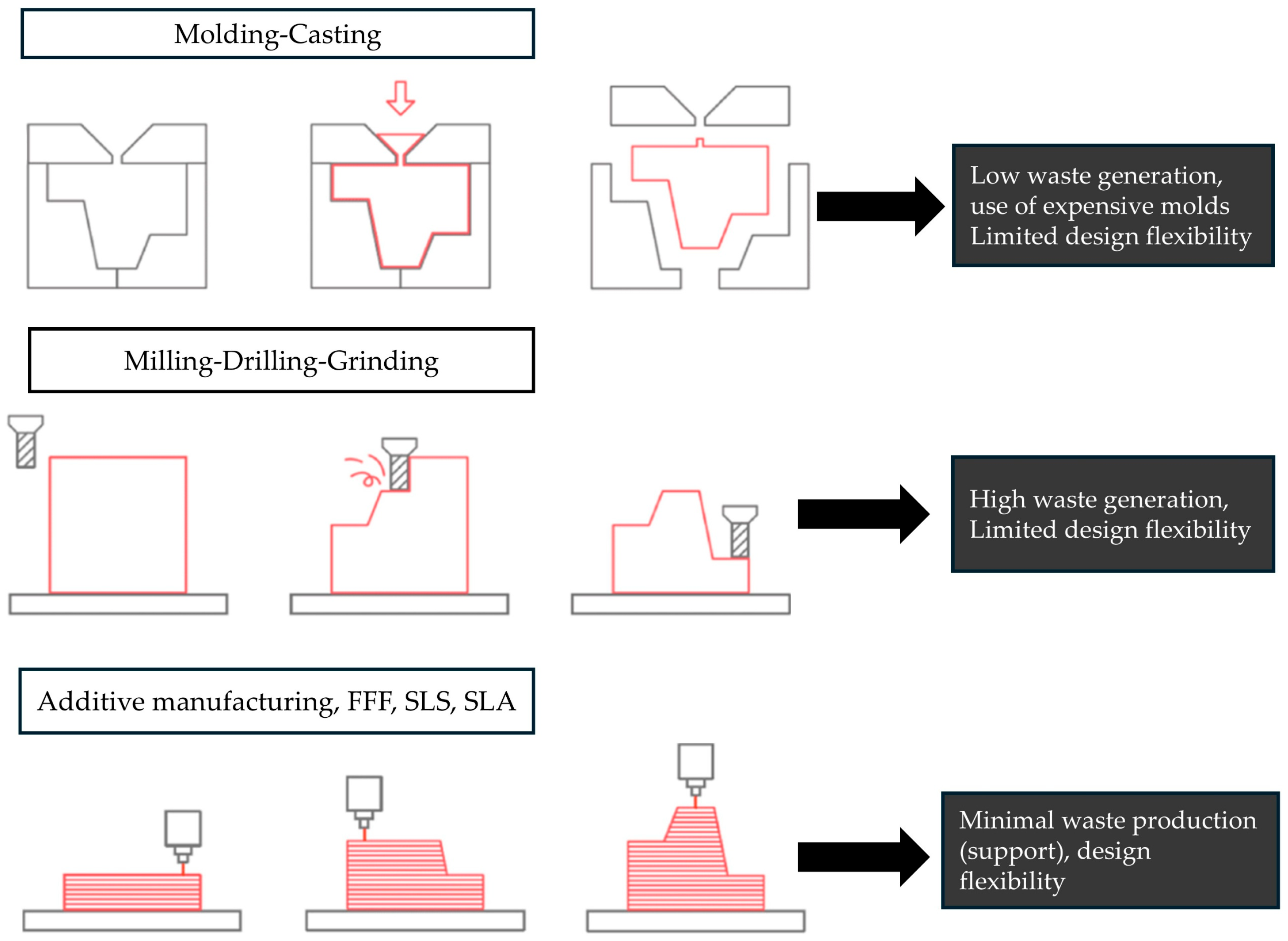

- Berman, B. 3-D Printing: The New Industrial Revolution. Bus. Horiz. 2011, 55, 155–162. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Elhazmiri, B.; Naveed, N.; Anwar, M.N.; Haq, M.I.U. The Role of Additive Manufacturing in Industry 4.0: An Exploration of Different Business Models. Sustain. Oper. Comput. 2022, 3, 317–329. [Google Scholar] [CrossRef]

