Abstract

This paper presents a detailed exploration of the development and characterization of multifunctional dual-purpose woven fabrics for thermal protective clothing. Through this research, 69 woven fabric prototypes have been carefully designed and produced, integrating various raw materials, yarn, and woven fabric construction parameters, with the aim of optimizing thermal protection properties while ensuring comfort and durability. The analysis led to the identification of two optimal woven fabric samples, which, upon further testing, exhibited exceptional dimensional stability, crease recovery, tear resistance, as well as abrasion and water resistance. Furthermore, the thermal properties were evaluated, demonstrating exceptional flame resistance, limited heat transmission, and high thermal insulation. Additionally, the study evaluated dynamic thermal properties, contact conductive heat transfer, air permeability, water vapour resistance, and thermal resistance of two clothing systems constructed from selected woven fabrics. Statistical analysis confirms significant differences between clothing systems, highlighting the influence of yarn composition and fabric structure on thermal performance and comfort, where one system exhibits better thermal insulation characteristics suitable for colder environments while the other excels in breathability for warmer climates. The developed woven fabrics meet high standards for protective clothing against heat and flame, surpassing currently available comparable woven fabrics on the market in terms of efficacy and performance. This research provides insights into the intricate balance between protection, comfort, and durability of woven fabrics, contributing to advancements in protective textile technology.

1. Introduction

In delving into the nuanced discourse surrounding woven fabrics, with an exploration of their evolutionary trajectory and the challenges inherent in protective clothing, it is imperative to underscore the transformative impact of cultural shifts and technological innovations on traditional textiles. Woven fabrics have undergone a paradigm shift from their conventional roles driven by research technologies facilitating the fulfilment of di-verse functional objectives. Protective textiles, constituting a substantive niche, encompass woven fabrics meticulously tailored to insulate the human body from external influences [1,2]. Textile materials assume a pivotal role within the domain of personal protective equipment, spanning an array of advanced garments. This extensive deployment seeks to shield the human body from potential exposure to hazardous substances and adverse environmental conditions. Termed as protective textiles, these specialized garments are engineered to mitigate specific risks and minimize the likelihood of exposure. The evolution of protective clothing is manifested in its adaptability to diverse threats and external factors, with textiles designed to safeguard against high temperatures or flames representing a salient category within this domain [3,4].

Over the past five decades, substantial endeavours have been directed towards the development of materials providing high-performance thermal protection and meeting stringent criteria, including flame resistance, structural integrity at elevated temperatures, thermal insulation, and liquid repellency. Historically, flame-retardant fibers, subject to chemical processing and sourced from natural or synthetic origins, were employed. However, contemporary advancements underscore inherently flame-resistant fibers as superior alternatives, thereby elevating the level of protection [5,6,7,8].

Protective textiles have seen significant progress through the incorporation of blended fibers combining different materials to improve performance and functionality. Blended fibers have attracted considerable attention for their potential to improve thermal protection while maintaining comfort and durability. Blending fibers, such as aramid (e.g., Kevlar), polyethylene, and polyester, with natural fibers, like cotton or wool, has shown improved resistance to wear, puncture, and tear. Moreover, the inclusion of inherently flame-resistant (FR) fibers, such as meta-aramid (e.g., Nomex) or modacrylic, improves protection against thermal hazards. Blends can greatly contribute to reducing moisture accumulation in outdoor clothing, potentially enhancing safety and comfort, as demonstrated through the blend of FR viscose/merino wool. However, it is also important to mention that blending certain FR fibers, such as FR viscose fibers, can sometimes lead to a compromise in durability, including decreased resistance to stretching, tearing, and abrasion. Research also shows that combinations, such as aramid with polyethylene or polyester, improve tensile strength and abrasion resistance, providing extended service life in demanding environments. Moreover, blending wool with para-aramid fibers in spun yarns has significantly enhanced fire retardance performance and thermal stability in textiles owing to synergistic effects facilitated by intimate fiber contact. Blending alginate fibers with polyamide fibers has yielded flame-retardant materials with self-extinguishing properties and substantial reductions in heat and smoke release compared to pure polyamide fibers. This underscores the potential of fiber blending in creating textiles with enhanced safety and performance characteristics [9,10,11,12,13,14].

This study utilized woven fabrics that represent the most complex textile materials both in terms of design and fabrication as well as properties and influential parameters. The intricate structure of woven fabric involves considerations at the macro, meso, and micro levels. Macro-level parameters encompass construction specifications, such as weave, thickness, mass, and fabric density, that exert influence over properties including air permeability, water vapour permeability, and thermal insulation. The meso level incorporates the structural parameters of yarn, where yarn fineness plays a pivotal role. Micro-level dynamics revolve around fiber properties, underscoring their fundamental influence on woven fabrics’ properties [15,16]. The overarching challenge resides in the optimization of woven fabrics’ properties stipulated by standards ensuring sustained effectiveness during usage.

As protective textiles progress, the focus transcends mere protection to encompass considerations of harmlessness, design, and comfort. The interplay of factors, such as raw material selection, woven fabric design, and integrated protection properties, defines the overall functionality and efficiency of protective clothing. Complex woven fabrics aspire to meet mechanical, thermal, and thermo-physiological requirements in a singular, cost-effective, and environmentally friendly process [17,18,19,20]. While flame resistance remains a focal point, other attributes influencing garment performance and wearer protection are garnering attention. Thermal behaviour, mechanical properties (including tensile strength, tear strength, and seam strength), air and water vapour permeability, and seam integrity constitute critical aspects. Studies of mechanical properties often neglecting external factors, such as ambient humidity and wetting, underscore the imperative for comprehensive investigations [21,22,23]. One of the critical properties in textile materials, air permeability, is defined as the fabric’s ability to transmit air. Its importance extends beyond mere comfort in clothing; it becomes a vital attribute for the functionality of thermal protective textiles. It is significantly influenced by a slight modification in fabric structure (weave, density, thickness, pore size and shape, and the distribution of space between yarns) as well as yarn and fiber properties, which are intricately linked with fabric porosity. Recognizing the significance of fabric porosity is paramount, as it serves as a crucial parameter for assessing both the comfort of clothing and the physical characteristics of fabrics [24]. Furthermore, woven fabric structure characteristics contribute to the overall breathability, promoting comfort and preventing heat-related issues. Striking a balance between thickness and density is key to maintaining breathability while ensuring optimal thermal protection.

In the realm of high-performance fabrics, thermal behaviour assumes a pivotal role, as evidenced by studies indicating a significant percentage of garments fail to meet established standards due to wear and tear. Consequently, evaluating resistance to heat or flame necessitates the simultaneous employment of multiple methodologies to ascertain the timeframe for changes or degradations [25].

Moreover, research initiatives have expanded to scrutinize the impact of extreme environmental conditions on clothing performance, thus extending considerations beyond flame retardancy. This primarily involves protection against heat flux as a key consideration given the potential heat intensity in professional environments. Heat transfer through protective clothing hinges on various factors, including textile geometry and the thermal properties of raw materials. Protective clothing becomes imperative in situations where life-threatening hazards or risks exist, necessitating a careful balance between protection and comfort [26,27,28].

