Abstract

20CrMnTi carburized steel is widely used in the manufacturing of gear transmission components. Gears often operate under complex working conditions that involve high pressure and temperature, and intermittent alternating loads. The material is frequently subjected to repeated compression and resilience cycles, which significantly affect dimensional accuracy and stability. This study investigates the influence of different temperatures and pressures on the compression resilience properties and microhardness of 20CrMnTi steel. The results indicate that temperature and pressure lead to a nonlinear increase in the compression curve, reduce resilience properties and the microhardness of the carburized layer, and affect the microhardness of the matrix. Microstructural analysis indicated that plastic deformation, carbide coarsening, and a lower elastic modulus led to the enlarged compression and diminished microhardness in the carburized layer. Work hardening, dynamic recrystallization, and plastic deformation in the matrix material weaken resilience properties and influence the distribution of microhardness in the matrix.

1. Introduction

As a carburized steel, 20CrMnTi is characterized by its favorable hardenability, excellent carburizing processability, and a superior combination of strength and toughness [,,]. The ability to fabricate parts with exceptionally high surface hardness and wear resistance, coupled with a core that retains substantial strength and toughness, has led to its widespread adoption in the production of gear transmission components for automotive, marine, aerospace, and machine tool applications []. Despite the long history of gear development and their generally reliable transmission performance, maintaining stable functionality remains significantly challenging due to their frequent operation under high-speed, heavy-load, and severe friction conditions. This issue is further complicated by frequent start-stop cycles or exposure to extreme environments during actual operation, which can easily lead to premature gear failure [,].

When gears operate under high-temperature and pressure conditions, their material properties can be significantly affected, leading to dimensional deformation [,]. Friction at gear meshing points generates localized high temperatures, which in turn exacerbate surface deformation of the material. This results in increased wear and reduced corrosion resistance, creating a vicious cycle []. For instance, in wind turbine transmission systems, insufficient lubrication in gearboxes can lead to lubrication issues, increasing friction and wear, raising temperatures, and ultimately affecting gear life and performance []. Wu [] pointed out that increased normal load and temperature significantly aggravated surface deformation of materials, leading to accelerated wear and diminished corrosion resistance. High pressure also has serious consequences. For example, motors and gearboxes in PT Angsana coal mining equipment continuously endure extreme loads and harsh environments, resulting in unexpected downtime of up to 706.9 h []. Furthermore, frequent load alternation during the start-stop cycles of transmission devices can induce intermittent high pressure and high stress states, adversely affecting the overall dimensional stability of gears []. Gears in a power plant’s condenser facility experienced over 7000 start-stop cycles and failed after accumulating only about 13,000 h of operation, demonstrating significantly more severe damage compared to gears under steady load operation [].

The high-temperature and high-pressure characteristics of 20CrMnTi gear steel are commonly investigated by researchers using hot compression tests to simulate and analyze the material’s deformation behavior during thermal processing. For instance, Zhao [] conducted experiments within a deformation temperature range of 1123 K to 1273 K and strain rates from 0.01 s−1 to 10 s−1, achieving a deformation degree of 60%. The results indicated that flow stress decreases with increasing deformation temperature and decreasing strain rate. Similarly, Wei [] studied hot compression deformation behavior at temperatures from 950 °C to 1150 °C and strain rates of 0.01 s−1 to 5 s−1, observing the same trend and establishing corresponding constitutive equations. Furthermore, Liu [] developed processing maps based on thermal simulation tests to identify stable and unstable regions of the material under various deformation conditions, thereby determining optimal processing temperature and strain rate ranges. Current research on gear steel materials primarily focuses on the effects of different austenitizing temperatures, yield limits, and strain rates on true stress–strain curves, aiming to optimize process parameters for hot working. However, limited attention has been paid to how alternating stresses within the elastic limit and austenitizing temperatures influence dimensional stability to ensure transmission accuracy.

It is evident that while modern materials and manufacturing technologies have enhanced the initial reliability of transmission systems, the demands for exceptional dimensional stability during long-term service under extreme operating conditions continue to present a challenge in engineering practice. Therefore, this study investigates 20CrMnTi steel, following carburizing and subsequent heat treatment, by conducting uniaxial hot compression tests that simulate the high pressure and temperature environments encountered in aerospace applications. Combined with analysis of surface hardness distribution and microstructure, the aim is to elucidate the underlying mechanisms through which elevated temperature and pressure influence the compression resilience behavior of 20CrMnTi. The findings hold significant engineering importance for assessing the in-service reliability of carburized steels.

2. Materials and Methods

2.1. Materials and Processing

The 20CrMnTi steel used in this study possesses a specified tensile strength of no less than 1080 MPa and a yield strength of no less than 850 MPa. The chemical composition analysis was conducted on an optical emission spectrometer (Foundry-Master Xpert, Oxford, UK). To obtain test specimens, block specimens with dimensions of 20 × 20 × 20 mm were extracted from the forging via cutting, meticulously avoiding any thermal overload that could induce microstructural alterations or elemental segregation. Subsequent surface preparation involved grinding with abrasive paper to achieve a flat, smooth finish devoid of pores, cracks, and inclusions, thereby ensuring the analysis surface fully covered and sealed the excitation aperture. Excitation was carried out with a silver electrode over a 30 s duration. The final composition values, presented in Table 1, are the average of three separate determinations and were validated by comparison with the Chinese standard GB/T 3077-2015 [].

