Performance of Flax/Epoxy Composites Made from Fabrics of Different Structures

Abstract

1. Introduction

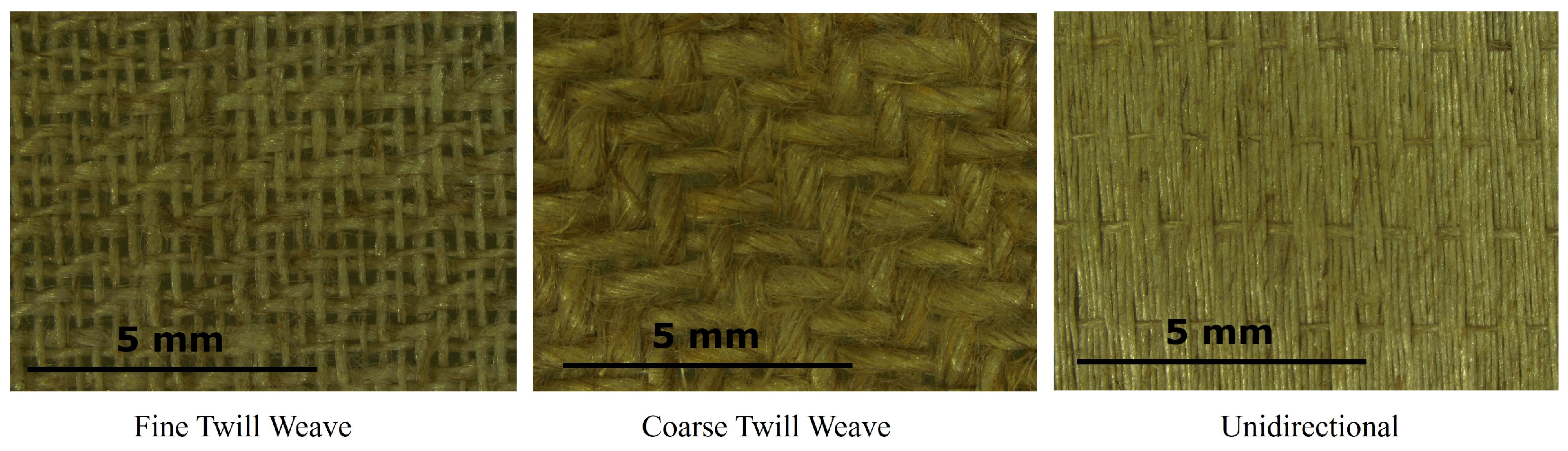

2. Materials and Methods

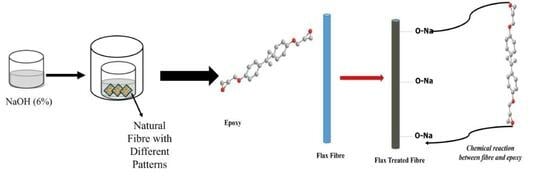

2.1. Chemical Treatment

2.2. Composite Manufacturing

2.3. Characterizations

3. Results and Discussion

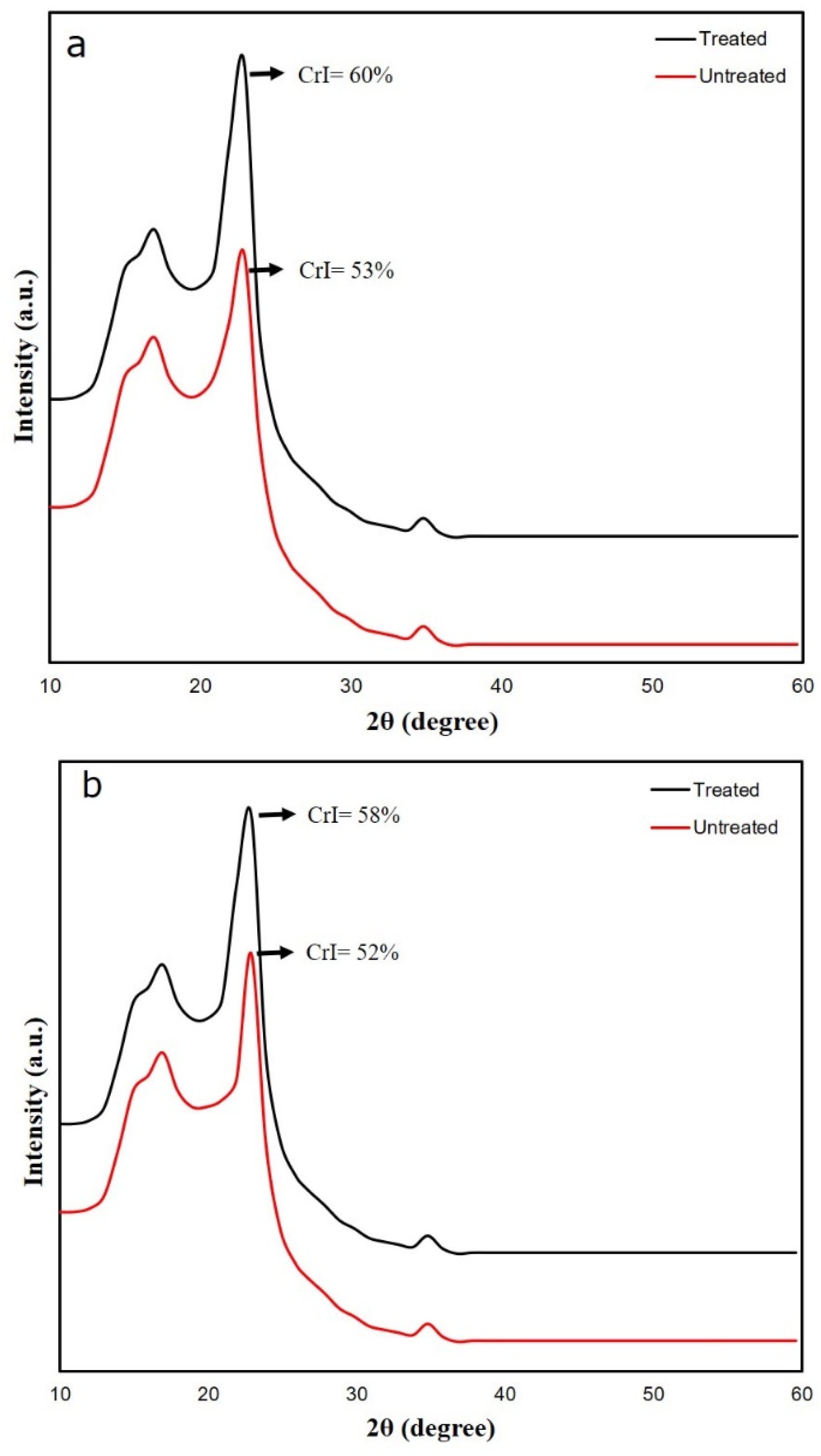

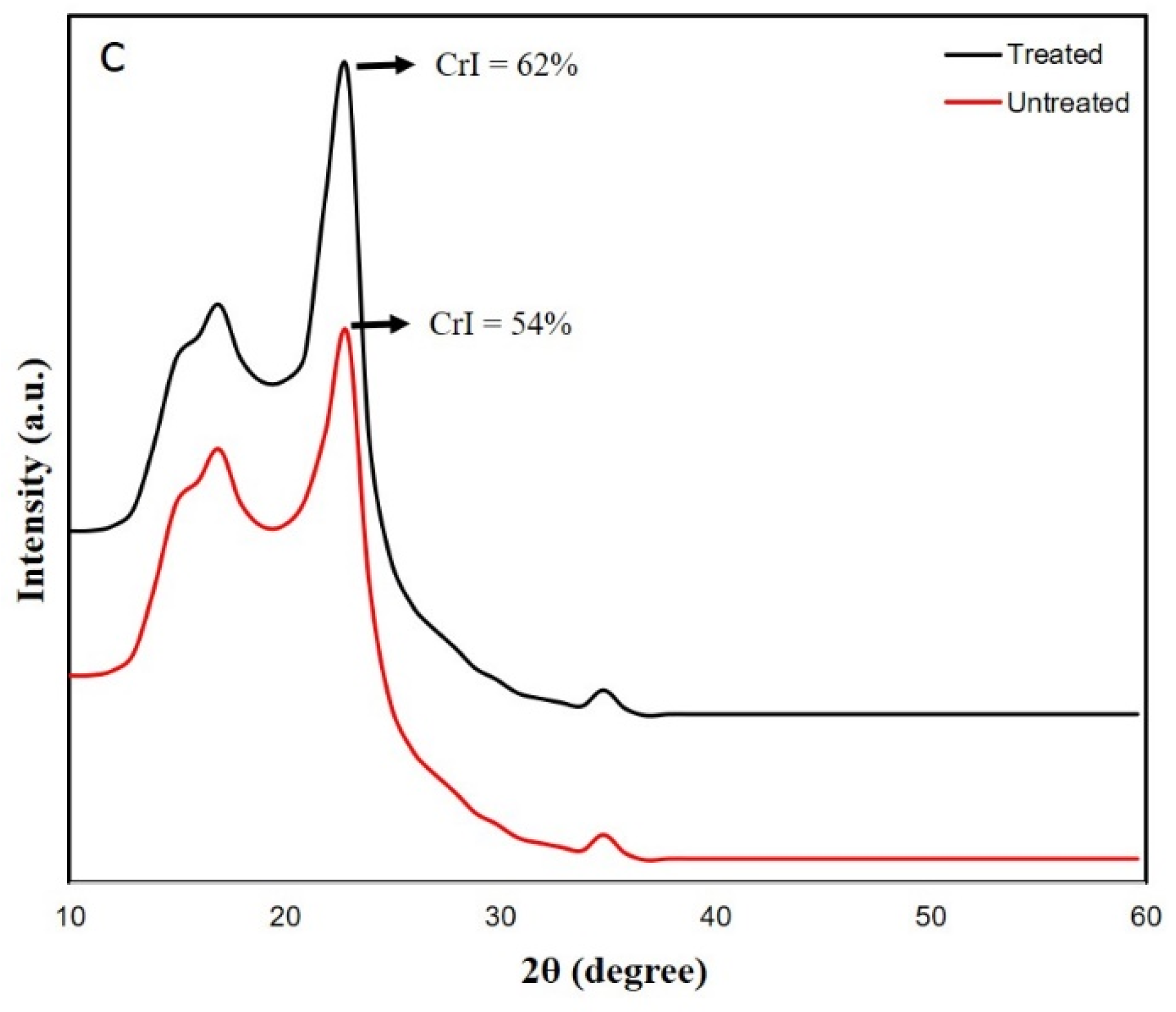

3.1. X-ray Diffraction

3.2. Tensile and Flexural Properties

3.2.1. Effect of Fiber Volume Fractions on Tensile and Flexural Properties

3.2.2. Effect of Chemical Treatment on Tensile and Flexural Properties

3.2.3. Effect of Direction in Unidirectional Fabric on Tensile and Flexural Properties

3.2.4. Effect of Flax Fabric Textile Structure on Mechanical Properties

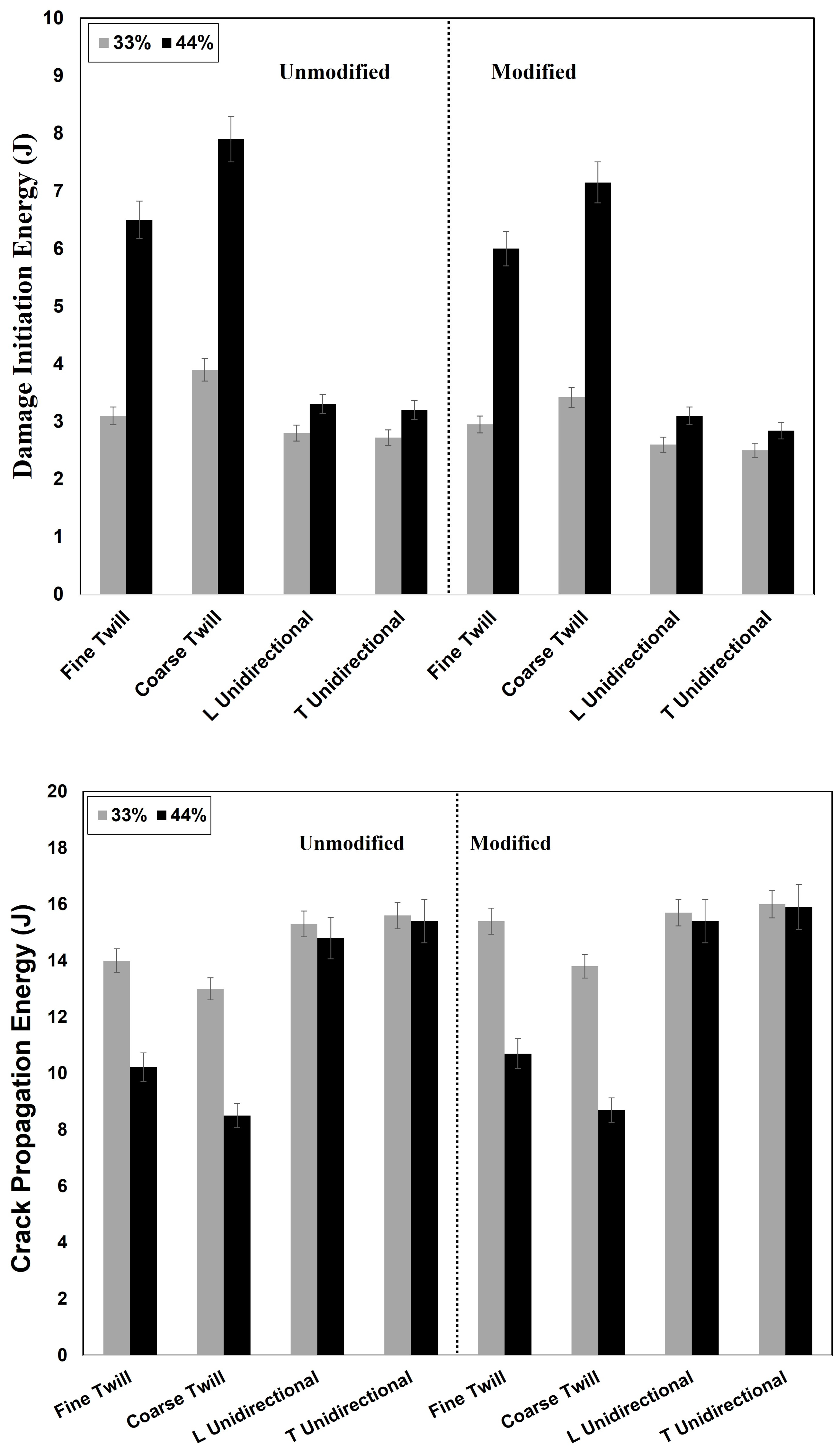

4. Impact Properties