The intrinsic connection between thermal comfort and the heat balance between the human body and its environment underscores the pivotal role of clothing in this thermoregulatory equilibrium. The exchange of heat occurs through various mechanisms, each conditioned by factors, such as body temperature, metabolism, environmental temperature, and humidity. Clothing, as a vital component, establishes an artificial microclimate that aids thermoregulatory mechanisms [29,30]. The challenge lies in potential discomfort arising from protective clothing hindering heat and moisture transfer. The human body’s homeothermic nature seeks to maintain core temperature, and the bulkiness of protective clothing can disrupt this equilibrium [31]. Issues, such as heat stress and increased core temperature, limit the wearer’s working times, underscoring the importance of achieving a balance between body heat production and dissipation through the textile layers [32]. The structural parameters of the fabric affect properties, such as fabric transport properties, air permeability, water vapour permeability, thermal resistance, and moisture vapour evaporation, that play crucial roles in determining clothing comfort and performance. Moisture management becomes a critical aspect of protective clothing, as accumulated moisture within the clothing system can compromise protection and comfort. The intricate interplay of moisture absorption, location, and duration of exposure to thermal radiation impacts overall moisture transfer through the clothing system. Achieving optimal physiological and sensorial comfort, particularly in the next-to-skin layer, becomes paramount for ensuring work efficiency and performance [33,34,35]. Thus, the effectiveness of thermal protective woven fabric hinges on its capability to simultaneously prevent external heat and facilitate the dissipation of metabolic heat. Striking a balance between comfort and protection involves a nuanced strategy encompassing fiber selection, fabric composition, and finishing processes. Managing the conflicting features of protection and comfort poses an ongoing challenge in the realm of protective textiles [36]. The formulation of protective clothing involving the integration of diverse fiber types and fabric layers necessitates meticulous consideration to optimize both protection and wearer comfort [37,38].

The evolution of protective textiles and woven fabrics reflects a dynamic intersection of technological advancements, cultural influences, and an understanding of the complex relationships between protection and comfort. From the historical use of chemically processed fibers to the contemporary focus on inherently flame-resistant materials, the pursuit of optimal performance endures. The multifaceted challenges posed by protective clothing underscore the need for continual research, technological innovations, and a holistic approach to ensure the effectiveness and comfort of garments in high-risk environments.

The global market for multifunctional dual-purpose woven fabric for thermal protective clothing demands fabrics that prioritize thermal protection, durability, and longevity while offering comfort, flexibility, and multi-functionality. These fabrics should be lightweight, low in bulk, and comply with regulatory standards, all while being cost-effective. Manufacturers need to address these demands to meet the diverse needs of industries. Through an analysis of currently available inherently non-flammable woven fabrics on the global market, the key factors influencing the applicability and efficacy of a product in a specific application area become apparent. Considering the raw material composition, the application of certain materials (AR, PA, CV, cotton) is evident, combined in various compositions and ratios, such as 65% CV-FR/25% p-AR/10% PA, 35% PA/35% CV-FR/30% AR, 88% cotton/12% PA, 54% CV-FR/36% p-AR/10% PA antistatic, and 93% m-AR/5% p-AR/2% PA antistatic. It is noteworthy that these fabrics are structurally available in either ripstop or twill weaves, with weights of approximately 220 g/m2. Analysis has determined that all woven fabrics provide satisfactory heat protection, indicating their usability in situations of exposure to fire or high temperatures. Considering the comfort properties, they vary, and in certain analyzed woven fabrics, they represent a significant drawback. However, the demand posing the most significant challenge to all currently available woven fabrics on the market manifests in meeting durability requirements, for which neither woven fabric design nor finishing processes have achieved satisfactory levels [39,40,41,42,43]. The analysis indicates a crucial need for further research and open opportunities for advancing development and innovation within the domain of technological advancements in woven fabric production.

Therefore, this study aims to address various challenges and integrate technological advancements to meet market demands and improve the overall effectiveness of woven fabric for thermal protection clothing.

2. Materials and Methods

A three-year-long research endeavour was undertaken to develop a multifunctional dual-purpose fabric that would optimally address the demands of the global market by combining certain characteristics, such as flame resistance (protection against thermal hazards), comfort, breathability, and durability. To achieve this objective, 69 different woven fabrics were designed and produced by varying key influential parameters, including raw material compositions, yarn construction characteristics, and fabric construction features.

To obtain specific protective properties in the woven fabric, a careful analysis was conducted, and a selection of fibers was made, involving aramid (AR), viscose (CV), polyamide (PA), flame-resistant (FR) cotton (Co), and FR modacrylic (MAC) fibers, which were blended in various combinations and ratios and spun using ring-spinning technology. All yarns used in this research are products of the company Litija, one of the leading European producers of specialty yarns made from natural and synthetic fibers as well as their blends. The combination of aramid, viscose FR, and polyamide 6.6 fibers demonstrated the optimal blend of fire resistance, excellent thermal properties (stability, conductivity, and resistance), and outstanding mechanical properties. Additionally, a blend of FR modacrylic and FR cotton fibers was utilized to achieve another facet of the protective woven fabric’s functionality, emphasizing comfort, lightness, and softness. Modacrylic fibers, unlike other inherently flame-resistant fibers, could be blended with natural fibers. Modacrylic fibers possess the ability to remove oxygen from non-FR fibers, thereby protecting themselves and other fibers in the blend from overheating and burning. The incorporation of cotton in the mix enhances the fabric’s comfort properties.

During the development process, a total of 44 different types of yarns were used, which, besides differing in raw material composition, also varied in construction parameters of fineness, numbers and directions of twists, and structure (1-ply, 2-ply). This segment of diversity was incorporated into the designing process through various combinations of woven fabric structural and construction parameters. Thus, fundamental weaves (plain, basket 2/2, ripstop, twill 1/3, 2/2, 2/1, 3/1) were used, with adjustments made to other construction parameters, such as yarn density, thereby influencing other relevant parameters, such as weight, thickness, and compactness, thereby determining key characteristics and properties of the woven fabrics (mechanical and thermal insulation). The weaving process was carried out using the laboratory weaving machine Fanyuan Instruments (FYI), Rapier Loom Machine DW598.

Based on comprehensive testing of the most relevant properties of all previously mentioned designed woven fabric samples conducted according to standardized methods in an accredited laboratory and their detailed analysis, two fabric samples (Table 1) have been identified which, with their characteristics and properties, stand out as the most effective in fulfilling the envisaged role of thermal protection according to EN ISO 11612:2015 and EN ISO 14116:2015. Afterwards, the selected samples were produced using an industrial weaving machine and submitted to a finishing process at a textile company, Čateks, Croatia.

Table 1.

Parameters of the yarns and structural characteristics of selected woven fabric H1 and J3.

Two selected samples of multifunctional woven fabrics were submitted for subsequent analysis, which were meticulously configured in the form of a clothing system consisting of a shirt and trousers with the same clothing construction (H1A5 and J3A5).

Tests of the complete thermal properties of the two protective clothing systems were carried out to measure the static (resting shape simulation) and dynamic thermal properties (walking simulation) (using the patented measuring system for determination of static and dynamic thermal properties of composite and clothing, PK20130350, State Intellectual Property Office of the Republic of Croatia, 2015), contact conductive heat transfer in both uncompressed and compressed states (using the patented multifunctional differential conductivity meter for textile composites and clothing, PK20171643, State Intellectual Property Office of the Republic of Croatia, 2020), air permeability (ISO 9237:1995), as well as thermal and water vapour resistance (ISO 11092:2014).