Table 1.

Chemical composition of the 20CrMnTi steel (mass fraction, wt.%).

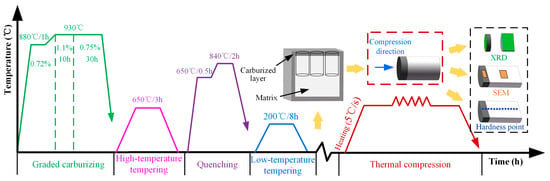

The processing protocol, performed sequentially, consisted of step carburizing, high-temperature tempering, marquenching, and low-temperature tempering [], as illustrated in Figure 1. Step carburizing was conducted in a propane atmosphere. During the first stage, the specimens were heated to 880 °C and held for 1 h at a carbon potential (Cp) of 0.72%. This stage aimed to establish an appropriate carbon concentration gradient at the surface, preparing the material for subsequent treatment. This was followed by a second stage (930 °C, 10 h, Cp 1.1%) to achieve a high surface carbon content, and a subsequent diffusion step (930 °C, 30 h, Cp 0.75%) to homogenize the carbon profile. The specimens were then slowly cooled to room temperature. The subsequent steps of high-temperature tempering, marquenching, and low-temperature tempering were employed to enhance overall toughness, refine mechanical properties, and relieve residual stresses, respectively.

Figure 1.

Heat treatment process and experimental scheme of the 20CrMnTi steel.

2.2. Mechanical Experiment

Uniaxial hot compression tests were conducted on a Gleeble-3500 thermal simulation apparatus (Poestenkill, NY, USA). The specimens were machined to dimensions of Φ8 mm × 12 mm, with all surface impurities cleaned and required perpendicularity and parallelism ensured. Each test involved heating the specimens to the target temperature at a rate of 5 °C/s, followed by a 180 s holding period for temperature homogenization. Upon reaching the target temperature, the compression load was applied, starting from 5 MPa at a rate of 0.5 MPa/s until the predetermined stress was achieved. Unloading was subsequently performed at the same rate, before cooling concluded the experiment. The experimental parameters were set at pressure of 35 MPa and 65 MPa, and temperatures of 100 °C and 500 °C, resulting in four distinct parameter groups, as summarized in Table 2. Three specimens were tested for each group, and the average value of the results was calculated for analysis.

Table 2.

Compressive resilience experiment scheme.

The compression resilience of the material was quantified by the compression ratio (CR) and the resilience ratio (RR), calculated using Equations (1) and (2), respectively [,].

where l1 is the initial specimen height, l2 is the height under maximum load, and δ is the height after load removal.

Microhardness measurements were conducted using a VH1130 tester (Wilson, Norwood, MA, USA) with a maximum capacity of 3000 HV. In accordance with the carburizing process protocol, microhardness measurements were taken along the centerline of the specimen cross-section from the carburized surface layer to the base material (0–12 mm). A profile of microhardness was subsequently plotted from these data points. The tests were conducted under a load of 1 kgf with a dwell time of 30 s, as illustrated in Figure 1.

2.3. Microscopic Testing

The compressed specimens were axially sectioned to create specimens for microstructural analysis, as illustrated in Figure 1. The cross-sectional surfaces were successively ground using 500#, 1000#, 1500#, and 2000# grit sandpaper. Following grinding, the specimens were polished using a polishing machine until a mirror-like, scratch-free surface was achieved. The polished surfaces were then etched by immersion in a 4% nitric acid alcohol solution. Etching was considered complete when the surface exhibited a uniform gray-black coloration.

Microstructural observation was performed using a JSM-7001F scanning electron microscope (SEM, JEOL, Tokyo, Japan). The SEM was operated at an accelerating voltage of 20 kV. The instrument is also equipped with an energy dispersive spectrometer (EDS), which was utilized to analyze the types and concentrations of elements in specific micro-regions of the material. Phase identification was carried out using a MiniFlex 600 X-ray diffractometer (XRD, Rigaku, Tokyo, Japan) with Cu Kα radiation. The operating parameters were set at a voltage of 40 kV, a current of 15 mA, and a 2θ scanning range from 30° to 95° with a step size of 1°/min. The resulting diffraction patterns were analyzed using Jade 6 software. SEM was primarily used to examine the microstructure of both the surface of carburized layer and the core matrix region of the sectioned specimens. XRD analysis was primarily conducted on the surface of the carburized layer. However, for the matrix region, measurements were taken on a cross-sectional surface from the central area to avoid interference from the affected surface layer, as detailed in Figure 1.

The dislocation density (ρ) was calculated from the XRD data using the Williamson–Hall method, as expressed in Equations (3) and (4) [,].

Moreover, the crystallite size (D) was estimated using the Scherrer formula, given in Equation (5) []:

In Equations (3)–(5), K is the Scherrer constant (typically 0.89 or 0.94), λ is the X-ray wavelength (0.154 nm), β is the full width at half maximum (FWHM), θ is the Bragg angle, D is the crystallite size, ε is the microstrain, b is the Burgers vector (0.289 nm for steel), and ρ is the dislocation density.