4.1. Effect of Fiber Volume Fractions on Impact Properties

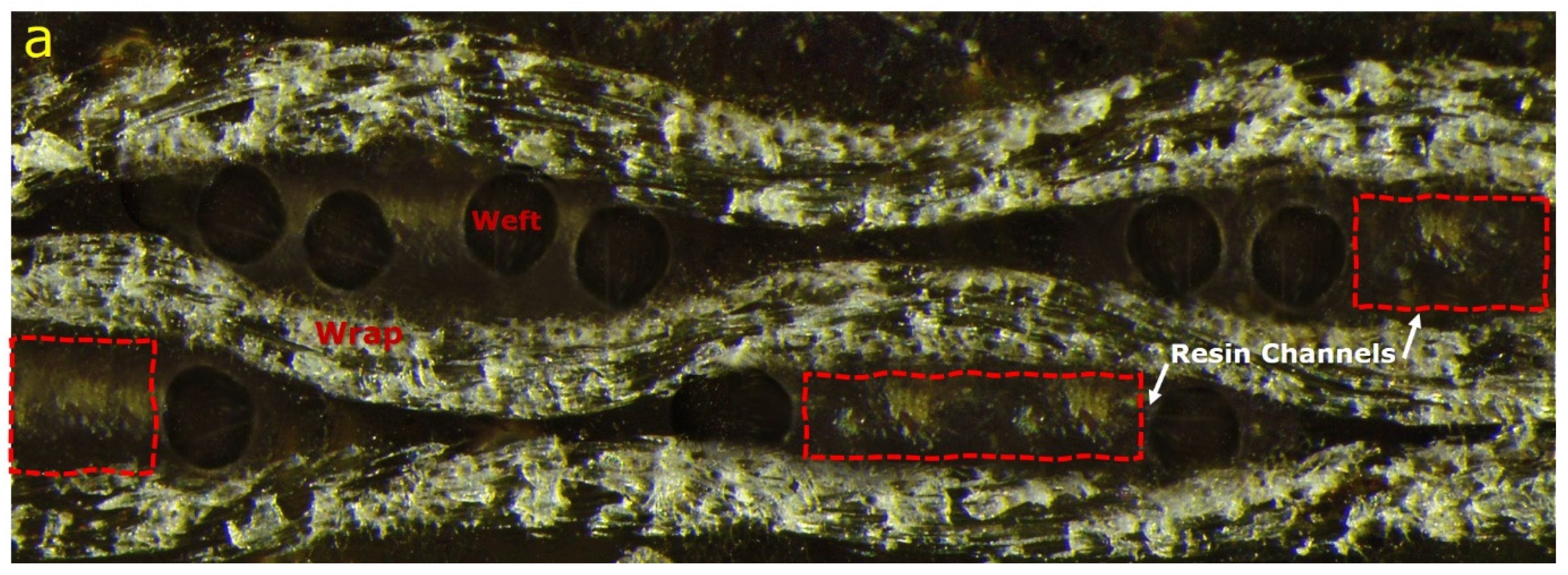

4.2. Effect of Flax Fabric Textile Structure Resulting from Different Yarn Diameters on Impact Properties

4.3. Effect of Direction in Unidirectional Fabric on Impact Properties

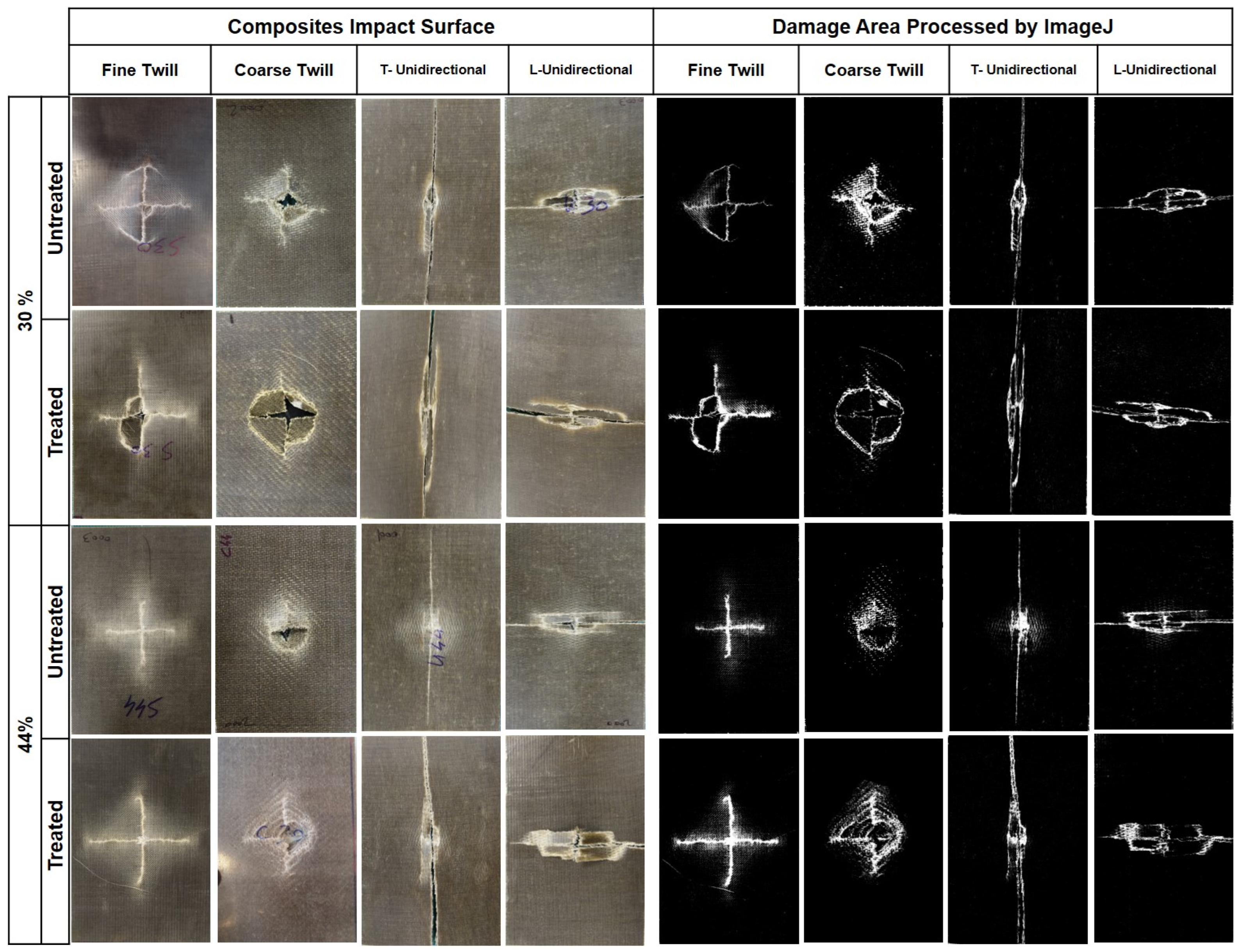

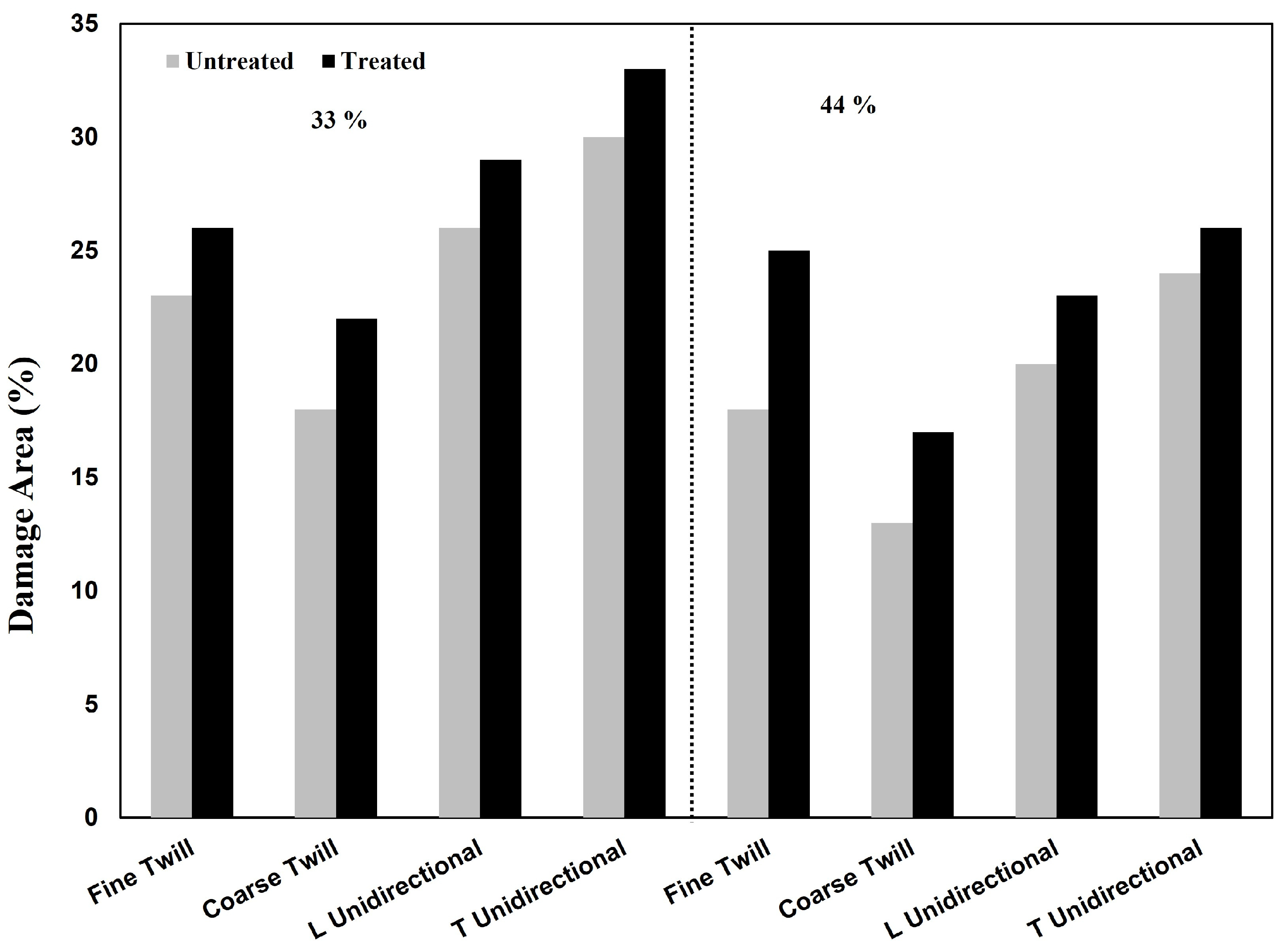

4.4. Inspection of Damage Induced by Impact Loading

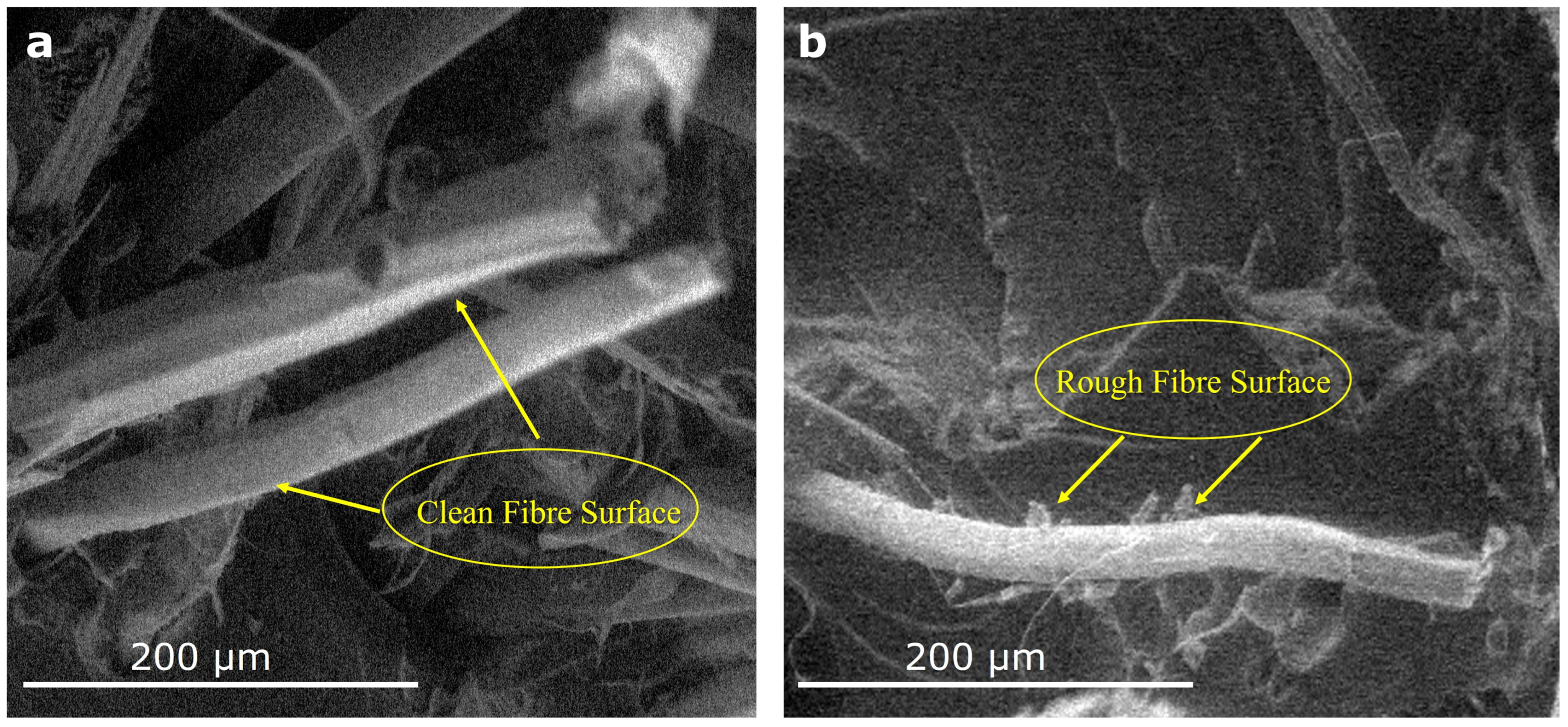

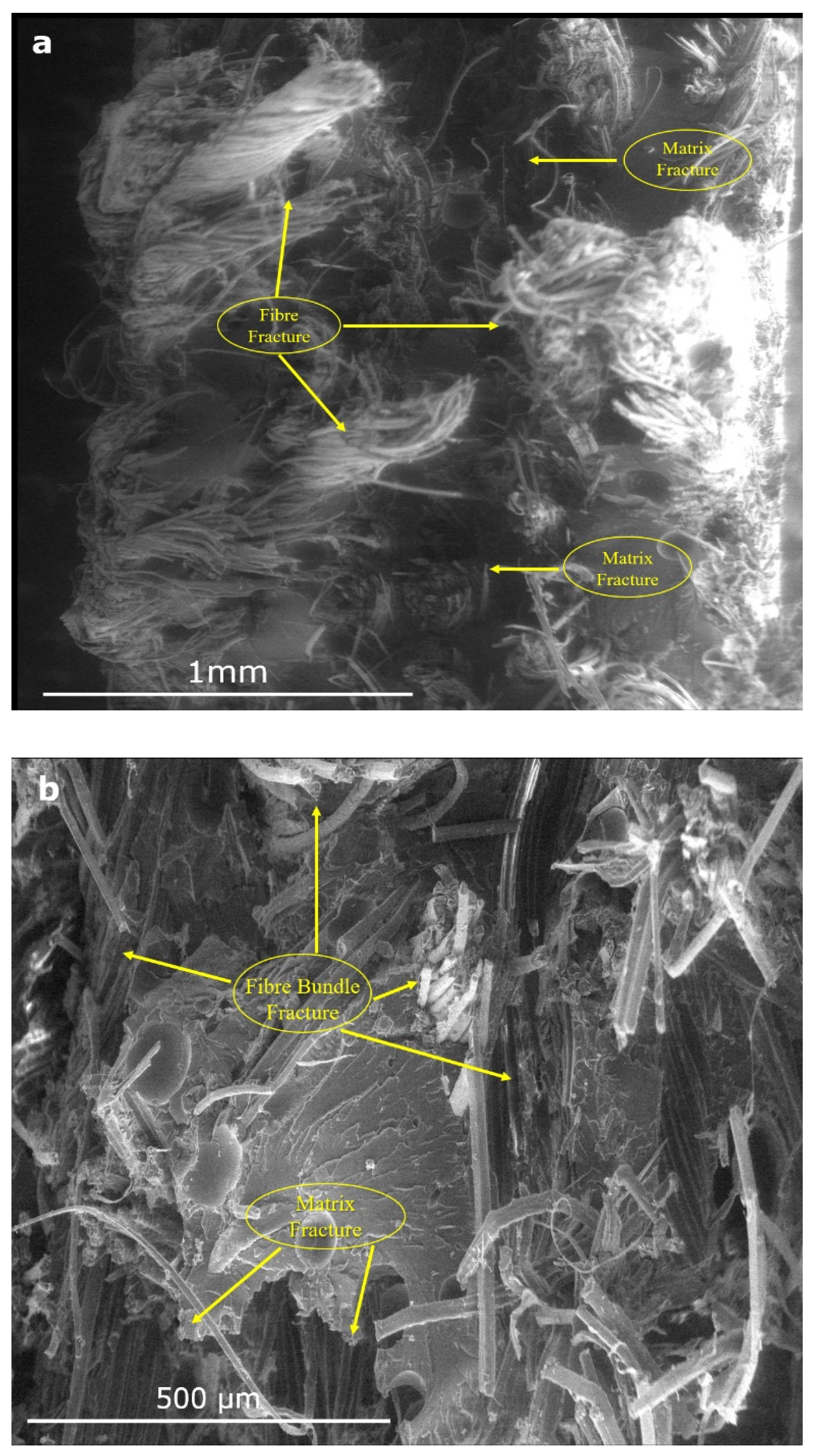

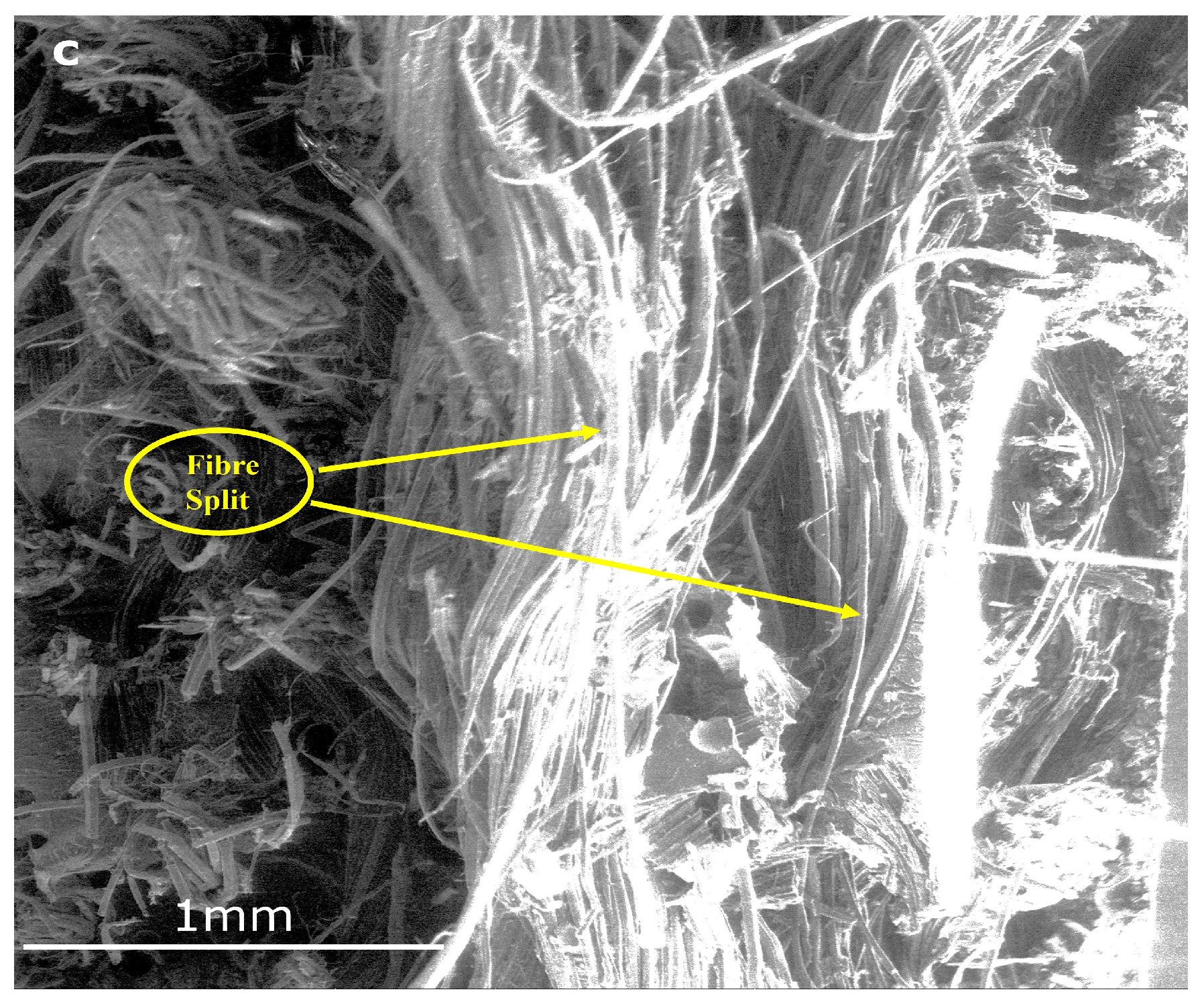

4.5. Microscopic Analysis of Impact Fracture Surface of Composites

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, W.; Chouw, N.; Jayaraman, K. Effect of thickness on the impact resistance of flax fibre-reinforced polymer. J. Reinf. Plast. Compos. 2016, 35, 1277–1289. [Google Scholar] [CrossRef]