As previously mentioned, thermal comfort is defined in the international standard ISO 7730:2005 as a state of mind that expresses satisfaction with the thermal environment [44], which is influenced by the clothing factor, the human factor, and the environment factor. Depending on the conditions in which people stay and perform their activities, they should wear different clothing systems to achieve thermal comfort. According to the ASTM F1291-16 [45], a Clo unit is defined as the insulation required to keep a resting human (producing heat at a rate of 58 W/m2) comfortable in an environment of 21 °C and air velocity of 0.1 m/s, which is approximately the insulation value of a heavy business suit [46]. Numerically, a Clo corresponds to 0.155 K m2/W. For example, for an office worker (ambient temperature of 24.5 °C and humidity up to 50%), a thermal insulating clothing system of 0.5 Clo is recommended; for a mechanic (ambient temperature of 18 °C and humidity up to 50%), a clothing system of 0.8 Clo is recommended; and for work in cold storage (ambient temperature of 6 °C and humidity up to 50%), a clothing system of 1.7 Clo is recommended [47,48]. Extremely cold weather refers to clothing with a thermal insulation of 3.5 to 4.0 Clo. The complete thermal properties of clothing include heat and water vapour transfer between the clothing and the environment and represent a quantitative analysis of the quality of protection provided by the clothing system to the wearer itself [49].