3. Results

3.1. Mechanical Properties

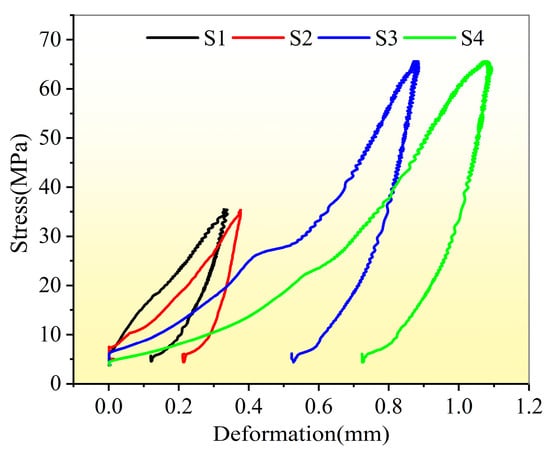

Following the experimental scheme, the stress–strain curves for each group were obtained. Representative curves from each group are plotted in Figure 2. All curves in the figure show a residual strain upon unloading, indicating that the deformation is not fully recoverable even under compression within the nominal elastic regime, which implies the occurrence of permanent plastic deformation. This is further supported by the non-constant slope observed during the loading stage. Compared to S1 and S3, the curves for S2 and S4 are shifted rightward in both their peaks and endpoints, demonstrating that increased temperature leads to greater compressive deformation and reduced resilience. Similarly, the curves for S3 and S4 are shifted rightward compared to S1 and S2, indicating that higher compressive stress also results in increased deformation and diminished resilience. Based on Equations (1) and (2), the compression ratios for S1–S4 are calculated as 2.79%, 3.13%, 7.30%, and 9.07%, respectively, while their resilience ratios are 64.03%, 42.58%, 40.29%, and 33.51%.

Figure 2.

Compression resilience curves of various specimen groups.

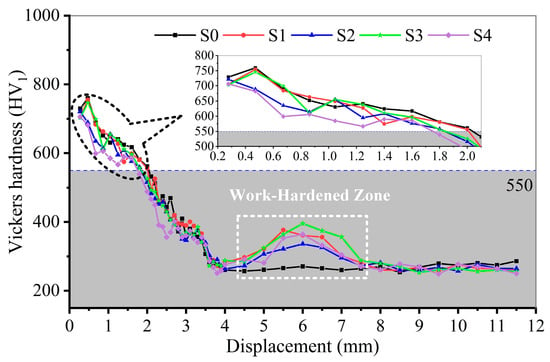

The compressed specimens were sectioned, and microhardness measurements were subsequently taken sequentially from the surface to the core. For comparative analysis, the uncompressed specimen (S0) was used as a reference, with the results presented in Figure 3. According to the GB/T 9450-2005 standard [], the Case Hardening Depth (CHD) is defined as the depth where hardness exceeds 550 HV. As shown in the figure, the measured CHD values for S0 to S4 are 2.0 mm, 2.0 mm, 1.8 mm, 1.8 mm, and 1.6 mm, respectively. The corresponding average microhardness values in the carburized layer are 648 HV, 639 HV, 616 HV, 634 HV, and 594 HV. These results confirm that the carburizing process achieved satisfactory effectiveness. However, it is evident that the combined effect of increasing pressure and temperature leads to a reduction in the microscopic hardness of the carburized layer.

Figure 3.

Microhardness profiles for the various specimen groups.

Figure 3 also shows the microscopic hardness decreases rapidly to approximately 250–300 HV with the reduction in carbon content. The region below 550 HV, spanning 4–12 mm, is identified as the matrix. An anomalous increase in microhardness is observed within the matrix at depths of 4.5–7 mm for specimens S1–S4, with peak values of 361.27 HV, 336.38 HV, 395.43 HV, and 364.1 HV, respectively. This indicates that the high-pressure, low-temperature condition (S3) significantly enhances matrix hardness, whereas the low-pressure, high-temperature condition (S2) substantially weakens this effect.

3.2. Microstructure Analysis

Based on the compressed specimens (S1–S4) and compared with the uncompressed reference specimen (S0), the microstructural evolution of the material was analyzed using techniques including XRD, SEM, and EDS. The investigation focused on changes in grain size, dislocation density, phase transformations, and carbide precipitation.

