Simple Non-Destructive Method of Ultrathin Film Material Properties and Generated Internal Stress Determination Using Microcantilevers Immersed in Air

Abstract

1. Introduction

2. Theory

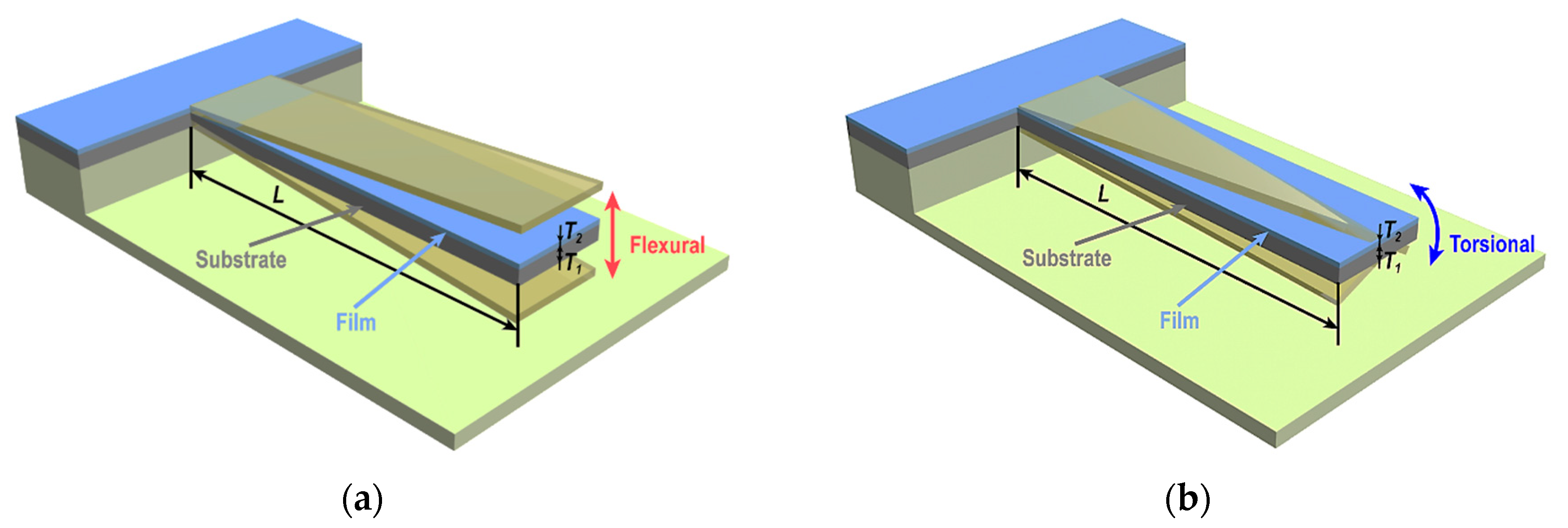

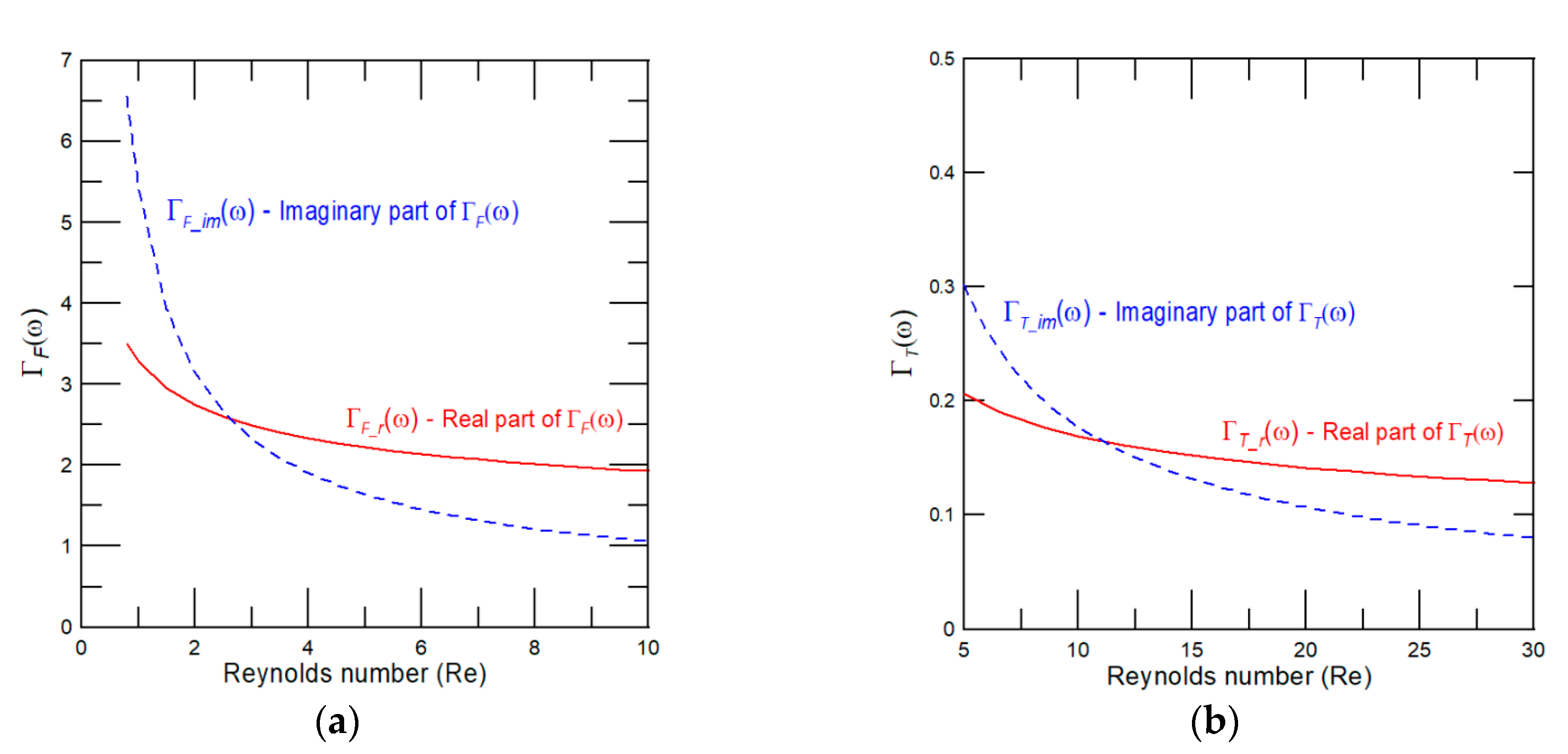

2.1. Flexural Oscillations of Two-Layered (Multi-Layered) Microcantilever Operating in Air

2.2. Torsional Oscillations of Two-Layered (Multi-Layered) Microcantilever Operating in Air

3. Results

3.1. Method of Determining Material Properties, Density, and Generated Internal Stress of Ultrathin Film(s)

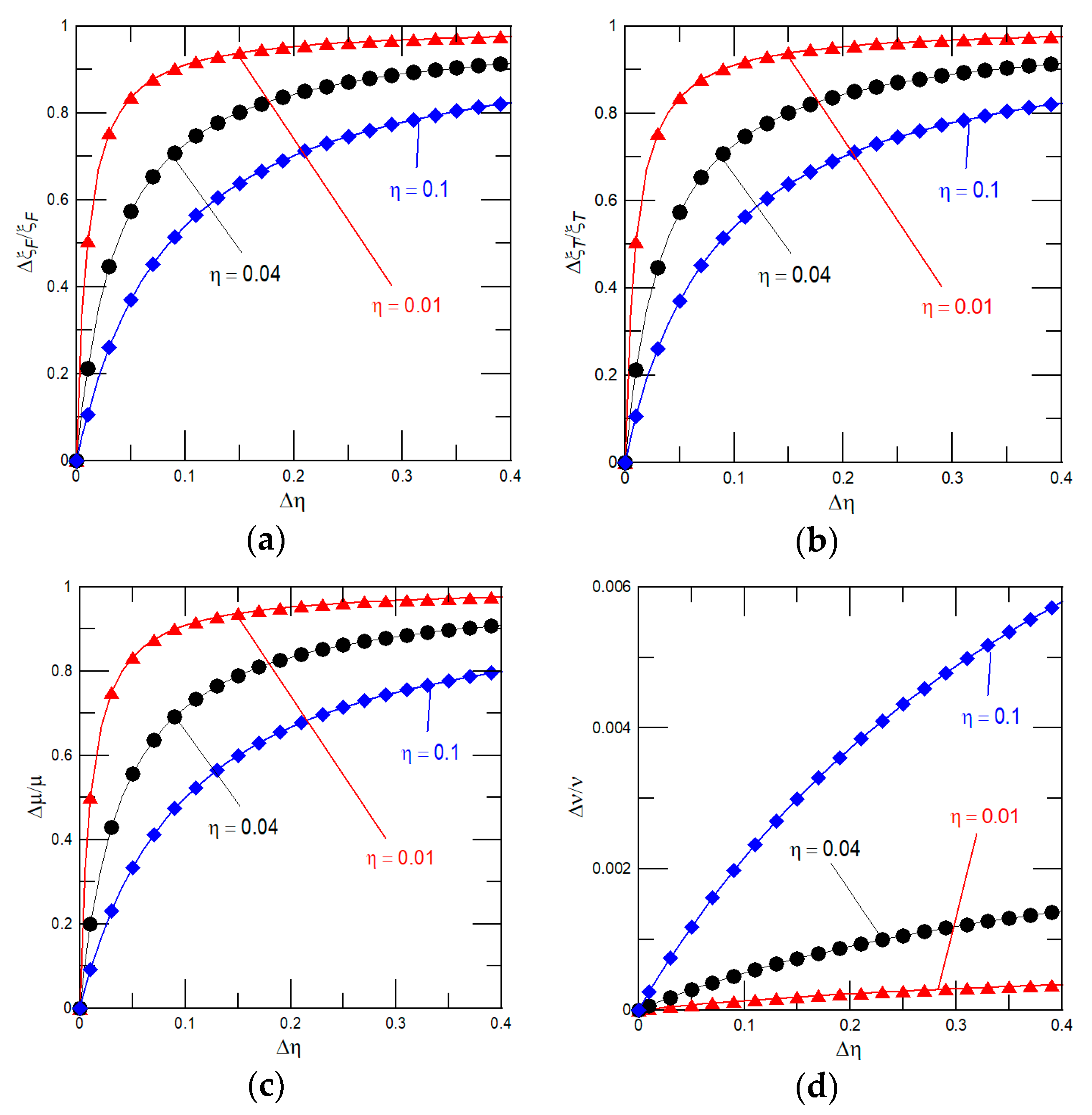

3.2. Impact of Errors in Dimensions, Frequency, and Quality Factor Measurements on the Accuracy of the Present Method