- Sathish, T.; Vijayakumar, M.D.; Ayyangar, A.K. Design and Fabrication of Industrial Components Using 3D Printing. Mater. Today Proc. 2018, 5, 14489–14498. [Google Scholar] [CrossRef]

- Narlıoğlu, N.; Salan, T.; Alma, M.H. Properties of 3D-Printed Wood Sawdust-Reinforced PLA Composites. BioResources 2021, 16, 5467–5480. [Google Scholar] [CrossRef]

- Eshun, J.F.; Potting, J.; Leemans, R. Wood Waste Minimization in the Timber Sector of Ghana: A Systems Approach to Reduce Environmental Impact. J. Clean. Prod. 2012, 26, 67–78. [Google Scholar] [CrossRef]

- Henke, K.; Talke, D.; Bunzel, F.; Buschmann, B.; Asshoff, C. Individual Layer Fabrication (ILF): A Novel Approach to Additive Manufacturing by the Use of Wood. Eur. J. Wood Wood Prod. 2021, 79, 745–748. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Das, A.K.; Agar, D.A.; Rudolfsson, M.; Larsson, S.H. A Review on Wood Powders in 3D Printing: Processes, Properties and Potential Applications. J. Mater. Res. Technol. 2021, 15, 241–255. [Google Scholar] [CrossRef]

- Helaoui, S.; Koubaa, A.; Nouri, H.; Beauregard, M.; Guessasma, S. 3D Printing of Biodegradable Biocomposites Based on Forest Industrial Residues by Fused Deposition Modeling. Ind. Crops Prod. 2024, 222, 119799. [Google Scholar] [CrossRef]

- Rosenthal, M.; Henneberger, C.; Gutkes, A.; Bues, C.-T. Liquid Deposition Modeling: A Promising Approach for 3D Printing of Wood. Eur. J. Wood Wood Prod. 2017, 76, 797–799. [Google Scholar] [CrossRef]

- De Rubeis, T.; Ciccozzi, A.; Pasqualoni, G.; Paoletti, D.; Ambrosini, D. On the Use of Waste Materials for Thermal Improvement of 3D-Printed Block—An Experimental Comparison. Buildings 2023, 13, 1136. [Google Scholar] [CrossRef]

- Zeng, W.; Guo, Y.; Jiang, K.; Yu, Z.; Liu, Y.; Shen, Y.; Deng, J.; Wang, P. Laser Intensity Effect on Mechanical Properties of Wood–Plastic Composite Parts Fabricated by Selective Laser Sintering. J. Thermoplast. Compos. Mater. 2012, 26, 125–136. [Google Scholar] [CrossRef]

- Yu, Y.Q.; Guo, Y.L.; Jiang, K.Y. Temperature Field Simulation of Wood Powder/PES Composite Powder Material. Key Eng. Mater. 2015, 667, 218–223. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Kudelski, R.; Cieslik, J.; Kulpa, M.; Dudek, P.; Zagorski, K.; Rumin, R. Comparison of Cost, Material and Time Usage in FDM and SLS 3D Printing Methods. In Proceedings of the 2017 XIIIth International Conference on Perspective Technologies and Methods in MEMS Design (MEMSTECH), Lviv, Ukraine, 20–23 April 2017; pp. 12–14. [Google Scholar] [CrossRef]

- Tomec, D.K.; Kariž, M. Use of Wood in Additive Manufacturing: Review and Future Prospects. Polymers 2022, 14, 1174. [Google Scholar] [CrossRef]

- Govedič, T.B.; Tomec, D.K.; Kuzman, M.K.; Oblak, L.; Glavonjic, B. Environmental Assessment/Evaluation of 3D Printing and 3D Printing with Wood-PLA Composites—Case Study. Drv. Ind. 2024, 75, 49–58. [Google Scholar] [CrossRef]