- Liang, S.; Gning, P.B.; Guillaumat, L. Quasi-static behaviour and damage assessment of flax/epoxy composites. Mater. Des. 2015, 67, 344–353. [Google Scholar] [CrossRef]

- Saadati, Y.; Lebrun, G.; Bouvet, C.; Chatelain, J.F.; Beauchamp, Y. Study of translaminar fracture toughness of unidirectional flax/epoxy composite. Compos. Part C Open Access 2020, 1, 100008. [Google Scholar] [CrossRef]

- Djafar, Z.; Renreng, I.; Jannah, M. Tensile and Bending Strength Analysis of Ramie Fiber and Woven Ramie Reinforced Epoxy Composite. J. Nat. Fibers 2020, 18, 2315–2326. [Google Scholar] [CrossRef]

- Li, N.; Yan, H.; Xia, L.; Mao, L.; Fang, Z.; Song, Y.; Wang, H. Flame retarding and reinforcing modification of ramie/polybenzoxazine composites by surface treatment of ramie fabric. Compos. Sci. Technol. 2015, 121, 82–88. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. The effect of alkaline treatment on mechanical properties of kenaf fibers and their epoxy composites. Compos. Part B Eng. 2015, 68, 14–21. [Google Scholar] [CrossRef]

- Krishna, K.V.; Kanny, K. The effect of treatment on kenaf fiber using green approach and their reinforced epoxy composites. Compos. Part B Eng. 2016, 104, 111–117. [Google Scholar] [CrossRef]

- Gheith, M.H.; Aziz, M.A.; Ghori, W.; Saba, N.; Asim, M.; Jawaid, M.; Alothman, O.Y. Flexural, thermal and dynamic mechanical properties of date palm fibres reinforced epoxy composites. J. Mater. Res. Technol. 2019, 8, 853–860. [Google Scholar] [CrossRef]

- Mahdi, E.; Ochoa, D.; Vaziri, A.; Eltai, E. Energy absorption capability of date palm leaf fiber reinforced epoxy composites rectangular tubes. Compos. Struct. 