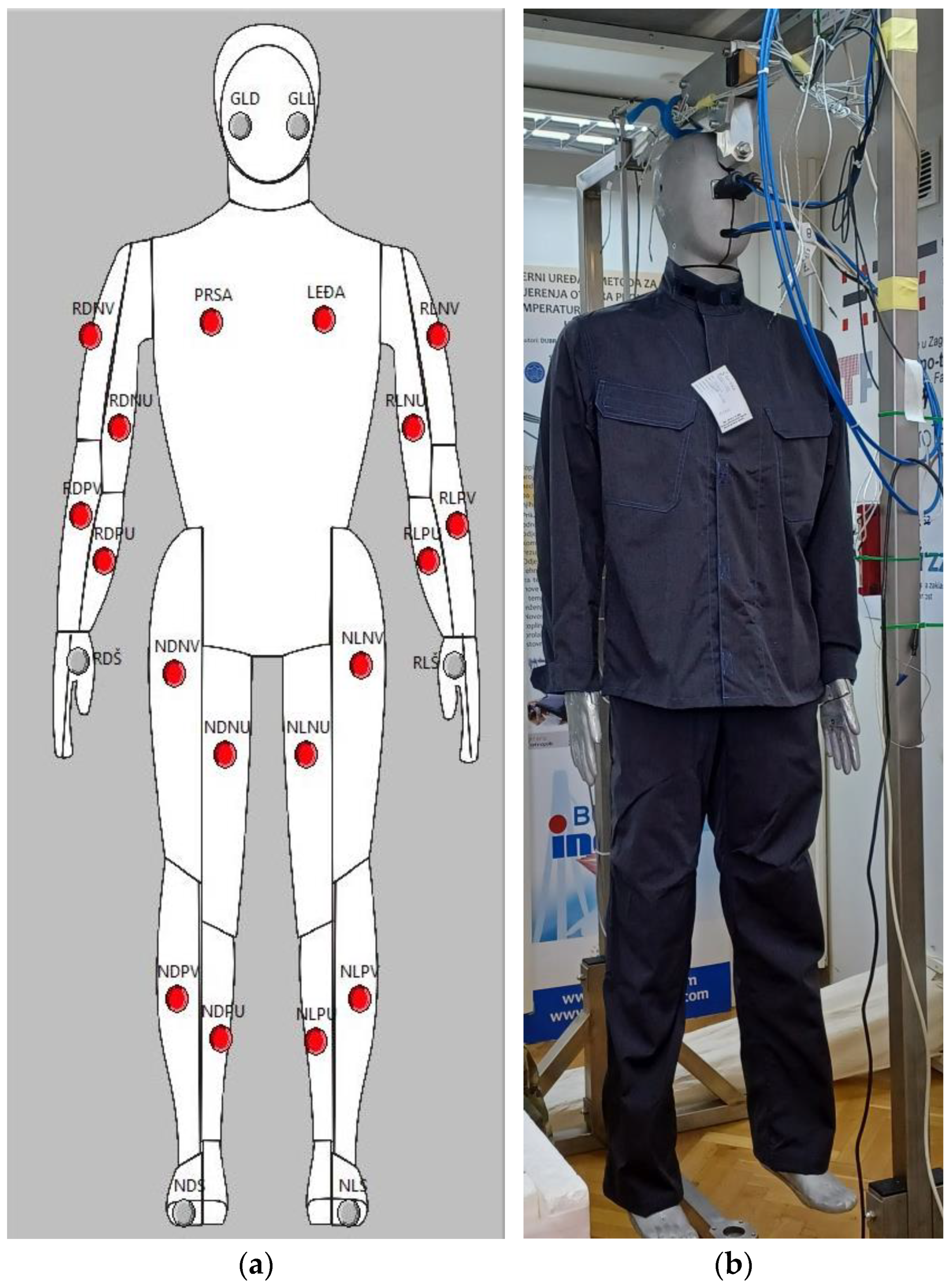

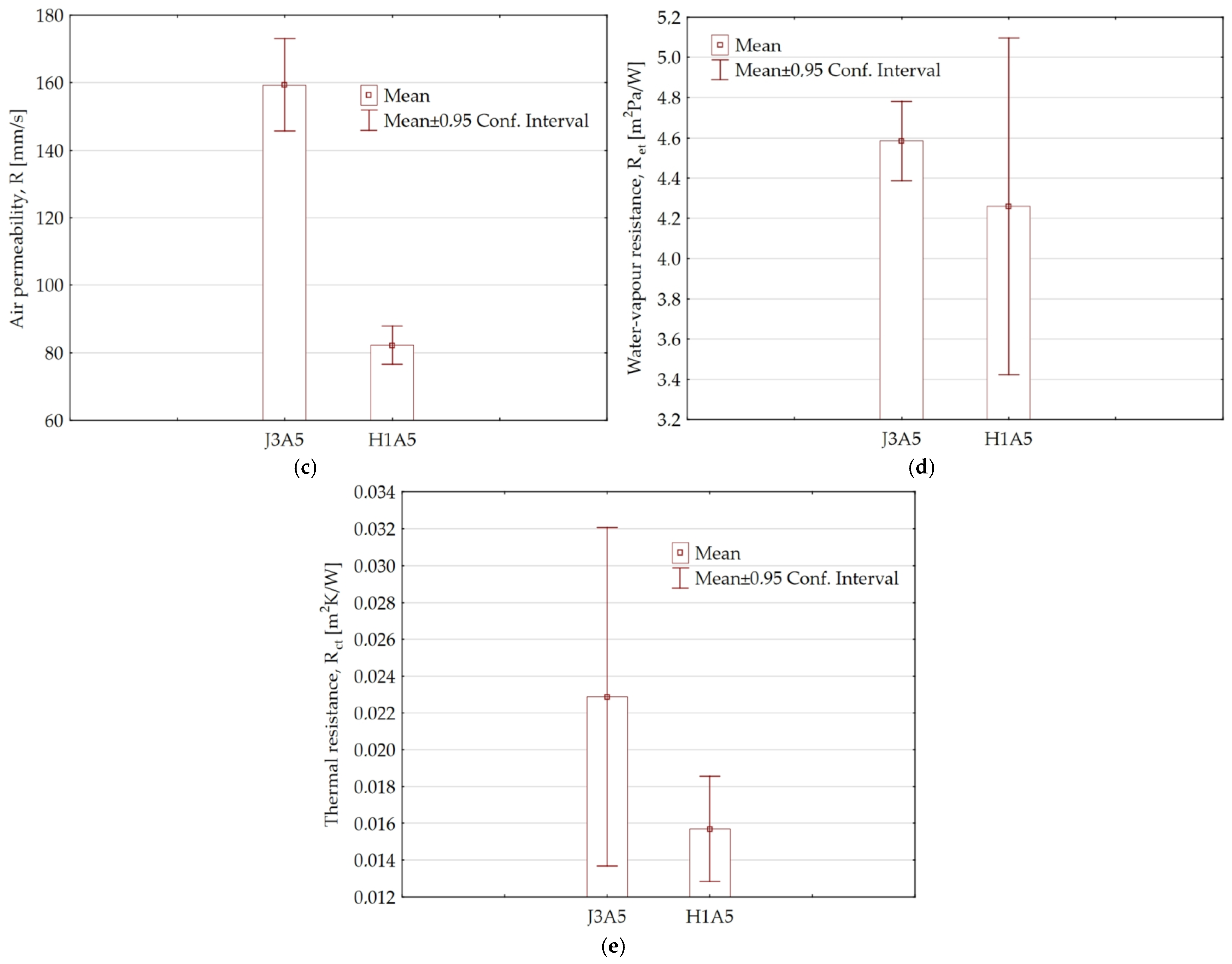

According to ISO 15831:2004, the surface temperature of a particular measured segment on a thermal manikin is 34 °C. The 1.70 m high thermal manikin consists of 24 segments (Figure 1a), with a total surface area of 1.77 m2. In dynamic mode, the thermal manikin performs 45 double steps per minute and 45 double hand movements per minute. The step length of the thermal manikin, measured from the tip of the front leg to the tip of the back leg, is 63 cm, and the hand movement length, measured between the wrist (front arm and back arm) at the base of the thumb, is 53 cm. When testing the thermal performance of selected clothing systems (Figure 1b), the following segments were measured with a total surface area of 1.51 m2: front torso, back torso, left upper arm, inner, left upper arm, outer, right upper arm, inner, right upper arm, outer, left forearm, inner, left forearm, outer, right forearm, inner, right forearm, outer, left upper leg, inner, left upper leg, outer, right upper leg, inner, right upper leg, outer, left calf, inner, left calf, outer, right calf, inner, right calf arm, and outer. Segments of the head (left and right), hands (left and right), and feet (left and right) were excluded from the test because they were not covered by measurement specimens when the thermal insulation properties were measured.

Figure 1.

Thermal manikin: (a) Thermal manikin segments; (b) Measurement of thermal insulation on a thermal manikin.

Once stable environmental conditions (temperature, relative humidity, air velocity) are established, the thermal manikin constant Rct0 should be determined using the equation:

where Rct0 is the resultant total thermal resistance of the measuring device including the thermal insulation of the boundary air layer, m2 °C/W; A is the total surface area of the thermal manikin, m2; Ts is the mean skin surface temperature of the thermal manikin, °C; Ta is the air temperature, °C; and H0 is the total heating power supplied to the thermal manikin, W.

The constant Rct0 under selected ambient conditions is 0.071960 m2 °C/W. After measuring Rct0, the thermal manikin is clothed with the clothing system, and the stabilization of the parameter value is waited for. Then, a series of measurements are taken on the manikin for 20 min. The values are recorded every 5 s, and, after one minute, an average value of 12 measurements is recorded, which means that the thermal insulation value Rct is based on an average of 240 values, according to the equation:

where Hm is the location where the electrical power required to maintain the temperature of the measuring surface on which the measurement sample is positioned is provided, W. The thermal insulation of clothing systems is expressed by the units m2 °C/W and Clo. The unit Clo is the unit of measurement for the thermal insulation of clothing and is numerically equal to 0.155 m2 °C/W.

A multi-purpose differential conductometer (MPDC) is used to determine contact conductive heat transfer in both uncompressed and compressed states (Figure 2). This is very important for determining the quality of clothing as well as for designing future clothing with certain thermal properties.

Figure 2.

Multi-purpose differential conductometer: 1-measuring cylinder, 2-measuring base.

The general expression for calculating the contact conductive heat transfer U, after restoring the stationary state (Ts = const., Ta = const., H0 = const., and q = const.), takes the form of an equation:

where U is the contact conductive heat transfer, W/m2 °C; Ug is the voltage of the stabilized source that supplies the non-inductive point heaters of the MPDC; PPWM is the ratio of the PWM at the interface output; Rg is the total electrical resistance of the non-inductive point heaters; AMC is the total surface area of the measuring cylinder of the MPDC, m2; TMC is the mean skin surface temperature of the measuring cylinder of the MPDC, °C; and TMB is the mean skin surface temperature of the measuring base.

When measuring contact conductive heat transfer at the MPDC, the measuring cylinder presses on the material with a certain force, according to HRN EN ISO 5084: 2003, and compression occurs. Therefore, contact conductive heat transfer is also measured in the uncompressed state (for knitted fabrics and textiles Fx1 = 0.95 N) and in the compressed state with 10 times the initial force (Fx2 = 9.5 N).

Tests were carried out under the same environmental conditions: ambient temperature 21 °C, humidity 35–40%, and air velocity 0.4 ms−1.

Thermo-physiological properties, including water vapour resistance and thermal resistance of the selected clothing systems, were determined using the standardized method ISO 11092:2014 (sweating guarded-hotplate test), while the air permeability property was measured in accordance with ISO 9237:1995.

3. Results and Discussion

The results of tests conducted according to standardized methods in an accredited laboratory on the newly designed and manufactured woven fabrics (H1 and J3) are presented in Table 2.

Table 2.

Properties of multifunctional woven fabrics samples H1 and J3.

The results of the dimensional stability analysis indicate that the processes of design, manufacturing, and finishing of the woven fabrics are successfully defined. It verifies the woven fabric’s ability to maintain its linear dimension and external boundaries. Shrinkage is minimal (only 1.5% in both tested directions) in the fabric woven in a ripstop weave, while in the fabric woven in a twill weave, dimensional stability is almost maximal, which is in accordance with the requirements of the standards (<3%).

Considering the tearing forces, it is clear to what extent the woven fabric’s structural parameters and raw material composition influence the results of tested woven fabrics. Although the difference in values between samples is significant, these results are still acceptable given the specified requirements (>10 N), as are the results of breaking forces along the fabric length and width (warp and weft direction), as they meet the minimum requirements of 300 N. The lower force in the fabric width, or weft direction, results from a combination of fiber raw material composition and thread density.

The values of crease recovery angles are very high, indicating that finished garments made from these tested woven fabrics require much less care after washing, experience much less wrinkling during wear, and are visually more appealing.

The property of abrasion resistance, as one of the fundamental requirements for fabrics used in thermal protective clothing, is exceptionally high in the selected fabric samples, exceeding the set requirement for some standards of 100,000 cycles with values >290,000 and 350,000 cycles (at 12 kPa).

Fabric water resistance tested using the Spray test indicates wetting of the fabric surface at the spray points, defined by an average rating of 3.

The analysis of the tested thermal properties indicates exceptional properties of the newly designed woven fabrics. For instance, the analysis of the test results confirms compliance with the set requirements with corresponding ratings: flame heat transmission—B1, radiation heat transmission—C1, and contact heat transmission at 250 °C—F1, while at 100 °C, the samples meet the highest rating, F3. The obtained results of the woven fabric limiting oxygen index (LOI) testing show values above 26%, confirming high flame resistance and the inherent nature of the newly developed functional FR fabrics. The slightly lower value for fabric H1 can be attributed to the presence of cotton in the fabric composition. Furthermore, the results of testing limited flame spread, surface ignition, and bottom-edge ignition determining the flammability of vertically oriented samples before and after pre-treatment (washing) indicate exceptional material properties (described in Table 2) with a defined highest rating of Index 3.