- Bi, X.; Huang, R. 3D Printing of Natural Fiber and Composites: A State-of-the-Art Review. Mater. Des. 2022, 222, 111065. [Google Scholar] [CrossRef]

- Sarker, R.; Bari, M.A.A.; Saad, S.; Akash, N.M.; Gupta, C.; Mahmud, C.K.; Kharraz, E.; Rabbi, M.F.; Ullah, A.; Hu, J.; et al. Investigation of Mechanical and Physicochemical Properties of Additively Manufactured Underutilized wood-PLA Biocomposites. Polym. Compos. 2025, 46, S650–S667. [Google Scholar] [CrossRef]

- Jasiński, W.; Szymanowski, K.; Nasiłowska, B.; Barlak, M.; Betlej, I.; Prokopiuk, A.; Borysiuk, P. 3D Printing Wood–PLA Composites: The Impact of Wood Particle Size. Polymers 2025, 17, 1165. [Google Scholar] [CrossRef] [PubMed]

- Agaliotis, E.M.; Ake-Concha, B.D.; May-Pat, A.; Morales-Arias, J.P.; Bernal, C.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Proust, G.; Koh-Dzul, J.F.; Carrillo, J.G.; et al. Tensile Behavior of 3D Printed Polylactic Acid (PLA) Based Composites Reinforced with Natural Fiber. Polymers 2022, 14, 3976. [Google Scholar] [CrossRef] [PubMed]

- Buschmann, B.; Henke, K.; Asshoff, C.; Talke, D.; Talke, M.-K.; Bunzel, F. Additive Manufacturing of Wood Composite Parts by Individual Layer Fabrication—Influence of Process Parameters on Product Properties. Compos. Part C Open Access 2024, 15, 100504. [Google Scholar] [CrossRef]

- Sultana, J.; Rahman, M.M.; Wang, Y.; Ahmed, A.; Xiaohu, C. Influences of 3D Printing Parameters on the Mechanical Properties of Wood PLA Filament: An Experimental Analysis by Taguchi Method. Prog. Addit. Manuf. 2023, 9, 1239–1251. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Zaoutsos, S.P. An Assessment of PLA/Wood with PLA Core Sandwich Multilayer Component Tensile Strength under Different 3D Printing Conditions. J. Manuf. Process. 2024, 131, 1240–1249. [Google Scholar] [CrossRef]

- Kervran, M.; Vagner, C.; Cochez, M.; Ponçot, M.; Saeb, M.R.; Vahabi, H. Thermal Degradation of Polylactic Acid (PLA)/Polyhydroxybutyrate (PHB) Blends: A Systematic Review. Polym. Degrad. Stab. 2022, 201, 109995. [Google Scholar] [CrossRef]

- Xie, G.; Zhang, Y.; Lin, W. Plasticizer Combinations and Performance of Wood Flour–Poly(Lactic Acid) 3D Printing Filaments. BioResources 2017, 12, 6736–6748. [Google Scholar] [CrossRef]

- Lv, S.; Tan, H.; Gu, J.; Zhang, Y. Silane Modified Wood Flour Blended with Poly(Lactic Acid) and Its Effects on Composite Performance. BioResources 2015, 10, 5426–5439. [Google Scholar] [CrossRef]

- Petchwattana, N.; Channuan, W.; Naknaen, P.; Narupai, B. 3D Printing Filaments Prepared from Modified Poly(Lactic Acid)/Teak Wood Flour Composites: An Investigation on the Particle Size Effects and Silane Coupling Agent Compatibilisation. J. Phys. Sci. 2019, 30, 169–188. [Google Scholar] [CrossRef]

- Satriyatama, A.; Rochman, V.A.A.; Adhi, R.E. Study of the Effect of Glycerol Plasticizer on the Properties of PLA/Wheat Bran Polymer Blends. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1143, 012020. [Google Scholar] [CrossRef]