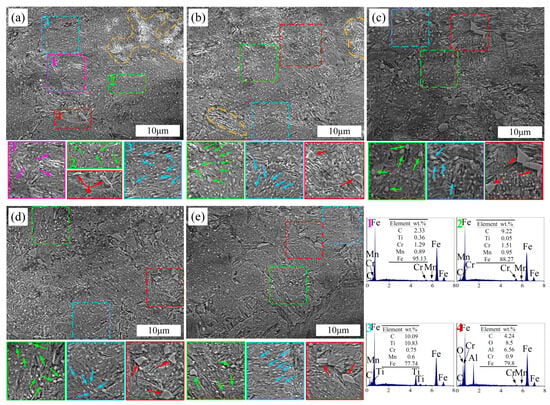

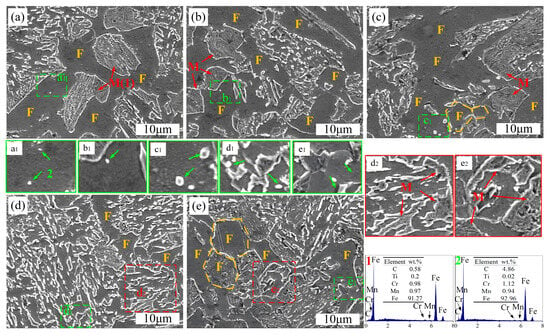

Figure 4 displays the surface microstructures of the carburized layer for different specimen groups. The microstructure in each micrograph is predominantly composed of acicular martensite. EDS confirmed a higher carbon concentration in this phase compared to the standard microstructure (spot 1), verifying effective carburization and the formation of high-carbon martensite. The elevated carbon content significantly depresses both the martensite start (Ms) and finish (Mf) temperatures, imposing stricter requirements for the complete transformation of austenite to martensite []. Consequently, small amounts of retained austenite are observed, as indicated by the yellow dashed lines in Figure 4a,b. Numerous carbides, identified as Fe3C (spot 2, green dotted line) and titanium carbide (spot 3, blue dotted line) based on their chemical composition, are distributed throughout the microstructure. In addition, large, angular particles are present, which EDS analysis (spot 4, red dotted line) suggests are non-metallic inclusions, such as Al2O3, commonly formed during the steelmaking process of 20CrMnTi steel [].

Figure 4.

Surface microstructure of the carburized layer for different specimen groups: (a) S0, (b) S1, (c) S2, (d) S3, (e) S4.

A comparative analysis in Figure 4 across the different specimen groups reveals that the retained austenite content progressively decreased from specimen S0 to S1. The microstructure of specimens S2 to S4 was composed primarily of martensite. The inherent instability of retained austenite at high temperature, supplemented by the mechanical driving force from applied pressure, collectively overcomes the transformation energy barrier. This directly induces the martensitic conversion through a mechanism analogous to Transformation Induced Plasticity (TRIP) []. Moreover, as shown in Figure 4c, the carbides in S2 are noticeably coarsened and unevenly distributed. The observed coarsening can be explained by Ostwald ripening [], a process thermodynamically driven by the system’s tendency to reduce its interfacial energy at elevated temperatures. In this mechanism, larger particles grow by consuming smaller, higher-energy neighbors. This is accelerated by the Gibbs-Thomson effect [], as the increased temperature enhances the diffusion of solute atoms from the smaller, higher-solubility particles to the larger ones. Figure 4e indicates that the carbide size in S4 is reduced compared to S2, likely due to the fragmentation effect exerted by the greater applied pressure on the carbides [].

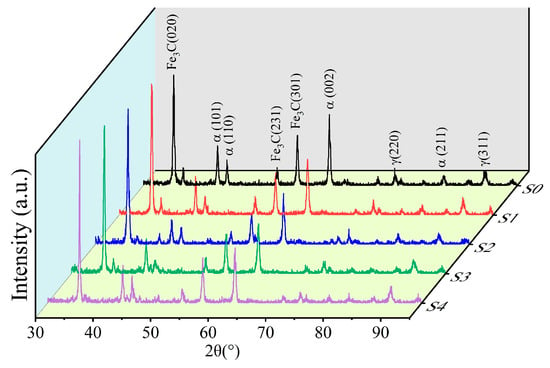

The phases present in the carburized layer of the 20CrMnTi steel were analyzed using XRD. The diffraction pattern from the carburized surface, shown in Figure 5, revealed the presence of martensite (α) as the primary phase, along with cementite (Fe3C) and retained austenite (γ). The detection of Fe3C indicates that the high concentration of carbon introduced during carburizing reacted with iron to form carbide precipitates.

Figure 5.

XRD patterns of the carburized layer for different specimen groups.

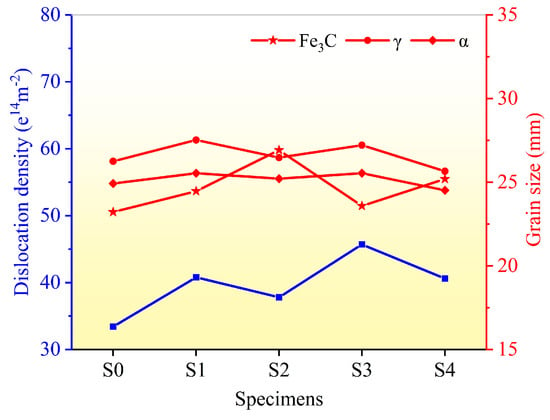

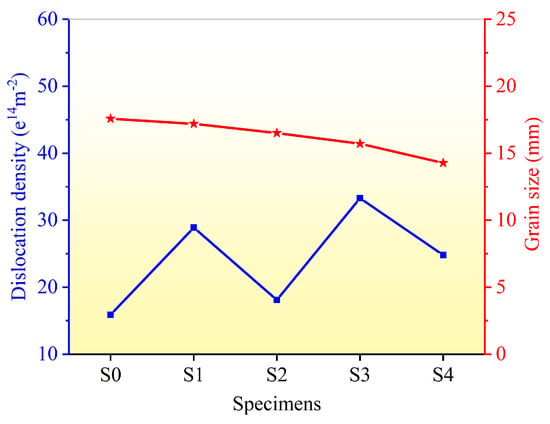

By utilizing the full width at half maximum (β) and diffraction angle (θ) data obtained from Figure 5, the dislocation density within the carburized layer was calculated employing Equations (3) and (4). Furthermore, the grain sizes of the constituent phases in the carburized layer were determined using the Scherrer formula (Equation (5)). The results of these calculations are presented in Figure 6. Compared to S0, all specimens S1 through S4 exhibited an increase in dislocation density. However, the extent of this increase was more pronounced in S1 and S3 than in S2 and S4. This observed variation can be attributed to two competing mechanisms. External stress introducing dislocations through plastic deformation [], versus thermal activation promoting dislocation annihilation and dynamic recrystallization (DRX) that reduces dislocation density []. The high dislocation density within the carburized layer is primarily attributed to the increased carbon content, which results in the inherent high dislocation density characteristic of high-carbon martensite []. The carburized layer exhibits minimal influence from thermo-compression, likely because it is situated in the upper portion of the specimen, away from the central region where compressive deformation is most concentrated. Its higher strength also renders it more resistant to deformation, leading to a relatively modest increase in dislocation density induced by the applied stress.