Furthermore, testing the dimensional changes of the woven fabric under the influence of convective heat at 180 °C reveals that both woven fabrics in both directions have the same percentage change values (shrinkage—1.8%), while at 260 °C, they show greater shrinkage, with a notable difference in the length and width of fabric H1, but it still meets the specified requirements of a maximum of 10%.

Additionally, standards prescribe requirements for meeting the material resistance properties to molten metal splash, which the tested woven fabrics also satisfy with corresponding rankings D1 (for aluminium splash) and E1 (for iron splash).

Although all of the above-mentioned tests and compliance with set requirements indicate woven fabrics with exceptional physical–mechanical and thermal properties, ensuring their stability, durability, resistance, and necessary protection against heat and fire, they still cannot provide a complete picture of the real usage conditions, which are in reality much more complex.

The results of the complete thermal properties of two clothing systems (H1A5 and J3A5) are presented in Table 3, including static (resting shape simulation) and dynamic thermal properties (walking simulation), contact conductive heat transfer in both uncompressed and compressed states, air permeability, water vapour, and thermal resistance.

Table 3.

Results of testing of the complete thermal properties of clothing systems.

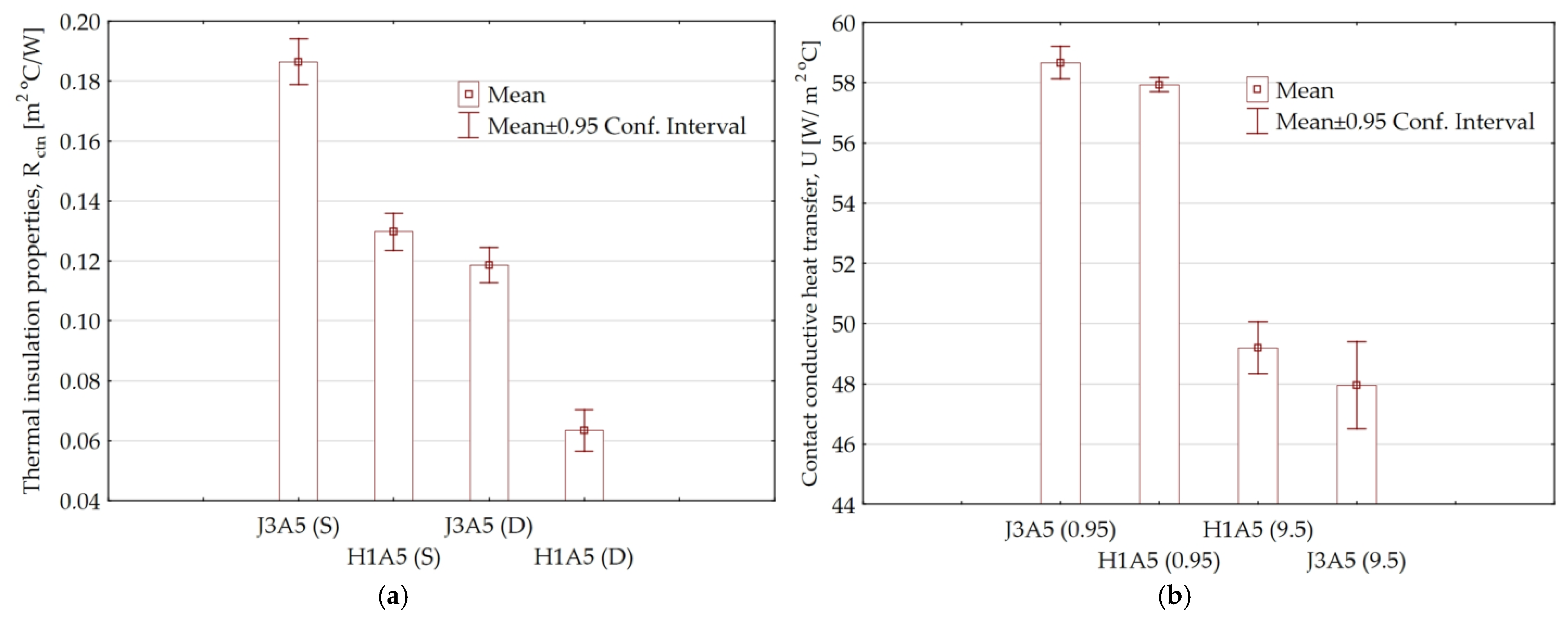

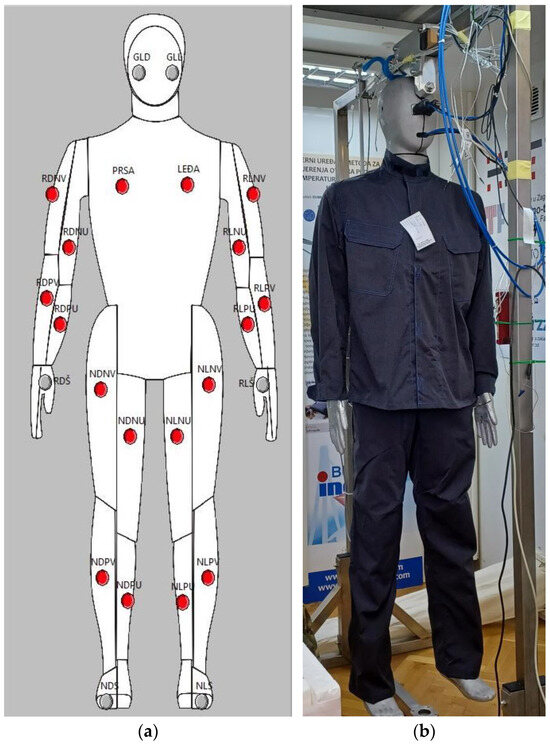

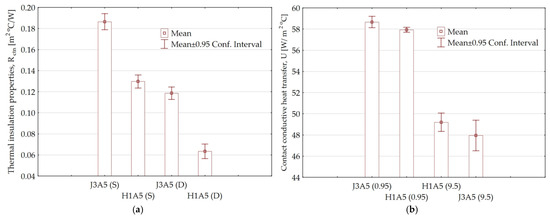

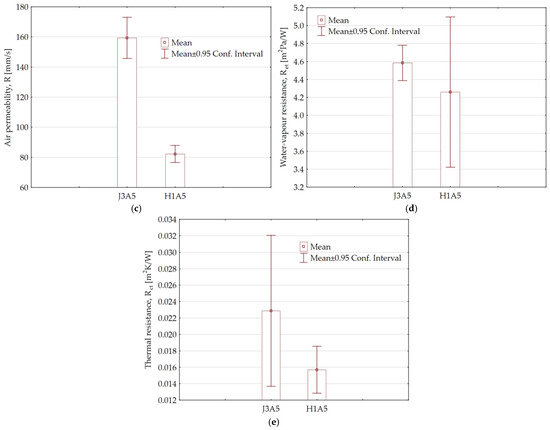

Based on the statistical analysis of the F-test, descriptive statistics, and t-test, as well as graphical representations of the measurement results (Figure 3), the following conclusions can be drawn.

Figure 3.

Graphical representations of the measurement results for H1A5 and J3A5 systems: (a) The thermal insulation in static and dynamic mode; (b) Contact conductive heat transfer in uncompressed state (0.95 N) and compressed state (9.5 N); (c) Air permeability; (d) Water vapour resistance; (e) Thermal resistance.

- The thermal insulation properties of H1A5 in static mode (M = 0.1865; SD = 0.037; n = 20) were hypothesized to be greater than the thermal insulation properties of J3A5 in static mode (M = 0.1297; SD = 0.01287; n = 20). This difference is significant, t(38) = 2.0244, p = 0.00000000000000875 (one tail).