- Tomec, D.K.; Schwarzkopf, M.; Repič, R.; Žigon, J.; Gospodarič, B.; Kariž, M. Effect of Thermal Modification of Wood Particles for Wood-PLA Composites on Properties of Filaments, 3D-Printed Parts and Injection Moulded Parts. Eur. J. Wood Wood Prod. 2023, 82, 403–416. [Google Scholar] [CrossRef]

- Seo, Y.-R.; Kim, B.-J. Fused Filament Fabrication of Poly (Lactic Acid) Reinforced with Silane-Treated Cellulose Fiber for 3D Printing. J. Korean Wood Sci. Technol. 2024, 52, 205–220. [Google Scholar] [CrossRef]

- Baig, M.; Almeshari, B.; Aabid, A.; Junaedi, H.; Almajid, A. The Effect of Maleic Anhydride Grafted Polypropylene Addition on the Degradation in the Mechanical Properties of the PP/Wood Composites. Heliyon 2024, 10, e30510. [Google Scholar] [CrossRef]

- Nenkova, S.; Dobrilova, C.v.; Natov, M.; Vasileva, S.t.; Velev, P. Modification of Wood Flour with Maleic Anhydride for Manufacture of Wood-Polymer Composites. Polym. Polym. Compos. 2006, 14, 185–194. [Google Scholar] [CrossRef]

- Khamedi, R.; Hajikhani, M.; Ahmaditabar, K. Investigation of Maleic Anhydride Effect on Wood Plastic Composites Behavior. J. Compos. Mater. 2018, 53, 1955–1962. [Google Scholar] [CrossRef]

- Samyn, P. Challenges for Wood–Plastic Composites: Increasing Wood Content and Internal Compatibility. Environ. Earth Sci. Proc. 2024, 31, 1. [Google Scholar] [CrossRef]

- Xi, F.; Zhao, L. Experimental Study of the Compressive Properties of a Wood–Plastic Composite at Different Temperatures. Polym. Compos. 2022, 43, 7372–7378. [Google Scholar] [CrossRef]

- Agbayani, M.A.R.; Paglicawan, M.A.; Margarito, M.T.; Basilia, B.A. Effects of Wood Flour Reinforcement on the Warpage and Compressive Strength of 3D Printed HDPEs. Mater. Sci. Forum 2023, 1085, 35–41. [Google Scholar] [CrossRef]

- Yu, W.; Li, M.; Lei, W.; Pu, Y.; Sun, K.; Ma, Y. Effects of Wood Flour (WF) Pretreatment and the Addition of a Toughening Agent on the Properties of FDM 3D-Printed WF/Poly(Lactic Acid) Biocomposites. Molecules 2022, 27, 2985. [Google Scholar] [CrossRef]

- Faidallah, R.F.; Nabi, A.M.A.-E.; Hanon, M.M.; Szakál, Z.; Oldal, I. Compressive and Bending Properties of 3D-Printed Wood/PLA Composites with Re-Entrant Honeycomb Core. Results Eng. 2024, 24, 103023. [Google Scholar] [CrossRef]

- Jain, A.; Austern, G.; Barath, S. Assessing Thermal-Mechanical Properties of Wood Powder Cellulose-Based Composites for 3D-Printed Architectural Components. Archit. Struct. Constr. 2025, 5, 28. [Google Scholar] [CrossRef]

- Muck, D.; Tomc, H.G.; Elesini, U.S.; Ropret, M.; Leskovšek, M. Colour Fastness to Various Agents and Dynamic Mechanical Characteristics of Biocomposite Filaments and 3D Printed Samples. Polymers 2021, 13, 3738. [Google Scholar] [CrossRef]

- Patti, A. Process–Property Correlation in Sustainable Printing Extrusion of Bio-Based Filaments. J. Compos. Sci. 2024, 8, 305. [Google Scholar] [CrossRef]

- Mazurchevici, S.-N.; Mazurchevici, A.-D.; Nedelcu, D. Dynamical Mechanical and Thermal Analyses of Biodegradable Raw Materials for Additive Manufacturing. Materials 2020, 13, 1819. [Google Scholar] [CrossRef] [PubMed]