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Cerdán-Pasarán, A.; López-Luke, T.; Esparza, D.; Zarazúa, I.; De la Rosa, E.; Fuentes-Ramírez, R.; Alatorre-Ordaz, A.; Sánchez-Solís, A.; Torres-Castro, A.; Zhang, J.Z. Photovoltaic properties of multilayered quantum dot/quantum rod-sensitized TiO2 solar cells fabricated by SILAR and electrophoresis. Phys. Chem. Chem. Phys. 2015, 17, 18590–18599. [Google Scholar] [CrossRef] [PubMed]

- Yunin, P.A.; Drozdov, Y.N.; Drozdov, M.N.; Korolev, S.A.; Lobanov, D.N. Study of multilayered SiGe semiconductor structures by X-ray diffractometry, grazing-incidence X-ray reflectometry, and secondary-ion mass spectrometry. Semiconductors 2013, 47, 1556–1561. [Google Scholar] [CrossRef]

- Matsuda, T.; Ishihara, H. Proposal of highly efficient photoemitter with strong phonon-harvesting capability and exciton supperradiance. Appl. Phys. Lett. 2017, 111, 063108. [Google Scholar] [CrossRef]

- Li, D.; Jiang, Y.; Zhang, P.; Shan, D.; Xu, J.; Li, W.; Chen, K. The phosphorus and boron co-doping behaviors at nanoscale in Si nanocrystals/SiO2 multilayers. Appl. Phys. Lett. 2017, 110, 233105. [Google Scholar] [CrossRef]

- Stachiv, I.; Sittner, P.; Olejnicek, J.; Landa, M.; Heller, L. Exploiting NiTi shape memory alloy films in design of tunable high frequency microcantilever resonators. Appl. Phys. Lett. 2017, 111, 213105. [Google Scholar] [CrossRef]

- Stachiv, I.; Sittner, P. Nanocantilevers with adjustable static deflection and significantly tunable spectrum resonant frequencies for applications in nanomechanical mass sensors. Nanomaterials 2018, 8, 106. [Google Scholar] [CrossRef] [PubMed]