- The thermal insulation properties of H1A5 in dynamic mode (M = 0.1187; SD = 0.0126; n = 20) were hypothesized to be greater than the thermal insulation properties of J3A5 in dynamic mode (M = 0.06347; SD = 0.01487; n = 20). This difference is significant, t(38) = 2.0244, p = 0.00000000000000160 (one tail).

- The contact conductive heat transfer (F = 9.5 N) of J3A5 (M = 58.6651; SD = 1.1527; n = 20) was hypothesized to be greater than the contact conductive heat transfer (F = 9.5 N) of H1A5 (M = 57.9331; SD = 0.5146; n = 20). This difference is significant, t(38) = 2.0555, p = 0.0077 (one tail).

- The air permeability of J3A5 (M = 159.3660; SD = 10.9831; n = 5) was hypothesized to be greater than the air permeability of H1A5 (M = 82.2320; SD = 4.5742; n = 5). This difference is significant, t(5) = 2.3060, p = 0.000000251 (one tail).

- The water vapour resistance of J3A5 (M = 4.5843; SD = 0.0794; n = 3) was hypothesized to be greater than the water vapour resistance of H1A5 (M = 4.2587; SD = 0.3370; n = 3). This difference is not significant, t(3) = 2.7764, p = 0.0893 (one tail).

- The thermal resistance of J3A5 (M = 0.0229; SD = 0.0037; n = 3) was hypothesized to be greater than the thermal resistance of H1A5 (M = 0.0157; SD = 0.0012; n = 3). This difference is significant, t(3) = 2.7764, p = 0.0893 (one tail).

The results show that the H1A5 system has better thermal insulation in static mode (1.2031 m2kW−1) and dynamic mode (0.1187 m2kW−1) than the J3A5 system (0.1297 m2kW−1 in static mode and 0.0635 m2kW−1 in dynamic mode). In dynamic mode, the thermal properties decrease by 36.35% for the H1A5 system and by 51.04% for the J3A4 system due to the “pumping effect” (air leakage due to mechanical movements of the manikin’s arms and legs).

Although both woven fabrics have almost the same mass per unit area (H1A5: =223.3 g/m2 and J3A5 = 222.0 g/m2), the raw material composition and yarn fineness have influenced the thermal insulation properties (Rctn). The weft yarn composition of 40% Co Long Stapel Combed and 60% MAC Armora in the woven fabric H1 and clothing system H1A5 provide better properties than the weft yarn composition of 20% p-AR, 55% CV FR dull, and 25% PA FR in the woven fabric J3 and clothing system J3A5. Also, a slightly coarser and structurally different yarn in the fabric H1 (warp: 20 × 2 tex and weft: 33 × 1 tex) with less twists (warp: 600 twist/m and weft: 620 twist/m) provides a softer and thicker woven fabric structure, which also influences better thermal insulation properties compared to the finer yarn in the woven fabric J3 (warp and weft: 17 × 2 tex) and a higher number of twists (warp and weft: 660 twist/m).

Finer yarn and a higher number of twists shape a thinner and denser woven fabric that results in poorer thermal insulation properties of clothing system J3A5 compared to clothing system H1A5, composed of the woven fabric with coarser and softer yarn with lower density. Therefore, it can be determined that the thickness of the woven fabric, raw material composition, and yarn structure play a crucial role in the thermal insulation properties of the woven fabric. Additionally, the woven fabric weave undoubtedly affects the thermal insulation properties, as the woven fabric with better thermal insulation properties that constitute the clothing system H1A5 is woven in a ripstop weave that provides an uneven surface structure and thus greater woven fabric thickness compared to the twill weave in the case of the other fabric that constitutes the clothing system J2A5.

This difference primarily arises due to the variance in yarn fineness between the tested systems. The woven fabric constructing the H1A5 system has a slightly coarser yarn in the weft (warp: 20 × 2 tex and weft: 33 × 1 tex) compared to the fabric constructing the J3A5 system (warp and weft: 17 × 2 tex), representing a 15% difference in the warp direction. Simultaneously, woven fabric densities exhibit differences of 8% in the warp direction (372 > 344 threads/10 cm) and 10% in the weft direction (242 > 218 threads/10 cm). By comparing differences in yarn fineness and fabric density and the results in Figure 3, it can be concluded that the air permeability is higher in the clothing system J3A5, whose fabric has a finer warp and simultaneously higher density. This difference influences the variation in air permeability between the tested systems. Other parameters undoubtedly contribute to this difference, such as the woven fabric weave, where the H1A5 system has a distinctive weave (ripstop) combining plain and rib, forming a surface with non-uniform woven fabric structure and thus resulting in fewer tension differences in yarns within warp and weft directions and leading to differences in woven fabric density.

The results from Table 3 show that H1A5 has a lower contact conductive heat transfer (57.9331 W/m2 °C) than J3A5 (58.6651 m2 °C), which was expected as it has higher thermal insulation. Figure 3 shows that the contact conductive heat transfer decreases with increasing compressibility. When the force is increased tenfold, the contact conductive heat transfer decreases by 17.78% for the H1A5 system and 22.34% for the J3A5 system. This is due to the fibers inserting into the free space between them as a result of the force and the decomposition of the material. In addition, by applying force and compressing the material, the fibers can fit into the free space between them. In addition, the amount of trapped air is reduced, which also leads to an increase in thermal contact conductivity, which increases significantly with a tenfold higher compression force.

All of this can be attributed to all of the defined parameters in the woven fabric design process, including the raw composition of yarns, as well as their parameters, and the woven fabric’s overall structure.

The systems tested are produced from fabrics H1 and J3. The fabric J3 has higher air permeability (157.112 mm/s), higher water vapour resistance (4.5832 m2Pa/W), and higher thermal resistance (0.0229 m2K/W).

The important role in achieving real differences in water vapour resistance (Ret) properties is played by fabric pores, which significantly influence this property through their number, shape, and size. This is primarily conditioned by the weave, yarn fineness, and woven fabric density and, consequently, the thickness and woven fabric mass. Given the above, it can be concluded that in addition to differences in the weave itself, overall finer yarns and higher woven fabric density of the J3A5 clothing system contribute to providing slightly higher water vapour resistance (only 7.33%) compared to the H1A5 system.

The results of thermal resistance (Rct) properties of the tested clothing systems follow the trend of the water vapour resistance results, but the previously mentioned influential parameters are further emphasized here. This indicates that when designing woven fabric, optimizing structural parameters (yarn fineness, woven fabric density, weave, mass, and thickness) is crucial for achieving the most efficient specific properties.

In light of these results, it can be concluded that the clothing system H1A5 has better thermal insulation properties and is more suitable for use in colder environments, while the clothing system J3A5 has better breathability and lower thermal insulation values, making it more suitable for use in warmer environments.

As part of the research in an accredited laboratory, an evaluation of the conformity of woven fabrics with standards defining requirements and testing methods for protective clothing against heat and flame was conducted. This confirms the applicability of the newly developed H1 and J3 fabrics for protective clothing against heat and flame according to the standards EN ISO 11612:2015 and EN ISO 14116:2015.

Summarily analyzing the properties of newly developed multifunctional woven fabric for thermal protective clothing in the context of key categories, such as heat protection, comfort, and durability, a detailed comparative presentation (Table 4) of meeting requirements with currently available comparable woven fabrics on the market has been provided, evaluating their applicability and efficacy for specific application areas. The presentation indicates a significant leap forward and progress in meeting high standards for thermal protective clothing with newly developed woven fabrics.