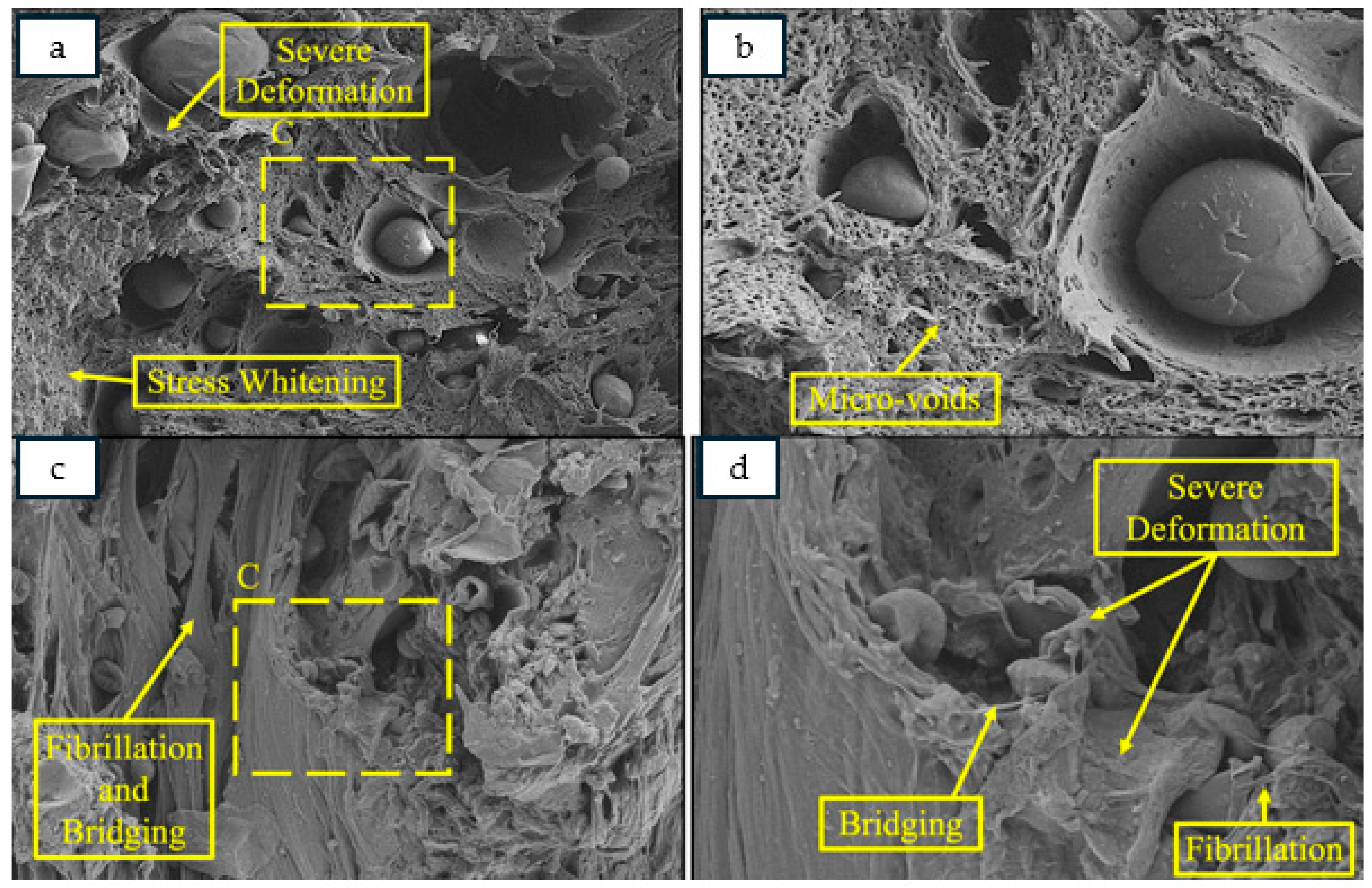

- Zhang, S.; Bhagia, S.; Li, M.; Meng, X.; Ragauskas, A.J. Wood-Reinforced Composites by Stereolithography with the Stress Whitening Behavior. Mater. Des. 2021, 206, 109773. [Google Scholar] [CrossRef]