Figure 6.

Dislocation density and grain size of the carburized layer in different specimen groups.

As further evinced in Figure 6, the data indicate an increase in the grain size of Fe3C within the carburized layer, which aligns with the microstructural evolution observed in Figure 4. In contrast, the grain sizes of the α and γ phases in the carburized layer remain largely stable. This stability is likely due to the strong pinning effect exerted on grain boundaries and dislocations by the high carbon content and abundant carbides, which significantly inhibit grain boundary migration and dislocation rearrangement [,]. The limited atomic diffusivity at 500 °C provides insufficient energy to overcome the pinning forces imposed by carbides and dislocation, thereby preventing recrystallization and resulting in negligible grain growth.

The compression ratio is primarily governed by the properties of the carburized layer, which acts as a protective shell due to its high strength and hardness. According to Hooke’s law [], the compressive strain should exhibit a linear relationship with the applied stress, given that the experimental stress is well below the material’s yield strength. However, as observed in Figure 3, pressure and temperature led to a slower slope in the compression curves, meaning that they resulted in greater deformation under a given load. The microstructural evidence elucidates the key mechanisms: (i) High temperature drives carbide coarsening, an effect only partially offset by pressure-induced fragmentation. (ii) Increased thermal vibration amplitude from heating weakens interatomic bonding, reducing the elastic modulus and deformation resistance. (iii) Both pressure and temperature facilitate the transformation of austenite into high-strength martensite. In summary, the weakening effects of mechanisms iii may surpass the strengthening effect of iii, leading to a net increase in compression. The application of stress at elevated temperatures resulted in the precipitation of inhomogeneously distributed, coarsened carbides on the material surface. These carbides promoted atomic diffusion and dislocation motion, thereby accelerating the tempering softening process. Consequently, the combined effect of temperature and pressure led to a reduction in the microhardness of the carburized layer.

Figure 7 illustrates the surface microstructures of the matrix for each experimental group. Microstructural morphology combined with EDS analysis reveals that the untreated specimen (S0) primarily consists of dark ferrite (F) and bright, blocky martensite (M) (spot 1, red dotted line), which exhibit clear phase boundaries and distinct contrast. A small amount of carbide (spot 2, green dotted line) is also present on the matrix surface. Analysis of Figure 7b,d indicate that increased compressive stress induces bending and fragmentation of the martensite regions, altering their distribution within the dual-phase structure. Furthermore, examination of Figure 7c,e demonstrate that elevated temperature promotes the development of more equiaxed ferrite grains, suggesting the occurrence of recrystallization in these regions [].

Figure 7.

Surface microstructure of the matrix for different specimen groups: (a) S0, (b) S1, (c) S2, (d) S3, (e) S4.

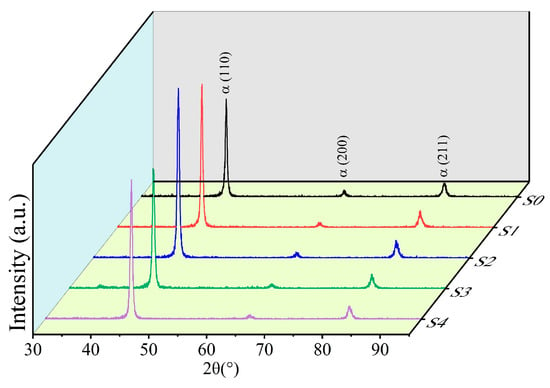

The XRD patterns of the matrix material are presented in Figure 8. Due to its low carbon content, the patterns for all specimens are predominantly composed of martensite (α) diffraction peaks. Therefore, the dislocation density and the grain size of the α phase in the matrix were determined from the diffraction data in the figure, following the identical methodology applied to the carburized layer. The resulting quantitative data are summarized in Figure 9.

Figure 8.

XRD patterns of the matrix for different specimen groups.

Figure 9.

Dislocation density and grain size of the matrix in different specimen groups.

A comparison between Figure 8 and Figure 9 reveals that the variation trends of dislocation density are generally consistent between the carburized layer and the matrix. The matrix region is significantly more affected by thermo-compression, primarily because its superior plasticity, inherent to the central area, facilitates more severe compressive deformation. This creates favorable conditions for dislocation multiplication and slip, leading to a more pronounced stress-induced increase in dislocation density and establishing prerequisites for work hardening in this region []. In Figure 9, the grain size of the α phase progressively decreases, demonstrating that both elevated temperature and applied pressure contribute to grain refinement. The weaker pinning effect, attributable to lower intrinsic dislocation density and fewer carbides, coupled with the superior plasticity of the matrix, facilitates this process. The accumulated distortion energy under combined thermo-mechanical conditions promotes the formation of strain-free, fine equiaxed grains [].