Table 4.

Comparative presentation of key categories of currently available comparable woven fabrics on the market and newly developed woven fabrics.

4. Conclusions

This scientific paper outlines an extensive research endeavour aimed at developing multifunctional woven fabrics for thermal protective clothing that meet the demands of the global market while achieving a balance between flame resistance, comfort, and durability. Through careful design, a range of woven fabric samples was developed that varied in raw material composition, yarn structure, and woven fabric construction.

Through detailed testing and analysis, two optimal woven fabric samples (H1 and J3) were selected. Optimizing the influential parameters, including blends of aramid, FR viscose, polyamide, and FR cotton and modacrylic fibers, spun in yarns of specific characteristics, together with the appropriate weave (ripstop and twill) and thread density, contributed to the fabrics’ optimal balance between protection, comfort, and durability. Selected woven fabrics exhibit exceptional dimensional stability, with minimal shrinkage and a high crease recovery angle indicating resistance to wrinkling and facilitating easier maintenance. Furthermore, breaking and tear forces surpass acceptable levels, as well as fabrics’ abrasion resistance, ensuring fabric durability and longevity and making them highly suitable for protective clothing. Regarding thermal properties, both newly developed woven fabrics demonstrate outstanding resistance to flame, radiation, and contact heat, surpassing specified requirements. Being subjected to convective heat, both woven fabrics achieve dimensional stability in accordance with the standards, while the results of the molten metal splash resistance test further strengthen the thesis of their suitability for use in protective clothing.

Further analysis of clothing systems constructed from the selected woven fabrics revealed nuanced differences between them. Considering thermal insulation properties, H1A5 clothing system outperforms J3A5, showcasing superior thermal insulation attributed to factors like yarn composition and woven fabric structure. Notably, H1A5 also displays lower contact conductive heat transfer under compression, highlighting its efficacy in maintaining thermal insulation even under pressure. In contrast, J3A5 demonstrates higher air permeability due to its finer yarn and fabric density, making it more breathable. The thermal resistance property is also more pronounced in the H1A5 clothing system, again emphasizing the importance of yarn fineness, fabric density, and weave in achieving optimal thermal properties. Overall, H1A5 is better suited to colder environments, providing superior thermal insulation, while J3A5 offers better breathability and lower thermal insulation, making it ideal for warmer conditions.

Both newly developed woven fabrics meet high standards for protective clothing against heat and flame, such as EN ISO 11612:2015 and EN ISO 14116:2015, highlighting their suitability for use in high-risk environments.

This research emphasizes a multifunctional approach in designing and optimizing woven fabric parameters for thermal protective clothing, thus achieving properties that comprehensively meet the high requirements for the specified purpose. In addition, it provides a general comparative assessment of woven fabrics currently available on the market, whose specific structural characteristics and properties, required to meet market demands, are more or less comparable. Furthermore, this research underscores the significance of ongoing research and technological advancements in developing protective woven textiles, addressing market demands, enhancing wearer safety and comfort, and paving the way for future research into specific structural parameters and targeted properties.

Author Contributions

Conceptualization, I.S. and S.F.R.; methodology, I.S.; software, D.R. and S.F.R.; validation, I.S. and S.F.R.; formal analysis, I.S. and S.F.R.; investigation, I.S., S.K., and S.F.R.; resources, I.S. and D.R.; data curation, I.S. and S.F.R.; writing—original draft preparation, I.S. and S.F.R.; writing—review and editing, I.S., D.R., S.K. and S.F.R.; visualization, I.S.; supervision, D.R. and S.K.; project administration, I.S.; funding acquisition, I.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been supported by the European Union through the European Structural and Investment Funds, the operational programme Competitiveness and Cohesion, and the European Regional Development Fund under the project KK.01.2.1.02.0064.

Data Availability Statement

The data presented in this study are available upon request from the corresponding authors.

Acknowledgments

We express our sincere gratitude to all associates from the University of Zagreb Faculty of Textile Technology, Zagreb, Croatia and the textile company Čateks, Čakovec, Croatia for their dedicated contributions to this research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pan, P.; Sun, G. Functional Textiles for Improved Performance, Protection and Health, 3rd ed.; Woodhead Publishing Limited in Association with The Textile Institute: Cambridge, UK, 2011. [Google Scholar]

- Song, G.; Wang, F. Firefighters’ Clothing and Equipment: Performance, Protection, and Comfort, 1st ed.; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Ertekin, M.; Ertekin, G.; Marmaralı, A. Analysis of thermal comfort properties of fabrics for protective applications. J. Text. Inst. 2018, 109, 1091–1098. [Google Scholar] [CrossRef]

- Torvi, D.A.; Hadjisophocleous, G.V. Research in protective clothing for firefighters: State of the art and future directions. Fire Technol. 1999, 35, 111–127. [Google Scholar] [CrossRef]

- Irzmańska, E. The impact of different types of textile liners used in protective footwear on the subjective sensations of firefighters. Appl. Ergon. 2015, 47, 34–42. [Google Scholar] [CrossRef]

- Houshyar, S.; Padhye, R.; Vijayan, A.; Jadhav, A.; Ranjan, S. The impact of super-absorbent materials on the thermo-physiological properties of textiles. Text. Res. J. 2015, 85, 601–608. [Google Scholar] [CrossRef]

- Nawaz, N.; Troynikov, O.; Watson, C. Evaluation of surface characteristics of fabrics suitable for skin layer of firefighters’ protective clothing. Phys. Procedia 2011, 22, 478–486. [Google Scholar] [CrossRef]

- Özdil, N.; Marmaralı, A.; Dönmez Kretzschmar, S. Effect of yarn properties on thermal comfort of knitted fabrics. Int. J. Therm. Sci. 2007, 46, 1318–1322. [Google Scholar] [CrossRef]

- Gu, H. Research on thermal properties of Nomex/Viscose FR fiber blended fabric. Mater. Des. 2009, 30, 4324–4327. [Google Scholar] [CrossRef]

- Kim, H.; Kim, S. Flame-Retardant and Wear Comfort Properties of Modacrylic/FR-Rayon/Anti-static PET Blend Yarns and Their Woven Fabrics for Clothing. Fibers Polym. 2018, 19, 1869–1879. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, Y.; Yan, X.; Shi, M. Efficient suppression of flammability in flame retardant viscose fiber through incorporating with alginate fiber. Mater. Lett. 2018, 215, 106–109. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, M. Flame retardant vinylon/poly(m-phenylene isophthalamide) blended fibers with synergistic flame retardancy for advanced fireproof textiles. J. Hazard. Mater. 2019, 365, 9–15. [Google Scholar] [CrossRef]

- Flambard, X.; Bourbigot, S.; Ferreira, M.; Vermeulen, B.; Poutch, F. Wool/para-aramid fibers blended in spun yarns as heat and fire resistant fabrics. Polym. Degrad. Stab. 2002, 77, 279–284. [Google Scholar] [CrossRef]

- Zhang, F.-Q.; Wang, B.; Xu, Y.-J.; Li, P.; Liu, Y.; Zhu, P. Convenient blending of alginate fibers with polyamide fibers for flame-retardant non-woven fabrics. Cellulose 2020, 27, 8341–8349. [Google Scholar] [CrossRef]

- Maurya, A.K.; Mandal, S.; Wheeldon, D.E.; Schoeller, J.; Schmid, M.; Annaheim, S.; Camenzind, M.; Fortunato, G.; Dommann, A.; Neels, A.; et al. Effect of radiant heat exposure on structure and mechanical properties of thermal protective fabrics. Polymer 2021, 222, 123634. [Google Scholar] [CrossRef]