- Kianifar, M.; Azadi, M.; Heidari, F. Evaluation of Stress-Controlled High-Cycle Fatigue Characteristics in PLA-Wood Fused Deposition Modeling 3D-Printed Parts under Bending Loads. PLoS ONE 2024, 19, e0300569. [Google Scholar] [CrossRef] [PubMed]

- Travieso-Rodriguez, J.A.; Zandi, M.D.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue Behavior of PLA-Wood Composite Manufactured by Fused Filament Fabrication. J. Mater. Res. Technol. 2020, 9, 8507–8516. [Google Scholar] [CrossRef]

- Müller, M.; Šleger, V.; Kolář, V.; Hromasová, M.; Piš, D.; Mishra, R.K. Low-Cycle Fatigue Behavior of 3D-Printed PLA Reinforced with Natural Filler. Polymers 2022, 14, 1301. [Google Scholar] [CrossRef]

- Guo, R.; Ren, Z.; Bi, H.; Song, Y.; Xu, M. Effect of Toughening Agents on the Properties of Poplar Wood Flour/Poly (Lactic Acid) Composites Fabricated with Fused Deposition Modeling. European Polymer Journal 2018, 107, 34–45. [Google Scholar] [CrossRef]

- Ferdinánd, M.; Várdai, R.; Móczó, J.; Pukánszky, B. A Novel Approach to the Impact Modification of PLA. Eng. Fract. Mech. 2022, 277, 108950. [Google Scholar] [CrossRef]

- Shahavi, M.H.; Selakjani, P.P.; Abatari, M.N.; Antov, P.; Savov, V. Novel Biodegradable Poly (Lactic Acid)/Wood Leachate Composites: Investigation of Antibacterial, Mechanical, Morphological, and Thermal Properties. Polymers 2022, 14, 1227. [Google Scholar] [CrossRef]

- Chien, Y.-C.; Yang, T.-C. Properties of Heat-Treated Wood Fiber–Polylactic Acid Composite Filaments and 3D-Printed Parts Using Fused Filament Fabrication. Polymers 2024, 16, 302. [Google Scholar] [CrossRef] [PubMed]

- Bae, S.-U.; Seo, Y.-R.; Kim, B.-J.; Lee, M. Effects of Wood Flour and MA-EPDM on the Properties of Fused Deposition Modeling 3D-Printed Poly Lactic Acid Composites. BioResources 2021, 16, 7122–7138. [Google Scholar] [CrossRef]

- Karagöz, İ. Production and Characterization of Sustainable Biocompatible PLA/Walnut Shell Composite Materials. Polym. Bull. 2024, 81, 11517–11537. [Google Scholar] [CrossRef]

- Ainin, F.N.; Azaman, M.D.; Majid, M.S.A.; Ridzuan, M.J.M. Low-Velocity Impact Behavior of Sandwich Composite Structure with 3D Printed Hexagonal Honeycomb Core: Varying Core Materials. Funct. Compos. Struct. 2022, 4, 035007. [Google Scholar] [CrossRef]

- Smardzewski, J.; Maslej, M.; Wojciechowski, K.W. Compression and Low Velocity Impact Response of Wood-Based Sandwich Panels with Auxetic Lattice Core. Eur. J. Wood Wood Prod. 2021, 79, 797–810. [Google Scholar] [CrossRef]

- Widheden, J.; Ringström, E. Life Cycle Assessment. In Handbook for Cleaning/Decontamination of Surfaces; Elsevier Science: Amsterdam, The Netherlands, 2007; pp. 695–720. [Google Scholar] [CrossRef]

- Nguyen, K.Q.; Vuillaume, P.Y.; Hu, L.; López-Beceiro, J.; Cousin, P.; Elkoun, S.; Robert, M. Recycled, Bio-Based, and Blended Composite Materials for 3D Printing Filament: Pros and Cons—A Review. Mater. Sci. Appl. 2023, 14, 148–185. [Google Scholar] [CrossRef]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; Van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2016, 22, 138–147. [Google Scholar] [CrossRef]

- BioHome3D—Advanced Structures & Composites Center—University of Maine. Available online: https://composites.umaine.edu/advanced-manufacturing/biohome3d/ (accessed on 4 August 2025).