The matrix, functioning as a spring, serves as the primary source of resilience, and thus the resilience ratio is predominantly governed by its properties. Contrary to Hooke’s law, which predicts complete recovery after elastic compression, the experimental data in Figure 3 exhibit permanent deformation. Microstructural analysis elucidates the underlying causes: (i) The increase in applied pressure induces a rise in dislocation density within the matrix, accompanied by pronounced work hardening in the central region, which is detrimental to resilience. (ii) This work hardening signifies the occurrence of irreversible plastic deformation. (iii) Owing to the relatively low initial dislocation density and fewer carbides in the matrix, DRX becomes prominent. Although this process refines the grain structure, it simultaneously dissipates the energy required for rebound. In summary, both applied pressure and elevated temperature compromise the material’s resilience. Furthermore, although applied stress introduces work hardening that increases microhardness, the concurrent high temperature promotes DRX, which counteracts this hardening effect and results in net softening of the material. Consequently, a combination of high stress and low temperature yields higher microhardness and CHD, whereas low stress and high temperature result in lower microhardness and CHD.

Based on the findings of this study, a high compression ratio in gears is often accompanied by significant compressive stress. The repeated application of such stress on the gear surface can accelerate the accumulation of fatigue damage. If the stress exceeds the material’s load-bearing capacity, it will further promote the initiation and propagation of cracks []. A low resilience ratio is also detrimental to gear performance. During operation, gears are continuously subjected to impact and alternating loads. If the deformation cannot fully recover after each cycle, plastic strain will accumulate, compromising geometric accuracy and meshing performance. This leads to increased transmission error, exacerbated vibration, and elevated noise levels []. Therefore, the influence of operating conditions must be adequately considered during gear operation to ensure the service life of the gear transmission system.

4. Conclusions

This research systematically investigated the compression resilience and microhardness of 20CrMnTi carburized steel under varying conditions of compressive stress and temperature. The crucial findings are summarized as follows:

Pressure and temperature induce plastic deformation, a decreased elastic modulus, and carbide coarsening in the carburized layer. These synergistic changes diminish the overall compressive resistance, resulting in a linear deformation–pressure relationship in the inelastic stage and a maximum compressibility of 9.07%.

Pressure induces work hardening and plastic deformation in the matrix through increase in dislocation density, while temperature promotes pronounced DRX, which consumes the energy required for resilience. This dual interaction leads to a minimum resilience ratio of 33.51%.

Under high pressure and temperature conditions, the carburized layer develops in homogeneously distributed coarse carbides and exhibits plastic flow behavior. These microstructural changes accelerate atomic diffusion and dislocation motion, thereby inducing a tempering softening process. As a result, the microhardness of the carburized layer decreases from 648 HV to 594 HV, accompanied by a reduction in case hardening depth (CHD) from 2.0 mm to 1.6 mm. In the matrix, although pressure-induced work hardening elevates the hardness to 395.43 HV, this strengthening effect is counteracted by dynamic recrystallization (DRX) activated at high temperature, ultimately reducing the hardness to 336.38 HV.

Author Contributions

Conceptualization, formal analysis, W.Z.; visualization, methodology, L.F.; validation, supervision, M.X.; writing—original draft preparation, L.T.; writing—review and editing, Y.L. (Ye Li); investigation, S.L.; resources, software, Y.L. (Yakun Li); data curation, D.S.; project administration, P.Z.; funding acquisition, P.Z.; funding acquisition, supervision, L.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Basic Research Program of Shanxi Province Joint Funding Project (TZCO) (TZLH20230818013), “Open Bidding for Selecting the Best Candidates” Science and Technology Major Project of Shanxi Province (202201140601023), Research Funding Project for Introduced Talents at Taiyuan Institute of Technology (21020213), Fundamental Research Program of Shanxi Province (202203021222283), Key Research and Development Program of Shanxi Province (202202150401007).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

Authors Wenjun Zhao, Lei Fan, Mengwen Xing, Yakun Li, Dan Shan were employed by the company TZ (TIANJIN) Binhai Heavy Machinery Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Liu, S.; Yang, F.; Liu, L.; Wang, J.; Peng, J.; Zhang, F.; An, S. Study on the effects of Al–Ce composite deoxidations on the modification behaviors of TiN inclusions in 20CrMnTi steel. J. Mater. Res. Technol. 2024, 29, 4863–4869. [Google Scholar] [CrossRef]

- Xu, J.; Li, X.; Lu, J.; Zhu, J. An investigation into mechanics and tribology of SnAgCu and MoO3 containing in 20CrMnTi based composites. J. Alloys Compd. 2020, 831, 154858. [Google Scholar] [CrossRef]

- Zhang, Y.; Yan, H.; Zhu, P.; Zheng, Z. Comparison of the effects of induction heating composite shot peening and conventional shot peening on residual stress, microhardness, and microstructure of 20CrMnTi gear steel. Surf. Coat. Technol. 2024, 485, 130887. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, S.; Yang, W.; Guan, J.; Li, G. Study on the Wear Performance of 20CrMnTi Gear Steel with Different Penetration Gradient Positions. Materials 2025, 18, 3685. [Google Scholar] [CrossRef]