- Stachiv, I.; Fang, T.-H.; Jeng, Y.-R. Mass detection in viscous fluid utilizing vibrating micro- and nanomechanical mass sensors under applied axial tensile force. Sensors 2015, 15, 19351–19368. [Google Scholar] [CrossRef]

- Ceccacci, A.C.; Chen, C.; Hwu, E.; Morelli, L.; Bose, S.; Bosco, F.G.; Schmid, S.; Boisen, A. Blu-Ray-based micromechanical characterization platform for biopolymer degradation assessment. Sens. Actuators B Chem. 2017, 241, 1303–1309. [Google Scholar] [CrossRef]

- Stachiv, I.; Fedorchenko, A.I.; Chen, Y.L. Mass detection by means of the vibrating nanomechanical resonators. Appl. Phys. Lett. 2012, 100, 093110. [Google Scholar] [CrossRef]

- Hanay, M.S.; Kelber, S.; Naik, A.K.; Chi, D.; Hentz, S.; Bullard, E.C.; Colinet, E.; Duraffourg, L.; Roukes, M.L. Single-protein nanomechanical mass spectrometry in real time. Nat. Nanotechnol. 2012, 7, 602–608. [Google Scholar] [CrossRef]

- Sage, E.; Sansa, M.; Fostner, S.; Defoort, M.; Gély, M.; Naik, A.K.; Morel, R.; Duraffourg, L.; Roukes, M.L.; Alava, T.; et al. Single-particle mass spectrometry with arrays of frequency-addressed nanomechanical resonators. Nat. Commun. 2018, 9. [Google Scholar] [CrossRef] [PubMed]

- Stachiv, I. Impact of surface and residual stresses and electro-/magnetostatic axial loading on the suspended nanomechanical based mass sensors: A theoretical study. J. Appl. Phys. 2014, 115, 214310. [Google Scholar] [CrossRef]

- Kim, M.G.; Kanatzidis, M.G.; Faccheti, A.; Marks, T.J. Low temperature fabrication of high-performance metal oxide thin-film electronics via combustion process. Nat. Mater. 2011, 10, 382–388. [Google Scholar] [CrossRef] [PubMed]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Vlassak, J.J.; Nix, W.D. A new bulge test technique for the determination of Young’s modulus and Poisson’s ratio of thin film. J. Mater. Res. 1992, 7, 3242–3249. [Google Scholar] [CrossRef]

- Srikar, V.T.; Spearing, S.M. A critical review of microscale mechanical testing methods used in the design of micromechanical systems. Exp. Mech. 2003, 43, 238–247. [Google Scholar] [CrossRef]

- Xiang, H.F.; Xu, Z.X.; Roy, V.A.L.; Che, C.M.; Lai, T.P. Method for measurement of the density of thin films of small organic molecules. Rev. Sci. Instrum. 2007, 78, 034104. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Umehara, H.; Kojima, I. Effect of deposition parameters on composition, structures, density and topography of CrN films deposited by r.f. magnetron sputtering. Appl. Surf. Sci. 2002, 201, 208–218. [Google Scholar] [CrossRef]

- Whiteside, P.J.D.; Chinisis, J.A.; Hunt, H.K. Techniques and challenges for characterizing metal thin films with application in photonics. Coatings 2016, 6, 35. [Google Scholar] [CrossRef]

- Tsai, P.C.; Jeng, Y.R.; Lee, J.T.; Stachiv, I.; Sittner, P. Effects of carbon nanotube reinforcement and grain size refinement mechanical properties and wear behaviors of carbon nanotube/copper composites. Diam. Relat. Mater. 2017, 74, 197–204. [Google Scholar] [CrossRef]

- Carlton, C.E.; Ferreira, P.J. In Situ TEM nanoindentation of nanoparticles. Micron 2012, 43, 1134–1139. [Google Scholar] [CrossRef] [PubMed]

- Ma, S.; Huang, H.; Lu, M.; Veidt, M. A simple resonant method that can simultaneously measure elastic modulus and density of thin films. Surf. Coat. Technol. 2012, 209, 208–211. [Google Scholar] [CrossRef]

- Stachiv, I.; Zapomel, J.; Chen, Y.L. Simultaneous determination of the elastic modulus and density/thickness of ultrathin films utilizing micro-/nanoresonators under applied axial force. J. Appl. Phys. 2014, 115, 124304. [Google Scholar] [CrossRef]