2019, 224, 111004. [Google Scholar] [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural fibers as sustainable and renewable resource for development of eco-friendly composites: A comprehensive review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- Mahboob, Z.; El Sawi, I.; Zdero, R.; Fawaz, Z.; Bougherara, H. Tensile and compressive damaged response in Flax fibre reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2017, 92, 118–133. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of flax fibre based textile reinforcements for composite applications. Appl. Compos. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J.; Licence, P. Fatigue life evaluation of aligned plant fibre composites through S–N curves and constant-life diagrams. Compos. Sci. Technol. 2013, 74, 139–149. [Google Scholar] [CrossRef]

- Rahman, M.Z.; Jayaraman, K.; Mace, B.R. Impact energy absorption of flax fiber-reinforced polypropylene composites. Polym. Compos. 2018, 39, 4165–4175. [Google Scholar] [CrossRef]

- Ma, H.; Li, Y.; Shen, Y.; Xie, L.; Wang, D. Effect of linear density and yarn structure on the mechanical properties of ramie fiber yarn reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 98–108. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M.; Berglin, L. Characterization of thermoplastic natural fibre composites made from woven hybrid yarn prepregs with different weave patterns. Compos. Part A Appl. Sci. Manuf. 2015, 76, 154–161. [Google Scholar] [CrossRef]

- Senthil Kumar, K.; Siva, I.; Jeyaraj, P.; Winowlin Jappes, J.T.; Amico, S.C.; Rajini, N. Synergy of fiber length and content on free vibration and Damping behavior of natural fiber reinforced polyester composite beams. Mater. Des. 2014, 56, 379–386. [Google Scholar] [CrossRef]

- Kumar, V.; Pradeep, K.K.; Rakesh, K. Impedance-spectroscopy analysis of oriented and mercerized bamboo-fiber reinforced epoxy composites. J. Mater. Sci. 2011, 46, 3445–3451. [Google Scholar] [CrossRef]

- Sreekumar, P.A.; Agoudjil, B.; Boudenne, A.; Unnikrishnan, G.; Ibos, L.; Fois, M.; Thomas, S. Transport properties of polyester composite reinforced with treated sisal fibers. J. Reinf. Plast. Compos. 2012, 31, 117–127. [Google Scholar] [CrossRef]

- Ansari, M.T.A.; Singh, K.K.; Azam, M.S. Effect of stacking sequence and fiber volume fraction on the static mechanical properties of woven GFRP Composite. In Trends in Materials Engineering; Springer: Singapore, 2019; pp. 51–58. [Google Scholar]