- Zhang, G.; Song, L.; Ma, Z.; Wang, Z.; Tong, B.; Yi, Y. Macroscale superlubricity enabled by the synergy effect of oil and S–C co infiltration coating on 20CrMnTi steel surface. Friction 2025. [Google Scholar] [CrossRef]

- Men, Z.; Li, S.; Lu, X.; Chen, Y. Improvement of Mechanical Properties of 20CrMnTi Steel through Microstructure Modification. Coatings 2022, 12, 662. [Google Scholar] [CrossRef]

- Song, C.; Wang, G.; Zhao, X.; Han, Q.; Yin, F. Enhancing wear resistance in CSS-42L gear steel at room and elevated temperatures via electroshocking treatment. Surf. Coat. Technol. 2025, 503, 132015. [Google Scholar] [CrossRef]

- Zhang, Q.; Xiao, Z.; Xiang, Z. Analysis of steady-state temperature field of planetary gears considering load distribution and mixed oil-air medium. Tribol. Int. 2024, 200, 110062. [Google Scholar] [CrossRef]

- Xu, T.; Wu, S.; Zhao, C.; Zhou, Y.; Shi, Y. Study on mechanism of improving wear and corrosion properties of 20CrMnTi ring gear surface by laser carburizing. Mater. Today Commun. 2022, 32, 104029. [Google Scholar] [CrossRef]

- Wu, Z.; Li, Z.; Zhang, Q.; Jiang, Y.; Liu, Z.G.; Yuan, Y.; Yang, X.; Wang, X. Effect of microstructure on wear resistance during high temperature carburization heat treatment of heavy-duty gear steel. Mater. Today Commun. 2024, 40, 109486. [Google Scholar] [CrossRef]

- Wu, X.; Gao, P.; Du, Y.; Tang, X.; Wang, X. Effect of Normal Load and Temperature on the Tribo-Corrosion Behaviors of 20CrMnTi Alloy Steel. J. Mater. Eng. Perform. 2025, 34, 19131–19139. [Google Scholar] [CrossRef]

- Muharom, D.; Okdinawati, L. Failure Prediction Models using Vibration Data Motor and Gearbox: A Case Research in The Mining Industry PT Angsana Coal. Asian J. Eng. Soc. Health 2024, 11, 2622–2641. [Google Scholar] [CrossRef]

- Ren, Z.; Li, B.; Zhou, Q.; Hou, R.; Zhang, Y. Optimization of high-speed grinding parameters for anti-fatigue performance of 20CrMnTi steel. Int. J. Adv. Manuf. Technol. 2022, 122, 3565–3581. [Google Scholar] [CrossRef]

- Drago, R.J. The Effect of Start-Up Load Conditions on Gearbox Performance and Life Failure Analysis, with Supporting Case Study. Engineering 2009, 6. [Google Scholar]

- Zhao, X.; Liu, D.; Wu, X.; Liu, G.; Chen, L. Flow behavior and constitutive description of 20CrMnTi steel at high temperatur. J. Cent. South Univ. 2018, 25, 1013–1024. [Google Scholar] [CrossRef]

- Wei, F.; Fu, Y. High temperature deformation behavior and constitutive modeling for 20CrMnTiH steel. Mater. Des. 2014, 57, 465–471. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, P.; Gui, H.; Li, J.; Zhao, G.; Xing, T.; Liu, H.; Zhang, C. Hot Deformation Behavior and Recrystallization Analysis of Pipe 20CrNiMo Steel. J. Mater. Eng. Perform. 2025, 34, 15787–15798. [Google Scholar] [CrossRef]

- GB/T 3077-2015; Alloy Structure Steels. National Standards of the People’s Republic of China: Beijing, China, 2015.

- Kong, W.; Zhang, D.; Tao, Q.; Chen, K.; Wang, J.; Wang, S. Wear properties of the deep gradient wear-resistant layer applied to 20CrMnTi gear steel. Wear 2019, 424–425, 216–222. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Y.; Chen, Z.; Lin, X.; Zhao, X.; Li, Y.; Yao, S.; Wang, X.; Zheng, X. Investigation on compression-springback performance of the SUS301 stainless steel gasket considering the residual stress. Mater. Today Commun. 2022, 33, 104296. [Google Scholar] [CrossRef]

- Zhan, Y.; Lan, M.; Zhu, X.; Lu, X. Research on Prediction Models for the Compression-Resilience Performance of Corrugated Metal Gaskets with Residual Stress. J. Press. Vessel. Technol. 2022, 144, 051601. [Google Scholar] [CrossRef]

- Al-Gharram, M.; AlZoubi, T. Probing the Optical Properties of CeO2/Polyaniline Nanocomposites for Next-Generation Optoelectronic Applications. Ceram. Int. 2025, 51, 57320–57336. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, Y.; Jiang, Z.; Huang, J. Enhancing low thermal expansion behavior and strength via induced Zr-rich intermetallic phase in Fe-36Ni Invar alloy. Mater. Des. 2023, 226, 111644. [Google Scholar] [CrossRef]

- Alam, M.K.; Hossain, M.S.; Bahadur, N.M.; Ahmed, S. A comparative study in estimating of crystallite sizes of synthesized and natural hydroxyapatites using Scherrer Method, Williamson-Hall model, Size-Strain Plot and Halder-Wagner Method. J. Mol. Struct. 2024, 1306, 137820. [Google Scholar] [CrossRef]

- GB/T 9450-2005; Steels-Determination and Verification of the Depth of Carburized and Hardened Cases. National Standards of the People’s Republic of China: Beijing, China, 2005.