- Illic, B.; Krylov, S.; Craighead, H.C. Young’s modulus and density measurements of thin atomic layer deposited films using resonant nanomechanics. J. Appl. Phys. 2010, 108, 044317. [Google Scholar] [CrossRef]

- Stachiv, I.; Vokoun, D.; Jeng, Y.R. Measurement of Young’s modulus and volumetric mass density / thickness of ultrathin films utilizing resonant based mass sensors. Appl. Phys. Lett. 2014, 104, 083102. [Google Scholar] [CrossRef]

- Dufrene, Y.F.; Martinez-Martin, D.; Medalsy, I.; Alsteens, D.; Muller, D.J. Multiparametric imaging of biological systems by force-distance curve–based AFM. Nat. Methods 2013, 10, 847–854. [Google Scholar] [CrossRef] [PubMed]

- Moreland, J. Micromechanical instruments for ferromagnetic measurements. J. Phys. D Appl. Phys. 2003, 36, R39–R51. [Google Scholar] [CrossRef]

- Hwang, K.S.; Lee, J.H.; Park, J.; Yoon, D.S.; Park, J.H.; Kim, T.S. In-Situ quantitative analysis of a prostate-specific antigen (PSA) using a nanomechanical PZT cantilever. Lab Chip 2004, 4, 547–552. [Google Scholar] [CrossRef]

- Sandberg, R.; Mølhave, K.; Boisen, A.; Svendsen, W. Effect of gold coating on the Q-factor of a resonant cantilever. J. Micromech. Microeng. 2005, 15, 2249–2253. [Google Scholar] [CrossRef]

- Lachut, M.J.; Sader, J.E. Effect of surface stress on the stiffness of cantilever plates. Phys. Rev. Lett. 2007, 99, 206102. [Google Scholar] [CrossRef]

- Karabalin, R.B.; Villanueva, L.G.; Matheny, M.H.; Sader, J.E.; Roukes, M.L. Stress-induced variation in the stiffness of micro- and nanocantilever beams. Phys. Rev. Lett. 2012, 108, 236101. [Google Scholar] [CrossRef] [PubMed]

- Pini, V.; Ruz, J.J.; Kosaka, P.M.; Malvar, O.; Calleja, M.; Tamayo, J. How two-dimensional bending can extraordinary stiffen thin sheets. Sci. Rep. 2016, 6, 29627. [Google Scholar] [CrossRef] [PubMed]

- Ruz, J.J.; Pini, V.; Malvar, O.; Kosaka, P.M.; Calleja, M.; Tamayo, J. Effect of surface stress induced curvature on the eigenfrequencies of microcantilever plates. AIP Adv. 2018, 8, 105213. [Google Scholar] [CrossRef]

- Sader, J.E. Frequency response of cantilever beams immersed in viscous fluids with applications to the atomic force microscope. J. Appl. Phys. 1998, 84, 64–76. [Google Scholar] [CrossRef]

- Stachiv, I.; Fang, T.H.; Chen, T.H. Micro-/nanosized cantilever beams and mass sensors under applied axial tensile/compressive force vibrating in vacuum and viscous fluid. AIP Adv. 2015, 5. [Google Scholar] [CrossRef]

- Zapomel, J.; Stachiv, I.; Ferfecki, P. A novel method combining Monte Carlo–FEM simulations and experiments for simultaneous evaluation of the ultrathin film mass density and Young’s modulus. Mech. Syst. Signal Process. 2016, 66–67, 223–231. [Google Scholar] [CrossRef]

- Kelly, S.G. Fundamentals of Mechanical Vibrations, 2nd ed.; McGraw-Hill International: Singapore, 2000. [Google Scholar]

- Chon, J.W.M.; Mulvaney, P.; Sader, J.E. Experimental validation of theoretical models for the frequency response of atomic force microscope cantilever beams immersed in fluids. J. Appl. Phys. 2000, 87, 3978–3988. [Google Scholar] [CrossRef]

- Van Eysden, C.A.; Sader, J.E. Frequency response of cantilever beams immersed in viscous fluids with applications to the atomic force microscope: Arbitrary mode number. J. Appl. Phys. 2007, 101, 044908. [Google Scholar] [CrossRef]

- Van Eysden, C.A.; Sader, J.E. Small amplitude oscillations of a flexible thin blade in a viscous fluid: Exact analytical solution. Phys. Fluids 2006, 18, 123102. [Google Scholar] [CrossRef]