- Janarthanan, M.; Vignesh, R.; Raia, K.; Ananclhababu, A.; Rosy, A. Comfort Properties of High Performance Fibers for Defence Applications. Man-Made Text. India 2011, 39, 61–65. [Google Scholar]

- Song, G.; Paskaluk, S.; Sati, R.; Crown, E.M.; Dale, J.D.; Ackerman, M. Thermal protective performance of protective clothing used for low radiant heat protection. Text. Res. J. 2011, 81, 311–323. [Google Scholar] [CrossRef]

- Mandal, S.; Song, G.; Ackerman, M.; Paskaluk, S.; Gholamreza, F. Characterization of textile fabrics under various thermalexposures. Text. Res. J. 2013, 83, 1005–1019. [Google Scholar] [CrossRef]

- Rochak, R.; Das, A.; Ramasamy, A. Study on the influence of constructional parameters on performance of outer layer of thermal protective clothing. J. Text. Inst. 2023, 114, 1336–1346. [Google Scholar] [CrossRef]

- Parés, F.; Ventura, H.; Capdevila, F.X.; Ardanuy, M. Influence of Multilayer Interlocked Fabrics Structure on Their Thermal Performance. Autex Res. J. 2022, 22, 466–476. [Google Scholar] [CrossRef]

- Pamuk, G.; Encan, B.C.; Yıldız, E.Z. Thermal Characteristics, Mechanical and Comfort Properties of Heat-Protective Textiles. Fibers Polym. 2023, 24, 4457–4468. [Google Scholar] [CrossRef]

- Kalazić, A.; Brnada, S.; Kiš, A. Thermal Protective Properties and Breathability of Multilayer Protective Woven Fabrics for Wildland Firefighting. Polymers 2022, 14, 2967. [Google Scholar] [CrossRef]

- Badrov, T.; Schwarz, I.; Kovačević, S. Multifunctionality of Thermal Protective Layer Interchanging Double Cloth Conditioned by Influential Parameters. Polymers 2022, 14, 4561. [Google Scholar] [CrossRef]

- Kalazić, A.; Badrov, T.; Schwarz, I.; Brnada, S. Incorporating Variable Porosity into the Determination of Effective Permeability in Interchanging Double Cloth Woven Fabrics Using Darcy’s Law. Polymers 2023, 15, 3048. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Tian, M.; Wang, Q.; Su, Y.; Li, J. Thermal degradation behavior of flame-resistant fabrics exposed to fires: Effect of air gap type and thickness. Text. Res. J. 2022, 92, 4313–4324. [Google Scholar] [CrossRef]

- Rossi, R. Characterizing comfort properties of flame resistant fabrics and garments. In Handbook of Fire Resistant Textiles, 1st ed.; Kilinc, F.S., Ed.; Woodhead Publishing Series in Textiles: Cambridge, UK, 2013; pp. 415–433. [Google Scholar] [CrossRef]

- Song, G.; Gholamreza, F.; Cao, W. Analyzing thermal stored energy and effect on protective performance. Text. Res. J. 2011, 81, 1124–1138. [Google Scholar] [CrossRef]

- Puszkarz, A.; Machnowski, W. Simulations of Heat Transfer through Multilayer Protective Clothing Exposed to Flame. Autex Res. J. 2022, 22, 298–304. [Google Scholar] [CrossRef]

- Mandal, S.; Annaheim, S.; Capt, A.; Greve, J.; Camenzind, M.; Rossi, R.M. A categorization tool for fabric systems used in firefighters’ clothing based on their thermal protective and thermo-physiological comfort performances. Text. Res. J. 2019, 89, 3244–3259. [Google Scholar] [CrossRef]

- Mandal, S.; Annaheim, S.; Greve, J.; Camenzind, M.; Rossi, R.M. Modeling for predicting the thermal protective and thermophysiological comfort performance of fabrics used in firefighters clothing. Text. Res. J. 2019, 89, 2836–2849. [Google Scholar] [CrossRef]

- Pan, N.; Gibson, P. Thermal and Moisture Transport in Fibrous Materials, 1st ed.; Woodhead Publishing: Cambridge, UK, 2006. [Google Scholar]

- Kenny, G.P.; Flouris, A.D. The human thermoregulatory system and its response to thermal stress. In Protective Clothing: Managing Thermal Stress, 1st ed.; Wang, F., Gao, C., Eds.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2014; pp. 319–365. [Google Scholar] [CrossRef]

- Tian, M.; Song, W.; Qu, L.; Chen, S.; Zhu, S.; Ning, F. Thermal response of skin underneath a thermal protective garment during post-fire exposure. Int. J. Thermophys. 2018, 39, 90. [Google Scholar] [CrossRef]

- Nayak, R.; Kanesalingam, S.; Houshyar, S.; Wang, L.; Padhye, R.; Vijayan, A. Evaluation of thermal, moisture management and sensorial comfort properties of superabsorbent polyacrylate fabrics for the next-to-skin layer in firefighters’ protective clothing. Text. Res. J. 2018, 88, 1077–1088. [Google Scholar] [CrossRef]

- Puszkarz, A.K.; Machnowski, W.; Błasińska, A. Modeling of thermal performance of multilayer protective clothing exposed to radiant heat. Heat Mass Transf. 2020, 56, 1767–1775. [Google Scholar] [CrossRef]

- Houshyar, S.; Padhye, R.; Troynikov, O.; Nayak, R.; Ranjan, S. Evaluation and improvement of thermo-physiological comfort properties of firefighters’ protective clothing containing super absorbent materials. J. Text. Inst. 2015, 106, 1394–1402. [Google Scholar] [CrossRef]

- Wang, F.; Gao, C. Protective Clothing: Managing Thermal Stress, 1st ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Song, G. Improving Comfort in Clothing, 1st ed.; Woodhead Publishing Series in Textiles; Woodhead Publishing: Cambridge, UK, 2010. [Google Scholar]

- TenCate protective fabrics. Available online: https://us.tencatefabrics.com/ (accessed on 20 July 2023).

- Milliken. Available online: https://www.milliken.com/en-gb/our-products/textile-products (accessed on 20 July 2023).

- Carrington Textiles. Available online: https://www.carrington.co.uk/en/ (accessed on 20 July 2023).

- Siamidis. Available online: https://siamidis.eu/ (accessed on 20 July 2023).

- Sofileta Santé. Available online: www.sofileta-sante.fr (accessed on 20 July 2023).

- ISO 7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. ISO: Geneva, Switzerland, 2005.

- ASTM F1291-16; Standard Test Method for Measuring the Thermal Insulation of Clothing Using a Heated Manikin. American Society of Testing and Materials International. ASTM: Philadelphia, PA, USA, 2016.

- Jussila, K. Clothing Physiological Properties of Cold Protective-Clothing and Their Effects on Human Experience. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 2016. [Google Scholar]

- Fanger, P.O. Assessment of man’s thermal comfort in practice. Br. J. Ind. Med. 1973, 30, 313–324. [Google Scholar] [CrossRef] [PubMed]

- Auliciems, A.; Szokolay, S.V. Thermal Comfort, 2nd ed.; Passive and Low Energy Architecture International (PLEA): Queensland, Australia, 2007. [Google Scholar]

- Oliveira, A.V.; Gaspar, A.; Quintela, D. Dynamic clothing insulation. Measurements with a thermal manikin operating under the thermal comfort regulation mode. Appl. Ergon. 2011, 42, 890–899. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).