- Wang, X.; Sun, X.; Zhang, K.; Zhang, D.; Du, C. Effect of intermediate cooling rate normalizing on microstructure and creep rupture strength of P91 Steel. Mater. Today Commun. 2024, 38, 108451. [Google Scholar] [CrossRef]

- Liu, S.; Yang, F.; Liu, L.; Wang, J.; Peng, J.; Zhang, F.; An, S. Effects of rare earth Ce on TiN inclusion modifications in 20CrMnTi steel under deoxygenation conditions of Si–Ca–Ba alloy. J. Mater. Res. Technol. 2024, 30, 223–230. [Google Scholar] [CrossRef]

- Xie, Q.; Pei, Z.; Liang, J.; Yu, D.; Zhao, Z.; Yang, P.; Li, R.; Eisenbach, M.; An, K. Transition from the twinning induced plasticity to the γ-ε transformation induced plasticity in a high manganese steel. Acta Mater. 2018, 161, 273–284. [Google Scholar] [CrossRef]

- Tang, F.; Hou, C.; Lu, H.; Zhao, Z.; Song, X. Grain-boundary segregation and grain growth in nanocrystalline substitutional solid solution alloys. J. Mater. Sci. Technol. 2024, 168, 239–249. [Google Scholar] [CrossRef]

- Du, J.; Zhang, Z.; Liu, Y.; Shao, Q.; Zhang, A.; Xiong, S.; Liu, F. Strength-ductility trade-off modulated by thermo-kinetic synergy of heat-treatable aluminum alloys. J. Mater. Res. Technol. 2023, 24, 7876–7895. [Google Scholar] [CrossRef]

- Xia, B.; Zhang, P.; Wang, B.; Li, X.; Zhang, Z. Effects of quenching temperature on the microstructure and impact toughness of 50CrMnSiVNb spring steel. Mater. Sci. Eng. A 2023, 870, 144856. [Google Scholar] [CrossRef]

- An, W.; Liu, C.; Xiong, Q.; Li, Z.; Huang, X.; Suo, T. Shear localization in polycrystalline metal at high-strain rates with dynamic recrystallization: Crystal plasticity modeling and texture effect. Int. J. Plast. 2023, 165, 103616. [Google Scholar] [CrossRef]

- Yuan, Z.; Wang, S.; Zhang, H.; Li, F.; Ma, R.; Bai, J. Microstructure Evolution and Dynamic Recrystallization Behavior of SLM GH3536 Superalloy During hot Deformation. Met. Mater. Int. 2023, 29, 3356–3370. [Google Scholar] [CrossRef]

- Masumura, T.; Inami, K.; Matsuda, K.; Tsuchiyama, T.; Nanba, S.; Kitahara, A. Quantitative evaluation of dislocation density in as-quenched martensite with tetragonality by X-ray line profile analysis in a medium-carbon. Acta Mater. 2022, 234, 118052. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, T.; Yang, Y. Microstructure and properties evolution of Nb-bearing medium Cr wear-resistant cast steel during heat treatment. J. Iron Steel Res. Int. 2020, 28, 739–751. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, W.; Ren, J.; Gao, Q.; Xue, H.; Tang, F.; La, P.; Guo, X. Grain boundary segregation strengthening behavior caused by carbon chain network formation in nanocrystalline NiCoAl alloy. J. Mater. Res. Technol. 2023, 26, 1016–1027. [Google Scholar] [CrossRef]

- Ling, S.; Jelagin, D.; Partl, M.N.; Sun, D.; Fadil, H. Predicting the mechanical properties of semi-flexible pavement material with micromechanical modeling. Mater. Des. 2024, 239, 112802. [Google Scholar] [CrossRef]

- Horiuchi, K.; Ogawa, T.; Wang, Z.; Adachi, Y. Three-Dimensional Analysis of Ferrite Grains Recrystallized in Low-Carbon Steel during Annealing. Materials 2021, 14, 4154. [Google Scholar] [CrossRef]

- Peng, H.R.; Huo, W.T.; Zhang, W.; Zhang, S.; Tang, Y.; Chang, G.; Li, L.; Li, X.; Dong, L.L.; Liu, F. Maximizing the yield stress via synergistic optimization of grain sizes and solute concentrations in extremely fine nanograined metals: A molecular dynamics study. Mater. Today Commun. 2024, 38, 108075. [Google Scholar] [CrossRef]

- Xu, J.; He, Q.; Jin, X.; Bian, S.; Shan, D.; Wu, H.; Xu, W. A 3D cellular automaton with inhomogeneous nucleation for simulating dynamic recrystallization of low-alloy steel with mixed-grain microstructure. J. Mater. Process. Technol. 2023, 322, 118171. [Google Scholar] [CrossRef]

- Li, S.; Anisetti, A. A tribo-dynamic contact fatigue model for spur gear pairs. Int. J. Fatigue 2017, 98, 81–91. [Google Scholar] [CrossRef]

- Ouyang, T.; Wang, J.; Mo, X.; Li, Y. Vibration and cavitation in high-speed gears caused by faults. Int. J. Mech. Sci. 2023, 250, 108322. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).