- Gallucio, G.; Tamke, M.; Nicholas, P.; Svilans, T.; Gaudillière, N.; Thomsen, M.R. Material Stories: Assessing Sustainability of Digital Fabrication with Bio-Based Materials Through LCA. In The 1st International Conference on Net-Zero Built Environment; Lecture Notes in Civil Engineering; Springer Nature: Cham, Switzerland, 2025; pp. 25–37. [Google Scholar]

- Forust Forust Technology. Available online: https://www.forust.com/technology (accessed on 4 August 2025).

- Kariž, M.; Tomec, D.K.; Dahle, S.; Kuzman, M.K.; Šernek, M.; Žigon, J. Effect of Sanding and Plasma Treatment of 3D-Printed Parts on Bonding to Wood with PVAc Adhesive. Polymers 2021, 13, 1211. [Google Scholar] [CrossRef]

- Donate, R.; Alemán-Domínguez, M.E.; Monzón, M. On the Effectiveness of Oxygen Plasma and Alkali Surface Treatments to Modify the Properties of Polylactic Acid Scaffolds. Polymers 2021, 13, 1643. [Google Scholar] [CrossRef] [PubMed]

- Miehe, R.; Full, J.; Scholz, P.; Demmer, A.; Bauernhansl, T.; Sauer, A.; Schuh, G. The Biological Transformation of Industrial Manufacturing-Future Fields of Action in Bioinspired and Bio-Based Production Technologies and Organization. Procedia Manuf. 2019, 39, 737–744. [Google Scholar] [CrossRef]

| Content | Tg (°C) | Tm(°C) | Main Findings |

|---|---|---|---|

| Elevated weight Fraction (up to 30 wt.%) | Stable | Increase | Steady molecular mobility, increased crystallinity |

| Fine particle size | Stable | Stable | Optimal thermal properties, good dispersion |

| Bulk particles | Stable | Stable | Thermal stability, printability issues due to structural disruption |

| Composite | Tg (°C) | E’ (MPa) | tan δ | Main Findings |

|---|---|---|---|---|

| Wood Sawdust/PLA | Increase | Increase | Increase | 25.7% energy storage increase, slightly increased Tg |

| Pine Fibers/PLA | Decrease | Increase | Decrease | Enhanced energy storage capabilities, slight decrease in Tg |

| Polyester/PLA | Decrease | Increase | Decrease | Higher strength, less damping |

| Wood Flour/Resin | Decrease | Unknown | Decrease | Poor compatibility, performance drop |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kyriakidis, I.F.; Karelis, A.; Kladovasilakis, N.; Pechlivani, E.M.; Tsongas, K. Valorization of Natural Byproducts Through Additive Manufacturing for Ecologically Sustainable Composite Materials: A Literature Review. Fibers 2025, 13, 157. https://doi.org/10.3390/fib13120157

Kyriakidis IF, Karelis A, Kladovasilakis N, Pechlivani EM, Tsongas K. Valorization of Natural Byproducts Through Additive Manufacturing for Ecologically Sustainable Composite Materials: A Literature Review. Fibers. 2025; 13(12):157. https://doi.org/10.3390/fib13120157

Chicago/Turabian StyleKyriakidis, Ioannis Filippos, Anargiros Karelis, Nikolaos Kladovasilakis, Eleftheria Maria Pechlivani, and Konstantinos Tsongas. 2025. "Valorization of Natural Byproducts Through Additive Manufacturing for Ecologically Sustainable Composite Materials: A Literature Review" Fibers 13, no. 12: 157. https://doi.org/10.3390/fib13120157

APA StyleKyriakidis, I. F., Karelis, A., Kladovasilakis, N., Pechlivani, E. M., & Tsongas, K. (2025). Valorization of Natural Byproducts Through Additive Manufacturing for Ecologically Sustainable Composite Materials: A Literature Review. Fibers, 13(12), 157. https://doi.org/10.3390/fib13120157