- Rahman, F.; Eiamin, M.A.; Hasan, M.R.; Islam, M.S.; Haque, M.M.; Gafur, M.A.; Dhar, S.A. Effect of Fiber Loading and Orientation on Mechanical and Thermal Properties of Jute-Polyester Laminated Composite. J. Nat. Fibers 2020, 19, 1741–1755. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Singh, S.; Dhawan, V. Influence of fiber volume fraction and curing temperature on mechanical properties of jute/PLA green composites. Polym. Polym. Compos. 2020, 28, 273–284. [Google Scholar] [CrossRef]

- Nam, T.H.; Ogihara, S.; Tung, N.H.; Kobayashi, S. Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly (butylene succinate) biodegradable composites. Compos. Part B Eng. 2011, 42, 1648–1656. [Google Scholar] [CrossRef]

- Cai, M.; Takagi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 589–597. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Immonen, K.; Brighton, J.; Abhyankar, H. Improving mechanical properties of novel flax/tannin composites through different chemical treatments. Ind. Crops Prod. 2015, 67, 346–354. [Google Scholar] [CrossRef]

- Kiasat, M.S.; Sangtabi, M.R. Effects of fiber bundle size and weave density on stiffness degradation and final failure of fabric laminates. Compos. Sci. Technol. 2015, 111, 23–31. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-14; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–13.

- ASTM D790-82; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials (Supersedes ASTM D790-81). ASTM International: West Conshohocken, PA, USA, 1981.

- ASTM D7136/D7136M-15; Standard Test Method for Measuring the Damage Resistance of A Fiber-Reinforced Polymer Matrix Composite to A Drop-Weight Impact Event. ASTM International: West Conshohocken, PA, USA, 2015.

- Segal, L.; Creely, J.J.; Martin, A.E., Jr.; Conrad, C.M. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- Reddy, K.O.; Maheswari, C.U.; Shukla, M.; Song, J.I.; Rajulu, A.V. Tensile and structural characterization of alkali treated Borassus fruit fine fibers. Compos. Part B Eng. 2013, 44, 433–438. [Google Scholar] [CrossRef]

- Cavallaro, P.V. Effects of weave styles and crimp gradients in woven Kevlar/epoxy composites. Exp. Mech. 2016, 56, 617–635. [Google Scholar] [CrossRef]

- Ravandi, M.; Teo, W.S.; Tran, L.Q.N.; Yong, M.S.; Tay, T.E. Low velocity impact performance of stitched flax/epoxy composite laminates. Compos. Part B Eng. 2017, 117, 89–100. [Google Scholar] [CrossRef]

- Nakano, T. Mechanism of microfibril contraction and anisotropic dimensional changes for cells in wood treated with aqueous NaOH solution. Cellulose 2010, 17, 711–719. [Google Scholar] [CrossRef][Green Version]

- Ishikura, Y.; Nakano, T. Compressive stress-strain properties of natural materials treated with aqueous NaOH. Holzforschung 2008, 62, 448–452. [Google Scholar] [CrossRef]

- Jacob, G.C.; Fellers, J.F.; Simunovic, S.; Starbuck, J.M. Energy absorption in polymer composites for automotive crashworthiness. J. Compos. Mater. 2002, 36, 813–850. [Google Scholar] [CrossRef]

- Richardson, M.O.W.; Wisheart, M.J. Review of low-velocity impact properties of composite materials. Compos. Part A Appl. Sci. Manuf. 1996, 27, 1123–1131. [Google Scholar] [CrossRef]

- Thomason, J.L.; Vlug, M.A. Influence of fibre length and concentration on the properties of glass fibre-reinforced polypropylene: 4. Impact properties. Compos. Part A Appl. Sci. Manuf. 1997, 28, 277–288. [Google Scholar]

- Romanzini, D.; Ornaghi, H.L., Jr.; Amico, S.C.; Zattera, A.J. Influence of fiber hybridization on the dynamic mechanical properties of glass/ramie fiber-reinforced polyester composites. J. Reinf. Plast. Compos. 2012, 31, 1652–1661. [Google Scholar] [CrossRef]

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural fibers composites: Origin, importance, consumption pattern, and challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- Vinoth, V.; Sathiyamurthy, S.; Ananthi, N.; Elaiyarasan, U. Chemical treatments and mechanical characterisation of natural fibre reinforced composite materials-a review. Int. J. Mater. Eng. Innov. 2022, 13, 208–221. [Google Scholar] [CrossRef]

| Laminate Code | Number of Woven Fabric Layers, n | Laminate Thickness (mm) | Fabric Volume Fraction (%) | Crimp Ratio of Yarns |

|---|---|---|---|---|

| 33 Fine Twill | 8 | 2.83 | 33 | 0.042 |

| 44 Fine Twill | 11 | 2.94 | 44 | 0.032 |

| 33 Coarse Twill | 2 | 2.8 | 33 | 0.049 |

| 44 Coarse Twill | 3 | 2.9 | 44 | 0.033 |

| 33 L Unidirectional | 6 | 2.8 | 33 | - |

| 33 T Unidirectional | 6 | 2.9 | 33 | - |

| 44 L Unidirectional | 9 | 2.8 | 44 | - |

| 44 T Unidirectional | 9 | 2.9 | 44 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alipour, A.; Jayaraman, K. Performance of Flax/Epoxy Composites Made from Fabrics of Different Structures. Fibers 2024, 12, 34. https://doi.org/10.3390/fib12040034

Alipour A, Jayaraman K. Performance of Flax/Epoxy Composites Made from Fabrics of Different Structures. Fibers. 2024; 12(4):34. https://doi.org/10.3390/fib12040034

Chicago/Turabian StyleAlipour, Abdolmajid, and Krishnan Jayaraman. 2024. "Performance of Flax/Epoxy Composites Made from Fabrics of Different Structures" Fibers 12, no. 4: 34. https://doi.org/10.3390/fib12040034

APA StyleAlipour, A., & Jayaraman, K. (2024). Performance of Flax/Epoxy Composites Made from Fabrics of Different Structures. Fibers, 12(4), 34. https://doi.org/10.3390/fib12040034