- Green, C.P.; Sader, J.E. Torsional frequency response of cantilever beams immersed in viscous fluids with applications to the atomic force microscope. J. Appl. Phys. 2002, 92, 6262–6274. [Google Scholar] [CrossRef]

- Gupta, A.K.; Nair, P.R.; Akin, D.; Ladisch, M.R.; Broyles, S.; Alam, M.A.; Bashir, R. Anomalous resonance in a nanomechanical biosensor. Proc. Natl. Acad. Sci. USA 2006, 103, 13362–13367. [Google Scholar] [CrossRef] [PubMed]

- Tamayo, J.; Ruz, J.J.; Pini, V.; Kosaka, P.; Calleja, M. Quantification of the surface stress in microcantilever biosensors: Revisiting Stoney’s equation. Nanotechnology 2012, 23, 475702. [Google Scholar] [CrossRef] [PubMed]

- Sader, J.E. Surface stress induced deflections of cantilever plates with applications to the atomic force microscope: Rectangular plates. J. Appl. Phys. 2001, 89, 2911–2921. [Google Scholar] [CrossRef]

- Morin, P.; Raymond, D.; Benoit, P.; Maury, P.; Beneyton., R. A comparison of the mechanical stability of silicon nitride films deposited with various techniques. Appl. Surf. Sci. 2012, 260, 69–72. [Google Scholar] [CrossRef]

- Colombi, P.; Bergese, P.; Bontempi, E.; Borgese, L.; Federici, S.; Keller, S.S.; Boisen, A.; Depero, L.E. Sensitive determination of the Young’s modulus of thin films by polymeric microcantilevers. Meas. Sci. Technol. 2013, 24, 125603. [Google Scholar] [CrossRef]

| Measured Quantity | SU-8 | 20 nm TiO2 | 50 nm TiO2 |

|---|---|---|---|

| Frequency in air (kHz) | 18.2 ± 0.32 | 21.0 ± 0.21 | 27.1 ± 0.18 |

| QF/QF0 | None | 1.11 ± 0.018 | 1.34 ± 0.019 |

| Young’s modulus (GPa), by Equation (28) | 4.04 ± 0.30 | 66.3 ± 14 | 96.9 ± 8 |

| Young’s modulus (GPa), [34] | 3.82 ± 0.13 | 60 ± 18 | 91 ± 15 |

| Measured Quantity | 20 nm Si3N4 | 50 nm Si3N4 |

|---|---|---|

| ωT/ωT0, Equation (17)/Numerically | 1.024 ± 0.003/1.026 ± 0.003 | 1.058 ± 0.003/1.061 ± 0.003 |

| QT/QT0, Equation (18)/Numerically | 1.045 ± 0.002/1.048 ± 0.002 | 1.114 ± 0.002/1.116 ± 0.002 |

| Density (g/cm3), Equation (19)/Numerically | 3.35 ± 0.01/3.52 ± 0.02 | 3.25 ± 0.01/3.26 ± 0.01 |

| Shear modulus (GPa), Equation (20)/Numerically | 100.48 ± 10.77/107.64 ± 11.11 | 100.39 ± 4.67/104.01 ± 4.74 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stachiv, I.; Gan, L. Simple Non-Destructive Method of Ultrathin Film Material Properties and Generated Internal Stress Determination Using Microcantilevers Immersed in Air. Coatings 2019, 9, 486. https://doi.org/10.3390/coatings9080486

Stachiv I, Gan L. Simple Non-Destructive Method of Ultrathin Film Material Properties and Generated Internal Stress Determination Using Microcantilevers Immersed in Air. Coatings. 2019; 9(8):486. https://doi.org/10.3390/coatings9080486

Chicago/Turabian StyleStachiv, Ivo, and Lifeng Gan. 2019. "Simple Non-Destructive Method of Ultrathin Film Material Properties and Generated Internal Stress Determination Using Microcantilevers Immersed in Air" Coatings 9, no. 8: 486. https://doi.org/10.3390/coatings9080486

APA StyleStachiv, I., & Gan, L. (2019). Simple Non-Destructive Method of Ultrathin Film Material Properties and Generated Internal Stress Determination Using Microcantilevers Immersed in Air. Coatings, 9(8), 486. https://doi.org/10.3390/coatings9080486